turfandrec.com

turfandrec.com

The FSA 135 R is the latest brushcutter in our battery-powered line-up that can be used in noise-sensitive situations. It is a lightweight, powerful and efficient choice for landscapers, municipal workers and those that have large yards to upkeep. The AP battery can be inserted directly into the powerhead, as opposed to using an adapter system. The ergonomic loop handle makes it comfortable to operate and easy-tomanoeuvre, while also providing a three-step speed adjustment with LED light. Built with a metal mesh air filter, it delivers a longer service life and provides optimum motor cooling. Also, a wide selection of cutting attachments can be used on the FSA 135 R to suit the job at hand.

NOTE: Bike handle version also available.

① Battery and charger sold separately. ② Weight without battery.

Battery Power. Made by STIHL.

STIHL’s Pro-Fleet Commercial Landscape Program is designed to provide commercial landscapers a volume discount on major purchases of five or more landscaping power tools. Visit your STIHL Dealer today to find out more and take advantage of the savings!

04 | From the editor

Yet another year of virtual conferences 30 | Health &

Mask up to keep your guard up this winter

The challenge of switching grasses at Pinehurst No. 2

Conversion to bermudagrass greens from bentgrass has paid off, superintendent says

06 | In the news Conference’s virtual format provides for greater value 17 | Industry innovators ‘Mini pitches’ help fill void in urban areas

By Mike Jiggens

It seems I was a bit overoptimistic when I penned my previous editorial in the November/December 2021 issue, gushing about the return of in-person industry events. At the time it was written, the term “Omicron” was barely spoken, and the pandemic forecast was beginning to look a little sunnier.

Winter is traditionally the conference and trade show season in this industry, and some organizations were proceeding with plans to bring back in-person events following a pause in 2021. Such groups included Landscape Ontario, the Canadian Golf Superintendents Association, the Ontario Golf Superintendents Association and the Western Canada Turfgrass Association. South of the border, the major industry players were all in for in-person events this year.

As Omicron began its rapid spread, however, it forced organizers of some of these events to retool their plans. The conference portion of Landscape Congress became a virtual event for the second consecutive year, and the joint CGSA/OGSA conference – originally scheduled for January – was not only pushed ahead to March but was converted once again to an online offering.

As I write this, I have already sat through the first day of the Landscape Congress education sessions, and each one of these has met Landscape Ontario’s usual high standards. Land-

scape Ontario has a tremendous track record of finding the best possible speakers to address the most relevant topics of the day. I’m already looking forward to the next couple of days of the conference.

The ability to present these conferences virtually is an acceptable Plan B. If this pandemic came about 25 or 30 years ago, there would have been no Plan B. The technology simply didn’t exist to allow for a virtual offering of these conferences. These events would have been canceled outright. The only other option would have been to gamble with our health and permit in-person events to proceed as planned.

The downside of virtual events, of course, is the lack of

The ability to present these conferences virtually is an acceptable Plan B

networking. There are some opportunities for this, but it’s not the same. Human beings like to be able to literally rub elbows with others in the industry. We’re a social species for starters, and a 10-minute chitchat with others can open new doors and opportunities.

The virtual “trade show floor” isn’t the same as the real thing. We can watch well-produced videos that show equipment in action, but decision makers want to see these items “in the flesh.” They want to feel the construction materials,

move levers and push buttons, and have any questions they may have answered on the spot.

Unfortunately, we’re going to have to endure another year of not having that opportunity – at most of these conferences and trade shows.

Going virtual is not all doom and gloom, however. For the education sessions, we can sit comfortably in our own homes and listen to several top-notch speakers sharing their words of wisdom. We don’t have to venture outside in the cold, drive a couple of hours to the conference site and book a hotel room for an evening or two.

This is actually a good selling point for those who need their continuing education credits, but the overall experience is still lacking.

The pandemic is challenging our interpersonal skills. We need to be around other people, albeit in a safe manner. Perhaps things will be different in 2023.

The upcoming Canadian Golf Course Management Conference is looking good. The change in plans during the holiday season by the CGSA and OGSA to proceed virtually has not resulted in a lesser education program. It was a solid virtual conference last year, and this year looks to be every bit as good.

Comparing virtual numbers wit in-person numbers is probably like comparing apples with oranges, but fortunately we live in a day and age when we have a workable Plan B.

www.turfandrec.com

Reader Service

Print and digital subscription inquiries or changes, please contact

Anita Madden, Audience Development Manager

Tel: (416) 510-5183 Fax: (416) 510-6875

email: amadden@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

Editor Mike Jiggens mjiggens@annexbusinessmedia.com

National Advertising Manager

Rebecca Lewis 519-400-0322 rlewis@annexbusinessmedia.com

Account Coordinator Mary Burnie 519-429-5175 mburnie@annexbusinessmedia.com

Group Publisher Todd Humber thumber@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada ISSN 1186-0170

PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Published 7 times a year – Jan/Feb, March, Apr/May, June/July, Aug/Sept, October, Nov/Dec

Canada – 1 year $35.00; 2 year $45.00 3 years $55.50 (plus applicable taxes HST 86717 2652 RT0001

Occasionally, Turf and Recreation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com

Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2022 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Toronto’s Dentonia Golf Club is likely to remain intact for the foreseeable future, following the city’s infrastructure and environment committee’s decision to pass over a staff recommendation that would have reduced the course’s length to nine holes.

The committee rendered its decision after listening to more than 40 deputations who argued that Dentonia and Toronto’s other municipal golf courses offered affordable and accessible play.

The increasing cost of having the proper insurance coverage to operate a snow removal business has become a Canada-wide problem, according to the co-owner of a landscaping company in eastern Ontario.

The increase in soaring rates is being blamed on a rise in slip-and-fall lawsuits with personal injury law firms operating on a contingency basis. The strategy has allowed personal injury lawyers to be more aggressive in their fight to seek larger payouts.

A new accessible baseball diamond in Brampton, Ont. is ready for play in the spring.

The Judith Nyman Field of Dreams was a partnership initiative between the city and Peel District School board with additional grant money from the Jays Care Foundation Field of Dreams. It includes an artificial turf infield with a natural grass outfield and a hard-packed gravel warning track. Modifications have been made to the base paths and pitcher’s mound.

Original recommendation for Dentonia club’s length.

The recent decision to turn the upcoming Canadian Golf Course Management Conference into a virtual event will allow attendees to get more bang for their professional development buck, the co-sponsoring organizations say.

The spread of COVID-19 and the escalating Omicron variant led to the Canadian Golf Superintendents Association and the Ontario Golf Superintendents Association to turn what was originally intended as a live January event in Toronto to one that will be virtually delivered March 1-3.

The Toronto Blue Jays Care Foundation has provided financial assistance to make the Judith Nyman Field of Dreams a reality in Brampton.

“The virtual format offers us a chance to increase education sessions, adding more value for your professional development dollar, and decreases registration and travel costs,” CGSA president John Scott and OGSA president Al Schwemler said in a joint statement. “Not to mention, that all sessions will continue to be recorded, offering delegates more

flexibility to earn CECs (continuing education credits).”

The opportunity for networking has not been lost with the change to a virtual format. Attendees will have the opportunity to connect via a live video chat during trade show hours and discover new innovations during industry presentations. Delegates who attended the 2021 virtual conference reported that they learned something from attending one of these sessions and would attend these in the future.

The CGSA and OGSA committed to a 50 per cent reduction in rates if they needed to go to a virtual conference format. The registration rate for members is $325 for members with a club price of $925. Both associations said they hope delegates will invest their professional development dollars to earn their CECs.

For more information about the conference or to register, visit www.golfsupers.com

Find the latest turf-related news, stories, blogs and analysis from across Canada, and access our forum . . . www.turfandrec.com

By Mike Jiggens

Any golf course that plays host to a PGA Tour event can be considered high end. Conditioning is spot on, greens are apt to be firm and fast, bunkers are raked to perfection, precision shot-making is demanded, and distances usually exceed 7,000 yards.

And then there are golf courses that are beyond high end, and which a lucky few are privileged to play. Many of these serve as the venue for the Tour’s major tournaments.

One such course is simply referred to as Pinehurst No. 2. It’s the crown jewel of a collection of nine 18hole courses and one nine-hole layout that help make up the renowned Pinehurst Resort in Pinehurst, N.C. It has been the site of three U.S. Open championships and will be the tournament venue again in 2024. In fact, an additional four U.S. Opens have been penciled in for Pinehurst No. 2 as far ahead as 2047.

Under the direction of architectural firm Coore & Crenshaw, the golf course underwent a significant renovation project in 2010-2011 that included a return to designer Donald Ross’ original vision and the resurfacing of its greens to ultradwarf bermudagrass from bentgrass.

Pinehurst No. 2 superintendent John Jeffreys shared the story of the restoration project and its challenges with University of Guelph turf management students in November during a virtual presentation.

He described the era from 1962 onward as a “dark period” in the course’s history, noting it had diverted from its intended rustic look to a more manicured appearance to take on more of an Augusta National

look. It was decided at the time that adding more grass would make the property look better and not appear as “scruffy.” Both the 1999 and 2005 U.S. Open tournaments were played under such grassier conditions. But, after the 2008 U.S. Amateur at Pinehurst No. 2, it was determined the golf course no longer resembled the original Ross design and was ripe for a change. Old photographs from its early years convinced Bill Coore and Ben Crenshaw to remove 35 acres of turf and replace it with sandy wiregrass as well as areas covered in pine straw. The $2.5-million restoration project included reducing the number of irrigation sprinkler heads to 500 from 1,450.

“That way the edges could stay unkempt-looking or rough and more Pinehurst-like,” Jeffreys said.

The preference was to promote the golf course as firm and fast and not necessarily lush and green. Jef-

freys, who has worked at Pinehurst the past 21 years, said it was challenging to keep the course’s bentgrass greens alive throughout the year. Since the putting surfaces were converted to ultradwarf bermudagrass, it’s been a lot less “mentally draining.”

From 1907 – when Pinehurst No. 2 was first constructed – until 1935, its “greens” were simply sand surfaces that were oiled in to allow for smooth putting.

“Donald Ross couldn’t find a grass suitable for our hot summers and cold winters,” Jeffreys explained.

It became necessary, however, to grass the greens so that Pinehurst could host the 1936 PGA Championship. Ross selected an older variety of bermudagrass and overseeded it with an Italian ryegrass to accommodate the tournament. The greens eventually gave way to bentgrass until they were resurfaced with ultradwarf bermudagrass during the Coore-Crenshaw renovation project.

Tarping greens is key

To better safeguard his new greens, Jeffreys covers them

when forecasted winter temperatures dip below designated thresholds. The process is labour-intensive, he said, but not as much as having to hand-water the greens.

The greens were sodded to ultradwarf bermudagrass between U.S. Thanksgiving in 2010 and New Year’s Day of 2011. Evergreen turf covers were used atop the new greens for their desired greenhouse effect. Jeffreys said black tarps were chosen to more effectively draw sunlight and heat.

He said it takes his staff about two hours to cover the greens at the end of the winter season golf day. If overnight temperatures are expected to be 20 degrees Fahrenheit or below, the greens will be covered. If the next day’s high temperature isn’t expected to go above freezing, the greens will remain covered.

Greens were covered 25 nights during the 2014-2015 winter golf season when the temperature threshold was established at 25 degrees (it was adjusted to 20 degrees in 2018). In 2015-2016, greens were covered 12 nights. The following season, they were covered 13 nights and then 19 nights in 2017-2018. By the 20182019 season, the temperature threshold was adjusted to 20 degrees, and only six nights required covers. Greens haven’t needed to be covered at all the past two full seasons.

The drawback to covering greens, he said, is the safety risk it can present. He noted some of his staff have experienced back injuries when strong winds have worked against the individuals laying the covers down, and occasionally a stake will fly up from the ground and strike someone.

In spite of such minor injuries, the covers have been effective.

Jeffreys said while air temperatures might be about 25 degrees, the temperature beneath the tarp are often closer to 50 degrees, especially when pine straw is placed atop the cover on particularly cold nights.

The first grens at Pinehurst No. 2 were simply oiled-in sand surfaces that were smoothed over to allow putting.

“It was a significant warming, knowing that we weren’t going to have winter injury. It’s a great insurance policy and helps you sleep at night when it’s getting cold, and you know your greens are covered.”

The greens at Pinehurst No. 2 are between 5,800 and 7,000 square feet in size. Jeffreys said covering his practice putting green, however, presents a biggest challenge. At 75,000 square feet, it requires six covers fastened together by Velcro.

“Covering that is a nightmare.”

Pinehurst No. 2 does not permit twilight play, and the absolute last tee time allowed during the winter season is 1 p.m. This enables staff to cover the greens before dusk sets in. All rounds must be a full 18 holes, and no nine-hole nor partial rounds are permitted.

Jeffreys said one of the things he likes best about his ultradwarf bermudagrass greens is the amount of traffic they can withstand. They can be mowed and rolled more aggressively with little to no stress.

During the last U.S. Open played at Pinehurst No. 2, when the greens were still grown to A-1/A-4 bentgrass, they were mowed at .125 inches.

“It’s not a very low height of cut, but we set up our bedknives to make them more aggressive so that the effective height of cut was slightly below .100, and we had counter-rotating brushes out in the front of the mowing units, so it effectively raised the grass, cut it and set it back down.”

In the end, there wasn’t much grass above .0625 inches, he said.

Going into the current winter season, the ultradwarf bermudagrass greens are being mowed at .125 inches. The desired speed and texture of the greens is achieved through double mowing. Mowers aren’t set low, but they’re set more aggressively, Jeffreys said.

During the summer, greens are double mowed daily. The first significant event held at Pinehurst since the restoration of its greens was the 2019 U.S. Amateur, held during the month of August. Greens were

mowed 84 times that month. Each morning they were cut down and back in the same pass, and the process was repeated on many afternoons. This allowed the greens to stimp at 15.

For the 2024 U.S. Open, Pinehurst’s greens will “just be waking up” before the June tournament, requiring an adjusted height of cut and different mowing practices. Desired green speed is typically achieved through frequency of mowing, vertical mowing and topdressing. The 13th green is stimped daily while various data is recorded, such as whether greens are both mowed and rolled, mowed only, topdressed and what fertility inputs were made.

“That way we can make more informed decisions and we’re not just guessing.”

Vertical mowing is a preferred practice at Pinehurst No. 2 to minimize the effect of grain on ball roll. Jeffreys said the ultradwarf bermudagrass greens tend to be in better shape following a USGA championship event. That wasn’t the case when the greens were grown to bentgrass.

“There was more traffic, more ball marks, more stress. I felt that with cool season greens that, after an event, the greens were worse. With the ultradwarfs, you have more people, more equipment, and more time to get things done in the

lead-up advance weeks, so the greens are always better after a championship.”

The golf course’s fairways are also grown to bermudagrass. Jeffreys said it means having to work a little harder to get the fairways in the right tournament conditions by brushing, mowing side to side and using plant growth regulators. Fairways can be sprayed with Roundup in January while they are still dormant to kill any winter annual weeds that may have popped up.

He said the dollar-to-dollar expense in fungicide costs is about the same between bentgrass and bermudagrass.

“The difference with bentgrass is, if we saw a disease, we could spray it and it could recover quickly. With bermudagrass, there seems to be a two-month delay. The disease is active when the soil temperature is 85 degrees in June or July, but the symptoms of that disease don’t show up until August. So, you missed your window to apply fungicide and you don’t see the effects until later.”

Moisture management also varied between bentgrass and bermudagrass. The former bentgrass putting surfaces would turn purple and footprints were often visible during periods of drought. Once hand-watered, it popped back up within an hour. Bermudagrass turns a khakibrown colour when it wilts and may take up to seven days to recuperate.

“It almost goes into a protection mode where it’s going dormant, and it takes a while to wake back up.”

The greens had been rebuilt in 1996 to USGA specifications – in a project overseen by Rees Jones – and based on drawings from the 1962 U.S. Amateur. Aerial photographs taken in 1943 were used during the Coore-Crenshaw project. Considered high in resolution for the time, the photographs offered precise details that enhanced the project.

Pinehurst No. 2 has significantly expanded its length over the years. When it first opened, it was slightly longer than 6,000 yards, but currently stretches beyond 7,600 yards, but usually plays to

about 7,300 yards.

More than 300,000 rounds of golf were played in 2021 at Pinehurst Resort’s 10 courses, including more than 40,000 alone at Pinehurst No. 2. The COVID-19 pandemic forced a six-week closure of the

resort’s hotels in March 2020, but golf continued to be played. The pandemic reduced the resort’s employee complement to about 90 from about 1,500. Among the layoffs were most of the golf maintenance staff.

“It took me back to high school when I worked on a small golf course,” Jeffreys said. “We learned how to overcome a lot of obstacles during that period of time.”

By June 1, 2020, some staff returned to work, but numbers still weren’t up to preCOVID levels. He said he had about 25 people on payroll in November 2021 – still short of normal – “but we’re definitely more fortunate than we were a year ago.”

Jeffreys began working at Pinehurst as an intern while in university and worked his way up the ladder, becoming an assistant superintendent in 2006 at the No. 2 course, and then taking on the superintendent’s position. His first notable experience at the No. 2 course was working the 2008 U.S. Amateur. He also played a key role in the 2010-2011 Coore-Crenshaw restoration project.

“To be part of so many things at one facility was really a great learning experience for me.”

Jeffreys is a strong proponent of internships among turfgrass students on the cusp of graduation and entering the workforce. Internships allow students to learn other management styles, he said, noting that if they choose to return to their home club afterward, they will have another perspective on things such as other agronomic techniques.

Recalling his internship at Pinehurst, he said his strategy for competing against other interns was to outwork them, acknowledging that he wasn’t necessarily smarter than the competition. It was also important to never make the same mistake twice, he added.

While serving as an intern at Pinehurst, Jeffreys’ duties included syringing the bentgrass greens in the morning and cutting holes. While working with interns in his capacity as superintendent, he asks them what the club can do to help them along their career path

“It’s your career,” he’ll tell them. “What do you want out of it.”

Jeffreys will also assure his young charges that if they successfully complete their internship, they will pretty much be guaranteed a full-time job upon graduation – perhaps not at Pinehurst, but at another club.

Alandscaping business will not be profitable or grow without the right people on board. And that can’t happen without the execution of proper hiring practices. Attracting career-minded employees who are looking for something bigger for themselves is the first step landscape contractors must take when investing in their businesses, says the CEO of LMN (Landscape Management Network Inc.).

Mark Bradley, speaking in January at a webinar directed at landscape contractors wishing to attract and retain better talent, said employee turnover is a common problem among landscaping businesses.

“If you’ve got turnover issues, often the best place to look is who you hired to begin with,” he said, noting the best landscaping companies will almost always claim they have no issues finding the right people.

Most companies, however, aren’t good

at fostering employee development, Bradley said.

A contractor himself, he admitted his hiring practices were once lacking, but he’s since developed strategies that have succeeded in attracting high-level and eager talent that have significantly boosted the growth of both his company and his employees.

Many companies tend to struggle with the hiring process, he said, suggesting many businesses don’t even have such a process. Landscaping firms without proper hiring processes tend to make mistakes along the way, and each new hire is handled differently, based on the time of year, the type of job role, and what might be happening in the day of the company owner or manager, “and I think things just start to snowball in the wrong direction very quickly.”

Bradley said he starts with advertising a job posting that thoroughly describes the vacancy and then prompts applicants to

fill out a five-page pre-interview form that helps to separate good candidates from the not-so-good. The forms are emailed to the applicant, filled in and returned. He figures job candidates who aren’t willing to take an hour to fill out the pre-interview form are likely not serious about a career in landscaping.

“Anybody who mindfully answers these questions…you’re going to be excited to meet with those employees. They are going to be the type of people who are going to want to be a part of a process-oriented company. They’re going to want to understand how to succeed in the business, they’re going to get engaged in training, they’re going to be passionate about becoming better at what they do, and they’re going to be there for the long haul.”

Would-be employees who simply pick up the telephone and ask what time they need to show up in the morning are undesirable applicants, Bradley said.

By incorporating a pre-interview level to the hiring process, he can work with a smaller list of good candidates that will require less work during the in-person interview phase. During his earlier years as a contractor, Bradley said he’d dedicate a day in the office to conduct interviews every half-hour with 16 to 20 applicants. Only three to five candidates, however, bothered to turn up, resulting in a wasted day. Since adopting the pre-interview step, those chosen for in-person interviews have always showed up.

“Pre-interviews are where we find the right people because we can ask tough questions, and questions I probably wouldn’t ask in an in-person interview because I think people might choke up a little bit on the spot.”

Bradley said, for example, he might ask the applicant to describe a past scenario in which he or she had dealt with an upset customer, and what had been done to resolve the situation. Or the candidate might be asked how he overcame tension when working with a difficult supervisor.

Many landscaping employees quit their jobs or are dismissed because they don’t take their positions seriously, he said.

“Ultimately, we have to break the cycle of the way we hire and the way we onboard and invest in these new people if we really think that we’re going to have some success.”

Bradley said the chances are usually slim among many landscaping businesses to retain a newly hired employee, even if the individual is outstanding. Many new hires go directly to a job site without any onboarding or training, creating not only a safety risk but increasing the odds that he’ll likely move on within two to six weeks. He said the employee arrives at work on his first day, climbs into a truck with others he doesn’t know, arrives at a job site for which he wasn’t foretold, and finds himself in an uncomfortable position.

“Almost immediately, they start to question if they made a good decision.”

Ultimately, the employee figures there may not be a future with that company and

looking for another job.

Landscape contractors need to understand what great people want, he said, adding not knowing may be the reason why some businesses lose great people. Employees want purpose, goals, responsibility and freedom, he said, and they must understand the business and how they can contribute towards its success.

Without a sense of purpose, the monotony of the “grind” can set in, Bradley said. Company culture can wane quickly because there is no feedback loop. If an employee has no understanding of whether a job is going well, for example, it becomes a grind.

“The easiest way to change that is to provide the attention and give the feedback. Make sure every field supervisor understands estimated versus actual.”

The degree of attention is where culture can take a turn for the better or the worse, he said, adding that by not providing feedback, the culture is typically not good.

Employees want an opportunity to advance their careers by plotting a path that leads to better wages and a higher position within the company. Bradley said this makes company transparency so important.

“A transparent company starts with a

transparent strategic plan, where everybody in the company understands what the one, two, three and five-year objectives look like so that they can see the opportunity for themselves and really dig in and do their part to help the company move forward.”

For employees to grow their own opportunity, it needs to come with increased compensation, better openings for yearround employment, more fringe benefits and flexibility, he said. Being able to gain access to benefits and a retirement savings plan not only is beneficial toward employee retention and company culture but is a key component toward building a good team.

“When you’re operating with a good, solid operating budget and you enter these costs (benefits and retirement savings plans) in, it’s usually surprisingly affordable. If it’s built into the operating cost of the business, it’s estimated, and the overhead markups are covering it. The difference on that price to the customer is not going to make or break your success in getting jobs, but it is a major make or break factor when it comes to hiring the right people and keeping the right people.”

Bradley said contractors who don’t offer benefits or retirement savings plans may wish to explore getting quotes and options so that as their employees continually climb the career ladder and are always

“Ultimately, we have to break the cycle of the way we hire”

unlocking better opportunities. Creating a more liveable wage in the landscaping industry is the secret to unlocking a better workforce, he said, and ensuring staff are cared for with such extras as benefits is important.

One of the pitfalls among contractors who struggle to find good employees is that they hire staff only when needed.

“That’s a mistake that’s all too prominent,” Bradley said, adding there is a lot of merit with having a year-round recruiting plan. Contractors are more apt to get applications at different times of the year than when they’re needed.

A typical landscaping company will have about 20 per cent of its staff classified as A level employees, with about 70 per cent regarded as B level while the remainder are ranked as C level employees. The top-level employees – or A level – are often regarded as such when they’re hired.

“In the interview, they stand out. They’re obviously more intelligent, they’re more motivated, and are a lot more likely to succeed in the business.”

Bradley said A levels employees should be easily identified.

“These people need to be incentivized, they need to be rewarded, and they need

to be moved along very quickly in your company or you’re going to lose them.” Employees considered as A level must be handled different than B level staff, he said, suggesting contractors may want to turn their B level employees into supervisors because they’ve usually been around for a long time and know how to do the work. Although they’ll need to be trained and developed for the opportunity to become A level, contractors must realize that many B level employees don’t wish to become managers, supervisors or foremen and simply prefer to continue to work independently.

“If they really love the work, I think it’s worth continuing to invest in training and improving their skill set, and at some point, they might become A level, which is typically a crew supervisor on up to management.”

B level employees are those who get the work done and generate revenue for the business, he added.

C level employees, on the other hand, are those who typically have bad attitudes, are unreliable, not trainable, not invested in the business, “and should have been fired long ago.” Many companies tend to hang onto this classification of workers far too long. These people could include managers, crew supervisors and, in some cases, a partner in the company.

“These are people who are not going to contribute to continuous improvement initiatives. They’re not going to make any positive impact on culture, no matter what you do with them.”

C level employees are always negative, and contractors don’t have the time to change or re-program them.

“The faster these people are removed,

the more likely you are to continue to grow with the middle 70 (per cent) and the top 20 (per cent).”

A successful company starts with hiring better people who respect what goes into the business and who understand that their job is to contribute to the company’s bottom line and grow alongside the company.

Bradley said a contractor’s biggest fear is investing in people who aren’t going to stick around but suggested that by putting in the time to find the right people who are career-minded helps to relieve stress.

“Ultimately, what we want is a highly skilled and efficient team, and that means having to slow down the turnover.”

Pest Management of Turfgrass for Sport and Recreation is the first comprehensive work on the plant-eating insects and mites of the grass and non-grass species currently maintained as ornamental lawns and sports turf playing surfaces throughout Australia, the South Pacific and South-East Asia.

This book provides an industry reference for the identification of pests affecting the roots, stems and leaves of turfgrass and control of these species through integrated pest management. It contains information on the distribution, ecology and biology of pests and how to monitor them. The integrated pest management approach outlined in the book includes natural environmental controls, beneficial and predatory species of arthropods, resistant cultivars and insecticidal and miticidal pesticides.

$141.95 Item #0643095144

Modular soccer pitches can give old, underused tennis courts a new

By Mike Jiggens

An Iowa-based company has come up with a solution to help municipalities make better use of underutilized urban spaces and provide recreational opportunities for youth of all ages. Musco Lighting, in association with the U.S. Soccer Foundation, conceived in 2018 what it calls a “mini pitch system” – a modular sports field that can be installed atop decaying or little-used tennis and basketball courts or former parking spaces.

One such system has already been installed in British Columbia, and several other Canadian applications are currently in the works.

Jenna Sullivan, inside sales specialist with soccer development for Musco Lighting, said the U.S. Soccer Foundation conceived the idea for the mini pitch soccer fields amid the growing enthusiasm for the 2026 FIFA World Cup, to be played in 16 North American cities, including Edmonton and Toronto.

The soccer foundation wished to have 1,000 mini pitches installed throughout the United States prior to the World Cup and contacted Musco about providing lighting. Other contractors were lined up to provide such additional necessities as fencing, goals and acrylic surfacing, but the soccer association was more of a fundraising organization than a project-based group.

“They came to us, knowing we can do

this from start to finish,” Sullivan said.

Three months later, Musco came up with a design, and the first mini pitch was installed in 2018 in Newark, N.J. A few design changes have been made since then, but the basic presentation has remained the same.

The pitches are available in three standard sizes: 40 feet by 84 feet, 50 feet by 102

feet and 60 feet by 120 feet. They are designed to be installed atop underutilized tennis courts that have fallen into disrepair over the years, having succumbed to cracks and weed growth. Because the basic asphalt or concrete surface is already in place, the municipality wishing to have a mini pitch installed needs only to repair the surface and put acrylic down.

“Parks and rec are starting to see the light on this,” Jeremy Maffei, Musco Lighting’s national sales manager for Canada, said.

The big selling point for the mini pitches is that their foundations are already in place and present an opportunity for underused spaces to be reutilized.

B.C. installation

Canada’s first installation – at a First Nations community on Penelakut Island in British Columbia – was installed in partnership with the Hope and Health initiative, the Vancouver Whitecaps Football Club and Kw’umut Lelum Child and Family Services. The pitch has given Penelakut Tribe youth an opportunity to develop soccer skills and be physically active.

Maffei said five additional projects are already in the making for other locations in the province, and he is working with Edmonton’s parks and recreation department on an installation there. Additionally, he has been working with a post-secondary institution in the Alberta capital for a mini pitch system to be installed in an open area between two buildings that had previously been used for parking.

Early discussions are also underway with potential customers in Ontario.

He said what he’s learned from his discussions in Edmonton is that if other sports can be added to soccer, it enlarges the demographic for a pitch’s use and opens the door for more fundraising opportunities. Basketball, pickleball, tennis and even hockey are among other potential recreational uses.

With one installation already in place in Canada and at least another half-dozen ready to get underway this year, Maffei said he expects the demand to build.

“It’s just going to keep growing with the 2026 World Cup coming,” he said. “It’s going to be massive.”

Although acrylic is the preferred – and cheapest –surface, the pitches are designed to accommodate an artificial turf surface if desired. The drawback to a synthetic playing surface, however, is that it may negate accessibility, he said, which can make it more difficult for wheelchairs to move about.

Because of their accessibility, mini pitches are often a cheaper option for municipalities that may also be considering other accessible recreational options that might exceed $1 million in cost. Depending on the size

of the mini pitch, costs can range from U.S. $60,000 to $120,000.

Maffei said the only significant upkeep required for the mini pitches, once installed, is to replace the acrylic surface every five years.

The acrylic surfaces are lined to accommodate the sports for which they’re designed. They offer a shiny, painted look, are weather-proof and can be logoed.

Feedback received following the first Canadian mini pitch installation in British Columbia has been positive, Sullivan said.

“They feel like their community is safer because they have a place for their children to play,” she said. “They say their community is more active because they have the space to do things. It’s brand new, clean, and they’re proud of it.”

The mini pitch system is compact enough to fit on one truck and can be installed in 12 hours with a three-person crew. Materials include square tubing and channel material, sheet metal and anchors for both asphalt and concrete surfaces. Lighting includes two LED luminaires and can be controlled for instant on/off scheduling and remote capabilities when equipped with Control-Link.

“Parks and rec are starting to see the light on this”

The all-in-one modular system includes benches and lockable storage, wheelchair-accessible gates, beverage holders, optional signage opportunities and optional video capabilities. The systems also feature a comprehensive long-term warranty.

For more information about the mini pitch system, including a link to a YouTube video, visit www.musco. com/mini-pitch/

By Joe Haynes

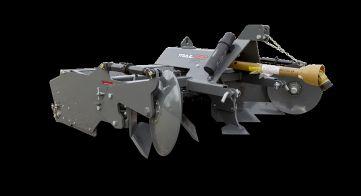

Working on a trenching project means different things to different people. Applications vary as much as the required trench depth and width. To some, a trench needs to be several feet wide and deep to place a culvert for drainage. For others, it is a shallow channel in which they can bury low voltage wiring or water lines for sprinkler systems.

Just as the applications vary, so do the solutions to efficiently tackle these applications. Mini trenchers offer versatile equipment solutions that take on a wide variety of applications and provide quick results.

Landscape contractors appreciate the easy handling and operation of small trenchers over manual digging or using a large, chain-driven trencher, which costs almost 10 times as much as a mini trencher.

Mini trenchers offer operators an ideal solution for shallow depth trenching, about 12 inches deep and two inches wide. This type of trenching works for a variety of applications, from sprinkler systems to electric underground dog fences to cutting trenches for propane. It also easily takes on surface root pruning and installing plumbing and drainage lines, as well as low voltage wiring, such as satellite dish, cable or phone lines or landscape lighting wires.

Compared to bulky-to-manoeuvre and in-

timidating chain-driven trenchers or the back-breaking work of shoveling by hand, mini trenchers cut through tough soils fast without strain. They’re easy to handle, offer fast cutting speeds, cut cleanly and reduce worksite damage – all benefits to an operator’s efficiency.

Safety and simplicity will further impact efficiency. Mini trenchers that allow operators to push the unit by walking forward rather than backward give users full control and enhance safety by enabling consistent sight of their travel path. Some forward walking units cut as fast as 30 feet per

minute, which helps customers accomplish tasks quickly, especially when compared to larger chain-driven trenchers. Using a mini-trencher saves time and trenches 20 per cent faster than chain-driven units that are cumbersome to move and expensive to buy.

Trenching is only half the job. Backfilling and cleanup requires time and effort as well, so it’s important to look for designs that minimize cleanup. Search for a mini trencher that piles dirt neatly to one side. This can reduce backfill times by as much as 50 per cent over those models that kick it out to both sides. Not only does that cut backfill and cleanup time, but it creates less of a mess. It also minimizes soil cupping since the trench is narrow and allows for the area worked to rehabilitate back to its natural state quickly.

Consider mini trenchers that feature pneumatic tires that don’t affect turf. Contractors won’t have to spend extra time repairing damaged turf caused by tracked machines, skid steers or other self-propelled units like chain-driven trenchers.

Mini trenchers that feature replaceable blades and teeth give contractors more options for different soils. A mini trencher with

21_2802_Turf_n_Rec_JAN_FEB Mod: December 28, 2021 3:33 PM Print: 01/13/22 12:11:00 PM page 1 v7

“Mini trenchers that allow operators to push the unit by walking forward rather than backward give users full control and enhance safety.”

heavy-duty rock teeth easily handles tough, rocky soil areas and even cuts through asphalt. The same mini trenchers also come equipped with a cutting blade option more suited for loose, sandy soil types. Required maintenance also impacts overall value and ROI. And it could mean the difference between staying productive on the job and experiencing downtime waiting on lengthy repairs. Mini trenchers that incorporate a built-in slip clutch guard the drive train from shock if the trencher hits a rock or obstacle by stopping the blade from turning, protecting the equipment. It also protects the cutter teeth and belt from excessive wear and damage. Look for models that feature bolt-on blades or cutting teeth so replacement will be simple and inexpensive. Some models weld teeth directly on the cutting wheel, causing the entire wheel to need replacement when a single tooth is damaged.

Final cut

Mini trenchers are a versatile and valuable tool for a wide variety of landscaping applications. These units help operators decrease damage and get trenching projects done quickly. Just because they are mini doesn’t mean users will see a small return on their trencher investment.

Golf course management strategies have evolved over time. By

Pat Differ

Sometimes, observations made after a passing of time are the most meaningful. The wonders of today may not be the wonders of tomorrow. Golf course management strategies over time have evolved. Greenskeepers became superintendents. Science was always involved.

When soil became sand, the importance of understanding science evolved and emerged as well. This was around the 1970s, and superintendents everywhere learned that sand and soil were much different.

Alternative methods of feeding the plants on our greens became an exploration of sorts. Liquids – solubles mostly from some form of agriculture – emerged in turf. In agriculture, where they had been used for decades, these products, for the most part, were always aimed at the soil.

Some were granular and were dissolved, then sprayed in large volumes of water per acre to minimize the “burn” potential. “Will it burn?” was a common question.

The truth is some would absolutely burn, and I still bear the scars of learning that the hard way. Mostly it was because I did not understand the raw materials or the mode of action. Many raw materials were fine for soil applications – more or less going into the ocean of exchange sites. The ability of soil to “buffer” such products offered some protection.

No longer do we sit back as superintendents and be “taught” this direction, as we have all learned about the importance of quality, as specific products were developed for foliar applications on turf. We became educated, and there was a thirst for this information which the brave wanted badly.

Snake oils at first slowly became accepted.

It is our responsibility as superintendents to be informed and correct in our decisions on this matter. We are nutrient technicians and specialists. What’s the stress? OK, here’s what will help. Issuebased management – knowing ahead of time heat is on the way – or tournament preparations requires this input.

When this began, it was new. It is no longer new, and those who sell complication are doing so for-profit motive. Growing grass is not going to the moon. The grass knows what to do, which will be mentioned later. We just need to help the plant complete its biological objective, which is the production of mature proteins in our golf environment.

Brave superintendents always experiment, and to do so is almost our duty. We

find a better way. I speak of a system that is all encompassing, including soil and the plant’s external and internal chemistries. There is balance.

Base nutrition for regular turfgrass is supplied through root zone absorption chemistry using granulars. Elite turfgrass is achieved by using supplemental internal plant chemistry components – just like an IV in your arm – allowing the plant stomata, to absorb these specialty combinations of organic acids, amino acids, and bio-stimulants, which assist the plant in reaching its biological objective for the next 1012 days. These supplements provide turgor, inner plant strength and a wear tolerance by propping up plant functions.

Golf evolved as well, and superintendents became challenged with demands, including faster greens and smoother surfaces. When the construction boom happened, golf became more manufactured and root zones of sand needed a different standard of care.

It was a perfect storm, really, with the demographic of boomers looking to retire and stay active. The lifestyle of golf was born in golf communities, and retirement communities sprang up all over. Construction boomed. Today, we know things to be much different.

Golf course maintenance also evolved with many new things entering the picture. Speciality equipment emerged, mowing heights were lowered, and speed was where it was at. Televised golf offered the chance to see the manicured grounds of high-end courses all over the world. Little did superintendents know they were thrust into an environment which would force them to learn.

Balancing all of these facts with the emerging science of plant management challenged super-

intendents to be better and to learn about soil and plant science. We must “own” this knowledge as it is an insurance policy for us. It is a system of learning based on plant chemistry understanding. Plants eat, sleep, have a day shift, and a night shift recovering.

Much of what we learned came from conferences and seminars –where we looked at university research into all aspects of grass management, learning how to elicit a response out of a plant we had always just maintained by setting the spreader on “F” and going. This was

fine in soil. It was beginning to become evident to me at the time that I could actually make a living at growing grass and not just cutting it. Sand root zones meant I had to change and learn.

This was a troubling cycle of feeding the plant and treating disease that would result. Literally, pounds of nitrogen per 1,000 square feet were applied in a manner which led to that result. This was plant maintenance and not plant management. Most of us were doing this. We were not “guilty” of doing this but were rather still in the learning

“Golf

mode (those of us who opened our eyes and were not afraid to learn new ways).

The guilt was in not trying to learn this new system that was driven by science. Today, it is my view that with what we have learned by experience, by doing our own testing and by knowing more about the grass plants we work with, we are at a time where a closer look at the definition of nutrition is necessary. It is more than just nutrient. It is organic acids and amino acids which link to produce those mature proteins, plant catalysts and plant defence components of the energy Krebs Cycle. We have these tools.

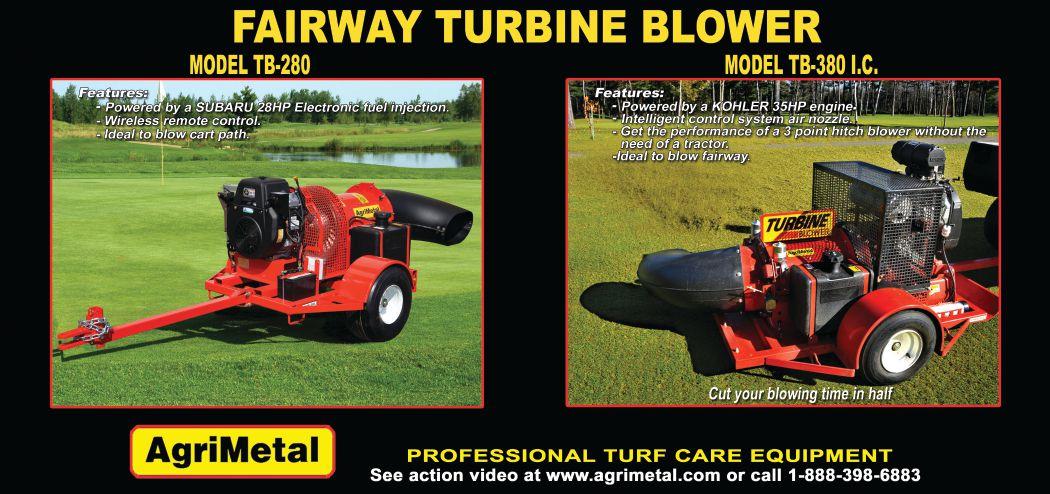

AGMTurbine:Layout 1 5/25/16 11:31 AM Page 1

Fast forward now to 2022. It’s time to retool again, to think, to challenge ourselves in a different time, and to understand how much we have learned over 30 years or so.

Science once again plays a leading part where we now know that plants “know” what to do. They have al-

ways known what to do.

The sand green, for certain, is part of our lives and has benefits, no doubt. The ensuing plant stress from low mowing and speed demands, really, are self-inflicted wounds. We live on the edge. How much of anything does that plant need? The answer is always…It depends.

We have been forced to go deep. Examine how a plant grows, and not take recommendations for multiple product tank mixes, as has become standard over the last three decades. This is in part because we were all learning these new ways at first. Sales theology needs to be separated from scientific facts.

Formulation chemistry has also evolved and become more specific. This is a good thing at a good time for superintendents in today’s world. This is a world of tight budgets and doing more with less.

Squeeze that nickel. Superintendents are where the buck stops. They have learned to manage their own destiny by choosing the combinations and the timing of applications according to the internal – and always running – clock in their heads. It is elite turfgrass management, with no time for programs in a can anymore. “Turf nutritionists” are in reality salesmen. You are the turf nutritionist.

Yet as superintendents, our “never compromise” attitudes demand that we always maintain that high level of care and high standards of elite turfgrass integrity. This is our job. Bear with me in this journey. Think.

Think about plants. Think about plants that turn towards the sun in search of energy. Think about our perception of plants. Some, we grow to eat and some, animals eat. Regions of the earth produce specific and amazing kinds of plants. All make their own food, all harvest the sun and adapt to their surroundings. It’s the order of nature. We must adhere to that order, understand it and use it to our advantage. It applies

The most powerful turbines on the market.

to turfgrass.

Superintendents grow in time windows around such high levels of created stress as low mowing, which immediately upsets the internal plant chemistry and balance. Add shade, traffic, golf conditions, weather, and there you have it – our challenge. There is a balance of club tournament scheduling versus necessary maintenance decisions for a living surface. Our greens are how we are judged, but this, of course, applies to all areas of intensely managed turfgrass – golf and sports fields alike.

Our target is often an eighth of an inch or less in golf or a bit longer on sport fields. Anything foliar must sit on the leaf to have a chance to be absorbed. How much do we really need to put on for that next window? We must balance that with root zone appli-

“There is a balance of club tournament scheduling versus necessary maintenance decisions for a living surface. Our greens are how we are judged”

cations of granular where there is a massive feeding structure –roots, or “plant brains.”

Plants are much more sophisticated in sensing than animals. Just to provide an example of this, every single root apex is able to detect and to monitor concurrently and continuously at least 15 different chemical and physical parameters. We tend to underestimate plants and their absolute ability to know what to do.

We watch nature shows and see David Attenborough. He is a wonderful admirer of nature and does great work. He has made some wonderful specials about plant behaviour. When he speaks about plants, everything is correct. When he speaks about animals, it is as if plants do not exist.

The blue whale is the biggest creature that exists on the planet. That is completely wrong. The blue whale is a magnificent creature, but it is dwarfed by the magnificent giant sequoia. This is a living creature that has a mass of 2,000 tons.

Plants are very sophisticated creatures, and that brings us to the meaning of this session. The fact about what we must recognize and learn – that is, on our golf greens today – we need not any longer be using the kitchen sink mentality when considering that very short growth window. “You want me to put how many things in the tank?”

It is our job, our challenge today, to understand the plant from a 2021 perspective, to use what we know to be facts of internal plant chemistry.

Plants move, and not only toward the sun. Take the Venus fly trap, for example, and watch it snap on a fly. It’s clear evidence that plants think and support themselves if they have what they need. Most of what they need they get from nature. What we do to them in a golf turfgrass environment is to upset that balance in nature, and we need to recognize that.

Really, do we need five, six, seven or eight things in a tank to hit a target that small to last for seven to 10 days? I think not, when we understand the internal workings of the plant. This plant is eating every day through a root system that is massive, and we do need to complement that base feeding with necessary components

which allow the plant to complete energy functions or immune system defence in the internal chemistry of the plant at times.

Plants, eat, drink, sleep and recover during the 24-hour cycle. There is a day shift where most stresses occur, and a night shift where most recovery happens.

Plants communicate in an extraordinary manner. They are able to distinguish between kin and non-kin. They communicate with animals by producing chemical volatiles, for example, during pollination. This is a very serious time for plants. They offer a sweet substance to pollinators – serious business – energizing substance for transportation of the pollen.

Charles Darwin, well known for his evolution theory, also did much work on the “power of movement in plants.” He wrote, “it’s hardly an exaggeration to say that the tip of the radical acts like the brain of one of the lower animals.”

The study of the root apex of a rye plant shows movement the same as a worm or snake and every animal that is legless. This movement takes a coordinated effort. The “transition zone” in this root apex consumes the highest level of oxygen in the plant and, more importantly, you have these signals which create the movement – the same as what we have in our brains, which are used to exchange information.

“We know through study that this root apex has just a few hundred cells that show this kind of feature, but we now know how big the root apparatus of a small plant like a rye plant is… it has almost 14 million roots and root hairs,” Stephano Mancuso, a professor of plant neurobiology at the University of Florence, has said. “We have 11-and-a-half-million root apex sections, and a total length of 600 or more kilometres of very highly active surface areas.”

This is a network not unlike the internet or the human nervous system, and all in a plant.

The point I’m making is that as we have evolved through this roughly three-decade journey of foliar nutrient plant management, the law of “a little bit” applies.

I believe we’ve come to a time in plant management chemistry

where we have reached the next level of understanding. Label rates for most sophisticated products today are for standalone applications. Formulations have evolved to now reduce into one jug what used to be in three jugs. When two or perhaps three of these are mixed together, a lower rate of individual product is, for sure, the best option. This dramatically reduces the cost of a plan while providing even more nutrition and plant impulse components to the grass plant. Be in charge of your own surfaces.

As always, when forced to learn, some will have reached a dropping-off point. Some say they don’t want to change what they’re doing out of a fear of trying something new. Superintendents, in a way, are like explorers, always wondering “what’s over there” in a kind of search for something better.

This is where we are again – how best to use this knowledge, to do our duty as professional growers in our industry.

It has always been about balance. We now know that to create that balance, we, too, must adapt to change and to use science and chemistry to our advantage if we are to be environmentally responsible and correct as turf managers and to continue this constant of learning.

Municipalities have their work cut out for them. Whether it’s city maintenance workers or general contractors hired to sustain parks in a city, town or borough, a day’s work can involve several industries’ skills rolled into one crew. They can be installing fence posts in the morning, replacing sprinkler lines mid-day and find themselves planting trees in the afternoon.

With so much variety, working smarter, not harder, is paramount to overall productivity. And having versatile tools that allow crews to better utilize labour safely, while also outperforming other methods, can have a major impact on efficiency.

The right earth drill can do just that. Some earth drills even enable safe oneman operation with nearly two times the productivity of other units. It’s just a matter of finding the earth drill that best meets the municipality’s needs.

Two popular earth drill choices for

grounds crews are mechanical and hydraulic drills.

For work in towns and cities that includes planting a lot of small greenery, installing fences or taking on other tasks that require crews to dig numerous footings quickly, a mechanical earth drill is a good choice. Perfect for fast, narrow hole drilling, some manufacturers even design these drills to allow for safe, one-man operation while providing the speed to help crews excel.

Look for manufacturers that offer augers in a variety of diameters and lengths. Additionally, some manufacturers offer multiple gear reduction ratio options to give the flexibility to choose a mechanical drill with a high RPM for loose, soft soils or one with a lower speed that is better suited for dense, rockier formations.

With a mechanical drill, crews can quickly install a long row of shrubs and then shift

to setting a pole for a basketball hoop in denser soil – all without missing a beat.

To further increase municipal staffs’ versatility, some manufacturers offer horizontal boring kits for mechanical earth drills. The horizontal boring attachment allows grounds crews to install everything from sprinkler systems and lighting wire to drainage pipes and more, all with an easy-to-connect attachment.

But, if heavy-duty applications and anchoring are abundant and soil types are consistently rocky and dense, hydraulic drills might be a better choice.

Hydraulic earth drills are designed with powerful torque, which is perfect for installing anchors or digging holes for large playground equipment, awning supports, sizable landscaping and other tasks that require deep, wide footings.

Like with mechanical drills, look for manufacturers that offer augers in a var-

iety of diameters and drilling depths. With auger options and the increased torque of hydraulic drills, crews can take on lighter tasks like planting landscaping and then quickly shifting to heavy-duty construction, like installing support beams for a sunshade. This gives crews the flexibility to divide and conquer whatever the municipality throws at them.

Hydraulic drills with precise auger rotations at low speeds can be perfect for anchoring. Some manufacturers offer anchor adapters for various applications from anchoring poles and beams to installing tent stakes, making them a versatile solution for municipalities. When pairing an anchoring attachment with a hydraulic earth drill, crews have an anchoring machine to secure footbridges, large playground equipment and more.

The extensive tasks that await city maintenance crews and contractors don’t have to mean an extensive set of tools. With a little knowledge about the applications, crews can choose an earth drill to carry them through the day – safely and efficiently.

Caterpillar’s new 302.7 CR, 303 CR and 303.5 CR hydraulic mini excavators, built on the Next Generation platform, offer consistent operator experience through the 1.5 to 10-tonne range. Boosting operating efficiency, servicing ease and operator comfort, each new model features exclusive stick steer, cruise control, operator-adjustable settings and a tilt-up canopy or cab as standard features.

Expanded use of common parts throughout the line plus their damage-resistant exterior construction help to reduce parts inventory investment and lower repair costs. Daily maintenance checks are quickly made from ground level through side doors, while

the tilt-up cab design offers access to components for servicing. Increased service intervals mean these excavators spend more time on the job and less time in the workshop. Combined, these features lower total ownership costs up to five per cent, compared to previous models.

At the same time, design enhancements for the new 302.7 CR, 303 CR and 303.5 CR deliver up to 10 per cent more performance in travel and trenching. Hydraulic system upgrades improve lifting performance and cycle times, while customizable operator settings improve efficiency.

The turbocharged Cat C1.1 Turbo engine

powers the 302.7 CR and 303 CR models, while the Cat C1.7 anchors the powertrain for the 303.5 CR. Both engines meet U.S. EPA Tier 4 Final emissions standards and offer 23.6 hp (17.6 kW) net power. Standard auto idle and auto engine shutdown help to conserve fuel usage at the site for more affordable operation. www.cat.com

Bobcat Company’s new TL619 telehandler gives operators in landscaping and snow removal the flexibility to accomplish a variety of demanding tasks with superior precision and performance. Featuring a redesigned comfort cab, turbo-charged engine and easy-to-access service points, the TL619 combines power and nimbleness to create a lifting, stacking, backfilling and reaching machine matched for the job.

The TL619 has a load capacity of 5,500 pounds and a lift height of 19 feet for ideal productivity with every lift cycle. With an optional, add-on counterweight, operators can extend their telehandler’s rated capacity throughout the lift cycle to reduce repetitive tasks and complete jobs more quickly.

The advanced Tier 4, turbo-charged engine delivers powerful, high-torque performance, excellent efficiency and achieves emissions compliance without the use of a diesel particulate filter (DPF) or selective catalyst reduction (SCR). Operators will also appreciate the new engine’s reliable cold weather starting and a variety of features that make maintenance and service more convenient.

Five operation modes give operators the versatility needed for a wide variety of applications:

• ECO mode allows the operator to maintain hydraulic performance without using the engine’s full power – working with lower rpm, less noise and lower fuel consumption.

• Smooth Drive mode is ideal for maneuvering across jobsites with mild acceleration and deceleration while carrying loads.

• Dynamic Drive mode increases responsiveness of the telehandler’s acceleration and deceleration for traveling between tasks.

• Flex Drive mode allows the operator to manage the engine speed independently from travel speed.

• Advanced Attachment Control mode allows for full auxiliary hydraulic performance.

The TL619 was designed to incorporate sleek and efficient Bobcat R-Series styling and enhanced visibility. The low-profile boom sits below operator eye level to provide an open view of the surroundings. The redesigned engine basket sits lower for increased line of sight. Front, top and rear window wipers help keep windows free of debris and precipitation. Multiple mirrors on the operator’s left and right provide added visibility when working in confined areas. An optional rear mirror kit, rear view camera kit and boom work light kit also are available.

The redesigned cab builds upon the Bobcat tradition of operator-centered design with high visibility, excellent ergonomics, a comfortable suspension seat, efficient HVAC system, and an easy-to-read, automotive-style instrumentation panel that Bobcat equipment operators will find familiar across R-Series machines. Bobcat telehandler cabs are designed and tested to Roll-Over Protection Structure (ROPS) and Falling Object Protective Structure (FOPS) level II standards.

A single, intuitive joystick controls the travel direction, lift and tilt functions, boom extension, and auxiliary hydraulics. This gives the operator fine adjustment for lifting loads with care. It also allows operators to control several machine functions at the same time and from one control point, enabling more precise control and higher productivity without having to remove their hand from the joystick.

On the front side of the joystick, the directional switch for forward, neutral and reverse can be operated with the index finger. The two-speed travel switch, lift-arm float, boom extension, machine function settings and auxiliary hydraulics are located on the rear of the joystick.

www.bobcat.com

The new Kansas City from KEEN Utility is a new work sneaker that seamlessly transitions between indoor and outdoor work. Landscapers, golf course maintenance staff and other industry professionals can move with ease throughout the workday with the versatile, lightweight safety shoe.

Featuring KEEN.BELLOWS Flex technology, its ergonomically engineered system is designed to offer multi-directional flexion, making bending, squatting, kneeling and knee-down work up to three times easier.

Other product highlights include a KEEN.ReGEN performance cushioning mid-sole that returns 50

per cent more energy than standard EVA foam, as well as an oil- and slip-resistant, non-marking lugged out-sole tread design for optimal traction.

Additional safety features of this medium-duty boot include asymmetrical carbon fibre toes that are 15 per cent lighter than steel, KONNECTFIT heel-capture system to lock the heel down for sure-footed stability, and a completely non-metallic construction combined with EH-rated protection underfoot from live electrical circuits.

The new Kansas City is available in low, midheight, and mid-height waterproof styles for men. www.keenfootwear.comg

ASV Holdings has launched its repowered RT-40 Posi-Track loader with a Yanmar engine. The manufacturer of all-purpose and all-season compact track loaders and skid steers notes the 38.2-horsepower engine adds more power to what was already a compact powerhouse, and it improves serviceability for machine owners by allowing them to have the Yanmar engine serviced at ASV dealers.

The increased power and convenient serviceability also add to the appeal of the RT-40 as a more productive, safer option than walk-behind and stand-on loaders. Additionally, the small-frame RT-40 showcases new comfort, visibility and performance features over its predecessor. It is a leading performer in applications that require work in tight spaces, including urban snow clearing and landscaping, making it an ideal rental product

for homeowners, rental fleets and contractors.

The repowered RT-40 includes a more powerful new 38.2-horsepower Tier 4, 3-cylinder Yanmar engine. The compact track loader allows contractors and homeowners to get more done in a day, featuring a 48.3-inch width, an 8.4-foot lift height, a 931 rated operating capacity and a 7.1 mph top speed. The machine also boasts high tractive effort, exceptional pushing and digging power thanks to ASV’s Posi-Power system. The RT-40’s quick attach fits a variety of attachments and works with an optional adaptor plate for full-sized or walk-behind/stand-on loader attachments.

The RT-40 comes standard with variable auxiliary hydraulic flow and can operate efficiently at a high auxiliary circuit flow rate, powered by 13.3-gpm of pump capacity and

3,000 psi of system pressure. Labour-intensive belt servicing is eliminated thanks to ASV’s signature use of a direct drive pump. This, along with the machine’s large line sizes and hydraulic coolers, transfer more flow and pressure directly to the attachment to help prevent power loss.

A highly efficient cooling system allows operators to get more out of their machine. The RT-40 is tested to operate at full load 100 per cent of the time in ambient temperatures from minus 40 up to 118 degrees F. View video at www.youtu.be/w569fH3I7Dg

By CCOHS

The Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well being of workers in Canada by providing information, training, education, systems and solutions that support health and safety programs and injury and illness prevention. www.ccohs.ca

Let’s face it, wearing a protective non-medical mask is still the norm for many workers, and for good reason. As part of a layered approach with other measures, masks help to prevent the spread of infectious respiratory droplets that lead to COVID-19. But, as temperatures dip during the winter, seasonal inconveniences like rain and snow, runny noses, and wet faces are not only annoying, but can also reduce your mask’s effectiveness. As new variants continue to spread, proper mask wearing is still a good way to protect yourself and your crew. Use it as an opportunity to provide reminders and encourage workers not to let their guard down this winter.

Whether they’re visiting the warehouse or office, on the road, or working in a public space, crews should be encouraged to wear a non-medical mask when they might interact with people from outside their immediate household.

When buying a fabric non-medical mask, the materials and design can make a difference in how effective it will be at limiting respiratory droplet spread. Three-layer masks are recommended for stronger protection. If three-layer masks are unavailable, consider layering several single-layer masks instead.

The mask should fit tightly over the individual’s nose, mouth, and chin. A loose mask with gaps will be less effective. They should make sure that the ear loops or head straps are secure. Being outside in the cold all day might drive workers to wear a winter face covering to keep warm, such as a scarf, balaclava, or ski mask. Keep in mind that these items are not a suitable face covering to protect against COVID-19. Wearing a mask under these face coverings during cold weather will provide better protection.

Be aware of several factors when wearing a mask outdoors. Masks that become

“Be aware of several factors when wearing a mask outdoors.”

wet may be less effective. They may also freeze in cold weather. Make workers aware that having a damp or frozen mask on their skin may cause frostbite. In addition, mask fabrics and ear loops may lose elasticity in sub-zero temperatures. They may be easily damaged when handled. Be prepared for any of these scenarios by stocking extra masks and making your crew aware of where they are kept when they need to replace theirs.

In general, individuals should avoid touching the outside of their mask. If they must touch their mask or face, encourage them to wash or sanitize their hands immediately after.

Make sure employees know that reusable fabric masks should be washed in hot soapy water and dried between each use, or when they become damp or soiled. Damaged masks are less effective and should be discarded.

Wearing a mask is only one of several ways to protect your crew from COVID-19. No single control measure will be 100 per cent effective on its own. Taking a layered approach provides the strongest protection from COVID-19 in the workplace. This approach combines public health measures with workplace health and safety measures. With each added layer of control, the risk of exposure gets lower.

In addition to following steps we can take as individuals, such as physical distancing and personal hygiene, there are practices that the workplace can do to keep workers safe.

Elimination and substitution: Where possible, offer options such as remote work and virtual meetings for office and support staff not directly involved in on-site operations. Follow public health measures (physical distancing, use of barriers in vehicles or office) when planning work, both indoors and outside.

Engineering controls: Consider adding physical barriers to shared spaces and offering contactless invoicing and payment options for clients. For those indoors, look at ways to improve ventilation.

Administrative policies: Provide clear communication and training, maintain staff cohorts for certain tasks, and amend sick leave policies to reflect the current situation.

Personal protective equipment: Provide appropriate equipment that meets regulatory standards.

Wearing a mask alone will not prevent the spread of COVID-19. However, masks do help to protect yourself and others when they are well-constructed, well-fitted, and are properly worn, handled, and cared for.

Don’t let your guard down this winter. Beyond wearing a mask properly, remember to maintain physical distancing, wash your hands frequently, and follow your local public health guidelines.

ADVANCED AUTOMATION, GUIDANCE & SAFETY

So you can rest assured the job’s being done right. REMOTE COMMAND & PERFORMANCE MONITORING

Operates 24/7, rain or shine, day and night.

EIGHT TIMES LOWER ENERGY COSTS

Compared to traditional mowers.

Because work doesn’t stop when you’re busy doing other things.

Better for the environment and our customers.

Avoid disturbing customers in noise-sensitive areas.