Double coated paperboard.

Double coated paperboard.

Your premium packaging will gain in performance

Renewable 100% Brightest ts

High performance and excellent sti ness featuring the whiteness that pleases the most demanding markets.

Suitable ontact

Suitable ontact

High Renewable 100% Brightest ts

Excellent achinability

Excellent achinability

It is made with a selection of noble raw materials that make the surface more uniform, increasing machine performance.

High Renewable 100% Brightest ts Suitable ontact

Excellent achinability

Drop

A

Welcome to issue 5 of Irish Printer for 2025.

In this issue of Irish Printer, we profile print firms that have invested in new technology. First up is Limerick-based SignZone who purchased a Mimaki CJV200160 integrated solvent printer/cutter through Spectrum Digital. The CJV200 has increased productivity at the print firm and improved service levels. It’s also allowing for faster turnaround times – a recent 21m by 1.6m installation was produced in a significantly shorter timeframe. Sustainability is also up; waste has been reduced and resources are put to better use. For more on SignZone’s new investment, turn to page 11.

Snap also made a significant investment this year with the installation of two of Konica Minolta’s flagship AccurioPress C12010 devices and an AccurioPrint 2100 in Galway, along with an AccurioPrint C7090 in the newest Snap Centre, Snap Midlands. Delivered by MJ Flood, the new technology is strengthening production capabilities, driving sustainability and ensuring consistent output. Snap has also invested in AccurioPro Flux workflow software which has, says Snap’s Ronan Walsh, fundamentally changed how the print firm works. “It’s not just about speed; it’s about smarter, more sustainable production. We’re getting more out of every sheet and every job is delivered with greater precision.” Turn to page 12 for more. Niamh Flannery, Prepress Studio Lead at Biopax Limited, was named a ‘Rising Star’ at the 2024 Irish Print Awards. She attributes her win to the culture of innovation and collaboration that exists at the Belfast print firm and the opportunities she’s been given since joining the firm three years ago. Go to page 16 for more on Niamh. Finally Brendan Lynch, Sales Director at Smurfit Westrock Security Concepts, chats about his first role in the industry – a part-time job at Kelly’s Print Works in Ballinasloe – and how it fuelled a lifelong love for print.

As always, we’d love to hear from you. If you have any thoughts on this issue, please drop us a line at editor@irishprinter.ie. Enjoy!

Editor: Denise Maguire

Email: editor@irishprinter.ie

Creative Director: Jane Matthews

Designer: Lenny Rooney

Production: Nicole Ennis

Contact: Irish Printer, Ashville Media Group, Unit 55, Park West Road, Park West, Dublin 12, D12 X9F

Tel: (01) 432 2200

Web: www.irishprinter.ie

Printed by: McGowans Print

Printed on: HP Indigo 10000 using Novatech paper supplied by Antalis.

All rights reserved. Every care has been taken to ensure that the information contained in this magazine is accurate. The publishers cannot, however, accept responsibility for errors or omissions. Reproduction by any means in whole or in part without the permission of the publisher is prohibited. © Ashville Media Group 2025. All discounts, promotions and competitions contained in this magazine are run independently of Irish Printer. The promoter/advertiser is responsible for honouring the prize. ISSN 0790-2026

Ideally located 5 minutes from the M50, 2 minutes from the M3

D15 RYY9

We provide Trade Finishing Services such as: Point of sale gluing | Foil Blocking | Handwork and division assembly with 48,000 square feet spread across two warehouses

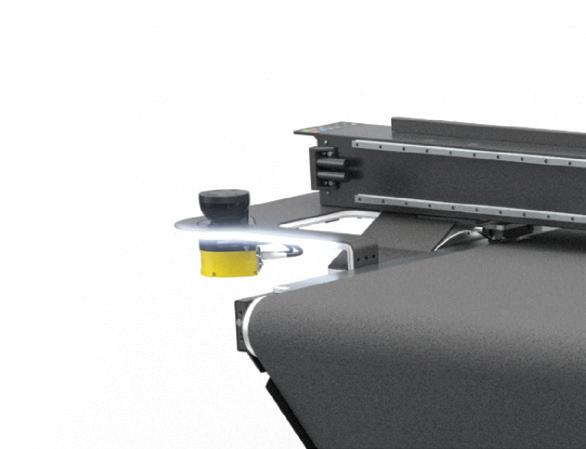

The TS200-1600 is the latest sublimation transfer inkjet printer from Mimaki Europe. Building on the success of the TS100, the new TS200-1600 delivers fast production speeds, high-quality and versatile applications at an a ordable price point, making it a good option for small shops, start-ups and businesses looking to expand into customised goods and short-run textile production. Mimaki says the latest press ensures smoother gradients, vivid colours and outstanding accuracy without compromising on speed. Its extended eight-colour ink set includes the addition of orange and violet inks, as well as new fluorescent pink and yellow inks. To maximise uptime and reduce waste, the TS200-1600 incorporates 2L degassed ink packs that prevent air bubbles and ensure consistent print quality. The improved ink supply system also allows operators to easily shake the inks without removing them from the printer.

»

» media

Achieves outstanding quality with a highresolution, high-definition print head – minimum 4pl dot ejection allows for finely detailed

Waveform control technology – droplets with high circularity can be ejected to make them accurately land on the

Variable dot control –various ink droplet sizes (large, medium and small) are precisely placed

» MAPS – prints path borders in a gradient tone to reduce banding and unevenness of colours

» Violet and orange inks added to lineup –reproduces rich bluepurple and vivid, well-defined orange tones. Enhances apparel and uniform designs for greater clarity

» High-quality print for everyone with simple operation.

Razar combines raised spot UV printing, cutting, creasing and taping into a single, automated pass

Ballyprint has signed up for the first Vivid Razar single pass spot UV digital coater with cut and crease. Ballyprint Managing Director Aaron Klewchuk got the opportunity to see the device in action at The Print Show where it was launched and was impressed. Described as the “Swiss army knife of finishing”, Razar combines raised spot UV printing, cutting, creasing and taping into a single,

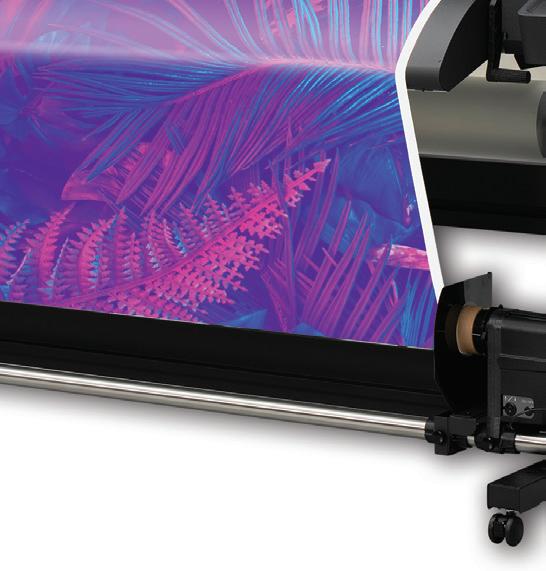

On October 9, printing professionals across the world shared “printspiration” across social media for International Print Day using the hashtag #IPD25. This year’s theme, #PrintSmart, showcased how print in all its forms becomes more valuable and measurable for customers and consumers.

#PrintSmart emphasised: Integration – combining print with digital tools, tracking and analytics

Relevance – creating targeted, personalised and meaningful print experiences

Value – demonstrating that print is intelligent, measurable and ROI-driven Sustainability – using smarter materials and processes that reduce waste and environmental impact.

“#PrintSmart is about showing the world that print is most effective when partnered with technology. For printers, it unlocks the ability to innovate, work faster, reduce waste, personalise at scale and prove value with measurable results. For customers, it opens the door to collaboration with

automated pass. It’s been designed for B2 sheet and roll-fed media, with a wide thickness range of 10–200 microns. Vivid Laminating Technologies says it offers exceptional flexibility and allows print businesses to bring advanced finishing in-house, cutting costs and lead times. It’s hoped the circa £60,000 machine will be installed at Ballyprint in January 2026 at its factory in Ballymena.

knowledgeable printing partners who bring the tools, data and strategy to enhance outcomes and show how powerfully print drives engagement,” said Deborah Corn, Founder of International Print Day.

At Labelexpo, held in Barcelona in September, Xeikon demonstrated the PX3300HD press with a fully integrated Xeikon LCU (Label Converting Unit). Xeikon says the live setup demonstrated how a single operator can produce finished, highquality labels in one pass, with no roll changes and no offline steps required. The Xeikon LCU can also run offline whenever parallel finishing is the smarter option. The company says its approach is defined by a digital-first design, purpose-built for integration rather than retrofitted from flexo technology. Xeikon emphasises that the real value is not in hardware specifications, but in workflow outcomes. By combining the press, the X-800 DFE and integrated finishing, customers reduce job change times, require fewer operators and increase throughput per shift.

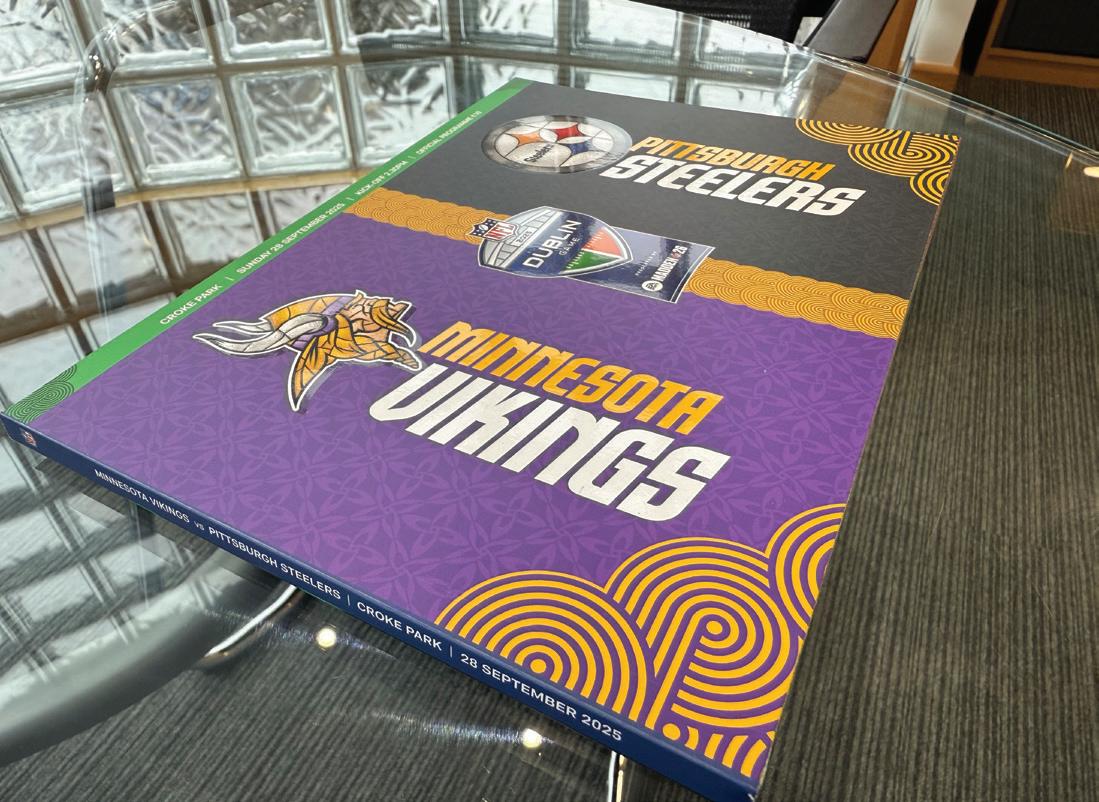

Anglo Printers Ltd was chosen as the preferred print supplier for the NFL’s first-ever game in Dublin, producing a 120 page and cover B5 landscape programme for the event at Croke Park. Both the event and the programme were a sell-out – it’s estimated that 35,000 foreign fans travelled to Ireland for the game.

Zeus Packaging has launched Zeus Sustain Carbon IQ – its first digital platform designed to help customers estimate packaging-related impacts such as carbon footprint, eco-cost and energy demand. It also allows users to compare material and design alternatives using a simple lifecycle assessment (LCA) approach.

Key Features of Carbon IQ

» Packaging Impact Estimation - input product specifications including materials, manufacturing processes and transport data to generate environmental performance metrics

» Product, Basket & Volume Comparisons - benchmark packaging alternatives side-by-side to support more sustainable selection decisions

» Lifecycle Insight - understand indicative performance across key stages of the packaging lifecycle (where available, end-of-life scenarios are included based on current disposal assumptions)

» Simplified Sustainability Gradingproducts are assigned A–E ratings for carbon, eco-cost and energy demand, using a custom methodology developed in collaboration with Nutritics (these ratings are intended to support comparison but are not aligned to any industry-wide standard)

» Economic Assessment - enables users to evaluate not only the environmental performance of packaging options, but also the price impact of alternative materials, formats and supply routesproviding a balanced view of sustainability and cost-efficiency.

With FIMI’s ownership we have the stability, focus and disciplined operating approach to deliver our plan

Mondi has expanded its six-colour digital printing range for corrugated packaging to include white ink, reflecting a growing trend of white digital printing on brown packaging. The packaging and paper group says a white underprint gives colours, logos and motifs the same stand-out contrast on brown corrugated board as they do on a white substrate. Halftone printing is also available which enables smooth gradients, di erentiated shading and chamfers that create three-dimensional image e ects.

Landa acquired by FIMI

Landa Digital Printing (LDP) has been acquired by private equity fund FIMI. The priorities now, says FIMI, are to enhance product performance and ensure supply resilience. “This is a defining milestone for LDP. With FIMI’s ownership we have the stability, focus and disciplined operating approach to deliver our plan: strengthening product performance in the field, ensuring reliable service and supply and re-energising our go-to-market with a sharp customer focus. Our teams are already moving and our priorities are clear,” said Gil Oron, Landa Digital Printing CEO. The company’s founder, Benny Landa, has expressed his support for the acquisition, saying he’s pleased that the company he founded and the technology he invented will continue to grow.

To celebrate its rebranded Keaykolour range, Antalis has collaborated with Amsterdam-based creative consultancy Design & Practice to develop a tool that aids in the selection of colour. The new tool features a series of cards with cut-out windows and marquetry-style combinations, incorporating sophisticated print processes such as micro-embossed hot foils and 3D sculpted embossing. By overlaying these cards, users can isolate and overlay colours, inviting experimentation and engagement with the diversity of shades within the range.

The tool features the full Keaykolour spectrum of 45 hues, tints and shades, available in various weights, as well as the new Extra-Rough paper grade in black and white and Keaykolour’s tactile embossed papers.

this year Limerick-based signage firm, SignZone, invested in a Mimaki CJV200-160 integrated solvent printer/ cutter, purchased through authorised Mimaki partner, Spectrum Digital. This is the latest in a line of investments by the Limerick firm in Mimaki hardware. “Brand fidelity is really important to us. We have been using Mimaki for many years and will keep doing so – they’re excellent machines,” said Production Manager, Giorgio Parravano.

For Giorgio and the team, consistency was a decisive factor. “Printing speed, quality of print and the peace of mind of knowing it’s always going to be right – that’s why we invest in Mimaki. Consistency is key in our business.” The CJV200 is already delivering just that, producing high-quality signage, banners and display graphics with sharp detail and accurate colour.

Equally important is the impact on workflow. With minimal downtime and efficient operation, the Mimaki has given

SignZone greater productivity and faster turnaround times, allowing the business to respond quickly to customer demand while maintaining its usual high standards. This reliability not only improves service levels, but also contributes to more sustainable operations through reduced waste and better resource use. SignZone regularly supplies grand format sized graphics and a recent 21m by 1.6m installation was produced in a significantly shorter timeframe with the company’s new printer.

Giorgio is also keen to acknowledge the role of Spectrum Digital in supporting the investment. “We’ve been really impressed with the support from Spectrum throughout the whole process – from helping us choose the right model to the smooth installation and after-sales assistance. Their team has been knowledgeable, approachable and quick to respond whenever we’ve had questions.”

For SignZone, investing in the Mimaki CJV200 is a continuation of a long-standing partnership and a step into the future. The firm says that with the quality and reliability of Mimaki behind them, they’re well positioned to keep delivering innovative, high-impact signage that helps their customers stand out – and to keep doing so with the confidence that comes from brand loyalty built over many years.

Printing speed, quality of print and the peace of mind of knowing it’s always going to be right – that’s why we invest in Mimaki. Consistency is key in our business

Snap Galway and Snap Midlands elevate production with Konica Minolta and MJ Flood

Snap Galway and Snap Midlands have entered a new era of print innovation, efficiency and quality following the installation of two of Konica Minolta’s flagship AccurioPress C12010 devices and an AccurioPrint 2100 in Galway, along with an AccurioPrint C7090 in the newest Snap Centre, Snap Midlands. To add to that, everything is now powered by Konica Minolta’s own AccurioPro Flux workflow software. This strategic investment, delivered and supported by MJ Flood, is transforming how Snap delivers for its customers, strengthening production capabilities, driving sustainability and ensuring consistently exceptional output.

The move signals a bold step in Snap’s long-term growth strategy and underscores the company’s belief in both technology-driven efficiency and the value of trusted partnerships.

For Snap Galway and Snap Midlands, the decision to invest in Konica Minolta technology was shaped not only by the machinery’s capabilities, but also by their enduring partnership with MJ Flood. “We’ve enjoyed a long-standing relationship with MJ Flood and have

always found their service and offering to be exceptional,” explained Ronan Walsh from Snap. “When it came to evaluating our next phase of investment, we knew we wanted to work with them again. The new technology available on the Accurio machinery made upgrading our equipment an easy decision.”

The installation process itself was testament to MJ Flood’s professionalism. The Snap team described it as “seamless”, thanks to thorough planning and early engagement. Access requirements, power demands and production continuity were addressed well in advance, ensuring the business could continue operating without disruption during the setup. “Downtime is simply not an option in our industry,” added Ronan. “The fact that MJ Flood enabled us to transition so smoothly, without impacting our customers, speaks volumes about their planning and delivery.”

At the heart of this transformation is the AccurioPro Flux RIP and workflow software, which has been described by Snap as a “real game

changer.” This advanced software optimises job processing, automates imposition and simplifies management of even the most complex workflows. The immediate impact has been remarkable – turnaround times have shortened dramatically, bottlenecks have been reduced and staff can now manage larger volumes of work more effectively. Equally important is the sustainability benefit. By improving efficiency and reducing errors, the software has helped Snap cut down on material wastage, delivering cost savings while aligning with their commitment to operate more responsibly.

“The Flux software has fundamentally changed how we work,” the Snap team noted. “It’s not just about speed; it’s about smarter, more sustainable production. We’re getting more out of every sheet and every job is delivered with greater precision.”

While efficiency is crucial, quality remains the cornerstone of Snap’s success. With two of the AccurioPress C12010 and an AccurioPrint 2100, Snap can now deliver output that is not only faster but also consistently flawless. The new machines guarantee exceptional colour accuracy, sharpness and reliability, giving clients confidence that their projects – whether high-volume marketing collateral or bespoke print runs – will meet the highest standards. “Our clients trust us with their brand and colour consistency is absolutely critical,” confirmed Ronan. “The Konica Minolta presses deliver that consistency every time, across every job. That’s a huge differentiator for us.”

Automation has also been a key driver of Snap’s investment. The Accurio series streamlines complex processes, reduces manual intervention and allows staff to focus on delivering value-added services rather than being tied up with repetitive tasks. By automating core workflows, Snap can handle jobs more quickly and with fewer errors, resulting in faster turnaround times for clients without sacrificing quality. “Our business is all about responsiveness,” explained Ronan. “Automation gives us the ability to deliver at speed while still ensuring the highest quality. It also frees up our team to concentrate on client service and creative problem-solving.”

We’ve enjoyed a long-standing relationship with MJ Flood and have always found their service and o ering to be exceptional. The new technology available on the Accurio machinery made upgrading our equipment an easy decision

Beyond productivity and quality, sustainability has become a major consideration for modern print businesses and Snap is no exception.

The new Konica Minolta systems support larger consumables, which means fewer replacements and less packaging waste. Combined with the efficiencies of the AccurioPro Flux software, this investment has significantly reduced Snap’s overall environmental footprint. “Environmental responsibility is something our clients increasingly care about, and it’s something we take very seriously,” said Snap. “These new systems allow us to be more sustainable in how we operate, without compromising on output or efficiency.”

For Snap Print Galway and Snap Midlands, this investment is more than just a technology upgrade, it is a deliberate step in shaping the future of the business. By enhancing capacity, streamlining workflows and reinforcing sustainability, Snap is equipping itself to meet the demands of today’s customers while preparing for tomorrow’s opportunities.

The benefits are already clear:

» Faster turnaround times mean clients receive work quicker than ever

» Consistent, high-quality output reinforces trust and strengthens Snap’s reputation

» Greater capacity allows the business to take on more work without compromising standards

» Reduced waste and improved sustainability align with both business values and customer expectations.

With the backing of MJ Flood and the advanced capabilities of Konica Minolta’s technology, Snap Galway and Snap Midlands are positioned for continued growth and success. The investment ensures the business can scale to meet evolving client needs, adapt to market changes and continue delivering the reliability, quality and service that have made it a trusted name in print.

“This investment future-proofs our business,” concluded Ronan. “It gives us the tools we need to deliver more for our clients, faster, smarter and more sustainably. With MJ Flood and Konica Minolta, we have partners we can trust to help us grow and succeed.”

RONAN WALSH, Manager at Snap Print Galway | Midlands, chats to Irish Printer about how a long-standing relationship with MJ FLOOD made for a seamless installation process

What motivated Snap to choose the AccurioPress C12010, AccurioPrint 2100 and AccurioPro Flux for their operations in Galway and Midlands?

We’ve enjoyed a long-standing relationship with MJ Flood and have always found their service and offering to be exceptional. The new technology available on the Accurio machinery made upgrading our equipment an easy decision.

How long did the installation process by MJ Flood take? Were there any challenges or notable moments during installation?

The installation process was seamless. From early discussions around access and power requirements to having a clear plan in place, we were able to continue producing jobs without interruption during the installation.

Has the initial performance of the new presses met your expectations?

The new RIP software has been a real game changer for us. It has significantly improved our turnaround times, allowing us to deliver projects faster and more efficiently. In addition, it has greatly reduced material wastage, helping us save on costs and operate more sustainably.

How does the addition of the AccurioPress C12010, AccurioPrint 2100 and AccurioPro Flux impact your overall print production capacity?

They have transformed our print operations. These investments have streamlined our workflows, reduced bottlenecks and allowed us to manage jobs far more efficiently. As a result, our overall production capacity has increased significantly, enabling us to take on more work, deliver faster turnaround times and maintain consistently high-quality output for our clients.

Were there any specific features of the new presses that stood out to you when making the purchase decision with MJ Flood?

Yes – the advanced RIP and imposition software were standout features that played a key role in our decision; improving efficiencies and workflow processes.

How has the AccurioPress C12010, AccurioPrint 2100 and AccurioPro Flux improved the overall print quality of your products?

The machines deliver exceptional colour consistency, ensuring we provide the highest quality service to our clients. The introduction of automation has also significantly accelerated our production processes, enabling us to deliver results more efficiently while maintaining high quality standards.

Have the new presses helped improve sustainability or reduce waste in your operations?

Yes, the machines have contributed to improving sustainability in our operations. The use of larger consumables means fewer replacements are required, which helps us significantly reduce waste.

How do these new technologies align with Snap Print’s long-term business goals and growth strategies?

We are always exploring new ways to deliver greater value to our customers. Our recent investment in these advanced machines ensures that we are not only well-equipped to meet today’s demands, but are also prepared to adapt and scale for the needs of the future. This commitment allows us to provide our clients with consistent quality, faster turnaround times and the confidence that we can support their evolving requirements.

C12010

Perfect image quality

» S.E.A.D. X 2,400 x 3,600 equiv. dpi x 8bit

Simply e icient

» Simitri V toner technology

» Image density control technology

» Automated engine linearisation

» Automated duplex registration

» Automated profiling

» Real-time adjustments

» Purge function

Sophisticated Media Handling

» Automatic media recognition

» Air-suction feeding technology

» Up to 14,140 sheets paper input capacity

» Up to 10 paper input trays

» Up to 2,300 sheets paper input for long sheets (up to 900 mm)

Ease of Use

» Simple paper catalogue settings

» Operator Replaceable Parts

High-end print control

» Proprietary Konica Minolta controller

» AccurioPro PrintManager for job management optimizes the overall workflow

Ready-made print products

» Stacking of up to 4,200 sheets

» Two-point and corner stapling of up to 100 sheets with automatic staple cut mechanism

» Booklet making up to 80 pages (20 sheets)

» 2- and 4 -hole punching

» Tri-folding up to 3 sheets

Durable performance

» Up to 100 A4 pages per minute

» Auto Inspection Technology

» Up to 56 A3 pages per minute

» A powerful suite of digital solutions –modules include Essential, Premium and Ultimate

» Centralised control and management, automated workflow processing, advanced colour management and seamless integration of di erent printing technologies

» Advanced features include greater personalisation and the ability to add images to page content at the last minute

» A Flux Label Impose option provides an automated label workflow for Konica Minolta’s label printers. Modules can be purchased individually or upgraded when required.

The package has enabled us to improve our quality and e iciency in digital printing, which in turn has allowed us to achieve cost leadership

NIAMH FLANNERY, Prepress Studio

Lead at Biopax Limited, chats about being named a ‘Rising Star’ at the 2024 Irish Print Awards and raising the bar in sustainable print

Congratulations on your wins at the Irish Print Awards. What do you attribute the win to?

Thank you! I think the win wouldn’t have been possible without the support I’ve had from Biopax from day one. That support is very much embedded in the company’s values and it allows people to thrive. I’ve been given opportunities to lead, to take on challenges and to grow, and that trust has been key. Biopax, under the leadership of our owner and Chairman, Dr Terry Cross OBE, is committed to raising the bar in sustainable print. That culture of innovation and collaboration, supported by investment in world-class technology partners like HEIDELBERG, is what made this award possible.

It’s been a journey of continuous learning and development within a company that has ambitious growth plans, including the expansion of our factory which is currently underway

How long have you worked at Biopax?

I joined Biopax three years ago with a background in Pre-Press design. That was the starting point and it gave me a strong technical foundation. Since then, I’ve progressed to lead the Pre-Press Studio and I’m now studying for a GQA Level 4 Diploma in Print Leadership. It’s been a journey of continuous learning and development within a company that has ambitious growth plans, including the expansion of our factory which is currently underway.

What does your role entail on a daily basis?

As Pre-Press Studio Lead, I oversee and manage a team of talented young people. We manage artwork, pre-flight checks and ensure that every file is print-ready and compliant with customer expectations. I also focus on streamlining processes and supporting my team’s growth. A big part of my role is also delivering on client sustainability goals, for example, developing innovative packaging for global brands. Working in a business equipped with HEIDELBERG printing presses and Masterwork finishing technology means we can deliver the highest standards of quality while meeting sustainability targets.

How did you get started in the print industry?

My entry point was almost 10 years ago when I joined a printing company through a university placement programme. This gave me real-world, hands-on practical experience alongside formal training, which offered a great insight into the industry. I learned the fundamentals of prepress, built confidence in my skills and could see a clear career pathway to progress. In more recent years, I have progressed into a management role with Biopax.

A big part of my role is delivering on client sustainability goals, for example, developing innovative packaging for global brands

Print is always evolving with new technologies, processes and sustainability requirements. There’s huge satisfaction in seeing packaging we’ve worked on for leading global brands move from design to shelf, knowing that the product is not only visually strong, but also aligned with sustainability targets.

Do you think more women should consider a career in print and if so, why?

Yes, without a doubt. Print has traditionally been a male-dominated sector, but that’s changing and the recognition at the Irish Print Awards is proof of this progress. I was thrilled to win Gold in the Rising Star Award and especially proud to receive Silver in the Women Leading in Print category, which shows there is real space for women to progress, lead teams and drive innovation. It was also a fantastic night for Biopax, with our team awarded Bronze in the Litho Packaging Printer of the Year category. At Biopax, under the leadership of Dr Terry Cross OBE, investment in people and technology has created opportunities for women at every level. Our ongoing factory expansion will create even more roles in a dynamic, forwardthinking environment and our partnership with HEIDELBERG ensures we remain at the forefront of industry innovation. It’s an exciting time for print and I believe women should be right at the heart of shaping its future.

would

Sustainability is both a challenge and an opportunity. Customers want packaging that reduces environmental impact but doesn’t sacrifice quality or brand presence. We have to keep innovating to meet those demands. Another challenge is attracting and developing the next generation of talent. Apprenticeships and training are vital in showing young people that print is a career with a strong future, room for creativity and leadership opportunities. At Biopax, we’re fortunate to have Dr Cross’s continued investment and an expansion programme underway, all of which help us stay competitive and future-ready.

I want to play a part in shaping how the industry approaches sustainability, ensuring print and packaging continue to thrive while supporting environmental goals

To complete the Level 4 Print Leadership Diploma and continue growing as a leader within Biopax. Longer term, I want to play a part in shaping how the industry approaches sustainability, ensuring print and packaging continue to thrive while supporting environmental goals. For me, it’s about mixing technical expertise with leadership to make a lasting impact on the industry.

Suitable for participant from all sectors of the industry (Litho, Digital, Finishing, Large Format, Packaging, Labels, Services).

Starting Autumn 2025

Run over 2 years.

Delivered through prominently on-line tutor led classes

Working with the trainees and the companies.

087 - 2565068

www dppskillnet ie

joe@dppskillnet ie

Accreditation provided on completion of the course.

This DPP Skillnet programme is co-funded by the Government of Ireland and the European Union

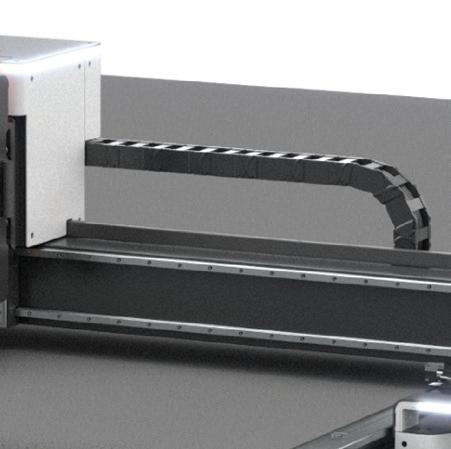

Kongsberg PCS appoints Canon Ireland as partner and reseller

The appointment of Canon UK & Ireland as a Kongsberg PCS distributor solidifies our commitment to Irish customers across the sign, display and packaging industries

Kongsberg Precision Cutting Systems (Kongsberg PCS) has announced the appointment of Canon Ireland to distribute Kongsberg products across Ireland. Canon Ireland’s Large Format Graphics organisation will now promote Kongsberg cutting solutions in conjunction with its Arizona flatbed and Colorado roll-to-roll wide format printers. Canon customers will benefit from Kongsberg’s specialist engineering and materials expertise, as all cutting tables will be installed and serviced by Kongsberg’s dedicated team. Speaking about the new partnership, David Preskett, VP EMEA & APAC, Kongsberg PCS, said: “The appointment of Canon UK & Ireland as a Kongsberg PCS distributor solidifies our commitment to Irish customers across the

Kongsberg cutting solutions are designed to match the speeds of our wide format printers, making them an ideal complement to our systems in demanding graphics and packaging production environments

sign, display and packaging industries. Canon is known for its high-quality, ultra-productive print production systems and this agreement is testament to Kongsberg’s ability to deliver marketleading cutting solutions that match those output capabilities. This agreement will increase our reach to print and converting businesses across the UK and Ireland and marks an important step in our established relationship with Canon.”

Duncan Smith, Country Director, Production at Canon UK and Ireland, said: “Kongsberg cutting solutions are designed to match the speeds of our wide format printers, making them an ideal complement to our systems in demanding graphics and packaging production environments, handling diverse materials, including the most challenging rigid media. The partnership with Kongsberg PCS will ensure that Canon customers are equipped with premium cutting solutions that help them to deliver premium quality finished

products and broaden the range of creative applications they can produce.”

As part of the agreement, a Kongsberg PCS X24 cutting table will be showcased at Canon UK’s Birmingham Customer Experience Centre. In addition to installing the cutting systems, Kongsberg engineers will also offer customers ongoing technical, application and maintenance support to help them achieve optimal performance.

To get in touch with Canon Ireland, reach out to marketing.ireland@canon.ie or visit canon.ie

The partnership with Kongsberg PCS will ensure that Canon customers are equipped with premium cutting solutions that help them to deliver premium quality finished product

Retailers keep trying to kill the leaflet, but consumers keep reading it and sales keep depending on it. Lidl’s Dutch experiment proved the point – drop the flyer and lose the shopper, writes Print Power MD ULBE JELLUMA

The mood at the recent Door Drop Media Congress in Brussels was strikingly upbeat. Far from being swept aside by digital channels, evidence presented by researchers and industry leaders confirmed what many retailers have already rediscovered: door drops marketing remains one of the most powerful, proven and persuasive tools in retail media strategies

Lidl’s Dutch experiment - drop the flyer, lose the shopper

6.2%

RISE IN EXPENDITURE AFTER LEAFLET REINSTATEMENT

The Lidl leaflet study in the Netherlands offers the clearest demonstration – covered here and updated in Brussels by researcher Arjen van Lin. When Lidl withdrew its flyers in Utrecht, grocery expenditure fell by 8.5% over 12 months. Once reinstated, expenditure rebounded, rising 6.2%. The real surprise lay with a competing hard discounter – after Lidl’s reinstatement, its rival recorded a 10.3% increase in grocery expenditure. Few marketing experiments provide such a controlled, data-rich view of what happens when leaflets disappear and return. Belgian research brought further weight to the congress. Jozefien Piersoul (NielsenIQ) presented figures showing that 87% of Belgians browse a leaflet, with 67% doing so weekly. Readership climbs sharply when consumers take on household purchasing responsibility – precisely the stage of life when shopping choices harden and loyalty matters most.

Digital vs print –search or browse?

Piersoul also drew a distinction between digital vs print leaflets. Digital formats are largely search-oriented, supporting consumers who know what they are looking for.

Printed leaflets, by contrast, encourage browsing and stimulate awareness, placing products and offers in front of shoppers who may not be actively searching but remain open to discovery. That difference between intent and inspiration is central to the effectiveness of print advertising.

SPEND OVER 10 MINUTES READING LEAFLETS 10% CUSTOMERS SPEND OVER 2-5 MINUTES READING LEAFLETS, WHILE 25%

Attention is the critical currency. Leaflets achieve levels of consumer attention unmatched by most online formats. Nearly a quarter of consumers spend two to five minutes reading a leaflet, while more than one in 10 devote over 10 minutes. In a world of thumb-stopping scrolls, this is marketing gold.

Retailers return to the letterbox

Retailers are taking note. Mark Davies, Managing Director of Whistl and President of ELMA, set out European perspectives on leaflet advertising, pointing to a consistent pattern. In the UK, brands such as Specsavers, Sky and the Co-op, abandoned door drops only to return – in some cases extending from regional campaigns to full national coverage. In Germany chains including Fressnapf, Kik, Mäc Geiz and Woolworth, halted distribution but soon reversed course. Globus Baumarkt has gone further, increasing its use of door drops. The message is clear: retailers returning to leaflets is no coincidence – when performance falters, they return to the letterbox. The Brussels event was not about nostalgia. It showcased the

resilience and relevance of a medium that continues to shape grocery retail advertising in Europe. In an era when retail media dominates boardroom conversations, the unassuming door drop continues to do what it has always done – reach households, command attention and drive sales.

Retailers can experiment at the margins, but the conclusion is inescapable. Ignore the leaflet at your peril.

Retailers can experiment at the margins, but the conclusion is inescapable.

Ignore the leaflet at your peril

Explorer Offset presents an unbeatable formula to guarantee the excellence on offset printing: it combines high levels of whiteness, opacity and bulk to give you the best printing results.

Explorer Pre-print is a paper specially developed to perform in all printing technologies: offset printing and a postpersonalisation in laser or inkjet equipment.

To request a sample, scan here to contact your local branch