BIOSECURE SALMON EGGS

How to design a genetic breeding program

Bacteriophages in shrimp hatcheries

Tool for live feed quantification

Vol 9 Issue 1 2021 Published by Aquafeed Media S.L.U. www.hatcheryFM.com info@hatcheryFM.com

Vol 11

CONTACT US

Editorial: editor@hatcheryFM.com

Editor/Publisher: Lucía Barreiro

Consulting Editor: Suzi Dominy

Assistant Editor: Marissa Yanaga

Conferences and webinars: info@hatcheryFM.com

Advertising enquiries/request media pack: sales@hatcheryFM.com

Accounts & all other enquiries: info@hatcheryfm.com

SUBSCRIBE

Digital editions are free to industry subscribers. You may also purchase print copies. Subscribe at HatcheryFM.com to receive your own digital copy of our publications.

https://bit.ly/HATCHERYSUBSCRIBE

FOLLOW US

We are grateful to the following companies for sponsoring this issue of the magazine. Their support allows us to make our publications available without charge.

FEED & MANAGEMENT

Aquafeed Media, S.L.U., Ames, 15220 A Coruña, Spain. Copyright© Aquafeed Media, S.L.U., 1998-2023 All rights reserved. Privacy Policy & Terms of use

Hatchery Feed & Management Vol 11 Issue 3 2023 EQUIPMENT HATCHERY FEED & MANAGEMENT VOL 11 ISSUE 3 2023 Contents 4 Interview with Finn Chr. Skjennum 7 News Review 10 AquaGen opens land-based full-cycle egg production facility in Norway *Cover photo 13 Selective breeding for a better catch 17 Expanding possibilities for aquaculture 20 Advanced simulations shed new light on how to design genetic breeding programs 25 French selection and reproduction centers delivering trout eggs worldwide 28 Don’t fall behind: Stay up to date with how technology is redefining live food management in the hatchery 32 Cultivating success through personal relationships and premium feeds: Tailored solutions through new production methods 35 The future of microalgae in aquaculture 38 Enhancing growth performance, survival rates and stress resistance in larval and early post larval rearing of Litopenaeus vannamei 43 Advancing sustainability in aquaculture with ozone and UV 46 Advancements in recirculating aquaculture systems: Enhancing fish density through innovative technologies 49 AI-powered cameras: Revolutionizing fish health monitoring in aquaculture 51 Smart technology for water purification in recirculating aquaculture systems

Bacteriophages in shrimp hatchery: An Indian experience

What’s new in the hatchery? Humic acid as a microbial control agent

New Zealand aquaculture: Poised for growth

Calendar of events To read previous issues in digital format or to order print copies, visit www.hatcheryfm.com

55

60

63

67

HATCHERY

The Centre for Aquaculture Technologies 15 Hatchery Feed & Management 19 FishFarmFeeder ......................................................19 Zeigler .......................................................................23 Reed Mariculture 27 Fresh-flo ....................................................................48 Socorex ....................................................................54 World Aquaculture Society 68

HATCHERY FEED & MANAGEMENT

ADVANCED SIMULATIONS TO BETTER DESIGN GENETIC BREEDING PROGRAMS 20

The expected improvement for a range of traits can be modeled and explore the economic impacts of different genetic programs.

TOOL FOR PRECISE LIVE FEED QUANTIFICATION 28

An automated rotifer and Artemia counting tool that requires far less time and effort while offering unparalleled precision.

ADVANCES IN RAS 46

Pivotal roles of RAS components in maintaining optimal water conditions while enlarging productivity.

HUMIC ACID AS MICROBIAL CONTROL AGENT 60

The development of non-toxic and environmentally friendly products to disinfect salmon eggs

VOL 11 ISSUE 3 2023

Contents

INTERVIEW with Finn Chr. Skjennum

HFM: In the early 2000s, cod farming was attempted but failed. How important has the Norwegian National Cod Breeding Program been for the resumption of the activity?

FS: The earlier failure of cod farming was caused by several factors occurring simultaneously. The market failed and the financial crisis came at the same time that cod farming was on the rise and still had several biological problems.

The National Cod Breeding Program has continued with genetic improvements despite the lack of commercial cod farming companies for more than ten years. New generations of cod and the current broodstock selection program have been an asset for a new start of the industry. Learning from previous cod farming activities as well as using progress from other farmed species has allowed this new start.

HFM: Cod farming is still a young industry with only a handful of companies currently in operation. Why did you decide to produce cod?

FS: We anticipated that Atlantic cod will be the next species that can be commercially produced in Norway and in the Norwegian fjords. The demand for protein in general and fish products is growing, and cod is a wellknown white fish species in several global markets.

HFM: Ode is a fully integrated Norwegian seafood company. Tell us where the company is today in terms of size, markets and production capacity.

FS: Ode AS is among Norway’s largest cod farming producers today and the company is anticipating growth in the years to come. Ode is in the process of building biomass and delivering several products to the market. The target is to reach more than 30,000 tons of

Hatchery Feed & Management Vol 11 Issue 3 2023 4

Finn Chr. Skjennum is Head of Juveniles in Ode AS

products within three years time. Farmed cod has been well received so far and will be delivered to the global fish markets.

HFM: Focusing on the hatchery, how were the current stocks built and what is the current breeding strategy? In terms of management, what have been the main improvements?

FS: Breeding of cod is still in the early process compared to more high-scaled farmed species such as salmon, and quality work will be among the most important tasks during the next few years. In general, the main target for the breeding program has been the domestication of cod that are better adapted to the current farming conditions, where “Best practice” in cod farming has been a target driven by technology, learning and economy of scale shown by the salmon farming industry.

We have a lot of competence and industry experience in Norway. Both fish growth and the quality aspects have, for instance, been improved in the cod hatchery at Ode Stadsbygd, and both the owners and the employees have strongly contributed to a hatchery process that is based on available broodstock and the best working skills. It is still important to focus strongly on both broodstock and hatchery management procedures and improve and develop the best commercial operating procedures. There is a challenge in the fact that we are presently taking small-scale procedures into largescale systems.

HFM: In terms of larval production, what are the current main challenges for the hatchery stages?

FS: First feeding (weaning onto dry feed) and creating strong fish as early as possible (without deformities) are the main challenges in today’s hatchery production. We still have seasonal variability in hatchery survival. In general, more than 30% survival can be achieved, but batch-to-batch stability is something that requires more focus on improvement in both broodstock management and operational procedures. These procedures as well as a need for more trials are in the process right now and should be achieved at a level that we presently also see in marine fish hatcheries globally.

HFM: In terms of feed, how do you manage first feeding? Have weaning diets been improved for optimal juvenile production?

FS: First feeding with dry feed is a challenge today, but it also requires the right live feed and broodstock management. Several steps with follow-up in the later stages are required – nothing gets better than the weakest stage. Feed to marine species has been developed but can still be better adapted to the cod.

HFM: Deformities and cannibalism have also been some of the hatchery issues in the 2000s. How did you manage to solve them?

FS: Good feed management and start feed quality are the most important issues. Deformities and cannibalism will be present despite the domestication through the

5

breeding programs, but managing cod properly through all the hatchery stages is still the most important factor in achieving high and stable survival.

HFM: How about biosecurity? Are diseases an issue in the early stages? Do you run RAS or a flow-through system?

FS: The hatchery process in Ode is presently done in flow-through technology. RAS development will require other technology and more trials. Biosecurity is a process going on from broodstock through the whole value chain of production. In Ode, we control what we are able to control internally, in logistics and in various production departments, and we have not seen any factors that should seriously affect biosecurity today.

HFM: Ode recently reached an important breakthrough in tackling cod’s early maturity in the grow-out stages. Is there room for more improvements at these stages?

FS: There will be room for more improvements over time. This is valid in the various departments and in all parts of the value chain in Ode. Achieving improvements will be important to be able to develop cod farming, improve fish quality and finally decrease production costs. Broodstock, light manipulation, deformity and vaccine control, as well

as feed, are all very important input factors in the value chain. More knowledge will contribute to improvements in production and the production cost of cod.

HFM: How do you see the future of cod farming in terms of markets and farming technology?

FS: The future of cod farming is promising, but it is dependent on capital and long-term commitment to developing the whole-year market. This will be a stepby-step process that requires a steady increase in the number of high-quality juveniles and it will depend on available sites for placing fish farms – both on land and in the sea.

We know that the market for cod is well developed with good yearly prices, but the essential is to produce and deliver cod at sustainable levels, which requires both scale and strong commitments. Diseases in cod have been under control so far. The industry will need to control diseases over time and also balance the value chain. This will require R&D programs, technology development as well as the ability to define the main bottlenecks in today’s value chain. Norway has a lot of good sites with farming activities that can be well adapted to the sustainable development of cod farming.

Hatchery Feed & Management Vol 11 Issue 3 2023 6

NEWS REVIEW

Highlights of recent news from Hatcheryfm.com

CPF introduces new products in India, plans $72 million investment

CAT unveils shrimp genetics innovation center

This state-of-the-art facility features a cutting-edge genome editing lab and tank space, quadrupling CAT’s shrimp research capacity. The facility’s opening sets the stage for revolutionizing shrimp genetic performance and accelerating next-generation breeding through the application of innovative genome editing techniques.

Charoen Pokphand Foods (CPF) India introduced new products in the Indian market in Vijayawada, Andhra Pradesh. The firm launched new shrimp feeds (Blanca Extra, CP Monodon Advance and Super Marine Extra) and seed products (Turbo Rocket and Turbo Kong). The new products available in the Indian market have been developed by CPF’s Thailand team especially for Indian farmers. Furthermore, the company plans to invest ₹600 (USD 73 million) in its aqua and agro-businesses in India soon.

Benchmark expands R&D team in reproductive technologies

Bangladeshi company unveils SPF monodon fry

ACI Agrolink, a subsidiary of the Bangladeshi ACI Group, plans to introduce SPF post larvae of black tiger shrimp into the Bangladeshi market. The initiative opens a new business line for the group that aims to enhance shrimp farming in the country and increase exports.

Benchmark has bolstered its research and development team with several new recruits in recent months. The new Reproductive Technologies R&D team has been established to ensure the company remains at the forefront of innovation, in particular, bringing breakthroughs in sterility and gene editing to the market in the coming years. Milestones in these technologies are expected to highly impact the salmon industry’s productivity, animal welfare, and sustainability.

7 NEWS REVIEW

BioMar expands hatchery trial facilities

RASLab, KYTOS join forces on microbiome management services in RAS

The expansion of the marine hatchery trial facilities at its Aquaculture Technology Centre (ATC) Hirtshals in Denmark will increase the capability of performing trials in semi-industrial conditions. They will serve as a hub for research and development activities, with the addition of six multinational R&D staff to the team of experts in marine hatchery operations. It will include units dedicated to larval rearing as well as live feed production, allowing for extensive research and testing of hatchery feeds for several marine species.

FAI Farms unveils shrimp welfare website and online training course

FAI Farms launched its Shrimp Welfare project’s new website, myshrimp. farm, a user-friendly platform that serves as a comprehensive resource hub, offering insights, guidelines, and practical solutions for optimizing welfare in shrimp aquaculture. The site features FAI’s welfare assessment protocol and its first online training course on shrimp welfare, available in English, Spanish and Portuguese, and soon Thai and Chinese.

The companies are collaborating to offer commercial services to manage and optimize the microbial health and performance of RAS systems. KYTOS offers a quantitative overview of the microbiome in the water and biofilter that complements RASLab’s RASseq services where next-generation sequencing identifies all of the bacteria in the biofilter. By undertaking these combined analyses, it becomes possible to understand how management decisions affect the biofilter in terms of performance and resilience as well as the total microbial environment of the RAS system. Using this information, bespoke services can be offered for optimizing system and fish performance.

Waterbase expands into Sri Lankan shrimp feed market

Indian shrimp feed producer, The Waterbase Limited (TWL), has entered the Sri Lankan shrimp feed market appointing Lucky Seven Aqua as its distributor for shrimp feed in Puttalam District, Sri Lanka. With the increasing popularity of vannamei shrimp farming in Sri Lanka, Waterbase sees immense potential for its high-quality shrimp feed products in the region.

“Farmed shrimp production in Sri Lanka has witnessed significant growth, particularly with the introduction of vannamei shrimp. Waterbase’s entry into the market is a positive development for the local aquaculture industry. Our high-quality shrimp feed products will play a crucial role in supporting sustainable shrimp farming practices and improving overall productivity,” said Dr. Mohandas, presidentsales at TWL.

Hatchery Feed & Management Vol 11 Issue 3 2023 8 NEWS REVIEW

Ace Aquatec unveils state-of-the-art biomass camera

Ace Aquatec added another innovative product to its suite with A-BIOMASS™, an automated AI camera system. The fully-automated camera is far smaller and easier to deploy than many on the market, weighing in at just 8.5kg, and has been proven to withstand the harshest environmental conditions.

World’s first breeding of bluefin tuna in a land-based facility achieved

First steps agreed in the creation of a Global Shrimp Council to boost worldwide consumption

More than 20 shrimp producers have held talks aimed at creating a Global Shrimp Council, to generally promote and grow shrimp consumption around the world by providing meaningful information about the industry. The meeting took place on the fringes of the Global Shrimp Forum in Utrecht. Producers from several countries including Ecuador, Mexico, India, Vietnam and Indonesia took part in the meeting, which was the initiative of industry leaders, Gabriel Luna, owner of Glunashrimp and David Castro, CEO of Manta Bay. The organization aims to be producer-driven and could be established within the National Fisheries Institute (NFI) in the US.

eFishery, ASC join forces to scale certification of smallholder farmers in Indonesia

eFishery signed a partnership with the Aquaculture Stewardship Council (ASC) to advance sustainable aquaculture in Indonesia and empower small-scale shrimp farmers across the region. By extending assistance towards obtaining ASC certification, the partnership aims to foster not only more sustainable farming practices but also wider access to premium international markets for these farmers.

Researchers from the Murcia Oceanographic Center of the Spanish Institute of Oceanography (IEO, CSIC) have achieved, for the first time, worldwide, the reproduction of Atlantic bluefin tuna (Thunnus thynnus) kept in captivity in a land-based facility. The IEO previously closed the cycle of this species in 2016 but in floating cages in the sea.

9 NEWS REVIEW

AquaGen opens land-based full-cycle egg production facility in Norway

Lucía Barreiro

Credits: Berre/AquaGen

AquaGen recently opened its new full-cycle facility, Profunda, in Barstadvik in Ørsta municipality, Norway, in an international event that gathered industry professionals from different countries. As Norway’s only land-based full-cycle broodstock and egg production facility, Profunda will deliver biosecure salmon eggs all year round and aims to supply customers across the globe.

AquaGen is a research-oriented breeding company that develops manufactures and delivers genetics start material and fertilized eggs to the global aquaculture industry. The company purchased Profunda in 2017 at a stage when the facility produced broodstock salmon for other customers. In 2018, the facility expanded its broodstock production capacity and in 2020, the company started to work on turning Profunda into a full-cycle land-based facility for egg production. The

plan was completed in 2023 and has already delivered salmoneggstocustomersinNorwayandtheU.S.

The location

Profunda is located in a scenic area with mountains and a deep fjord. Why did the company select this location? AquaGen wanted to bring pathogen-free farming that has been implemented in other livestock species for years to salmon. The main focus was finding a location with the best water inlet quality After discarding the ozonation option, the company looked at the results obtained by the Mediterranean aquaculture farms using sandstone filtration for seabream and seabass. AquaGen found that the nature around Barstadvik has very special geological features with deposits of sand and gravel that have built up since the lasticeage.

Hatchery Feed & Management Vol 11 Issue 3 2023 10 SPOTLIGHT

last deglaciation when the ice melted and carried down the rivers with sand, clay and stones to the sea. The water movement of the fjord removed all small particles accumulating and settling down sand and gravel in this area. This is quite unique with very few locations like this in the world.

The facility has access to both marine and fresh groundwater which is taken from deep wells, and Profunda, which means “deep”, is named after them. Both are filtered through the sand deposits which offers several advantages. It minimizes water temperature variations and in the case of seawater, it brings oxygenrich seawater from the fjord bottom and aerobic bacteria that settle down on the sand acting as a biofilter. Therefore, the water that comes in is very clean and unique.

Both waters are also disinfected through UV systems. Artec Aqua has been the turnkey contractor for the project. The facility features a flow-through system and a hybrid system for the quarantine and egg departments. The facility also features a system to recover part of the heat before the water is released into the sea again.

Genetics

Aquagen has more than 50 years of balanced breeding experience with a breeding program consisting of more than 1,000 families. Starting its activity in the 1970s,

more than 14 generations have been bred selecting different traits, the most important being growth and disease resistance, but adding others, such as growth in seawater, sexual maturation, and quality traits (color and fillet texture). Genomic selection is made by over 70,000 different markers to find the fish with the best traits.

Back in the day, the initial generation time was four years, and over 12 generations, and through long-time genetic progress, it has now been reduced to three years nowadays. Thanks to its milt cryobank, AquaGen recently performed a study to quantify the effect of genetic selection for increased growth throughout these years and model future growth. Results showed that to reach a 4-kilo salmon, it takes 22 months in generation 0 (in the 1970s), 16 months in generation 6 (in the 1990s)

11 SPOTLIGHT

and 9 months in generation 11 (2010s). By improving the inherent growth potential of Atlantic salmon through genetic selection, the model predicted a 50% reduction in production time (7 months in seawater) and lower mortality in 2050.

Egg production

With 10,000 broodstock and a production capacity of 100 million eggs per year, Profunda acts as a breeding nucleus. Broodstock live their entire life cycle, from egg to egg, in a high-tech facility with the highest level of biosecurity that does not need to take eggs or milt from other facilities.

Broodstock production takes about three years. A comprehensive screening program ensures fish health throughout its life cycle. Each broodstock is individually monitored and screened after egg release including an autopsy and a PCR test.

Each egg batch is maintained separately in a quarantine room until the screening test results are negative. Eggs follow quality tests and sorting to remove unfertilized or dead eggs and eggs with anomalies and are disinfected. They are then packed in storage boxes and delivered to the final customers. The whole process ensures complete traceability.

Biosecurity

At Profunda closed plant, all aspects are under control and the risk of contamination from outside has been

eliminated, which, in turn, takes minimal risk of disease. The company has designed a scientificallybased surveillance program for its disease-free status. The facility has periodic inspections by external services. Disease-free tests are made for eggs and customers can request those that have been carried for their egg batch.

Water is continuously monitored. The facility has installed specially designed louvers where seawater aerosols and humidity are trapped. The different rearing areas are independent with special areas to disinfect equipment and staff. Profunda is a closed system meaning new biological material is not introduced in the facility.

Since Profunda aims to supply salmon eggs to international customers, it needs to have the status as a specific pathogen-free segment from the World Organization for Animal Health (WOAH). The company is currently working on a two-year surveillance program to document freedom for relevant diseases and independence from the surroundings that will end in March 2025.

Profunda also aims to be approved by the European Union as a close compartment and also comply with the specific requirements of the countries that plan to supply eggs. Currently, the company has market access to the U.S. and other third countries.

Hatchery Feed & Management Vol 11 Issue 3 2023 12 SPOTLIGHT

AquaGen Profunda facility

Selective breeding for a better catch

John Buchanan, Anastasia Karelova, The Center for Aquaculture Technologies

In the rapidly evolving world of aquaculture, where the demand for seafood continues to rise, improved efficiency and sustainability are crucial. To meet this growing demand, the industry has turned to a timetested strategy: selective breeding. In this article, we will explore the significance of selective breeding in aquaculture, review various types of breeding programs and offer insights to make informed decisions.

Why selective breeding matters

Technically speaking, selective breeding is the process of improving one or more desirable traits of a cultured species through the selection of superior parents. A breeding program is how this idea is put into action, using specific tools and methods. It should be designed to maximize the economic return for a commercial aquaculture producer. Therefore, selective breeding

isn’t just a buzzword; it’s a practical strategy that helps aquaculture achieve critical goals:

Improved quality: One of the primary motivations behind selective breeding is to enhance the quality of farmed aquatic species. By selectively breeding for desirable traits like rapid growth, disease resistance, and survival, we can produce fish and other aquatic organisms that meet consumer preferences and market demands.

Enhanced productivity: Productivity is the lifeblood of aquaculture. Selective breeding allows us to create strains of fish, crustaceans, or shellfish that grow faster and more efficiently, leading to increased yields and reduced production costs.

Sustainability: Sustainable aquaculture practices are essential for safeguarding our aquatic ecosystems. By selectively breeding for traits that minimize

13 GENETICS

GENETICS

environmental impact, such as reduced waste production and efficient feed utilization, we can create a more sustainable future for the industry.

Exploring options

There are numerous ways to organize a breeding program. Here are three common options to consider.

Mass selection assisted with molecular markers

Mass selection is a process where you pick the best individuals based on visible traits (phenotypes) and cross them to create the next generation. However, it comes with a caveat – this strategy works effectively for straightforward and direct traits like size, shape, or color.

There’s another crucial aspect to consider. In mass selection, you might end up selecting closely related individuals (leading to inbreeding). This can cause issues in the long run, as after several generations, genetic gains can diminish, potentially causing the program to collapse. To prevent this, molecular markers and genomic information are often employed to track diversity and levels of inbreeding within the population, ensuring that the breeding program remains robust and sustainable.

Consider the case of Ecuador’s thriving shrimp farming industry, where the adoption of mass selection programs has brought about a transformative impact. These programs have been primarily geared towards enhancing growth. By selecting the biggest shrimp, farmers have achieved a two-fold benefit. Not only have they raised the bar on the quality and quantity of their shrimp, but they’ve also significantly bolstered the economic feasibility of their operations. This means they can produce larger shrimp in a shorter span, resulting in increased profitability.

Family-based breeding

This approach involves selectively crossing the most promising families within a population to produce the next generation. It relies on the careful consideration of both observable traits (phenotypic) and ancestry records (pedigree). By combining individuals from families with superior characteristics for any type of trait, this method estimates the genetic effects of specific traits in various environments, ultimately enhancing the desired traits in the succeeding

generations. Importantly, several traits can be selected at the same time using this approach and a selection index.

One notable example is the family-based selective breeding program for Nile tilapia (Oreochromis niloticus) in Egypt. In this program, researchers and aquaculture practitioners identified families of Nile tilapia with superior growth rates, disease resistance, and other desirable traits. These selected families were then bred together to create the next generation of tilapia. Over time, this approach has resulted in significant improvements in the growth performance and disease resistance of Nile tilapia stocks in Egyptian aquaculture. By focusing on family lines with consistently favorable characteristics, this family-based breeding program has contributed to higher production yields and economic gains for aquaculture farmers in Egypt, highlighting the effectiveness of such programs in achieving specific breeding objectives.

Genomic selection

Genomic selection is an advanced breeding strategy that identifies and mates the most promising individuals based on their Genomic Estimated Breeding Values (GEBV) to create the next generation. This highly effective method integrates phenotypic data, pedigree, and genomic information to significantly enhance precision and responsiveness in selecting specific traits and adapting to various environmental conditions. This method generates the most rapid genetic gain per generation, maintains genetic diversity extremely well, and can address improvement in multiple traits.

Norwegian aquaculture companies have harnessed the power of genomic selection to elevate the growth rate, improve flesh color, and increase yield and disease resistance of their Atlantic salmon populations. In this initiative, researchers conduct extensive genomic analyses to determine genomic relatedness and identify regions of the genome associated with trait improvement. By selectively breeding salmon with favorable genomes, they achieved rapid and substantial improvements. This strategic move not only boosted the productivity of salmon farms but also curtailed the need for antibiotics and other treatments, promoting sustainability and environmentally friendly practices in Atlantic salmon aquaculture.

Hatchery Feed & Management Vol 11 Issue 3 2023 14

Shrimp's DNA Unleashed: Making waves with AQUAarray HD vannamei 50K Empowering breeders to drive transformative advancements through genetic improvement. www.aquatechcenter.com T E C H NO LO G I E S AQ UACU LTUR E T H E C E N TE R FO R ALL vannamei populations Fast turnaround Quality control Expert advice Genomic Selection and more Harness the power of a single tool for all your shrimp breeding needs! More tools and more species in our AQUAarray catalogue

Building the foundation

To effectively implement selective breeding programs, aquaculture companies must possess a range of critical capabilities. This begins with having the necessary technical expertise in genetics and breeding principles to make informed selections of breeding candidates. Efficient data collection and analysis tools are vital for evaluating traits and tracking pedigree information accurately. For genomic selection programs, access to cutting-edge genomic technologies is essential for precision.

It’s important to note that there’s no competition between the types of breeding programs you can implement. Instead, the choice depends on your specific situation. Each breeding program has its strengths and is suited to different contexts. Mass selection, familybased breeding, and genomic selection are all valuable tools in the aquaculture industry’s toolbox, and the right choice depends on the unique goals and resources of each company. The key is to make an informed decision that aligns with their aquaculture operation’s objectives and long-term vision.

“Many clients approach us with a strong inclination toward genomic selection, considering it the industry’s go-to solution. However, we believe in a tailored approach. By thoroughly evaluating their business

structure, production methods, goals and available resources, we often recommend a different path that aligns better with their unique circumstances,” says Alejandro Gutierrez, director of breeding at the Center for Aquaculture Technologies

From this perspective, having access to specialized expertise can be a gamechanger. Producers often find it beneficial to collaborate with partners who have expertise in genetic analysis, breeding program development, and genomic technologies. Companies like CAT offer consultancy and breeding services tailored to the unique needs of aquaculture operations and can provide valuable guidance and technical assistance. By leveraging these services, producers can enhance their capabilities, make informed breeding decisions, and optimize their breeding programs for improved outcomes.

Selective breeding programs serve as the foundational step in shaping the genetic characteristics of aquaculture species. Once these programs have laid a solid genetic groundwork, genome editing techniques can then be employed to precisely fine-tune specific traits, offering even greater control over the genetic makeup of aquatic organisms. This combined approach provides a robust foundation for the sustainable growth of the aquaculture industry.

More information here.

Hatchery Feed & Management Vol 11 Issue 3 2023 16 GENETICS

Expanding possibilities for aquaculture

Dave Conley, AquaBounty Technologies

AquaBounty’s expertise in R&D and vertical integration drive future growth.

Fish farming is the fastest growing form of food production in the world, and with good reason. World population growth will continue to drive increased demand for protein in the coming decades. Blue foods such as salmon are not only an excellent source of protein, but a healthy, lean source with many other proven health benefits.

But even as demand for seafood continues to grow, supply is constrained. Ninety percent of the world’s fisheries are fully fished or overfished, and rising ocean temperatures negatively impact wild salmon populations and even net-pen farmed fish

“Our oceans are being pressured like never before, and we must protect and preserve delicate and

stressed ecosystems and fisheries,” said Sylvia Wulf, AquaBounty CEO.

Amid these demand and supply pressures, AquaBounty is using its research and development (R&D) expertise and vertical integration to continuously improve production at its land-based farms and ensure a sustainable source of healthy seafood.

AquaBounty: Preparing for future demand

Among land-based aquaculture companies, AquaBounty has made R&D a key focus since the development of its GE salmon over 30 years ago. AquaBounty has continued to invest in its R&D capability, and today, it is expanding its research efforts at its Fortune Bay facility

17 GENETICS

on Prince Edward Island (PEI), Canada, where scientists are using the latest biotechnologies to improve fish breeding, health and nutrition, and genetics.

As a vertically integrated company, AquaBounty seeks to continuously improve salmon health and production across the salmon lifecycle, from broodstock to hatch to harvest. Vertical integration allows AquaBounty to leverage decades of expertise in fish breeding, genetics, and health and nutrition to deliver disruptive solutions that address food insecurity and climate change issues by shifting salmon production out of the ocean to land-based recirculating aquaculture system (RAS) farms. The company uses the latest RAS technology in its freshwater tanks to nurture the fish in a safe, sustainable way, leveraging its extensive RAS operational experience. Vertical integration is a competitive advantage that allows AquaBounty to raise its GE salmon with even greater efficiency and sustainability.

“AquaBounty’s vertical integration through each phase of our salmon lifecycle, from control of egg and broodstock production through grow-out and harvest, allows us a unique degree of insight and control over every aspect of our operations,” said Wulf.

Expanding production now

AquaBounty’s farm in Rollo Bay, PEI, specializes in broodstock husbandry, egg production and hatchery efficiency and is currently undergoing expansion to increase salmon egg production of both GE and nonGE salmon eggs. The expansion will allow AquaBounty to increase production of its FDA-approved GE Atlantic salmon and sell non-GE salmon eggs to other ocean-pen and land-based salmon producers. By capitalizing on its R&D expertise and integrated production capacity, AquaBounty is ensuring land-based aquaculture is

Hatchery Feed & Management Vol 11 Issue 3 2023 18 GENETICS

“AquaBounty’s vertical integration through each phase of our salmon lifecycle, from control of egg and broodstock production through growout and harvest, allows us a unique degree of insight and control over every aspect of our operations,”

Sylvia Wulf, AquaBounty CEO.

positioned to meet the growing demand for salmon with sustainable practices.

Fulfilling the promise of land-based aquaculture

AquaBounty has strategically aligned its proficiency in RAS technology with the added advantages of vertical integration and a deep commitment to R&D to continuously improve operational efficiency, employing the most advanced research to enhance fish health and nutrition. Land-based aquaculture has the potential to provide a sustainable source of lean, healthy protein to meet an ever-growing demand, even as population growth and climate change challenge traditional fisheries and ocean farming. AquaBounty is fulfilling

the promise of land-based aquaculture so the world can expect to enjoy sustainable, healthy seafood for generations to come.

More information:

Dave Conley, MSc Director, Corporate Communications

AquaBounty Technologies, Inc.

E: dconley@aquabounty.com

19 GENETICS

LAND • SEA • RAS

Systems

Vaccinator

Aquaculture Feeding

Feed

The only manufacturer worldwide that covers all feeding stages of fin fish and shrimp for land or sea based systems

Live

Dry Feed Aquaculture Europe 2023 - Booths 16-17 18 - 21 Sept 2023 • Vienna

(AUSTRIA)

For Medium and Big-Scale Hatcheries

For Medium and Big-Scale Hatcheries

For Labs and Small-Scale Hatcheries

For Labs and Small-Scale Hatcheries

Automatic Feeding System of Artemia, Rofiter and Microalgae.

Dosing of Micro Diets from 200 up to 800 microns

Advanced simulations shed new light on how to design genetic breeding programs

Dr. Mark Looseley, Dr. Marie Smedley, Xelect

Dr. Mark Looseley, Dr. Marie Smedley, Xelect

While selective breeding in aquaculture still lags behind the main livestock and agricultural species, the last decade has seen genetics move from the margins to the mainstream. We’ve made significant progress, but many producers are only just beginning to explore how a genetics program can affect the profitability of their production.

When designed correctly, a selective breeding program should deliver a return on investment many times over, but knowing how to implement it can be a daunting task. Firstly, there’s a bewildering array of genetic technologies and approaches available. How do you know which one is right for you? Secondly, every single farming operation is unique – both in

terms of the actual production environment and their commercial situation.

At Xelect, we know that no two breeding programs are the same, even with the same species. To help farmers make informed choices about how to structure their breeding programs, we’ve built sophisticated bioeconomic models that combine advanced genetic simulations with real-time commercial data, allowing us to explore how the choices you make about your breeding program directly affect your profitability. We effectively create a virtual version of your farm and can simulate how small changes made now can make big changes in the future.

Hatchery Feed & Management Vol 11 Issue 3 2023 20 GENETICS

In this article, we’ll cover some of the common choices that need to be made, and use data from our simulations to explore some of the big questions in aquaculture breeding.

Genomic selection:

Is the gold standard right for everyone?

The question of which selective breeding tools make the most economic sense will be different for every producer based on the species, environment, commercial values and scale of operation. For many of our customers, we recommend pedigree-based selection programs, which estimate the genetic value of each selection candidate by combining measures of its own performance with those of its close relatives. This allows us to separate genetic effects (that get passed on to its offspring) from environmental effects (that do not). Under this type of selection, the relationships between individuals are taken directly from pedigree records.

Genomic selection takes this to another level, using high-density genetic data to make more accurate estimates of the genetic relationships between individuals, which, in turn, allows the genetic value of each individual to be estimated more accurately. This can result in faster rates of genetic gain. Genomic selection is particularly valuable in traits that cannot be measured in the broodstock candidates, such as disease resistance or fillet yield.

The price of operating a genomic selection program has fallen significantly in recent years, so it’s tempting to assume that it is now the “go to” for any modern breeding program. In reality, genomic selection is best suited to larger-scale production, but even then, it is important to base financial decisions on sound forecasting.

We can use our simulations to look at how a genomic selection program is likely to perform in two different scenarios.

For this first example (Fig. 1), we consider two different businesses farming a high-value salmonid species in different parts of the world, with distinct environmental conditions and associated pathologies. Both farms are identical, with the same running costs, feed costs and production levels. However, Farm 1 has a higher level of mortality during the on-growing stages than Farm 2, which has better survival values at the end of the cycle.

The question is simple: Is genomic selection worthwhile for both producers?

The findings are remarkably clear. Genomic selection provides significant profitability savings compared to pedigree-based selection where the mortality levels are high, but pedigree selection methods remain more appropriate where mortality levels are low. The scale of these savings is modest for a smaller scale of production and therefore may not merit investment in GS technology given the higher upfront costs with this technology. Once pedigree and genomic selection technology are implemented appropriately, the genetic program makes up just a tiny percentage of the costs of the operation and the resulting commercial improvement is significant.

Of course, this comparison tests two particular scenarios for two scales of operation, but every farm is different. We work with our customers to carefully

21 GENETICS

Figure 1. Simulations comparing the projected gains in weight and survival when using genomic selection and pedigree selection. Farm 1 had a highe level of initial mortality compared to Farm 2.

design the program that best meets their needs – but the costliest solution does not always produce the best return on investment. The important thing is to take the time to understand what kind of strategy will give you the biggest return on your investment.

The trade-off of traits: How many is too many?

There’s a large list of traits that could be improved by genetic selection – such as growth rate, size at harvest, sexual maturation, survival, resistance to pathogens and parasites, FCR, body shape, flesh color and stress tolerance. If you can measure for it (and it is heritable) you can – in theory – select for it.

But if you overload your breeding program with too many traits of interest you will simply see diminishing results on the ones that really matter. Firstly, measuring and managing multiple traits can have a cost, through additional work and measuring equipment. More importantly, the economic value of genetic improvements is not identical across traits and selection pressure is limited. The more traits you select, the lower the response will be in each. Finding the right balance of traits requires a careful consideration of how much each of them is really worth to you. In this second example, we looked at two different scenarios, one where only 4 traits were selected, and carefully balanced based on their

commercial impact. In the second, we simulate a program that was designed to give improvements in 8 traits at once without any consideration of their value. Our simulations show that both programs give improvements to every generation, but the more focused program, designed to improve only the most valuable traits, rapidly outperforms a program that attempts to improve too many traits at once (Fig. 2). Once the program is established, and generational improvements are realized, the relative economic gain is significant. Our advice is usually to identify the traits that will really change the dial when it comes to commercial returns and focus on those to generate maximum return on your breeding program costs.

Prioritizing your spend: How do you maximize the return on your investment?

When designing a selective breeding program, there are many areas of investment to consider and choices to make on where to spend money. Again, simulations can help. For this last case, we will continue with the same Farm 1 as the first simulation in the article – a high-value species producer with an unfortunate high mortality scenario (Fig. 3).

The farmer has decided to invest in their breeding program, but they are faced with two choices. They could start a genomic selection program (using

Hatchery Feed & Management Vol 11 Issue 3 2023 22 GENETICS

Figure 2. Simulations showing the projected economic return from focusing on 4 commercially valuable traits vs 8 traits.

high-density genotyping, which typically costs more per sample) or they could allocate the same budget to have a larger broodstock and sample more of their fish using a smaller SNP panel (so there is a lower genotyping cost, but higher running costs as more individuals need to be maintained). In this case, we can see that for harvest size there may be a small advantage to using additional broodstock. However, for disease resistance, we can see that genomic selection comes with substantial gains while spending the same money on additional broodstock makes almost no difference to rates of genetic gain.

Take your time with your program design

The sophistication of selective breeding programs is evolving rapidly, and as new technologies are developed the answer to the question “What’s the right genetics program for me?” will change over time. Based on the biological performance of your farm we can model the expected improvement for a range of traits and explore the economic impacts of different genetic programs. Our bio-economic modeling simply

23

GENETICS

Figure 3. Simulations showing a comparison of projected gains in harvest size and survival when using a more expensive genomic selection approach vs spending the same budget on analysing additional broodstock.

GENETICS

shows that there is no one-size-fits-all when it comes to aquaculture. The first stage of your program design should be to accurately model the likely returns from a range of program designs and select the perfect blend of technologies and traits based on real-world calculations.

More information:

Marie Smedley Senior Breeding Programme Manager Xelect

E: info@xelect.co.uk

E: info@xelect.co.uk

SNP PANELS – IS BIGGER ALWAYS BETTER?

Single nucleotide polymorphism (SNP) panels– the tools that we use to analyze the genetic code of each individual – come in all shapes and sizes. For many classical, pedigree-based, selection programs, a SNP panel with about 150 SNPs is the usual tool of choice for assigning offspring to parents. This means that your genetic services company is looking at 150 variable regions on the genome of an individual to understand their pedigree.

For genomic selection techniques, many more SNP markers are required compared to pedigree-based approaches. High-density SNP chips, which are usually around 50,000 SNPs, allow you to analyze an individual in much greater resolution and run genomic selections. It’s more expensive to build and design the chips, and usually, routine genotyping costs are significantly higher unless you process

an extremely high number of samples to bring economies of scale.

While the number of SNPs can make a big difference to the efficiency of genomic selection it’s worth taking the time to evaluate what size of panel is right for you. In many circumstances our simulations show that you don’t need tens of thousands of SNPs – and this can make a big difference to your genotyping costs.

For many purposes, the primary use of the SNP chip is simply to make a highly accurate estimate of the true genetic relationships between individuals. In typical aquaculture breeding program designs, you can often make that prediction accurately based on just a few thousand SNPs, after which point a higher number of SNPs is unlikely to change your conclusion, are you simply wasting your money?

In a typical aquaculture breeding program, a sentinel group comprising full siblings of the selection candidates is used to measure destructive traits. Under this scenario, our simulations show that there

is generally no additional improvement in prediction accuracy from increasing the number of SNPs above around 5,000 SNPs. This can result in significant cost savings for a producer.

Hatchery Feed & Management Vol 11 Issue 3 2023 24

Figure 4. Chart comparing selection accuracy for broodstock vs sentinels based on the number of SNPs.

French selection and reproduction centers delivering trout eggs worldwide

Frederic Cachelou, Viviers Aqua

Viviers Aqua is a French group of selection and reproduction centers dedicated to trout that produces fertilized trout eggs for fish farmers around the world. In 2022, the group produced and sold 150 million fertilized eggs.

The company

In 1975, a small fish farm located in the Sarrance village in the Pyrenees, in the southwest of France, was bought by the Salmona group to become its trout egg production center. This farm has been selected for the

quality of its spring water: pure, fresh, and abundant all year round, with perfect conditions for trout breeding. In the early eighties, the first rainbow trout eggs were imported from the North American West Coast and other European farms. Fish were then raised for two years until first reproduction to obtain the original Viviers strain.

Since 1985, no live fish have been introduced to the Sarrance farm, and the Viviers strain has been improved year after year by breeding the best individuals of each generation, taking care to maintain maximum genetic

25 SPOTLIGHT

variability. Viviers will shortly start its 20th generation. In January 2009, the company Viviers de Sarrance was created, when Frederic Cachelou took the lead of the Sarrance reproduction center. The production rose in five years from ten million eggs exclusively dedicated to the group to 50 million exported all over the world. In 2014, Cachelou became the unique owner of Viviers de Sarrance, when the Norwegian owners of Salmona group (currently Norway Seafood) decided to sell all their fish farming activities in Southern Europe.

Cachelou decided to expand the company by buying another fish farm in Rébénacq village, near Sarrance.

Viviers Aqua group currently owns three fish farms, all located in the Pyrenees: Sarrance dedicated to the production of rainbow trout eggs; Escot, a small farm that raises the broodstock; and Rébénacq has ideal conditions for producing large amounts of trout eggs. The production now reaches 150 million eggs per year, which places the group in the world’s top 5 trout egg producers. Further developments are planned.

The production of fertilized eggs

Female trout are reared until their first spawning at the age of two years. The first eggs collected are not fertilized because they are too small and too fragile to be used safely as farm eggs. They are sold as “caviar eggs” for human consumption. Females are then kept for 2-3 additional years in order to harvest the second, third and possibly fourth laying. These eggs are collected and fertilized.

Thanks to the R&D work carried out 30 years ago, all the males used by Viviers Aqua are XX males which allows the company to produce exclusively allfemale eggs, allowing farmers to avoid sorting between males and females.

All-female eggs can also be sterilized immediately after fertilization to obtain triploids sterile eggs. Sterile eggs are ideal for trout farmers producing large trout up to 2-3 or even 4 kg. The sterilization process is a non-GMO process using a pressure shock on eggs, without any use of chemicals.

After fertilization, eggs are incubated for a full month, up to the eyed stage, before being ready for delivery. At the end of this incubation period, the eggs are counted, graded and sorted to eliminate all non-fertilized or noneyed eggs. This process is carried out using the latest IMV Quicksorter and Prosorter machines. A final sorting is done by hand just before shipping, to ensure 100% perfect eggs on delivery.

The genetic selection program

The Viviers strain has been developed through a mass selection program. The initial selection criteria were growth, morphology (long and thin fish) and external shape (nice and colored fish). In 1990, the Prosper selection method was implemented in Sarrance farm. This selection method has been developed by Chevassus from the French research center INRAE. Prosper is a mass selection method improved by the control of genetic variation of the initial population, the

Hatchery Feed & Management Vol 11 Issue 3 2023 26 SPOTLIGHT

crossing plan, and all non-genetic parameters. It gives the fastest improvements and makes Viviers strain one of the most successful strains in the world. More recently, new selection methods were applied such as BLUP method and later genomic method.

The Viviers strain has been separated into two genetic lines, the female line and the male line, with newly implemented selection criteria: filet yield; spawning performance to improve the production of eggs for clients producing caviar eggs as well as large trout; robustness to improve performance of fish under rough conditions; and disease resistance, such as Flavobacterium, IPN, etc. All these developments are supported by SYSAAF, the French Technical Center for Fish Breeders, and carried out according to the most modern methods of genetic selection. Thanks to these R&D efforts, Viviers strain is internationally recognized as one of the most efficient, which allows the group to export 70% of its fertilized eggs worldwide.

Commercial distribution

Viviers sells 30% of its eggs in its domestic market, France, but also 40% to neighboring countries, such as Spain, Germany or Poland. Other markets are Russia (until 2022) and the former Soviet countries, Turkey, Iran, the Middle East and the Far East (Vietnam, Taiwan, etc.)

The only important markets in which the group is not present are Peru and Colombia. Despite requests made several years ago, and despite the excellence of the health record presented by the company, Viviers has still not obtained health approval to export to these countries. The complexity and slowness of the administrative procedures in these countries are probably responsible for this situation. New markets such as India or China will soon be explored to replace the Peruvian and Colombian markets if they continue to be closed for unfair reasons. All the eggs are sold under the VIVIERS DE SARRANCE brand name.

More information:

Frederic Cachelou CEO Viviers Aqua E: office@sarrance.com

27 SPOTLIGHT

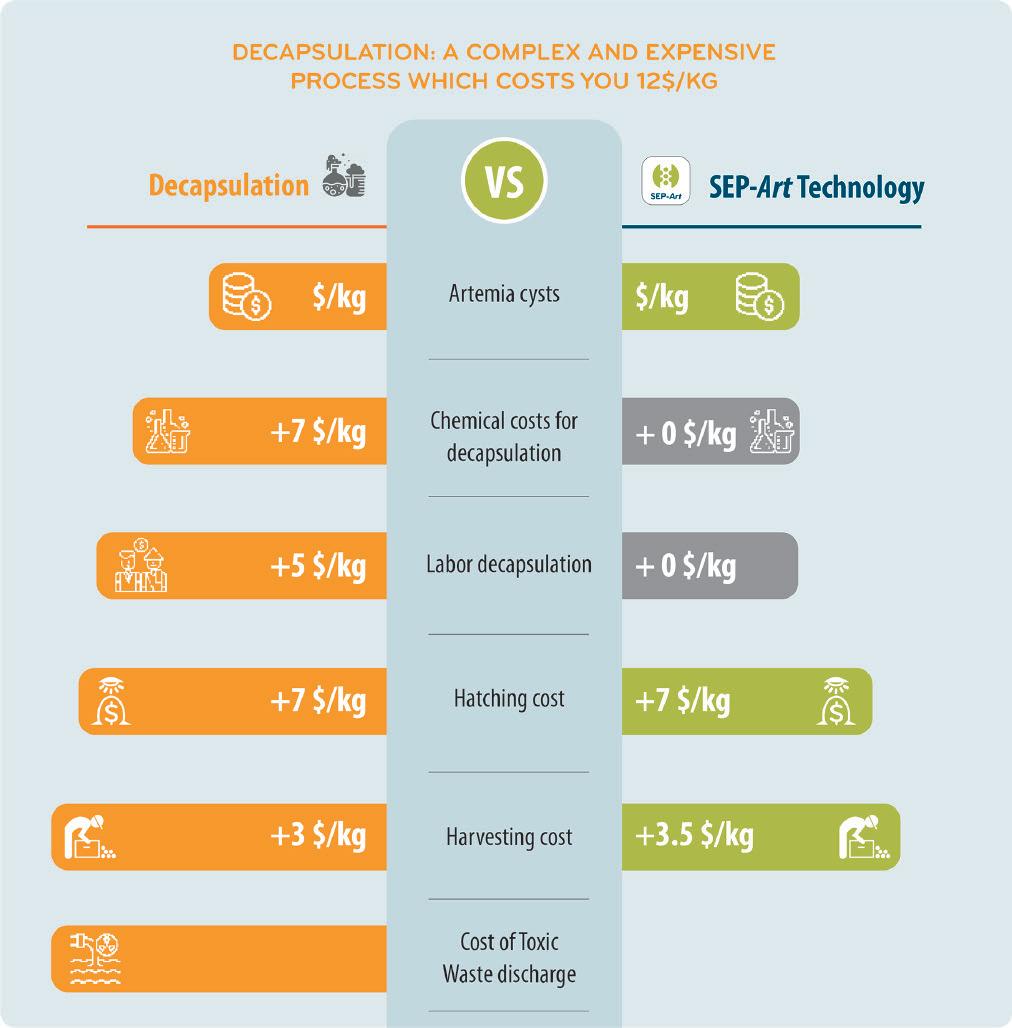

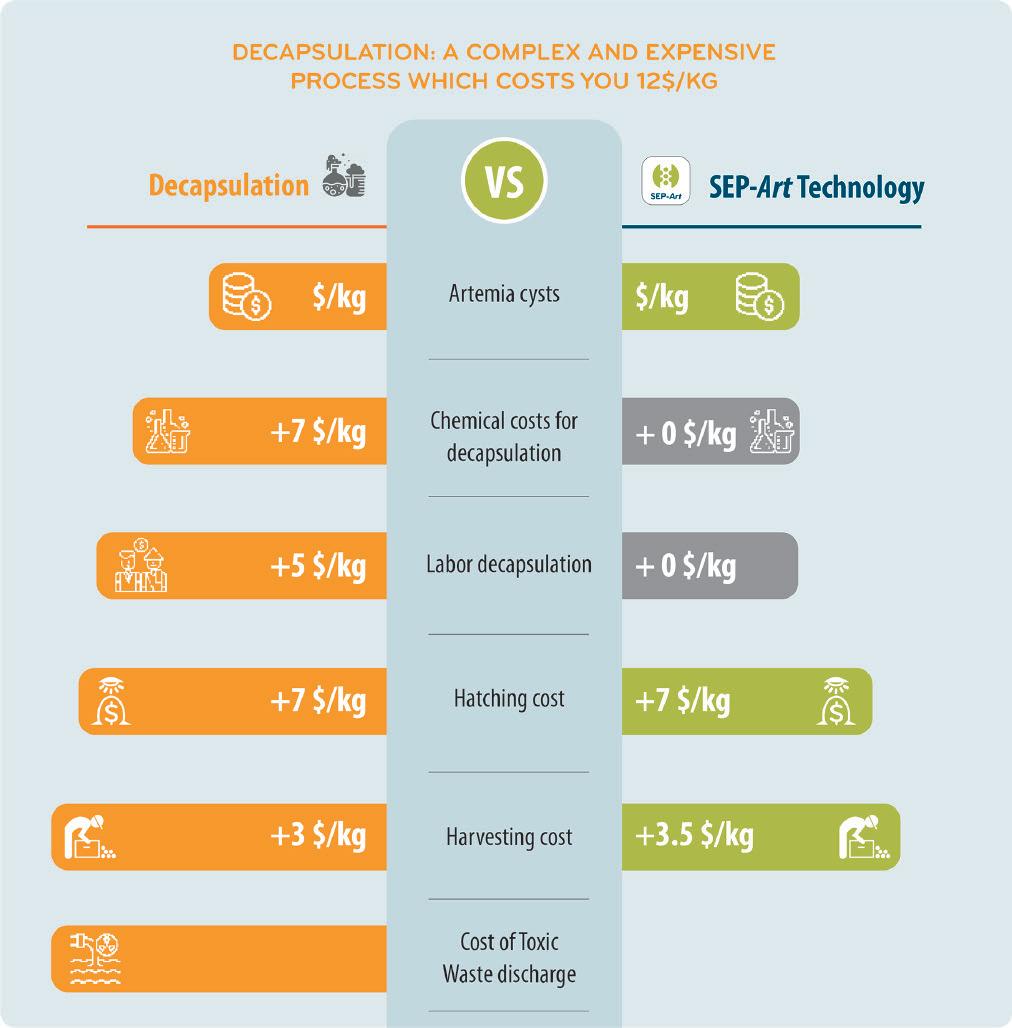

Don’t fall behind: Stay up to date with how technology is redefining live food management in the hatchery

Geert Rombaut, INVE Aquaculture

The cost-efficient production of live food, such as Artemia and rotifers, remains one of the crucial success factors for fish and shrimp hatcheries worldwide. This is why a growing number of hatcheries rely on the latest technologies to streamline their live food management. By moving away from traditional harvesting methods (e.g. double sieving or chemical decapsulation of Artemia cysts), more and more hatcheries are embracing safer, more efficient, and more sustainable ways to get the most Artemia out of every Euro/dollar spent.

New and better ways to harvest Artemia

The key to harvesting Artemia is getting a maximum number of viable nauplii and efficiently separating the nauplii from the empty cyst shells. One of the most significant developments in this regard has been the

introduction of SEP-Art technology by industry-leading Artemia supplier INVE Aquaculture. Thanks to the application of a unique magnetic coating to Artemia cysts, hatcheries can benefit from a simplified and efficient way to harvest their live food.

How does SEP-Art Technology work?

The patented SEP-Art technology allows INVE to treat Artemia cysts with a non-toxic magnetic coating. This makes it possible to collect the nauplii and separate them from their cyst shells far more easily using specially designed magnetic tools. The process is faster, more efficient, and significantly reduces the labor involved in food recovery.

INVE’s patented SEP-Art technology offers several benefits

Improved cost-efficiency and sustainability

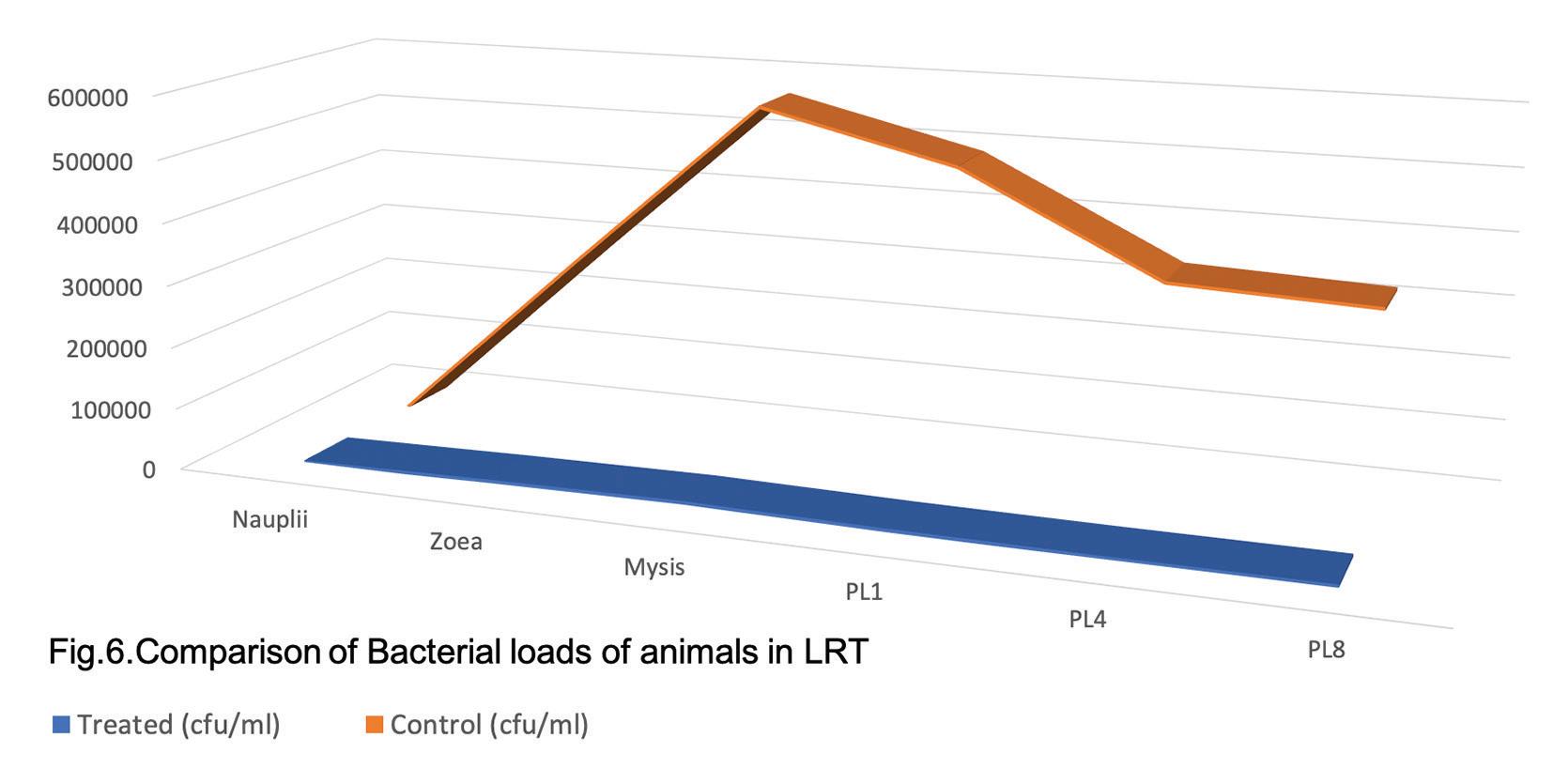

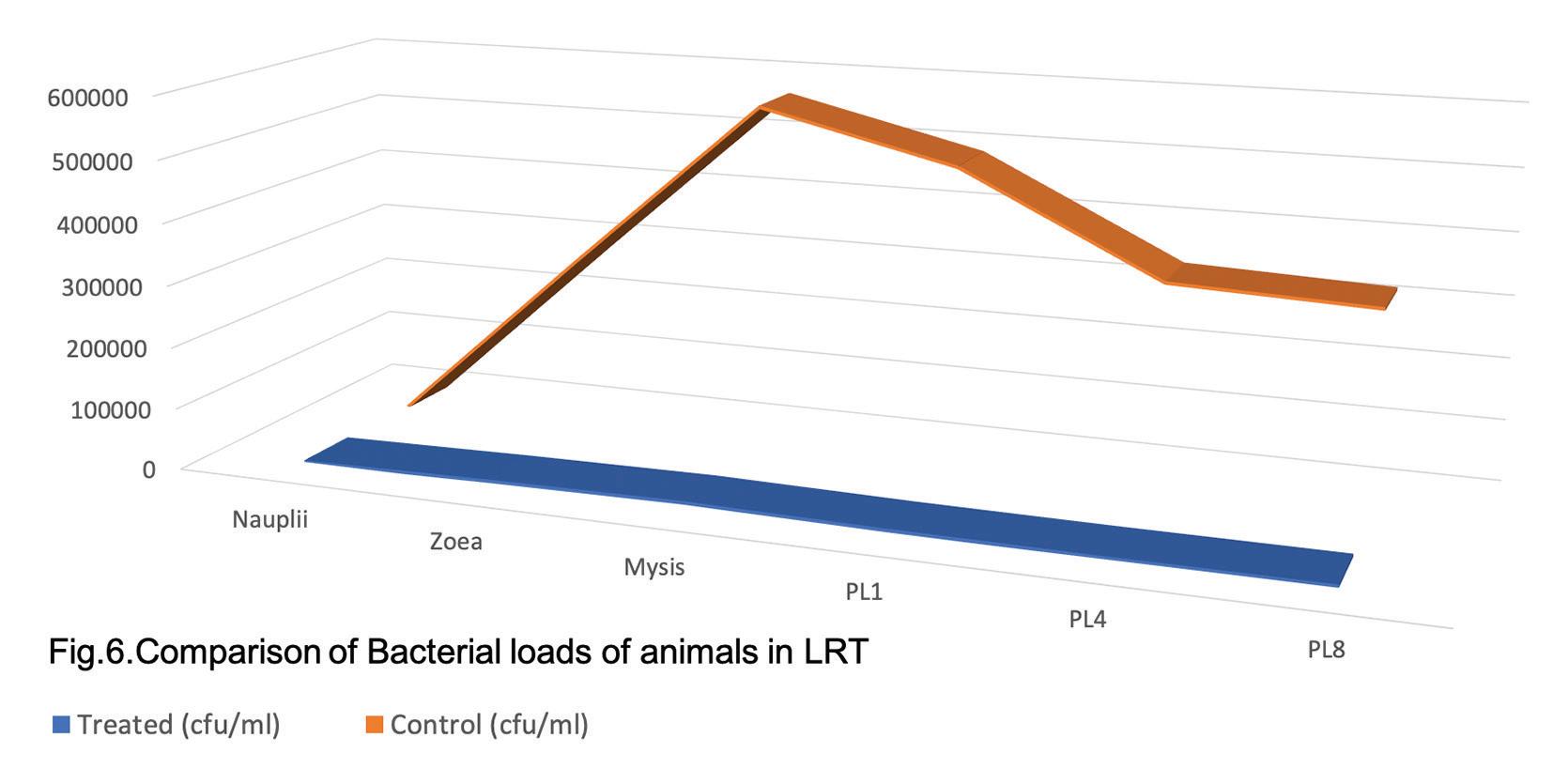

• SEP-Art decreases the operational costs linked to producing Artemia nauplii significantly. Compared to the decapsulation method, up to USD 10/kg of product can be saved (no need for chemicals and reduced labor).

• It reduces the amount of remaining empty shell

Hatchery Feed & Management Vol 11 Issue 3 2023 28

FEEDS

material, and thus improves the biosecurity in the larval tanks (less risk of bacterial load, e.g. Vibrio).

• It reduces the risk of gut obstruction or failed ingestion caused by empty shell material.

• It is better for the environment because it eliminates the use of hazardous chemicals, the discharge of waste or by-products, and the accumulation in the food chain.

Safer, simpler, and more comfortable work

• SEP-Art eliminates the use of hazardous chemicals and the release of toxic fumes or gasses during the Artemia harvesting process.

• The SEP-Art method maximizes the recovery of the hatching output and speeds up the harvest and collection of the nauplii thanks to specially developed and easy-to-use magnetic tools.

INVE SEP-Art AutoMag is a fully automatic tool that was specially designed to harvest medium to large hatching volumes (up to 15 kg of SEP-Art cysts) with minimal labor input and maximum biomass outcome. The system can be connected to the Artemia hatching tank and has integrated piping for clean sea water, air,

and oxygen. As the hatching tank is emptied into the AutoMag, the built-in magnets capture the magnetized cysts and empty shells while the nauplii are instantly concentrated and rinsed. The result: a dense and clean suspension of pure nauplii only. The self-cleaning system of the AutoMag evacuates the collected cysts, leaving clean magnets for the next batch of Artemia.

The AutoMag’s fully automated process allows fast harvesting: typically, a 5-ton hatching tank (10 kg of EG SEP-Art 240 cysts hatched at a density of 2 g/l), is handled in less than an hour. Similar SEP-Art tools are also available in manual (SEP-Art HandyMag) and semimanual (SEP-Art CysTM 2.0) versions, tailored to the needs of different hatchery sizes.

The SEP-Art technology drastically improves the quality of live food. By simplifying the harvesting process, maximizing the output of high-quality live food, and reducing risks by preventing unwanted material from being transferred to the larval tank, it plays a crucial role in facilitating a more predictable and standardized post-larvae (PL) and fry production. In addition, the Artemia SEP-Art tools are a sustainable solution designed to maintain quality nauplii, reduce losses and ensure safety for workers and the environment. These

29 FEEDS

benefits establish SEP-Art cysts as an indispensable tool in modern hatchery practices.

Embracing the future of feed management with automated, AI-powered live food quantification

During Aquaculture Europe in Vienna, INVE Aquaculture introduced yet another leap forward in aquaculture technology. Together with Aris, INVE has developed SnappArt: a revolutionary AI-powered live food counting device that automates the quantification of rotifers and Artemia. The project was supported by Eurostars, a European funding instrument for collaborative R&D and innovation projects.

The end of manual inspections

Until now, the adequate production and quality control of Artemia and rotifers demanded meticulous manual inspections. These labor-intensive and errorprone procedures conducted on limited sample sizes often lead to inconsistent feed administration.

Moreover, skilled staff is hard to find, and sampling methods are not globally standardized. All the above too often jeopardize the predictability of highquality shrimp and fish production. Representing a monumental shift in live food quantification, SnappArt replaces conventional manual counting with a method that requires far less time and effort while offering unparalleled precision. This groundbreaking technological innovation propels hatcheries towards more time- and cost-efficient, sustainable, and consistentlivefoodproduction.

Easy-to-use device with advanced AI-driven software

Designed with advanced computer technology, the SnappArt device looks deceivingly modest. The real innovation, however, lies in the AI-driven image analysis softwarethatensuresrapid,preciseanalysisofsamples. And a highly intuitive user interface makes the device remarkably easy to operate.

Hatchery Feed & Management Vol 11 Issue 3 2023 30 FEEDS

results. With reduced inspection time and data-driven decision-making, hatcheries can boost their profitability, optimize growth ratios, and improve their overall production efficiency.

This innovative tool is set to rapidly become a musthave for any hatchery wishing to ensure the consistency and reliability of their production practices thanks to: Speed and efficiency: The automated tool swiftly processes large volumes of samples, significantly reducing counting time and freeing up valuable human resources.

Accuracy and consistency: By eliminating the inherent subjectivity and variability associated with manual counting, the AI-based tool provides highly accurate and consistent results, ensuring precise feed management. Data tracking and analysis: The tool generates comprehensive data reports, enabling hatcheries to

monitor live food, and optimize live food utilization strategies.

24/7 access to expertise: Automation of the counting process reduces tedious but very important labor, saving both time and costs for hatcheries. At the same time, the device relies on expert knowledge that is accessible to the hatcheries 24/7, securing and standardizing knowledge year-round.

Conclusion

With the introduction of SEP-Art technology and the SnappArt counting tool, the aquaculture industry is on a new path toward more streamlined, efficient, and sustainable hatchery practices. By simplifying the recovery process, improving the quality of live food, and introducing a reliable counting method, these innovations are pushing the boundaries of what is possible.

These technologies represent the industry’s commitment to continuous improvement, innovation, and sustainable practices. With the rapidly increasing adoption of innovations such as these, the aquaculture industry continues to grow profitably and sustainably while meeting the world’s increasing demand for seafood.

More information about SEP-Art and Snapp-Art can be found on artemia.inveaquaculture.com

More information:

Geert Rombaut

Product Manager Artemia

& Live Food, INVE Aquaculture

E: g.rombaut@inveaquaculture.com

31 FEEDS

Cultivating success through personal relationships and premium feeds: Tailored solutions through new production methods

Björn Ronge, PTAQUA

In recent years, marine aquaculture has experienced a significant surge in growth and productivity. Both Mediterranean and cold-water species are cultivated in an innovative approach to increase sustainability and address the challenges in the industry. However, successful marine larviculture requires careful attention to various factors, one of which is the nutrition of the cultured fish. To pave the way for enhanced fish health,

reduced environmental impact and increased efficiency, specialized premium fish feeds have emerged as a game-changer.

Meeting high quality standards

One example in the European aquaculture landscape is seabream production which has always been a pressured and economically significant sector. To

Hatchery Feed & Management Vol 11 Issue 3 2023 32 FEEDS

New WinWrasse diets from SPAROS have helped improve health and survivability in ballan wrasse.

From left to right: João Henriques from SPAROS and Charlie Cross from MOWI

maintain the high standards of quality and sustainability required by this industry, European seabream producers have turned to innovative solutions. Among these solutions, Otohime, the premium fish feed supplied by PTAQUA, has emerged as a significant improvement.

Otohime is a Japanese feed and is considered the gold-standard larval diet in Japan. It contains only the freshest and highest quality krill and fishmeal which makes it highly attractive and nutritionally suitable for marine larvae. Today, many of Europe’s biggest seabream producers are choosing Otohime for their aquaculture operations after achieving outstanding results.

Otohime is fast becoming the number one choice for seabream and seabass producers and is also growing in popularity amongst sole and turbot producers. Also, Otohime has played a pivotal role in the successful production of ballan wrasse (cleaner fish for salmon) production in Norway over the past few years.

One of the standout achievements of Otohime in European larval production is its ability to deliver exceptional growth rates and survivability. Seabream raised on Otohime exhibits robust growth patterns, allowing producers to bring their fish to market size efficiently.

Otohime’s commitment to using the highest-quality ingredients and its focus on digestibility through the production method of agglomeration play a crucial role in promoting the health of seabream. Healthier fish are more resilient to diseases and stressors, resulting in lower mortality rates and more consistent production.

This not only increases productivity but also enhances the economic viability of seabream farming operations.

Customized feed solutions

The success of Otohime in European seabream production can be attributed not only to its superior quality but also to the personalized support and customer relationships fostered by PTAQUA. The company’s commitment to understanding the specific needs of each producer has built trust and loyalty within the industry as success often hinges on more than just the quality of the product itself. It’s also about the relationships built and the personalized solutions offered. PTAQUA has made personalized customer relationships a cornerstone of its business strategy. With new recruitments in 2023, PTAQUA now has an even stronger coverage of each individual market and customer in Europe. They recognize that no two aquaculture operations are identical. Fish species, production systems, water conditions and goals can vary significantly from one customer to another.

One of the key benefits of PTAQUA’s approach is the ability to offer premium and customized feed formulations. By partnering with specialized feed producers such as SPAROS and understanding the nuances of a customer’s operation, PTAQUA can tailor its feeds to meet the exact nutritional needs of the fish being raised.

SPAROS produces species-specific bespoke diets that eliminate bottlenecks in larval production. One example is WinWrasse, a special diet for ballan wrasse larvae to eliminate the high mortalities post-weaning. Another product is WinFast, a diet designed for the special nutritional needs of fast-growing species, such as meagre and seriola. SPAROS also produces specialized diets for flatfish such as turbot, sole and halibut. This level of customization ensures that fish receive the optimal diet for growth and health.

High quality feeds

Both Otohime and SPAROS diets share the philosophy of producing the highest quality feeds through innovative production methods and the highest

33 FEEDS

Lumpfish, one of the many species Otohime is an essential diet for.

quality raw materials. In the quest to create premium fish feeds, one key production technique that stands out is agglomeration. This often-overlooked process plays a pivotal role in improving the digestibility of feeds, ensuring that fish can efficiently utilize the nutrients provided.

digestion. The compacted structure of agglomerated feeds ensures that the nutrients are more evenly distributed throughout each pellet. As fish consume the feed, their digestive enzymes can access and break down the nutrients more efficiently. This results in increased nutrient absorption and utilization, contributing to better growth and health. Also, agglomerated feeds are less prone to disintegration in water compared to loose powders. This characteristic reduces the risk of feed wastage and minimizes the pollution of aquatic environments and helps maintain water quality.

transforming marine aquaculture by delivering products

that epitomize precision, quality, and sustainability. With tailored nutrition, enhanced digestibility, immune-boosting properties, and a commitment to personal relations with customers, PTAQUA are helping aquaculture operators achieve higher growth rates, improved fish health and long-term partnerships. As marine aquaculture continues to play a vital role in meeting global seafood demand, PTAQUA are poised to be a cornerstone of success in the industry, ensuring

More information:

Björn Ronge

Global Marketing Director

PTAQUA

E: b.ronge@ptaqua.eu

Hatchery Feed & Management Vol 11 Issue 3 2023 34 FEEDS

Tunisian seabream fed with PTAQUA diets

The future of microalgae in aquaculture

Doron Eisenstadt, BarAlgae

Doron Eisenstadt, BarAlgae

Microalgae are a unique group of photosynthetic, primary producers that have a profound impact on the oceanic and global food webs. As a fundamental feed source in aquaculture practices, microalgae species are used throughout hatcheries, including fish, shrimp, and bivalves. Microalgae, packed with essential fatty acids, amino acids, vitamins, and unique bio-active ingredients, serve as a stable, balanced diet for the initial larval stages resulting in better health and increased survival rates. Selected species of microalgae also serve as a stabilizing agent for water quality. Traditional practices in hatcheries consist of openpond cultivation of a limited number of species under sub-optimal conditions resulting in unreliable supply and low quality of algal biomass. Additionally, growing

algae on local seawater is a hazard of transmitting marine pathogens and contaminants into the hatchery tanks. The solution lies in combining shelf products of top-quality microalgae blends, cultivated at closed systems on purified media. Such cultures of microalgae are grown using optimized nutritional profiles and therefore present a sustainable and affordable feed for enhanced production.

Introduction to microalgae

About 3,500 million years ago, the ocean and the atmosphere started to be oxygenated by a group of photosynthetic bacteria. Two thousand million years later, eukaryotic phytoplankton acquired this ability and microalgae began to dominate the aquatic environment forming the basis for all plant life as we know it.

35 FEEDS

Current estimations regarding the biodiversity of microalgae range from 200,000 to a staggering 1 million species in nature, whereas only a fraction of them are scientifically described, and even fewer are commercially cultivated.

Microalgae’s ability to photosynthesize makes them primary producers – they convert sunlight, carbon dioxide and nutrients not only into biomass such as carbohydrates, proteins, and lipids but also solely produce unique and essential bioactive molecules not available from other natural feed sources. These bioactive molecules include essential DHA and EPA, vitamins, pigments, phycobiliproteins, enzymes, etc. Biologically active substances from microalgae are capable of exhibiting antioxidant, antibacterial, antiviral, and many other beneficial effects. These compounds are in demand in pharmacology, nutraceuticals, cosmetics, and the chemical industry but naturally, the first industry to appreciate their potential and to exploit in huge quantities was aquaculture.

Current usages

Microalgae are an essential food source in the rearing of marine aquaculture species. Most commonly used at hatcheries for the larval stages of fish, shrimp and zooplankton live feeds, such as rotifers and Artemia. Microalgae are also used for filter feeders, such as bivalve mollusks (clams, oysters and scallops), the larval stages of some marine gastropods (abalone and conch), and even more exotic animals like sea cucumbers. Between 20 and 30 species are used around the world as direct and primary feed, as complimentary feed, as well as a water conditioning agent (green water technique or for oxygen generation). Additional applications can be found in aquaculture water treatment facilities.

Traditional cultivation methodologies

Most hatcheries are producing their own microalgae biomass by cultivation using rather simple methodologies. They usually keep a simple culture collection and an inoculum at indoor or lab-scale facilities using household illumination and supplying basic nutrition for the upkeep of the cultures. They later transfer the cultures into plastic containers to allow algae growth, and finally, they inoculate ponds or tanks of various shapes and sizes to allow the final

stages of growth. The cultivation media in these production processes are usually local waters (with or without filtration like sand filters or mechanical filters, sometimes applying some levels of ozone) and are fertilized by basic nutrients. To apply the algae cells as feed, water containing the algae is pumped or otherwise transferred into the production tanks.

Problems associated with low-quality algal feeds

While the understanding that the best possible application of microalgae cells is when they are intact and viable, several problems associated with utilizing locally grown algae arise.

First, the traditional cultivation methodologies described above lead to inconsistent supply. Due to ever-changing weather conditions, water qualities, etc., different cycles of cultivation will result in significant differences in cell count, and cell quality. Often suffering from complete crushes of cultures, the hatcheries cannot always rely on the expected outcome of biomass so they must grow extra amounts of algae and operate many more tanks at a considerable cost, as backup.

Second, the variations in cell composition due to differences in cultivation conditions, nutrient bioavailability and even changes in light intensities result in inconsistent feed composition for the first, critical stages of larval development.

Third, some preferred algae species (nutritionally) are hard to grow since they require unique conditions, continuous and delicate care, and a high level of

Hatchery Feed & Management Vol 11 Issue 3 2023 36

FEEDS

Figure 1. Trials conducted at a commercial vannamei hatchery. Trial conditions: From Naupli5 to PL12, 6 tanks (3 treated tanks, 3 controls); larvae density: 250/L; algae cell density: 30K; tank volume: 8MT; stocking: 2,000,000 per tank.

proficiency for consistent algae production. To make things even more complicated, growing multiple species in parallel makes it almost impossible to self-supply a balanced diet.

Lastly, the general cultivation conditions of open algae tanks filled with local waters will necessarily introduce contaminations and marine pathogens into the larvae tanks, risking their health during the very sensitive first days of their development.

Modern technologies for microalgae cultivation

Producers of algae-based products that are utilizing similar open-pond methodologies will inherently suffer from the same problems and, therefore, achieve similar results. New advanced ways of growing microalgae have developed over the past 20 years and have dramatically improved in recent years. Ranging from autotrophic (using light as a sole energy source) to mixotrophic (combining light and carbohydrates) and heterotrophic (using carbohydrate source only) processes, the microalgae industry is nowadays able to select the optimal ways to grow different species for selected products. Utilizing sensors and computer control for the upkeep of cultures, image analysis for quality assurance during the production process and for final products, automated fertilization for enrichment and increased bio-actives in microalgal biomass, and even machine learning for the prediction of cultivation outcomes is an industry standard for top algae-producers.

Shelf products of high-quality microalgae

Growing top-quality cultures of selected species of microalgae with optimized nutrient composition allows for specialized products for various aquaculture species. A green algae-based product for green water technique, for example, will be inherently different from a diatom-