Reliability that counts

FSA 135 R BATTERY BRUSHCUTTER①

HIGH POWER SOLUTION FOR PROFESSIONALS.

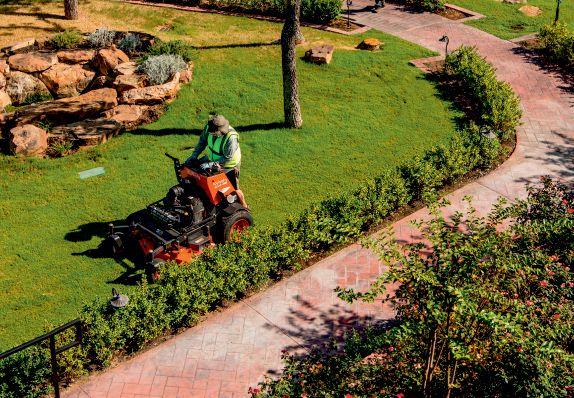

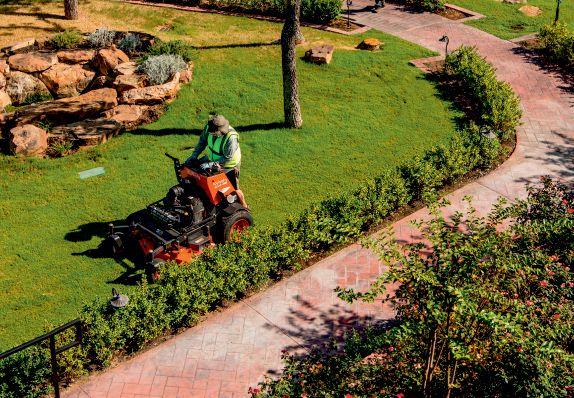

The FSA 135 R is the latest brushcutter in our battery-powered line-up that can be used in noise-sensitive situations. It is a lightweight, powerful and efficient choice for landscapers, municipal workers and those that have large yards to upkeep. The AP battery can be inserted directly into the powerhead, as opposed to using an adapter system. The ergonomic loop handle makes it comfortable to operate and easy-tomanoeuvre, while also providing a three-step speed adjustment with LED light. Built with a metal mesh air filter, it delivers a longer service life and provides optimum motor cooling. Also, a wide selection of cutting attachments can be used on the FSA 135 R to suit the job at hand.

NOTE: Bike handle version also available.

SPECIFICATIONS

① Battery and charger sold separately. ② Weight without battery.

Battery Power. Made by STIHL.

PRO-FLEET COMMERCIAL LANDSCAPE PROGRAM

STIHL’s Pro-Fleet Commercial Landscape Program is designed to provide commercial landscapers a volume discount on major purchases of five or more landscaping power tools. Visit your STIHL Dealer today to find out more and take advantage of the savings!

GrandPrize HARLEY-DAVIDSON®MOTORCYCLE

By Mike Jiggens

Marking Earth Week amid reversal of ban

Ashort while ago, Turf & Rec celebrated Earth Week online, with a couple of webinars, themed newsletters and the arrangement of content specifically packaged to draw attention to trends and practices deemed eco-friendly.

Although Earth Week is officially recognized in April, it’s really a year-round observance within this industry as efforts continue to be made to reduce emissions, decrease our reliance on pesticide products, scale back our use of water and promote sustainability.

The call for emissions reductions has picked up steam of late, to single out one such strategy. It has already happened in Vancouver, it’s currently happening in Ottawa and it’s being pressed to happen in Toronto and Calgary. When some of Canada’s largest cities have already made strides to ban gasoline-powered outdoor maintenance equipment in favour of battery and electric-powered tools, it can only be a matter of time before other Canadian municipalities follow suit.

This was the pattern several years ago when individual municipalities decided it was time to do away with traditional pesticide products, promoting instead alternative products that were deemed eco-friendlier. This led to individual provinces finally stepping in to introduce bans of

their own which nullified all existing municipal edicts so that a level playing field could be realized in all corners of each province, with the same rules and regulations applying to all.

Perhaps this is the way things will go with equipment. Maybe the provinces will lay down all-encompassing rules that will be standardized within their borders.

When these bans became law, it looked like there was no turning back

Unlike the execution of pesticide bans, which caught many lawn care companies and municipalities off guard when few effective alternatives were available, it’s a bit of a different story with equipment. Manufacturers of trimmers, hedgers, chain saws and other landscaping equipment saw the call for battery-powered tools coming for several years and prepared for the day when gasoline-powered equipment might find itself grounded.

By and large, most battery-powered tools are pretty much as effective as their gasoline-powered counterparts. Adapting to these isn’t as much of a stretch as it was to switch to the limited availability and performance of alternative pest control products when cosmetic bans were first introduced.

When these bans became law, it looked like there was no turning back. The political powers that be seemed hellbent to ensure they were ironclad.

So, it came as somewhat of a surprise to recently learn that Manitoba planned to reverse the pesticide ban it set in place eight years ago. The province argued the alternative products available to keep weeds at bay were much more costly than the traditional products that were banned. Individual municipalities are saying the cost of preventing unsightliness in their landscapes is putting a strain on their overall budgets. Residents in Manitoba’s various municipalities suggest their hometowns are presenting an unflattering appearance of themselves when dandelions and other weeds refuse to fully succumb to alternative products.

Will other provinces with bans currently in place follow Manitoba’s lead? So far, none has budged. These other provinces are likely to stick to their guns for the foreseeable future and stay the course.

But who really knows for sure? Aesthetics and expenses may trump environmentalism, especially if testing on traditional products is revisited which might produce data to suggest that certain products weren’t as environmentally unfriendly as they were once perceived to be.

One thing is certain. No matter what obstacles have been tossed at this industry over the years, it has always found a way to overcome them.

www.turfandrec.com

Reader Service

Print and digital subscription inquiries or changes, please contact

Anita Madden, Audience Development Manager

Tel: (416) 510-5183

Fax: (416) 510-6875

email: amadden@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

Editor Mike Jiggens mjiggens@annexbusinessmedia.com

National Advertising Manager Rebecca Lewis 519-400-0322 rlewis@annexbusinessmedia.com

Account Coordinator Trish Ramsay 416-510-6760 tramsay@annexbusinessmedia.com

Group Publisher Todd Humber thumber@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada ISSN 1186-0170

PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Published 7 times a year – Jan/Feb, March, Apr/May, June/July, Aug/Sept, October, Nov/Dec

Canada – 1 year $35.00; 2 year $45.00 3 years $55.50 (plus applicable taxes HST 86717 2652 RT0001

Occasionally, Turf and Recreation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com

Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2022 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Calgary group seeks to ban leaf blowers

About 700 Calgary residents have signed a petition in hopes the city will ban gas-powered leaf blowers to reduce emissions and noise levels.

Project Calgary, which launched the petition, says noise levels have become a serious issue since more people are working from home during the COVID-19 pandemic.

Other large Canadian cities, including Vancouver, Toronto and Ottawa have also addressed the same issue in recent months.

‘Doggone it’ says football club at park idea

A new off-leash dog park has been proposed for Victoria, B.C.’s Royal Athletic Park, but the idea isn’t being fully embraced by everyone.

The Mount Doug Rams football user group is concerned it could lose its use of the park. A Rams spokesperson said conversion of a portion of the park for dog use could jeopardize the football group’s tradition of playing Friday night light games.

‘Take Kanata golf dispute to Supreme Court’ – councillor

The ongoing dispute over the Kanata Golf & Country Club between the City of Ottawa and ClubLink needs to be heard before the Supreme Court of Canada, a city councillor says.

Kanata North Coun. Cathy Curry says ClubLink, developer of the property, is disregarding an agreement that states 40 per cent of the land must be maintained as green space and turned over to the city if it ceases to operate as a golf course.

What we’re willing to pay to play at Augusta National

As most of the world’s finest professional golfers got ready to tee it up for the 2022 Masters Tournament, recreational golfers throughout North America could only dream what it would be like to play at the fabled Augusta National Golf Club.

It’s a golf course that 99.9 per cent of us will never play, but we can always dream. A survey of more than 1,000 recreational golfers revealed the “price” many would be willing to pay for the opportunity to play 18 holes at Augusta National. The survey revealed both the figurative and literal prices golfers were prepared to pay if given the chance to play.

Forty-three per cent of those surveyed said they would willingly shave their heads for the chance to play. Among the other top concessions golfers were prepared to make included giving up drinking for a year, taking a one-year hiatus from playing golf

(after playing Augusta National), abstaining from sex for a year and quitting their jobs.

In terms of dollars golfers were willing to spend for a round of golf at Augusta National, those earning more than $100,000 annually said they would pay $3,189 to play the course. Those earning between $80,000 and $100,000 said they’d pay $1,225. At the bottom end of the scale, golfers with incomes of less than $20,000 said they’d still pay $388 to play.

Augusta National also ranked No. 1 among the top five dream courses to play. Rounding out the top five, in order, were Pebble Beach in Pebble Beach, Calif.; the Old Course in St. Andrews, Scotland; Torrey Pines in La Jolla, Calif.; and TPC Sawgrass in Ponte Vedra Beach, Fla.

To read the survey’s results in their entirety, visit https:// time2play.com/blog/what-golferswould-do-to-play-augusta/

target-specialty.ca |

Mitch Davidson

Southern Alberta, Kootenays mitch.davidson@target-specialty.com 587.223.2083

Jason Hooper

Lower Mainland & Interior Bc jason.hooper@target-specialty.com 604.317.2476

Chris Paterson

Southern Alberta & Kootenays chris.paterson@target-specialty.com 403.540.0157

Eric Gratopp Northern Alberta eric.gratopp@target-specialty.com 587.284.4744

Gregor Kowalski

Vancouver Island gregor.kowalski@target-specialty.com 250.686.3909

Josh Seibel Saskatchewan & Manitoba josh.seibe@target-specialty.com 306.861.8296

Mark Scenna Sales Manager, Canada mark.scenna@target-specialty.com • 416.458.2396

Perry Brazeau Toronto / East perry.brazeau@target-specialty.com 416.705.8006

Jason MacRae Quebec North & West jason. macrae@target-specialty.com 514.712.8006

Chris Nelson Toronto West / Niagara chris.nelson@target-specialty.com • 647.382.6868

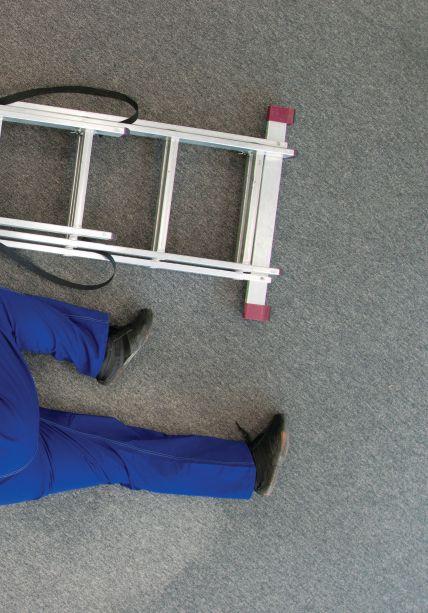

Don’t get caught skimping on safety

Make sure your golf maintenance shop complies with all safety regulations

By Mike Jiggens

Adisorganized golf course maintenance shop is an accident waiting to happen. Whether there are batteries stored on the floor, tools carelessly leaning against walls, flammable materials stored under stairwells, electrical outlets overloaded or any one of a dozen other safety infringements, a major fire, a serious injury or a loss of life could occur.

Golf superintendents attending the virtually delivered Canadian Golf Course Management Conference in March learned the “do’s and don’ts” of proper maintenance shop organizational practices to ensure their facilities meet the highest possible safety standards and are poised to pass an unexpected safety audit.

The online presentation was delivered by safety consultant Bill Godkin of Amherstview, Ont.-based CESafety. The company specializes in performing risk analysis audits, delivering safety training and designing safety programs necessary to achieve government compliance. Clients minimize the risk of injury and fines and save money on insurance premiums.

He said the golf superintendent is the person charged with keeping the maintenance shop in order, and the one responsible for ensuring all safety hazards are eliminated. Inattention to safety hazards results in consequences, he added.

“Things you look at every day could be a safety hazard that you’re simply not aware of,” Godkin said. “An outside set of eyes will find things that you look at every day, and you’re not aware of it being a safety hazard.”

Close calls and minor injuries could lead to serious injuries when maintenance shops are left in disarray, he said.

Godkin said the first thing he looks for when walking into a maintenance shop is the state of its housekeeping, adding it’s also what government officials check

first. Suggesting there’s no excuse for a shop that’s in a state of disorder, the condition of its housekeeping is the best place to start to identify and eliminate safety hazards. A floor-to-ceiling approach is an ideal means to find things that are out of place and decide where improvements can be made.

By scanning the floor, potential tripping hazards such as hoses or batteries can be readily identified. Water from rain or melting snow can be tracked onto a floor, presenting a slipping hazard.

Addressing such hazards will eliminate tripping and slip-and-fall accidents.

BATTERY STORAGE

Godkin said the storage of batteries on the floor is a common occurrence in maintenance shops. He suggested creating battery storage areas and to wear long-

An eyewash station is a must in golf course maintenance shops. An employee’s vision may depend on it if he gets chemical or another hazardous substance in his eyes.

sleeved neoprene gloves when handling batteries. Smaller, disposable gloves are useless against battery acid, he pointed out, adding goggles should also be worn for eye protection and to have baking soda close at hand to neutralize spills.

“Make sure you store the batteries away from anything flammable or combustible because battery acid and flammable liquids don’t mix well.”

Items that are at eye level or slightly below need attention, Godkin said, adding they may “stick out” and possibly tip over. Such items include rakes and shovels. Ladders that aren’t in use should be secured against a wall.

“Some of the nastiest hazards I see in a shop are stored overhead.”

Items hanging over a shelf’s edge can fall and strike someone. They should be stored elsewhere, removed or discarded, he said. Items that aren’t firmly secured overhead can be jarred loose by the vibrations of a running tractor engine, causing them to fall onto someone below. These items might be out of sight and

out of mind, but nevertheless present a hazard.

Godkin suggested golf course maintenance staff schedule a cleanup day to dispose of unwanted items and place everything else in a safe and logical manner.

“That will free up storage space and eliminate some safety hazards. If you have surplus equipment you’re not using anymore, see if you can sell it. Put the money back into your budget.”

A cleanup day could include setting out empty water barrels for the secure storage of shovels and rakes and painting walkways to encourage visitors to not stray from those areas. Cleaning the floors to remove dirt and oil will reduce the risk of tripping and slip-and-fall accidents.

Godkin recalled an incident in which a stepladder was placed against a wall, but there was grease or oil on the floor below. As a worker began to climb the ladder, the ladder’s feet gave way on the slick floor, causing both the employee and ladder to crash to the floor. The worker was seriously injured, and the club was fined $20,000 for not performing basic ladder safety.

Ladders should have non-slip feet and be free of damage. Ladders are graded based on weight-load capacity with a Grade 1 ladder recommended for use in a maintenance shop. Godkin said they are rated for upwards of 300 pounds of load capacity. Although Grade 2 ladders are also commercial grade, they are rated for about 225 pounds. Grade 3 ladders are mainly for consumer use and have a load capacity of about 200 pounds.

Chemicals must be stored according to a proper chemical storage program. Flammable or combustible items must never be stored under a stairwell or any form of egress. Fire extinguishers should be checked monthly and their tags initialed. Godkin said fire extinguishers should be easily accessible, and all staff must be trained to use them properly.

Safety First

The state of a maintenance building’s housekeeping speaks volumes as to its safety standards. One where everything is in its place makes for a safer environment.

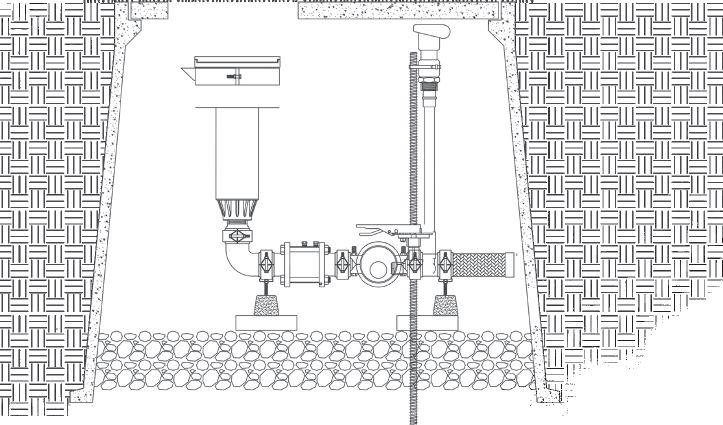

Gas storage is an especially important aspect of meeting the proper safety standards, he said. Outdoor gas tanks generally have adequate barrier protection and the tanks themselves are double walled. But single-walled tanks require barrier protection and secondary containment to hold 110 per cent of the largest tank’s volume. A fire extinguisher must also be within 15 metres of tanks.

GAS TANKS SHOULD BE DOUBLE WALLED

Godkin recommended gas tanks not be purchased. If they’re leased or belong to a local fuel provider, they should be double walled. If tanks are single walled, the company providing them should be told to replace them with double walled tanks.

“Virtually every single client I’ve suggested that to has done that. They’ve found their diesel fuel and gasoline provider were more than happy to do that.”

An emergency fire escape plan, with designated exits and proper signage, must be enacted, and smoke and carbon monoxide detectors should be in working order and checked regularly.

Electric tools’ cords must be inspected for signs of damage, and all plugs must have proper grounds.

“You have to have ground fault circuit interrupter protection available in your shop.”

An electrician can install 20-amp GFCI outlets at various places around the shop. Superintendents who choose to do this should paint the face plates a bright green colour, Godkin suggested, noting it will give workers added incentive to use them and demonstrate to visiting government inspectors that there is ideal GFCI protection.

He added outlets must not be overloaded, power bars need to be checked for their condition and breaker panels are properly labeled and clear of obstructions for up to one metre of distance. The Canadian Electrical Code states objects cannot be stored in front of or below an electrical panel within a one-metre distance.

“It really bothers me when I see things like portable fuel containers stored beneath an electrical panel.”

Extension cords cannot be left about and pose tripping hazards. Instead, he said, extension cord reels should be positioned overhead, allowing workers to pull the cord downward when needed. Overhead lighting should be adequate – at least 50 foot-candles of illumination – and all electrical equipment must be CSA-approved, Godkin added.

Chemicals and other materials must be stored in an orderly manner and be easily accessible. He said only authorized personnel and licensed applicators should have access to a chemical storage room. As an added safety precaution, superintendents can fill an inexpensive tub with splash-proof goggles, long-sleeved neoprene gloves, sanitizing wipes and an eyewash bottle, and keep the items close at hand in the event of an emergency.

Incompatible materials must never be stored together, Godkin warned, citing battery acid and gasoline as a good example.

Purchasing a secondary containment pallet will help contain leakage from drums. Keeping kitty litter on hand will help in the event of spills. Containers of flammable materials must always be tightly sealed, and all work areas must have adequate exhaust ventilation.

“You are responsible for safety,” Godkin told his audience of superintendents.

Personal protection equipment (PPE) should be readily available, and all employees must know how to wear it properly, he said, adding superintendents may wish to monitor their staff once a week to ensure those operating mowers and other equipment are properly attired in the right safety gear.

KEEP SAFETY DATA SHEETS CURRENT

Safety data sheets must be current and readily available and be compatible with the latest Workplace Hazardous Materials Information System (WHMIS) regulations. Industry suppliers can provide the most up-todate safety data sheets for everything they sell. WHMIS safety reviews should be conducted annually.

“I guarantee that from one year to the next, someone’s going to forget something,” he said, suggesting safety data sheets should be looked at each spring because changes often occur during the winter months.

Godkin recommended industrial-grade metal shelving be favoured over wooden shelves, noting the latter tends to warp, crack and give off splinters when exposed to chemicals, heat, cold and moisture.

‘Some of the nastiest hazards I see in a shop are stored overhead’

A significant offence he often sees in a maintenance shop is a bench grinder without a guard on one or both of its wheels.

All hoses, including hydraulic and air hoses, should be labeled accordingly and regularly inspected, he suggested.

Ladder safety is of the utmost importance in a maintenance shop. Make sure ladders can adequately bear the employee’s weight and that they have non-slip feet.

Safety showers and eyewash stations must be available, clean and accessible and be within 55 feet or 10 seconds away from shop employees. Eyewash stations must have an upward water flow and be cleaned, flushed and inspected weekly.

“Do it every Monday morning. Someone’s vision may depend on it.”

Eyewash bottles are merely supplementary devices used in first aid. If an employee gets chemical in his eyes, he must get a co-worker’s attention and be guided to the nearest eyewash station for eye flushing. Godkin said it’s important for someone to yell out what is happening to ensure another individual summons an ambulance and provides paramedics with the chemical’s safety data sheet information.

Eye flushing may need to continue for upwards of an hour, if necessary, until the attending paramedic determines it’s time to go to a hospital. Godkin said it’s why he recommends splash-proof goggles be worn when dispensing liquid or powdered chemical.

In addition to proper eye protection, hearing protection is required when noise levels reach 85 decibels or higher. Thresholds should ideally be lowered to 65 or 70 decibels, he said. Workers who choose to wear ear buds to listen to music and drown out excessive noise can be easily distracted when operating machinery, he cautioned.

Checklists should be filled out for all motorized equipment and kept on file for at least a year, he added.

First aid kits must always be close at

hand, Godkin said.

“You must always have someone on site who is trained in first aid, whenever your club is open. Post the names of those trained in first aid with the first aid kit. This way you know exactly who has the

proper training in the event of an emergency. Make sure to keep a logbook inside the kit to note what contents have been used and what needs to be replaced. Also, post the names of those trained in the use of defibrillators beside the kit.”

Field painting must have turf in mind

Painting sports fields is much different from painting walls. By Mike Jiggens

There’s a lot to be considered when painting lines, hash marks, numbers and logos on a sports field. The paint must be easy to use, effortless to dilute, give “pop” to the field’s aesthetics, and minimize the amount of damage to the turf plant.

Unlike paints used on interior home walls, athletic field paint on natural turf is meant to remain intact for a short period of time – usually a week or so – and look good under lights.

Dr. Adam Thoms, an assistant professor in commercial turfgrass management at Iowa State University, shared information from athletic paint research currently being conducted with a virtual audience of sports turf managers during February’s Ontario Turfgrass Symposium.

Field paint research isn’t new, he said, noting studies have been made to examine its impact on transpiration, canopy temperature and photosynthesis light quality. Further studies, however, are exploring

ways to extend the life of a painted line, learn more about workable ratios of paint to water, and examine improvements in its applications on synthetic turf surfaces.

Unlike wall paints, which can be applied atop a white primer, athletic field paints must adhere to tight specifications within pH levels on natural turf surfaces and can’t be allowed to stray far off the spectrum before the paint becomes toxic to the turf plant.

Field paint is typically made up of pigment, glue, water and additives that include thickeners, surfactants and biocides. White pigments are usually titanium dioxide, clay and calcium carbonate and come in a variety of grades, from white to a dull brown.

“The closer you get to a bright white, the more you’re going to spend,” Thoms said. “There’s more pigment in there as well.”

He said the highest quality ingredients are used to make athletic field paints. A computer-guided system is used to obtain an exact colour match.

Glue is the paint’s binder. Latex is the most frequently used binder in field paint due to its unique structure and its ability to be reduced with water.

“Latex works well with water, so that’s positive for those who want to stretch their budget and water down their athletic field paint.”

Once dry, the paint forms a unique layer of polymers structured in a lattice-like arrangement. The lattice system is a series of crosses that build onto each other, allowing the plant beneath to breathe and transpire because it isn’t a solid coating.

Heavily coated field areas will sometimes require the placement of sod over the paint, “so there has to be a better management method than resodding all the time.”

The cost of paint

Thoms said Iowa State uses 140 gallons of paint per game on its premier game field. This includes the need to paint large logos in both the end zones and mid-field plus

The right spray tip must be used when painting lines on a sports field with the goal of simply coating the leaf tissue.

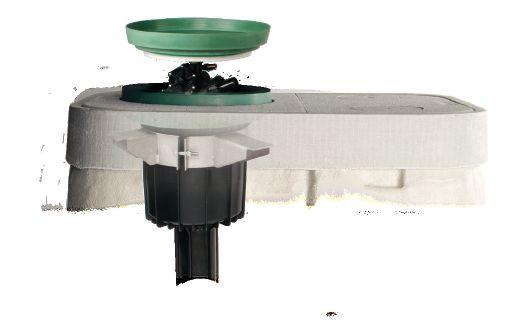

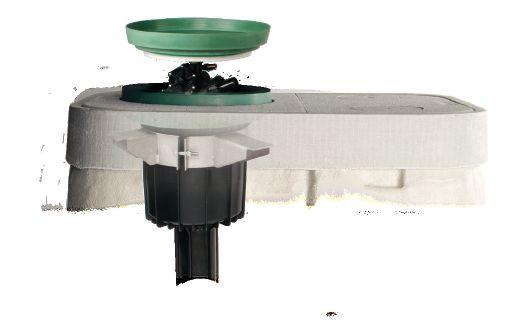

SYNTHETIC TURF IRRIGATION MVP

You’re serious about sports. We’re serious about irrigation. With our new, all-in-one ST-1600-KIT, keeping synthetic turf ready for action just got easier!

Powerful Performance

Heavy-duty unit delivers a radius up to 165' with an exclusive ST Infill Barrier System that accommodates every field surface configuration.

Total-Top-Serviceability

Quickly access all rotor components through the top for easy maintenance. The field stays intact for added player safety.

Easier to Order and Specify

Handy system reference guides list everything you need for easy ordering. New kit structure makes specifying simple too

Get in the game with the industry’s first and only fully integrated synthetic turf irrigation solution!

https://hunter.info/st1600

the traditional field markings. Over the course of a season, 1,120 gallons are needed to paint the field. A gallon of paint that once cost $15 turned into a $16,800 annual expense for the premier field alone. With four practice fields and several others requiring paint, the cost to the university is significant.

Many Canadian municipalities have limited budgets and wish to find ways to stretch their dollar further when athletic field painting is required. Research is being conducted to see how much water versus paint can be mixed to add longevity to a can of paint without compromising the quality of the markings. Typically, the mixture ratio is three parts water to one part high-quality paint that contains plenty of good white pigment. Thoms said the mixture stands up as well as a one-to-one ratio with a lower-quality white pigment.

Water content is especially important in field paint for synthetic turf surfaces. Many removable synthetic turf paints contain a chemical compound that requires plenty of water to prevent clogging of the turf backing. When removing paint from synthetic turf, the material is washed through the backing and out the bottom to the root zone. Synthetic turf typically drains quickly because of the array of holes in the backing, but paint that isn’t efficiently washed away can build up and clog the holes. This can hamper drainage during a heavy rain event and cause the crumb rubber or cork fragments to move about and create other concerns.

Crumb rubber clumping

Thoms said that when synthetic turf paint isn’t properly removed, it can lead to the crumb rubber or cork clumping together

to form a hard and firm surface, creating a possible injury hazard for athletes.

Turf paint not properly removed from synthetic surfaces can also produce “shadowing,” or a lingering impression of a marking where a little bit of pigment remains behind.

Thoms said there are field paints intended for natural turf that lack a latex binder and can easily be removed with water. Sports turf managers find these products work well as long as no rain is forecast during a game, or a heavy dew isn’t expected. He said these paints are more “chalk-like” compared with traditional field paints, and lines and logos will disappear quickly during a sudden downpour. An advantage of this paint type, however, is that if a logo needs to be painted quickly for a “one-off” event, “this is the way to go for natural turf.”

AN EXCAVATOR THAT SIDE HUSTLES AS AN AUGER, A GRAPPLE, AND A HAMMER.

NEVER IDLE

Whether it’s getting in where big iron can’t or going it alone, our compact excavators are models of efficiency. Thanks to countless attachments to tackle whatever the task at hand, and engcon compatibility for even greater productivity. All backed by our tried-and-true dealer network, to keep your compact workhorse punching above its weight.

INDUSTRY INNOVATORS

Visit one of these participating Exmark Dealers to learn more about the full line of professional Exmark models.

ALBERTA

CALGARY . . . .

RED DEER

ALBERTA FOREST & GARDEN ......... EDGE EQUIPMENT LTD FUTURE AG INC

403-248-0878

780-455-3343

403-343-6101

BRITISH COLUMBIA

ABBOTSFORD

CHILLIWACK

COURTENAY

KAMLOOPS

KELOWNA

N . VANCOUVER

PARKSVILLE

MANITOBA

FORESHORE EQUIPMENT AND SUPPLY

CHILLIWACK OUTDOOR POWER EQUIP .. PILON TOOL RENTALS 1972

604-313-0251

604-744-0547

250-338-5361

B & L SMALL MOTORS LTD SAVOY EQUIPMENT ARROW EQUIPMENT LTD ............ HI-WAY POWER AND MARINE LTD

250-376-0033

250-868-1010

604-987-9926

250-248-3621

NEW BRUNSWICK

BOUCTOUCHE .

IRISHTOWN . . . . B.M. MARINE INC .................. SMALL ENGINE HOSPITAL INC ........

506-743-8566

506-854-2807

ONTARIO

HURON TRACTOR LTD

MERCER MOBILE EQUIP REPAIRS .....

BRADFORD RENTAL SALES & SERVCE

GREEN TRACTORS INC

BOBCAT OF BRANTFORD INC

B.R. DICKSON EQUIPMENT INC .......

CHATHAM OUTDOOR POWER

BRUCE SERVICE

MARTIN’S SMALL ENGINES LTD

CAMPEAU OUTDOOR POWER EQUIP ....

HURON TRACTOR LTD ..............

A.S.E. EQUIPMENT/CARTWORLD INC

OUTDOOR SUPPLIES & EQUIPMENT

MUSKOKA AUTO PARTS LIMITED ......

ZEHR’S SALES AND MANUFACTURING ..

WPE LANDSCAPE EQUIPMENT

W.E. ENTERPRISES LTD

MITCHELL CYCLE INC

PRICELESS PRODUCTS LANDSCAPE ...

M.C. POWER SPORT

ALPINE LAWN & GARDEN EQUIP

DBA MCGILL EQUIPMENT

CAMPBELL’S OUTDOOR POWER EQUIP. .

HURON TRACTOR LTD

M.R. BLAIS SALES & SERVICE INC

A TO Z RENTAL CENTRE

VEHICLE VENTURE .................

SASKATOON . . . RST

519-666-2300

705-503-3535

905-775-7101

905-846-2511

519-752-7900

905-331-5040

519-354-3990

519-363-6345

519-669-2884

519-727-5031

519-285-3845

519-820-9708

905-578-2411

289-963-9666

519-595-7579

905-569-2055

905-629-1424

519-348-0490

416-410-2158

705-748-5189

416-292-8900

416-751-4455

519-245-2428

519-285-3845

613-443-1230

519-885-5590

519-966-8642

Research at Iowa State University has been conducted to learn how soil’s physical properties change with repeated paint applications. Four different scenarios were studied: painting once a week, once a month, once every two weeks and unpainted control. Paint was applied in a one-to-one, water-to-paint ratio using a Graco handheld painter. The paint was applied evenly and at the same height for each plot.

The six-month study mimicked a typical season in Iowa with researchers focusing on water infiltration rates and particle size analysis based on fine gravel, very coarse sand, coarse sand and medium sand. Decreases in water infiltration were observed in plots painted weekly and once a month. Athletic field paint caused root zone mixtures to shift with a larger percentage of coarse material from the original mixture. Thoms surmised two possible reasons for the shift: paint acted like a glue and was binding smaller particles together; and repeated paint applications were building up in the root zone, making it a fine gravel material.

No increases in silt and clay-sized particles were seen. Water infiltration was reduced in two of the three painted plots compared to the unpainted control plot.

Researchers also wanted to know if athletic field paint differently impacted specific turf species and weeds. Although most athletic fields tend to be predominantly Kentucky bluegrass, they are rarely mono stands, and weeds often have a presence due to pesticide restrictions. The study found field areas covered in weeds were 50 per cent harder and had a bearing on both turf quality and safety. Researchers were curious to know if added paint contributed to those concerns.

The study included Kentucky bluegrass, crabgrass, dandelions and white clover. The sampled areas were maintained at three inches and mowed twice a week to simulate an athletic field. The plots were also irrigated at about an inch per week to ensure they weren’t stressed.

“We knew the paint would stress them, so we didn’t want to stress them with anything else.”

Fertilizer was applied throughout the study to ensure the plots had ample nutrition.

Data indicated the growth rate of dandelion and white clover wasn’t conducive for repeated paint applications and that more paint would be required if those weeds were prevalent on a field. Broadleaf species will not maintain paint applications as well as grass species, Thoms said, adding it was also decided that paint curing times would be longer on weeds.

He recommended using a wand or an extension to limit the amount of paint buildup, suggesting less paint will be required, more even applications will be made, and it will be easier on the applicator’s back. Spraying should be done at as low a pressure as possible with the correct spray tip, aiming to coat the leaf tissue as opposed to blasting paint down into the root zone.

If painting by rollers, only the leaf tip is meant to be coated. Thoms warned not to over-apply paint which could result in it moving off the leaf tip and getting into the soil.

Opportunity to grow = retention

An employee given the chance to grow and advance within a company is likely to stick around longer

By Mike Jiggens

Employee turnover in a seasonal profession tends to be a common occurrence. When that profession is highly competitive, finding the right people to hire and then retain them for the long term is especially challenging.

The cost of employee turnover in the lawn care profession is “incredibly high,” says Chris Lemcke, technical director for Weed Man.

Speaking in February at the virtually delivered Ontario Turfgrass Symposium, he said there is considerable cost associated with finding the right people, while retaining them has a further impact upon those expenses.

“If you can retain people, you’re not going to have to put in ads and you’re not going to have to go to different websites to post. All that can be fairly expensive if you’re trying to outcompete your competitors and trying to get the same people.”

Employee retention is the key, Lemcke said, adding discrepancies about wages, company culture and a work-life balance tend to be secondary reasons for people leaving their jobs.

“It’s really a lack of growth opportunities,” he said, noting that if employees aren’t happy where they are, they will go elsewhere. If a company isn’t growing and if it’s not creating opportunities for its

company.

employees to advance within, the likelihood of retaining people is small, he added.

Employees don’t want to be stuck in a low-level position with no opportunity to climb the ladder.

“That can stymie or create issues for people because most individuals want to move up in the ranks of an organization.”

Key people companies wish to retain for the long term must be presented with a chance to grow along with the business. The strategy at Weed Man, Lemcke said, is to show new employees that they can potentially become managers or run franchises, even if they were hired as an entry level technician or salesperson. The company is willing to help aspiring employees write their licences to become certified technicians.

“We have a management program where, if people show interest, we put them in the program and start to build

those skills on how to manage operations.”

He said there have been numerous instances at Weed Man in which an employee has started at the bottom – whether in sales or as a technician – and has attained the position of sales manager or technical manager.

Weed Man ties people to their performance, allowing them to earn more if they succeed in what they’re doing, Lemcke said.

MOTIVATED EMPLOYEES

Employees who are motivated will perform better and succeed within the company while those who aren’t are simply there for the hourly wage and won’t work any harder than necessary, he added.

“We’re looking for people motivated by the possibility of increased income.”

Weed Man endeavors to coach people so that they can be the best employees possible, but Lemcke said the company some-

Employees stuck in a low-level position with few chances to climb the ladder aren’t likely to remain long with a

KUBOTA PROVEN DURABILITY.

Choose a mower that can stand up to the toughest jobs. The Kubota SZ Series stand-on mowers are engineered to be the quickest and most comfortable in its class, with a commercial-grade Kawasaki engine and exceptional maneuverability in tight spaces that professionals demand. Affordable and durable, it’s the right choice – for many more summers ahead.

times encounters those who aren’t the right fit for the position, and the business doesn’t wish to invest a lot of time into people unwilling to give their best.

“A lot of people try to work with their employees, but there’s that one person who seems to bring everyone down, and it’s a nightmare to have to hire again and train someone.”

Allowing such a person to remain with the company can be a culture killer, he said, adding it can negatively affect employee morale.

Knowing when to terminate an employee and recruit others is critical to a company’s culture. Lemcke said the larger a company grows, the more challenging it becomes to create a positive culture.

Smaller companies for which the owner is more involved in everyday matters tend

to develop a culture much easier and quicker.

Workplace culture can be fostered through such things as team building and social events, regular performance meetings, bonuses, employee recognition, diversity and treating people with respect.

Many employees are concerned by work scheduling. Since the lawn care season is so short and there is little time to get everything done, scheduling is a factor in retention.

“I think last year was probably the most difficult I’ve seen for a lot of our franchises to get work done because of the difficulty in keeping good people.”

Since the start of the COVID-19 pandemic, some workplaces have explored the idea of implementing four-day work weeks with longer hours stretched out

over four days. In the lawn care profession, however, such a scheduling strategy can be nearly impossible to pull off because the business is dependent upon Mother Nature’s cooperation. If a significant rain event wipes out a day during the week, it might mean having to get work completed on Saturdays.

“Getting people to work six days is becoming more and more difficult. They want their weekends off.”

WORK INCENTIVES

Offering incentives such as additional pay for working extra hours on a weekend helps to retain key people, Lemcke said.

A reality of today, he said, is that many people change jobs every couple of years, unlike previous eras when most employees remained with their employer their entire working life.

“If you have job security where people can work year-round, especially in a seasonal business, and you can find ways to do that, it does help to keep people longer.”

Weed Man endeavors to keep key people working throughout the year, having them work on equipment, doing marketing business or helping with such add-on businesses as Christmas Décor.

Lemcke said Weed Man likes to keep things simple when it comes to the company’s vision and mission, wishing to amaze both customers and employees. Its core values include honesty and the development of people along with a business plan.

“If you don’t have a business plan, then you have no plan. You’re basically flying by the seat of your pants. You don’t have a plan to develop people.”

At Weed Man, 10-year business plans are developed for several franchisees so that as they grow, they’ll know what positions need filling.

Recruiting and training always has room for improvement, he said.

“It’s not 100 per cent perfect, but we do our best to try and do it right the first time.”

Weed Man employees are empowered and trained properly, Lemcke said.

Their work is monitored and if gaps in training are found, the company follows up on it.

‘You’re going to have to be competitive to get people to work’

“The biggest part where most people fail is they don’t follow up and check. They let things go because they’re too busy doing other things or they don’t have the time to verify or they’re not putting systems in place to actually have the ability to do this.”

He said when technology is used in recruitment, it simplifies finding the right people for the job. For example, using the word “technician” in an advertisement tends to draw candidates of a higher level than if the term “general labourer” is used.

Lemcke said if a company lacks a solid procedure to get people in the door, it will lose those people to a competing business.

A company claiming it can’t find the right people or has difficulty hiring has poor processes in place, he said. This includes not getting back to candidates immediately to schedule an interview. If potential recruits aren’t interviewed immediately, they’re likely to be “scooped up” by a competitor.

Competitive rates must be offered, he said, adding Weed Man has had to increase its rates in the Toronto area the past few years to stay competitive. Increases must be passed along to the consumer, or a company will no longer be competitive, and employees will constantly be replaced.

“You can’t be afraid to increase prices because inflation is going up. You’re going to have to be competitive to get people to work.”

Businesses wanting to attract the right people must make the job sound interesting in advertisements and on company websites, Lemcke said, adding employers must know their demographic and ensure the job and benefits fit the lifestyle of prospective employees.

The facts and fiction of blue-green algae

How we can prevent blue-green algae from showing up in our ponds.

By Julia Webber

Each year as we near another summer, news articles of blue-green algae often rear their ugly heads. As we read these stories, they cause alarm that the algae in ponds, lakes and streams around us may not be safe. Let us look at blue-green algae together and explore what it is, why it can be of concern, how to figure out if you have it, and how to prevent it from showing up in your pond.

First things first, blue-green algae aren’t actually a type of algae, but rather a very misleading name. It can superficially look like algae, but it is not related and functions completely differently. In addition, it can be a dark blue-green colour, but it can also be olive green, brown or even red. To help with this, I am going to refer to blue-green algae as cyanobacteria for the rest of this article. This name is not only much more accurate but more importantly is a better descriptor.

What are cyanobacteria? Cyanobacteria, as the name would suggest, are a type of bacteria that use light to produce energy, just like plants and algae. This is part of the reason they are often green. They are generally single-celled organisms and can be invisible to the human eye unless there is a bloom. A cyanobacteria bloom is a rapid increase in number and quantity of organisms and is usually created when conditions are favourable.

Blooms can look like paint on the water surface that drifts with the wind and are most visible at shorelines but can also form below the water surface where they are not visible. They are most common in the late summer or early fall and thrive in shallow, slow-moving water but are not limited to them.

What is the big deal with cyanobacteria? The problem is that some types of cyanobacteria produce cyanotoxins which are very poisonous to humans, pets and wildlife. The most famous example of a cyanobacteria bloom is the red tide that is experienced in the ocean. The big problem is that there is no easy way to tell if the cyanobacterium in your pond is producing this toxin, so caution should always be used if you see or suspect it. As the density of cyanobacteria increases, such as during a bloom, so does this toxin. Cyanotoxins have a wide variety of symptoms, depending how you come into contact.

One of the common contact methods is ingestion while swimming. This can cause stomach pain, headache and neurological symptoms – for example muscle weakness and dizziness, vomiting, diarrhea and liver damage. Pets and livestock can also suffer severe symptoms by ingesting water by drinking water from a pond, stream or lake that has cyanobacteria in it. If you think there is cyanobacteria present, always prevent access to the pond.

Spotting the difference in algae

How can we tell if the “algae” in our pond is cyanobacteria or just normal algae? Unfortunately, there is no easy test that can tell you if there are cyanotoxins in your water. But there are a few DIY tests that can help us determine if cyanobacteria are

Blue-green algae blooms along the shore of a lake.

A sign warns the public about the dangers of blue-green algae.

Julia Webber is president of Fish Farm Supply Co. Inc., which has been serving the lake and pond industry since 1989.

present in your pond which were developed by the Kansas department of health and environment in 2012. I have included a link here for more detailed information on these tests (https:// www.pca.state.mn.us/sites/default/files/wq-swm1-04.pdf).

Basically, there is a jar test and a stick test that will let you know if the most common cyanobacteria are present. As with all things these are not fool proof but certainly helpful and I would recommend reading the notes included in the document so you are aware of what they cover. More information is always better when evaluating for cyanobacteria.

What can we do to prevent cyanobacteria blooms? The most favourable conditions for most cyanobacteria are warm, still and nutrient-rich water. Although affecting the temperature of our water is not reasonable, it does help us to know when to be most alert for blooms.

Water movement can be accomplished with an aeration system – either air diffuser aeration or a fountain – and has the added benefit of adding oxygen which greatly increases the health of any water body.

The most impactful way that we can prevent cyanobacteria blooms, though, is to reduce the nutrients that enter our water.

Fertilizer, manure and compost are all nutrient rich and help our gardens and lawn look their best, but just as they make our lawns green so, too, do they make our water green. Preventing nutrients from entering our water can be done many different ways such as establishing berms around ponds so that water will filter through the ground before entering them; leaving a fertilizing buffer – an area that where no fertilizer is applied directly to it with the knowledge that when it rains it will absorb nutrients; applying nutrients only when there will be no excessive rain events; or applied in a form that is absorbed quickly into the soil.

Every property is unique, but managing the nutrients that could flow into our ponds and lakes will greatly help reduce not only cyanobacteria blooms but also algae blooms and excessive plant growth.

Although the cyanobacteria blooms are likely something we will continue to see going forward, there are ways that we can work together to help reduce them. As awareness grows on all levels and we work together to manage nutrient sources that may enter our waterways, we can help to reduce this not-sopleasant part of our summer.

Keep sprayers clean for top performance

Turf managers must protect their investment through regular cleaning. By Ryan Beauchamp

Outside of labour, the largest operational costs for a turf manager are the products applied through a turf sprayer. This includes fertilizers, surfactants and plant protectants. Because of their high value, it is critical for managers to protect their investment with proper application and avoid issues caused by equipment that isn’t running smoothly.

MAINTAIN SPRAYER PERFORMANCE

Sprayer cleanout removes fertilizer and pesticide residue in your equipment that can cause lines and nozzles to clog and/or cause turf damage during subsequent applications. Sprayer cleanout allows your equipment to continue to perform properly each and every time you use it.

REGULAR CLEANING INTERVALS

Sprayers should be cleaned after each application is complete and before switching to a new product application.

Sprayers should be cleaned at the end of every workday to prevent buildup of residues in the equipment that may become more difficult to remove later. New, demo or borrowed equipment always requires an initial cleanout. You should also clean and winterize your sprayer prior to winter storage.

PERSONAL SAFETY AND PROTECTION

Always wear personal protective equipment, including chemical-resistant gloves, boots, an apron, and a face shield or goggles. Make sure your protective equipment is clean and is being worn correctly. Clean your sprayer in an area that is not used by people or animals, and not in an area close to water sources such as ponds, ditches, creeks or wells. Stay away from catch basins that might cause rinsate to enter and contaminate water courses. Avoid leaving rinsate water puddles where children or animals may encounter them.

STANDARD CLEANING PROCEDURES

Clean the entire sprayer, including the tank, chemical inductor (side tank), valves and hoses. If the end of the boom extends beyond the last nozzle, residues may collect in this area. Remove boom end caps and collect any solids that have accumulated. Label this container as agricultural chemical residue, store it safely in your pesticide storage and dispose of the product properly at the next obsolete pesticide collection program in your province.

Replace the boom end caps. Missing any of these areas during cleanout could result in damage during later applications. Following the first rinse, use gloves to inspect and place all screens, filters and nozzles into a pail and clean with a small brush using the same solution as used in rinse number two (see Triple Rinse Cleanout Procedure below). Use this pail only for this cleaning and label it as such. Rinse these items with clean water prior to re -

A sprayer at work on a golf course fairway. Regular cleaning of sprayers is the key to its return on investment and ensures there are no issues with the product being applied.

Weighing less than 11 pounds, the all new 525LST string trimmer is designed for all day use. With Husqvarna's LowVib™ anti-vibration technology and rubber grips with improved ergonomics, feel comfortable job after job. Learn more at husqvarna.com.

EQUIPMENT

placing them into the sprayer for the third rinse.

Place rinsate from the pail into the sprayer for disposal. Don’t forget to clean your measuring containers at the same time and in the same manner. Remember that improper mixing sequence creates additional application issues.

CLEANING PRODUCTS

Each pesticide label will have directions about what cleaning product to use, quantity to use and how to use it. Usually, this information is located near the end of the label. If you cannot find the label directions, contact the manufacturer listed on the front of the chemical label

for advice. Each product has specific recommendations for best cleanout results.

Follow the cleaning product label’s directions for safety and mixing directions. Some labels may require the cleaning solution to remain in the tanks and hoses for extended periods, such as overnight. Remember, your goal is to remove dried residues, solubilize oily residues and reduce corrosion.

CLOGGED NOZZLE DAMAGE

Typical cleaning products used per 100 gallons:

• Water only, if not specified on the label, or

• 3 kg (TSP) trisodium phos-

phate cleaner detergent, or

• Commercial tank cleaner, such as Inside-Out from Precision Lab Inc. (follow instructions)

TRIPLE RINSE

CLEANOUT PROCEDURE

Cleaning a sprayer is similar to cleaning pesticide jugs for proper disposal, which is a triple-rinse procedure.

Rinse One (Rinse): Fill tank 10 per cent full of clean water and circulate in the sprayer for a minimum of 10 minutes. Remove boom ends where possible, and flush out booms, filters, screens and nozzles. When tank is empty, remove nozzles, filters and

screens as outlined above.

Rinse Two (Clean): > Fill tank 10 to 15 per cent with clean water and then add the cleaning product as directed by the product label. Be certain to rinse any chemical inductors while doing each of the three rinses. Run the sprayer for a minimum of 10 minutes, flushing the cleaning solution through each boom and the entire sprayer.

Rinse Three (Rinse Again): Replace all screens, filters and nozzles and repeat rinse number one as outlined above, and run solution through all booms. Wash the exterior of sprayer with soap and water.

PROPER DISPOSAL

It is recommended that sprayer rinsate is applied to the same areas where that chemical has just been recently applied. Application here allows any tank residue to break down in a known manner and does not apply product above the recommended label use rate. application issues.

WINTERIZATION

After the final rinse, add a plumbing anti-freeze mixture into the tank. Never use automotive anti-freeze. Use a product such as Recochem Inc. Sprayer Winterizer for farm equipment. Always follow your sprayer manufacturer’s directions. This usually includes circulating this

mixture through your entire sprayer, including booms and nozzles, using agitation for at least five minutes and then draining. Make sure there is no water left in the system. Consult your municipality for proper disposal of the plumbing anti-freeze or follow the manufacturer’s directions for disposal of the product.

Even the most thorough cleaning procedures will always have some inherent limitations that keep them from being 100 per cent effective. By following proper procedures and regular maintenance schedules, you can extend the life of your equipment, keep it running properly, and prevent costly downtime and product loss.

Ryan Beauchamp is territory sales manager with Bayer Environmental Science Canada. He can be reached to answer any questions about this article or sprayer cleaning strategies by email at ryan.beauchamp@bayer.com. Questions can also be asked of any local territory sales manager with Bayer.

DELIVERING SUPERIOR SOD WITH QUALITY SERVICE

A triple-rinse cleanout process is recommended to ensure sprayers are cleaned thoroughly.

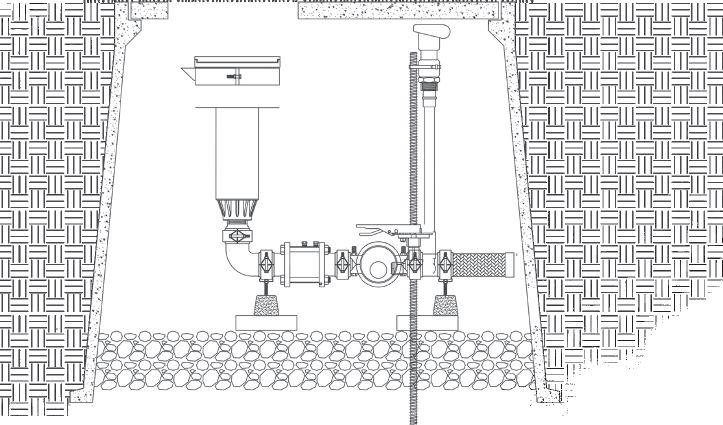

Quick and easy greens trenching

Minimal disruption to putting surface is key to appearances

By Joe Haynes

Looks matter – especially in the golf course industry.

Maintenance and landscaping improvements are ongoing. Finding an equipment solution that provides maximum efficiency with minimal disruption to the green is key to maintaining that country club appearance.

Mini trenchers are an ideal solution for boosting productivity without tearing up the greens.

When selecting a mini trencher, here are some features to look for to get the reliable results a golf course requires.

Green preservation features

To protect the course against soil cupping that can occur after backfilling wide trenches, look for a mini trencher that digs narrow trenches. Mini trenchers require minimal backfill, which reduces the chance of cupping and helps ensure consistent grass growth.

With the turf’s appearance in mind, look for a mini trencher that also features pneumatic tires to virtually eliminate damage caused by tracked machines or skid-steer-type trenchers.

Manoeuverability and safety features

Look for a mini trencher with a compact body to allow greenskeepers to easily manoeuvre in tight spaces while pruning tree roots. Combine the compact body with a push-forward operation to enhance

safety by giving the operator a clear view of what’s ahead.

By contrast, trenchers that require the operator to pull it while walking backward add the risk of tripping and falls, which might cause costly workers’ compensation cases.

Maintenance features

Prioritize a mini trencher that offers features for minimal maintenance by protecting key components. This might include a built-in slip clutch, for example, to protect the drive train from shock if the trencher hits a rock or other obstacle. Maintenance can be further reduced

with blades that are quick and easy to replace. Some manufacturers offer stand-alone blades and teeth that bolt onto the cutting wheel, making replacing the teeth simple and inexpensive. Other manufacturers weld teeth directly onto the cutting wheel, causing the entire wheel to need replacement when a single tooth is damaged.

Greenskeepers can improve golf course quality in minutes with the right equipment solution. Mini trenchers are a versatile and valuable tool for a wide variety of golf course management applications. These units help operators decrease damage and get trenching projects done quickly.

Joe Haynes is president of Little Beaver Inc., a Texas-based manufacturer of drilling equipment and accessories.

ABOVE: Mini trenchers will boost productivity without tearing up greens.

LEFT: Efficiency and reliable results are the goals in mini trenching.

Health & Safety

By CCOHS

The Canadian Centre for Occupational Health and Safety (CCOHS) promotes the total well being of workers in Canada by providing information, training, education, systems and solutions that support health and safety programs and injury and illness prevention. www.ccohs.ca

Keeping vibrations in check at work

The human body was built to be mobile. It was not, however, meant to vibrate. In small doses, vibration is harmless, even useful –think of the massage chair at the mall or your electric toothbrush. However, vibration can also be a significant hazard when it comes to outdoor recreation workers and the tools and machinery, they regularly use to do their jobs.

The effects of ongoing and frequent exposure to this vibration can be disabling and permanent.

But injuries and illnesses from vibration are preventable. If the exposure level is low, so is the health risk. Workers can start to experience symptoms as exposure increases.

WHOLE-BODY VIBRATION

Workers who operate mobile machines, such as lawnmowers, rototillers, skid steers or loaders, are at risk of exposure to whole-body vibration. Operators of offroad vehicles may experience considerable vibration, depending on the condition of the vehicle’s suspension system, shock absorbers, seats, and tires.

Workers exposed to whole-body vibration may experience fatigue, loss of balance, stomach problems, headaches, and shakiness. The effect has been described as motion sickness, or the general malaise some people feel after a long car or boat trip. Long-term effects from daily exposure over several years may cause several health effects, such as back disorders and gastrointestinal issues.

To help reduce the risk of injury, ensure a smoother ride. When possible, use machines that generate low vibration. Vehicles and mobile equipment should be well maintained, so suspension systems in the cab, tires and seats can help absorb vibration. On vehicles and mobile equipment, replace solid tires before they reach their wear limits. Having the proper seats also reduces vibration.

On off-road vehicles and mobile land-

Workers can start to experience symptoms as exposure increases

scaping equipment, certain built-in features can help. Seats with armrests and lumbar support or air-ride suspension, suspended cabs and properly inflated tires help control whole-body vibration in vehicles.

Employers should train vehicle operators on how to:

• adjust the seat position and controls (where adjustable) and, on suspension seats, the driver weight setting

• smoothly steer, brake, accelerate, shift gears and operate attached equipment

• match vehicle speed to ground conditions

Workers should be trained to use vehicles and machines that have the right power, size, and capacity to suit the work.

HAND-ARM VIBRATION

Certain power tools cause excessive vibration exposure to the hands and arms. This vibration can cause a range of conditions such as carpal tunnel syndrome, vibration-induced white finger, and Raynaud’s Syndrome or dead finger.

Numerous hand-held power tools and equipment can cause illness from handarm vibration. Some common sources of vibration are grinders, sanders, mowers, hedge trimmers, needle guns, jackhammers, riveting and chipping hammers, and chainsaws.

Hand-arm vibration damages blood vessels in the hands and fingers. It reduces blood flow and can harm the skin, nerves, and muscles. The worker may experience a tingling sensation or numbness in the fingers, a weakened grip, hand and arm pain, and general clumsiness with the hands. When the fingers are cold and wet, the tips might turn white or blue, then red and sore. With continued use of high-vibration tools, these symptoms will likely progress to permanent numbness in the hands, inability to pick up small objects, and more frequent white finger episodes. Smoking and exposure to the cold reduce blood flow to the hands.

Workers exposed to vibration should wear sufficient clothing to keep them warm and dry, which will encourage good blood circulation and help protect them from developing vibration white finger.

HOW TO PREVENT INJURY

The best way to avoid injury and lasting damage from vibration is to minimize workers’ exposure to it.

Provide non-vibrating tools for workers whenever possible, or those that have built-in features to reduce vibration.

Workplaces should maintain exposures as low as possible. In many work applications, manual tasks can be mechanized, removing workers from harmful exposures to vibration.

Design work in such a way that those exposed to vibration have long rest breaks or shake-free tasks between exposures. Older employees, those with back problems or workers who are pregnant, should certainly avoid long periods of exposure. Limit the use of vibrating hand tools to only a few hours per day and days per week, with a 10-minute break each hour.

ADVANCED AUTOMATION, GUIDANCE & SAFETY

So you can rest assured the job’s being done right.

AUTONOMOUS

Operates 24/7, rain or shine, day and night.

EIGHT

TIMES LOWER ENERGY COSTS

Compared to traditional mowers.

Because work doesn’t stop when you’re busy doing other things.

EMISSIONS-FREE OPERATION

Better for the environment and our customers.

Avoid disturbing customers in noise-sensitive areas.