Reliability that counts

bR 800 c-e BACKPACK BLOWER

OUR BIGGEST MOST POWERFUL BACKPACK BLOWER.

Landscapers, parks and recreation crews and golf courses…be prepared to be blown away. To tackle large properties and heavy debris, there is nothing like the clean-up power of the BR 800 C-E. The most powerful backpack blower in the STIHL line. The BR 800 C-E offers maximum blowing force as well as optimal comfort. The BR 800 C-E will make a great addition to your fleet.

⬤ Robust Blowing Force – 3.2 kW engine power; offers 20% more power than the BR 700

⬤ Sturdy Performance – Best power-to-weight ratio in STIHL gasoline blower line; machine is more compact and easy to carry

⬤ Ergonomic Carrying System – S-shaped shoulder straps, chest strap and hip belt; provides operator comfort

⬤ Telescopic Tube – Quick adjustment of the length for various conditions; no tools required

⬤ Pull Cord – Handy access to the side starter cord; machine can be restarted from your back after taking a short break

SPECIFICATIONS

① Excluding fuel. ② With tube at nozzle end.

STIHL’s Pro-Fleet Commercial Landscape Program is designed to provide commercial landscapers a volume discount on major purchases of 5 or more landscaping power tools. Visit your STIHL Dealer today to find out more and take advantage of the savings!

DEPARTMENTS

By Mike Jiggens

Field work returns, but for how long?

Alot has changed in the world over the past seven months. That includes our operation here at Turf & Rec. Although it’s still business as usual – for the most part – there have been some changes to the way in which it’s being done.

I’ve been working remotely since the middle of March and have been largely confined to quarters. Without the daily, in-person repartee with co-workers, we’ve resorted to weekly Zoom meetings to keep one another abreast of what we’ve been doing – both in terms of the business at hand and accounts of our personal well-being.

But, with the isolation associated with working from home, and especially with the bulk of this seven-month period having encompassed the better weather months, it has contributed to a case of cabin fever – at least in a business sense. But finally, in mid-September, I was able to get out of the house for part of a day to do my first bit of field reporting since the beginning of March. I arranged to meet face to face with a couple of individuals for an interview and photo session for this issue’s cover story.

The weather was perfect, driving conditions were ideal and our chosen meeting venue – the Guelph Arboretum – was tranquil and tailor-made for a safe, physically distanced place to talk shop. It just felt good

and right to be “out of the office” again, and I had long wondered when I might have that chance again. But now, as the number of COVID-19 cases are on the rise again, it has me thinking that my next opportunity to conduct some actual field work might not come for another long while.

It’s been the field work that I think I’ve enjoyed the most these past 26 years. Having the chance to meet face to face with Turf & Rec’s readers on a regular basis during the course of a typical year has been an enjoyable and rewarding experience. It’s also good to get away from the office/home setting periodically for a change of pace. It’s what maintains your enthusiasm for your ca-

It’s good to get away from the office/home setting for a change of pace

reer, and it’s just plain good for the soul.

With spikes in the number of positive cases, schools back in session for the year and speculation that a second wave of the pandemic is imminent, the odds of getting out for further field work anytime soon seem slim. Industry summits and symposiums have turned into virtual events to allow the same quality presentations to be delivered in a safe manner. But there’s still no substitute for traditional in-person gatherings. Online networking doesn’t

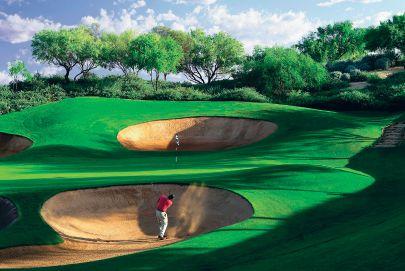

have the same impact. When we might return to these in-person events is anyone’s guess. Fortunately, the professional turf and grounds maintenance industry in Canada has by and large stayed the course amid this pandemic. Golf course openings were later than usual in most provinces and landscapers were limited to what they could offer their customers at first. The maintenance end of golf course operations has experienced a busy season this year as the amount of traffic on the fairways and greens has exploded on most courses. Landscapers and lawn care professionals are finding residential customers are willing to invest more in their properties this year as more of them choose to stay put at home where it’s safe. Municipal sports turf managers continued to maintain their fields for the most part during the initial stages of the lockdown, even though the playing surfaces were off limits to the public for much of the spring/summer seasons. When limited play was finally given the green light, many of the higher-end fields were in tiptop shape at a time of year when the signs of wear would normally be evident.

On Sept. 23, Canada joined several other countries around the world to thank golf superintendents for the job they do in keeping golf courses playable and enjoyable.

“Golf is such a healthy and positive activity,” CGSA president Darren Kalyniuk said. “And superintendents really take that to heart”

www.turfandrec.com

Editor Mike Jiggens mjiggens@annexbusinessmedia.com

National Advertising Manager

Rebecca Lewis 519-400-0322 rlewis@annexbusinessmedia.com

Nashelle Barsky 905-431-8892 nbarsky@annexbusinessmedia.com

Account Coordinator Mary Burnie 519-429-5175 mburnie@annexbusinessmedia.com

Circulation Manager Anita Madden 416-510-5183 amadden@annexbusinessmedia.com

Group Publisher Todd Humber thumber@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada ISSN 1186-0170

PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Published 7 times a year – Jan/Feb, Mar, Apr/May, Jun, Aug/Sept, Oct, Nov/Dec Canada – 1 year $35.00; 2 year $45.00 3 years $55.50 (plus applicable taxes HST 86717 2652 RT0001

CIRCULATION

email: blao@annexbusinesmedia.com Tel: 416.442-5600 ext 3552 Fax: 416.510.6875 (main) 416.442-2191 Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Occasionally, Turf and Recreation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office

privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2020 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Tough enough to handle any job. Comfortable enough to keep your crew happy. Kubota mowers are built for lawn care pros. Our zero-turn mowers are engineered for lasting dependability and performance. This lineup brings Kubota’s advanced technology in every detail and function to ensure both superior mowing and supreme operator comfort. kubota.ca |

Artificial turf field’s $3.7-million

cost shared by city, board

Holy Cross Secondary School in Peterborough is getting a new $3.7-million dollar artificial turf field to headline a project that also includes stadium lighting, a rubber track and new bleachers.

The cost of the project is being jointly paid for by the Peterborough Victoria Northumberland Clarington Catholic District School Board and the city. Although the work is expected to be completed later this fall, it won’t be ready for play until the spring.

The project had been delayed for a number of weeks due to the artificial turf being held up in Montreal because of a port strike.

London-area course could be Canada’s next golf destination

Could the recently purchased Tarandowah Golfers Club become Canada’s newest golf resort destination? The club’s new owner – London-based Perpetually Innovative Homes – says its vision is not to develop the golf course, but to add value to the golf experience.

The long-term plan is to enhance the golf experience and turn the setting into a destination, similar in nature to that of Cape Breton Links and Cape Breton Cliffs.

COVID’s border issues force early closure of Cape Breton courses

At Nova Scotia’s Cabot Links and Cabot Cliffs – one of Canada’s top golf and tourism destinations – the lack of golfers who would ordinarily come from the United States and Ontario is prompting the courses to shut down a month earlier than normal.

Golfers in Atlantic Canada have taken over some of the tee times originally booked by Ontario and U.S. golfers, but it wasn’t enough. The courses were due to close Sept. 27.

$3.7M

cost of project shared by two groups

Golf rounds up by 20 per cent amid pandemic in Ottawa area

Ottawa-area golf courses are reporting packed tee sheets this season and having to turn away golfers looking to get in a round. The number of rounds being played in the National Capital Region amid the continuing COVID-19 pandemic is up by about 20 per cent over last year as more people are looking for a safe way to get outside to enjoy some recreational activity.

“It’s an awesome problem to have,” Joe Warner, the director of golf at Stonebridge Golf Course, told the Ottawa Business Journal.

had played it only sparingly – who were looking for a means to escape the confines of home.

Sept. 27 closure date for Cabot courses

It was realized early during the pandemic that golf was a sport that could safely be played amid such a health crisis, with few adjustments required to the game itself. Because it was perhaps the only sport that could be played safely and the only one permitted to be played in the beginning, golf courses became inundated with enthusiasts – some of whom had never played the game before or

Golf has been considered a sport that was ready-made for physical distancing. Only a few minor adjustments were made to prevent common touch points – such as the absence of bunker rakes and the need to leave flagsticks in the holes – and to ensure complete safety. Golfers naturally maintain a safe distance from one another during 18 holes of play and have done away with such items of etiquette as post-round handshakes, opting instead for putter taps or other alternative measures.

The weather in most parts of Canada was also favourable this year, adding to the appeal of golf.

Among those who have contributed to the spike in golfer participation this year are spouses of regular golfers, who were seeking an activity that could be enjoyed together, and juniors.

Assistant super’s skill set a boon

Computer savviness adds to Innisfail’s operations

By Mike Jiggens

Combine a passion for golf course maintenance with a savviness for computer technology, and it’s a recipe for a more productive and efficient operation. That is what’s being realized at the Innisfail Golf Club, thanks to the efforts of assistant superintendent Curtis Playfair.

Employed for the past seven years at the Alberta club, Playfair took it upon himself to utilize his computer skills and develop a website dedicated to turf maintenance operations. Information aimed at superintendents, assistants, mechanics and others involved in the day-to-day agronomic operations includes such content as record-keeping, budgeting, cultural practices, water quality data and job boards, to name a few.

“There’s a little bit of everything,” he said, adding there is also a section for Audubon-related information that includes wildlife sightings and entomology records. Innisfail is a fully certified Audubon co-operative sanctuary.

Information posted to the website is split between private and public content, with private information accessible only to industry insiders while public content can be enjoyed by golfers and other members of the general public.

Playfair embarked on his website project a few years ago on his own time during his Christmas break and updates its content daily. Information that delves into equipment inventory, fertilizer calculations and fungicide applications have contributed to a more efficient, more productive golf

course operation.

The website has been configured to record data each night and compiles everything into pie charts for easy, at-a-glance viewing. For example, job hours worked by the grounds maintenance staff are meticulously broken down to reflect the actual amount of time spent on greens,

‘I’ve always been into computers’

tees, fairways and roughs as well as time devoted to bunker maintenance, equipment maintenance, irrigation and administrative matters. Personnel information such as sick days are also figured among the compiled data.

“I’ve always been into computers,” he said, and much of his data entries can be input with his cell phone. “It’s been huge for time management and record keeping.”

The graduate of Olds College has shared

what he’s done with turfgrass management students at his alma mater.

The electronic job board Playfair created can be readily viewed by seasonal staff and has helped considerably with time management. Both morning and afternoon jobs are detailed. Each employee’s name is listed on the board along with the day’s scheduled tasks. In a separate column, notes are posted to indicate such additional information as the relocation of tee markers and the cleaning of restrooms.

Record-keeping includes daily accounts of temperature (including wind chill), rainfall and snowfall.

The 27-hole Innisfail club is made up of the Aspen, Spruce and Hazelwood nines. Data is entered and compiled specifically for each set of nine holes.

Playfair also utilizes his own drone and Go Pro to accurately measure the entire golf course property and document the progress of ongoing construction projects.

“He’s definitely spent a lot of time developing the website and electronic job board and deserves the recognition,” superintendent Erwin Alvarez said.

Growing lawn care business makes new change at top

Van Haastrecht family believes Hometurf Lawn Care might be Canada’s largest independently-owned lawn care company. By Mike Jiggens

Mississauga-based Hometurf Lawn Care has been in the Van Haastrecht family since the business’ inception more than 30 years ago, having been presided over by two generations of the family. Founded in 1988 by Bruce and Debbie Van Haastrecht, the continually-growing lawn care business was passed on to son Joel, who served as its president the past several years.

Now, taking over the reigns as company president is British Columbia native Matt Hooper who heads a group of investors that found the independent

lawn care business to be a perfect fit for their long-term vision.

“I was looking to invest in a small business in Canada and, in the midst of undertaking a search to find a small business that would have certain characteristics, I met Joel and learned more about the Hometurf story and his family story,” Hooper said, adding the two originally met a little more than a year ago. “It really seemed to be a strong fit, both in terms of the fundamentals of the business and the industry, but also what Joel was looking for and what he was looking for in a partner and what I was looking for in a company.”

Hooper and Van Haastrecht met during the summer of 2019, but began formal discussions about Hometurf’s future during the winter months.

“The more we talked about it, the more it seemed like a good fit and for what Joel was looking to do long-term for himself and his family,” Hooper said.

The past year was spent discussing details surrounding the business’ transfer while the coming year will see the two working together to achieve a smooth transition.

“For the next year, we’ll be working hand in hand, and after that I’ll be an active board member so that I can con -

tinue to advise Matt,” Van Haastrect said. “He’s really gotten to know the business well prior to taking on this role.”

Hooper grew up on an apple orchard in the Okanagan Valley and brings a general business background to the table. He came to Ontario to pursue his MBA at Queen’s University in Kingston and then spent a couple of years in Prague, Czech Republic immediately afterward. Returning to Ontario in 2012, he embarked on a management consulting career for the next seven to eight years.

“I got a fairly broad experience working across a number of different industries, and then decided I didn’t want to be a consultant for the rest of my life. I really wanted

‘We’ve taken a lot of market share in the last 10 years and have grown quite substantially’

to invest my time in a project that would allow me to see more of a long-term return for my efforts as opposed to going from one project to one company to the next. I’ve always had an entrepreneurial spirit and wanted an equity stake in a company and be able to grow it and be able to see the value, not only for myself but also watching that company grow and continue to support its employees in the community they exist in.”

Company’s core values

What attracted Hooper to Hometurf was its set of core values, its people and its products, he said, acknowledging the company has been growing at a strong and consistent rate, especially over the past 10 years.

“It fundamentally met all the characteristics we were looking for in a business, and the more I got to know Joel the more it seemed like a good fit for myself and for what he was looking to do in terms of suc-

The ultimate mini snow machine.

The factory-installed, heated 2R Cab. The 360 view inside out. The flashing work lights to keep safe. The comfort of the command chair. This heated cab knows no peer in this size and power of tractor (25 HP* 18.6kW). Add an optional snow blower, or a snow plow blade or a spreader for salt to keep streets or paths clear of snow and ice. Come build your own ultimate mini snow machine at JohnDeere.com/2Series

NOTHING RUNS LIKE A DEERE™. RUN WITH US.

cession planning and transition.”

Hooper said he’s already taken it upon himself to learn as much as possible about the lawn care industry and has enrolled in the coming turfgrass managers’ short course at the University of Guelph. He said the off-season is an ideal time “to get up to speed” on the industry and its trends and to learn more about Hometurf’s choice of products and the services it offers its customers.

Hometurf was originally founded in Brampton, where Van Haastrecht’s parents were living at the time. Head office eventually relocated to Mississauga, and regional offices were later established in Guelph and Calgary.

“The vision for the business was always growth,” Van Haastrecht said, adding he believes Hometurf might be Canada’s largest independently-owned lawn care company. “We’ve taken a lot of market share in the last 10 years and have grown quite substantially.”

At its outset in the late 1980s, starting with a small customer base, Hometurf built decks and fences to supplement its revenue stream. Once the business began to grow, it expanded from Brampton into Mississauga and Burlington and then into the Greater Toronto Area.

“In 2010, we made another really big move and moved to regions outside the GTA as well as Calgary, and we continued to grow within those regions and added other areas,” Van Haastrecht said.

The decision to take Hometurf outside of Ontario was made in 2009, coming after the implementation of Ontario’s cosmetic pesticide ban.

“We always wanted to open a regional office. In our business, we need a density of homes in order to be efficient and effective.” Van

Haastrecht said that outside of the GTA, Calgary was the next Canadian city with the desired density. “At the time, there was the fear of what that ban was going to do to our industry, and Alberta was still allowing traditional pesticide use. It was a good place to diversify and still be able to work with those products as we saw fit, and it had all the right attributes for a successful regional operation.”

With its seasonal and full-time staff, Hometurf employs about 100 people. Its primary services include fertilization, weed control, aeration and overseeding for a residential customer base.

Van Haastrecht said Hometurf was prepared for the cosmetic pesticide ban that was enacted in Ontario in 2009. Prior to the province-wide legislation, individual municipalities were already introducing bans and restrictions of their own.

“We were very involved in keeping up to date with what was happening and focusing on next steps,” he said.

In the first year of the ban, Fiesta had yet to hit the commercial lawn care market, prompting some anxiety within his company and the industry in general. Another government-approved replacement product for 2,4-D was available, but Van Haastrecht said he found it to be ineffective.

“During the one-year period between the ban’s start and the creation of Fiesta, we actually pulled weeds, which was quite onerous and labour-intensive, but it kept our customers satisfied.”

Van Haastrecht said Hometurf was one of the first lawn care companies to adopt Fiesta once it became available. “We took hold of it and worked with it right away throughout 2010. It was really a saving grace for us.”

Hometurf’s focus has always

centred around conservation, Van Haastrecht said, noting that proper fertilization and seeding not only grows grass, but battles weeds and contributes to a healthier soil.

“The more grass you have, the less weeds you’ll have.”

Liquid aeration

When the COVID-19 pandemic hit in the spring, Van Haastrecht said Hometurf had to make adjustments to its aeration service for safety reasons. Previously, two technicians worked together when aerating a customer’s lawn, but both people riding in the same vehicle was no longer feasible. Speaking with industry suppliers and other professionals, it was learned that liquid aeration was an effective measure that could be practised by only one person.

“Once COVID hit, we needed a solution to still provide that aeration and not jeopardize the safety

of our staff,” Van Haastrecht said, adding conventional core aeration was off the table this year.

He said he was skeptical at first about a liquid alternative to conventional aeration, “but I’m genuinely surprised and extremely satisfied with the results, as are our customers and technical staff. Not only is it easier for our technicians to apply, it really has a beneficial effect on the turf.”

Other lawn care companies that have been offering liquid aeration services have since sold off their aerating equipment, he said, adding other benefits of liquid aeration include not having to mark off sprinkler heads on installed irrigation systems and not having cores lying on the surface.

The process of delivering liquid aeration versus core aeration takes about the same amount of time, Van Haastrecht said. Once the current pandemic has run its course, both aeration options will likely be offered to Hometurf’s customers, but both methods will be monitored

to determine if it’s better to invest in one option over the other.

Operating under the cloud of COVID-19 this year presented itself as a challenge at first, but Van Haastrecht said the company was able to adapt and continue to satisfy its customers.

“It smacked you in the face at first, but we’re fortunate that we work outside with generally one technician per service vehicle.”

Office staff successfully transitioned into working from home, and it’s since been mostly business as usual, he added. Government restrictions in the early spring forced a later-than-usual start to the season, but customers were largely sympathetic to the lawn care business’ limitations.

“Folks were pretty understanding of that,” Hooper said. “Joel and the team of managers did a really exceptional job. Once we were legally able to get out on the lawns and it was safe to do it for our technicians, we were able to put in the extra time to catch up as quickly as possible and get our spring work done in fairly short order.”

Efforts were made to get as much done in the summer and fall in order to stay ahead of the work required in the event of a possible government-mandated setback.

“We’re in a position where we feel comfortable we can complete the season for our customers ahead of schedule,”

Hooper said, adding he’s excited about the 2021 season. “Even if it’s a challenging scenario again with COVID that will be in place, we have learned how to adapt our processes and systems in the way we operate to support that in doing it in a safe way.

“What you’re starting to see is that as people restructure their lives and spend a lot more time at their homes, the way that folks are gathering has changed fundamentally. People used to spend a lot more time gathering at restaurants or museums or whatever the case might be, but they can’t do that anymore. Yet people still crave some form of social interaction, getting families together and getting kids together, and we’re starting to see this massive shift. The front yard has become an entertainment zone and you’re seeing families coming from down the street and they’re setting up in the front yard while other folks are on their deck talking and sharing a laugh, and that puts more of an emphasis on the health and beauty of their properties and outdoor spaces. I think there’s going to be more emphasis on the quality of folks’ lawns.”

Hooper’s excitement about 2021 has already had a head start. In mid-September, the new Hometurf president was actively working hands-on on customers’ properties.

“It’s great to have someone who wants to be as actively involved,” Van Haastrecht said.

Nanobubbles: a chemical-free solution for algae

Tiny bubbles eliminate harmful algae and the buildup of unwanted odours

By Christian Ference

Many Golf Clubs have become world-renowned because of their elaborate water features, from Grand National Lake Course to Coeur d’Alene. These ornamental water features can be both a source of attraction for golfers and a money drain for golf clubs due to extensive maintenance costs.

Golf course ponds are particularly prone to nutrient runoff from fertilizers and turf treatments, which makes the maintenance of these water bodies all the more challenging.

Ponds and water features on golf courses are often shallow, stagnant, and warmer throughout the spring and summer seasons. This depletes these waterways of dissolved oxygen, which in turn creates an environment that’s ideal for bacteria and algae growth.

Maintenance of these features has traditionally been done either by using chemicals (algaecides), by bottom-mounted aerators or fountains. Oftentimes these methods are ineffective in resolving long-term imbalances in dissolved oxygen, nitrogen and phosphorus levels. These methods require recurring costs and are less effective for golf or pond management companies, and can also require submerged piping systems that are both labour and capital intensive.

HOW CONVENTIONAL AERATION WORK

Bottom mounted aeration circulates water, relying on mixing of the water to improve dissolved oxygen instead of gas transfer from the bubbles themselves. However, this solution to preventing algae blooms is often ineffective in small, shallow ponds and water features found at most golf

courses. This is because aeration creates large bubbles of air that can quickly rise to the surface and escape in shallow bodies of water, so oxygen transfer to the water is limited, with an oxygen transfer efficiency (OTE) rate of one per cent to three per cent per foot of water.

HOW ALGAECIDE CHEMICALS WORK

Using chemicals to treat ponds and clean water features is effective but can quickly become costly and can have negative effects on the aquatic ecosystem and human health.

If maintenance employees are not especially careful, adding the incorrect amount of chemical mixture can vastly impact the water body. Too high a dosage can cause the pH levels in the water to plummet, killing off the aquatic ecosystem, which can in turn put the aquatic life that inhabits the waterbody at risk.

Additionally, if the pond has had a buildup of algae, the algae cells can be disrupted too quickly causing the release of toxins that can become airborne, which have proven to cause human respiratory irritations. This can quickly lead to significant complaints from golfers and prompt health concerns.

A NEW ALTERNATIVE: NANOBUBBLES

Golf courses have turned their attention to a new, cost-effective method for accelerating the treatment of ponds and water bodies, eliminating harmful algae and the buildup of unwanted odours.

Nanobubbles are tiny bubbles that are 2,500 times smaller than a grain of table salt. These bubbles are so tiny, that they don’t float to the surface. Instead, these bubbles follow a process called Brownian mo -

tion, where they stay suspended in the water for long periods of time, moving throughout the entire water column due to the natural mixing of the water. There are three main benefits to using nanobubbles to treat water.

Nanobubbles provide a long-term, cost-effective solution for maintaining and improving golf course water features:

• Nanobubbles provide a cost-effective method for ongoing golf course pond maintenance. Nanobubble generators are not as energy or labour intensive as traditional aeration methods, and do not require expensive chemicals. Nanobubble generators are a simple, shore-mounted, plug-and-play system that can be easily installed with minimal technical setup.

Nanobubbles reduce the need for chemicals, and improve pond water clarity:

• Nanobubbles break down organic debris through a mild oxidative impact and positively affect oxidation reduction potential, which is the ability for a water body to cleanse itself or break down waste products. It’s the tiny size of oxygen nanobubbles that gives them a negative surface charge to help them break down unwanted organic compounds, eliminate their toxicity or reduce them to harmless products like carbon dioxide, water, and salts.

Nanobubbles are an effective, sustainable solution to improving and maintaining aquatic ecosystem health during golf season’s warmer months:

• Nanobubbles dissolve nearly all their oxygen into the water, returning the aquatic ecosystem to balance, preventing buildups of unsustainable levels of nitrogen and phosphorus, and mitigating against harmful bacteria and pathogens. Nanobubbles effectively oxygenate water in warm temperatures independent of depth, providing an advantage over traditional aeration methods. This helps prevent the outbreak of harmful algae blooms and obnoxious odours that can disturb golfers and spectators.

• Nanobubbles also improve the water quality for irrigation purposes. Oxygen-filled nanobubbles have significantly improved water quality and fungicides’ effectiveness for irrigation, preventing course browning from heat stress and fungi. This is the result of better dissolution of pesticides, and the inhibition of certain anaerobic pathogens (botrytis, pythium, and alternaria), and microorganisms (salmonella and E coli).

FINAL WORD

Nanobubbles are already being used to treat more than a dozen golf courses across the world, including

several PGA courses, and this trend is expected to continue. Moleaer, is a leading nanobubble technology company, developing and deploying nanobubble generators to treat ponds, lakes, and water features throughout North America. Moleaer’s technology has cleaned dozens of golf course ponds in Florida, managed by SOLitude Lake Management, a leading pond management company.

Treating water, whether it’s a small pond or a large lake, can be a challenge – and this challenge is only going to intensify with climate change. The fast-growing nanobubble industry provides a sustainable, cost-efficient, and chemical-free solution to treat almost any water body.

A key lesson learned getting caught off guard

By Mike Jiggens

There is nothing like the first storm of the winter season to initiate a new employee into the world of snow and ice management. But when that first storm also happens to be what would become the biggest and worst of the season, and a snow and ice contracting company is caught unprepared for it, it becomes an extremely trying time for everyone involved.

Officials from Skyview Landscapes Inc. in Waterford, N.Y. shared their experience dealing with a late 2019 storm with virtual attendees present at the Snow & Ice Management Association’s (SIMA) snow and ice symposium in August. Originally scheduled to be a live event, the symposium became a virtual offering due to the ongoing COVID-19 pandemic.

Skyview owner Michael Scaringe said his company was busy in November completing fall season cleanups, enhancements and construction projects to finish its landscaping season when he heard the area might be getting a blast of winter at the beginning of December.

“In the back of my mind, as the business owner, you’re thinking the first storm of the year can’t be the big one,” he said of the Dec. 1 weather event.

Scraringe pushed his employees toward finishing up their fall cleanup work and ensuring their properties were “buttoned up” before the storm hit. But he admitted he didn’t take the weather forecast seriously enough, acknowledging company trucks were still outfitted with leaf cleanup boxes and crews were still installing patios.

The Dec. 1 storm hit, dumping 24 inches of snow over a prolonged duration and leaving intense pockets of snow in places. Additionally, temperatures plunged, and bonding issues with the pavement were being experienced.

“Everything was there to be a full blown snow event right at the beginning of the season,” Scraringe said, adding it was frustrating, aggravating and embarrassing.

Bolstering Skyview’s team were nine landscaping students from the State University of New York (SUNY) College in Cobleskill, who had some basic classroom and equipment training yet hadn’t “cut their teeth” in a significant storm. Among the students was James Wilson, an intern with the company at the time.

“What we weren’t really bargaining for was that this storm was going to be the biggest storm of the season,” he said.

CAST INTO THE FIRE

The students were briefed the day before the storm by their college instructor, who told them what they might expect and the things that could go wrong. Wilson said he and his fellow students were told to prepare for what could be a serious undertaking that was apt to be more than just a two-inch snow event. They were going to be cast into the fire where they would see if they sank or remained afloat.

Wilson and four others were assigned to a large commercial office park while others tended to parking lots or clearing driveways and keeping roads open.

An audio clip was played during Scraringe’s and Wilson’s joint presentation, depicting the frustration experienced by student Gavin Erdody, an advanced snow management (ASM) operator working for Skyview during the storm. He recalled a “white knuckle” drive to his job site, only to find the road reduced to about a foot in width and nothing marked up. He and a partner had never previously visited the site and were assigned to plow driveways that weren’t marked.

“ We didn’t even know where the road was at this place,” Erdody said. “There’s nothing. The feeling of being overwhelmed had already sank in as soon as we started to make this drive from where we were to where we were going.”

The company’s plan was to continue working until 10 p.m. Crews were to rest afterwards and return in the early morning to continue removing snow.

“ That was never conveyed to us at all,” Erdody said. “We just kept on going, going, going, wondering ‘Where is everybody?’”

He and his partner got 45 minutes of sleep before continuing to plow. Residents had awakened, telling them they needed their driveways plowed so that they could go to work, but Erdody said he wasn’t even sure where the driveways were located because they were buried under two feet of snow. To complicate matters, their snowblower clogged up every five minutes and they were caught without a shovel. They resorted to their plow, but then realized it was broken.

“At that moment I knew the ship was

sinking and it was sinking fast.”

Erdody said he and his partner felt overwhelmed at the prospect of having to clear 55 driveways with a broken plow and a blower that kept clogging up. He admitted he briefly thought about “throwing in the towel,” but he understood there was

still a job to be done. In spite of the setbacks, he said learned a lot about preparedness from the experience.

Scraringe said, as the owner of the business, it hurt to hear what his employees were saying and added he realized he was behind the game going into the storm,

There is no such thing as a Parts Tree.

But there is Parts NOW.

Commercial mowing parts don’t just appear magically out of nowhere. Thankfully, you can count on the next best thing: Parts NOW, part of our NEVERSTOP™ Services and Support. With Parts NOW, you can have a John Deere Parts Onsite™ cabinet right in your shop. Your dealer keeps it stocked with the parts you use the most. And with our Next Day Parts Guarantee, you’ll have the parts you need the next day – or it’s free. You can even order parts online, anytime you want.

You can wish for parts. Or you can have them right when you need them. Talk to your John Deere dealer today about what Parts NOW can do for your business.

Hybrid technology comes to a new category of fairway mowing.

With our 6080A and 6500A E-Cut™ Hybrid Fairway mowers, you’ll be amazed at what comes with these 24.7 hp units: electric reel motors that eliminate all hydraulic leaks in the reel circuit. And like our 6080A, 6500A, and 6700A PrecisionCut™ mowers, they also feature our passcode-protected TechControl display, allowing you to control mow speed, turn speed and transport speed, to name a few. They also come with LoadMatch™ for excellent cut quality in tough conditions. And our direct drive eHydro™ traction system, electronically controlled with no belts or linkages. Plus all units are built on a true fairway mower frame. Don’t settle for less. Call your local John Deere Golf distributor for a demo today.

Trusted by the Best

even though more snow fell than was forecast.

Following the storm, the company enacted a set of solutions for moving forward: keeping an open mind, communicating, empowerment, preparation and analyzing, and improving and optimizing.

Scraringe said he should have forewarned his staff that the snow event was apt to be their first experience with a storm and things might not go right. He also had a message for his leaders with regard to what they should be saying to their subordinates, including the tone of their delivery.

“You as the leader set that tone,” he said. “If you’re upbeat and positive and you set the expectations correctly, I think it will go much better for the people around you. The way you conduct yourself and hold yourself is a direct conduit as to how your people are going to do the same.”

REFLECTING ON THE STORM

Wilson said there were two possible ways to look at the storm experience – to either look at it as simply a job, or to create an investment into people so that they understand they are providing an essential service.

“Having an open mind helps that because it’s not necessarily going to be an easy experience to handle,” Wilson said. “By preparing the expectations of your new team mem-

bers, that sets us up to know that maybe this wasn’t going to go right the first time, but we will build on it for the next time and we’ll continue to keep building on it until we feel we are delivering the level of service, both as an employee and the company we represent.”

Scaringe said a dependable line of communications is imperative during a large snow event.

“From an operations standpoint, it’s important for everyone to have each other’s phone numbers so that there is a pipeline of information in

the field among leaders and staff,” he said. “With everyone so busy during the event, there wasn’t really the time to communicate properly, and that’s where the communications broke down and a lot of the frustration started, and that’s where we lost control of some of our sites.”

The failure to relay the company’s message that snow removal work was to stop at 10 p.m. to allow the crew to rest before hitting it hard again a few hours later was a key breakdown in the line of communications, Wilson said.

PCHECK THIS OUT

“That was never passed along the proper chains,” he said. ”And what ended up happening was we had a crew in a tractor until the very early hours of the morning as nobody had passed along that message.”

Scraringe said it’s important to follow through with communications, including both the good and bad aspects.

“I’m a firm believer that solutions only happen when you’re honest with each other and when you’re able to talk things out and really grow for each other.”

Empowerment and decision-making go hand in hand, he said, adding mistakes are going to happen when people without the real life experiences an owner might have are empowered.

“As long as everyone is staying safe and we’re servicing the client to the best of our ability, you have to take those mistakes as training aids for the future, learn from them and put them out there for the rest of your team so that they don’t make those same mistakes.”

Empowering people allows them to feel they are a valuable component of the operation instead of feeling “they’re just the new guys.”

Preparation ensures everyone on the team knows and understands the company standards before a snow event happens.

They need to know where the snow is to go once it’s cleared as well as the equipment and de-icing material stages.

“Everyone needs to know this,” Scaringe said.

Wilson said new operators were seeing the company’s sites for only the first time last year during the storm, and at night and under a foot of snow. Plans this year are to ensure staff familiarize themselves in advance with the company’s sites and have the necessary site maps.

“We’re going to focus on doing these things right and hitting on all the details that we saw during this snow event that really became a hindrance to the operation,” he said.

The need to analyze, improve and optimize became apparent after the company lost one of its snow removal contracts in the aftermath of the Dec. 1, 2019 storm.

“They thought we really dropped the ball on that,” Scaringe said, adding it can be difficult to secure new work today. “If we do get that big storm again, whether it’s the first or last storm of the season, we will be prepared.”

Wilson said the Dec. 1 storm, from a student’s perspective, was “the greatest lab you could possibly ever have. Every storm provides an opportunity to learn new lessons.”

Irrigation system winterizing

Extend

the life of a system’s components by following these steps By Chris Davey

An irrigation system that hasn’t been prepared for falling temperatures is at risk of damage from ice expanding in the components. Winterizing, sometimes called decommissioning, involves a few quick steps before winter’s arrival that will help you avoid a lot of lost time (and money) later.

When to winterize depends on your location and how you use your system. If you’re in an area warm enough that you continue to irrigate during the fall or winter months, winterizing may not be needed. In general, once you have three or more days with the temperature below freezing (32 degrees Fahrenheit or zero degrees Celsius), it’s time.

The ABCs of winterizing

Regardless of your location or the type of property you maintain, all it takes is some quick upfront work to protect the system and increase its service life.

A. Begin by turning off the water and electricity. Before you take any winterizing action, it’s essential to make sure there’s no source pressure in the system and that the electrical supply to the pump or other components is turned off. This protects you and also protects the system by ensuring that it can’t accidentally get

turned on during the winter months. Suppose you have a water feature that runs year-round or an automatic system with valve controls to actuate. In that case, you can maintain the flow of electricity by connecting the wires from the controller. You can also actuate solenoids individually by using a commercial handheld actuator.

B. Drain the system. With the power and water supplies now off, it’s time to remove the water from the system so that it can’t freeze and cause damage. Your system likely already has drain valves installed at the lowest point of every lateral, but, if not, plastic or brass drain valves are affordable and simple to install. Glue in a T and thread it so that it’s upside down for draining into six to eight inches of gravel. Gravity is your friend and will drain the system, though it’s a good idea to use a pressure source such as an air compressor to ensure the water is purged.

C. Make sure valves and solenoids are drained.Don’t stop at only draining the pipes. While the system doesn’t need to be bone dry, most manufacturers recommend actuating or manually bleeding anything connected to the source. It’s common for water to get trapped in solenoid ports and in the valve above the diaphragm. If that water freezes, it’s likely that the rubber tip on the plunger will be damaged. Drain all valves, solenoids,

atmospheric or pressure vacuum breakers, and reduced pressure actuators.

Go easy when using pressure

There are certain actions to take if you’re using a pneumatic pressure source to empty out your system. First, to prevent moving the water too quickly and damaging components, keep the air pressure below 50 psi. Your goal isn’t only to remove the water, but also to protect the system. By slowly displacing water, you reduce the risk of a trapped water pocket breaking loose and distressing or breaking pipes, fittings, sprinklers and valves.

How long to allow

Obviously, the larger your property, the longer winterizing will take. The rule of thumb is that larger sports fields six or four-inch mains and three-inch laterals (or golf courses with a six, eight or 10head fairway system) can take several hours per zone to complete all the steps

and check the heads. As you scale up, keep a four-to-one ratio in mind. In other words, if the pipes are twice as big and the heads are twice as big, it’s going to take four times longer.

Open all drains at the low points and vent the high points to maximize airflow. If you’re working with compressed air, attach the compressor to the highest point possible so that you work from the top down. Ideally, drain the system over several days using the compressed air at short intervals and then pause to let gravity do the work. Continue working from high points to low points until the expelled air looks clear.

Fall is ideal for maintenance, too

It might seem logical to think about springtime for maintenance, but, actually, maintenance is often overlooked or shortchanged because it’s such a busy

time for sports venues. At many facilities, activities slow during the fall, making it an ideal time for maintenance. Plus, throughout a typical season change, the ground is likely to freeze, thaw and re -

freeze several times, which can put rubber components such as O-rings under considerable stress if they aren’t lubricated

With your system decommissioned and drained, it’s a great time to disassemble and clean large commercial sprinklers and nozzles. Check for debris at the end of the line, especially if pressurized air was used to drain the system. Toro also recommends that you lubricate O-rings and other components before reassembly.

Winterizing is good business

A little winterization time spent in the fall will save you a lot of time in the spring – and it could also save you a lot of hassle. If you don’t drain the system and it freezes, you risk damage to delicate parts like valves, diaphragms and pressure vacuum breakers. In the worst-case scenario, you could end up having to dig and replace the lines and sprinklers.

Save money and save headaches. Winterize your system each year.

For more detailed, step-by-step information, read theIrrigation System Winterization and Pressurization Procedures Guide at https://chs.toronsn.com/pub/ WinterizationGuide.pdf.

Chris Davey is product marketing manager at Toro. He also co-hosts a radio show called The Water Zone, sponsored by Toro, which is broadcast on Thursdays at 6 p.m. on iHeart radio and throughout Southern California on NBC News Radio stations. The podcast is available on iTunes.

Greenjacket-1-6-Turf and Rec.qxp_Layout 1 4/12/17 4:28 PM Page 1

PLUS:

• GreenJacket PERMEABLE Grow-in Covers to dramatically i n c re a s e t h e sun’s ability to germinate and GROW healthier turf while allowing the underlying turf and soil to breathe.

• Patented IMPERMEABLE Reinforced Cover to protect your turf from cold-weather damage

Buck Storlie is product line manager for ASV Holdings Inc., a Yanmar Compact Equipment company, which designs and manufactures a full line of compact track and skid steer loaders primarily for the landscaping, construction and forestry markets.

Finding a snow worthy track loader

A compact track loader can excel in snow and maybe outperform a skid steer

By Buck Storlie

What’s better for clearing snow, a skid steer or a compact track loader? The common perception is that a wheeled machine would fare better, and it’s often true with many track loaders. It’s why many compact track loaders are parked for the winter while their wheeled counterparts keep working. However, it’s possible to choose a compact track loader that not only excels in snow, but performs as well as or better than skid steers.

Operators have a lot to consider when looking for a snow-worthy compact track loader. Machine ground clearance, track surface contact, weight distribution and more can have a huge impact on performance, productivity and return on investment. Careful consideration of the machine’s undercarriage, the desired application, ROI possibilities and comfort could lead to a track loader that performs all year long.

IT STARTS WITH THE TRACK SYSTEM

The process for choosing a track loader for snow and ice clearing works best from the ground up, starting with the tracks. A variety of options exist, including some modern designs that feature extra length and width and an extremely effective bar-style tread to achieve maximum contact with the ground. The extra ground contact allows maximum traction on snow, ice and slush, running contrary to a perception that an aggressive track pattern is necessary for traction in winter applications.

Dedicated snow tracks are offered by many manufacturers and may improve performance for some track loaders, but operators will see a higher return on investment by choosing a machine with tracks meant for year-round use that don’t have to be changed with the season.

Advanced suspension systems can improve traction even more by keeping the track in contact with the ground. Look for

a dual-level system that features independent torsion axles between the undercarriage and machine, as well as bogie wheels that flex with the track. This combination not only minimizes vibrations to the machine and operator for improved comfort and ride quality, it also maximizes ground contact for extra traction.

For example, when loaders without independent torsion axles engage the bucket, the front part of the tracks can lift off of the ground, reducing traction by leaving only the back end of the tracks to push the loader. Independent torsion axles in that same situation will push the tracks downward to maintain maximum ground contact. The same thing happens when the track flexes over small obstacles.

Purpose-built track loaders also feature optimal weight distributions compared to models converted from skid steers. Loaders converted from skid steers are often too back heavy, affecting stability on slopes and reducing overall performance. The back of

a back-heavy machine can sink and get stuck in deep snow as well as reduce traction and pushing force on ice because of uneven weight distribution. Look for a track loader with a 50-50 weight balance that spreads the machine’s weight evenly and allows for greater traction and pushing power.

Track bogie wheels also play a role in weight distribution and therefore traction in snow. Most track loaders only feature a handful of bogie wheels in contact with the ground. Consider choosing a purpose-built track loader, such as some all-rubber track models, which can feature as many as four times more ground contact points than steel-embedded models.

The combination of even weight distribution and increased track surface area improves flotation and provides the ability to virtually drive on top of the snow – similar to the concept of snowshoes – while a higher ground pressure is more likely to sink and get stuck. Ground pressure on a mid-sized all-rubber track machine, for example, can be about four psi while a similarly sized steel-embedded rubber track machine may be 5.5 psi. Loaders with a low ground pressure can even drive up snow piles, giving operators the ability to stack snow higher before needing to start a new pile.

Finally, choosing a loader with high ground clearance has year-round benefits. The greater the distance between the bottom of the machine and the ground, the less likely it is to get hung up on snow or other obstacles. It can also improve speed by reducing belly drag. Some purpose-built compact track loaders achieve ground clearances as high as 15 inches, almost double that of other models.

CONSIDER THE JOB

Contractors should think about what machine characteristics fit their most common jobs. Overall machine size is a big consideration. Many jobs would be suited to a mid-sized model, but sidewalks and alleyways may call for some of the industry’s smallest sit-in compact track loaders. Small loaders allow access to tight areas that may otherwise have required manual shoveling, snow blowers or other open-air equipment. This can improve productivity and allow contractors to move to the next job faster. Larger spaces such as parking lots naturally call for the largest track loaders. Also look at lift height and whether the desired loader will be able to load dump trucks.

Take speed into account for a machine that will allow faster job completion. The fastest track loaders on the market use internal drive sprockets with replaceable steel rollers that fit with molded rubber lugs to move all-rubber tracks. The system greatly reduces friction compared to steel on steel designs seen in many loaders, and therefore improves speed. It also eliminates direct wear between rollers and track lugs. Plus, individually replaceable sleeves mean operators don’t need to change out the entire sprocket when rollers are worn down.

Don’t forget about comfort. A cold, uncomfortable cab could mean less employee retention for a contractor and higher fatigue for an owner-operator. Look for sealed, all-weather cabs with heating and cooling. Added features such as Bluetooth, cupholders and radio can also enhance user experience.

MONEY WELL SPENT

Just like with any equipment purchase, it’s important to evaluate potential cost of ownership and return on investment. Selecting a track loader that excels in snow clearing is an ROI benefit in itself because the machine can be used during the winter months instead of being parked. The characteristics that make a loader ideal for snow also translate perfectly to operating on soft surfaces in spring, summer and fall applications, such as landscaping, general construction and agriculture.

In addition to selecting a machine with tracks that don’t need to be changed with the season, look for other characteristics that promote year-round use. Similar to how many manufacturers offer specific snow tracks, it isn’t uncommon to need to switch out a loader’s fluids and lubricants with the seasons. Either that, or a manufacturer may charge for a winter package.

Evaluate whether any of the loader options come standard with all-season fluids tested to be able to handle both high and low ambient temperatures. Some manufacturers offer fluids and lubricants optimized for their equipment, allowing high performance at temperatures ranging from minus 30 degrees Fahrenheit to 118 degrees F. Other standard features to look for include engine block heaters and full temperature-range batteries.

Simple solutions to remedy common lawn care problems

Beware of contributing factors that can derail a lawn

By Mike Jiggens

There are several obstacles that can get in the way of achieving a healthy home lawn. Inadequate sunlight, insects and too much or too little water are among the primary reasons that can keep lawns from reaching their full potential.

Lawn care professionals attending Nutrite’s 11th annual spring lawn care seminar in Guelph were presented with scenarios of various turf problems they are apt to encounter each season as well as the solutions to overcome them.

Healthy soil physics and chemistry and good microbial activity are what good lawns have in common, Nutrite professional turf sales representative Mark Schneider said.

“We’ve been looking at soil microbiology for thousands of years, but really in only the past 20 or so years have we started to get our head around what’s going on down there,” he said.

Schneider pondered why some lawns fail while others thrive, citing inadequate sunlight as perhaps the No. 1 culprit. He reminded his audience that if there was one thing to be learned in university, it is that a plant requires air, light, water and food in order to grow.

Large trees not only block much-needed sunlight, but their roots compete for water, depriving turfgrass of its necessary fill.

“The tree wins every time.”

But there are other contributing factors that can derail a lawn, including root competition, heavy traffic and homeowner mistakes. Often, the latter is a leading contributor to a lawn that falls short.

“Quite often, you guys can do the best work possible, but if the homeowner isn’t doing one of these right – cutting too low or not irrigating when he should – it can make you guys look not so good and you may not get the results you’re after or they may not get the results.”

Schneider said that when a homeowner installs an irrigation system, the result is almost predictable.

“They’re going to have bentgrass in a couple of years because they like to go out every night after dinner and have a coffee

or drink and turn on their sprinklers and just water, water, water for that five or 10 minutes. That encourages bentgrass which is why every golf course in the world has sprinklers around the greens, tees and fairways. They are encouraging bentgrass.”

Homeowners, on the other hand, can actually grow bentgrass without trying, Schneider said, adding it just happens and then is difficult to get out.

A lawn care professional is often handicapped by a property’s soil type. He could be dealing with a sandy soil on a property in one end of town and one that is clay in another part of town. A soil’s physical, chemical and biological properties “can really determine how successful your plants and your programs are.”

Soil type

The professional must learn to deal with the soil type he’s been given.

“Soil physics is probably the No. 1 thing I encounter as the leading issue of the turf problem. Aerification and overseeding are essential. You’ve got to keep it up. Keeping that air in there and opening that soil up at the right time of year is essential.”

Maintaining soil pore space is vital as the ability for air to move down and water to adequately infiltrate also influence nutrient uptake. Nutrients applied won’t be as readily available to the plant if the soil is hard packed and not opened up.

Although a soil’s pH level is an important consideration, Schneider said little can be done to either raise or lower levels that aren’t optimum. The ideal pH range for a home lawn is between 6.5 and 7.2, but Schneider said good turf can still grow on soils outside those numbers.

“I’ve seen great turf on soils that were eight and excellent turf at 5.5. There’s a big swing in there.”

Testing for soil pH isn’t necessary every year and not even on every property, he said, but noted periodic testing of sections within a professional’s territory is encouraged.

Microbial activity in the soil isn’t readily apparent until May when the soil has had the chance to sufficiently warm up. Microbial activity typically drops off during the heat of summer, particularly when soil temperatures exceed 25 degrees Celsius.

Recalling the excessively wet spring of 2019 in much of Ontario, Schneider said there wasn’t a lot of microbial activity at the time. Once waterlogged soils began to dry out, activity picked up, including that of earthworms.

“Golf courses don’t like worms, but we like worms. Those are nature’s aerators. They’re doing the work that we don’t have to. It’s also the sign of a healthy soil.”

Carefully planning out fertility programs for lawn care customers is essential, Schneider said, including the need to select the right product to be used at the right time. He said three to five pounds is the typical range for Ontario, although some areas may need more while others require less.

“Don’t overstimulate the turf. Don’t use a really quick-release product in the spring unless you have to. If you have a poor lawn, you want some activity, but don’t add gas to a fire.”

A product with plenty of readily-available nitrogen that is 50 per cent slow release isn’t what should be used in mid-summer, he said, because of the potential for increased phytotoxicity or a higher salt index due to the urea content.

“Don’t make it a price per bag decision.”

Having to mow more frequently because of the product choices made will negatively impact revenue, he added.

“Don’t be chasing grass. It’s not good for the plant and it’s not good for your bottom line, either.”

When dealing with new turf that’s less than a year old, another pound can be added to a three or four-pound rate, Schneider said, adding if it’s a more organic, sandy soil, then another pound can be added.

lishing good seed-to-soil contact.

Laying sod is a service many lawn care companies prefer not to offer due to its labour intensity, yet sodding is sometimes a better option than “monkeying around” with a poor lawn, he said.

“Sometimes you have to pull the plug and start from scratch.”

Sodding is also an expense most homeowners wish to avoid. If sodding is necessary, however, it’s best to avoid doing it during the heat of summer. A starter fertilizer applied beneath the sod helps it to establish faster. After-care will be required, including watering and rolling.

“Roll and water, roll and water, roll and water. It’s essential.”

Schneider said rolling will alleviate air pockets under the sod to promote better root establishment.

“Water frequently for the first two to three weeks until you can’t pull that sod up.”

Oxford2016:Layout 1 12/16/15 3:36 PM Page 1

“If you have a really sandy site, you might need a little more food.”

Added nitrogen

In an excessively wet year, such as that experienced in 2019, a pound can be added because it’s working quicker through the plant. He cautioned, however, to never exceed six pounds or apply less than three.

Three pounds of nitrogen three times a year with one product isn’t a bad program, he said.

“Don’t put your peaks and valleys in the wrong spot.”

Fertilizer should never be placed inside a moist hopper, he said, noting it will clog up the machinery.

Three fertilizations, three weed controls and two aerations make up a typical program, but Schneider suggested the best time to aerate is in August or September to help relieve turf of the stress of summer. Aerating in the spring is fine as long as the ground is dry, he added, but emphasized that the practice not ever be done in the heat of summer.

Overseeding a lawn can ideally be done in conjunction with aeration by dropping seed into the holes and estab -

A lawn care professional needs to allow for other essential services, Schneider said, rather than focusing mostly on weed control.

“We’ve got to stop killing weeds and we’ve got to grow grass. It used to be, ‘let’s kill the weeds now and think about growing grass later.’”

New stylish work boots for outdoor workers

A new-style, heavy-duty work boot will be making its debut later this year, offering outdoor workers the ultimate in foot comfort throughout the day.

KEEN Utility has introduced the Philadelphia Wellington which has been built to withstand the toughest work environments. The boots featured a full-grain, barnyard-resistant, waterproof leather to help resist the damaging effects of oleic acid, urea, sodium chloride, and ammonium hydroxide. Other features include:

• Left and right asymmetrical, non-metallic carbon-fibre toes for an unobtrusive fit and which is 15 per cent lighter than steel

• KEEN Luftcell, an air-infused, PU midsole for weightless comfort with each step

• Three-quarter Goodyear welt construction for enhanced durability and flexibility under extreme working conditions

• Oil- and slip-resistant non-marking rubber outsole

• Removable, dual-density PolyAer PU footbed with aerated pillow-top cushioning

• Electrical hazard (EH) or Electric Shock Resistant (ESR) footwear provides a secondary source of protection in case accidentally coming into contact with live electrical circuits

• Heat resistant, rubber outsole rated up to 572 degrees Fahrenheit (300 degrees Celsius)

• 100 per cent non-metallic construction for easily passing through metal detectors in highly-secured areas

The new men’s Philadelphia Wellington will be available this fall in both Canada and the United States. For more information about KEEN’s Philadelphia boots and the company’s other lines of professional footwear, visit www. keenutility.com.

For more than a decade, the Color Atlas of Turfgrass Weeds has been the leading authority for green industry professionals in their ongoing quest to control weeds and limit deleterious effects: the weed clumps, color variation, and unsightly patches that disrupt turf uniformity. The Second Edition of this essential resource has been expanded and updated to provide control information that professionals need to maintain the quality that is so vital to the golf, sports field, and managed landscape industries. $176.00 Item #0470189511

Health & Safety

By CCOHS

The Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well being of workers in Canada by providing information, training, education, systems and solutions that support health and safety programs and injury and illness prevention. www.ccohs.ca

The scoop on snow shovelling safety

As Canadians weathering cold, snowy winters, most of us are all too familiar with the arduous, strenuous job of shovelling snow. It can be hard work and, whether you shovel at work or at home, there are some tips you should consider to protect yourself from the hazards that can go along with the task: cold exposure; fatigue; muscular strains; back injury and potentially a more serious injury such as a heart attack.

Fit for the job? If it’s the first snowfall of the season and you are unaccustomed to shovelling, or you’re not in good physical shape, shovelling snow can be a strain on your heart and back. If you are older or have a history of back or heart problems, you should avoid the task altogether and delegate it to someone else or use a snow-blower to clear the snow.

Warm up. As with any exercise, consult with your doctor to ensure you are fit enough for this physically demanding activity. Before you begin shovelling, do warm-up stretches and flexing exercises to loosen up the muscles and prepare them for the job ahead.

Lighten the load with the right shovel. It’s important to match the shovel with the task. A snow shovel should be lightweight, about 1.5 kilograms or a little more than three pounds, and the blade shouldn’t be too large. For example, a large push-style shovel will move large amounts of snow but may result in lifting too much weight. A smaller blade shovel (25 to 35 centimetres or about 10-14 inches) should be used for lifting and throwing snow. The smaller blade will decrease the weight that is lifted and decrease the risk of injury. The handle of your shovel should be long enough so that you don’t have to stoop to shovel and the grip should be a D-shape handle made of plastic or wood – metal gets too cold. This kind of shovel will also help avoid awkward wrist positions. As a general guideline, the shovel (blade plus

Before shovelling, do warm-up stretches and flexing exercises to loosen up the muscles

handle) should be elbow height when standing upright.

Bundle up. Wear several layers of warm, lightweight clothing that is easy and comfortable to move in. The inner layer should be made of material that allows perspiration to escape from the skin surface. Additional layers should provide insulation suitable to the weather and, if working in wet conditions, the outer layer should be waterproof. When choosing materials, avoid cotton clothing as it can get damp quickly and won’t keep you warm. Instead, wool and synthetic fibres make better options as they retain heat when wet. Make sure your head (especially your ears), feet and hands are well covered. Your winter boots should be warm, water-resistant and high-cut, and provide good traction. Gloves should be light and flexible and give you a good grip. If it is really cold, wear something over your mouth. And do not shovel at all if the temperature drops below minus 40 degrees Celsius, or below minus 25 to 30 degrees when it is windy.

Pace – don’t race. Shovelling snow in heavy-duty clothing can be as strenuous as weightlifting. You may want to get the job over with as fast as you can, but it is

better to keep moving and work at a steady pace. A good recommended rate for continuous shovelling is usually considered to be around 15 scoops per minute. Shovelling is going to make you sweat and, if you stop, you could get a chill. The trick is to shovel efficiently without becoming fatigued.

Push – don’t lift Push the snow rather than lift it. If you must throw it, take only as much snow as you can easily lift. And remember, the wetter the snow, the heavier it is.

Face – don’t twist. Turn your feet to the direction you’re throwing – don’t twist at the waist. Do not throw the snow over your shoulder or to the side.

Get the scoop. Consider using a snow scoop to push the snow instead of lifting. The scoop helps you to move snow with less effort by riding up over the snow to allow you to move it without ever having to lift it.

Rest and recover. Take frequent breaks and drink some warm non-alcoholic fluids. In extreme conditions, such as very cold and windy weather, 15 minutes of shovelling should be followed by 15 minutes of rest.

Recognize the danger signs. Stop shovelling and call 911 if you feel discomfort or heaviness in the chest, arms or neck; unusual or prolonged shortness of breath; a dizzy or faint feeling; or excessive sweating or nausea and vomiting.