AN INNOVATION TO HELP GROW YOUR BUSINESS

When it comes to survival and success in today’s competitive food market, innovation is key. BENEO-Orafti, the driving force behind the prebiotic market, has the right chain of expertise to provide support at all levels and to make product innovation easier for you.

Orafti® inulin and oligofructose ingredients combine technological, nutritional and health benefits. They can easily replace sugar and fat, have a positive effect on digestive health, bone health, weight management and enhance your customers’ overall health and sense of well-being!

BENEO-Orafti offers tasty ingredients for delicious food, with every health claim based on solid scientific facts.

From application experience and know-how, to regulatory advice, marketing or security of supply, you’ll have BENEO-Orafti’s unique support at every stage of the chain. Keeping your business more than one step ahead - naturally.

To learn more about how BENEO-Orafti’s natural ingredients can benefit your business and your customers, visit www.BENEO-Orafti.com.

A new bakery owner in Nova Scotia brings her business back to its roots.

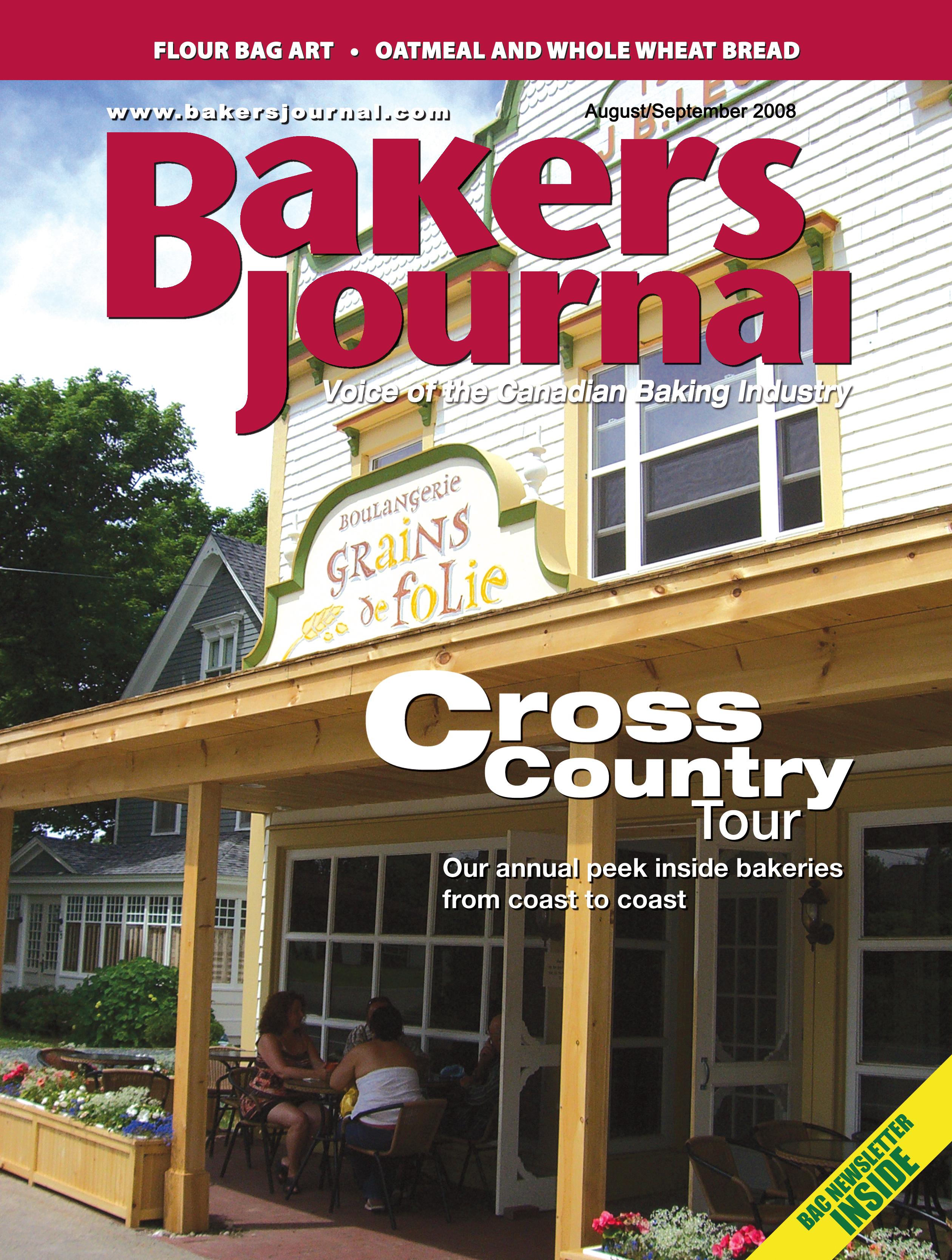

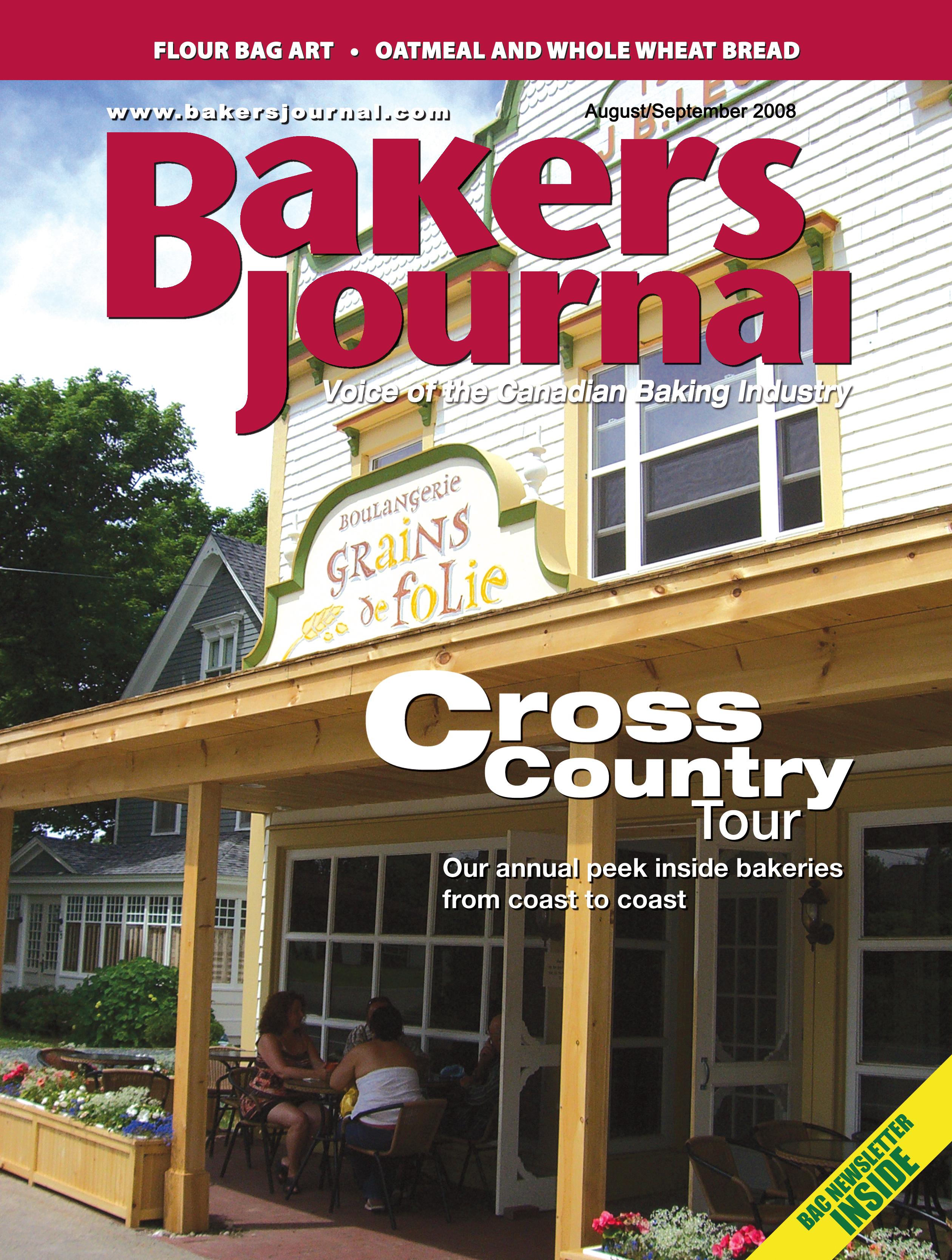

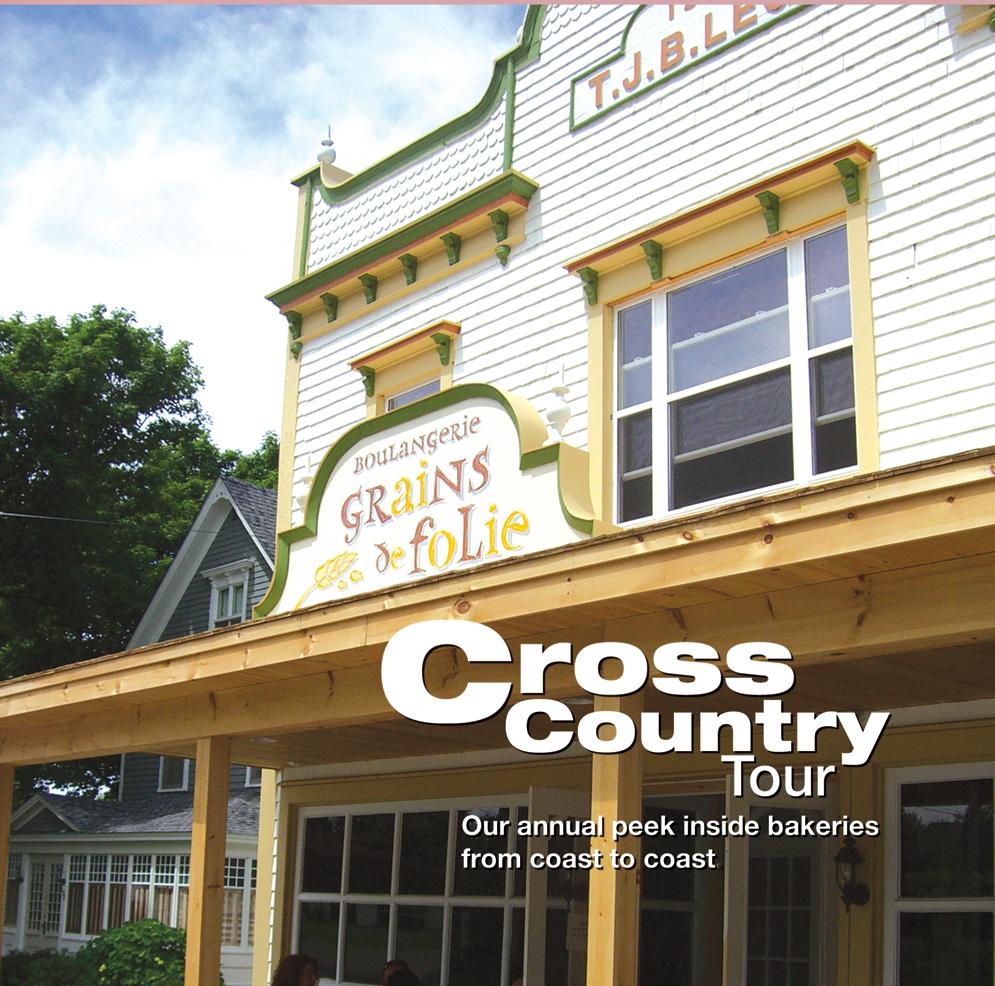

How a newly opened northern New Brunswick bakery set up shop and attracted a pair of husband and wife bakers from France.

How one Toronto businessperson went from mixing a sour dough starter in her apartment to supplying many of Toronto’s finest restaurants and grocery stores.

An Edmonton baker infuses passion into every loaf.

From winning a national contest, to developing a new brand, one British Columbia bakery is doing it all.

Flour bags are honoured as pieces of beauty and inspiration at a new German museum.

A roundtable of bakers and industry suppliers chat about challenges, solutions and the value of what the trade does.

Michelle Brisebois offers advice for introducing a side order of digital media into a traditional advertising

Fifteen quick-fix tips to enhance retail merchandising in your bakery from Diane Chiasson.

Tracey Muzzolini

Jane Ayer

In May, during Bakery Showcase, Bakers Journal convened a roundtable of bakers, suppliers and industry consultants to discuss many of the challenges the industry is currently facing (yep, the topic of commodity prices was way up there on the list of talking points). We carried coverage of the meeting in our July issue, and continue with that in this issue and in the upcoming October issue (and that’s with some editing because of space limitations in each of the issues, baking industry folk can be very opinionated). A common refrain we heard, one most people at the roundtable agreed with, is that too many bakery owners are great in the production room, but lousy on the sales floor.

“I think there’s a fundamental problem in the baking industry of having too many bakers that are not business people running bakeries,” said Jack Kuyer, owner of the long-running Valley Bakery in Burnaby, B.C., “That is really a big part of our issue. When I see a small little bakery that can’t afford to paint their store on the inside and there’s an owner slugging it away 12 hours a day, six days a week — I just don’t want to even be in there.”

And chances are he’s not the only one. The care and thought you put into the premises of your business say much to customers. As good as your products might be, a shabby storefront can do more to deter your clientele than the smell of freshly baked bread might do to attract them.

In this issue, we once again offer up our Cross Country Tour. We’ve visited five bakeries across the country, sampled their baked goods, and spoke with the owners about what inspires them and what they do (or have done) to reinvigorate their businesses. Bouillabaisse Café & Bakery in Parrsboro, N.S., recently underwent a change in ownership and a change in name (how’s that for reinvigorating a business?). Liz Garnhum, the new owner, also initiated a switch from mix products to scratch products, and, as evidenced by how quickly the bakery runs out of its goodies each day, the bakery’s customers are thrilled with the results.

Then there’s Boulangerie Grains de Folie, way up on the tip of northern New Brunswick. Talk about an invigorating business: it’s the only bakery of its kind (selling European-style breads, pastries and viennoiseries) for hundreds of kilometers. The owners brought in a set designer to create the atmosphere they wanted and even managed to attract a pair of husband and wife bakers from France.

Fred’s Bread, a Toronto-based wholesaler of really great breads and sourdoughs (I can never get enough of their products), keeps its business fresh by constantly looking to grow, whether it be by expanding its production facility or branching out to exhibit at a foodservice trade show for the first time or introducing new and unusual products (see this year’s annual recipe collection, Baking Across Canada, for a sampling of one of Fred’s Breads unique grape pizza).

All of the businesses we feature in this issue are making great products, they know their customers and they’re not afraid to shake things up a bit.

Step back from your business, see what other bakeries are doing (whether it be through the pages of our magazine or visiting bakeries when you’re travelling), connect with each other, get out to trade shows.

“I go to (Bakery Showcase) to look at the exhibit spaces,” says Jack Kuyer, “but more than that, I need to get a little motivated, I want to get a little excited about things again.”

Bakers Journal is always excited about the baking industry and looking for ways to share that excitement with you, our readers. Let us know how you get reinvigorated about your business, and how you turn that around to spice up your business, energize your staff — and ultimately motivate your customers to come back for more. ❖

Vol. 68, No. 7 August/September 2008

Editor Jane Ayer editor@bakersjournal.com 1-888-599-2228 ext. 250

Technical Editor John McColl, Puratos Canada jmccoll@puratos.com

National Advertising Manager Stephanie Jewell sjewell@annexweb.com 1-888-599-2228 ext. 268

Sales Assistant Pauline Cecile pcecile@annexweb.com 1-888-599-2228 ext. 273

Production Artist

Brooke Shaw

VP/Group Publisher

Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710 RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, PO BOX 530, SIMCOE, ON N3Y 4N5 e-mail: sbrady@annexweb.com

Periodicals postage paid at Buffalo, N.Y. USPS 007-277, ISSN 0005-4097. Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Publishing & Printing Inc. US Office of publication c/of DDM Direct.com, 1223 William St., Buffalo, N.Y. 14240. US Postmaster send address change to P.O. Box 611, Niagara Falls, N.Y. 14304. Printed in Canada ISSN 0005-4097

Circulation e-mail: sbrady@annexweb.com Tel: 866-790-6070 ext 206 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5 Subscription Rates

Canada – 1 Year $ 31.80 (includes GST – #867172652RT0001) USA – 1 Year $ 40.00 Foreign – 1 Year $ 60.00

From time to time, we at Bakers Journal make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2008 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Read these stories and more at www.bakersjournal.com

CANADIAN TO HOST BREAD BAKERS GUILD WORKSHOP

ACE FEATURED IN NEW BOOK

GEORGE WESTON Q2 PROFIT FALLS WITH HIGHER COMMODITY PRICES

MAPLE LEAF Q2 LOSS WIDENS TO $9.4 M, BUT COMPANY

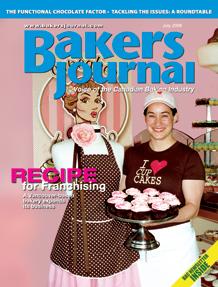

Frosting Straight Up

Think you can handle a shot of the hard stuff? Better sidle up to the bar with your toothbrush. The bake shop boom that has fueled the oh-soretro love affair with cupcakes has spawned a new – albeit micro – trend that has Saturday night hipsters doing a new style of shot that won’t burn your gullet like 150 proof. See the exclusive story at www.bakersjournal.com.

Just how did Jae Park and Bread ’N’ Buns win a $10,000 cash prize this past year? Find out details about the contest, along with a complete list of the winners from each category.

See the exclusive story at www.bakersjournal.com.

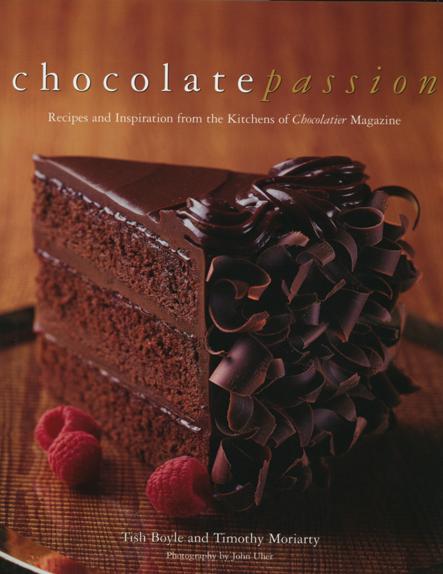

Chocolate Passion:

Recipes and Inspirations

Blending passion with expertise, this book will become a chocolate-lover’s instant favourite. Fifty-four luscious new recipes developed and tested by editors at Chocolatier magazine celebrate chocolate at its best, including the whimsical Tahitian vanilla swirls, the elegant milk chocolate mousse roulade, and the smooth, sophisticated black satin chocolate raspberry cake. With separate sections on white, milk, and dark chocolate, and gorgeous full-colour photographs of techniques and finished desserts, Chocolate Passion makes it easy to learn and master the secrets of working with every type of chocolate. Visit www.bakersjournal.com and click on bookstore to learn more about the book and order a copy.

Take part and view results of our regular polls…

Do you offer any organic products in your bakery?

Yes: 57%

No: 43%

• Barbie™ has danced her way into the hearts of little girls the world over. In celebration of her timeless appeal, DecoPac is pleased to present a new Barbie “Perennial Ballerina” DecoSet® featuring Barbie™ as a beautiful Ballerina Princess.

• The San Francisco Chocolate Factory is pleased to introduce the chocolate straw. The straws make any glass of milk taste like chocolate milk, which means no more battles over getting kids to drink their milk. The new straw is designed with fun packaging that is attractive to both parents and children.

• Munson Machinery introduces a new miniature rotary batch mixer that blends bulk ingredients, adds liquids and achieves 100 per cent batch uniformity in less than three minutes while heating or cooling the batch.

Looking for a new oven, a certain ingredient or a consultant to offer baking advice? Look no further than here, in Bakers Journal’s annual Buyers Guide & Directory. Search here for your baking needs.

To sign up for a free trial of the digital version of Bakers Journal, go to www.bakersjournal.com.

Fleischmann’s introduces price changes

Fleischmann’s Yeast introduced price changes effective the beginning of August, or as contracts expire. Due to ongoing cost increases from its raw material suppliers, the company will guarantee pricing and terms to customers for no more than 90 days. It’s also requiring minimum purchase amounts per order to reduce delivery frequencies.

Fleischmann’s has raised the perpound price of fresh yeast by $0.10 US and dry yeast by $0.18 US. The company says unprecedented input cost increases on energy, distribution, phosphoric acid

and fermentable substrates are the main drivers.

In addition, due to continuing, dramatic increases in raw material costs, Fleischmann’s has increased calcium propionate pricing by $0.12 US per pound. The two primary suppliers to the mold inhibitor industry recently announced dramatic increases on propionic acid, the main component of calcium propionate. The suppliers cited surging energy, feedstock and transportation costs.

“We are continually working to implement cost control initiatives to minimize customer impact. However, we cannot absorb these unprecedented and unforeseen increases and unfortunately will need to pass along some of the costs to ensure that we do not sacrifice quality or service,” said Greg Strauss, vice-president of sales and marketing, Fleischmann’s Yeast.

The Mimac Glaze family lost company founder Bill Miles in July. Bill was a long time member of the Canadian baking industry, serving as both president of the Bakery Production Club of Ontario and chair of Bakery Showcase (from 1970 to 1972). He founded Mimac 30 years ago, after working for both Weston and Standard Brands. He retired from the company in 1990, passing over control of the business to his son Dave, who still runs Mimac, with daughter Marion. A memorial service was held August 1. Expressions of sympathy may be made to a charity of your choice.

Malaspina University-College has gone through a name change. In April, B.C. Premier Gordon Campbell and Advanced Education Minister Murray Coell announced the school would become a university, known as Vancouver Island University (VIU).

“As the first-ever Vancouver Island university based outside the greater Victoria region, Vancouver Island University will be a critical educational, social and economic hub, giving thousands of students from Vancouver Island a chance to get the education they want closer to home,” said Campbell. “VIU will build on its international reputation for its Aboriginal-focused programs, leading-edge Coastal Resource Management programs, and trades and technology programs.”

One of those programs includes a very popular baking and pastry program.

The school began as a community college in 1969 and became a vocational school in 1971 to provide career, technical and trades programs. In 1989, Malaspina was designated a university college. It has campuses in Nanaimo, Cowichan, ParksvilleQualicum and Powell River. Malaspina University-College has an enrolment of 19,124 students, including 1,129 international students.

To find out more about the school, and its baking program in particular, go to the website at www.viu.ca/baking/about.asp

Researchers have launched a national survey project to determine how many Canadians suffer from potentially fatal food allergies.

The survey of 9,000 Canadians across the country will also delve into how effective food labels are in warning consumers about such allergy-causing ingredients as peanuts.

Co-principal investigator Susan Elliott of McMaster University says results of the survey will help Canadian policy-makers take steps to prevent, diagnose and manage allergic diseases.

Elliott says the survey findings will also help companies develop clearer and safer labelling for food products.

The prevalence of serious food allergies is known to be rising in Canada and elsewhere in the world, and scientists are trying to figure out why.

Allergies to peanuts, tree nuts, fish, shellfish and sesame seeds can cause a potentially fatal reaction known as anaphylaxis.

(Source: The Canadian Press)

Master-Bilt appoints new reps

Commercial refrigeration manufacturer

Master-Bilt has announced the appointment of five additional manufacturer representative groups throughout Canada. The company has also added a new, fully stocked warehouse in Mississauga, Ont.

Joining forces with Master-Bilt to provide additional support in the Canadian marketplace are: The BASK Enterprises in Vancouver; Brent Wells Sales in Edmonton; Copperfield Agencies, Ltd. in Nova Scotia; Simpson Wilson, Ltd. in Winnipeg; and STL Marketing in Quebec. Master-Bilt has had a presence in Canada since 2003 with its current manufacturer representatives: Trillium Sales Marketing, based in Ancaster, Ont.; and Bill Smith Marketing, Ltd. in Calgary, Alta.

“Each of our new Canadian rep groups brings the experience our customers rely on when purchasing refrigeration equipment,” says Bill Huffman, vice-president of sales and marketing for Master-Bilt. “We welcome them to our family and are excited to see how they will strengthen our operations throughout Canada.”

The fourth annual Salon Passion Chocolat & Cie will take place this fall from Nov. 7 to 9 at the Palais des Congrès in Montreal. Quebec’s top artisanal chocolatiers will be present to tempt the public with their exquisite creations.

This year, the exhibition will feature world-famous chef Gérard Joël Bellouet all the way from France. This culinary star, who is a member of the Académie culinaire de France, holder of the Grand Cordon d’or award for French cuisine and author of many books of international acclaim, will preside over the jury

Ottawa threatens enforced trans fat regulations

Fast-food chains are cutting trans fats under voluntary guidelines, but the federal government is threatening to force suppliers of fat-packed baked goods to find a healthier alternative.

Junior health minister Steven Fletcher calls the latest trans fat statistics from Health Canada “great news for Canadians.”

in the chocolate pieces competition. Visitors will have the opportunity to meet Bellouet during the various presentations he’ll deliver throughout this three-day extravaganza.

The Salon Passion Chocolat & Cie is a once-a-year event, where chocolatiers from around the province unite under one roof to offer the public an array of exclusive chocolate products.

“On top of the tastings and the opportunity to buy some sumptuous products, the Salon Passion Chocolat & Cie delivers one-of-a-kind activities in a fun and lively atmosphere,” said Isabelle Racicot, spokesperson for the event.

“Among them is a chocolate hat fashion show, clothing and accessories made from chocolate, other innovations in chocolate, live demonstrations, competitions, seminars, contests, famous guests, and the list goes on. Suffice it to say, visitors will be treated to plenty of pleasant surprises over the course of three full days.”

To find out more, go to www. salonpassionchocolat.com.

But Fletcher, speaking at a fast-food restaurant in Ottawa, said more must be done.

In June 2007, Ottawa asked the food industry to voluntarily reduce trans fat levels to five per cent of the total fat content of food products and two per cent in vegetable oils and margarine.

Health Minister Tony Clement gave the industry two years to reach these targets and said regulations would be considered if they fell short.

But while restaurants are falling into step, the baked-goods sector remains a challenge. Only a few pastry manufacturers have made strides to reduce trans fat in their products.

“There is a possibility of regulation if industry doesn’t meet the goals that have been outlined by the trans fat task force,” said Fletcher.

“It’s important to highlight the fact that the industry is doing this voluntarily.”

The Heart and Stroke Foundation criticized margarine and doughnut manufacturers for their lack of effort to develop healthier options for consumers.

Stephen Samis, the group’s director of health policy, targeted producers of soft margarines, some of which have up to 30 grams of trans fats.

“There is no reason for that and it really is a lack of will, not a lack of ability,” said Samis, who acknowledged that healthier alternatives can come with a price tag, but says the short-term cost is necessary to ensure the health of Canadians.

“The cost of reformulating your product is there and we salute those companies that have made the difference and we’re really concerned about those who are just not moving on it.”

Popular doughnut chains Coffee Time, Robin’s Donuts and Dunkin’ Donuts also made the list of companies The Heart and Stroke Foundation rated as not doing enough to curb trans fats in their products. ❖

(Source: The Canadian Press)

A new bakery owner in Nova Scotia brings her business back to its roots.

By Jane Ayer

Originally from Nova Scotia, Liz Garnhum moved to California years ago when she was presented with a business opportunity she couldn’t refuse. She says she loved it there: the climate (warm and sunny), the work (both managing and running restaurant or foodservice operations). But eventually, the time came to return home. She did that in 2007, with thoughts of buying her own business forefront in her mind. Garnhum scoured the province, looking for the right fit. When she drove into Parrsboro, a small town on Nova Scotia’s Minas Basin in Northern Nova Scotia that claims some of the highest tides in the world, Garnhum fell in love, both with the town and the business she was there to visit.

“I pulled into town and I never left.”

She bought Carole’s Bakery, a small business that had been on the go for decades at the end of Main Street. The building also housed a Greco Pizza outlet and Captain Submarine franchise. Once both of those businesses moved out, Garnhum’s work began. She says the building was barebones and “stark white.” Fresh paint and well-selected decorations brought a more welcoming, seaside flavour to the business, as did a name change: Bouillabaisse Café & Bakery, with the café on one side of the building and the bakery on the other.

While the bakery was well established in the town, Garnhum wasn’t completely thrilled with a lot of the products it was making and selling. Most of them came from mixes, and Garnhum says they just didn’t have the flavour profile she wanted.

“They were very economical to make, but they didn’t have that homey taste I was looking for,” she says. “I’m all about the flavour and naturalness of food.”

And so the switch-up: Garnhum encouraged the two bakers, Helen and Heather, to find new recipes for some of the baked goods they’d been making for so long. And slowly, bit by bit, new, fromscratch breads and cookies and pies replaced the from-mix products its customers were used to. They were a hit, both with Garnhum, who sampled and gave the stamp of approval to each of the new products, and with the customers, most of whom are locals. The bakery’s scratch donuts are consistent best-sellers (I tried them hot from the deepfryer when I was there, and can absolutely understand why), the fresh pies (coconut cream with “mile-high cream,” lemon meringue, seasonal berry pies) are also a hit (Garnhum says, “I could fix the world if I could give everyone a slice of our pie and coffee”), and the bakery’s gooey, oozing sticky buns have earned themselves a reputation throughout the province, complete with

Above: Owner Liz Garnhum sits in front of Bouillabaisse Café & Bakery in Parrsboro, N.S.

Left: All of the bakery’s offerings are made from scratch, including its everpopular gooey sticky buns.

accolades on one of the CBC radio programs which airs out of Halifax.

The bakery also offers wedding cakes, does catering, and has become known for its willingness to take special requests. One customer called to see about ordering a cranberry pie, something they’d had as a child and had never seen at a bakery since then. Garnhum says the bakers set to work, and created something that was exactly what the customer was looking for.

“I had to try some myself,” says Garnhum. “It was quite nice tasting.”

Bouillabaisse has done some advertising to get the word out, placing flyers at local tourist bureaus, along with newspaper ads in local papers in the county, but mostly, it relies on word of mouth to spread news of both the bakery and the café. Garnhum has also become quite involved in the community in the short time she’s lived in the area. She’s a member of the Parrsboro Board of Trade, and made certain Bouillabaisse takes part in any local parades and events. For the town’s annual Christmas parade, Garnhum even sourced a gingerbread costume from the U.S. that she wore herself, handing out cookies and treats to the towns kids. The gingerbread

Continued on page 18

How a newly opened northern New Brunswick bakery set up shop and attracted a pair of husband and wife bakers from France.

By Jane Ayer

If you follow the New Brunswick coastline north, you’ll eventually hit the Acadian Peninsula. Keep driving, another hour or so, through pristine, well-kept Acadian towns and villages and you’ll come to the town of Caraquet, at the northeastern tip of New Brunswick on the Chaleur Bay. Known as the capital of Acadia, Caraquet was established in the 1750s by Acadian settlers who were victims of the British deportation in the south. Although it has its roots in Acadia, Caraquet is a Micmac term which means, “the meeting of two rivers.”

It’s there that you’ll stumble upon the newly opened Boulangerie Grains de Folie, housed in a massive century building that it shares with a yoga studio, a tiny, but well-stocked bookstore and an épicerie fine (fine grocery store) featuring both local and imported products. With its wooden trim, screen doors and colourful window boxes, the bakery looks right at home in the century-old building, exactly what owners Lorraine Haché and Claude Bergeron worked long and hard to do.

After growing up in the area, and moving away to live and work for some years in the southeastern New Brunswick city of Moncton, the pair made the decision to return to Caraquet. Both had extensive experience in the human resources field, and Haché had also taught at the University of Moncton (where she continues to work, now at the university’s campus in Caraquet). When they returned to the Acadian Peninsula, Haché says they missed one thing: good, crusty, Europeanstyle bread.

“Every time we travelled, we were drawn to small bakeries and cafés,” she says. “When we lived in Moncton, we were used to buying bread from the market there and when we moved back here it was difficult to return to regular grocery store bread.”

And so, without any kind of baking or café experience under their belts whatsoever, the two mused about setting up a bakery, a European-style one that could supply them with the kind of bread they’d become accustomed to. They bought the century-old building, with thoughts of a bakery and also a yoga studio (one of Haché’s many hats is also that of yoga instructor), which required much updating and retrofitting, but Haché and Bergeron loved its historical aspects and insisted on keeping many of its original features, including a beautiful tin ceiling. After being told a firewall was required in the ceiling for insurance purposes, the contractor the pair hired carefully pried off each tin tile, numbering every one of them to be able to put them back in exactly the right place. They also brought in local set designer Luc Rondeau to create just the right atmosphere for the bakery.

“What we wanted was a warm, homey style where people wouldn’t feel rushed,” Haché explains. “We definitely didn’t want a

Above: French bakers Didier and Isabelle Goulier (on the left), arrived to work in Boulangerie Grains de Folie in northern New Brunswick in February. The bakery is owned by Claude Bergeron and Lorraine Haché (right).

Left: Didier and Isabelle make all of the usual pastries they used to make in their bakery in Rouen, France.

fast-food type of place.”

Gleaming wooden floors, wooden tables like you might find in a family’s kitchen (including mismatched wooden chairs), wooden railings and wooden beams all complete the warm, comfortable feeling Haché and Bergeron were looking to create.

Next on the agenda? The big task of actually finding bakers to fill the bakery’s display cases with breads and pastries and croissants. When Haché’s son expressed an interest in learning how to

Continued on page 18

Toronto, ON ON

How one Toronto businessperson went from mixing a sourdough starter in her apartment to supplying many of Toronto’s finest restaurants and grocery stores.

By Jane Ayer

here’s a certain alchemy, a magic that happens when flour and water are mixed together and allowed to ferment and grow from the yeast living in the air around it. It was that magic that first captivated Andrea Damon Gibson back in 1991 while working as a pastry chef at Toronto fine dining institute Splendido. Damon Gibson, fresh from what she describes as a “pilgrimage from San Francisco to L.A.” to visit such bakery legends as The ACME Bread Co. and La Brea Bakery, was inspired to try her own hand at making “good” bread.

“I wanted to make good bread and ACME was sort of the benchmark,” says Damon Gibson.

She started testing out various formulas and, after much experimenting, found something that worked and that Splendido’s customers enjoyed. A few years later, seeing a need to be filled at other restaurants in the city, and having always wanted to run her own business, Damon Gibson decided to strike out on her own. After mixing her first sourdough starter in her apartment at the end of 1994 and getting help from husband Steve Gibson (an MBA graduate working for Black & Decker at the time) on a business plan to take to the bank, so was born Fred’s Bread. Having read about James MacGuire’s legendary Le Passe-Partout restaurant in Montreal and the bread he was making there, Damon Gibson got in touch with MacGuire and soon enough found herself on her way to Montreal to complete a one-week stage at MacGuire’s in-house bakery.

manager and a part-time driver. Damon Gibson would make dough in the afternoon, bake the bread overnight, catch a nap on a futon couch in the office sometime during the day, and, in between, make sales calls. Scaramouche (another longestablished Toronto eatery) and high-end grocery store Pusateri’s were among the bakery’s first customers (Damon Gibson is proud of the fact both are still customers). Damon Gibson’s father, Paul, came on board to help out where needed, mostly with accounts payable, and husband Steve left Black & Decker in 1998 to join Fred’s Bread full time.

“He’d always helped out with business and we decided the time was right to do it together,” says Damon Gibson.

Together, the pair decided Fred’s Bread would never venture into the retail business of selling bread, says Damon Gibson. Fred’s Bread would always be wholesale.

“The focus was always going to be the restaurants,” says Damon Gibson. “The idea was never to run the retail side of things ourselves, it’s too expensive.”

“It was great,” remembers Damon Gibson. “I spent the nights with his baker and it was a really terrific experience. Eighteen years ago, sourdough was described as some mystical experience and there was no one here to teach you about it. (James) sorted out some misconceptions that I had about the process.”

Misconception #1: That starters had to be extremely sour and taste like vinegar. The breads MacGuire made were flavourful and nutty, but not extremely acidic.

Misconception #2: That starters would only grow with spring water and organic flour. Not necessary, suggested MacGuire.

Misconception #3: That instead of measuring and moderating the precise temperature for everything (the water, the air temperature, the starter itself), one should just go with feel and touch. Temperature, emphasized MacGuire, was key.

Damon Gibson returned to Toronto re-inspired, setting up shop in a tiny unit just north of the 401 in the city’s west end. The business consisted of Damon Gibson as the baker and salesperson, an office

The bakery’s customers are still 60 to 70 per cent restaurants, with grocery stores and other high-end food stores making up the rest of the business, something that helps protect the bakery’s margins when the economy tightens up. A recent move to offer customers frozen dough products has also allowed the business to expand both its product line and its customer base, to those outside the immediate GTA. Damon Gibson says demand for Fred’s Bread breads has also grown because of in-store sampling at the retail level and participation in such shows as the CRFA Show in Toronto this past March.

All that growth requires more space for baking and doing business. Fred’s Bread has already expanded into the unit beside it, giving it 4,200 square feet to squeeze in everything from the sales office to the newly installed Miwe deck oven (“our Caribbean condo,” jokes Damon Gibson). With double-digit growth in the past year alone, the bakery will expand into another unit this fall, upping its space to 6,400 square feet.

Fred’s Bread currently employs 30 staff members altogether, eight of whom are bakers. Because of the never-ending difficulty in finding skilled bakers, Damon Gibson trains the bakers herself. Most of the work is still done by hand, although a molder, hydraulic divider and that new Miwe oven (complete with an automatic loader) have made the process a little more efficient.

Continued on page 18

Edmonton, AB AB

By Nordahl Flakstad

Close your eyes. Bite into a slice of Tree Stone bread. Taste the beauty of a blue Alberta sky, The natural goodness of a shining wheat field And savour the pleasure Tree Stone offers. Statement from Tree Stone Bakery brochure

Tree Stone Bakery recently celebrated its 10th anniversary. But the roots of the Edmonton artisan bread bakery run deeper than that. Its origins trace back to the mid-’80s, when Tree Stone owner Nancy Rubuliak spent a year travelling and soaking up the sights, sounds and, most importantly, the tastes of Europe. What really impressed her was not only that different countries offered varied bakery products, but also that regions and towns and even individual bakeries produced baked goods, and particularly breads, with signature tastes and characteristics. In many respects, they amounted to the very opposite of franchise operations characterized by predictability, consistency and uniformity.

“In Europe I learned a lot about food by paying attention. It left me wanting to learn more about breads. I believed I could do it – I realized that making good bread is not rocket science,” explains the Tree Stone proprietor sitting down for a breather after closing up her shop on 99th Street, a busy thoroughfare a few blocks north of Whyte Avenue in Edmonton’s trendy Old Strathcona district.

While the European experience had planted the idea of someday starting her own bakery and making the French sourdough breads that now form Rubuliak’s stock-in-trade, the concept took some time to leaven. She returned Canada to work within her then chosen field as a registered social worker.

Baking bread may not be rocket science, but Rubuliak figured some expert advice would be useful. So, in 1997, she enrolled in a course given by bread guru Didier Rosada at the National Baking Center in Minneapolis. That was followed by a three-month renovation project to convert and rewire what had been a street-level print shop to house a two-deck, six-pan oven and other bakery equipment. (That has been followed by two expansions into adjacent premises to accommodate a small café and a four-deck Miwe oven with a loader.)

While she approached the venture in a businesslike way - complete with a business plan and the intent of earning a living – Rubuliak admits she was heading out on a wider adventure. Like braided bread, the business goals had several strands. A central mission was making good, nourishing bread that people really would enjoy eating.

On yet another level, Rubuliak concedes, “I really wanted to do something that would serve the planet.”

At one time, she considered making that connection with the earth through farming but ultimately decided that she could achieve a similar link by caringly shaping products from what the land offered.

That earthly connection even came into play in choosing Tree Stone as the business title. Rubuliak sees the name as symbolizing life

represented by a tree and by the earth on which that life rests.

That down-to-earth approach is evident throughout Tree Stone Bakery’s operation. For instance, wheat and rye used in whole-grain products are grown by two Edmonton-area organic producers and then are ground in-house at Tree Stone. White flour comes from organically certified mills in Lethbridge, and Camrose, southeast of Edmonton. While Rubuliak didn’t set out to meet such targets – and in fact began her business before the concept gained much of its current popularity – many of her ingredients satisfy the criteria of the 100-mile diet.

Ongoing and strong links with suppliers help ensure the quality of Tree Stone inputs and reflect the kind of relationship-building Rubuliak also extends to customers.

At one time, she may have envisioned setting up a “neighbourhood bread shop.” In fact, her base of customers – many of whom have European backgrounds and a strong appreciation for good bread – extends far beyond the immediate Strathcona area. Some regular customers definitely break the 100-mile-diet rule by travelling from as far away as Calgary. Mostly, the reputation of bread that pleases the pallet has been spread by word of mouth.

Continued on page 19

From winning a national contest, to developing a new brand, how one British Columbia bakery is doing it all.

By Tuija Seipell Coquitlam, BC BC

What Jae Park did with the $11,000 he won at this year’s California Walnut Inspiration Contest at the CRFA Show in March, pretty much summarizes what you need to know about the man and the company he operates with his family.

Representing his family firm, Bread ’N’ Buns Factory of Coquitlam, B.C., Jae won both the Best in Show (with a prize of $10,000) and the Breads category (with a prize of $1000) for his California Walnut Raisin Rye Bread. (See details of the contest by going to www.bakersjournal.com and clicking on Web Features).

“We had a big company dinner at a nice restaurant with all of our employees,” Jae says. “We also had a bowling and pizza night where every participant received $50 and the first prize winner received $300, second $200 and third $100. We also bought some new uniforms. So, most of the winnings went back into our company through our employees.”

Hard work and mutual respect permeate everything at this bakery business, established by Jae’s father, Doo Yun Park more than 20 years ago. When Jae accepted his prize in Toronto he said, “I’m proud to represent my family and accept this honour on their behalf. I learned everything I know about baking bread from my father and am excited to be recognized for our winning product.”

Bread ’N’ Buns operates a 4,000square-foot retail bakery and deli (of which 2,200 square feet are retail and the rest is bakery and support area) in a strip mall in a residential area of Coquitlam, about 45 minutes’ drive from Vancouver. The commissary where the par-baking takes place is in an industrial area close to the store. Currently, about 40 per cent of the revenue comes from wholesale – distribution by Snowcap to grocery stores and hotels – but the main business is retail.

The key players leading the 30-person staff team are Doo Yun Park and Jae Park, who run the “back” of the business, and Linda Park (Jae’s mother), Yvonne Park (Jae’s wife) and longtime store manager Irmgard Schelesny, who run the “front.”

“We are really a dream team because everyone is doing what they love to do,” says Doo Yun Park with obvious pride and pleasure.

Jae became a full-time employee in 2002, after graduating from Simon Fraser University with a business degree. He explains the division of responsibility between father and son.

Above: All in the family: the key players of the Bread ’N’ Buns Factory include, from left to right: Yvonne Park (wife to Jae); Irmgard Schelesny, the store’s longtime manager; Doo Yun and Linda Park (holding grandkids) and Jae Park.

Left: Bread ’N’ Buns operates a 4,000square-foot retail bakery and deli (of which 2,200 square feet are retail and the rest is bakery and support area) in a strip mall in a residential area of Coquitlam, about 45 minutes’ drive from Vancouver.

“My father is a seasoned businessman but he gives me as much responsibility as I can handle. He lets me experience things on my own even if it means that it’ll take longer or I’ll make mistakes.”

Variety brings customers

“We are known for our bread and buns,” says Irmgard. “We make our bread without sugar or preservatives. It is real bread that does get stale after a few days. Our customers love the quality and taste.”

The company makes about 30 varieties of bread and 18 kinds of buns, with the light rye bread being the best-seller. The cake selection is currently expanding. Children’s birthday cakes are really successful, says Irmgard, showing off the fresh cakes decorated with SpongeBob SquarePants, Nemo, Winnie the Pooh and various princesses.

The store also has a large deli section with cold cuts, cheeses and other deli items. In addition, there is a selection of European groceries – pickles, dry breads, crackers, jams and so on - and even some European hand-painted serving plates, bowls and pitchers, all

Continued on page 22

WhatmakestheVemagDoughDividersospecial? Versatilityandweightaccuracy.TheVemagDivider addsversatilitytoeveryproductionlineandis perfectforalltypesofbreads,buns,rolls andEnglishmuffins.Itfeaturesapositive displacementdoublescrewsystemthat isthemostgentleextrusiondivider onthemarket.TheVemagiseasily adjustabletoproducearangeof exact-weightportions,dough absorptionsandcrumbstructures. Seeforyourself–callustodayfora freeDVDortosetupademonstration.

Batchafterbatch,theVemag consistentlyproducespreciseweight portionsat1%standarddeviation.

TheVemagDough Dividerproduces uniformlyspaced doughportions ontotheconveyor, eliminatingdoubles anddowntime. Itcanbeeasily convertedtoa two-laneset-upto produceupto200 cutsperminute.

TheVemagdoesnotrequiremineral oil,savingthousandsofdollarsannually whileeliminatingproductairpockets andsurfaceblisters.

TheVemagiseasilyadjustable toproduceawiderangeof portionsizes–from5gto20kg.

TheVemagiseasilyadjustedto producebothopen-crumband uniformtight-crumbstructures.

TheVemagcanhandleabsorptionrates from45%to95%–fromstiffbagel doughstosoftEnglishmuffins.

ReiserCanada 1549YorktonCourt#4,Burlington,ONL7P5B7•(905)631-6611

Reiser 725DedhamStreet,Canton,MA02021•(781)821-1290 www.reiser.com

Continued from page 10

man also makes an appearance at kids’ parties held at the bakery, where he acts as host of the party and helps lead cookie-making and cake-decorating sessions.

Garnhum has worked hard to make herself and her business a big part of the community. But that doesn’t mean the bakery was immune when commodity prices shot through the roof, not long after she took over. Garnhum says she struggled with how to deal with the issue.

“We did do a few small price increases, but my philosophy is to kill with volume, not prices,” she says. “When things got really tight, we expanded, starting up a wholesale business with the local grocery store. That really helped and will pull us through.”

Expanding the bakery’s commercial business even more is something Garnhum very much has on her mind, though likely not for another year or two. Along with that, Garnhum would love to expand the premises, perhaps including a warehouse for storage and some of the baking and cooking. Already the owner of a cube van, delivery wouldn’t be the issue, says Garnhum: cooking and baking space is the biggest premium right now, and more of that could mean more business for café and bakery.

But in the meantime, Garnhum says she’s happy with how things are going and is grateful to call both the bakery/café and the town of Parrsboro home.

“I love rural Nova Scotia,” she says. “I’ve only left to go into the city and then I can’t wait to get back. I love it here.” ❖

Continued from page 12

The bakery makes 25 varieties of bread every day, although it has 45 to 50 varieties on its product list, with over 200 SKUs. Damon Gibson admits having a hard time paring down that list: part of it is a connection to the products she’s developed, but part of it is also the fact customers have come to expect variety from Fred’s Bread.

“We’ve developed a reputation for offering a huge variety of interesting products,” says Damon Gibson.

Many of those products evolved out of customer requests (the yeasted products like a French baguette, an organic French baguette,

Continued from page 11

bake bread, he went to a Quebec college to seek training. It was around the same time Haché and Bergeron received a call from town officials. And this is when Caraquet, besides being the “meeting of two rivers,” also became a meeting of two worlds.

Let’s travel, for a moment, to Rouen, France, where husband and wife team Isabelle and Didier Goulier were running their own bakery. Didier, with 30 years’ experience as a baker and pastry chef, happened to hear a news story on the local radio station that government officials from Canada were in the area, giving presentations on immigrating to Canada. They were specifically looking for bakers. His curiosity piqued, Didier made some phone calls, finally speaking with immigration authories in Fredericton. They put him in touch with a bakery owner from Moncton who had been on the recent trade mission to France (along with town officials from both Moncton and Caraquet) and who was looking for a baker, but someone with a little less experience than Didier (and who might not expect the same sort of compensation). Moncton town officials then contacted Caraquet officals, explaining the situation. Haché and Bergeron just happened to be working on getting all of the required permits at the time, and when they heard a baker from France was interested in finding work in New Brunswick, they jumped at the opportunity. The Gouliers came to visit Caraquet in the fall of 2007, and, with their sense of adventure sparked, agreed to come back in

and a pain rustique, many of them out of Damon Gibson’s interest in local, seasonal and organic products. Some of the seasonal products have included a concord grape pizza (see the formula in this year’s annual recipe collection, Flavours of Canada), an asparagus flatbread and a pizza terra, covered with local new potatoes, sweet potatoes, beets, toasted sage and caramelized onions.

Damon Gibson says Fred’s Bread will continue to offer its customers the quality, high-end products it’s become known for. But that doesn’t mean she wouldn’t make a few changes. First on the list would be expanding into a separate, production facility, one with lots of room for more growth. Fred’s Bread is also in discussion with a

February, this time for good.

“We wanted a change of horizon,” says Didier.

Besides the new horizon, the pair have also had to become used to other changes, from the pace of work (“The rhythm of work was much slower,” says Didier. “There’s a very nice quality of life here.”), to the Acadian accent (very different from French accent), to the ingredients (common Canadian ingredients like blueberries and cranberries are not so common overseas), to the grocery stores.

For the first little while (until Haché’s son finished his training in Quebec), Didier and Lorraine made all of the products for the bakery, including breads, pastries and vienoisseries. Although many of the formulas required some adjusting (mostly because of the difference in flour strength), Didier says the transition was smooth for the most part, and the bakery opened full time on Feb. 21 of this year.

Overall, the pair has settled in well to the community. Their son just recently arrived for a visit and they now own a car and a home in the area. I ask them how long they think they’ll stay.

“We just arrived,” Didier says with a smile, “give us some time.”

The bakery’s name, “Grains de Folie,” means a streak of madness, exactly what seems to have transpired in this small northern New Brunswick town, with a series of events Bergeron and Haché could never have foreseen when they first set the wheels in motion to open a bakery. But it worked. And the pair has high hopes for the future. ❖

distributor in the U.S. And Damon Gibson has also played with the idea of a little retail spot attached to the business, along with expanding into take and bake products. The opportunities, Damon Gibson says, are endless, despite increased competition from other high-end bread makers.

“There are more people in the upper end of the market, but I think it’s a good thing. It means the market has grown. There’s more competition but it keeps us on our toes.”

The market may have changed and grown, and Fred’s Bread along with it, but one thing hasn’t at the bakery: the sourdoughs still take about 20 hours from start to finish. That alchemy is still allowed to work its magic. ❖

Continued from page 14

“The only way to make it was to specialize and to make it better – Grade A,” Rubuliak insists. “Our prices are definitely higher than in supermarkets – we bake for people who really care about bread.”

What customers find is an intentionally fairly restricted selection of about a dozen types of hand-formed breads – including white, whole wheat, multigrain, baguettes, country rye and maslin. No additives or preservatives are used and most of the breads are proofed using wild yeast (pain au levain) cultures. Visitors to the Tree Stone can enjoy a coffee and some brioche – one of the few concessions for those with a sweet tooth – in the adjacent café.

“We are definitely not a full-line operation,” Rubuliak observes. There are other ways in which Tree Stone differs from other bakeries, which thanks to an overnight shift may have fully stocked shelves first thing in the morning. Nancy Rubuliak typically begins work at 5 a.m. and usually continues baking until the early afternoon.

Reliance on the slower sourdough techniques, rather than faster-rising baker’s yeast,

also tends to stretch out production. The result can be that customers think the store is sold out, only to be encouraged, “Please come back in an hour, we’ll have something then.”

For Rubuliak, this somewhat flexible production schedule partly stems from selfpreservation. She plays a central role in running the store – including not only baking but also serving the goods. Even with a five o’clock start, it’s not unusual for Rubuliak’s day to run till 6 p.m.

Along with many other Alberta business

operators, Rubuliak shares the challenge of finding and retaining good staff. That’s particularly true when it comes to hiring experienced bakers but also extends to sales personnel. Shortages have become all the more acute in recent years amid the province’s bubbling-hot energy boom.

For seven years, Rubuliak was fortunate to retain the services of a young woman she herself trained in the craft. Following that employee’s departure last December, Rubuliak has tried without success to hire suitable journeymen bakers. Generally they have the sort of commercial experience that doesn’t fit well in a very hands-on artisan operation.

For Rubuliak, difficulty in hiring the right people has meant, “I can’t produce enough to meet demand.”

Recently, she took on a new apprentice with a view to again sharing her knowledge, as well as her love and commitment to making good bread. That passion has not gone stale after a decade of running Tree Stone.

“I have worked to make the best bread possible. It’s been a great experience and it has given me a lot personal satisfaction – it’s really a life-giving work.” ❖

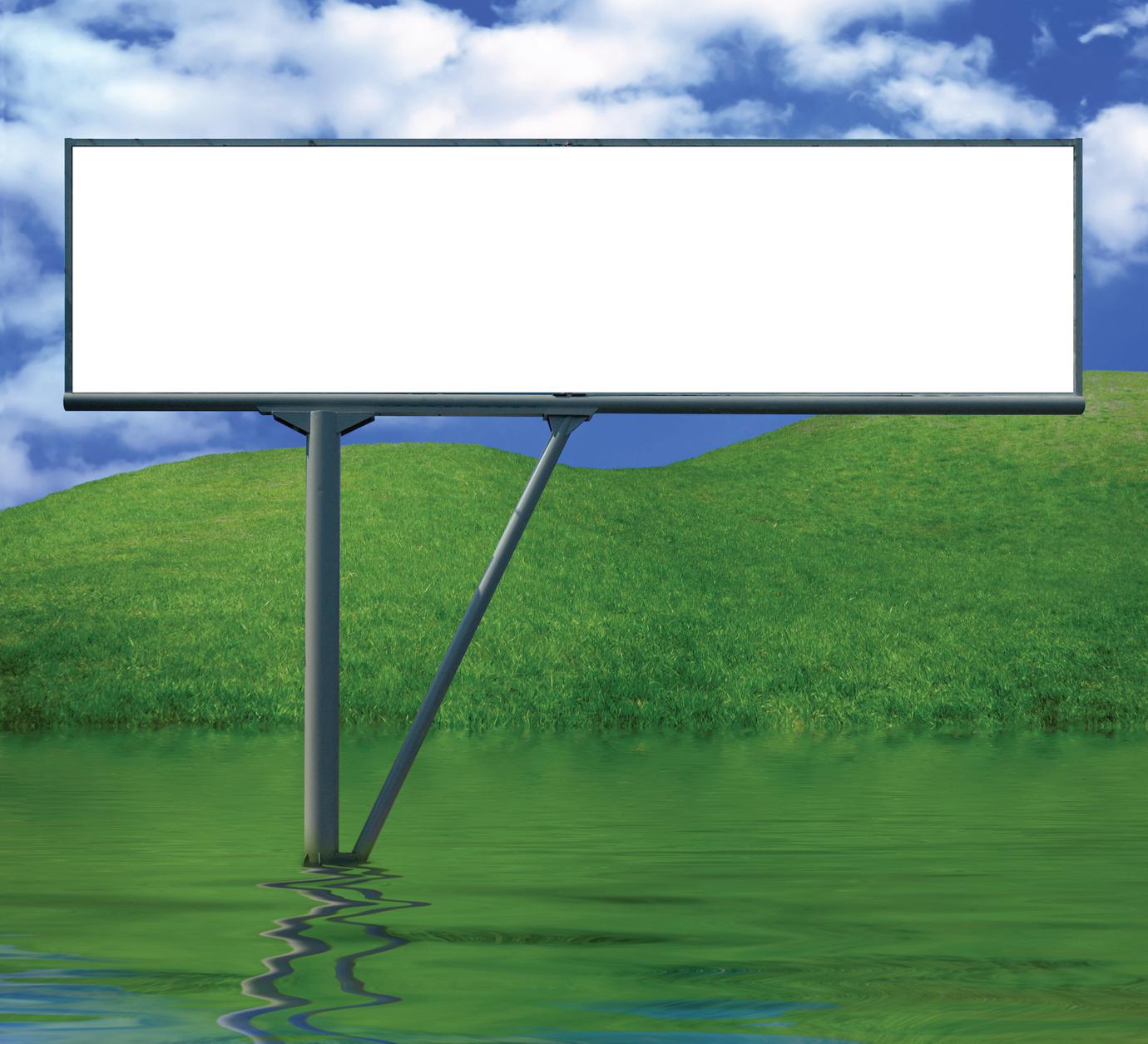

Michelle Brisebois offers advice for introducing a side order of digital media into a traditional advertising gameplan.

You’ve probably seen them popping up in grocery stores, Canadian Tire, public transit and even on the wickets at your bank. Digital signage is taking the interactivity of the web and marrying it with traditional posters, creating a dynamic message centre capable of communication strategies that are showing great results for some retailers. You may be thinking that it’s too complicated or expensive for a smaller business but that’s not the case. The hardware is as close as your favourite electronics store and with the right web master or mistress, your messages can literally come to life.

Just what is digital media anyway?

Digital messaging can be defined as offering a user experience that engages many of the senses and cannot be realized with other technologies. Digital media involves the distribution of digital entertainment as a whole category, not just digital music, and it’s a growing channel for consumers to get their entertainment fix. Many consumers are now accessing their digital content outside of the home via mobile devices, which makes the marketing possibilities expand for service providers, content providers, and manufacturers, as well as advertisers. To try a digital media solution in your operation, all you really need is a plasma screen and a DVD player. You’ll also need a webmaster to animate the images into a montage

about an hour or so. Words like “new”, “best-seller” and “limited time offer” are surefire attention getters. A group of influential advertising executives made a list of the best ads in history and dissected the copy to glean some best practices. They reported that good copy follows these rules:

Be five words in length.

Don’t mention the brand name (the logo will say it all visually).

Be declarative.

Be grammatically complete.

Be otherwise standard (use the same fonts and formats for all messages).

Contain alliteration, metaphor, or rhyme.

Digital messaging offers a user experience that engages many of the senses and cannot be realized with other technologies.

of about two minutes and then save the sequence to a DVD or memory stick. This medium isn’t intended to play TV commercials – it’s about taking the same information you would place in a newspaper ad or poster and animating it.

First, be clear about your intended goal with digital messaging. As with any other marketing strategy, you must make sure that the message clearly addresses the business objective. If you want to intercept consumers to entice them into a store then you need to engage all of the senses. Ask your webmaster to create a digital sequence that uses music in the background with bright, clear images and short messages. It’s important that the visual still work without the music because your in-store team will tire quickly of hearing the same audio loop over and over. Do turn on the audio at peak times but tell your team it will be turned down after

Be clear about what you want the digital signage to accomplish. If you want the digital messaging to increase your conversion rates (shopper becomes buyer) then leverage messages that speak to product bundles of several items at a special price. Use moving pictures to entice the consumer. Tim Hortons does a great job of making those donuts look extra sexy as the warm chocolate dances across the pastry while we’re standing in line. Some retailers (such as banks) use digital signs to decrease perceived wait time in line. Wirespring.com reports that Wal-Mart tested digital screens first in 2003. Their post-game analysis showed that sales rose 17.5 per cent, versus the prior 30-day period without screens. Of those surveyed, 88 per cent said signs sparked interest in products; 72 per cent found them entertaining; 13 per cent said the ads increased interest in a product; four per cent attributed a purchase to the ads.

Digital signage can also link to your database and website. It’s possible to collect e-mail addresses with a touch-screen option. Once you collect some permission-based e-mail addresses, you may want to send electronic coupons to subscribers to keep them coming to your location(s). It is possible for you to collect user statistics from those consumers who interact with a digital screen. This is where the rubber really hits the road because it’s now possible to see what information they’re interested in and how they navigate the screen. You will be able to promote upcoming new product launches and relay ingredient listings, nutritional analysis and any allergen issues.

Continued on page 22

Northern Light Food Processing has added Cranwise, a patented cranberry protein flour, to its line of branded nutritional fruitderived ingredients. Cranwise™ cranberry protein flour is produced by a patented cold extrusion and filtration process from seeds of the American cranberry, without enzymes or extraction solvents. The flour is a concentrated source of complete protein, potassium, calcium, insoluble fibre and oxygen-resistant essential fatty acids. It is suitable for use in protein drink powders, dietary supplements, functional foods, and beverages.

Find out more about Cranwise™ cranberry protein flour by going to www. marketwisenutrition.com or calling 239221-8640.

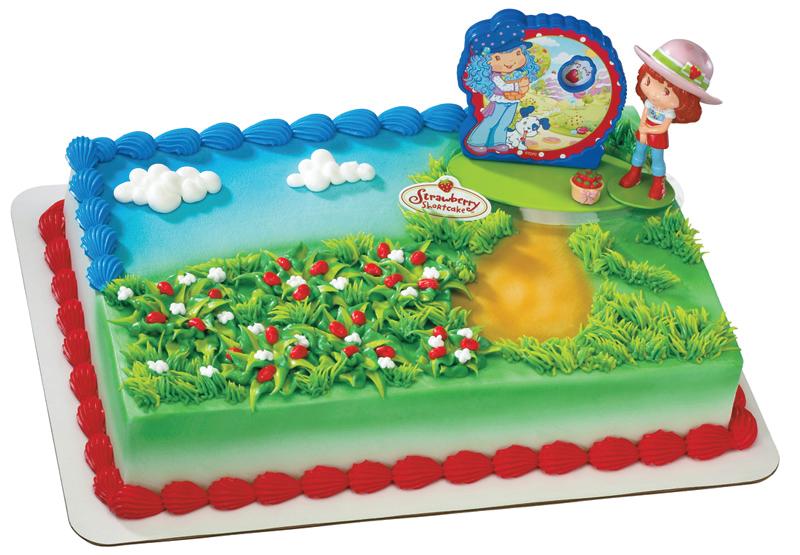

It’s a Berry Sweet world in the carefree land of Strawberry Shortcake and friends! The charm of this classic favourite is captured in DecoPac’s new Sweet Berries DecoSet, featuring Strawberry Shortcake, Blueberry Muffin and a spinner piece containing several “berry cute” phrases. Check out the new Strawberry Shortcake Sweet Berries DecoSet #30165 and DecoPac’s full line of Strawberry Shortcake products. Contact DecoPac at 1-800-DECOPAC or go to www.decopac.com.

Continued on page 32

Continued from page 16

of which Irmgard selects personally.

For the customers, this variety has made Bread ’N’ Buns a “community centre,” a place where you go for your daily bread, your lunch sandwiches and picnic baskets, where you get your hostess gifts and all of your party goods, from deli trays to specialty cakes. It is a distinctly European concept, a place where everyone knows and meets everyone, and where life’s joys and sorrows are shared.

“We now serve some third-generation customers,” says Irmgard.

So, when Jae started the process of rebranding the company, creating a new name, Inno, and a new logo, the regulars got nervous. The ever-responsive team came up with a compromise – for now, the front of the awning says Inno, but the sides still say Bread ’N’ Buns.

The Parks are developing the Inno concept in preparation for opening additional stores. The Inno concept will be close to the existing store concept, and the plan is to open the first new store later this year.

When Jae entered the business full time, many things started to move ahead at an accelerated pace. One of those was the move to a separate commissary and to the use of frozen dough. “There was a lot of stigma in the past about that, but centralizing the mixing and manufacturing in one location actually improves our quality control compared to making everything fresh every day at the back of the store,” says Jae. “We can control the environment at the factory and we can train specialized staff. We have given them the specialized tools they need at the factory and at the store level, we still do retarding proofing which increases flavour and texture and we have stack ovens for the artisan-style breads and two rack ovens with steam, so we have not lowered the quality. In fact, we now feel more comfortable about opening another store because we have control over quality.”

Ralf Tschenscher, Western division manager for Lesaffre Yeast Corporation, knows the Park family and their business well.

“To keep their quality consistent, Mr. Park and Jae knew they needed to have loyal and committed employees,” he says. “They streamlined their production by moving into a commissary. This move has allowed the bakers to start production at 7 a.m., which is unheard of in the bakery business. Their employees are very happy about this, and they are still able to provide fresh baked bread and buns by 9 a.m. when the store opens.”

Jae Park explains further: “My father and I believe in making work easy for everyone. The bakery business is a difficult place to work in, as are many food industry businesses. We feel that in our system everyone is doing a job in which they can specialize. Everyone is doing a job that they are good at to the maximum potential of their skill.”

With streamlined production, a growing product line, a new store in the works and a product that’s singled out as one of the best in the country, it would appear that Inno is a winning concept in the making.

See this year’s annual recipe collection for Jae’s winning California Walnut Raisin Rye Bread formula. For more information on the California Walnut Inspiration Contest, go to www.bakersjournal.com and click on Web Features. ❖

Continued from page 20

Of course, the drawback to any new technology? Crashing. It’s likely the new technology may have its malfunctions so you’ll need to source a service provider who can repair it when needed.

Digital messaging has many advantages over traditional print. You can switchup content depending on time of day, location, and target audience. It’s environmentally friendly (compared to print)

and can truly engage the consumer. Why not try one screen to start? The cost to try a digital solution is relatively low and the potential upside quite attractive. ❖

Michelle Brisebois is a marketing professional with experience in the food, pharmaceutical and financial services industries. She specializes in helping companies grow their brands. Michelle can be reached at On Trend Strategies by e-mail at: briseboismichelle@ sympatico.ca.

Health Canada’s second release of its trans fat monitoring program continues to show progress by the food industry in replacing trans fat with healthier alternatives. In June 2007, the Government of Canada called on industry to voluntarily reduce the levels of trans fat in the Canadian food supply to the levels recommended by the Trans Fat Task Force, and announced that the Government would monitor the progress.

The Trans Fat Task Force recommended a trans fat limit of 2% of the total fat content for all vegetable oils and soft, spreadable margarines, and a limit of 5% of the total fat content for all other foods, including ingredients sold to restaurants.

The second set of data released as part of the monitoring program demonstrated progress by fast food chains and family restaurants in replacing

trans fats. While the news was overall positive, certain products such as donuts in a number of cases continued to show trans levels higher than the Task Force recommendation.

The Trans Fat Monitoring program will continue and it is expected baked goods such as pastries and cakes will come under increasing focus in future reports. As such bakers if they have not already done so are encouraged to work with their industry suppliers in reformulating their products to reduce trans fat levels in line with the Task Force’s recommendations.

The second data set from the monitoring program may be found at the Health Canada web site: http://www.hc-sc.gc.ca/fn-an/nutrition/grastrans-fats/tfa-age2-eng.php

April 26th & 27th 2009, the Bill Copeland Centre in Burnaby B.C., will host BAC’s Congress 2009 conference and trade show. Back in BC after a four year hiatus, the event will feature a variety of activities for the entire trade including an anticipated 140 booth trade show. With limited space, companies interested in exhibiting should contact Rosemary Dexter 1.888.674.2253 ext 24 rdexter@baking.ca.

W.C. (Bill) Miles passed away peacefully, surrounded by the love of his family, on the morning of July 29, 2008. Bill was a Past President of the Bakery Production Club of Ontario, Honorary BAC Member and Bakery Showcase Chair from 1970 to 1972.

B.C. Chapter’s Annual Golf Tournament Raises Money For Local Baking Programs and Team Canada

A blue sky and very mild temperature was the perfect recipe for the members of the BAC – B.C. Chapter to host their annual Golf Tournament held June 25th at the Newlands Golf and Country Club in Langley, B.C. Golfers arrived after 11:00 am and enjoyed a great BBQ along with the opportunity to socialize prior to and during the golf tournament. This year’s tournament of 140 participants enjoyed their day and after dinner highlights included the winning 50/50 raffle ticket of $1,960 to Don Easton of Gourmet Baker and a one year golf membership won by Ron DeLaet from Weston Bakeries/Ready Bake.

Benefiting from the proceeds of this major event are Vancouver Community College and Malaspina University College (now the Vancouver Island University), which will

provide them with the opportunities to purchase new equipment, send students to Skills Canada as well as put funds towards scholarships/bursaries for the baking sector. Benefiting also will be Team Canada as they work towards the next World Cup of Baking.

On behalf of the B.C. Chapter Executive, I would like to thank again all our sponsors listed in alphabetical order below as well as all the players and dinner guests. I am looking forward seeing you all again at our 2009 tournament.

Best Regards, Ralf Tschenscher

BAC-BC Chapter Chairman

ADM Milling

Anita’s Organic Mill

BakeMark Canada

BC Bakery Deli Foundation

Boxmaster Packaging

Bunge Canada

Canada Bread

Canbra Foods

DATAPAX Bakery Software Manufacturing & POS

Dawn Foods

Dover Flour

Ellison Milling

EM Bakery Equipment

Fiera Foods

Freybe Gourmet Foods

Gourmet Baker

Hershey Canada

Horizon Milling GP

HY Louie

Island City Baking

Lesaffre Yeast

LV Lomas

Malaspina Professional Baking Program

Max’s Donuts

Maxim Truck & Trailer

Menasha Packaging

National Starch Food Innovations

Original Cakerie

Overwaitea Food Group

Pace Processing

Puratos Canada

Richardson Food Group

Rogers Foods

Rogers Sugar

Sandel Foods

Semper Foods

Snow Cap Enterprises

Sugarplum Desserts

Target Uniforms

Thrifty Foods

Unifiller Systems Inc

Vancouver Community College

Vanderpol Eggs

Weston Bakeries/Ready Bake Foods

In July, the Government of Canada announced new labelling guidelines for the use of the voluntary Product of Canada and Made in Canada claims.

A food product may claim Product of Canada when all or virtually all major ingredients, processing, and labour used to make the food product are Canadian. This means that all significant ingredients are Canadian and non-Canadian material must be negligible. Ingredients that are present in a food at very low levels and that are not generally produced in Canada, including spices, food additives, vitamins, minerals, and flavouring preparations, may be used without disqualifying the food from making a Product of Canada claim. Ingredients in a food that are not grown in Canada, such as oranges, cane sugar or coffee, when present at very low levels, may be considered minor ingredients. Generally, the percentage referred to as very little or minor is considered to be less than a total of 2 per cent of the product.

For example: a cookie that is manufactured in Canada from oatmeal, flour, butter, honey and milk from Canada, and vanilla may use the Product of Canada claim, even if the vitamins in the flour and the vanilla were not from Canada.

A qualified Made in Canada claim could be applied to a label or advertisement when the last substantial transformation of the product occurred in Canada, even if some ingredients are sourced from other countries. When a food undergoes

The City of Toronto is proposing to require any bakery whose primary business is not retail to annually report the amount of volatile organic compounds (VOCs) annually released by baking as part of its Environmental Reporting and Disclosure by-law. The by-law based on the premise of community right to know will require all bakers emitting 100kg of VOCs, (the amount from an estimated 5,000 loaves of bread) to report as part of an overall list of 25 substances including VOCs. Businesses failing to report will face fines up to $5,000 for first offences and up to $100,000 for third and subsequent offences.

BAC had worked with the City and advised them that unlike other industries, the emissions from bakeries are almost entirely naturally occurring ethanol resulting from the production of breads and rolls. Ethanol begins in the dough fermentation process and is released during baking.

BAC has been successful in achieving an exemption for bakers whose business is primarily retail.

The new by-law is expected to come into effect within the next 12 months.

processing which changes its nature such that the food becomes a new product bearing a new name by which the food is generally known by the consumer, it is considered to have undergone substantial transformation. Those processes which result in a substantial transformation may be outlined in more specific legislation, such as the Meat Inspection Regulations.

When a food contains ingredients which are sourced from outside of Canada, the label would state “Made in Canada from imported ingredients.” When a food contains both domestic and imported ingredients, the label would state “Made in Canada from domestic and imported ingredients.”

For example, a cookie manufactured in Canada from imported flour, oatmeal, shortening and sugar may be labelled or advertised with the claim “Made in Canada from imported ingredients”. A cookie manufactured in Canada using Canadian flour, oatmeal and shortening and imported sugar may use the claim “Made in Canada from domestic and imported ingredients”.

The revised guidelines will come into effect on December 31, 2008 and will be enforced by the Canadian Food Inspection Agency. While CFIA recognizes that many products produced or manufactured before this date may already be on store shelves it is expected that all products produced after this date would be in compliance with the new guidelines.

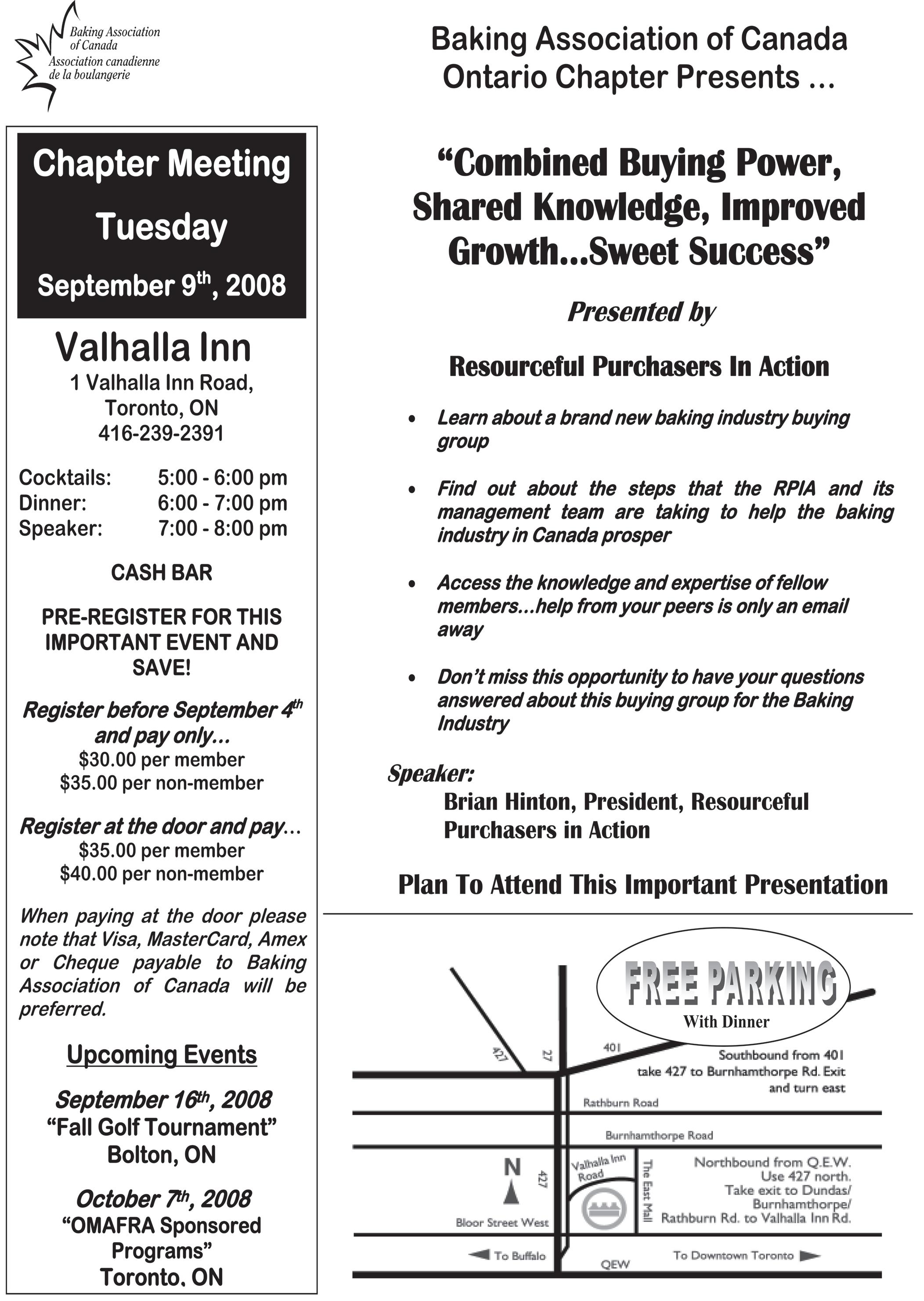

ATTENDEE I NFORMATION

PleasenoteallregistrationsreceivedafterSeptember 4th willrequirea creditcardpayment.Norefundswillbegiven.

Pleaselistnamesofallattendees:(attachseparatesheetifnecessary)

Health Canada has finally published is long awaited proposal for food allergen labelling regulatory amendments in Canada Gazette, Part I (CGI), and is now urging industry to be diligent in responding to these impending changes by listing priority food allergens, gluten sources and added sulphites on the labels of prepackaged foods during the consultation period between CGI and their publication in Canada Gazette Part II (CGII).

The following foods or protein derived from (one of the following foods) are considered priority food allergens: almonds, Brazil nuts, cashews, hazelnuts, macadamia nuts, pecans, pine nuts, pistachios or walnuts, peanuts, sesame seeds, wheat, kamut, spelt or triticale, eggs, milk, soybeans, crustaceans, shellfish or fish

Under the new regulations it is proposed that the gluten source will need to be declared when a food contains gluten protein or modified gluten protein from barley, oats, rye, triticale or wheat, including kamut or spelt.

The new regulations will also require added sulphites to be declared when directly added to a food, or when the total amount of added sulphites contained within the food is 10 parts per million or more.

In Canada, the Food and Drug Regulations currently require that a complete and accurate list of ingredients appear on the label of most pre-packaged foods. However, certain components of ingredients are currently exempt from declaration in the list of ingredients. For example, when flavours, flour, seasoning and margarine are used as ingredients in other foods, their components are not required to be included in the list of ingredients. As a result, a pre-packaged food product labelled with a list of ingredients may be unsafe for food allergic consumers if some of those ingredients are priority food allergens, gluten sources and added sulphites and are not declared on the label.

This approach is intended to apply to such substances whenever they are added to pre-packaged foods having a list of ingredients, whether they are added as ingredients, or as components of ingredients. It also focuses on multi-ingredient foods where priority food allergens, gluten sources and added sulphites are deliberately added to a food, and are considered to pose a potential risk to consumers having food allergies, intolerances or sensitivities. It is consistent with those proposed regulatory amendments that are being published in CGI for comments, which will enhance food allergen labelling; also, this is consistent with the food labelling requirements recently promulgated by Canada’s major trading partners. The CFIA has developed and will maintain a guidance document to assist food manufacturers and importers in following this recommendation.

Until these amendments become mandatory, Health Canada is reminding industry that it still must address all identified health risks to food allergic consumers stemming from possible undeclared priority allergens, gluten sources and added sulphites. Health Canada is therefore urging food manufacturers and importers to declare priority food allergens, gluten sources and added sulphites on food labels without exception, either in the list of ingredients or in a statement such as “Allergy and Intolerance Information: Contains ...”.

Some foods such as those produced strictly for retail are exempt from the regulation. The full exemption list may be found in B.01.008 paragraph 2 and B.01.003 (a) of the Regulations.

However, it is important to note that, if a manufacturer chooses to include a list of ingredients on the label of one of these foods, then all priority allergens, gluten sources and added sulphites present in the product should be declared in accordance with this recommendation.

For more information see the Health Canada web site : http:// www.hc-sc.gc.ca/fn-an/label-etiquet/allergen/index-eng.php

Atlantic Chapter

September 15

Annual Golf Tournament

Magnetic Hills Golf Course

Moncton, NB

BC Chapter

Vancouver Island Committee

November 1

AGM Dinner & Social

Dunsmuir Lodge

Sidney, BC

Ontario Chapter

September 16

Fall Golf Tournament

Glen Eagle Golf Club

Bolton, ON

Congress 2009

April 26 & 27

Bill Copeland Centre Vancouver (Burnaby), BC

Victoria Manley

Manley’s Country Cottage

Gary J Morris

Kingsway Brokerage Ltd

Glenn Peaslee

Half-Baked Ideas

April Qureshi

The Sweet Chef

Congratulations To Our Most Recent Correspondence Course Grads!

Limneo Austria

Bakery Technology II

Jane Ayer

Bakery Technology II

Zaklina Mazur

Bakery Technology I

Richard Pacheco

A Foundation for Sanitation

Debbie Patterson

Bakery Technology I

Peter Storm

Bakery Technology II

Jennifer Fraser-Smith

Certified Bakery Specialist (CBS) Diploma

For information on correspondence courses for baking industry employees and the Certified Bakery Specialist (CBS) program, please contact ext. 21 at the BAC office or check out our website, www.bakingassoccanada.com.

Quadra is a leading provider of nutritional and functional ingredient distribution services in Canada. We offer a broad range of ingredients and specialty products for food, pharmaceutical, nutraceutical, and animal nutrition markets.

Our specialized sales team, strong technical support, market knowledge, logistical expertise, and extensive national infrastructure enable us to be a value-added partner to many of our customers and suppliers.

Quadra is a Specialized, Effective and Trusted distributor that aims to be the supplier of choice for ingredient sourcing in the Canadian market.

Quadra is proud to have exclusive distribution partnerships with some of the world’s best ingredients manufacturers such as Budenheim, Orafti, Remy, Glanbia, MGP Ingredients, and BTSA. Our Representative Office in Shanghai, China allows you access to high quality Chinese products at a competitive price. We ensure each production facility meets North American standards through recognized international formal certification processes. This enables you to take advantage of new supply channels while maintaining quality.

NEW: Quadra is pleased to announce our expanded Hydrocolloid Gum product line through the recent acquisition of Prescott & Company Canada Ltd.

Serving the baking industry with a complete line of Nutritional and Functional Ingredients – Specialty Phosphates, Inulin & Oligofructose, Nutrional Dairy Ingredients, Preservatives, Starches & Proteins and many other ingredients.

Quadra has recently expanded our Ontario Distribution Centreinvesting in national infrastructure to better serve our customers.

Continued from page 22

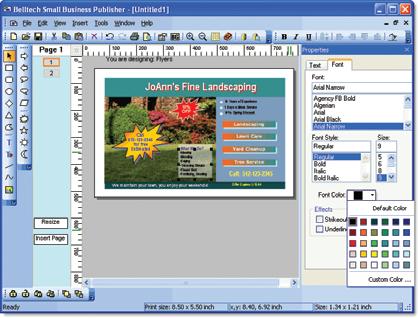

Belltech Systems, Inc. introduces Small Business Publisher

5.0. Belltech’s new designing and printing software devised exclusively for business printing, helps users create professional quality printing such as, flyers, letterheads, brochures, labels, newsletters, advertisements, envelopes, postcards etc. with graphics, backgrounds and artwork. Belltech’s Small Business Publisher 5.0 is also equipped with advanced design tools for creative design such as the ability to add beautiful colour blends, shadows, object rotation, transparency and texture. This application offers normal cut-copy-paste features, as well as undo/redo functionality for all design elements. Small Business Publisher 5.0 comes packed with advanced design tools and professional design templates for every small business printing needs. System requirements

are Windows98/ME/2000/NT/XP/Windows 2003/Vista, 64 MB of RAM and about 30 MB of hard drive space. A single user licence costs just $54.95 US and includes user support and free upgrades. A free evaluation copy of Belltech’s Small Business Publisher 5.0 can be downloaded on the Belltech website.

For more information, visit www. belltechsystems.com.

Innoseal Systems, Inc., based in Charlotte, N.C., with locations in Salinas, Calif., and Aurora, Ont., is please to introduce its new tamper-evident bag sealer called the InnoSealer LT. The Innosealer LT stands for “longer tab” and creates the same virtual airtight seal as its predecessor, the InnoSealer, but with a longer tape and paper closure for easier opening and resealing. Users of the InnoSealer LT will also have more room to brand their company on the longer tab, creating more added-value to their products. The Innosealer standard model is already used in thousands of vegetable processing and bakeries worldwide. “We have a major supermarket chain in Canada now testing