Reliability that counts

NEW HT 135 GAS POLE PRUNER

The most powerful gas pole pruner in the STIHL line-up with a 4-MIX™ engine for professional work in tree maintenance, orchards and local municipalities. For delimbing trees, removing dead wood or breakage from storms, and for cutting back trees. The lightweight HT 135 has a 3/8" PM3 saw chain, and includes a compact transmission with cast-on robust branch hook. Features a professional telescopic shaft with rapid adjustment for precise biting characteristics and a precise cut. Total length 270-390 cm.

① Weight without fuel.

PRO-FLEET COMMERCIAL LANDSCAPE PROGRAM

STIHL’s Pro-Fleet Commercial Landscape Program is designed to provide commercial landscapers a volume discount on major purchases of five or more landscaping power tools. Visit your STIHL Dealer today to find out more and take advantage of the savings!

DEPARTMENTS

06 | In the news ‘Give a little and gain a lot,’ course owner suggests for growing golf 17 | Industry Innovators

Making comfort a priority in track loader and skid steer design

JIGGENS

MIKE JIGGENS

By Mike Jiggens

2022 is the year to test golf’s growth

Canadian golf courses experienced a rebound in their fortunes in 2020 during the first year of the COVID-19 pandemic. With few outdoor recreational options available due to government-mandated shutdowns, golf was one such activity that was allowed to proceed.

Men, women and children took full advantage of this opportunity. Tee sheets were being filled by golfers who had played only occasionally in previous years and by a throng of others who took up the game for the first time.

This growth was exactly what the industry needed, but was 2020 to be merely an anomaly? Was this an act that 2021 couldn’t possibly follow, especially as vaccines had become readily available and restrictions on other outdoor activities were starting to loosen? Interestingly, 2021 not only measured up to the previous year, but it also topped 2020’s figures for the most part.

The 2022 season is now poised to be the real test for golf in Canada. COVID-related restrictions have all but disappeared across the board, and Canadians have an unlimited number of recreational options to pursue this time around. Can golf maintain its momentum and keep its resurgence going?

This issue’s cover story

looks at how golf course architects – working in conjunction with superintendents –can incorporate design features that require less labour and fewer inputs. In spite of the game’s recent growth, maintenance budgets – for the most part – haven’t necessarily increased correspondingly, and labour shortages are still a reality.

Golf must continue to grow, but there are other factors that should be considered to minimize the number of obstacles that could stand in the way of its continued growth. Golf can be a frustrating game to play for the best of players, and newcomers – who represent the game’s future – must be deprived of as much of this

“The game has to be fun for them to play so they’ll stick

with

it”.

frustration as possible. The game has to be fun for them to play so they’ll stick with it, yet it can’t be completely devoid of challenge.

The architects featured in our cover story noted a significant difference in the philosophies between Australian and North American superintendents. Superintendents “down under” focus their attention on maintaining areas where the ball “is supposed to be” and devoting less attention –if any – to those areas where the ball “isn’t supposed to be.” That contrasts with the way

things are largely done in North America.

On the one hand, the Australian strategy is a logical cost-saving measure. It frees up dollars so that superintendents can focus more on their greens and other pressing areas. This approach, however, caters to the stronger golfer. Newer, weaker golfers are going to miss the fairway often and could find themselves in an assortment of predicaments on their journey from tee to green. Frustration will set in early and frequently if their ball constantly finds three inches of rough after every shot. They’ll curse about having to play from such a lie and may not even find their ball at times. This will negatively impact the pace of play which will also sap the fun out of the game.

To retain this target demographic, some form of compromise is necessary to keep the game flourishing. The weaker golfer must be able to find his ball and have a chance to hit it while the stronger golfer won’t want to see his golf course cheapened to completely serve the whims of the high handicapper. At the same time, superintendents can’t be “breaking the bank” by mowing, spraying and raking everywhere to the point where green fees are to be disproportionately bumped up. That by itself will apply the brakes to the game’s growth.

COVID, in its own backhanded way, has presented a gift to golf. It’s now up to Canada’s golf courses to figure out the best way to ensure it’s the gift that keeps on giving.

www.turfandrec.com

Reader Service

Print and digital subscription inquiries or changes, please contact Anita Madden, Audience Development Manager Tel: (416) 510-5183 Fax: (416) 510-6875

email: amadden@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

Editor Mike Jiggens mjiggens@annexbusinessmedia.com

National Advertising Manager

Rebecca Lewis 519-400-0322 rlewis@annexbusinessmedia.com

AccountCoordinator

Trish Ramsay 416-510-6760 tramsay@annexbusinessmedia.com

Group Publisher Todd Humber thumber@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada ISSN 1186-0170

PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Published 7 times a year – Jan/Feb, March, Apr/May, June/July, Aug/Sept, October, Nov/Dec

Canada – 1 year $35.00; 2 year $45.00 3 years $55.50 (plus applicable taxes HST 86717 2652 RT0001

Occasionally, Turf and Recreation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office

privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2022 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

MINIMIZE PASSES, GUESSWORK, AND HEADACHES.

It’s all about doing more with less. So we did, with the widest range of machines equipped with grade management tech to suit your job needs today, and tomorrow. From 2D Laser Control to fully-integrated SmartGrade,™ it allows any operator to grade with precision. Reducing passes, labor costs, and dreaded rework, to boost your bottom line.

B.C. golf courses report 2021 rounds doubled 2020’s

Golf has proven to be one of the COVID-19 pandemic’s silver linings. Growth of the game more than doubled at British Columbia’s largest golf courses during the second year of the pandemic with a 14.3 per cent increase in the number of rounds played.

This compares with a 6.5 per cent increase in the pandemic’s first year over 2019 figures.

The data was collected by Business in Vancouver.

Grub populations explode on lawns in New Brunswick

Lawns across New Brunswick are experiencing a nasty year for grubs. Not only are the larvae of chafer beetles present in large populations, the raccoons, skunks and crows looking for a tasty treat are tearing up lawns left and right.

Lawn care professionals in the province are saying this is one of the worst years ever for grubs. New Brunswick’s weather has been a factor the past couple of years in the population explosion of grubs.

One lawn care operator said the grub problem began a few years with one affected lawn but has since become an epidemic.

Scotiabank funds construction of First Nations soccer fields

A Scotiabank-backed program has provided for the construction of six mini soccer fields in Indigenous communities in British Columbia. Scotiabank Futbol Club (Scotiabank FC) has earmarked $450,000 for Hope and Health, a B.C.-based, Indigenous-led organization dedicated toward helping children in the province reach their highest potential.

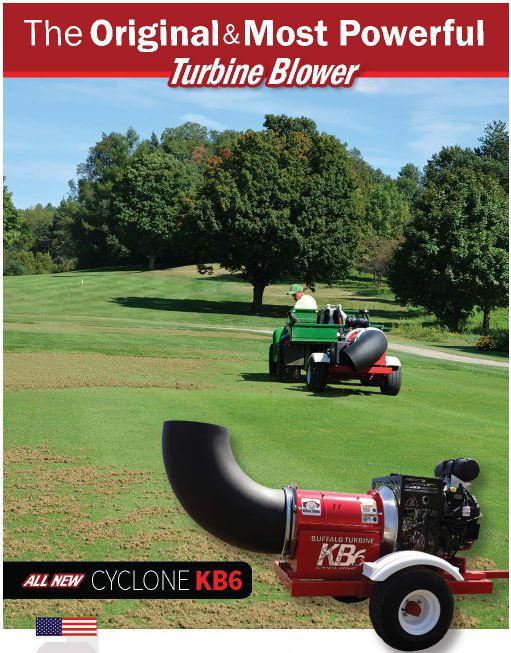

‘Give

a little and gain a lot,’ course owner suggests for growing golf

The golf industry has a new challenge on its hands in 2022. With more and more restrictions associated with COVID-19 lifting and giving the public more recreational and entertainment options, golf may no longer be people’s preferred choice.

Golf’s popularity during the first two years of the pandemic soared to heights unseen in decades, but the game now has competition. The owner of Muskoka Highland Golf Links in Bracebridge, Ont. believes the answer to retaining golfers – especially a new generation of younger golfers – is to “give a little and gain a lot.”

Donald MacKay says the industry needs to gain the confidence of the next generation of golfers. He had posted a Facebook message about a conversation he had with a 25-year-old golfer who stopped into the club’s pro shop to buy a golf bag. The golfer told Mackay

that golf was expensive to play, but the owner offered him a deal by multiplying $15 times the golfer’s age. For $375, the young golfer could play anytime he wished – a deal that included range time.

The golfer inquired about the “catch,” but Mackay said there wasn’t any, adding the youngster represented the game’s future.

Randy McDonald, writing for Golf Industry Network, said it took a virus to grow the game and that prior to the pandemic, the industry was unable to generate new enthusiasm for golf. Millennials seemed uninterested in the game, forcing golf courses to consider new strategies to keep things afloat, including reduced green fees, scaled back staff salaries and creating larger holes.

McDonald also writes that significant changes have taken place in the industry in recent decades, such as sales of equity memberships and conglomerate takeovers of courses.

Golf course design amid thin budgets

How architects can help superintendents deal with reduced labour and fewer inputs

By Mike Jiggens

Although golf has experienced a resurgence during the COVID-19 pandemic – in terms of rounds played – course superintendents are still dealing with reduced labour issues and shrinking budgets that have impacted their inputs.

Renovation projects or new builds must have superintendents and architects on the same page to ensure design work and alterations incorporate such restraints.

A trio of Canadian golf course architects shared their views about designing with reduced staff and fewer inputs during the virtually delivered Canadian Golf Course Management Conference in March.

The panel included Ian Andrew, Ian Andrew Golf Design; Jeff Mingay, Mingay Golf Course Design; and Keith Cutten, Whitman, Axland and Cutten.

Andrew, who has worked to restore a multitude of golf courses designed by such luminaries as Stanley Thompson, Donald Ross and Robert Trent Jones, said that by thinking about how to move around a property, plenty of solutions can be found without undoing the visions of the original architects. Such “intrusions” superintendents may face on a golf course include having to cut around trees, dealing with steep slopes and ravines and not having good access points to reach greens.

“If you had an open field that was all fairway of 100 acres and you cut it, you can actually cut it with very little staff and not a lot of time,” he said.

Mingay, who has been working on an improvement project of late at the Richmond (B.C.) Country Club, said he has tapped into the mindset of Arthur Vernon Macan Jr., the original architect of the golf course. He noted Macan fell in love with Augusta

National Golf Club at the time it was constructed in the 1930s, particularly relishing is bunker simplicity. The home of The Masters was built with only 22 bunkers but has almost doubled that number over the decades.

Macan, Mingay said, believed that slope, contour and angles, in addition to as few bunkers as possible, gives a golf course its essence. He designed Richmond with “turtleback” greens like those at Augusta National and Pinehurst, even though the course itself was flat. During the “extravagant 1980s,” a master plan was commissioned, and changes were made.

“Instead of the turtleback greens falling off to these cool short-game areas, mounds were built up around the greens,” Mingay said. “Instead of having 40,000 square feet of bunkers, there had to be 110,000 square feet of bunkers.”

Maintaining golf course bunkers is one of the most labour-intensive chores for maintenance staff. Reducing the number of bunkers minimizes the time and labour needed to deal with washouts following a heavy rain event.

Reeling in bunkers

Macan originally designed the golf course with few maintenance staff in mind. Mingay has worked to halve the total area of bunker space, allowing for 50 per cent of the time and expense previously allocated to raking – “that didn’t really have any purpose” –dedicated toward fairway expansion, restoring strategy to the game and giving higher handicap golfers more latitude.

Cutten, whose firm’s current work includes a renovation of the Brantford (Ont.) Golf & Country Club and other projects in British Columbia and Oregon, said when working with a master plan or a new build project, the architect must look at the landscape holistically and determine what core issues might exist and how they can be resolved, realizing that a site might have a uniqueness, nuance or quirkiness “because some of those things are what makes great golf.” Architects are attracted to certain golf courses

because they’re special and have elements that make them unique and stand out from others.

“Our role as architects is to understand when we’re presented with a new client, is to really dive into the nuances of the day-to-day operations of a club or course and understand what makes things tick,” he said.

The architect, Cutten said, must understand what tasks the maintenance staff are doing most of the time. These could include mowing, maintaining bunkers, repairing cart paths or fixing irrigation leaks. The challenge for the architect is to address the things that occupy most of a worker’s time and resolve them while wisely investing the club’s money. Achieving this must also factor in making the golf course better, ensuring the game is fun to play, providing accessibility to players of different skill levels, and making the course stand out among the crowd.

“That’s what we as architects can bring to the mix,” Cutten said.

The historic Brantford Golf & Country Club was originally designed by Nicol and Stanley Thompson and renovated in the 1960s by Robbie Robinson. Cutten said when he became involved in the current renovation project, he found that its bunkers were tailored to several different styles which created visual inconsistency.

“It was our goal to define something from their history – a certain look we could put into the club,” he said, adding something historic was desired with the objective of minimizing the inputs of the maintenance staff.

The solution was to shape the bunkers according to Nicol Thompson’s original vision in a style that would minimize washouts and reduce the number of maintenance staff headaches. Other considerations included providing easier bunker access for members, installing liners to minimize sand contamination and improve drainage.

Bunker design

Cutten said it’s important to look at things bunker by bunker, asking why some are necessary or if they should be located elsewhere.

Reconsider fescue, path curbing

Andrew suggested it’s perhaps time to give up on fescue on golf courses, “unless you’re a really highend club and you can put in the amount of work that it takes to produce a fescue that is playable.”

He said there are other things that can be eliminated on golf courses to reduce time and labour such as curbing cart paths. Although curbs are meant to keep golf cars from straying from paths and damaging turf, they require edging which can be labour-inten-

Over the years, several different bunker styles became present at the Brantford Golf & Country Club.

sive. Cart paths tend to point toward play and require annual resodding of their exit points, he added.

Outdoor furniture such as benches gives golfers a chance to sit, but they must be moved to allow for mowing or trimmed around the legs.

These are things that tend to get in the way, Andrew argued, and they create needless tasks.

“We need to do away with some of the things we do on a yearly basis,” Andrew said.

Mingay’s sentiments about cart paths were similar to Andrew’s, adding he’d rather not see them at all. He noted a northwestern golf course that is open year-round has “wall-to-wall” cart paths to deal with the area’s extremely wet weather but suggested the course would be better off to invest that money on drainage.

Bunkers and trees often define the inside corners of dogleg holes, but there are other options to accomplish the same purpose, the architects agreed.

Bunkers are always secondary features on dogleg corners, Cutten said. Working with the landscape and shaping features of interest should come first, he added.

“It’s oftentimes more interesting than putting a bunker somewhere,” he said. “A bunker for your average player is a big deal. For a good player, it’s like it’s not even there.”

Bunkers today tend to be designed so that a ball entering the hazard rolls down into the middle, allowing golfers to hit their shots without great difficulty. Instead of a bunker, adding contour to a dogleg’s design gives the hole an interesting slope and changes the way a golfer hits the ball. The ball could lie above or below a golfer’s feet.

“Contour is one of those things

that has stood the test of time, and I think always will,” Cutten said.

Andrew said if mounds are adopted in favour of bunkers, they eliminate a course’s “disaster” maintenance. A significant rain event won’t be a big issue because it’s just grass, and nothing will be washed out.

A golf course that doesn’t have “stuff” won’t be an interesting course and will have few clients, he said.

“So, you have to have stuff,” Andrew said. “You don’t have to have super high flashes of sand and 220 bunkers. You don’t have to have that to be good.”

Mingay said mounds shaped in a

out caused by a heavy rain event. Working with the superintendent at the outset of a design or renovation project is important to achieve a common understanding of the maintenance ramifications a particular design might have.

“The earlier in the process I know that something I’m doing could be an obstacle, the earlier that we can talk through it and quickly resolve it is key,” he said. “At the end of the day when I leave, it’s the job of the superintendent to maintain what I’m doing and, if it’s not working, it’s going to change. I want to know that what I’m leaving behind is going to be successful and it’s only going to improve.”

“Contour is one of those things that has stood the test of time, and I think always will.”

dune-like fashion, with side slopes and dents, bear a “cool” look.

“Sometimes, the coolest-looking mounds mean you simply can’t just ride a rough mower over them,” he said. “You might have to send a guy over there with a weed whacker or a smaller push mower to maintain a cool-looking feature like that.”

Cutten acknowledged that bunkers can present a major labour issue in the aftermath of a wash -

The absence of bunkers not only frees up maintenance, but it also speeds up the game, Cutten added.

British and Australian thoughts

Most golf course maintenance in Great Britain and Australia is focused on greens and tees, where most shots are made, Cutten said.

“Everything else is maintained to a certain level,” he noted. “It changes throughout the year.”

Not only can trees cast shade for extended periods of time on golf greens, they are obstacles that maintenance staff must work around when mowing. Architect Ian Andrew suggests trees growing in key areas of a golf course should be removed.

In Scotland, the ball rolls further and golfers have more fun when fairways burn out during the summer.

“Golf is played in nature, and nature changes season to season,” Cutten said. “We’re sort of homogenizing one season to another, trying to have them all play the same versus accepting that this is a game played outside, and we should relish the changes that occur.”

Australian superintendents don’t understand North American maintenance practices because they maintain areas of a golf course where the ball “is supposed to go,” and don’t bother with areas not meant to be in play, Andrew said.

“It seems we have an overemphasis on maintaining where you’re not supposed to go,” he said. “That was their criticism of us.”

Great golf architecture is all about

angles, Mingay said, suggesting an ideal green design can set up angles that prevent “overbunkering” tee shots. Instead of decorating holes with bunkers, the challenge is to make a hole interesting without overdecoration.

Andrew said it’s the slopes, tight mowing and highly contoured greens that make Augusta National so challenging, and not its hazards.

“If you’ve got a really interesting green surface that’s very complicated and tilted to a particular side, you actually don’t need fairway bunkering,” he said. “The strategy and difficulty are set by the green itself. You don’t need smaller greens and you don’t need smaller fairways. You need less intrusions.”

The architects were asked how they would design a golf course with less

Back to Back in the Battle Against

maintenance in mind.

Mingay said he would make the course “interesting for the best and enjoyable for the rest” without decorating to the point where logic and practicality are abandoned.

Cutten said he would stick to the basics by routing greens and adding contours and drainage.

“It’s the nuts and bolts of what makes a great golf course good,” he said.

Andrew said he would cut down every tree possible.

“That would remove much of the maintenance and would actually be the most efficient way of reducing inputs and not having crap to mow around anymore. The more trees you get rid of, the more efficient you are, and the less labour you need,” he said.

Lawn Weed Killer

Grass Weed Moss Algae Killer

A primer for snow and ice pricing

Concepts and strategies for setting pricing of snow services for the coming season

By Mike Jiggens

Pricing for snow and ice services can be tricky.

Several considerations must be made by contractors to determine which method of pricing is best for him or her. Such factors include market rates, production hours, time and materials, contract types, and the actual cost of providing the service to customers.

Steve Steele, a financial practice leader with Bruce Wilson & Co. in Scottsdale, Ariz., shared his expertise about snow pricing with North American contractors during a recent virtually delivered webinar sponsored by the Snow and Ice Management Association (SIMA).

Market rates are used by all contractors to some extent, he said, suggesting they help determine a price range that lets contractors know if the rates they’re charging for plowing, hand removal or salting fall within the range the market has determined.

“Sometimes we fall into the trap of believing that market rates are the only way we can price,” he said.

Steele warned market rates by themselves should never determine how services are priced because each company has different costs for various inputs which all demand recognition for how prices are set.

“Don’t let the market tell you what you have to charge. Make sure what you’re

charging is based on the factors that are important to your company.”

Every contractor has production hours to sell, and this can be a good indicator of what a product or service’s base pricing should be, he said. If a contractor charges $60 an hour for hand removal and understands the job will take four hours,

the price should be about $240. Contractors must price correctly and ensure that hourly rates consider the cost of production, he added.

Time and materials pricing can represent a base for how snow contracts are written, Steele said, adding it provides the least amount of risk because contractors

SNOW & ICE

are charging for actual hours and materials on the job.

“If you don’t know what you’re supposed to charge, time and materials is a good way to make sure you’re not going to lose your shirt in terms of production.”

He cautioned, however, that contractors could potentially realize lower margins with time and materials pricing because they’re charging for actual time and materials at a predetermined rate for labour, materials and equipment. That rate could be lower than what they might be able to get in a per push, seasonal or flat rate contract.

Time and materials pricing could also come with a possible large administrative burden that’s needed to calculate invoice pricing. This is something newcomers to the industry should know, Steele said.

Flat rate contracts

Flat rate contracts are ideal because they provide consistent revenue, he said. Customers are told what they’ll be charged monthly during the snow season, no matter how many times snow removal services are rendered. The downside for this type of contract is that pricing is based on a “sometimes win, sometimes lose” proposition.

Steele said if contractors wish to consider a flat rate contract for a new customer, they should be viewed as three-year contracts. Perhaps the first year will see less snow for the contractor to remove which presents a “win” because his costs are far less than what the customer is being charged. The second year might be a “loss” for the contractor who might have to push

Types of contracts

Contractors need to decide about the type of contracts they wish to engage in with their customers

more snow than anticipated. The third year might strike more of a balance between the amount of snow to be removed and the terms of the contract.

Contractors should be aware, however, of such flat rate contract safeguards as abnormal storms that may fall outside of standard pricing, he said, adding a “blizzard clause” should be written into every contract.

“When you base that flat rate contract on normal snow conditions, it doesn’t take into account things that fall outside the contract. Make sure that you have some protections that allow you to charge more for blizzard-type conditions on top of that flat rate you’re charging.”

“Per push” contracts allow for consistent flat rate prices for single removal services, are easy to bill and can provide consistent revenue. If a “push” is determined by a snowfall amount of at least two inches, both the contractor and customer must know that the same rate will be charged every time it snows two inches or more. Steele said it’s important for contractors to master their production rates, noting that if they are unsure about the time it will take to remove two, four or eight inches of snow, and are simply guessing, they could face something that may haunt them the entire season.

“An incorrect calculation of the required labour and materials isn’t something you’re going to eat just one time. You’re going to eat it every single time you perform that snow removal service for that property.”

Such a dilemma can be prevented by knowing how much time and material are needed on a per push basis.

Flat rate contracts can work for or against the contractor, depending on the number of snow events that occur during the season.

Priority and minimums

An inverse relationship generally exists between priority and minimums, Steele said. Customers with a low minimum removal, such as zero tolerance, are typically given the highest priority. A homeowner’s association (HOA) that has a four-inch minimum push are likely to be a lower priority for the contractor. Minimums must be factored into pricing, he said. If the same HOA wishes to be a high priority customer for a four-inch push, the contractor may need to charge more or establish that the customer won’t be first in line.

Inputs including labour, equipment and fixed overheads must be factored into pricing along with such other considerations as equipment maintenance costs and sub-contractor costs. Steele said if a contractor sets his prices higher than those of his competitors, he might “price himself out of the market.”

For many contractors, snow removal services are an add-on component of seasonal landscaping services. Snow budgets should be separated from “green” budgets, Steele said.

“There’s a good reason for that. Snow is fickle. You never know from year to year whether you’re going to have a good snow year or a bad year.”

By balancing out a green budget so that performed services are profitable at a desired level without the need to factor in snow revenue, contractors should be safe in any year. Contractors should avoid falling into a trap where they demand high snowfall amounts to cover their profit margins and overheads, he warned.

From time to time, contractors will have to contemplate price increases for their customers. The “do nothing” approach may be favoured by the customer who is apt to remain loyal to the contractor if he continues to provide quality work, but opting not to increase his prices is the worst business decision a contractor can make, Steele said.

One strategy contractors may consider is a blanket amount increase in which pricing is increased by a certain percentage across the board to all or most custom-

ers. Although it’s better than doing nothing, contractors who implement a blanket amount increase tend to be influenced by the amount they think the market will bear rather than thinking critically and acknowledging the amount needed to

maintain margins and offset the increased costs for labour and materials, he said.

A third option is a minimum increase based on the producer price index (PPI). Steele said the reason PPI is considered rather than the consumer price index

IN-FIELDER

“Time and materials is a good way to make sure you’re not going to lose your shirt”

(CPI) is because it’s based on the cost of finished goods, considering the increased costs of such inputs as labour and materials.

The most recent PPI, which came out in April, was the largest increase ever on record, he said, emphasizing how critical it is to pass along some type of increase to the customer. Even if the entire amount can’t be passed along, a compromise must at least be reached.

“The biggest strategy for increasing prices is a combination of your profitability goals internally and a recognition of what your increased costs are, and then balancing them out with what you believe the market

will bear in terms of increased costs to the client.”

Market considerations also factor into pricing and contract types. Understanding the types of properties he services, a contractor may realize that a per push contract isn’t something he can sell in his market, forcing him to consider other contract options.

Snow sales and operations are a year-round process and shouldn’t be placed on the back burner until the end of the green season, Steele said. Delegating snow sales and other related tasks to full-time staff throughout the year “will make that transition into the snow season a little bit smoother for you.”

Snow customers are aware of today’s rate of inflation and will likely expect a price increase, he said, but when discussing renewals with them, the conversation shouldn’t be focused on price alone. A positive spin should be placed on the renewal discussion.

“Maybe it’s a better service or higher quality. Maybe it’s better quality of staff through training. Whatever it is, make sure you put a positive spin on that for your client base.”

INDUSTRY INNOVATORS

Buck Storlie is product manager for ASV Holdings Inc., a Yanmar compact equipment company that designs and manufactures a full line of compact track and skid-steer loaders primarily for the landscaping, construction and forestry markets.

Operators peg comfort as #1 priority

Less fatigue means more production when operating track loaders and skid steers

By Buck Storlie

For more than 25 years, Tim Fredericks has been designing irrigation systems. On Friday, Nov. 18, the partner in Fredericks McGuire Ltd., based in Bolton, Ont., shared his experiences in the field with the members of the Manitoba Golf Superintendents Association as one of a roster of speakers at the annual Manitoba Golf Superintendents Association annual general meeting.

Comfort while operating equipment used to be more of an afterthought. That all seems to be changing. Based on a recent survey from a top manufacturer, comfort is the No. 1 factor customers look at today when considering which configuration of a compact track loader or skid steer to purchase.

And it doesn’t take much contemplation to see why. Manufacturers across the board continue to up the ante with modern comfort features, meaning operators have become accustomed to a certain level of luxury, especially in the last few years. For the design/build landscape construction business owner struggling with employee recruitment and retention, having equipment that is enjoyable to operate could make all the difference in maintaining a strong, reliable crew.

Let’s not forget productivity. Operators who are comfortable experience less fatigue, allowing them to not only spend

more hours in the cab in a day, but to be more alert while they work, increasing both productivity and safety.

Options for comfort features on modern compact track loaders and skid steers are plentiful. Understanding the options available can help contractors choose the best configurations to maximize their investment in both comfort and productivity.

Creature comforts

Inside the cab is where comfort features are most obvious. Most newer models of compact track loaders and skid steers have suspended seats, adding at least a minimal buffer between the operator and the machine’s frame. Many manufacturers now offer air ride seats for even better protection for the operator, whether standard or as an option. Some brands take it a step further by adding full adjustability. These innovative sets allow adjusting of recline, slide, weight and even

the four-way arm rest, allowing for a comfortable fit for any body type.

But cab comfort doesn’t stop with the seat. The integration of a single-sided lap bar enhances comfort further as opposed to the more cumbersome and restricting overhead lap bar design. A single-sided bar frees up space around the operator’s waist and makes entry and exit easier.

Roominess in the cab is primary feature for accommodating multiple operator body types and for comfort during long hours in the cab. While the maximum possible cab space will, by necessity, be limited by the size class of the machine itself, some manufacturers use strategic engineering to squeeze in every inch of operator space they can. The resulting cabs make even the smallest sit-in compact track loaders and skid steers far more comfortable than designs where cab roominess was less of a priority.

Other modern features may not affect the

Operators who are comfortable experience less fatigue, allowing them to not only spend more hours in the cab in a day but to be more alert while they work, increasing both productivity and safety.

INDUSTRY INNOVATORS

cab comfort or ergonomics but certainly impact the overall experience. These added features can include Bluetooth radios, speaker quality and placement, USB charging ports and cell phone trays and chargers.

Visibility & ergonomics

Ease of operation and visibility play significant roles in operator comfort. Intuitive controls, minimal ergonomic inefficiencies and high visibility can make the operator more productive and less fatigued at the end of the day.

Visibility is one such attribute of a compact track loader or skid steer that can improve operator comfort and safety. More visibility means operators don’t have to shift their bodies around as much to get a better view, whether it’s of the attachment, proximity to obstructions or other individuals on the jobsite.

Clear visible area is one of the biggest factors of visibility. Some modern compact track loaders and skid steers have floor-to-ceiling visibility, including all-clear sides and frameless doors. These machines rely on advanced engineering, such as high-strength polycarbonate glass and strategic configurations to pull off almost 360-degree visibility while retaining the same level of operator protection as previous designs.

Ergonomics should always be part of the discussion when considering ease of use. Factors like intuitive switch placement, adjustable joystick controls and control panels may seem like small touches, but make all the difference when repeating the same actions hundreds of times a day. When trying out equipment, pay attention to the accessibility of these features.

Ride quality

To work comfortably and effectively for long periods of time, operators must be able to endure the

ride. For both skid steers and compact track loaders, ride quality starts from the ground up.

When looking at compact track loaders, contractors can think of undercarriages in two main categories: rigid and suspended. Rigid-mounted undercarriages, also known as solid mounted, typically provide little to no suspension, transferring the effect of bumps through the entire machine and to the operator.

For the reasons mentioned, suspended undercarriages are becoming more and more popular. But not all suspended undercarriages are the same.

One of the most advanced options a contractor could find is known as dual-level suspension, found on some mid- and large-frame modern compact track loaders. This style of undercarriage features not only the independent torsions between the undercarriage and the chassis, but also torsions allowing bogie wheels to flex with the track.

This configuration keeps more track on the ground, improving operator comfort, traction and machine performance, and keeps more material in the bucket. Some designs maximize this advantage using tracks with a polycord internal as opposed to steel for the best possible ground contact. The flex-

ing track can morph around smaller obstacles like rocks, sticks or debris, minimizing rocking of the entire machine that can occur with rigid or single-level suspensions.

Skid steers are a little simpler when considering ride quality options since their designs are less complex and varied than their tracked counterparts. Two major factors affect ride quality: tire choice and wheelbase. Premium tires that provide an air tire feel with flat-free functionality offer the most comfortable ride.

When considering wheelbase, longer means more stability and a more comfortable operator. A short wheelbase results in the machine’s tendency to buck and hop, tipping back and forth drastically on virtually any terrain with imperfections. A long wheelbase, by contrast, provides a flatter and more stable platform with less jarring for the operator.

Bringing it home

With so many comfort features and options available on modern skid steers and compact track loaders, it can seem overwhelming for the contractor to decide which machine to bring home. But taking the time to evaluate which features make the most sense for a contractor’s business is undoubtedly worth the effort.

Dual-level suspension systems feature not only independent torsions between the undercarriage and the chassis, but also torsions allowing bogie wheels to flex with the track. This configuration keeps more track on the ground, improving operator comfort, traction, machine performance, and it keeps more material in the bucket.

Mitch Davidson

Southern Alberta, Kootenays mitch.davidson@target-specialty.com 587.223.2083

Jason Hooper

Lower Mainland & Interior Bc jason.hooper@target-specialty.com

604.317.2476

Chris Paterson

Southern Alberta & Kootenays chris.paterson@target-specialty.com 403.540.0157

Eric Gratopp

Northern Alberta eric.gratopp@target-specialty.com 587.284.4744

Gregor Kowalski

Vancouver Island gregor.kowalski@target-specialty.com 250.686.3909

Josh Seibel Saskatchewan & Manitoba josh.seibe@target-specialty.com 306.861.8296

Mark Scenna Sales Manager, Canada mark.scenna@target-specialty.com • 416.458.2396

Perry Brazeau Toronto / East perry.brazeau@target-specialty.com 416.705.8006

Jason MacRae Quebec North & West jason. macrae@target-specialty.com 514.712.8006

Chris Nelson Toronto West / Niagara chris.nelson@target-specialty.com • 647.382.6868

Better soil health aids climate change

Soils have the potential to offset the footprint of greenhouse gas emissions

By Mike Jiggens

As Canada and the world strive to significantly reduce greenhouse gas emissions in hopes of meeting targets set for 2030, professionals employed in the turfgrass industry can play a key role in helping to achieve this goal.

The Compost Council of Canada, in partnership with the Soil Conservation Council of Canada, have developed a “roadmap” for Canada, entitled, “Recruiting Soil to Tackle Climate Change.” The document outlines how the agricultural and turfgrass sectors can enhance soil health by including beneficial organic amendments, including compost, in their programs and keeping soil organic carbon in the soil.

Glenn Munroe, manager of special projects with the Compost Council of Canada, spoke in January at Landscape Ontario’s virtually delivered Landscape Congress, highlighting the document and explaining the benefits of carbon sequestration as a means of fighting climate change.

The report notes that soils have the potential to completely offset agriculture’s greenhouse gas emissions footprint.

He acknowledged the problem facing the world today is that most of the carbon formerly found in the ground – in fossil fuel deposits – is now ending up in the atmosphere. It is estimated there are

about 750 gigatonnes of carbon in the atmosphere at any given time, and the number continues to rise. Significant amounts of carbon are found in fossil fuel reserves and, as they’re burned, carbon is being added to the carbon cycle at extraordinary levels.

“And that creates a problem,” Munroe said.

The earth is currently “running a fever” with climate change, especially in the north, he added. Temperatures are rising in the polar regions at a faster rate than in other locations around the world.

Weather extremes have become commonplace in recent years, and more are likely to be experienced in the years to come, he predicted.

The urgency directed at ending the heating up of the planet is based on these weather extremes as well as the melting of glaciers, the acidification of the oceans and other climate change-related issues.

Munroe said science suggests about a tonne of carbon for every hectare of every year can be sequestered in the ground. Using an industry analogy, he said one golf course could conceivably reduce

The carbon cycle vector illustration

ECOLOGY

Visit one of these participating Exmark Dealers to learn more about the full line of professional Exmark models.

ALBERTA

CALGARY

ALBERTA FOREST & GARDEN EDGE EQUIPMENT LTD FUTURE AG INC

BRITISH COLUMBIA

ABBOTSFORD

FORESHORE EQUIPMENT AND SUPPLY . CHILLIWACK OUTDOOR POWER EQUIP PILON TOOL RENTALS 1972 B & L SMALL MOTORS LTD SAVOY EQUIPMENT ................ ARROW EQUIPMENT LTD HI-WAY POWER AND MARINE LTD

403-248-0878

780-455-3343

403-343-6101

604-313-0251

604-744-0547

250-338-5361

250-376-0033

250-868-1010

604-987-9926

250-248-3621

MANITOBA

NEW BRUNSWICK

BOUCTOUCHE . . IRISHTOWN . . . . B.M. MARINE INC .................. SMALL ENGINE HOSPITAL INC

NOVA SCOTIA

MILFORD . . . . . THE TRACTOR DOME INC

ONTARIO

HURON TRACTOR LTD ...............

MERCER MOBILE EQUIP REPAIRS

BRADFORD RENTAL SALES & SERVCE

GREEN TRACTORS INC

BOBCAT OF BRANTFORD INC .........

B.R. DICKSON EQUIPMENT INC .......

CHATHAM OUTDOOR POWER

BRUCE SERVICE

MARTIN’S SMALL ENGINES LTD

CAMPEAU OUTDOOR POWER EQUIP ....

HURON TRACTOR LTD

A.S.E. EQUIPMENT/CARTWORLD INC

OUTDOOR SUPPLIES & EQUIPMENT

MUSKOKA AUTO PARTS LIMITED ......

ZEHR’S SALES AND MANUFACTURING ..

WPE LANDSCAPE EQUIPMENT

W.E. ENTERPRISES LTD

MITCHELL CYCLE INC ...............

PRICELESS PRODUCTS LANDSCAPE ...

506-743-8566

506-854-2807

902-758-2220

519-666-2300

705-503-3535

905-775-7101

905-846-2511

519-752-7900

905-331-5040

519-354-3990

519-363-6345

519-669-2884

519-727-5031

519-285-3845

519-820-9708

905-578-2411

289-963-9666

519-595-7579

905-569-2055

905-629-1424

519-348-0490

416-410-2158

carbon emissions by about 48 tonnes annually.

The five principles

There are five principles involved to help make this happen, he said. The first is to keep live roots in the ground. Growing vegetation draws carbon dioxide from the atmosphere.

“The more carbon photosynthesized, the more ends up in the soil where the soil organisms can do their work.”

Soil disturbance should be kept to a minimum.

“Disturbing the soil in any way is like wrecking somebody’s home,” Munroe said about the second principle.

When soil is disturbed, a complex ecosystem is broken up and important fungi can be significantly damaged. Occasionally, soil must be disturbed, such as when planting a tree, but it should otherwise be kept to a minimum, he said.

The third principle is to optimize inputs which includes using compost and proper amounts of nutrition.

“Excess nutrients in the soil is a recipe for losing your carbon.”

Promoting diversity in the soil is the fourth of five principles. Munroe said diversity above ground leads to diversity below the surface.

The fifth principle, he said, is to ensure the soil remains covered. If it isn’t, weather will affect the organisms living in the soil, and they will either die or become dormant.

Soil should act like a sponge, Munroe said, noting that when rain falls, water must fill the holes to prevent runoff and flooding. Soil structure, therefore, should be “crumbly” and aggregated, he said.

“Healthy, well-structured soils will sequester more carbon.”

Without well-structured soils, populations of beneficial soil fungi will be sparse, Munroe said, cautioning that synthetic inputs – especially fungicides – can be detrimental if not used carefully.

“They kill the bad buys, but they also kill the good guys.”

If good soil health can be achieved, fungicides may not be necessary, he said, adding fertilizers must be used appropriately and carefully. By soil testing regularly, only certain inputs will be needed.

Munroe urged the input of compost tea extract and the mulching of grass clippings when maintaining turf, noting compost helps to build and sustain fungal populations and, by association, soil structure.

PETERBOROUGH

M.C. POWER SPORT

ALPINE LAWN & GARDEN EQUIP

DBA MCGILL EQUIPMENT

CAMPBELL’S OUTDOOR POWER EQUIP. .

HURON TRACTOR LTD

M.R. BLAIS SALES & SERVICE INC

A TO Z RENTAL CENTRE

VEHICLE VENTURE .................

SASKATCHEWAN

SASKATOON . . . RST MAINTENANCE INC

705-748-5189

416-292-8900

416-751-4455

519-245-2428

519-285-3845

613-443-1230

519-885-5590

519-966-8642

306-492-2599

“It brings you good levels of beneficial fungi.”

Those who manage soils can help control climate change by sequestering carbon. It’s the soil’s organisms that are doing the work and helping to mitigate climate change, he said, adding that failure to create a soil sponge without good soil structure will require having to continually add inputs.

The use of compost will make the effort work better and more carbon will be sequestered, he said.

To download a copy of “Recruiting Soil to Tackle Climate Change,” visit http://www.compost.org/wp-content/uploads/2022/04/Recruiting-Soil-to-Tackle-Climate-Change.pdf

It will soon be time to winterize equipment

By Chris Isaac

It won’t be long before the leaves start changing colour and the temperature starts to drop. With winter’s return just around the corner, knowing when and how to winterize your equipment will ensure that it keeps working as hard as you this winter.

Winterization is the process of preparing your equipment for winter conditions, either to continue working in the cold or to be stored until the weather warms up again and you get back to work. In general, winterization is one of the most important pieces of regular maintenance to do on your compact equipment, especially if you need it to perform in the cold and harsh conditions of a Canadian winter.

The main reason to winterize equipment is to prevent internal engine corrosion and deterioration, but it also provides a perfect opportunity to clean equipment and to identify and repair any damage and wear that have occurred over the summer.

When to start winterizing your equipment depends a lot on where in the country you are and what the forecast is. A good rule of thumb is to start winterizing your equipment when the frost starts to hit the ground.

Once the conditions indicate that it is time to start preparing for winter, the best

way to start is to conduct the routine maintenance. Seasonal maintenance should be conducted regardless of temperatures to ensure the smooth running of equipment, but it is especially important as part of your winterization checklist. Checking and changing fluids and filters, and potentially even changing fluid types to one designed to perform in freezing temperatures is a must. Each climate is different so you should check the owner’s manual for your equipment on what fluids to use.

A good example of the importance of changing fluids comes in the fuel tank. In some colder regions, it’s necessary to change from the typical No. 2 Diesel (2-D) to No. 1 Diesel (1-D) for the snowy months. This change is done to prevent fuel gelling and ice crystals forming. However, in some cases a blend of 1-D and 2-D may be the most appropriate. If you aren’t sure what fuel or fuel blend your equipment needs, check the owner’s manual as it will have information

on what your specific equipment needs. When thinking about winter operation, coolant probably isn’t the first thing that comes to mind. However, even in the winter, it is important that the equipment’s cooling system is operating properly. Check to ensure you have proper coolant levels. Always use the manufacturer’s recommended mixture, testing the antifreeze to ensure it is the appropriate mixture.

Another fluid that needs to be checked is the oil. Cold, thick oil takes a toll on engines as they start up. When operating in the winter, thinner oil can make a big difference on the performance of your engine. A lower viscosity oil flows better within the engine when the temperature drops.

Removing summer implements

The annual winterization maintenance is also the time to remove summer implements, such as mowers, and install the winter ones. Summer implements should

Winterizing prevents internal engine corrosion and deteriorating equipment

Equipment needs to be winterized, whether it’s to keep working during the winter months or if it’s to be stored until the spring.

Chris Isaac is an outdoor power equipment industry expert with Kubota Canada.

be cleaned and have annual maintenance performed before putting it into winter storage. The winter implements can be attached and should be inspected and tested to ensure proper function before the first snowfall.

It’s also a good idea to test the battery as part of the winterization maintenance. As the weather gets cold, batteries lose their crank ing power. This will be compounded if the battery is already old, with reduced performance. Additionally, parasitic draws will slowly drain the battery of energy when the equipment isn’t in use. If the equipment isn’t used regularly in cold temperatures, it is a good idea to use a battery maintainer.

If the equipment is stored outside for long periods of time, it is good practice to remove and story the battery indoors to extend its lifespan. If you need to test your battery, most agriculture and automotive dealers will test a battery for free, or a battery tester can be purchased. Checking the battery now will make sure the engine starts in the winter when you need it to.

Once the flurries fly, there are a few additional points to keep in mind. Whenever possible it is best to store equipment indoors, ideally somewhere heated. Keeping your equipment inside a building or shed will reduce the winter strain on it. If the equip ment can’t be stored in a heated garage, make sure to leave enough time to allow the machinery to properly warm to above 40 degrees Celsius before starting work. The engine will function better when warm. Just like in your car, adding a block heater to your equipment will shorten the time needed to warm up the engine as well as help with cold starting performance.

While it can be time-consuming, setting aside the time to inspect your equipment on a daily basis can be critical for oper ating in the winter. It can be tempting, when the temperature drops, to just get to work so you can be done sooner and get out of the cold. No matter how cold, it is always worth it to take the extra time to complete daily cleaning and inspections. This will help you identify and fix small problems before they have the

chance to turn into major ones.

It’s important to be particularly diligent in examining fluid hose lines regularly for cracks – cold wintery conditions put added stress on hoses, which often can crack in very cold temperatures. Also be sure to inspect oil and grease lubrication, coolant, fuel levels, battery function and the undercarriage, removing any excess snow, ice and salt that has built up. Cleaning the undercarriage and other areas of buildup is also essential if operating in salty conditions.

In addition to clearing off salt residue, the regular application of undercoating to the frame and metal components at the end of the workday will keep your equipment in top condition.

By catching problems when they are small, you can prevent major breakdowns and keep you and your equipment working not just for the current winter, but for the winters to come. From giving your equipment a thorough cleaning, washing away built-up dirt, grass and debris, to checking the engine fluids, filters and tire pressure, properly preparing your equipment for the arrival of winter conditions is one of the most important things you can do to ensure the long-term performance of your equipment.

Winterizing also allows for identifying needed repairs to equipment.

Good user group relations are vital

Parks manager says solid relations can help free up funding. (First of two parts). By Mike

Jiggens

Rory Doucette recently began his third career position directing the needs of a municipality’s parks and recreation department. Having previously served in the same capacity in Oakville and Waterloo, Welland’s new manager of parks and open spaces says it’s a good idea to become acquainted as early as possible with a municipality’s user groups, its field inventory and its council members.

Doing so will not only build positive relations with key people but may free up funding for facility improvements.

Speaking in February at the virtually delivered Ontario Turfgrass Symposium, Doucette cited community involvement as one of his first considerations upon arriving in Welland, suggesting that’s where the money comes from.

Among his first orders of business was to reach out to the city’s user groups and schedule meetings with them.

“Those meetings are important because I’ll find out what they need, I’ll find out

what we do well and what we do poorly and find a way to reach common ground so that we can work together,” he said.

Such meetings should never be adversarial because everyone is part of the same team, Doucette said, adding input from user groups provides him with more ammunition when he stands before council to ask for money to fund new fields or upgrade existing facilities.

Taking advantage of social media is another way to help get needed funding, he said. Using Facebook, Twitter and other platforms to promote local tournaments and give shoutouts to championship-winning teams helps to boost the city’s image. It is helped even more when photographs are posted that depict the tiptop conditions of the community’s sports fields.

“It’s all about that positive imaging,” Doucette said, adding council appreciates knowing the value it brings to the city.

When a municipality plays host to a major provincial or national tournament, it’s a community boon as such businesses

as restaurants, gas stations and hotels and motels prosper. Acquiring fields that can adequately accommodate such tournaments or upgrading existing facilities so that they’re able to handle larger-scale events, directly benefit a municipality.

Parks and recreation departments function differently from one municipality to another and may have differing policies and cost structures.

Welland, for example, didn’t have an inclement weather policy in place for its sports fields when Doucette became its parks and open spaces manager. It was a shortcoming he was determined to fix as soon as possible.

“If people are going to play and hurt themselves on your field because the weather is poor, that’s not ideal, but the worst piece of that is they’re paying anywhere between $15 to $30 – depending on your municipality – for an hour of play, and in that hour, they’re going to destroy your field and it’s going to cost you thousands of dollars to repair it.”

It’s important for parks and facilities managers to work closely with their user groups to keep everyone satisfied with their amenities and field needs.

He suggested field inspections should be made at least once a month to avoid potential litigation, and that everything should be documented and saved for up to seven years.

“Everyone finds a reason to sue. If you’re not doing your inspections or you’re not doing your preventative maintenance, or your due diligence and you lack the ability to prove that, your municipality will pay for it.”

The need for field safety

Field safety cannot be overlooked, Doucette said. This can be achieved through regular inspections and detailed documentation of the time spent on field maintenance.

Playable sports fields are the product of healthy turf. A key strategy for maintaining sports fields used primarily for soccer is to periodically shift the nets so

that worn goal mouths have a chance to recover.

During his time in Oakville, Doucette shifted nets forward, backwards or left and right about six feet every couple of weeks, allowing time for goal mouths in their previous position to recover.

This approach, however, is highly dependent upon a field’s initial planning, he said. Concrete pads laid too close to the field negates the ability for shifting.

On Oakville’s major fields, shifting was done about six times during the season, allowing for the necessary cultural practices to take place.

To properly shift a field, painted lines must have faded so that field dimensions aren’t thrown out of sync.

“Make sure you deliver on that. If you tell your painters not to go out and you

don’t shift that field when you’re supposed to and you have no lines on the field, you’re going to hear about it.”

When coming from another community, it’s important for a parks manager to “dig into” his new municipality’s history to obtain information he can use to streamline his operations.

“As someone who has changed municipalities twice now, it’s vital to have that information, which is lost most of the time, so you have to go searching for it.”

Much of his time is spent bringing older facilities up to code to ensure they are accessible.

In the second part of this story, to be published in the August/September issue, Doucette talks more about user group relations, the means to achieve healthy turf, field lighting and obtaining necessary funding.

The updated Third Edition of Sports Fields: Design, Construction, and Maintenance is a comprehensive reference for professionals who are responsible for the design, construction, renovation, and maintenance of athletic facilities. This book contains illustrative examples of specific design elements of the most popular sports facilities. This Third Edition contains new chapters on safety, public relations, and professionalism for future sports field managers, as well as fresh drawings and photos that highlight innovative field layout, grading, irrigation, and drainage. Allnew case studies review best practices and techniques for sports fields ranging from youth and high school fields to fields that are designed for professional athletes.

New stuff

The Muckster II Mid boot and Originals Ankle boots are designed for women involved in outdoor work who wish their feet to remain dry and comfortable. Both are products from the Original Muck Boot Company.

The Muckster II Mid features rubber outsoles that are designed to easily shed debris and provide great multi-surface traction. They are designed with a fold-down upper to wear at two different heights. Whether it’s gardening or other outdoor activity, the boots easily slip on and off. They can be worn rolled up to highlight a subtle wheat print or rolled down to reveal a deep purple interior lining. The boots’ primary colour is a muted clay. They are 100 per cent waterproof, featuring a four-millimetre neoprene bootie for comfort and performance and a breathable mesh sandwich-fabric lining to improve air circulation. Their self-cleaning rubber outsole is built for work in the lawn or garden. An added feature is its bioDEWIX footbed insert topcover with NZYM for odour control and moisture management. Lightweight and offering sturdy foot support, their

temperature comfort zone ranges from sub-freezing to 18 degrees Celsius.

The Originals Ankle is inspired by the iconic chore boot and is a collection of light-duty, yet essential footwear. Their full neoprene booties are wrapped in soft, hand-laid rubber for comfortable, 100 per cent waterproof protection. The easy on/off design and durable outsole with breasted heels offer traction, style, and performance for outside tasks.

The footbeds’ bioDEWIX antimicrobial odour and moisture management insert keeps wearers fresh all day. The boots feature 3D Airmesh linings for breathability and a molded PU insert with memory foam for superior underfoot comfort. www.muckbootcompany.ca

Safety footwear offers day-long comfort, breathability, traction

KEEN Utility’s new Vista Energy Shift safety footwear offers professionals the safety they need on the job as well as the comfort they require to complete a full workday.

Its lace-less design makes slipping the shoes on and off a breeze. The CSA Vista Energy Shift builds on the success of its predecessor. The footwear is built for fast-paced indoor work environments where convenience, comfort, and agility are critical.

This next generation of work sneaker features a breathable, lightweight two-layer engineered mesh upper that delivers an ideal blend of athletic performance without sacrificing safety. The shoes include a KEEN.ReGEN midsole that returns 50 per cent more energy than standard EVA foam, an oil- and slip-resistant outsole with water-diverting channels to maximize surface area and to improve traction. The soft, plush upper heel prevents painful chafing of the Achilles tendon common in footwear that has yet to be broken in.

The Vista Energy Shift is non-metallic, featuring a flexible woven textile puncture-resistant midsole plate as well as asymmetrical carbon fibre toes that are 15 per cent lighter than traditional steel while providing a more unobtrusive fit.

The footwear is available for both men and women.

www.keenfootwear.com

Commecial walk-behind mowers tackle tough jobs with ultra-maneuverability

Bobcat Company has an all-new WB700 commercial walk-behind mower lineup that made its initial debut at the 2021 GIE+Expo show.

The WB700 is an ultra-maneuverable, powerful solution equipped to tackle tough turf jobs. The WB700 comes in three width options (36-inch, 48-inch and 52-inch) to give contractors added versatility in rounding out their grounds maintenance equipment lineup.

“Owners will be able to shred grass and tough turf with ease thanks to the ultra-powerful Kawasaki FS series engine, operator-friendly controls, and updated hydraulic transmissions,” Ron Scheffler, senior product manager at Doosan Bobcat North America, said.

The WB700 is uniquely designed with a commercial floating deck, which allows the operator to adjust the height without the need

to unbolt any components and saving significant time. With ease of maintenance in mind, the WB700 comes equipped with a tool-free oil drain and deck access, as well as a handy external oil filter location and easy battery access. The five-gallon fuel tank means many hours of mowing before a fuel-up is needed.

Thanks to easy-to-use ergonomic controls, the WB700 is built from the ground up to maximize operator comfort, day-in, day-out.

With a unique bullhorn design and reliable TufDeck cutting system, the mower allows grass to pop up quickly for an outstanding quality of cut, increasing efficiency with fewer passes.

In addition, the WB700 comes equipped with a hydraulic drive and innovative Hydro-Gear ZT-2800 hydrostatic transaxles, which deliver smoother, simpler operation with heavy-duty torque output and comfortable ground speeds up to 6.5 mph.

The WB700 has a 1.5-inch x 2.5-inch, 11-gauge structural tube frame. It also features a seven-gauge engine mounting plate and reinforced box section. The frame accepts a sulky to easily transform the WB700 into a stand-on mower for increased comfort. The 20-inch drive tires provide ample ground clearance to minimize ground disturbance. www.bobcat.com

Health & Safety

By CCOHS

The Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well being of workers in Canada by providing information, training, education, systems and solutions that support health and safety programs and injury and illness prevention. www.ccohs.ca

Preventing heat-induced illnesses

Lana works at a golf course, where she spends most of her time outside. On hotter days, she finds it more challenging to perform her daily tasks. These are tasks she is used to doing, so why would they be harder to perform in the heat? Working outdoors in the summer months can be taxing on the body, and the exposure to heat can even be dangerous. Workers like Lana who are potentially exposed to extreme heat conditions may be at increased risk of heat stress. Heat stress is a combination of body heat generated from the effort exerted while working, the clothing and equipment being worn, and the environment. Air temperature, humidity, air movement, radiation from the sun, and hot surfaces or sources can all affect the worker’s environment.

Most people feel comfortable when the air temperature is between 20°C and 27°C and when relative humidity ranges from 35 per cent to 60 per cent. When air temperature or humidity is higher, we may feel uncomfortable, but our bodies can cope with a little extra heat. However, very hot environments can overwhelm the body’s natural cooling systems, leading to serious and possibly fatal conditions.

Five illnesses caused by heat exposure

All workers are at risk of heat-related illness. However, workers at greater risk include those who have pre-existing health issues, are over 65 years old, or take medications that may affect how their body reacts to heat. Having skin diseases can also make people more susceptible to heat illness, as it might affect the body’s natural ability to regulate its temperature.

Heat puts workers at risk for illnesses such as heat edema, heat cramps, heat syncope, heat exhaustion, and heat stroke. Heat can also lead to incidents resulting from the slipperiness of sweaty palms or contact with hot surfaces. As a worker moves from a cold to a hot environment, fogging of eyeglasses can briefly obscure

Very

hot environments can overwhelm the body’s natural cooling systems

their vision, presenting a safety hazard.

Heat edema is swelling which generally occurs among people who are not acclimatized to working in hot conditions. Swelling is often most noticeable in the ankles. Recovery occurs after a day or two in a cool environment.

Heat cramps are sharp pains in the muscles that occur when there is a salt imbalance. Cramps occur most often when drinking large amounts of water without enough salt (electrolyte) replacement.

Heat syncope occurs when people feel dizzy or lightheaded, or faint suddenly and lose consciousness. It can be caused by blood pooling in the legs (which lowers blood pressure), or by the loss of body fluids through sweating. It occurs mostly among unacclimatized people. Resting in a cool area usually brings about a quick recovery.

Heat exhaustion is caused when a worker loses body water and salt through excessive sweating. Signs and symptoms of heat exhaustion include heavy sweating, dizziness, intense thirst, nausea, headache, vomiting, diarrhea, and tingling and numbness of the hands and feet. People usually recover after resting in a cool area and drinking cool drinks, such as water, clear juice, or sports drinks.

Heat stroke is the most serious type of

heat illnesses and requires immediate first aid and medical attention. Signs of heat stroke include body temperature of more than 41 degrees Celsius, and complete or partial loss of consciousness. Sweating is not a reliable symptom of heat stress because there are two types of heat stroke –“classical” heat stroke where there is little or no sweating (usually occurs in children, the chronically ill, and the elderly), and “exertional” heat stroke where body temperature rises because of strenuous exercise or work, and you do sweat. Heat stroke can cause death if medical treatment is delayed.

Prevention tips for employers

Every year, Canadian workers are at risk because of heat-related issues. As an employer you must manage this risk – evaluate the situation and determine appropriate controls. A heat stress control program can help reduce the risk by managing work activities so that they match the employee’s physical condition and the environment.

Provide workers with training on the health risks of heat illness, how to avoid it, how to recognize the symptoms and what to do if it happens. Provide first aid attendants with training in heat stress response measures.

Keep workers cool and hydrated and allow some flexibility in work arrangements during hot conditions. Schedule heavy tasks and work that requires personal protective equipment for cooler times such as early mornings or evenings. When working outside, take frequent rest breaks and provide at least a shaded, cool area, but air-conditioned rest areas are preferred where possible. Provide plenty of water and encourage workers to drink even if they don’t feel thirsty.

Heat illness is a serious but preventable health risk. Workers like Lana should be trained on the dangers of heat exposure and how to look out for signs and symptoms in themselves and others, and how to get first aid. And don’t forget to equip your crew with resources to help keep them safe while working outside this summer.