PLANT-BASED INGREDIENTS

Disease prevention and management

Novel ingredients

Sustainable aquafeeds

PLANT-BASED INGREDIENTS

Disease prevention and management

Novel ingredients

Sustainable aquafeeds

SINGLE-CELL PROTEINS IN AQUAFEEDS 23

A review summarizes how Methylococcus capsulatus is a suitable replacement for animal protein in aquafeeds.

SOYBEAN PEPTIDE IN FISH-FREE FEEDS 36

Soybean peptide products from the fermentation of dehulled full-fat soybean or soybean meal can replace fishmeal in different species.

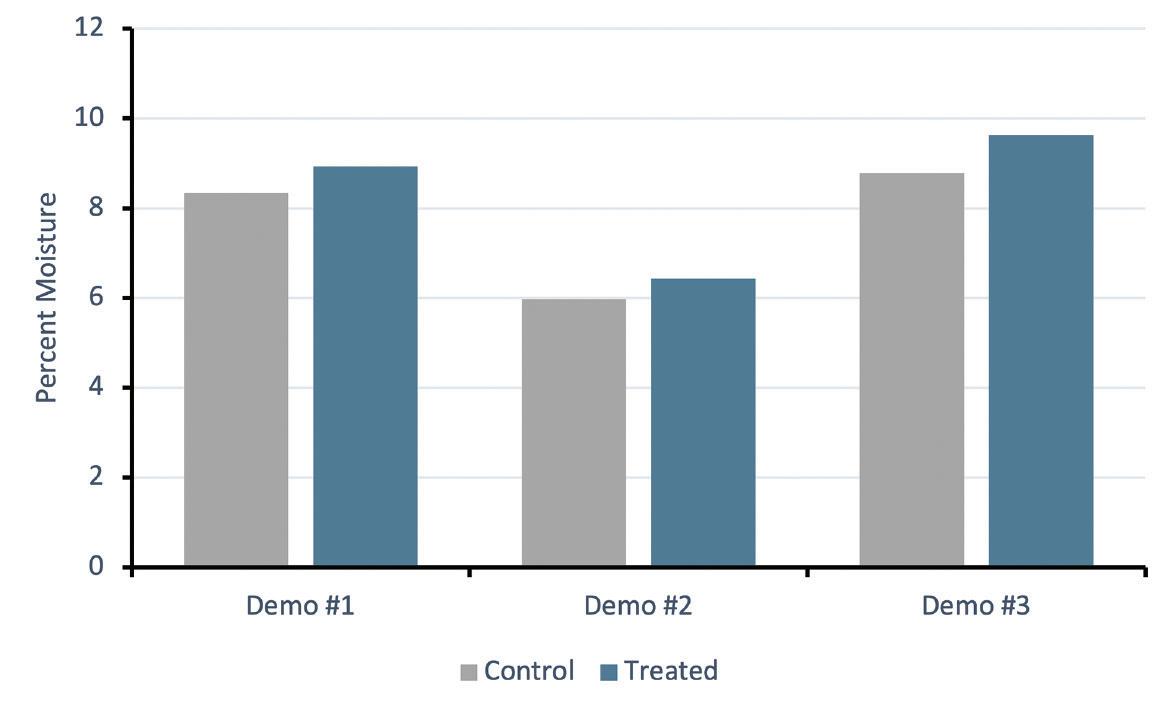

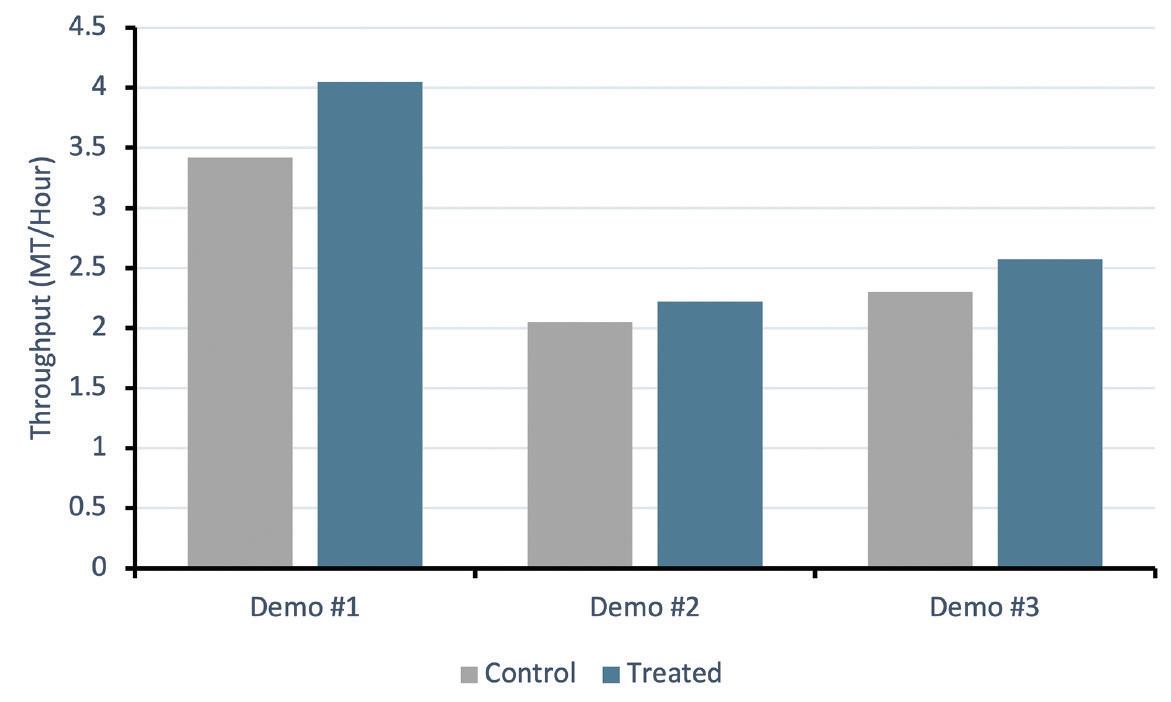

MOISTURE RETENTION IN AQUAFEEDS 45

How to optimize the inclusion, penetration and retention of moisture within aquafeed formulations during extrusion.

Lucía Barreiro

Consulting Editor: Suzi Dominy

Technical Editors: Peter Hutchinson, Albert Tacon, Ph.D

Assistant Editor: Marissa Yanaga

info@aquafeed.com

There is a prominent section in the program that focuses on fish feed for the first time, focusing on circular aquafeed solutions for the sustainable development of EU aquaculture. As speakers, the conference will have Brian Thomsen, chair of the EU Aquaculture Advisory Council and Yngve Torgersen, director general of the Norwegian Department of Aquaculture. Registration to the FEFAC 30th Congress is open until February 28, 2023. We talked with Alexander Döring, FEFAC secretary general, to get some insights on what to expect in the aquafeed field.

AQ: FEFAC has been recently discussing the potential of nutrient recovery through animal nutrition and the role of circular feed will the key topic of the 30th Congress. What are FEFAC suggestions specifically for aquafeeds?

FEFAC, DAKOFO, and FS, representing respectively the European, Danish and Swedish feed industries, are jointly organizing the 30th FEFAC Congress from June 14-16, 2023 in Ystad, Sweden. The conference theme is dedicated to the Resilience of Sustainable EU food production systems – Role of circular feed.

Considering the current EU energy crisis debate on EU food security and resilience of the EU agri-food chain, the congress explores how the European feed industry can assist the livestock and aquaculture sectors in meeting the EU Green Deal and sustainable food systems targets while providing affordable foodstuffs of animal origin to citizens.

AD: Indeed the contributions of the feed sector to enhance nutrient recovery have been a key feature of FEFAC communication on sustainability and in particular, the role of circular fish feed in the sustainable development of aquaculture in recent times. As a member of the Aquaculture Advisory Council, FEFAC’s Fish Feed Committee experts are contributing to the exchange of views with value chain partners and competent European Commission authorities to develop professional recommendations for the transition process. We have developed a conceptual approach to what circular fish feed may provide, including parameters such as a low land use ratio, a non-food grade status and a good FIFO (Fishin-Fish-Out) ratio. All value chain actors will benefit from a policy framework with clear, operational definitions, characterization and a single methodology to assess environmental impacts. This approach will facilitate our own sector investments driving circularity in fish feed production, based on the adherence to the EU food waste hierarchy principles to ensure that these circular resources are not diverted to outlets with lower nutrient recovery output, such as bioenergy or fertilizer production.

Taking a future perspective, public authorities should also take an active role in identifying the current bottlenecks, including legal standards, that restrict circularity in feed production. In aquafeed production, it is also worth looking at the potential lifting of prohibitions on the feed use of certain nutrient sources providing they fulfill all relevant feed safety requirements.

Market acceptance will remain a key factor as well in driving circularity, meaning we need the buy-in of the value chain downstream, including the retail sector, that circularity in fish feed production is one of the key elements in further enhancing sustainability in the sector. Insect meal, algae, seaweed and the use of marine ingredients from the lower trophic level are prime examples of this approach and move to more circularity.

AQ: What do you think are the key trends in the next couple of years for the aquafeed industry?

AD: Aquaculture production is traditionally known for having a low carbon footprint per kg of produced animal protein. A key trend that the aquafeed industry will have to cater to is that food production overall will be increasingly asked to also provide data on robust measurable sustainability performance indicators. Most fish feed companies have already started to dive further into their supply chain to obtain information on the fish feed resources production methods. But we have to be mindful that the sustainability claims will increasingly have a legal scrutiny dimension, including labeling.

FEFAC, together with its farmer customers including FEAP, is therefore upgrading the existing joint Code of Good Feed Labeling Practice to cover voluntary information on the environmental impacts of compound feed, including fish feed, and the scientific justification for claims on environmental benefits of circular feeds, using the PEF methodology approved by DGENVI in 2018 and the global LCA Feed database set up by GFLI in 2019.

Wenger.com

Built on partnership and innovation, Wenger is providing more opportunities for client success.

For almost a century, Wenger has delivered extrusionbased innovations to our partners. We’ve worked alongside you to develop new processing solutions and better products, providing our industry-leading expertise and ongoing support every step of the way.

We don’t plan on stopping any time soon.

Wenger’s global food processing family is growing, and we look forward to the exciting opportunities that lie ahead. We will continue to deliver even more innovations and technologies to benefit companies that share our vision of tomorrow.

A key trend that the aquafeed industry will have to cater to is that food production overall will be increasingly asked to also provide data on robust measurable sustainability performance indicators.

Highlights of recent news from Aquafeed.com

Cargill, together with its partner Naturisa S.A., has reached an agreement to partner with Skyvest EC Holding S.A. to create a new joint venture that will serve Ecuadorian shrimp farmers’ increasing demand for high-quality shrimp feed. Through this new joint venture, Cargill will expand its shrimp feed production capabilities to own and operate the shrimp feed production facility currently owned by Skyvest subsidiary Empagran, located in Guayaquil, Ecuador. The feed plant that will be operated by Cargill was built in 2018, has a production capacity of 156,000 metric tons and employs more than 200 people.

Oxiris Chemicals introduced a new aqueous dispersion of BHT, IONOL® AQUA50. The new product has been specifically designed for human and animal nutrition and is safe for all species. IONOL® AQUA50 contains a high concentration of small-sized antioxidants dispersed in an aqueous medium, therefore, it requires a lower dosage than other products to obtain the same results. This product can be added to different types of products, both in oil-based and aqueous formulations.

The company opened a new fish feed factory, Lotus II, in Vietnam. Skretting's second aquafeed facility in Vietnam is located in Long An province due to its proximity to the Mekong Delta, which is regarded as the cradle of Vietnam’s seafood industry.

The new factory is the “most modern and largescale factory in Vietnam”, according to the company. Located in an area of 20,800 m2 and built in the shape of a tall tower – a symbol of new heights – the USD 24-million factory has

INVE Aquaculture and the Singapore Food Agency (SFA) signed an MoU to jointly set up SFA-INE Hatchery Technology Centre at SFA’s Marine Aquaculture Centre (MAC). The proposed center will bring together SFA’s expertise in hatchery design and production for tropical marine species, as well as INVE's knowledge of specialized fish nutrition for early developmental stages. SFA and INVE scientists will jointly research to develop advanced hatchery technologies. The center will also serve as a training hub for farmers from Singapore and the region for knowledge transfer.

At AquaExpo 2022, the company introduced two innovations, a mobile automatic feeder and a high-precision shrimp counting service, that will be on the market in 2023. In addition to nutritional solutions, for the past few years, Nicovita has been complementing its value proposition with a portfolio of digital and technological products and services, and expert

The company opened a USD 6-million Aquaculture Innovation (AI) Guayas Research Station in Guayaquil, Ecuador that aims to advance more sustainable and innovative feeds for the shrimp farming industry. The center will study all stages of shrimp production, from larvae to harvest-size animals. The research will include health and welfare topics, as well as growth and feed efficiency. Another area of interest will be the digestibility of new and existing feed ingredients and balanced diets.

advice providing comprehensive solutions tailored to the challenges and needs of producers.

Adisseo has signed an agreement to acquire NorFeed and its subsidiaries, a French group that designs, manufactures and markets plant-based specialty ingredients and plant extracts for animal nutrition. This investment will allow Adisseo to continue its strategy of developing specialty ingredients, by offering natural and sustainable solutions to its customers, positioning itself in a market with an annual growth of almost 10%. Nor-Feed focuses on the preventive role of nutritional strategies by promoting botanical extracts from agricultural coproducts in animal nutrition and hygiene, to limit the use of antibiotics, coccidiostats, and pesticides.

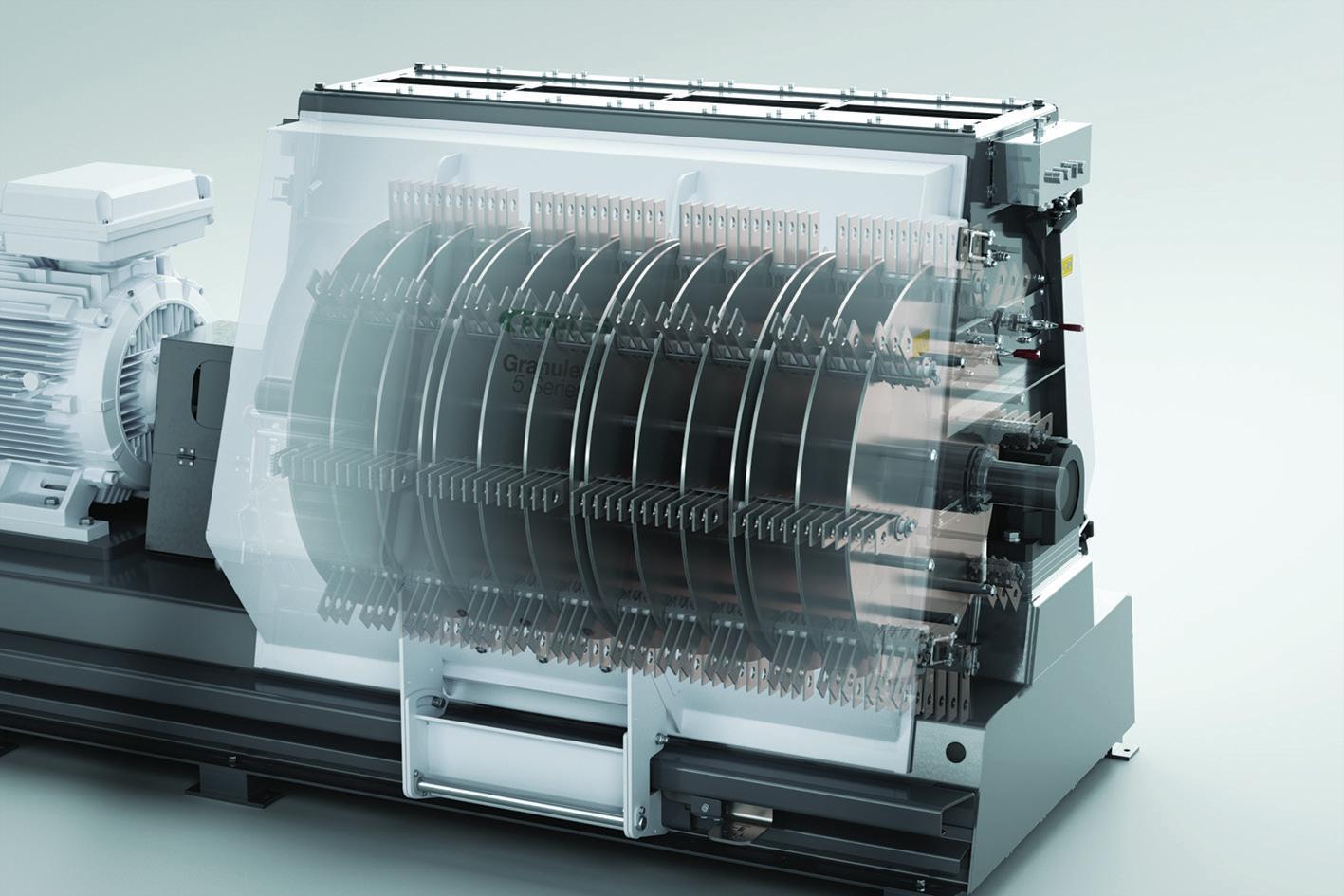

The company unveiled Granulex® 5 series, a new hammer mill platform that allows 10-30% reduction in energy consumption per ton. It also has high throughput ranges, an improved granulation profile, and an operator-friendly design.

The hammer mill aims to optimize the grinding process to avoid over- and under-griding. Capacity is increased by 10% – up to 120 tons per hour – and the time required for screen changeovers is reduced by 50%. The finest particle size achieved is 100-150 microns. The new solution can also be connected to Bühler Insights to enable nonstop data-based decision-making.

In 2022, geopolitics took center stage significantly impacting the global economy. This, together with high inflation, has slowed down the recovery at a time when the industry continues to struggle to stabilize after the pandemic. In this context, Aquafeed.com talked with feed companies, ingredients and technology suppliers about the 2023 expectations.

Credits: Cargill

In the current context, a first look should be made at protein demand. Rising inflation may have implications downstream in the supply chain. Changes in the consumers’ demand directly affect upstream operations –matching supply and demand is of paramount importance – and feed companies are aware of this, making distinctions between regional trends. “Demand for certain animal proteins might be reduced in some developed countries, but in areas where food security may be a greater risk, fish, poultry and pork remain important to consumer diets. Livestock and aqua farmers are needed now more than ever to

ensure global nutritional demands are met,” said PierreJoseph Paoli, president, Feed Additives & Ingredients, ADM Animal Nutrition.

Inflation had a strong impact, especially on feed ingredients’ prices. “The impacts can be very different from region to region, with Europe suffering additional inflation pressure due to elevated energy costs, apart from the inflated ingredient prices. Many feed mill customers expect some of the ingredient prices to come down in 2023 but there is great uncertainty on

when and how much. Most of us believe that prices will remain far higher than ‘normal’,” said Peter Coutteau, business unit director aquaculture at Adisseo.

As part of the solutions to cope with these high prices, novel ingredients are an alternative to add to the raw material basket and allow feed producers better adapt to the market dynamics. For example, “algal omega-3 oils were more attractive in 2022 due to the tremendous shortage of fish oil globally,” Coutteau said. More novel ingredients are coming online in 2023. Another trend in Europe was the return of Processed Animal Proteins (PAPs) into the feed in 2022, albeit at a limited scale due to all kinds of restrictions, such as the non-cannibalism principle, Huvepharma stated. Some suppliers have already implemented cost control measures to limit the knock-on effects of external forces, such as inflation and rising supply chain costs.

“We have also had to introduce price increases that are necessary to maintain production capabilities and fund innovation needed to ensure adequate supply for our customers today and develop future breakthroughs that will add value for them while decarbonizing the feed and food value chain. While in the short term this

is an effective solution, we know that this doesn’t fix the underlying vulnerability of global supply chains. As such, we’re looking beyond the horizon and investing in ensuring our supply chains are robust and diversified,” Benedict Standen, head of marketing aquaculture global at DSM Animal Nutrition and Health, explained.

At the same time, climate events have been affecting commodity yields. In marine ingredients, no changes in fishmeal yields worldwide have been reported, whereas yields of fish oil have been varying in different parts of the world reflecting local oceanic conditions, Martin Johannessen, director general of IFFO, explained.

“Climate events increase the risk of crop loss at harvest, and along the post-harvest supply chain. Studies estimate about 5% to 30% of global agricultural crops produced are damaged, lost or wasted annually along the post-harvest supply chain,” said Saravanan Subramanian, global programme manager aqua at Selko Feed Additives, who suggests improvements in the supply chain to cope with climate change.

In times of scarcity and volatility, flexibility is key, making sure not to be dependent on one ingredient, supplier or region. “The industry should take a step

back and reflect on how it contributes to climate change, and how it can drastically and rapidly reduce its carbon and other environmental footprints, as well as social impacts. This is so that it can reduce climate events from happening in the first place, as well as their severity when they do happen,” Therese Log Bergjord, Skretting’s CEO, stated.

Supply chains have been disrupted across the globe during the pandemic and also after. “During the pandemic, the vast majority of purchasing companies followed ‘just-in-case’ buying to secure supply and build inventory due to high uncertainties. In the second half of 2022, we observe the supply chain is becoming more stable and better managed and freight costs are coming down. But on the other hand, rising inflation means one must have better control of inventories and thereby working capital. In 2023, I expect the industry will cautiously move back to ‘just-in-time’ buying practices to rebalance the risk from the supply chain to manage financial risk,” Subramanian explained.

In 2022, aquafeed companies have been looking for more sustainable solutions. “There is a strong focus in the industry on energy conservation, sustainability, and process optimization. As these elements are all tied together, we see customers looking for suppliers that can offer complete solutions. Additionally, business owners are looking for companies that can not only provide equipment and services but also can contribute to the optimization of the entire process,” Gunnar Hallmann, industry director Aqua & Pet at Andritz, mentioned. Geopolitical tension in Europe is creating an energy crisis and EU feed companies and technology suppliers are taking action to address this. “The current situation in Europe has caused some new developments in the market. People are looking for alternative energy sources to ensure production continues in the event of energy supply changes,” said Hallmann. “With the rise in energy costs and the priority on sustainability, customers are willing to invest more to ensure that energy is reused, recycled, or utilized in another way. An example is the use of excess heat in the production processes, which often accumulates under the roof of the building. There are practical ways to capture and reuse the energy, either to heat other areas of the factory or to preheat the air going into the dryer.”

The challenge while increasing efficiency is that it requires a significant financial investment. “Efficiency is the simple yet effective way for sustaining the feed mill industry, being efficient is not the same as stopping spending. Essential spending will still need to be done,” Albert Wang, sales manager at Idah, said. “In Asian countries, the point of efficiency lies in the introduction of new production technologies to shift feed production from a labor-intensive to a more automated process. European markets have matured and fully developed, but with the energy crisis, industrial practitioners need to find ways to be efficient with energy usage, not only from a cost perspective but also an environmental (carbon footprint) view.”

Farmers have been adapting their production to the changes downstream but they are also expressing concerns that higher feed prices, driven by higher ingredient costs and other inflationary pressures, are impacting operating costs and margins. What are the mitigation measures farmers can adopt to reduce the impact of inflation? Stakeholders suggest increasing feed efficiency and formula optimization.

“Feed is the animal farming sector's biggest cost in a world that is set up for the lowest costs. The rising prices of feed ingredients have been narrowing the margin between production costs and selling prices in many regions. In such a scenario, improving feed conversion ratios is of paramount importance for both feed producers and farmers,” said Johannessen.

“In times of high ingredient prices, it becomes even more important for the farmer to minimize the amount of feed that goes to waste, both the uneaten feed and the undigested feed. The latter has both direct and indirect costs. More efficient diets not only yield lower FCRs but they reduce the requirement for aeration, water treatment, etc.,” said Mark Rowel Napulan, Asia sales manager at Zeigler.

Coutteau also supports this idea. “We focus a lot of our research and customer support on improving the digestive and metabolic efficiency of fish and shrimp. Through the use of digestive aids, our feed mill customers are able to get more out of the currently available ingredients and provide better cost-efficiency to their farm customers,” Coutteau explained. Check out the full story on Aquafeed.com

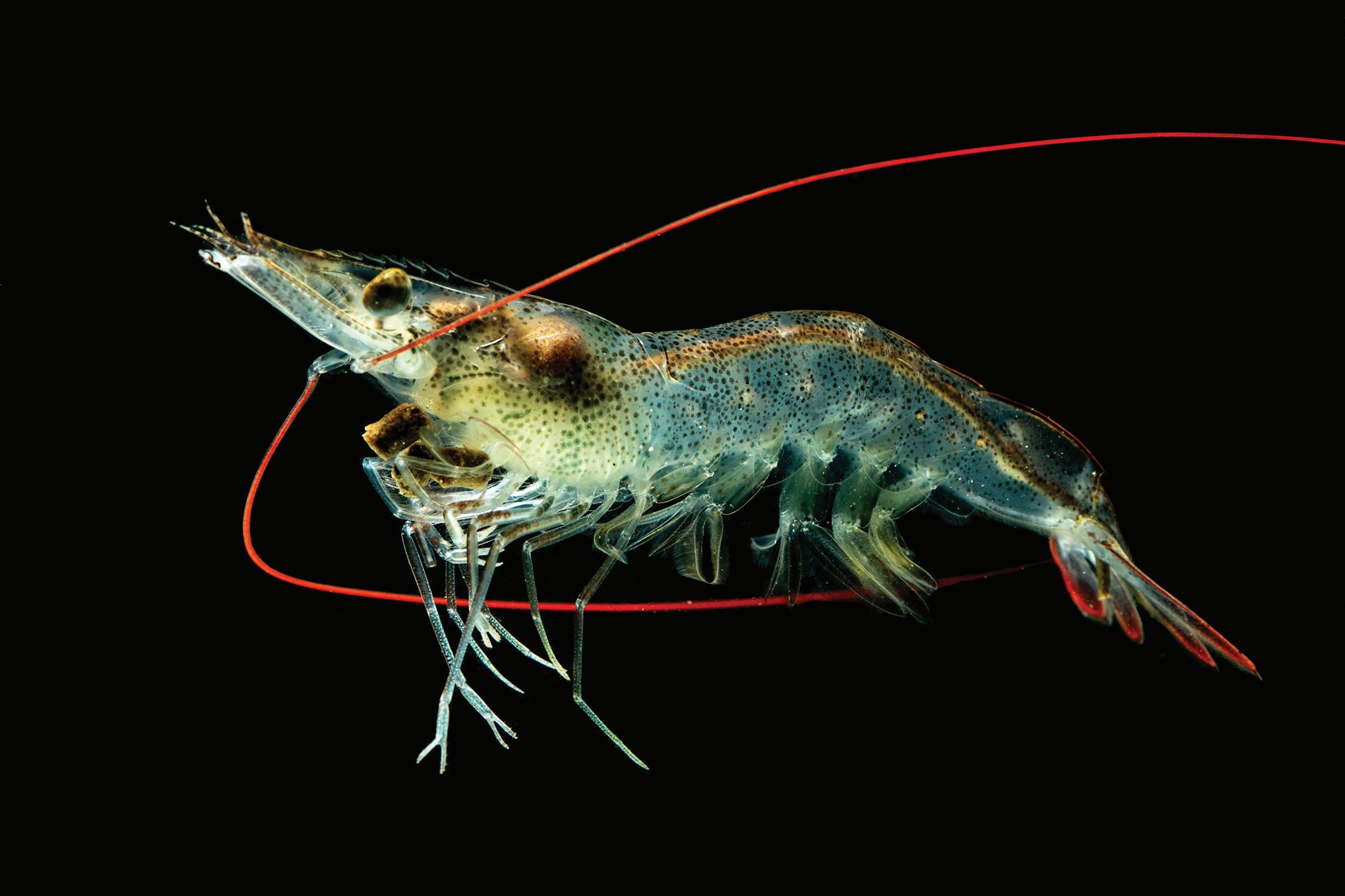

The immune system, in general terms, is founded in three major “control barriers”, namely the “physical barriers” or first line of defense, the innate immunity based on the recognition and destruction of pathogens without specific “memory” against them, and the “adaptative immunity”, in which the host fights against microorganisms through pathogen-specific actions. This adaptative barrier is not present in shrimp; therefore, immunocompetence is greatly supported by the activation of hemocytes as a major part of the innate response.

When a pathogen gets in touch with the host shrimp, it is recognized by receptors located in the membranes of hemocytes and cell tissues. After this first recognition, a series of complementary responses are unchained, including phagocytosis, apoptosis, nodulation, encapsulation, melanization, clotting, and production of antimicrobial peptides (AMPs). Two types of AMPs exclusive to shrimp are penaidins and crustins.

• Penaidins have a strong antimicrobial action against gram + bacteria and fungi, and opsonic activity against gram – bacteria, releasing a signal to activate phagocytosis by hemocytes.

• Crustins present antimicrobial activity against both gram + and -, and opsonic activity to help in the phagocytosis of bacteria by hemocytes. AMPs play a crucial role in supporting shrimp survival under infection. Therefore, by promoting the effective production of key AMPs, we can stimulate a faster and

better-coordinated response, thus increasing survival and productivity.

Co-infections caused by bacteria and virus (e.g. Vibrio spp. + White-Spot Disease Virus (WSDV)), or by bacteria and parasite (e.g. Vibrio spp. + Enterocytozoon hepatopenaei (EHP) such as White Feces Syndrome (WFS)) are common in shrimp farming. It has been demonstrated that shrimp previously exposed to WSDV are more easily infected by Vibrio parahaemolyticus (VP) (i.e. causative agent of Acute Hepatopancreatic Necrosis Disease (AHPND)) and shows a suppressed capacity for recovery (de la Peña et al., 2017). In addition, WSDV infection can be accelerated and exacerbated by the secondary AHPND infection (Han et al., 2019). Therefore, not only can WSDV shrimp easily develop AHPND, but shrimp infected with the two pathogens at the same time will face a reduced recovery rate and higher mortality. AMPs including crustins and penaidins have been identified as an important humoral defense mechanism in co-infections such as the WFS (Tassanakajon et al., 2017).

Co-infections can only be minimized from a preventive approach in shrimp aquaculture – there is no other option for success: single bullets will no longer be effective in multifactorial disease scenarios. The first approach to control multiple infections is based on improved farming and biosecurity practices. On-farm biosecurity should consider high PL health status, as well as control of active and passive vectors. A second approach is to reinforce prevention

strategies via functional nutrition devoted to supporting immunocompetence and gut health/integrity and reducing the impact of systemic infection.

This article presents the efficacy of a phytobioticbased functional additive (Sanacore® GM) towards enhancing shrimp immunocompetence through the promotion of antimicrobial peptides (AMP) as a mechanism to reduce the severity of co-infections and therefore enhance survival and productivity. Laboratory and field trial data are presented to demonstrate the efficacy of the additive under two different co-infection scenarios.

Sanacore®GM stimulates AMP production and improves shrimp survival under co-infections

A laboratory trial evaluated the effect of Sanacore®GM to boost penaidin and crustin production in shrimp and improve survival under a co-infection challenge based on WSDV and VP.

Shrimp specimens below one gram were stocked in tanks and fed with a preventive dose of the additive for 28 days. At the end of this period, shrimp hepatopancreas of nine shrimp per group was sampled for gene expression analysis of penaidins and crustins (Soonthornchai et al., 2010; Rahimnejad et al., 2018). Subsequently, a total of 21 shrimp per treatment were selected in triplicate groups and subjected to WSDV infection, followed by VP infection two days after (Han et al., 2019). Infection by WSDV aimed to weaken shrimp, while the subsequent infection by VP triggered mortality. Mortality was monitored for 24h after infection.

Results showed a statistically significant increase of three times and seven times in the expression of penaidin and crustin (Fig. 1), respectively, in shrimp supplemented with Sanacore®GM. Penaidins and crustins have proven antimicrobial effects against VP (Mai et al., 2021). Interestingly, increased AMP expression was correlated with a numerically 40% improvement in the survival rate at 6-12 hours after the co-infection challenge (Fig. 2).

These results confirm that additive supplementation supports immunocompetence and enhances protection against co-infections.

A field test evaluated the efficacy of Sanacore®GM to reduce the impact of co-infections in a shrimp farm located in Bratasena Lampung (Indonesia). During the previous four crops, ponds tested positive for EHP and showed water Vibrio load over 102 CFU/ mL along with typical signs of WFS. Historical data of the previous four crops was compared with the current crop under two application strategies of the additive in feed:

1)a strategy based on preventive supplementation at a low dosage from the start of the cycle combined with corrective supplementation at a high dose during the high-risk period (around DOC 25), and 2) only corrective at high dose during the high-risk period. A total of 10 ponds were selected for each application strategy. Historical farm data were used only for comparison purposes and were not included in the statistical analysis. Independent t-test was used to assess the difference in efficacy between the two application strategies.

Survival was improved by 58% and 169% by the corrective and the combined preventive and corrective strategies, respectively, as compared with historical data (Table 1). The preventive use of Sanacore®GM resulted in an additional and numerical improvement of 48% in relation to only the corrective application.

Feed conversion ratio (FCR) was also improved by supplementation; corrective application showed an improvement of 11% in relation to previous crops, while the combined preventive and corrective strategy resulted in an additional and significant 21% improvement (Table 1).

Overall, the corrective strategy improved the pond biomass by 10% when compared to previous crops, while the combined preventive and corrective strategy achieved a 64% improvement. Remarkably, the use of a preventive dosage resulted in an additional and significant improvement of biomass by 50% as compared with just corrective supplementation (Table 1). These results are in line with previous field evaluations showing that corrective application of the additive reduces the signs of infection, but only preventive supplementation has proved to maximize post-outbreak growth rates. Sanacore®GM increased feed cost per ha when compared to the farm’s historical data, but this investment was well paid off by the biomass gain and economic returns. The return on investment (ROI) calculation indicated that for each US dollar invested in the additive application, USD18 and USD40 were additionally gained for the corrective and combined preventive and corrective strategies, respectively.

The present article demonstrates the efficacy of the phytobiotic-based additive Sanacore®GM to support shrimp survival and productivity under co-infection challenges. An important mechanism of the additive to promote immunocompetence and reduce the impact of infections is via increased production of AMPs. Preventive application of the additive seems to be a more successful strategy to modify the course of the infection and maximize post-outbreak growth rates. References available on request

More information:

Ruth Garcia Gomez BDM Aquatic Health and Farm Care APAC and ISC Adisseo

E: ruth.garcia@adisseo.com

Shrimp diet supplementation with Kera-Stim®50 induces higher survival rates and confirms observations previously published from monitored experimentations under immune challenges.

Free amino acids are essential in shrimp nutrition and are well known to induce positive effects on different metabolic pathways. From laboratory and field experiences, the application on shrimp feed of Kera-Stim®50 a mix of 17 free amino acids (MFAA), obtained from extensive hydrolysis of poultry keratin, generates direct benefits on zootechnical performances and is a regular source of survival improvement in normal sanitary conditions. These survival improvements are significantly higher in the case of immune challenges with viral and bacterial pathogens. Effectively, in two previous studies conducted in

partnership with Concepto Azul-Incabiotec, Peru, and published in Aquaculture International (Kersanté et al., 2021), we have shown that free amino acids supplementation strongly improves shrimp survival under monitored White Spot Syndrome Virus (WSSV) and Acute Hepatopancreatic Necrosis Disease (AHPND)infections.

More recently, during a zootechnical trial initially focused on growth performances, we faced a natural WSSV infection that occurred after a strong water temperature drop induced by external meteorological factors. Interestingly and in correlation

with our previously monitored investigations and field information, animals fed with Kera-Stim®50 supplementation showed a better response to this sanitary event with a significantly higher survival rate and biomass production.

After a pre-growing step of four weeks in raceway systems, nine hundred and sixty juvenile Litopenaeus vannamei shrimp of 1g initial body weight (weight variation < 10%) were placed in twelve tanks of 1000 liters at 80 shrimp per tank, in quadruplicates, for a 70-day trial. A premium quality commercial feed (36% protein) was used as a basal diet (Control). Two different concentrations of KeraStim®50 were supplemented and tested: 2.5g/kg of feed (MFAA0.25) and 5g/kg of feed (MFAA0.50). The MFAA was added to the feed by top coating. Shrimp were fed 5 times per day according to the biomass evolution.

Shrimp individual body weight (IBW), biomass, and survival were monitored once a week until the end of the experiment. Data were submitted to ANOVA, and a Duncan test was performed in case of significance (P≤0.05). Statistical analyses were made with the SPSS software.

All the tanks were maintained under continuous aeration (5.54-6.72 mg/L) and filled with the same seawater (29-35 ppt) previously treated in a reservoir with 20ppm of chlorine for 24h, before being neutralized with 10ppm of thiosulfate and strong aeration. We also applied a complementary treatment with 10ppm of EDTA and replaced 75% of the water twice a week.

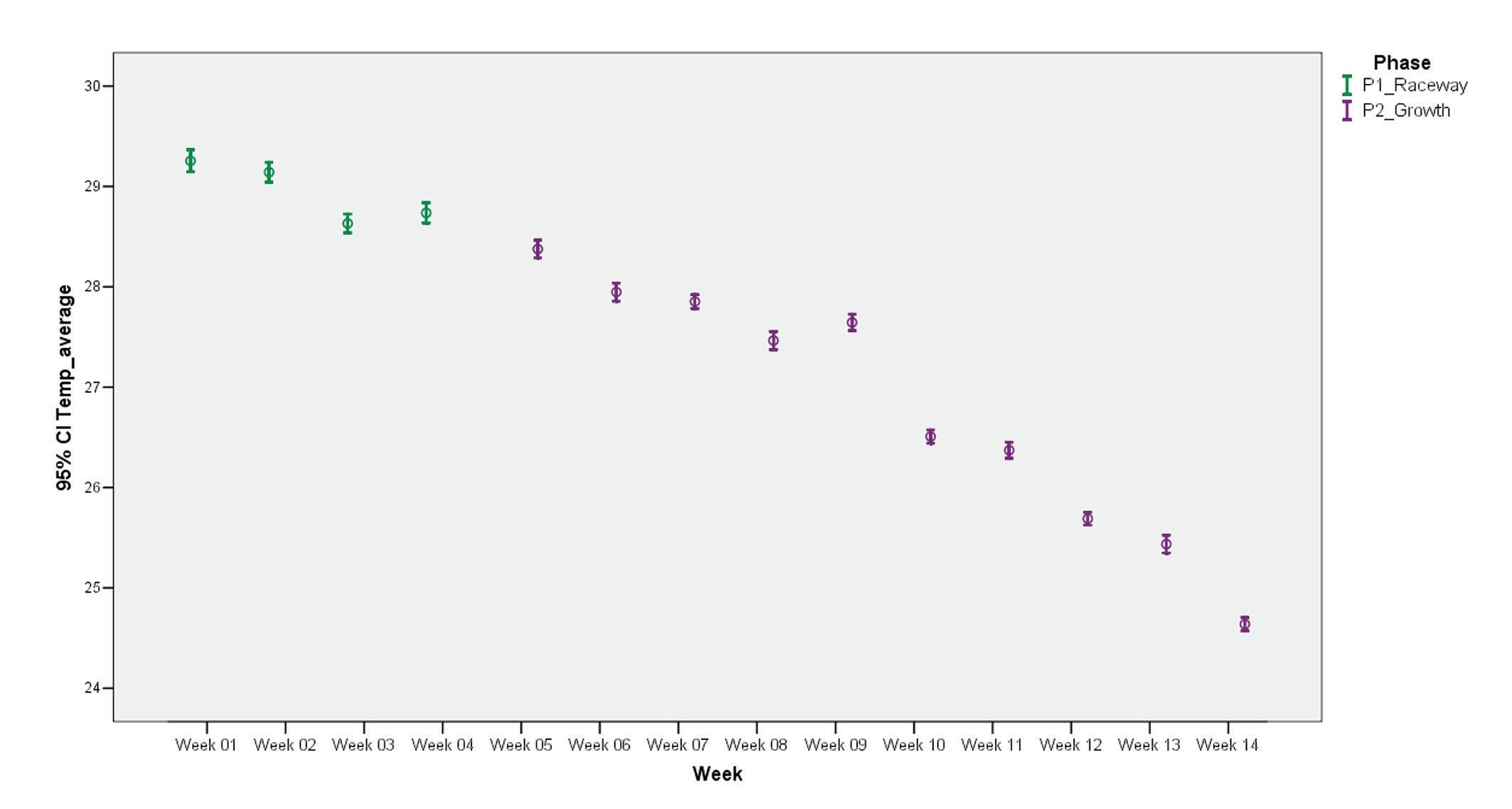

During this trial, we observed a progressive decrease in average water temperatures from 29.3-24.6°C. These changes were correlated to the local degradation of meteorological conditions in our shrimp production area (Northern Peru-South Ecuador). This evolution principally affected the experiment between week 9 and week 10 with a 1.2°C drop within a few days (Fig. 1).

It is important to mention that the shrimp post larvae (PL) used in this trial were purchased from certified disease-free broodstock and analyzed at stocking by Polymerase Chain Reaction (PCR) to confirm the absence of specific pathogens such as White Spot Syndrome Virus (WSSV), Acute Hepatopancreatic Necrosis Disease (AHPND), Necrotizing Hepatopancreatitis (NHP) and Infectious Hypodermal and Hematopoietic Necrosis Virus (IHHNV). Despite these sanitary precautions, abnormal mortalities were observed in all treatments

from week 9 until the end of the trial. Survival evolution was strongly correlated with the diminution of water temperature. Such “winter outbreaks” are frequently reported by Ecuadorian and Peruvian shrimp farmers during this period of the year. Subsequent nested PCR analysis performed on dead and moribund animals revealed the presence of WSSV at the first and second step PCR.

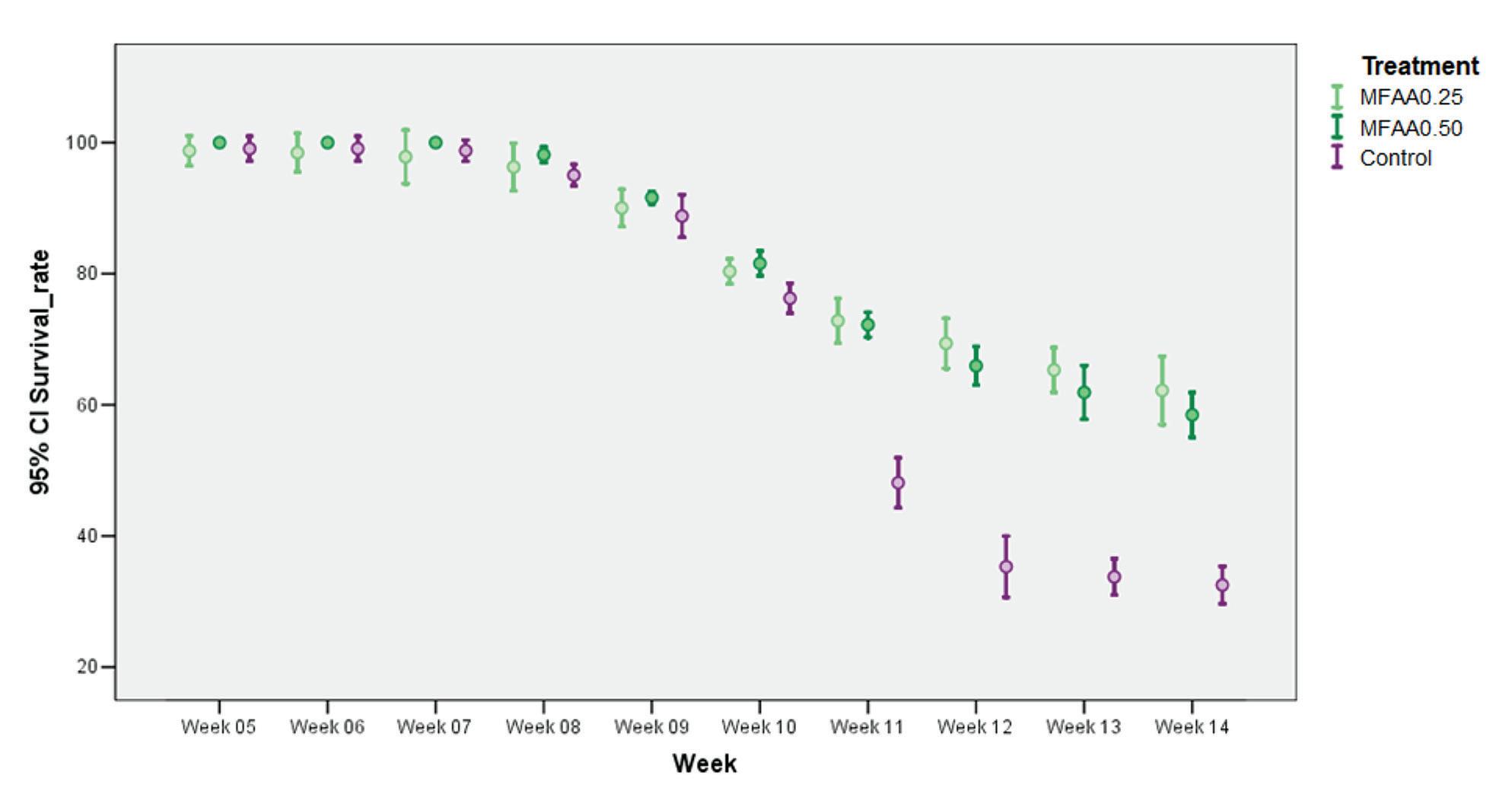

WSSV outbreak principally affected the shrimp fed with the control diet whereas shrimp fed with MFAA treatments offered significantly higher survival

rates, respectively superior by 91.2% and 79.8% for treatments 0.25% and 0.50% of MFAA (Fig. 2).

Logically, the WSSV infection also impacted biomass evolution, following the same kinetic as the survival rate (Fig. 3). Interestingly, we noted significantly higher biomass production for animals fed with MFAA treatments and these improvements were respectively 97.2% and 83.6% for treatments 0.25% and 0.50% MFAA.

Probably due to these challenging sanitary conditions, if individual body weight evolution was in a positive

trend for animals fed with MFAA, we did not underline significant differences between treatments regarding this parameter at the end of the trial (Table 1). Nevertheless, we noted strong and significant improvements regarding zootechnical FCR calculated at week 14, with a respective reduction of 50.8% and 46.3% for treatments 0.25% and 0.50% MFAA (Table 1).

This study offers an interesting picture of what happens at the farm scale when adverse environmental variations hit the cultures. In this particular example, a WSSV natural infection occurred after a strong drop in the water temperature induced by external climatic factors despite a well-monitored water treatment system and tank management. It is important to underline that all farms belonging to the same production area were simultaneously affected by the same conditions with sanitary damages on their production performances.

In these challenging conditions, it is noteworthy that animals fed with Kera-Stim®50 supplementation at 0.25% and 0.50% showed higher significant survival rates and biomass production in comparison with the control feed. We also underlined a positive influence on feed utilization, with a reduction of the zootechnical FCR with MFAA supplementation.

This study confirms previous investigations underlining the positive effects of MFAA on shrimp PL survival in case of bacteriological and viral challenges. Amino acids are essential in shrimp and fish nutrition and their fast assimilation directly improves the response during these sanitary events. We can hypothesize synergetic effects between these different amino acids on different metabolic pathways and synergies between these benefits themselves. Interestingly, MFAA supplementation not only benefit shrimp but also the

carnivorous fish Asian seabass and the omnivorous fish tilapia that present radically different feeding behavior, digestive and assimilation systems (Wangkahart et al., 2022) showing potential for application of MFAA in other aquaculture species. These studies are also in correlation with field observations reported from farm applications, where Kera-Stim®50 supplementation on feed allows to delay and reduces sanitary impacts on production performances. Altogether, these results contribute to a better understanding of the MFAA supplementation effects as an antioxidative agent and non-specific immune response booster.

References available on request

More information:

Pierrick Kersanté

R&D Aquaculture Manager

BCF Life Sciences

E: pkersante@bcf-lifesciences.com

Benoit Diringer

R&D Manager and CEO

IncaBiotec-Concepto Azul

E: diringerb@yahoo.fr

Juan Quimi

R&D

ManagerIncaBiotec-Concepto Azul

E: juange8406@hotmail.com

With its rapid growth trajectory, the aquatic food production sector requires a stable supply of a protein source that is optimal and sustainable, ensuring the growth, health and well-being of farmed animals. The stagnating production of fishmeal (FM), price volatility, environmental impact of reduction fisheries and growing scrutiny on the conversion of food-grade fish to fishmeal and fish oil and discussions over “fish-in fish-out ratios” are issues of concern. Bacteria are advantageous due to their high growth rates and efficient conversion of substrates to proteins. Methanotrophic bacteria utilize methane as a carbon and energy source. The efficient energy utilization of the methanotrophic bacteria in the conversion of methane to protein reduces greenhouse gas emission substantially.

String Bio, a Biotech company’s microbial protein, is manufactured in a sustainable way by leveraging the String Integrated Methane Platform (SIMP). SIMP is an original technology that enables sustainable

manufacturing of products of interest for agriculture, animal nutrition and human food from methane. The SIMP platform is also tuned to produce tailored SCPs of interest.

Single-cell proteins (SCP) from fungal, algal and bacterial sources are considered to have wide applications in animal nutrition and as ingredients for everyday living and are getting more and more attention (Chama, 2019, Ritala et al., 2017). SCPs from methanotrophs (Piper, 2004) are becoming more prevalent due to their generation time and the ability to get a favorable composition of protein than fungi or yeast.

String Bio’s PRODG is a high-quality protein source derived from methanotrophic bacterial fermentation process, with an ideal amino acid profile (Table 1) with >70% crude protein content, 15% carbohydrates, 5% fat and <1% crude fiber. The process of PRODG manufacture is traceable and sustainable (Table 2).

Soybean meal (Plant based) Fishmeal (Animal based) PRODG (Microbial based)

Deciding on the right alternative protein source that is both safe and meets the nutritional requirements of different species of fish and shrimp can be challenging. The nutritional value of the protein is dependent not only on its amino acid composition but also on its digestibility. Validation studies of this specific methonotrophic SCP undertaken with different aquatic animals such as Pacific white shrimp ( Felix et al., 2023), rainbow trout ( Rajesh et al., 2022), yellowtail kingfish ( Pilmer et al., 2022) and barramundi ( Woolley et al., 2023) have demonstrated a significant increase in body weight gain of animals, with good digestibility and feed conversion ratio (FCR) (Table 3) and are found to be a good alternative to FM.

Rajesh et al. (2022) evaluated the dietary fishmeal (FM) replacement potential of the StringBio bacterial protein meal in rainbow trout. Triplicate groups of juvenile rainbow trout were fed five isonitrogenous (49.4–51.1%) and isoenergetic (21–22.1 MJ/kg) diets containing 0, 12.5, 25, 37.5 and 48% of this SCP over 9 weeks. Although there was a reduction in feed intake with high levels of dietary SCP with a consequent reduction in growth, there was no significant difference in the apparent digestibility of protein and the feed and protein efficiency ratios did not differ between dietary groups. The authors concluded that 12.5% of this novel SCP can be safely included in the diets of rainbow trout, as a sustainable substitute for fish meal.

Woolley and colleagues (2023) investigated the effect of replacing fishmeal with this methanotrophic SCP in the diets of barramundi or Asian seabass. They found that the inclusion of SCP significantly improved weight gain and feed efficiency. They also found this SCP to be

highly palatable to barramundi and can replace up to 75% FM in the feeds.

Pilmer et al. (2022) reported that yellowtail kingfish fed a diet containing 10% of this SCP ate less feed, but had equal growth; despite a reduction in feed intake, feed efficiency was equal across all SCP inclusion levels. Their study showed that this SCP can replace 25% of fishmeal in a 400 g/kg FM diet. They also noticed that the addition of palatability enhancers was ineffective in improving feed intake in this species.

A study undertaken with Pacific white shrimp by Felix et al. (2023) showed that the digestibility of the singlecell protein was very high and that this SCP can be used

in the diets of Pacific white shrimp up to 200 g/kg with good growth and nutrient utilization. Nitrogen (N) and phosphorous (P) gain and retentions were improved in shrimp fed diets containing up to 200 g/kg SCP. They also showed that the innate immune response was higher in Pacific white shrimp fed diets with SCP than those fed a control diet.

The digestibility studies, histological observations and relative gene expression data indicate that the methanotrophic SCP promotes the health status of the fish without any adverse effects. These studies clearly validate that this microbial protein from the methanotrophs is a protein ingredient with a high biological value for the different aquatic animals. As the SCPs are manufactured by fermentation process utilizing the greenhouse gases (GHG) such as methane, the carbon footprint (land and water usage) is less leading to low carbon economies, making it a sustainable feed/food protein source. This has a positive effect with reduction in GHG emissions and thereby promotes a circular economy.

The use of methane as a carbon source for SCP is reaching commercial scales and more protein-rich products are being derived for both food and feed. Choosing the right protein source for use in aquaculture feed implies ensuring consistent ingredient quality, meeting the target animals’ nutritional needs and also addressing regulatory standards. The physical, chemical, and nutritional quality of aquafeed ingredients are influenced by the source of the raw material used, including production and harvesting costs, as well as the cost of processing, storage and transportation of the final product.

Microbial SCP from methanotrophs exhibit various positive attributes that can efficiently be used as aquafeeds without any negative impact. The use of methane to produce bacterial biomass is economical and is also a good means to reduce GHG emissions thus integrating feed production with animal farming.

The production of a “sustainable” protein from potent greenhouse gases is indeed considered an exciting opportunity to address challenges in the supply of reliable and feed/food proteins with high biological value. Methanotrophic bacteria are thus considered to represent an appealing opportunity to convert methane, a potent greenhouse gas, into a highly nutritious single-cell protein source for animals. Almost all major aquafeed corporations are committed to developing sustainable and traceable fish feeds to meet the growing demand for aquaculture products while ensuring the protection of marine resources and reducing their carbon footprints.

For microbial SCP to be used as animal feed, use in specific target species, scaling up the production capacity are the key factors that need to be considered. Scaling up economical and modular fermenters for the production of high-quality ingredients from greenhouse gases; the process of commercial acceleration of this new raw material; joint adventures for production and commercialization meeting the global demand for reliable, traceable and sustainable novel feed/food protein sources are the ways forward to mitigate the challenges. Given that the advantage of this platform is localized manufacturing, depending on the location of the aquaculture facility, a sustainable strategy can be employed to cater to the demands.

References available on request

More information:

Ezhil Subbian

Co-founder & CEO

String Bio Private Limited

E: subbiane@stringbio.com

There is a clear move by the aquaculture industry to be sustainable. One approach has been to consider the source of various diet components, including protein and find ways to reduce the reliance on animal proteins, particularly those derived from wild-caught fish. Several so-called alternative proteins have been tested including those from animal, plant and microbial sources. Microbial single-cell proteins (SCPs) generally refer to a dried whole or partial cells of algae, bacteria, yeast and fungi that have been incorporated into diets with varying degrees of success. One bacteria that has been tested extensively is Methylococcus capsulatus, a non-pathogenic bacteria grown in methane gas. Calysta is one of several companies commercializing M. capsulatus, and in a joint venture with Adisseo, have recently commissioned a plant in China producing 20,000 tonnes of FeedKind per year, with plans for expansion over the next 2-3 years in the Middle East. Given the large number of papers published, it felt timely to produce a short review of the literature. The majority has been published by Calysta and collaborators, with some early works published on behalf of Norferm (as BioProtein) and a small number published by researchers working with StringBio (as ProDG).

The whiteleg shrimp (Penaeus vannamei) is one of the most widespread farmed crustacean species globally. The drive towards sustainability and the need to identify methods to control disease outbreaks in farmed animals has led numerous research groups to test alternative proteins as a potential replacement for marine-derived protein in their diets. One major disease of concern is acute hepatopancreatic necrosis disease (AHPND), caused by the bacteria Vibrio parahaemolyticus. Two studies by Jintasataporn et al. (2021) and Chen et al (2021) showed that the inclusion of 10-15% FeedKind

significantly reduced mortality associated with the AHPND agent. No differences in growth parameters or palatability due to FeedKind inclusion were apparent (Chen et al., 2021, 2022; Jintasataporn et al., 2021; Longshaw et al., 2022).

Salmonids, in particular salmon and rainbow trout, are one of the top three most important fish species in aquaculture. Salmonids require diets containing around 40-50% protein and with an annual production of over two million tonnes, there is a high demand for protein, much of which is derived from fishmeal. As a result, there is a need to find alternative sources to partially replace fishmeal and soy proteins in their diets to help the salmonid aquaculture industry achieve its intended sustainability targets.

Early studies were conducted in the 1990s and 2000s using BioProtein to assess a range of outcomes in freshwater and marine salmon. Salmon readily accept diets containing up to 40% M. capsulatus and although there are some differences in study design, survival and growth, were generally unaffected by SCP inclusion at levels of between 19% and 30% (Skrede et al., 1998; Storebakken et al., 2004; Berge et al., 2005; Aas et al., 2006a; Glencross et al., 2022). Interestingly, the inclusion of M. capsulatus at 30% of total diet led to the recovery and prevention of soybean enteritis in salmon (Romarheim et al., 2011, 2013a, 2013b).

Similar growth and digestibility results have been obtained for rainbow trout. Inclusion of M. capsulatus at up to 27% of diet did not affect weight gain (WG), specific growth rate (SGR), feed efficiency ratio (FER) or feed intake (FI) (Aas et al ., 2006b), although Rajesh et al. (2022) suggested that optimum inclusion was better below 12.5%. Apparent digestibility coefficients (ADC) for nitrogen

in rainbow trout range from 85% (Rajesh et al., 2022), to 89% (Øverland et al., 2006), and up to 95% (Aas et al., 2006b). No negative reports on intestine structure or function have been reported in rainbow trout.

Attempts have been made to farm various flatfish, including Atlantic halibut and turbot, with some success. The inclusion of either 9% or 18% M. capsulatus (as BioProtein) in Atlantic halibut diets was tested by Aas et al., 2007. Although the higher inclusion rate led to a reduction in SGR, FI, and FER, there was no difference in these measures when M. capsulatus was added at 9%. ADC for nitrogen (as a proxy for protein) was around 87%, irrespective of inclusion level. Based on the study, it is apparent that the inclusion of 9% M. capsulatus in halibut diets is acceptable and could be used as a suitable fishmeal replacement in their cultivation.

Turbot farming, particularly in China and Europe, is somewhat more advanced than halibut, with around 60,000 tonnes of fish produced annually. Hoerterer et al. (2022a) tested the effect of replacing fishmeal with either processed animal proteins or plant proteins in market-sized RAS-reared turbot. They also included insect meal and FeedKind at 8.75% or 13.7% in the diets. While the study was not designed to understand the effect of replacing fishmeal with FeedKind, the study showed that diets with lower plant proteins, insect meal and FeedKind performed better than those containing processed animal proteins. The authors suggested that diets containing a combination of sustainable ingredients, including FeedKind, had the potential to be used in turbot cultivation.

A second study by Hoerterer et al. (2022b), followed a similar study design in juvenile turbot. However, the inclusion of FeedKind was limited to 2.5% of the diet. As before, the study was not designed to test the effect of FeedKind and while no inference can therefore be made on how FeedKind affected the outcomes, it appears to be tolerated by juvenile turbot at a 2.5% inclusion.

A detailed study by Zheng et al. (2023) did examine the effect of altering FeedKind inclusion levels in turbot diets, replacing up to 100% of the fishmeal with up

to 60% FK in the diet. Crude protein ADC was around 90% when FeedKind inclusion was less than or equal to 27.5% but decreased with increasing inclusion. Growth parameters were unaffected when FeedKind inclusion was at 18% or lower but substantially reduced when above this level. In addition, as long as the inclusion of FeedKind was below 36% of total feed, no effect was seen on a range of health measures. Above this level, antioxidant capacity, liver health and protein metabolism were compromised, making it clear that although there is an upper limit of inclusion, fishmeal can be successfully replaced with FeedKind in turbot diets.

The two main farmed Seriola species are S. lalandi (yellowtail amberjack) and S. quinqueradiata (Japanese amberjack). Biswas et al. (2020) included FeedKind at up to 67.5% of the diet of Japanese yellowtail. Although no effect was noted on growth measures when inclusion was at 17%, there was a reduction in growth parameters as inclusion levels increased. This was partly overcome by adjusting the diet formulation and the downstream processing of FeedKind, including addition of palatants, so that inclusion of up to 20% was possible without impacting growth. Protein digestibility was 89% at low inclusion levels, decreasing as inclusion level increased. Using Pro-DG, Pilmer et al. (2022) successfully replaced 25% of the fishmeal in yellowtail amberjack diets with feed conversion ratios being similar across all groups; feed intake fell as M. capsulatus inclusion increased indicating that palatants should be considered at high levels of M. capsulatus or low levels of fishmeal.

A wide range of studies on the inclusion of M. capsulatus in perch-like fish has been conducted. Species examined include largemouth bass, spotted seabass, black seabream, red seabream, gilthead seabream, barramundi, and groupers (Biswas et al., 2021; Xu et al., 2021; Liang et al., 2022; Woolley et al., 2023; Yu et al., 2023).

Three trials with largemouth bass have been published examining the potential of adding FeedKind to diets. Guo et al. (2022) added low levels of SCP into the diet at 3%, 6% and 9%. For all three diets, survival growth,

antioxidant capacity and gut microbiota were all improved. Zhang et al. (2022) increased the inclusion levels, testing the protein source at levels between 4.3% and 21.5% of the diet. They found that the SCP could be included at up to 13% with no detrimental impact on growth and that it was particularly beneficial to intestinal health at 4.3% inclusion. Digestibility of M. capsulatus in largemouth bass is around 91-92%, higher than other microbial, plant and insect protein sources tested at the same time (Guo et al., 2022; Shi et al., 2022).

Two important farmed species in the Mediterranean are gilthead seabream and European seabass, accounting for nearly two-thirds of the production in the area. A complex diet formulation that included insect meal, plant proteins, yeast, and two SCPs, including 10% FeedKind was tested in gilthead seabream by Piazzon et al. (2022). The diet was to test whether gilthead seabream could be grown on fishmeal-free diet, rather than specifically on the effect of M. capsulatus in the fish. Fishmeal-free diet showed optimal growth with no impact on health and, when challenged with the intestinal myxozoan parasite Enteromyxum leei, showed similar levels of infection, suggesting that the diet had no effect on susceptibility.

A further study by Carvalho et al. (2023), looked specifically at the difference in diets containing either insect meal or FeedKind at two different inclusion levels, namely 5% or 10% each. The SCP outperformed the insect meal in the trial, allowing 66% of the fishmeal to be replaced in gilthead seabream diets. Improved final body weight (FBW), SGR, and feed conversion ratio (FCR) were apparent in fish fed SCP compared with the insect meal and were comparable to the control groups. Importantly, inclusion of FeedKind at 5% increased the fatty acid content of the fillets.

Testing the effect of replacing processed animal proteins in European seabass diets, Petereit et al. (2022) developed diets that contained several alternative protein sources from insect meal, plant proteins and SCPs, including 10-15% FeedKind. Diets had no adverse effects on growth or welfare parameters and did not affect the sensory characteristics of the fillet suggesting that these diets were appropriate for European seabass.

Inclusion of FeedKind in the diets of Japanese seabass at 3.5% led to significant improvements in growth

performance and a range of health measures (Yu et al., 2023), with the study showing that up to 40% of the fishmeal could be replaced without affecting growth. For hybrid groupers, inclusion of FeedKind at 12% of the diet was possible with reductions in cholesterol and improvements in antioxidant capacity noted (Liang et al., 2022). Improvements in WGR and FCE, as well as improved plasma biochemistry of barramundi were reported by Woolley et al. (2023) who were able to replace up to 75% of the fishmeal with ProDG. Finally, replacing fishmeal with up to 25% FeedKind in the diets of black seabream had no effect on growth outcomes and at 8% inclusion, there were significant increases in whole-body protein content, lipid digestibility and amylase activity (Xu et al., 2021).

Cyprinids

Common carp has a protein requirement of around 30-40%. A study by Yu et al. (2022) examined the effect of replacing around half of the soybean meal in the diet with up to 10% FeedKind. There was a significant increase in FBW, WGR, and SGR as well as a significant decrease in FCR with increasing FeedKind inclusion. Total antioxidant capacity (T-AOC) increased with increasing FeedKind inclusion, while malondialdehyde (MDA), glutamate and blood urea nitrogen decreased. The changes in T-AOC and MDA showed that the inclusion of FeedKind in carp diets reduced oxidative stress. In addition, reductions in glutamate indicate that absorption and utilization of glucose were promoted by FeedKind, while a balanced amino acid profile in the diet tends to lead to reduced blood urea nitrogen. A second component of the study to look at digestibility was also conducted by the same authors who showed that ADC for crude protein and amino acids were 90% and 88% respectively.

One of the most widely farmed freshwater fish is Nile tilapia, reported from at least 120 countries with global production valued at more than USD 12 billion. They are omnivorous with a crude protein requirement of around 30-40%, depending on stage and weight. Chama et al. (2021) fed juvenile tilapia in outdoor ponds with diets containing increasing amounts of FeedKind, ultimately replacing 100% of the fishmeal in the diet at an 8.5% inclusion rate. WGR, SGR, FI, FCR, and survival

rates were unaffected by any of the diets offered. The authors also measured several immune, biochemical and enzyme markers in the serum and intestine. Immunoglobulin M, albumin and total antioxidant capacity increased with increasing FeedKind inclusion, showing a positive effect on immunity due to FeedKind. In contrast, malondialdehyde, nuclear factor-kappa B, tumor necrosis factor-α, interferon y, interleukin 8, interleukin 10 and interleukin 16 all decreased with increasing FeedKind inclusion suggesting that the fish would be able to fight infections and reduce any associated inflammation.

The studies to date have shown that Methylococcus capsulatus is a suitable replacement for animal protein that can be safely used in aquaculture. As well as having a balanced amino acid profile similar to fishmeal, it has been shown to act as a postbiotic, defined as dead bacteria or their components that have a beneficial

effect on the host. In the case of M. capsulatus, it has positive effects on the microbiome, gene expression, inflammatory responses, immunity, and antioxidant capacity as well as improving growth outcomes in a range of species. However, these effects are speciesspecific and driven by the inclusion level in the diet. Future work will focus on testing the SCP in new species and exploring its effect on a range of biological processes in these animals.

References are available from the senior author on request.

More information:

Matt Longshaw Senior Scientist

Calysta

E: mlongshaw@calysta.com

Michel van Spankeren, Protix

Michel van Spankeren, Protix

As pressure on global resources compounds, the aquafeed industry cannot escape the reality that sustainable sourcing is crucial to long-term survival. Since the emergence of modern aquaculture in the 1970s, the main ingredients of fish feed have shifted from predominantly marine origin to mainly vegetable, and notably from fishmeal to soy protein concentrate as primary protein sources. While the use of ingredients, such as guar protein, sunflower meal, coconut oil and linseed oil, is increasing, fishmeal and fish oil still comprise a large proportion of aquaculture feed. However, extracting many of these resources is at odds with current awareness of the impact on the environment and biodiversity.

Fish farmers, therefore, want more sustainable feed, without compromising on palatability and efficiency.

The challenge facing feed manufacturers is to reduce the environmental footprint of their feed and enable fish farmers to create end products that are in line with consumers’ ethical aspirations.

A new Life Cycle Assessment (LCA) by the German Institute of Food Technologies (Deutsches Institut für Lebensmitteltechnik DIL e.V.) illustrates a low environmental footprint for insect ingredients. The use of insects, specifically the black soldier fly as a sustainable source of protein and other nutrients, is a relatively new yet natural and logical step in creating a positive footprint while maintaining high palatability and performance.

Consumers are increasingly aware of fish and shellfish as part of a healthy diet. Oily fish is rich in omega-3

fatty acids which are reported to support a healthy heart. (Shell)fish plays a major role in nutrition and food security around the world.

WRI projects fish consumption to rise 58% between 2010 and 2050 and, with the growing population, around 220 million tons of fish to be produced in 2050 (World Resources Institute). Fish production is a potentially lucrative market, but the challenge lies in marrying high yields with sustainable cultivation.

Black soldier fly:

A new approach to high-performance

To meet the apparently contradictory demands of responsible sourcing of sustainable feed and the economic reality of good yields, one revolutionary solution the aquaculture industry is considering is insect-based ingredients.

Specifically, the larvae of the black solder fly (Hermetia illucens) are a rich source of protein and lipids. They quickly convert low-grade food waste into body mass. They need little room to grow, and use less land than alternative sources of protein and lipids. They can be farmed in a local and circular production process close to where they are needed, thus reducing transport. The larvae are tasty, and in land-based shrimp farming, show a significant improvement in growth and survival rates.

The recent DIL Life Cycle Assessment shows outstanding scores for insect-based ingredients. It was performed in 2021-2022 at the Protix facility in Bergen op Zoom, the Netherlands. Each of Protix’s four insect

ingredients was evaluated individually, and each ingredient’s contribution was estimated across three key impact categories:

• Global warming potential

• Land occupation

• Water use

The IMPACT2002+ v2.12 (Jolliet et al., 2003) approach was used for the impact contribution analysis of the first two categories and AWARE v1.01 (Boulay et al., 2018) for water use. The results of the environmental impact of insect-derived products were further analyzed for uncertainty and compared to the results of benchmark products available in the literature and databases (AgriFootprint and ecoinvent 3).

For aquafeed, the results of ProteinX®, a protein meal, and LipidX®, an insect oil, are of most interest.

The first highlight of the study is found in the land use for LipidX®: LipidX® uses 0.898 m2 of organic arable land. LipidX® is very comparable to coconut oil, which is, for example, used in Norwegian salmon and trout feeds. Replacing coconut oil with LipidX® returns over 12m2 of organic arable land to nature for each kilogram of fats, since coconut oil uses 12.98 m2 of land. This will help save the biodiversity of our planet. Table 1 shows that LipidX® also uses significantly less water than coconut oil, and has a smaller impact on global warming.

A second highlight is found in the water use of ProteinX®: one kilogram of ProteinX® saves 330 liters of water when it replaces soy protein concentrate. Though seen as a good source of protein, one kilogram of soy protein concentrate requires 520 liters of water to produce.

Soy protein concentrate is also associated with deforestation, loss of biodiversity and global warming. Table 2 shows that ProteinX® has a carbon footprint that is almost seven times lower than soy protein concentrate.

The LCA also compared fishmeal against insect-based ingredients. Naturally occurring fish do not need to be nurtured through human intervention in the resources required for the fish to grow. Therefore, the only land and water needed are for the final processing of the fish to create fishmeal. This results in low LCA metrics for land and water use, yet the impact on the ecosystem can still be large. An analysis of CO2 emissions shows very comparable results. However, fishmeal production is a major contributor to over-fishing and the depletion of ecosystems. From a biodiversity perspective,

replacing fishmeal with insect-based ingredients means the production of more ingredients to feed the growing world population is avoided since current waste streams are re-used. This prevents further environmental destruction and broken ecosystems.

Insect feed is derived, among other sources, from by-products of the milling industry and alcohol production. According to an earlier study by Smetana et al. (2019), mass production of Hermetia illucens larvae requires a significant amount of energy per operation, hence the source of energy is highly important. The electricity to produce the insects is supplied by producers relying on wind energy production which, with the upscaling effect, reduced the impact of insect production compared with the 2019 LCA figures.

The aquafeed industry is increasingly seeking sustainable sources of protein and fats while maintaining feed palatability and health benefits. The use of insects as a consistently high-quality feed ingredient may be in its infancy, but as the impressive LCA results demonstrate, there is huge potential. The results can be used by aquafeed manufacturers to reduce their ecological footprint.

References available on request

Bruno Duranthon, A-Systems

Some databases can attribute environmental values to most raw materials used in animal feed production. These values, obtained through analyzing the life cycle of the raw materials, can be used in the formulation as they are additive variables. The impact of a mix of raw materials will therefore be the sum of the impacts of each ingredient, weighed by the incorporation rate in the mix. It is thus already possible to calculate, and limit, the environmental impact of the feed. How are these environmental criteria taken into account? In formulation software, this can be done by creating characteristics in raw materials that, as a standard nutrient, will describe the environmental values of the ingredient. For example, the carbon footprint linked to the production of raw materials, its impact on deforestation, and so on. Formulas will then be optimized on the least cost and the environmental criteria will be evaluated, with eventually maximum constraints on some of the criteria. Forcing limits to the formula will of course imply an over cost on the diet. The formulator will have to try, by trial and error, to find the best balance between the various criteria, while keeping an eye on the cost of the diet so as not to let it increase excessively. The economic optimum is not necessarily the environmental optimum. If environmental criteria have been aggregated in a single function, it can still be relevant to check the weight of each criterion individually.

In current formulation software, it is not easy to consider multiple objectives in optimization. The “economic function” of the optimization is the price. It is the price that we want to minimize while respecting the constraints of the formula. If we wanted to minimize the carbon footprint of the formula, for example, it would mean going through a series of complicated

processes to replace the price of raw materials with their carbon footprint and setting the price as a nutrient in the raw material in order to put constraints on the price of the diet. For practical reasons, this could not be done as part of the daily work. Results would be fairly complicated to interpret.

Taking into account the environmental impact in single formulation

To allow consideration of several criteria in the optimization of diets, A-Systems developed, in the formulation software Allix, the multi-objective optimization. This new optimization allows formulators to minimize the environmental impacts of feed formulation while still controlling the price of the diet. It is also possible to know what over-cost can be accepted

to allow minimizing the environmental impact of feed production. Based on factory and market context, the formulator can choose the weight to put on each criterion, as well as the cost of the feed.

A second method is to minimize the environmental impact of the overall feed production of the factory. It is possible to calculate a multi-formulation of all formulas of the factory, each weighed by the tonnage planned to be produced. Environmental impact constraints will measure and limit the impact of all raw materials on pre-selected criteria. Furthermore, if the data was available, which is sadly not the case today, it would be possible to consider impacts linked to the production of the feed (grinding, granulation, etc.).

Through the rearing cycle, an animal will receive various types of feed, for example, starter, grower, and

finisher feeds. It is more relevant to work on the full life cycle of the animal than on individual feeds. This will allow the minimizing not only of the impact of a single feed but also of the full rearing cycle, at least from a feeding perspective. That is why A-Systems now suggest the optimization of “feeding plans” with the multiobjectives formulation. It will be possible to minimize the economic costs of the diets while finding the environmental optimum. Depending on the limitation posed by the agricultural sector, it is also possible to distribute the impact in a measured and optimal fashion through the rearing cycle.

These three new methods of optimization developed by the A-Systems teams are innovative and broaden considerably the scope of feed formulation. Indeed, we spoke here mainly of environmental impact. But the same tools can also answer other questions! For example, what would be the optimal level of selected nutritional criteria for an agreed-upon overcost of the feed?

E: contact@a-systems.com

The changing landscape of aquafeed formulations Since first appearing as a buzzword in the 1980s, sustainability has become inseparable from the aquaculture and aquafeed industry in the past two decades. Aquafeed is a big, if not the largest, contributor to the environmental footprint of the aquaculture industry, especially in the farming of species that still rely on marine proteins and fats such as salmon and marine species (MOWI, 2022). The feed contribution in this equation can to some extent be influenced by the fish farm management striving for a low feed conversion ratio (FCR), but the ingredients used in feed

formulations have much more impact and are beyond the control of the fish farmer.

The aquafeed industry has already come a long way by reducing fishmeal and oil content in diets (FIFO1) and implementing vegetable-origin ingredients, as well as animal by-products (ABPs2). However, although ABPs nowadays are perfectly safe and legal in Europe, there are still some negative consumer sentiments associated with the latter. This negative perception is related to the Bovine Spongiform Encephalopathy (BSE) crisis that developed in the late 1990s and still hinders the use of ABPs in some European aquafeed markets.

Soybean meal, soy protein concentrates, wheat and corn gluten, sunflower seed and rapeseed meal, or dried distiller grains (from biofuel production) are commonly used plant-based ingredients in aquafeed. Since the beginning of the COVID-19 pandemic (2020) and the recent Ukraine invasion (2022), logistics and continuity of supply have become important factors to consider when sourcing sustainable feed ingredients. At the same time, feed producers need to be aware of the change in perception of the ingredients they use. For example, until recently, soybean products such as soybean meal (SBM) and soy protein concentrate (SPC) were required to be non-GMO for animal feed applications in Europe. More recently, “deforestation-free” or “conversionfree” are becoming the new standards and several mostly multinational feed companies have already adopted them. Life cycle assessments, carbon footprint calculations and other environmental measurements are rapidly finding their way into the aquafeed and aquaculture industries.

Global annual production of faba beans is currently 5.7 mln tons and due to their outstanding nitrogen (N2) fixation system, they are an interesting crop for crop rotation with cereals for example. Thanks to their ability to fix atmospheric nitrogen, faba beans offer potential for more sustainable agriculture, reducing the need for fertilizers and contributing to better soil conditions. Faba beans are non-GMO and can be grown all over Europe as well as in many other places in the world. They represent a very good candidate to reduce the carbon footprint and improve sustainability in aquafeeds and fish farming alike.

In Europe, faba beans are presently used among others in salmon, trout and marine feed with inclusion rates typically up to a maximum of 5-6%. Unprocessed faba beans’ nutritional attributes are ± 27% highly digestible protein, ± 60% carbohydrates – of which up to 13% is fiber (total dietary fiber) and ± 40% is starch. The high fiber content prevents higher inclusion rates due to the maximum formulation limits imposed by the feed formulator. On the other hand, faba beans’ starch content nicely contributes to the binding properties when properly gelatinized in the production process of fish or shrimp feed pellets.

The combination of moderate protein content with relatively high starch and fiber levels in faba beans limits higher inclusion rates in grower feeds for most species, but especially in the nutrient-dense diets of younger animals.

To take advantage of the “hidden” potential of faba beans despite these limitations, BENEO, a leading manufacturer of functional ingredients from natural sources, developed two ingredients that maximize the protein and starch content, while reducing fiber levels.

BENEO developed and launched new faba bean products, a protein concentrate and a starch-rich flour, that are separated from the ground dehulled beans by dry fractionation. This separation method is an energy and water-efficient process which doesn’t require any solvent extraction and has a much lower environmental impact than other processes. The replacement value

(shadow price) of faba bean protein concentrate and starch-rich flour has been assessed in several European aquafeed formulations.

The protein level in the concentrate is specified at a minimum of 63% on dry matter. It still contains some starch, and the fiber content has been drastically reduced by the beans’ dehulling, which makes the FPC also suitable for application in the starter and pregrower feeds for salmon, trout, seabass, and seabream, among others (Table 1).

The nutritional composition of the FPC resembles that of soy protein concentrate (SPC). In BENEO’s formulation simulations in salmon diets (without processed-animalproducts (PAPs)) in Europe, the FPC competed with the other vegetal protein concentrates like SPC or other cereals’ derived protein sources. Also, in trout diets, the FPC partially replaced the other vegetal protein concentrates since the value of FPC hovered between the price of these ingredients. In Mediterranean marine species, both the hemoglobin meal and vegetal protein concentrate were reduced when introducing FPC into these feed formulas. The results from the tests showed that a 5 to 10% inclusion level of FPC in most fish feeds is an acceptable solution and a good compromise between nutrient profile and price.

The company’s second faba bean ingredient is a costeffective starch source with a typical starch level of more than 57% (on dry matter basis), while also adding some quality protein (min. 21%) to the feed formulation. Like the protein concentrate, the FSF brings very little additional fiber, which aquafeed producers

generally want to keep at the minimum level in their fish feed formulas. While running the product valuations of FSF in standard salmon, trout, and Mediterranean marine fish diets, the formulation value of the FSF hovered slightly above that of other vegetal starch sources, and even a bit higher in aquafeeds without PAPs, across species. When combined with other binders, such as wheat and vital wheat gluten, a 5 to 10% inclusion of FSF can in theory provide sufficient binding to extruded fish feed pellets.

Next steps

Both the faba bean protein concentrate and starch-rich flour are presently introduced to aquafeed producers in Europe. Bigger product availabilities are foreseen as of 2024, when BENEO’s new pulse processing plant in Offstein, Germany is operational, thereby reinforcing supply security. At the same time, additional tests to analyze the binding properties of the faba bean starch-rich flour versus wheat and the whole bean, and nutritional studies to evaluate the optimum inclusion level of the faba bean protein concentrate in juvenile fish feed are under consideration.

Given that sustainability aspects become increasingly important for feed producers, faba bean products can be a promising solution as they score well with regard to their carbon footprint while providing good nutritional and technological properties.

Martineau-Côté, D. (2022). Faba Bean: An Untapped Source of Quality Plant Proteins and Bioactives. Nutrients, 14, 1541.

Mínguez, I. (2021). Faba bean. In: Crop Physiology Case Histories for Major Crops (pp. 452-481). Academic press.

MOWI (2022). Salmon Industry Handbook 2022. Bergen, Norway: MOWI.

More information:

Hans Boon Managing Consultant

Aquaculture Experience

E: hboon@aquaculture-experience.com

Carnivorous fish and shrimp are widely consumed aquatic products. According to the FAO report 2022, the sustainability of marine fishery resources is a big concern. Capture fisheries production is decreasing year-by-year, while the share of aquaculture production is increasing especially in Asia and China. When producing the same volume of animal protein, the feed conversion rate of aquatic animals is considerably lower than livestock and poultry, and the overall carbon emissions are much lower.

For the sustainable development of the aquaculture industry, it is very important to replace fishmeal with a terrestrial protein source, especially plant protein, as much as possible with less or no influence on the growth and quality of fish.

Jiangsu Fuhai Biotech Co. has developed some soybean peptide products from the fermentation of dehulled full-fat soybean or soybean meal to replace

fishmeal, these products are named Fatide series. We performed several small-scale and commercial trials to assess the performance of soybean peptide in different aquaculture species.

The Ocean University of China collaborated with us to test feeds containing soybean peptide in largemouth bass and Pacific white shrimp.

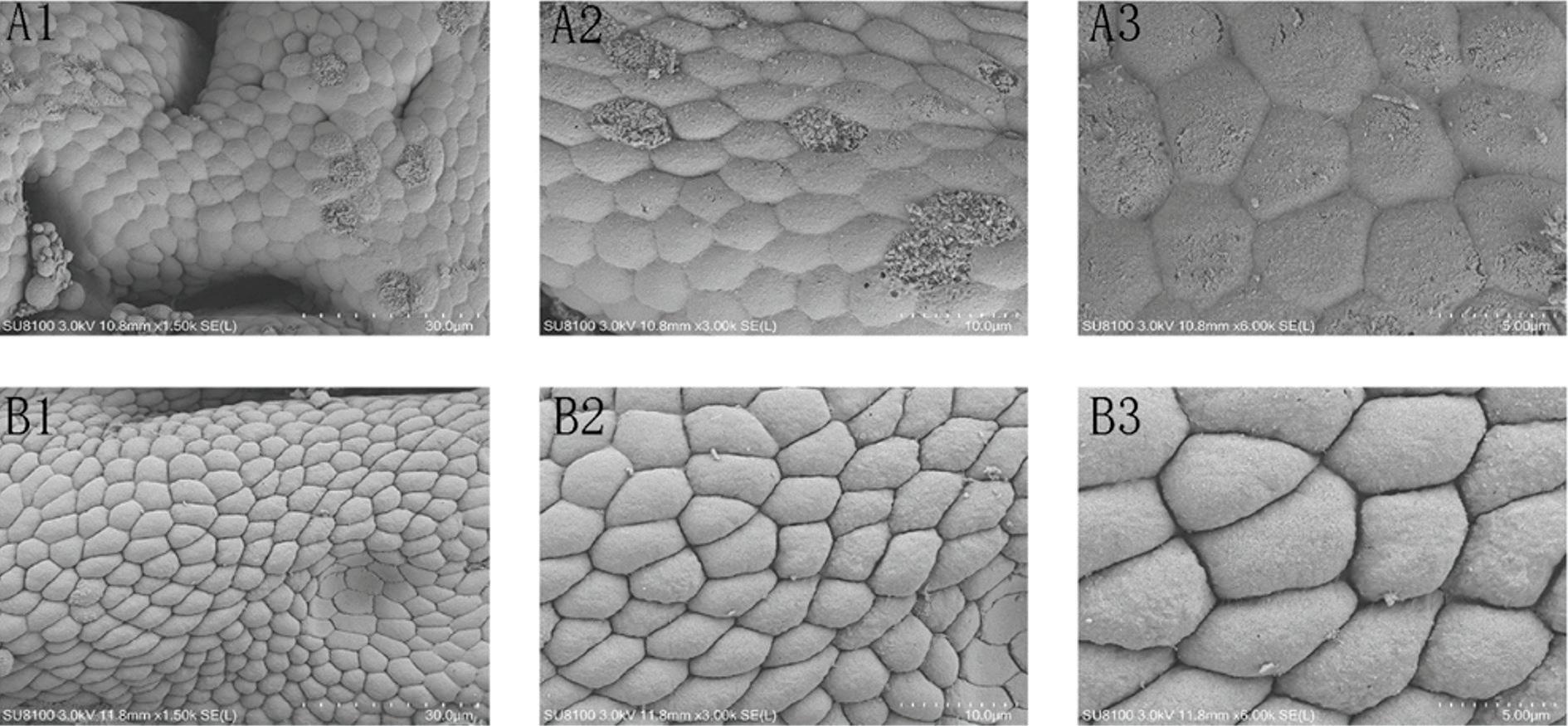

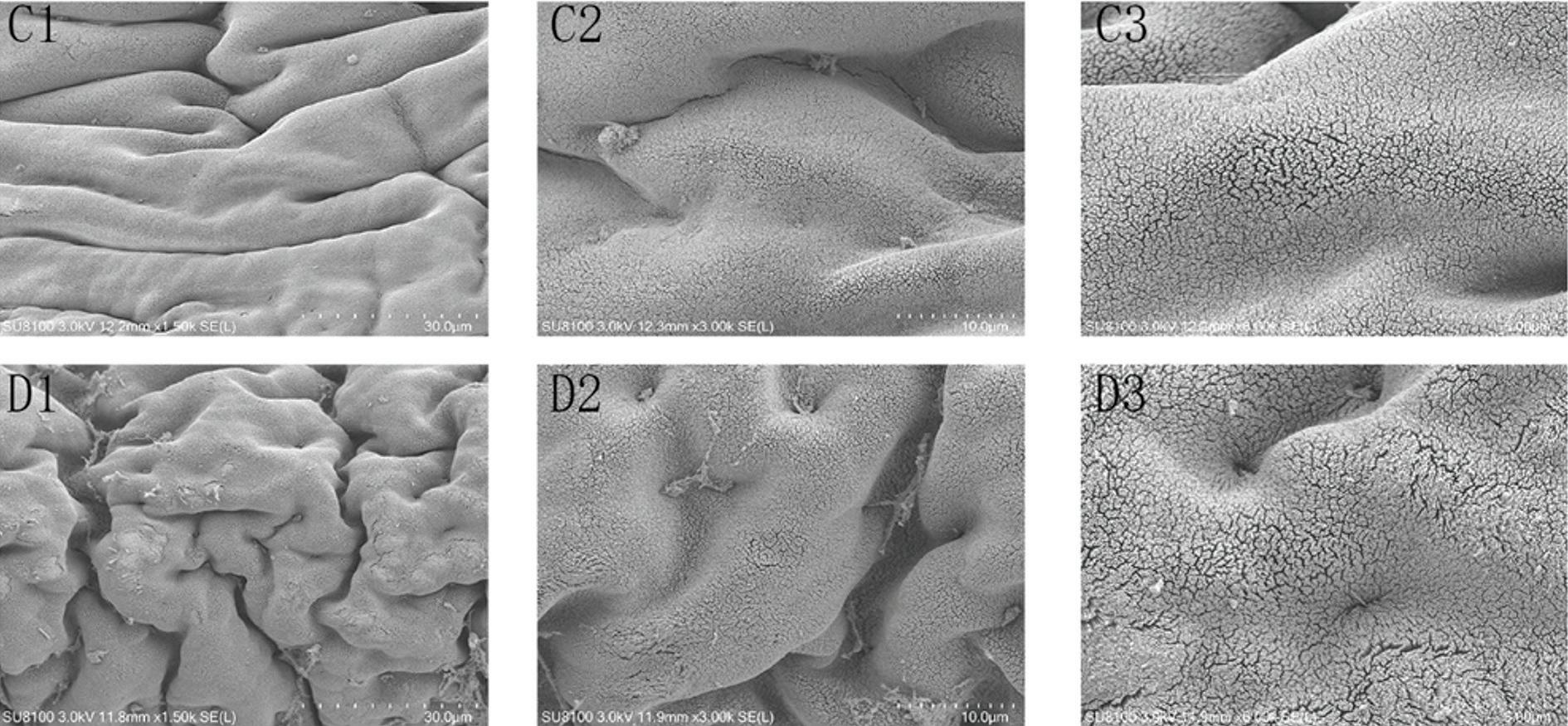

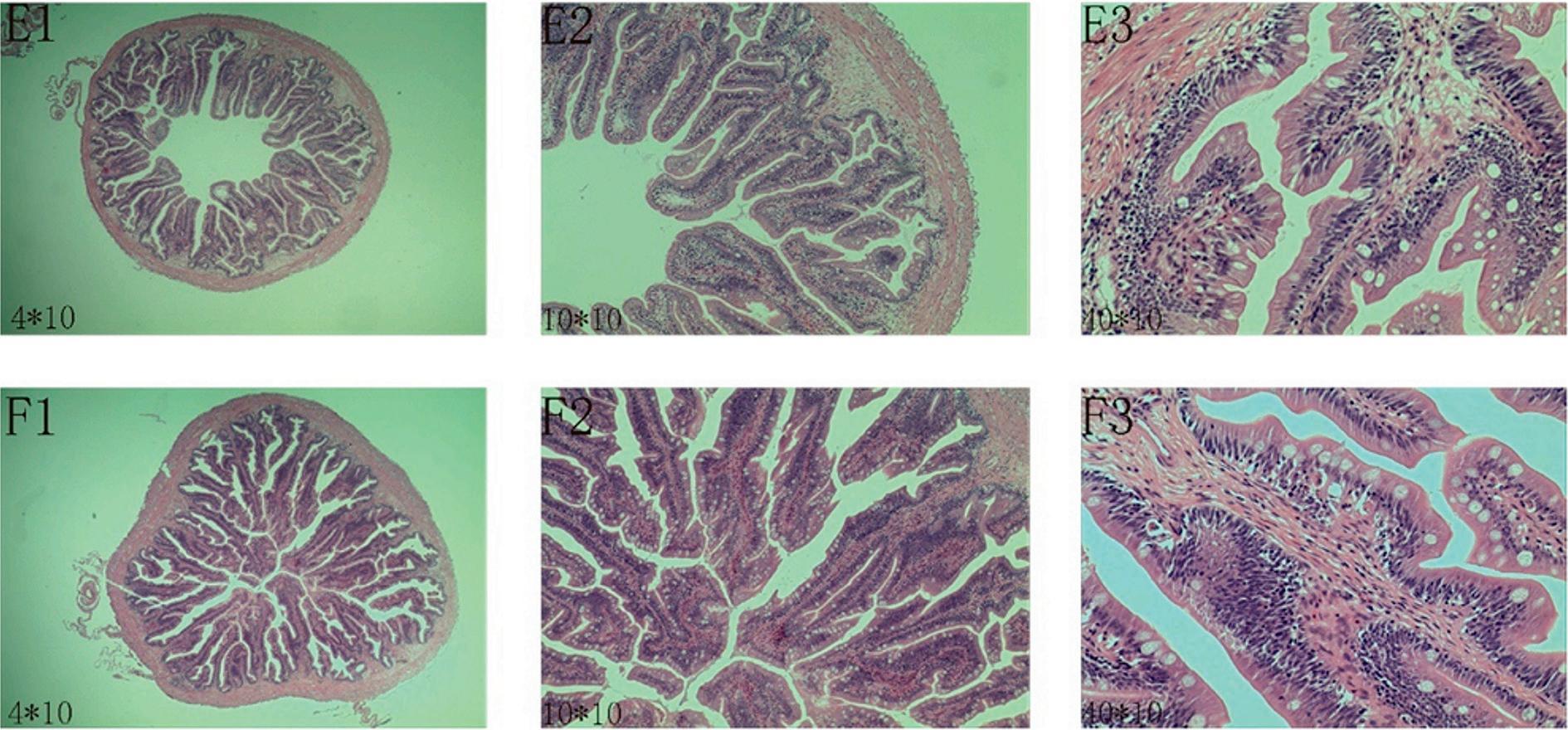

In 2018, in a trial in largemouth bass, a control feed with 56% of Peruvian super steamed fishmeal was compared with feeds with a 7-28% replacement of the fishmeal with soybean peptide. The results showed that, compared with the control, the test groups significantly improved the body gain and specific growth rate, and reduced the feed coefficient. The intestinal wall was thicker than the control group.

25% Peruvian super steam fishmeal and was compared with diets with 8-48% replacement of the fishmeal with soy peptide. There were no significant differences in performance between the groups.

In 2021, in cooperation with Soochou University, a trial was performed to evaluate the effect of enzymehydrolyzed soybean peptide (EHSB) replacing fishmeal and chicken meal on the growth performance, serum biochemical indices and gastrointestinal structure in channel catfish (Ictalurus punctatus). The channel catfish (initial weight: 21.25 ± 0.25 g) was fed four isonitrogenous, isolipidic and isophosphorous diets for 60 days. The control diet (CON group) contained 8% fishmeal and 5% chicken meal. EHSB was used to replace fishmeal (100%, RF group), chicken meal (100%, RC group), and 100% of fishmeal and chicken meal (RFC group).