While COVID-19 may have started to fade from headlines throughout 2022, we have continued to deal with the ongoing ramifications of the global pandemic and its impact on the economy. Continued supply chain disruptions contributed to material and supply shortages, led to manufacturing challenges throughout the construction industry, and proved to be a major challenge for the industry.

The global economy continues to be weakened by the Russian-Ukraine war, causing significant disruptions in trade and resulting in food and fuel price surges. These factors are contributing to high inflation and subsequent contraction in global financing conditions, ultimately creating a highly volatile business landscape. The Bank of Canada continues to raise interest rates to curb inflation, which has reached its highest level in decades, leading to an expected slowing of the economy for 2023.

In addition, we continue to manage through a major shift in how businesses operate, with the work-from-home and hybrid models made possible by the pandemic and now appearing to be here to stay. This adjustment, combined with the ongoing shortage of skilled labour within the industry, has compounded the

market uncertainty that we have seen throughout 2022.

On a positive note, we took major steps in the journey to decarbonization with Ash Grove by joining the Cement Association of Canada in the Net-Zero Challenge – a voluntary initiative led by the Government of Canada that encourages businesses to develop and implement credible and effective plans to transition their facilities and operations to Net-Zero emissions by 2050. We are also thrilled to announce a new partnership with North America’s largest urban innovation hub, MaRS, with which we will be working to advance enterprise solutions in Ash Grove-leading industry categories for safety and sustainability (see page 2).

Finally, and most importantly, thank you for your ongoing business and support throughout an incredibly challenging 2022. We know that it was a year of unrelenting and unexpected obstacles, but we look forward to continuing to work with you and contributing to your successes in 2023.

We wish you and your loved ones a joyous, peaceful, and safe holiday season.

Emma Schindler Vice President, Sales & Marketing Ash Grove Cement

Ash Grove North Region would like to congratulate Sy Steppacher, who was promoted to the position of Ontario Sales Manager in September. He has worked for the company full-time for the last ten (10) years and previously held the positions of Project Coordinator within the Engineering Department and Production Supervisor (for Ontario Redimix). Most recently, he was the Cement Sales and Logistics Specialist for the provinces of Alberta and Saskatchewan.

In addition, we would like to thank Mike Gowan, who no longer works with us, effective November 18th. Although his time with us was short, Mike was a key part of our Ontario Sales team since 2021. We wish him all the best in his future endeavors!

We would also like to welcome Jasmine Samadi, who returned from maternity leave in October. Jasmine has returned to her position as a Technical Services representative. Welcome back, Jasmine!

Ash Grove announced a new partnership with North America’s largest urban innovation hub, MaRS, a Canadianbased non-profit and results-driven organization dedicated to furthering the Canadian economy through ambitious projects in various fields. Its history of building strong partnerships with key Canadian companies has led them to Ash Grove to assist in company-wide decarbonization ambitions and advance enterprise solutions in Ash Grove-leading

industry categories for safety and sustainability. To date, MaRS has assisted thousands of companies to scale their impact, accelerate growth and surpass goals.

The construction industry is rapidly evolving in the area of sustainability and MaRS will help Ash Grove remain at the top of its field and on track toward a ‘Net-Zero” approach. This partnership will provide access to a wide array

of resources and ensure local market engagement, as well as provide insights into venture ecosystems and solutions. The expertise of MaRS will help to improve our processes and exceed our sustainability and safety goals, allowing us to remain a leader in the construction industry. We always strive for continuous improvement, and this collaborative partnership will help accelerate Ash Grove in our Purpose of “reinventing the way our world is built”.

The cement industry of Canada has been devoted in its obligation to tackle the pressing issue of climate change and reach net-zero by the year 2050. With our unique partnership with the Government of Canada, we intend to demonstrate the importance of building a sustainable world. Through this partnership, we have created a Roadmap to Net-Zero Carbon Concrete by 2050 that provides a framework for different technologies, tools, and policies required for the entire Canadian cement industry to achieve the goal of a net-zero carbon emission, all the while ensuring it remains competitive in a global net-zero economy.

Co-led by the Cement Association of Canada and Innovation, Science and Economic Development Canada, the Roadmap to Net-Zero Carbon Concrete was spearheaded by a joint government-industry working group. The key players in this working group include the federal government, the concrete industry, the Canadian Cement Association, and necessary relevant environmental experts. The Cement and Concrete industry plan of action is to produce net-zero concrete by the year 2050, which would include notable milestones and ensure carbon emissions are cut by up to 40% by the year 2030.

“Decarbonizing concrete is a necessity, and Canada’s Cement and Concrete industry has demonstrated that it is up to the task. This roadmap demonstrates our industry’s leadership in CO2 emissions reduction and positions us to achieve our goal of net-zero cement by 2050. But it’s just a start. We look forward to continuing our work with the Government of Canada to implement the priorities identified in the Roadmap and to ensure that the right combination of incentives and regulatory policies continue to be put in place for our industry to thrive and succeed in a competitive net-zero global economy” said Marie Glenn, Chair of the Board, Cement Association of Canada.

Recently, CRH Canada hosted our annual CRH Canada Excellence Awards ceremony, which celebrated the winning projects of 2021. The winning Canadian projects and teams for the 2021 AMAT Innovation Awards were recognized by Ty Nofziger, President of The Great Lakes Division. The CRH Management Team presented all the winners of our Canadian program.

We are thrilled to announce that Ash Grove North was awarded Silver, for the Innovation and Sustainable Business Solutions Awards category for the Joliette and Mississauga Cement GUL Transition Project.

Over the past few years, both the Mississauga and Joliette cement plants have been working on converting General Use (GU) cement to General Use Limestone (GUL) cement. Integrating more limestone into the product results in a 10% reduction of CO2 by mass.

In 2021, this project gained momentum and further allowed the product to be adopted by the market, resulting in lower overall emissions for the business and improved utilization of existing equipment.

We want to take this opportunity to thank all the teams from both the cement and concrete businesses in Quebec and Ontario, constantly working on the success of this project. We are now able to provide low-carbon concrete offerings to the market and push the boundaries of our business in the area of innovation and sustainability.

There is a lot of chatter on concrete’s Life Cycle Assessment (LCA) calculators. My math skills are sharp and I typically don’t need these gadgets, but I might need some help figuring out what these LCA calculators being published are. Can you explain what it means for me and how to use it?

Sven Aight NineHave a question?

Atif has the answer! Here to address all your cement-related questions, don’t hesitate to reach out to him at atif.asif@ashgrove.com and read his answer in the next edition.

Climate change is rapidly escalating and we have hard work to mitigate its effects. For building professionals, that has typically meant increasing energy efficiency and pushing for renewable energy production, thus reducing the carbon generated by fossil fuels consumed to operate our buildings. As crucial as that is, it’s not enough. We also need to think about the greenhouse gases emitted to construct our buildings in the first place: the embodied carbon.

An LCA is a standardized tool for quantifying the lifetime environmental impact of a construction project. It takes into consideration all the steps from raw materials through manufacturing, distribution and usage, to final disposal. This can include concrete, construction and other materials and processes that produce CO2. An LCA can both measure a building’s lifetime impact and, at the same time, quantify the impact of a single material in the building or structure. We discussed Environmental Declarations (EPDs) in the December 2021 edition of the Dispatch and Low Carbon Procurement in the May 2022 edition. An LCA puts these concepts together to determine the impacts throughout the entire construction project.

· Evaluating building site options to select the lowest impact choices

· Comparing design alternatives to choose the lowest impact ones

· Calculating the lifetime impact of building materials and products to help find the most sustainable options

Note: it’s important to factor the life expectancy of the construct. Some building materials may have a lower environmental impact, but come with a much shorter life expectancy.

· The very first question to ask for any project is whether new construction is needed. By avoiding the use of new materials, we avoid their impacts altogether. Building and incorporation of salvaged building materials can greatly reduce the embodied carbon of construction.

· It’s also vital to think about the end of life of new buildings before they’re even built. It doesn’t make sense to emit carbon two or three times when the same building could serve two or three different uses over its lifetime. Consider design for future uses of whole buildings and design for deconstruction of systems so that materials can have a second life in another building. A good example of this is turning a corporate high-rise that is no longer needed into affordable housing for the population in that area.

This number is assessed on a Global Warming Potential (GWP) value, in kg of CO2 equivalent produced per m3 of concrete. This GWP is already being asked by some municipalities, as well as larger tenders driven by the Government of Canada. Starting January 1, 2023, all contractors bidding on federal projects above $10M in value that require more than 100m3 of concrete will need to submit the embodied greenhouse gas emissions of their concrete mix(es) along with calculation(s) (via a calculator – further explanation below) showing they are 10% less than those of the baseline mix(es) in the Regional Industry Average. The project cost will be further reduced to $5M on January 1, 2024.

Concrete Ontario gathered member data in 2021 and released a calculator that allows concrete producers to select their raw materials and obtain a resulting value. Below outlines how to use the calculator.

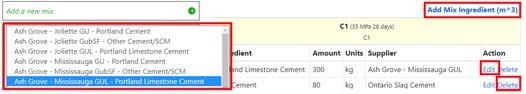

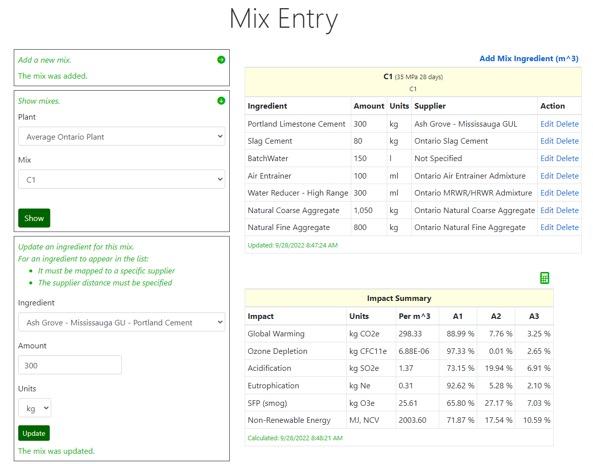

1 Click on “Add Mix Ingredient” and enter the ingredient and amount.

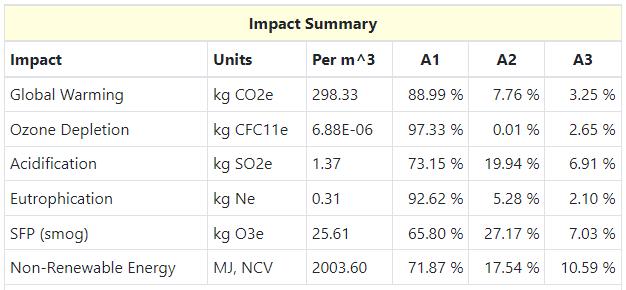

2 Once the mix is complete, click the “calculate” button to generate the impact summary (see table 2 – Impact summary).

Note: the summary breaks down the impacts into three areas (A1, A2 and A3). These represent the percentage that comes from the raw material supply (A1), transportation (A2) and manufacturing (A3) components. For example, if a job requires 1,000m 3 of concrete, given the report below, the supplier’s total GWP for the concrete provided would be 298,330kg of CO 2

4 Once the mix is created, you have the option to edit any quantity. Once the change is made, re-click the “calculate” button.

If you have additional questions regarding EPDs, LCAs, GWP or other cement and concrete matters, please reach out to our Technical Services team.

3 The Impact Summary (see table – Impact Summary) will outline what the GWP value is on a m3 basis. Other environmental impacts are also listed in the report.

This past summer, Dufferin Construction Company (DCC), Ash Grove’s sister company, was busy working on three separate airport projects in Canada. Two were in Alberta for the Calgary and Edmonton international airports and the other was in Ontario for the Toronto Pearson International Airport. This required a lot of planning to successfully complete these projects in the short window provided. The projects consisted of runway rehabilitation, apron restoration, and new cargo aprons.

Although DCC has a long history of working for each of these three airport authorities, it is rare that the

timing of projects and their completion would align. To make matters even more complex, beyond the tight fall completion timelines, DCC also faced industry-wide labour and cement shortages. Securing drivers (aggregate haulers, cement tankers, and dump trucks) was a difficult task regardless of the city in which they were working. DCC mitigated this impact by working closely with several carriers, including Ash Grove’s primary haulers, to stay on schedule. Continued shipments to maintain healthy inventory levels were managed on the peak production days and as the down days (including weekends) to ensure they were ready for

any upcoming big pour days. The existing plant cement and supplemental cementitious materials (SCM) storage capacities were minimal and, to minimize the risk of a stock outage, additional cement storage guppies were provided by Ash Grove. The juggling of skilled labour from project to project was also required to mitigate delays, some of whom were flown out of Toronto to Edmonton and Calgary when there was not enough local help.

Cement and SCM supply was also a challenge with the industry across North America impacted by tightening supply and allocations this year. The scheduling of large pour days

for all three airport projects had to be modified based on supply availability. Typically, DCC would take advantage of good weather and have their large pours scheduled back-to-back. However, with the constraints in supply, the schedules were stretched to add weeks (depending on the site) to ensure pours could be completed without the risk of a stock out. This challenge was exacerbated when the weather did not cooperate.

DCC utilized three separate production plants located adjacent to the airports and within close proximity to the sites. On the large pour days, these sites would see between 5-10 cement haulers and

35-50 aggregate haulers bringing in raw material, eventually leading to 80-120 dump truck loads of finished product being hauled out to the site. Thanks to the strong relationships we have with our cement customers, we were able to connect DCC with them to optimize logistics by getting access to the raw materials locally and broaden the hauler pool (The RMC Group of Companies – RM Aggregates/ FL Carriers; DECAST, Pidherney’s and others).

Ash Grove is proud to work with DCC, along with some of our other customers, to supply high-quality cement to these airport projects. Here are some highlights for each:

Toronto

· Rehabilitation of runway

· Timeline: mid-May to mid-October

· Estimated total volume: 12,000m3 (Portland Cement Concrete) and 40,000m3 (Cement Stabilized Base)

· 1,500m3 of high early strength concrete poured to meet spec req. (flexural/ compressive) within 24 hours

Edmonton International Airport,

· New cargo apron

· Timeline: mid-July to mid-September

· Estimated total volume: 11,000m3 (Portland Cement Concrete) and 19,000m3 (Cement Stabilized Base)

· Seven large pour days of PCC that were in excess of 1,700m3

Calgary International Airport,

· Apron restoration

· Timeline: end of May to beginning of July

· Estimated total volume: 5,000m3 (Portland Cement Concrete) and 1,000m3 (Cement Stabilized Base)

· Plans in place to complete apron restoration in 2023 of the three-year project

Safety has always been one of our top-most priorities and our employees have always ensured the highest standard for a great safety performance. In appreciation of our employees and drivers for all their efforts, we celebrated Safety Recognition Week from October 3rd to October 7th.

During the week, the commercial management team visited all of our North Region plants and terminals in Canada and the Great Lakes region. It was an opportunity to recognize our front-line employees and local carriers who have continued to put safety first, as well as to highlight some of the many safety initiatives they have rolled out at their respective facilities over the past year. During the visits, employees and drivers were provided with a lunch and given appreciation gifts for all their

efforts in working safely. Employees also had the opportunity to speak on the initiatives they rolled out, what drove those initiatives, and to reflect on the past year.

To conclude the week, we want to thank and congratulate all Ash Grove employees for their outstanding safety performance. Pictured are some safety recognition week activities at the Lethbridge Terminal Team site.

Seven years ago, when we lived in Alberta, we began a tradition of sending Christmas cards to our family and friends back in Ontario. Now, these were not your usual Christmas cards that showcased beautiful matching outfits in a winter wonderland backdrop, in a barn or forest, taken by a professional photographer. They were a simple snapshot of our messy home, with our kids in whatever state they were in at the time, and sometimes in matching pajamas. We thought they were funny and so cost-efficient.

During the early times of the pandemic, like many families out there, restrictions and social isolation were taking a huge toll on the mental well-being of our family members across the country. So in 2020, we stepped it up a notch, hoping to put a smile on some faces. We cleaned our home, put up a few construction lamps, got some matching outfits, and contracted our photo-editor friend to help us out, whom we paid with wine. That year, our Christmas card looked like an ad for a new family sitcom on Netflix. It showed my three children duct-taped on the wall, while my wife and I had wine on the couch. It was meant to sum up what the past year had been like for us and for so many other families out there. It resonated with many of our loved ones and we felt it brought some joy to a very crappy year.

Since then, we’ve continued creating these Christmas cards, attempting to capture the past year and put a smile on the faces of our friends and family.

This year, my family and I once again moved across the country, this time coming back to our home province of Ontario. This is what we captured in this year’s Christmas card.

At the end of November, we go and cut down our Christmas tree from a local farm. We always cut one too large and that takes up more of the living room than we would like. We decorate it as soon as possible to enjoy the tree for as long as we can. We do a big no meat dinner on Christmas Eve with the family and open presents afterward as well. On Christmas Day, we open more presents and then visit my wife’s family for a more traditional Eastern European lunch, filled with fresh cold cuts, cheeses and plenty of vodka. The rest of the holidays is spent with friends and family, and we get as many campfires in as we can.

– Robert Richer, Technical Service Rep, Ash Grove North