BY DON HORNE

BY DON HORNE

We’re all pretty good at what we do, right?

Heck, we’re great! We love the work we do and always put in 100 per cent.

Operating a crane is a demanding job, and ensuring that it is done safely is crucial. Sadly, it is only when something goes wrong that a crane at a worksite and the operator make the news – and that can be tragic as well.

Maintaining those skills are very important, which makes incorporating new technology and techniques vital – and what makes the Falcon Crane Rodeo in Surrey B.C. so much fun to test our skills as operators, and the SC&RA Crane & Rigging Workshop in Oklahoma City, Oka. so necessary to improve those very same skills.

At the SC&RA Crane & Rigging Workshop that should be wrapping up as you receive your copy of the magazine, there was a lot to absorb insofar as new technologies and techniques in the industry.

This year’s workshop debuted a new session, The Power Panel on Utilizing New Crane & Rigging Technologie s. The panel focused on the latest and greatest crane and rigging technologies, with key points including safer lifting operations to reduce tagline injuries; the evolution and application of AR and VR technology and software; and effective digital tools to standardize safety practices, streamline workflow and improve visibility of business analytics.

The panelists weighing in on these cutting-edge technologies included Elliott Chenger, vice president of software engineering, Ribbiot; Randa Fernandes, director of operations and customer experience, WrightPlan; Casey Savlov, executive vice president, Industrial, Vita Inclinata Technologies; Patrick Witte, software developer, A1A Software; and Wayne Wille, business development manager, Technology Solutions, The Crosby Group.

Throughout the workshop, there were eight Breakout Sessions covering a variety of interesting and enlightening subject matter, ranging from certification issues, wire rope, strand jacks, lift planning and much, much more – all containing valuable

tips and advice for best practices so that safety and skill can be combined.

In the session A Bird’s Eye View of a Methodical Tower Crane Assembly & Disassembly, a panel discussed critical elements of communication, site meetings climbing procedures and checklists.

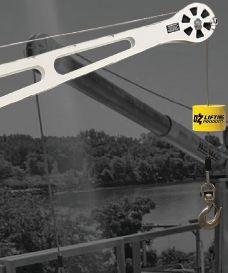

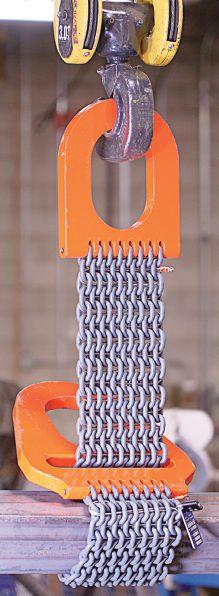

Jeff Ferchen of Associated Wire Rope Fabricators led the Utilizing Chain for Overhead Lifting and Rigging Operations session, where attendees learned about the different grades of chain on the market and what ASME/OSHA mandate as grades required when used as an overhead lifting system.

Following the workshop’s underlying theme of the latest market developments, Lift Planning Trends: What We’re Seeing Out There, showcased the crucial elements of lift planning in crane and rigging operations.

Rigging with Heavy Lifting Strand Jacks will cover application considerations for using a heavy lifting strand jack system along with some hands-on opportunities, with best practices and maintenance discussed by Enerpac’s Alex Gollup and John Fleischman.

The Falcon Crane Rodeo – hosted by Falcon Equipment’s Surrey branch – on Sept. 16., proved to be another popular event, with a lot of crane operators testing their skills against others to see who is the best in B.C.

We have some incredibly talented folks in the crane and hoist sector, and it is not only important to improve those skills constantly, but to show off and share those skills so that the newcomers can take our place and keep doing the same magnificient work that has been done for decades.

Don Horne

Send us your favourite memories

Crane & Hoist Canada magazine will be celebrating 15 years as a publication next year, and we’d love to share your stories once again from over the years.

If you have a copy of the magazine, an article we’ve done on you or a favourite story you would like to see again, drop me a line at dhorne@annexbusinessmedia.com.

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: (416) 510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | DON HORNE dhorne@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER | LAURA GOODWIN lgoodwin@annexbusinessmedia.com • 289-928-8543

MEDIA DESIGNER | SVETLANA AVRUTIN savrutin@annexbusinessmedia.com

ACCOUNT COORDINATOR | FARWA SIDDIQUI fsiddiqui@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER | URSZULA GRZYB ugrzyb@annexbusinessmedia.com • 416-510-5180

CONTRIBUTORS | Matt Jones; Emily Newton

GROUP PUBLISHER | DANIELLE LABRIE dlabrie@annexbusinessmedia.com

PRESIDENT/COO | SCOTT JAMIESON sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues)

Canada: $37.00 + tax per year • USA: $37.00 USD Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT. 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

PRINTED IN CANADA ISSN 1923-788X

Publications Mail Agreement #PM40065710

Annex Privacy Officer

Privacy@annexbusinessmedia.com Tel: 800-668-2374

The contents of Crane & Hoist Canada are copyright ©2023 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Advertising Deadline: October 27, 2023

Don’t miss the opportunity to be part of this exciting industry publication. For more information, or to reserve space in the next issue, call Laura Goodwin at our Advertising Department Tel: +1-289-928-8543 lgoodwin@annexbusinessmedia.com

Next Editorial Deadline: November 1, 2023. For writers’ guidelines and submission requirements get in touch with the editor, Don Horne, at dhorne@annexbusinessmedia.com

MEMBER OF:

Ontario will be spending $3.6 million to provide free training and attract more women and young people to work in the construction industry, as the province seeks to address a labour shortage that could put its housing goals at risk.

The funding will go toward three projects that are expected to help 2,200 women and young people “prepare for meaningful and well-paying careers in the construction trades,” the province said in a news release, as the province projects it will need more than 100,000 new skilled trades workers over the next decade to meet its infrastructure goals, including its target of building 1.5 million new homes by 2031.

However, 82,600 construction workers, or 18 per cent of the industry’s workforce, are set to retire in the next 10 years, according to a report from construction lobby group BuildForce Canada. Many of those who are expected to retire are senior workers with decades of experience and specialized skills. Currently, women make up less than five per cent of Ontario’s construction workforce, the province noted in the release.

Some of our readers are asking: Where have you gone? You’ve disappeared!

Canadian Bill C-18 has impacted your ability to see news and information from trusted industry sources like ours, but that doesn’t mean you have to miss out – Subscribe today at: https://annex.dragonforms. com/loading.do?omedasite=CHC_prefsnew

And as always, you can find everything on our homepage online: www.craneandhoistcanada.com

Ontario is updating its safety regulations under the Occupational Health and Safety Act (OHSA), with most of those changes coming into effect Jan. 1, 2024.

Amendments to various crane-related provisions of O. Reg. 213/91 (Construction Projects) under OHSA include:

• Clarifying or adding new design, installation, maintenance, inspection, and record-keeping requirements;

• Requiring more comprehensive inspections of tower cranes, including referencing the Professional Engineers of Ontario’s practice standard for tower crane review, and clarifying and expanding the role and responsibilities of professional engineers in the design, erection, and inspection of tower cranes;

• Introducing new, and updating existing, references to relevant national and international standards relating to the design and operation of tower cranes;<b>

• Addressing advances in technology, including adding and amending requirements that take into account specific operational needs for self-erecting tower cranes; and

• Clarifying requirements for cables, slings and rigging that apply to all cranes and cover hoisting operations by other equipment.

Amendments to O. Reg. 420/21 (Notices and Reports Under Sections 51 to 53.1 of the Act – Fatalities, Critical Injuries, Occupational Illnesses and Other Incidents) under the OHSA have also been approved.

The amendments will add a new requirement for the ministry to be notified of a failure to control a crane or a load, including any rigging failure, at a construction project, and for an engineer’s report on the cause of the incident. Most amendments will come into force on Jan. 1 of next year.

Other requirements, including those that may require equipment upgrades, will come into force on Jan. 1, 2025, to provide stakeholders with additional time to comply with the changes.

According to the new report Tower Crane Rental Market, by Allied Market Research, the tower crane rental market was valued at $3.8 billion in 2020, and is estimated to reach $6 billion by 2032, growing at a CAGR of 4.2 per cent from 2023 to 2032.

Emerging markets such as Asia-Pacific, Latin America, and Africa have witnessed a rise in population, economic growth, urbanization, and increase in technological advancement in machinery that aid in the improvement of workflow.

The population in Asia-Pacific and Africa has grown at a rapid pace, thus creating a surge in demand for housing accommodation as the increase in rate of the population is higher than the availability of housing. Most of the countries in these two regions are emerging nations and have experienced strong economic growth.

The growth of the economy in the emerging countries has fueled the expansion of commercial, industrial, corporate, and residential properties.

Manufacturers having significant tower crane rental market share are developing advanced equipment, which are economical and sustainable.

For instance, in March 2021, ACR launched a tower crane, which uses smart power control and electronic integrated hydraulic system. It has an in-house designed fuel optimization system to improve fuel efficiency and deliver ideal job performance with loss-free power and speed. Moreover, integration of IoT is expected to help to overcome shortage of skilled laborers and enhance safety of operators & end users.

These factors are anticipated to offer remunerative opportunities for expansion of the global market during the tower crane rental market forecast period.

There are three new faces in new positions at Link-Belt.

Thomas Taylor Announced as Marketing Product Specialist

Link-Belt Cranes is pleased to announce the new hire of Thomas Taylor who has joined the product marketing group as Marketing Product Specialist for Rough Terrain Cranes. Taylor will provide marketing and sales support for rough terrain crane products to internal and distributor sales personnel.

Taylor brings rental and retail experience from a national trucking company as well as heavy equipment transportation experience from his ongoing service in the Kentucky Army National Guard. He is a graduate of the University of Kentucky, with a Bachelor of Arts in Business Administration.

Will Hatton Named Public Relations Specialist at Link-Belt

Will Hatton has been named Public Relations Specialist at Link-Belt Cranes effective June 19.

Hatton will coordinate job story creation, promoting new products and features via the company’s communication to trade press, distributors, and other target audiences. He will also handle maintenance of linkbelt.com with updates to product literature and specifications.

Hatton is an eight-year veteran of the U.S. Army, having most recently worked for the U.S. Department of Veterans Affairs in Big Spring, Texas. He has additional communications experience in television, radio, and other related mass-media.

Casey Smith Named Supervisor, Marketing Information at Link-Belt

Casey Smith has been promoted to Supervisor, Marketing Information at Link-Belt Cranes effective April 1. In his new role, Smith will oversee website development, product marketing content, and the company’s communication with trade press.

Smith began his career at Link-Belt in 2012 as a Public Relations Coordinator, covering Link-Belt Cranes in the field with case studies on new machines, maintaining linkbelt.com, and assisting with creation of Link-Belt promotional materials. He has a Bachelor of Arts in Communication from the University of Kentucky, and a Master of Arts in Public Relations from Ball State University.

The Erectors Hoisting and Rigging has added a new LTM 1300-6.3 to its fleet, a mobile crane that has the longest boom in its class and can be carried at 13.2 tons (12 tonnes) axle load, which the Ontario company states will be used for erecting and dismantling tower cranes and as a taxi crane in crane rental.

“The LTM 1300-6.3 complements our fleet perfectly: the 300-tonne crane is a crane of the future and makes our fleet even more innovative,” says Justin Tabani, one of the founders of The Erectors.

Founded by Marco Ottorino, Jeffrey Burke and Justin Tabani , the Canadian company specializes in tower crane erection, dismantling, maintenance in addition to mobile crane rental.

The mobile crane includes integrated features such as ECOmode, ECOdrive, VarioBase Plus, VarioBallast, Auto-Ballast, single-engine concept and the wind speed load charts.

A new report is shining a positive light for the industrial construction industry in Canada, but notes that risks remain with ongoing inflation, high interest rates, and labour shortages.

The Q2 Canadian Country Commodity Report, from global construction consultant Linesight, describes “encouraging growth” as Canada’s Real GDP exceeded expectations and job growth continued in Q1 2023.

“While a decline in the residential sector contributed to a contraction in the construc-

Despite economic challenges, the industrial construction sector has shown positive trends in investments and building permits since the start of 2023, the report says, and is projected to achieve a growth rate of 15.5 per cent in 2023.

tion industry, the industrial sector is poised for growth,” the report states. “The Canadian government’s commitment to establish Canada as an industrial hub and investment in EVs, green hydrogen, metals and materials processing will help drive growth in the energy and high-tech industrial sectors.”

“The signs are promising for the Canadian economy overall, but the construction industry faces lingering challenges,” added Patrick Ryan, executive vice president for the Americas at Linesight. “Labour shortages –due to growing demand for healthcare, infrastructure, data centres, and life sciences – are still impacting project delivery and budget. Multiple sectors are expanding in Canada, all of which will put increasing demand on materials.

“For example, we’re seeing two major gigafactories going up in Southern Ontario soon, and the government’s investments in

healthcare, life sciences, and infrastructure will all be materials intensive.”

The data in the report suggests:

• The construction industry is expected to shrink by 5.2 per cent in 2023 as the residential sector has declined more than expected. Regardless, construction is likely to grow by 2.7 per cent between 2025 and 2027 thanks to investment in the industrial, energy, and transportation sectors;

• Lumber prices are stable this year after two years of high volatility. Prices picked up due to the wildfires in June of 2023. Though prices may appreciate slightly in the coming months, the trend in coming quarters looks to be one of weakness due to the housing downturn;

• Copper prices have dropped 5.5 per cent in Q2 2023 and stabilized but are likely to be volatile for the next two quarters, influenced by high interest rates and weakening residential construction on one side, and investment in electric vehicles and renewable energy on the other;

• Steel rebar prices are down from 2022 highs and likely to continue edging downwards in the months to come. Demand for steel will be driven by significant infrastructure investment, with upward pressure limited thanks to cheaper steel imports and easing production costs; and

• Cement costs have continued to increase due to stricter environmental regulations but will likely drop in the coming quarters. Prices are rising at a slower pace than before and an awaited drop in production costs and construction output may help prices decline.

Looking to the report’s outline of sector-specific trends, the data centre sector in Canada has experienced what the report calls “remarkable growth,” driven by increasing demand for cloud computing, IoT favourable climatic conditions, and a low risk profile. Currently, there are numerous data centre projects in the pipeline, totaling a value of over US$7.4 billion, with a significant concentration in the Ontario and Quebec regions. Despite economic challenges, the industrial construction sector has shown positive trends in investments and building permits since the start of 2023, the report says, and is projected to achieve a growth rate of 15.5 per cent in 2023. The sector’s output will be bolstered by investments in Electric Vehicle (EV) markets and the government’s ambition to establish the country as an industrial hub.

We’re your one-stop dealer for all your equipment needs

Need Crane equipment?

From machinery to service, parts and certification. Your trusted partner for every project.

Manitowoc combines revolutionary VPC technology and the dynamic Crane Control System (CCS) to provide load charts. The extreme productivity and versatility of the multi-purpose work site ensure an exceptional return on investment.

Fortify your heavy equipment and secure your remotes to keep equipment safe By Emily Newton

Cranes and hoists are essential for any operations involving heavy lifting. Many also have smart features preventing the load from exiting a specified zone or bringing it to a target position. Such offerings keep everyone safer, making workflows more productive.

However, all smart hoists and cranes need internet connectivity to work. That makes them potential targets for hackers. There’s even the possibility that someone — recognizing the value in such equipment — could try to restrict access or physically take it. These realities mean construction site managers, equipment operators, repair technicians and other relevant parties must take strategic steps to safeguard the heavy machinery.

The chances of a hacker gaining access to smart equipment increase when too many people have access to the machine or any online portals. Broadly speaking, that’s because there are more opportunities for things to go wrong.

Many people reuse passwords, increasing the reach hackers have. Workers may also share them with colleagues, seeing this action as an innocent way to assist others. However, it can erode cybersecurity. Traditional access control allows people to leave themselves logged into a portal accidentally, then step away from the computer long enough for others to take advantage of their account privileges.

These shortcomings of conventional passwords have compelled people to explore more robust access-control measures. Some common ones restrict what people can do based on their roles or responsibilities. Someone who works in a construction company’s customer service department and never needs to operate a smart

crane would not have the credentials that let them do it.

That strategy also tackles problems such as theft or attempted usage by people not trained to use the equipment. Keeping equipment and the associated access sites or apps safe also means revoking someone’s credentials once they leave the company or otherwise no longer need them. Such management becomes much easier once administrators can see and control current access specifics from a dedicated portal.

Access control extends to smart equipment accessories people often overlook, including remotes. The best strategy for those is to deploy a layered approach. Keep them in a locked cabinet within a locked room and require people to open it with a personal swipe card, for example. Installing tracking devices on the remotes also makes it easier for supervisors to see who has one at any time.

Cybersecurity experts frequently say employees are among the weakest links of a company. Indeed, they may make mistakes or show intentional carelessness. However, many workers are not familiar enough with internet security best practices — especially if they didn’t grow up with the internet or participate in tech-centred roles throughout their careers.

That reality means employees could be the gateways allowing hackers to orchestrate their attacks. Phishing and related scams are some of the most common ways cybercriminals launch ransomware attacks. Ransomware locks entire networks and everything connected to them, leaving smart hoists, cranes and other equipment inoperable. Sometimes, hackers threaten to leak the data they stole, providing even more incentive for victims to pay the ransom.

However, phishing awareness is an excellent ransomware preventative. Set aside time in employees’ schedules to give them relevant, engaging training. Structure the content to include scenarios they’ll likely encounter in real life, plus tips for responding to them.

Consider the most convenient ways for people to receive the training, too. If all attendees don’t have desks and offices, that could make the delivery trickier. However, offering a dedicated area with mobile devices such as iPads helps people receive the training at the right times.

The construction and heavy equipment sector was not historically among the first to adopt smart devices. However, with adoption rates rising, so are the risks of hacks. Cybercriminals view this as a high-value sector, knowing even minor disruptions are prohibitively costly. Thus, even if a hacker can’t steal gigabytes of data from a smart crane, they could lock down the machine with a ransomware attack or use malware to spread a virus that makes it inoperable.

Cybercriminals look for outdated software and other vulnerabilities, using them as entry points for beginning their attacks. Software updates may be outside of concern for many smart-equipment owners, but that must change.

A good starting point is to ask the manufacturer how updates occur. It’s often possible to receive periodic over-the-air updates that require little or no intervention from equipment owners. Alternatively, the user interface for a smart crane or hoist may have a feature allowing people to activate automatic updates. Then, the software downloads and installs automatically, meaning people don’t need to do anything to confirm they want the latest software. Managers should also tell employees to alert them to any popups they see about new updates needing installation. The same worker who sees the message may not be responsible for getting the software on the system. However, many people see such notifications as workflow disruptions. They might click to ignore and dismiss the message rather than take the time to see what it says and let the appropriate person know about the availability of the software.

Construction companies get hacked more often than many people realize. That’s due to a variety of reasons, including that companies often have their equipment spread across multiple sites and offices. Plus, many decision-makers don’t immediately consider their businesses as likely targets for hackers. As heavy equipment becomes more connected, people must change their protection strategies.

Better Protection Starts With an All-Encompassing Strategy

Protecting smart hoists and cranes from malicious parties requires carefully considering all risk factors, access points and vulnerabilities. Gathering that data makes it easier for leaders to assess where things stand and what they must do to follow all the applicable best practices.

Even if moving forward represents significant time and effort, it should pay off in the long run by enabling better safeguarding of a company’s vital assets. Even if only one piece of critical equipment becomes dysfunctional for a few days due to a cyberattack, that issue could dampen customer confidence, hurt the bottom line and severely restrict the workflow. That means prevention is always the best plan for limiting cyberattacks’ effects.

No matter how challenging your needs, AIROMAX AM 27 is your best ally for mobile cranes in industrial applications. The tire is particularly suitable for road usage. Thanks to its All Steel casing and the special tread design, AIROMAX AM 27 provides extraordinary traction along with high load capacity.

AIROMAX AM 27 is BKT’s response to withstand the toughest conditions in the construction industry.

For info: Western Canada 604-701-9098

Eastern Canada 514-792-9220

Utilizing new crane and rigging technologies featured in Oklahoma City

The 2023 SC&RA Crane & Rigging Workshop was held in Oklahoma City, Okla. This month, bringing together the crane and rigging industry for education and networking.

The workshop debuted a new session, The Power Panel on Utilizing New Crane & Rigging Technologies, focusing on the latest and greatest crane and rigging technologies. Key points included safer lifting operations to reduce tagline injuries; the evolution and application of AR and VR technology and software; and effective digital tools to standardize safety practices, streamline workflow and improve visibility of business analytics.

Panelists included Elliott Chenger, vice president of software engineering, Ribbiot; Randa Fernandes, director of operations and customer experience, WrightPlan; Casey Savlov, executive vice president, Industrial, Vita Inclinata Technologies; Patrick Witte, software developer, A1A Software; and Wayne Wille, business development manager, Technology Solutions, The Crosby Group.

In the Keynote Session: Be the Leading Indicator: Cracking the Code on Mental Health, attendees heard from Josh Rizzo, a Bronze Star Medal recipient and long-time construction industry expert, about how to lead while taking care of yourself and the teams you serve.

Throughout the Workshop, there were eight Breakout Sessions covering a variety of interesting and enlightening subject matter, ranging from certification issues, wire rope, strand jacks, lift and planning.

Safety is always the number one priority for every company, and everyone wants to know the latest and best practices. In the session, Is Your Safety Program Ready for Recent Regulatory Changes? speakers focused on FMCSA Performance Metrics for crane companies, dash cameras and telematics. Speakers included NationsBuilders Insurance Service’s Keith Adolf, AVP, risk management and Tyrone Silva, AVP risk management, alongside National Interstate Insurance Company’s Mike Gillen, senior product manager and Brian Parker, loss control consultant.

In the session A Bird’s Eye View of a Methodical Tower Crane Assembly & Disassembly, there was a discussion on the critical elements of communication, site meetings climbing procedures and checklists, with a panel that included David Brown, co-training director, Local 14-14b; Dan Durrett, vice president, engineering services, Maxim Crane Works; Matt Finnerty, owner, Finnco Services; and JR Moran, director of crane operations, Brasfield & Gorrie.

The presentation How to Avoid the Insurance Sucker-Punch featured a discussion of some of the lurking risks of doing business including employment practices liability, professional liability, OCIP/CCIP, bare rentals and inland marine (rental and loss of income). Panelists included Cameron Boots, area vice president, Allied Insurance Brokers; Dave Wittwer, executive vice president, Brown & Brown; Rick Emery, president, Emery & Karrigan; and Jeff Haynes, CEO, USI Insurance Services.

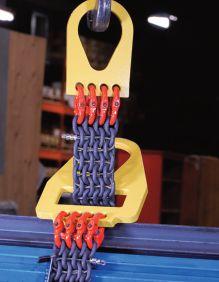

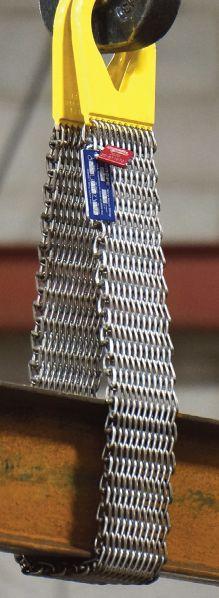

Jeff Ferchen of Associated Wire Rope Fabricators led Utilizing Chain for Overhead Lifting and Rigging Operations, where attendees learn-

ed the different grades of chain on the market and what ASME/ OSHA mandate as grades required when used as an overhead lifting system.

Following the workshop’s underlying theme of the latest market developments, Lift Planning Trends: What We’re Seeing Out There showcased the crucial elements of lift planning in crane and rigging operations. This session was led by Christian Coronel, manager, Engineering Division, Bragg Companies; Coltin Gleave, lead engineer, Borsheim Crane Service; Todd Harding, global rigging manager, Bechtel Equipment Operations; and Kevin O’Neill, lift planning and rigging engineer, Bay Crane Companies. Rigging with Heavy Lifting Strand Jacks covered application considerations for using a heavy lifting strand jack system along with some hands-on opportunities, with best practices and maintenance were discussed by Enerpac’s Alex Gollup and John Fleischman.

Technical Committee boosts membership, influence

The Canadian Crane Rental Association (CCRA) has experienced exponential membership growth this year and much of it may have had to do with increased visibility of the Technical Committee initiatives, states Claire Bélanger-Parker, Executive Director of the association.

According to Bélanger-Parker, the CCRA Technical Committee has formed a team of highly specialized engineers and industry experts who analyze industry requests for information to tackle any industry request; one of the association’s several sub-committees formed to expedite access to critical information and provide solutions for various topics.

The current technical sub-committees include:

• CSA-Z150;

• CSA-Z248;

• Rotating Telehandlers;

• Weights & Dimensions (formally Boom Dolly Research);

• Cranes working near power lines; and

• Lighting cranes near airports.

As members of the International Crane Stakeholders Assembly, the CCRA has delegated technical experts who collaborate on international technical task forces with crane industry experts from around the world.

“The association has been through major changes these past years and these changes are paying off,” says Shannon Moir-Riendeau, Chair of the Board of Directors. “The Technical Committee is now

in position to actively participate in the development of industry policies and regulations.”

If you are interested in joining the CCRA or learning more about the Technical Committee, visit www.ccra-aclg.ca or send an email to info@ccra-aclg.ca

The committee is led by Paul Walchuk, President of Kova Engineering. Committee members include Ryan Burton, Managing Partner at Bigfoot Crane Company, Jean-Louis Lapointe, IUOE Local 905, Eugene Reed, Shop Manager, Myshak Crane & Rigging Ltd, Lance Rydbom, Reginal Business Manager, Tadano America, and Julien Raby, Engineering Manager, Irving Equipment Ltd.

A representative from the Crane Rental Association of Ontario will soon be named by the CRAO Board to join this initiative.

Darin Richards, past President of Red Associates Engineering Ltd., now Vice-President of Regulatory Affairs with Kova Engineering, provides support to the TC’s coordination efforts. Over 30 subject matter experts currently contribute to the CCRA technical committees.

“We want to know what our members think are the most pressing issues for the crane rental industry in Canada,” says Paul Walchuk. “Only then we can take action to support them.”

The sun always shines in Vancouver

Here are a few photos from the annual general meeting in Vancouver, B.C. back in May (see opposite page) when the CCRA gathered with some of the major players in the industry.

Earlier this year, Murata Machinery USA Inc (aka Muratec), introduced a new mini-load crane unit which can be used to make storing and retrieving small, lightweight goods quicker and more efficient. The Ledger A3 AS/ RS is a mini-load with high-speed carriage loading and unloading of four totes, designed to provide high-density storage and retrieval in high-throughput distribution applications.

“This product is sort of a hybrid for us,” says Rickey Woodley, Murata Machinery’s National Sales Manager for North America. “There’s a number of mini-loads in the market, but they’re either extremely high speed or have capacity – it’s normally one or the other. You need the storage capacity, or you need the throughput. But this bridges the gap between a considerable amount of storage capacity, with extremely fast throughput being able to handle four totes at one time.”

The Ledger A3 would be ideally used in warehouses or other situations where small, lightweight goods are handled. The name ‘ledger’ references paper size, which each tote having an area roughly the size of ledger sized paper - 11 x 17 inches - and carrying up to 15 lbs. for a total maximum of 60 lbs. between all four. The unit travels at 984 feet per minute.

While one might think that small equipment like nuts or bolts would be the ideal application, the weight of items like that adds up too quickly to be appropriate for the system. While other smaller construction items could be utilized if they are light enough, the miniload is primarily focused on

small consumer goods including pharmaceuticals (syringes or pill bottles), cosmetics (tubes, bottles or jars) and some food and beverage industries (candies, gum or other confectionary products). Muratec representatives also said that they expect their customers to find other applications that they haven’t yet thought of.

“It’s primarily focused on things where you have large volumes, but lightweight,” says Woodley.

Woodley says that the Ledger A3 is a full turn-key system – no existing infrastructure will be required, the mini-load will come with everything needed to set it up.

The Muratec Ledger A3 is a unique mini-load with high-speed carriage loading and unloading of four totes for storing, picking and sorting small, lightweight goods.

“It’s going to come with the full software package, integrating with whatever ERP [enterprise resource planning – a software system which organizes automation and processes] the customer may be using,” says Woodley. “All of the software to actually drive and run the system on the hardware is full turn-key.”

Typically, the ideal set up for the mini-load would be a warehouse type situation between nine and 44-45 meters tall. However, if a company’s logistics run larger than that, multiple systems could be installed next to each other or stacked on top of each other. If a company has logistics that fall outside of those parameters, Woodley

says he wants to hear from them.

“The cornerstone of our business is specializing and being special,” says Woodley. “Nothing is out of the realm of possibility, as long as you have the finances to support that kind of R&D, then we could work with most anyone on any application.”

The Ledger A3 combines with Muratec’s rail-guided, bi-directional shuttle sortation loop –called Shuttliner – to operate as a goods-to-person system, minimizing handling errors and boosting throughput. Promotional materials claim that the two systems working in concert saves warehouse floor space and builds long-term expansion flexibility.

“When Muratec develops a solution, we will typically take a look at all of our other equipment, like the Shuttliners,” says Woodley. “We try to be a total solution provider from door to door. Most things we’re the OEM and manufacturer, though for some things we do partner with very specific people to add the missing parts and pieces so we can truly be a turnkey solution from door to door.”

Murata Machinery USA General Manager Scott Matlock was quoted in promotional materials as saying that the Ledger A3 is perfect for applications requiring more in/out capacity and would help reduce manual labour costs.

“In today’s rapidly changing marketplace, consumers are demanding their products immediately, if not sooner, leaving businesses to react to tighter speed of delivery expectations across manufacturing, warehousing, and distribution markets,” said Matlock. “Automation is no longer an optional luxury but a competitive necessity.”

Cropac carries a wide range of equipment:

• Boom Trucks

• Tower Cranes

• Forklifts & Telescopic Handlers

• Crawler Cranes

• Rough Terrain Cranes and much more!

Equipment Inc. SINCE 1977, CROPAC EQUIPMENT HAS BEEN COMMITTED TO PROVIDING QUALITY EQUIPMENT, PARTS, AND CUSTOMER SERVICE ACROSS CANADA. Cropac has branches in: ONTARIO - QUEBEC - ALBERTA -

Our readers have a knack for making the choice for #1 difficult

By Don Horne

We had an amazing response from Crane & Hoist Canada magazine readers for our 2023 Cover Photo contest, and you made it very tough for us to choose a winner.

Like last year, I turned to our magazine design team to select the best photo to grace our cover.

After a lot of deliberation and back and forth, we finally agreed on a winner to grace our cover: Justin McConnell’s photo of a Potain MD 310B crane at a two-condo site in Hamilton, Ont., which was being dismantled by Gabrielli Crane Erectors, run by the project manager Luis Correia.

Here are a few of the many excellent submissions that arrived, thank you everyone! And a special thanks to Terex for sponsoring our contest.

Justin McConnell OF TORONTO BEYOND MEDIA

When: 06/14/2023

Where: Hamilton, Ont.

Project: Photos were all taken at a two-condo site at 45 King St. E in Hamilton, Ont., as the crane was being dismantled by Gabrielli Crane Erectors.

Model: Potain MD 310B

Nicolas Rioux OF GUAY INC.

Where: Trois-Pistoles, Que.

Project: The erection of a wind turbine at the Nicolas-Riou EDF site in Trois-Pistoles, Que. with our 700-tonne crawler crane.

Model: Conventional Crawler Crane – 700 tonnes.

Terrie Tavares-Pereira OF UCI ENGINEERING INC.

When: 06/30/2023

Where: Etobicoke, Ont.

Project: Inspection of a Recom crane.

Schildhouse OF BRODERSON MFG. CORP.

When: 06/27/2023 Where: Ontario

Project: Our dealer, Cropac, installing a permanent outdoor swimming pool. Model: IC-200

Fournier

When: 06/05/2022

Where: Alberta

Project: Plug and perf multi-well, multi-stage hydraulic fracturing.

Rhea Billey OF MARCON

When: 02/11/2022

Where: Burnaby, B.C.

Project: Southgate City, Burnaby, B.C., is a multi-high-rise residential/ commercial site. I was the site safety coordinator for one of the projects.

Carrigan

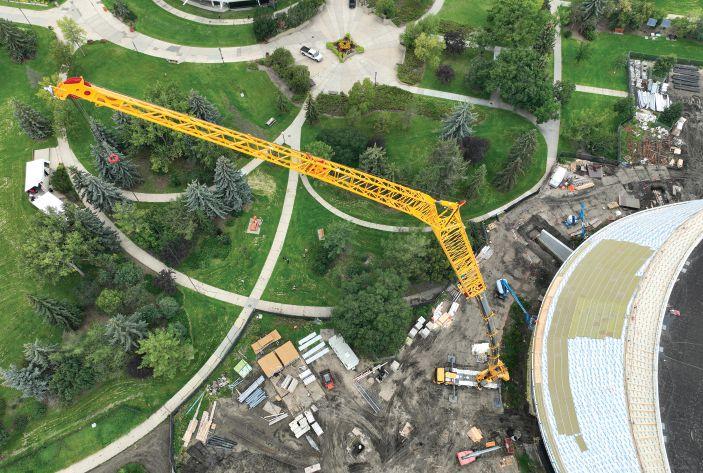

When: 08/22/2023

Where: Edmonton, Alta.

Project: Lifting skylight sections into the Coronation Park Sports and Recreation Centre in Edmonton. The project underway is a $153.41 million dollar expansion that will include a link to the existing Peter Hemingway Fitness & Leisure Centre and will include complete gymnasia and walking/running tracks as well as a sanctioned indoor velodrome for cycling training. With the connection to the existing Hemingway pool facilities, this new centre will offer a one-stop facility for triathletic training year-round.

Model: XCMG XCA150U, manufactured by Xuchou Construction Machinery Group.

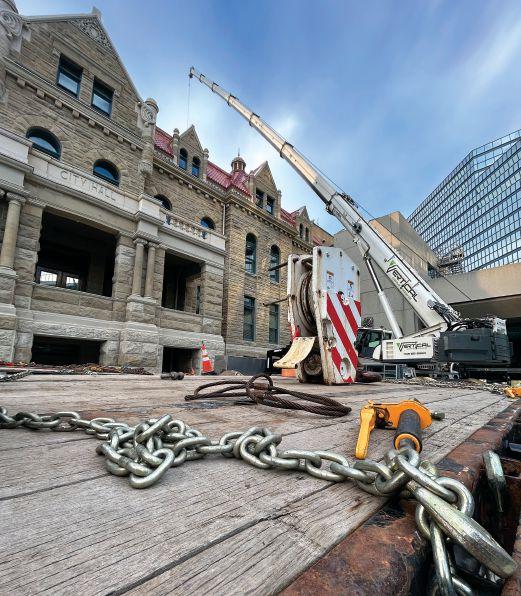

Vanessa Tavares OF VERTICAL CRANE & RIGGING

When: 07/24/2023 Where: Calgary, Alta.

Project: Calgary’s Historic City Hall Restoration - restore and preserve the heritage of the building.

Model: 2015 Terex Explorer 5600

Ryan Wilbee OF MOTOR CITY CRANE RENTAL INC.

When: 06/03/2023 Where: Cochrane, Ont.

Project: Hoisting sheet piles and vibro hammer. Use of suspended man basket for worker access for dam reconstruction.

Model: TEREX AC 170

Brett Symington OF STERLING CRANE

When: 01/24/2022 Where: Kicking Horse Canyon, Golden, B.C.

Project: This crane is on a project of a major upgrade of the Trans-Canada Highway improving the highway through the most challenging section of the Kicking Horse Canyon in the Rocky Mountains near Golden, British Columbia. The crane is sitting on a platform on the edge of the mountain. The highway is being upgraded from two lanes to a divided four lane.

Model: Kobelco CK2750G

Jamie Cruz OF STERLING CRANE

When: 05/11/2023 Where: Alberta.

Project: This was taken during a shutdown at the site to be left unmanned.

Model: CC2400 and a CK275G.

Theresa F. OF CJM CRANE SERVICES LTD.

When: 01/22/2023 Where: British Columbia / Alberta. Project: CJM Crane Services’ LTM1250-5.1 at a pipeline project near Mt. Robson in the winter of 2023.

Model: LTM1250-5.1

Brad Metro OF CJM CRANE SERVICES LTD.

When: 07/06/2023 Where: Whitehorse, Yukon.

Project: CJM Crane provided turnkey crane services to assist in the construction of some of the first wind turbines to be constructed by an indigenous group in Canada and the Yukon.

Model: LTM1350-6.1 and LTM1090-4.1.

Arbid OF KONECRANES

When: 02/21/2014

Where: Alberta Oil Sands.

Project: Maintenance on overhead cranes / de-icing.

✓

✓ Unprecedented

✓

✓

✓ Fast set up & move

When: 08/17/2023 Where: Edmonton, Alta.

Project: The Parks; a commercial and residential high rise.

Model: Peiner sk415.

When: 05/08/2023 Where: Edmonton, Alta.

Project: A residential and commercial mix project overlooking Rogers Place.

Model: Terex Peiner SK-315.

Sabir Palani OF MCINTYRE CRANE

When: 07/12/2023

Where: Airdrie, Alta.

Project: We were north of Calgary installing 40+ HVAC units with our Terex 160-2 crane. Our 200-ton was in the shop for nearly two years and this was its first job back.

Model: Terex 160-2 crane.

Up to $20,000* in help is available right now!

Apply for your grant at

When: 05/31/2023

Where: Pearson International Airport. Project: Bombardier’s new $510 million facility being built near Pearson Airport. The 770,000-square-foot facility at Toronto’s Pearson International Airport is expected to enhance operations to build the company’s global business jets, including the industry flagship Global 7500 aircraft.

When: 02/10/2023

Where: 43 kilometres west of Regina, Sask.

Project: This 297 Tonne boiler was transported from the United States on its side, due to center of gravity and height restrictions, and needed to be rotated upright from the over the road transport for installation. Generally, this process would use several cranes; instead, the Mammoet team used two AT cranes (LTM 1130 & LTM 1220) and a 700 Tonne to perform the rotation, saving time and money for our client. Once the boiler was up righted it was placed onto SPMTs and transported to the foundation where it was Jack & Slide into location.

Model: 700 Te Gantry, LTM 1130, LTM 1220.

Thomas Moore OF CRS CRANE SYSTEMS INC.

When: 12/06/2016 Where: Northern Alberta.

Project: Crane to span the expansive Valve Matrix at an oil and gas terminal.

Model: TRSG Bridge Crane 3T/122’ span and runway system.

Thomas Moore OF CRS CRANE SYSTEMS INC.

When: 04/11/2012

Where: Northern

British Columbia

Project: A mining project in B.C. Model: 60 Ton overhead crane.

Thomas Moore OF CRS CRANE SYSTEMS INC.

When: 11/15/2018 Where: Fort McMurray, Alta.

Project: Tailings Pond dredging barge.

Model: 3 Swing Controlled Jib Cranes 2T with 10m span and fall-arrest system.

Thomas Moore OF CRS CRANE SYSTEMS INC.

When: 06/15/2022 Where: Welland, Ont.

Project: Cranes used to rebuild a facility then keep work-flow processes operating at peak efficiency once they opened as their needs grew.

Model: TRDG and TRSG bridge cranes.

Thomas Moore OF CRS CRANE SYSTEMS INC.

When: 10/17/2014 Where: Edmonton, Alta.

Project: Manufacturing facility. Model: Bridge and jib cranes.

or

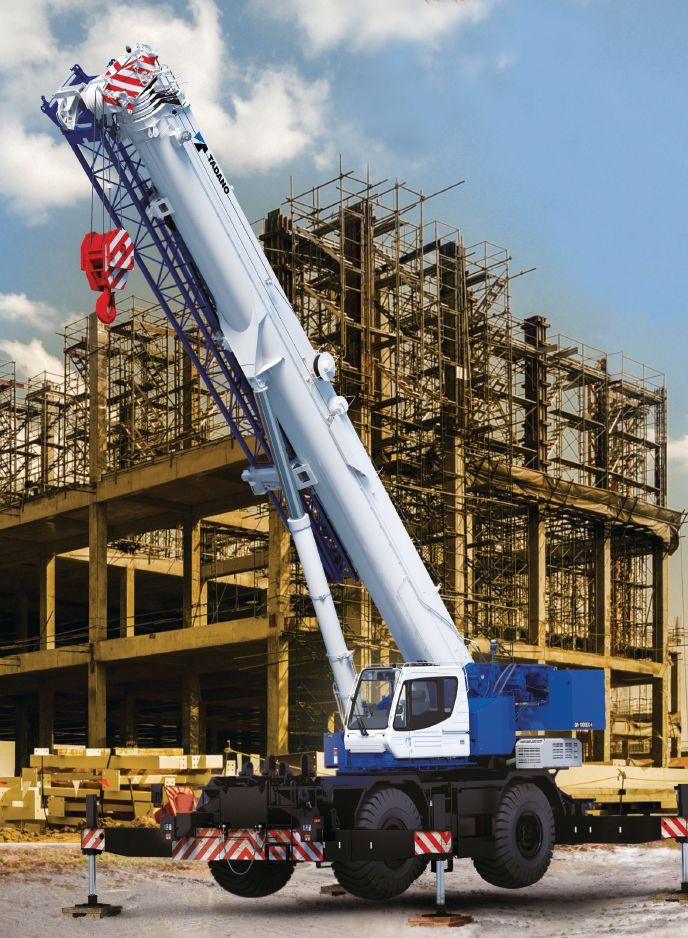

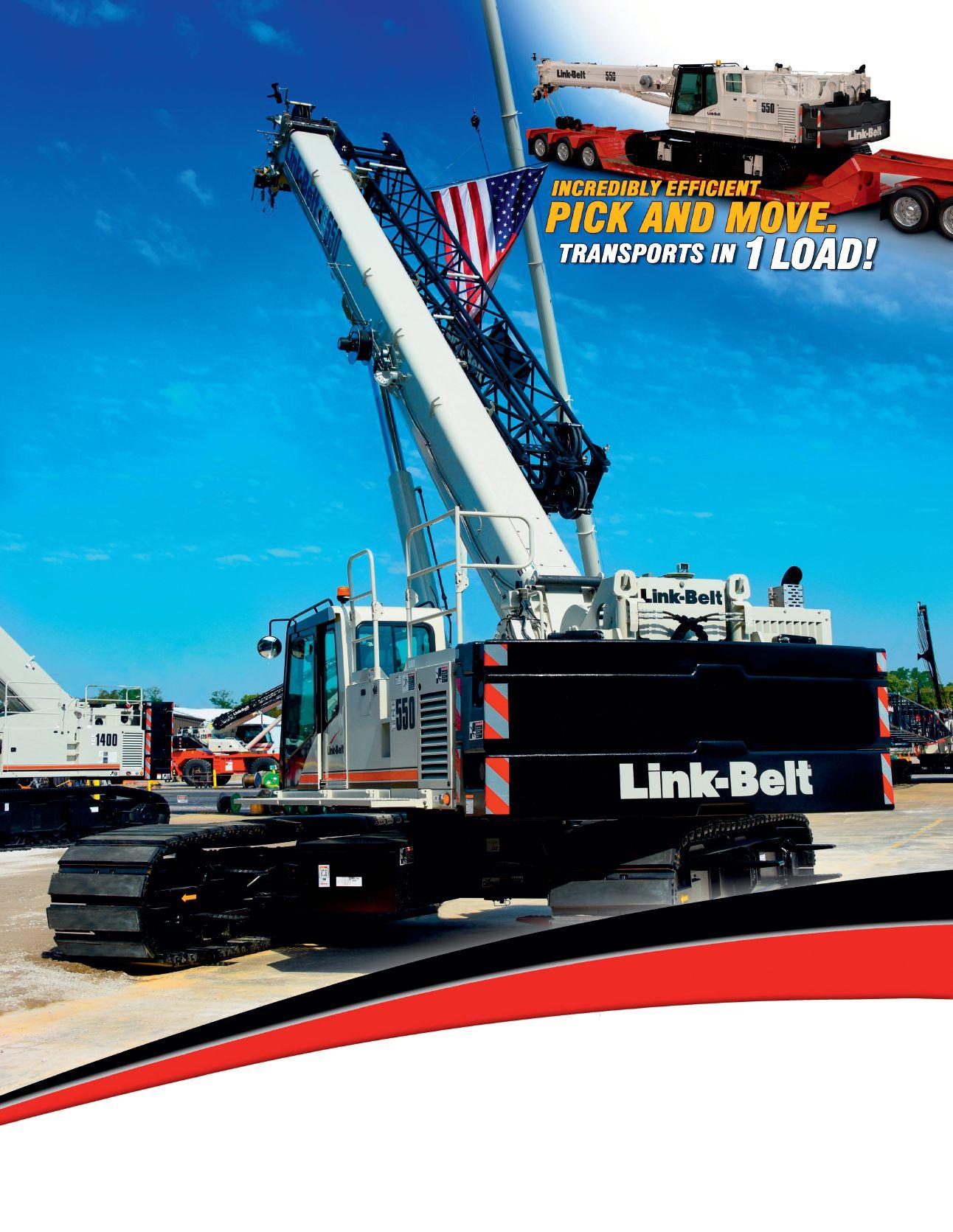

Full Load Chart Capacity

Maintains the same lifting capacity as standard counterweight

Power Pack Mounting

Customized to the power pack of your choice

Quick Set-up

Mounts in place of standard CWT; no modification to the superstructure required

The Tadano GTC lineup now has some additional foundation options for road and bridge builders, a Third Winch and Power Pack Mounting. In fact, Tadano is the only OEM offering the Third Winch option and an Integrated Power Pack Mounting on a Teleboom Crawler Crane. These versatile machines are already known for their full load chart pick-and-carry, quick setup, auto-switching load charts and superior travel performance. And now, Tadano can help you score another utilization win with two options previously not seen on Teleboom Crawler Cranes.