BEING PREPARED FOR DISASTERS

DEPENDABLE PERFORMANCE EVERYDAY

The STIHL FS 94 R 2-stroke brushcutter delivers an excellent power-to-weight ratio in its class, weighing just over 10 pounds - great for manoeuvring around hills, landscaping stones and other terrain. The innovative ECOSPEED throttle set wheel allows the user to set the most effective throttle speed for a particular job, such as low throttle around delicate plants. This allows professionals to reduce unnecessary fuel consumption, keeping you working longer between fill-ups. Combined with a highpowered, low exhaust emission engine and anti-vibration system, this brushcutter is a landscaping tool that every professional should have in their fleet.

• Powered by a low-emission 2-stroke engine with excellent power-to-weight ratio

• Equipped with a variable speed control ECOSPEED throttle, which allows precise control of cutting speed

• Features a simplified starting procedure – semi-automatic choke lever; hit the throttle and the lever returns to normal operating position

• Fleece air filter offers extended life and long replacement intervals

• Lightweight and compact design for comfortable operation over long periods

• For use with nylon line heads and metal grass blades, STIHL PolyCut ™ 20-3 and DuroCut 20-2

PRO-FLEET COMMERCIAL LANDSCAPE PROGRAM

STIHL’s Pro-Fleet Commercial Landscape Program is designed to provide commercial landscapers a volume discount on major purchases of 5 or more landscaping power tools. Visit your STIHL Dealer today to find out more and take advantage of the savings!

QUALITY AT WORK FOR OVER 90 YEARS.

For over 90 years, STIHL has been a world market leader and innovator in outdoor power equipment. German engineered products featuring the latest pioneering technologies make STIHL the preferred choice for professionals, consistently providing uncompromising quality. STIHL products are only available at independent STIHL Dealers who provide personal advice and expert service. Thank you for the continuous support and for making STIHL the brand you trust.

* “#1 Selling Brand in Canada” is based on an independent market share analysis of gasoline-powered handheld outdoor power equipment from 2017. Source: TraQline Canada.

DEPARTMENTS

06 | In the news A Toronto landscaper has been charged with multiple murders.

| Health & Safety Don’t rush, lift safely and avoid back pain.

BY MIKE JIGGENS

BY TOM BILLIGEN

By Mike Jiggens

Looking forward to ‘normal’ spring

Like anyone else, turfgrass professionals are looking forward to the end of winter and the start of growing season. In most regions of Canada, that time is just around the corner. These professionals have chosen careers in this field largely because they have a natural love of the outdoors. Although the winter months periodically require them to spend some of their time outside, that’s merely an off-season add-on and not their primary reason for wanting to be out in the sun and fresh air.

During the off-season, they have attended industry conferences and trade shows to better educate themselves, learn about new technologies and to see what new products might be helpful. There is something about these industry events that reignites the enthusiasm they have for their careers and the “can’t wait for spring” attitude that is consequently fostered.

Sometimes the new season begins on the right foot and sometimes it doesn’t. In the golf industry, a well-insulated, snow-covered course will produce a better head start for the superintendent than one that was ice-covered for a lengthy period of time. It wasn’t that many years ago when the latter significantly delayed the start of golf season as greens had to be either resodded or re-seeded, throwing a wrench into superintendents’

normal routine.

In the world of landscaping, a wetter-than-usual spring can adversely affect the timing of mowing. This was the case in Ontario not too many years ago. Mower operators had to be careful about rutting their customers’ lawns while at the same time having to contend with excessive growth that required multiple mowing visits.

This year, we hope, will be one that is more typical for everyone.

What may or may not happen during the coming growing season is difficult to predict at this time. Might the spring be wetter than usual? Will we experience extended drought during the middle of summer? Will disease and weed pres -

One thing turfgrass professionals do time and time again is overcome adversity

sures be more abundant? Will there be issues among employees? There could be any number of possibilities that could make professional turf upkeep somewhat more challenging than other years.

Sometimes a challenge has a silver lining. It can test a professional’s mettle, giving his clients or customers an indication as to how he’s able to fare under unusual situations and if he’s able to produce the same quality results, in spite of whatever adversity he might face.

A little bit of adversity can sometimes be a good thing for a turfgrass professional to face. Not only does it test his mettle, but it also staves off complacency and allows him to put his continued education to work.

One thing turfgrass professionals do time and time again is overcome adversity and find a way to produce quality playing surfaces or front and back yards that stand up to the most discriminating critics.

Tight budgets might not allow the professional to work with some of the new “toys” he’s had his eye on, but perhaps he can make a case for some or initiate a plan to upgrade his toolbox in the nottoo -distant future.

In this issue, we present some offerings that could prove helpful in terms of spring startup. One story deals with tips for seasonal engine checks to ensure the year gets off to the best possible start.

Another story takes a look at the various technologies that landscapers can use to make their companies more efficient and profitable. These are technologies that weren’t around a decade or so ago and might be a little difficult for some old school professionals to grasp or fully comprehend.

But they’re perhaps right down the alley of some of the millennials working for these companies or who might be owners themselves. Younger generation contractors who have already been introduced to these software programs and apps have already embraced them, and they are poised to forge ahead with their businesses. @TurfandRec

www.turfandrec.com

Editor Mike Jiggens mjiggens@annexweb.com

National Advertising Manager Nashelle Barsky 905-431-8892 nbarsky@annexweb.com

Sarah Otto 519-400-0332 sotto@annexweb.com

Account Coordinator Mary Burnie 1-888-599-2228 ext 234 mburnie@annexweb.com

Circulation Manager Anita Madden 416-442-5600 ext 3596 madden@annexbusinessmedia.com

Group Publisher Scott Jamieson sjamieson@annexbusinessmedia.com

COO Ted Markle tmarkle@annexbusinessmedia.com

President & CEO Mike Fredericks

Printed in Canada ISSN 1186-0170

PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Published 7 times a year – Jan/Feb, Mar, Apr/May, Jun, Jul/Aug, Sept/Oct, Nov/Dec Canada – 1 year $34.00; 2 year $44.00 3 years $54.50 (plus applicable taxes HST 86717 2652 RT0001

CIRCULATION

email: blao@annexbusinesmedia.com Tel: 416.442-5600 ext 3552 Fax: 416.510.6875 (main) 416.442-2191 Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Occasionally, Turf and Recreation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2018 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

HUSQVARNA PROVIDES THE TOTAL SOLUTION

Tangled bird dies after caught in net

A large bird, thought to be an owl or hawk, died in early February after getting caught in a soccer net mesh at Memorial High School in Sydney Mines, N.S.

It’s believed to be the first such incident since the school was built in the mid-1970s.

Cape Breton-Victoria Regional School board operational services director Paul Oldford said the possibility of taking meshing down during the off-season is something the board will review.

Landscaper rescues woman in burning car

A Calgary landscaper and snow removal contractor has been hailed for his bravery in saving the life of a woman trapped inside a burning car. Christian Prado spotted the burning vehicle during the early hours of Jan. 29 and cut the seat belt of the 21-year-old occupant to free her from the wreckage.

Alcohol and speed were cited as factors in the car crash. The car’s driver died at the scene.

Environmental fines too costly for course owners

Unauthorized construction over a wetland area has cost the owners of a Nova Scotia golf course $540,000 in environmental fines.

The Aspotogan Ridge Golf Course near Hubbards will be auctioned off after its owners said they couldn’t afford to pay the large fines.

Development of the golf course came to a standstill after only nine of the intended 18 holes were built.

Depending on the outcome of the auction, what has already been constructed could still open this summer as a golf course.

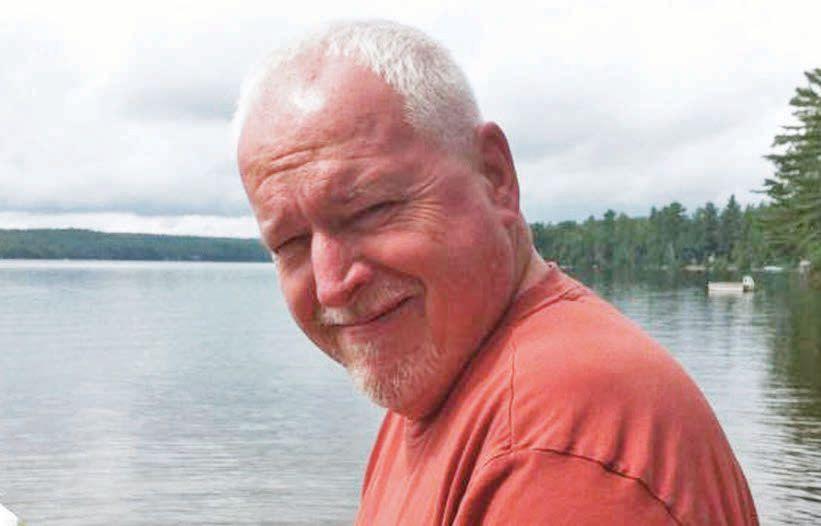

Probe into Toronto landscaper more complex than Pickton case

The investigation into the murders of five men in Toronto, allegedly perpetrated by city landscaper Bruce McArthur, is still in its early stages, and a prominent criminal lawyer says the case is even more complex that that of convicted Vancouver serial killer Robert Pickton.

The case against McArthur is being called one of the most complicated and extensive police probes in Toronto’s history.

Body parts of six individuals were discovered by police in planters at a home where McArthur had done landscaping work.

In a typical homicide case, about 2,000 crime scene photographs are presented as evidence. It is expected that 30,000 photos will be presented in the McArthur case. Other pieces of evidence are to include surveillance videos and computer messages.

The probe is now reaching beyond Toronto. Lawyer Monte

McGregor says he figures the case’s preliminaries won’t begin for about 18 months.

Meanwhile, McArthur appeared via video link in a Toronto courtroom on Feb. 14. He has been formally charged with five counts of first-degree murder and could face additional charges.

Only one set of remains has been positively identified – those of Andrew Kinsman, 49, whose family was present in the courtroom.

Construction workers and police searched pipes underneath the road in front of the property linked to the murders, and forensic teams have excavated land and searched planters at the site. A portion of pipe was sent for testing.

The midtown Toronto neighbourhood that had been searched was a property where McArthur worked and stored landscaping equipment.

The occupants of the home were forced to leave Jan. 18.

Mowing 50 degree slopes is never child’s play

BY BRIAN LOWE

Although the Slope-Pro® is operated by remote control, this mower is far from child’s play. The Slope-Pro is capable of operating on a side slope of up to 50 degrees! To put this in perspective, you need to climb a 50 degree slope, you cannot walk up a slope that steep. Considering that a ride-on zero turn mower (ZTR) should not be operated on slopes greater than 15 degrees, Slope-Pro’s 50 degree capability opens up areas considered too treacherous to maintain by other means, including areas close to water or drop-offs. There are other mowers that claim to have steep slope capability, albeit much less than 50 degrees, but they require doubling up tires, shifting operator weight or some other means to enhance stability. But what makes these options even riskier is that the operator still needs to ride on the machine placing the person in a potentially dangerous position. The same concern holds true for hand-held string trimmers; the operator is still on the slope and injuries are a ‘when’ not ‘if’ consideration. When mowing on steep slopes, Slope-Pro’s

remote operation is a huge advantage in light of the risk of a slip and fall or a rollover.

Like all Progressive’s mowers, the SlopePro is a rotary mower. Introduced in 2011, it has twin blade spindles that produce a 52" wide cut with an on-the-fly adjustable cut height between 2.25" and 8". Powered by a 747cc Kohler gas engine, the Slope-Pro can cut vegetation up to ¾" thick, 300 feet away from the operator and travel up to 4.5 mph. Running on rubber tracks, it features great maneuverability, stability, and low ground pressure.

The Slope-Pro is a great example of how sharing technology benefits all Progressive’s extensive mower line-up. Several of the features now found in Progressive’s larger sod and golf mowers are also found in the Slope-Pro, and vice versa. One of their key design principles is to reduce maintenance on their mowers, and thus the cost of operation. For example, reducing the number of grease points (the Slope-Pro has only two), extending PTO greasing intervals, and incorporating features such as maintenance-free blade spindles are some of the game changing features shared across all models.

The Slope-Pro® at work

Following an unfortunate incident that resulted in an injury to an operator, an 1,800 acre landfill in Iowa* needed a better way to maintain the vegetation growing on their site. Various mechanical means were tried, including tractors with dual tires and bat wing mowers, and ATV’s equipped with tracks pulling a small mower. Each method had its drawbacks— tractors were large and heavy with a high centre of gravity, and an ATV offered no protection for the operator. The need to look for a better way to maintain the steep slopes became a priority.

Having seen the remotely controlled Slope-Pro® at a recent industry trade show, management at the landfill called the local dealer for a demonstration. It revealed that the Slope-Pro was easy to operate and capable of negotiating the steep slopes and terraces that surrounded both the active and closed cells of the complex. To the management’s satisfaction, the Slope-Pro was able to maintain the vegetation that had grown since the previous control cycle.

In Spring 2013, a Slope-Pro was purchased for the landfill. With employees experienced in operating a wide range of track-based rolling stock, the Slope-Pro was soon ‘right at home.’ From a management perspective, the remotely controlled Slope-Pro addresses many issues that all landfills face: employee safety, costly equipment maintenance and repair, and the ever-present insurance risk. If the goal is that ‘every accident can be avoided,’ then Slope-Pro fits the bill.

* It is the policy of the landfill referenced that testimonials are not provided. Progressive Turf Equipment respects their position. They have continued using the Slope-Pro since early 2013.

For over 30 years, Progressive Turf Equipment has been designing and manufacturing innovative, rotary finishing mowers for turf grass producers, golf courses and municipal/ general use around the globe. Progressive’s investment in the latest 3D CAD software, integrated ERP system and CNC manufacturing work-cells, drives their commitment to provide their customers with high quality products that deliver unmatched productivity, reliability, durability and quality of cut Slope-Pro integrates each of these attributes —then adds remote technology, providing added safety in the workplace.

For all inquiries, please contact Progressive Turf Equipment directly at www.progressiveturfequip.com/SLOPE-PRO/

Have a crisis plan ready

Deer Ridge Golf Club passed test when 100-year flood hit in 2017

By Mike Jiggens

As an outdoor sport, golf is at the mercy of Mother Nature. Rain, strong winds and even hail will have an impact on a golfer’s performance. Not only do extremes in weather make him feel personally uncomfortable and unable to perform at his best, the playability of the golf course itself is compromised.

To protect both players and the course from harm, golf courses enact a standard set of procedures in times of extreme weather conditions. In the event of lightning in the area, golfers are herded off the course and into a protective shelter. When a morning frost blankets much of the course, tee times are delayed to protect the turf from the damage caused by foot and cart traffic.

But sometimes an extreme weather event comes along that is completely unexpected and throws the entire golf course operation for a loop. Such was the case in June of 2017 at Kitchener, Ont.’s Deer Ridge Golf Club.

Shortly after successfully hosting the PGA of Canada’s national championship and initiating a

post-tournament aerification program, Deer Ridge fell victim to a 100-year flood event. Speaking to his peers in January at the Ontario Golf Superintendents Association’s annual conference in Niagara Falls, course superintendent Jason Winter shared details of the flood damage and the subsequent restoration work involved. More importantly, he outlined Deer Ridge’s crisis management plan and how its lines of communication were especially instrumental in not only k eeping members abreast of all developments, but in rounding up the assistance necessary for the cleanup and restorative processes.

“It’s a beautiful piece of property that’s surrounded by the Grand River,” Winter said of Deer Ridge’s valley setting. “You wouldn’t even know you’re in the city.”

The private golf course was one of architect Thomas McBroom’s earlier designs. When it was originally constructed, a hydraulic cor ridor was included as part of the project as a means of relieving pressure from the river during high-water events. It was speculated a corridor might be needed to contend with a rising river issue that might occur one day in the future.

“When you live on the river like I do, you’re very aware of how the river moves and responds to different rain events, and the GRCA (Gr and River Conservation Authority) does a fabulous job of controlling the reservoirs and dams that make up that watershed.”

On the night of Friday, June 23,

a former co-worker of Winter’s tweeted about a major storm system brewing in an area about 1½ hours nor th of Kitchener. Only a few millimetres of rain were falling at the time in the city, but Winter sensed something more extraordinary might be imminent. He conferred with the club’s general manager, recommending a pr ecautionary eblast be sent to members to forewarn them of the possibility the golf course might be impacted.

An electronic message was immediately circulated that included some impor tant statistical information. It was stated that a water v olume of 400 cubic metres per second was enough for the river to spill its banks and impact the golf course. Winter once recalled experiencing a volume of 480 cubic metres per second that he thought was immense. At that volume, the ponds are at capacity and three or four of the holes become inaccessible. But he added such a volume w as short-lived and the problem resolved itself relatively quickly.

’That’s a lot of water’

Throughout the evening of the 23rd, Winter monitored the volume which increased at a rate of about 40 cubic metres per second each hour, “and it just kept going and going.”

By the next morning, the volume of water reached 926 cubic metres per second.

“That’s a lot of water.”

Arriving at work before dawn on the 24th, his truck’s headlights were trained on the fifth hole, and

926m3 per second was the volume of rain by the morning of June 24, 2017

all he could see was the sheen of a flooded fairway.

The volume of water was so abundant that only holes two, 15 and 18 weren’t flooded.

“It not only filled our hydraulic corridor, it did a lot of damage to the golf course.”

Winter said the most effective way to deal with the predicament was to have a communication plan in place, getting all of the facts, developing a crisis management plan, and working with insurers. He said that seeing such an alarming radar image upriver from a relatively short distance away was enough to get the process started. Thinking ahead of what might happen and what the club might be up against was key.

“I thought this is bigger than anything I’ve ever experienced before.”

Whi le sitting in his truck and viewing the fifth hole – unable to see the full impact of the flood in the pre-dawn light – he began to consider what it was going to take to get the golf course back in shape.

Those listening to Winter’s presentation at the OGSA conference watched a short video captured by a member-piloted drone that show ed the impact of the flood on the property. The images were recorded four hours after the water’s peak.

Minutes after 5 o’clock on the morning of Saturday, June 24, an email message was sent to the board of directors so that key decisions could be rendered immediately. Winter also emailed colleagues at neighbouring golf c ourses along the Grand River, seeking their input. It was vital, he

said, that communications kept members informed of the extent of the flooding and that there was no confusion. Other messages were sent by the professional staff at Deer Ridge to ensure everyone was kept abreast of all developments.

Winter assumed the role of “point person” in getting communications established before the club’s general manager carried on from there.

“Communication was frequent, it was consistent, it was realistic and also a bit empathetic because it was a traumatic experience for the members who couldn’t play golf.”

It was important to give members some reassurance that a plan was in place to get the golf course back in playing condition. Reciprocal playing arrangements were sought at other courses to

2017 timeline of events at Deer Ridge Golf Club

June 12-15

Deer Ridge is host to PGA Tour of Canada national championship

June 18

38 millimetres of rain hit Deer Ridge, leaving soil unable to absorb much more

June 23, evening

Major storm brews 1½ hours north of Kitchener

June 23, shortly afterward

Deer Ridge superintendent Jason Winter confers with club GM, recommending members be told of possible flooding

June 23, throughout the evening Winter carefully monitors the weather

June 24, before dawn Arriving at the golf course, Winter sees fifth hole fairway already flooded

June 24, shortly afterward Electronic messages sent to board of directors, initiating plan of action

Days after most water has receded Cleanup efforts are underway to remove debris and silt and return the course to playing condition

The flooded Grand River covers the fairway at the fourth hole, abutting the green.

accommodate the displaced members.

Winter said the forecast for the Kitchener area called for between five and 10 millimetres of rain on June 23, but only five millimetres fell at Deer Ridge. The majority of the rainfall occurred between 3 a.m. and 6 a.m. on June 24 at a point north in the watershed. About 38 millimetres of rain fell on June 18, rendering the soil incapable of absorbing much more.

Winter said he suspects the deluge of rain that led to the flood was the result of a cell that Environment Canada was unable to predict. It possibly grew faster to the west and was moving east when it became stationary, dumping a significant amount of precipitation into the Grand River watershed where it eventually reached Deer Ridge.

‘If we didn’t stay on top of the stuff we knew we could cut, we’d start falling behind because all our forces had to get set aside for the cleanup of the flood’

Largest rainfall since 1963

It was the largest volume of rainfall in the area since 1963 – the equivalent of 1½ months of rain in four hours. The rain covered about one-third of the watershed and was the highest estimated flow of water to come down the Grand River in 54 years. The Grand River watershed, at about 6,800 square kilometres, is the largest of its kind in southern Ontario.

Winter said the GRCA’s reservoirs, dams and other responsibilities provide for “a lot of moving parts. It’s in their (GRCA) best interests to manage that water as best they can.”

In all, 13 of 21 greens at Deer Ridge were partially or fully submerged as well as 11 fairways. Ten irrigation satellites were destroyed, several bunkers were damaged to various degrees, about 600 tons of bunker sand disappeared, and immense quantities of mulch were lost.

Winter said it’s important to have a crisis management plan in place because extreme weather situations are on the rise. In the event of a flood, it is imperative to keep everyone away from the water.

“It’s dangerous when it’s flowing that fast.”

If it’s a case of extreme wind, safe structures must be identified. Fire or power outages need attention to ensure everyone is safe. Priority No. 1 in disaster situations is to make sure all club personnel are safe

Joining in the cleanup efforts at Deer Ridge were several of the club’s members who, equipped with backpack blowers, blew debris from the fairways.

and accounted for, he said.

A meeting place should be arranged and an emergency protocol in place, Winter said, adding EMS personnel will need to be directed as to where they can enter the course, whether an injury is serious or not.

Having a supply of plywood on hand to be placed in sensitive areas of the course will allow access points for equipment without adding to the damage already present.

“You have to make sure you have the right equipment and materials for these types of events.”

On the evening of Friday, June 23, Winter was on the telephone with a supplier to get pumps procured. Priorities were established and contractors were reached.

“I wanted to keep it all in perspective. We had to put a plan together that wasn’t frantic or chaotic.”

Pumps were put into action moving water from areas obstructing the golf course while an army of volunteers helped clean up debris, including silt from the greens. In-play areas of the course were given preferential attention “because we had to start maintaining the property pretty much as soon as the water had receded.”

While Winter coordinated the planning process, his assistant Jake Martin was in charge of scheduling. About 80 individuals, including members, volunteers, Deer Ridge’s maintenance staff and others from neighbouring courses, were engaged in cleanup efforts. Several fish washed up onto the course during the flood.

The three holes that weren’t affected by the swollen waters still required daily maintenance during the cleanup process, and ways to access the holes needed to be devised.

“If we didn’t stay on top of the stuff we knew we could cut, we’d start falling behind because all our forces had to get set aside for the cleanup of the flood.”

Cleanup efforts began daily at 7:30 a.m. Volunteers were treated to buffet lunches and drinks, and a party was thrown afterwards to thank everyone for his or her efforts.

The entire cleanup process was documented through an abundance of photographs that chronicled everything, including electrical components, buildings, infrastructure, drainage, irrigation systems, bunker linings, cart paths and putting surfaces.

New irrigation satellites were installed within 19 days of the flood.

“Getting these back in place quickly was really important for us.”

Winter said the golf course had prepared an

13 of 21 greens at Deer Ridge were partially or fully submerged as well as 11 fairways.

The cart path along the third hole sustained extensive damage from the flood.

Visit one of these participating Exmark Dealers to learn more about the full line of professional Exmark models.

ALBERTA RED DEER

FUTURE AG INC .

SHERWOOD PARK ALL SEASON EQUIPMENT .

BRITISH COLUMBIA

CAMPBELL RIVER

C & L SUPPLY (1988) LTD .

COURTENAY

PILON TOOL RENTALS 1972 .

KAMLOOPS

B & L SMALL MOTORS LTD .

KELOWNA

SAVOY EQUIPMENT .

LANGLEY PRAIRIECOAST EQUIPMENT INC

SIDNEY RICHLOCK RENTAL

SUMMERLAND SUMMERLAND RENTAL CENTRE .

SURREY

403-343-6101

780-464-7788

250-287-9231

250-338-5361

250-376-0033

250-868-1010

250-656-9422

. 250-494-6916

ARCOM POWER EQUIPMENT INC . . . . 604-533-0081

SURREY

FRASER VALLEY EQUIPMENT LTD . . . . 604-590-1433

VANCOUVER WEST COAST GARDENERS . . . . . . . . . 604-430-4117

MANITOBA

HEADINGLY

HEPBURN ENTERPRISES INC .

NEW BRUNSWICK

GREATER LAKEBURN ADVANCE POWER EQUIPMENT .

ONTARIO

204-889-3392

506-384-1030

ALFRED CARRIERE & POIRIER EQUIPMENT . . . 613-679-1103

BRANTFORD

BOBCAT OF BRANTFORD INC .

ELMIRA

519-752-7900

MARTIN’S SMALL ENGINES LTD . . . . . 519-669-2884

FERGUS ADVANCED SMALL ENG .&MARINE INC . 519-843-1161

HAMILTON

OUTDOOR SUPPLIES & EQUIPMENT . . 905-578-2411

LIMOGES M .R . BLAIS SALES & SERVICE INC . . . 613-443-1230

MARKHAM YORK REGION EQUIPMENT CENTRE . . 905-604-1797

MILLBANK

ZEHR’S SALES AND MANUFACTURING . . 519-595-7579

PETERBOROUGH M .C . POWER SPORT .

QUÉBEC

LAVAL

MOTEURS INC

REPENTIGNY

705-748-5189

450-687-9171

LOCATION LE GARDEUR INC . . . . . . . . 450-581-6345

inventory sheet prior to the flood that documented every item that was supposed to be at each hole, including rakes and water coolers. All items collected during the cleanup process were placed in a common area to update the inventory count for insurance reasons.

Tests were conducted to see if the flood changed any of the characteristics of the golf course, including drainage, the physical identification of silt layers and permeability.

“We were lucky we didn’t lose any of the features themselves.”

To restore the golf course to the state it was in prior to the flood, various cultural practices were conducted, including verticutting, aerating, topdressing and punching through the surface to get at the silt on the property. Brushing was done to remove smaller debris once larger litter items were removed from fairways.

Winter said it’s important for a golf course to know the details of its insurance policy, understanding what is covered and for how much, if components of an irrigation system are covered and if other features such as retaining walls are covered.

“In the end you always need a great team, whether you’re managing a weather disaster like this or you’re just preparing your golf course every day. These are the people who make it happen.”

Committed volunteers and the Deer Ridge team banded together to get the course back into playable condition as soon as possible.

ALL OF WHAT WE’RE KNOWN FOR IN A REDESIGNED, VALUE-ORIENTED PACKAGE.

The all-new Radius® delivers the commercial durability and comfort, simple operation, low-maintenance reliability, and flat-out performance that our pro and residential customers expect from an Exmark® zero-turn rider. Ready to experience our signature cut quality, reduced-maintenance and increased productivity in a stylish, value-oriented package, all at a lower total cost of ownership than competitive machines? If so, the next step’s an easy one. Step onto a Radius.

Visit one of our 1,500+ servicing dealers to experience the most innovative and reliable mowing products on the market. You’ll see, first hand, why the most respected landscape professionals trust Exmark 2-to-1 over the next best-selling brand of zero-turn mowers.*

www.exmark.com

Technology a boon to landscapers

Specialty software, apps help to make operations more efficient. By Mike

Jiggens

New technology in the form of specialty computer software and mobile apps are giving landscape contractors a leg up in the business world and are allowing them to be more efficient in their operations.

Mark Bradley, CEO of Toronto-based TGB Landscape and founder of LMN landscape estimating and timekeeping software, said both his and other software available to the industry have been i nstrumental in helping to grow his landscaping company and have enabled him to smoothly run his operations.

“I was always looking to do technology to help control the growth and ultimately run a little smoother operation with ideally a little bit more profit than the industry average,” he said in February during a webinar arranged by Jeffrey Scott, a business growth expert in the landscape and contracting industries. It was the second of a three-part contractor

conversation series of webinars presented by Scott.

Bradley began his landscaping company in 1997 in a “pickup truck and wheelbarrow scenario,” but said he didn’t have the business background he felt he needed.

“I felt I had the work ethic to make up for that.”

By 2007, TGB Landscape was doing about $7 million in business. Bradley said he was looking for business software at the time, but couldn’t find what he wanted, acknowledging he was experiencing issues related to his rate of growth.

“I knew I wanted to grow the business beyond where it was, so I thought it would be a good idea to build our own software at that point in time.”

He set aside $300,000 to build the ideal software “and somehow managed to spend a couple million within a few years.” He aspired to build a software

program that could also be used by others in the industry.

By 2009, LMN software was available for sale in the industry. Today, it boasts 35,000 users, making it a leader in the landscape operational software industry. Users of LMN software have generated a total of $4.1 billion in landscape estimates.

Bradley expanded the software to support the growth of his own landscaping business whose peak revenue has stopped just shor t of $50 million.

“The past few years I’ve been trying to slow it down a little bit,” he said, noting TGB Landscape was doing a lot of highway construction work and large scale civil jobs in addition to its own landscape operations.

“I’ve always focused on keeping my overhead really low so that I can compete in a competitive market and make profit where my competition can’t. Right now my overhead is hovering at about four per cent, and I think the reason we’re

Landscape contractors can grow their businesses and smoothly run their operations with a number of different software programs and apps.

able to operate with such a low overhead is because we use technology in every area of the business to eliminate middle management.”

Bradley said many contractors are “petrified” of adopting technology to better streamline their operations. He said that when he gets to know his LMN customers, he soon comes to realize they’re not taking advantage of readily available software to take care of the dayto-day issues.

“There’s a big problem in the industry with the labour shortage. A lot of times business owners are afraid of millennials. They’re afraid of this young workforce.”

But Bradley said he figures those who will be best at using technology and helping to bring such traditional industries as landscaping into the future are the millennials. The younger generation doesn’t like doing things “the long way,” he said, adding they realize the better way involves working with technology.

“I really think that millennials are the answer to the labour shortage. Keeping millennials engaged and getting them to work at their best involves using technology. I feel a lot of business owners dismiss t heir suggestions, and I think that millennials are more likely to move on when they get the feeling that they’re stuck in a rut with a business owner.”

Bradley said he has heard from several landscaping employees who say they would love to work with the software available today, but their business owners don’t understand the technology and can’t comprehend its usefulness.

“ I am amazed at how many great millennials are out there who really have it, but the owners just aren’t listening.”

Greg Wildeboer, CEO of Whispering Pines Landscaping in Orangeville, Ont., is an advocate of technology designed to streamline a business’ operations.

“ Technology needs to be instrumental in your business,” he said, speaking in the same

‘I really think that millennials are the answer to the labour shortage. Keeping millennials engaged and getting them to work at their best involves using technology.’

webinar. Technology has allowed his company to grow yet remain lean and nimble. The software Whispering Pines has adopted is a combination of that which is already available on the market and that which the company has custom developed.

Having embraced technology has allowed Whispering Pines to become a paperless company.

“The frustration of having to fill this paper out and that paper out was very high,” Wildeboer said. “By simplifying the process, the information can get entered within seconds in most cases and it’s accurate. They (employees) can do their job, they can be productive and we’re not hounding them for proper information or new information or ‘why did you not do something?’”

Bradley offered a brief outline of the various software technologies TGB Landscape utilizes, including his own LMN (Landscape Management Network) software. Its uses include scheduling and routing, automated invoicing, job costing and analysis, job site photos and file storage and mobile GPS time tracking.

Basecamp is a project management and team collaboration software, available as both an app and in a web-based format. It creates a virtual file for a project where people can collaborate. It often involves pre-construction when efforts are made to get jobs out of the ground. It allows users to go

through checklists and issue tasks to ensure things have happened before a project begins. TGB Landscape uses the software for its larger projects and especially those in the commercial sector.

“It really provides that portal for all parties to collaborate and get things done,” Bradley said.

Dropbox is a program that allows the sharing of drawings, pictures, files and ideas to eliminate the need for meetings. Bradley said the software has allowed his company to reduce the number of its meetings by half, noting it’s much easier to share information electronically than to drive to a customer’s location and sit

Mark Bradley

Greg Wildeboer

down to review a document in person.

“Everybody’s too busy to have these countless meetings.”

The software permits easy sharing of files, allowing a simple telephone call to discuss details.

To better manage its fleet of equipment, TGB uses two different Caterpillar software programs to track preventative maintenance, schedule maintenance, order parts online, get online diagnostics before a problem exists and generate costing analysis. Bradley said one of the

reasons he chooses to use Caterpillar equipment is because of the quality of its software and its “forward thinking.”

Fleetio, powered by GPS truck location tracking software Geotab, is software that manages TGB’s preventative m aintenance records, safety records, paperwork and fleet inspections as well as operating costs, fuel consumption and preventative maintenance planning.

“It helps to keep the fleet in order.”

As TGB started to take on larger projects, commercial work and large residential

‘I think people come and go in the landscape industry because we don’t train them enough. Online training gives a company flexibility.’

work, it found that having accurate grading plans before getting to the site had a huge impact on build time and labour and material costs. The company turned to Trimble grade control systems to allow for faster build times, reduced labour costs and reduced material waste. The software also permits less skilled operators to work.

Skid steers, some excavators and small dozers are fitted with GPS equipment to allow teams with hand-held units to shoot grades quickly.

“Things that were taking days are done in hours using that kind of technology. Things are set perfect the first time.”

Bradley said the Trimble software goes hand in hand with AutoCAD, a design software that allows better collaboration. TGB designers can work mor e efficiently with homebuilders because homes are built based on AutoCAD drawings that show landscape plans and exterior features.

Jobsite Watch is a software program

GPS truck location tracking software helps inject efficiency into the day-to-day operations of landscaping companies.

that gives customers access to crew locations in real time and helps to sell high priority, high profit work, he said.

Greenius is a software program that provides online training for workers.

“I think people come and go in the landscape industry because we don’t train them enough. I think online training gives a company the flexibility to train their staff from a distance and at a much, much higher level of detail than any one company could create.”

Most landscape companies, Bradley said, aren’t doing as well as they could with their marketing in the area of social media and other web-based strategies. Facebook ads, Google ads and Google Analytics can drive some targeted leads and effectively grow a business at a low cost, he said.

Bradley said he has seen many weak websites.

“If your work is far nicer than your website, then your No. 1 priority should be to get your website to look as good as your work.”

Wildeboer is an advocate of LMN’s software as well as Dropbox and Greenius, and has created its own truck and equipment management software.

A strategy he has enacted – called “3 o’clock snapshot” – was devised in conjunction with a company policy that prohibits employees from visiting suppliers to obtain materials. He said crews at one time would visit their local supplier where they would be lined up with 10 other crews, each trying to obtain material. In response, Whispering Pines Landscaping developed the “3 o’clock snapshot” so that information per taining to anything needed the following day would come into the office, prompting the operation manager to order supplies for delivery by day’s end. Crews would have the needed material first thing in the morning and could go straight to the job site.

For more information about LMN software, visit www.golmn.com

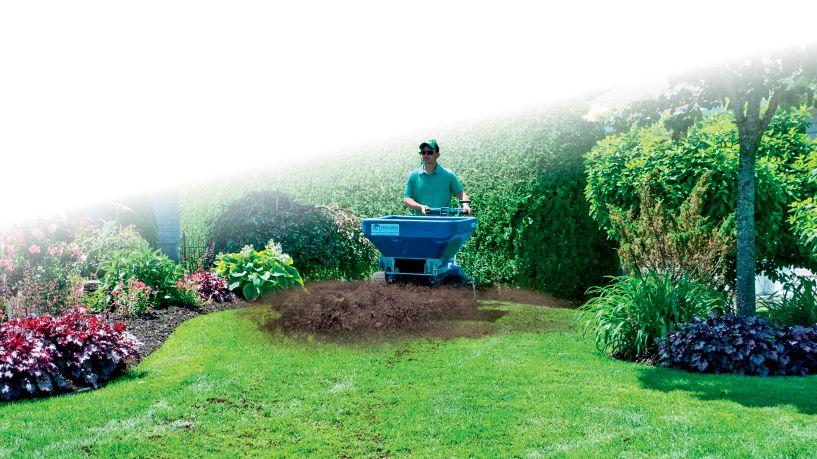

Earth and Turf Topdressers

• Pull type or self propelled walk behind models

• Capacities from 4 cu. ft. to 26 cu. ft.

• Spreads wet or dry material

Gandy Drop Spreaders for Granular Application

• Sizes from 24” up to 144”

• Walk-behind, pull-type or tractor-mounted

Millcreek Large Area Topdresser

• Capacities from 1 cu. yd. up to 5 cu. yds. • Sabre tooth beater for even wet material spreading

• High flotation turf tires

• Tractor PTO or hydraulic drive

• Handles slopes up to 75 degrees

• 40” flail head • 800m range • 22 hp gas engine

• Tracks with rubber spikes won’t damage asphalt

• Replaces up to 10 men with string trimmers

Gandy Sweepmaster

• Quickly brushes topdressing into established turf

• Incorporates crumb rubber into synthetic turf

• 72” wide deck

• Patented angled double-diamond brushes

• Choice of hitches: basic tow, manual lever lift, electric or hydraulic

3pt. hitch front and rear

Lynex TX1500 Remote Control Slope Mower

13’ cutting width

Lynex LX1000 Extreme Slope Radio Controlled Mower

Chemical effects in de-icing pavers

It’s important to know the impact chemicals could have on pavers.

By David Smith, ICPI technical director

Interlocking concrete pavements are a flexible and durable system that performs successfully in the most demanding applications, conditions and climates. One of the more extreme conditions is the application of de-icing chemicals to prevent or reduce ice buildup that can contribute to slips, falls and loss of vehicular control.

This technical note outlines factors that contribute to a low risk of damage from de-icing materials on concrete pavers.

Unit properties impacting paver durability

Ice that may form and expand inside the paver can cause stresses that may lead to degradation. De-icing materials mixed with the ice can increase the damage potential. Properly manufactured concrete pavers, however, are very durable and resistant to degradation because the high density of a paver limits de-icing materials from entering. In addition, high cement content helps a paver resist damage from the stress of expanding ice. Research and experience have highlighted factors affecting the winter durability of concrete pavers, including the utilization of:

• Ag gregates with low absorption that will not degrade when subject to freezing and thawing and de-icing materials;

• Proper aggregate gradation that allows

for high-density compaction;

• S ufficient cement paste to coat the aggregate and reduce capillary pores; and

• Sufficient compaction during manufacturing to ensure maximum density and uniformity.

Units manufactured with these

characteristics typically yield a high density, low absorption, high compressive strength, resulting in a durable paver.

ASTM C936 standard specification for solid concrete interlocking paving units includes freeze-thaw durability criteria for assessing the freeze-thaw durability and resistance to de-icing salts. C936

Understand what is being sprayed onto concrete pavers and what effect different chemicals will have when used in de-icing.

Zander2014:Layout12/19/161:52PMPage1

references the test method ASTM C1645 standard test method for freeze-thaw and de-icing salt durability of solid concrete interlocking paving units.

C936 includes an optional lower freezing temperature for regions of the United States that experience severe freezing conditions based on a climatic zone map. The optional testing in three per cent saline for these regions is equivalent to the testing required in the Canadian concrete paver standard, CSA A231.2 precast concrete pavers. To obtain a copy of ASTM C936 or ASTM C1645, visit www.astm.org (link is external). The CSA standard is available from www.csagroup.org (link is external).

Comparison to ready mixed concrete

Properly air-entrained and finished ready-mix concrete can resist freezethaw degradation, although overfinished, cast-in-place slabs or those made with re-tempered concrete with too much water can be susceptible to surface scaling. Compared to readymixed concrete, concrete pavers have the following advantages when exposed to freeze-thaw conditions and deicing agents:

• Stronger aggregate bonding from higher cement content than typically used in pa vement quality ready-mix concrete;

• Smaller aggregates (more surface area for the cement to bond);

• Lower water/cement ratio as well as vibration and compaction during the manufacturing process to increase aggregate-cement contact and to eliminate the possibility of over-watering;

• Produced in a highly controlled manufacturing plant leading to lower variation in material properties with elimination on over-finished surface; and

• Can be successfully installed in cold weather because they are properly cured before they leave the manufacturing plant.

Research prepared for the Utah Department of Transportation* in 2013 found that concrete exposed to sodium

chloride experienced only minor, if any, adverse effects, while specimens exposed to calcium chloride, magnesium chloride, or calcium magnesium acetate (CMA) experienced significant deterioration, including scaling, cracking, mass loss, and compressive strength loss. While the literature review did not specifically address unit pavers, the findings are directly related to cured unit concrete properties. The report recommends that

Continued on page 31

Concrete is canvas for pool art

Handcrafted rocks and waterfalls make hardscaped art.

Rock Miller isn’t a typical artist. A concrete pump takes the place in his hands where others would grip a paintbrush or pencil. His canvas isn’t cotton or linen, but concrete and rebar. Yet Miller’s work designing commercial and residential swimming pools for his family business, Pool Crafters, in West Palm Beach, Fla., is nothing shor t of a masterpiece. Each pool features handcrafted rocks and waterfalls, showcasing Miller’s passion for design.

A PROCESS WORTH PRESERVING

Miller’s father, Charles D. Miller, founded Pool Crafters in 1962 and since the younger Miller was 12 years old he spent summers helping his dad while learning the tricks of the trade. Of course, back in those days, Miller and his father hand-packed the concrete to build the pool walls. Through the years, they added concrete piston pumps to speed

up the process. While these pumps certainly proved more efficient, Miller recently found himself faced with a challenge. As with any artist, his desire and passion for the fine details led him to question the quality achieved with piston pumps when creating rocks.

“I had to run my piston ball pump at full throttle to pump a two or three-inch slump and would end up giving myself too much concrete to work with when doing detailed work,” Miller said. “Not only that, but I’m turning 60 this year, so I need a machine that slows down the process.”

Miller’s process starts by setting rebar up to extend every six inches from the pool’s beam. He then ties and shapes the rebar into rock waterfalls, careful to round any sharp edges before spraying the concrete with a high pressure pump.

“We try to make the rocks with a bit more rounded edges,” Miller said. “You don’t really notice when you look at

them, but they’re safer for pools, and safety is our No. 1 priority.”

The rocks are then waterproofed, coloured and texturized. Miller combines sand and seashells from the beach with a cement product to form his specialty – artificial Palm Beach Cap Rock. It’s a popular item for Miller, as sandstone found in authentic Palm Beach C ap Rock absorbs water – a problem owners of older pools made with this rock are experiencing. Not only is Miller’s artificial Palm Beach Cap Rock a popular answer for these customers, but it also appeals to first-time pool buyers.

“As far as I know, I’m the only guy in south Florida making rocks like this,” Miller said. “We developed a niche market because of it, and it’s a process I knew I had to preserve.”

With increasing demand to repair older swimming pools as well as to build new pools with that look, it was time to find an innovative equipment solution.

Pool Crafters, a South Florida pool company, sought help from Blastcrete Equipment Company to provide a machine to slow down the concrete pumping process. They received a customized solution that paid for itself after just three jobs.

SAYING NO TO THE NAYSAYERS

Miller stumbled upon Blastcrete Equipment Company, an Alabama-based manufacturer of concrete pumping equipment, while searching YouTube for ideas. He was impressed with what he saw and reached out to the company. After a few phone conversations with Tripp Farrell, Blastcrete president, and Scott Knighton, vice president, Miller faced the decision of whether or not to try using the squeeze pump model they proposed. He was skeptical at first after speaking with a few concrete pump manufacturers in south Florida who firmly believed a squeeze pump would not work. They said the challenges faced by contractors pumping in the south where concrete contains crushed limestone as opposed to river rocks in the north, would not be compatible with a squeeze pump.

“I remember Tripp saying, ‘Rock, you need to trust me on this,’” Miller said. “It’s a big investment, but it ended up working out great. We’ve completed three jobs with our Blastcrete pump, and it’s already paid for itself.”

The Blastcrete D6528 concrete pump attaches to Miller’s T550 Bobcat, which powers the pump. This drastically cuts down on operation costs and is significantly less expensive than purchasing

‘We developed a niche market because of it, and it’s a process I knew I had to preserve.’

a stand-alone pumping unit. The company even customized the machine’s size for Pool Crafters by making the unit smaller. Most importantly, with the D6528 Miller can slow down his work to five or six yards of concrete pumped per hour, allowing more time for detailed shaping.

SOLVING THE MAINTENANCE MYSTERY

Beyond operational savings, the squeeze pump offers Miller maintenance and cleaning advantages. Unlike swing tube piston pumps that contain several wear parts, squeeze pumps only contain one, the rubber pumping tube, making them the most

Continued on page 32

Spring start-up tips for engine success

Get the most out of your engine by following these tips.

By Tom Billigen

Increasing productivity and limiting downtime is – and always will be – a top priority for landscape professionals. As contractors put away winter equipment and start prepping cutters and trimmers for spring, it’s important to make sure everything is tuned up and running efficiently.

While sharp blades, greased fittings and sunshine all factor in to the success of the season, it’s important to remember what’s at the heart of your equipment – the engine. Here are a few engine tips to keep in mind this spring, whether you’re using EFI, propane or regular, carbureted gas engines.

Start the year fresh

Getting the most out of an engine starts with the fuel you put in the tank. The most common reasons engines sputter out early in the season are fuel related. Since fuel refineries gear products toward the automotive industry, the amount of chemical additives in gasoline fluctuates seasonally to improve performance based on the conditions.

Winter blends are particularly problematic for outdoor power equipment because they’ve been formulated to be more volatile in order to promote reliable combustion in cold weather. As a result, the gasoline has a shorter shelf life since the more flammable molecules evaporate quickly. When the temperature heats up, winter blends can literally boil inside the

tank of a small air-cooled engine, resulting in poor performance and possibly vapor lock. To avoid any problems, be sure to start the season off with fresh, season-appropriate gasoline.

EFI

As EFI engines continue to become more and more prevalent in the industry, it’s important to keep in mind the differences

in seasonal maintenance. Compared to carbureted models, EFI engines are generally less susceptible to stale fuel damage. However, improper winter storage can still result in damage to the fuel system, and will almost certainly require a trip to the dealer.

By treating the engine with fuel stabilizer before storing it, components such as the fuel pump module and injector spray

For commercial turf applications, EFI engines provide better fuel economy than carburetored engines.

Tom Billigen is customer education training manager for Briggs & Stratton.

tips – which are expensive to replace –will remain safe from the damaging effects of stale and gummy fuel. If the proper steps are taken in the fall, EFI engines can simply be topped off with fresh fuel in the spring.

Propane

Propane engines – like EFI – are also becoming more popular with commercial turf contractors. Since propane does not degrade quickly, the way gasoline does, these engines also require minimal attention in the spring.

One important thing to be mindful of with propane engines is the spark plugs. Propane spark plugs are nearly identical to gas spark plugs, and in some cases even have the same part number. However, the spark gap for propane combustion is narrower – a whopping 10-thousandths of an inch narrower.

This miniscule gap difference intensifies the spark and, because propane is more difficult to ignite than gasoline, can make all the difference in the world when it comes to the engine’s performance. When purchasing spark plugs, be sure to specify they are for a propane engine. If there’s any confusion, the engine’s manual should specify a recommended spark gap.

For propane engines, it’s also smart to inspect the fuel system from time to time for signs of wear. Check the system’s rubber fuel lines for cracking or signs of dry rot. If a leak is suspected, spray the area with a mixture of soap and water to check for bubbles, which will confirm the presence of a leak.

Breathe easy

intervals. Many of today’s newer filters can hold a lot of dust before it becomes visible. This is especially true for engines with cyclonic air filtration, since large particles – the ones we can easily see –are ejected before reaching the filter.

Taking a little extra time at the start of the season to make sure each piece of equipment, particularly the engine, is tuned up and operating properly, can go a long way toward reducing downtime as the season wears on.

For air-cooled small engines, fresh air is vital for sustaining peak performance. Spring equipment tune-ups are a great time to check air filters to ensure that no regular service intervals have been missed. A clogged or old air filter will restrict airflow and adversely affect the air-fuel mixture, resulting in decreased horsepower and fuel economy.

Even if an air filter looks clean, stick to the manufacturer’s suggested service

Health & Safety

By the CCOHS

The Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well being of workers in Canada by providing information, training, education, systems and solutions that support health and safety programs and injury and illness prevention. www.ccohs.ca

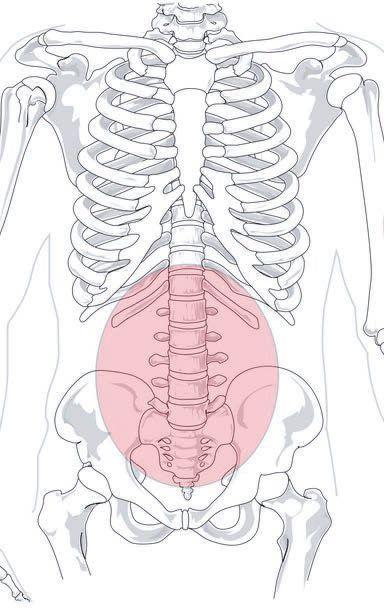

Don’t rush, lift safely, avoid back pain

You only have an hour left to work and there is still a truckload of items needing to be loaded. Determined to meet the deadline, you pick up the pace, lean over to lift a large object without bending your knees, and suddenly you feel a surge of pain up your back. You’ve just joined the thousands of workers in Canada who are injured or even permanently disabled by back injuries each year.

It is probably fair to say that every worker who lifts or does other manual handling tasks is at some risk for musculoskeletal injury. About three of every four workers in Canada whose jobs include manual materials handling suffer pain due to back injury at some time, accounting for about one-third of all lost work and 40 per cent of all compensation costs. Each year, several thousand workers in Canada are permanently disabled by back injuries.

Lifting is the most common cause of low back pain at work in Canada. The number and the severity of injuries can be greatly reduced by preparing and planning for the lift, and practising safe lifting and handling techniques.

Before: plan and prepare

Dress appropriately. Wear lightweight clothing that is flexible but that won’t easily tear, avoiding exposed buttons, zippers or loose flaps that could get caught in the load. Protect your hands and feet by wearing safety boots with toecaps and slip-resistant soles; and protective gloves, appropriate for the materials being handled.

Plan your lift. Make sure that the path to where you are taking the load is clear of obstacles and debris – such as grease, oil, water, and litter – that can cause you to slip and fall. Remove anything that is in the way.

Warm up your muscles with gentle stretches to prepare them for the

Lifting improperly can cause severe back pain, contributing to lost work. Proper lifting and handling methods can protect you from getting injured.

physical stress of the lift and other handling tasks. This is an especially important step for workers who only lift occasionally and may not be accustomed to handling loads.

Test the load for shifting contents and weight by pulling or sliding it toward you. Determine if you can lift it without overexerting yourself. A big load of the same weight will put more strain on your body than a small load. Do not lift if you are not sure that you can handle the load safely. Get help with heavy or awkward loads, or when possible use equipment such as hoists, lift trucks dollies or wheelbarrows.

Tips for the lift

Specific handling and lifting techniques are needed for different kinds of loads or materials being handled (for example,

compact loads, small bags, large sacks, drums and barrels, cylinders, sheet materials like drywall).

There is no single correct way to lift because lifting can always be done in several ways. Because of this, on-site, task-specific training is essential. There are some general lifting rules to follow:

• Stand close to the load facing the direction that you’ll be moving.

• P lace your feet wide apart to keep your balance.

• Get and keep a good grip on the load using both your hands – not just your fingers. Grasp opposite corners and balance your load evenly between both arms.

• As you lift keep your back as straight as is comfortable, tightening your abdominal (stomach) muscles.

• Bend your legs so they do the lifting.

• Lift the load smoothly, without jerking, keeping it as close to your body as possible.

• Keep the load in the middle, between shoulder and knee height.

• Avoid twisting and side bending while lifting. Step or pivot, turning your whole body.

• Plan wher e to set the load down, ideally on a raised platform that won’t require you to bend down with the weight of the load. Avoid placing loads directly on the floor.

It is also important to take advantage of rest periods to relax tired muscles and recover your strength between lifts to be able to work safely. Switch between heavy loads and lighter ones. Rest more often when it is hot and humid and when it is cold, and take more time to warm up your muscles.

Proper lifting and handling methods can protect you from getting injured. Learn to think before you bend to pick up an object, and eventually safer lifting techniques will become good habits.

Visit www.ccohs.ca for additional health and safety information.

Achieving greens that perform high

High performance is having a lot of flexibility to what can be done with putting surfaces. By Mike Jiggens

Achieving high-performance putting greens doesn’t just mean fast and firm, but how well they cope with traffic, an associate professor of turfgrass science at Cornell University said in January at the Ontario Golf Management Conference in Niagara Falls.

Dr. Frank Rossi, who is also New York state extension turfgrass specialist, said golf course greens must be resilient and keep up with varying climates. Superintendents should be able to “play defence” on them and not have to aggressively push them, yet can “play offense” on them as well for such high-end events as member-guest days.

“I don’t want you to think that high performance simply means fast greens,” he said. “I think that if you are doing 35,000, 45,000 or 50,000 rounds a year – if it’s a high traffic rate – you may have greens that are not necessarily faster than

nine or 10 feet on the stimpmeter, however, they hold up to the wear and tear really well.”

Rossi said, to him, high performance is having a lot of flexibility to what can be done with putting surfaces. Firm, he said, has trumped speed “because we know that if they’re firm they’re likely to be fast.”

By focusing on firm, speed will likely be the result, he said.

Much of that has to do with how well firm greens hold up under mowers and the way mowers are set up to allow high performance on the surface. Not only must greens be firm, they must be able to breathe.

“If they’re not breathing and they get wet, they’re going to be dead.”

To ensure they don’t stay wet, Rossi said they need “holes” in order to drain, but he warned an excessive number promotes a counter effect.

“You can’t have it all like Swiss cheese because you won’t be able to get them firm.”

It is difficult to get sand into the profile in a manner that allows for widely graded sand that is more likely to firm up. He said one of the challenges of the United States Golf Association system is that if the right sand isn’t used, it will be more difficult to achieve firm greens.

Rossi said if greens aren’t put under stress levels purposely created by superintendents wishing to achieve higher performance surfaces, sometimes failure occurs. He emphasized the need for stress tolerant plants, knowing that they’ll hold up better.

When greens are managed for high performance, the plants are being stressed. Mow tighter and the surface becomes denser. Verticutting greens promotes density, allowing them to be mowed lower. Boosting traffic, including rolling, helps to manage organic matter.

“They don’t get as thatchy if you’re wearing on them a little bit all the time.”

Mowing activates plant defences, he

While it’s important for greens to be firm, they must first be able to breathe.

said, while rolling and a little bit of stress likely activate some plant defences that help in other ways.

Potassium levels

Regulating potassium levels is important when favouring bentgrass over annual

bluegrass or vice versa.

“The less potassium you put on, generally the less annual bluegrass you could potentially have. We know that one needs more than the other.”

Rossi said he wouldn’t recommend the use of potassium at all if annual bluegrass

putting surfaces are desired.

If greens have chronic areas that fail no matter what is sprayed on them, it is important to see what wants to grow there, he said, suggesting seed be put down to see how re-grassing goes. It can’t be done unless deliberate stress is imposed, he added.

Basal rot anthracnose won’t infect actively growing plants, he said.

“It’s a very weak pathogen by definition.”

Because it’s so weak, the pathogen will only be successful when the plant is in a weakened condition that is the result of the cultural conditions imposed upon it.

Rossi said mowing, topdressing and applying nitrogen are perhaps the three most important factors that can collectively achieve the desired green speed without creating too much stress. Topdressing must continue during stressful times, especially if anthracnose is present, because some distance needs to be created between the plant’s crown and the mower.

“Topdressing is probably the single most important cultural practice that you have to maintain throughout the growing season for high performance putting surfaces.”

Annual bluegrass becomes more susceptible to basal rot anthracnose when it is deficient in potassium, he said, adding if levels get below two per cent, higher levels of anthracnose are likely to be realized.

“Applying regular potassium in ratios that make sense with your nitrogen is pretty much what we would tell you for good annual bluegrass management, depending on how much growth you’re getting.”

Nitrogen is important for achieving high performance surfaces, he said.

“I would be really careful about striving to drive your nitrogen rate down unless you feel it’s excessive.”

Golf courses that don’t have a rolling program won’t realize greens that are as firm as they should be, Rossi said.

“The key to a rolling program is that you have a program and that you do it consistently.”

Research shows that the cumulative

effect of rolling is the benefit. But Rossi said he is becoming suspicious about good topdressing practices coupled with the increased amount of stress emanating from the amount of rolling being done, noting collar dams are beginning to develop. Rolling quickly in the same direction and then slowing down once getting to the green’s edge can create a shift in the sand, forming tire tracks that can produce collar dams.

Still, he said, rolling must be done if firm greens are the goal.

Breaking up the surface?

Fifteen years ago, aerating greens during the growing season was rarely practised, but it’s a common procedure today that helps to firm up putting surfaces. Breaking up the surface to get air in and out is vital.

“If they’re breathing and you’re topdressing them and you’re rolling them, they’re likely to get firm.”

Those practices must be balanced with nutrition and growth regulation, Rossi added.

Research suggests that given the choice of topdressing with fine sand or not topdressing at all, use fine sand. He said about 40 cubic feet of sand per 1,000 square feet a year is what the research recommends, but there are no absolutes and the numbers might have to be tweaked.

“Frequency matters. You don’t want to go long periods of time with significant amounts of organic matter accumulation and then put a bunch of sand on it.”

If the profile isn’t kept uniform, firm greens won’t be achieved. Water management also plays a role.

Using nitrogen to keep up with traffic and to deal with pest issues results in a lot of low ground growth when finer sands are used, and an abundance of organic matter will result in dense and firmed up greens, Rossi said. Superintendents must therefore be diligent with keeping their greens porous. He cited the Dryject machine as an ideal means to blast sand down and create channels with little surface disruption. The method allows for enormous amounts of

sand to enter the soil profile by breaking through layers. It’s a way to incorporate larger particle sizes such as two or three millimetres to help with uniformity and help firm up the system.

Fast and firm greens are more likely to be true, he said.

One of the most critical aspects of mower setup is the bedknife position, which is relative to sand and firmness.

“It’s still something we’re not considering as much as we should.”

The further back the bedknife attitude is set from behind the centre line, the more the reel dips into the canopy. The geometry of the entire mower unit is altered because of the bedknife position.

If sand is put down to firm the green and the mower’s bedknife is positioned back of centre, not only will the canopy be thinned out, sand will be picked up. Rossi

said that’s the time to adjust the mower setup “and not sacrifice the mower as a sand mower.”

It’s one way of dealing with a uniformity problem that might exist with some sands, he added.

Superintendents must be aware of plant growth and collect the appropriate data, including the amount of clippings generated, “not because it’s going to tell you how fast or slow your greens are, but because you need to determine sand rates, PGR (plant growth regulator) rates, nitrogen rates, how they’re holding up to traffic, and maybe disease.”

Studies show growth regulator applications on collars need to be less frequent than those on greens, Rossi said. If collars are put on the same PGR program as greens, they are likely to be overregulated and thin out dramatically.

Mower provides faster cut on sod farms

A new self-propelled, hybrid turf mower has been introduced to the sod growing market, enabling fast, precision cutting and decreasing the average cost per acre.

The FireFly Automatix M220 was highlighted this month at Turfgrass Producers International’s education conference and field day in Tucson, Ariz.

It features:

• Front-mounted mowing decks for a 22-foot-wide precision cut (with speeds up to 10 mph) before anything runs over the turf.

• One-touch height adjustments, enabling operators to change the height while maintaining the precise level of the mower’s decks.

• High flotation tires and balanced design, which keep fields in great condition, minimizing soil compaction and rutting.

• No PTOs. The M220’s design allows direct

power transfer without gears and power take-off (PTO) shafts to wear out. Eliminating PTOs provides increased safety, more efficient power, and decreased ongoing maintenance. No more belt slipping or greasing PTOs and U joints.

• Automated, adaptive speed control for optimal mowing speeds for each environment.

• A high comfort, high visibility, climate controlled cab that provides full heating and A/C, comfort suspension seating, Bluetooth stereo system and cup holders.

“The M220 represents a paradigm shift in turf farm mowing,” Steve Aposhian, the company’s founder and CTO, said. “Like our ProSlab turf harvester, the mower has been designed and purpose-built from the ground up to be the most efficient mowing machine on the market. We’re in the business of creating value

Billy Goat’s Cutting Edge Renovation Takes Your Fleet to

Next Level!

for our customers, and by combining proven best-of-breed technologies with new innovations, we deliver on that promise.”

According to FireFly CEO Andrew Limpert, increasing labour costs and labour shortages in areas previously flooded with available workers continue to threaten the future of farming, so automating manual repetitive tasks is critical to its survival.

“While sod harvesting only happens once a year, it needs to be mowed weekly to keep it healthy, so we’ve expressly designed and built this mower from the engine to the decks for this specific and necessary task, with future versions offering even more autonomy,” Limpert said.

For more information regarding FireFly’s M220, visit www.fireflyequipment.com/m220.

Remote mower can cut slopes up to 55 degrees

The Spider remote-controlled slope mower has taken another step forward with the ILD02, offering four-foot cutting widths and ability to climb slopes up to 55 degrees.

Among the product’s highlights is its patented drive system – the Dancing Step – that utilizes a patented chassis design and enables omni-directional mowing without complicated manoeuvering. Four-wheel drive and four-wheel steering allows the mower to move and mow forward, sideways and backwards with unlimited continuous turning of all wheels through 360 degrees.

The innovative design provides ideal manoeuverability in all types of terrain, superior climbing ability and gentle treatment of the turf, even in wet or soft conditions. Its weight of 809 pounds is an advantage on steep hillsides and weakened terrains. The lighter weight ensures tight turns without damaging the turf.

For more information, visit www.slope-mower.com.

New stuff

Stand-on mowers are company’s first for commercial market

Husqvarna’s newest additions to its portfolio of professional outdoor power products were unveiled at the recent GIE + Expo in Louisville, Ky. New product introductions include several entirely new series of innovative and performance-optimized wheeled products, additions to the versatile professional handheld and battery-powered lineups, as well as the company’s line of accessories. The introduction of Husqvarna’s first-ever commercial stand-on mower series complements the company’s wheeled offerings with products that combine efficiency, durability and a compact design with superior manoeuvrability. Available with a 48 or 54-inch commercial ClearCut deck, the V548 and V554 stand-on mowers provide excellent grass cutting and management, ensuring efficient operation throughout. The heavy-duty construction combined with industrial-strength drive systems deliver

long-lasting operation in any commercial operation, and is backed by Husqvarna’s five-year commercial warranty.

Husqvarna’s current zero-turn lineup is seeing an overhaul full of innovative design changes to enhance productivity, durability, cut quality, serviceability and operator comfort. The new zero-turn mower series consists of 11 products, four Z500 models and seven Z500X models, ranging from the Z548 to the Z572X. They stand out with their weld-reinforced, two-by-three-inch tubular steel frames, seven or 10-gauge cutting decks and 10-inch-diameter spindles. All are protected by Husqvarna’s five-year limited commercial warranty. A new line of commercial hydro-walk mowers

provides additional options for lawn care professionals who looking for versatile equipment to complete their fleets. The W548 and W552 hydrostatic walk mowers can handle large mowing areas as well as difficult terrain and are capable of side discharge, mulching or collecting. They also require minimal trailer space due to an optimized footprint and are capable of working in light and difficult-to-reach areas, improving productivity.

Rounding out Husqvarna’s professional wheeled portfolio is the company’s new walk-behind mower. The L421P is a 21-inch durable and robust commercial grade mower, designed with a lightweight body to maximize manoeuvrability and efficiency. Its PremierCut deck yields professional results, whether

collecting or mulching.

The company also announced a new line of commercial zero-turn mower blades featuring Fisher Barton’s laser-edge cutting technology. Due to the laser edge, the blades feature long-lasting sharpness, reducing downtime for lawn care professionals and increasing cut

quality and fuel efficiency. The new blades will be available for the M-ZT 52 to 61-inch decks as well as the 54 to 72-inch decks of the P-ZT, PZ and the new Z500 and Z500X series. Husqvarna also continues to move forward in the battery-powered market segment with technology that matches gas-powered

• Tapered spikes leave a uniform surface for even seeding

• Double spike roller makes up to 1700 perforations per square yard

• Oscillating rollers maintain close ground contact on uneven terrain

• Four models sized to suit any sized property or application