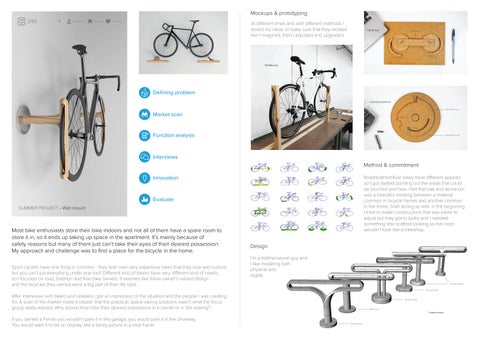

Mockups & prototyping

At di erent times and with di erent methods I tested my ideas to make sure that they worked like I imagined, then I adjusted and upgraded.

Most bike enthusiasts store their bike indoors and not all of them have a spare room to store it in, so it ends up taking up space in the apartment. It’s mainly because of safety reasons but many of them just can’t take their eyes of their dearest possession. My approach and challenge was to find a place for the bicycle in the home.

Sport cyclists have one thing in common - they both own very expensive bikes that they love and nurture, but you can’t put everything under one roof. Di erent kind of bikers have very di erent kind of needs, so I focused on road, triathlon and fixie bike owners. It seemed like these owner’s valued design and the bicycles they owned were a big part of their life style.

After interviews with bikers and retailers I got an impression of the situation and the people I was creating for. A scan of the market made it clearer that the practical, space saving solutions wasn’t what the focus group really wanted. Why should they hide their dearest possession in a corner or in the sealing?

If you owned a Ferrari you wouldn’t park it in the garage, you would park it in the driveway. You would want it to be on display, like a family picture in a nice frame.

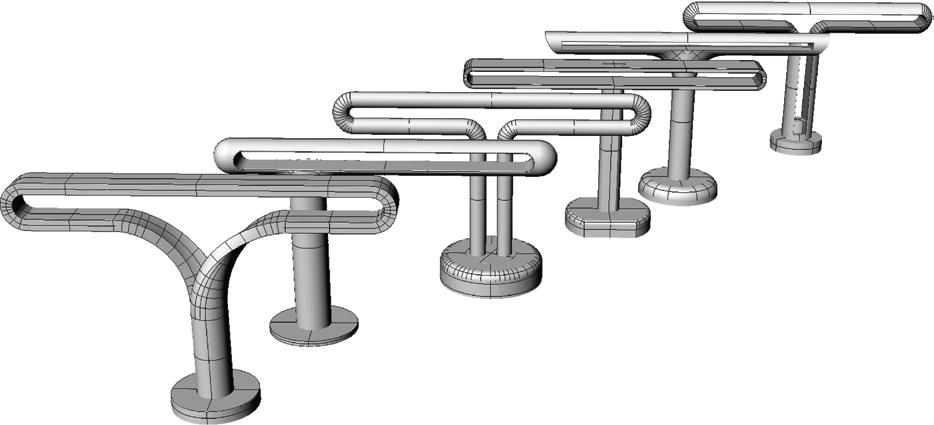

I´m a tridimensional guy and I like modeling both physical and digital. Design

Method & commitment

Road/triathlon/fixie bikes have di erent appeals so I got started pointing out the areas that could be touched and how. I felt that oak and aluminum was a beautiful meeting between a material common in bicycle frames and another common in the home, both strong as well. In the beginning I tried to make constructions that was easer to adjust but they got to bulky and I needed something less sca old looking so the room wouldn’t look like a bikeshop.

Screw and nail box

The pointy tips makes it easy to find the right spot when connecting the male to the female button. The lid is sealed with rubber and is connected to the box with a strap that forms a grab friendly loop.

At smaller construction sites carpenters often chare the same set of screws or nails, so they all grab a fist and put them in their pockets. Di erent nails and screws get mixed up and the workers have to walk back and forth to refill their pockets. After a day of work the workers rarely sort them out and put them back in the packages they all charred during the day.

Over a cup of co ee me and my friends sketched and brainstormed for o couple of hours, working on finding a good solution. We wanted to make a product that could work with Snickers Workwear. The project grew on me so I decided to develop it a little bit further.

The Screw box is made to fit in the connection of a Snickers tool belt. The connection on the tool belt is not quick and easy to attach to, so we designed the Screw box with a “connection on a connection”. This makes is easy to fill and empty, or replace with a bigger or smaller version.

The Magnetic lot attaches with a nail lock on the users cloth, making it suitable for di erent kind of equipment and requests. The set is designed to be as easy as possible to use, making the carpenter’s workflow more productive.

Magnetic lot

The magnetic lot is made of rubber with two plastic locks and a magnet. It can be attached anywhere on the users cloth with a nail that penetrates the fabric and locks in place on the other side.

A fist of screws

One of my senior friends had worked as a carpenter himself, so he had the knowledge that was needed. All we had to do was to attack him with the right questions and give our ideas a little time to grow. We wanted an easy solution that could fit the carpenters habits.

My part

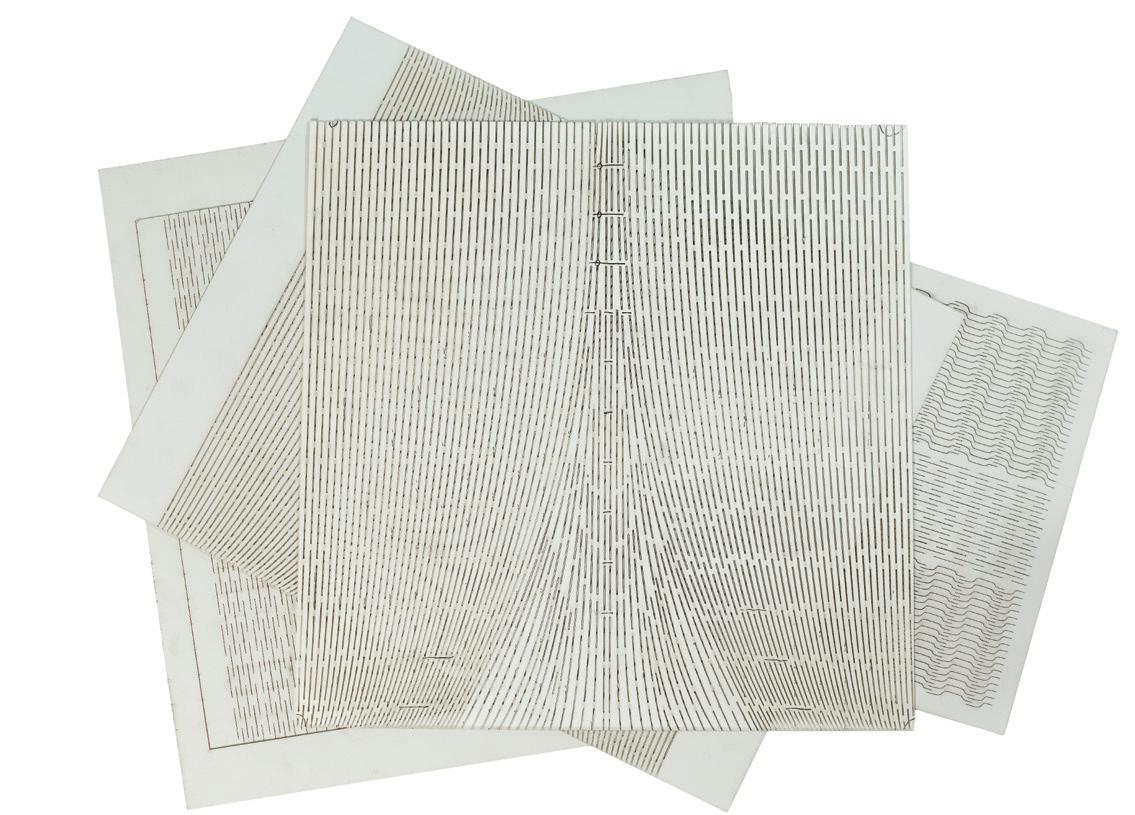

Sense there were four of us we divided the work at di erent times. The laser cutting technique was something we experimented with and all of us really wanted to make it useful. The idea of a slide function came late. While working on the model the idea hit me. My friend got it right away and in a blink of an eye he had an idea for the construction. With this new feature we just managed to finalize the model, but I really got to know the machine and the technique.

Method

The process started with di erent methods to understand both technical and sensorial characteristics of the materials. We used mind maps and photos to make our thoughts and feelings more distinct. When we got to know the materials we saw new opportunities by bringing two into one. Veneer combined with fabric emphasized the high quality expression and kept the sti /flexible characteristics.

Me and my group worked with two composite materials from Lacroix Groupe, currently used for premium food packaging. Our goal was to make a display item that emphasized the properties and addressed the facilities of a material. We ended up with a vinyl convolute with a sliding function for the vinyl, entirely made of one material.

Lacroix Goupe is a manufacturer of packaging products split into three categories; wooden, cardboard and plastic packaging. We started up with two materials, one made of veneer combined with plastic and the other combined with cardboard. After a lot of “getting to know” our materials we saw an opportunity to combine veneer with fabric to lift the original intention of a premium packaging material.

The marriage between wood and fabric resulted in a composite material that suited “shopping products”, such as; accessories, electronic products and clothing etc. We also wanted to present a laser cutting technique to intrigue companies to use this as a new way to add value.

A vinyl convolute was the perfect artifact to show the di erent possibilities of coloring, engravement and construction. It also manifested both the inherited beauty and the new characteristics of the material.

Material and treatment

We experimented with di erent techniques to process our material. The inherited character of wood owns a compelling look and feel that we didn’t want to lose, therefore we stained it. We chose a soft and glossy fabric to give the convolute a premium look at same time as it protects the vinyl.

Elaborating

The pattern we chose can’t be stretched or squeezed, so we could only achieve single-curved surfaces. Nothing more was necessary, but we wanted to intrigue companies to think of double-curved surfaces as well. During the process I realized that the pattern could help the slide to move in a linear motion.