NPA

NPA

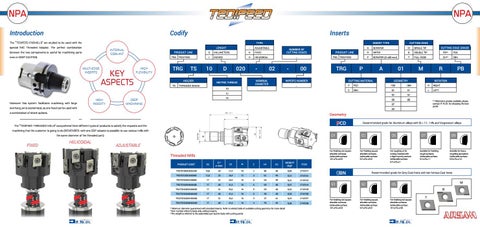

Introduction

Codify

Inserts

The “TEDIFEED ENDMILLS” are studied to be used with the

TYPE

special IMC Threaded Adaptor. The perfect combination

INTERNAL COOLANT

between the two components is useful for machining parts even in DEEP CAVITIES.

MULTI-EDGE INSERTS

PRODUCT LINE TRG

KEY ASPECTS

HIGH FLEXIBILITY

TEDI FEED

TRG

TS

LENGHT

-

ADJUSTABLE

D

MILLIMETERS

N

FIXED

I

INCHES

H

HELICOIDAL

10

HOLDER TS

INSERT TYPE

THREADED SHANK

D

020

-

NUMBER OF CUTTING EDGES

METRIC THREAD

NOMINAL DIAMETER

10

...

TRG

...

02

-

PRODUCT LINE

00

TEDI FEED

TRG

WIPER’S NUMBER

SCRAPER

M

SINGLE TIP

R

WIPER

B

DOUBLE TIP

PB**

PCB

P

SCRAPER (Ø ≤50 mm)

T

FULL EDGE

CH**

CBN

P

A

HIGH RIGIDITY

M

R

PCD

CBN

R

RIGHT

C

CBN

01

91

L

LEFT

02

92

05

05

** Alternative grades available, please contact IT.TE.DI. for choosing the best grade

07

overhang yet is economical, as one head can be used with

09

a combination of shank options.

PB

ROTATION

GEOMETRY

PCD

16

DEEP MACHINING

01

P

12

Moreover this system facilitates machining with large

CUTTING EDGE GRADE

A

CUTTING MATERIAL

...

CUTTING EDGE

Geometry

PCD

The “TEDIFEED THREADED MILLS” comprehend three different types of products to satisfy the requests and the

Recommended grade for Aluminum alloys with Si < 12 - 14% and Magnesium alloys

machining that the customer is going to do (REMEMBER: with one ODP adaptor is possible to use various mills with

01

the same diameter of the threaded part):

FIXED

HELICOIDAL

02

05

07

09

ADJUSTABLE For finishing not square shoulder surfaces. Achievable surface: 0.3 ≤ Ra ≤ 0.8

Threaded Mills PRODUCT CODE1

D2

D* ø nom.

D1

M

Z

H1

H2

WEIGHT (kg)2

ITEM

TRGTS10D020-02-00

10,5

20

21,4

10

2

58

38

0,03

2743141

TRGTS12D025-03-00

12,5

25

26,4

12

3

62

40

0,14

2743142

TRGTS16D032-05-00

17

32

33,4

16

5

65

40

0,24

2743143

TRGTS16D040-06-00

17

40

41,4

16

6

65

40

0,31

2743144

TRGTS16D032N05-00

17

32

33,4

16

5

65

40

0,26

2743149

TRGTS16D040N06-00

17

40

41,4

16

6

65

40

0,33

2743150

TRGTS16D032H03-00

17

32

33,4

16

3

67

42

0,24

2743157

TRGTS16D040H04-00

17

40

41,4

16

4

70

45

0,35

2743158

* Minimum diameter guaranteed with standard inserts. Refer to related table of available cutting geometry for more detail 1 Item number refers to body only, without inserts. 2 The weight is referred to the assembled part (cutter body with cutting parts)

For finishing square shoulder surfaces. Achievable surface: 0.3 ≤ Ra ≤ 0.8

CBN 91

For roughing or for cutting material with a high impurity content. Achievable surface: 0.4 ≤ Ra ≤ 1

Suitable for finishing rough surfaces Achievable surface: 0.4 ≤ Ra < 1

Suitable for heavy roughihg operations Achievable surface: 0.8 ≤ Ra ≤ 3.2

Recommended grade for Grey Cast Irons and non ferrous Cast Irons

92

M

05 B

For finishing not square shoulder surfaces. Achievable surface: 0.4 ≤ Ra ≤ 0.8

For finishing square shoulder surfaces. Achievable surface: 0.4 ≤ Ra ≤ 0.8

For finishing not square shoulder surfaces. Achievable surface: 0.4 ≤ Ra ≤ 0.8

T