Data drives innovation. Th rough CTE InSight , advanced statistical analysis identifies opportunities for improvement and predicts the most impactful change for plant performance. Better data clarity enables optimization. Turn InSight into action.

President & Editor Tom Bryan tbryan@bbiinternational.com

Senior News Editor Erin Voegele evoegele@bbiinternational.com

Contributions Editor Katie Schroeder katie.schroeder@bbiinternational.com

Features Editor Lisa Gibson lisa.gibson@sageandstonestrategies.com

Vice President of Production & Design Jaci Satterlund jsatterlund@bbiinternational.com

Graphic Designer Raquel Boushee rboushee@bbiinternational.com

CEO Joe Bryan jbryan@bbiinternational.com

Chief Operating Officer John Nelson jnelson@bbiinternational.com

Senior Account Manager Chip Shereck cshereck@bbiinternational.com

Account Manager Bob Brown bbrown@bbiinternational.com

Senior Marketing & Advertising Manager Marla DeFoe mdefoe@bbiinternational.com

Ringneck Energy Walter Wendland Commonwealth Agri-Energy Mick Henderson Western Plains Energy Derek Peine Front Range Energy Dan Sanders Jr.

Minneapolis, MN (866) 746-8385 | www.safconference.com

Serving the Global Sustainable Aviation Fuel Industry Taking place in September, the North American SAF Conference & Expo, produced by SAF Magazine, in collaboration with the Commercial Aviation Alternative Fuels Initiative (CAAFI) will showcase the latest strategies for aviation fuel decarbonization, solutions for key industry challenges, and highlight the current opportunities for airlines, corporations and fuel producers.

St. Louis, MO (866) 746-8385 | www.fuelethanolworkshop.com

Now in its 42nd year, the FEW provides the ethanol industry with cutting-edge content and unparalleled networking opportunities in a dynamic business-to-business environment. As the largest, longest running ethanol conference in the world, the FEW is renowned for its superb programming—powered by Ethanol Producer Magazine —that maintains a strong focus on commercialscale ethanol production, new technology, and near-term research and development. The event draws more than 2,300 people from over 31 countries and from nearly every ethanol plant in the United States and Canada.

St. Louis, MO

(866) 746-8385 | www.sustainablefuelssummit.com

Customer Service Please call 1-866-746-8385 or email service@bbiinternational.com. Subscriptions Subscriptions to Ethanol Producer Magazine are free of charge with the exception of a shipping and handling United States. To subscribe, visit www.EthanolProducer.com/Subscribe, send an email to subscriptions@bbiinternational.com or call 866-746-8385. Back Issues, Reprints and Permissions Select back issues are available for $3.95 each, plus shipping. Article reprints are also available for a fee. For more information, contact us at 866-746-8385 or service@bbiinternational.com. Advertising Ethanol Producer Magazine provides a specific topic delivered to a highly targeted audience. We are committed to editorial excellence and high-quality print production. To find out more about Ethanol Producer Magazine advertising opportunities, please contact us at 866-746-8385 or service@bbiinternational.com. Letters to the Editor We welcome letters to the editor. Send to: Ethanol Producer Magazine Letters to the Editor, 308 2nd Ave. N., Suite 304, Grand Forks, ND, 58203, or editor@bbiinternational.com. Please include contact information. Letters may be edited for clarity or space.

Please recycle this magazine and remove inserts or samples before recycling

COPYRIGHT © 2025 by BBI International

The Sustainable Fuels Summit: SAF, Renewable Diesel, and Biodiesel is a premier forum designed for producers of biodiesel, renewable diesel, and sustainable aviation fuel (SAF) to learn about cutting-edge process technologies, innovative techniques, and equipment to optimize existing production. Attendees will discover efficiencies that save money while increasing throughput and fuel quality. Produced by Biodiesel Magazine and SAF Magazine, this world-class event features premium content from technology providers, equipment vendors, consultants, engineers, and producers to advance discussions and foster an environment of collaboration and networking. Through engaging presentations, fruitful discussions, and compelling exhibitions, the summit aims to push the biomass-based diesel sector beyond its current limitations. Co-located with the International Fuel Ethanol Workshop & Expo, the Sustainable Fuels Summit conveniently harnesses the full potential of the integrated biofuels industries while providing a laser-like focus on processing methods that deliver tangible advantages to producers. Registration is free of charge for all employees of current biodiesel, renewable diesel, and SAF production facilities, from operators and maintenance personnel to board members and executives.

We hear so much these days about getting carbon capture pipelines done and, parallel to it, positioning ethanol for massive growth through sustainable aviation fuel (SAF) production. Truth be told, both things are moonshot endeavors, and neither is really happening at scale, yet. But CO2 pipelines still have real momentum—towels are not being thrown in—and there’s overwhelming consensus that ethanol-to-jet (ETJ) simply must happen for global SAF goals to be met. These parallel industry pursuits—necessary, inevitable or both—converge in this issue through the lenses of policy, economics, science and legacy.

In “Angle of Ascent,” on page 14, we take a pragmatic look at the near- and mid-term profitability of SAF derived from alcohol. ETJ is widely expected to be a major piece of the global SAF movement—perhaps larger than HEFA, ultimately—but the profitability of making the fuel will unquestionably hinge on state, federal and international incentives. Our story is based mostly on presentations given at this summer’s International Fuel Ethanol Workshop & Expo, which took place prior to the passage of the One Big Beautiful Bill Act and the 45Z enhancements housed within it (which should have a favorable impact on SAF economics). But nothing in the bill changes the fact that ETJ will require low-carbon production strategies and creative business plans that fully leverage stackable incentives for ethanol-based SAF and its coproducts.

Next, in “Unleashing Ethanol’s Potential,” on page 22, we bring you highlights and key takeaways from the FEW. The industry’s big summer event, once again in Omaha, Nebraska, was one of the best in memory with nearly 2,500 participants representing 45 U.S. states, 30 countries and, most importantly, over 94% of the installed ethanol production capacity in America. Renewable Fuels Association President and CEO Geoff Cooper gave this year’s keynote, delivering a mid-year state of the industry speech that focused on industry priorities under the second Trump administration. The policy panel that followed dove deeper into many of the same legislative and regulatory issues. And the FEW’s annual awards presentation was, once again, full of inspiring stories, which our coverage includes.

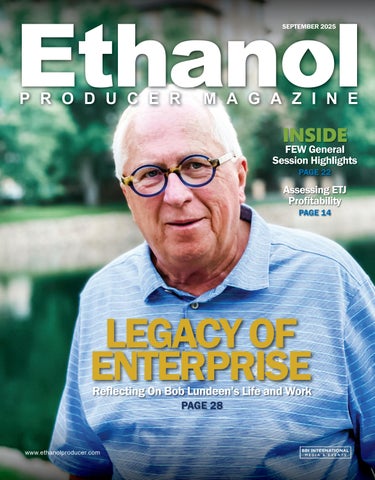

On page 28, we bring you “The Legacy of Bob Lundeen,” a piece about the life and work of the late founder of Mid America Agri Products/Wheatland, a 48 MMgy ethanol plant in Nebraska. Through the memories and reflections of Lundeen’s wife and daughter, as well as others, we get to know this special industry leader, a one-of-kind entrepreneur who made a lasting impact on not only his friends and family, but his community and, indeed, the greater ethanol industry. MAAPW is pursuing CCS, participating in the planned Tallgrass Trailblazer CO2 pipeline, which was perhaps Lundeen’s final career aspiration. Bob may be gone, but one of his last successes is still unfolding.

Enjoy the read.

Emily Skor CEO of Growth Energy

It has been twenty years since Congress passed the Renewable Fuel Standard (RFS)—a bold, bipartisan commitment to strengthen our nation’s energy independence, support rural economies and reduce harmful emissions. For two decades since, the RFS has done exactly what it was designed to do. It has delivered real, measurable benefits to consumers, farmers and the environment. But as we celebrate this milestone, we also need to recognize how to build on our success.

Let’s start with consumers. Every time drivers fill up with fuels like E15, they’re saving money at the pump. The RFS introduced competition into a market previously dominated by fossil fuels. This helped hold down fuel prices for American families, especially during volatile periods for global oil markets. The sum of these savings has kept billions of dollars in Americans’ pockets. It’s a powerful reminder that energy policy can directly improve lives when it puts American innovation and consumers first.

The RFS has also unlocked a wider economic revitalization in rural America. Across the heartland, biorefineries have created tens of thousands of high-quality jobs in engineering, plant operations, research and transportation. These aren’t just numbers on a page. They’re real careers in communities that broader economic shifts have all too often left behind. For rural towns across the Midwest, biofuels are a cornerstone of economic opportunity and growth.

And no one understands the impact of the RFS more deeply than America’s farmers. For generations, farmers have fed our families and fueled our economy. By creating a reliable, high-demand market for corn, soybeans and other feedstocks, the RFS has given farmers a source of stability that is nothing short of essential. This steady demand helps farm families invest in their operations, adopt more sustainable practices and navigate the ups and downs of global commodity markets. The result is a more resilient agricultural sector.

Of course, the RFS is also a cornerstone of U.S. energy security. Two decades ago, we were heavily reliant on foreign oil. Today, thanks in part to the RFS, we’ve dramatically increased our use of domestically produced renewable fuel. Every gallon of ethanol or biodiesel made here in America is one less gallon we need to import. That strengthens our national security and gives us more control over our energy future.

And the environmental impact? According to Growth Energy’s research, the RFS has helped curb over 725 million metric tons of carbon emissions since its inception. That’s the equivalent of taking more than 150 million cars off the road for a year.

For all the progress we’ve made, there’s more work to do. We need strong, stable biofuels blending targets and consistent oversight of refinery exemptions. We need policies that reward innovation, open up new pathways for sustainable aviation fuel and ensure that new technologies like carbon capture are fully recognized under the RFS.

The next chapter of the RFS must be one of momentum. That’s why I’m calling on policymakers on both sides of the aisle to recommit to the promise of the RFS. A promise to America’s farmers, to rural communities, to consumers and to our clean air future. That is a promise worth fighting for.

• Delivers up to 15% increased corn oil recovery

• Enables pathway to produce low-CI cellulosic gallons

• Dewaters corn kernel fiber for reduced natural gas consumption

• Maximizes plant operability

To learn more, contact your account manager.

A framed photo on my desk tells a story, a moment frozen in time. It’s February 2020, and I’m among colleagues from Canada and the U.S., our faces bright as we spoke of expanding ethanol markets and seamless trade. Shortly after, COVID-19 disrupted everything. Though pandemic challenges are now behind us, industry policies and market conditions continue to evolve—not to mention the shifting trade landscape.

Trade still binds our continent, with policy as its driving force. In 2024, U.S., ethanol exports reached an impressive 1.9 billion gallons with over a third destined for Canada. These figures represent more than mere statistics; they demonstrate how our cross-border partnership fulfills both Canadian biofuel mandates and supports U.S. agricultural economics. However, the focus of renewable-fuels policy is clearly shifting.

Robust policy initiatives like Canada’s Clean Fuel Regulations (CFR), the U.S. One Big Beautiful Bill (and the now extended 45Z production tax credit) and British Columbia’s Low Carbon Fuel Standard (LCFS) domestic-content requirements are reshaping the industry dynamics. Today, our sector trades not just in ethanol volume but in carbon intensities and energy-security assurances. The emerging reality is clear: biofuel policy and trade have become inextricably linked. Success on both sides of our border requires understanding this new dimension while preserving the shared values that unite the Canadian and U.S. ethanol industries. Namely, that a strong domestic ethanol sector directly supports the vitality of rural communities and the prosperity of farmers.

For the United States, maintaining global market leadership and safeguarding their position as the world’s leading ethanol exporter is crucial, while also bolstering rural America’s economy. For Canada, strengthening its rural economy is equally important, and ethanol policy offers a two-part approach. First, ethanol producers and farmers should collaborate more closely on policies that increase the value of local crops, as demonstrated in the recently launched Farms and Fuels Alliance initiative. Second, Canada’s national Clean Fuel Regulations are designed to encourage lower-carbon fuels. This positions Canada to be not only a clean fuel importer but an innovator as well, provided the proper policy signals are in place. Both countries can pursue these goals simultaneously, fostering modern trade relationships and ensuring long-term economic success on both sides of the border.

The pandemic taught us the high cost of disruption, but policy changes today could reshape our markets profoundly as well. Together, the U.S. and Canada can create better rules for biofuel trade and develop policies that strengthen the ethanol industry and local farming communities in both countries. By embracing the new reality where policy and trade are intertwined, we can secure decades of rural renewal.

Experience the Alcohol School like never before. With revamped sessions, fresh topics and more opportunities to connect, this year’s event blends cutting-edge innovation with expert-led education.

Se ptember 7-12, 2025 | Montreal, Quebec, Canada REGISTER TO DAY

El evate your exper tise.

Alto Ingredients, a producer and distributor of specialty alcohols, renewable fuels and essential ingredients, named Gilbert Nathan as chair and Dianne Nury as vice-chair of its board of directors, and announced that Alan R. Tank and Jeremy T. Bezdek were elected as directors at the company’s annual meeting in late June.

and are excited to add their wealth of experience and expertise.”

“I am honored to serve as chairman and look forward to working with the board and management as we progress on our strategic initiatives to increase shareholder value,” Nathan said. “We welcome our new board members

Bezdek is an accomplished senior executive with three decades of expertise, including experience in leadership, business development, project development, finance and commercial roles across the energy, renewables and advanced manufacturing sectors. Tank brings more than three decades of executive leadership and board experience across the agriculture, food and renewable energy sectors.

Gevo’s RNG Subsidiary Closes $40 Million in New Bond Sales, Refinances

Gevo announced that Barclays Capital has purchased $40 million of newly issued non-recourse tax-exempt private activity bonds issued by the Iowa Finance Authority for the benefit of Gevo’s wholly owned subsidiary, Gevo NW Iowa RNG. The bond proceeds were used to refinance $40 million of the previously issued Iowa Finance Authority Solid Waste Facility Revenue Bonds (Gevo NW Iowa RNG Renewable Natural Gas Project), Series 2021, which were issued in the aggregate principal amount of $68.2 million and se-

cured by an irrevocable direct pay letter of credit. This partial refinancing of the previous bonds enabled Gevo to release $40 million of restricted cash that was securing the letter of credit and increase its balance sheet liquidity by approximately $30 million after paying transaction costs and funding reserves associated with the 2025 bonds.

Gevo expects to release additional restricted cash later this year by refinancing the remaining balance of the previous bonds through the issuance of an additional series of 2025 bonds.

The Nebraska Ethanol Board announced the publication of the interim report for Phase II of the E30 Demonstration. The project is demonstrating the viability of E30 fuel (a blend of 30% ethanol and 70% gasoline) in non-flex fuel vehicles. Phase I was conducted in 2019, and the ongoing Phase II began in 2023. So far, the 94 State of Nebraska light-duty vehicles involved in Phase II have collectively driven more than 215,000 miles on E30 fuel. The research

team, from the University of NebraskaLincoln, has found further evidence of the conclusions from Phase I: E30 is safe and effective for non-flex fuel vehicles, and E30 is economically viable for broader consumption.

Currently, E30 fuel is only approved for flex fuel vehicles, but the demonstration has specific approval from the U.S. EPA to test E30 in non-flex fuel vehicles.

Our team of experts have over 20 years of ethanol plant maintenance expertise. We o er full service and parts for all Fluid Quip equipment to ensure peak performance.

• OEM Parts Warehouse

•$2 million+ inventory on-hand

Scientists at Oak Ridge National Laboratory have developed a first-ever method of detecting ribonucleic acid, or RNA, inside plant cells using a technique that results in a visible fluorescent signal. The technology can help researchers detect and track changes in RNA and gene expression in real time, providing a powerful tool for the development of hardier bioenergy and food crops and for detection of unwanted plant modifications, pathogens and pests.

RNA is a signaling molecule inside cells that is used to read the deoxyribonucleic, or DNA, code and convert it into functional parts such as proteins that are essential for plant growth and stress response. The ORNL-developed biosensor continuously monitors RNA levels in live plants, replacing a traditional destructive, time-consuming method used by scientists of collecting, processing and analyzing tissue.

•Factory Trained & Certified Techs

•MZSA™ Screens

•Paddle Screens

•Grind Mills

•Centrifuges

•Gap Adjusters

Ethanol-to-jet volumes are expected to eventually match or surpass HEFA, but more incentives—even stacked together—are needed to make alcohol-based SAF profitable.

By Susanne Retka Schill

While there may be only one ethanol-to-jet (ETJ) pathway registered with EPA to generate D4 RINs right now—LanzaJet’s facility in Soperton, Georgia—experts speaking in Omaha at the International Fuel Ethanol Workshop & Expo this June all said they expect ETJ to become a viable source of sustainable aviation fuel (SAF) in the future. The goals are substantial. In the U.S., the SAF Grand Challenge calls for 3 billion gallons of SAF by 2030 and 35 billion gallons by 2050. Based on announcements, 2025 SAF production is expected to reach 660 million gallons globally, according to Azadeh Rohani, senior consultant with Worley Consulting. The International Air Transport Association projects 120 billion gallons of SAF will be needed annually to achieve net-zero carbon emissions by 2050.

With 850,000 flights operated using SAF since 2011, Tim Hughes, project director with the Commercial Aviation Alternative Fuels Initiative, says the aviation industry is moving forward in decarbonizing its fuel.

Other data collected by the Air Transport Action Group indicates that globally:

• $45 billion dollars have been committed by airlines to date in forward purchase agreements for SAF;

• 69 airports are regularly supplied with SAF;

• 50 airlines have committed to 2030 SAF goals ranging from 5-30%, with most committed to 10%.

• 20 million metric tons of SAF uptake by 2030 could be possible under proposed and committed policies.

Eight SAF technology pathways and three coprocessing pathways have been tested and approved by ASTM, Hughes says, with the HEFA pathway being the most prominent right now. “But we’re also looking at alcohol-to-jet. And, we know that in laboratories we can take any type of carbon source and produce a fuel out of it. Some are more complicated than others, and some require a lot of energy in order to make [them] work.” CAAFI’s technical committee, made up of companies like Boeing, Airbus, GE and Pratt & Whitney, look closely at any new fuel, he says, to make sure it performs at high altitudes, is stable and safe, and works in all different engine types around the world.

GAINING LIFT: Without incentives, the cost of producing ETJ would be prohibitive. The goal, experts say, is to bring down costs while finding creative ways to stack and maximize state, federal an international credits.

“Ethanol-to-jet can be competitive compared to HEFA, the main process at the moment for SAF, keeping in mind the limitations we see with HEFA feedstock availability,” says Worley Consulting’s Rohani.

The HEFA (hydroprocessed esters and fatty acids) process uses fats, oils and greases to manufacture SAF using the petroleum refining process with specialized catalysts.

The ethanol-to-jet process, also catalytically driven, involves the dehydration of ethanol to ethylene, followed by oligomerization to link the smaller chains together, which are then saturated with hydrogen in a hydrogenation step and, finally, fractionated to separate the SAF from the byproducts of renewable diesel and renewable naphtha.

ETJ compares favorably to HEFA in terms of carbon intensity reduction and lands slightly higher in cost of production, Rohani says. (See accompanying chart, “Technologies: Typical CI and COP for SAF”) When com-

SOURCE: WORLEY CONSULTING

paring soybean oil, the main HEFA feedstock, to corn, the SAF yield per acre of corn is five to six times greater than the SAF yield from an acre of soybeans, Rohani adds, another point in corn ethanol’s favor.

Looking at the cost of production for ETJ, ethanol feedstock is the largest component, followed by capital cost. Revenue projections, Rohani says, indicate ETJ can be profit-

able, but only if incentives are added to the jet and byproducts price. (See the accompanying “Economics” illustration.) In one analysis, the cost of production comes to $5.80, while the potential revenue, including incentives, is $6.20. “The numbers support profitability and competitiveness of the ethanol-to-jet pathway, which gives us some comfort about investing in this process,” she says.

ETJ, however, will only be profitable if the ethanol feedstock and ETJ process meet the carbon reduction thresholds prescribed in the various incentive programs. “Those solutions are really dependent on a specific case,” Rohani says. Carbon capture and sequestration of the CO2 from fermenters offers the biggest opportunity for CI reduction—around 30%. Integrating CCS with cogeneration offers another 20-30% reduction. Using lowcarbon hydrogen, low-carbon power and capturing carbon in the ETJ process itself offer smaller CI reductions. “The steps you take to reduce carbon intensity gives you higher [45Z] credits per gallon.” In the example she gave in her FEW presentation, the total CI reductions could receive $1.10 in 45Z credits. Note: after the FEW, changes were made to the 45Z biofuels tax credit when the OBBB Act was signed into law by President Donald J. Trump on July 4.

Sofia Cabrera, SAF price reporter for S&P Global Commodity Insights, projects that in the short- and medium-term, HEFA

COMBINING CREDITS: ETJ can be profitable, but only if stacked incentives are added to the jet and byproduct revenue.

SOURCE: WORLEY CONSULTING

technology is going to predominate. “We are also seeing ETJ gaining some space in the mid- to short-term, but we forecast that in the long term, the three main technologies, HEFA, ETJ and e-SAF (power-to-liquid) are going to gain the same market share.”

Airlines are, in part, turning to SAF in response to customers and investors pushing for more sustainable fuels, Cabrera says, “but SAF demand is driven primarily by policy.” Globally, governments take two approaches. One focuses on carbon intensity and green-

house gas reduction with various incentives. In the other approach, governments mandate blending volumes. Then there are book-andclaim programs being developed, alongside other voluntary carbon reduction frameworks promoted by international aviation organizations like IATA and CORSIA.

In Europe, the ReFuelEU mandate began this year, requiring 2% blends, increasing to 6% by 2030 and 70% by 2050. The mandate is layered on top of the Renewable Energy Directive (REDIII). The challenge, Cabrera says, is that individual EU members are taking different approaches, with Germany and Denmark looking at CI while others are focused on blending obligations. European regulations also include feedstock requirements.

In Asia, China, Thailand, South Korea and Japan have mandated SAF blending levels. In South America, Brazil has its Fuel for the Future program, Chile has a Road Map for SAF and Columbia is developing a program. “Many countries are putting a lot of effort into pushing this industry forward,” Cabrera says.

In the U.S., prior to the recent enhancements to the 45Z clean fuels production tax credit, and amid shifting dynamics of oilseed and waste fats, markets had paused some HEFA and renewable diesel projects, Cabrera says. “Other policies like the LCFS in Califor-

nia or the purchase credit for SAF in Illinois haven’t been sufficient to compensate for the amount of uncertainty in the market.” Time will tell whether the enhancements to 45Z will be enough to turn things around.

When asked which were more effective, incentives or mandates, carrots or sticks, Kristine Klavers, managing director at EcoEngineers, says that in Europe, the penalties are so big that “the money will be there. But we see so much more activity here in the U.S. in investments to get incentives, and if we look back in history, incentives have been more effective than penalties.”

Klavers cautions that prospective SAF producers need to contact compliance consultants like EcoEngineers, early in their development process. “You don’t know how many calls I get from companies saying, ‘I have my technology and engineering completed, I have financing, I’m ready. Can I get a credit?’” But unlike established biofuels, where compliance details wait until the end, SAF specifications and regulations need to be considered from the beginning. SAF needs to first meet ASTM specifications, she explains. ETJ has an approved ASTM pathway with non-specific requirements that can be challenging to navigate. Getting approval using a different process can take years. Then, the fuel itself has to meet ASTM specifications. ASTM isn’t a regulation, she adds, “it’s a specification created by engine manufacturers. They’re not going to let anything through unless they’re 100% certain that their airplanes are safe using the fuel.”

Then, SAF must meet the requirements for the targeted market. “There is only one fuel, but many, many markets, and each and every country is trying to create their own regulation,” Klavers says. “If you want to go to Europe, you have to have at least 50% reduction in the carbon intensity score. But if you’re building a new plant and you want to go to Europe with your SAF, you have to be at least a 65% reduction. So, that’s just your entrance ticket.” The European market, which has blending mandates being phased in, also has layers of regulations in overlapping directives, regulations on allowable feedstocks, plus

differences among countries in how they individually apply the regulations.

In the U.S., the first step is to get a Renewable Fuel Standard pathway approved to be able to generate D4 RINs. There is one ETJ pathway approved already, Klavers adds, but it is plant and feedstock specific. For others, “you better come to a company like ours and file a petition to go to the government and ask for a pathway.”

State credits can be stacked on top of the RINs value, but each state’s program differs slightly. And, even after the passage of OBBB, it is yet to be determined just how the 45Z production tax credit will operate. In Canada, British Columbia has had its own low carbon fuel standard in place for a few years, plus the nationwide Clean Fuel Regulations are getting underway.

In the Q&A after their presentations, the speakers were asked bluntly: Does ethanol-tojet stand on its own from a profitability point of view, without all the stackable credits?

Rohani replied no. “That’s a definite answer, and that’s part of the challenge for the future,” she said. The cost of production, at the moment, is higher than the revenue that you could get without the incentives. Maybe in the future—the technologies are getting mature fast and there will be advances. The price of utilities, the price of feedstock, all of those would have a contribution, but without those incentives, at the moment, it’s not profitable.”

The current uncertainty around U.S. policies has dampened progress, Cabrera says. “Some projects we were expecting to take off in the next two years, we now expect to move to eight or 10 years.” The policy uncertainty is expected to be short term, however, and doesn’t mean SAF development is stopping, she says. “SAF is still very nascent, and everyone is trying to move forward. That is great, but even the fuel needs some fuel, and that will come from policy, in my opinion.”

Author: Susanne Retka Schill writer@bbiinternational.com

BASF’s xarvio BioEnergy – Setting the Standard for Verified Low-Carbon Intensity Feedstocks

In today’s bioeconomy, every gallon matters. Ethanol producers, fuel suppliers, and chemical companies must secure sustainable, verifiable agricultural feedstocks to unlock 45Z tax credits, access premium low-carbon markets and future-proof their supply chains.

That’s why BASF built xarvio BioEnergyTM, a purpose driven digital platform that simplifies the complexity of farm level practice verification, CI data collection and compliance with the highest level of integrity.

Seamlessly connects the supply chain:

• Links farmers, retail agronomists, ethanol plants and grain elevators.

• Ensures traceable, auditable data whether feedstock is sourced directly or through grain elevators.

Delivers field-level precision:

• Supports the retail agronomist with ag-

ronomic insights to help maximize yield and lower carbon intensity utilizing xarvio Field Manager™

• Provides verified, MRV-compliant CI data for every bushel.

Built for today, ready for tomorrow:

• Unlocks 45Z credits now that can be generated from low CI grain

• Future-readies access to potential LCFS markets, sustainable aviation fuel (SAF), marine fuels and chemical markets

• Prepares for evolving domestic and international sustainability standards like ISCC and EU RED III

With decades of agronomic knowledge, sustainability leadership and digital innovation, BASF’s xarvio BioEnergy provides more than compliance, it delivers confidence in every data

point, enabling bio-processors to meet market demands today and anticipate the opportunities of tomorrow.

“Xarvio BioEnergy was designed from the ground up to simplify the complexities of connecting farmers, agronomists, and ethanol producers,” says Jeff Carver, commercial and technical service manager with BASF. “By ensuring clean, verifiable data, we help processors unlock the full value of sustainable feedstocks.”

“Xarvio isn’t just a tool to unlock 45Z credits,” says Chad Asmus, sustainability market development manager with BASF. “It’s a long-term solution that future-readies your supply chain as low carbon intensity markets expand and new opportunities like SAF and low-carbon chemicals emerge.”

Ready to secure verified feedstocks for the future of low-carbon markets?

Learn more at www.xarvio.com/us/en/ products/bioenergy.html.

We’r e making it ea sy to ma ximize pr oduc ti vity and pr ofi tability.

Simply adding the Phiber Flex™ pr ogram to your oper ation can have major impacts down the line. By combining the power of XylaPlus® and CelluMax™ enzymes, PhiberFlex can:

Impr ove cellulosic ethanol conver sion —quali fy ing for D3 RINs

Impr ove corn oil pr oduc tion

Incr ease ethanol y ields

Lower residual star ch

A sk your Phibro repr esentative about tr ialin g the Phiber Flex pro gram.

By Katie Schroeder

The 2025 International Fuel Ethanol Workshop & Expo’s attendees represented a wider swath of the U.S. ethanol industry’s capacity than ever before, with 94% of the nation’s installed capacity spoken for at the mid-June event. During his opening remarks, Joe Bryan, CEO of BBI International, thanked the speakers, sponsors and exhibitors for coming together to discuss shared challenges and opportunities. He also praised the work, vision and commitment speakers and exhibitors bring to the panel sessions and sprawling expo. “Every year, we are still in awe when we walk out on the trade show floor and see the investment and the time and creativity that our exhibitors and sponsors bring to the table,” Bryan said.

John Nelson, chief operating officer with BBI International, shared that the 2025 FEW had 373 exhibiting companies and 2,490 attendees representing 45 U.S. states, eight Canadian provinces and 30 countries.

Optimizing ethanol’s growth and addressing industry constraints were the key focuses of the keynote address delivered by Geoff Cooper, president and CEO of the Renewable Fuels Association. He discussed the state of the ethanol industry under the second Trump administration and how ethanol fits into President Trump’s goal of “Unleashing American Energy.”

“If there was ever an energy sector that needs to be let off the leash and allowed to run free, it is today’s ethanol industry,” Cooper said. “For far too long, bureaucratic barriers, regulatory indecision, and policy uncertainty have been holding the U.S. ethanol industry back and preventing us from reaching our full potential.”

Cooper covered the regulatory challenges and opportunities the ethanol industry is currently facing, and he explained what needs to be done to truly unleash ethanol’s potential. The actions he presented in-

cluded finalizing strong RFS volumes, passing year-round E15 legislation, prioritizing trade barrier removal, establishing a technology-neutral approach to federal policy that allows biofuels to compete with electric vehicles and clarifying the implementation of the 45Z Clean Fuel Production Credit.

Trade, 45Z and E15 also dominated the conversation during the policy Q&A with Brian Jennings, CEO of the American Coalition for Ethanol; Chris Bliley, senior vice president of government affairs for Growth Energy; Troy Bredenkamp, senior vice president with the Renewable Fuels Association; and moderated by Ben Rhodes, executive director of the Nebraska Ethanol Board.

The panelists explained that the trade actions taken by the Trump administration have been mostly helpful to the American ethanol industry, particularly in addressing trade imbalances with Brazil and restrictions on fuel ethanol in India. On 45Z, Bredenkamp talked about the momentum behind the One Big Beautiful Bill Act—which was passed and signed into law three weeks after the FEW—and he explained that there hadn’t been talk of removing 45Z from the legislation, which proved to be prescient. Jennings noted that he believes there is reason for “cautious optimism” under the current administration.

The group also discussed talking points that the industry should focus on under Trump, discussing how different economic policies play better under different presidencies. Bliley recommended talking about ethanol’s consumer benefits and the way it provides jobs for small communities, and Bredenkamp advocated for emphasizing national security.

Expertise sharing was not limited to the general session at the FEW. Producers attended panels on process efficiency, technology, coproducts and more, continuing the tradition of the FEW being a hub of productive conversation and problem solving.

The 2025 FEW honored four individuals for their exceptional leadership, research, advocacy and innovation.

By Katie Schroeder

The ethanol industry is privileged to have numerous unassuming leaders—advocates, innovators, visionaries and trailblazers—who work with a quiet passion, never expecting praise or prize. Each June, however, the industry honors a select few of these deserving professionals with hand-crafted accolades and heartfelt gratitude at the world's largest ethanol event.

For a quarter of a century, the International Fuel Ethanol Workshop & Expo has bestowed two annual awards: the Award of Excellence and the High Octane Award. Building on that legacy, BBI International added the Women In Ethanol Award in 2023 and the Distinguished Service Award in 2024. This year, in Omaha, Nebraska, the tradition continued with four deserving professionals being honored at the FEW for their work.

Gillian Harrison, CEO of Whitefox, received this year’s Women In Ethanol Award, an accolade sponsored by CTE Global. Her journey in the biofuels industry began back in the early 2000s, when she left her successful decade-long legal career to pursue entrepreneurship with Whitefox Technologies. Longing for an opportunity to build something rather than help companies make deals and sign contracts, Harrison took the risk of starting something new. “I was prepared to take a chance to leave a very successful legal career and begin an entrepreneurial career,” she says.

Harrison believes that humanity has used its ingenuity and brilliance to accomplish amazing things and will continue to do so. As custodians of the earth for future generations, she says, we must utilize that ingenuity to avoid damaging the natural world unnecessarily. “We should be able to have a great quality of life in our generation, but not at the expense of future generations,” she says. “And I think that we have shown through the Industrial Revolution how brilliant we can be at turning different resources into the energy and the products that give us that quality of life.”

Leveraging innovation to improve efficiency and reduce energy consumption drives Whitefox, so Harrison was a perfect fit there. She started at the company in 2007, serving as general counsel and head of business development for South America until she became CEO in 2009.

Reflecting on her career, Harrison identifies one moment as her proudest: signing the first U.S. ethanol producer to install Whitefox’s membrane technology. When the company first started promoting it, many producers were interested, but all wanted to “be the first to be third,” Harrison explains. After months of promotion, she met Neil Kohler at a conference in Hungary and struck up a conversation with the West Coast ethanol producer. It was a pivotal moment for Whitefox.

“[We] got to that point of the conversation where he said, ‘Well, who else is doing it?’” At that point, Harrison said, she took a breath, repeated her pitch and acknowledged that no other U.S. producers had installed the technology—yet. “And he said, ‘Well, I love being first.’ And so, I shook his hand and said, ‘You, Neil, will be first.’” Kohler’s company, Pacific Ethanol—now known as Alto Ingredients—installed Whitefox’s technology in 2016, kicking off a series of installations over the next decade that have made Whitefox and its technologies well known and respected in the industry.

Reflecting on her career in ethanol, Harrison says the most rewarding elements of her work are the friendships she’s gained throughout the industry. “I love the generosity of the ethanol industry,” she says. “People give you their time. They share their stories. They share their pains. They share what they’re looking to achieve. And I’ve developed good friendships in the ethanol industry because people do give you their time.”

Steffen Mueller, principal economist with the University of Illinois at Chicago Energy Resources Center, received the 2025 Award of Excellence. Mueller’s origins in a rural community in central Germany informed his perspective on the value of biofuels production—specifically its impact on rural farming communities.

Mueller moved to the United States 30 years ago through an exchange program that allowed engineers from Germany and the U.S. to spend time working in each other’s countries. He began his career with an energy engineering firm, then attended night school to get his Ph.D. in economics. For his doctorate degree, Mueller wrote his dissertation on how energy technologies are adopted. He took on a position at the University of Illinois Chicago Energy Resources Center and became involved in the biofuels space. In 2004, Mueller visited Adkins Energy, an ethanol plant in northwest Illinois, to analyze the plant’s combined

RESEARCH: As noted by his nominator, Steffen Mueller (pictured second from left) served as a principal researcher on the ongoing Biofuels Research Project led by the Hormel Institute that studies the carcinogenic effects of compounds originating from aromatics.

heat and power system as part of a study funded by a U.S DOE grant. His study examined the energy consumption used by ethanol facilities, proving that ethanol producers were using less energy than the current lifecycle model estimated.

“It was published in 2010, but in 2008, 2009 [and] 2010, we collected data from ethanol plants to document that their energy consumption was much more rapidly declining than previously believed, and that resulted in lower lifecycle emissions on the corn ethanol produced,” Mueller says. His work informed updates on ethanol plant energy consumption to the “Greenhouse Gases, Regulated Emissions, and Energy Use in Technologies” (GREET) model.

That first biofuels-related study would not be the last. Mueller went on to serve on the advisory committee for California’s Low Carbon Fuels Standard, execute studies on land use change and author or co-author 40 different papers.

Biofuels constitute a unique field of study within the energy space, Mueller explains. It allows scientists to examine land-use change interactions between food, fuel, feed and biochemicals, and learn more about how we can blend ethanol to produce cleaner fuels. “My research shows that biofuels are contributing to greenhouse gas reductions and harmful aromatics reductions in our transportation fuels, and that’s sort of a big mission of mine to support,” he says.

Rick Schwarck, president and cofounder of Absolute Energy, was the recipient of this year’s Distinguished Service Award, which was accepted at the FEW by Tyler Schwarck. With a background in financial services, Schwarck helped found Absolute Energy in 2008 and started up the plant at a capacity of 100 MMgy. After expansion, the plant now runs at around 135 MMgy and is planned to expand up to 150 MMgy in early 2026. A native of Mitchell County, Iowa, Schwarck has spent decades investing in rural America through the ethanol facilities he has been involved with, while also being an active advocate for the industry.

Coordination and cooperation help make advocacy effective, and over the years Schwarck has helped industry trade organizations like the Renewable Fuels Association, the American Coalition for Ethanol and Growth Energy coordinate with one another. “I’m on all the boards and I kind of serve as a mediator to try bring us to together, [on] the same message as best as possible, so that when we go to … the media or government, we’re all singing from the same songbook,” he says.

Schwarck also dedicates time and energy to communicating the health benefits ethanol offers, as well as the positive impact it has had on farming communities around the world, by increasing the domestic market for American crops via the Renewable Fuel Standard. Working with the U.S. Grains Council, he has been able to promote ethanol’s benefits internationally, including the way DDGS helps address the “starch bottleneck” in the world’s food supply. Although a corn kernel only has 8% protein, once the starch in the kernel is turned into ethanol, the DDGS left over is protein-rich in comparison at around 34%. “There’s still excess starch in the world, but a need for more protein,” Schwarck says. “And so, making more ethanol will help accomplish that as well.”

Food and fuel are not the only beneficial aspects of ethanol that Schwarck has championed. Another key accomplishment of his career

was assisting scientists at the Hormel Institute in gaining the funding needed to research the health impacts of Benzene, Toluene, Ethylbenzene and Xylenes (BTEX) as a gasoline additive. The studies done by Gail Dennison, Lena Clark, Shujun Liu and others explored BTEX’s impact on lung cancer, breast cancer and other health problems. Schwarck would like to see the U.S. increase the national standard ethanol blending percentage up to an E30 blend, fully replacing BTEX.

Although he has already had a storied career in ethanol, Schwarck is not done yet. “I’ve got … a lot of things yet to accomplish. [The] past has been great, but the future is even brighter in my opinion.”

Michael Jerke, CEO of Southwest Iowa Renewable Energy was given the 2025 High Octane Award. An Iowa native, Jerke grew up familiar with farm work. After a summer job working at a grain elevator, Jerke decided to pursue grain marketing and management. His education at Iowa State University gave him a deeper understanding of the economics of farmer co-ops and their value to rural America. Ethanol plants have a similar positive impact on farmers, he explains.

Jerke got his start in grain elevator management for ADM but transitioned to the ethanol industry in 2001, serving in a leadership role at Quad County Corn Processors in Galva, Iowa. Over the last 24 years, he has worked in a leadership capacity at a total of five ethanol plants. Reflecting on his career, he says he’s proud that he left every ethanol facility in a better place than when he arrived. Jerke finds it “a real joy” to work with like-minded individuals in the industry who share the same drive, passion and focus.

“The through line for me is really just being very passionate about rural America and seeing the farm economy improve and seeing the way that people are really self-starters in this industry and just doing things to better their situation and the situation of the community,” Jerke says.

As an involved industry advocate, Jerke believes producers shouldn’t assume that policymakers understand the ethanol business; he says they have to continually engage with state and federal legislators to help them understand ethanol’s value. “One person can truly make an impact when they’re able to share a solid story, explain a position and then engage with people that are in [regulatory] positions [or] elected,” Jerke says.

Looking forward, Jerke is excited for what lies ahead. “I’ve never been more optimistic about the future of the ethanol industry than I am now,” he says. “I think the industry has embraced decarbonization as society as a whole is recognizing the real benefits ethanol brings to the concerns people have around carbon, climate, sustainability and energy independence.”

Motivated by the pursuit of excellence and desire to improve the lives of people and the health of the environment, each of the 2025 FEW awardees has built a legacy in relationships made, discoveries shared and innovations developed.

Author: Katie Schroeder katie.schroeder@bbiinternational.com

Robert Lundeen impacted his family, business associates and the ethanol industry in a way that lives on today.

By Luke Geiver

Robert “Bob” Lundeen never wanted to be a common man. He was a big thinker, a problem solver, a risk taker, according to everyone that knew him. Lundeen was the type of person willing to mortgage everything on a vision he believed in. Just ask his wife, Sandy, who says she had to sign-off on life altering projects more than once. He was always a forward thinker blessed with a relentless work ethic, a strategic business acumen and way about him that turned most of his business associates into lifelong friends.

His career accomplishments in industrial construction and ethanol proves he was anything but ordinary. When the second bore of the Eisenhower Tunnel came up for bids around 1975, Bob put in his own. At the time, he was working with his father in commercial plumbing, heating and cooling, and the job seemed far too big for the small company. It certainly wasn’t a project his dad thought the team could ever dream of working on. The job called for completing the second tunnel of an interstate infrastructure project connecting traffic traveling through the Rocky Mountains and the Continental Divide. The contract was bigger than big—and they got it. Bob and his team finished their work, handling the ventilation, drainage, air cooling and other tasks on what would ultimately be considered the highest tunnel in the world, according to the Colorado Department of Transportation. To this day, millions of vehicles pass through the tunnel every year.

capture and transport networks for his plant and the greater ethanol industry.

TINA LUNDEEN SMITH

After that complex job outside of Denver, Lundeen continued taking on large-scale industrial projects, even though his initial plans in life were to go into finance. He worked on hydroelectric projects to gasification systems, installing or building turbines and generators at several plants in the Columbia River Valley.

“I asked him once when he was ever going to be satisfied,” Sandy says with a smile

during one of several interviews for this story. “He was never going to retire.” One day, in the early 2000s, she recalls, Bob came home and said they were shifting away from their current work at the time and getting into ethanol.

Lundeen’s vision and well-documented ability to get things done were responsible for putting Mid America Agri Products/Wheatland (MAAPW) on the map in 2007 in ru-

ral Nebraska. The 48 MMgy plant Lundeen founded has been operating successfully since and will become one of a small group of ethanol plants commercially capturing, sequestering or transporting carbon dioxide when the long-haul CO2 Trailblazer pipeline operated by Tallgrass goes into operation as soon as late 2025. Those that have collaborated on the carbon capture efforts with Lundeen all say it was his visionary mindset that got a major pipeline supplier working with the largest ethanol producers in the world (ADM and POET) to even consider the Madrid plant.

“Bob was an embodiment of the project’s name: a trailblazer. Even in the face of uncertainty surrounding implementation of CCS at Midwest biofuels facilities, Bob supported the Trailblazer CO2 project and held steadfast in his belief of doing what was best for his family and community,” says Steven Davidson, vice president of public and government affairs for Tallgrass. “The MAAPW facility is the life-

blood of Madrid, and Bob truly cared about empowering his friends and neighbors to meet changing market demands and take advantage of new opportunities.”

Lundeen’s pioneering and relentless pursuits in ethanol are worthy enough to make him a first-ballot ethanol hall of famer, according to everyone who worked with him, from plant managers to industry advocates. The current connection between CO2 capture and ethanol production may not be what it is today without the foresight by Lundeen to link the two. Lundeen was the earliest to sign with Battelle Memorial Institute on a study to look at CCS at his relatively small ethanol facility in Nebraska. Listen to Sandy, or his daughter Tina Lundeen Smith, and it’s easy to see why Bob is, and will always be, celebrated and inspiring to those who worked or spent time with him inside the ethanol sector. Most don’t just revere him, they want to be like him. Currently, Sandy is the largest shareholder of MAAPW and Tina has

left her career as a senior marketing executive in the tech sector to help lead the next evolution of MAAPW. She joins her brother-in-law, Prestin Read, current CEO at MAAPW, leading the cohesive and skilled leadership team in place. Read has been instrumental in leading the MAAPW plant and representing Nebraska producers within the greater ethanol industry. He was also an important part of Lundeen’s life and a trusted confidant who understood Bob’s priorities and vision.

“Without dad’s vision,” Tina says, “our future would look a lot different.”

Lundeen passed away in 2023, but not before leaving an impact on those he called family and those he worked with. According to many that knew him, Bob had a way of turning most relationships into lasting friendships. He was unique, most agree, and the type of person anyone could draw inspiration from.

Kelly Manning, senior vice president of development at Growth Energy, considered him a friend beyond the work the two did to advocate for biofuels. Former Nebraska Governor Pete Ricketts, now U.S. Senator, considered Bob a friend. Even the nurses at Mayo Clinic that treated him before his passing recognized that being around Bob was special.

Tom Solon, director at Solon Advisory, not only considered Lundeen a friend, but also a mentor. Solon worked with Lundeen for many years, often reaching out to him for insight on engineering, procurement and contracting. Solon helped Bob’s team get the capital stack in place for the CO2 work Lundeen wanted to pursue starting in 2019 with Battel-

le. Later, Solon also helped Lundeen’s efforts to become one of the first ethanol producers in the country to transport CO2 via long-haul pipeline.

“Bob was a connector, he could bring people together,” Solon says. “He could also see things in the future.” Solon specifically remembers a time during Bob’s last period of work before his passing when he brought everyone working on the pipeline project together. He reminded everyone that they would need to continue building trust with each other and the only way the work would ever get done was by working together, not alone.

Part of Lundeen’s abilities to get things done stemmed from his knack for connecting with people, Solon believes.

“He didn’t just reach out to you when he needed something,” Solon says.

In North Platte, Nebraska, where the Lundeen’s called home for many years, people knew Bob as a giver. His generosity often came through the donation of books. A voracious reader who could finish multiple books per week, he was always giving books to people, sometimes out of a collection he kept in the

back of his Suburban, Sandy explains. Some people in North Platte simply knew him as the guy with books in his trunk.

For any and all projects, he immersed himself into the action, committing to the people and problem-solving efforts that were needed. Although he traveled the world with his family and owned and frequented a boat in the Pacific Northwest, Lundeen always showed an appreciation for time at home and around the dinner table.

After most business meetings with potential partners or business connections of the most powerful sort, Lundeen often ended the day by hosting his clients or business associates to dinner at his home.

“I remember getting so many calls from him asking if we had room for three more at the table for supper,” Sandy says.

During one memorable evening dinner with a business associate, Sandy recalls the guest taking a particular liking to a Ducks Unlimited painting hanging above the fireplace. At some point during the evening, she says, Bob stood up, grabbed the painting off the wall and handed it to the guest. “He just said, ‘Here. It’s yours now.’”

At his funeral, most everyone there were great friends, regardless of what their technical connection to Bob was.

“He just had a way about him. Ever since I met him. He was the guy that walked into a room and everyone lit up,” Sandy says.

Bob had several beliefs he lived by. He always dressed as well as he could. Remember, he was committed to being more than com-

mon. His family recollects many of his sayings. If you find a shirt (or something you like) buy a dozen. When you can advance, do it. When in doubt, purge. Always be generous with what you have. And as Solon notes, take action.

“Bob was always a man of action,” Solon says. “When he made a plan, he’d attack it and then assess along the way.”

As Sandy and Tina sat in silence during one of our calls for this story, both trying to recollect the things Bob used to say, it was a song that broke the silence. Both his wife and daughter smiled in unison as they recognized that they’d both remembered Bob’s theme song to life, they said. Sandy and Tina laughed with the type of heavy eyes people can’t hold back when they remember something of meaning about someone they miss, the lyrics “Can’t nobody hold me down, can’t nobody break my stride,” filling the silence on the call.

Following Bob’s passing, Sandy took his place on the board at MAAPW. Don’t be fooled into thinking she was never part of Bob’s success during all those years working on the Eisenhower tunnel or expanding the Nebraska ethanol industry. Sandy knows her stuff, even if she exudes modesty about her role in growing the family legacy.

Tina recalls many nights when Bob would run ideas and plans by Sandy.

“She was his sounding board. He would always run things by her,” Tina says of her mom.

Tina is also a Lundeen with a major role to play in the future. Tina was elected chairperson of the board and now helps represent MAAPW to the industry and the world. She is not short on passion or ideas for continuing the work of her father. When asked what the future holds, she responded with a litany of questions she is exploring with her team on topics ranging from plant expansions to partnerships or new technology.

“There are a lot of directions we can go,” she says. “We’re looking at everything. Dad always pushed the envelope. So will I.”

Sandy doesn’t hesitate or dance around describing her daughter Tina and her expanded role with MAAPW.

“People all tell me the apple doesn’t fall far from the tree when they talk about Tina,” Sandy says very matter-of-factly. “She brings so much energy and business acumen. She is so much like her dad, full of piss and vinegar.”

Tina says she wants to help guide the company to the next level. But it hasn’t been easy. In part because taking the reins of any business is hard, especially one that was run by such a dynamic person. No one has sat in Bob’s chair at the headquarters since he passed (literally).

Currently, Lundeen Smith believes MAAPW has two great selling points. The plant will be one of the first to transport and sell carbon. And, the facility in Madrid could easily be expanded. Lundeen Smith says she’ll use all the lessons her father taught her. Most are remembered when thinking of him and how he lived. “He was always excited about everything and there was never a line between friendship and business,” she says. “He found a way to get things done.”

The last time Tina was alone with her dad was in December of 2022. They were at the ethanol plant. It was the 23rd. On the 22nd, Madrid had begun experiencing bitterly cold weather. Parts of the plant were exposed and in need of protection to get through the unexpected cold snap. Tina remembers driving to a Cabela’s with her dad to buy all sorts of warm gear so that her, Bob and other team members could deal with the cold and maintain operations.

Most people you talk with about Bob have similar stories of how he took on problems by taking action. When the Traillblazer pipeline starts transporting ethanol-based

CO2 this year or next, Lundeen’s legacy will grow with each ton of CO2 transported. Participating in CCS is a historic feat for MAAPW and the entire ethanol industry, which Bob always endeavored to transform. He wanted the industry to move from being thought of as a producer of commodities to a provider of differentiated products.

Bob’s full story is too complex and long to fit into the pages of a magazine piece. There are so many fun stories. Just ask Sandy about the times when Bob was young and would jump the train from Milbank, South Dakota, to Minneapolis. Or the buffalo head they have in their house and why it’s there, or the summer before Sandy’s senior year when Bob was driving by on his way to a different date. He stopped to swing open the door of a ’59 powder blue Ford and just started talking to Sandy. He never made that other date, or called any other woman the love of his life. Ask Tom Solon about Bob’s ability to problem solve and help other people do the same. Or Sen. Ricketts, ask him about what a man from North Platte meant to the state and its rural areas. Ask Manning about Lundeen’s vision and friend-

ship and how it helped further the ethanol industry in D.C. The team at Tallgrass also has much to say about working with Lundeen to turn a 390-plus mile pipeline from a natural gas route running one way, to a CO2 transport line running the opposite way.

“What may surprise those outside the agriculture sector is just how interconnected the bioeconomy is. While the project is opening new markets for the entire industry and impacting more than 6,000-plus workers,” Davidson says, “it is also benefiting the tens of thousands of family farms that supply corn, and the equal number of livestock producers that utilize ethanol products in their operations.”

In some ways, Bob Lundeen’s story— about ethanol or otherwise—is not yet over. He left a legacy, a wonderful trail of business lessons and a blueprint for living life as a bold, action-oriented problem solver. While he is at rest, Bob’s work continues.

Author: Luke Geiver writer@bbiinternational.com

By Matt Bilski and Marina Tschida

In ethanol production environments, where numerous decisive factors are out of operators’ hands, it is crucial producers control the things they can, tightening their grip on core operations as much as possible.

But, for too many ethanol producers, a fundamental lack of visibility is forcing them into a reactive position, especially when it comes to the cleaning and sanitation of core equipment like evaporators. Instead of acting proactively and strategically, companies are defaulting to frequent hydroblasting and arbitrary, inherited cleaning procedures that make process optimization all but impossible.

New digital tools are changing this. But to make the most out of ethanol’s digital revolution, producers must have a firm grip on the obstacles in their way and how, exactly, new technologies help mitigate them.

When it comes to cleaning core equipment like evaporators, ethanol producers’

EFFECTIVE CIP: Solutions like Evaporator IQ reduce CIP downtime through digital monitoring that provides a quick evaporator performance review, trending data and immediate feedback of CIP effectiveness.

challenges converge on one issue: visibility. There’s a lack of clarity over whether equipment is being cleaned frequently or thoroughly enough. For example, many producers take their equipment offline for deep cleaning with excessive frequency out of an abundance of caution. On the other side of the coin, some producers wait until their equipment is so soiled that it requires immediate attention, which undermines productivity.

Both of these outcomes are a far cry from optimization and threaten to drive up energy and water costs, which undercuts the potential achievement of sustainability goals.

Productivity data is often relegated to outdated tools like spreadsheets, which adds further uncertainty fueled by human error: Not knowing whether a clean was carried out often means another round of CIP and another production delay.

Digital monitoring solutions can help. Here’s how.

'Digital tools should maximize efficiency and prevent timeconsuming shutdowns with insights that enable proactive and targeted cleaning.'

- Matt Bilski and Marina Tschida, Ecolab

In nearly every business situation where visibility is a primary issue, the effect is the same: a dreaded reactive posture. For CIP, that might mean when an issue arises (bringing downtime with it), operational teams respond with the tools at their disposal until the issue is resolved. The plant is back in action until the issue crops up again. Rinse and repeat.

This approach keeps ethanol supervisors afloat, but it does little to keep them competitive in a thin-margin industry. In fact, in an environment of extreme volatility, this reactive posture can actually undermine the long-term health of the organization.

Ethanol producers can’t afford simple reactivity. They need to adopt a proactive approach to CIP operations that actively streamlines core processes, minimizes dis-

ruptions as much as possible and continuously improves outcomes across a number of important KPIs.

Digital tools can accomplish this by delivering real-time insights into productivity metrics, which allow for a more strategic approach to cleaning processes and schedules. Every operation will need to make their

digital transition in their own way using their own criteria, but there are many shared factors that all ethanol producers should consider when going digital.

-Maximizing uptime and throughput. Digital tools should maximize efficiency and prevent time-consuming shutdowns with insights that enable proactive and tar-

geted cleaning. Instead of waiting for severe drops in functionality or relying on scheduled cleanings that fail to target problem areas, producers can minimize downtime and maximize throughput by forecasting cleaning needs and addressing soil buildup before it becomes an issue.

- Managing costs. More frequent hydroblasting means higher energy and water bills, to say nothing of the expense of skilled labor. Digital monitoring allows ethanol producers to strategically deploy lower-lift cleanings that prevent the types of buildup that require hydroblasting.

- Better sustainability. In the long term, producing ethanol sustainably is directly tied to the longevity of the entire industry. As other alternatives to fossil fuels continue to gain market share, ethanol producers must position their product as a sustainable option for fueling equipment incompatible with electrification (e.g., planes). Overreliance on hydroblasting undermines this key goal by ratcheting up emissions related to higher energy use and contributing to complicated water management issues that threaten to derail sustainability initiatives. But, by drastically reducing or eliminating the need for hydroblasting, digital monitoring tools can help ethanol producers stay on track to more eco-friendly operations.

- Managing generational turnover. As a new generation of factory leaders takes the mantle from valuable retirees, ethanol producers won’t be able to rely on institutional knowledge anymore. Digital tools create an intuitive means of centralizing productivity insights and backing up cleaning protocols with hard data and thoroughly documented procedures. Instead of relying on well-

honed instincts or ad hoc, rudimentary insights, facility leaders can ensure production continuity through easily digestible data analysis and intuitive dashboards that all employees can understand and use.

The Evaporator IQ system from Ecolab offers a glimpse of what this proactive approach to CIP can look like in practice. It also demonstrates how digital insights can exist within a more comprehensive approach to CIP, one that actively strategizes ways to avoid productivity issues instead of simply responding to them.

The system’s three-pronged approach enables a progressively more proactive approach to CIP that producers can implement at their own pace:

1. Cleaning Solution: A targeted cleaning solution attacks buildup and mitigates the threat of blockages

2. Scale Inhibition: Scale inhibitors curb the development of calcium oxalate and magnesium phosphate formations

3. Digital Insights: Real-time data translates a complex web of production variables into a unified, holistic productivity metric

The digital monitoring tool uses a facility’s existing sensor technology to supplement evaporator function with real-time insights into pressure, flow rates and percent solids. By turning these variables into a unified “cleanliness factor” metric, the digital tool helps plant managers respond faster to production slowdowns and make smarter, more targeted cleaning decisions that minimize downtime and support higher levels of efficiency.

“Same ol’ same ol’” will not be enough for the next generation of evaporator management, or ethanol production as a whole. To position themselves competitively, ethanol producers need to consider the full breadth of positive outcomes that digital monitoring tools make possible.

Solutions like Evaporator IQ are just one piece of the puzzle, but they can set producers on a path toward smarter operations powered by digital insights. Combined with the right chemistries, the right people and the right strategies, digital insights are poised to define the future of ethanol production.

Authors: Matt Bilski, RD&E Program Leader, Food & Beverage at Ecolab Marina Tschida, Senior Chemical Engineer at Ecolab

Think of IRmadillo™ as your early warning system. Always monitoring what’s going on inside your fermentation tanks. Instantly alerting you to anything out of the ordinary IRmadillo gives you lab-grade accuracy in real time, continuously measuring the concentrations of lactic acid, ethanol and more. All from a device that’s been called “the most robust instrument we’ve seen.”*

So while other plants wait 8 hours for the HPLC to inform them of a disaster that’s already started, get ahead of the lactic acid curve while you can still do something about it.

Buy an IRmadillo

*Julian

Parra, Engineering Manager, Pannonia Bio

AI is beginning to show real promise as a tool to support operators’ decision-making, deliver real-time insights and turn “golden batch” outcomes into repeatable standards.

How one ethanol producer scaled AI from a fermenter to the plant level to improve production efficiency and yield.

By Jessica Morrison

CONTRIBUTION: The claims and statements made in this article belong exclusively to the author(s) and do not necessarily reflect the views of Ethanol Producer Magazine or its advertisers. All questions pertaining to this article should be directed to the author(s).

Fermentation has always been the heartbeat of ethanol production. When it runs well, the whole plant benefits. When temperature, pH or timing slip, even the highest-performing teams struggle to maintain efficiency and yield.

Jessica Morrison VP, Strategic Partnerships & Growth

Automation and instrumentation have brought major advancements to fermentation control, but repeatable success—consistently hitting those perfect yield or efficiency numbers—remains elusive. With a growing stream of plant data crossing 50 million logs per day at many plants, producers struggle to sort through and make sense of it all. In most cases, they don’t understand what’s driving their wins, losses and variability, and they’re unequipped to interpret and act on their data fast enough to improve outcomes when production trends off course.

This is where artificial intelligence (AI) is beginning to show real promise—not as a replacement for experienced operators, but as a tool to support their decision-making, deliver real-time insights and turn “golden batch” outcomes into repeatable standards.

Unlike traditional automation systems, human-centric AI is designed to learn alongside and from people. These systems take in high volumes of plant data—temperatures, levels, rates and lab results—and identify correlations between what’s happening and what works best.

Instead of just surfacing patterns in reports, the AI presents clear, actionable recommendations while fermentation is underway, if conditions begin to slip. Think of it as a virtual coach—trained on historical plant data, tuned by operator input and constantly learning from time-series data and outcomes.

At a Midwest ethanol plant, a team piloted an AI-driven fermentation modeling system on a single highly instrumented fermenter. The tank had inline sensors for temperature, pH, DO and agitation, as well as lab data for sugar conversion and alcohol yield. Using this data, the AI analyzed the relationships between these variables, production efficiency and yield, and created a dynamic profile of what “optimal” looked like based on actual production performance, not theoretical models.

Once trained, the system was deployed across all 11 fermenters in the plant. In just six weeks, the system was delivering actionable guidance, and the team reported measurable improvements: faster

detection of deviations, better fermentation efficiency, higher yield and less variability.

Most teams rely on backward-looking reports that arrive hours or days behind, handicapping their ability to meaningfully influence outcomes. AI systems process live data and flag patterns in real time, empowering teams to act early and stay ahead. Advanced systems can even write back to PLCs—creating an optional, human-approved feedback loop where trusted recommendations can be executed automatically under predefined conditions. As teams build trust in AIdriven production intelligence and guidance, they turn to the ladder to save time and ensure higher, tighter performance.

By definition, golden batch isn’t a dream, it’s an outcome that has been achieved numerous times. The trick is hitting it with regularity. Making it the rule and not the exception. Rather than celebrating a successful batch as a one-off, teams can now recreate the conditions that led to its success with AI and set golden-batch conditions as their baseline for live comparison, early warnings and guidance.

Beyond improvements in ethanol yield (3-8% in some cases) and production efficiency (a reciprocal 3-7% reduction in bushels/gallon), early adopters report faster root cause analysis, less reliance on spreadsheets and increased alignment across shifts and teams—all without major capital overhauls.

As the ethanol industry evolves, producers need tools that can deliver fast ROI without disrupting operations. Human-first AI meets this moment: scalable, flexible and designed to enhance—not replace—the people driving ethanol production.

Jessica Morrison is vice president of strategic partnerships & growth at Golgix, a Midwest-based company focused on applying AI to manufacturing and industrial operations. With 15+ years of experience in the water, energy and manufacturing sectors, she partners with ethanol producers to turn process data into operational advantage using a human-centered approach.

Author: Jessica Morrison VP, Strategic Partnerships & Growth, Golgix www.golgix.com

International 308 2nd Ave. N., Suite 304 Grand Forks, ND 58203