Reliability that counts

bR 800 c-e BACKPACK BLOWER

OUR BIGGEST MOST POWERFUL BACKPACK BLOWER.

Landscapers, parks and recreation crews and golf courses…be prepared to be blown away. To tackle large properties and heavy debris, there is nothing like the clean-up power of the BR 800 C-E. The most powerful backpack blower in the STIHL line. The BR 800 C-E offers maximum blowing force as well as optimal comfort. The BR 800 C-E will make a great addition to your fleet.

⬤ Robust Blowing Force – 3.2 kW engine power; offers 20% more power than the BR 700

⬤ Sturdy Performance – Best power-to-weight ratio in STIHL gasoline blower line; machine is more compact and easy to carry

⬤ Ergonomic Carrying System – S-shaped shoulder straps, chest strap and hip belt; provides operator comfort

⬤ Telescopic Tube – Quick adjustment of the length for various conditions; no tools required

⬤ Pull Cord – Handy access to the side starter cord; machine can be restarted from your back after taking a short break

① Excluding fuel. ② With tube at nozzle end.

STIHL’s Pro-Fleet Commercial Landscape Program is designed to provide commercial landscapers a volume discount on major purchases of 5 or more landscaping power tools. Visit your STIHL Dealer today to find out more and take advantage of the savings!

By Mike Jiggens

Can game of golf make a comeback?

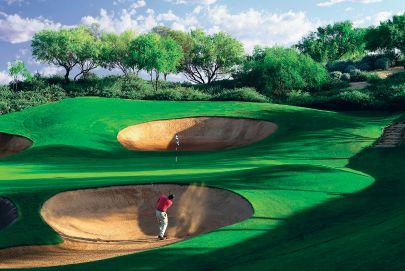

For at least 15 years now, we’ve been hearing the same refrain that the game of golf is dying, that its popularity is diminishing at an alarming rate, as well as all sorts of other not-so-flattering things about the sport.

Yes, we’re not in the same position we were 20 or so years ago when golf was enjoying its biggest boom ever. We reached a pinnacle of growth then that we may never experience again. As we crossed over into the new millennium, however, supply had overtaken demand and things began to go downhill.

But now we’re hearing some encouraging things about the state of the industry. During some casual conversations with industry authorities in January at the Ontario Golf Superintendents Association’s annual conference in Niagara Falls, talk was made that golf appears to have finished bottoming out and is actually moving in a forward direction once again.

Where there’s a will, there’s a way, it would seem.

Superintendents are doing their part not to skimp on the maintenance required to keep playing conditions at a desirable level. After all, that’s why we choose to play this game. Course playability must always be in top order if the game is to rebound. Maintenance budgets may have shrunk significantly over the years, but

superintendents and their teams are a smart and innovative lot, and continue to find ways to make things work.

One such superintendent is Jim Riopelle of the Glenboro Golf & Country Club in Brandon, Man. With 36 years of experience in the industry, he knows a thing or two about the industry and has plenty of ideas about how to help build the game back up again. Wearing the hat of guest columnist, he shares with us in this issue his thoughts about the state of golf from a superintendent’s perspective, and presents a number of suggestions aimed at keeping golf alive and perhaps giving it a helping hand to move it forward as well.

Maintenance budgets may have shrunk significantly over the years, but superintendents are a smart lot

His outside-the-box thinking includes such ideas as better maintenance scheduling that can still achieve playable conditions yet save money on labour, tapping into technology that is either cheap or free and waiting for new chemistries to be tried by higher end golf courses before prices decrease.

He offers several other forward-thinking approaches that even tie in with a golf course’s food and beverage service – all aimed at eliminating waste and

inessentials to allow golf courses to move forward.

There are too many of these good ideas to list here, and I don’t wish to spoil Jim’s well-written guest column by revealing any more than I have already.

The industry is doing its part to produce a better breed of assistant golf superintendent who is one rung away from climbing to the top of the leadership ladder. The Green Start Academy, a program co-sponsored by John Deere and Bayer Environmental Science, gives deserving assistant superintendents a leg up toward becoming full superintendents by teaching them aspects of the job they wouldn’t ordinarily learn at the post-secondary level.

In this issue, we share the experiences of five of the eight Canadians who were selected to participate in the fall program. The academy helps to move golf forward by producing individuals who are ready to step into the role of superintendent, bringing with them a knowledge that puts them ahead of the curve. This bodes well for the industry and is another strategic step toward growing the game again.

Syngenta has sponsored a similar program for both assistants and superintendents in recent years, demonstrating that industry suppliers are taking on an active role in trying to reinvigorate the game.

Golf will move forward again only when all parties come together. This means all departments within the club as well as the club itself and vested interest groups.

www.turfandrec.com

Editor Mike Jiggens mjiggens@annexbusinessmedia.com

National Advertising Manager

Rebecca Lewis 519-400-0322 rlewis@annexbusinessmedia.com

Nashelle Barsky 905-431-8892 nbarsky@annexbusinessmedia.com

Account Coordinator Mary Burnie 1-888-599-2228 ext 234 mburnie@annexbusinessmedia.com

Circulation Manager

Anita Madden 416-442-5600 ext 3596 madden@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

President & CEO Mike Fredericks

Printed in Canada ISSN 1186-0170

PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Published 7 times a year – Jan/Feb, Mar, Apr/May, Jun, Jul/Aug, Sept/Oct, Nov/Dec Canada – 1 year $35.00; 2 year $45.00 3 years $55.50 (plus applicable taxes HST 86717 2652 RT0001

CIRCULATION

email: blao@annexbusinesmedia.com Tel: 416.442-5600 ext 3552 Fax: 416.510.6875 (main) 416.442-2191 Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Occasionally, Turf and Recreation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2019 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Council turns down $25,000 study for golf course

A proposal to allocate $25,000 to study the potential expansion of the Pincher Creek Golf Club to 18 holes has been defeated by the Alberta town’s council. One councillor said the decision is likely to delay the expansion’s planning by a year.

Coun. Mark Barber said the study was worthwhile, claiming it would have identified the cost of changing the golf course’s irrigation system. He added there is some urgency to proceed with the planning.

Field’s infill options being weighed before new turf laid

Bowen Island Community School’s artificial turf field has reached the end of the road and needs replacement. The local British Columbia town’s council has opted to continue with a half-sized field for the time being, but is considering various options for the field’s infill.

The municipality is considering three infill options, including crumb rubber, thermoplastic elastomer and ethylene propylene diene monomer. Crumb rubber is the cheapest option and is the industry’s standard.

Special needs landscaping program offered in Kamloops

A landscaping trades assistant program for students with disabilities needing extra support is being launched in February at Thompson Rivers University in Kamloops. The 32-week program combines classroom, lab and practical experience. Students in the program will be offered hands-on, project-based and experiential learning opportunities. The program includes a six-week, off-campus practicum.

4-3

Ousted snow and ice customers bailed out by another

The sudden closure of a Montreal-area snow removal business has had a silver lining for many of its customers who were left out in the cold.

Local contractor DLC took on 3,700 new customers in the wake of Bo Pelouse’s unexpected closure and has hired 20 of its former drivers.

Bo Pelouse, a West Island snow contractor that had been in business for 30 years, ceased operations in late December, leaving more than 5,000 customers without snow removal services. The business closure occurred on the eve of a storm during which more than 15 centimetres of snow was forecast.

In order to accommodate the additional business, DLC added several new tractors to its fleet. The company operates several smaller snow removal companies on the West Island, taking care of the needs of about 9,000 customers.

contractor

Former Bo Pelouse customers inconvenienced by the company’s closure were left searching for answers immediately following the unexpected closure. An online apology was made on Bo Pelouse’s website with a note that the business could no longer continue operations.

Its owner, Marc Guindon, expressed his thoughts “with deep sadness” and “with a heavy heart.” He said he had no other option than to close his business.

Former customers expressed disappointment that the company didn’t reach out with an explanatory email or telephone call. Many customers paid up front for the season’s snow removal services and suspect they won’t get their money back.

Guindon said he has been hurt by some of the messages posted about him on social media that imply he had taken customers’ money for the purposes of living abroad.

Find the latest turf-related news, stories, blogs and analysis from across Canada, and access our forum . . . www.turfandrec.com

Futurist to headline golf conference

Jim Carroll to address ‘the future and innovations’

Jim Carroll, a leading global futurist, will be keynote speaker March 2 at the Canadian Golf Course Management Conference in Ottawa. His address is titled, “the future and innovations.”

For the past 25 years, more than two million people have shared his insights. Organizations from around the world have turned to Carroll for strategic guidance into strategies they need to adopt and trends with which they must align.

Conference education sessions scheduled for Monday, March 2 include:

• Ninja level poa growing: optimizing plant health while minimizing annual bluegrass weevils and leather jackets (presented by Dr. Ben McGraw, Penn State University)

• Technician beyond the wrench (presented by Hector Velazquez, Hector’s Shop)

• Drones and golf: gaining detailed insight from above (presented by Willie Carroll, Location Intelligence & Design)

• The tactical technician (presented by Hector Velazquez, Hector’s Shop)

• Learn to develop a culture of accountability and ownership (presented by Mark Thompson, The McKinley Group)

Conference education sessions scheduled for Tuesday, March 3 include:

• Golf course operations and health & safety: do you know what you don’t know? (presented by Sheila James, Workplace Safety & Prevention Services)

• Clues for winter damage repair (presented by Dr. Leah Brilman, DLF Pickseed)

• Personal resiliency (presented by Cynthia Schoopmann, HumanaCare)

Conference education sessions scheduled for Wednesday, March 4 include:

• Putting it all together: species, genetics and management for less problems (presented by Dr. Leah Brilman, DLF Pickseed)

• Contemporary issues in turf disease control (presented by Dr. Rick Latin, Purdue University)

• Balancing life on and off the course: where turf management and mental health meet (presented by Judy Johnson, Light of Day Coaching)

• Using information about how golf is played to solve turf management problems (presented by Dr. Brandon Horvath, University of Tennessee)

• Sand characteristics and impact to topdressing and aerification backfill

(presented by Dr. James Murphy, Rutgers University)

• The five levels of leadership (presented by Stephen Keating, the Toro Company)

In addition to the conference education sessions, two specialized learning workshops will be presented on Sunday, March 1. The first is titled, “21st century turfgrass insect control: successes, failures and strategies for managing pests in changing environments,” to be presented by Dr. Ben McGraw of Penn State University. The second session is titled, “Managing your most important asset – human capital,” to be presented by Mark Thompson of The McKinley Group.

Dr. Brandon Horvath of the University of Tennessee will present a third specialized learning workshop on Thursday, March 5, titled, “Managing bluegrass greens: ecologically sound disease management.”

BASF, Bayer and Belchim Canada will make product presentations during the day on Tuesday, March 3.

The conference is a presentation of the CGSA.

For more information about the conference, visit https://golfsupers.com/ottawa2020.

Winter damage will be discussed at the Canadian Golf Course Management Conference in Ottawa in March.

irrigation Sports field irrigation

Make sure your system is in working order and uses water efficiently.

By Mike Jiggens

The creation of sports fields for public play represents a significant investment on the part of a municipality, and parks and recreation departments are obligated to protect that investment as best as possible. One strategy is to outfit a sports field with an irrigation system, especially if it’s a high-end playing surface that will serve as a venue for major tournaments aimed at bringing revenue into the community.

Steve Hernandez, sales representative for Turf Care Products Canada’s residential/commercial irrigation and landscape lighting division, spoke about the need to perform best irrigation maintenance practices during September’s Sports Turf Canada field day in Oakville, Ont.

“The benefit of an irrigation system is to protect your large investment,” he told a large group of sports turf managers in attendance at the annual event.

In sports turf management, there is a requirement to irrigate at some point in order to maintain a healthy playing surface. Irrigation doesn’t necessarily have to be provided through an installed system. Fields can be watered through a quick coupler or water can be broadcast from a valve or from above ground irrigation sprinkler heads.

“We want to make sure it’s efficient use of water,” Hernandez said, noting that installed systems ensure water is used effectively. There is less waste because systems are specifically designed to cover targeted areas of turf on soccer fields, baseball diamonds or other playing surfaces. Automatic features also help save time.

“Manual systems are a little bit more labour intensive,” he said. “The automatic irrigation systems will help you save time and you can schedule irrigation

systems to come on when you wish them to come on. You want to have it so it’s not impacting playing time with too much water at that time, and you can actually control that with scheduling.”

Sports turf managers involved in the design of an irrigation system need to look where water is lost and how the loss of that water can be mitigated, Hernandez said.

As part of his presentation, he outlined a system’s major components and how they work, starting with the master valve which is tied into an irrigation main line. The master valve allows an irrigation system to function without water filling the main line.

“The master valve will hold back water to the main line irrigation system, and only when that zone or zones is requested to turn on will the master valve open and allow that water to enter into that main line.”

Hernandez said there have been occurrences of damage to the main line and, unless the matter is ob -

Irrigation specialist Steve Hernandez talks about system components at Sports Turf Canada’s field day in Oakville, Ont.

vious where water can be seen gushing out of the ground, the problem is sometimes missed. Water will otherwise leak through the main line for the duration of the irrigation season.

“If it’s not caught right away, that’s a significant amount of water that’s leaking into the ground that’s not for irrigation purposes.”

KEEPING A LID ON WATER, MONEY LOSSES

The use of a master valve will control both water and money losses. Incorporating sensors will also save water and should be something to include when designing an irrigation system, Hernandez said. Rain sensors and soil moisture sensors will allow the irrigation system to shut down if there has been a significant amount of rainfall experienced.

“If we don’t need to irrigate because of rainfall, we are actually now saving more water from being used.”

Overwatering of sports fields is virtually eliminated by the use of soil moisture sensors. In most places in Canada, there is a desirable amount of precipitation in

terms of rain and snow as well as a fair amount of available fresh water. Although sports turf managers consider themselves as water stewards, it’s still important to use water wisely, Hernandez said.

“It’s not so that we can just throw out an abundance of water onto a sports field just because we have it available to us.”

Most irrigation system manufacturers have sprinkler heads designed to shoot water a certain distance by using a certain size nozzle. Head-to-head coverage in which the spray from one sprinkler head reaches another and vice versa is the objective of a well-designed system.

“If you are designing an irrigation system for a sports field, it’s imperative that we design it in such a way that we’re using proper design techniques in terms of layout and in terms of spacing of the sprinkler heads.”

When designing a system for a soccer field, irrigation contractors and designers will consider the most trafficked parts of the playing surface such as goalmouth areas and the centre length of the pitch. They will ensure sprinkler heads are positioned accordingly so that water will reach key wear areas with the proper volume.

Hernandez recommended the installation of other valuable irrigation system components such as flow sensors to determine the amount of water running through the system when the sprinklers are on.

“It tells you in terms of volume or gallons per minute how much you’ve used on that cycle.”

Central control systems allow sports turf managers to tie information derived from flow sensors to determine if there was an excessive flow the previous night. In the event of an excessive flow, it can be determined why too much water was used based on what the system was designed to do. The flow sensor allows the sports turf manager to determine whether or not he’s had excessive flow in order to prevent water waste.

Central control

allows sports turf managers to use information from flow sensors to determine if there was previously an excessive flow.

Hernandez said more municipalities are tapping into central control as a means of keeping better tabs on their water usage. Without central control, more time is spent going from field to field to determine where there might be a fault in the system and why one area of a field is drier than another.

“Sometimes you have to inspect that system in order to verify where the problems are.”

Flow sensors are measured in different sizes because of different sized main lines. Some main lines allow thousands of gallons of water a minute to flow through.

“If you have a break in it, that’s a lot of water that can be released.”

Hernandez said the flow sensor might determine an excessive flow contrary to the volume of water that is supposed to flow through a particular zone. In such an instance the master valve can shut down if it registers

an excessive flow, preventing large volumes of water from escaping.

INSPECT THE SYSTEM

Like any mechanical structure, an irrigation system must be maintained with its components monitored and the system itself regularly inspected. All components must be adjusted to ensure they work properly and that the desired coverage is attained.

“We have to ensure the irrigation can and will function as it was designed to do. A properly working irrigation system will keep the landscape healthy and vibrant and will show water isn’t being wasted.”

An irrigation system should be inspected at least once a year, Hernandez recommended, adding it absolutely must be winterized in the fall. Failing to do so will result in the freezing and expansion of water within the system that can cause significant damage to the piping and workings of the system.

All aspects of an irrigation system’s components must be inspected. If the system is operated by central control, it will notify a sports turf manager when issues arise. Without central control,

‘The benefit of an irrigation system is to protect your large investment’

physically going out to inspect a field’s system is imperative, he said.

Before opening a water source in the spring, it is important to check for any damage that might have occurred during the winter and to inspect the system’s backflow prevention device, which must be done annually by law, Hernandez said. A backflow prevention device is a check valve that allows water to flow through it and into the irrigation system while not allowing water to re-enter potable water. It protects potable water from any contaminants or any back siphonage that may occur that could potentially suck back into potable water.

He cautioned that when starting up an irrigation system in the spring to open the valve slowly.

“If you just crank that valve open, the valve itself will allow water to shoot through that system and potentially shatter. It will break piping and shatter fittings.”

Filling the main line needs to be done slowly, he said, adding the amount of pressure in the pipe “is extraordinary.”

Visual inspections of a field should be made to ensure there is nothing out of the ordinary such as leaks or anything else the system wasn’t designed to do, Hernandez said. Valves, manifolds and valve boxes are other areas that should be closely inspected. A look inside a valve box can ensure there are no valves leaking and that the wiring to the valves is intact. The PVC manifold holding the valve in place should also be checked for leaks or cracks.

DON’T OVERLOOK WIRING

Wiring must not be overlooked, he added, suggesting it can be a “nightmare” if there is a problem. Connectivity between the actual irrigation electronic valve and the timer must be in good standing, and nothing should be corroded or exposed. The inspection needs to ensure the timer

“is talking to the valves.”

Hernandez suggested that when opening up water to an irrigation system – allowing entry at a slow rate – that each valve be cracked open zone by zone, allowing water to enter into the valves at the same rate.

“You don’t want to fill up the main line and then crack open a valve immediately, filling that valve which has been empty from the winterization, and now it’s filling up at a rapid rate.”

The water is under high pressure in many cases and could damage fittings, sprinkler heads and pipe. He suggested allowing water to enter into the lateral line side of a sprinkler zone at a slow rate when operating a system for the first time in the spring.

“Do so for each one of those valves until everything has had a chance to fill up with water. Then you can open the main line fully, close off all your valves and start testing from there.”

Scheduling is a vital part of the irrigation process to not only avoid overwatering, but under-watering as well. The signs of stress will be readily apparent with under-watering. Knowing the condition of the soil is a key consideration when scheduling. Sports turf managers need to know how much water each sprinkler head puts out. If the infiltration rate of the soil doesn’t allow water to enter the soil at a quick rate – such as with heavy clay – scheduling becomes important. A limit may need to be placed on the amount of water put down at one time, possibly spreading it out over the course of a week, depending on play.

“You want to make sure the schedule is tied into the type of watering we’re doing and the soil condition on which it sits.”

The sprinkler heads’ nozzles determine the volume of water being broadcast, making it imperative to ensure they are still

in place in the spring. If not, they will need replacement. Hernandez said checks must be made to ensure all heads are delivering the proper coverage, including distance, rotation and arc. They need to pop up to their required height to establish the proper coverage yet not exceed that height so as to become a tripping hazard.

All components such as rain sensors, soil moisture sensors, flow sensors and the master valve must be tested each year to make sure they remain functional, he added.

Before putting a system to bed for the winter, components and piping need to be emptied of moisture before frost sets in or serious freezing temperatures occur. The compressor to be used in winterizing an irrigation system should be sized in accordance with the system itself, Hernandez suggested. Compressors, measured in

cubic feet per minute, blow compressed air into the system to rid it of all water. The compressor can be detrimental to an irrigation system, however, because compressed air reacts differently from water and can damage piping, heads and valves if not used properly, he warned.

Compressors are designed to put out a significant amount of pressure, and irrigation products don’t require the same amount of pressure to allow heads to pop up or valves to open.

“If we run excessive pressure through that irrigation system, we could end up damaging that irrigation system.”

When running a compressor, outputting more pressure isn’t the best practice. Hernandez said between 40 and 60 pounds per square inch is adequate.

Before running a compressor on a system with a flow sensor, the sensor’s paddle

should be removed, he said, noting the sensor might otherwise sustain significant damage.

“You remove the flow sensor paddle, put in a plug, and away you go and start winterizing.”

Special attention needs to be given to areas separated by isolation valves, he added.

“Once you’ve blown out that one section, close the isolation valve so you can maintain a certain pressure to blow out the rest of that system.”

When the system is being blown out, water will emerge from the heads followed by a mist. Once mist is no longer visible, it is likely that air has run through the sprinkler head for too long, Hernandez said, noting that sprinkler heads have small plastic mechanical gears that can overheat and damage the sprinkler head.

Getting a head start on climb up ladder

Eight Canadians participate in 14th annual Green Start Academy

By Mike Jiggens

Eight Canadian assistant golf superintendents have been fast tracked toward becoming full superintendents after having taken part in a specialized training program last fall. The assistants were participants in the 14th annual Green Start Academy in Raleigh, N.C., a program co-sponsored by John Deere and Bayer Environmental Science.

The program was conceived in the aftermath of the golf market crash at which time there was an overabundance of both golf courses and assistant superintendents in North America. Turf schools were producing scores of budding assistants at the time, but few positions were available, and not enough superintendents were retiring.

“When a job did become available, it was highly competitive,” Mike Hirvela, customer marketing manager of golf and sports turf for Bayer, said. “A lot of times it was who you knew and not necessarily what you knew.”

This led to the development of a program designed to give assistant superintendents a competitive advantage in the market when a job became available. Most assistants were already well versed in the agronomics associated with the position, but had little knowledge of other key aspects necessary for them to move up the ladder.

“What could we do to give them budgeting skills? What could we do to give them people management skills? What could we do to provide them with a network of peers that, if they do get in trouble, they can work through these challenges?”

Hirvela has been involved with the

academy for seven years. The 2019 program was his first time as Bayer’s facilitator.

Ren Wilke, John Deere’s North American tactical marketing manager, said the academy is the longest running program of its kind in the industry. Officials from John Deere and Bayer receive between

Grant Murphy, superintendent at the Barrie Country Club, served as one of the mentors at the recent Green Start Academy in Raleigh, N.C.

125 and 150 applications each year from assistant superintendents throughout North America who wish to participate in the program. From that number, 50 assistants are accepted based on their resumes, reference letters and applications.

Each applicant is “blind scored” by a panel of judges.

“The panelists have no idea who the applicants are and they’re judged solely on their applications,” Wilke, who has been involved in the program the past six years, said.

Since he’s been involved with the academy, the number of participating Canadian assistants has grown steadily, he said.

“Eight out of 50 is a really good showing from the Canadian group.”

The assistants speak Geoff Griffin, assistant superintendent at the Port Carling (Ont.) Golf & Country Club, said learning how to grow the best turf possible is taught at the post-secondary level, “but we don’t really learn how to manage people, and managing people is one of the biggest parts of our job.”

Learning how to get the best out of a maintenance department’s workers and becoming the best manager possible were key lessons learned at the academy, he said.

“You don’t only learn how to manage, but how to deal with members as well and the best way of communicating with them,” Griffin said. “It’s always an ongoing

process. You never stop learning. I feel one step closer to obtaining a position I want as a superintendent.”

Cody Little, assistant superintendent the past three seasons at Springbank Links Golf Club in Calgary, said he was encouraged to apply to the academy by his superintendent, adding he was “pretty keen” on the idea.

“The academy helped realign my goals as a manager and what I actually need to put forth to achieve what these guys (academy instructors) have achieved and all the hard choices they had to make and everything they did,” Little said. “It teach-

‘Eight out of 50 is a really good showing from the Canadian group’

es you to rely on your team and boost morale and just know that they’re there to help you achieve your goals. It’s hard to do on your own, so all these people are here to help you and make the job a little easier.”

Cole McKenzie, who just completed his sixth season as assistant superintendent at Calgary’s municipal Shaganappi Point Golf Course, said the academy for him was about career building and using his personal tools to advance toward a superintendent’s position. Being upwards of 10 years older than most of the other academy participants provided a spark for him.

“I found that really pushed me to look outside of what I know of city golf and look more towards a career aspect as where the next gig will be because it might not be as a superintendent for the City of Calgary,” he said. “It might be taking a superintendent’s role in the private industry in order to advance my ca-

Miranda Robinson of Cordova Bay Golf Course in Victoria, B.C. was among the Canadian group at the academy.

reer and really diversify my skills.”

McKenzie said he has always considered himself a good communicator, and the academy pushed the need for good communications and team building. He said the program prepared him to “step up” his interviewing skills and become more professional.

“What I took home from the academy is there is more than one way to get into the position that you want,” Adam Kimber, assistant superintendent at Kitchener, Ont.’s Westmount Golf & Country Club, said. “That panel of superintendents and directors of agronomy all had their own stories of where they came from and how they got there. They stressed not to get caught up in titles and what other people are doing. Just focus on what you’re doing and hone your own craft and build your own brand. Through that process, if you’re doing things the way you want to do them, then you’re going to get to where you’re going.”

Kimber said he wants to continue to build his knowledge base and work on his people management skills.

The academy’s networking aspect introduced him to a wide range of personalities, and he said he enjoyed the exchange of stories of the various challenges everyone faces.

“We’re all different people but at the

same time we’re all trying to do the same thing.”

Geoff Hay, assistant superintendent at Oakfield Golf & Country Club in Enfield, N.S., said the academy’s message to him was clear.

“It was more about managing people and managing yourself,” he said.

Hay’s role at Oakfield is to manage the grounds maintenance staff, and the academy taught him how to maximize the productivity of his workers by tailoring his people management skills to each individual and not necessarily treating them all the same.

“Having Green Start, if I walk into an interview, that’s just another positive,” he said. “It’s an extra little bump that if somebody sees that, they’ll go, ‘That’s a very respected program.’ It’s really nice to have that on my resume. I’m sure it gives me a leg up on the majority of people.”

Networking

Hirvela said the academy’s networking aspect was a critical part of the program.

“One of the big changes we’ve made is to create peer groups prior to the event where the assistants can reach out and meet with the mentor superintendent who’s in charge of them, and they’re having conference calls, they’re reading books, they may be doing Harvard busi -

ness reviews – different things to work on their individual development.”

The implementation of more connection among the participants helped give the event “life and legs” beyond the three days spent in Raleigh. The formation of peer groups ahead of the academy was a strategic move, Hirvela said.

“They know each other already, so when they show up they have a level of comfort with 20 per cent of the people at the event.”

Wilke said the academy helps the assistant gain the necessary knowledge required for the next career step.

“Do you work better in a public environment? Do you work better with a board? Do you work better with a single owner? Do you work better with a municipality? It’s really about giving the assistants the empowerment to find their next move and to make sure it’s a successful move and not just taking a job because it has the title of superintendent. Is it really the best step for you?”

The other Canadian assistant superintendents who participated at the Green Start Academy were Paul Sullivan from the Mississagua Golf Club in Mississauga, Ont., Miranda Robinson of Cordova Bay Golf Course in Victoria, B.C. and Daniel Gelder of the Devil’s Paintbrush in Caledon, Ont.

The 50 assistant superintendents – including eight Canadians – attending the 14 annual Green Start Academy pose for a group photo.

The art of scaling

To get a leg up in the industry, a firm must be ‘uncommon’

By Mike Jiggens

Building a better landscaping business doesn’t happen on its own, nor is it solely the accomplishment of the business owner himself. It takes a well-trained team to scale a company and it begins with goal setting and strategic planning while being “uncommon.”

Mark Bradley, founder of TBG Landscape and CEO of Markham-based LMN, a landscape estimating and timekeeping software system, shared his advice for building a company with a roomful of landscape contractors attending January’s Landscape Congress in Toronto.

“If you start strategic planning on your own, you’re really not strategic planning,” he said. “Strategic planning involves everybody in the company, so you’re going to have to pull in everybody on the team.”

Even a small company with only a handful of employees requires the input of everyone, he added.

Goals must be set at the outset of the year with a focus on creating a list of desired outcomes.

“I think the more complicated part is creating strategies to make sure that those goals actually happen,” Bradley said. “It’s pretty easy to measure results and it’s pretty easy to identify where things are going good and bad if you’ve got goals.”

The difficult part, he said, is tweaking strategies and sharing them with everyone else in the company to cause meaningful

change and improve the day-to-day business. The strategic planning process involves everything from the way the telephone is answered and how equipment is managed to the way staff are hired and trained.

“As owners or managers, it’s up to you to identify the strategies that are missing in your business.”

The highest return on a landscape contractor’s invested time will come from strategic planning, Bradley said.

“Things just start to operate smoother, things happen faster and your business is going to generate a lot more revenue than you can ever do on your own because other people ‘can finish your sentences.’”

Landscape contractors must pay their employees fair wages if they wish to scale their businesses, Mark Bradley, founder of TBG Landscape, says.

CONQUER 25 ° SLOPES.

The PRO Z 972 SD and the NEW PRO 972 SDL offer unmatched hillside confidence and maximized comfort to provide the ultimate mowing solution for municipalities, commercial cutters and properties with varying terrain. Visit cubcadet.ca/pro to discover our newest additions to the The PRO 972 SDL and PRO X 600 rounding out a complete line-up of unmatchable power, strength, and comfort.

Canadian Turf Distributors

Atlantic Provinces

Irri Plus Inc. (902) 405-4774

Quebec

Central Irrigation Supply

Ville St. Laurent, QC (514) 788-5884

Site One Landscape Supply

Ville St. Laurent, QC (514) 913-6719

Ontario

Site One Landscape Supply

Concord, ON (5 locations) (800) 347-4272

Vanden Bussche Irrigation Milton, ON (6 locations) (800) 263-4112

Central Irrigation Supply

Mississauga, ON (5 locations) (905) 795-8088

Manitoba

Consolidated Supply

Winnipeg, MB (204) 632-7643

Site One Landscape Supply Winnipeg, MB (204) 694-9442

Saskatchewan

Saskatchewan Consolidated Supply

Saskatoon, SK (306) 653-5444

Site One Landscape Supply Saskatoon, SK (306) 931-2440

Alberta Emco

Calgary, AB (403) 278-1470

Corix Water Products

Calgary, AB (5 locations in AB) (800) 242-3176

Consolidated Supply Calgary, AB (403) 203-7550 Edmonton, AB (780) 413-3173

Site One Landscape Supply (2 locations in AB) (403) 236-0102

British Columbia Andrew Sheret Ltd. (24 locations in BC) (250)-386-7744

Consolidated Supply Kelowna BC (250) 863-8291

Corix Water Products Langley, BC (11 locations in B.C.) (800) 667-2445

Site One Landscape Supply (4 locations in B.C.) (250) 544-0401

Van-Kel/EMCO Corporation (8 locations in BC) (800) 667-8825

Vancouver Irrigation Supply

Vancouver, BC (604) 251-2258 (4 locations)

Rain Bird International Inc. www.rainbird.com/ca

What that means, he said, is that a welltrained team knows how the company operates and won’t have to ask the business owner the type of aggregate that needs to be placed under a base in a construction project or where certain materials are stored. The business owner won’t have to run around dealing with such matters. The operation will be more efficient with little or no flow interruption. The time spent training staff and creating systems for them to execute and finish the owner’s sentences will produce a return on that time investment.

“If you’re out doing the work because you’re better than them, you’re probably not really a business owner. You just own your job. Don’t try to fool yourself into thinking you’re going to scale your business up. You really have to change your mindset and believe you can build a team that can finish your sentences.”

To develop the ideal team, the owner must ensure his business is the company of choice for prospective staff. That won’t happen, however, if he pays his employees only minimum wage, Bradley said.

Paying fair wages

“We have to create a career where people can be successful, personally, if we want to be successful as business owners. So that means we have to pay fair wages. We have to have benefits. We have to have pension savings programs so that they can be successful people.”

The biggest challenge among landscape contractors is finding the right employees who wish to remain with the company after they’re hired, he said.

“If you want to scale your business, you’ve got to be fair. If you want to scale your business, you’ve got make sure that everybody who’s working for you comes up the ladder with you because you can’t get there on your own. And if you keep losing your best people every year, it’ll be a really slow crawl to the top.”

Bradley said if starting employees are hired through an apprenticeship program, their wage should be $18 to $20 per hour. A certified landscaper should be paid $35 an hour plus benefits and a pension plan,

he added, while foremen should realize a six-figure income (for a large design-build and maintenance operation).

Getting the right people on board and having them stay will happen only if the company is a “well-oiled machine.” Systems must be created to allow great people to execute without much day-today direction. With the right people on the bus, the owner can step out of the way and allow his staff to take over.

“That really allows us to focus on what we’re best at. You may be a fantastic designer, you may be a great salesperson, or maybe you’re more of an operational person.”

The business owner’s weaknesses are the things that need systemizing the most, Bradley said, adding the better the contractor gets at systemizing and delegating duties, the sooner he’s going to be successful and the sooner his business can scale.

“You can’t scale if you’re going to try to do all this alone. We have to be good marketers because, ultimately, we’re not going to get the work that we want in this business if we’re not good at marketing.”

Establishing a good website and using social media to drive attention to a company’s landscape projects are vital, Bradley said, adding if business owners themselves aren’t experts in these fields, the work can be outsourced.

A company that’s scaling must always pursue new work.

Scaling up through sales

“I think the difference between the companies that scale up in a big way and the companies that don’t often have a lot to do with their sales process. I think the way we handle our sales process has a huge impact on our ability to scale and definitely our ability to scale profitably.”

Scaling won’t happen if the wrong type of work is sold to the wrong type of customer, he said.

The customer experience must be considered, especially when the average customer turnover rate in the landscape maintenance business is 58 per cent.

“That’s crazy. You’re replacing 58 per

Battery-Operated TBOS-BT.

Bluetooth-enabled smartphone control.

• Pairs with the Rain Bird app for easy access at your fingertips

• IP68-rated case can be installed anywhere, even underwater

• Vandal-proof design is ideal for public, high-traffic areas

Learn about the TBOS-BT and our full lineup of control solutions at rainbird.com/TakeControl-BT

cent of your customers every year? That is way too high.”

Contractors may think price is the reason customers switch to other companies, but that’s really not the case, Bradley said. Customers are looking for something they’re not getting.

When enhancements are sold, the customer interprets the extras as topnotch customer service and is willing to pay for the additional services.

“The profit margin is off the charts on those services. The landscape maintenance business can be every bit as profitable as a design-build business if it’s managed properly, but it all relies on customer service. If you want to make a lot of money in landscape maintenance, ask yourself what systems are missing to drive those enhancement sales to increase the price to the keep the turnover on customers down.”

Crews are going to think and perform more efficiently when their company has created systems that eliminate flow interruptions. Bradley said the average landscape company is producing only 60 per cent of the revenue it is capable of producing, meaning 40 per cent of the time crews are either waiting or wasting time doing something that isn’t adding value to the business.

“A $600,000 company operating at 60 per cent efficiency is

actually a million-dollar business. You’re just throwing $400,000 out the window with downtime and waiting. It’s shocking that we allow that to happen, but that is the way the industry operates, unfortunately.”

Performance metrics

A company is going to need performance metrics in place if it hopes its people are to produce work in a profitable way on an ongoing basis, he said.

“These performance metrics are a lot easier to set up than most people think, but most companies don’t have them. The difference between the companies that are making the double-digit profits and the industry average at one per cent is that everybody in the company understands what the production rates are. They understand what the estimated hours are. They understand how the job went afterwards. They understand estimated versus actual.”

Bradley asked his audience to ask themselves why customers choose their business, noting systems that are missing in a company has a lot to do with a customer’s perception of his experience from the time the telephone rings to the project’s completion and through to the time the warranty period ends, or the time the renewal period comes up on a landscape maintenance contract.

“The customer experience really has everything to do with your ability to produce a profit and succeed as a business. If we can’t make sure that our customers have a great experience from first call to completion, then we’ll never be successful.”

It’s not what makes a business unique that’s important, but what makes it uncommon, Bradley said. The way a customer is greeted on the telephone is going to have a significant impact as well as how the contractor and customer meet. Sitting down with the customer at the kitchen table is a good way to get the process started before all parties go outside to look at the project site.

“When I get out of my truck, I walk up to the front door. I’m scanning the house. I want to see the roofing materials. I want to see everything, but the reason I want to get to the kitchen table is because that’s my chance to start to be uncommon.”

Bradley said the approach provides him with some valuable education about the customer.

“I understand them before I start talking. That’s where you’re going to be uncommon. The way we handle the customer is the uncommon part. It’s the things you say and the things you do.”

A contractor will be uncommon based solely on his ability to deliver the customer experience. If the contractor wishes to be uncommon and successful and sell his work for more money than the bargain landscaper, the customer experience will be the only thing that makes him uncommon and the only thing that lands him work.

Mark Bradley

The state of golf: a super’s outlook

Superintendents can lead the way in cutting costs, promoting efficiencies

By Jim V. Riopelle, CGSA, AGS

There was a time near the end of high school when I remember the confusion of not knowing what I wanted to do with my life.

As I mulled over this question for much too long, I got a job on a golf maintenance crew for the summer. I believe the year was 1976.

Well, I fell in love with the work and instantly knew what my future path would be. I continued to work on the crew while attending university. After graduation, I secured employment at a high-end golf course and my foray into golf course maintenance began to take shape. Thirty-seven years and a few golf courses later, the passion burns as strong as ever. There isn’t anything I would rather be doing than caring for golf courses.

I’ve experienced the good times in our industry but more recently have seen a beleaguered industry, as our core players age, younger people don’t play, and revenues struggle to keep up with expenses. Perhaps it’s just me, but national associations on both the player and maintenance side seem to be in denial of the facts. More than 800 facilities across Canada and the U.S.A. have closed over the last decade, yet there is little, if any, conversation going on. Why it’s so hush-hush, I don’t know.

So I thought it was time I put in my proverbial two cents and offer a few prac-

tical solutions to help courses survive –what looks like – a permanent downturn.

There was a time when courses were packed from dawn to dusk and then some. Junior members numbered well more than 100, with each having burgeoning men’s and ladies’ memberships. Pay-asyou-play golfers struggled to secure a tee-off time.

All that has gone away. We are now

dealing with reduced membership numbers, with few, if any, juniors, reduced green fee players and empty restaurants. Sure, there are courses that are doing well, but most are upper end private facilities with strong membership bases and clubhouse minimums. The construction boom of the 1990s is now a faint memory. Many facilities tried in vain to hold on, but eventually failed, and maybe that’s not

Are ball washers and other golf course accessories really necessary on every hole?

Jim Riopelle is superintendent at the Glenboro Golf & Country Club in Brandon, Man. and has 36 years of experience in the golf industry. He has previously worked at a number of other courses in Canada, from Alberta to Quebec, and owns his own consulting business.

a bad thing. The marketplace was saturated and competition fierce among golf facilities. PGA-like course conditions were and are not sustainable at most facilities, but golfer demand for these conditions persisted and eventually drove courses to the brink of financial meltdown. Bar and restaurant facilities at one time held their own and made an overall profit, but more recently have struggled to stay out of the red.

Until recently, golf course superintendents, like myself, have been reluctant to reduce expenses, citing local competition as their reasoning, and that is a valid argument in a burgeoning industry, but that’s just not the case for golf anymore. As superintendents, we must be proactive in identifying and implementing not only cost savings, but also efficiencies within our entire operation.

It must be noted here that superintendents and their staff are very dedicated individuals who love their facilities and rarely compromise on quality. My suggestions attempt to not compromise on quality, but reduce course conditioning to help save facilities and the employment of the people who maintain them.

Herein, I will list a few based on my 35 years of experience as a golf superintendent, but it’s by no means a complete list. Each facility, being unique, will have its own ideas for revenue generation and/or cost reductions.

Operate golf facilities as one operation rather than three separate entities (pro shop, restaurant, greens department). Too many courses operate with these entities at arms length from each other. Bringing them all together will improve efficiency and communication within the

entire operation and not only save money, but improve customer service. The golf season is a hectic and busy time for all operations, but it is essential to have department heads meet on a regular basis. Controlling expenses is not just the GM’s responsibility. It’s rather a team effort. Greens departments need to take one day a week off or at the very least have two short days during the week. Obviously it cannot be from a Friday to a Monday due to busy weekends. On most courses, Monday, Wednesday, and Friday are full cutting days (greens, tees, collars/approaches, fairways, rough, pins, bunkers, etc.). This leaves Tuesday and Thursday that could be four-hour days or make one of these days a day off. Either way you’re saving eight hours of time per employee per week. That can translate to approximately $20,000 in savings over the course of a season with an

unnoticeable effect on course conditions. Golf courses can be maintained in very good condition with reduced inputs. It just takes a little creative scheduling and a “willingness” to do it.

All superintendents need to utilize their education and skills to become better golf agronomists. Without insulting anyone, because that is not my intention, we need to get out on the course more and stop relying on calendar days for when we apply plant medicines or nutrients. We have marvelous technology available to us today that needs to be utilized to its fullest potential. I’ll give a shameless plug to the “Greenkeeper” app (free), and “Turf Log” (inexpensive) that are both wonderful apps for greens departments – the latter being a diary-based program.

As superintendents, we purchase some products that we could do without. Sure, it’s exciting to try new products and chemistries, but they’re usually expensive and unproven under real world conditions. I tend to let the high-end courses experiment with new chemistries before jumping in. By that time their use has been tweaked, cost reduced, and they become more palatable to utilize.

In the case of fertilizers and supplements, there are so many available products out there. The old adage still remains. If you don’t see a discernible difference in the plant, then why use it? There are no magic bullets in plant nutrition. Decipher your soil test results and get back to basics when it comes to plant nutrition. Have a solid understanding of nutrient sources, release rates, and their corresponding effect on plant growth. I have been utilizing a methyl urea/ammonium sulfate blend on fairways and roughs with excellent results for the past few years. As an added bonus, it’s significantly cheaper than the newer technology. I get more bang for my buck. If your soil test results don’t show P or K deficiencies, then why purchase a fertilizer that contains them? Stay on top of your soil test results and apply deficient nutrients as required. Keeping your soil in proper balance is the key to success and will save money long term.

Greens are one area where I do not

compromise on quality when it comes to the products I utilize, although I do only supply three or four granular applications per season. The remaining nutrient applications are all soluble through the spray tank along with a growth regulator and an

iron product. Growth regulators are only applied based on a growing degree day (GDD) schedule rather than calendar based. The “Greenkeeper” app has this function built in. This will also save money over the course of a season.

Multi-spiked roller

850 perforations per square yard

Honda engine with Eaton Hydrostatic Drive

Rear smooth packing roller

Cam-adjusted seed gate

User-friendly controls

Seed calibration tray

Addition of Optional rear multi-spike roller increases to 1700 perforations

24” SELF PROPELLED AERASEEDER

Monitoring temperature, humidity, moisture content, dew and guttation water formation can impact the application of plant medicines. Mowing is an important cultural management practice for dew/guttation water removal and may have a positive impact on reducing plant medicine applications over the course of a season.

again, from an efficiency perspective, you’re ahead of the game and therefore saving more money.

Purchase used or refurbished equipment rather than new. It’s available at a significantly lower purchase cost and has usually just come off lease from a course where it was well maintained. And on that note, retain a good mechanic. They are worth their weight in gold. My last mechanic had no experience whatsoever with golf equipment when he started, but ended up being the best I ever had. I know he saved me thousands of dollars and, better yet, he was also passionate about his work. Needless to say, he fit right in.

within our power to increase food service use and, conversely, revenues. Charging exorbitant amounts for our food has not enamored us with our clientele over the years and has done nothing but create animosity toward our food service operations. There are opportunities to generate “volume based revenues” within our food service facilities.

In the case of course fixtures (ball washers, tee blocks, bunker rakes, water coolers, spike cleaners, ropes, tee signs, etc.), do we really need a ball washer on every hole? Probably not. Even with a modest yearly replacement program, they’re expensive. So why not have them on every second hole instead and use the remainder as replacements when needed. Think back to your own experience playing golf. How many times did you actually utilize a ball washer at a tee? Reduce the quantity of rakes in bunkers. Unfortunately, most players don’t use them anyway, and they’re inefficient for mowing personnel who have to get off their machine to move them. Reducing their numbers on the course will provide for replacements when required.

If you don’t have a mechanic at your course, then you’ll have to put on that hat as well. Find someone who can help you with the complicated stuff. Otherwise, it’s not that difficult to keep up on regular maintenance.

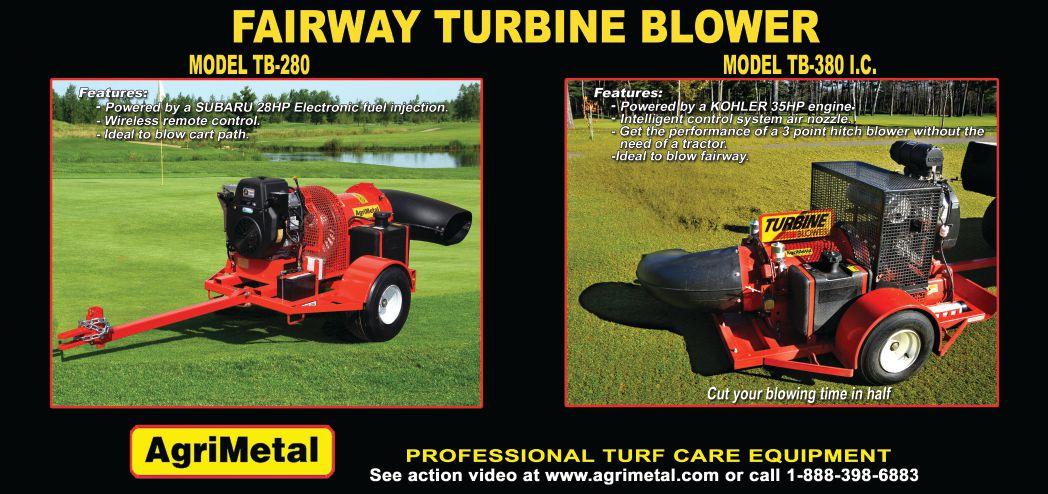

AGMTurbine:Layout 1 5/25/16 11:31 AM Page 1

Keep ropes and signage to a minimum except on those wet days and shoulder seasons when they’re really needed. Once

• Although I have limited experience in the restaurant end of the operation. I do think we need to simplify menus and provide good food at a reasonable cost to our customers. Although a higher end menu may work at exclusive facilities, I don’t believe that type of menu works at most clubs. People are very price conscious today, so we must do everything

• We need to get more young people exposed to the game. If it means providing free clinics and a club to use, then that’s what we have to do. We need to align ourselves with schools and business so that we can “grow the game,” or at the very least maintain existing numbers. Every facility should have a driving range of some sort. The revenue potential is too good to pass up.

These are just some ideas from a golf superintendent. There are many more cost saving and revenue generation proposals that can and will work. Raising fees for green fees and club membership is not the answer. That ship has since sailed. Members and the golfing public will not be receptive to increased fees. They will be receptive to good value and service. Keeping this great game accessible and affordable to the masses is in everyone’s best interest.

The most powerful turbines on the market.

Check your attitude

Improper reel selection, improper bedknife selection and improper reel attitude setup lead to inefficient cutting.

By Mike Slack

Good day, turf people. My name is Mike Slack. I have owned and operated Slack Reel Service Inc. in Burlington, Ont. for the past 30 years.

Turf & Rec has requested that I write a periodic article on reel mowers – in particular the common issues that golf and turf technicians face on a regular basis. My company services several golf courses throughout Ontario, and one of the most common issues I come across is that technicians cannot get their mowers to cut as efficiently as required. Problems such as choppy or serrated cuts, scalping issues and comments like “It looks like it ain’t cutting but there is grass in the bucket!” are common.

I would like to share my thoughts on the most common reasons for this that I

see in my travels. Before I do, I would like to mention that our industry has had a shortage of technicians in previous years, not unlike most trades today.

We are seeing other mechanical industries, such as auto, filtering into the turf field. Some of these people are great at diagnosing issues with the mechanics of the unit, but have never worked on reels before in their career. Reel training is extremely limited in our industry and most often comes down to a “who you know” way of business. Some OEM manufacturers offer one or two-day seminars for mechanics that are a start, but it has always been easier to have someone deal with your specific issues at your specific turf property.

The three most common reasons for

mowers not cutting as efficiently as possible are improper reel selection, improper bedknife selection and improper reel attitude setup.

Improper reel selection

Reels vary in several ways but one difference is their number of blades. Reels can have five, seven, eight, 11, 14 or 15 blades. There is a good reason for this. It is referred to as the “clip rate.” Clip rate is defined as the forward distance travelled between successive blade contacts at one shear-point.

If you have too many blades for your height of cut, it is extremely possible that as the reel cuts, the grass blades do not have enough time to stand up between each blade, resulting in grass blades being

The rule of thumb in reel selection is, the lower the height, the more blades are required.

missed and giving a shaggy cut.

If you have too few blades, it is entirely possible to end up with a serrated cut or a “choppy look” cut.

Rule of thumb: the lower the height, the more blades required.

Another factor that contributes to cut quality is ground speed. Your operator might come in and say, “I just cut 18 fairways in 45 minutes! I deserve a medal.” If he is driving the unit as if he has been entered in the Daytona 500, there will be a great chance of poor quality of cut.

Bedknife selection

A bedknife provides the second edge in the shearing action of the reel. Selection of the proper bedknife is crucial for the height of cut you are attempting to attain.

Rule of thumb: The lower you go in height of cut, the thinner the bedknife

needs to be.

It is important to select a bedknife that best suits your height of cut and one that is not too thin for the job. Otherwise, it will result in having to replace the bedknife more often.

Most bedknife manufactures will provide a bedknife guide to assist you in finding the proper bedknife for your required height of cut, but this does not normally take into consideration reels that are worn, which leads me to “reel attitude.”

Reel attitude

Real attitude is the relationship between the bedknife angle to the cutting surface. This can be set aggressively for a crisper, cleaner cut. A negative attitude can be detrimental to any “quality of cut.” I usually explain “attitude” to technicians this way: picture a pile of dirt and grass on

your shop floor because your operator does not truly understand the meaning of “cleaning the machine” after use. Try to pick up the dirt and grass clippings by laying a shovel flat on the ground. With the same dirt and grass clippings and shovel, try it again but now tip the shovel on a 20-degree angle while scooping up the pile. The shovel tipped to 20 degrees provides a more aggressive angle and should pick up more off the floor. This is the same idea with bedknives and turf.

Roller maintenance

Always ensure your rollers are in good working shape. A faulty roller will affect your quality of cut. Rollers may require a change in bearings or seals after prolonged use. Always remember to keep your rollers greased if necessary. Reels and rollers should be inspected prior to each use.

I hope these tips are of help to your turf technician. As vast as the turf industry is, we are a very tight-knit group, and I’m sure a fellow tradesman or at the very least, myself, can get you on your way to excellent mower setup, resulting in great turf conditions.

Please send your comments on this article or any problem ideas you may be having, and we will do our best to address them in future articles.

Mike Slack is the owner of Slack Reel Services, which has been serving the golf and turf industry since 1989. The business is family run and deals with various companies across Ontario and other parts of Canada, specializing in reel mower sharpening, parts distribution and on-road service technical work, mainly in Ontario. The business may be reached by calling (905) 516-4757 or by emailing slackreelservice@gmail.com.

On the market

Trimmer joins commercial-grade lineup

The SRM-2620T is the newest addition to ECHO’s commer cial trimmer lineup, providing a significant step up from the current SRM-225. The 21.2cc professional-grade engine comes with chrome cylinder plating and two-stage air filtration system to deliver long engine life and a full wrap tank stand, plus insulator plate to improve hot restartability. The lower end delivers a class leading 2.07:1 torque and a flex-cable drive to reduce vibration and ensure a smooth cut. The larger D-shaped handle provides improved precision and user comfort for extended day-long commercial use, and the SpeedFeed trimmer head saves landscapers valuable time by loading in seconds. For more information, visit www.echo.ca

A natural remedy to skin irritations

Outdoor workers subject their skin to a number of afflictions, including burns, sunburns, abrasions, chafes, raw sores, insect bites and poison ivy.

An ointment made from pure and natural ingredients provides relief to those who may suffer from such skin afflictions.

Zincuta Ointment is made from oleic and linoleic acids, zinc oxide, beeswax, styrax benzoin, elm bark, wintergreen, lavender and bergamot – all designed to moisturize, suppress itching, relieve inflammation and give a pleasant scent. It can be applied to hands, knees, elbows, face and lips or anywhere else where skin is affected. It is non-messy and won’t leave a residue on clothing and has both anti-bacterial and antiseptic properties. The product should be applied to the affected skin area. It penetrates the skin, and softens, soothes, protects and heals all surfaces where applied.

For more information, visit www.zincuta.com

Breathable –

Efficient – Does your turf cover have Smart Edge technology, reducing the need for extra grommets/hemmed edges?

Attachments for clean boring

Little Beaver is making it easy to create clean, horizontal bores with its horizontal boring kits. Its two types of horizontal boring attachments turn Little Beaver’s mechanical earth drills into horizontal boring machines that can be used in a variety of applications, including conduit, pipe and irrigation installments. The boring kits are easier than physically forcing a pipe through soil by hand, and more cost effective than purchasing or renting expensive hydraulic and pneumatic moles, especially for those who already have a Little Beaver mechanical earth drill.

Coupled with a Little Beaver mechanical earth drill, the dry auger kit can efficiently create small bores up to five feet long. The kit includes a five-foot auger with a three-inch diameter bit, a horizontal drill key, and five-foot extension with a universal wiggle joint. With the extension connected to the auger by the wiggle joint, users are able to stand while boring. The earth drill provides the torque necessary to drill smoothly through the soil from one side of the sidewalk to the other.

Due to the low drilling load, torque tubes are unnecessary with horizontal boring. Instead, users attach a horizontal drill key to the torque tube connector on the power unit to engage the safety interlock and bypass the engine kill switch.

The wet drilling kit is ideal for jobs that require horizontal boring to lengths up to 50 feet, such as those under driveways and streets.

Boring may begin once the user has assembled the kit’s pieces and dug a starter trench.

For more information, visit http://www.littlebeaver.com.

Ease of Use – Is your cover lightweight, and manufactured in one piece?

Peace of Mind – Does your turf cover offer the best warranty, from a company with over 35 years of experience?

Durability – Can your turf cover withstand harsh winters, while offering quick germination and easy maintenance?

Low-flow mulcher head for skid steers

A new low-flow mulcher head has been introduced by Fecon Industries for use with most standard skid steer loaders, Avant-type wheel loaders and other carriers that can provide 17 to 27 gallons per minute of hydraulic flow, have enclosed cabs that can be properly protected with appropriate polycarbonate guarding, and have the ability to carry the 1,300-pound attachment.

The new mulcher head features 22 knife or carbide-type cutting tools and has a 50-inch working width. Operating from 2,400 to 3,600 rpm, it can shred brush and small trees up to four inches in diameter, making it an ideal tool for rental fleets as well as landscapers, arborists, farmers, ranchers, land owners/ property managers, parks and recreational facilities, municipalities, Christmas tree farms, and others tasked with managing brush and vegetation.

Weighing just 1,300 pounds with mounting plate and push bar, this new mulcher head can easily be handled by the carrier, yet is stout enough to provide a long service life. Overall width is approximately 60 inches with a cutting width of 50 inches, and overall height is 52 inches, with a depth of 33 inches. It is adaptable with varying mounting plates to fit several types of carriers.

For more information, visit https://www.fecon. com/

Board

For more than a decade, the Color Atlas of Turfgrass Weeds has been the leading authority for green industry professionals in their ongoing quest to control weeds and limit deleterious effects: the weed clumps, color variation, and unsightly patches that disrupt turf uniformity. The Second Edition of this essential resource has been expanded and updated to provide control information that professionals need to maintain the quality that is so vital to the golf, sports field, and managed landscape industries.

Health & Safety

By the CCOHS

The Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well being of workers in Canada by providing information, training, education, systems and solutions that support health and safety programs and injury and illness prevention. www.ccohs.ca

Watch out for frostbite, hypothermia

It’s been a cold winter with some parts of Canada plunged into freezing temperatures. This is bad news for outdoor workers for whom working in the cold can not only be hazardous to their health, but also life threatening.

Hypothermia and frostbite are the two most common cold injuries. Learn more about the health effects of cold stress and get some first aid tips that could help prevent permanent injury.

FROSTBITE

Frostbite is the second most common cold injury. Noses, ears, cheeks, fingers and toes are most often affected. The freezing constricts blood vessels, which impair blood flow and may cause permanent tissue damage. If only the skin and underlying tissues are damaged, recovery may be complete. However, if blood vessels are affected, the damage is permanent and could result in the amputation of the affected part.

FIRST AID FOR FROSTBITE

• Seek medical attention.

• If possible, move the victim to a warm area.

• Gently loosen or remove constricting clothing or jewelry that may restrict circulation.

• Loosely cover the affected area with a sterile dressing. Place some gauze between fingers and toes to absorb moisture and prevent them from sticking together.

• Quickly transport the victim to an emergency care facility.

• DO NOT attempt to rewarm the affected area on site (but do try to stop the area from becoming any colder) –without the proper facilities, tissue that has been warmed may refreeze and cause more damage.

• DO NOT rub area or apply dry heat.

• DO NOT allow the victim to drink alcoholic beverages or smoke.

HYPOTHERMIA

Hypothermia (low body temperature) is the most common cold injury. Prolonged exposure to the cold causes the body to lose energy faster than it is produced, dropping body temperature. The sensation of cold followed by pain in exposed parts of the body is one of the first signs of mild hypothermia. As the temperature continues to drop, or as the exposure time increases, the feeling of cold and pain starts to diminish because of increasing numbness (loss of sensation). If no pain can be felt, serious injury can occur without the victim’s noticing it. Next, muscular weakness and drowsiness are experienced. Additional symptoms of hypothermia include interruption of shivering, diminished consciousness and dilated pupils. When body temperature reaches 27 degrees Celsius, coma (profound unconsciousness) sets in. Heart activity stops around 20

degrees and the brain stops functioning around 17 degrees.

FIRST AID FOR HYPOTHERMIA

Hypothermia is a medical emergency. If any symptoms of hypothermia are present, immediately call for emergency assistance (911). The survival of the victim depends on a co-worker’s ability to recognize the symptoms of hypothermia. The victim is generally not able to notice his or her own condition.

• Ensure that wet clothing is removed.

• Place the victim between blankets (or towels, newspaper, etc.) so the body temperature can rise gradually. Body-to-body contact can help warm the victim’s temperature slowly. Be sure to cover the person’s head.

• Give warm, sweet (caffeine-free, non-alcoholic) drinks unless the victim is rapidly losing consciousness, unconscious, or convulsing.

• Quickly transport the victim to an emergency medical facility.

• Do not attempt to rewarm the victim on a specific site of the body (e.g., do not use hot water bottles or electric blankets).

• Perform CPR (cardiopulmonary resuscitation) if the victim stops breathing. Continue to provide CPR until medical aid is available. The body slows when it is very cold and, in some cases, hypothermia victims that have appeared “dead” have been successfully resuscitated.

REACHING NEW HEIGHTS IN PRODUCTIVITY

Exmark has expanded its line of 30-inch walk-behind mowers with the introduction of its new Commercial 30 X-Series model. With a new, more powerful engine and transmission, the Commercial 30 X-Series gives landscape maintenance professionals a more productive option, ideal for smaller properties. The increased displacement of the powerful Kohler Command Pro CV200 engine gives it 30-percent more torque than competing engines to quickly power through the toughest, thickest grass. The positive drive transmission delivers increased wheel torque, with easier side hill tracking and variable forward speed up to 3.8mph. The 3-in-1 design also offers the ability to quickly change from side discharge, to bagging or mulching, without tools, and the compact deck enhances maneuverability in tight spaces.