STEADYING INFLUENCE

Steadiwear’s glove provides stabilizing relief p.12

POWER

SIMPLIFIED

Non-isolated dc-dc converters streamline your power needs p.16

COOLING DOWN

AI solutions increase thermal demand on computing systems p.20

Steadiwear’s glove provides stabilizing relief p.12

Non-isolated dc-dc converters streamline your power needs p.16

AI solutions increase thermal demand on computing systems p.20

COVER STORY

NOVEMBER/DECEMBER 2025

4 EDITORIAL

Canada’s medtech start-ups lead with purpose

6 WEST TECH REPORT

Nordic AutoFeed’s automated tech keeps horses healthy

7 THINK GREEN

Digital transformation reinvents global supplyt

In every issue

5 NEWSWATCH

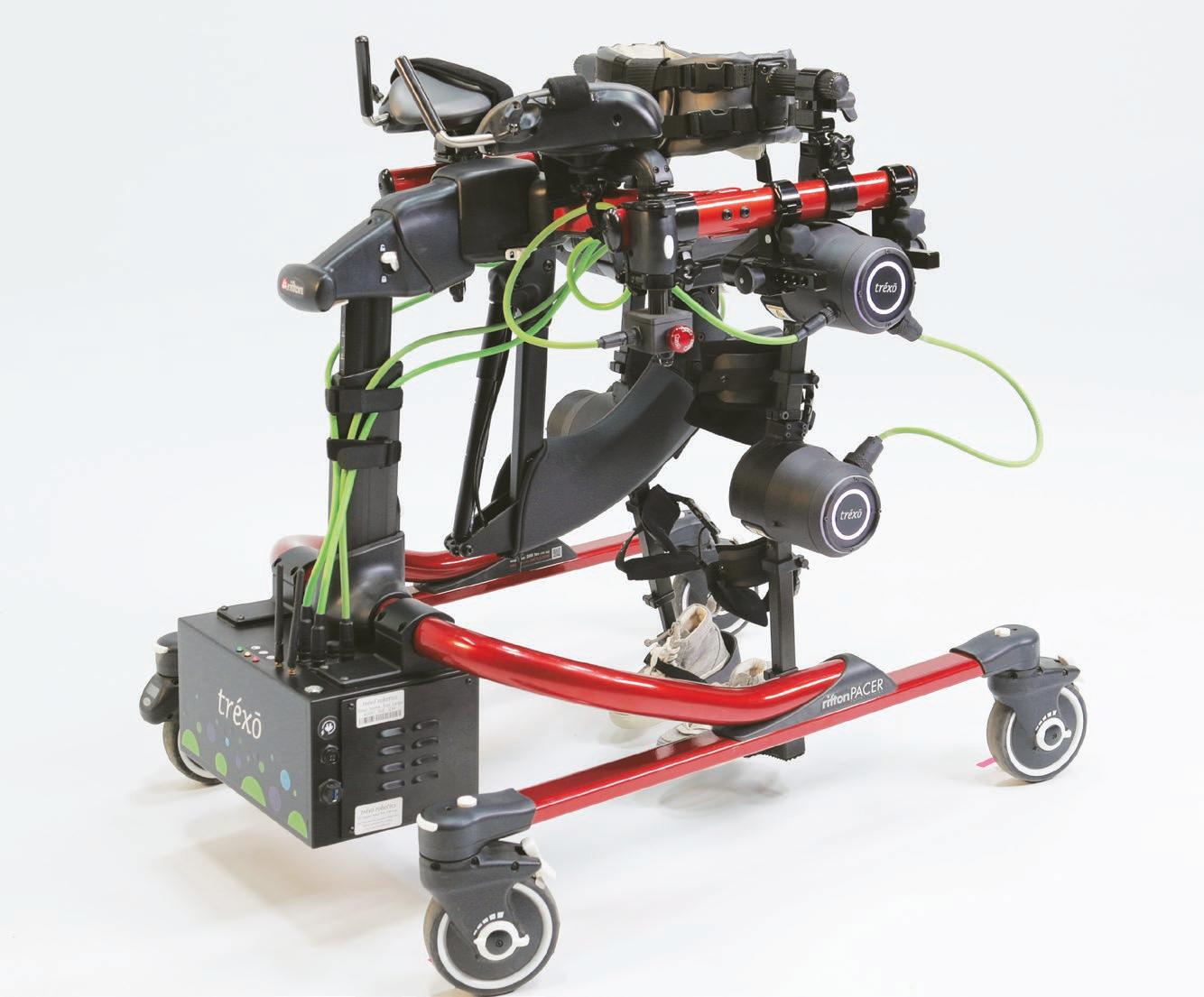

8 LEADING WITH PURPOSE

Trexo Robotics is rewriting the narrative around childhood mobility with its exoskeletons.

12 SHAKE IT OFF

Steadiwear develops groundbreaking wearable that blends mechanical innovation with human-centered design.

16 CREATING A POWER BUDGET

Tips on how to tackle planning a system or machine’s power architecture.

20 THIN AND QUIET

Insufficient cooling results in systems being throttled, both in design and in operation. Columns

16

20

22 SUPPLY SIDE

22 AD INDEX

In recent years, Canada’s standing as a global player in medical electronics has advanced from promising to pivotal. Once regarded primarily as a source of component-level innovation and research, the country is now producing a new generation of medtech companies that combine deep engineering expertise with a human-centred mission — bridging technology and compassion in remarkable ways.

The result is a wave of start-ups and scale-ups that are not just designing electronics for medical applications, but redefining how those technologies interact with the body and enhance quality of life. This edition of EP&T Magazine - takes a close look at that transformation.

Two stories in particular highlight the ingenuity, persistence, and social purpose driving Canada’s medtech ecosystem. The first, Mississauga-based Trexo Robotics is rewriting the narrative around childhood mobility. Founded by University of Waterloo-trained mechatronics engineers, Trexo has developed a wearable robotic exoskeleton that helps children with disabilities and walking impairments experience over-ground walking - both in clinical environments and, increasingly, at home.

The Trexo system, known for its sleek design and adaptive functionality, represents a fusion of advanced robotics and practical rehabilitation. It translates years of mechanical, electrical, and software engineering into something profoundly simple: a child’s ability to take steps, to move independently, to feel included. Beyond the technical marvel, it underscores how

medical electronics can transcend function to deliver emotional and developmental benefits. For engineers working in this field, it’s a reminder that innovation is most powerful when it restores a fundamental human experience.

Equally inspiring is SteadiWear, a Toronto-based company that has achieved what many in the field thought impossible: tremor stabilization without batteries. Its flagship device, the Steadi-3, is a lightweight, non-invasive glove that instantly stabilizes hand tremors for individuals living with Essential Tremor and Parkinson’s Disease. Drawing on principles of mechanical damping and advanced materials science, SteadiWear’s engineers have produced a purely mechanical solution that requires no charging, no downtime, and no intrusive calibration — just steady hands, restored confidence, and renewed independence.

What’s striking about both of these Canadian medtech pioneers is that they’ve taken the principles of wearable technology, such as sensors, actuators, feedback loops, and ergonomic design — and applied them in ways that meaningfully improve lives. These are not consumer gadgets chasing convenience; they are purpose-built systems engineered to address human challenges at the intersection of health and electronics.

The convergence of biomedical engineering, microelectronics, and artificial intelligence is propelling this new era forward. Across the country, research institutions like the University of Toronto’s Institute of Biomedical Engineering, McGill University’s Bioelectronics Lab, and the University of Waterloo’s Mechatronics and Rehabilitation Robotics programs are nurturing the next wave of innovators. Meanwhile, networks such as Ontario’s OBIO (Ontario Bioscience Innovation

Canada’s information leader for electronic engineers and designers

NOVEMBER/DECEMBER 2025

Volume 47, Number 7

READER SERVICE

Print and digital subscription inquiries or changes, please contact Angelita Potal Tel: (416) 510-5113 Fax: (416) 510-6875

Organization) and Québec’s Technum Québec are helping bridge the critical gap between prototype and production.

Canada’s advantage lies not only in its talent pool but also in its culture of collaboration. In the medtech world, breakthroughs often depend on cooperation between clinicians, engineers, and entrepreneurs — and Canada’s ecosystem excels at fostering exactly that kind of interdisciplinary dialogue. The line between lab and life has never been thinner.

EP&T has long championed the innovators working behind the scenes to bring life-changing technologies to market. But what’s emerging in medical electronics feels different — more personal, more urgent, and more globally relevant than ever before. It’s worth noting, too, that this progress is not limited to startups. Major electronics firms and component suppliers are increasingly turning their attention to healthcare applications, viewing medical electronics as both an ethical imperative and a growth opportunity. Semiconductor design houses, pcb manufacturers and sensor developers are all finding new demand from the medical sector, where precision, reliability, and safety are non-negotiable. Read for yourself our coverage of such successes in medtech in this issue (Trexo Robotics on page 8 and SteadiWear on page 12), both which serves as a window into the broader story of Canadian innovation. Medical electronics isn’t just about circuits, code, or control systems — it’s about care. And Canada, it seems, is proving to the world that compassion can indeed be engineered.

STEPHEN LAW Editor slaw@ept.ca

Connect with EP&T @EPTmagazine facebook.com/EPTmag/ /ept-magazine info@ept.ca ept.ca

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

EDITOR Stephen Law slaw@ept.ca · (416) 510-5208

WEST COAST CORRESPONDENT Mike Straus · mike@brandgesture.ca

BRAND MANAGER Joanna Malivoire jmalivoire@ept.ca · direct (416) 881-0731

ACCOUNT COORDINATOR Shannon Drumm sdrumm@annexbusinessmedia.com

MEDIA DESIGNER Alison Keba akeba@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER Anita Madden amadden@annexbusinessmedia.com (416) 510-5183

GROUP PUBLISHER Paul Grossinger pgrossinger@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annesbusinessmedia.com

EP&T is published eight times per year by ANNEX BUSINESS MEDIA 111 Gordon Baker Road, Suite 400 Toronto, ON M2H 3R1 Tel (416) 442-5600 Fax (416) 510-5134 annexbusinessmedia.com

SUBSCRIPTION RATES Canada – $59.67 one year; $95.88 two years USA – $136.68 (CAD) per year International – $187.17 (CAD) per year Single copy – Canada $15.00

ISSN 0708-4366 (print)

ISSN 1923-3701 (digital)

PUB. MAIL AGREEMENT NO. 40065710 Return undeliverable Canadian addresses to: EP&T Circulation Department, 111 Gordon Baker Rd. Suite 400, Toronto, ON M2H 3R1

© 2025

EP&T. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions or validity of the claims in items reported. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication. Occasionally, EP&T will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department.

PRINTED IN CANADA

Volatus Aerospace Inc. an Ontario-based provider of aerial intelligence and unmanned aircraft systems, and VoltaXplore Inc., a lithium-ion battery manufacturer and subsidiary of NanoXplore Inc., have signed of a Letter of Intent (LOI) for the future supply of Canadian-made lithium-ion battery cells to power Volatus’ next-generation drones.

The agreement strengthens Volatus’ product differentiation and supply chain security while positioning both companies for growth across civil, defense, and Arctic surveillance markets. By securing a domestic source of advanced, silicon-dominant battery cells, Volatus strengthens domestic sourcing and supply management, enhances technological self-reliance, and aligns with anticipated federal investments in Canadian manufacturing capacity.

“Incorporating VoltaXplore’s silicon-dominant cells will give our drones greater endurance, faster charging, and reliable performance in even the most extreme environments, from summer heat to the cold Arctic tundra,” stated Glen Lynch, CEO of Volatus Aerospace. “This partnership ensures the entire value chain, from advanced materials to finished aircraft, remains in Canada, building domestic aerospace capacity and strengthening our defense industrial base.”

For VoltaXplore, the agreement opens a new aerospace market vertical, complementing its existing presence in electric mobility and energy storage, and supports NanoXplore’s long-term growth strategy.

Quebec City–based CEM Fabrique Manic has expanded its production floor less than two years after opening its doors, following rapid customer growth that outpaced the company’s initial expectations.

“When we launched in the spring of 2023, our focus was on flexibility and fast turnaround,” said company president Dominic Gauvreau. “That

approach attracted far more customers than we anticipated. Many were small companies with few options at the time, and their growth became our growth.”

Fabrique Manic began operations with modest equipment, including “a screen printer, a small tabletop pick-and-place, and a five-zone oven producing about one board every 10 minutes,” Gauvreau explained. “Through-hole components were soldered entirely by hand.”

Today, the company runs two full inline SMT lines complete with conveyors, screen printers, highspeed pick-and-place machines, an eight-zone oven, automated optical inspection, and a selective solder wave machine for through-hole assembly.

AEM will supply U.S. Dod with specialized avionics and audio systems for mission critical operations.

“With each upgrade, we’ve kept the focus on quality and flexibility. This has allowed us to handle far higher volumes while continuing to support both new and long-standing customers,” said Gauvreau. The company’s customer base spans sectors as varied as industrial automation, medical devices, mining, telecommunications, agriculture, and entertainment.

Seneca Polytechnic’s Bachelor of Engineering – Software Engineering program has been accredited by the Canadian Engineering Accreditation Board (CEAB) for the maximum possible term of three years. An exceptional achievement for a first-time submission, this milestone reflects

the excellence of the curriculum, the dedication of faculty and the talent of Seneca students.

“This accreditation is a testament to the rigorous academic standards and industry-informed learning experiences students will find within this program,” says Dr. Kacem Habiballah, Dean, Faculty of Applied Science & Engineering Technology. “Our commitment to innovation, hands-on learning, human skills and industry engagement is embedded in this program ensuring our graduates are not only career-ready but world-ready.”

CCC, Canada’s foreign military sales agency, has been awarded a contract by the U.S. DoD for magnetic amplifiers made by Anodyne Electronics Manufacturing Corp (AEM). The components will support the internal communication system of V-22 Osprey aircraft operated by the U.S. Navy.

Based in Kelowna, BC, AEM is a leading designer and manufacturer of specialized avionics and audio systems for mission-critical aircraft operations. The firm serves a global market, supplying components to major aircraft manufacturers like Boeing, Bell, Airbus Helicopters, and Sikorsky. Among its innovations, AEM produces magnetic amplifiers tailored for highnoise aircraft environments, including the Bell Boeing V-22 Osprey. These systems are designed to overcome extreme operational noise, delivering clear, powerful audio for crew and passenger communication.

BY MIKE STRAUS, WEST TECH CORRESPONDENT

For many horseback riders, a horse is like a member of the family. So when a rider loses a horse, it can be emotionally challenging. Ashton Shura, co-founder of Nordic AutoFeed in Kelowna, B.C., experienced this loss personally when her horse died of colic.

“Colic is a gut issue, an intestinal twist,” Shura explains. “It comes from feeding the animal multiple times a day. Horses are grazing animals; they’re designed to be out in the wild grazing. So through that loss, my sister Kirsten and I decided to create a better feeding solution that better mimics their natural feeding habits.”

Shura explains that there’s a lack of technology in the horse industry; horse ownership has largely been tradition-based, and for a long time, horses were fed out of buckets. The past decade has seen the rise of automatic waterers that decrease the time and energy involved in giving horses water, but there are very few automatic feeding solutions on the market.That’s the problem Shura set out to solve when she and her sister Kirsten founded Nordic AutoFeed.

“Autofeeding is a complex problem,” Shura says. “What sets our feeder apart is that it’s weight-based; it feeds the horse a certain number of pounds of hay per day. As a result, we can offer much more customization (than other autofeeders).”

Shura and her sister invented an automatic hay feeder with a low door on one side so that horses can pull the hay out, instead of having the feeder dispense the hay. Engineering this product was a challenge, though, and the sisters went through several different designs that didn’t work as intended. Weight-based feeding mechanisms are challenging to build, as they involve creating load cells and rubber matting. Furthermore, Shura explains, large animals like horses tend to be hard on these kinds of products, and the units themselves live outside – so the autofeeder must be hardy enough to withstand a harsh environment, but refined enough to deliver consistent results.

The Nordic AutoFeed system boasts a display screen that gives the user the total hay weight inside the unit. After setting the time zone and calibrating the scale, users can set how many times per day they want to feed, and how much weight they want to feed per day. From there, the machine’s software takes the desired poundage and divides it by the number of feeding times. The feeding door

Ashton says her favourite part of the product is the weight sensors.These sensors, placed at the bottom of the cabinet, provide constant feedback to ensure the weight matches up with the feeding schedule.

Other horse feeding technologies like hay nets and other autofeeders, Ashton says, work on the basis of trying to slow the animal’s consumption rate and lengthen the feeding time. But when one slows down the animal’s rate of eating, it creates anxiety for the animal. There’s also wear and tear on teeth, and the animal’s nasal drain is impacted. Finally, hay nets present the potential risks of horses getting caught in them.

“Instead of slowing the consumption rate, we’re breaking up how often they’re fed,” Ashton explains. “With our technology, horses can eat from the feeder or the ground, and from the ground is the most optimal way for animals to feed. That way we’re not slowing the animal down, but we’re moderating the amount of food they eat at a time.”

opens automatically when it’s feeding time, then closes after the designated poundage of hay has been taken out. This method gives the horse enough time to eat the hay, but minimum and maximum open-door times ensure the horses are fed without overfeeding or underfeeding.

Ken Shura, Ashton and Kirsten’s father, is the engineer responsible for creating the electronics in the AutoFeed system. Ken explains that load cells weigh the feed, then send the feed weight to a microprocessor. The microprocessor performs calculations at the start of each feed cycle to determine how much feed should be dispensed and for what period of time. Once the designated amount of feed has been taken, the feed door closes.

“We have an analog interface,” Ken says. “We deliberately made it analog to make it easy to use.The user turns a dial to set the start and end times, then sets the number of feeds per day. From there, the computer figures out how many pounds are needed to be released per feeding. The timer activates the weight sensor. The system also has battery backups, so if the power goes out, it’ll continue to feed the horse for a full day.”

The AutoFeed system uses a 24-volt power supply and can be run off standard landscape lighting cables. Nordic AutoFeed also has provisions for solar power and rechargeable lithium batteries.

Ashton explains that horses can get ulcers and other health problems if they don’t eat at least every 4 hours, so the autofeeder is set to match the horse’s natural eating pattern and prevent ulcers and other health issues.

For Ashton, part of running a family business is the joy of collaboration:

“My sister comes from a medical background, so she can provide a lot of context around the human benefits, like reduced dust exposure and fewer lung infections that come from the manual tossing of hay. My background is more in business and tech. We’ve both owned a number of horses over the years, which allowed us to process how this product can be useful to a wide range of animals.”

The firm is expanding operations, while continuing to test and refine its product, adding better functionality all the time. The team is also prototyping a product to handle grain instead of hay. Finally, the Shura sisters are actively involved in educating horse owners through partnerships with vets and nutritionists.

Mike Straus is EP&T’s West Coast correspondent. mike@ brandgesture.ca

Nordic AutoFeed is a Kelowna, B.C.-based manufacturer of agricultural technology. For more information, visit https://www.nordicautofeed.com/. Photo:

BY ROB PICKEN, SVP DIGITAL TRANSFORMATION & PARTNERSHIPS, SOURCEABILITY

Supply chains today are operating in an environment defined by uncertainty and constant change. From geopolitical tensions and evolving trade policies to raw material shortages and changing consumer expectations, the traditional ways of managing global networks are no longer enough. Businesses are realizing that the supply chain can’t just be efficient, it needs to be intelligent, adaptive, and resilient. That pivot is driving a surge in advanced technologies and data-driven insights as companies rethink strategies to mitigate risk, improve proactivity, and position themselves for long-term growth.

Supply chain challenge

As a reminder of just how fragile global supply chains can be, one can look back on the 2021 Suez Canal blockage. When a container ship ran aground and halted one of the world’s busiest trade arteries for nearly a week, the disruption cascaded far beyond the canal itself. This doesn’t even begin to touch how facility shutdowns in the early days of COVID sent the semiconductor supply chain into a downward spiral that took time to recover from. The ripple effects these incidents caused underscored how a single point of failure can paralyze industries worldwide.

These crises exposed the vulnerabilities of global supply chains and continue to underscore the urgent need for resilience, intelligence, and adaptability. Organizations that take a proactive approach and invest in advanced intelligence tools, such as real-time visibility, predictive analytics, and AI-driven scenario modeling, are better positioned to mitigate risk. By anticipating downstream effects, adjusting inventory strategies, and seamlessly rerouting shipments, these companies demonstrate that the

Organizations that take a proactive approach and invest in advanced intelligence tools, put themselves in a position to mitigate risks.

future of supply chains lies in data-driven agility and resilience, not just efficiency.

Adopting emerging technologies such as AI, IoT, digital twins, and blockchain can greatly enhance supply chain visibility, traceability, and proactive risk management. For example, BMW uses AI and data analytics to monitor suppliers and anticipate potential delays, ensuring smoother operations. The recently deployed Generative AI tool AIconic has transformed the company’s purchasing and supplier network. By integrating diverse data sources, the tool has reduced the amount of time teams are spending on analyzing suppliers.

At the component level, predictive analytics are crucial for informing design risk, price and inventory trends, market availability, and multi-source availability while simultaneously bringing attention to possible disruptions. Powered by machine learning, these tools become more accurate as they learn from collected data – primarily on raw material availability, consumer behavior, sales data, weather conditions, logistics, and historical trends. Through pattern recognition, predictive analytics determines the likelihood of breakdowns

along the supply chain, and which components are prone to future risks. IoT sensors, RFID tags, GPS, and connected machines feed AI systems with live updates on inventory, shipments, and production status. AI integrates these data streams into a unified digital twin of the supply chain, so the system has a continuously updated picture of what’s happening to effectively inform strategy.

Companies are looking for ways to build ecosystems that not only react to disruption but anticipate it, systems that can learn, adapt, and even self-correct as conditions change. This evolution is blurring the line between operations and innovation, turning the supply chain from a

behind-the-scenes function into a central driver of competitiveness. This brings procurement and purchasing teams into the spotlight, and these tools ensure they stay ahead.

Companies that fail to modernize these processes are unable to keep up with customer demands and struggle to compete with other manufacturers in the supply chain.

Ultimately, investing in adaptive supply chains is no longer optional, it’s a critical move for long-term success in today’s unpredictable global market.

Sourceability provides real-time market data and end-to-end electronic component distribution. https://sourceability.com/

BY STEPHEN LAW, EDITOR EP&T

From a small startup concept born at the University of Waterloo to an internationally recognized leader in pediatric mobility, Trexo Robotics has redefined what’s possible in assistive technology. Founded by Manmeet Maggu and Rahul Udasi, the Mississauga-based company develops robotic exoskeletons that allow children with mobility impairments to walk—powered by cutting-edge mechatronic engineering and intelligent electronics design.

Combining precise motion control, sensor fusion, and real-time feedback systems, Trexo’s technology embodies the convergence of robotics and healthcare innovation that’s positioning Canada as a growing force in advanced medical electronics. Manmeet Maggu’s university education in Mechatronics program Waterloo combines software, electrical, mechanical engineering to give students strong systems engineering skills. The program covers how these disciplines work together to create integrated mechatronic systems, according to Maggu.

“This foundational knowledge was essential in designing the first Trexo. From the first semester, the program’s project-based approach had us building robots. The early hands-on experience helped, combined with the co-op program, which gave Rahul and myself exposure to companies developing advanced robotics and mechatronic systems. This knowledge informed many of our architectural and design decisions,” said Maggu.

At the heart of Trexo’s system lies complex sensor integration. The robotic exoskeleton has sensors on each of the actuators, that monitors each joint’s kinematic and dynamic state and how the user is affecting that. These include encoders/hall sensors and torque sensors. Each motor controller runs on a real-time operating system, while the main CPU coordinates the overall system, handling trajectory planning

Mississaugabased Trexo Robotics develops assistive exoskeletons that allow children with mobility impairments to walk—powered by cutting-edge mechatronic engineering and intelligent electronics design.

and synchronizing joint movement. All of this is handled on a serial communication bus, which allows for smooth and reliable processing of information. When it comes to power management and portability, the motor control algorithms are designed for energy and efficiency, minimizing unnecessary power draw through field-oriented control. The system includes onboard

thermal monitoring to maintain safe operating conditions, according to Maggu.

“Portability was a key design consideration, as a Trexo unit can be easily loaded into an SUV or wheelchair-accessible van, and when disassembled, it fits in most car trunks,” he said.

Trexo’s control algorithms must adapt dynamically to each child’s mobility needs. As a result, embedded electronics continuously collect sensor feedback from each joint, enabling closed-loop control that dynamically adjusts assistance for each user.

“Large quantities of time series data is collected and used to teach AI models for future controllers and diagnostic purposes,” Maggu explained, adding that specialized controllers are tuned to accommodate a range of mobility needs, such as high muscle tone or spasticity. Multiple operating modes, including strength and endurance, allow for different walking experiences tailored to goals of the parents or physical therapist.

“Our hardware and software teams

work in collaboration, iterating together throughout the development process. Our team also includes engineers with mechatronics/systems level knowledge, and are able to work across multiple engineering disciplines,” Maggu noted. “Our approach emphasizes rapid iteration cycles and continuous feedback from real users and customers to guide design improvements and system optimization.”

Maggu says that before Trexo, the most complex robot found in most homes was a Roomba. Deploying hundreds of exoskeletons for regular and reliable home use presented significant challenges.

“We built custom components to allow a high degree of control and flexibility. Some examples include our motor controllers, infrastructure for OTA updates, and doing 100% testing of each device we assemble,” he said.

Custom cable assemblies were also developed to withstand repetitive motion over millions of steps, and the leg structures were subjected to accelerated life-cycle testing to validate

performance under sustained loading conditions.

Component sourcing and reliability for a medical-grade robotic device like Trexo, can be somewhat trickly especially given global supply chain fluctuations in the electronics sector. Medical-grade standards require long product lifecycles and a stable supply chain. To support this, components are selected with longevity and availability in mind.

Traceability is part of the design “We employed a dual-sourcing strategy for critical parts, which helps mitigate global supply risks. Strong partnerships with trusted vendors for motors, sensors, and electronics ensure consistent quality,” explained Maggu. “Traceability is part of the design and manufacturing process, enabling precise tracking of components and ensuring compliance with regulatory requirements. This approach allows early detection and resolution if any part fails to meet the required standards.”

Connectivity plays a significant role

The robotic exoskeletons provide mobility assistance to disabled children.

for Trexo, as its system connects with mobile apps and cloud platforms. Families and clinics are supplied with a tablet preloaded with the Trexo app. The system connects viaWi-Fi and uses encrypted data transmission protocols. Secure over-the-air updates maintain system integrity, ensure compliance, and deliver ongoing improvements.

“We also conduct regular cybersecurity testing including external penetration tests.We have data privacy policies in place with continuous monitoring of critical infrastructure,” Maggu added.

As for the future, Maggu’s mission is to see his firm become the leading exoskeleton company globally. While the current focus is children, Trexo will expand to support a wider range of users.

“Success begins with empathy. Gaining a deep understanding of the problem and the user’s needs allows for a stronger prototype. Then, think big and move fast. Iterate continuously, based on real-world user feedback,” Maggu concludes.

https://www.trexorobotics.com

25_010731_EPandT_NOV_DEC_CN Mod: September 11, 2025 4:54 PM Print: 09/25/25 page 1 v2.5

BY STEPHEN LAW, EDITOR

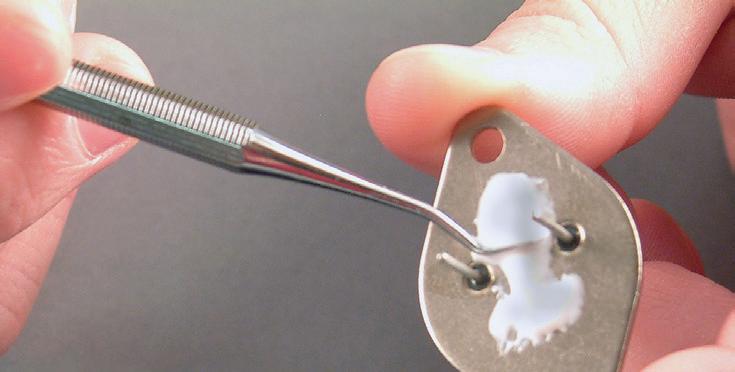

Toronto-based Steadiwear Inc. is redefining the boundaries of assistive medical technology through its focus on elegant, engineering-driven solutions to human motion disorders. Founded with a mission to restore independence and dignity for people living with hand tremors, the company has developed a groundbreaking line of wearable devices that blend mechanical innovation with human-centered design. Its latest release—the Steadi-3, billed as the world’s lightest battery-free tremor stabilizing glove—marks a major leap forward in non-invasive tremor management for individuals affected by Essential Tremor and Parkinson’s Disease.

Unlike conventional powered devices that rely on batteries, motors, or electronics, the Steadi-3 employs a proprietary mechanical damping system inspired by automotive and aerospace vibration control technologies. The result is an instant, passive form of stabilization that operates quietly and efficiently, without charging or maintenance. For users, this translates to newfound ease in daily tasks such as writing, eating, or handling tools—simple activities that can feel monumental when tremors are severe.

As medtech innovation continues to intersect with advanced materials and mechatronic design, Steadiwear stands at the forefront of this evolution. Co-founder and CEO Mark Elias, who studied mechatronics engineering at the University of Toronto, has guided the company from research concept to commercial reality. In the following Q&A, Elias discusses the science and engineering behind the Steadi-3, the journey of developing a passive stabilization platform, and the broader impact of Steadiwear’s technology on the lives of patients around the world.

Q: What core engineering or physics concepts guided the development of Steadi-3’s tremor stabilization mechanism?

At the heart of Steadi-3 lies a principle known as tuned mass damping—a physics concept used in skyscrapers and bridges to counter unwanted oscillations. We miniaturized that principle into a wearable form. By using magnetic springs and carefully tuned counterweights, the device absorbs and cancels tremor energy across a broad frequency range. The guiding idea was simple: let physics do the work—no batteries, no motors, just pure mechanical intelligence.

Q: Steadi-3 is described as battery-free. How does the device achieve this, and what are the advantages compared to powered solutions?

Instead of relying on electronics, Steadi-3 uses passive magnetic stabilizers. Tremor energy itself powers the system—the motion of the hand transfers energy into the device, which is then absorbed and dissipated. The result: no charging, no downtime, and no failure from power loss. It’s lighter, more discreet, and far more reliable. While it doesn’t generate active counter-forces like a robotic system, its passive physics deliver immediate, maintenance-free relief that fits seamlessly into daily life.

Q: What types of sensors are embedded in Steadi-3, and how does it respond to involuntary tremors in real time?

Streadi-3 employs a mechanical damping system inspired by automotive and aerospace vibration control technologies.

Steadi-3 doesn’t rely on electronic sensors. Instead, it uses the body’s own tremor energy as the input signal. The internal mechanism responds mechanically—oscillations naturally trigger the stabilizers to move in opposition, canceling tremors instantly. In that sense, the glove is self-sensing—it adapts in real time without any software or calibration.

Q: How does the damping mechanism work, and what materials were key to its smooth, stable performance?

The smart glove uses the body’s own tremor energy as the input signalmaking the medtech device self-sensing.

Inside the glove, a precision-balanced disk suspended by custom magnetic springs shifts in response to tremor motion. This counter-motion stores and releases energy in perfect opposition to the tremor, causing the internal system to shake instead of the hand. Precision alloys, magnetic composites, and lightweight structural polymers were critical to achieve natural, fluid stabilization without bulk.

Q: What were the biggest hurdles in miniaturizing the technology into a wearable form while maintaining comfort and performance?

Scaling down from bridge-scale physics to a 230-gram wearable was an immense challenge. The trade-off between mass (needed for stabilization) and comfort (needed for wearability) required thousands of simulations and prototypes. Precision manufacturing at small scales and close collaboration between mechanical engineers, materials scientists, and

industrial designers were essential to achieve all-day comfort with clinical-grade performance.

Q: How did you test and validate the long-term durability of Steadi-3?

We perform accelerated wear testing, simulating years of tremor motion in just weeks. For Steadi-4, we’re validating durability for three years of daily use. This ensures long-term reliability so patients and clinicians can trust that the device will perform consistently day after day.

Q: How did Steadi-3 evolve from earlier prototypes, and what lessons guided the final design?

Our first product, Steadi-2, proved that patients would adopt a wearable stabilizer, but it was bulkier and less refined. With Steadi-3, we simplified the mechanical system, optimized magnet geometry, and reduced overall weight by nearly 40%. The biggest takeaway: simplicity wins. By eliminating electronics, we achieved a lighter, quieter, and more dependable device.

Q: What manufacturing challenges did you face, and how did they shape the design?

Producing high-grade custom magnets with precise tolerances was our biggest challenge. Even micro-variations could alter performance. Designing for manufacturability became central—every component had to be both high-precision and scalable. The end result is a device that’s not only functional but also reproducible with exceptional consistency.

Simplicity wins: by eliminating electronics, we achieved a lighter, quieter and more dependable device

Q: How did materials engineering contribute to Steadi-3’s tremor suppression performance?

Every material decision mattered.The stiffness of the polymer housing, the smoothness of the damping surfaces, and the stability of the magnetic

alloys all affected energy transfer. Lightweight polymers reduced fatigue, while precision metals ensured internal balance and consistency over time. It’s where physics and materials science meet biomechanics.

Q: What’s next for Steadiwear in terms of design and technology?

With Steadi-4, we’re extending stabilization to arrhythmic and jerky tremors—a much more complex mechanical problem. We’re also developing data integration features to allow clinicians to track tremor severity, treatment response, and daily fluctuations. The long-term vision is clear: evolve Steadiwear from a relief device into a clinical insight platform that helps advance tremor research and care.

Steadiwear Inc. is a Toronto-based medical equipment OEM and developer of Steadi-3 anti-tremor device created to help manage hand tremors associated with conditions such as Essential Tremor and Parkinson’s.

https://steadiwear.com/

By using just one country-specific power cord from the wall outlet, an accessory power strip, and IEC 60320 plugs, plug connectors, inlets, outlets and jumper cords, your exportable electrical design may just soar to frequent-flyer fame. However, your country-specific power cord will likely need a license to fly— often it will need approvals and certifications from a safety agency in a specific country or region before exportation. Next, it will need a “landing strip” for deployment: an accessory power strip bearing at least one IEC 60320 inlet (C14, C20). The remaining 4-12 outlets in the strip will likely be IEC 60320 Sheet Fs or Sheet Js. Lastly, your piloted cord will need IEC 60320 jumper cords to run from the strip to multiple AC machines and devices.

A country-specific plug and strain relief, such as a Continental European CEE 7/7, is molded onto international cable and terminated on the opposite end with an IEC 60320 C13 connector. The C13 mates with a C14 inlet in the accessory power strip. Now, 4-12 IEC 60320 jumper cord sets can plug into the APS to power multiple devices using an IEC 60320 Sheet E jumper cord plug connector on the strip side while the opposite end of the cord bears a molded C13 connector to plug into the inlets of machines and devices. Alternatives are also available, such as choosing C19 connectors that plug into C20 inlets in the strip, requiring jumper cords with Sheet I plug connectors on the strip side and C19 connectors on the opposite end to plug into the inlets of equipment—the C19/C20 combo adds 6 amps to the international rating.

Often, saving time is saving money. Having cords shipped and ready to use out of the box is less time-consuming than reconfiguring unterminated cords into electrical designs—and even dangerous without electrical knowledge. That, and the peace of mind that Interpower cords have been thoroughly tested multiple times.

Interpower offers 1-week U.S. lead times and same-day shipping on stocked products. Blanket or Scheduled orders run one calendar year—Blanket ordering: lock in your price, and order cords throughout one year when needed. Scheduled orders: set predetermined dates year-round to receive your cords.

BY TDK-LAMBDA AMERICAS INC.

The initial planning of a system or a machine’s power architecture can be a complex task as there can be several ways to derive the required voltages and currents. Cost, efficiency, size and certainly a consideration for system expansion are factors that should be considered. Many engineers create a “power budget” to determine what is needed to achieve this.

There are many types of ac-dc power supplies available, ranging from fixed, single output products to modular types with multiple outputs. Each type has their advantages and their disadvantages. For example, Industrial ac-dc DIN Rail mountable 24V power supplies continue to gain popularity due to their low cost, convection cooling and a number of back-up power

accessories. As they do not rely on forced air cooling, they are larger than an open frame product.

To provide the low voltage, low power outputs required for control boards and other circuitry, traditionally isolated board mount dc-dc converters have been used, drawing their input power from the system power supply. These typically range from 0.5W to around 60W, have either single or dual outputs, and rely on either convection or conduction cooling. Although trim pins for output voltage adjustment are provided on single output converters, their range is quite narrow, in the order of -10% to +10%.

If higher power isolated dc-dc converters are required, 50 to ~900W industry-standard

‘brick’ modules tend to be used. These are referred to in the industry as sixteenth, eighth, quarter, half, and full ‘bricks’. These rely on system airflow and an optional heatsink. Like board mount converters, these also have minimal output adjustment.

At first glance, it would seem that using a non-isolated dc-dc converter in a system would be an infringement of the primary -secondary safety barrier. This is not the case as the system ac-dc power supply is designed to meet the appropriate safety standards and will have sufficient creepage and clearance to meet the demands of the international standards including IEC62368, IEC61010 and IEC60601.

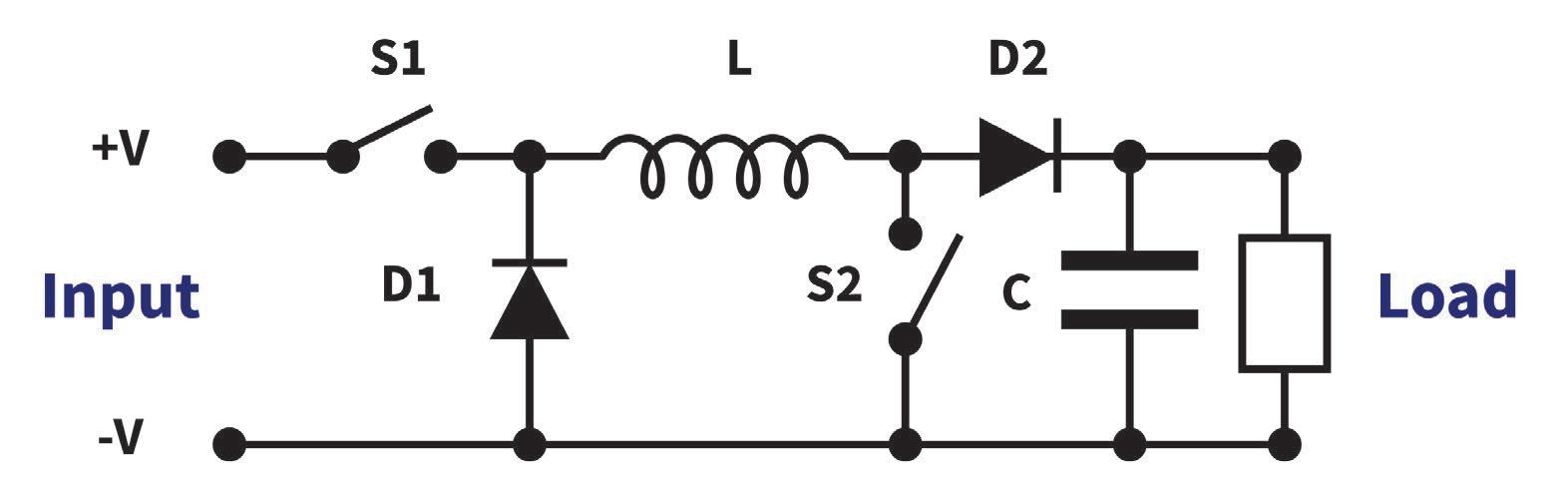

The most widely used types of these converters are buck, boost and buck-boost dc-dc converters.

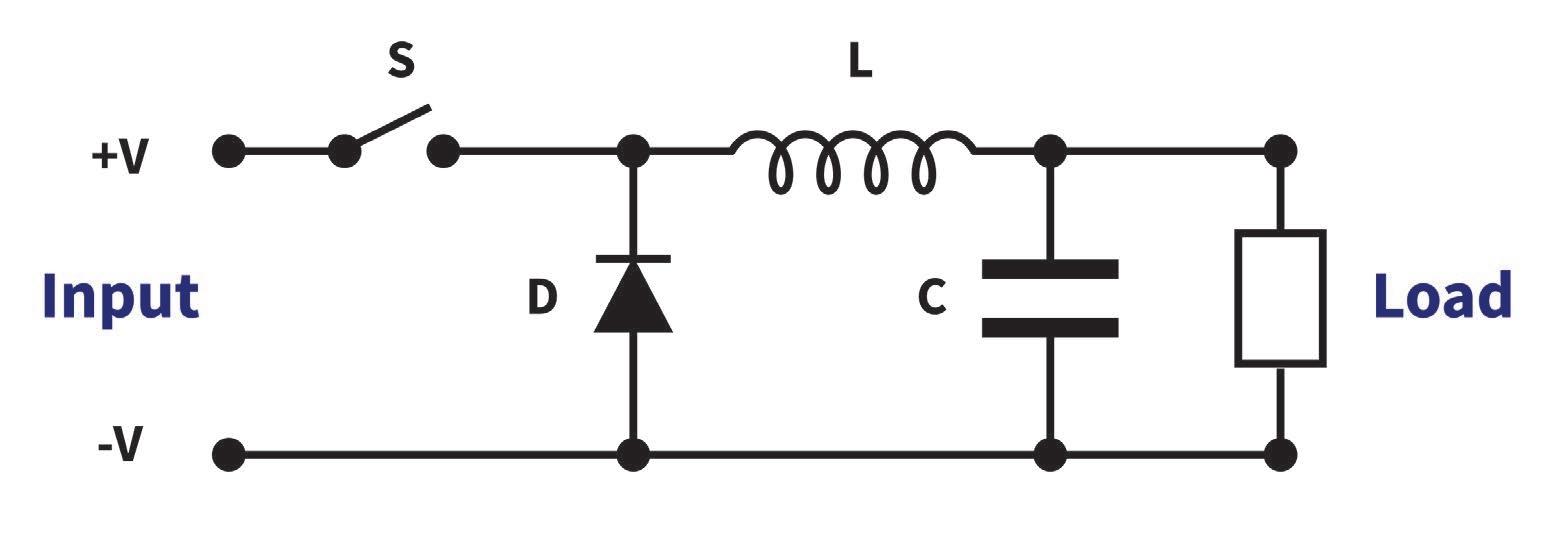

A buck converter reduces the voltage and the output voltage is lower than the input voltage. See Figure 1.

When transistor S is turned on, energy is stored in inductor L as the current flows to the load and Capacitor C is charged. When S is off, the energy stored in L is released and current flows into the load and circulates via diode D. Capacitor C also provides energy to the load. This is repeated at high frequencies, greater than 100,000 times a second. The length of the time S is turned on defines the output voltage.

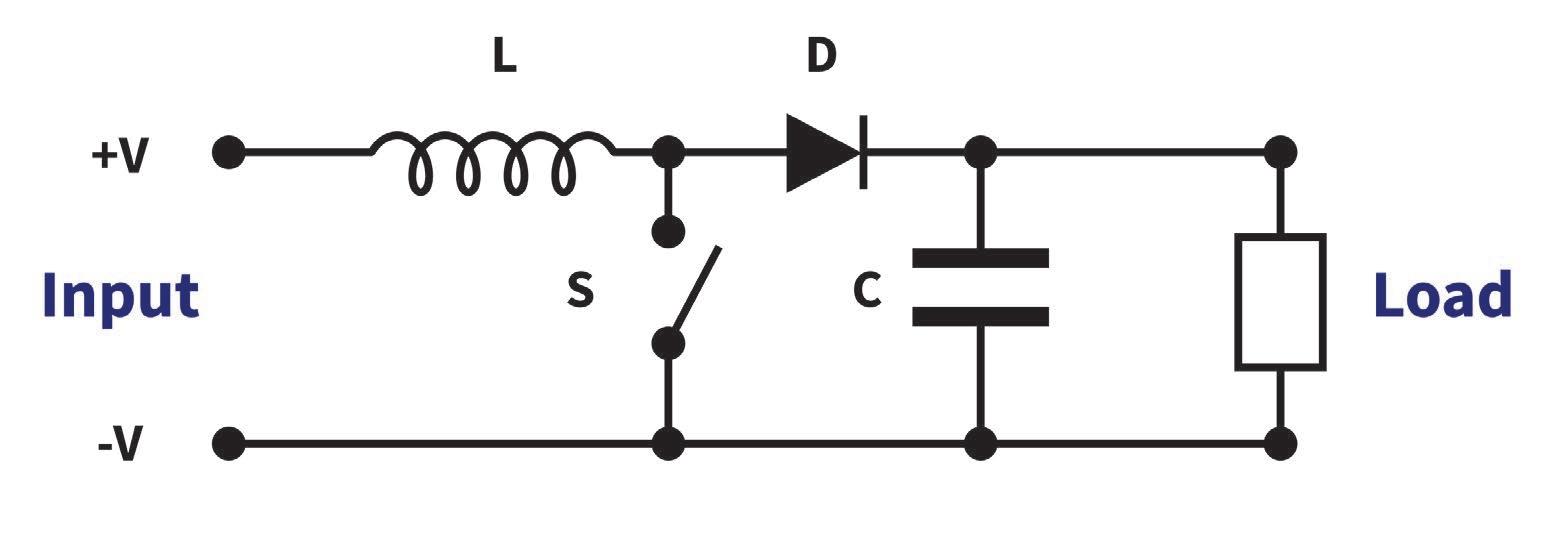

A boost converter increases the output voltage higher than the input voltage. See Figure 2

When transistor S is turned on, current flows through inductor L, through transistor S back to the input. During this period energy is stored in the inductor. When transistor S is off, the inductor acts a voltage source in series with the input voltage. The inductor’s stored energy is circulated through diode D to the load. This charges capacitor C to a higher level than the input voltage. Again, the length of the time S is turned on defines the output voltage.

A buck-boost converter is a combination of a buck and boost converter. The output voltage can be higher or lower than the input voltage. See Figure 3.

As you can see the circuit is more complicated and has more components, S2, L, and D2 is the boost converter and S1, L and D1 the buck section.

A non-isolated dc-dc converter is inherently simpler and lower cost than an isolated converter. There is no isolation transformer and no optocoupler, resulting in a more compact product and lower heat losses and overall efficiency. When the load is subject to sudden changes, a non-isolated circuit has a better transient response with faster recovery.

Automated guided vehicles (AGV), industrial mobile robots (IMR), drones, commercial off-the-shelf (COTS), industrial, test, measurement and medical applications are now increasingly relying on batteries to provide their source of power. This introduces new challenges to the designer including battery life, physical space and weight limitations, minimal system cooling and increasingly higher costs.

In addition to having higher power density and efficiency, many non-isolated modules feature a wider adjustable output range streamlining inventory management by enabling a single part number to support multiple output voltages and be used across various products. Many non-isolated models offer a choice of cooling formats. These include open frame, cold-plate mount (for sealed enclosures using thermal gap filler pads and threaded mounting screws) and a heatsink for forced air cooling.

When selecting a supplier of non-isolated dc-dc converters, chose a manufacturer that has a large range of products to best optimize your system performance. If the product is powering a drone, weight will probably be of high importance and may require an open frame or baseplate model, rather than a version with a heatsink. A customer selecting an industrial mobile robot (IMR) operating in a warehouse will require an extended battery run-time, to maximize its operation and minimize its recharge time.

For applications requiring remote adjustment of the output may consider a model with a digital interface to reduce the charging time of the on-board battery. It is anticipated that the output power of non-isolated converters will continue to rise and provide even more features. Before starting a new program, contact your local field application engineer for free advice.

TDK-Lambda Corp. is a global supplier of highly reliable power conversion products for industrial and medical equipment worldwide.

https://www.jp.lambda.tdk.com/en

Schleuniger’s portable Strip Series B300 delivers fast and reliable stripping of wires with crosssections from 32 to 8 AWG. The machine‘s ergonomic design and intuitive user interface offer unrivaled ease of use, while repeat accuracy, mechanical precision, and short process cycles ensure maximum productivity.

Compact modular design

High-resolution 5” color touch screen

LED lighting for clear view of work area

Highly sensitive trigger mechanism

High process reliability

Wire Solutions for a Connected World

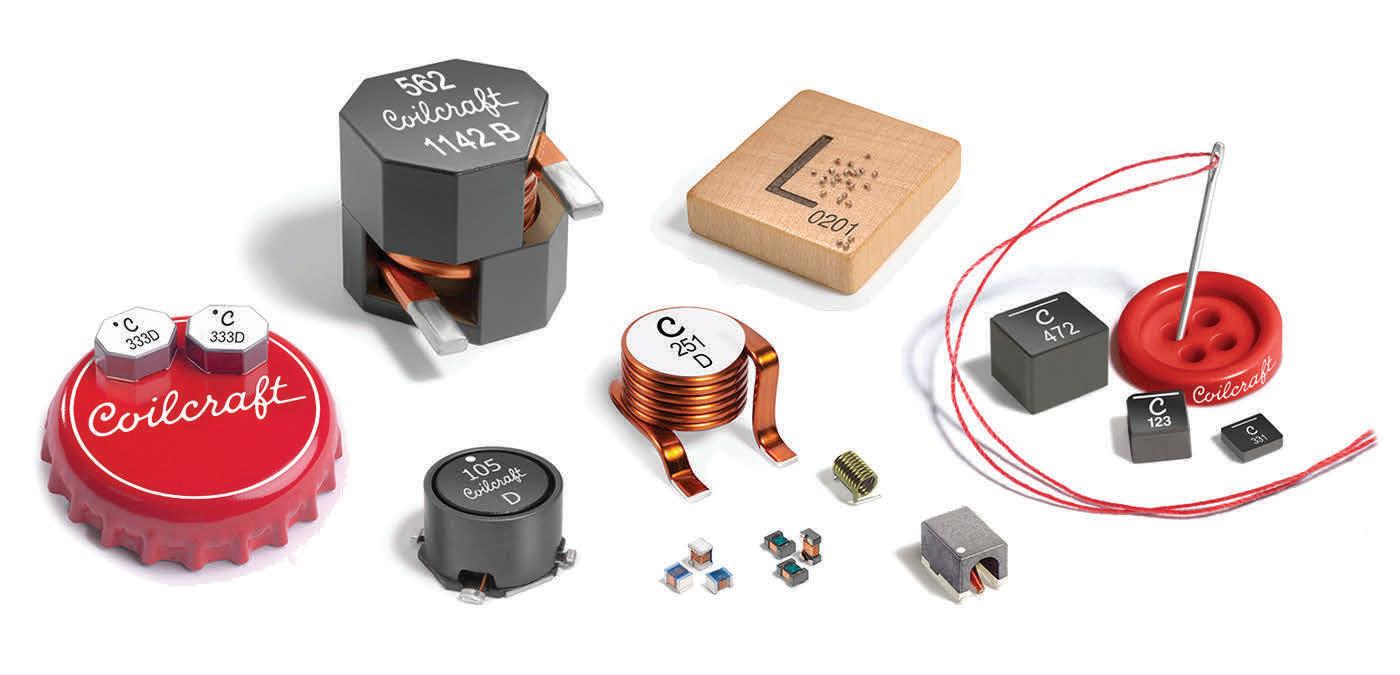

Coilcraft offers a wide range of voltage-rated power inductors that assure the safe, reliable operation of your designs.

Coilcraft voltage-rated inductors support applications such as high-voltage DC-DC and AC-DC power supplies, industrial and home automation controls, appliances, and automotive, including electric vehicles (EVs).

Our XEL and XGL Families of molded power inductors offer operating voltage ratings from 60 V to 120 V, and many of our

LPS and MSS Family inductors are suitable for 400-volt operation or higher.

Our new MSS1514V Series offers an 800 V rating in a 15.5 x 15.5 mm footprint, with excellent current handling and low DCR. Learn more about operating voltage ratings for inductors and see our full line-up at www.coilcraft.com/ HighVoltage.

Headquartered outside of Chicago in Cary, Illinois, Coilcraft is a leading global supplier of magnetic components including high performance RF chip inductors, power magnetics and EMI filters. In addition to a large selection of standard components, we also design and manufacture custom magnetics to meet your exact electrical requirements. Engineers and buyers consider Coilcraft a preferred supplier because of our reputation for quality, reliable delivery, engineering support and the superior performance of our products. In independent surveys, engineers consistently rank Coilcraft the number one magnetics company they would recommend to a colleague.

• Wirewound chip inductors as small as 01005 size – the smallest in the world!

• High-performance SMD power inductors including our ultra-low loss XGL Family

• Wideband RF transformers

• Planar transformers and inductors

• RFID transponder coils

• Power over Ethernet transformers

• High-reliability magnetics and testing services via Coilcraft CPS (Critical Products & Services)

Engineering Support

• The most comprehensive website in the magnetics industry

• Our patented MAGPro® Design Tools to simplify product selection and performance analysis

• Liberal free sample policy with same day shipping

• Designer’s Kits containing samples of all values in a product family

• Free product samples for student design projects and complete RF and Power Magnetics Kits for engineering instructional labs

• Lab posters and selection guides

• Broad range of technical resources and easy-to-use design tools @ www.coilcraft.com/students

Coilcraft supports students and educators with free product samples, lab kits and technical resources

BY BRIAN CUMPSTON, DIRECTOR OF APPLICATION ENGINEERING, VENTIVA

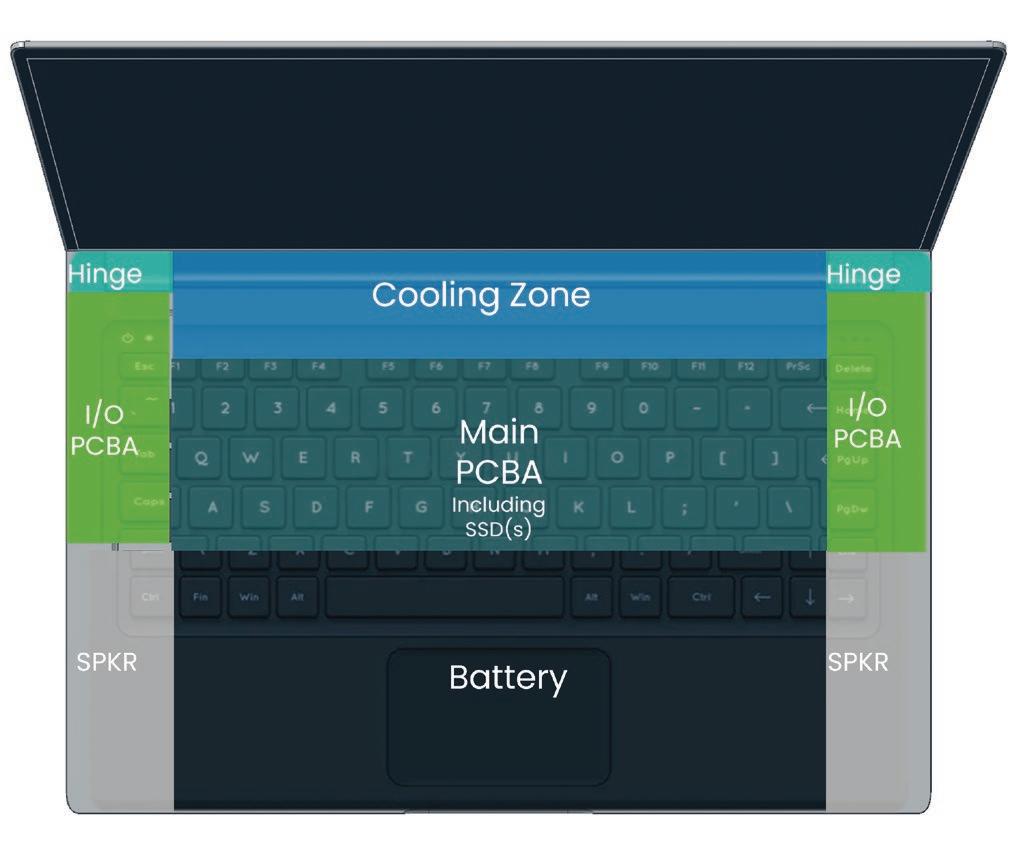

As AI usage continues to gain traction, system designers must balance the demand for smaller form factor devices with higher performance capabilities that generate significantly more heat.

The increasing performance and ‘always on’ requirements of AI at the edge, in laptops, edge appliances, and even smartphones, are over-taxing conventional cooling solutions. The additional heat generated by processors and AI accelerators has a big impact on system design, limiting how thin or small a device can be—particularly if that system requires a mechanical fan to cope with the heat. It also compromises the reliability of the system, as the fan is often one of the first components to fail.

commonly used in data centers and desktop computers, this approach has not been sufficiently miniaturized in a cost-effective manner to be deployed in laptop computers and smaller devices. Although liquid cooling can reduce the reliance on air blowers, these solutions add significantly to device complexity, risk, and cost, especially for portable systems. With all the focus on processor cooling, other parts of the system present significant cooling challenges for thermal design engineers. Chassis surface temperatures as well as peripheral components such as SSD and DRAM often receive secondary consideration. System dimensions, such as laptop thickness, are often limited by the distance between the thermal module and chassis surfaces. Placement of peripherals is frequently dictated by placement in airflow streams such that their temperatures can be appropriately maintained.

What system designers need is more freedom to layout components and affect industrial design without needing to base everything around large fans. Blowers take up a tremendous amount of space leading to pcb waste and complexity as well as lost opportunity for product differentiation. Designers need a new cooling solution that addresses the increasing demand placed by AI while still providing more space for additional peripheral devices or a larger battery.

Insufficient cooling results in systems being throttled, both in design and in operation, to stay within a specific thermal envelope. In addition, localized heating may compromise neighbouring components such as SSDs and DRAM, reducing their performance and reliability. As thermal demands increasingly constrain design, the industry needs alternative cooling technologies that promise more than just heat mitigation.

The design of space-constrained computing systems like laptops has not evolved much in the past decade. Despite advancements in component miniaturization, particularly in data storage solutions, thermal solutions have remained largely frozen in time. The desire to minimize acoustic noise has forced designers to select fans that are up to 90mm in diameter. These fans consume a large amount of

space in a laptop and force the motherboard into the remaining space, creating waste and electrical layout headaches.

The adoption of AI solutions continues to place a greater thermal demand on all personal computing systems, including laptops. The general rule of thumb is that for tasks such as querying and photo editing, which remain on the NPU, or for light-duty video editing, which moves to an integrated GPU, using a large language model (LLM) adds an extra 5-10W in heat load. This increase in power raises even entry-level model laptops to at least 20-25W TDP. When designing a device with a speech-based interface, baseline acoustic levels become even more important to maintain information fidelity. To address these challenges, essentially all laptops need to employ two large blowers in the thermal design. Only in this way can sufficient airflow be achieved at low enough fan speeds to maintain acoustic levels <28dBA.

Another option for tackling the heat problem in processors is liquid cooling. While

The solution: ionic cooling engine (ICE) technology that enables low-profile, solid state air movement systems. In addition to providing a completely silent cooling solution, ICE technology dramatically opens design options for smaller, high-performance AI-enabled devices.

ICE technology leverages electrohydrodynamic (EHD) airflow to deliver intelligent air movement that cools devices without moving parts, noise, or vibration. ICE devices are much smaller than traditional fans and have a thin, design-friendly rectangular form factor. Breaking a system down into discrete zones (power, computing, and cooling) allows for greater design flexibility. For example, motherboards, which focus on distributing power and enabling communication between components, need no longer be encroached upon by bulky fans. In addition, ICE technology can be scaled to dimensions much smaller than can be achieved by a fan. This presents an opportunity to use multiple small, low-profile blowers in just the right place to cool peripheral components and maintain comfortable surface temperatures. Overall, ICE technology can reduce the size

and complexity of systems while enabling the higher performance needed for next generation designs.

Thermal management solutions that leverage ICE technology provide more than just a fan replacement. By themselves, ICE solutions enable airflow with complete silence.

Independent testing shows that ICE-based subsystems operate at <15dBA, which is well below any available conventional fan. But ICE-based devices are also significantly smaller than fans which easily allows for a zoned architecture approach as shown below. The zoned architecture completely compartmentalizes different functions leading to efficiency and cost savings.

Using the zoned approach, the motherboard no longer needs large cutouts for fans. This simplifies PCB depanelization and milling and reduces waste. Traces on the PCB no longer need to travel through narrow pinch points created by fan cutouts. Direct routing of traces from IO boards to the motherboard can eliminate the need for costly signal repeaters. In some cases, the number of layers in the PCB can be reduced due to the increased space for routing.

Ventiva’s ICE solutions can free up to 80% more board space currently taken by traditional fans, allowing designers to increase the size of a battery or add functionality without changing the overall footprint dimensions of their machine. This allows designers to offer more brand differentiation and give consumers several expansion options.

All the cost and area savings mentioned are enabled by using a zoned architecture. These benefits are in addition to the silent, reliable cooling made possible by ICE technology.

The rise of AI is increasing the thermal burden on consumer systems, from laptops to smartphones. This extra power dissipation is a major headache for system designers who are looking to make high performance devices that are smaller and thinner. Existing cooling technologies such as fans have reached their limit, while other approaches such as liquid cooling can be complex and expensive. Solid state ionic cooling solutions offer a completely silent and reliable fan replacement in existing designs, but this is just the starting point.

By taking advantage of the zoned architecture enabled by ionic cooling devices, designers also reap the rewards of reduced cost and increased area in their system—space that can be used to extend battery life, increase storage capacity, and more.

Thermal management subsystems powered by ionic cooling technology are expanding design possibilities for developers, offering a low-profile, compact form factor solution with flexible placement options. These devices can unobtrusively break out of the cooling zone to

direct airflow to troublesome hotpots. Being able to place an air blower right where cooling is needed can further help developers integrate the latest AI technologies in their products to enhance the user experience, while still reducing the size of the system.

Dr. Brian Cumpston is director of application engineering at Ventiva, a supplier of thermal management products based in Freemont CA. Cumpston leads the integration of advanced thermal management technologies into consumer electronics and computing platforms. https://ventiva.com/

Qualcomm Technologies Inc. has agreed to acquire Arduino, an open-source hardware and software company. The transaction accelerates Qualcomm’s strategy to empower developers by facilitating access to its portfolio of edge technologies and products.

The deal builds on the firm’s recent integrations of Edge Impulse and Foundries.io, reinforcing its commitment to delivering a fullstack edge platform that spans hardware, software and cloud services.

By combining processing, graphics, computer vision and AI with Arduino’s community, Qualcomm aims to boost developer productivity across industries. Arduino will preserve its open approach and community spirit while unlocking a full stack platform for modern development.

Two global giants of the electronics connectivity sphere - Samtec Inc. and Molex, have announced a license agreement naming Molex as a second source for the Samtec Si-Fly HD product family. This deal provides customers with extended product availability and supply flexibility to a portfolio of connectivity solutions for a wide range of applications.

DuPont’s board has formally approved the spin-off of its electronics business, now branded Qnity Electronics Inc. Qnity will house DuPont’s semiconductor-materials and interconnect solutions lines under a dedicated, independent structure. The new name — combining ‘Q’ (for electrical charge) and ‘unity’ — reflects the firm’s focus on connectivity and integration in advanced electronics.

ABB is accelerating the development of gigawatt scale next-generation data centres

in collaboration with NVIDIA. Innovation will focus on the development and deployment of cutting-edge power solutions needed to create high-efficiency, scalable power delivery for future AI workloads. The research and development projects will support NVIDIA’s planned introduction of 800Vdc power architecture for 1 megawatt server racks.

Delivering this level of power efficiently requires major advancements in power distribution technologies and architecture. Future data center power architectures will combine a medium voltage UPS with direct current power distribution to the server room using solid-state power electronics devices.

Our annual Canadian Electronics Industry Report unpacks the trends driving the future

• Canadian design teams show resiliency with uncertain supply chain.

• Are time-to-market and cost pressures creating more risk-adverse designs?

• AI has arrived in design circles – what impact will it have?

• Home alone? Designers wrestle with inoffice, hybrid and remote work options.

• Have we reached a tipping point with environmental sustainability in design?

Sponsored by:

Hammond has over $30 million of in-stock inventory and over 16,000 unique product skus to choose from.

At Hammond, we are proud of our Canadian roots. We manufacture in Canada, we warehouse in Canada, and we employee over 900 Canadians. We are Canada’s Enclosure Company.