Reliability that counts

HIGH POWER SOLUTION FOR PROFESSIONALS.

The FSA 135 R is the latest brushcutter in our battery-powered line-up that can be used in noise-sensitive situations. It is a lightweight, powerful and efficient choice for landscapers, municipal workers and those that have large yards to upkeep. The AP battery can be inserted directly into the powerhead, as opposed to using an adapter system. The ergonomic loop handle makes it comfortable to operate and easy-tomanoeuvre, while also providing a three-step speed adjustment with LED light. Built with a metal mesh air filter, it delivers a longer service life and provides optimum motor cooling. Also, a wide selection of cutting attachments can be used on the FSA 135 R to suit the job at hand.

NOTE: FS 135 bike handle also available.

SPECIFICATIONS

PRO-FLEET COMMERCIAL LANDSCAPE PROGRAM

STIHL’s Pro-Fleet Commercial Landscape Program is designed to provide commercial landscapers a volume discount on major purchases of 5 or more landscaping power tools. Visit your STIHL Dealer today to find out more and take advantage of the savings!

STIHLCANADA

Super shares his skills with

assistants at growth academy A program aimed at fast tracking assistant golf superintendents to climb the ladder toward becoming superintendents themselves is not only rewarding for the young participants, but their mentors as well.

By Mike Jiggens

Golf’s next challenge: retaining new golfers

Golf season has come to an end in most of Canada, and 2020 will long be remembered as the year that began in doubt and ended on the highest of notes. While the COVID-19 pandemic took its toll on most other sports – and not in a good way – it actually catapulted golf to another level.

Courses throughout Canada reported record numbers of rounds played, increases in memberships and months of full tee sheets upon shutting their doors in October and November. Simply put, the game was tailor-made for COVID-19. It was really the only sport in which physical distancing could be guaranteed and where there was no need for any of its participants to touch any type of common item.

Golf hadn’t experienced such numbers since the latter part of the 1990s when Tiger Woods was largely credited for propelling the game forward. The so-called “Tiger effect” resulted in massive new course construction throughout North America, significant renovations made to existing courses and a new enthusiasm for the game.

But the bubble burst within a handful of years. It wasn’t long before supply outweighed demand, and many of these new golf courses were half empty. The Tiger effect, it seemed, was no more than just a flash in the pan, and the game went into a period of

decline – until 2020.

The difference between 2020 and the latter part of the 1990s is that golf had little competition this year while 20 to 25 years ago there were many other things one could pursue.

Does this mean 2021 will be a repeat of 2020 in terms of golfer participation? Maybe, if the pandemic continues to drag on into next year and there are still few COVID-friendly options available. At the very least, a seed has been planted in which those who took up the game for the first time this year and enjoyed themselves will likely want more of the same when courses reopen in the spring.

Depending on the status of the pandemic as the 2021 golf season nears, the challenge for

How can superintendents play a role in making this happen?

golf courses will be to retain these new golfers and those who stepped up their playing frequency, especially if the door swings wide open again for other activities to take place. Now that these new golfers have tried the game and like how it tastes, the objective is to keep them.

So how can golf superintendents play a role in making this happen? For one, they can instruct their maintenance staff to avoid difficult pin placements. Three-putting is one of the biggest turnoffs in golf and is a good way to alienate new

golfers. Do what’s needed to keep the game simple. Reserve the tougher pin placements for club championships and highend tournaments.

Don’t get too carried away with roughs. Don’t penalize these new golfers any more than is necessary. They’ll want to be able to play their next stroke from a reasonable lie following an errant tee shot and not have to spend all day looking for a lost ball.

Perhaps leave bunkers alone. Although rakes are universally outlawed at all golf courses under COVID-19 protocols, some clubs continue to groom their bunkers while others don’t. At courses where bunkers are maintained, golfers are expected to play their next shot “as it lies” and then use their foot to “rake” the sand as smooth as possible when leaving. Other courses have chosen to leave their bunkers alone and have instructed golfers to simply take relief at point of entry without penalty.

The latter option is certainly more golfer-friendly, especially for newbies, and allows beginning golfers to reap more enjoyment from the game without having to experience the frustration associated with sand play. Once they’ve had a season or two under their belt, then perhaps it’s time to introduce them to bunker play.

Temporarily taking bunkers out of play also frees up valuable time for maintenance staff to focus on other tasks.

Eventually, golf will return to the way it was meant to be played, complete with the optional removal of the flagstick when putting.

www.turfandrec.com

Reader Service

Print and digital subscription inquiries or changes, plesae contact

Anita Madden, Audience Development Manager Tel: (416) 510-5183 Fax: (416) 510-6875 email: amadden@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

Editor Mike Jiggens mjiggens@annexbusinessmedia.com

National Advertising Manager Rebecca Lewis 519-400-0322 rlewis@annexbusinessmedia.com

Nashelle Barsky 905-431-8892 nbarsky@annexbusinessmedia.com

Account Coordinator Mary Burnie 519-429-5175 mburnie@annexbusinessmedia.com

Group Publisher Todd Humber thumber@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada ISSN 1186-0170

PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Published 7 times a year – Jan/Feb, Mar, Apr/May, Jun, Aug/Sept, Oct, Nov/Dec Canada – 1 year $35.00; 2 year $45.00 3 years $55.50 (plus applicable taxes HST 86717 2652 RT0001

Occasionally, Turf and Rec will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2020 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

STAND UP FOR SERIOUS MOWING.

The Kubota SZ Series stand-on mower outperforms its price point. It’s powered by a commercial grade Kawasaki engine to deliver nimble zero-turn mowing in tight spaces and on tough slopes. The foldable operator platform lets you get on or off with ease. Plus, it’s built for lasting durability. Best of all, the SZ is compact, so you can fit multiple units on a trailer—ideal for when a big job demands it. Now that’s outstanding.

Private members bill aimed at paring back insurance costs

A private members bill passed by the Ontario Standing Committee on Regulations and Private Bills aims to pare back the cost of liability insurance for snow contractors by reducing the number of “frivolous” slip-and-fall claims.

Introduced by Parry SoundMuskoka MPP Norm Miller, Bill 118 will shorten the amount of time individuals have to notify snow contractors, property owners or tenants. The notification period will be reduced to 60 days from a previous two years.

Bill 118 is awaiting third reading in the Ontario Legislature.

World Golf Awards names Tobiano GC best in Canada

Tobiano Golf Course in Kamloops, B.C. has been recognized as Canada’s best golf course in the seventh annual World Golf Awards.

The World Golf Awards celebrates and rewards excellence in golf tourism, world-class courses and golf destinations. The worldwide voting event consisted of a nomination process followed by voting from Feb. 23, 2020 to Sept. 1, 2020.

Votes were cast by professionals working within the golf travel and tourism industry as well as those of public golf consumers.

College sports facility expects to be best of its kind in Canada

Windsor’s newly-opened St. Clair College Sports Park is expected to be seen as the premier sports facility in the Canadian college system, its vice-president of international relations, campus development and student services says.

The $25.8-million facility officially opened Nov. 17, giving the campus a state-of-the-art sports park.

Proposed new notification period from two years

Landscape Congress 2021 going virtual amid pandemic

In spite of a record attendance in January, the Landscape Ontario Congress trade show and conference has been forced to switch gears and turn its annual event into a virtual offering for 2021.

“For the first time in almost 50 years and after enjoying record attendance last year, we have been forced to postpone Congress 2021 due to the (COVID-19) pandemic,” Tony DiGiovanni, executive director, Landscape Ontario Horticultural Trades Association, said. “This has not been an easy decision, but it is the right one.”

Organizers are planning a virtual experience called Congress Connect, adding there are advantages of going virtual such as not having to worry about weather and accessibility. Congress Connect will be held Jan. 12-14.

services they need to perform their work all in one place. There will still be hours of relevant education and professional development opportunities that will advance the profession. Congress Connect will still be dedicated to your future.”

Among the sessions for the conference that have already been confirmed include:

• Get New Clients and Retain Them With Effective Marketing, presented by Catherine Luzena-Hall of Practical Marketing Group. Practical strategies and best practices to obtain new clients with little effort and money.

$25.8 million Cost of St. Clair College’s state-of-the-art facility

“Even though Congress Connect will be accessed through a computer, we will enhance and reflect the values that make event experiences so relevant,” DiGiovanni said. “Congress Connect will stimulate and showcase innovation. It will be a place to reveal new products. It will allow attendees to access goods and services and connect with exhibitors through video chat, chat or email. You will still be able to renew old acquaintances and build new relationships. Buyers will still find products and

• Professional Sales for the Professional, presented by Rob Redden of in-Lite Outdoor Lighting. Ethical sales skills to understand the right business lead and how to move past bad leads.

• Sustainability: Leading Your Team, Clients and Community to a Better Way, presented by Paige Parker and Scott Wentworth of Wentworth Landscapes. Taking a leading stewardship role in applying sustainability principles.

• How to Increase Your Profit per Employee by $1,000 per Year, presented by Domenic Richichi of EIO Solutions. Revenue per employee is a strong analytical tool.

Visit https://locongress.com/.

Thatch helped create ‘the perfect storm’

Mowers were cutting 95 per cent of greens and annihilating the rest

By Mike Slack

What a year! I hope everyone is safe and enjoyed this record-setting year in golf!

I have had numerous calls about mowers scalping greens, and many factors have impacted this issue. Hence, the perfect storm!

As we were told in March to shut down operations and pursue only “essential maintenance” (isn’t everything we do essential?), most golf club owners laid off staff and let the superintendent keep the place in order. As late April and May came, the grass was in fine growing form, and the super needed help. So, the chef, pro and secretary were bestowed on the course to help “cut grass.” However, what about spring aeration? Topdressing? Verticutting? There were no people to do that.

So, our friend Mr. Thatch decided to ramp up operations and create puffy turf.

“Golf courses can open,” Ontario Premier Doug Ford said, leaving five days for superintendents to prepare for May 23rd openings. Staff had to be brought back and trained in disinfecting equipment and staggered start times, if they weren’t making more on CERB.

Then here comes the heat and his little friend humidity (what a year for a pool). July had the third highest temperature on record. Too much heat, so we can’t verticut, topdress or aerate – this along with 200-plus golfers a day at most courses. (What owner wants to hold tee times to do cultural practices anymore?).

High humidity makes the turf very tacky, thus allowing the bedknives to slide smoothly across the turf and, with thatchy conditions, it allows the knife to tip up and dive into the greens which therefore scalps the turf. Mechanics were pulling their hair out trying to figure out how the mower could cut 95 per cent of a green perfectly and annihilate five per cent. Then, due to the heat, we watered and watered and watered, making the turf soft and spongy, especially on the perimeter of the green where traffic and compaction is not as prevalent.

I spoke with a few colleagues regarding the issue and how to get through it. Here are some of their comments.

Jim Moore at Puslinch Lake said, “as soon as the humidity hit, on went the front solid rollers.” They are not as aggressive as a Wiehle roller, especially around the green perimeter, as they slide and don’t furrow the turf.

Duane Schmitz of Woodstock Meadows stated, “I raised my heights .025 right away.”

In the words of legend Bill Hynd, “Some

grass is better than no grass!”

In conclusion, we all know the important cultural practices in our industry are to provide optimum playing conditions. Just this year between the shutdown, quick opening, full-to-capacity golfers, heat and humidity, we were caught in the perfect storm!

As September approached, temperatures cooled down, and verticutters, topdressers, and aerators were lined up like the Indy 500 in every shop, I’m sure.

Side note: Is anyone else having issues with some disinfectants corroding hour meter sensors, key switches and cart windshields? I digress.

Mike Slack is the owner of Slack Reel Services in Burlington, Ont., which has been serving the golf and turf industry since 1989. The business is family-run and deals with various companies across Ontario and other parts of Canada, specializing in reel mower sharpening, parts distribution and on-road service technical work, mainly in Ontario. The business may be reached by calling (905) 516-4757 or by emailing slackreelservice@gmail.com.

A season of ample heat and humidity presented a challenge for mowing greens without some scalping.

Robotic mowers making their way onto Canadian turf

Commercial application of robotics starting to make headway in Canada.

By Mike Jiggens

It may look to many like a scene from a science fiction movie as unmanned, mechanized machines move about cutting grass in random patterns across corporate properties, sports fields and other green spaces of significant square footage, but it’s science fact at work and advanced technology that is now making inroads in the commercial turfgrass market.

Robotic mowers have been in use for a number of years now in the residential market, but professionals are starting to take a shine to these machines as well. Europe was the first continent to adopt robotic mowers and has realized substantial growth with their autonomous technology.

“While it’s not anywhere close to unseating traditional mowers, it’s making pretty big inroads across the pond,” Jake Vollbeer, national sales manager for Echo’s U.S. robotics division, said.

The technology has been catching on in North America and, although growth is slower on this side of the Atlantic, it has been significant, he said.

“As adoption grows, you’ll start to see more and more of these. As the technology gets better and better, the adoption will grow.”

Vollbeer said Echo has been selling

robotics in the United States for the past few years, but it’s been only this year that the Canadian market has been tapped.

“Our target market with these products are commercial landscapes.”

Jenna Sanders, director of sales for Husqvarna commercial robotics in North America, said robotic mowers are being used for just about every type of commercial application.

“Commercial green space managers

are seeing the cost benefits, the reliability and consistency of robotic mowing,” she said, adding commercial property management companies are realizing a return on investment in one to two years.

Sanders said the mowers’ consistency is a key attribute as well as their ability to be operational at all hours of the day.

“Because they work all of the time and they keep the grass consistently mowed, you don’t have to worry about if it rained

A robotic mower keeps a municipal park’s turf in top shape. Husqvarna photo.

three days in a row and now the grass is really high and landscapers are trying to catch up,” she said.

Robotic mowers move in a random pattern inside an electromagnetic field delivered by a buried wire. Reading the perimeter wire prevents the mowers from straying onto roads or sidewalks or anywhere else they shouldn’t be. They can be scheduled to mow within their defined areas at optimal times of the day, such as between games and practices in sports field applications or after dark.

Less leaf blade cut

“The idea is to give it as much time to work the area as you can,” Vollbeer said. “When it’s doing that, it’s cutting off just a little bit of the grass blade at a time.”

The robot maintains a prescribed cutting height whereas conventional mowing may require more of the leaf

blade to be cut, depending on when its operator can get to the job site. Clippings are alleviated through robotic mowing and the plant tends to be healthier, he said.

“You get a very nice looking, low cut parcel of property that is healthier, has a tendency to green up a little bit earlier in the spring and stays a little healthier in the fall.”

Sanders said only about an eighth of an inch is being mowed at a time and the cuttings are mulched.

“You use less fertilizer and some of the chemical treatments, so the quality of the turf just looks so much better over time,” she said.

When people see a robotic mower at work, knowing that its cutting disk is much smaller than the deck of a commercial zero turn, they are inclined to think it’s meant for residential use,

New! Bannerman Model B-IS-F145

Stone & Debris Burrier

• Controls weed infestation in walking paths, warning tracks and baseball infields.

• “One Pass” ground preparation for seeding or sod replacement in goal mouth areas

• Tractor PTO Driven - (30 to 45HP) recommended

• 28 Special Centra Rotating “Hoe” Blades Leveling

• Grader Blade on Screw Jacks

• Rear Adjustable “Net” Roller complete with Soil Scraper and Brush

• “Net” Roller can be offset to work close to fences, walls and curbs

• Working width 57”, Standard 3 Pt Hitch Cat # 1 & #2

Sanders said.

“There are a lot of applications that we haven’t even scratched the surface of covering with the lineup we have today,” she said, noting manufacturers are already looking ahead to such large acreages as golf courses, sports fields and air fields.

In 2019, Husqvarna launched a GPS-oriented robotic mower that is wire-free. Advances have also been made in connectivity.

“Having GPS and cellular connectivity – being able to control the mower from your app – we have a fleet services dashboard now for our commercial managers so you can pull it up on your phone or laptop and see your entire fleet of mowers, and you can control them all with one click of a button.”

If a significant rain event is forecast and the property manager doesn’t want

Trilo VCU 200 Verticut

The Trilo VCU 200 Verticut unit is specially designed for sports fields, flat areas and parks, and is the solution for all your thatch problems. Features include:

• Removes thatch build-up • Allows increased aeration

• More effective utilization of fertilizer

• Increased water penetration

• Earlier spring green-up

• Fall seed bed preparation

• Completely mechanically driven, no hydraulics

• Working width of 78” • Removes thatch down to a depth of 1.5”

• Multi-tipped blades, 3mm thick on 1.25” centres

• Quick depth of cut, adjustable by calibrated screw jacks

• Cable debris scraper on gauge roller

• Requires minimum 20 HP tractor

Robotics permits mowing, ball picking done in tandem

Echo’s robotics division has introduced a product aimed at the golf market that works in tandem with robotic mowing. An autonomous ball picker, coupled with a robotic mower, picks up balls while the driving range is simultaneously mowed.

Conventional methods of picking balls can result in scalped balls and partially buried balls because it’s not a clean pick. The mower-picker combination accomplishes two tasks at once, but even the mower working alone can still do its job with a range blanketed with balls.

to risk the mower from encountering flooded areas, he can click “park” to send it back to its charging dock.

“With the introduction of the wirefree solution, it opens it up for more sports fields because if you need to aerate, there is always the concern about cutting a wire,” Sanders said. “You now eliminate the wire you might nick or damage when aerating.”

Vollbeer said GPS functionality also allows robotic mowers to find their charging stations more quickly.

No emissions, low noise levels

He said that in addition to their agronomic attributes, robotic mowers have other significant benefits. Without the need for fuel, there are no emissions, and noise levels are greatly reduced.

“They’re completely quiet and are actually hard to hear until you get right up on them,” Vollbeer said. “They’re very unobtrusive and you wouldn’t even know they’re there other than the grass is cut and you see a rather large, grey robot traversing the area from time to time.”

The robots utilize sonar to detect obstacles in their path. Upon detection, their forward speed automatically slows from a maximum of 2½ miles per hour.

“Once it detects an object it will reduce its speed to just a fraction of that,” Vollbeer said, adding a “bump” sensor at the front of the mower will activate, sending the robot in another direction.

The mowers communicate data to a portal. Once the robot is activated, it can

be sent a command via the portal and it will provide real time information as to where it’s located on the parcel being mowed. If it’s stolen from the property, real time data will help locate it.

About two hours of run time are provided for each hour of charge time.

New features and functionalities continue to be incorporated into robotics, Vollbeer said.

“As that continues to grow, you’ll see the utilization grow and at some point – probably within the next 10 years – it will make up a pretty substantial amount of the mowing equipment that’s sold in North America,” he said.

Sanders said Husqvarna has introduced an all-wheel-drive model which allows steep slopes to be mowed.

Vollbeer said the take-home message behind robotic mowing is that it represents a major paradigm shift in the way grass is mowed, and people must understand that the method of mowing is noticeably different than that of conventional mowing.

“While it’s a great product, it’s a little bit different,” he said. “It works in a random pattern. It needs as much time to mow as you can give it, but it’s always going to show up for work and it’s never going to complain about what it has to do. It’s always going to work, but it still needs to be managed. Just because it always does what it’s told doesn’t mean you shouldn’t pick up on it. There is less human interaction required, but they do need human interaction to make sure they are functioning and working properly.”

“With just the mower itself traversing and mowing you’ll always keep that area mowed and never have to worry about chopped up golf balls or losing golf balls,” Jake Vollbeer, national sales manager for Echo’s U.S. robotics division, said. “It just continues to keep that height of cut.”

The range picker averages about 100 collected balls per traverse, dropping a full load of 300 balls into a ball management system when full before making another sweep. It is capable of picking up about 12,000 balls on a normal cycle.

Driving ranges never need to shut down to allow mowing, and both the mower and picker can continue to function after dark.

Vollbeer said the system helps prevent clashes between club pros, who want to keep the range open as long as possible in order to drive revenue, and the golf superintendent, who needs to mow the range regularly yet finds scheduling difficult when it’s in constant use.

Condominium properties and other large acreage green spaces are seen as ideal venues for the commercial application of robotic mowers. Husqvarna photo

Echo’s ball picker works in tandem with a robotic mower. Echo photo

Co-piloting on brine for sustainability

Customers prefer service suppliers that demonstrate corporate responsibility

By Krista Kent

One of a contractor’s most significant stakeholder groups is its customers. As such, it is important to understand what values, themes and aspects are most important to their brand initiatives. Doing so aligns the contractor and customer in their preferred outcomes, ensuring a productive partnership for all parties. Most recently, the word sustainability has dominated the scene when it comes to a company’s desired narrative.

Sustainability in the outdoor service industry is not just about reducing a company’s environmental impact, it also largely consists of risk management and finding operational efficiencies.

Whether or not one identifies sustainable initiatives as a value for his business, one thing is certain – customers prefer service suppliers that demonstrate corporate responsibility. Innovation is inevitable, change is constant, and along with those comes advancements in snow technology and equipment. These circumstances leave contractors in a position of either adapting or being left behind.

Clintar Commercial Outdoor Services views environmental sustainability as an opportunity to find efficiencies in business operations while reducing our environmental footprint. Naturally, brine became a topic of discussion, so we decided to pilot sustainable ice control products and processes in a project headed by John Cardella,

Clintar’s corporate sustainability manager.

We partnered with several major clients for the 2019-20 winter season to collect relevant information to help determine the effectiveness of brine in a variety of weather conditions.

Picking partners

The first step involved sourcing client partners in this contemporary working relationship. Clients who already had strong connections with the business were approached first and were very receptive to the idea. This could have been anticipated since today the most widely recognized and globally successful brands are aggressively placing sustainability at the centre of their market narrative.

If there was no compromise in service or health and safety, most of the clients we identified were willing to pilot this program. To ensure these standards were maintained, rural and industrial property types with less foot traffic were predominantly considered.

Starting small

Next, resources had to be assembled. It was determined that the best course of action was to start with a small operation. This lessened the financial risk that comes

with investing in new equipment, processes and innovative techniques. A single three-man crew was assembled, armed, trained and assigned to the properties where this service would be put to the test. The largest monetary investments were spent on a new brine application unit for an ATV, the installation of weather cameras, and labour costs allocated to proper training for the crew members.

This modest approach, accompanied by consistent data collection and analysis, will lay a solid operational foundation for the delivery of this type of service in the 2020-21 winter season – if deemed worthwhile for both invested parties.

The mission of this campaign focuses on driving results that benefit the snow and ice industry by providing a greater understanding of costs and environmental impacts or benefits.

Krista Kent is manager of corporate training/health & safety for Clintar Commercial Outdoor Services and is a member of the Snow Business editorial advisory committee. Contact her at krista.kent@clintar.com. This information originally appeared in Snow Business magazine, the official publication of the Snow & Ice Management Association. Learn more about SIMA’s snow and ice resources at www.sima.org.

Super shares his skills with up-andcoming assistants at growth academy

Grant Murphy was in the right place at the right time to become academy mentor.

By Mike Jiggens

Aprogram aimed at fast tracking assistant golf superintendents to climb the ladder toward becoming superintendents themselves is not only rewarding for the young participants, but their mentors as well.

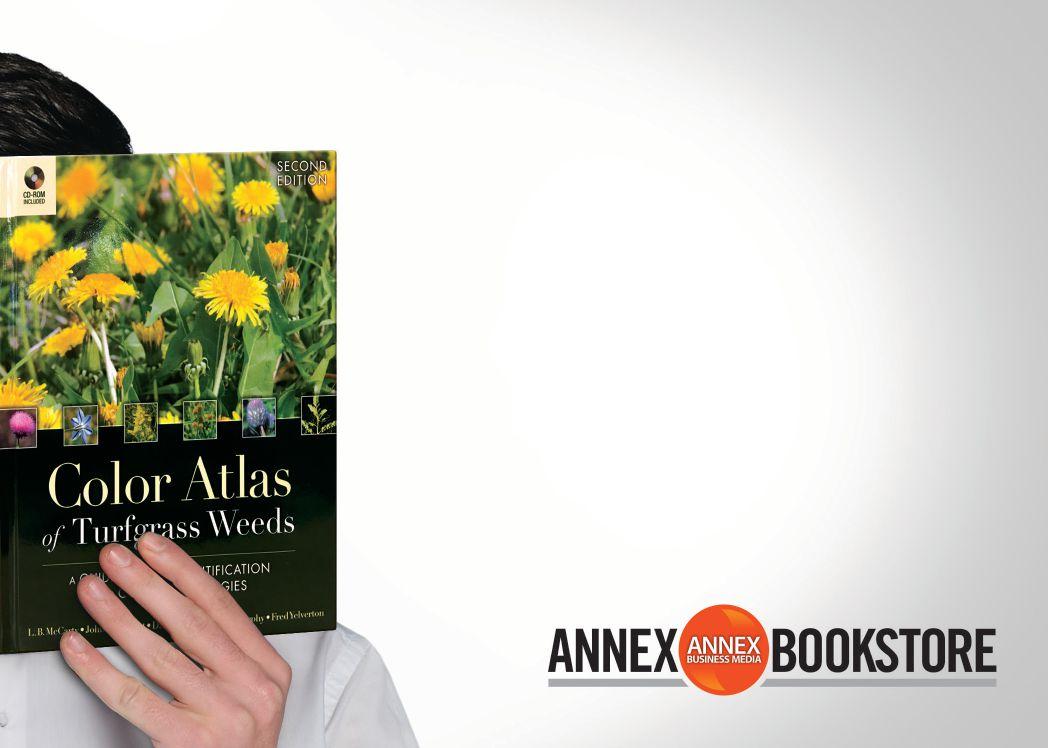

Grant Murphy, superintendent at the Barrie Golf & Country Club, has been a “mentor” or leader the past several years at the Bayer Environmental Science and John Deere-sponsored Green Start Academy, and says he gets just as much out of the program as the assistants.

The lone Canadian on a panel of seasoned leaders says what he brings to the table is his ability to teach relationship management strategies that are not only beneficial toward developing a team culture among a club’s turf maintenance staff, but which build positive relationships with other colleagues, vendors, stakeholders and members.

“For me, it’s more about relationship language and how that plays into your style as a leader,” Murphy said.

This marks the Green Start Academy’s 15th year, giving 50 assistant superintendents from across North America a unique opportunity to develop people management, communication and leadership skills that are critical in transforming them into full superintendents. Nine Canadians were among the group of assistants who had to apply for acceptance into the program. Due to the ongoing COVID-19 pan-

demic, the academy was presented this fall as a virtual experience. Normally, the program is held in Raleigh, N.C.

The opportunity for Murphy to become involved with the academy came as a result of pure serendipity.

“I was at the right place at the right time,” he said, recalling how he was recommended by Chris Dew, superintendent at The National Golf Club of Canada, to fill in

Barrie Golf & Country Club superintendent Grant Murphy (with microphone) has been using his relationship-building skills for several years as a mentor at the Green Start Academy, sponsored by Bayer Environmental Science and John Deere.

when a scheduling conflict prevented Dew from mentoring in what would have been his third straight year at the academy.

Hoping Bayer and John Deere would wish to continue with some Canadian input at the mentorship level, Dew recommended Murphy, who was then associate superintendent at The National.

“I stepped in to fill his spot and have been invited back ever since then,” Murphy said.

His experience and confidence as a public speaker helped to make him a credible substitute for Dew. The role of mentor, he said, is to present a general message to the audience of assistant superintendents and then be available for individual conversations that includes advice giving and networking opportunities.

“It’s a very wide-ranging role and depends on what the candidate needs.”

Each mentor speaks to his own personal strengths.

“Your presentation ends up as something you can really sell,” Murphy said, noting his personal strength is relationship building. “As a speaker, if you have an audience that is interested in listening to you, you’re set up to succeed. The audience is ripe to listen to what we have to say. As a presenter, it’s unbelievably gratifying. You’re almost guaranteed that most of the audience is listening, which is great when you’re speaking publicly.”

One thing not included in the Green Start curriculum is any instruction that addresses agronomic matters. Instead, it’s meant to build the participants’ interpersonal skills.

Murphy, who became superintendent at the Barrie club in 2019, said the quality of the assistant superintendents is outstanding, and the individual conversations he’s had with them have been “invigorating” and range from “humbling” to “fantastic.”

FEEDBACK FROM PARTICIPANTS

In his first year as an academy mentor, he said he put a lot of time and effort into his presentation, taking the experience seriously. Shortly after returning home that year, he received 15 hand-written letters from among the participants who thanked him and told him something he said during his presentation resonated with them. In subsequent years, he has received calls, texts

and email messages from assistants who hope to personally connect with him at the winter U.S.-based Golf Industry Show.

“I’ve had people who’ve got jobs (as superintendents) who have reached out and thanked me. It’s incredibly gratifying because what I offer in my presentations are not things that are proprietary to me.

I really think it’s just wisdom.”

Murphy said that’s not to suggest he’s wise – admitting he’s made plenty of mistakes over the years – but he’s done a lot of listening and has learned much during his career.

“I have been given the ability to be able to communicate those things and pass

them on, so this wisdom, I think, is what they’re hearing.”

The need to turn this year’s academy into a virtual event had its share of both pros and cons, he said. The biggest drawback, he admitted, was the lack of personal contact which has always been one of the program’s greatest assets.

“There’s a lot to be said about body language and posturing, and that was missing.”

The feedback received from a live audience is usually so invigorating that it extends the conversation with the participant, and a virtual offering limited that, Murphy said.

Feeling that continuing his involvement this year in a virtual setting might not be for him, Murphy said he changed his mind after speaking with fellow mentor Carlos Arraya, assistant general manager and director of agronomy at the Bellerive Country Club in St. Louis, who noted “sometimes you need to push yourself outside of your comfort zone for someone else who might need you.”

that conversation.”

The virtual experience was also advantageous for not requiring anyone to travel to Raleigh. This allowed all past participants in the program to be invited back to listen in to the keynote address.

But a return to the live and personal academy experience is what is most desired, Murphy said.

“I don’t think that we can ever move away from the literal personal connection because, in general, the world needs that.”

has ever considered applying to something like this to do so, because the one thing I’ve seen year after year after year is that there is always a reasonable number of the candidates who don’t think they belong there. That sense that you don’t belong there will handcuff you. When you get in that group and start to rub shoulders and break bread with these people, you will realize that you do belong.”

AGMTurbine:Layout 1 5/25/16 11:31 AM Page 1

With that advice, Murphy said he realized that one’s need to talk and feel he’s not alone – even in a virtual sense – has to be considered among the program’s pros.

“There’s definitely a pro to continuing

The exclusiveness of the program – that only 50 assistant superintendents are chosen from among several more applicants – should not be viewed as a detriment by those thinking of applying, Murphy said.

“I would encourage any assistant who

The nine Canadian assistants who took part in the program this year included Csaba Boros of D’Arcy Ranch Golf Club in Okotoks, Alta.; Lance Wakefield of Cottonwood Golf & Country Club in Foothills, Alta.; Paul Davey of Cordova Bay Golf Course in Victoria, B.C.; Wissam El Masri of Elm Ridge Country Club in Saint-Genevieve, Que.; Clinton Glass of Sutton Creek Golf Club in Essex, Ont.; Elizabeth Hachey of Oliver’s Nest Golf Club in Oakwood, Ont.; Jeff Hoffart of Derrick Golf & Winter Club in Edmonton, Alta.; Joseph Grebenc of Port Colborne Country Club in Port Colborne, Ont.; and Marcus Blech of Coyote Creek Golf & RV Resort in Sundre, Alta.

Joining Murphy and Arraya as mentors were Dan Meersman of the Philadelphia Cricket Club, P.J. Salter of the Riviera Country Club in Miami and Bob Farren of Pinehurst Resort in Pinehurst, N.C.

The most powerful turbines on the market.

The price of safety is cheaper than cost of jobsite accidents

Once workers’ compensation and legal fees are factored in, the cost of an accident can be astronomical. By Mike Jiggens

The actual cost of a golf course workplace injury can be astronomical when everything from damaged equipment and lost productivity to workers’ compensation and legal fees are factored in. A health and safety consultant who has been working with golf courses for more than 25 years told superintendents in the spring there are ways to invest in accident prevention that are a fraction of the cost of being on the hook for an expensive payoff.

“Safety is cheaper than having an injury,” Sheila James of Workplace Safety and Prevention Services said at the Canadian Golf Course Management Conference in Ottawa.

The return on investment for every dollar spent on health and safety practices is between $1.50 and $6.15, she said.

The process begins with the purchase of safe and reliable equipment that is maintained regularly. Equipment operators need to be trained to do proper circle checks on all equipment, big and small, James said. The potential dangers of all pieces of equipment need to be itemized in writing, she added.

“You need to have this in writing and need it for all high risk jobs and tasks.”

James shared a number of stories of golf course grounds personnel who were seriously injured because they failed to make the necessary checks or hadn’t been adequately trained. One worker had replaced the disk on a handheld grinder, but failed to properly secure it in place. The loose disk came flying off and struck the operator, creating a gash that needed 25 stitches to close. The same disk then struck a co-worker,

breaking his leg.

“You have to show workers how to put a new grind wheel on the equipment, and it should also be in writing.”

James said there are at least 50 golf course maintenance tasks that can be considered high risk, and each one requires a written safe work procedure. She acknowledged the task of putting all safety procedures into writing is “a huge job,” but added it’s a good project to undertake during the winter months.

If a course maintenance employee is injured on the job and the incident is investigated by the labour board, the board representative will want to see verification that proper training was provided and that the employee was made aware of the hazards of the job.

The costs associated with a workplace accident – both directly and indirectly

A tractor equipped with ROPS (rollover protection structure) can save an operator’s life if the vehicle tips over.

– are high, James said. A tractor rollover, for example, has to take into account damage to the equipment and the turf, the cost of the tractor being righted, the time it takes to right the tractor and remove it from the course, the cost to have paramedics respond to the injured worker, and the inconvenience the accident causes to golfers. The indirect costs can be about four times more than the direct costs, she added, noting someone else on staff must complete the injured worker’s job. The substitute worker may already have a full array of tasks to perform and may require the training needed to fill in for his co-worker.

The longer the injured worker remains off duty, the more time will be required to fill out the necessary compensation paperwork. If the accident occurs at a smaller golf course that doesn’t have its own human resources department,

the paperwork is apt to become the superintendent’s responsibility.

James told the story of a worker who injured his elbow on the job and was told by his doctor to take a day off. When he returned to work, he complained his elbow was still sore and sought a second opinion from another physician, who also recommended a day off. As the required paperwork

your calculation of how much an injury costs your business.”

WORKERS’ COMPENSATION COSTS

James warned that workers’ compensation costs can be higher if an injured employee returning to the job isn’t offered light duty or modified work. Having to pay out can increase the cost of workers’ com-

“Safety is cheaper than having an injury.”

mounted, the employee went to a physiotherapist who recommended he take two weeks off. She said it was later discovered the injured employee moonlighted as a drummer in a band, which brought into question the legitimacy of the injury.

“How much of your time is spent doing paper work? Factor that into

Tractor rollovers among the most costly accidents

Tractor rollovers may not be the most frequently occurring accidents to take place on golf courses –they happen about once a year on a course somewhere in Canada – but they are at the top of the list of the most costly.

They are also perhaps the most preventable, Sheila James, a health and safety consultant with Workplace Safety and Prevention Services, says.

Tractors not outfitted with ROPS (rollover protection structure) can be an accident waiting to happen. Because of their high centre of gravity and the fact that two-thirds of their weight is positioned toward the rear, tractors can easily roll over. If the operator is wearing a seat belt and the tractor is equipped with ROPS, a rollover likely won’t result in a fatality. Even if the tractor flips upside down, the operator will remain in place and will be safeguarded by the ROPS frame of protection.

Centrifugal force is another contributor to tractor rollover. If the operator is making a turn while on a slope, his chances of rolling over are increased. James said workers must be trained to know the factors that cause rollovers.

Operators should avoid backing up downhill or

pensation premiums for up to six years.

Labour board fines assessed to an individual can start at $100,000 if the injured worker wasn’t forewarned about the potential hazards of the job or wasn’t trained accordingly, James said. Fines leveled toward a corporation can be as much as $1.5 million. She said the labour

driving forward uphill because of the unbalanced weight of a tractor. They should also avoid driving near slopes, bunkers and water hazards because those areas tend to be where most accidents occur.

If a front end loader on a tractor is positioned high, it changes the machine’s centre of gravity “not in a good way.” If the bucket is filled with material and is positioned high and the operator drives over a bump, “it doesn’t take much for the tractor to roll over.”

James said operators must be reminded to keep the bucket set low so that they can see over the top of it and allow the tractor to adopt a lower centre of gravity.

When operating a tractor around hills, bunkers and slopes, its heavier rear end should go up first. If done the other way, the tractor will want to pop backwards because of its lighter front end.

“If you add a turn on there, it will roll over. You’d be surprised at how quickly and easily they roll over. When they roll over, it happens so fast you cannot jump clear. There’s no way you can jump clear.”

If the tractor isn’t equipped with ROPS and the operator isn’t wearing a seat belt, he’s liable to be pinned beneath the machine, resulting in serious injury or death.

A golf course mechanic must do a good job at maintaining tractors, she said. If he needs to remove the safety shield from the PTO for whatever reason, the machine should not be used until the shield is properly

fit back in place. The PTO spins fast and has immense power, and workers must be trained to be aware of the dangers. The PTO must be turned off when the tractor isn’t in use to lessen the chance of injury.

James shared the story of a worker who stepped over a still spinning PTO shaft in order to obtain a tool. Instead of taking a few more seconds to walk around the tractor to obtain the tool, he tried stepping over the PTO which grabbed his pant leg, pulling him in quickly. It ripped the lower half of his abdomen and severed his penis.

“You can imagine what the rest of his life was like. How much time did he save by taking that short cut?”

A fully enclosed cab not only offers comfort to the operator, but provides the best in safety.

board could take upward of a year to go over all records before charges are laid. The superintendent or supervisor may lose plenty of sleep during that time and will have to hire a lawyer to fight against the fines, contributing further to the overall cost.

James said when an employee is seriously injured on the job, a number of non-financial costs can be incurred. Employee morale can take a hit, “and your course’s reputation is not so good.” Hopes of hosting a major tournament might be dashed if a critical injury occurs, she added.

“A positive image reflects so much better on your reputation, and can help attract members, customers and workers.”

Safety pays, James said, and is much cheaper in the long run when a golf course invests in safety. The cost of in -

vesting in safety is much cheaper than the costs incurred as a result of a worker being injured on the job. Every time a “near miss” happens, the better the chances are to prevent the “big one” from happening. When a close call or near miss occurs, the superintendent needs to be notified, she said.

“When you use those near misses as a tool to make improvements for your health and safety program, it can really help in your productivity, your business costs and your health and safety – all simultaneously.”

Another benefit to having a solid health and safety record is it helps to attract higher calibre workers, “and they stay.”

Safety training needs to be conducted at the beginning of a golf season, James said. It should include such topics as:

• Back pain. Workers need to be shown how to lift properly by keeping their backs straight and bending at the knees. They shouldn’t be filling a wheelbarrow to capacity, for example, focusing instead on moving two smaller loads.

• Noise protection. Noise levels of more than 85 decibels require workers to wear hearing protection in Ontario. A noise level app is available for smartphones to gauge the amount of noise being emitted from a particular piece of equipment.

• Cannabis. Cannabis remains in a person’s system for a longer period than alcohol. A worker smoking a cannabis joint on a Sunday will still be impaired on Monday and into Tuesday.

Match play tourney honours late super and his bee hobby

GLAGS downs KEGS in first Honey Cup Fall Classic, in memory of Paul Brown

By Mike Jiggens

For an 11-year period spanning 2009 to 2019, two regional Ontario associations of golf course superintendents battled one another on the golf course in a friendly match play showdown to not only earn bragging rights, but to hoist the much coveted Syngenta Cup trophy and championship belt.

The organizer of the annual October event was former Syngenta turfgrass specialist Ryan Beauchamp, himself a former superintendent at both the Glen Abbey Golf Club in Oakville and Union’s St. Thomas Golf & Country Club. Late this past summer, circumstances saw Beauchamp change careers, and he has since taken on a similar role with Bayer Environmental Science.

Not wanting to discontinue the match play event he founded more than a decade ago, he convinced his colleagues at Bayer to take over sponsorship of the fall showdown between the Greater London Association of Golf Superintendents (GLAGS) and the Kent-Essex Greenkeepers’ Society (KEGS). Instead of renaming the event with Bayer in the spotlight, however, he felt it was important the competition be rechristened to

honour the memory of the late Paul Brown, former superintendent at the Sarnia Golf & Curling Club, who died in an on-course accident in June of 2017. Thus, the first Honey Cup Fall Classic, in memory of Paul Brown and sponsored by Bayer, was played Oct. 6 – fittingly – at the Sarnia club.

The term “Honey Cup” is derived from Brown’s passion for beekeeping and honey production which he started several years ago while the superintendent at Maple Downs Golf & Country Club in Vaughan, Ont. Although his hives were located on the private course’s property, they belonged to Brown. They were eventually turned over to superintendent Paul Dermott at the Oakdale Golf Club in Toronto when Brown left to become superintendent at the Sarnia club. Beekeeping and honey production was

something Brown loved, his son Greg said.

“We did all the work ourselves,” he recalled from those days at the Maple Downs club. “We had an old hand crank and I’d sit there at night, spinning all the honey out.”

Greg Brown is currently assistant superintendent at the Essex Golf & Country Club in Windsor and was among the KEGS team in October’s competition. He said he was “blown away” by the idea to rename the match play event after his father and wasn’t expecting such a gesture.

“The support from everyone in this room and the industry and from everyone at this club (Sarnia Golf & CC) has been beyond what I could ever expect,” he said. “When Ryan brought this up, I was floored by it.”

Jamie Spencer, captain of the GLAGS team, wears the championship belt after his team defeated the KEGS team in the first Honey Cup Fall Classic, in memory of Paul Brown. Looking on are, from left, Gregg Menard, captain of the KEGS team; Bayer’s Ryan Beauchamp, organizer of the golf event; and Joel Henderson, superintendent of the host Sarnia Golf & Curling Club.

Paul Brown resurrected his passion for honey production upon his arrival in Sarnia, and the labour of love has continued under the supervision of his successor Joel Henderson, who said there are currently four hives located adjacent to the second hole and which produced about 125 pounds of honey this year.

Henderson noted that one of the club’s members, who also sits on the board of directors, wished to get involved in a project that honoured the memory of Sarnia’s late superintendent. The member sponsored the lunch and dinner for the participating GLAGS and KEGS golfers.

Although he didn’t play in the event, Henderson served an important role as on-course chef, offering his beef brisket and potato leek soup to participating golfers who stopped by his food station. At the end of the day, it was the GLAGS team which persevered over the KEGS team, winning the match play event by a score of 9½ to 5½ – a “shellacking,” in the words of Beauchamp. The 18 holes of play were divided into three segments of six holes apiece, with one point awarded to the winner of each segment. Five twosomes from each side competed against one another in best ball, alternate

shot and scramble legs. Counting the previous former Syngenta-sponsored competitions, the victory by GLAGS was its second in a row, giving the association an overall 7-5 edge over its KEGS rival.

Only two of the five matches – one on each side – were 3-0 sweeps while GLAGS dominated the remaining three matches.

GLAGS will be the home team in 2021 at a yet-to-determined venue.

During breaks in the five-course meal served after golf, Beauchamp led a round-table discussion of Bayer products and best practices, highlighting Tetrino for the foliar and systemic control of such turfgrass pest insects as white grubs and the annual bluegrass weevil, and Dedicate Stressgard for the control of snow mould.

• Match 1: Doug Wilson (Black Horse Golf & Country Resort) and Dan Lavis (Tarandowah Golfers Club) of GLAGS won 2-1 over Steve Hatch (Seven Lakes Golf Club) and Tim Steen (Bayer) of KEGS.

• Match 2: Jamie Spencer (Westminster Trails Golf Club) and Tim Hornick (Arkona Fairways) of GLAGS won 2 ½-½ over Gregg Menard (Wildwood Golf & RV Resort) and

A special beer has been brewed to honour the memory of the late Paul Brown and his love of honey production. The back of each can reads: “This beer is brewed in loving memory of our dear friend, Paul Brown. Every time we step on our beautiful golf course, you are remembered. Every time we raise this can, you are celebrated.”

Steve Percy (Ambassador Golf Club) of KEGS.

• Match 3: Dan Friesen (Orchard View Golf Club) and Vince Gagnier (Rochester Place Golf Club) of KEGS won 3-0 over Todd Currie (West Haven Golf & Country Club) and Joel Johnston (RiverBend Golf Community) of GLAGS.

• Match 4: Fred Schmoelzl (Blue Water Golf Club) and Kyle Brodhagen (Stratford Municipal Golf Course) of GLAGS won 3-0 over Greg Brown (Essex Golf & Country Club) and Derek Brown (Talbot Trail Golf Club) of KEGS.

• Match 5: Patrick Brennan (The Fox and Ironwood golf clubs) and Mike Jiggens (Turf & Rec) of GLAGS won 2-1 over Chris Andrejicka (Essex Golf & Country Club) and Ryan Beauchamp (Bayer) of KEGS.

Joel Henderson, superintendent at the Sarnia Golf & Curling Club, serves up some brisket to Essex Golf Club superintendent Chris Andrejicka in between holes.

Misusing chemistries can be expensive, but it’s avoidable

Store similar-looking products in separate areas to prevent confusion

By Mike Jiggens

Most chemical products professionals use to maintain high turfgrass standards aren’t cheap, and misusing them can be costly and negatively affect the bottom line. There are a number of do’s and don’ts to follow to maximize chemical efficacy and increase the return on investment.

Kyle Miller, a senior technical specialist with BASF, addressed the subject of best practices for chemical applications in September during a virtual lawn care industry forum, sponsored by SiteOne Landscape Supply.

“Everyone makes mistakes at one point,” Miller said, noting that although it’s important to avoid miscues in the first place, it’s equally important to know what to do if one is made. Sometimes the mistake made is the use of the wrong product or perhaps it’s the right product, but applied at the wrong rate.

Properly organizing a chemical storage building, whether it belongs to a lawn care company, a golf course or it’s for municipal sports turf maintenance, will help ensure products meant for one purpose are kept separate from those

used for other treatments. Pre-emergent herbicides should be stored in a separate area from post-emergent products, Miller said, and fungicides, insecticides and plant growth regulators need to be stored in different locations as well.

“So when you go in there, you know you’re pulling product from the right area. Do not repackage. Having two people do this is really smart. Pulling product, measuring, mixing, loading –two people doing it is really going to eliminate the chance of making a misapplication and you losing your job or something worse than that happening. Two people, to me, makes a lot of sense.”

Other common mistakes made include confusing one product for another when they are kept in similar-looking containers, or pouring lesser amounts of product into smaller containers and mislabeling them. Transferring a product from one

container into another should ideally be avoided, Miller said.

The sooner a mistake is realized, the better, he added. If the miscue is realized an hour after spraying, activated charcoal can be used to bind the product in the thatch or in the soil if the product has residual. Heavy watering can also help to move a product through the soil profile, especially with sandy soils.

“If you don’t find out for some amount of time, that’s the worst situation.”

Colourants, amino acids or humic acids can be used to help with discoloured turf.

Miller warned, however, that fertilizing to promote new growth and get turf to quickly recover should be avoided.

“That turf is stressed. You don’t want to fertilize and cause any additional stress.”

When an application of about 50 gallons per acre is made, only about a teaspoon of water is being put down per square foot, requiring nozzle selection to

When storing chemicals, be sure to keep products that look similar in separate areas to avoid misusing one for another.

be precise.

“We need to make sure the nozzles we’re using are performing as well as they can perform.”

Miller recommends replacing nozzles each year if not more frequently.

“It is a cheap investment to get the best weed control or disease control or insect control.”

Nozzles wear out fairly quickly and need to be replaced at least annually.

PRE-EMERGENT WEED CONTROL

Mulch, irrigation and other cultural controls help to keep weed populations in check in landscape beds.

“Anything we can do to reduce those weed populations is certainly going to help,” Dr. Zac Reicher of the Bayer Green Solutions Team said. “The safest and

“(A nozzle) is a cheap investment to get the best weed control or disease control or insect control”

most effective is to control weeds prior to emergence, and so pre-emergent herbicides are always the most effective way to do it. It’s the safest over the ornamentals, especially when the ornamentals are dormant.”

He said when applying a pre-emergent herbicide, he recommends a non-selective product at the same time to control anything that has already emerged, adding pre-emergent herbicides aren’t particularly effective with small amounts of emerged crabgrass, annual bluegrass

and other weeds.

“If you have emerged weeds, you have to have a selective or post-emergent herbicide in the tank.”

Controlling emerged weeds and non-dormant ornamentals is difficult, Reicher said, adding the lack of selectivity makes over-the-top applications tougher, and some herbicides will drift and volatilize onto ornamentals and neighbouring trees, “and that gets really ugly.”

CONTINUED ON PAGE 28

GPS tracking aids landscapers during COVID-19 pandemic

Technology allows both social distancing and fleet tracking.

Story by Advanced Tracking Technologies

In the midst of the COVID-19 crisis, landscaper business owners and fleet managers still need to manage their fleets, but may not want to go to the office daily and risk possible exposure to themselves or others.

Fortunately, by using new technology offerings like a real-time GPS vehicle tracking system via a smartphone, tablet or PC – remotely, in addition to email, Zoom meetings, etc. – they can socially distance as well as dynamically manage their fleets and work crews throughout the day without missing a beat.

In fact, compared to traditional techniques like meeting face-to-face and shuffling paperwork, the advanced technology now available actually improves control and allows immediate response and adjustment to the inevitable emergencies and changing demands

that occur throughout the day.

“With an advanced, real-time GPS vehicle tracking system, essentially all employees can socially distance,” says Ben VanAvery, director of sales and marketing at Advanced Tracking Technologies (ATTI), a Houston-based designer and manufacturer of GPS tracking products. “To avoid potential viral transmission from other employees and vehicles, they can leave from their homes in their typical company vehicle and go directly to the job site without returning to the office, except to retrieve any needed supplies.”

Such a GPS tracking system can facilitate social distancing and virtually eliminate the need for routine personal interaction, while ensuring that drivers and work crews stay on task.

When logistics during the pandemic require it, emergencies occur, or work must be handled by the nearest qualified, available technician, such a system can be advantageous. With real time GPS vehicle tracking, landscape company managers can see which technicians they have across the area, including who is nearest and who is experienced and properly qualified for the job. And by accessing real-time traffic data in the software, they can identify who is easiest to send to that location as well.

As an example, one particular GPS vehicle tracking device transmits 10-second updates, showing precisely where vehicles are the moment the fleet manager or dispatcher needs to know.

Compared with some other GPS tracking devices that may only update every

GPS tracking technology allows landscapers with such large fleets and personnel as this to keep tabs on their vehicles and stay safely distanced.

few minutes, the system provides real-time location updates as well as speed and idle time alerts if something is amiss. This data is transmitted via satellite and cellular networks to a smartphone or PC on a 24/7 basis. The system has access to nation-wide speed limits in its database.

Dispatches can be made throughout the day and sent directly to the driver’s phone to tell the work crew the next job site address. Once a job is completed, it is recorded in the system, so the dispatcher, owner or fleet manager can stay apprised. In that way, it can serve as a remote time sheet.

Greg Hamman, owner of Prime Landscape Services in Dallas-Fort Worth, has already put such a capability to good use. Currently, the landscape contractor has about 20 lawn maintenance crews serving north Texas, and a total of about 55 service vehicles company-wide.

According to Hamman, he can display the real-time location of his entire vehicle fleet on a map via a phone app, and zoom in on any specific truck. At a glance, he can see if a truck is moving (displays green) or stopped (displays red). If he touches a truck icon, the app will display where the truck has been, where it stopped, and how long it has idled. All this helps with customer sup -

port, and with on-the-fly coordination.

“I can pull up my smartphone and see exactly where my trucks are in route, if they’re picking up material, or stuck in traffic,” says Hamman. “So, I can tell a customer almost to the minute how soon a truck will arrive. I can also sit in the office for an extra hour and do billing or call customers while my crew is out getting materials.”

According to Hamman, the systems can also improve drive route efficiency.

“With the GPS tracking system, you can hit a button and print a map of how your foreman drove his route to a jobsite,” he says. “You can see where he got stuck in traffic, and whether doing far jobs early and close jobs later could minimize any wasted downtime.”

To instill greater self-monitoring and efficiency during the pandemic, landscape company managers can configure the system to automatically send real-time text or email alerts to individual drivers, groups, or the entire fleet if factors such as traffic congestion, travel route, vehicle speed, starts, stops, or idling pose a concern or deviate from policy.

ENHANCE EFFICIENCY AND SAFETY

During the pandemic or any period when a quick response is required, advanced GPS tracking systems can also improve efficiencies on more established routes.

For example, because the GPS system is automated, travel reports can be generated that analyze vital historical data, such as on-time pick-ups or drop-offs, can also be emailed without anyone having to open software. The reports can be customized as needed to include as much detail as needed, such as how many stops, how long per location, top speed, mileage, idle times of the day, etc. Identifying and implementing more efficient routing and performance, in turn, enables individual drivers and the fleet as a whole to accomplish more in less time.

When landscape company owners and fleet managers are busy dealing with

the logistical impacts of the COVID-19 crisis, such a system can also help individual drivers to drive more safely and take greater responsibility for their own conduct without the need to micro manage. A maximum vehicle speed, of perhaps no more than eight miles per hour over the posted limit can be set and drivers informed of this. The system will then track their vehicle speed and compare this with the speed limit in its national data base, with exceptions automatically emailed to the driver and fleet manager in a report, if desired.

In addition, implementing real-time GPS tracking can increase driver accountability by making them less inclined to take unauthorized excursions, such as for personal errands, when not on a job or rescue. This can help to minimize unnecessary vehicle mileage, fuel use, and wear and tear. On the plus side, GPS tracking can also be used to recognize and reward consistently rapid employee response.

For landscapers, the bottom line, however, is that today’s advanced GPS tracking systems can help to keep everyone as socially distanced from each other as possible, while still enabling optimal vehicle and crew management for work productivity.

This article was provided by Advanced Tracking Technologies.

A smartphone used for GPS tracking enables safe social distancing.

Enhancing your investment with one-person drills

Using a manageable one-person drill can save valuable time on work projects.

By Mike Hale

At both the collegiate and professional level, great quarterbacks are few and far between, and for good reason. In addition to the hard work and dedication it takes to reach that level of competition, quarterbacks face a slim margin of error on every down. To complete a single pass, a quarterback must know the roles of defenders and anticipate their actions, account for the speed and timing of his receivers, and, of course, make a precise throw into a small and fleeting window of opportunity.

Running a small business can feel much the same. Between capitalizing on opportunities, attracting and retaining customers, hiring and motivating good employees, fending off the competition and managing expenses, the margin for error is small, at best.

Two of the most impactful variables affecting profits for business owners in the fencing and decking industries are labour and equipment costs. For this reason, discovering efficient and durable equipment that can also reduce labour costs is a gamechanging play.

Managing manpower

For starters, wages, benefits and payroll

A

taxes add up quickly, which is why labour is often a company’s largest expense. For fencing, decking and other high-volume hole digging businesses, taking a look at the equipment crews use to dig holes is one of the best ways to solve this issue and increase profits.

A lot of landscape contractors who offer fencing and decking use powerful, highspeed mechanical earth drills to dig holes. While mechanical drills provide high auger speeds – up to 360 rpm – for fast hole digging, they come with a major drawback. Many fail to protect operators from the torque and kickback associated with the drill’s power and speed and, as a result, require two operators to mitigate the risk of injury.

Two or three employees often make up an entire fence or deck crew, so when two are tied up digging holes, projects get off to a slow start. For many contractors this is the norm, but it doesn’t have to be. With

equipment that allows for one-person digging, contractors can free up that second operator. Choosing wisely, however, is important, as there are several one-person digging solutions available, including skid steers, hydraulic drills and compact utility loaders. They all get the job done, but at the expense of efficiency, jobsite space and ease of manoeuverability, or all of the above.

Many contractors find the ideal solution to maximize their labour is with torquefree mechanical drills. These units accomplish high-speed digging and safe one-person operation through a unique design. The units’ engines are mounted on a separate carrier that attaches to the drill’s handles and drives the auger via a steel torque tube. This transfers the drill’s torque and kickback to the engine carrier, as opposed to the operator, making safe one-person operation with a compact drill possible. The manageable size and efficient design

one-person hole-digging operation is both safe and productive.

of torque-free mechanical drills make it possible for contractors to reduce labour costs and complete jobs faster, increasing their capacity to take on additional work.

How it adds up

For a single residential fence project – an 80-by-40-foot standard backyard wood fence with eight-foot-long sections – approximately 20 holes are required. From unloading the drill to finishing the final hole, this portion of the job takes about an hour for two people to complete. With a one-person drill, however, the work can be completed in roughly half the time while the second person starts on other aspects of the project, such as unloading materials and placing posts.

Ultimately, this can shave as much as 30 to 45 minutes – more for larger jobs – off of the total time it takes to finish the pro-

ject, so crews can move on to the next one faster. Although it may not sound significant, 30 minutes per job adds up quickly and can be enough to help a single crew complete an additional job or two every month. By the end of the busy season, a contractor with multiple crews can take on dozens of additional jobs, equating to thousands of dollars in revenue.

Even in areas where contractors do not have a backload of projects, completing each in less time reduces the cost of labour per job. If a two-person crew, for example, shaves 30 minutes off of each job, the contractor pays for an hour less of labour. At 15 dollars per hour, the contractor can reduce labour expenses by $50 to $100 per week, again adding up to thousands of dollars per year.

For smaller jobs, such as fence repair and sign installation, labour can be cut in half,

since drilling is the only portion of the job requiring a second person. In addition to reducing the cost of labour required per job, torque-free drills help protect employees – as well as employers – from the burden of workplace injuries.

Worker safety

On-the-job accidents and injuries remain common in manual labour professions. This results in employees missing work –eight days, on average – as they recover. With more serious injuries, employers also encounter costs associated with worker’s compensation claims.

While workplace injuries are not a new concern, it’s becoming increasingly important for employers to re-evaluate equipment that is more prone to causing sprains, strains and soreness. The fact is, the average age of the labour force in these industries con-

20_2178_TurfnRec_NOV_DEC_CN Mod: October 19, 2020 9:23 AM Print: 11/17/20 10:31:39 AM page 1 v7

tinues to trend older. From 1998 to 2014, the proportion of workers who are 55 or older increased from 31.3 per cent to 40 per cent and is expected to continue to rise. Data also shows that as the average age of the workforce increases, the risk of injury goes up.

Another reason for employers to place a greater emphasis on user-friendly equipment is the role it plays in attracting younger employees who avoid manual labour jobs. By minimizing the physical stress on operators and reducing the likelihood of injuries, contractors can attract both older, more experienced workers as well as young employees.

In addition to employee safety, one-person mechanical rigs designed with features for durability and ease of operation can further chip away at labour costs.

Efficiency is profitability

Equipment repairs, inevitably, take time to complete, not to mention the downtime that can occur when a drill breaks down mid job. Even a basic repair, such as dull points and blades, can lead to as much as an hour of lost productivity between the crew members at the jobsite, as well as the time it takes for an employee to make the fix.

Features such as a heavy-duty transmission and centrifugal clutch, however, lessen the likelihood of untimely breakdowns. When drilling, it’s common to strike rocks, roots and other buried objects. If the auger hits an object, the centrifugal clutch releases, stopping rotation and preventing dam-

age to both the auger and transmission.

Meanwhile, features such as snap-on augers and handle-mounted on/off switches also boost efficiency. Snap-on augers take employees seconds to change, while a

conveniently located on/off switch can save the drill from unnecessary damage if it needs to be shut off quickly. These time-saving features further reduce the time it takes for crews to complete their work and move on to the next job.

Drilling down to the dollar

While quarterbacking a successful business is no easy task, finding solutions that increase the gap between revenue and ruin is a great way to ensure success. In industries that rely on earth augers, safe one-person drills provide exactly that.

Mike Hale started in the fence-building industry in 1974, and began working at Little Beaver Inc., a leading manufacturer of portable earth drills and accessories, in 1996. As the sales manager, he offers businesses his expertise on fence installation and hole digging equipment. He can be reached at mikeh@ littlebeaver.com or at 800-227-7515.

The benefits of one-person hole-drilling operations

Equipment Showcase

The Max-Snow

snow blower from Agrimetal offers high performance under the worst conditions. Developed in conjunction with professional snow removal contractors, it has been designed to increase productivity as a heavy-duty, light and more manoeuvrable snow-clearing machine. It is also more efficient than other two-stage snow blowers, enabling snow to be removed faster. The frame’s structure is made of high-quality steel. The high-strength QT-400 steel is used in strategic areas to increase structure rigidity while reducing overall weight. The design of the snow deflector makes it virtually impossible to clog the chute, even under wet snow conditions. agrimetal.com/en/max-snow-snow-blower

Kubota RTV520

The Kubota RTV520 is the ultimate utility vehicle for everyday performance. This new model is known as one of the easiest RTV’s to operate and maintain, making it a perfect tool for any customer. The durable Kubota designed variable hydrostatic transmission and gas engine helps you tackle any job with confidence. The narrow 54.7” stance and tight turning radius allows you to take on any terrain from jobs along sidewalks, between fences or on tight trails. Other notable features include the heavy duty metal cargo bed and elevated comfort. Production is set for January 2021. Starting at MSRP $11,982.00. kubota.ca

Iron Ant

Bannerman’s Debris & Stone Burrier Machine (Model B-IS-F145)

can renew walking trials, warning tracks and baseball diamonds. Prepare areas around new building sites prior to sodding or seeding with no need to remove dead sodded areas, one pass will bury all debris. This machine renews the surface. Available with a new optional seeder box attachment that lets you prepare the soil to receive seed, and the rear “Nett” roller presses the seed into the soil. “One Pass Light Renovation” for goal mouth and centre field ware areas.

sportsturfmagic.com

The Iron Ant is a must have for rental operations and landscapers. Designed to move compactor plates on and off trucks the Iron Ant can also be used to move them around a job site. Landscapers will appreciate its versatility for moving just about anything that needs to be lifted such as landscape rocks, tree balls, and even pavers. Easy to use, two high torque drills power the shafts providing full four-wheel drive and skid steer like operation.

reistindustries.com

Bauman Drop Spreaders

Bauman Drop Spreaders deliver uncompromised product quality. The spreaders prevent waste and property damage with the most accurate de-icing equipment on the market. Bauman drop spreaders are available with hydraulic, PTO or electric drives. Options include hopper extensions, galvanized or vinyl covers and a number of mounting brackets to fit most makes and models of compact tractors and skid steers. Backed by a tradition of quality for over 40 years and with 10 models to choose from, Bauman drop spreaders can cover all your de-icing needs.

baumanmfg.com

CONTINUED FROM PAGE 21

Misusing chemistries can be expensive, but it’s avoidable

If the plan is to use a post-weed control, it’s best to make targeted applications around the base of ornamentals by using a wick applicator and a non-selective herbicide, he said. Pre-emergent weed control can be done in one shot with up to six months of control. Timing is critical and applications must be made prior to emergence.

Reicher added that coverage is critical.

“These pre-emergent herbicides do not move in the soil, so you have to have good accurate applications.”