STIHL

FS 91 R BRUSHCUTTER

Landscapers will find that completing the trimming needs is effortless with the performance and reliability of the FS 91 R brushcutter. With the low-emission engine and the larger fuel tank of the FS 91 R, it is able to run 30% longer than its predecessor. When you’re out in the field all day, you require a starting system that is dependable and ready to go. STIHL has the solution for you...the 3-2-1 starting procedure and the stop switch with “standby” mode of the FS 91 R has got you covered. It also features a superior air filtration system that allows an extended service life. The FS 91 R is exceptionally reliable, outstandingly easy to maintain and built with uncompromising STIHL quality. Everything that is needed for working on large areas of tough grass and navigating through obstacles.

• Engine is always ready to start – Engage Choke, Pull, Open Throttle and Go!

• Stop switch with “standby” mode – Always ready to go

• Large 710 mL fuel tank enables longer running times

• Efficient filtration system that delivers an extended service life

• Improved rubberized loop handle design to offer extra comfort with fewer vibrations

• Redesigned guard to reduce weight

STIHL’s Pro-Fleet Commercial Landscape Program is designed to provide commercial landscapers a volume discount on major purchases of 5 or more landscaping power tools. Visit your STIHL Dealer today to find out more and take advantage of the savings!

For over 90 years, STIHL has been a world market leader and innovator in outdoor power equipment. German engineered products featuring the latest pioneering technologies make STIHL the preferred choice for professionals, consistently providing uncompromising quality. STIHL products are only available at independent STIHL Dealers who provide personal advice and expert service. Thank you for the continuous support and for making STIHL the brand you trust.

* “#1 Selling Brand in Canada” is based on an independent market share analysis of gasoline-powered handheld outdoor power equipment from 2018. Source: TraQline Canada.

By Mike Jiggens

Here we are in the latter third of May (at the time of this writing), and I’ve got snow on the brain. It’s not that I’m looking forward to snow again any time soon –good lord, it seems like we just saw the end of it – but this is our snow and ice preview issue.

Within these pages we have a story that takes a closer look at the advantages of liquid deicing strategies so that salt can be avoided, and we have a number of new winter products to showcase as well.

Wearing my professional hat, I understand that landscape contractors who engage i n winter snow and ice management services are starting to think about the coming snow season and may want to consider other options beyond salt, and might also be interested in learning more about some of these new pieces of equipment that are showcased.

Wearing my after hours hat, though, I don’t want to see another snowflake until at least the last week of November. In fact, I’d prefer not to see another raindrop for the next few weeks.

Even though it doesn’t seem quite right to be thinking about winter before summer has arrived, we have a responsibility to our readers.

The Snow and Ice Management Association is holding its

22nd annual Snow and Ice Symposium in Grand Rapids, Mich. later this month and several Canadian contractors are likely to attend this closeto-the-border event. Technically speaking, we’re closer to the last snowfall than we are to the next (in most places in Canada), but it’s important to always be looking ahead. Issues such as the salt shortage experienced this past winter means advanced strategizing is essential.

I’m personally in no mood to be thinking of winter just yet. If I were, I’d simply hang out in the frozen foods section at my local supermarket for a half hour or so.

I don’t want to get ahead of myself by fast forwarding to

Wearing my after hours hat, though, I don’t want to see another snowflake until at least the last week of November

winter and would prefer to see how our lawns, golf courses and sports fields fare this summer first. Come to think of it, I’d like to get through fall before winter arrives.

I learned long ago that this industry – whether it’s the summer or winter version of it – does not play things by ear. Advanced planning is imperative and those employed in this industry cannot be caught with their pants down at inopportune moments. The

right equipment and materials must be close at hand at all times, whether it’s in response to an unexpected blizzard or a prolonged drought stress.

Publishing a snow and ice preview in June is really no different than having turfgrass conferences in January. It’s all about keeping one step ahead of the game and being prepared.

Thinking about summer in winter is much more pleasurable, however, than thinking about winter in summer. At least it is for most of us, I would imagine.

Our cover story this issue profiles an individual who wears two different hats for two different seasons: summer and winter.

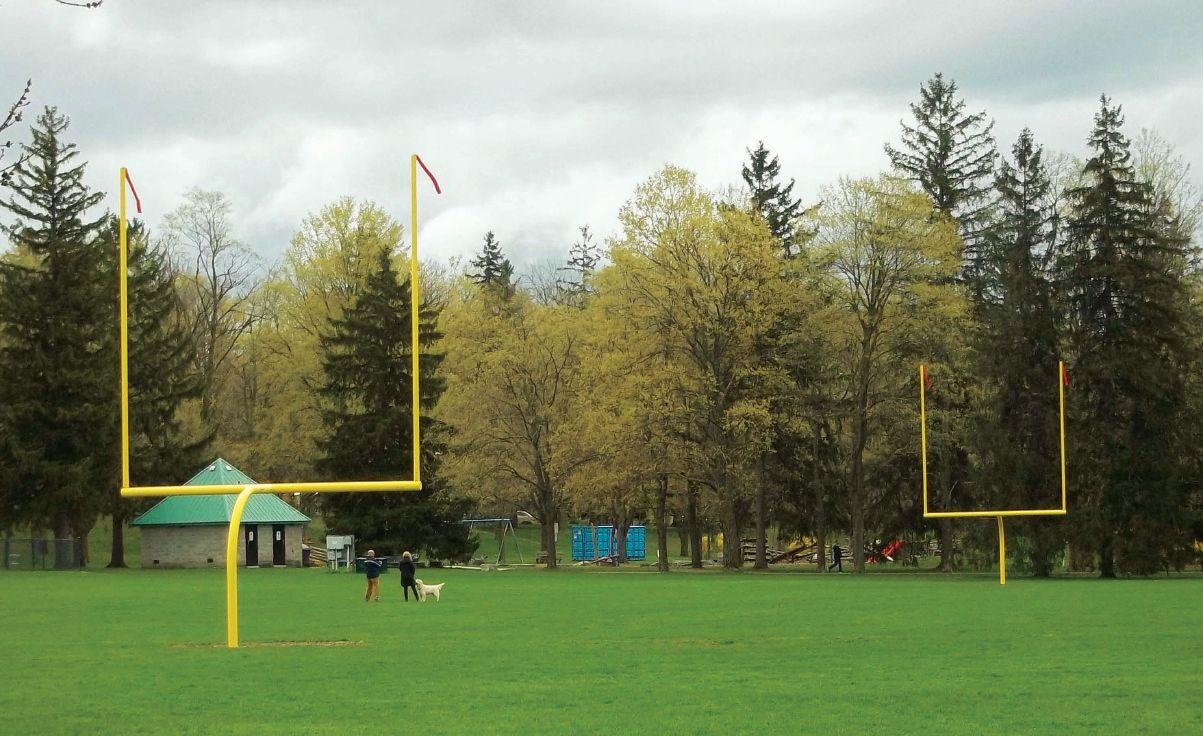

Dave Boehmer of Guelph, Ont. was recently named by Sports Turf Canada as the country’s sports turf manager of the year. The lead hand of sports fields and winter maintenance for the city was honoured for the work he does dur ing the summer months during which time he oversees the maintenance of more than 100 fields in the city.

It’s no easy feat to keep constant tabs on so many sports fields, and he credits his staff for being his eyes and ears when he can’t be everywhere at once.

Having come from the golf ranks, Boehmer brings plenty of agronomic know-how to the table and has implemented a number of strategies aimed at producing better playing conditions for the city’s customers – its user groups.

Congratulations to Dave and his staff.

www.turfandrec.com

Editor Mike Jiggens mjiggens@annexbusinessmedia.com

National Advertising Manager

Rebecca Lewis 519-400-0322 rlewis@annexbusinessmedia.com

Nashelle Barsky 905-431-8892 nbarsky@annexbusinessmedia.com

Account Coordinator

Mary Burnie 1-888-599-2228 ext 234 mburnie@annexbusinessmedia.com

Circulation Manager

Anita Madden 416-442-5600 ext 3596 madden@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada ISSN 1186-0170

PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Published 7 times a year – Jan/Feb, Mar, Apr/May, Jun, Jul/Aug, Sept/Oct, Nov/Dec Canada – 1 year $35.00; 2 year $45.00 3 years $55.50 (plus applicable taxes HST 86717 2652 RT0001

CIRCULATION

email: blao@annexbusinesmedia.com Tel: 416.442-5600 ext 3552 Fax: 416.510.6875 (main) 416.442-2191 Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Occasionally, Turf and Recreation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office

privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2019 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

When you’re sitting atop the KIOTI ZXC SE, the world is yours. And the way this baby is built, the control and power you’ll have to tackle any type of turf can be addicting. With one of the most advanced zero-turn mowers in the market, the most intuitive controls known to lawn-kind, and enough get-up-and-go to make those blades of grass want to cut themselves, if an entire army of mercenaries bursts into your palace, you’ll have everything you need to mow them down.

A Regina man has no problem with dandelions on his lawn and will even visit his neighbours to harvest the weeds from their lawns so that he can incorporate them into his daily diet. He uses dandelions in his tea, salads and wine.

He said they are rich in vitamins A and K.

Dandelions also provide small amounts of pollen for bees.

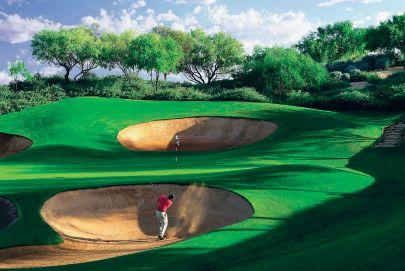

Calgary’s McCall Lake Golf Course is opening the first nine holes of its revamped 18 holes today. The public course recently underwent $6.7 million in renovations to its greens, tees, fairways, pump stations and clubhouse.

Bunkers and hazards were relocated to other areas to better match modern driving distances, and new forward tees were added to accommodate all golfers’ skill levels.

The golf course is 38 years old.

With rainfall in the Burlington, Ont. area having surpassed the two-month average in only two weeks, the city has shut down its sports fields until further notice. The city’s manager of park operations said it will take several days of drying before the fields will be ready for use.

The excessive rainfall hasn’t allowed fields to properly drain. The city’s manager of parks operations said the wet ground wasn’t firm enough to support a mower or the dozens of people who would use the fields. Player safety was also an issue.

$6.7 million: cost of renovations to greens, tees, fairways and more

Neighbours of a Toronto high school’s newly refurbished sports field have taken their dispute with the local separate school board to court over the issue of all-hours noise. They claim teams are playing well into the night and are “screaming their heads off.”

The FIFA-grade artificial turf field at St. Patrick’s Catholic Secondary School sees not only play from its own athletes, but from others who rent the field from a private company called Razor Management Inc.

Neighbours Benjamin and Christine Stein, who have lived near the school since 2005, say noise levels have escalated since the field’s refurbishing and reopening two years ago. They claim their bedtimes are now dictated by the field’s hours of play.

Other claims include trespassing, property damage and

drinking in the parking lot.

Local Coun. Paula Fletcher paid a visit to the Steins to listen first hand to the source of the complaints and confirmed it is an issue.

The Toronto Catholic District School Board acknowledged a problem exists and said it will continue to work with the city and Razor to find a mutually accepted resolution.

Stein said the final straw came during the morning of Sunday, April 21 when individuals were kicking balls and yelling at 7:30.

In addition to noise complaints, neighbours are upset that field lighting shines into their homes late at night.

Eight local families have been encouraged to keep “sound logs” of the noises they hear and the hour they are heard.

The next court date was scheduled for June 3.

By the CCOHS

While young workers are busy thinking about starting new summer jobs and others are rejoining the workforce, they may not realize that their “newness” to the world of work could be hazardous to their health. Research from the Institute for Work and Health (IWH) reveals that new workers in the first month on the job ha ve more than three times the risk of a lost-time injury as workers with more than a year’s experience on the job. According to the Association of Workers’ Compensa-

tion Boards of Canada (AWCBC), in 2017, there were 3 1,441 accepted lost time claims by young workers (aged 15-24) in Canada, and 23 died from work-related injuries or illnesses. Workers, parents and employers all have a shared responsibility for health and safety.

As a parent, when you see your teenager off to his or her new summer job, take the time to talk with them about their work as well as precautions that can help ensure they come home healthy and safe. Perhaps share some of the safe work practices from your own workplace. As an employer, you have the

If you are unsure of anything, always ask your employer or supervisor to go over any procedures or practices until you feel comfortable proceeding

responsibility to create and foster a safe and healthy work environment and to protect the health and safety of all your workers. You need to ensure you have a comprehensive orientation program and upon hire, you communicate health and safety roles and responsibilities. This sets the tone for the workplace and ensures that workers are

starting on safe footing. New workers are different from young workers in that they are not necessarily entering the workforce for the first time. They could be returning to work after an absence such as maternity leave or an injur y, and it’s possible that conditions and procedures have changed. Or they could be working for the same company, but in a new role or location. As a result they may be facing new hazards for which they are not prepared or adequately trained. These workers should also undergo the orientation program and have an opportunity to review and discuss their return to work, ask any questions and receive appropriate training. All workers need to know their rights. These include the right to know what hazards are present on the job and how to pr otect themselves, the right to participate in k eeping their workplace healthy and safe and a right to report unsafe conditions and practices. They also have the right to refuse dangerous or unsafe work, making sure to follow specific procedures when doing so.

Timely and effective training is essential when starting a new job. The IWH study showed that just one in five workers in Canada received safety training in their first year with a new employer. Learning on the job, or waiting several months for a classr oom course, are not good options.

Visit one of these participating Exmark Dealers to learn more about the full line of professional Exmark models.

ALBERTA

DRAYTON

HORIZON FOREST & GARDEN EDGE EQUIPMENT LTD FUTURE AG INC

BURNABY

CAMPBELLRIVER COURTENAY

KAMLOOPS

KELOWNA LANGLEY SIDNEY SUMMERLAND SURREY

SURREY VANCOUVER

MANITOBA

HEADINGLY ST ANDREWS

FORESHORE EQUIPMENT & SUPPLY

C & L SUPPLY (1988) LTD

PILON TOOL RENTALS

B & L SMALL MOTORS LTD

SAVOY EQUIPMENT

PRAIRIE COAST EQUIPMENT INC

RICHLOCK RENTAL

SUMMERLAND RENTAL CENTRE

ARCOM POWER EQUIPMENT INC

FRASER VALLEY EQUIPMENT LTD

WEST COAST GARDERNERS

HEPBURN ENTERPRISES INC ST ANDREWS PARTS & POWER NEW BRUNSWICK

IRISHTOWN

SMALL ENGINE HOSPITAL NOVA SCOTIA

FALL RIVER

HEBB’S CROSS

ALFRED

BARRIE

BRADFORD

BRANTFORD

BRODHAGEN

BURLINGTON

CREEMORE

ELMIRA

FERGUS

HAMILTON

LIMOGES

MARKHAM

MILLBANK

MISSISSAUGA

MISSISSAUGA

NIAGARA FALLS

NORTH YORK

PETERBOROUGH

SCARBOROUGH

THAMESFORD

WINDSOR

THE LAWN GUY CROSS SMALL ENGINE REPAIR

CARRIERE & POIRIER EQUIPMENT

MERCER MOBILE EQUIPMENT REPAIRS

BRADFORD RENTAL SALES & SERVICE

BOBCAT OF BRANTFORD INC

B & K TIRE AND BATTERY

B.R. DICKSON EQUIPMENT INC

MAPLE VALLEY SALES & SERVICE

MARTIN’S SMALL ENGINES LTD

ADVANCED SMALL ENGINES

OUTDOOR SUPPLIES & EQUIPMENT

M.R. BLAIS SALES & SERVICE INC

YORK REGION EQUIPMENT CENTRE

ZEHR’S SALES & SERVICE

W.E. ENTERPRISES LTD

WPE LANDSCAPE EQUIPMENT

E & R LAWN & GARDEN EQUIPMENT

PRICELESS PRODUCTS LANDSCAPE

M.C. POWER SPORT

ALPINE LAWN & GARDEN EQUIPMENT

HURON TRACTOR LTD

CARRIER TRUCK CENTERS INC

D-MINI MOTEURS INC

FAUTEUX MINI MOTEUR 2010 INC

BLANCHARD MINI MOTEUR INC

G.H.L. DISTRIBUTION INC

LOCATION LE GARDEUR INC

Effective training methods include:

• H ands-on or simulation training (before starting the actual work).

• Mentoring by experienced workers

780-542-4446

780-455-3343

403-343-6101

604-436-9312

250-287-9231

250-338-5361

250-376-0033

250-868-1010

604-530-4644

250-656-9422

250-494-6916

604-533-0081

604-590-1433

604-430-4117

204-889-3392

204-953-0030

506-854-2807

902-404-8008

902-543-9683

613-679-1103

705-503-3535

905-775-7101

519-752-7900

519-345-2248

905-331-5040

705-466-3138

519-669-2884

519-843-1161

905-578-2411

613-443-1230

905-604-1797

519-595-7579

905-629-1424

905-569-2055

905-358-0729

416-410-2158

705-748-5189

416-292-8900

519-285-3845

888-956-8785

450-687-9171

450-646-6976

450-460-3033

450-467-5459

450-581-6345

• Apprentice programs

• Written procedures which are clear and concise

• Practice time and opportunity to ask questions and obtain feedback

• Programs written in an active voice with clear instructions

• Gr ouping equipment or tasks with similar functions

When you are at your job interview, keep an eye out for signs that the employer takes safety seriously. Look for warning signs in hazardous areas, employees wearing protective equipment, safety posters, etc.

As a new worker, you may have questions about your work. If you are unsure of anything, always ask your employer or supervisor to go over any procedures or practices until you feel comfortable pr oceeding. Seek feedback from your supervisor or instructor to make sure you are performing the tasks correctly. Make sure that you have been properly fitted with personal protective equipment (PPE) and shown how to wear it, clean it, and store it properly.

Here are some other suggestions for workers to consider for a healthy and safe work environment.

• Ask experienced employees and/or your supervisor about workplace hazards

• Know what to do in an emergency situation, such as a fire alarm or power failure

• Ask for a copy of the health and safety rules, if you aren’t given one

• Follow all safety precautions

• Report any accidents or unsafe conditions to your super visor immediately

• B e a safety leader and walk the talk

• Develop a compr ehensive health and safety program.

• Work with your health and safety representative and/or committee to identify and control hazards

• Assign suitable work. Avoid assigning jobs to inexperienced workers that require lo ng training times, a great deal of responsibility, critical or risky tasks, or working alone

• I nstruct workers not to perform any task until they have been properly trained

• Provide detailed training on equipment, safety features, and control systems

• C ommunicate with the worker about the job tasks clearly and frequently, repeating and confirming this tr aining over the first few weeks of work

• Encourage workers to think in a safety-minded way about all of their work. Tell workers that if they don’t know or are unsure about something, to ask someone first.

• Train workers on what do in case of fire, injury, or other emergency

Whether you are a young or new worker; retraining or re-joining the workforce, you must be properly trained and prepared for the job at hand. Everyone in the workplace has a role to play in making sure we all stay on safe footing.

By Mike Jiggens

Eleven years ago, the thought of being named Canada’s sports turf manager of the year would likely have been the furthest thing from Dave Boehmer’s mind. At that point in his career, he was working in the golf industry as assistant superintendent at Milton, Ont.’s Glencairn Golf Club – a ClubLink property.

But as fate would have it – at a stage in his life when he was starting to look at potential superintendent positions – the City of Guelph was looking to fill the newly created position of sports field operator. Already a resident of the city, he applied for the position and was offered the job.

Over the past 11 years, Boehmer has since climbed the ladder to become lead hand of sports fields and winter maintenance, beginning his third season in that capacity, and oversees three city sports field operators. He said he wasn’t aware he had been named sports turf manager of the year until he attended April’s spring industry forum and annual general meeting of Sports Turf Canada at Toronto’s BMO Field.

Boehmer was nominated for the honour by Ian Ferguson, program manager of turf and sports fields for the City of Guelph, and believes the nod may have come as a result of his relations with his staff.

“I think in his mind, one of my biggest strengths is dealing with the staff,” Boehmer said. “It’s been a combination over the years of him witnessing how I deal with staff and the fact that we can actually take on more and different projects now.”

In his position as lead hand of sports fields and winter maintenance, he supervises Guelph’s three sports field operators in the upkeep of about 40 ball diamonds and upwards of 60 soccer fields of varying

Many of Guelph’s sports fields are overused by as much as 150 to 200 per cent of their recommended usage

dimensions. Also included among the sports turf under his supervision is a lawn bowling green and green space used for Australian rules football and cricket.

During the winter months, he oversees the snow and ice management of the city’s arena parking lots and walkways. His staff swells from 10 employees during the winter months to about 40 during the outdoor playing season, including a couple of sixmonth contract positions and several summer students.

The city’s higher end fields are situated within three sports complexes located in different parts of Guelph. Boehmer said the city has an arrangement with the local separate school board to mow and groom its playing fields and look after booking for a number of them. The city also maintains one of the public school

board’s fields – a fenced-in facility that is regarded among Guelph’s better quality fields.

“About 90 per cent of the ball diamonds are stone dust,” he said, adding the others are clay, including its premier diamond – Hastings Stadium, which is home to the Guelph Royals of the Intercounty Baseball League.

None of the fields in Boehmer’s care is artificial.

“We’re lacking space for making any new facilities, even to switch one over to artificial turf.”

He said land is at a premium in Guelph, and there is virtually nowhere in the city to build any new fields to address the challenge of demand outweighing supply.

“We don’t have enough fields to support the user groups, so they’re often overbooked and overused. They’re all overused…pretty much all of them.”

Some fields, he said, are seeing up to about 150 per cent of the recommended usage and sometimes realize double the intended use.

‘As far as the grass goes, we have a pretty good program’

“For what it’s worth, the grass isn’t that much of a problem,” he said, noting when he first began with the city, it didn’t have an elaborate maintenance program. The fields have since undergone regular aeration, are being overseeded more frequently and are being fertilized with a better product. “As far as the grass goes, we have a pretty good program.”

Fields are inspected almost daily, including the city’s category C diamonds.

Boehmer described his position as lead hand as “multi-faceted,” saying he is in constant touch with the city’s bookings department to better control the amount of traffic on its fields. The challenge in communicating with the bookings department lies with the degree of staff turnover it has experienced in recent years. Its longest standing employee has been there only one year.

Although he says he maintains a good relationship with the department, it can be a daunting task when suggesting certain fields shouldn’t be played on during wet spring periods or that older athletes shouldn’t be booked to play on smaller fields meant for younger children.

“They’ve (bookings department) gone through a whole bunch of changes, so all the people who used to know things aren’t there anymore. So they can’t circumvent some of the questions and concerns some of the user groups have and funnel them in the right direction.”

Reflecting back on his years in the golf industry, Boehmer said it was comparatively easy for a superintendent to check daily on all 18 of his golf holes to monitor for emerging trends and issues, but it’s a different ball game in the sports turf sector.

“ There’s so much to see that I’ll never see it in a day.”

For that he depends on his sports field operators and other staff who see things daily.

“We have it broken up into sections so that we have eyes (for monitoring for things that need attention).”

As far as agronomic practices are concerned, the soccer and multi-purpose fields demand the most attention, Boehmer said.

“For baseball, there are only three guys who run around in the outfield, so that grass doesn’t need as much attention.”

Most of the maintenance of the ball diamonds is concentrated on the skinned infields.

Although the Royals are the primary user group at Hastings Stadium, the field is also booked for play by the Guelph Minor Baseball Association, which receives the same field treatment the Intercounty team g ets. New this year, however, are a few scheduled maintenance days for the ballpark during which no user groups are permitted on the field on the day prior to select Royals’ home dates.

“This year we’ve actually incorporated a few maintenance days. We’re doing our best to train the user groups and bookings department.”

The infield at Hastings Stadium is mainly Kentucky bluegrass while the outfield is a blend with some poa annua in the mix. The diamond has been in its current location for the past century.

Two softball fields are located adjacent to Hastings Stadium – beyond the outfield fence – and are also clay fields. Another field set up for football and rugby is located within the same complex and is used to a large extent by athletes from Guelph Collegiate Voca-

‘We’re doing our best to train the user groups and bookings department’

tional Institute who have no field of their own for physical education classes or for football and rugby practices. The field is also popular among dog walkers.

Boehmer said most projects pertaining to the fields in his care are tackled in house, acknowledging he has the necessary staff and equipment with little need to rent anything. Technical support is provided occasionally by the University of Guelph, which is regarded as perhaps Canada’s foremost institution for turfgrass management training.

The university was the training ground for Boehmer’s formal education in turfgrass management. D uring his nine years with ClubLink, he established relations with personnel from both the university and Guelph Turfgrass Institute and remains in touch with much of the staff.

He began his golf career at RattleSnake Point Golf Club in Milton before leaving for nearby Glencairn to help with its grow-in period. He worked briefly at Greenhills Golf Club in London before moving to Oakville’s Glen Abbey Golf Club for one season to help with the 100th anniversary of the Canadian Open. He returned to Glencairn afterward to become its assistant superintendent.

Boehmer said he began in the turf industr y later in life and pursued his formal education three years afterward.

“I put in three seasons at the golf course and realized I better get an education if I want to go any further.”

Julia Webber is president of Fish Farm Supply Co.; www.fishfarmsupply.ca; julia@fishfarmsupply.ca

By Julia Webber

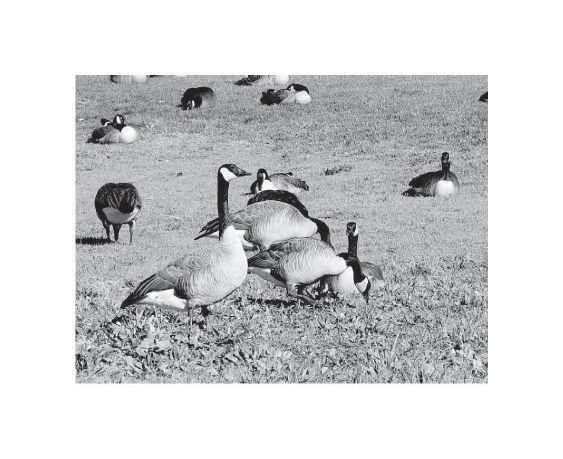

Nuisance animals can be a challenge in any industry, but in industries that manage turf around lakes, ponds and streams, there are few that cause as many problems as Canada geese. Over the years I have had the privilege of getting to know the people in this industry and it is full of those who look at problems creatively and push themselves to find innovative solutions.

Like so many other problems, the first step is always to arm yourself with the information you need to make the right decisions. In this article I hope to share this i nformation and explore some of the techniques and common problems with managing geese and their hazardous waste.

First, let me acknowledge that there is rarely a quick fix or a single solution that will work in all situations. Geese are as numerous and widespread as they are because they are highly adaptable. They have moved into our urban areas in ways that seemed unfathomable a couple of decades ago.

It is not an unusual sight to see geese building a nest in the smallest parking lot garden, to the peril of anyone who parks in its proximity. This adaptability also extends to the deterrents that we use, which means they will learn and test de -

terrents which, over time, may become less effective not only at that site but at other sites. For deterrents to remain effective and be useful for everyone they need to be used correctly and at the correct time.

The lifecycle of the Canada goose is fairly well understood and is actually very

important to the timing of deterrents. Most (there are starting to be some exceptions) Canada geese migrate south in the winter. How far they travel varies but many of them travel well into the southern states and some as far as Mexico. The time they are gone seems to be shrinking as they often stay here into November, or

Leading the market in leaf and debris cleanup with its Force™ walk-behind blower, Billy Goat’s new addition of the Hurricane X3000 and Z3000 now offers the largest line-up of blowers on the market from 6 - 35hp!*

and Stratton® Billy Goat’s Hurricane™ Stand-On Blower adds the next level of clean-up productivity to its blower line-up!

even December some years, and are back as early as March.

Once they are back, they will start scouting to set up a nest, and once the geese have started setting up a nest most will defend that site, but some will opt to move along to an easier place if they feel threatened. However, as soon as eggs are laid this changes drastically. The adults become very aggressive and protective, sometimes even to their own peril. Eggs are laid between March and June, and each batch can contain four to eight eggs. It generally takes about a month for the eggs to hatch. Within two days of the young hatching, they are moved onto the water, which offers them some safety from predators, since they are not yet able to fly.

Over the next couple of months the chicks will grow their feathers, and, once the feathers have grown in, the adults will begin to teach the young to fly in preparation for the fall migration. Then the cycle starts over again.

How does knowing this help us to manage geese? By identifying key parts of their lifecycle, when behaviour can be more easily affected, we can concentrate our efforts in these areas to lead to better results. For example, once geese have nested and laid eggs, getting them to relocate is almost impossible. Using deterrents will not only be ineffective but will probably also mean they will not work later in the season since the adults will have either tested or attacked the deterrent.

In contrast, both the site selection stage and right after the chicks have hatched are much easier times to influence their behavior. The most common mistake people make is putting out deterrents much later than they will be effective, and then leaving them in place long after they need to be.

Deterrents should be put out at the end of February or beginning of March, removed if a pair nests and reintroduced as soon as the chicks hatch. If it is not possible to have the deterrent out prior to the pair setting up the nest, wait until after the chicks hatch before putting out any other deterrents. This seems counter-intuitive but it will serve you better in the long run. Why does it matter? Do we really need to manage geese on our courses and in our parks? Although geese can be aggressive in protecting their nests and chicks, most of these altercations can be avoided by keeping humans away from the nests. The biggest danger from geese is in fact the waste they leave behind. Goose waste, like all waste from warm bodied animals, contains E. coli. High geese populations are linked to beach closures every summer as their waste enters the water. Simply contacting goose excrement can be dangerous and can expose you to E coli, salmonella, listeria and many other pathogens.

Contacting waste can be as simple as taking off your boots, cleaning a mower or other equipment and can be a real hazard for all workers that manage turf and the equipment used to maintain it. The waste from geese is also unsightly and can be slippery when it accumulates. So, managing the waste they produce is just as important as managing the geese.

Deterrents are our main method of control for geese. There are many types of deterrents on the market and each of them is designed for a specific part of their life stage. When purchasing a deterrent, inquire about when it should be used and how it works most effectively. Deterrents can be predator decoys, visual deterrents, physical barriers and taste or odour deterrents. Each of these deterrents works best in a different way and in different situations.

Predator decoys are designed to make geese feel like they or their young are at risk from predators. One of the keys is that the decoy has to be a natural predator of the adults or young, and it needs to be moved often enough so that it seems realistic. Natural predators would include coyotes, eagles, alligators, bobcats and foxes. Owls, however, do not normally prey on geese or their young. As such, owl decoys, although widely available, are very ineffective.

Also know that even if the predator does not live in your area, such as alligators, it can still be effective since the geese don’t know they don’t live here but recognize them from migration. All of these predators are something that geese of all ages know to avoid. Often nesting adults will defend their nest against these predators, so again, timing is important. Use these once the chicks have hatched or before the pair have laid eggs.

Another common mistake with predator decoys is that they are not moved regularly enough. Many ground-based decoys now have moving parts, like moving tails, but they still need to be relocated at least every couple of days. If they are left in one

place too long, they stop being realistic. The realism of any decoy can be compounded if you can add another element to the decoy.

Since most decoys are visual, try adding scent by using urine matched to the area. For example, with coyote decoys, you could purchase coyote urine at a hunting store to use in the area to add another level of realism to the decoy. Choosing predator decoys that move on their own, such as floating or kite decoys, if you are not able to move them regularly, can also help maintain the realism which will help keep them effective.

Visual deterrents change behaviour by creating an environment that is unfamiliar and irritating. Visual deterrents can create motion, such as pinwheels. These put geese on edge, which can be exhausting and cause the geese to move to an area that they feel safer and can let their guard down. Other visual deterrents are designed to reflect light in a way that mimics fire, such as iridescent tape. Since animals and birds instinctively avoid fire, they leave the area to avoid it. Visual deterrents work best when they are placed in visible areas with access to wind so they can move and have sunshine to reflect.

Physical barriers prevent the movement of the geese into specific areas. These could include fences and other physical barriers but could also include planting around the edge of the water. Planting taller grasses and plants around

the edge of the water creates a barrier, since it can conceal predators. Especially when the chicks are young, geese tend to avoid these areas due to the possibility of hidden dangers.

If you are planning to use plants as barriers, be aware that adults may pull out new plants until they are established. Protecting the plants with fences until they are established and well rooted is important and can also train the geese that this area is to be avoided.

Scent and taste deterrents are still a developing area of deterrent, but they work by making food sources less appealing. These work primarily during the gr azing stage, once the chicks have hatched. Generally, they do need to be re-applied on a regular basis until the geese realize that the deterrent will be a

constant and move on to a more appealing area. These can be particularly helpful in deterring geese from grazing in specific areas such as greens.

Another technique that can be used with almost any deterrent is making one area of the property less appealing than another. In essence, you are telling the geese, “Over there is fine for you, but we don’t want you here.” On larger properties, and as geese populations continue to grow, this is often a more realistic approach. This can be a technique that can be used for par ticularly sensitive areas such as greens and tees or higher value areas such as beaches. This technique is about picking your battles instead of completely excluding geese altogether. If you take this approach, be clear what your goal is and make sure you communicate it to staff and guests so that everyone is on the same page.

Deterrents are not a simple solution to the growing goose problem in the turf industry, but they can be useful tools when used properly. Deterrents can also be used in combination, or rotated, to maintain their effectiveness. This also allows you to pick the deterrent that will work best for your given situation at the specific life stage of the geese.

With an adaptable species like the Canada goose, it is important to use new techniques so that you can find the right solution and prevent them from getting too comfortable with any deterrents that you are using.

Whatever your mowing job, our ZD Series were designed to mow. Engineered with a lower center of gravity means slopes and uneven grounds are no problem. Best of all, our zero-turn mowers are also incredibly fuel efficient so you can expect to see more green—in the field and in your pocket.

The airflow inside the ACS Kubota Pro Deck has been optimized for faster, more efficient cutting and discharge resulting in reduced power consumption, and increased fuel efficiency, which means you’ll get better work performance—up to 27% better.*** ***Kubota in-house test results

By Mike Jiggens

As director of the Guelph Turfgrass Institute and a professor with the University of Guelph’s department of plant agriculture, Dr. Eric Lyons says his goal is to move the turf industry towards sustainability.

Speaking before the Ontario Golf Superintendents Association at its January conference in Collingwood, he said each person’s interpretation of sustainability tends to differ, yet there are three recognized pillars of sustainability: economic, environmental and social. It’s not just about economics, he said, nor is it just about the environment. It’s mostly about social sustainability, he offered.

“A lot of what we do to maintain sustainability has absolutely nothing to do with economics or the environment,” Lyons said. “It has to do with people’s opinion of our industry. You’re in control of how your brand is seen. You can take hold of that and push forward.”

By his definition of sustainable action, one must act in a way so as to not prevent future generations from acting in the same way.

“You must not exhaust a resource. If someone gets rid of something low in reserve, future generations can’t use it. You can’t destroy ecosystems because future generations can’t do what you did that caused that.”

Lyons said people cannot rely on unknown innovations to save society, adding humanity has pretty much worked its way out of every problem it has created.

“Eventually, innovation won’t save us. We have to act in a way that doesn’t prevent future generations from acting this way.”

Plants are essential to sustainability and serve such important purposes as producing oxygen, preventing erosion, sequestering carbon and reducing urban heating. Although all plants do this, turfgrass is inherently different, he said.

Turfgrasses have dense, fibrous root systems and a lot of tillers. They prevent runoff and help storm water management by slowing water’s movement across its surface. But the biggest difference between turfgrass and other plants is that turf is the only one that can be walked upon and played on. In fact it’s designed to be walked on, Lyons said.

It has evolved after intensive grazing by large animals, he said. Golfers can take divots out of turfgrass, and the plant heals up within a couple of weeks.

“Turf is different because it’s an urban plant that increases sustainability and has a wonderful social aspect that you can play on it.”

Lyons said that shortly after the Ontario government enacted its cosmetic pesticide ban on home lawns and sports turf, the University of Guelph pared back its number of natural turf sports fields from eight to two and now has five artificial fields.

British Columbia

Oakcreek Golf & Turf Inc.

Kelowna 250-860-5090

Surrey 604-882-8399

Duncan 250-701-0766

Alberta

Oakcreek Golf & Turf Inc.

Calgary 403-279-2907

Edmonton 780-469-2332

Saskatchewan

Oakcreek Golf & Turf Inc.

Saskatoon 306-975-1110

Manitoba Mazergroup

Winnipeg 204-253-2900

Ontario Turf Care Products

Canada Limited

Carp 613-821-1880

Medina 519-349-2400

Newmarket 905-836-0988

Québec

Les Produits Turf Care

Canada Limitée

Vaudreuil-Dorion 450-218-4544

Atlantic Canada

Vesey’s Equipment

York, P.E.I. 902-892-8873

1-866-455-TURF (8873)

“How is plastic more sustainable and better for our urban environment than a plant?”

Golf courses, specifically, serve as a city’s urban green spaces. They help to cool urban areas and help with flood control by acting as outlets. Golf courses are often big parts of remediation sites and areas destroyed by humans. They also increase property values.

But golf courses also have an identity crisis, Lyons added.

“They are viewed as inaccessible, private and for the elite.”

That may not necessarily be true, but it is the perception and “it hurts our sustainability.”

Golf courses are also perceived as monocultures that require high inputs and are a poor use of land, he said, noting if a golf course was replaced by a park, it would present a different problem. Parks are accessible to the public but tend to be poorly maintained and are seen as a cost to the taxpayer.

What sets a golf course apart is that it is viable, he said.

“Golf courses are the largest economically viable green spaces in our urban environment. In fact when you lay two or three golf courses next to each other along a river, it is the largest, biggest corridor of green space in most of our cities.”

Lyons said if a city or municipality cares about urban green spaces and cares about cooling, storm water management, wildlife and exposure to wildlife among young people, they should care about golf courses because they are the largest economically viable green spaces in the urban environment.

When talking about sustainability, there is a tendency to lose track of every management habit it costs, he said. There is a cost to social outreach and a cost to keeping members happy, he said. Ball roll distance, for example, was once correlated to putting green surface quality, but that’s no longer the case.

Whether the subject is sustainability or integrated pest management, it’s all about cost-value ratios, Lyons said.

“How much does that management cost? What is the value of that to my customer? What is the value of that to the environment? What is the value of that to my social inner path? What is the value-cost ratio of irrigating the area between the tee and the fairway on a course of this calibre (a high-end course)?”

Lyons argued that a golf course looks better if that section of turf isn’t irrigated because it produces a striking contrast of colour and contrast of texture. But golfers will say they don’t want to visit a course to see burnt grass.

One must think of every action as having a value and a cost, he said, citing dollar spot as an example and wondering whether golfers really care if it’s there.

“Is there true value to your client or true value to your operation by eliminating that dollar spot?”

If a green is afflicted with a patch yet it doesn’t affect play, the question must be asked if the superintendent is willing to accept it, and perhaps it’s OK as far as the client is concerned.

Intelligent design is a means to improve the positive impact of golf courses

Lynx Smart Module is the latest, best-in-class, two-wire innovation from Toro that provides more control than ever before.

SPEED: Provides information faster than other two-wire brands, reducing test times from minutes to seconds

PRECISION: Apply water with one-second resolution

UPGRADEABLE: Upgrade remotely with just a click

DURABLE: Best in class surge protection to help weather the storm

by maintaining aesthetics, playability and maintenance, Lyons said.

“I hate playing four really bad holes to get to one beautiful view.”

Oxford2016:Layout112/16/153:36PMPage1

He said he has played a number of courses where it seems the top of the ecosystem has been destroyed, such as trees being cut down to accommodate a hole that lends a picturesque view across a bay.

The generally perceived negative impact on golf is about 90 per cent perception, Lyons said, with watering, fertilizer and

pesticide use, and carbon being the biggest targets, but golf is moving towards sustainability. Most of the research being conducted at the Guelph Turfgrass Institute is geared toward sustainability, he added.

Moss invasion, for example, is a result of the growing environment. There is a product that will knock it back, he said, “but if you don’t change the growing environment, you’re always going to have it. All you’re doing is making it go dormant for a short period, but it’s going to come back.”

Syringing when it’s hot is a leading cause of moss as well as “ridiculously low” mowing heights. Lyons said golf courses are setting up a system where a non-rooted plant is being chosen over a rooted plant. Watering a little bit every day or every other day will bring about significantly more moss than if watering is done every four days. If by July 20 mowing is being done at one tenth of an inch, a little bit of watering may have to be done every day. But by Aug. 20, when the weather starts to cool off, that same watering practice needs to stop.

“Give the vascular plant a chance to outcompete it (moss). If you do that you’ll also increase your rooting depth.”

Soil moisture meters tend to provide

precise readings, but they are calibrated for sand, not soil, he said.

Turf gets a bad rap because of how much it is watered. Cities will issue bans on lawn watering, but residents can still freely water other plants. Lyons said one of his neighbours tore out his lawn in favour of bedding plants because he knew that once a municipal watering ban was enacted, he could continue to water his alternative plants.

“Why do we ban water for turf, but we don’t ban water for these plants?”

Other plants take more water. Kentucky bluegrass on home lawns will go brown in a dormant state, but will come back. When turfgrasses are given excessive amounts of water, they will use excessive amounts of water, Lyons said.

“ That’s why the estimations of turfgrass water use are completely wrong. They assume every one of you is watering the plant to saturation almost every day.”

Turfgrasses have a fairly high evapo-transpiration rate overnight and are adept at sur viving drought as compared to their competitors. Their goal is to dry out the soil as quickly as possible, Lyons said, adding that – evolutionarily – wasting water when it’s clinical helps them compete against weeds that can’t survive drought. Turfgrasses want to be on the edge because weeds have less ability to compete.

By Pam Buckley

Contractors agree that sidewalks pose some of the biggest challenges in winter maintenance –high labour and high risk. Taking a preventative approach to sidewalk maintenance provides solutions for both of these concerns. It also allows companies that are inter ested in adding liquids to their operations to start out on a smaller scale.

The objective of anti-icing is to inhibit accumulation from forming an ice bond with the pavement. Brine can be used to prevent that bond before, during and after a storm. The preferred protocol is to apply brine directly to the surface by direct liquid application (DLA). This practice and the way in which it is executed offer a variety of benefits. When just getting started, it is recommended to limit your service areas until you become accustomed to how these materials and practices perform.

When applied prior to a storm, brine waits in the pores of the sidewalk and goes to work as soon as the first snow falls to insulate the surface and to maintain optimum levels of surface friction until the sidew alk can be cleared. Depending on conditions, an effective anti-icing/pre-treatment application will melt the first 0.5 to 1.25 centimetres of snow, after which it maintains a protective slush barrier on the bottom.

Used appropriately as a post-treatment, brine produces faster results and c an recover the desired surface conditions faster than dry salt, which takes

longer to produce results since it must first go into solution and form brine before it will melt anything. Appropriately used, taking a pr eventative anti-icing approach reduces the risk of slip-and-fall accidents.

Liquids can be applied with precision and stay on the sidewalk until they dry. They are not shoveled, blown or broadcast off the surface where they can damage adjacent landscape. A pre-treat-

ment can last for days on a sidewalk, and because it leaves no excess salt, there is no labour required to clean it up afterward. This results in substantially less tracking into customers’ businesses and damage to entryways and lobby floors. By shifting sidewalk resources to preventative anti-icing measures, contractors can utilize up to 75 per cent less salt and substantially less labour than what’s required to achieve similar results by de-icing. This can significantly mitigate the damaging impacts of salting on cus-

tomer properties and the environment, reduce crew fatigue, and decrease overhead costs. Contractors have seen a reduction in the use of bagged product as well as rock salt, thanks to their transition to anti-icing for sidewalks.

For sidewalk liquid treatment applications, walk-behind push sprayers and UT V-mounted sprayers offer various pros and cons depending on operating needs and the areas in need of treatment.

Electric-powered push sprayers make for a relatively low-cost investment to get started. They also are extremely portable and easy to maneuver and use on any width of residential walks and driveways. Some models on the market are equipped with an adjustable spray wand for spot-spraying tougher spots to reach, like stairs.

Push sprayers offer a limited tank volume, so users need to have a plan for refilling the tank on site as work continues. The sprayers are also fairly heavy to lift when filled with brine. A good sprayer battery should keep its charge for at least 12 hours for longer working shifts, but it will still require users to be diligent and recharge it frequently.

To step up into brine application on larger jobs, contractors can invest in a UTV-mounted sprayer with greater capacity in the 100-gallon range. This is a great option for applying liquids faster when addressing long stretches of sidewalks and pedestrian walkways wide enough to accommodate a UTV.

These sprayers feature a boom – usually around four feet wide for models being used on a UTV – that allow operators to easily position the nozzles to adjust application rate and spray pattern. Typical noz zle position settings include triple stream, single stream and wide fan. Of course, a UTV may not be able to reach all surface areas that require treatment, so select models will also feature a wand and 50-foot hose for spot spraying those hardto-reach places like curbs and stairs.

Understanding application rates and

best practices is essential to making a successful transition into the use of liquids. Successful brine application is rooted in science, but it takes practice to truly get it right. By refining best practices with experience over time, contractors can develop their own standards based on the unique needs of their operations.

Among the factors to consider is what your contractual requirements are and how much time you have to meet your customer’s expectations. This will determine whether to pre-treat, post-treat or both. The actual makeup of a storm –timing, intensity, pavement temperature, present and anticipated accumulation – will affect the choice of brine, rate, and the timing of its application.

When the temperature drops low enough, the material may stop working and you may need to introduce additional chemicals to increase performance. Salt brine (NaCl) is considered an effective choice for anti-icing down to a pavement temperature of minus 9 degrees Celsius. Suggested application rates increase incrementally as the pavement temperature decreases. Adding a blend of up to 30 per cent calcium or magnesium chloride is necessary to prevent freeze conditions and to expedite results when the pavement temperature drops below minus 9 degrees.

Having success with liquids does require some advance preparation before the storm arrives. Using pavement temperature data from the days preceding an event, along with air temperature trends, can help with estimating the pavement temperature range for the event.

This data can then be used to calculate the desired brine makeup and application rate. Store enough brine for a couple applications per site in at least t wo storms. Establish a standard application rate and calibrate all spraying equipment to that rate.

Pre-treatments are typically executed one to three days before the event. As long as rain is not in the forecast, you can start applying brine and continue up to

the start of the storm. A good practice is to schedule your sidewalk applications when there is minimal pedestrian traffic to limit tracking.

Upon arrival on site, unload the equipment and fill the tanks. Check the nozzles and adjust spr ay to ensure adequate coverage without extending off the sidewalk. Test the pavement temperature to confirm the desir ed application rate. Then apply the brine and allow it to dry.

On the day of the storm, monitor sidewalks regularly to prevent refreeze and optimize pedestrian safety. Shovel and treat the surface every two hours or after every 2.5 to 4 centimetres of accumulation. Drifting snow and roof b uildup falling on walks will require more immediate attention.

Areas like handicapped ramps, stairs, crosswalks, under downspouts and shaded areas may require shorter cycle times or higher application rates. These situations may also call for augmenting the post-treatment with a light application of bagged material to extend the dur ation of application effectiveness and add traction for pedestrians. Again check the surface temperature to confirm the application rate, and apply brine immediately after clearing to remove residual snow and prevent ice from bonding to the pavement. De-icing with brine for bonded ice and hard-pack is not recommended. This requires advanced experience, significantly higher rates and high-pressure nozzles capable of penetrating hard-pack.

one of the contractor’s most daunting challenges from both a liability and overhead cost standpoint. Changing to a proactive/preventative approach utilizing liquids is transforming how the industry is tackling that challenge.

The use of liquids to anti-ice sidewalks produces safer outcomes for customers, pedestrians, work crews and the en vironment. Most importantly, the use of liquids is increasing the contractor’s bottom line.

To increase uptime, mowers need to be regularly maintained during the summer season

By Nick Minas

Summer has arrived, meaning professional landscape contractors are in the thick of the mowing season. With customer demands high and busy schedules testing the durability of equipment, it is it critical to arm all operators with the information they need to keep machines up and running, regardless of demands they face each day. As many professional landscape contractors know, the key to a quality cut is the performance of the machine and, specifically, the mower blades.

With the peak mowing season underway, it’s important that landscape contractors keep their machine well maintained and ready to go, especially as business picks up over the next few months. In the midst of the busiest time of the year, easily avoidable downtime simply isn’t an option, and there are simple things professional landscape contractors can do to ensure their machines are primed for work and their businesses

have the right policies in place to maximize each day.

No matter how good the crew may be, it doesn’t matter if the equipment isn’t up and running. To increase uptime, it is important to properly maintain machines per the directions in the operator’s manual.

Each day operators should start with a daily walk-around, checking everything from nuts and bolts to belts. They should keep an eye out for any loose or worn parts, and always be sure to tighten nuts and bolts, replace filters, and check and replace belts as needed. It’s extremely crucial to identify missing parts and replace them as quickly as possible, especially before operations. Failure to do so ma y result in a machine going down mid-job, causing delays. Also, give tires a once over, checking the tire pressure and examining treads for wear and tear. Pay extra attention to the mower deck

and blade, which is the most critical part of the machine in regard to cut quality. A sharp blade is the key to creating a clean, crisp cut when mowing. Check blades for dullness and corrosion. If the blade is dull, sharpen it to ensure a high-quality cut. Additionally, replace any exhausted blades that are no longer effective. It is also important to check blade balance for an even cut.

In addition, there are several other areas of the mower deck that should be regularly monitored for wear and tear. The mower belt should be taut and in good condition. If there is any fraying or wear that changes the belt’s profile, be sure to replace it. Also, look for any loose cords or chunks of the belt missing.

Routine maintenance is another thing to keep in mind, especially during summer when mowers are being put to work. Following the outlined maintenance schedule in the operator’s manual, make sure to perform the necessary work as specified by the manufacturer. Also ensure that the

right fluids are being used, as recommended by the manufacturer. While switching fluids might not seem like a big deal, using the wrong fluid can lead to major damage down the road.

Be sure to keep tabs of all of the maintenance that is done throughout the summer season. Proper service is key when it comes to keeping machines running smoothly, and many professional landscape contractors do not realize how quickly they forget what service was completed even weeks before. Track maintenance in a log book, which will provide something to refer to during the upcoming months.

While this may seem obvious, the first step to ensure a quality cut is to keep machines clean. Each day once work is complete, the crew should ensure machines are debris-free before closing shop for the day. Not only do clean machines look nice, but this important step can also help increase machine uptime.

During mowing, equipment accumulates a fair amount of crud and debris, particularly when mowing in areas that frequently deal with rainy weather. This debris can lead to damage if left untouched, making it extremely important to thoroughly remove before putting away machines. Additionally, when performing daily walk-arounds and machine checks, extra dirt and crud can

make it difficult to see if parts are missing or need to be replaced.

Parts management serves as one of the most vital elements to combat machine downtime. Taking the time to properly revamp the company’s parts department will improve its overall profitability. First, assign inventory ownership, limiting the number of employees with access to parts storage. With one person overseeing the parts department, it ensures efficient management of the inventory.

Properly organize and label bin locations, creating a designated part storage location so that crew leaders are aware of where things are and what needs restocking. Include a minimum stocking level on the label so managers know when parts need to be replenished. Also, consider incorporating a system that allows you to track parts usage by machine. By tracking what parts were used for each machine and the cost per part, landscapers can identify repair costs for each particular model and help determine whether a machine should be repaired or replaced.

When the mowing season picks up in the summer, it is important to have resources lined up to help manage downtime. The

equipment dealer is one of the best resources available, as not only do they know everything about the equipment, many dealers are prepared to support professional landscape contractors with the downtime they will face.

Professional landscape contractors should consider their dealer as an extension of their business, as they are just as invested in the business as the owner is. When speaking with their dealer, landscapers should discuss beneficial support offerings they provide. For example, John Deere dealers offer a mower loaner program, which provides customers with a loaner mower to use when a machine experiences downtime. This ensures that the business never skips a beat, even when something unexpected happens.

The dealer also plays a key role in parts delivery, and can work with the customer to ensure they have the parts they need before they need them. Many dealers can set up a recurring delivery, which works in tandem with the parts management department to restock common parts once a minimum inventory has been reached.

Additionally, if a new equipment purchase is needed, the dealer is there to help streamline the process. Not only will the dealer help the customer determine the right equipment for their business, most dealers can help simplify the financing process, especially if the manufacturer offers financial support, like John Deere Financial does.

Summer is a great time to schedule a crew refresh, as protocols and processes often fall by the wayside as crews get deeper into the mowing season. Sit crews down to discuss important things, including maintenance schedules, company rules and mowing best practices. It is important to remind them of a few basic, but essential, mowing dos and don’ts. For example, they should always make sure that lawns are clear of debris or hazardous materials before each cut. While this may take a few extra minutes, staying true to this best practice helps protect and maintain equipment, and allows for mower blades to remain sharper longer.

Warmer months are when professional landscape contractors are most profitable, making it important to have crews and equipment ready to go. As a landscaper, it is critical to prioritize mower care, as working machines are vital to keeping the business running all season long. Additionally, make sure the business and crew are ready to go by maintaining processes that streamline things and increase productivity. Finally, don’t forget that the equipment dealer is always there to support the business and help keep things moving. Dealers are extremely invested in their customers, and most dealers offer a range of services to help increase uptime.

Nick Minas is product mgr. for John Deere Commercial Mowing.

GMC Sierra provides both for those who want it all

By Mario Cywinski

The word off-roading usually brings a smile to most people’s faces, even if they aren’t the ones doing the driving. The connotation is usually a positive one, and most people associate it with having some fun in their vehicle. Now, if you own a sedan like I do, off-roading is not the best idea. However, for many who own an SUV or pick-up truck, they have at the very least driven on a dirt road with some potholes.

For years when a standard vehicle was sold as an off-road model that meant some cosmetic changes, rugged tires, and the like. Fortunately for those who actually want to take their vehicles off-road, that is no longer the case. Most OEMs that produce trucks are now offering dedicated off-road models based on their standard 1500 series trucks, and General Motors is no exception.

GM recently invited journalists to San Diego, Calif. test out the GMC Sierra AT4 (GM speak for its off-road model). The drive started out downtown with the street by the hotel being blocked off to display the trucks. Soon after, the drive to the desert helped to demonstrate the AT4’s capabilities.

While driving up and down the side of a hill on the rather rough terrain, we encountered Border Patrol, other motorists, and, of course, the ever-present cliff on one side of the road. GM did warn those who have any issue with heights to take

the part of the drive that goes uphill and not down. At the end of the day, everyone in the convoy of AT4s navigated the drive without any problems apart from the odd GoPro being lost somewhere along the way, but that seems to be par for the course on these drives.

At the lunch spot, a short but more extreme off-road course was set up to really show off the vehicle’s capabilities. Participants took the AT4 up and down the side of a rock face, which was relatively steep with uneven terrain. Again ever yone was able to navigate the challenge without any issues.

The drive demonstrated what the AT4

could do but what does it have that allows it to do it? Well, the AT4 model offers a suite of standard features that are important off-road equipment.

T hey include: two-inch factoryinstalled suspension lift, off-road-tuned Rancho monotube shock absorbers, 4WD with a two-speed transfer case, locking rear differential and skid plates, hill decent control, and traction select system. Stylistically the AT4 has black chrome finish on fog lamp bezels, fender surround and grille insert, body-colour grille surround, door handles and bumper, and red vertical recovery hooks. The interior is also updated from the

standard Sierra model.

“The all new Sierra light duty AT4 brings off road capability to the premium truck market,” Mark Alger, national marketing manager, GMC Canada, said. “The AT4 is designed for customers who are looking for off road capability but don’t want to sacrifice style or a comfortable cab. Customers in the resource sector and other off roaders will benefit from the two-inch factory lift kit, standard fourwheel drive, skid plates, Rancho shock absorbers, locking rear differential and standard 33-inch all-terrain tires or available mud rated tires.”

Introduced on the GMC Sierra 1500, and standard on the AT4 is the MultiPro tailgate, which offers six positions and functions, which allow for more flexibility when loading, unloading, as well allowing for easier access to the box. Also available is a pickup box that is made of carbon fibre.

Two segment first options available are the rear camera mirror, which allows the rear view camera to be displayed in the rear view mirror (the rear view mirror can also be used traditionally), and a multi-coloured heads-up display.

As with many pick-up trucks these days, a full line of safety features are available, and the GMC Sierra AT4 is no exception. It comes available with 360 camera, blind spot monitoring, front pedestrian braking, and low speed automatic forward braking.

“ The AT4 features a signature body colour and black chrome exterior, red vertical tow hooks and an exclusive Jet black/Kalahari leather interior with dark aluminum accents,” Alger said. “Commercial customers looking for functional featur es without sacrificing premium design and comfort need to check out the all new AT4.”

An off-road performance package is also available on the Sierra AT4. It offers performance air intake, performance exhaust system, 18-inch machined aluminum wheels, and a 6.2L V-8 engine mated to a 10-speed automatic transmission.

Based on extensive testing and three decades of SnowEx® hopper spreader innovation, the new HELIXX™ poly hoppers feature an advanced material delivery system.

Combined with a multi-dimensional tub design, the HELIXX system vastly outperforms traditional augers and delivers top material flow. It also offers the triple threat capability to spread, pre-wet and spray with one machine.

The corkscrew – or “helix” – design of the patent-pending HELIXX material delivery system is optimized for efficient and cost-effective use of salt and was engineered to operate in the target range for salt spreading best practices. Whether spreading 100 per cent salt, 100 per cent sand, or any mix in between, the HELIXX is engineered to prevent clogs and provide a flow of material superior to that of traditional auger spreaders.

A key advantage of the HELIXX is that it runs the full length of the poly hopper with variable flights. Combined with strategically positioned ribs/ angles in the multi-dimensional tub, the HELIXX promotes optimal material flow and even unloading.

The unique cab forward hopper design delivers better payload distribution to reduce stress on the truck. The HELIXX extends beyond the hopper and into the patented pre-wet mixing chamber to help prevent leaking/spilling during transport while providing an ideal location for pre-wetting material.

By adding accessories such as the pre-wet tanks, a pump and a set of boom-less nozzles, the HELIXX poly hopper becomes a triple threat to spread, pre-wet and spray. Not only can the spreaders pre-wet materials, but they can also be used for spraying brine directly onto the driving surface for anti-icing and de-icing applications.

Designed for use with full-size pickups, flatbed trucks or dump-bed trucks, the HELIXX poly hopper lineup includes four different models, ranging in capacity from 1.5 to 5.0 cubic yards. The hoppers are supported by a corrosion-resistant, stainless-steel frame that features a unique leg and sill design to form a ridged backbone structure for greater durability. For quick installation and removal, fork pockets are built into the legs.

Baffles within the spreader’s chute direct material to key areas on the spinner, resulting in an even and consistent spread pattern, while also reducing material directed back at the vehicle. Three spinner height adjustments (standard on the two largest models) allow the spreaders to achieve a consistent spinner height of 18 to 22 inches off the ground, regardless of vehicle type. A dual variable-speed control allows independent adjustment of spinner and HELIXX speeds for precise material delivery, whether at low or high output. It also features no-blast startup and an auto reverse function.

Additional standard features include dump switches, a flip-up and removable chute, tarp cover, top screen, vibrator and work light. Available options and accessories include an inverted “V” for materials susceptible to compacting, strobe lights, secondary work light, ratchet straps, chain kit, pre-wet tanks and spray boom.

For more information, visit www.snowexproducts.com.

SnowEx® introduces its new STORM SEEKER™ LED headlamps with EdgeView™ technology, providing one of the widest, fullest and farthest light patterns of any snow plow lights on the market. Featuring a durable design and best-in-class LED output to simulate daylight, the headlamps produce up to twice the light output of halogen bulbs to increase safety and productivity while plowing.

The STORM SEEKER LEDs offer exclusive EdgeView technology, which features a dedicated lens and LED bulb that directs light through the outer edge of each headlamp. The design provides a full 180 degrees of light visibility from plow edge to plow edge for the best all-around view of the plow’s operating environment. Even without EdgeView active, the LEDs offer a superior light pattern that illuminates wider and farther than other headlamps.

To combat snow and ice build-up, the LED headlamps boast an intuitive heating system that senses temperature

on the lens and only heats when necessary. To help prevent ice bridging, the headlamp structure is designed with a forward sloped lens and has no bezel, a common point for ice to begin forming on other lamps.

Built with durability in mind and compliant with FMVSS 108, the headlamps offer a compact design that is less prone to shock and vibration while plowing. Featuring a completely sealed, weatherproof housing to stand up to harsh weather conditions, the headlamps have undergone thorough testing including hot and cold thermal shocking, cold-water submersion, corrosion tests, and impact simulations.

The new STORM SEEKER LED headlamps will be offered as an option for SnowEx truck plows. To verify vehicle compatibility, visit www. snowexproducts.com for the most up-to-date vehicle applications. More detailed information on the new LED headlamps will be available at www. snowexproducts.com in May.

The Steiner 450 tractor is a true year-round machine, featuring more than 25 attachments for all seasons, including a professional snow blower attachment and rotary sweeper. The 450 tractor’s improved hydraulic weight transfer and traction boost system provide additional control that handles the toughest professional jobs, from cleaning up after blizzards to brushing off sidewalks. Its value is in its versatility, and the Quick-Hitch™ System makes it easier than ever to switch between attachments. The lift arms are 50 per cent stronger, and attachments can be changed in less than a minute without any tools.

DriftBuster™ snow throwers deliver “no-clog” performance, even in deep, wet snow. The discharge spout rotates 180 degrees and propels snow 30 feet away. The Retain True Zero-Turn™ maneuverability offers maximum productivity in adverse conditions.

The DriftBuster is available in 48 and 60-inch widths for Grasshopper FrontMount™ power units, with cab enclosure and heater for select models.

For more information, visit www.grasshoppermower.com.

The Western® Impact™ UTV professional-grade snowplows are exclusively designed and built to turn UTVs into winter workhorses. The tough, six-inch-wide V-plow can easily adapt to handle five-foot sidewalks and gates whether in angle, scoop of V mode. The six-foot straight blade is a professional-grade plow is a lighter-weight package, allowing it to fit more UTVs. Both feature a simple mounting system that provides exceptional ground clearance and the Western Scrape Lock system for cleaner scraping, especially when back dragging.

A major strength of the book is the wealth of information presented on management strategies, complete with do-it-yourself instructions for site selection, soil preparation, seed rates and planting, turf establishment, and renovation. Time and cost-saving techniques for effective mowing, thatch control, pest management, water conservation, water management, fertilizer use, stress management, and pest management are presented in a user-friendly manner—complete with helpful checklists, and step-by-step instructions. A vast amount of useful reference material will ensure the success of your maintenance program.

BY BRIAN LOWE

Although the Slope-Pro® is operated by remote control, this mower is far from child’s play. The Slope-Pro is capable of operating on a side slope of up to 50 degrees! To put this in perspective, you need to climb a 50 degree slope, you cannot walk up a slope that steep. Considering that a ride-on zero turn mower (ZTR) should not be operated on slopes greater than 15 degrees, Slope-Pro’s 50 degree capability opens up areas considered too treacherous to maintain by other means, including areas close to water or drop-offs. There are other mowers that claim to have steep slope capability, albeit much less than 50 degrees, but they require doubling up tires, shifting operator weight or some other means to enhance stability. But what makes these options even riskier is that the operator still needs to ride on the machine placing the person in a potentially dangerous position. The same concern holds true for hand-held string trimmers; the operator is still on the slope and injuries are a ‘when’ not ‘if’ consideration. When mowing on steep slopes, Slope-Pro’s

remote operation is a huge advantage in light of the risk of a slip and fall or a rollover.

Like all Progressive’s mowers, the SlopePro is a rotary mower. Introduced in 2011, it has twin blade spindles that produce a 52" wide cut with an on-the-fly adjustable cut height between 2.25" and 8". Powered by a 747cc Kohler gas engine, the Slope-Pro can cut vegetation up to ¾" thick, 300 feet away from the operator and travel up to 4.5 mph. Running on rubber tracks, it features great maneuverability, stability, and low ground pressure.