External Wall Insulation Systems

Roofline Closure Systems for PAS 2035 Projects

External Wall Insulation Systems

Roofline Closure Systems for PAS 2035 Projects

InAugust2024,theUKGovernmentannouncedthatRooflineClosureSystemscouldbe usedinPAS-compliantretrofitprojects,subjecttospecificconditionsanddesign principles.ThisdecisionbytheDepartmentforEnergySecurityandNetZeromarked theendofafour-yearperiodduringwhichthesesystemswereprohibitedinprojects fundedbypublicmoneyorrequiringathird-partywarranty.PAS2035:2019stipulated that"metalorplasticcappingsandtrimsshallnotbeused"atroofinterfaceswith eavesandverges,arestrictionreiteratedinPAS2030:2023 Theoriginalbanstemmed fromwidespreadindustryfailureslinkedtotraditionalvergetrims,whichhadbeen usedforthepast40years.Asaresult,theonlyallowedmethodforprotectingthetop ofexternalwallinsulation,wheretheexistingroofoverhangwasinsufficient,involved extendingtheroofline-anapproachthattypicallyincreasedcostsandcomplexity.

Incertainsituations,suchaswithmid-terraceproperties,extendingaroofonitsownis eitherimpossibleorhighlyimpractical.Thiscanleadtocomplicationswith neighboringpropertyinterfaces,aesthetics,planningapprovals,rainwaterdrainage, andotherissues Priortotherecentpolicychange,thesechallengesoftenresultedin propertieswithinadequateroofoverhangsbeingexcludedfromretrofitprograms,as theyweretypicallymorecomplexandcostly.Consequently,manyhouseholdsmissed outonthebenefitsofessentialinsulationmeasures.

TheNationalInsulationAssociation(NIA),theSolidWallInsulationGuaranteeAgency (SWIGA),andtheInsulatedRenderandCladdingAssociation(INCA)formedaworking grouptodeveloppracticalsolutionsforreintroducingappropriatelydesignedclosure systems CollaboratingwiththeGovernment,BSI,theRetrofitStandardsTaskGroup, andTrustmark,thegroupestablishednewDesignPrinciplesandanupdated WeatheringGuide,titled“ExternalWallInsulationSpecificationforWeatheringand ThermalBridgeControlGuide,August2024.”ThesedocumentsoutlinehowRoofline ClosureSystemscanbeeffectivelyincorporatedintoretrofitdesignswhilemeetingthe compliancerequirementsofPAS2030/2035.

RooflineClosureSystemshavebeenapprovedbyDESNZspecificallyforPASprojects. ThesesystemsaredesignedtoofferversatileandrobustprotectionforExternalWall Insulation(EWI)systems,shouldarooflineextensionnotbeanoption

Rooflinerequirementsvarysignificantlywithinaschemeorproperty,requiringmultiple solutions Sincestandarddetailscannotcoverallscenarios,asetofDesignPrinciples hasbeenestablished.

Theseprinciplesareasupporttoolfortherooflineclosuredetailsdocumentedinthe Externalwallinsulationspecificationforweatheringandthermalbridgecontrolguide 2022 Itisrecognisedthatthedocumenteddetailsarenotexhaustiveandtherefore theseprinciplesaredesignedtobeusedtodevelopnewRooflineclosuresolutions thatcomplywiththePAS20302019.

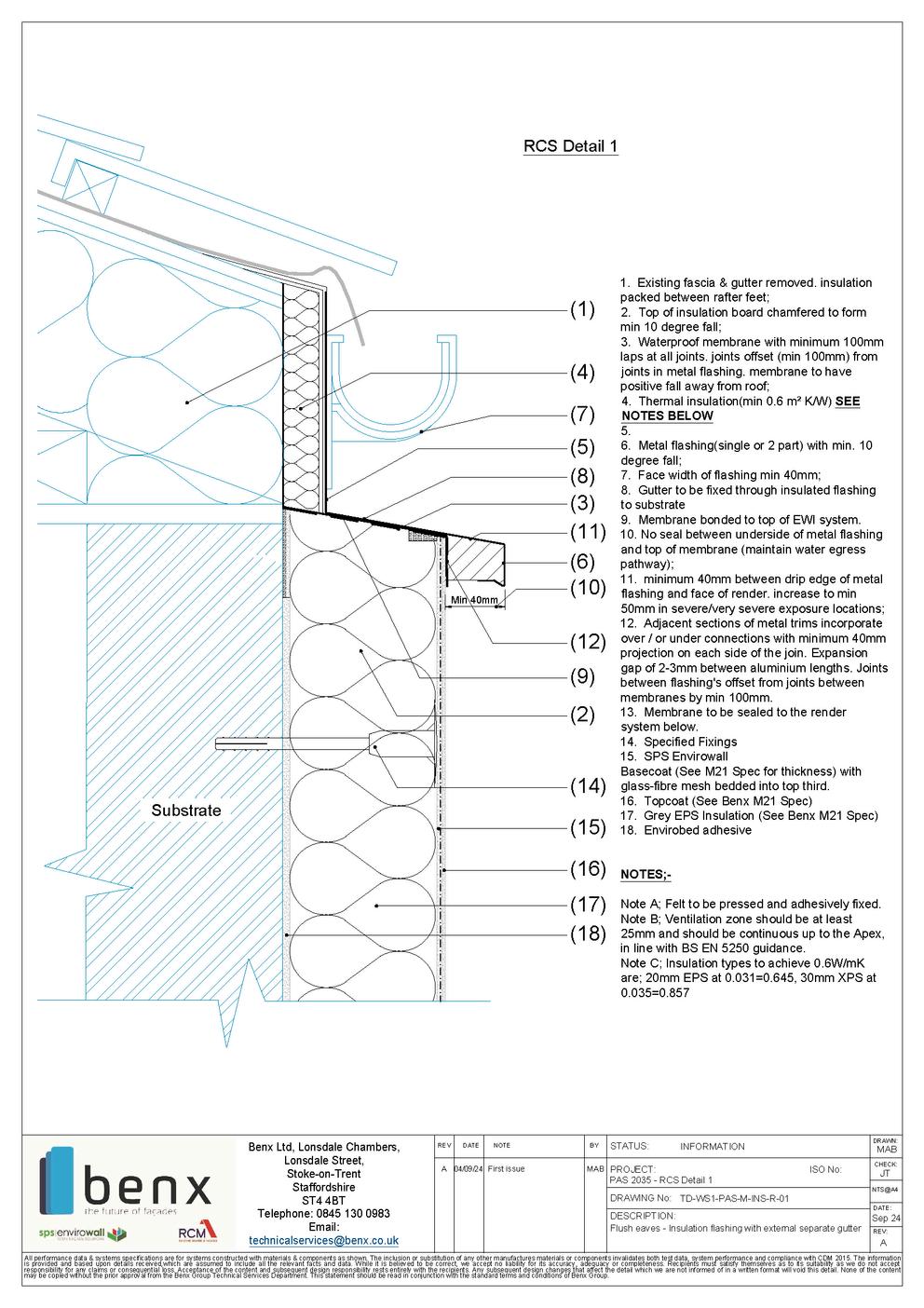

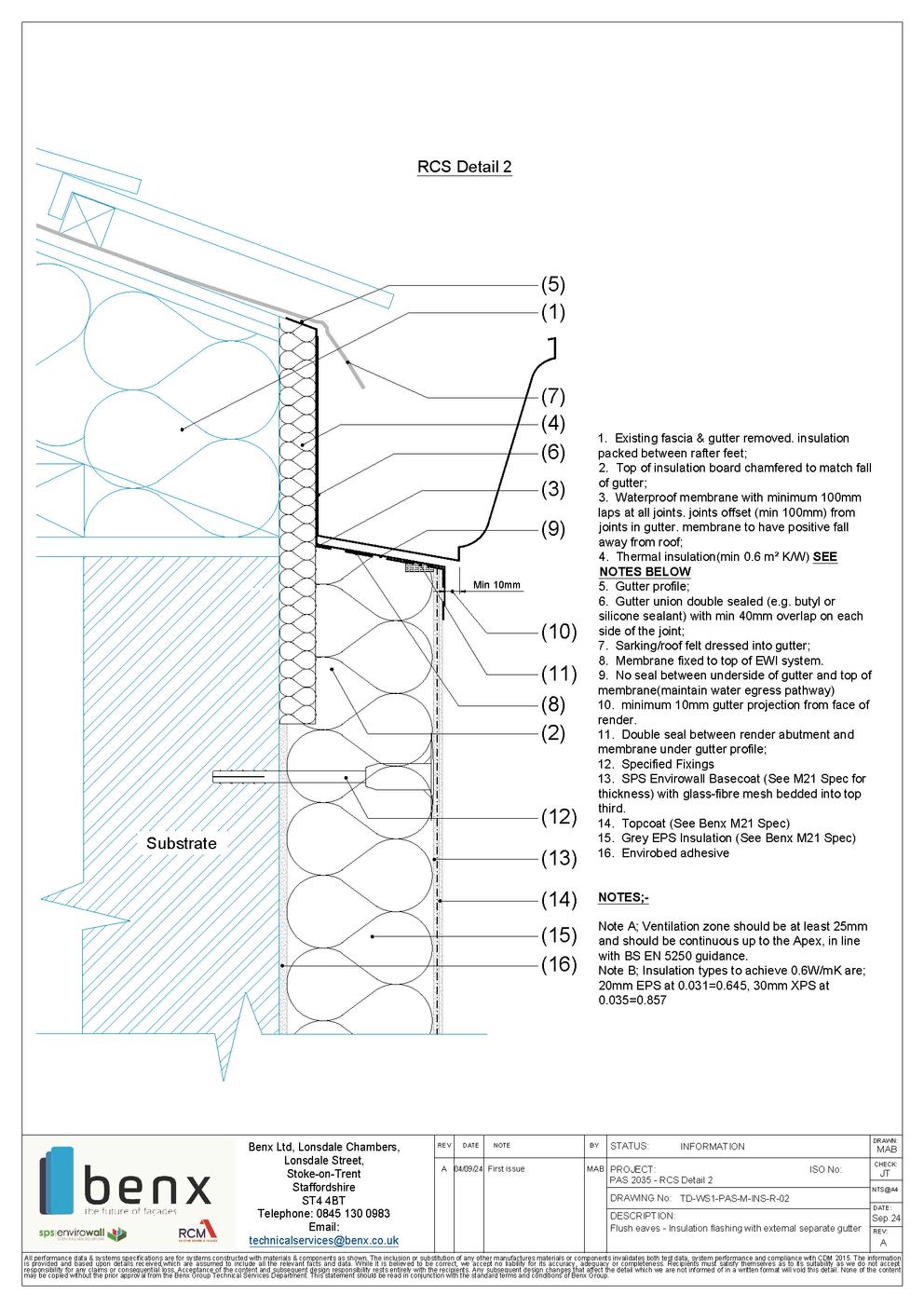

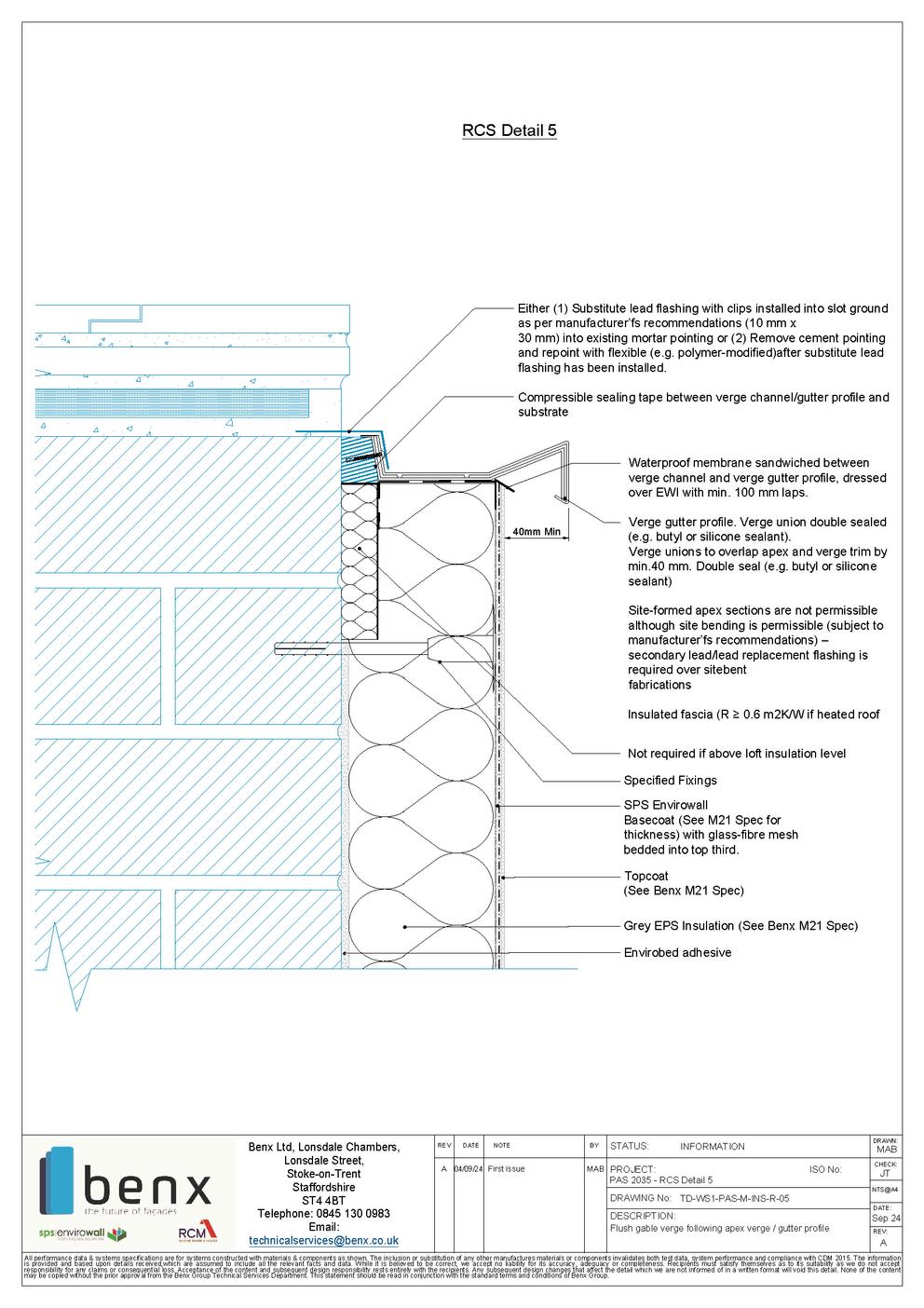

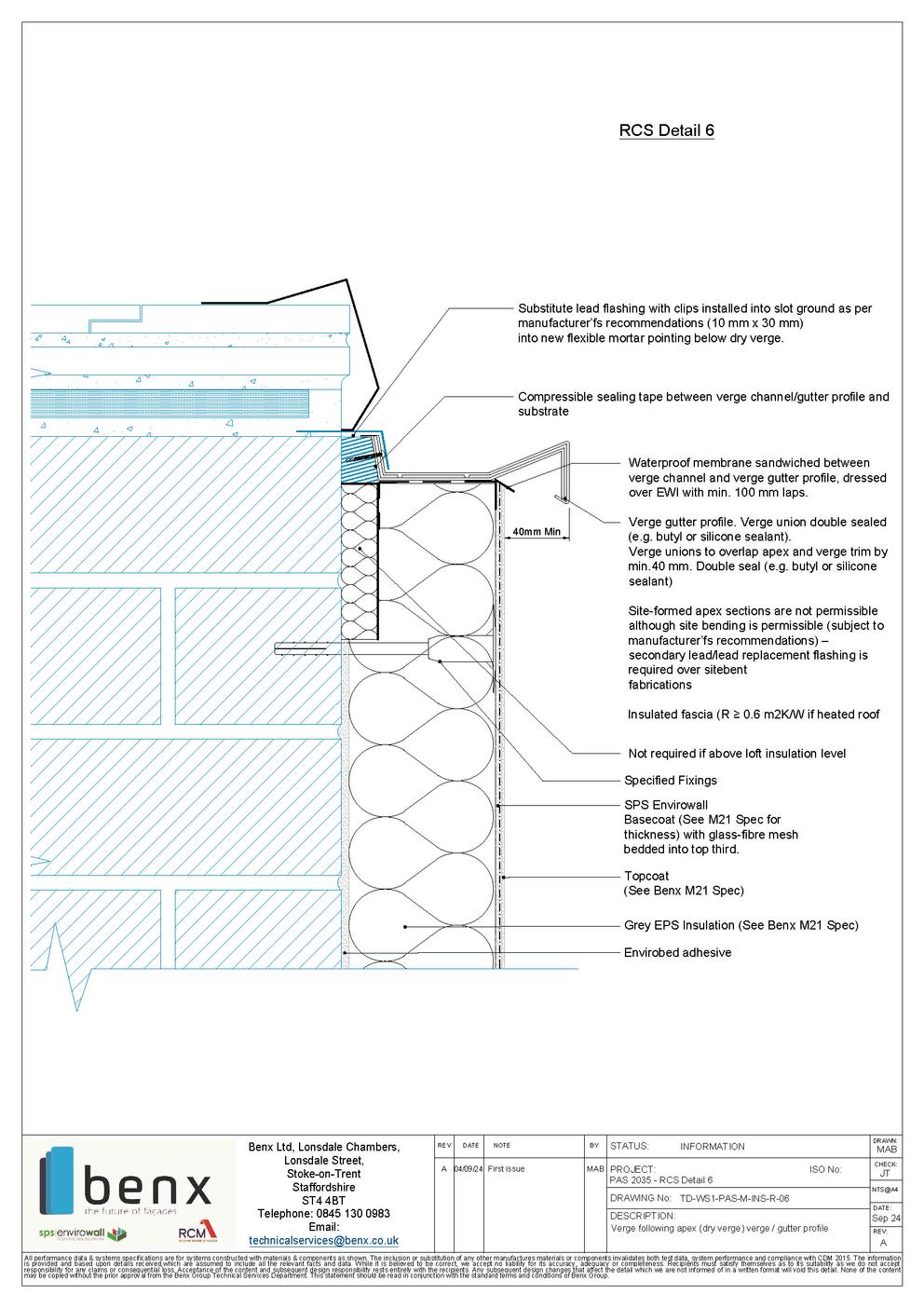

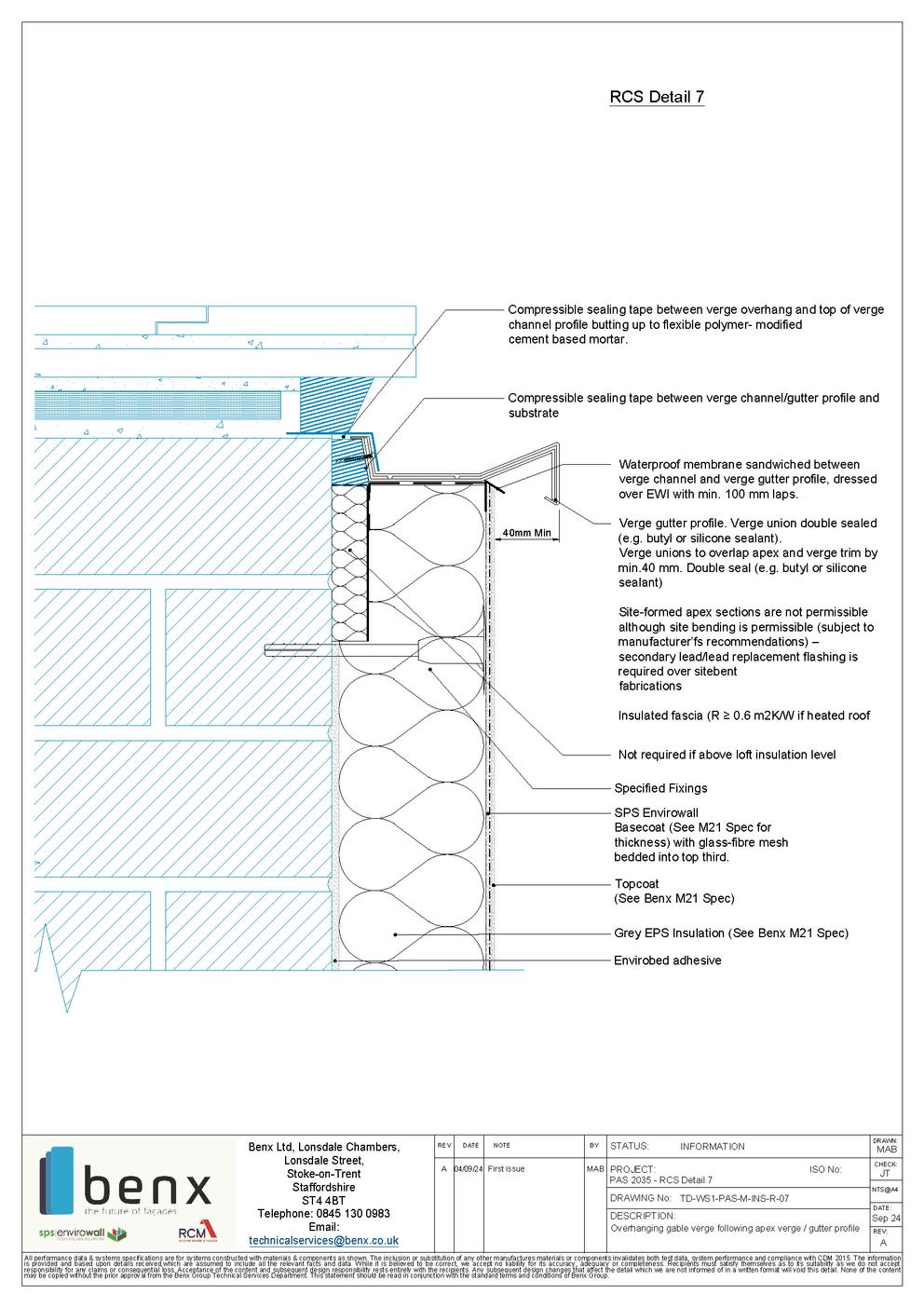

Atleasttwolinesofweatheringprotectionarerequired

Sealantsshallnotbeemployedtoprovidetheprimarybarriertowaterpenetration

Additionalredundancycanbeachievedwithanadditionaltrimorsuitablemembrane AlljointsmusthaveadoublesealtocomplywiththePASrequirements

ProtectionaffordedtothetopoftheEWIsystemmustincludeasecondarywaterproof membraneand/orflashingthattucksundertheexistingsarkingfelt

Overhangmustbeappropriateforexposurezone,(40mmmoderateorshelteredexposure –50mmsevereorverysevereexposure)basedontheBREwinddrivenrainmapinBR262 Thermalinsulation:avoidingrisks–AppendixA:WP2/(publishingservicegovuk)

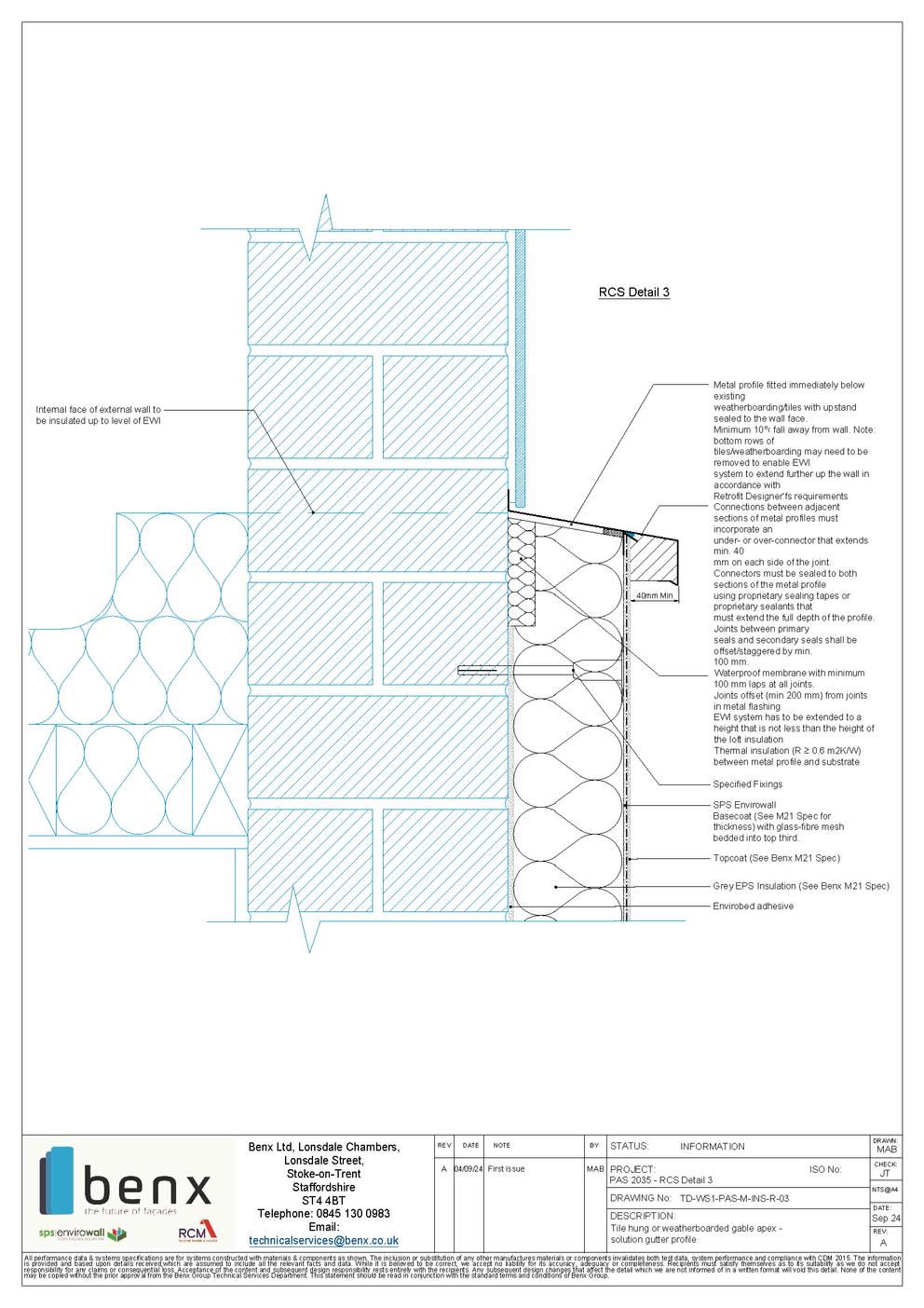

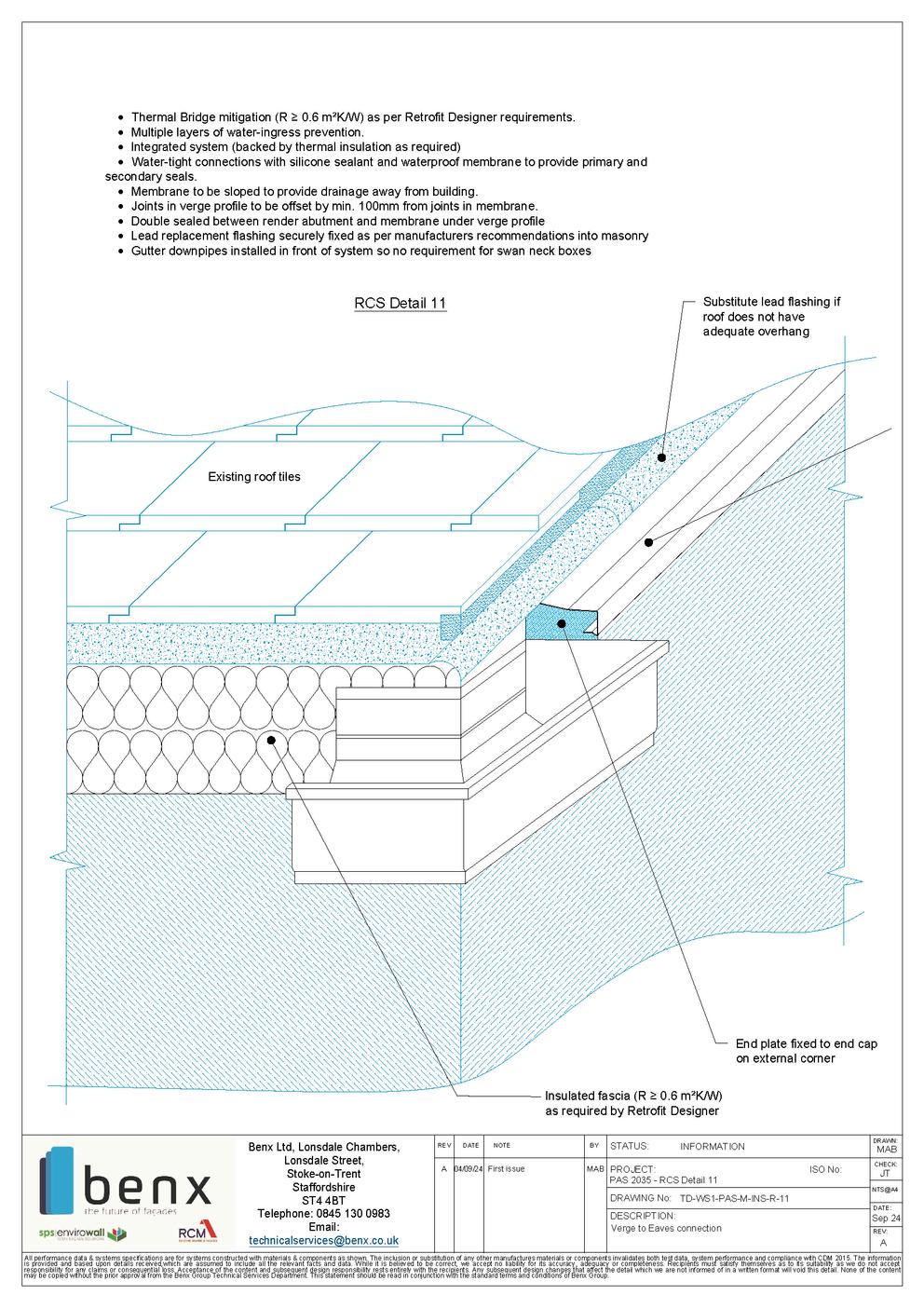

2.Gable-to-EavesJunctions

Mustbeachievedwithoverlapping,prefabricatedunits/connectors

Sitefabricationisnotpermissiblethoughminorsitetrimmingispermissible Anyjointsbetweentheprimaryandsecondarysealmustbestaggeredby100mm Insulationtobemaintainedincornerofgablewalluptolevelofloftinsulationasper RetrofitDesignerrequirements

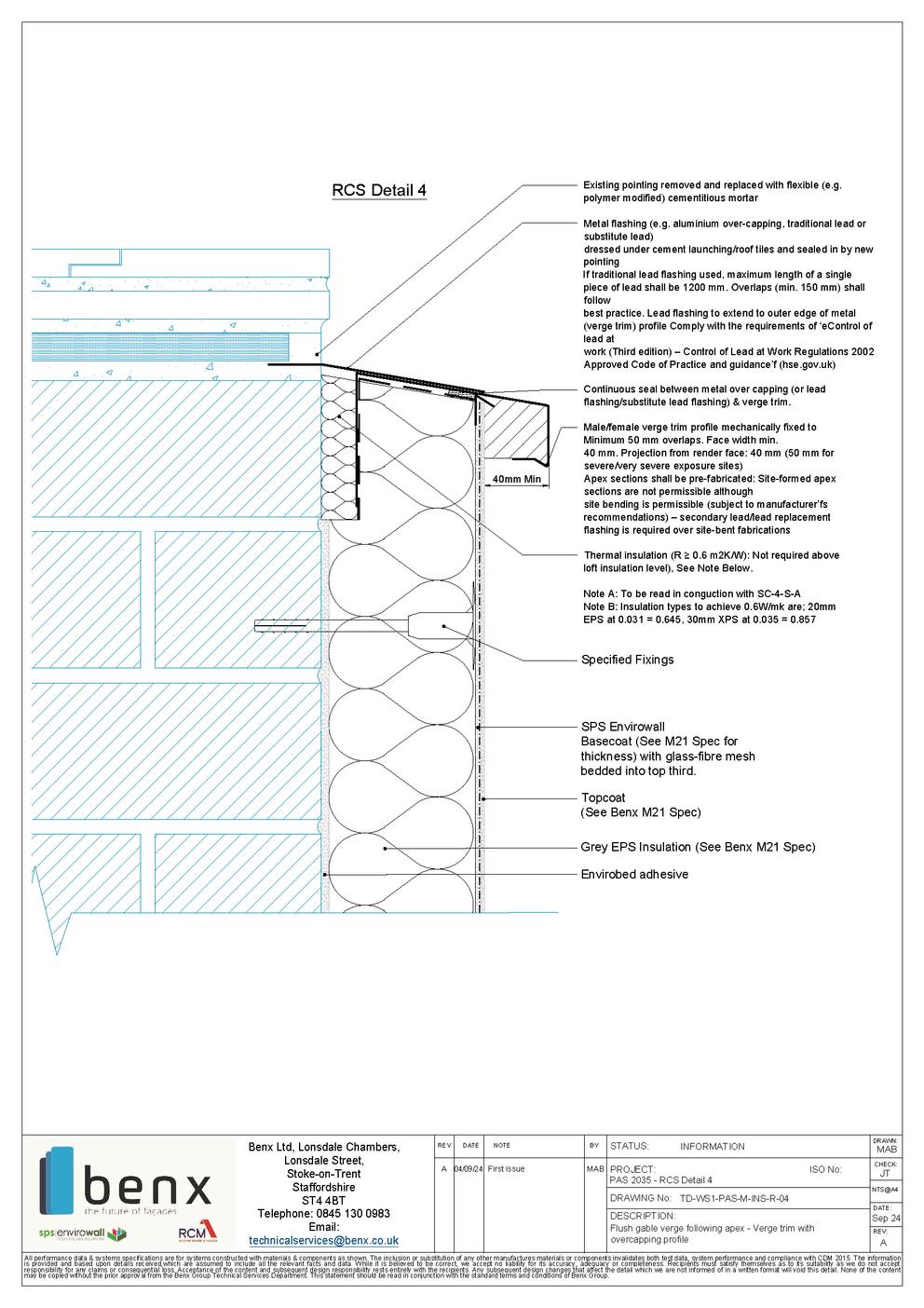

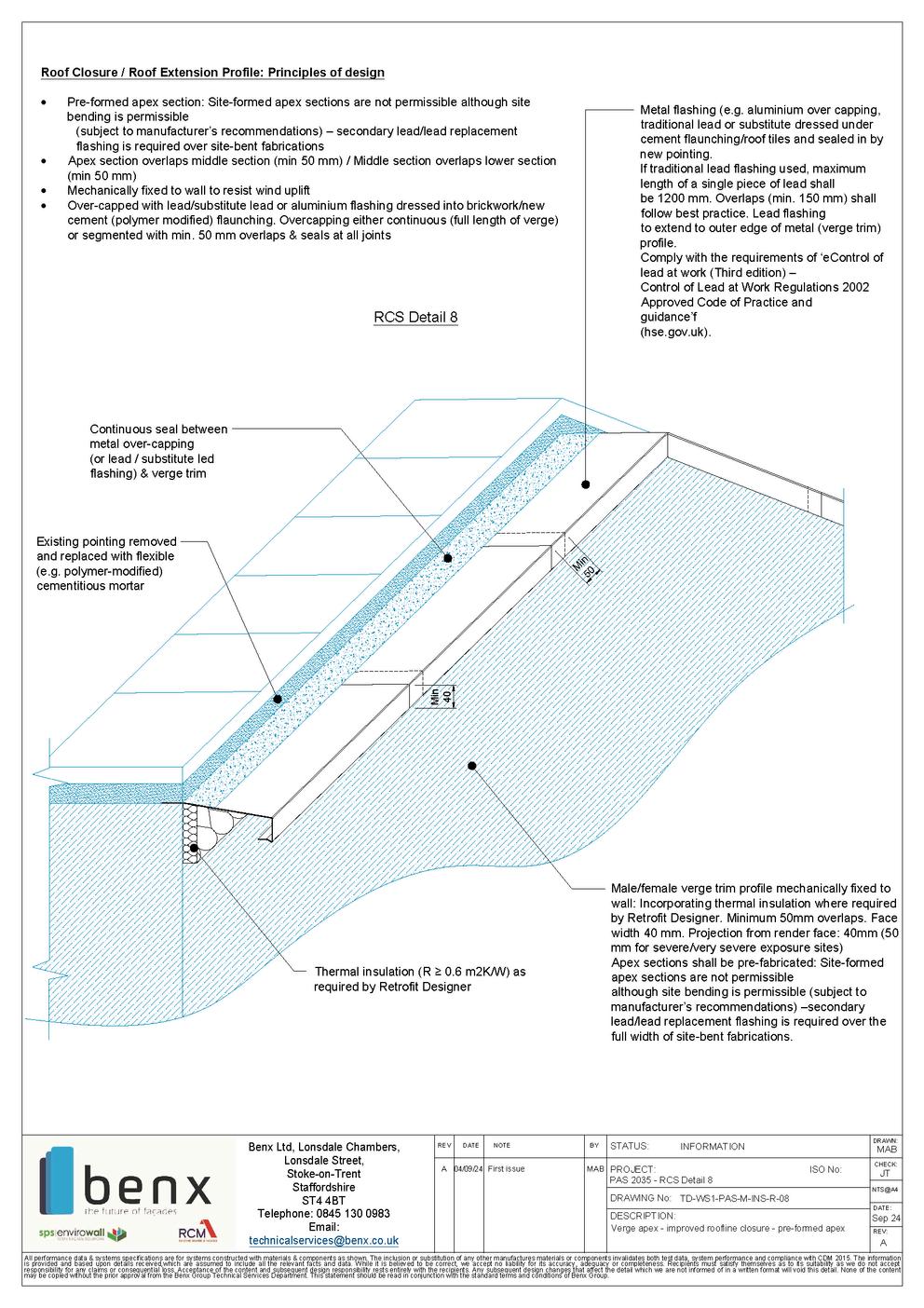

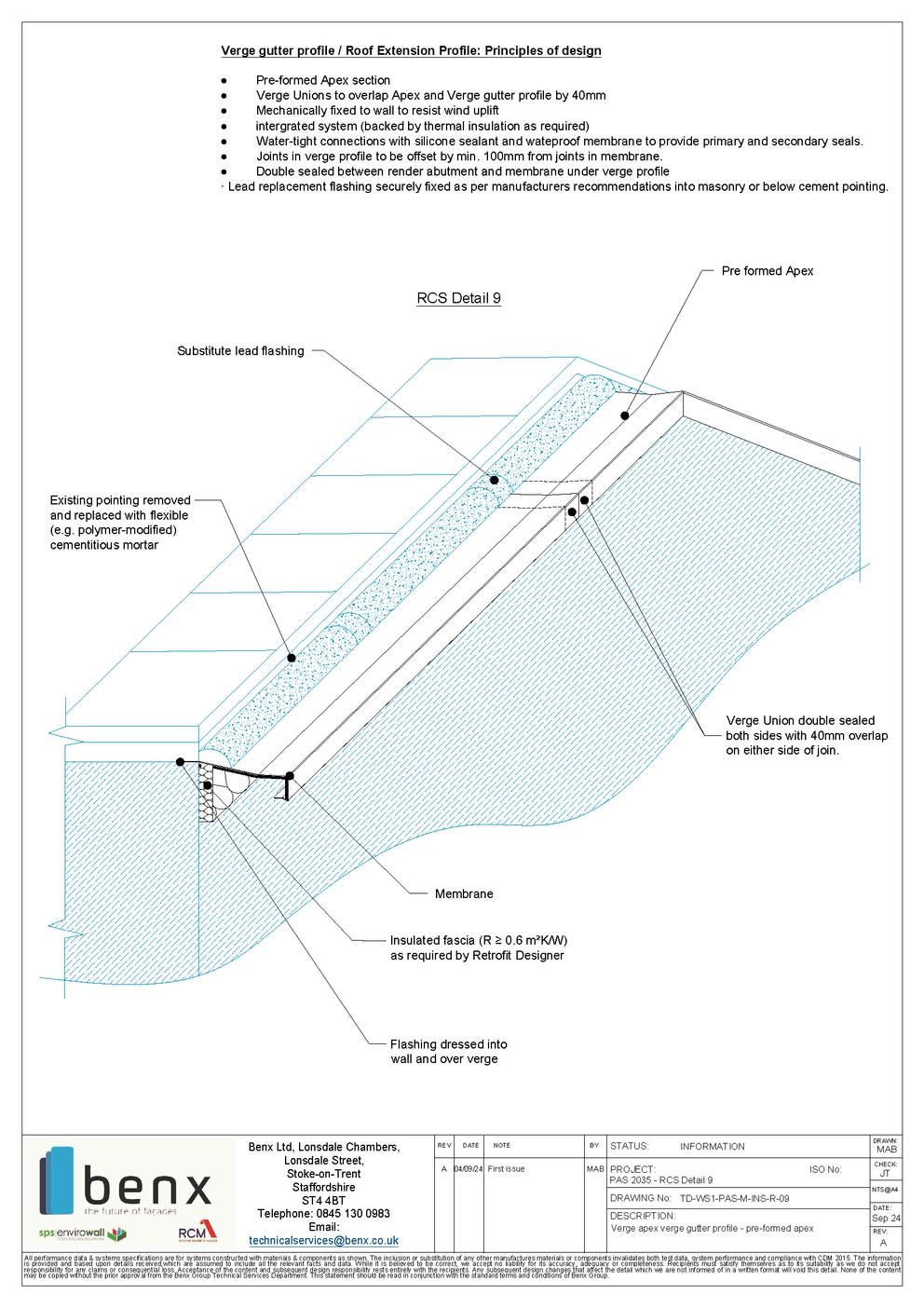

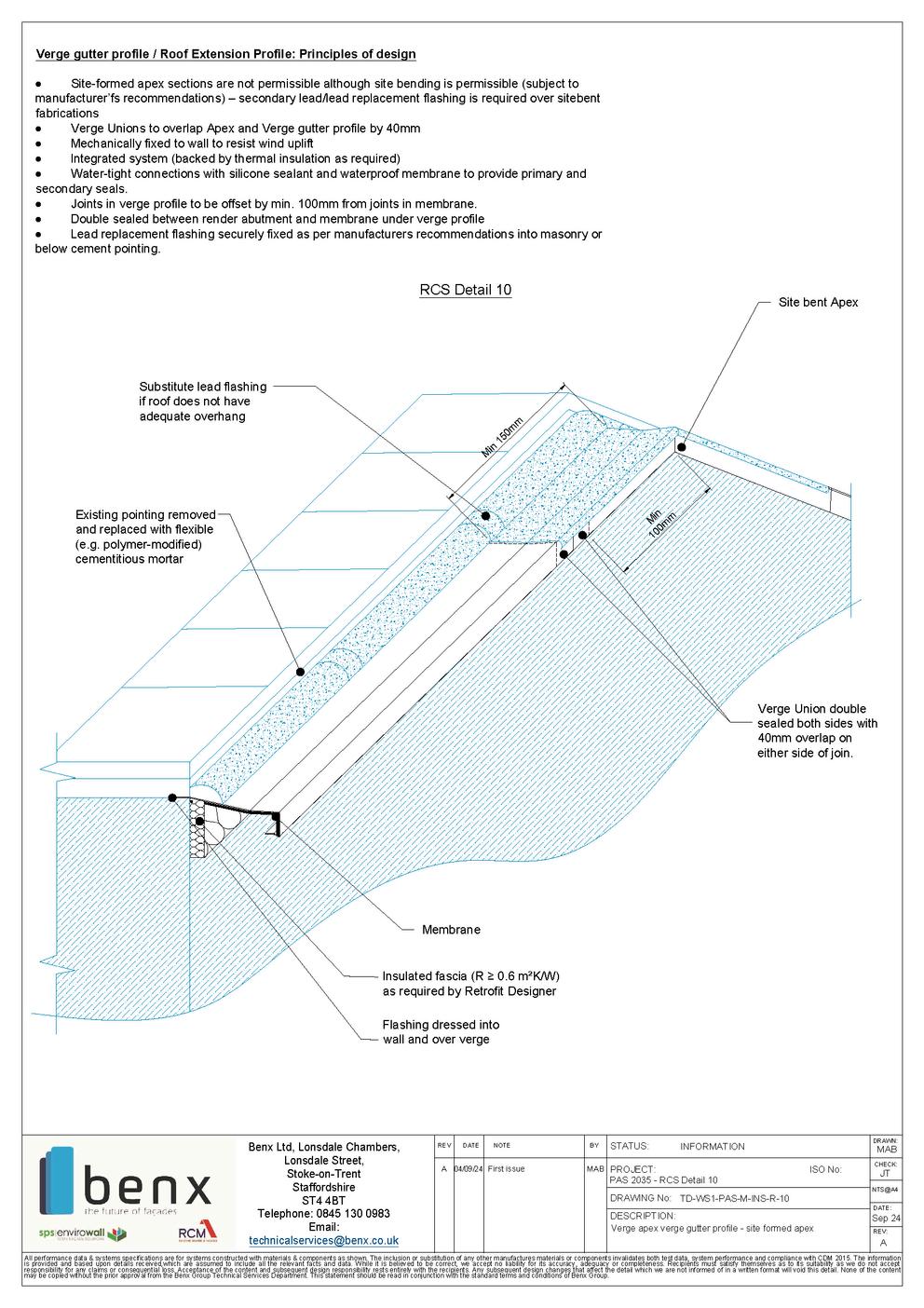

3.GableApexesFormation

Mustbeformedusingprefabricatedelements

Sitebentflashingcanbeutilisedhoweversecondarylead/leadreplacementflashing requiredovertheapex

Site-formedmitrejointsusingtwoseparateprofilesarenotpermissible

Mustincorporateanunder-oroverconnectorthatextendsmin 40mmoneachsideofthe joint Connectorsmustbesealedtobothsectionsofthemetalprofile(rooflineclosure,etc)using proprietarysealingtapesorproprietarysealantsthatmustextendforthefullwidthofthe trim

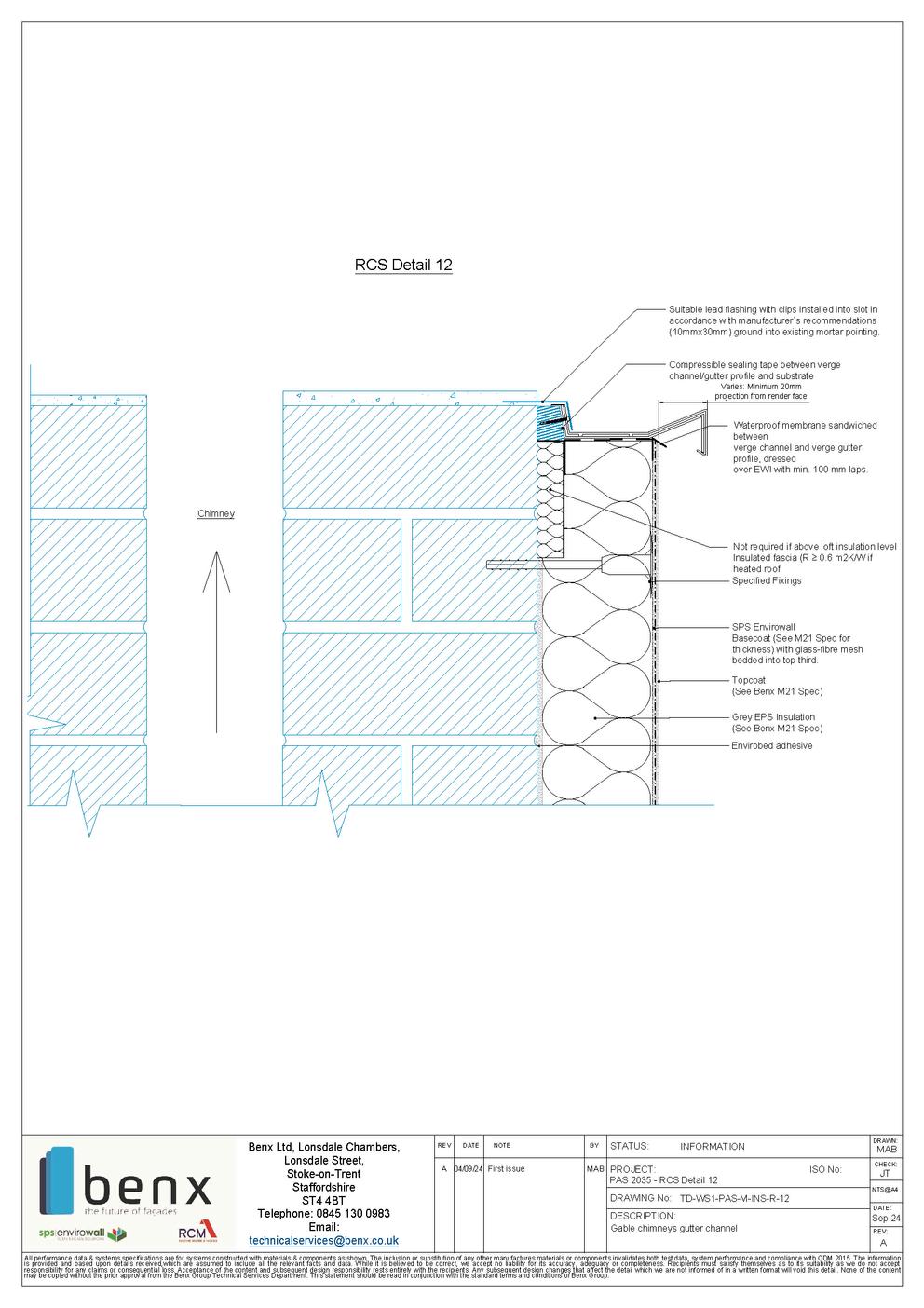

5.LeadFlashing:

Anyjointsbetweentheprimaryandsecondarysealmustbestaggeredby100mm

Ifusingleadasasolutionthemaximumlengthinasinglepieceshouldbe1200mmand overlapsshouldfollowbestpractice. EnsurehealthandsafetyrequirementsarecompliedwithControlofleadatwork(Third edition)-ControlofLeadatWorkRegulations2002ApprovedCodeofPracticeand guidance(hse.gov.uk)IfLeadreplacementflashingsareused,theseshouldbesecurely fixedinaccordancewiththemanufacturer’srecommendations.

Loft or Roof Insulation

Aminimum40mm(50mmforhighexposure)isrequired,iflessthentrims/flashings shouldbeembeddedintothemasonry,orbelowthecementpointingatvergesandsealed Anyjointsbetweenaprimaryandsecondarylayerofredundancymustbeoverlappedbya minimum100mm

Thesandandcementfilletshouldbereplacedwithasuitableflexiblemortar

Theinstallationoftheweatheringprotectiondetailsmustbeseparatelyincludedwithinthe EWIsystemholdertrainingthatisprovidedtoregisteredEWIinstallationcontractors.

8.MinimalThermalResistance

Inallcasesthereshouldbecontinuityoftheroofinsulationandtheinsulated rooflineclosuresolutiontoprovideaminimum“thermalresistanceof0.6m2K/W (andensurenothermalbridging).

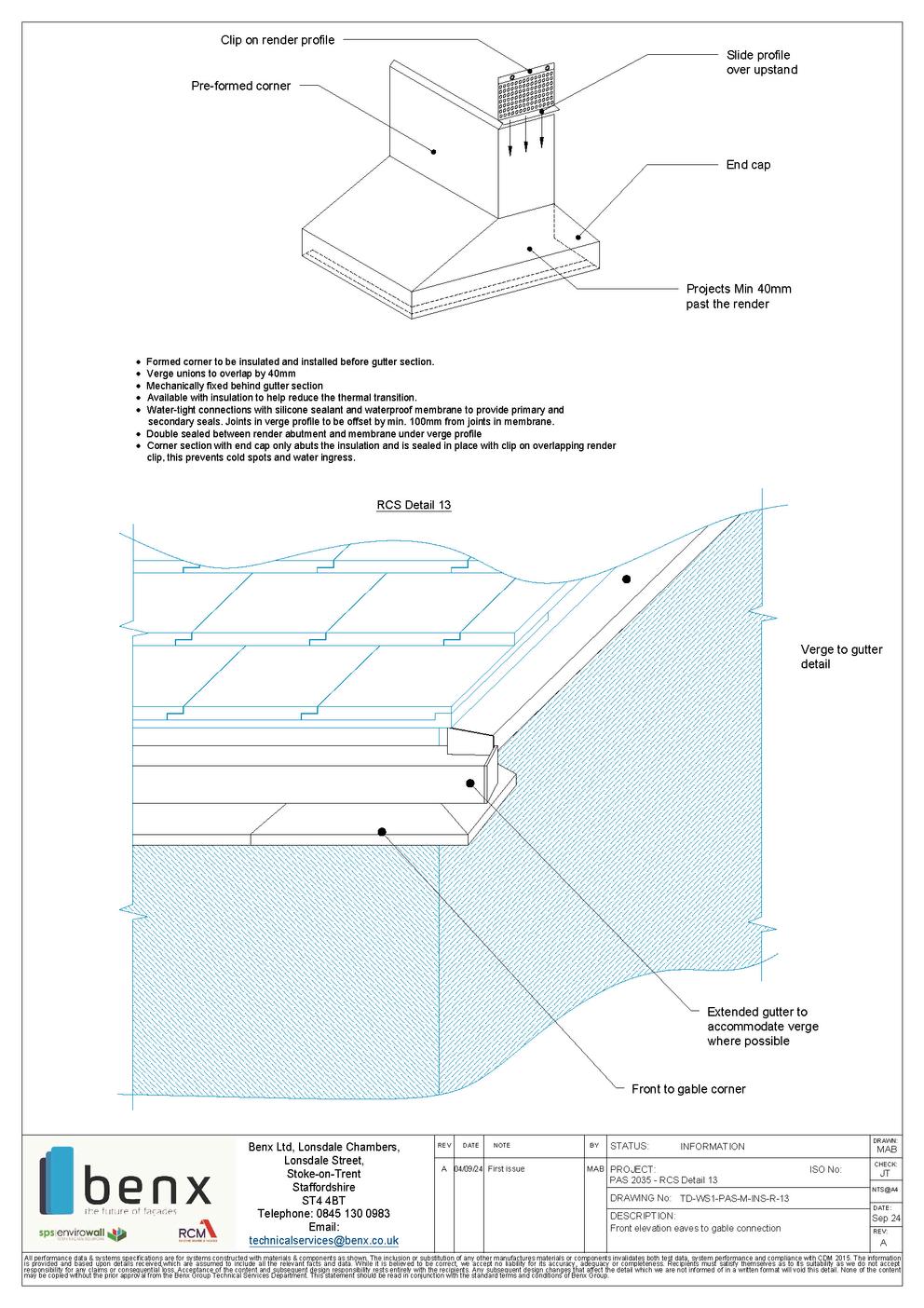

ToenhancetheprotectionoftheEWIsystems,ourRooflineClosureSolutions incorporateasecondlineofdefencethroughmembranesorsecondaryflashingsfully inlineandcompliantwiththedesignprincipalsdetailedabove

SuitableBaseMaterials

MinimumAluminiumspecifications1050A–Otherhighergradesareacceptable–3000/5000

MinimumStainless-Steelspecifications304–Otherhighergradesareacceptable–316

MinimumThickness

12mmaluminiumwithatolerance+/-10%tobeusedfortrimwidthsupto160mm Fortrimwidthsover160mmortrimstobeusedinexposedareas,minimum50mm overhangfromfaceofrendersystem,15mmaluminiummustbeconsideredforadded strengthandstability

Frontfaceofroofflashingwillnowbeaminimumof40mmdeep

PolyesterPowdercoatedaluminiummusthaveaminimumcoatingthicknessof40microns toBSorQualicoatstandardsandPowderCoatersmustbeBSorQualicoatapproved applicators

Pre-coatedaluminiummustbepolyestercoatedonbothsidesandthethicknessmust conformtoEN13523-1

Inareasexposedtoseverewinddrivenrain(Zone4ofBREwinddrivenrainmap)ordirectly facingthecoast,amarinespecificationcoatingshouldbeconsidered

Conductingacomprehensivesurveyisessentialto determinethesuitabilityoftheRooflineClosureSystem foreachspecificproperty

Clickheretodownloadacopyofthesurvey-LINK

Accuratemeasurementanddocumentationoftheexistingroofoverhangarecrucial astheydeterminetherequiredspecificationsforthesystem.Additionally,assessing thesubstrate'sconditionisessentialtoensureitcansupporttheinstallation, especiallywhenusinggrind-inflashings

Relevant Considerations

ExistingOverhang

RafterPositioning

SubstrateCondition

ExistingInsulation& PotentialColdBridging

CornerDetails

ExistingFeatures

Ventilation

Determinecompatibilitywiththeexistingrooflineand substrate.

Ensuretheoverhangisuniformacrossboththeeavesandthe verge

Raftersmayneedtobeenclosed,navigatedaround,or modifiedasnecessary

Whenconsideringgrindingin,ensurethesubstrateisstable andcanwithstandtheprocesswithoutdamage.

Ensurecontinuityofroofinsulationwitheachdetail installation,maintainingaminimumthermalresistanceof 06m²K/Wtopreventcoldbridging

Confirmhowtheeavesandvergewillintersecttoensurea cohesiveandfunctionaldesign

Elementssuchascorbelsandquoinswillneedtobe considered,astheymaypreventthesedetailsfrombeing installed.Thiscouldnecessitatesite-specificdesignsin accordancewiththeRooflineClosureprinciples.

Roofventilationmustnotbeobstructed/restrictedwhen installingRoofClosureSystems

Duringinstallation,achecklistformmustbecompletedtodocumenthowtheRoofline ClosureSystemprinciplesarebeingadheredto Photographicevidenceofthevarious installationstepsisalsorequired,andthisinformationmustbesubmittedtoapplyfor aprojectwarranty.

DESNZwillbeobservingandmonitoringinstallationsthatareusingthisnewly introducedmethod–SPSenvirowallarefullysupportiveofDESNZandthenew measuresandwillprovidewhatassistancewecantohelpallpartiestoensurefull complianceandtoavoidanypotentialfutureissues.

TohelpsupportandguideinstallerswiththelatestupdatestoPAS,weofferaone-day PAS2035&Refurbishmenttrainingcourseatourfourbranchlocations.Theall-new coursecanbeviewedandbookedonlinehere: https://spsenvirowall.co.uk/training course/

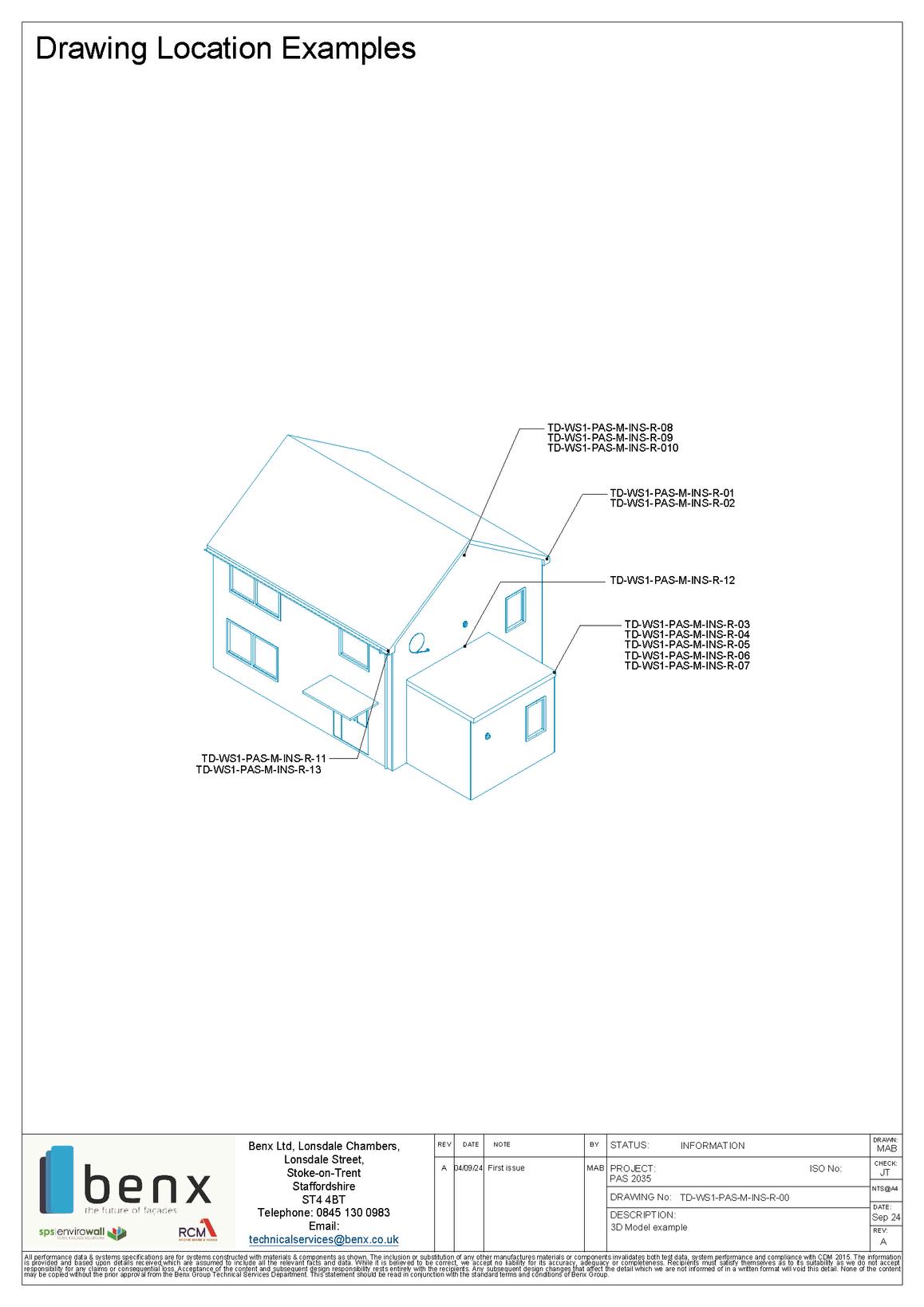

13detailshavebeenagreedbyPASDESNZforRooflineClosureinstallation.

Thedetailingshownisindicativeandcanbemodifiedandupdatedwithinagreed parameterstosuitspecificprojectrequirements