AQUAFEED Advances in processing & formulation Vol 16 Issue 2 April 2024 Published by: Aquafeed Media, S.L.U. www.aquafeed.com info@aquafeed.com

EXTRACTS

PLANT-BASED

Micro aquafeed production

An Aquafeed.com publication

Functional properties of insect meal

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 2 AQUAFEED VOL 16 ISSUE 2 2024 Contents 4 Interview with Marcelo Costero 6 News Review 14 How to avoid oil leakage in aquafeed 17 Producing micro aquafeed via extrusion cooking technology 21 Oregano essential oil and Quillaja saponaria extract as dietary supplements to improve the health and growth performance of aquaculture species 26 Making all shrimp eat: The impact of a neurosensory additive on feed intake and size homogeneity 30 Use of selected polyphenols to improve fish reproductive performance 34 From field to fin: The soy-powered future of aquaculture 37 Where are we in the search for new protein in aquafeeds? 41 Understanding BSFL meal as a functional feed ingredient for aquaculture 44 Silkworm pupae meal vs. conventional protein meals: A comparative study for aquafeed formulation 50 Calendar of events To read previous issues in digital format or to order print copies, visit www.aquafeed.com We are grateful to the following companies for sponsoring this issue of the magazine. Their support allows us to make our publications available without charge. Extru-Tech 13 Process Integration 16 Biochem 20 Anpario 25 Phodé........................................................................................ 27 Nouvelles Vagues 29 ISFNF 33 Berg + Schmidt 36 Phytosynthese 40 FeedTechExpo 2024 ............................................................... 49 Aquaculture Philippines 51 WAS 52 CONTACT US Editorial: editor@aquafeed.com Editor/Publisher: Lucía Barreiro Consulting Editor: Suzi Dominy Technical Editors: Peter Hutchinson, Albert Tacon, Ph.D Assistant Editor: Marissa Yanaga Conferences and webinars: info@aquafeed.com Advertising enquiries/request media pack: sales@aquafeed.com Accounts & all other enquiries: info@aquafeed.com SUBSCRIBE Digital editions are free to industry subscribers. You may also purchase print copies. Subscribe at Aquafeed.com to receive your own digital copy of our publications. https://bit.ly/AQUASUBSCRIBE FOLLOW US Aquafeed Media, S.L.U., Ames, 15220 A Coruña, Spain. Copyright© Aquafeed Media, S.L.U., 1998-2024 All rights reserved. Privacy Policy & Terms of use.

Contents

PRODUCING MICRO AQUAFEED VIA EXTRUSION COOKING TECHNOLOGY

Modern, continuous cooking extrusion technology has developed i high-quality and high-capacity micro aquafeeds.

OREGANO ESSENTIAL OIL AND QUILLAJA SAPONARIA EXTRACT AS DIETARY SUPPLEMENTS 21

Their properties make them an effective solution in aquafeeds.

A SWOT ANALYSIS OF PROTEIN INGREDIENTS 37

Where are we in the search for new protein sources in aquafeeds?

FUNCTIONAL PROPERTIES OF BLACK SOLDIER FLY MEAL 41

There is evidence that functional antimicrobial peptides are present in a commercially available insect meal product.

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 3

VOL 16 ISSUE 2 2024

AQUAFEED

INTERVIEW with Marcelo Costero

AQ: Where is Vimifos today in terms of markets served?

We are the main supplier of aquaculture feed –shrimp and tilapia – in Mexico, with production plants in the Northwest, West and Southeast of Mexico, practically covering the country regionally. We contribute to a lesser extent in feeding trout and marine fish. We are also leaders in the production of feed for pigs, poultry and cattle.

AQ: How is the volatility of the feed ingredients market affecting Vimifos? Are you prioritizing local ingredients?

Mexico has a certified sustainable fishmeal and fish oil industry that covers the demand for aquaculture. This puts us in a good position to provide highly competitive feed to our customers. Furthermore, in the northwest of the country, where farmed shrimp is produced, we have very important wheat and corn production areas in the west and southeast of the country.

AQ: What is the status of the shrimp farming industry in Mexico? What are the main challenges in the country?

Farmed shrimp production has remained stable over the past 10-12 years. The supply of larvae of consistent quality – in growth and survival – is the most critical step. On the other hand, we have a local market that demands fresh shrimp all year round at very attractive prices, which makes the industry profitable. Mexico is a net importer of processed shrimp for selfservice.

AQ: Vimifos has more than 45 years of experience in animal nutrition. Why did you decide to enter the aquaculture industry?

MC: The company decided to venture into aquaculture at the beginning of 2000, almost 25 years ago, due to the emergence of the shrimp farming industry in the Northwest of Mexico. Aquaculture farmers required specialized feed that generates results and covers all the quality requirements for the good growth of their animals.

AQ: Tilapia is another important aquaculture species in Mexico. What is the status of tilapia farming in the country? What are the main challenges? How does Vimifos support the tilapia sector?

MC: The tilapia farming industry has suffered a very sharp decline in the past three years. This was mainly due to farming practices that have brought in health problems, viral and bacterial, which have caused the industry to fall to 25% of what was produced three years ago. The lack of disease-free offspring is, like in the case of shrimp, the most delicate step. Our company decided to venture into the production of tilapia fingerlings by partnering with a local producer.

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 4

Marcelo Costero is Sales Manager Aquaculture at Vimifos

We provide them with resources and cutting-edge technology from a leading company to have tilapia fry available for our customers and feed.

As in the shrimp industry, we are the number 1 supplier of feed for the industry in Mexico. Currently, Mexico is a major importer of tilapia, with more than 100,000 MT of whole-weight equivalent tilapia imported per year, primarily for self-service.

AQ: Vimifos has an Aquaculture Research Center. What is the objective of this center and what have been the main projects developed?

MC: It is a center for verifying the performance of our shrimp and tilapia diets before they are launched on the market. We also verify the growth of different genetic lines from different suppliers and evaluate the effect of functional additives on survival and growth, before promoting them to our clients.

AQ: Vimifos has been one of the first aquafeed manufacturers to obtain the ASC Feed certification. What does this certification mean for the company?

MC: We are the only company certified in Latin America by ASC Feed Standard for shrimp and tilapia. This is the result of our commitment to the quality of our products, processes and services, in the quest to provide the best technologies in aquaculture nutrition to our clients.

AQ: What are the company's main sustainability objectives?

MC: Vimifos' sustainability goal is to satisfy the needs of the present without compromising the capacity of future generations, caring for the environment and social well-being. We use local byproducts to reduce the carbon footprint and our diets are also designed using byproducts from the animal production industry and thus reduce dependence on wild-caught fish stocks. Moreover, we maintain precise control of some ingredients such as phosphorus and we use enzymes to optimize nutrient utilization.

AQ: Vimifos provides support services to farmers. What are the main ones?

MC: Importantly, we promote value to our clients, helping them in the application of the best farming practices, as well as with the supply of the highest quality offspring, as is the case of tilapia. We also support farmers with agile

Responsible seafood farming needs responsibly produced feed. ASC’s Feed Standard is the first standard to take into consideration the impacts created across all key ingredient groups and across the entire ingredient supply chain. Feed mills have to meet strict requirements for the sourcing of all major feed ingredients, addressing environmental and social risks down to the raw material level.

Vimifos is in the leading pack of feed companies that is paving the way for the rest of the industry. By achieving ASC certification, they are playing a crucial role in moving aquafeed production – and the aquaculture industry as a whole – towards sustainability through greater transparency and traceability. There is an incentive for other feed companies to follow in Vimifos' footsteps: all feed mills that get certified in 2024 will not have to pay license fees on the volume of compliant feed they produce this calendar year.”

Alexandra Warrington, Senior Coordinator, Feed Standard at ASC

and sufficient credit for their operations with our financial subsidiary Vimifos Capital.

AQ: What are Vimifos' growth projections in the short and medium term?

MC: Vimifos aims to maintain the constant growth we have had in the aquaculture industry, focusing on our efforts to consolidate sales in Mexico, and Central and South America.

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 5 INTERVIEW

NEWS REVIEW

Highlights of recent news from Aquafeed.com

De Heus opens shrimp feed mill in Vietnam

The company opened a new shrimp feed mill in Co Chien Industrial Zone, Vinh Long province in Vietnam. Spanning an area of 29,300 square meters, De Heus' new shrimp feed mill has an annual capacity of 50,000 metric tons, featuring five production lines exclusively dedicated to shrimp feed products.

BioMar’s new product helps manage salmon stress and improve performance

Calm is the latest BioMar’s offering to complement the SmartCare range of products in salmon feeds. Made from natural ingredients, Calm can be added to grower diets and used in addition to other already wellestablished SmartCare products. Recommended to be used strategically before and immediately after any planned stress event, SmartCare Calm can be a useful addition to the feed for the farmer to help mitigate these risks to welfare which will help them maintain the expected level of performance.

Green Plains unveils new specialty feed ingredient brand

The company unveiled a new brand for its specialty feed ingredient, reflecting its quality performance, versatile formulation opportunities, proven nutritional benefits, digestibility and low carbon footprint. Sequence™, a foundational feed ingredient produced at scale using proprietary mechanical separation technology, delivers a combination of corn and yeast protein, concentrated at a minimum of 60%.

Aquasoja unveils new feed for tilapia and carp

The company has recently formulated a new product to fulfill the nutritional requirements of both species, maintaining the focus on high-quality protein ingredients and fish health conditions. POND PLUS is an extruded, floating feed, designed for semiintensive to intensive production of both species. This highly digestible and low-fat feed includes more than 25% high-quality poultry ingredients, and around 15% marine ingredients, namely fishmeal from trimmings, shrimp hydrolysates and fish oil, being well-balanced in terms of carbohydrates content and sources, as well as vitamins and minerals. The combination of selected macro ingredients with health-promoting materials will maximize growth performance, health and survival throughout Nile tilapia and European carp’s on-growing period.

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 6

NEWS

Calysta protein receives MARA approval for use in aquafeeds

Calysta’s FeedKind® protein has received formal approval for use in aquafeeds in China as the company’s joint venture with Adisseo, Calysseo, prepares to deliver the first product to customers through the Adisseo sales network in China. The country’s Ministry of Agriculture and Rural Affairs (MARA) has formally given Calysta’s single-cell protein full approval for use in fish and shrimp feeds after an extensive evaluation process.

Omega-3 camelina varieties achieve regulatory milestone

The USDA-APHIS’s Biotechnology Regulatory Services (BRS) has determined that Yield10’s Camelina sativa varieties developed using genetic engineering (modified Camelina) to produce omega-3 fatty acids are not subject to the regulations under 7 CFR part 340, and may be grown and bred in the United States. “This regulatory milestone represents a critical step for enabling the ramp-up of camelina planting to commercial scale in the U.S for producing omega-3 oil for key markets including aquafeed and human nutrition,” the company said.

Skretting unveils

barramundi grower feed line

Utilizing Skretting’s extensive knowledge of the species' specific nutritional requirements and digestive capabilities, Cosmos has been carefully developed over the past three years. It aims to enable producers of premium-quality barramundi to achieve optimal levels of fish performance and farm efficiency, including higher growth rates at lower feed conversion levels. The diet’s formulation offers precisely balanced digestible protein, energy, and phosphorous levels. Cosmos will first be available in Australia, with more countries to follow.

Veramaris secures Canadian authorization for algal oil in aquafeed

The company has completed the necessary threeyear registration process for its use in Canadian salmonid farming. The authorization allows Veramaris to provide Canadian aquaculture with a secure source of ASC- and MSC-certified EPA and DHA. The algal oil, produced in Blair, Nebraska, USA, is a regional solution that supports the industry's move towards adopting alternative omega-3 sources and reducing dependency on fish oil as a primary source of essential fatty acids for salmon feed.

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 7 NEWS

Entobel, Vinh Hoan partner to accelerate the transition towards more sustainable pangasius production

The companies expanded their strategic partnership which includes an offtake agreement by Feed One, a subsidiary of Vinh Hoan, to purchase a substantial volume of insect protein produced at Entobel’s Vung Tau factory in 2024. In addition to the offtake for 2024, through this agreement, Vinh Hoan will purchase a minimum of 15,000 metric tons of insect protein from Entobel over the next three years, from 2025 to 2027.

ESG risk assessment tool for feed ingredients unveiled

Innovafeed expands product portfolio, unveils new brand

To support the acceleration of its production and sales growth, which more than doubled in 2023, Innovafeed unveiled its new brand, Hilucia™, redesigning its offer around a complete range of high-quality ingredients for animal and plant nutrition with minimal environmental impact. The company’s product range has been extended with the launch of two new solutions, an insect oil for aquaculture and an insect protein for monogastrics.

The Global Salmon Initiative (GSI), in partnership with the World Wildlife Fund (WWF), launched a first-of-its-kind environmental, social, and governance (ESG) risk assessment tool for feed ingredients. The tool will improve visibility into supply chains, allowing stakeholders to better identify and address possible ESG risks. GSI and WWF designed the tool to support the salmon farming sector, but the wider animal protein production sectors, including livestock, may also benefit from its use. The tool provides a consistent and aligned framework for farming companies to engage with their respective feed suppliers in order to get a holistic overview of possible risks in the feed supply chain. It can also help companies assess the scalability of future novel ingredients.

dsm-firmenich to separate its animal nutrition business from the group

The company started a process to carve out and separate the Animal Nutrition & Health (ANH) business from the rest of the group. ANH is driven by different dynamics from the rest of the group, which has become even more apparent with the unprecedented challenges in the vitamins market. The company believes that the full potential of the ANH business could be best realized through a different ownership structure for which all potential separation options will be considered. The company would expect to be in a position to separate the business in 2025. Given Veramaris’ significant potential in dietary supplements, it is expected that it would remain part of the group.

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 8 NEWS

BioMar inaugurates new hatchery R&D facility

BioMar’s Aquaculture Technology Centre at Hirtshals Denmark opened a new wing dedicated to research and development in the hatchery segment. “The facility enables us to do trials with a very high degree of control over all production parameters. We can simulate conditions that our customers experience in different hatcheries around the world and do trials with both marine and freshwater larvae,” the company said.

Bühler develops fully automatic bagging station with Premier Tech

Bühler, in partnership with leading Canadian packaging equipment manufacturer Premier Tech, launched CHRONOS OMP-2090 B, a fully automatic bagging station. The new bagging station was developed for a wide range of powdery and other non-freeflowing products. It delivers maximum productivity through reliable, fully automatic operation, outstanding bagging accuracy and high product and operational safety.

Unlocking the power of alpha-gal immunity to help mitigate parasitic infestation in fish

The collaboration between startup microXpace and Lallemand Animal Nutrition has reached a significant milestone as both partners prepare to enter the product development phase for AlphaGal-based technology. The production of Alpha-Gal antibodies, triggered in response to microbiota expressing the Alpha-Gal glycan, plays a vital role in recognizing and binding pathogens' surfaces. This powerful technology offers new possibilities to help maintain animal health by supporting resilience to infectious diseases affecting aquaculture and poultry production worldwide. The successful proof-of-concept stage of the microXpace-Lallemand partnership has led to the identification of a broad range of parasite targets, paving the way for the development of an AlphaGal-based product aimed at enhancing resilience against major parasitic diseases prevalent in the aquaculture and poultry farming industries.

A-Systems signs partnership to expand to South Asia

Animal feed formulation software supplier, A-Systems, signed an agreement with Dr. Amit Das to distribute A-Systems products to animal feed producers in South Asia. With this partnership, A-Systems aims to strengthen its position in South Asia – India, Bangladesh, Nepal and Sri Lanka.

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 9 NEWS

IDAH unveils TwinTech extruder for the aquafeed market

Since 1974, Taiwan-based IDAH has been developing innovative products for the aquafeed, food, pet food and biomass markets. When IDAH joined CPM in 2023, they gained access to a range of collaborative opportunities, expertise and tools that they could use in developing their own products. At Victam Asia 2024, IDAH launched the clearest evidence of that collaboration: the all-new TwinTech Twin Screw Co-Rotating Extruder.

The innovative extruder updates IDAH’s industryleading twin-screw extruder with innovations and design techniques from Ruiya Extrusion, along with a long-lasting gearbox and energy-efficient motor from CPM Industrial Solutions.

“This extruder is a collaboration between IDAH and Ruiya,” said Albert Wang, assistant sales manager at IDAH. “We combined their insights on design and cost efficiency with our knowledge in feed production to introduce a new technology.”

CPM Industrial Solutions’ gearbox and motor also offer real-world benefits in TwinTech. “The gearbox allows rotational speeds up to 600 RPM, facilitating heavy-duty processing and increased output, along with a proven long-life track record,” said Wang.

The TwinTech’s motor from CPM Industrial Solutions is a permanent magnet synchronous motor (PMSM) that offers significant advantages. “The CPM motor has lower energy requirements,” said Wang. “It also has a reduced size, and reduces noise output by about 30%.”

Combined, these innovations create a marketleading twin-screw extruder that delivers capability, value and reliability.

TwinTech features

The TwinTech extruder offers a range of new features developed by both IDAH and partner brands within CPM.

Enhanced Gearbox Technology:

Powered by CPM’s field-tested gearbox technology, the TwinTech extruder features a high-speed, heavyduty gearbox capable of achieving

rotational speeds of up to 600 RPM. This allows for increased processing capacity and efficiency. Energy-efficient design: The TwinTech extruder is powered by a permanent magnet synchronous motor (PMSM), which is highly efficient and about 50% smaller than traditional air-cooled motors. This motor design contributes to energy savings, reduced noise pollution (up to 30% lower) and the option for water cooling to maintain motor efficiency and stability.

Density control unit: An optional feature, the density control unit, allows TwinTech to produce different types of fish feed, including sinking and slow-sinking feeds, by using positive pressure inside the cutter chamber. This versatility allows manufacturers to produce a wide range of fish feed with a single machine.

Advanced preconditioning and cooking systems:

The TwinTech extruder introduces a new thermal hydrator and updates the differential diameter conditioner to improve the hydration and retention time of materials. These systems are designed to enhance the cooking process by ensuring efficient steam integration and retention, leading to better processing efficiency and product quality.

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 10 NEWS

ANDRITZ introduces automation and digitalization solutions for the feed industry

The company is introducing a comprehensive portfolio of automation and digitalization solutions for the feed industry under its Metris digital platform. This continuously evolving, universally compatible platform supports operational efficiency, resilience, readiness and sustainability, and aims to allow for fully autonomous feed plant operations by 2027. “The journey to autonomous operations is paved with bold steps of those who embrace every facet of automation and digitalization, turning challenges into opportunities for growth,” said Sohail Nazari, head of Automation & Digitalization, ANDRITZ Feed & Biofuel. “Combining expertise and state-of-theart digital technologies, we never stand still and enable businesses to thrive. ANDRITZ will be with you every step of the way in your journey, ensuring your plant and your business never stand still.”

Operational efficiency

Operational readiness

Simulation-based engineering has shortened ramp-up times in greenfield projects across various industries by up to 20% and significantly increased revenues through saved production losses. For the first time in the feed industry, ANDRITZ is offering full-scale digital twin technology to enable virtual commissioning, allowing up to 90% of potential issues to be resolved before on-site commissioning.

With digital technologies for process optimization, asset management, operator training and knowledge management, ANDRITZ ensures a holistic, turnkey approach to feed processing. This enables feed producers to unlock their plants’ full potential over the full lifecycle, enhancing profitability and reducing the total cost of ownership. The use of ANDRITZ’s Metris digital platform has led to throughput increases in the range of 7% to 16% in various industries.

Operational resilience

Protecting feed operations from cyber risks is crucial. With its in-house provider of cyber security solutions OTORIO, we ensure full visibility across all assets and operations on demand, effectively enabling IT-OT convergence and proactively mitigating digital risks to IEC 62443 standards.

Advancing sustainability

ANDRITZ automation and digitalization solutions have been instrumental in achieving reductions in specific energy consumption ranging from 3% to 17% across various industries. By proactively identifying malfunctions and maintaining asset integrity, they effectively minimize production disruptions and enhance sustainable operations.

Improving decision-making

In today’s dynamic business environment, plant managers are always looking to transform complex operational data into actionable insights, while company management seeks robust data for planning and strategic decisions. ANDRITZ automation and digitalization solutions deliver tangible, measurable and replicable value as a basis for data-driven decisions.

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 11 NEWS

Vimifos, Skretting first feed mills to attain ASC Feed Certification

Mexican-based feed producer Vimifos, the Chilean branch of Skretting, and Thai Union’s Mahachai Plant in Thailand are the first feed mills to achieve certification against the requirements outlined in the Aquaculture Stewardship Council (ASC) Feed Standard.

Vimifos was the first to achieve multi-site certification for three of its feed mills in Mexico that produce feed for shrimp, tilapia, trout and marine fish.

Skretting has also achieved multi-site certification for two feed mills in Chile that produce feed for salmon.

Thain Union’s single-site certification for their Mahachai Plant, located in Thailand’s Samut Sakhon province just west of Bangkok, is the first ASC Feed Standard certification in Asia. The feed mill produces feed for seabass, seabream, meagre, tilapia and shrimp.

“There is no responsible seafood farming without responsible feed. Companies involved in its production face increased reporting demands to assess the ‘upstream’ environmental and social impacts of feedingredient supply chains. By setting strict requirements for the sourcing of all major feed ingredients, ASC addresses environmental and social risks down to the raw material level. Ensuring responsibly sourced feed supports responsible seafood farming and thereby responsible sourcing of seafood products on shelves. With these first certifications, the journey towards more responsibility coming from greater transparency

and traceability in feed production has gathered significant momentum,” said Chris Ninnes, ASC CEO.

Skretting CEO, Therese Log Bergjord, commented, “We are extremely proud to be the first salmon feed company in the world to achieve ASC Feed Standard certification. This is a highly demanding standard that moves in the right direction towards ensuring a positive impact across our supply chain, but we know that the journey doesn’t end here. We’re already implementing the learnings from Chile to accelerate the certification process across the rest of our operations and, with that, ensure that our customers can keep relying on Skretting to maintain their own certifications for fish and shrimp.”

Peerasak Boonmechote, CEO of Thai Union Feedmill, added that “securing the first ASC Feed certificate in Asia underscores our deep commitment to sustainability at the heart of our operations. This is a key step in increasing the availability of responsible feed as part of Thai Union Group’s commitments under its global sustainability strategy, SeaChange® 2030. This certification also reinforces our dedication to leading the industry towards a more sustainable and responsible future.”

ASC certified farms have until October 2025 to switch

NEWS

Shutterstock

PEOPLE IN THE NEWS

Therese Log Bergjord, CEO of Skretting, has announced her decision to leave the company after seven years on June 1, 2024. Therese will be succeeded by Bastiaan van Tilburg, currently managing director for Trouw Nutrition Europe and

Duong Anh Tu

Fabricio Vargas

BioMar-Viet Uc joint venture in Vietnam is now headed by Duong Anh Tu as managing director, who has extensive commercial experience from the feed and food sector in Asia. Duong Anh Tu replaced Franck Bodin, who was appointed to launch the business in Vietnam.

Latin American feed group Vitapro, owner of Nicovita and Salmofood, named Fabricio

Fulco van Lede

Fulco van Lede has also announced that he will be stepping down from his role this summer after leading the company for the past three years. David Blakemore will succeed Fulco as CEO.

Cedric van den Bossche

To lead the growth strategy for the Asian markets, BioMar appointed seasoned animal nutrition and aquaculture expert Cedric van den Bossche as vice president for the Asia division, which today comprises the business units in Vietnam and China.

Manuel Maire

Lesaffre appointed Manuel Maire as general manager of Phileo by Lesaffre, its animal

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 13 NEWS

EXTRU-TECH AQUAFEED UNIVERSE P.O. Box 8 100 Airport Road Sabetha, KS 66534, USA Phone: 785-284-2153 Fax: 785-284-3143 extru-techinc@extru-techinc.com www.extru-techinc.com Master Your Aquafeed Universe Sinking to floating. Sub-millimeter to pellet. When you select an Extrusion Processing System from Extru-Tech, you have a complete Universe with the ability to maintain size yields over 95%. As your business evolves, you have the flexibility to change your finished product without the need for significant capital expenditures. Contact Extru-Tech and optimize your flexibility and profitability. Sub 1 Millimeter Pellet ET-338B.indd 1 1/28/21 8:48 AM

How to avoid oil leakage in aquafeed

Peter Sønderskov, Process Integration

Extruded aquafeed is a well-known and essential process in the value chain of the global aquaculture industry. Aquafeed accounts for a large portion of the costs to farm fish, making it imperative that the pellets end up where they are intended, in the fish's stomach. However, various factors introduce new challenges, potentially leading to significant economic consequences for aquafeed manufacturers and environmental challenges in the sea.

Sufficient pellet cooling is crucial

The oil content in fish feed pellets significantly influences fish development, and inadequate cooling can lead to substantial problems. Peter Sønderskov, sales manager for Process Integration (PI), who has decades of experience in aquaculture technology, has witnessed some dire examples of what can happen when things

go wrong. "If, for example, moisture or temperature is too high during coating and where the pellets are packed, the oil may leak out, potentially requiring either reprocessing the entire batch or disposal. Right-first-time is, of course, preferable, making it essential to address this issue promptly. While fat sealers can apply an external layer, they may not always be sufficient."

Design changes or new technology

Extruded pellets aren't a new technology, so why are problems arising now? Peter Sønderskov explains, "Several reasons contribute to the problem. It could be due to improper plant design or incorrect calibration. In such cases, process knowledge is crucial for making the necessary adjustments to minimize the problem. Additionally, some feed plants lack dedicated cooling systems, relying instead on facilities like

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 14 FEED

PROCESSING

The right-dimensioned plant design can avoid oil leakage in the aquafeed factory. Credits: Process Integration

warehouses for cooling. However, with temperatures generally rising, adequately cooling the pellets can be challenging or impossible, necessitating installing a chiller system. Here, it's crucial to assess the entire factory before installation and to explore whether there's excess energy elsewhere in the process that can be utilized."

The picky salmon

It's a well-known fact that salmon are picky eaters. If pellets are broken or sinking properties are incorrect, they may end up on the bottom of the sea, creating

further challenges. "Even if the pellets, despite oil loss, still make it to the feed barges, they'll be more porous and prone to breaking. In such cases, salmon may refuse to consume them, leading to expensive feed becoming pollution in the sea instead of growth of the fish. Whole pellets will have a lower oil content, adversely affecting salmon growth. So, overall, the repercussions are significant," notes Peter Sønderskov.

Noted the above will also apply for other species, where the challenges are similar, even if the oil content of the pellet is much lower, but during processing and forming of the pellets, issues may occur.

Solution and costs

What does it cost to reprocess products not having a well-functioning cooling system? It depends on factors like the plant location, production capacity, and final oil content requirements. The overall performance of the plant is determined by the uptime, right-firsttime percentage, and the number of pellets requiring reprocessing. Other factors like capacity utilization and product changeovers are not taken into account here.

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 15

FEED PROCESSING

Figure 1. Flow diagram for chiller and cooling tower

Figure 2. Pellet diameter, fat content and cooling time. Temperature difference: 40°C (product in 55°C, product out 15°C)

FEED PROCESSING

Imagine this: daily production is 200 tonnes of feed and due to poor plant design and insufficient cooling of the pellets, the creation of dust and breakage, can typically mean up to a high 5% rework of the feed. As earlier stated, and as shown from studies, the fish does not eat broken pellets and in addition, salmon does not eat floating feed. With a production cost of e.g. €1 per kilo, this means that you will lose €10,000 every day, plus it reduces the throughput of the plant. A fact that can cause sleepless nights.

Pellet breakage depends on many things and with an acceptable feed quality, a correctly designed plant, and a fully functioning cooling system it is possible to achieve rework figures below 1%. This makes optimized cooling one of the priorities to minimize rework for the best production results and improve the profitability of your plant.

By reviewing your plant, PI can optimize your plant to reduce rework and optimize throughput thereby lowering your production cost and making production more profitable.

40 years of process experience

Many employees at Process Integration have been with the aquafeed industry since its beginning and are familiar with aquafeed production globally. Today, the company primarily focuses on designing, engineering, and installing process plants for a wide range of industries, specializing in plant optimization, replacement and upgrading of equipment, expansions, and servicing, whether it's for fish feed, pet food, human food, or powders and liquids. Headquartered in Denmark, Process Integration has sister companies in Chile, Norway, and the USA. For more information, visit processintegration.dk

More information:

Peter Sønderskov

Sales manager

Process Integration Aps

E: pes@processintegration.dk

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 16

We integrate your process visions Denmark • Norway • Chile • USA www.processintegration.dk • Engineering • Project management • Equipment supply • Installations • Turnkey solutions Aquafeed Petfood Sustainable Proteins Liquid Food & Beverage Service

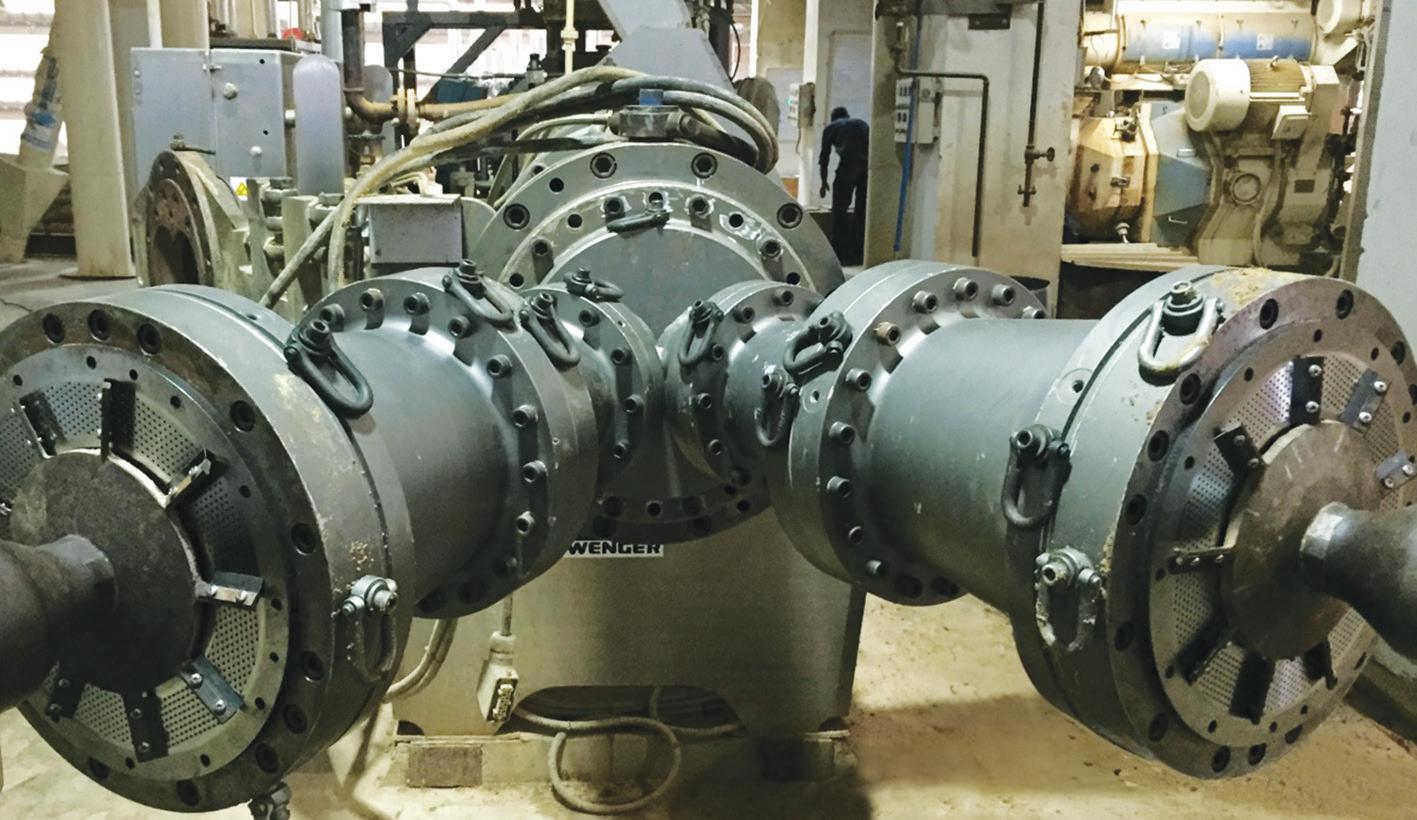

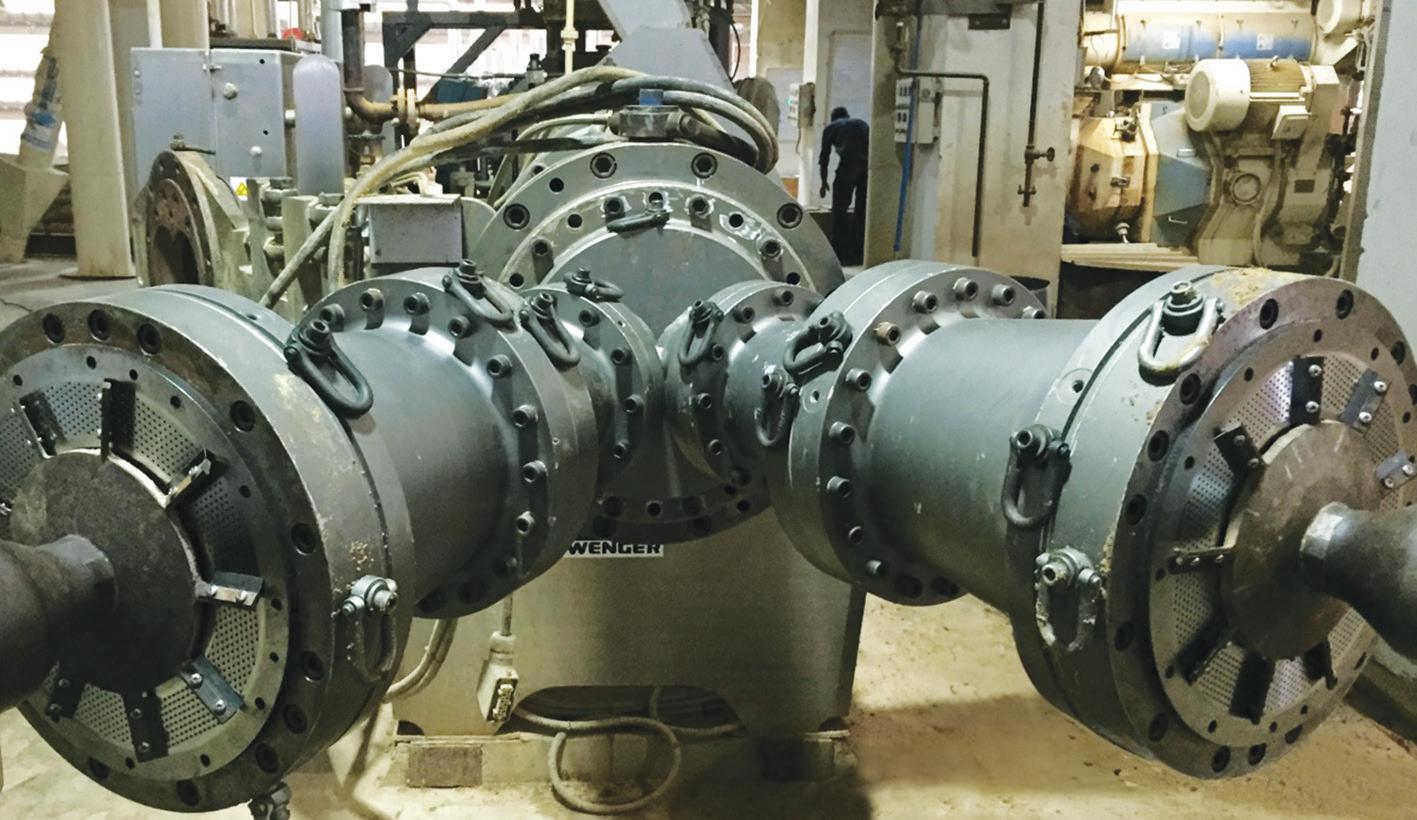

Producing micro aquafeed via extrusion cooking technology

Brian Streit, Wenger Manufacturing

Micro aquafeed production has been a historical challenge in terms of consistent product quality, low throughput, and energy sustainability. However, recent advancements in continuous extrusion cooking technology and recipe development are now enabling feed producers to accomplish these aspects.

Micro aquafeeds are products in which the final product is 1,000 microns and smaller in size. Continuous extrusion cooking, which includes single and twin screw technologies, along with appropriate preconditioning and precise feed control to the process, has become a proven method for consistently producing high-quality and high-capacity micro feeds. The difference in the extrusion technologies involves processing and recipe flexibility. Both single screw and twin screw systems utilize mechanical and thermal energy inputs, through direct and indirect steam and water, under pressure, to gelatinize (“cook”), shape, and size the product to a specific density for the targeted aquatic species. By design, a continuous extrusion cooking system, versus traditional pellet milling, provides control of the specific recipe phase transition through compression, kneading, melting, and texturization prior to the final shaping –allowing for optimized starch gelatinization to yield a uniform product with long water stability. The flexibility in today’s extrusion technology provides many tools to manage this phase transition control including:

• accurate metering of the recipe and preconditioning control

• adjusting extruder barrel fill through modern variable speed controls

• unique extruder screw and barrel configurations

• sophisticated screw element design

These innovations provide more process control across a broad range of ingredients and recipes than alternate methods of aquafeed production. Extrusion process controls provide the ability to impart differing levels

of specific mechanical energy (SME or “shear”) and specific thermal energy (STE or “heat”) into the recipe to effectively manage the process whether producing floating, fast sinking, or slow sinking micro products. Equally important is the control of the upstream systems to deliver accurate recipe metering control and preconditioning prior to the extrusion process. With today’s technology, the metering control of the dry feed recipe – through sophisticated loss-in-weight systems – can consistently deliver accuracies down to 1.0%. Additionally, new preconditioning technology is available to effectively blend, with even distributive and dispersive continuous mixing, the dry recipe with water, steam, and fats or oils. Using automated controls, the preconditioning process can be adjusted for retention time, differential shaft speed, and mixing impacts to dial in the process parameters specific to the requirements of the recipe or product. This can be done while in production without the need to shut down and make mechanical adjustments. Given this level of control, current preconditioning technology can deliver a reduced coefficient of variation down to 2.0%.

Reducing variability in the metering and delivery systems of the dry feed recipe and preconditioning to the extrusion process will result in a more stable process, with reduced external factors influencing performance, and enhancing product quality attributes such as uniformity, density, moisture content, and starch gelatinization which directly impacts the associated water stability. The improved level of control and variability reduction is important for all aquatic feed production, however, it is critical when the target product is micro aquafeed, given the inherent challenges of producing small diameter products at high capacities.

So, what is the correct extrusion system to produce micro aquafeed? This question is best answered

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 17

FEED PROCESSING

FEED PROCESSING

by considering the range of ingredients, recipes, throughputs, and final products desired. In short, how much flexibility is needed in the process?

Single screw extruders

Single screw extruders – as indicated in the name –have a single shaft, typically with a set of configurable screw elements to produce a classified range of products, either floating or sinking, with output ranging from 1,000 to 30,000 kg/hr. With modern additional components, such as variable screw speed control and in-line restriction devices, the flexibility of a single screw extrusion system has increased in recent years. However, changing from a floating to sinking product will typically require modification to the screw element configuration to optimize production. Additionally, some recipe or ingredient modifications may be required, such as the carbohydrate, protein, and inherent fats or oil sources and inclusion ratios, to provide the capability to produce the range of products desired. Generally, the operating and recipe window for single screw extruders is narrower than that of its twin screw counterpart.

Twin-screw extruders

Twin-screw extrusion provides the ultimate flexibility in process and recipe control to produce the broadest range of micro aquafeed products without the need for changes in mechanical components or configuration – resulting in increased uptime. Simply changing the final die for the specific product diameter is usually all that needs to be done. Flexibility comes from utilizing unique screw element designs with longer specifically

designed processing zones to enhance the kneading, mixing, and cooking while allowing for higher levels of specific thermal energy inputs to provide instantaneous adjustments to the SME to STE ratios specific to the recipe or product being produced.

The ability to utilize higher thermal energy inputs and reduced mechanical energy inputs, or “shear”, not only reduces wear costs but also improves the final product texture – yielding a finer cellular structure that enhances water stability and nutrient retention. This is especially important in the production of micro feeds used in Recirculating Aquatic Systems (RAS) using complex filtration systems. The improved water stability and nutrient retention reduce the particulate and suspended oils that tend to be released from the product yielding cleaner water with less stress on the RAS filtration systems as well as delivering the intended nutrition to the fish (improving feed conversion ratios). The twin screw extrusion process is further enhanced by the ability to adjust the screw speed to optimize barrel fill within the target cooking zone, providing a balanced process to increase uniform gelatinization. This is an important requirement to achieve consistent final product quality, especially in terms of size, water stability, nutrient retention, reduced leaching of oils and fine particulate, and density control reducing the prevalence of random off-specification floating or sinking product.

The basic characteristic of a twin screw extruder, utilizing two rotating shafts and screw elements, provides increased positive displacement and uniform pumping capability across a broader range of viscosities into the shaping, die, and cutting zone of the extruder.

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 18

Floating micro feed (left) and sinking micro feed (right)

For micro feed extrusion, where it is typical for the final die to include a high quantity of die holes (upwards of 5,000) to increase total open area, controlling uniform flow and displacement into each die opening over the entire cross section of the die is even more important. Precisely controlling the flow provides the best opportunity to appropriately shape the final product at high throughputs while maintaining the required uniformity.

Given the industry's desire for increased throughputs, there is increased focus on the final die configuration, and associated total open area limitations. Especially true in producing micro aquafeeds, the limitation to throughput is not the volumetric capacity of the extrusion process but rather the available final die surface area to provide the necessary total open area. To address this challenge, newer die technologies have been developed to utilize multiple dies connected to the same twin screw extruder to significantly increase the production capacity of 300-1,000 micron-sized final products. This approach can yield production upwards of 8,000 kg/hr without the need for external density management chambers. The utilization of multiple dies at the extruder discharge further emphasizes the need for the referenced positive displacement that a

twin screw extrusion process can provide for uniform consistent extrudate flow to each set of dies and specific die openings.

The flexibility of twin screw extrusion for producing micro feeds goes beyond just the processing and production side. It also provides the opportunity to broaden ingredient and recipe options, opening the opportunity for utilization of sustainable ingredient sourcing and lower-cost ingredients while yielding highquality products. A flexible process, with advanced controls in recipe delivery, preconditioning, and a broader cooking zone that the twin screw extrusion process provides, allows for the utilization of higher

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 19

FEED PROCESSING

Wenger dual die head assembly for the AFX-3000 enables high volume output of extruded micro feed

FEED PROCESSING

inclusion of vegetable carbohydrates and proteins, fibrous ingredients, and increased utilization of internal fats and oils and without the need for special binders to control water stability, which can lower costs. Additionally, this flexibility provides the opportunity to adjust the recipes and substitute ingredients without significant research and development time when individual ingredient cost fluctuation is a challenge. Thus, extruder flexibility enables least cost formulation

and reduced operating expenses, while still producing the same high-quality product.

Conclusion

Modern, continuous cooking extrusion technology has developed into an effective and efficient process for producing high-quality and high-capacity micro aquafeeds. When the correct extrusion technology is used (either single screw or twin screw), producers can meet market expectations for nutrition and performance, as well as their own throughput and product cost goals.

More information:

Brian Streit

Sr. Vice President –

Innovation and Process

Wenger Manufacturing

E: bstreit@wenger.com

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 20

biochem.net Contact us: info@biochem.net The high levels of mannan-oligosaccharides (MOS) in TechnoMos® bind and remove pathogens before they become a problem. In addition, it’s highly effective ß-1,3-1,6-glucans boost the immunity of your animals to ensure the best disease resistance and performance. The secret behind TechnoMos®? - it’s made from selected primary grown yeast!

For Best ProtectionIn All Conditions!

A typical Wenger dryer for aquatic feed uses multiple horizontal passes to ensure proper air flow through the product bed.

Oregano essential oil and Quillaja saponaria extract as dietary supplements to improve the health and growth performance of aquaculture species

Aquaculture is continuously expanding as a consequence of the demand for healthy and nutritious food, which, along with the global saturation of wild fishery production, has encouraged considerable growth in the sector. It is currently the fastest-growing food-producing sector in the world, growing at a rate between 5.6 to 7.8% per year. Recently, interests have shifted towards

using innovative feed additives, such as phytogenics, to enhance the nutritional value of aquafeeds and improve the health status and growth performance of aquaculture species.

Phytogenic feed additives can provide an unwavering number of benefits, with a well-documented efficacy in improving the health status and growth performance

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 21

EXTRACTS

PLANT

Otter Ferry Trial Facility

PLANT EXTRACTS

across numerous aquaculture species including, but not limited to, Nile tilapia (Oreochromis niloticus), Pacific whiteleg shrimp (Litopeneaus vannamei ), Atlantic salmon (Salmo salar), common carp (Cyprinus carpio), and rainbow trout (Oncorhynchus mykiss). Anpario’s Orego-Stim Forte (OSF) is specifically designed for use within aquaculture, comprising a unique source of 100% natural oregano essential oil (OEO) and Quillaja saponaria (QS) extract, which contain multiple highly functional compounds that work in synergy to provide a complex mode of action.

Effects of oregano essential oil and Quillaja saponaria as an aquafeed additive

Antioxidant

Oxidative stress occurs when there is an imbalance between the production and accumulation of reactive oxygen species and the ability of a biological system to neutralize these reactive molecules. Negative effects associated with oxidative stress include damage to cellular components such as membranes, proteins, deoxyribonucleic acid, and lipids. Phenolic compounds of OEO and QS can stop oxidation by donating an electron to the reactive free radical without becoming unstable themselves. This neutralizes the free radical and becomes less reactive. Additionally, OEO and QS function as an antioxidant activity enhancer in fish which promotes the activities of antioxidant enzymes; serum and hepatic catalase, superoxide dismutase, and glutathione peroxidase enzymes together with reduced levels of malonaldehyde.

Anti-inflammatory

Inflammation is an essential biological response of a host’s innate immune defense strategy against harmful stimuli; infectious and non-infectious tissue injuries. However, chronic inflammation causes immunological and tissue damage to the host, which is currently a major limiting factor for the production efficiency of aquaculture. The combined administration of OEO and QS downregulates the expression of genes for pro-inflammatory mediators in the gut, including cyclooxygenase-2 and cytokines, mainly tumor necrosis factor alpha, interleukin (IL) -1 beta (β), and IL-6. Additionally, OEO and QS limit the deleterious effects of prolonged inflammation by upregulating antiinflammatory cytokines such as IL-4, IL-10, IL-13, and transforming growth factor-β, which controls the production and action of pro-inflammatory cytokines. Consequently, supplementation of OEO and QS prevents collateral tissue damage in fish by restoring physiological homeostasis through tissue repair.

Immunomodulatory

In the last two decades, the aquaculture sector has suffered major economic tragedies due to infectious diseases, estimated at more than $6 billion per year. However, phytogenics are one of the most significant approaches for improving the immunity of aquaculture species. Numerous studies show the beneficial effects of OEO and QS supplementation on the health status of aquatic species, including an improved hematological profile by increased counts of red blood cells, white blood

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 22

Figure 1. Average specific growth rate (left) and feed conversion ratio (right) of ballan wrasse fed one of three dietary groups; control, T1 (OSF at 0.10%), and T2 (OSF at 0.35%).

cells, hemoglobin, and differential immunoglobulins. OEO and QS have also shown promising results in improving innate and adaptive immune responses in fish, mainly via; improving lysozyme, protease, and complement system activities, and increasing the production of phagocytes, cytokines, B cells as plasma cells, and T cells including T helper cells and cytotoxic T cells.

Antimicrobial

Aquaculture is plagued by a plethora of bacterial pathogens, and the rearing of fish/shrimp at high population densities in aquaculture facilities makes them particularly susceptible to disease outbreaks, causing massive mortalities. The use of antibiotics is the main solution to manage bacterial diseases; however, antimicrobial resistance (AMR) has become a major challenge in aquaculture. Supplementation of OEO and QS in fish and shrimp diets has demonstrated a high level of efficacy in preventing and controlling bacterial diseases caused by strains of Flavobacterium, Aeromonas, Vibrio, Francisella, Salmonella, Pseudomonas, and Streptococcus

The detergent properties of QS destroy bacterial membrane lipids, making the cell membrane permeable which facilitates the influx of molecules through the

bacterial wall and disrupts cell homeostasis. OEO exhibits a broader antimicrobial action which is attributable to the lipophilic nature of its phenolic compounds. These compounds induce the death of bacterial cells by inhibiting adenosine triphosphatase activity and disrupting cell homeostasis – increasing the fluidity and permeability of the cell membrane. Consequently, this causes an intracellular pH reduction in the cell, leakage of vital intercellular constituents, and a metabolic imbalance.

Growth promoter

In fish, several studies have examined the beneficial effects of supplementing OEO and QS to improve growth rate, mainly via improving intestinal histomorphometry and increasing activities of digestive enzymes. Across a multitude of fish and shrimp species, inclusion rates of OEO and QS between 0.25-3.50g/kg and 150-300mg/kg, respectively, have demonstrated efficacy in increasing villus size and quantity, thus improving the intestinal absorption capacity and nutrient utilization. The improved intestinal histomorphometry may be attributable to the antimicrobial activity of OEO and QS, causing a reduction of harmful bacteria and consequently, reducing mucosal damage. The activities

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 23

PLANT EXTRACTS

Otter Ferry Trial Facility

PLANT EXTRACTS

of endogenous digestive enzymes are often used as a benchmark for determining the digestive capacity and nutritional status of fish. Supplementing OEO and QS in O. niloticus and C. carpio diets demonstrated a significant improvement in the stimulation of amylase, lipase, and protease activity, which resulted in improved growth indices for both species.

Orego-Stim Forte (Anpario plc) improves the growth performance of juvenile ballan wrasse Ballan wrasse (Labrus bergylta), as cleaner fish, is viewed as a sustainable and effective management tool for the biological control of sea lice in salmon farming. A study using 1,350 L. bergylta was conducted over 83 days by an independent research provider,

Otter Ferry Seafish, located in Scotland, UK. This trial concludes that OSF (OEO+QS) supplementation, at both concentrations, improves the specific growth rate (SGR) and feed conversion ratio (FCR) of L. bergylta (Fig. 1). The greatest SGR and FCR improvements are seen in the diet containing 0.35% OSF, which is 13.2% and 10.7%, respectively, more advantageous compared to the control.

Antagonism of Orego-Stim Forte against fish pathogens – in vitro

The University of Plymouth conducted a trial to determine the in vitro efficacy of OSF against multiple pathogenic bacteria. The results in Figure 2 demonstrate the inhibitory efficacy of OSF against all five pathogens

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 24

Figure 3. Post-challenge cumulative mortality of shrimp fed one of three dietary groups; D1 (control), D2 (OSF at 0.10%), and D3 (OSF at 0.35%).

Figure 2. Mean clearance zones (mm) of Orego-Stim Forte against significant bacterial pathogens.

PLANT EXTRACTS

when included at 2500ppm (2.5kg/t feed). Such findings highlight the potential for natural solutions, such as OSF, to support fish/shrimp health, safeguard antibiotics, and protect against AMR.

The effect of Orego-Stim Forte on the survivability of shrimp challenged with Vibrio parahaemolyticus Vibrio parahaemolyticus is ubiquitous to many aquaculture environments and can cause diseases such as acute hepatopancreatic necrotic disease (AHPND) in L. vannamei, resulting in significant losses for the shrimp farming industry. This trial used 20 tanks, containing 80 shrimp per tank, with four replicates and was conducted by Nong Lam University in Vietnam.

In Figure 3, the mortality of L. vannamei challenged with V. parahaemolyticus shows a decreasing tendency with increasing administration doses of OSF, thus supporting the antimicrobial activity of OEO and QS. A significant difference was observed between the control and OSF diet at 0.35% (D3), which highlights the efficacy of OEO + QS for in vivo scenarios.

Concluding remarks

With the significant growth trajectory of the aquaculture sector coupled with the booming human population, it is essential, now more than ever, to provide aquaculture producers with highly effective and sustainable solutions that improve the health and growth performance of aquaculture species. The antioxidant, anti-inflammatory, immunomodulatory, antimicrobial, and growthpromoting natural properties of OEO and QS extract, make them highly effective, yet sustainable solutions.

References available on request.

More information:

Gerred Fuchs

Aqua Technical Sales Manager

Anpario plc

E: gerred.fuchs@anpario.com

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 25

Visit www.anpario.com or email orego-stim@anpario.com Interested? High quality eubiotic composed of 100% natural oregano essential oil & saponins. Cost Effective, Natural Solution to Support Health & Performance in the Absence of Antiobiotics.

Making all shrimp eat: The impact of a neurosensory additive on feed intake and size homogeneity

Amine Chaabane, Phodé Laboratories

The large growth of shrimp farming in the past few years has been followed by a larger demand for shrimp feed, with a high diversity of challenges to be addressed. As growth usually is matched with progress, this situation led to a significant improvement in the quality of shrimp feed, gradually catching up with historical species feed such as salmon or trout in terms of technology and nutrition. But there are still many aspects to be improved to meet the expectations of producers across the globe.

Technology-wise, the manufacturing of extruded shrimp feeds is becoming more widespread in South America but remains minor in Asia. The different environmental conditions in each zone, the different production methods, stocking densities, and varying

market typology are at the origin of a major variability between shrimp-producing countries, which is reflected in production costs.

This diversity in shrimp farming led notably to Ecuador's position as a regulator of the export market, given its extremely low production costs compared to other top-producing countries, making Ecuadorian shrimp the most competitive on the market, pricewise. These low prices are unfortunately passed on to the farmers themselves, as 2023 production exceeded demand.

The consequences of the cost issues in 2023, due to shrimp's low selling price but also to global inflation, have led producers from around the globe to minimize costs, starting with feed costs.

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 26 PLANT EXTRACTS

Feed represents up to 65% of total production costs; especially in shrimp, as carnivorous animals require protein-rich feeds which are significantly more expensive than omnivorous species, depending on the sourcing of proteins.

The reduction of feed costs is usually started at the raw material level, fishmeal and fish oil being the more expensive, and keener to be substituted. They are often replaced with plant-based ingredients (soy, corn, canola), animal byproducts (Processed Animal Proteins –PAPs, poultry, or blood meal), other marine ingredients (krill meal, squid meal, finfish, or shellfish hydrolysates), or more recently, alternative proteins (insect meal, single-cell protein from yeasts or microalgae). Most feed formulators will also rely on local ingredients, being more accessible and usually at a better cost, to replace their usual raw materials.

Current formulation knowledge and technology, and state-of-the-art shrimp nutritional requirements, are quite advanced and allow for the formulation of low-cost feeds that are theoretically iso-nutrients to standard formulas. A key aspect of the feed is often

PLANT EXTRACTS

neglected: attractivity and palatability. Indeed: what’s the purpose of producing a good feed, nutritionally speaking, if it is not eaten?

The Phodé Laboratories, experts in olfaction in living beings and its effect on the brain on well-being, have been studying the link between olfaction and behavior to design products that act in this sense. Phodé technology has been put into practice in many shrimp farms and hatcheries around the world.

Phodé has drawn on this experience to design a new product for feed manufacturers, Olpheel Eat, based on their knowledge of shrimp feed intake behavior and chemoreception. Olpheel Eat is a blend of attractive and aromatic compounds (non-marine and non-animal based) for feed attractivity and palatability, with the addition of plant extracts stimulating feed intake at a cerebral level.

To evaluate the effects of Olpheel Eat Shrimp on shrimp feed intake in several conditions, Phodé Laboratories have conducted a study in Vietnam in partnership with the ShrimpVet (MinhPhu AquaMekong) research facility.

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 27

PLANT EXTRACTS

Palatability testing

To evaluate the benefits of Olpheel Eat on the feeding shrimp behavior, a feeding tray test was conducted. A total of 100L whiteleg shrimp (Litopenaeus vannamei, 3.0-3.5 g average weight) were separated in four 75liter tanks filled with brackish water (20 ppt). Two groups were tested: a group fed a control shrimp feed, and a group fed a feed including Olpheel Eat Shrimp at 1 kg/t, each in duplicate. After being starved for 12 hours before the test, shrimp were given 15 g of feed on one small feeding tray that was placed in the tank for 90 minutes. After 90 minutes, the feeding tray was taken out and the remaining feed was dried and weighted to evaluate feed intake. Results are presented in Figure 1. The test was repeated two months later with the same diets stored in wet and hot conditions (Vietnam summer-autumn conditions), to see the effect of storage on feed intake.

Results displayed a significant improvement in feed intake in the Olpheel Eat groups compared to the control groups, with a 16.3% increase in shrimp feed intake fed with fresh Olpheel Eat-containing diets. After two months, the palatability of both feeds was decreased, as feed intake dropped from 50.29 mg feed /g shrimp biomass in the fresh diet to 40.22 mg in the control group. In the Olpheel Eat group, feed intake was better, with a stronger difference compared to the control group at two months, with a difference of +31.2% of feed consumed vs. the control group.

These results globally indicate that the inclusion of Olpheel Eat improves the palatability of shrimp feeds and maintains it over storage time.

Feeding test

To validate these results on long-term conditions, a feeding test was performed in the same facility.

For this test, a total of 500 shrimp with an initial weight of 1.56 ± 0,19g were placed into ten 400-liter tanks filled with brackish water (20 ppt). Shrimp were divided into two groups (control feed and Olpheel Eat supplemented feed) with five replicates each. Shrimp were kept in these tanks and fed ad libitum 5 times a day for 58 days where several parameters such as feed intake, Feed Conversion Ratio, and survival rate were measured. As no significant difference in survival rate was observed during the trial with high survival rates (above 90% on average), the results of the final biomass are displayed in Figure 2.

Results show a higher average biomass in the Olpheel Eat group compared to the control group, which was not significant as a high variability was observed in the control group. However, this difference in variability was statistically different, as homogeneity inside the 5 replicates was higher in the Olpheel Eat group compared to the control group.

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 28

Figure 1. Palatability of the feeds as total feed intake for 90 minutes; *p<0.05.

Figure 2. Final biomass at the end of the 58 days feeding trial; *p<0.05.

Figure 3. Feed Conversion Ratio (FCR) at the end of the 58-day feeding trial; *p<0.05.

Following the pattern observed for biomass, a nonsignificant decrease in FCR was observed (Fig. 3), from 1.4 in the control group to 1.34 in the Olpheel Eat group. This difference was nevertheless significant too in terms of homogeneity between the five replicates. These combined results suggest that Olpheel Eat could lead to higher homogeneity in shrimp feed intake, stimulating individual shrimp feeding behavior, and leading to more consistent productivity for shrimp farmers, as observed in Phodé Laboratories farm experience.

Conclusion

The results of this study indicate that a neurosensory additive, Olpheel Eat Shrimp, could effectively enhance feed attractivity and palatability by maintaining a homogenous feed intake even after storage time. Further studies should be carried out to evaluate this effect in more challenging conditions.

More information:

Amine Chaabane

Species & Product Manager –Aquaculture

Phodé Laboratories

E: achaabane@phode.fr

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 29

PLANT EXTRACTS

Use of selected polyphenols to improve fish reproductive performance

Joseph Bernot, Paul Engler, Nor-Feed

Current farming conditions:

Why do they generate stress?

Compared to livestock species, the domestication of most fish species for aquaculture is recent. The rapid progress in nutrition and genetic selection lead to great improvement in growth rates in aquatic species. The trade-off of these increased metabolic rates is a proportional increase in harmful radical species production. This results in heightened pressure on the organism. This can lead to an imbalance between radical species and antioxidant defenses, known as oxidative stress.

Free radicals and oxidative stress

Free radicals are molecules or atoms with unstable electron pairings. Most are produced at

the mitochondrial level via the respiration chain. Free radicals play an important role in the body in gene regulation, cellular signaling, and apoptosis. However, when present in excessive amounts, they attack surrounding molecules to scavenge their electrons, causing damage to macromolecules such as lipids, proteins, and nucleic acids. When mismanaged, it results in visible impacts on performance, immunity, and meat quality. This is why the antioxidant system exists.

The role of an antioxidant

Antioxidants are molecules stable enough to donate an electron to a free radical, thereby neutralizing it. They can thus terminate chain reactions caused by free radicals. In other words, they act as “bodyguards”

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 30 PLANT EXTRACTS

PLANT EXTRACTS

of the cellular constituents. The antioxidant system is a complex organization of several types of defenses and a distinction is made between endogenous antioxidants, produced by the body, and exogenous antioxidants, obtained through diet. Endogenous antioxidants include enzymes, such as superoxide dismutase (SOD), glutathione peroxidase (GPX), or catalase (CAT), which need trace element co-factors to be functional (the most well-known one being selenium for the GPx). Exogenous antioxidants mainly include vitamin E, vitamin C, polyphenols and carotenoids. Contrary to most endogenous defenses, these do not require co-factors to be functional. Each antioxidant acts in a specific way, positioned at different locations within the cell, blocking oxidative chains at different points. They interact with each other, and some can regenerate others, acting like a team. Because of this intertwining of actions and synergies, diversification of antioxidant sources leads to better protection than the use of a single type of antioxidant.

Bringing back vitamin P

Amongst the huge variety of potential antioxidant defenses, polyphenols stand out for being particularly rich in powerful candidates. This large family of bioactive molecules has been extensively studied for nearly 50 years. Their most active subfamily, flavonoids, was however discovered nearly 100 years ago, when realizing they could potentiate the activity of vitamin C against scurvy and earned them the name of "Vitamin P" for close to half a century.

Polyphenols are a huge chemical family with a wide chemical structure range. This means that despite sharing some common ground, their activity also varies widely. Among the most powerful sources of active antioxidant polyphenols, polyphenols found in grape extracts are of particular interest due to their high concentration and their ability to regenerate vitamins E and C, increase endogenous antioxidant production, and directly neutralize free radicals.

While natural composition and yield can vary a lot, using a characterized and standardized grape extract such as Nor-Grape 80®, developed by Nor-feed, guarantees consistency of composition at the same time as an optimized profile of flavonoids for optimal bioavailability and activity.

Reproduction is oxidative

Oxidative stress is more pronounced during periods of high metabolic activity, such as smoltification, shrimp molting periods, etc. High temperatures promote faster metabolism and increased production of free radicals. In general, any situation that does not allow an organism to be in its optimum comfort will result in increased oxidative stress.

Reproduction also entails intense metabolic activity in fish. The evolutionary strategy of producing numerous gametes to ensure the survival of a few descendants capable of reproducing themselves requires significant mobilization of nutrients and energy. The result is increased production of free radicals during gamete production. Recent research has highlighted the complex relationship between oxidative stress and the processes of egg and sperm production. High levels of oxidative stress can lead to a decrease in the number of viable fertilized eggs and developmental abnormalities in offspring.

Nor-Grape 80 in trout broodstock to improve the next generation’s performance

To enhance antioxidant defenses, several trials have been conducted on different species at different times using Nor-Grape. A study was notably conducted on rainbow trout breeders to determine the effect on reproduction and the potential effect on the N + 1 generation. The trial was conducted at the PEIMA station (Inra, France) and compared 260 rainbow trout separated into 2 groups of 80 females and 50 males each receiving either a control diet (“CTL”: classic feed, 200ppm vitamin E) or a supplemented feed (“NG”: CTL + 80ppm Nor-Grape 80) during the whole gametogenesis. Eggs were then collected and fertilized with the semen of males from the same group. Fertilized eggs were then incubated and the resulting fry from both groups were raised for 8 weeks. Fry from both groups were fed the same diet, without Nor-Grape.

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 31

PLANT EXTRACTS

Growth performances (weight gain, FCR, mortality) of fry were recorded, as well as several reproduction parameters (egg weight, percentage of ovulating female, embryonic survival, post-resorption survival). While no significant differences were observed between the two groups of breeders in terms of ovulation rate, eggs tended to be bigger in the NorGrape group. Moreover, the relative embryonic and global survival rates tended to be improved in batches obtained from supplemented fish. Finally, fry obtained from supplemented breeders had a faster growth as evidenced by a significantly higher average weight at 6 weeks (+4.7%, p<0,01, t-test) and 8 weeks (+5.2%, p<0,01, t-test).

Enriched eggs

To delve deeper and understand the reason for this performance improvement, analyses on the eggs of the supplemented groups were conducted. Analysis of the quantity of dry matter showed a significant increase of 3.1% in the dry matter content for the supplemented group, thus evidencing that the larger egg size was not due to higher water content, but rather to a higher deposition of nutrients for the embryo development. This in turn provides a good explanation for the higher survival rates and faster growth rates post-hatch and resorption in the fry from the supplemented group.

Conclusion

Further studies have been conducted with Nor-Grape in various species. This is also the case in whiteleg shrimp

where the supplementation of broodstock was shown to increase the number of eggs and consequently of nauplii produced per spawn (+5.2%), thus improving the profitability of the hatchery.

Overall, mismanagement of oxidative stress around reproduction may lead to altered reproductive performances. The supplementation of Nor-Grape in broodstock has shown a beneficial effect on the prolificacy of breeders and on the next generation’s performance, resulting in faster growth, despite not being supplemented themselves. This example thus shows how targeted and specific nutritional intervention in broodstock can help reduce the bottleneck of reproduction for higher fry quality and better prolificacy in aquatic species.

References available on request

More information:

Joseph Bernot

Aquaculture Technical Manager

Nor-Feed

E: joseph.bernot@norfeed.net

Paul Engler

PhD; Aquaculture R&D Manager Nor-Feed

E: paul.engler@norfeed.net

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 32

Figure 1. Progeny performance

From field to fin: The soypowered future of aquaculture

Tom D’Alfonso, Morgan Cheatham, USSEC

Aquaculture accounts for more than 50% of total global seafood production volumes, and aquaculture production volumes are increasing at a rate of 3.3% globally (FAO, 2024). Meanwhile, capture fisheries volumes have remained relatively constant for decades, and have declined slightly in recent years. Demand for seafood products will continue to increase with the increasing global population (FAO, 2023; IFFD, 2024). By 2050, global demand for protein will increase by 20%,

leading to a corresponding rise in demand for seafood. The FAO predicts that aquaculture production volumes will reach 140 million metric tons (MMT) by 2050, which means that aquafeed production volumes will also minimally double during this time (FAO, 2024). The aquaculture industry will have to find alternative protein sources for feed production to achieve this growth sustainably. Soy products are well positioned to play a key role in this effort.

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 34

PLANT-BASED INGREDIENTS

PLANT-BASED INGREDIENTS

Transitioning to sustainable feed sources

Moving away from a reliance on marine-derived ingredients has been a priority for the aquaculture industry for decades. Plant proteins are already the most used ingredients in aquafeed production globally. Soy has been a key ingredient used to replace marine ingredients in aquaculture, and its use has played a critical role in the aquaculture industry’s rapid expansion over the past two decades. Soy is a highly digestible protein source for aquatic species and presents advantages throughout the supply chain to ingredient purchasers, feed millers, and fish producers.

Advantages of soy in aquafeed

Using quality protein sources in aquafeed formulation is essential for the performance and, ultimately, cost efficiency of feeds. Access to a consistent, non-seasonal supply of one protein source benefits a feed miller who will not have to modify formulations regularly to account for variability in ingredient availability. Using soybean meal with consistent protein, amino acid content, and digestibility reduces, or sometimes eliminates, the need for safety margin used in feed formulation. Undamaged soybeans of consistent quality before crushing provide this advantage. This consistency reduces the cost of feed production, which is a saving that can then be passed down to the end user. Soybean meal is also easily stored in

bulk at the feed mill, eliminating the need for multiple ingredient storage containers and increasing feed mill organization and efficiency. It is also a commonly and easily shipped cargo.

Nutritional and operational benefits

Soy is a protein-rich, low-cost feed ingredient suitable for inclusion in the diets of many aquatic species. The amino acid profile of soy protein products matches that of many finfish and crustacean species, and these amino acids are generally highly digestible and available to the fish. The benefits of soy extend beyond protein and amino digestibility to energy content. An example is the sucrose levels of U.S. soy, which are significantly higher than soy of other origins. The increased energy content can greatly benefit fish with high metabolic demands.

Enhancing sustainability with soy

Improved environmental sustainability is yet another benefit of soy utilization in aquaculture. U.S. soybean yields have increased by over 100% per hectare since 1980. This yield increase has improved land use efficiency by 48%, while U.S. forestland has increased by 742 thousand hectares and cropland has decreased by 3.6 million hectares over the last twenty years. This differentiates U.S. soy from soy of other origins and is an increasingly important consideration for those purchasing soy products. Soybean farmers in

Aquafeed: Advances in Processing & Formulation Vol 16 Issue 2 2024 35

PLANT-BASED INGREDIENTS