Shrimp

Water quality

Vol 9 Issue 1 2021 Published by Aquafeed Media S.L.U. www.hatcheryFM.com info@hatcheryFM.com Vol 12

IN PANGASIUS HATCHERY PRODUCTION

ADVANCES

Sustainable salmon hatchery feed

biosecurity checklist

CONTACT US

Editorial:

editor@hatcheryFM.com

Editor/Publisher: Lucía Barreiro

Consulting Editor: Suzi Dominy

Assistant Editor: Marissa Yanaga

Conferences and webinars: info@hatcheryFM.com

Advertising enquiries/request media pack: sales@hatcheryFM.com

Accounts & all other enquiries: info@hatcheryfm.com

SUBSCRIBE

Digital editions are free to industry subscribers. You may also purchase print copies. Subscribe at HatcheryFM.com to receive your own digital copy of our publications.

https://bit.ly/HATCHERYSUBSCRIBE

FOLLOW US

We are grateful to the following companies for sponsoring this issue of the magazine. Their support allows us to make our publications available without

Hatchery Feed & Management Vol 12 Issue 1 2024 EQUIPMENT HATCHERY FEED & MANAGEMENT VOL 12 ISSUE 1 2024 Contents 4 Interview with Dat Nghe *Cover photo 7 News Review 10 Genetics to deal with diseases in tilapia farming 13 Moving towards precision breeding 18 Icelandic microalgae for aquaculture 22 A better choice for the fish and the environment 26 Feeding for success: Unravelling the key principles of optimal larval shrimp nutrition 30 Is poor water quality hurting your shrimp farm productivity? A biosecurity checklist 34 Supporting animal health and welfare in the Asia-Pacific region 37 Is there still an opportunity for aquaculture in Europe? 40 Spectral sensitivity and water biosecurity in RAS 43 Achieving optimal production in RAS 46 Monitoring and management systems in RAS 49 Experimental comparison of the design parameters of a moving bed biomedia reactor design 53 Calendar of events To read previous issues in digital format or to order print copies, visit www.hatcheryfm.com

Aquafeed Media, S.L.U., Ames, 15220 A Coruña, Spain. Copyright© Aquafeed Media, S.L.U., 1998-2024 All rights reserved. Privacy Policy & Terms of use HATCHERY FEED & MANAGEMENT

charge. Hydrotech 11 Reed Mariculture 17 FishFarmFeeder ......................................................25 Tianjin Ranova ........................................................33 Zeigler 35 Fresh-flo ....................................................................39 Hatchery Feed & Management .........................45 World Aquaculture Society 54

GENETICS AND TILAPIA DISEASES

Tilapia producers are quickly learning that biosecurity in the hatchery and nursery is extremely important to have a successful production.

SUSTAINABLE FEED FOR SALMON HATCHERIES 22

A

reduce

Hatchery Feed & Management Vol 12 Issue 1 2024 VOL 12 ISSUE 1 2024 HATCHERY FEED & MANAGEMENT

Contents

A microalgae facility is integrated with one of the world’s largest geothermal plants to produce a carbon-negative, sustainable and cost-efficient microalgae with a high nutritional value.

solution to

the emissions of phosphorus and zinc implemented in salmon hatchery feeds.

INTERVIEW with Dat Nghe

HFM: Vinh Hoan is the world’s largest pangasius producer. How did it all start?

DN: Vinh Hoan was established in 1997 in Dong Thap Province and has been continuously improving the process of pangasius farming and processing, achieving standards such as ISO 9001:2000, ISO 14001:2004,

BRC: 2005 and IFS version 4, and expanding factories. In 2010, Vinh Hoan became the leading company in export value in the pangasius industry and currently maintains this position.

HFM: Where is the company today in terms of size, production capacity and markets served?

DN: We have been establishing an integrated and sustainable development of the corporation with many company divisions from hatchery to farming, processing, collagen, gelatine, oil, fishmeal processing, growing and processing fruit and agriculture products.

In total, around 10,000 workers process a capacity of 1,200 tons of pangasius per day. We now export to almost all markets in the globe such as the US, China, EU and UK.

HFM: Vinh Hoan has been developing a high-tech pangasius hatchery. Why did the company decide to make this investment? Where is it located? What is the production capacity?

DN: The hatchery is located in Tan Chau District, An Giang Province, Vietnam. This place is upstream of the Mekong River and has optimal conditions for hatchery production. We invested much effort and finance in this aspect because the quality of fingerling is the key to the sustainable development of the pangasius industry. The production capacity is 30 million fingerlings and 1.6 billion fry of pangasius per year.

Hatchery Feed & Management Vol 12 Issue 1 2024 4

Dat Nghe is Vice Director of Hatchery Operations at Vinh Hoan

HFM: What have been the main upgrades in this hatchery? Does this new hatchery mean a change in mindset in pangasius hatchery procedures?

DN: The hatchery features a broodstock in a greenhouse with controlled water parameters that produce larvae with high and stable quality in both hot and cool seasons. It also features a water treatment process, quality control of live feed, larvae from genetically selected broodstock, vaccinated fingerlings, and the application of biotechnology to the farming process.

This new hatchery complies with many strict standards and applies highly scientific achievements, creating a novel fingerling with high disease resistance and fast growth rate that provides strength for grow-out stages.

HFM: Does Vinh Hoan have its own genetic selection program? What are the main traits?

DN: We have been performing our own genetic selection program, focusing on growth rate and diseaseresistant traits.

HFM: Have you been able to reduce larval culture time and improve fingerling quality with improvements in feed management?

DN: We grow our own live feeds from phytoplankton to zooplankton for the larval stages. We are proficient in culturing and enriching live feed as well as the application of microorganisms, enzymes, and biological products for optimal conversion of nutrients. Therefore, the culture time and quality of fingerlings have improved substantially.

HFM: How does Vinh Hoan manage biosecurity at the hatchery stages? Do you have a vaccination program before fingerlings are transferred to the grow-out stages?

DN: Our biosecurity regime involves the control of different steps. Equipment and labor of different areas and stages must be separated and disinfected when moved to different areas as well as broodstock, live feed and fingerlings. Water input must be settled down, and then disinfected before pumping into ponds. Visitors must follow the biosecurity protocol in each area.

We have been testing vaccinating fingerlings before transferring to grow-out ponds with positive results and we are now expanding the vaccination to all ponds.

Hatchery Feed & Management Vol 12 Issue 1 2024 5

Pangasius larvae

Pangasius fry

Vinh Hoan pangasius hatchery

HFM: Vinh Hoan is also testing a circular water system. Would you let us know what it consists of?

DN: The water source has been continually reduced and aquaculture with a circular water system will be key in the near future. Due to the specific characteristics of pangasius as well as cost-effectiveness barriers, we have not yet implemented a large-scale circular water system. We are testing it on a small scale and trying to adapt the system to pangasius. The system consists of passing the pangasius pond water through a sediment pond to remove the sludge, a biological treating pond and then aerate it, to finally pump it back to the culturing pond.

HFM: Despite being difficult to make predictions, how do you see the pangasius hatchery farming in the short and medium terms?

DN: One of the main limitations is the water source. Furthermore, climate change and abnormal weather phenomena have been frequently occurring. This will make breeding in hatcheries more difficult.

Despite this, other technological aspects will bring improvements. We have been implementing genetic selection and vaccine programs as well as other biotechnological applications. In the near future, if we apply the results of these projects together with a good hatchery farming protocol, I think hatchery farming will be more effective and sustainable

Hatchery Feed & Management Vol 12 Issue 1 2024 6

Pangasius broodstock

NEWS REVIEW

GenoMar unveils premium genetic line in Brazil

GenoMar 1000 is selected for fast growth that reduces the production cycle with a consequent increase in farm productivity. The product also combines robustness, resistance to specific pathogens and a competitive fillet yield. The company plans to launch two additional products in the coming years.

BioMar inaugurates new hatchery R&D facility

BioMar’s Aquaculture Technology Centre at Hirtshals Denmark opened a new wing dedicated to research and development in the hatchery segment. The new facility is advanced and versatile. The facility can simulate conditions that farmers experience in different hatcheries around the world and do trials with both marine and freshwater larvae.

Benchmark Genetics expands genetic support services to the global aquaculture industry

The company now offers a complete suite of genetic improvement services ranging from advanced multi-trait programs to cost-effective, targeted programs that fit seamlessly into existing commercial farming operations. Benchmark’s updated portfolio includes high-density arrays and genotyping services for a wide range of farmed aquaculture species, along with mediumdensity solutions for others. Additionally, Benchmark introduces low-density, low-cost genotyping solutions for parentage assignment and the analysis of genetic diversity in broodstock populations. The company also collaborates with partners to design and launch new genotyping tools, ensuring accessibility and affordability.

Merck Animal Health to acquire Elanco’s aqua business

Merck Animal Health, known as MSD Animal Health outside of the United States and Canada, signed a definitive agreement to acquire the aqua business of Elanco Animal Health for $1.3 billion in cash, consisting of an innovative portfolio of medicines and vaccines, nutritionals and supplements for aquatic species; two related aqua manufacturing facilities in Canada and Vietnam; as well as a research facility in Chile. The acquisition is expected to be completed by mid-year 2024, subject to approvals from regulatory authorities and other customary closing conditions.

Hatchery Feed & Management Vol 12 Issue 1 2024 7 NEWS REVIEW

Highlights of recent news from Hatcheryfm.com

Inalve raises €2 million to accelerate biofilm-based microalgae production

Inalve, established in Nice, France, has developed a unique proprietary process for cultivating microalgae on rotating conveyors, using minimal water, maximizing light exposure, and reducing contribution to climate change compared to traditional cultivation systems. “Thanks to our innovative process, our goal is to produce large volumes of microalgae with consistent quality, enhanced nutritional characteristics, continuous supply, competitive prices and, at the same time, significantly reduce the environmental footprint of microalgae production,” the company said.

Billund Aquaculture to build first large-scale RAS hatchery for striped bass

Mexican company Pacifico Aquaculture has commissioned Billund Aquaculture to design and implement a RAS project for its new land-based hatchery and nursery, which will be the first in the world to produce striped bass (Morone saxatilis) at scale. The facility will be built in the Ensenada Bay area of Baja California, Mexico and produce 80g juveniles that will subsequently be transferred to the company’s grow-out sites, located nearby, about 20km from the coast of the Pacific Ocean.

Ecuador unveils sustainable shrimp hatchery management project

The Sustainable Shrimp Partnership (SSP) and the National Chamber of Aquaculture (CNA) launched a program to develop sustainable management of hatcheries. “Through this program, we are innovating as a sector, leading the way for achieving the Sustainable Development Goals, and providing a response to climate change. With this initiative, we aim to prepare and support hatcheries during the implementation and development of best production practices that

Skretting, ViAqua make progress in developing a solution for shrimp viral disease

together: an edible RNA substance that can be put into microcapsules – so tiny they can’t even be seen with the naked eye – and help shrimp cope with challenges linked to white spot syndrome virus (WSSV). So far, the technology has delivered exceptional results in R&D trials performed in renowned facilities, demonstrating that its formulation significantly improves shrimp health.

Hatchery Feed & Management Vol 12 Issue 1 2024 8 NEWS

REVIEW

SyAqua appoints chief technology officer

SyAqua appointed Dr. Craig L. Browdy as its Chief Technology Officer (CTO). With his extensive experience and expertise in marine shrimp research spanning over four decades, Browdy is set to lead SyAqua’s cutting-edge research initiatives and drive innovation in the field of aquaculture.

Aquaculture technology companies merge

Two technology companies specializing in aquaculture feeding and sustainable fish growth, Havida from Norway and GroAqua, are merging. This strategic alliance strengthens their position in the international market by providing innovative technological solutions for sustainable fish growth.

dsm-firmenich extends sustainability service to seabass and seabream

The company unveiled a marine fish module for Sustell™, allowing aquaculture producers of seabass and seabream to map the full environmental footprint of their operations. “Now marine fish producers of species such as salmonids, seabass and seabream can conduct full life cycle assessments at scale, ensuring a strong return on investment and providing a credible and accurate footprint, and a great user experience,” the company said.

ASC farms supported with extended feed supply transition period

Following extensive industry consultation, the Aquaculture Stewardship Council (ASC) has extended the transition period for ASC certified farms to switch to ASC compliant feed. Farms now have until October 2025, as opposed to January 2025, to change their supply of feed to come from mills that have been certified against the Feed Standard. The change in feed supply is necessary for producers to continue meeting the ASC Farm Standards and to retain their certification. Vimifos and Skretting are the first feed companies to achieve ASC certification for multiple feed mill sites in Mexico and Chile, respectively, and more sites are already in the audit process.

Ozone specialists sign distribution partnership

BIO-UV Group entered into an exclusive partnership agreement with US-headquartered Pinnacle Ozone Solutions to leverage the company’s QUADBLOCK ozone water treatment products in Europe, Middle East, Africa and Asia. Florida-based Pinnacle is one of the largest suppliers of ozone technology in the North American municipal, aquaculture, and industrial markets. Pinnacle’s patented advanced ozone technology will increase BIOUV Group’s ozone product capacity to >30 kg/h, which will open a much larger market opportunity worldwide. Reciprocally, Pinnacle will support BIO-UV Group’s strategy to establish its range of water treatment solutions across the North American continent.

Hatchery Feed & Management Vol 12 Issue 1 2024 9 NEWS REVIEW

Genetics to deal with diseases in tilapia farming

Tilapia is the common name of several farmed cichlid species with a global annual production of 6,100,719 t in 2020 (FAO, 2022). Nile tilapia (Oreochromis niloticus) is the most popular species used in aquaculture and the third most farmed finfish species worldwide with 4,514,615 t produced in 2020 (FAO, 2022).

Despite being widely produced, the tilapia industry is not free of challenges. Diseases are one of the most important ones. Streptococcus agalactiae 1a is currently affecting most Latin American tilapia farmers. The big issue with this disease is that it affects all life stages, from 1g all the way to broodstock, proving to be quite difficult to manage its negative effects. Infectious Spleen and Kidney Necrosis Virus (ISKNV), Tilapia Lake

Virus (TiLV), Francisella and other Streptococcus strains are still present and affect production around the world, especially during El Niño.

Many of the regions around the world are facing similar challenges even with different pathogen names. A lack or poor water quality, high temperatures and low biosecurity lead to challenges in tilapia production.

But there is hope for farmers. Tilapia producers are quickly learning that biosecurity in the hatchery and nursery is extremely important to have a successful production. If broodstock are infected with a disease it will affect the entire production plan and could lead to large gaps in stocking and biomass production as farmers wait for a new generation of breeders to reach sexual maturity.

At the same time, there is a challenge for small-scale producers to compete with production costs compared to medium and large-scale farmers. The ability to negotiate prices on items such as feed gives largerscale producers a competitive advantage. Access to markets also limits the ability of small-scale producers to maximize their gains on products sold as they are relegated to selling to brokers.

Selected tilapia to the rescue

Accessing a high-quality and biosecure, selected tilapia strain can increase profitability for a farmer. Through selection, a farmer can gain access to animals that achieve faster growth rates, and increased tolerance to selected pathogens. The return on investment is clear when analyzing all the benefits that a farmer can receive from having access to advanced genetic material.

Running an in-house program can be expensive and risky especially if a farmer attempts to operate within an area that has a high disease pressure. Looking at other protein production industries, such as beef, chicken, poultry, shrimp and salmonids, breeding programs are a fundamental part of the industry and the only way farmers can remain commercially competitive is by working with a professional breeding program.

Hatchery Feed & Management Vol 12 Issue 1 2024 10 GENETICS

Farmers usually need to decide between growth, disease resistance or balanced lines. “The balanced line is the most common approach as this allows farmers to use just one strain throughout the year. Growth is still the most sought-after trait despite all of the different disease pressures around the world. The balanced line remains the most demanded option as most farmers know that even if they are not facing a specific disease pressure today, history has shown these diseases find their way across different regions over time. Therefore, it is best to be prepared and protected against potential pathogenic threats,” said Carlos López, co-owner and commercial director of Spring Genetics.

Recent improvements

Spring Genetics is working on its 12th generation of breeders that will become available beginning in June 2024. Genetic markers that indicate resistance to Streptococcus iniae were recently identified and are currently applied in Spring Genetics selection programs. “The advantage of using genomic tools for resistance to Streptococcus iniae is that we do not have to detract from our selection from other traits due to the precision that we are able to work with using genomics. Family selection is highly effective and we continue to implement it every year. However, there are so many ways that you can slice the ‘genetic pie’ using family selection before you are too diluted to see any results,” López said.

GENETICS

The latest pathogen that was tested in its disease challenge model together with the USDA-ARS was Streptococcus agalactiae 1a. “We were able to get a functional challenge model in place and we found heritability for the tolerance to this pathogen which we are very excited about,” López said.

“We have also added disease resistance to TiLV in our 11 generation with good results during challenge testing. Firstly, Dr. Ben Lafrenz and his team at the USDA-ARS were successful in developing a challenge model and we had an excellent challenge where we were able to find heritability for disease tolerance to TiLV,” López explained.

Monosex males are still in high demand in the industry due to the advantages that come with a reduction in CV at harvest and better feed conversion. López said that the industry is closer to the genetic solution that will be driven by delayed maturation and increased growth rates.

Company buyout

Spring Genetics recently completed the management buyout of the business from the Benchmark Group. “The decision was made as Benchmark was looking to focus on other species and we as a management team decided to continue the work that has been going on since 2010 on one of the most advanced breeding programs in the world for Nile tilapia. The market is in need of biosecure, disease-free and highly selected

Smarter, stronger, more economical drum filters

The Hydrotech Value Drum Filter series focuses on reduced maintenance, increased component quality and simplified operation – all to give your plant maximum filtration performance at a minimum operational cost. There are more than 50 technological improvements in the new series, compared to the previous series, that make these filters excellent value for money.

Let us help you! Call +46 (0)40 42 95 30, or visit www.hydrotech.se

Hatchery Feed & Management Vol 12 Issue 1 2024 11

GENETICS

strains that can be delivered on a yearly basis to farmers around the world,” López said.

However, the company plans to continue working with Benchmark Genetics to advance the tilapia selective breeding program. “We are continuing our family selection program and our collaboration with the USDAARS research facility for our disease challenge models. We will continue to develop strains with tolerance to commercially relevant pathogens utilizing the latest and best technologies available in genetics,” said López.

Looking forward, in the short term, Spring Genetics sees the tilapia industry facing difficult times with all of the disease pressure. “In the medium term, we are sure that farmers will solve these issues as we have many scientists from many different fields around the world

working to find solutions to various disease pressures that exist. Together, using the power of science, we can solve the problems that tilapia producers are facing today and have a bright future ahead of increased production capacities and profitability for farmers. We do expect the demand for advanced genetics to continue to grow globally and we are ready to continue supplying our current customers and new customers in the future,” López concluded.

More information:

Carlos Víctor López

Commercial Director - Spring

Genetics

E: carlos.lopez@spring-genetics.com

Hatchery Feed & Management Vol 12 Issue 1 2024 12

Moving towards precision breeding

Classical genetic selection techniques using pedigree relationships have resulted in transformative gains in aquaculture production and sustainability over the past 40-50 years. More recently, advances in genomics have seen improved methods of aquaculture breeding, including marker-assisted selection and genomic selection, resulting in accelerated rates of genetic progress. However, incomplete assemblies of genomes at the chromosome level and an almost complete lack of understanding of how the millions of letters of the genetic code relate to characteristics of importance to aquaculture remain a barrier to further progress.

EU Horizon 2020 project AQUA-FAANG: Advancing European aquaculture by genome functional annotation brought together 13 leading academic groups and ten companies to address these bottlenecks.

The research focused on six species, Atlantic salmon, rainbow trout, common carp, gilthead seabream, European seabass and turbot, which account for around 90% of commercial finfish production in Europe. The AQUA-FAANG project addressed the major challenge of infectious diseases, while generating datasets and approaches relevant to understanding and exploiting the functional genetic architecture of diverse traits of importance to aquaculture, including growth, embryonic development, flesh quality, reproduction, and sexual maturation and dimorphism, across the targeted farmed fish species.

Functional annotation

AQUA-FAANG produced extensive new datasets to identify regions of the genetic code that impact biological traits in the main finfish species farmed

Hatchery Feed & Management Vol 12 Issue 1 2024 13

GENETICS

GENETICS

in European aquaculture. These regions are called functional, and they include DNA elements that control how genes are expressed in different conditions, for example, during development or following a challenge to the immune system. Genetic variants in such regions of the genome are much more likely to affect traits of importance to aquaculture than randomly selected variants.

The project generated genome functional annotation data across diverse sample types in the six species, including different stages of embryonic development, tissues of adult fish of both sexes at two stages of sexual maturation, and after immune stimulation with viral and bacterial molecular signals.

This comprehensive set of samples was used to generate almost 5,000 new sequencing datasets across the six target species. In addition to producing comprehensive genome functional annotations for each species, a key focus was on revealing changes in genome activity dictating the host immune response to pathogen challenges. These functional annotations were shared as open data through the Ensembl genome browser which enables researchers and industry to scan the

genome of each target species to identify functional regions of interest. Furthermore, Ensembl unlocks opportunities for researchers and aquaculture breeding companies to quickly and easily overlap their datasets with AQUA-FAANG annotations empowering new opportunities for precision breeding applications in different countries and organizations across the globe.

Focus on diseases

The project had a particular emphasis on immune responses and resistance mechanisms to some important diseases that threaten the sustainability and profitability of fish farming. One of the most complete proof-of-concept studies focused on viral nervous necrosis (VNN), a viral disease that causes periodic and sometimes massive mortalities in farmed fish including European seabass, Asian seabass, grouper, Senegalese sole, gilthead seabream, and turbot. Recent studies have identified a major QTL that confers resistance to VNN in different seabass populations and this region was subsequently fine-mapped using whole-genome sequencing (WGS) data.

In AQUA-FAANG, resistance to VNN was studied in a tank-based disease challenge, and the combination

Hatchery Feed & Management Vol 12 Issue 1 2024 14

GENETICS

Hatchery Feed & Management Vol 12 Issue 1 2024 15

of WGS, imputation, RNA-Seq and genome functional annotation led to the identification of two putative causative SNPs in the promoter of an interferonstimulated immune gene underlying a major QTL for resistance to VNN, explaining >37% of the genetic variation in the resistance trait. The incorporation of functional annotation was key to pulling apart those putative causative SNPs from the hundreds found in the same region, thereby identifying targets for CRISPRCas9 gene editing to confirm the causative gene and causative mutation.

AQUA-FAANG also carried out an in-depth study on the infection of rainbow trout by Viral Haemorrhagic Septicaemia Virus (VHSV) and by the bacterium Flavobacterium psychrophilum (Fp), responsible for two important diseases of rainbow trout in freshwater that cause significant mortality and economic losses. Using double-haploid rainbow trout isogenic lines with opposing resistance/susceptibility to VHSV and Fp, the immune pathways associated with resistance were found to be different for the two pathogens, and therefore, the resistance traits are unlikely to share a common genetic basis; meaning selection will need

to be conducted for each disease independently. The mapping of transcriptome and epigenetic responses to infection will provide a better understanding of the genomic basis for differential resistance mechanisms to support more targeted selection that minimally affects immune responses to other pathogens.

How can this data be used to advance precision breeding?

AQUA-FAANG datasets add multiple new layers of information on the genetic architecture of farmed fish characteristics, and allow researchers, for the first time, to prioritize genetic variants with increased probability of impacting traits in the target species. This information can be used in a range of applications, including building new genetic tools and approaches for breeding that have better accuracy without adding significant financial costs. It can also help reduce the current reliance of industry on measuring important breeding traits (e.g. disease challenge experiments) across different generations, which is expensive and problematic in regard to animal welfare. Such knowledge and associated resources have the potential to improve

Hatchery Feed & Management Vol 12 Issue 1 2024 16 GENETICS

GENETICS

sustainability and boost production in aquaculture by accelerating genetic gain for health and robustness to infection while reducing the requirement for animal testing.

Genome editing is a powerful tool for inducing precise genetic changes that can improve the long-term sustainability of aquaculture. A major bottleneck for implementing this technology is the need to identify high-priority regions for editing. AQUA-FAANG data provides these target regions and will allow scientists to make more precise changes in the genome, which will be vital not only for research but also for potential future applications in aquaculture practice.

The ability to predict traits in aquaculture has been hampered by limited understanding of the functional mechanisms linking genotype to phenotype. Combining AQUA-FAANG results with emerging methods that further improve the ability to discover genotype-to-phenotype relationships paves the way for more accurate selection and increased genetic gain.

In summary, AQUA-FAANG has opened the door for precision aquaculture, contributing to the development of a sustainable, resilient, and competitive EU aquaculture sector.

References

I. A. Johnston, M. P. Kent, P. Boudinot, M. Looseley, L. Bargelloni, S. Faggion, G. A. Merino, G. R. Ilsley, J. Bobe, C. S. Tsigenopoulos, J. Robertson, P. W. Harrison, P. Martinez, D. Robledo, D. J. Macqueen, S. Lien (2024) Advancing fish breeding in aquaculture through genome functional annotation. Aquaculture, Volume 583, 2024, 740589.

https://doi.org/10.1016/j.aquaculture.2024.740589

Hatchery Feed & Management Vol 12 Issue 1 2024 17

AQUA-FAANG team

Icelandic microalgae for aquaculture

Christel Nys, VAXA Technologies

VAXA‘s location in Iceland is no coincidence. Iceland is the land of ice and fire, the land of glaciers covering the country and volcanic and geothermal energy that nests in its grounds. VAXA microalgae facility is integrated with one of the world’s largest geothermal plants, Hellisheiði Power Plant. This unique location allows VAXA to have access to the resource streams of the geothermal plant, namely 100% renewable energy, hot and cold water and natural CO2 emissions which are necessary to cultivate microalgae indoors.

Today VAXA cultivates Nannochloropsis oculata and Spirulina ( Arthrospira platensis) photosynthetically in photobioreactors (PBR) using artificial lights. The unique production system has important advantages not only for the environment but also for the quality of the algae. This system results in a yearround consistent microalgae composition thanks to consistent growth conditions. The closed PBR cultivation system, coupled with the usage of pristine Icelandic

freshwater (not seawater), minimizes the risk of marine pathogen contamination.

After years of research, the VAXA team of microalgae experts developed not only a carbon-negative, sustainable and cost-efficient microalgae production process but also selected microalgae strains with a high nutritional value.

Hatchery Feed & Management Vol 12 Issue 1 2024 18 HATCHERY FEEDS

Nannochloropsis

Icelandic Nannochloropsis grown under controlled, indoor conditions in PBR with LED irradiation has a unique composition of 40% crude protein on a DW basis and a minimum of 6.2% of its DW is eicosapentaenoic acid (EPA). This high amount of EPA is unique in the market. Moreover, the omega-3 essential fatty acid in Nanno is conjugated with polar (glyco- and phospho-) lipids, contributing to its high bioavailability.

Nannochloropsis has a hard cell wall which makes it a good candidate as live algae paste. VAXA offers ULTRA Nanno, Nannochloropsis in a paste of standard 18% DW and a cell density of 40-70x109 cells/mL. A paste of 12% DW is also available. The viability of the algae paste is high and stays around 85% even after 7 weeks of storage in the refrigerator.

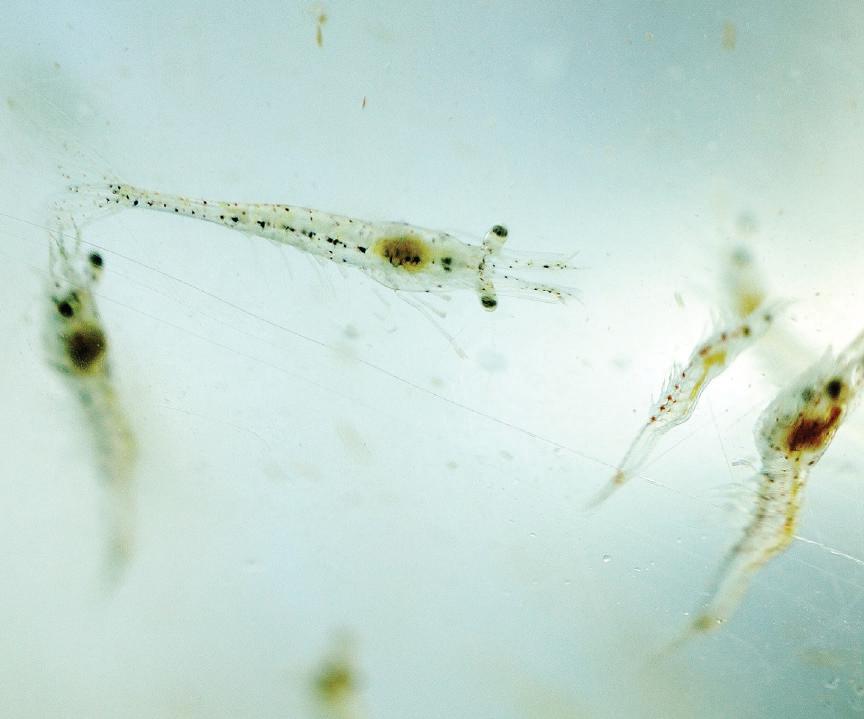

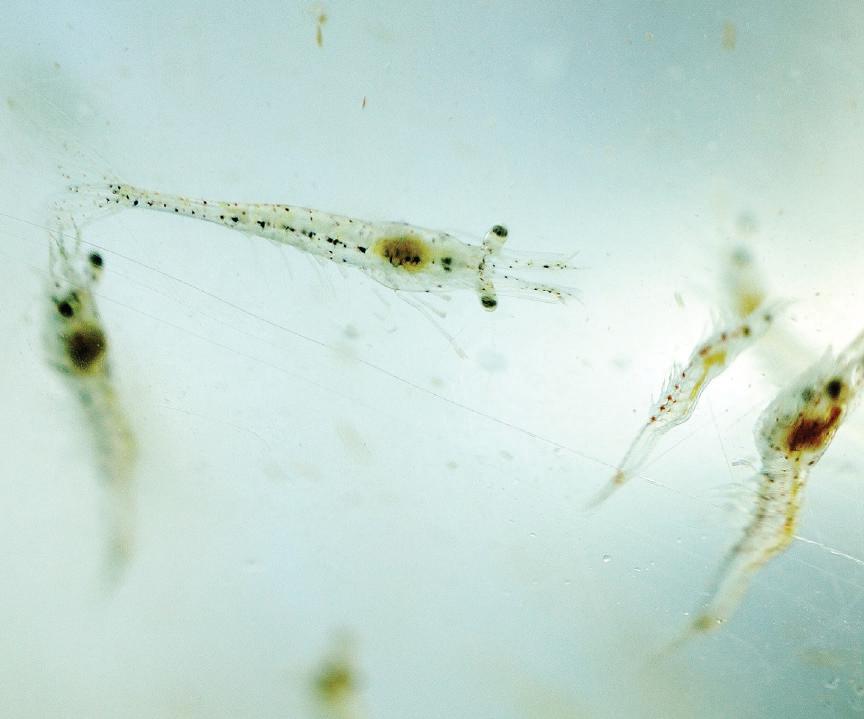

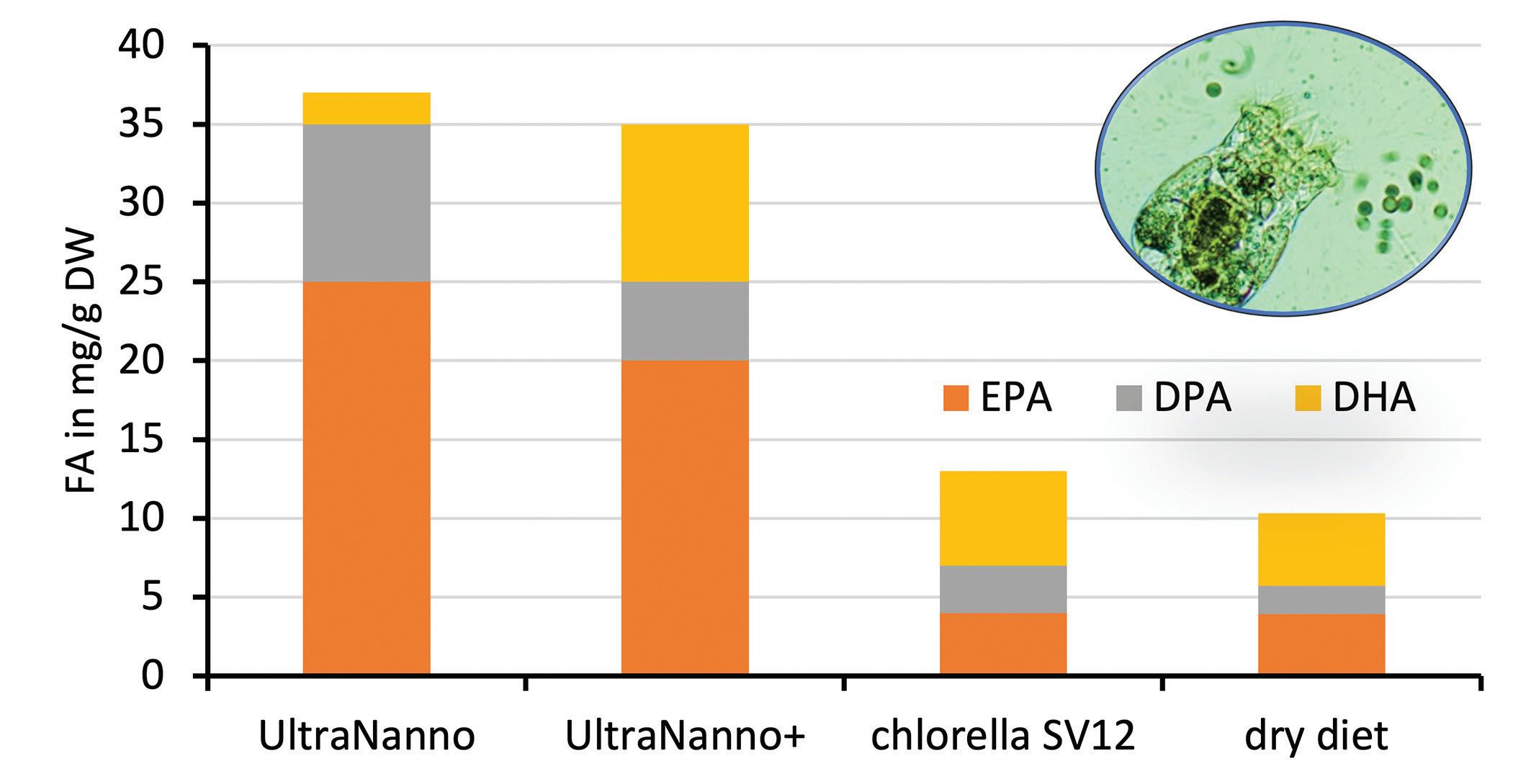

Rotifers

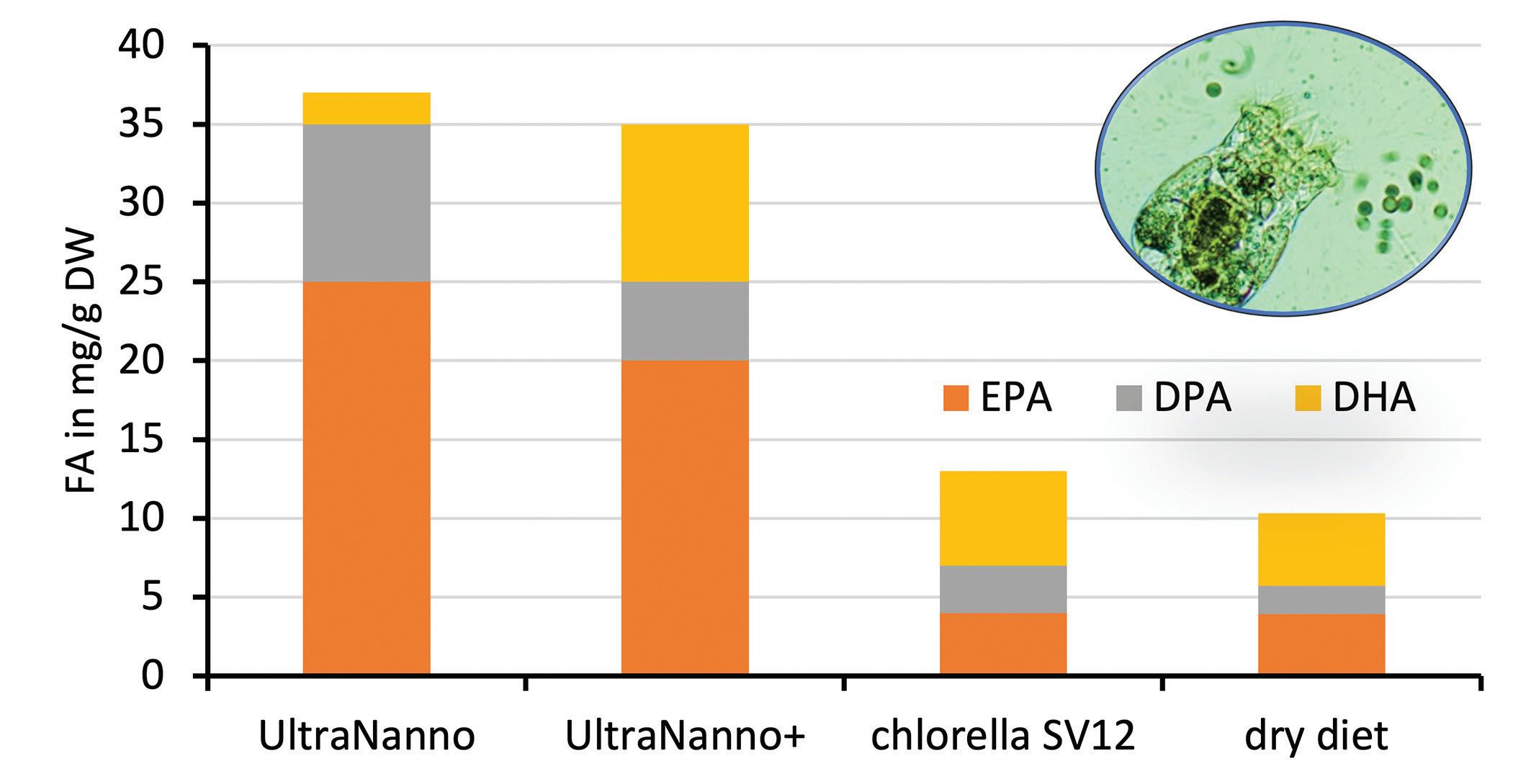

Nannochloropsis is a very small green microalgae of 2-3 µm and has proven to be a superior feed for rotifers. Since the nutritional composition of rotifers mimics their feed, it is of major importance to select the right feed for rotifers. Since Nannochloropsis doesn’t contain docosahexaenoic acid (DHA), UltraNanno can be fortified with PLUS (+), ULTRA Nanno+, a dispersion of different microalgae cells, high in DHA, antioxidants and pigments.

Rotifers cultured with ULTRA Nanno(+) have a superior omega-3 composition of more than 35 mg/g DW compared to rotifers cultured with dry diets or Chlorella

HATCHERY FEEDS

paste (Fig. 1). Using ULTRA Nanno(+) in rotifer culture eliminates the need for separate enrichment tanks and oil-based emulsions, resulting in healthier and cleaner rotifers for first feeding larvae.

However, most of the European marine finfish hatcheries are used to enrich rotifers in a separate tank before feeding them to the larvae.

UltraNanno+ can also be used as enrichment feed. In a trial in a commercial Greek hatchery, rotifers (Brachionus plicatilis) were enriched with ULTRA Nanno + in a separate enrichment tank of 1,500L and at a density of 1,500 rotifers/mL. Rotifers were cultured with ULTRA Nanno. At the start of the enrichment, the rotifers were fed with UltraNanno, 2 dosages of 750 mL of PLUS+ were administered to the rotifers at T8h and T16h, with rotifers being harvested at T24h. FAME analyses of the enriched rotifers confirmed the high and stable content of EPA because EPA in Nanno is conjugated with polar lipids. The long-term enrichment with PLUS+ increased the DHA level of the rotifers significantly. The total omega-3 composition of the rotifers was >80mg/g DW and a DHA/EPA ratio of 2 was reached.

If ULTRA Nanno is also used in the larval rearing tank as a green water application, rotifers will have superior feed available so they will maintain their nutritional quality and their pelagic behavior and availability.

Additionally, in comparative tests, rotifers cultured with ULTRA Nanno+ during the whole culture period are enriched with HUFA (DHA, EPA and ARA), not only

Hatchery Feed & Management Vol 12 Issue 1 2024 19

Figure 1. Omega-3 fatty acid composition of rotifers ( Brachionus plicatilis ) after 3 days batch culture. Source: Laboratory of Aquaculture, University of Ghent, Belgium

in their digestive system but also in their tissues. This is important since rotifers empty their gut under stressful conditions, e.g. when released in the larval rearing tank.

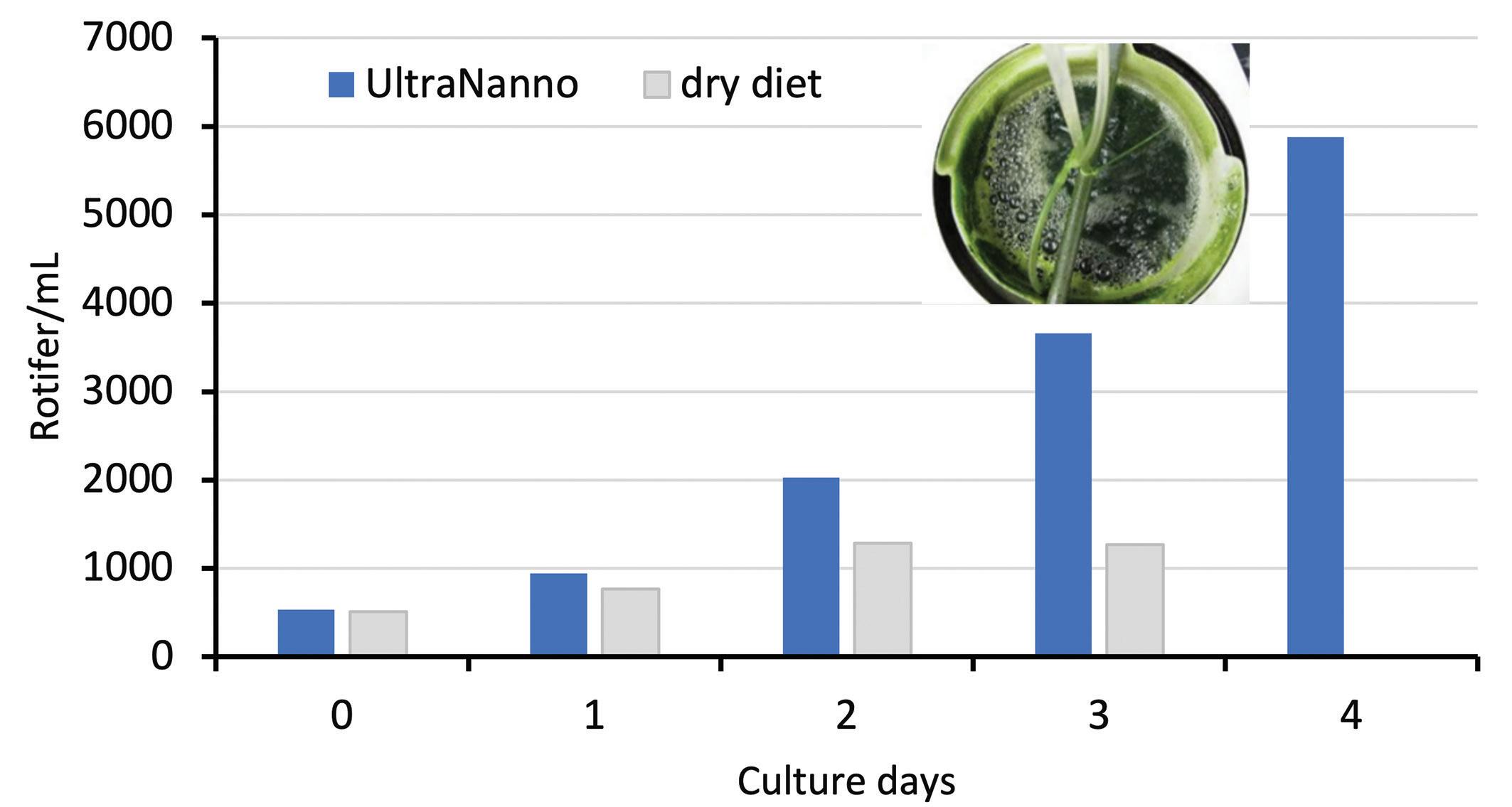

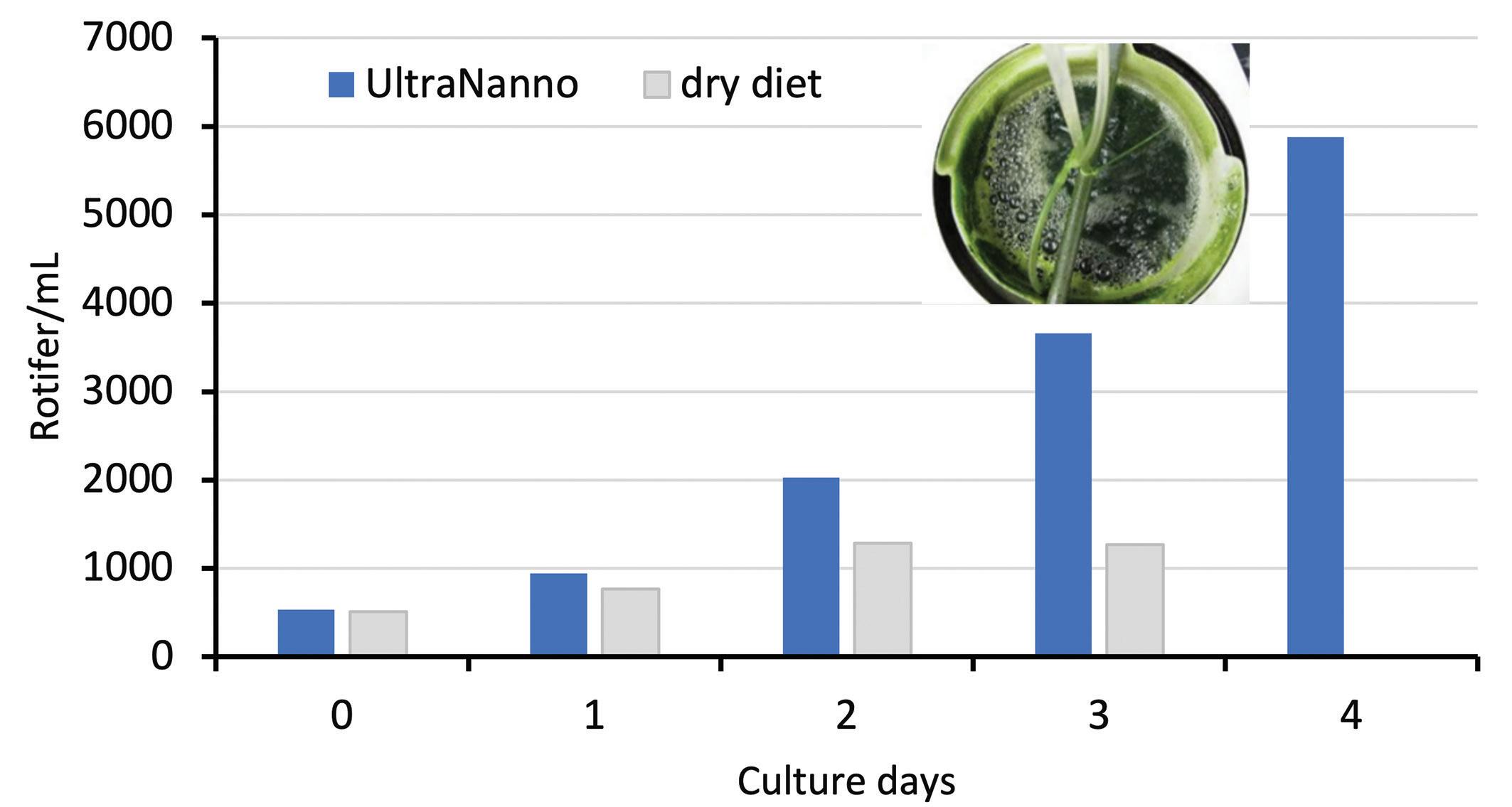

Not only is the composition of rotifers cultured with ULTRA Nanno(+) superior, but so is the growth of the rotifers. In small-scale lab trials at the Laboratory of Aquaculture, University of Ghent, Belgium and at the Institute of Marine and Environmental Technology at Maryland, US, Brachionus plicatilis feeding with ULTRA Nanno resulted in stable and superior rotifer growth with multiple factors of more than 10 after 4 days of batch culture (Fig. 2).

Higher growth leads to less culture tanks, space and manpower and thus reduced cost for the hatcheries.

Where traditionally rotifer culture with dry diets can’t continue for more than 3 days because of the build-up of organic matter, ammonia and low oxygen levels, live algae paste, ULTRA Nanno, can be used in batch culture for a longer period without diminishing rotifer growth.

In fact, ULTRA Nanno is a premium algal paste for highdensity rotifer cultures, where high-density continuous or semi-continuous cultures are maintained for several months through the adoption of flow-through and recirculation technologies. In this system, filtration and water quality are of key importance. A trial was conducted in 2020 at the Marine Aquaculture Center in Singapore in a semi-continuous rotifer culture with Brachionus rotundiformis (S-rotifers) in 2,500-liter tanks. Rotifers were maintained at 1,000 rotifers/mL.

A percentage of the volume of the culture was harvested daily and replaced with fresh seawater. The first week, the tank was gradually filled with water starting from 200L to 2,500L. Rotifers grew from 200 million to 5,019 million within one week fed with ULTRA Nanno. The average daily growth rate was 85% in the ULTRA Nanno tank. During the following 19 days of semi-continuous culture at 1,000 rotifers/mL, the average daily growth rate of the rotifers with ULTRA Nanno was 55%.

Continuous rotifer culture systems with fully controlled (nutrients, pH, temperature, oxygen, algae density and rate of water inflow) hemostat models are based on concentrated Nannochloropsis sp. and are available commercially. Oded Zmora et al. found that it takes 0.30.4g (dw) of algae to produce 1 million B. rotundiformis at 3,000-7,000 rotifers/mL. The use of ULTRA Nanno in hatcheries enables high-density rotifer culture and thus can significantly reduce the production cost of rotifers.

Spirulina

In Iceland, VAXA cultivates year-round, biosecured, indoor, food-grade Spirulina. It is a superfood not only for humans but also for different aquaculture species. Because of its high protein content, it can be used in feed for carnivorous fish, especially larval feed with high protein content.

Spirulina contains a high amount of glutamic acid. Dietary supplementation with glutamate and glutamine to farmed fish can improve their growth performance,

Hatchery Feed & Management Vol 12 Issue 1 2024 20

HATCHERY FEEDS

Figure 2. Rotifer ( Brachionus plicatilis ) average growth curve in batch culture.

HATCHERY FEEDS

intestinal development, innate and adaptive immune responses, skeletal muscle development and fillet quality, ammonia removal, and endocrine status. Fish fed Spirulina have an improved quality in terms of flesh flavor, consistency and color due to the high levels of beta-carotene and zeaxanthin.

Artemia enrichment

VAXA developed an Artemia enrichment product, ULTRA Artemia, based on a mix of algae including Icelandic ULTRA Spirulina and Icelandic ULTRA Nanno.

Artemia as a first feed for marine fish larvae is deficient in omega-3 HUFA, especially DHA, but also EPA and ARA, phospholipids, C, E, B1 and B12 vitamins, iodine, selenium, and free amino acids such as glycine, threonine, arginine and lysine.

Spirulina and Nannochloropsis offer the perfect combination to naturally balance the nutritional composition of the Artemia.

Ultra Artemia enables a fast enrichment: with 1 dosage of 750 ppm for 12h enrichment one can reach DHA/ EPA>2,5 and total HUFA >30mg/g DW. Enrichment to T22h with an extra dosage of 750ppm further increases the EPA content of the Artemia and total HUFA content to 45 mg/g DW and DHA/EPA ratios are still >2.

The effect of Artemia enriched with ULTRA Artemia was evaluated on the performance of European seabass larvae (Dicentrarchus labrax) during a 60-day trial. Results on the larvae’s oxidative status suggested that ULTRA Artemia may exert potential preventive effects

against oxidative stress which could be translated into enhanced fish larvae robustness and, in the long-term, improved health status of the fish.

Shrimp feeds

Since Spirulina can be fed directly to larvae of Penaeus vannamei and Penaeus monodon and in combination with diatoms form an ideal diet that results in strong postlarvae. VAXA developed a shrimp larval feed based on Icelandic microalgae. This product will be released in the market soon.

VAXA is a young, fast-growing microalgae producer in Iceland. Its unique location and technology bring high-quality microalgae to the market with constant composition year-round. VAXA is all about cost-efficient and sustainable solutions to modern land-based mariculture operations.

References available on request.

More information:

Christel Nys

Aqua Feed Expert

Vaxa

E: reine@vaxa.life

Hatchery Feed & Management Vol 12 Issue 1 2024 21

Figure 3. Fatty acid profile of Artemia (EG 280, INVE Aquaculture NV) enriched with Ultra Artemia (UA): 1 dosage of 750 ppm for 12h and 2 dosages of 750 ppm for 22h. Source: Laboratory of Aquaculture, University of Ghent, Belgium

A better choice for the fish and the environment

Marcus Søyland, Pål-Arve Dypaune, Skretting Norway

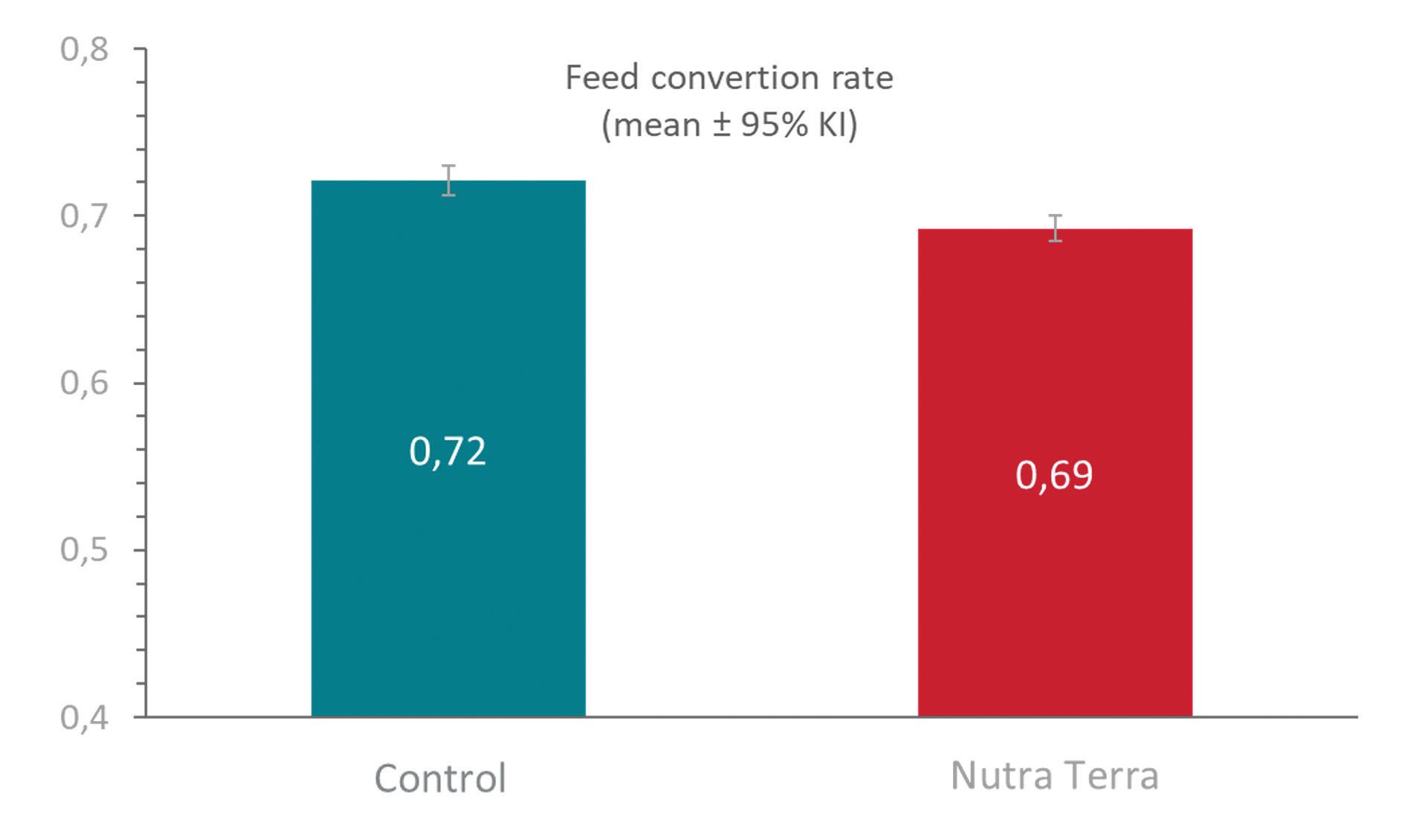

Technological advancements in Norwegian salmon production have led to more sustainable feed innovation. Now, the consumption and emissions of phosphorus and zinc are reduced, while the fry performs better than before.

Each year the Norwegian salmon industry releases 9,000 to 12,000 tons of phosphorus. Today, this is the largest source of human-made phosphorus along the coast of Norway. Although this does not pose a major problem for the marine coastal areas, both authorities and the salmon industry itself want to reduce the discharge of nutrients and make use of it as a resource.

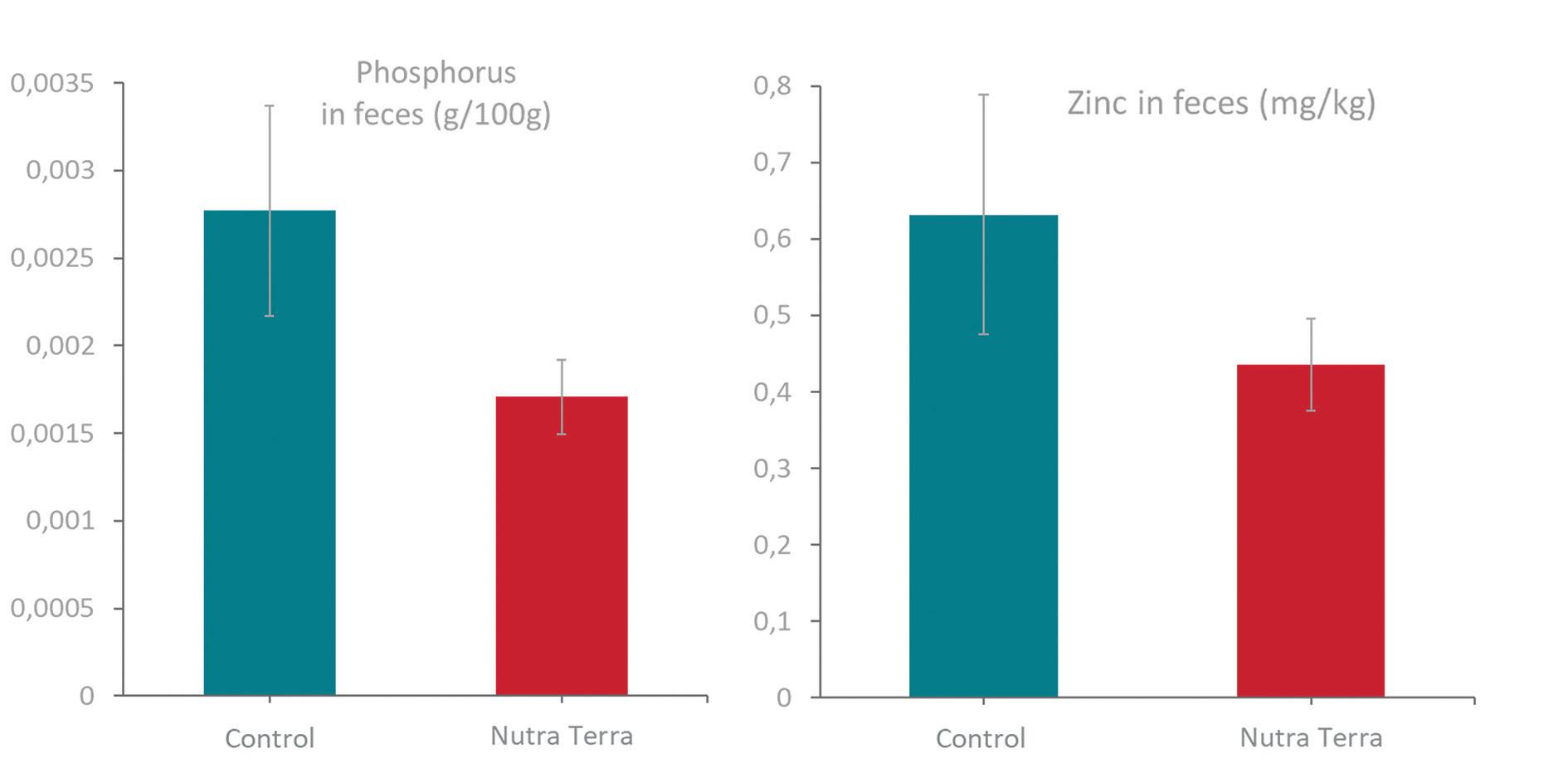

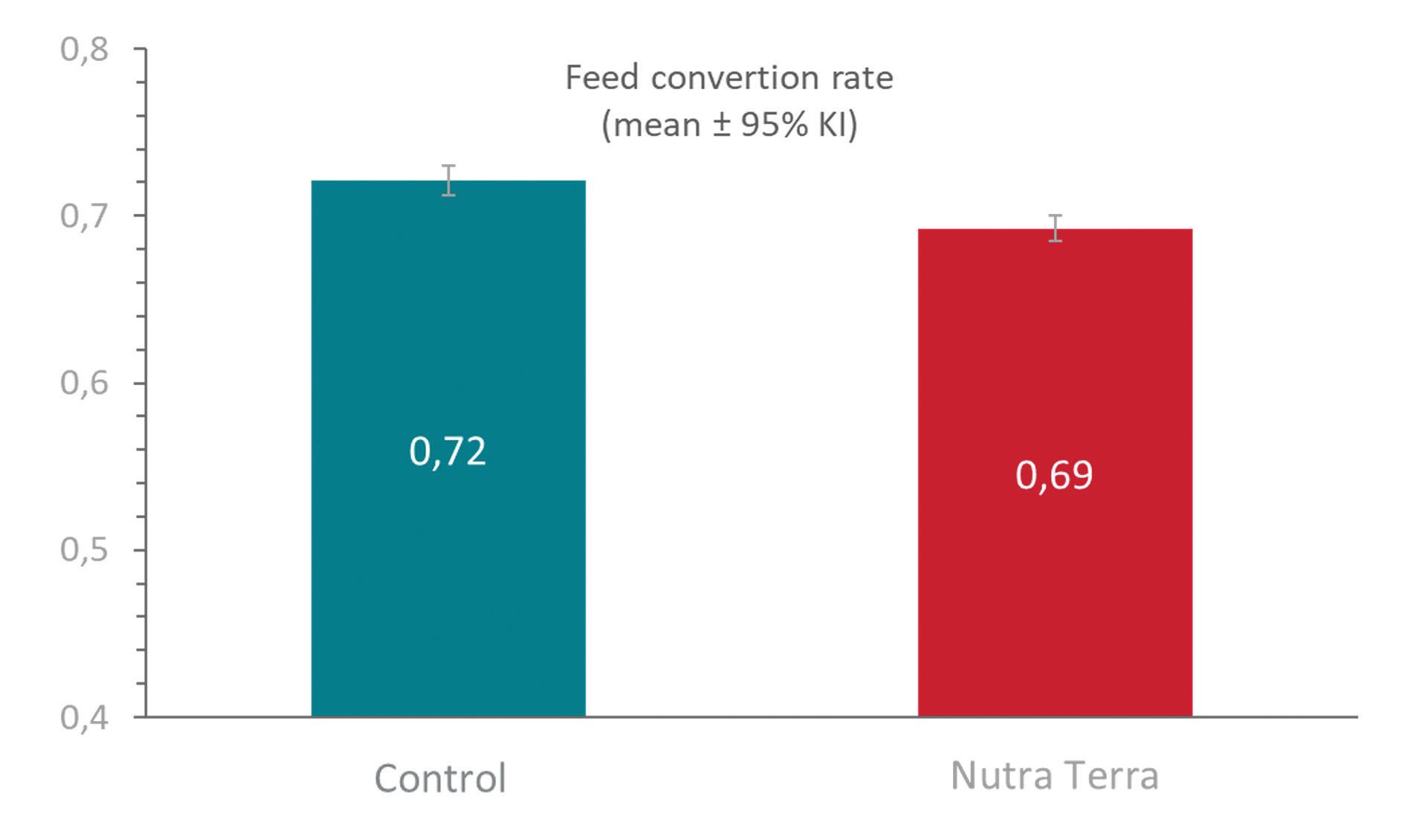

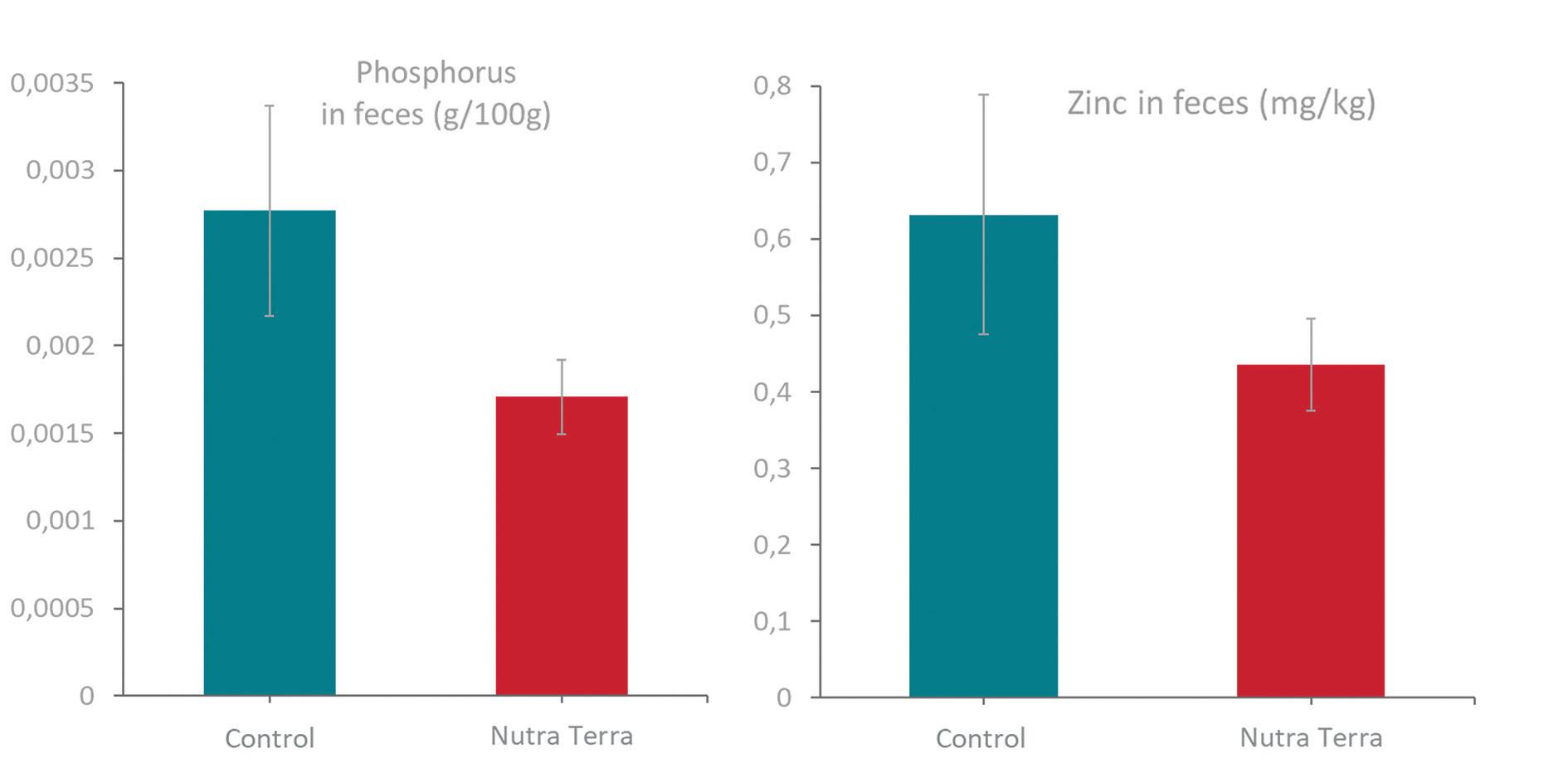

Fish feed producer Skretting has found solutions that significantly reduce the emissions of phosphorus and

zinc. The solution is implemented in the fry feed Nutra Terra, which was launched in the Nordic hatchery industry late last year.

“This feed reduces the amount of phosphorus and zinc in feces by 30%. At the same time, experiments conducted at our research facilities show that phytase in feed results in improved phosphorous and zinc uptake,” said Marcus Søyland, product manager land-based farming Skretting Norway.

Hatchery Feed & Management Vol 12 Issue 1 2024 22 HATCHERY FEEDS

HATCHERY FEEDS

Salmon needs phosphorus and zinc

Both salmon and other fish depend on receiving phosphorus and zinc through their feed. Phosphorus is part of the salmon’s DNA and is important for skeletal development and almost all energy-demanding processes. Zinc is important for gills, eyes, skin, and wound healing.

Only a limited amount of phosphorus remains to be extracted from the mines around the world.

Approximately 85% of the global phosphorus extraction is used to produce synthetic fertilizers for agriculture and is a very important resource for producing enough food for a growing population.

“It is important that we find ways of optimizing the use of phosphorus in aquaculture feeds so that the diets meet the nutritional requirements of the fish. Too little phosphorous can affect growth, metabolism, and the skeleton, meanwhile too much will end up as waste in the environment,” Søyland explained.

Using decades of knowledge

For more than 20 years, the fish feed producer Skretting has screened and analyzed thousands of different feed ingredients and has a unique overview of the nutrients found in them. Minerals such as phosphorus and zinc are found in many raw materials, but in plant ingredients, some of these minerals may not be available for fish.

“Fish need all the right nutrients, not necessarily specific raw materials. We are now using all the knowledge

available to us to adapt feed formulations that maintain or improve feed performance, reduce our consumption of limited ingredients such as phosphorus and zinc, and reduce emissions from the fish,” said Søyland.

As the aquaculture industry and the demand for feed has grown, the proportion of vegetable feed ingredients in salmon feed has increased significantly. Many plants contain anti-nutrients to protect the seed from being eaten. One of these anti-nutrients is phytic acid, which also acts as a storage molecule for phosphorus. Monogastric animals like salmon cannot digest phytic acid and thus cannot benefit from the phosphorus the plant ingredient contains. The phosphorus that the fish cannot absorb in the intestine is excreted in feces.

Win-win with phytase

Skretting’s solution to this challenge is the enzyme phytase which can break down phytic acid. By adding phytase in feed, more of the plant’s natural phosphorus content and important minerals like zinc become available to the fish.

“When the fish can absorb more of what naturally occurs in plants, the need to add extra phosphorus and minerals to the feed decreases,” said Marcus Søyland. In Nutra Terra some of the fishmeal is replaced with protein from insect meal. Fishmeal, like phosphorus, is a scarce resource, while insect meal is a new ingredient made from black soldier fly and yellow mealworm. In the wild, insects are part of the salmon’s diet during

Hatchery Feed & Management Vol 12 Issue 1 2024 23

HATCHERY FEEDS

“In validation trials, we have seen a 7% increase in growth and a 4% lower feed conversion ratio with Nutra Terra. We were very happy and excited to see this kind of performance from a feed that also helps reduce the use of zinc and phosphorus by a solid 15-18%,” Søyland explained.

The extensive series of trials on the different raw materials and the validation trial of Nutra Terra conducted at our research station outside Stavanger, Norway, document that fish absorb more phosphorus and the same amount of zinc, despite the feed containing lower amounts than the control feeds. The validation trial with the new feed formulation shows that the phosphorus and zinc contents in feces are reduced by 38% and 31%, respectively.

Technology change boosts effect

Nutra Terra was introduced to the Norwegian hatchery industry in the fall of 2023 and is only produced in Skretting’s factories in Norway. Therefore, the feed is currently only available for the Nordic market. In Norway, the salmon industry has demanded larger smolt. This is done

Hatchery Feed & Management Vol 12 Issue 1 2024 24

to reduce the time the salmon spend in net pens, which can reduce the risk of parasite and disease transmission. In 2023, the average size of smolt delivered to Norwegian net pens exceeded 280 grams. This is a doubling of the average weight in just a few years. Norwegian hatchery facilities must adhere to emissions limits set by the authorities. When salmon grow larger in land-based facilities, emissions from production also increase.

“The introduction of Nutra Terra is our way of contributing to increase smolt production within the limits set by emission permits,” explained Pål-Arve Dypaune, sales manager hatchery.

The emergence of larger fry facilities on land means that there isn’t always enough freshwater of good quality where the facilities are built. Many, therefore, invest in RAS (Recirculating Aquaculture System) technology, which recycle up to 95-98% of the water taken in. This requires significant water treatment and control of water chemistry but also allows for increasing the temperature of production water. In many facilities, the water is maintained at 12-14°C for faster growth of fish during the freshwater phase.

Previously, the enzyme phytase has been used in feed for trout and Arctic char. It has long been assumed that the enzyme does not have the same effect in feed for salmon. Skretting’s hypothesis that the enzyme’s effect would improve with RAS technology has proven to be correct. In addition, today’s version of phytase is better adapted to Atlantic salmon compared to previous versions.

“The enzymatic reactions depend on temperature and pH. Thus, phytase works more effectively in RAS facilities with slightly higher water temperatures. We also believe that lower salinity in post-smolt facilities with this technology makes the enzyme more effective,” Dypaune concluded.

More information:

Marcus Søyland

Product Manager

Land-based Farming

Skretting Norway

HATCHERY FEEDS

Pål-Arve Dypaune

Sales Manager Hatchery

Skretting Norway

Aquaculture Feeding Systems

Live Feed

Dry Feed

Hatchery Feed & Management Vol 12 Issue 1 2024 25

Vaccinator LAND • SEA • RAS

The only manufacturer worldwide that covers all feeding stages of fin fish and shrimp, for land or sea based systems

Aquaculture Europe 2023 - Booths 16-17 18 - 21 Sept 2023 • Vienna (AUSTRIA) For Medium and Big-Scale Hatcheries For Medium and Big-Scale Hatcheries For Labs and Small-Scale Hatcheries For Labs and Small-Scale Hatcheries Automatic Feeding System of Artemia, Rofiter and Microalgae. Dosing of Micro Diets from 200 up to 800 microns

Feeding for success: Unravelling the key principles of optimal larval shrimp nutrition

Dr. Natthinee Munkongwongsiri, Dr. Lumpan Poolsawat, SyAqua Siam Co. Ltd.

In the dynamic world of aquaculture, where innovation propels the industry forward, one crucial aspect remains paramount to the success of shrimp hatchery – nutrition. With the escalating demand for high-quality shrimp, the pursuit of unlocking the secrets of optimal nutrition has become a central focus for researchers, scientists, and shrimp farmers alike. In this expedition, SyAqua embarks on a journey into the intricate tapestry of shrimp nutrition, striving to decipher the code governing the health, growth, and sustainability of these aquatic marvels.

Shrimp larvae, known for their delicate yet resilient nature, require a precise balance of nutrients to thrive.

Recent breakthroughs in scientific understanding, coupled with technological advancements, have opened new avenues in the quest to provide larvae with the perfect diet. From innovative feed formulations to a deeper comprehension of macronutrient and micronutrient value, digestibility, and absorption, the realm of larval nutrition is undergoing a transformative shift.

Come along with us as we uncover the secrets to providing the best nutrition for shrimp larvae — a journey that delves beyond the surface and into the heart of aquaculture innovation. From cuttingedge research to on-the-ground success stories, this

Hatchery Feed & Management Vol 12 Issue 1 2024 26 HATCHERY FEEDS

exploration aims to illuminate the nutritional factors and their balance. As we navigate the complexities of this nutritional code, a clearer picture emerges, promising not only healthier and more robust shrimp but also a sustainable and thriving industry.

Balanced diets for shrimp:

A focus on amino acid and fatty acid profiles

Traditionally, discussions surrounding shrimp nutrition have revolved around proteins, fats, and carbohydrates. However, the vulnerability of larvae necessitates a more tailored approach, with essential amino acids emerging as pivotal in ensuring proper development. Simultaneously, the role of fatty acids in energy metabolism and structural development takes on heightened importance, guiding the formulation of diets that transcend sustenance to promote thriving larvae populations.

Amino acids serve as substrates for protein synthesis, contributing to the growth of aquatic animals. They play essential roles in regulating feed intake, intermediary metabolism, cell signaling, immune response, and the overall health of farmed animals, including fish and crustaceans (D’Mello, 2003; Mai et al., 2022; Wu, 2021).

Categorized into nutritionally essential, conditionally essential, and non-essential amino acids, ensuring the balance of 10 essential amino acids (EAAs) is crucial (see the reference values in Table 1). Any imbalance is likely to disrupt protein synthesis and turnover, leading to adverse consequences, such as

HATCHERY FEEDS

nitrogen loss into the environment. Alternative protein sources, animal byproducts and plant proteins are becoming popular to reduce cost in manufacturing, but those feedstuffs are usually less digestible and deficient in EAAs, especially methionine and lysine (Simon et al., 2021).

Methionine is very important to the physiology and metabolism of shrimp, and it is the most impacted EAA in low fishmeal diets (Chen et al., 2011). Lysine is one of the most limiting EAA in plant-based protein diet, which can significantly promote protein synthesis and growth performance of shrimp (Xie et al., 2012). In addition, both EAAs can support the application of other EAAs by eliminating the oxidation rate (Richard et al., 2010). The dietary methionine and lysine levels are 0.7-0.9% and 1.6-2.1% of the diets for cultured shrimp, respectively (NRC, 2011). The nutrition basedformulation approach with crystalline amino acids (CAAs) is widely recommended to provide a proper balance of EAAs in aquafeeds – CAAs are digestible amino acids, which are synthetically manufactured by bacteria through the fermentation process (Swanepoe et al., 2023). Therefore, the CP is not the only indicator to consider the feed quality, but the well-balanced amino acid profile and digestibility are also important to meet.

The lipid requirement of shrimp depends on their essential fatty acid profile and phospholipid content (Gonzalez-Felix et al., 2002). The increasing lipid level affected the increase of lipid deposition in hepatopancreas and muscle but without significant effect on growth. Notably, fatty acid profile, especially unsaturated fatty acids like linoleic acid (18:2n-6), linolenic acid (18:3n-3), eicosapentaenoic acid (20:5n-3, EPA), and docosahexaenoic acid (22:6n-3, DHA), is more meaningful in terms of nutrition value concern (see the reference values in Table 2). Maintaining the optimum levels of highly unsaturated n-3 fatty acids, EPA and DHA, at 0.5-1.0%, is crucial for achieving higher final weight and growth, as an imbalance, more than 2%, negatively affects nutrition and stunts shrimp growth

Hatchery Feed & Management Vol 12 Issue 1 2024 27

HATCHERY FEEDS

(Gonzalez-Felix et al., 2007). Additionally, an imbalance of lipids by over-supplementation exceeding 8% can depress protein digestibility, growth performance, and feed utilization (Chookird, 2010).

Optimum feed quality through digestibility

Understanding feed digestibility is a fundamental step in optimizing nutritional intake for shrimp. The composition and quality of feeds play a pivotal role in determining how effectively shrimp can break down, absorb, and utilize essential nutrients.

A highly digestible feed facilitates the shrimp’s digestive tract in absorbing macronutrients and micronutrients from feed to the bloodstream, leading to effective nutrient utilization for growth, energy, and overall physiological functions. Especially during the larval stage, digestion efficiency is limited due to early development. Higher digestibility in feed leads to greater nutrient utilization by larvae.

In light of this, our exploration delves into factors contributing to feed digestibility, including ingredient selection, processing techniques, and the role of enzymes in aiding nutrient release during digestion. For instance, different types of protein sources, such as fish-based protein and plant-based protein, or varying

grades of protein sources, premium or standard, can significantly impact feed digestibility. Research has shown that premium fishmeal, with a balanced amino acid profile, exhibits higher apparent crude protein digestibility and promotes greater growth compared to lower-grade fishmeal with similar amino acid values (Chookird, 2010). This underscores the direct positive correlation between good digestibility, nutrient absorption, and growth feasibility.

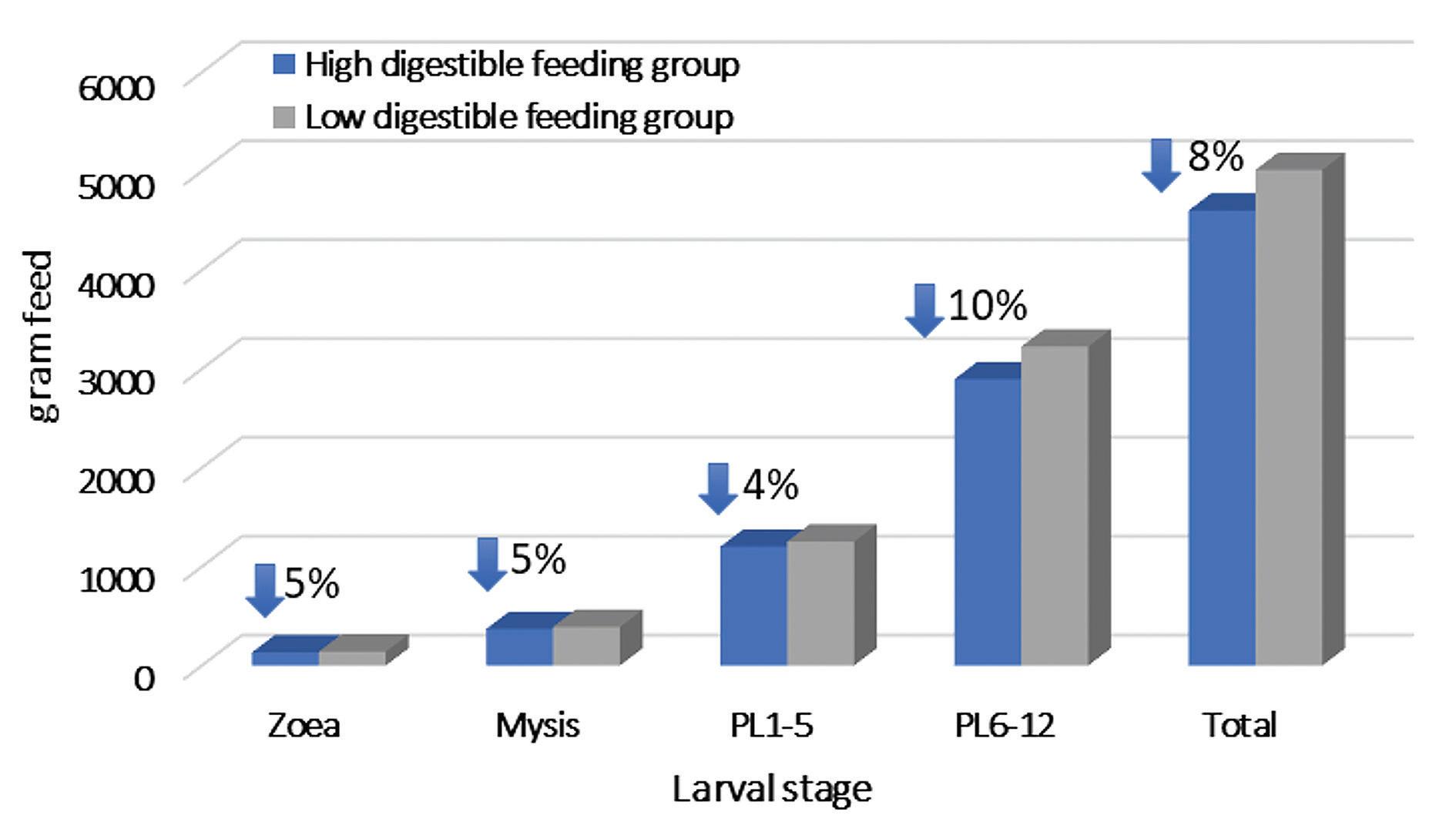

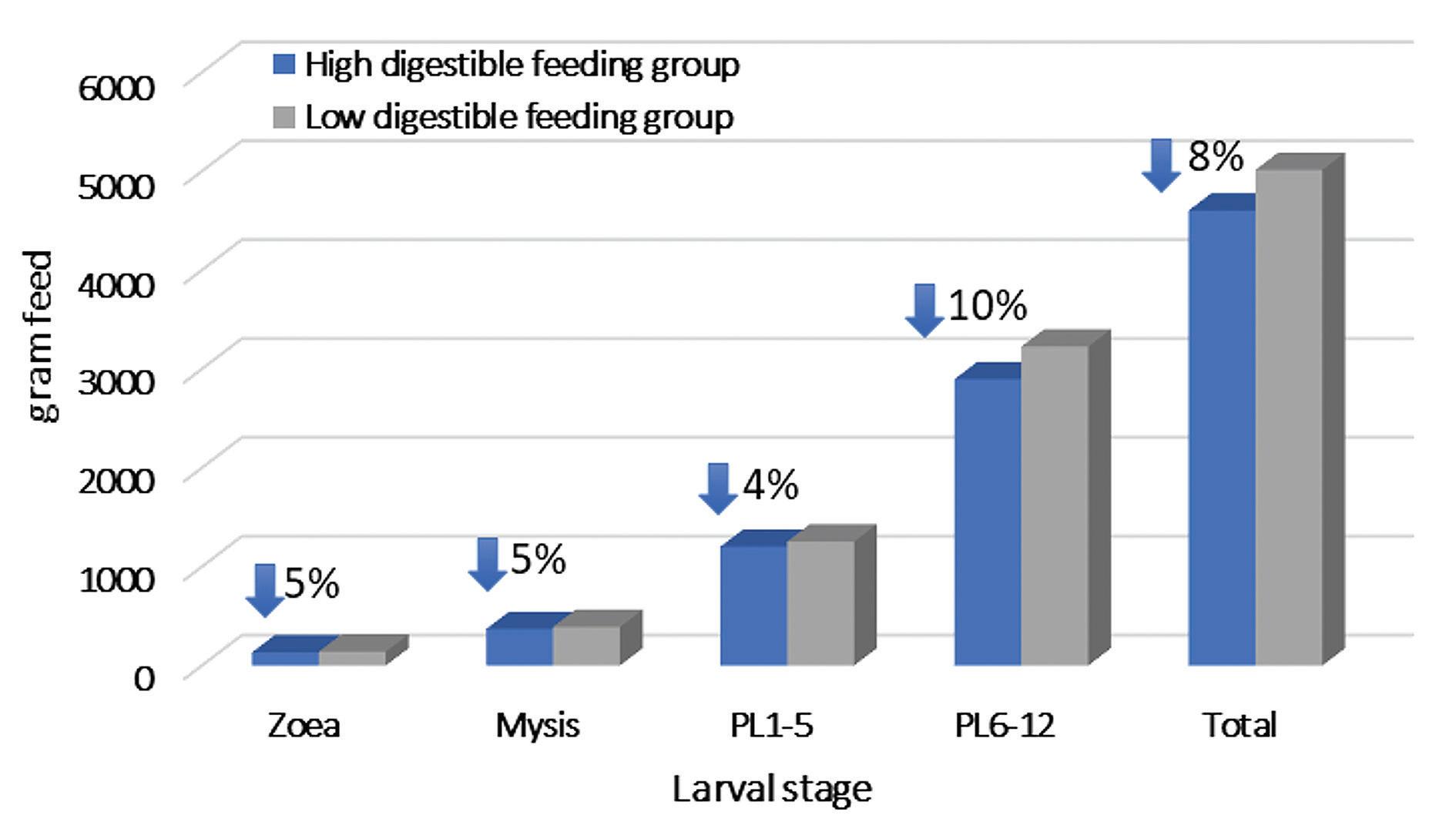

Moreover, the quality of raw materials significantly impacts feed utilization, influencing digestion, absorption, and overall growth efficiency. SyAqua explores how premium-grade, enriched, and easily digestible feed promotes higher rates of digestion and absorption, resulting in lower feed consumption and a reduced feed conversion ratio. This not only minimizes organic waste in the water column but also enhances water quality, necessitating less management in the culturing tank.

SyAqua’s internal trials reveal an exciting breakthrough in optimizing larval nutrition through enhanced feed digestibility. Our findings demonstrate a clear advantage in protein digestibility between high- and lowdigestible feeds, showcasing the potential for significant improvements in larvae growth and development.

Hatchery Feed & Management Vol 12 Issue 1 2024 28

Amino acid Requirement for Penaeid shrimp (% diet) Reference Arginine 2.5% Chen et al., 1992 Histidine 0.42 - 1.17% Millamena et al., 1999 Isoleucine 0.52 – 2.02% Millamena et al., 1999 Leucine 0.95 - 2.95% Millamena , 1999 Lysine 1.6-2.1% NRC, 2011 Methionine 0.7-0.9% NRC, 2011 Phenylalanine 0.62 – 2.12% Millamenaet al., 1999 Threonine 1.4% Millamena et al., 1997 Tryptophan 0.2% Millamena et al., 1999 Valine 1.3-1.5% Millamena et al., 1996

Fatty acid profile Requirement for Penaeid shrimp (% diet) Reference EPA (20:5n-3) 0.50% Gonzalez-Félix et al., 2003 DHA (22:6n-3) 0.50% Gonzalez-Félix et al., 2003 Total HUFA Max 2% Gonzalez-Felix et al., 2007 Total n-3 Min 1% Kanazawa et al., 1979

Table 1. Essential amino acid requirements by penaeid shrimp

Table 2. Essential fatty acid requirements by penaeid shrimp

HATCHERY FEEDS

Notably, larvae fed highly digestible feed consume approximately 8% less, meaning low FCR and leading to reduced feed costs and increased profitability for hatcheries (Fig. 1). These results underscore the critical importance of prioritizing feed quality and digestibility in larval nutrition strategies, not only for enhancing performance but also for maximizing economic gains.

SyAqua’s commitment to elevating the nutritional value of each feed pellet underscores its dedication to ensuring a consistent and high-quality nutrition source, from machine to hatchery. Join us in the revolution of shrimp nutrition, where science and technology converge to shape the future of aquaculture.

References available on request.

More information:

Dr. Natthinee Munkongwongsiri Field Research Manager

SyAqua Siam Co. Ltd.

E: natthinee.m@syaqua.com

Dr. Lumpan Poolsawat Nutritionist

SyAqua Siam Co. Ltd.

E: lumpan.p@syaqua.com

Hatchery Feed & Management Vol 12 Issue 1 2024 29

Group Protein digestibility (mM DL-alanine/g feed/Trypsin activity) High digestible feed 55.41 ± 8.25 b Low digestible feed 39.27 ± 3.29 a p-value 0.035

Table 3. Comparison of in vitro protein digestibility between high digestible feed and low digestible feed used for culturing shrimp larvae

The different superscript letters mean statistical differences (p < 0.05) (a < b).

Figure 1. Feed consumption of high digestible feeding group and low digestible feeding group for culturing 1 million PL12

Is poor water quality hurting your shrimp farm productivity? A biosecurity checklist

Brian Murphy, Genics

When I talk to clients about how to improve their shrimp farm productivity, I often start by running through a checklist of foundational water quality tactics. Waterborne diseases and contaminants significantly impact shrimp operations and cause major economic losses. So, decontamination and water pathogen monitoring are cost-effective ways to elevate performance quickly. Improving water quality is a highly achievable goal, so let’s take a quick look at the most important aspects of an effective biosecurity strategy.

Why water biosecurity matters

Consumer safety

Water decontamination is a crucial aspect of sustainable shrimp farming. It not only protects the health of the shrimp but also safeguards the environment and ensures the production of safe, high-quality food for consumers.

Regulatory compliance

Many countries have regulations and standards to

Hatchery Feed & Management Vol 12 Issue 1 2024 30 HEALTH

Water quality is vital to improving shrimp farm productivity. Credits: Genics

HEALTH

Credits: Genics

Credits: Genics

ensure the quality of water used in aquaculture. Failure to comply with water quality standards may lead to legal and regulatory consequences. Adhering to regulations is not only essential for the well-being of the shrimp and the future of your business but also for the sustainability of the shrimp industry at large.

Shrimp health and pathogen control

Shrimp are extremely sensitive to water quality, and many contaminants can negatively affect their health

and growth. Unhygienic water conditions and poor biosecurity are also the leading causes of disease in shrimp. To protect your animals and the productivity of your business, rigorous biosecurity, and pathogen control must be a top priority.

Pathogen control reference tables

To make solving shrimp pathogen issues easier, Genics has created a set of handy reference tables. The methods available are on the left of the tables, while

Hatchery Feed & Management Vol 12 Issue 1 2024 31

the top row lists the pathogens. To identify the most effective decontamination method, locate the pathogen in the top row and follow the corresponding column downwards. Please note that these tables should be used as a general guide in combination with advice from accredited pathogen management experts.

What does a good biosecurity regime look like?

The sanitary condition of your shrimp facilities will impact every aspect of production, from hatchlings to breeding pairs and the quality of your harvest. The ideal water decontamination regime for your farm will involve a combination of physical, analytical, and chemical measures to maintain water quality. The specific protocols you use may vary depending on your farm’s location, the available water sources, and the shrimp species you are cultivating. But let’s go through some critical components of water decontamination regimes that apply to all shrimp farms.

1. Intake pre-filtration

Depending on whether intake water is pumped or fed tidally, intake pre-filtration can take the form of either a mesh screen around the inlet of the suction pipe or a screened barrier at the entrance to the intake canal. This screen is usually a coarse 1-2cm gauge mesh primarily used to exclude contaminant vectors such as fish and invertebrates like wild shrimp and crabs.

Settlement ponds, either permanent or used alternatively, provide a reservoir of water to supply the hatchery or farm. Settlement can often be the most cost-effective form of filtration, but it depends on land availability. Retention time should be at least 48 hours to settle particulate matter, but you can also improve settlement timing by using baffles and flocculants.

3. Secondary filtration

Although you can use settlement ponds to do double duty as treatment ponds, transferring settled water through additional filtration to a secondary treatment pond is preferable. This secondary filtration can be in the form of mesh socks, drum filters, sand filters, etc.

4. Proactive disease management

To optimize your farm’s biosecurity protection, you’ll want to implement a comprehensive shrimp disease early warning program, including regular pathogen testing performed by an accredited laboratory. Consulting with aquaculture experts and considering local conditions can help tailor your pathogen decontamination strategy to your farm’s unique needs.

5. Treatment

Ideally, your treatment ponds should be fully lined to enable thorough cleaning between batches of water.

Hatchery Feed & Management Vol 12 Issue 1 2024 32 HEALTH

Shrimp need clean, pathogen-free water to thrive. Credits: Genics

Chlorine and potassium permanganate are both commonly used treatment chemicals.

Regardless of the treatment you decide to use, it’s vital to consider the water volume, chemical dosages, and residual chemical constituents to achieve the prescribed concentration.

6. Sterilization and water conditioning

Ultraviolet (UV) light is a good sterilization option to eliminate potential water recontamination at the filling point. You can use UV with additional filtration methods, such as sand or gravel filters to optimize water quality.

Pond conditioners and probiotics can be useful to enhance water quality and support the development of beneficial microorganisms.

Be sure to check water parameters and adjust them to an optimal range before beginning the stocking and aeration process. Maintaining sufficient oxygen levels and circulation are vital measures to keep your animals healthy, but you need to start with clean water.

7. Organic matter and nutrient management

Implementing an organic matter management strategy will go a long way toward preventing the accumulation of contaminants in ponds or tanks. It’s also essential to carefully manage nutrient input to avoid imbalances and inadvertent overfeeding.

8. Quarantine and biosecurity

Once you begin stocking your ponds, it’s vital to ensure that your shrimp come from reputable suppliers and are pathogen-free. It’s also crucial that an accredited

HEALTH

laboratory has provided SPF (Specific Pathogen Free) certification for your animals before delivery.

Every farm should establish biosecurity protocols to minimize the risk of contamination from external sources, such as equipment, personnel, or wild organisms. A biosecurity audit by an accredited company may be beneficial to identify specific areas that need addressing to reduce the chances of introducing pathogens.

9. Monitoring and testing

Farm water quality should be monitored regularly to minimize stress on your shrimp, and should also examine parameters such as ammonia, nitrite, nitrate, dissolved oxygen, and pH.

It’s essential to routinely screen your animals and the water on your farm for pathogens to ensure that decontamination processes and biosecurity procedures are working. This will also provide early detection of pathogen outbreaks, allowing you to take corrective action before diseases can seriously damage your stock.

More information:

Brian Murphy

Global Client Success Manager

Genics

E: info@genics.com.au

Hatchery Feed & Management Vol 12 Issue 1 2024 33

Supporting animal health and welfare in the Asia-Pacific region

Thitiwan (Poo) Patanasatienkul,

In modern aquaculture, aquatic animal health and welfare have been a concern for farmers and that is why the World Organisation for Animal Health (WOAH) launched the Aquatic Animal Health Strategy in 2021.

The WOAH Aquatic Animal Health Strategy 20212025 was developed to enable veterinary services and aquatic animal health services to meet the opportunities and challenges of the growth in aquaculture. It sets priorities for collaborative actions to protect aquatic animal health and welfare and fully realize the potential of aquatic animal production. The strategy has been designed to guide actions to strengthen four areas of the aquatic animal health system: standards, capacity building, resilience, and leadership.

The Asia-Pacific aquaculture industry Aquaculture is a significant food sector in the AsiaPacific region and a key player in international trade. Farming fish and crustaceans means moving and transferring live aquatic animals and their products to different countries with the risk of pathogen spread. Several diseases have been circulating in the region over the past decade: Acute Hepatopancreatic Necrosis Disease (AHPND) in shrimp and Tilapia Lake Virus (TiLV) in tilapia are recent examples.

The movement of live juveniles is essential to producing the final food product but this also introduces the potential to simultaneously move pathogens. For this reason, hatcheries play a crucial role in aquaculture biosecurity by controlling disease transmission and supplying healthy juveniles to farms. In the Asia-Pacific region, hatcheries vary in their biosecurity practices, with some adhering to highest standards while others having room for improvement. Despite these advancements, there are still challenges, including inconsistent enforcement of regulations, limited access to technology and expertise, and gaps in infrastructure and resources. Addressing these issues through enhanced training, technology transfer, and regulatory enforcement can further strengthen biosecurity measures in hatcheries across the region, ensuring sustainable and resilient aquaculture practices.

At the hatchery, diseases can be transmitted horizontally and vertically. If broodstock carry a disease-causing pathogen, it may pass on pathogens to their offspring. This can occur through various means, such as infected eggs or sperm, or through the transfer of pathogens during spawning or fertilization. Vertical transmission of diseases can have significant implications for aquaculture operations, as it can

Hatchery Feed & Management Vol 12 Issue 1 2024 34 HEALTH

lead to the propagation of diseases within hatcheries and subsequent stocking of infected juveniles into production systems. Therefore, effective biosecurity measures and disease management strategies are essential to minimize the risk of vertical transmission and maintain the health of aquatic stocks.

Supporting farmers

Emergency response and preparedness for emerging diseases has been identified as an important area for aquaculture both globally and regionally. One of the ways the WOAH is supporting Asia-Pacific farmers in its way is through a collaboration framework, the Asia Pacific Aquatic Animal Health Network (AP AquaNet). The network was established in 2019 to strengthen collaboration among countries, experts, and international organizations, and share information and expertise to prepare for and combat emerging threats to aquatic animal health. The AP AquaNet is considered a success story in the Asia Pacific region. The network provides a platform for countries and experts from WOAH Reference Laboratories

HEALTH

and Collaborating Centers to share information, and experience in diagnostic methods, prevention and control of diseases in aquatic animals. This is a collaborative framework with a continuing effort to combat existing and new emerging diseases.

To prevent disease from entering the farm, biosecurity measures should be adopted as a routine practice in every aquaculture farm. The WOAH, in collaboration with NACA, published the report Collection and Evaluation of Existing Guidelines and Awareness Materials on Aquaculture Biosecurity for Small-scale Farms in the Asia-Pacific Region, which provides information on the guidelines on aquaculture biosecurity existing in countries in the region.

Moreover, since the launch of the Aquatic Strategy, the Aquatic Code and Manual standards have been revised, adding new chapters on biosecurity for aquaculture establishments and information on new diseases. There has been an increase in the use of the WOAH Performance Veterinary Service Pathway for capacity building, and practical antimicrobial resistance (AMR) guidance has been provided. Several ongoing activities

Hatchery Feed & Management Vol 12 Issue 1 2024 35

HEALTH

have been planned to achieve the goal identified under the Aquatic Strategy, including the plan to formalize procedures for a coordinated WOAH approach to disease emergencies and the development of guidelines for collaborative emergency response.

Regulation barriers

Regulations regarding aquatic animal disease prevention and control vary across countries in the Asia-Pacific region. Some countries have robust regulatory frameworks in place, while others may have gaps or inconsistencies in their regulations but all countries use the WOAH Aquatic Animal Health Code to guide their regulations in some manner.

Opportunities for enhancement are frequently identified in areas such as enforcement, resource allocation, coordination among agencies, and addressing emerging challenges. Effective enforcement ensures regulations are implemented, while more resources are needed for surveillance, research, and response. Better coordination among agencies is vital for a cohesive approach to disease management. Additionally, adapting to emerging challenges, such as new diseases and environmental changes, requires proactive strategies. Overall, optimizing these aspects leads to more resilient and efficient disease prevention and control systems. However, most countries encounter barriers, including limited funding, inadequate infrastructure, complex governance structures, and transboundary challenges. Solutions to address these challenges require investment in capacity building, infrastructure, and international cooperation to strengthen regulatory frameworks and address emerging threats effectively.

Investment and capacity building to increase biosecurity

Encouraging investment in biosecurity for aquaculture farms in the Asia-Pacific region is feasible but challenging. It requires educating farmers about biosecurity importance, sharing best practices and increasing risk perception on the economic risks of disease outbreaks. At the same time, implementing government standards and incentives and offering loans and grants are also key as well as developing cost-effective technologies.

Limited resources and competing priorities pose challenges, especially for small-scale farmers.

The collaboration between government, industry, and financial institutions is crucial to overcome these hurdles.

WOAH collaborates closely with the government of each member country through WOAH Delegates and Focal Points, aiming to ensure that its support reaches farmers. One objective of the WOAH Aquatic Animal Health Strategy is to bolster capacity building and aid small-scale aquaculture. In the Asia-Pacific region, the plan involves conducting research to comprehend on-farm biosecurity in small-scale aquaculture, with the results intended to enhance overall aquaculture biosecurity.

Furthermore, AP AquaNet shares information, strengthens collaboration, and implements flagship activities, such as aquaculture biosecurity, emergency response for diseases, and disease reporting. WOAH also contributes to the fight against AMR in aquaculture by providing training on the collection of national AMU data, which helps in understanding the occurrence of AMR in the aquatic animal sector.

Future perspectives

Aquaculture farming is expected to continue expanding in response to global demand for food and animal protein. However, as aquatic animals are reared in water, they are inevitably susceptible to the effects of climate change. Species raised in open environments, such as salmon in open-sea cages, tilapia in riverbased open cages, and shrimp in ponds using water from natural water bodies, are particularly vulnerable to shifts in water quality, such as algal blooms or droughts, alterations in pathogen survivability and virulence, and increased animal susceptibility due to climate-induced stress. Vigilance is paramount and needs ongoing monitoring and the development of emergency response plans to address these challenges. Further research is essential to fully comprehend the implications of climate change on aquaculture.

More information:

Thitiwan (Poo) Patanasatienkul Aquatic Animal Health officer World Organisation for Animal Health (WOAH)

Hatchery Feed & Management Vol 12 Issue 1 2024 36

Is there still an opportunity for aquaculture in Europe?

Credits: Sutterstock

Credits: Sutterstock

In 2023, the European Court of Auditors (ECA) released a special report on the EU aquaculture policy titled Stagnating production and unclear results despite increased EU funding. Despite the EUR 1.2 billion made available for 2014-2020, the auditors note that overall EU aquaculture production has flatlined. It has even decreased in two of the largest producers (Italy and France). The socio-economic indicators do not look promising either. The number of aquaculture businesses is declining, and employment in the sector fell from around 40,000 people to around 35,000 between 2014 and 2020.

The European Commission replied to ECA recognizing that under shared management it cannot continuously monitor the effectiveness of the use of EU funds nor, even more broadly, the environmental sustainability of

EU aquaculture altogether. The Commission believes that there is a solid basis to allow the EU aquaculture sector to grow and reach its full potential in terms of contributing to the objectives of the European Green Deal. However, it considers that it is still early to evaluate the results of the new strategy.

Hatchery Feed & Management talked with the Federation of European Aquaculture Producers (FEAP) to get their insight into these results. FEAP represents 24 members drawn from 23 states across the European continent that produce 2.5 million tons with an ex-farm value of over EUR 8 billion. FEAP is convinced that aquaculture in the EU has great potential to provide aquatic food, economic development, and employment opportunities just like this same activity does in other parts of the world and that this long-standing stagnation

Hatchery Feed & Management Vol 12 Issue 1 2024 37 REGIONS

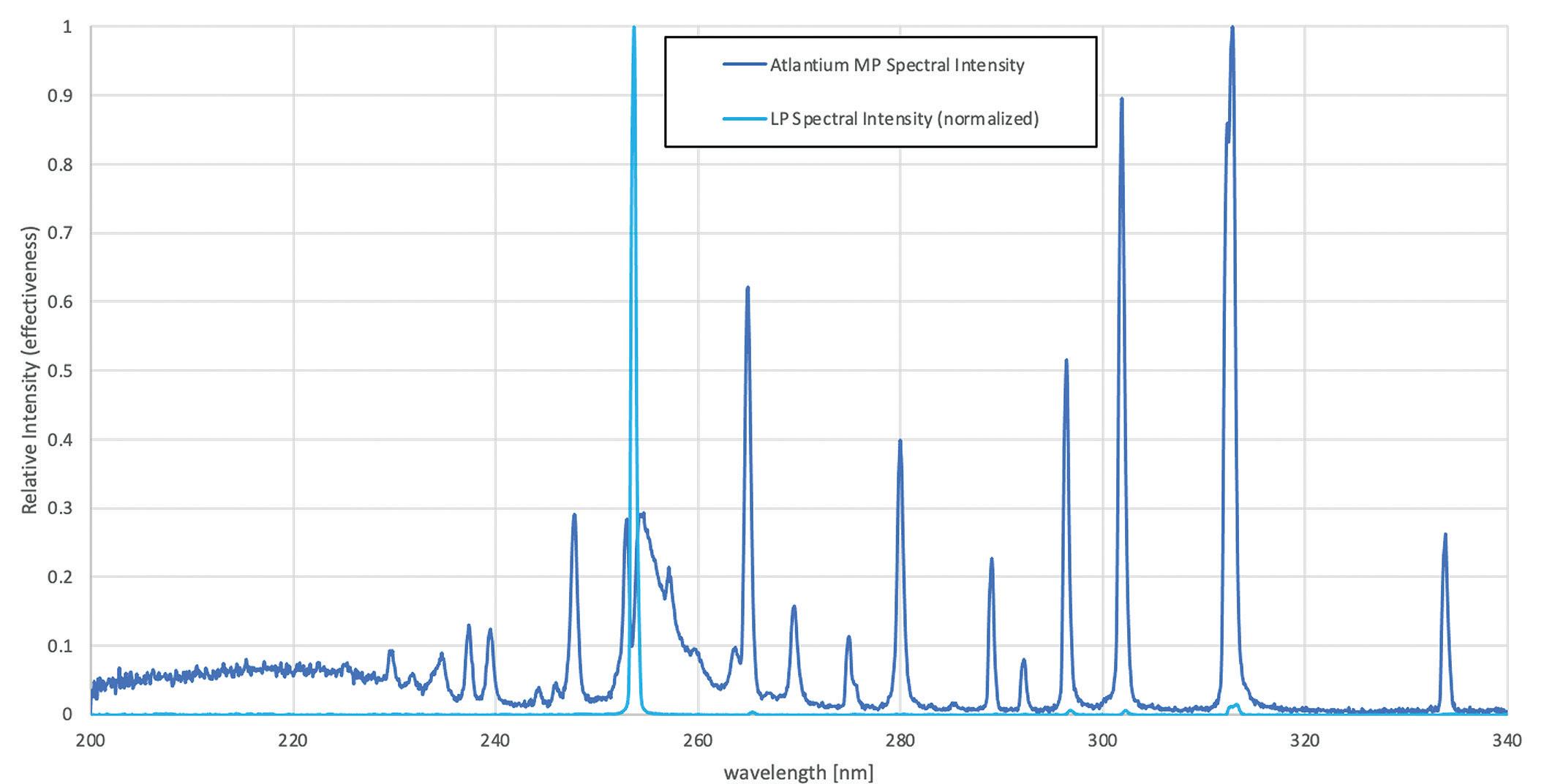

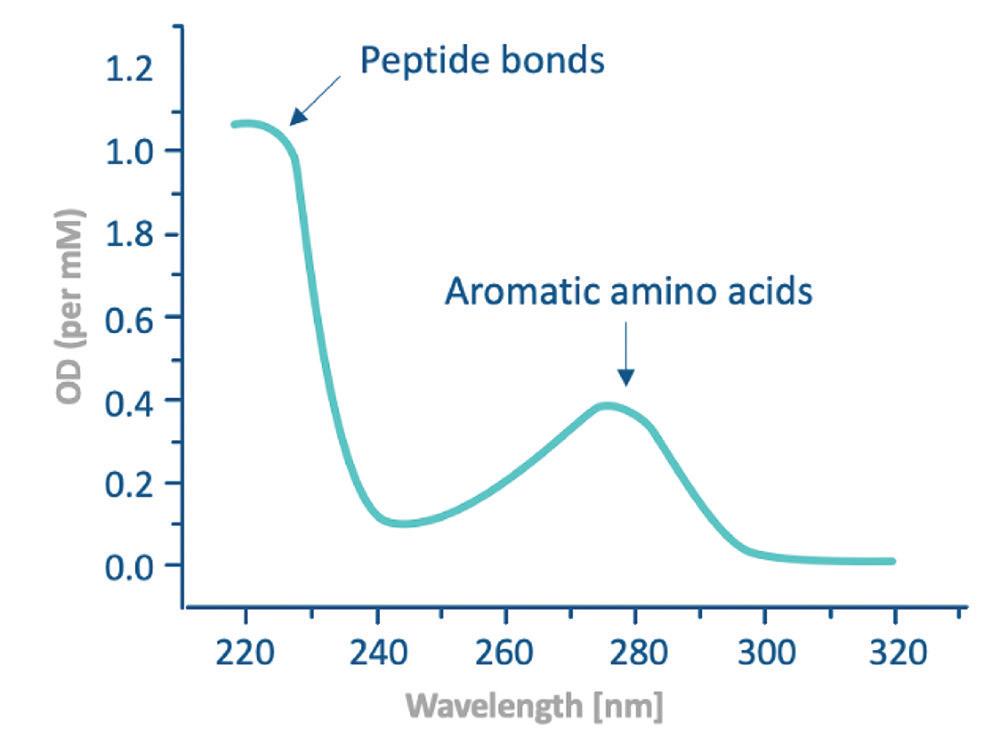

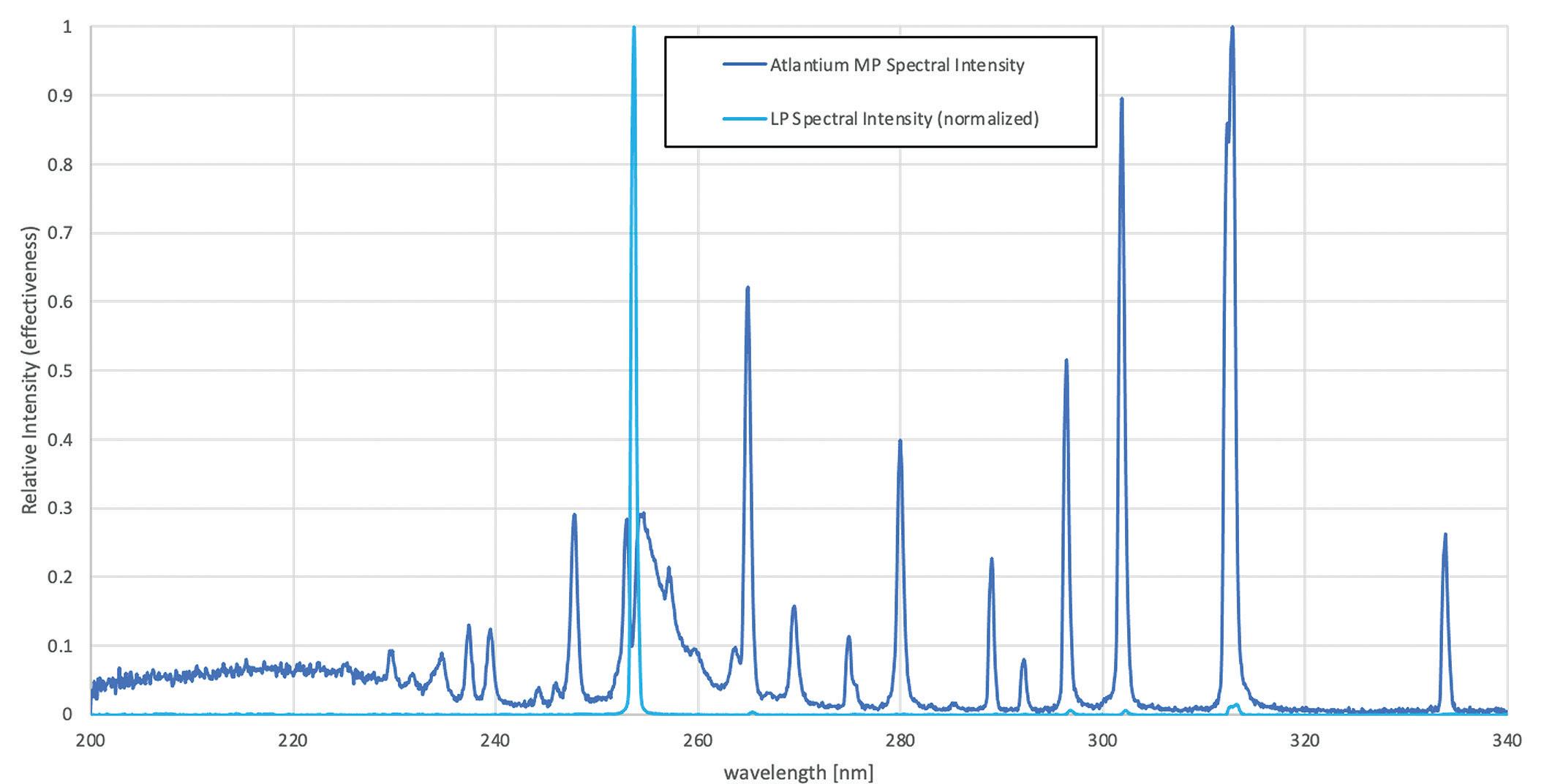

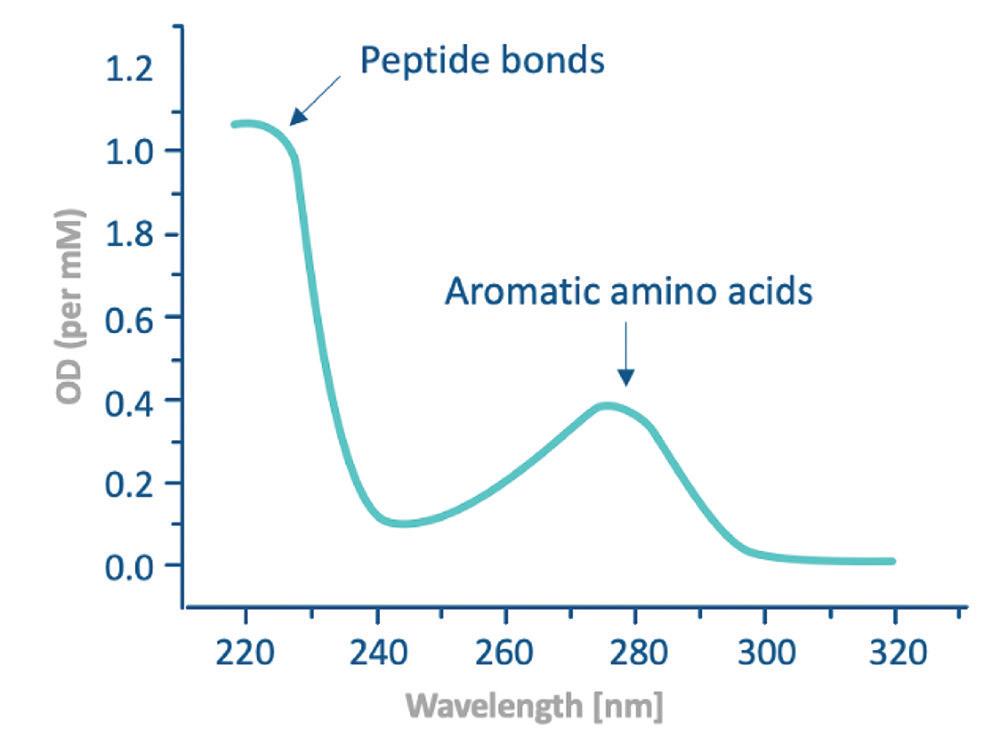

situation of aquaculture in the EU can be solved if the right actions are taken.