FBO EXPECTATION MANAGEMENT

HOW FIXED BASE DELIVERABLES DRIVE LASTING LOYALTY AND PROFIT

BY PHIL LIGHTSTONE

The quality of a Fixed Base Operator’s facilities and services can found on a sliding scale from Five Star amenities to a trailer equipped with vending machines. Aircrew, aircraft owners and passenger bar of expectation will be set by FBO’s that deliver a Five Star rating. FBO Expectation Management (FEM) is very much a two-headed coin. FEM should be viewed from both the FBO’s and customer’s perspective. With both perspectives balanced, all parties win when the coin is tossed. However, both parties must have reasonably set their expectations. In any customer facing role, staff hiring and training practices sets the stage for the customer experience.

The bulk of interactions between FBO personnel, aircrew and passengers are pleasant resulting in a positive experience. However, as with most customer service focused industries, there are the odd exceptions where either party might be having a bad day and may have unreasonable expectations. Financial expectations of fuel discounts and waived landing fees should be managed before the aircrew departs their home base for the destination airport. For those individuals who do not do their homework, with unmanaged

expectations, the idea of paying a bit more is untenable and can result in that individual crossing a line during the interaction. This puts the FBO staff into the position of trying to keep a positive attitude during an interaction with a rude individual, while deescalating the conversation.

Anthony Norejko, President of the Canadian Business Aviation Association (CBAA), reminds us that schedulers and dispatchers are often making the FBO selection decision. With a focus toward optimizing fuel pricing, these back-office personnel may be influenced by air crew’s experiences, but with fuel price transparency through contracted rate uploads into their scheduling tools, FBOs are creating relationships with these decision makers.

The folks at Banyan Air Service at Fort Lauderdale Executive (KFXE), led by Don Campion, puts customer service at the top of their deliverables list. Campion created Banyan in 1979 with a focus on managing quality and customer expectations in their FBO and MRO services, and Jet Runway Café. Banyan’s FBO lobby reminds you more of a Five Star hotel and less like a typical FBO. The FBO lobby has an energy created by the FBO staff, aircrew and

Banyan Air Service at Fort Lauderdale Executive (KFXE), led by Don Campion, puts customer service at the top of the deliverables list.

GOOD TO GO.

Vision | To be globally recognized as a superior provider of aviation maintenance by being a forward-looking employer. Notre Vision | Être reconnu mondialement comme un fournisseur supérieur de maintenance aéronautique en étant un employeur tourné vers l’avenir.

passengers. A stone’s throw from the FBO is Banyan’s Pilot Shop, a 5,000-squarefoot showroom packed with the latest in pilot supplies and two fully featured flight simulators installed in the cockpit of a Gulfstream II corporate jet fuselage. My wife, while sitting in the shade on Banyan’s ramp, was asked by three different Banyan staff if she would like a bottle of ice-cold water. Although my wife is not hard to please, this level of attention to detail was something that resonated with her.

Campion focuses on Employee Empowerment allowing the staff, or as he calls them “Teammates”, to make decisions without the need to escalate to the senior leadership, using “what’s good for the customer” as a guiding principle. This begins at the recruiting and hiring process, creating a team dynamic which weeds out those not passionate about excellence. Campion’s approach is based upon the notion that focusing on the customer experience, and not price, will yield loyal customers and therefor ultimately improve revenue and profitability. He is essentially using company culture as a competitive advantage. “At Banyan we strive to be more than just another aviation company, not only by what we provide our customers, but also by what we give back,” says Campion. For the past 12 years, Banyan has led the rebuilding of a hospital and nursing college in the bush of Nigeria (egbehospital.org).

From an FBO’s perspective, the diversity, quality and cost of services is proportional to the business activity at that specific airport and FBO. Geography plays a factor in creating a differentiator. During a layover in Savanna (KSAB), Signature Flight Support had a wonderful FBO environment, with helpful front-line staff. Walking out to the crew car area, I saw six Signature fleet cars (same models, painted with Signature logos). Compared to the Canadian context, the norm of airport transportation at many FBOs is Uber. But some Canadian FBOs have crew cars for itinerant air crews and passengers to use. Million Air at the Toronto Buttonville Municipal Airport (CYKZ) has one Mercedes and one minivan for aircrew use. For corporate pilots waiting on their passenger’s return from a business trip in Greater Toronto, access to an aircrew car can take them to great restaurants.

Front line ramp staff training is critical to ensure that an aircraft is properly serviced, fueled, towed, hangared and tied down. I have found many line staff struggling with the fuel caps and fueling port on the Commander that I fly. While the Commander’s fuel system is somewhat unique to the General Aviation fleet, asking the pilot for help during refueling not only makes the flight line staff look like a hero, but also prevents

damage to the fueling system. As a result, I prefer to be at the aircraft when it’s fueled, ensuring that a small mistake does not ground the aircraft. From an aircraft owner’s perspective, it is about getting the big things right, like ensuring the aircraft is not misfueled.

My previous aircraft was a turbocharged Commander with the words “Turbo Commander” on the side of the fuselage. While on a trip, I had to correct a flightline individual before he fueled the aircraft with JetA. He honestly thought that “Turbo” meant turbo prop versus turbocharged. That would have been a costly mistake. While most FBOs do a great job of keeping fuel orders straight, mistakes can and do happen.

As for pilots, sometimes it’s not feasible to stand around waiting for the fuel truck to ensure the right fuel is being poured into the aircraft tanks. FuelTape from Aircraft Spruce ($10.70) is a highly durable, weatherproof masking tape that clearly indicates to the fueler which grade of fuel must be used. Simply tear off a piece and stick it over the fuel caps and you have a low-cost, reliable system to keep your tanks safe. FuelTape is available in both 100LL and Jet A versions.

But it’s also the little things, which illustrate a sense of detail. For example, placing a fueling wing mat over the wing and fueling inlet helps protect the aircraft’s paint from wear and tear caused when the linemen place the fueler’s hose on the wing. Well run FBOs will ensure that their trucks are equipped with fueling mats at the beginning of each shift.

From a passenger and aircrew perspective, having well trained staff to help with getting the user’s technologies (iPads, laptops, etc.) attached to the FBO’s secure WiFi environment helps eliminate IT created

frustration. Little things such as a quite comfy room, coffee, high-speed internet, and a home theatre environment, allows aircrews to have an enjoyable home-awayfrom-home experience.

From an FBO’s perspective, Gateway Aviation located at Windsor Airport (CYQG) has been in operation for less than three years. Being the new kids on the block, in a small market, Gateway is using customer service as a differentiator. Essentially creating an atmosphere of a home away from home for aircraft owners, passengers and aircrews.

“The vast majority of the time, we’re dealing with satisfy clients and I strongly believe it stems from our line crew and CSRs dedication to delivering an outstanding elite experience to our customers,” says Gateway’s Mike Hogan.

Gateway’s management style trickles down to the front-line staff who are spring loaded to listen to the comments and questions of their customers. Keeping clients satisfied is their main goal. As an example, one customer mentioned that they’d like to see a wider selection of tea. A week later, Gateway had sourced and purchased a selection of high-quality teas. To help manage their customers’ financial expectations amidst inflation rates, they ensure that catering orders are set up in advance, allowing the customer to manage both the menu and cost. Gateway Aviation Windsor is proving how employee customer service training leads to a successful FBO business plan.

There are many things which are outside of the control of the FBO, such as weather delaying flights; catering provided by third parties; municipal owned airport knowledge; construction projects impacting the FBO’s environment; internet and telecommunication provider outages and services;

Embassair recently built a new FBO terminal at KOPF designed by French architect Jacques Rougerie.

pandemic impacted staffing; and even the implementation of an FBO’s ownership exit strategy. Well-run FBOs have backup strategies in place to deal with outages which impact aircrew and passengers, helping to smooth out speed bumps.

Setting the quality assurance and customer satisfaction bar high is not only a reflection of the management style of the FBO’s senior leaders but also the economic realities of the marketplace in which they are situated. While not all airports are created equal, the level of aircraft activity can vary greatly. A medium-sized U.S. airport, for example, may see 200 to 300 aircraft per week as compared to a Canadian airport seeing 20 to 30 aircraft. Volume and velocity will drive topline revenue, changing both the profitability levels and return on investment (ROI), but hopefully not impacting customer service.

Embassair of Miami-Opa Locka Executive Airport (KOPF) has built a new FBO

terminal building and hangers. The terminal designed by Jacques Rougerie, a world-renowned French architect, looks like a bird in full flight and was designed with a focus on passenger security, confidentiality and privacy. This boutique FBO is focusing on a limited number of patrons, essentially Very VIPs. With 25 hand-picked customer focused staff (growing to 50 by the third quarter), expectations are set beginning with greeting the aircraft. The incoming aircraft is marshaled onto the ramp or hangar by traditional FBO staff, but it is also immediately meet by a member of the concierge staff, beginning a unique experience for the aircrew and passengers alike.

Confidentiality and privacy of the passengers is maintained throughout their stay at the FBO, based upon the design of the facility, beginning with a U.S. Customs and Border Protection office in the FBO.

With Embassair focusing on a small number of customers,

it has implemented a training program which endeavors to ensure that the staff understand their corporate goals and the delivery of a higher quality of customer engagement than the norm, inclusive of customer surveys delivered on each customer engagement.

Volume and velocity drive topline revenue, but hopefully not customer service.

“We want to offer the finest door-to-door service for both business and leisure travelers, providing best-in-class concierge services, modern architectural designs that incorporate the latest technologies, and the highest standards of safety and security,” says Frank Devaux, Embassair’s founder. “Embassair’s FBO is one of the

most innovative terminals in the world and a true work of art. It is based on Embassair’s values of innovation, luxury and security.”

Expectation management is the fine art of balancing experience, temperaments, process, personalities and training, while operating in the constraints of financial realities and staffing availabilities. The freedom of flight inherently allows FBO interactions to be compared with an eye to the competition both at a specific airport and afar. As compared to flying the airlines, BA, GA and charter operators provide an opportunity for FBOs to deliver products and services to their customers, inclusive of passengers, in an environment completely different from the average airline-focused terminal. Delivering a higher level of customer engagement in a quality environment will drive more corporations and passengers to consider BA, GA and charters, with the result of increasing economic activity. | W

NET ZERO FLIGHT POTENTIAL

FUTURE OF FLIGHT IN A NET ZERO CARBON WORLD: NINE SCENARIOS AND LOTS OF SUSTAINABLE AVIATION FUEL

BY CANDELARIA BERGERO AND STEVE DAVIS

Several major airlines have pledged to reach net-zero carbon emissions by midcentury to fight climate change. It’s an ambitious goal that will require an enormous ramp-up in sustainable aviation fuels, but that alone won’t be enough, our latest research shows.

The idea of jetliners running solely on fuel made from used cooking oil from restaurants or corn stalks might seem futuristic, but it’s not that far away. Airlines are already experimenting with sustainable aviation fuels (SAF), including biofuels made from agriculture residues, trees, corn and used cooking oil, and synthetic fuels made with captured carbon and green hydrogen.

United Airlines, which has been using a blend of used oil or waste fat and fossil fuels on some flights from Los Angeles and Amsterdam, recently announced plans to power 50,000 flights a year between its Chicago and Denver hubs using ethanol-based SAF by 2028. United also launched a US$100 million fund in February with Air Canada, Boeing, GE Aerospace, JPMorgan Chase and Honeywell to invest in SAF startups to expand the industry.

In a new study, we examined different options for aviation to reach net-zero emissions. The bottom line: Replacing fossil jet fuel with SAF will be crucial, but the industry will still need to invest in direct-air carbon capture and storage to offset emissions that can’t be cut. Each pathway has important trade-offs and hurdles.

SCENARIOS FOR THE FUTURE

Before the pandemic, in 2019, aviation accounted for about 3.1 per cent of total global carbon dioxide emissions from fossil fuel combustion, and the number of passenger miles traveled each year was rising. If aviation emissions were a country, that would make it the sixth-largest emitter, closely following Japan.

In addition to releasing carbon emissions, burning jet fuel produces soot and water vapour, known as contrails, that contribute to warming, and these are not avoided by switching to sustainable aviation fuels. Aviation is also one of the hardest-to-decarbonize sectors of the economy. Small electric and hydrogen-powered planes are being developed, but long-haul flights with lots of passengers are likely decades away.

We developed and analyzed nine scenarios spanning a range of projected passenger and freight demand, energy intensity and carbon intensity of aviation to explore how the industry might get to net-zero emissions by 2050. We found that as much as 19.8 exajoules of SAF could be needed for the entire sector to reach net-zero CO2 emissions. With other efficiency improvements, that could be reduced to as little as 3 exajoules. To put that into context, 3 exajoules is almost equivalent to all biofuels produced in 2019 and far surpasses the 0.005 exajoules of bio-based jet fuel produced in 2019. An exajoule is a measure of energy.

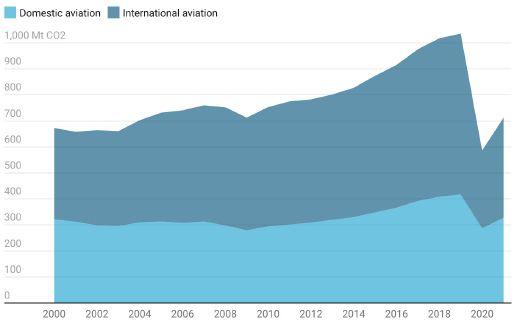

Carbon dioxide emissions from domestic and international flights were rising until the pandemic began in 2020 and demand dropped. Emissions have since begun to rebound.

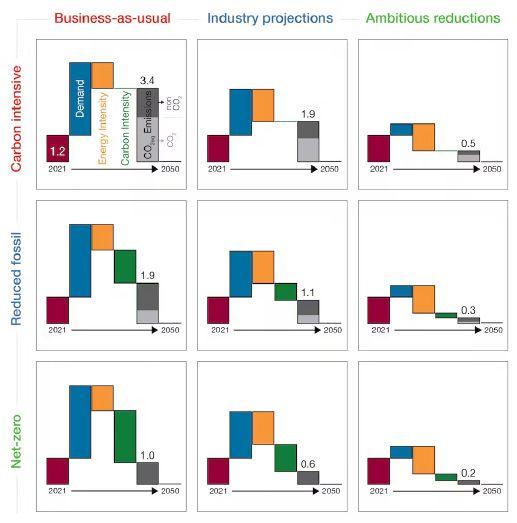

Nine scenarios illustrate how much carbon offsets would be required to reach net-zero emissions, depending on choices made about demand and energy and carbon intensity. Each starts with 2021’s emissions (1.2 gigatons of carbon dioxide equivalent). With rising demand and no improvement in carbon intensity, a large amount of carbon capture will be necessary. Less fossil fuel use and slower demand growth reduce offset needs.

Flying less and improving airplanes’ energy efficiency, such as using more efficient glide landings that allow airlines to approach an airport with engines at near idle, can help reduce the amount of fuel needed. But even in our rosiest scenarios – where demand grows at 1% per year, compared to the historical average of 4%,

ATAC’s Canadian Aviation Conference and Tradeshow is the premier national gathering offering Canada’s best networking, learning, and sales opportunity for operators, suppliers, and government stakeholders involved in commercial aviation and flight training in Canada.

TUESDAY, NOVEMBER 14 TO THURSDAY, NOVEMBER 16

FAIRMONT QUEEN ELIZABETH HOTEL MONTREAL, QC

For more information contact: Debbie Simpson, Tradeshow Manager 613-884-7728 tradeshow@atac.ca www.atac.ca

FLY WITH CONFIDENCE.

A ward

To be awarded at ATAC's 2023 Canadian Aviation Conference and Tradeshow, Nov. 14 to Nov.16, 2023 - Montreal, Qc.

e Award recognizes and honours a ight instructor, either xed or rotary wing, who has made a signi cant contribution to safety in Canada, also having demonstrated superior teaching skills.

Jane & Rikki Abramson established this Award in 2003 through Air Transport Association of Canada, and will personally present this year’s award. e recipient’s name will be engraved on the prestigious perpetual trophy and entered in the associated logbook, both on permanent display in the Canada Aviation & Space Museum in Ottawa.

e Award is Generously Sponsored By: Nominations can be made at any time throughout the year, prior to the deadline of September 14th, 2023 For entry requirements contact Jane Abramson, Founder & National Administrator Email: janeabramson@videotron.ca

www.dcamaward.com

and energy efficiency improves by 4% per year rather than 1% – aviation would still need about 3 exajoules of sustainable aviation fuels.

WHY OFFSETS ARE STILL NECESSARY

A rapid expansion in biofuel SAF is easier said than done. It could require as much as 1.2 million square miles (300 million hectares) of dedicated land to grow crops to turn into fuel – roughly 19% of global cropland today.

Another challenge is cost. The global average price of fossil jet fuel is about US$3 per gallon ($0.80 per litre), while the cost to produce bio-based jet fuels is often twice as much. The cheapest, HEFA, which uses fats, oils and greases, ranges in cost from $2.95 to $8.67 per gallon ($0.78 to $2.29 per litre), but it depends on the availability of waste oil.

Fischer-Tropsch biofuels, produced by a chemical reaction that converts carbon monoxide and hydrogen into liquid hydrocarbons, range from $3.79 to $8.71 per gallon ($1 to $2.30 per litre). And synthetic fuels are from $4.92 to $17.79 per gallon ($1.30 to $4.70 per litre).

Realistically, reaching net-zero emissions will likely also rely on carbon dioxide removal. In a future with similar airline use

as today, as much as 3.4 gigatons of carbon dioxide would have to be captured from the air and locked away – pumped underground, for example – for aviation to reach net-zero. That could cost trillions of dollars.

For these offsets to be effective, the carbon removal would also have to follow a robust eligibility criteria and be effectively permanent. This is not happening today in airline offsetting programs, where airlines are mostly buying cheap, nonpermanent offsets, such as those involving forest conservation and management projects.

Some caveats apply to our findings, which could increase the need for offsets even more. Our assessment assumes SAF to be net-zero carbon emissions. However, the feedstocks for these fuels currently have life-cycle emissions, including from fertilizer, farming and transportation. The American Society for Testing Materials also currently has a maximum blend limit: up to 50% sustainable fuels can be blended into conventional jet fuel for aviation in the U.S., though airlines have been testing 100% blends in Europe.

HOW TO OVERCOME FINAL HURDLES

To meet the climate goals the world has set, emissions in all sectors must decrease – including aviation.

While reductions in demand would help reduce reliance on sustainable aviation fuels, it’s more likely that more and more people will fly in the future, as more people become wealthier. Efficiency improvements will help decrease the amount of energy needed to power aviation, but it won’t eliminate it.

Scaling up sustainable aviation fuel production could decrease its costs. Quotas, such as those introduced in the European Union’s Fit for 55 plan, subsidies and tax credits, like those in the U.S. Inflation Reduction Act signed in 2022, and a carbon tax or other price on carbon, can all help achieve this.

Additionally, given the role that capturing carbon from the atmosphere will play in achieving net-zero emissions, a more robust accounting system is needed internationally to ensure that the offsets are compensating for aviation’s non-CO2 impacts. If these hurdles are overcome, aviation could achieve net-zero emissions by 2050. | W

This article was originally published by The Conversation. Candelaria Bergero is a Ph.D. Student in Earth System Science, University of California, Irvine, and Steve Davis is a Professor of Earth System Science, University of California, Irvine.

BOOK NOW

RHYME NOR REASON

In this post-pandemic period, Canada’s aviation industry has been struck by another curse that is causing great havoc on the sector’s recovery efforts. That is Transport Canada’s unwillingness to venture out of Tower C to discover first-hand the impact of some of its regulations, the poor state of the department’s level of service, and the inability to see reason in industry’s request for regulatory reprieve in these times of dire human resources shortages.

The timing of some compliance deadlines and the refusal to allow tolerances to facilitate a smooth and workable implementation timeline is unacceptable given the many challenges facing industry. We rely on the Minister to challenge his department and impose a new approach, not one where the industry’s plea for tolerance or temporary reprieve is seen as an obstruction or as a disguised refusal to comply.

FLIGHT AND DUTY TIME

ATAC wrote to the Minister in November asking that the implementation deadline for compliance to the new Fatigue Risk Management regulation for the 703 and 704 operators be pushed back by 18 months beyond December 12, 2022, the date originally set by the department. We received a perfunctory response from the department, suggesting the same dismissive attitude unfortunately too often displayed when faced with constructive feedback from operators.

The labour shortage is a huge problem requiring all parties to work together towards a solution. The Government must acknowledge that the very existence of smaller regional carriers is threatened by the challenge of holding on to the few experienced pilots available as the demand far exceeds the supply of available qualified pilots. There could not be any worse timing for imposing regulations that exacerbate the biggest threat that our industry has faced outside the pandemic. To impose a new regulation at this time that requires an overnight increase of 30% of pilots required to offer the same level of service suggests a total disregard for sustained air services to Canada’s remote regions.

Once again, we ask that Tower C accept the reality facing our industry and the threat to the continued delivery of service to Canadians, especially in remote regions. Undoubtedly, Transport Canada will blame industry for the cut in service, totally dismissing the role it plays in setting our working environment.

ATAC Operators have given numerous examples of cases where Fatigue Risk Management Regulations need to include a minimal

level of tolerance if they are to be practical, operationally and financially. The suggested Fatigue Risk Management System, the usual Transport Canada go-to answer, has been amply proven to be impractical and impossible to implement except for perhaps Canada’s largest carrier.

PASSENGER PROTECTION IS EVERYONE’S RESPONSIBILITY

Minister Alghabra announced in February that he will be tabling legislative and regulatory amendments to the Air Passenger Protection Regulations (APPR). Industry certainly agrees that some amendments are very much needed if requests for compensation are to become user friendly rather than a burden to all stakeholders.

Why is the air transport industry held to standards no other industry or government service is ever expected to meet? What other industry is penalized to such extremes for delay or cancellation of service? The delays for air operators to settle a passenger request for compensation are ridiculously short, especially considering that passenger requests can be filed up to twelve months after the flight. Oddly enough, the CTA allows itself 18 months to manage a request for compensation, Clearly, the Government is holding the commercial air transport industry to levels of service it doesn’t begin to hold itself to.

Changes are needed to enhance the accountability and the shared responsibility of all parties dealing with passenger services, not simply the carriers. Amendments need to propose a model where all share in the responsibility, including the passenger, the carriers and all others involved in managing or impacting air travel in Canada, including airports, CATSA, NAV Canada, or ground service providers. Also, amendments to the APPR should aim to make their application simple and practical for both the passenger and the service providers.

It must not be forgotten that the air carriers’ number one concern is the safety of passengers. Considering that over 160 million people travel by air annually in Canada, and that in no instances of the Holiday Season disruptions of service cited was the safety of passengers threatened, it could be concluded that this industry did an excellent job in very difficult circumstances.

ATAC and all of industry stand ready to work with the Government to reach a workable consensus that would improve the passenger experience in Canada.

John McKenna President and CEO

Transport Association of Canada

By Lorenzo Marandola |

From the ground up

M1 Composites celebrates 10 years as it grows through

innovation

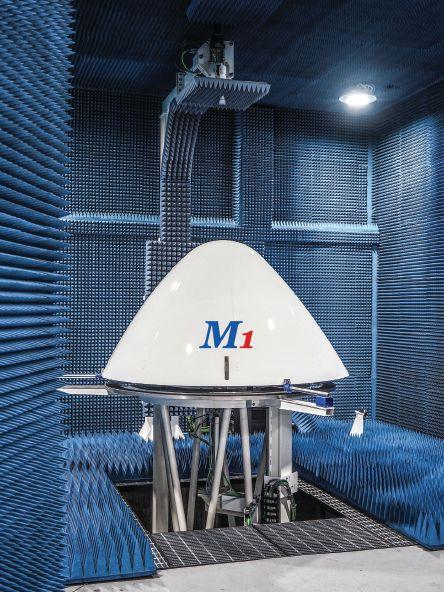

On the tip of the nose, radomes are vulnerable to bird strikes, hail damage, lightning, and static discharge. They protect highly sensitive radar antennas from weather and improve aerodynamic loading. Though highly important to aircraft structure, radomes are often overlooked. The slightest changes to their physical characteristics can adversely affect aircraft performance.

Ensuring optimal radome performance is crucial to flight safety and performance.

M1 Composites, based in Laval, Quebec, has long been repairing radomes. In 2022, it took a major leap forward and opened its new indoor Compact Radome Test Range (CRTR) to conduct transmissivity testing of weather radomes.

Housed in an 82,000-square-foot facility, the test range is a spherical near-field testing facility that ensures that the aircraft's weather radar system is functioning optimally. The CRTR is the only one of its kind in Canada and one of only a handful in the world.

M1 can test military and commercial weather radomes 24/7/365 regardless of weather and provide the quickest turnaround time to all of its customers.

Another key development in M1’s product range are its new engine covers. These covers are unlike any other on the market today. Developed and produced to protect the thousands of aircraft and engines grounded at the height of the pandemic, M1’s engineers worked side-by-side with one of its largest airline customers to find a solution. The result? A highly durable, lightweight and transportable engine cover that requires only two technicians to install in under five minutes per engine. Its ease of use – no ladders or scaffolding required –ensures fast installation and the prevention of falls from heights.

When not in use, these engine covers can be carried in the cargo bay for use in off-base operations and in all inclement and adverse conditions. Made of a highstrength synthetic fabric, the cover protects

M1 Composites in 2022 opened its CRTR site for transmissivity testing of weather randomes.

and prevents corrosion and premature degradation of engine lips, parts and components. This new engine cover saved that initial customer $4 million annually in engine MRO costs.

This unique cover has already gained acceptance across the industry and aircraft types, including Boeing 737 MAX, 777, 787, Airbus A220, A320 and A330. M1 has since been awarded a contract by a major airline to provide these engine covers for an entire fleet. It is a testament to the quality of M1’s products, solutions and attention to changing customer needs.

Evolving with the changing needs of customers is at heart of M1’s mission. The success of its new CRTR and engine cover

are just some examples of M1’s commitment to research and development. Led by experienced engineers in search of cutting-edge technologies or improving tried, tested and true ones, M1 is a Transport Canada Approved Maintenance Organization (AMO) and Design Approval Organization (DAO) specializing in advanced composites and sheet metal structures.

M1’s push in engineering innovation and business growth has not gone unnoticed in the industry. In 2021, it was awarded the MACH 5 accreditation by AeroMontreal for continuous improvement.

In 2022, M1 Composites celebrated its tenth anniversary and the company continues to grow its unique market position and product portfolio. It is a leader in the repair of radomes, nacelles, flight control surfaces, and other structural elements for both commercial and military aircraft.

M1 has set its sights on innovation to expand and grow with the ever-changing needs of aviation industry, exemplified by CRTR and engine cover investments. The Canadian company is grounded in its commitment to provide innovative products and solutions to all its global customers. Innovation is not just a passive marketing term here. It is at the very heart of what M1 Composites does everyday. | W

Lorenzo Marandola is President of M1 Composites Technology in Montreal, Canada. He is a licenced member of the Order of Engineers of Québec with almost 30 years of experience in engineering design, analysis, production, testing and management.