SEPTEMBER/OCTOBER 2022 www.craneandhoistcanada.com

SEPTEMBER/OCTOBER 2022 www.craneandhoistcanada.com

It was a tough choice picking the winner of our Cover Photo contest, but we finally chose p. 16

INSIDE

Is a Mini Crane Better Suited For Your Client’s Needs? p. 12

Transforming the User Experience For Crane Owners p. 20

We’re your one-stop dealer for all your equipment needs

From machinery to service, parts and certification. Your trusted partner for every project.

The Manitowoc MLC300 continues to reshape the landscape of the 300t capacity class. Already known for its VPC technology that delivers unprecedented li ing performance the MLC300 incorporates a wide array of boom/jib configurations including 3.5m wide boom kit for exceptional capacities with Extended Upper Boom Point and with VPC-MAX. Further the MLC300 has a fixed position counterweight configuration with multiple drum options to create the versatile li ing solution Manitowoc has been known for.

This

How

How

BY DON HORNE

Allow me to post a disclaimer to begin with: I hate winter and do prefer summer.

These old bones feel the cold more than ever, and the warmth of our alltoo-short Canadian summer season is very much appreciated by this Gen Xer.

So, when I say I am eager for September, it doesn’t mean I am anxious for fall and winter to arrive.

But the Canadian Utility Engineering and Equipment (CUEE) Trade Show and Marketplace?

This has been long overdue and is very much welcome after two years of COVID lockdowns.

The return to an in-person event on Sept. 13-14 at the International Centre in Mississauga, Ont. is Canada’s most important distribution and transmission show, as the CUEE brings together thousands of professionals including contractors, engineers, trades personnel and key buyers from myriad municipalities and utilities.

This year, the CUEE 2022 will feature product and service demonstrations and exhibits from more than 200 companies, and those attending can see first-hand the latest in equipment and utility technology with the opportunity to meet one-on-one with thousands of key buyers.

With more than 50 years of historical success behind it, the CUEE features more than 100,000 square feet of exhibit space and has more than 45 different exhibit categories of products and services that are relevant to the utility industry.

While 2022 marks a rebirth for the CUEE, it also a major milestone for the Electricity Distributors Association (EDA) – as it was 110 years ago in 1912, that 14 communities came together to form the precursor of the EDA, the Ontario Municipal Electric Association (OMEA).

Today, Ontario’s distribution sector – the vast majority of which is represented by the EDA – encompasses 59 utilities of varying sizes, which collectively serve more than five million customers.

And while we are celebrating a return to

“normal,” we are also in the realm of the “new normal.”

New COVID variants continue to pop up like dandelions – as the flu virus is wont to do – and those mass vaccinations from a year ago now offer minimal protection.

And for those who haven’t had their booster shots, no protection at all.

Because that is how flu shots work: much like COVID shots, you must continue receiving them as new variants pop up.

We may not like it; we may search online for any reason or excuse not to have them, or to take precautions – like wearing a mask or meticulously sanitizing – but the cold reality is this isn’t going away with thoughts and prayers.

It was a little over a year ago that Judy Mellott-Green – who has three decades of experience working in the overhead crane industry and was the recipient of the 2016 CSA Award of Merit in recognition of exemplary goal-oriented leadership – spoke with Crane & Hoist Canada about the need to up our measures to protect workers from the ravages of COVID.

Now governments have relaxed the mandates, and people can go about their business without masks or social distancing – and those who chose not to be vaccinated can now enjoy the same freedoms and accessibility as those who did “get the jab” in 2020-21.

And now shows like the CUEE 2022 are returning – and that is a good thing.

But it doesn’t mean we should let our guard down or abandon all precautions in the belief that the “new normal” is really “back to normal.”

I urge everyone who will be attending CUEE in September to be safe, stay safe, and above all else – be considerate.

I have heard from many of my colleagues that there has been sniggering or even outright harassment of those who choose to wear a mask at events.

You now have the freedom not to wear a mask – but please don’t impose your opinions on those who do choose to continue to wear one.

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: (416) 510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | DON HORNE dhorne@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER | LAURA GOODWIN lgoodwin@annexbusinessmedia.com • 289-928-8543

MEDIA DESIGNER | SVETLANA AVRUTIN savrutin@annexbusinessmedia.com

ACCOUNT COORDINATOR | KRISTINE DEOKARAN kdeokaran@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER | URSZULA GRZYB ugrzyb@annexbusinessmedia.com • 416-510-5180

CONTRIBUTORS | Matt Jones, Emily Newton, Andrew Klukas, George Koch

GROUP PUBLISHER | DANIELLE LABRIE dlabrie@annexbusinessmedia.com

COO | SCOTT JAMIESON sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues)

Canada: $37.00 + tax per year • USA: $37.00 USD Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT. 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

PRINTED IN CANADA ISSN 1923-788X Publications Mail Agreement #PM40065710

Annex Privacy Officer

Privacy@annexbusinessmedia.com Tel: 800-668-2374

The contents of Crane & Hoist Canada are copyright ©2022 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect

Next Advertising Deadline: September 30, 2022

Don’t miss the opportunity to be part of this exciting industry publication. For more information, or to reserve space in the next issue, call Laura Goodwin at our Advertising Department Tel: +1-289-928-8543 lgoodwin@annexbusinessmedia.com

Next Editorial Deadline: September 30, 2022. For writers’ guidelines and submission requirements get in touch with the editor, Don Horne, at dhorne@annexbusinessmedia.com

The Electricity Distributors Association’s CUEE (Canadian Utility Engineering and Equipment) Trade Show and Marketplace is an institution within the Ontario and Canadian electricity sectors, running for more than half a century.

In 2020 the CUEE took a pause as COVID was sweeping the world – and finally it will return to the International Centre in Mississauga, Ont. on Sept. 13-14.

“Crane and hoist service and equipment suppliers are a key business partner to the utility sector and will be well-represented among CUEE exhibitors and are among the sectors that attendees will be keen on connecting with,” says Marica Macura, director of member relations at the Electricity Distributors Association (EDA).

CUEE is Canada’s largest trade show in the electricity transmission and distribution space, attracting a loyal base of exhibitors, who provide first-hand opportunities to see the latest in equipment and utility technology; and this year, app-based interaction opportunities will be added.

“The event is designed to enable on-site equipment displays, and hands-on presentation to and testing on the part of prospective buyers,” says Macura. “Given that CUEE has an extensive outdoor show area, this extends to even large equipment such as cranes and hoists.”

Included in this year’s show will be more than 45 product and service categories.

“CUEE has always been a uniquely valuable marketplace for both exhibitors and for utility attendees,” states Teresa Sarkesian, president and CEO of the EDA. “And that will be even more the case this year, after a long period when in-person contact with potential customers just wasn’t possible.”

For more event information and exhibitor booth bookings, visit: www.eda-on.ca/ EVENTS/CUEE or contact Event Specialist Jane Yuan at jyuan@eda-on.ca.

Port Saint John to install two new container cranes

DP World have announced significant investments into the multi-purpose container terminal at New Brunswick’s Port Saint John. Among other additions, this investment will include two super-post-Panamax quay cranes capable of reaching 21 rows wide.

“The cranes are manufactured by Hyundai Heavy Industries – they are ship to shore cranes with a rated load of 50LT under spreader and 65LT under head frame,” says

DP World Saint John General Manager Terrence White. “They feature a 100’ rail gauge, a 58-meter outreach, 35-meter lifting heights with the tip of the boom 108 meters high. The hoist speed is up to 130 meter per minute and trolley speed is up to 152 meters per minute. And they will utilize a Cutler-Hammer Crane Control System.”

These will be the second set of new cranes that DP World have added to Port Saint John and will allow two container vessels to be handled simultaneously. They will allow the terminal to handle ships up to 10,000 twenty-foot-equivalent units (TEU).

Other asset investments at Port Saint John include additional reach stackers, internal transfer vehicles, container trailers and other technology solutions including an upgrade to the terminal operating system, a new truck gate system and financial management systems.

“We are thrilled that our partners at DP World are investing in both new terminal equipment and additional larger gantry cranes at Port Saint John,” says Craig Bell Estabrooks, president & CEO of Port Saint John. “These significant investments will enable the terminal to further this period of remarkable growth and provide much needed resiliency in Canada’s supply chain.”

These investments are intended to enhance and modernize operations at Port Saint John, which will allow it to provide more varied logistic services such as transloading and warehousing. DP World has also invested $205 million into constructing a second container berth which is due to come online in early 2023. With this project, annual container throughput capacity at Port Saint John will increase from 150,000 TEUs to 350,000 TEUs.

“This significant investment is about building the right trade ecosystem to make Port Saint John the logistics hub for the east coast,” says Maksim Mihic, CEO & general

manager DP World (Canada) Inc., “By creating additional capacity, we provide more options for Canadian exporters to reach global markets leading to sustainable economic growth for the region.”

The expansion of the port has been supported by the Government of Canada, with the announcement of more than $42 million in support through the National Trade Corridors Fund. That investment includes $21.16 million to upgrade rail terminals in Saint John and McAdam and $21 million to the Saint John Port Authority to increase capacities at the terminal and to allow wheeled cargo capabilities. Each investment was matched by a local partner.

“The enhancements to the modernization project will build additional capacity to meet the increased demand being created by the private sector, create jobs and make the port competitive with Halifax and Montreal,” says Minister of Economic Development and Small Business and minister responsible for Opportunities New Brunswick, Arlene Dunn.

– Written by Matt Jones

ALL Erection & Crane Rental, a member of the ALL Family of Companies, has been honoured with the Longevity Award from the Specialized Carriers & Rigging Association (SC&RA), recognizing its decades of

leadership. SC&RA is an international organization with more than 1,350 members from 46 nations serving all aspects of heavy industry including specialized transportation, lift equipment, machinery moving, maintenance, and more.

SC&RA’s Longevity Awards are presented to member companies for their longtime support and dedication to the association and its mission. ALL was recognized with the 50 Years Award.

ALL has a deep history with SC&RA. Its Dawes branches are among the seven founding companies that formed the association. More recently, Dawes general manager Steve Freckmann received the association’s Pinnacle Award in 2020 in recognition of his more than decade and a half of involvement in leadership positions within the association.

“The ALL Family believes in the power of our industry to move the world forward,” said Michael L. Liptak, CEO and president of ALL. “SC&RA is a vital organization to our industry, working hard to advocate for effective, prosperous operations that serve the needs of customers and projects all around the world.”

Firms from around the world submit dozens of entries to the SC&RA Awards competition each year. The awards program recognizes worldwide excellence in the crane, rigging, and specialized transportation industry.

“We’re proud to be recognized by SC&RA with this Longevity Award and to be aligned with an organization that does so much to further the interests of our industry and its constituencies,” said Liptak.

MYCRANE has appointed industry veteran Piet Kraaijeveld as chief operating officer, strengthening the global management team of the Dubai-based digital disruptor for the cranes and construction space.

Based in Dubai, Piet’s task will be to grow the MYCRANE business in all respects, including working with the crane rental platform’s existing franchisees around the world, and encouraging global energy, procurement and construction (EPC) contractors to register as customers on the site. He will also oversee sales activities to the full range of MYCRANE clients, including prime contractors, ports, petrochemical and mining operators.

MYCRANE has pioneered a free-to-use, digital crane rental service, allowing users to post their lifting requirements free of charge online. Crane rental companies then respond directly with their commercial offers, eliminating the need for customers to make multiple offline requests. Other MYCRANE services include a free crane Selector tool to help identify the right crane, advice for engineering, project management and support, and a Marketplace where equipment, rigging equipment, spare parts, auxiliaries and industry vacancies can be posted.

Born in the Netherlands, Piet has 30 years’ experience in the heavy lift and transport industry, working on multiple continents including North America, Europe, the Middle East and Africa. He spent 11 years at General Electric and has extensive industry contacts among the EPC community, as well as the

heavy lift and construction sectors.

He spent 18 years in management roles at global heavy lift and engineering specialist Mammoet, serving in both Canada and Dubai. Most recently, Piet worked in Dubai as strategic account manager for Ritchie Bros., the international auctioneer for heavy industrial equipment.

Piet joined MYCRANE on June 22. Welcoming him to his post, MYCRANE founder and CEO Andrei Geikalo said: “Piet is a proven leader with deep experience in our sector and it is a pleasure to have him join MYCRANE in this critical role.

“I’ve no doubt Piet’s extensive international connections and entrepreneurial spirit will be a great asset to MYCRANE as we continue to roll out our service in more global markets.”

Piet said: “This is an exciting move for me because MYCRANE is offering much-needed change in the construction sector. I can’t wait to get started and help customers save time and money on the crane procurement process.”

CRAC celebrates safety at AGM

The Crane Rental Association of Canada (CRAC) announced the recipients of the Safety Awards for their outstanding safety standards in 2020 during the Annual General Meeting, placing 13 crane rental companies on centre stage for their commitment and dedication in creating a safe work environment for their staff, operators and the public.

The companies are:

ABCO Crane Services – Nisku, Alta.

Amherst Crane Rentals Ltd. – Toronto, Ont.

Canlift Crane Inc. – Grande Prairie, Alta.

Canadian Crane Rentals Ltd.

– Wingham, Ont.

Canuck Concrete Pumping & Crane

– Yellowknife, N.W.T.

Energy Crane Service/Div. of Myshak Group

– Stony Plain, Alta.

Irving Equipment Limited – Saint John, N.B.

Mammoet Canada – Edmonton, Alta.

Myshak Crane & Rigging Ltd – Acheson, Alta.

NCSG Crane & Heavy Haul Services Ltd.

– Acheson, Alta.

Radius Crane & Rigging Inc. – Niksu, Alta.

RKM Services Ltd. – Langley, B.C.

Sterling Crane – Edmonton, Alta.

“The Crane Rental Association of Canada is dedicated to improving the safety of the Canadian crane industry and it is more important than ever to celebrate safety among our membership. We congratulate these companies on their performances,” said Gijs Verdeijen, chairman of the board, who announced the awards during the virtual meeting on May 26.

The Crane Rental Association of Canada’s members are crane rental companies, manufacturers and suppliers of cranes and equipment, and supplier of service used in the specialty crane rental business in Canada.

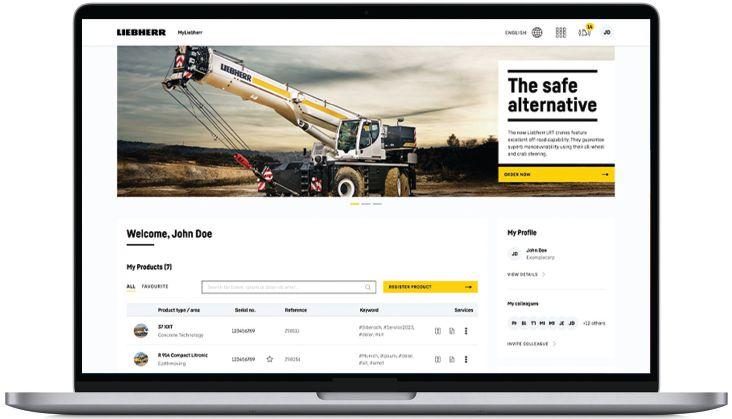

The homepage of the MyLiebherr online portal has a new look. Thanks to the modern design users benefit from a clearly structured, intuitive user interface and a clearly arranged homepage. Optimised and additional features round off the design update.

Biberach an der Riss (Germany), 10 May 2022 – Finding a spare part with a click of the mouse or quickly accessing documentation for a machine: with the MyLiebherr online portal Liebherr customers have access to information and services at any time of the day. It is available for products ranging from construction machines, mining equipment, mobile and crawler cranes, material handling technology, components to maritime cranes. The redesign of the MyLiebherr homepage marks the start of a new phase in the further development of the portal. In addition, major parts of now have a mobile version.

In the course of the development of the new design special attention was paid to the user-friendliness of the MyLiebherr homepage. The key areas are now combined and clearly structured. This means that users see all their products at a glance and can skip directly to the areas “Personal data” and “Business relationships”. In addition, all licence managers and administrators of a company are now displayed to the user with their respective contact details. The previous navigation was replaced with the “Apps” area and offers easy and quick access to the key portal applications. Whether they need the shop, the spare parts catalogue or product documents – users can now enter applications by clicking on the new large tiles. With the new pop-up windows users also receive feedback on error messages or information about the status of requests.

The profile management was optimised and even better tailored to the needs of users. In the “Address Book” section company administrators can now create and manage addresses that are available either to themselves or all users of their company. For orders, the appropriate delivery address can be selected directly without having to enter it again each time. In the “Products” section company administrators or product

managers have the option to store keywords for each machine. Products can thus be assigned to corresponding topic clusters, enabling them to be found more quickly. These keywords are then visible to all users of a company.

The changeover to the new user interface is automatic. When visiting the website www. myliebherr.com the MyLiebherr portal automatically appears in the new design without users having to make any additional settings. The login data also have unlimited validity. New features for MyLiebherr will be gradually rolled out during the year.

Grove started as a farm machinery manufacturer in the 1940s but quickly pivoted to crane manufacturing and by 1967 had grown into a vast operation with more than 1,000 employees, producing a range of rough-terrain and truck cranes. Today, Grove is one of the world’s bestknown crane brands with operations across the globe.

Innovation has been at the heart of Grove’s success over the past 75 years. A range of engineering breakthroughs over more than seven decades has helped the company create some truly iconic cranes.

From the dozens of innovations the company has rolled out over the years, we pick out three technologies that are synonymous with Grove and which have helped the company write its own history.

1970 – The trapezoidal boom

Grove’s trapezoidal boom was released in 1970 and represented a major engineering accomplishment. It provided the company’s cranes with the optimum strength-to-weight ratio in the boom and more rigidity at higher capacities. Compared with conventional booms, the Trapezoidal boom delivered greater reach and better capacity along the load chart.

This improved strength and rigidity were not only down to the trapezoidal design, but also the use of very high strength steel –a design philosophy that Grove has long applied to its cranes, to ensure best-in-class performance. Overall, the result was a deeper, wider, and lighter boom that offered greater resistance to both lateral and vertical deflection.

The design was patented and marketed under the tagline “If it’s Trapezoidal…it’s a Grove.”

Manitowoc introduced its Crane Control System (CCS) in 2013, on the Grove GMK3060 and Grove RT550E. Shortly thereafter, CCS was introduced on Manitowoc and Potain products as well, making Manitowoc the first manufacturer to adopt a common operating platform across multiple product lines. Each CCSequipped crane features the same control layout that includes jog dials and two full-graphic displays with standardized ISO symbols recognized globally. There are only seven major components that comprise CCS, simplifying service and maintenance, and helping deliver better reliability.

Startup and setup are made easy with an intuitive setup wizard. Outrigger functions are controlled from the operating display with a jog dial. A boom configurator mode allows for easy setup and optimal configurations. A visually organized and consolidated screen with all crane functions, gauges and alerts help enhance daily work. Customization options increase the precision of the operator’s commands.

The benefits of CCS standardization — such as streamlined manufacturing and operator training across crane ranges — propelled Manitowoc to apply its principles to other areas of engineering design, including counterweights, engines, drive systems, boom, and jib options.

Because of its customer-first philosophy, a lot of Grove’s innovation has focused on getting better performance from an existing machine. The best recent example of that is the MAXbase system for outrigger positioning. With MAXbase, crane owners can position the crane’s outriggers in a wider variety of configurations, including in asymmetric layouts, to deliver greater versatility on the jobsite.

While only a few years old, this optional addition is already a popular choice with many owners who love the capability it offers to maximize a crane’s full potential. The MAXbase system also works seamlessly alongside another relatively recent innovation – CCS, or Crane Control System, which offers easy set-up and operation. Throughout 2022, Grove will be sharing stories about its people, products, and history on social media and on Looking Up

No matter how challenging your needs, BKT is with you offering a wide range of OTR tires specifically designed for the toughest operating conditions: from mining to construction sites. Sturdy and resistant, reliable and safe, able to combine comfort and high performance.

BKT is with you, even when work gets tough.

For info: Western Canada 604-701-9098 Eastern Canada 514-792-9220

This Italian manufacturer has evolved the selfpropelled machine for a variety of minicrane applications. By Matt Jones

Italian crane manufacturer Jekko are introducing their newest self-propelled minipicker, the MPK10. An evolution of their previous MPK06, the new model has a higher capacity (990 kg) and other new features. The MPK10

is optimized for moving glass panes but could be used for a variety of minicrane applications in tight environments.

“The main reason we wanted to make a bigger robot was that we noticed that the dimensions of glass panes were

The Jekko MPK10 minipicker is optimized for moving glass panes but would also be effective for any minicrane applications in tight environments.

The MPK10 can also be fitted with a six-cup glass handling attachment.

getting bigger and also heavier,” says Jekko marketing manager Cristina Da Frè. “600 kilograms maximum capacity was not enough. Also the length of the boom is a bit higher than what the MPK06 can reach.”

Da Frè notes that some customers had expressed a desire for a mid-sized minipicker solution, something larger than the MPK06 but not as large as the company’s MPK20 and MPK50. The unit weighs 970 kg, though it can reach a final weight of 1200 kg with counterweights employed. The MPK10 features much of the same details as the company’s previous minipickers – four rechargeable batteries powering an electrohydraulic unit which controls crane handling and electrical actuators to control the vacuum manipulator for glass panes. Though optimized for moving glass panes, a traditional hook can be substituted for the glass manipulator for more traditional lifting applications. The MPK10 also uses a noiseless zero-emmissions electric motor which will make it valuable for working indoors.

One of the biggest advantages of Jekko’s minipickers is the +/- 9° slewing of the turret, as Da Frè explains.

“It comes handy if you see that you’re not placed in the right position and you need to shift the glass a bit and place it in

a different position,” says Da Frè. “With this rotation, you can adjust and you can get closer and with the remote control and you can lock the movement of the crane horizontally and only move back and forth to get into the right position.”

The MPK10 also features side outriggers and off-road run-flat tires that can adapt to uneven surfaces and front twin wheels for increased traction and stability on steeper ground. Though those can be swapped out for white, non-marking tires for indoor use.

Alberto Franceschini, Jekko sales director, is quoted in Jekko marketing materials as saying that the MPK10 is “part of Jekko’s next generation of products in the minipicker range destined to meet the requirements of a vast customer base asking for user-friendly, simple, safe and reliable machines to be used in small or large lifting works.”

The MPK10 minipicker is available through Jekko’s Canadian dealer, Leavitt Cranes. Da Frè says that they are also

A close-up view of the controls of the MPK10, which also for very precise movement, including a +/- 9° slewing of the turret.

planning on working with Leavitt to ensure that potential customers are made familiar with the benefits of this type of minicrane.

“In Europe, we are very used to this type of glass robot because we have

regulations about a limit on what a worker can lift,” says Da Frè. “These regulations led to the development of these cranes and we have to make new markets understand what the platform can be used for.”

By Emily Newton

Aportable mini crane machine is the perfect for handling construction work with dexterity and convenience. For many types of unique projects or tasks, a full-sized crane is unwieldy and may not even be an option — especially with many interior jobs.

Because quite simply, portable mini cranes are more agile to work with.

They’re also perfect for certain types of rigging tasks, so it is helpful to know how to explain to customers some of the best use cases for a mini crane, as well as the advantages of mini cranes over other types of rigging equipment.

Advantages of Portable Mini Cranes

Those clients who have not used a mini crane machine before may wonder why they should use one at all – and that is where you can explain the many benefits in opting for a mini crane compared to a fullsized piece of equipment.

For instance, since mini cranes are significantly smaller than others, they are much easier to transport from one site to another. And given the skyrocketing price of fuel, they can reduce costs, especially the battery-powered models.

Mini crane machines can act like a Swiss army knife on construction sites, with a variety of attachments for many jobs, from lifting to winching to operating a man basket.

Maneuverability, dexterity and portability are huge plusses.

Some models are small enough to fit through doorways and cramped aisles, making them ideal for tasks in interior sites – requirements that some customers can sometimes overlook.

These characteristics make portable mini cranes more convenient to use in many situations and can also create safer sites as a result. With a crane small enough to work indoors, site workers don’t have to worry about trying to lift heavy objects just because they don’t have compact rigging equipment, and this reduces the likelihood of on-site injuries on-site when handling heavy objects.

Use Cases for Mini Crane Machines

While mini crane machines are fantastic for all sorts of applications, there are a few

they are very well-suited for, and many of your customers may be struggling to do the work when a mini crane would make it so much easier.

These use cases are among the most popular applications for mini cranes, and you can use these to explain to potential clients their distinct advantages:

On both indoor and outdoor sites, there are often situations where a team needs to move or install something delicate. These situations call for a mini crane machine. Examples include glass installation, moving statuary and plants for landscaping and moving unique objects such as pianos. Construction crews can even use mini cranes for tasks on the roofs of buildings. When performing tasks like this, agility is crucial. Portable mini cranes can provide this flexibility in virtually any space.

You can explain in detail to customers how the spider-like legs of these small machines allow them to remain stable on uneven surfaces, such as slopes or stairs. With the proper attachment, a mini crane can maneuver a pane of glass into place or move a delicate sculpture while minimizing the risk of breaking anything during transit or installation.

Delicate lifting assignments can include work on outdoor sites where space is minimal, such as urban settings. In these situations, it may not be that the objects being lifted are fragile but that the surrounding buildings and objects are delicate.

Mini cranes are perfect for navigating this kind of work site. Even if a construction team doesn’t need a mini crane all the time, it is helpful to have a mini crane employed for occasional use, one of the benefits of renting equipment rather than buying.

One of the most valuable use cases is interior crane work. Not all work sites are outdoors and there are plenty of situations where a team might need a crane indoors. A prime example of this is museums.

A museum might want to move a heavy artifact for a new exhibit. Carrying it with a crane is far safer than transporting it by hand, but a full-sized crane would be far too

unwieldy indoors and might even endanger other artifacts.

Scaffolding is commonplace on work sites but may not always be necessary. One of the most convenient benefits of employing a mini crane machine is the versatility they bring to sites. Construction crews can eliminate or minimize scaffolding by using a mini crane with a man basket instead.

This use case for portable mini cranes is beneficial on rapid-build projects that are short-duration but still require the use of scaffolding or rigging for specific tasks. A great example is 3D printed construction, which is gaining popularity in housing.

The 3D printer builds most of the structure, but crews need to install things like windows and roofing separately. A portable mini crane is perfect for this, minimizing the time required to install these structure parts. In cases where builders are constructing a whole neighborhood, they could easily move a mini crane from one build site to another.

One of the most popular applications for mini cranes is in the entertainment industry. These machines are perfect for moving and building things on film sets and stages. Set pieces, structures and people tend to crowd these types of spaces, and that can be a challenge to navigate around.

Sets and stages are continually shifting from one project to another as well, so there is a constant need for compact rigging equipment on site.

Mini crane machines bring the portability, agility and convenience entertainment sites need, and one crane can meet a set’s rigging needs, from man basket to winch to heavy object transportation and even stunts; and a plus for client’s is that a mini crane’s compact size ensures they are also easy to store.

Portable mini cranes have a wide array of applications in many work sites, and crews can use them to set up an art gallery space, organize landscaping fixtures or build a concert set.

By employing a portable mini crane in the right situations, construction teams can give themselves an edge — even in challenging workspaces; and those are strong selling points when renting or selling these highly effective machines.

It was a tough choice picking the winner of our Cover Photo contest, but we finally chose. By Don Horne

We had an amazing response from Crane & Hoist Canada magazine readers for our 2022 Cover Photo contest, and you made it very tough for us to choose a winner.

Like any good editor, I passed the buck to someone else to decide, turning to our magazine design team to select the best photo to grace our Sept/Oct cover.

After a lot of deliberation and back and forth (trust me, there were more than a few photos that could have made it), we finally agreed on a winner to grace our cover: Michael Demelo’s high above the clouds submission from Oxford Builders Supplies.

We want to thank the following for their excellent contributions:

• Aaron Cromarty, Cambie Forming Ltd.;

• Rachelle Guernette, Sterling Crane;

• Marc-André Martineau, Premium Groupe Industriel;

• Ryan Long, A W Leil Cranes & Equipment;

• Thomas Moore, CRS Crane Systems Inc.;

• Jordan Friesen, DeKoning Innovations / IRONCO Enterprises;

• Will Robinson, Easy Green Yard;

• Jordan Couse, National Crane Services Incorporated;

• Michael Demelo, Oxford Builders Supplies;

• Manbir Bharj, Guelph, Ont.;

• Jamie MacKinnon, Sling Choker;

• Mike Ryane, Premier Crane & Services Ltd.;

• Sabrina Christie, Phoenix Truck & Crane;

• James Kampen, Leavitt Cranes;

• Claire Gjertsen, Kristian Electric Ltd.;

• Derek Rauch, Vertical Crane;

• Roland Noestler, Liebherr; and

• Steve Parr, Atlas Polar Company Ltd.

Here are a few of the many excellent submissions that arrived – thank you everyone!

When: 6/9/2022

Where: Burnaby B.C.

Project: 56-storey residential tower by Concord Pacific

Model: 2021 Liebherr 280 HC-L 12/24

Where: Alberta

Project: All Terrain getting ready to head out on a job

Model: LTM1400

Marc-André Martineau of Premium Groupe Industriel

Where: Chibougamau, Que.

Project: Chantiers Chibougamau plant

Ryan Long, A W Leil Cranes & Equipment

When: May 2022

Where: Trans Canada Hwy Rte 104, near Middle Brook, N.S.

Project: Lifting bridge girders for a new a bridge as a part of the highway twinning project

Model: 660T Demag CC2800NT Crawler Crane

Thomas Moore, CRS Crane Systems Inc.

When: 12/22/2016

Where: Northern B.C.

Project: Mining project in Northern British Columbia

Model: 15 Tonne 28 m span with standby heaters

Thomas Moore, CRS Crane Systems Inc.

When: 7/15/2014

Where: British Columbia

Project: Overhead crane supplied to a shipbuilding facility in B.C.

Model: 15 Tonne 64 foot span

Thomas Moore, CRS Crane Systems Inc.

When: 12/10/2016

Where: Southern United States

Project: Mining project in the southern U.S. Model: 10 Ton 29 foot span gantry crane

Jordan Friesen, DeKoning Innovations / IRONCO Enterprises

When: 4/6/2022

Where: Detroit, Mich.

Project: The crew pictured is using a 12 Ton lifting bridle, to efficiently offload prefabricated walls at a construction site. The I-Lift Lifting Bridle is designed, and manufactured at IRONCO Enterprises near Neepawa, Man. The customer was Ennova Facades Inc, and Contract Glaziers, near Windsor Ont.

Model: I-Lift 12 Ton Lifting Bridle

Will Robinson, Easy Green Yard

When: 5/3/2022

Where: Oliver, B.C.

Project: Soil delivery using cubic yard bags (bulk bags) below a finished rock wall on the shore of Tuc-el-nuit, Lake Oliver, B.C.

Model: HIAB 200C

Jordan Couse, National Crane Services Incorporated

When: 3/23/2021

Where: P&H Moosomin, Sask.

Project: Replacing a motor.

Model: Gmk135

Michael Demelo, Oxford Builders Supplies

When: 10/28/2019

Where: Toronto, Ont.

Project: It was construction of the commercial tower at 81 Bay Street in Toronto.

Model: Climb CTL630 Crane

Manbir Bharj

When: 5/6/2022

Where: Guelph, Ont.

Project: Hoisting panels onto the side of a building for a construction company on Highway 6 in Guelph, Ont.

Model: 30 ton boom truck

Jamie MacKinnon, Sling Choker

When: 2/16/2016

Where: On site

Project: Regular maintenance.

Mike Ryane, Premier Crane & Services Ltd.

When: 6/7/2022

Where: Vancouver, B.C.

Project: Building a greenway on top of a high rise building downtown Vancouver.

Model: Manitex 50155SHL

Sabrina Christie, Phoenix Truck & Crane

When: 5/26/2022

Where: Vancouver, B.C.

Project: Installing massive pieces of glasses to a brand-new building on Alberni Street in downtown Vancouver. We were there with our 165 Ton Hydraulic crane for over three weeks, used glass cup that no one had ever used before and will need to go back for more.

Model: Groove GMK 5165

Sabrina Christie, Phoenix Truck & Crane

When: 3/26/2022

Where: Langley, B.C.

Project: Installing a new outdoor sign at Willowbrook Mall.

Model: 30-ton Stiff Boom (National Crane)

James

Kampen, Leavitt Cranes

When: 7/9/2022

Where: The Leavitt Cranes yard

Project: We just received delivery of our new Jekko SPX1280. Our technicians are nothing if not thorough. They always read the manual first!

Model: Jekko SPX 1280

Claire Gjertsen, Kristian Electric Ltd.

When: 3/16/2022

Where: Edmonton, Alta.

Project: This project features the installation of overhead crane safety lights on a 5 Ton Overhead Bridge Crane. Crane safety lights alert workers in the area of the position of the overhead crane and are a low-cost method to prevent worker injury and equipment damage caused by suspended loads.

Model: KEL Crane Safety Light

Sabrina Christie, Phoenix Truck & Crane

When: 11/19/2019

Where: Under the Granville Bridge

Project: It’s hard to believe that it’s been 7

years since Vancouver city council approved the project to install a $1.2 million chandelier under the Granville Street Bridge – but now having witnessed the result, we know it was worth the wait! Commissioned by developer Westbank Corporation, this impressive piece, measuring fourteen feet by twenty-one feet is an 18th century replica and was created by Vancouver artist Rodney Graham. We sent our unit 5160 to hoist and install this beautiful 7,500-pound piece of art, made of stainless steel, LED Lamps and faux crystals.

Model: Copma 1600.8

Derek Rauch, Vertical Crane

When: 11/6/2019

Where: Alberta

Project: The demolition and removal of an outdated doppler radar station.

Model: Grove - TMS 9000E

Roland Noestler, Liebherr

Where: Toronto

Project: A 130to Liebherr crawler crane is doing shaft excavation for a micro tunnel project in Toronto with the local company Ward and Burke.

Model: LR 1130.1

When: 2018

Where: Ontario

Project: Residential construction is booming! Everywhere you look, truck-mounted cranes are hard at work on job sites in urban and rural areas coast to-coast. Drywall is an integral load delivery for all of them. Specialty truck-mounted cranes like this HIAB 265K-3 are purpose-designed for precise building materials delivery in tight spaces and perfectly suited for this picture-perfect garden setting.

Model: HIAB 265K-3

Steve Parr, Atlas Polar Company Ltd.

When: 2015

Where: Montreal, Que.

Project: This soaring image of a HIABHIAB XS 211EP-5 crane stationery mount was taken while renovation work was underway on the Saint-Sauveur Church, on the corner of Viger and Saint-Denis streets in Montreal.

The HIAB transformed the 1865 stone facings of this once proud church to become the face of the Centre Hospitalier de ‘Université de Montréal (CHUM). Maneuvering a large crane surrounded by soaring towers and acres of glass, with pedestrians below, is an increasing sight in big city centres. Working storeys up on a historic building takes those challenges to new levels, requiring absolute precision and safety.

Model: HIABHIAB XS 211EP-5

Editor’s note: While we couldn’t include all the photos that were submitted, we will be posting them online - and we thank you once again!

Tadano telescopic boom crawler cranes offer full load chart pick-and-carry, quick setup, auto-switching load charts and superior travel performance. These versatile machines - perfect for infrastructure, heavy civil and energy projects - maximize productivity on confined job sites or challenging terrain, and provide reliable performance in challenging conditions.

Operators and owners now can view real-time crane information, receive alerts and exchange data By Don Horne

Manitowoc continues its expansion and investment in support services with the launch of CONNECT, a new digital platform that will make its debut at bauma 2022 in October.

The platform enables remote monitoring through an app-based system that gives owners and operators the ability to view real-time crane information, receive alerts, exchange data, and more with further functionality to be added in the future.

The CONNECT platform, with its wide-ranging capabilities, will advance fleet management, boost sustainability, streamline service and maintenance for users, and improve connectivity to cranes with the easy-to-use platform working across smartphones, tablets, and laptops, according to Manitowoc.

“The launch of CONNECT kickstarts a new digital era of owning and operating Manitowoc cranes. In a matter of seconds,

users can access a range of features or data related to their cranes through the appbased platform,” says Dirk Wolfsteller, vice president of Aftermarket for Grove in Europe. “They can analyze performance, check service gauges, diagnose faults, and more. It allows unprecedented insight into their cranes, transforming performance, sustainability, and ultimately profitability linked to their investments.”

The new platform will be phased in, initially on Potain tower cranes and Grove all-terrain cranes. The Company plans to add other product lines and brands in due course. CONNECT delivers an optimized user experience, assisting with set-up, simplifying maintenance, providing driver assistance systems, and more. Owners get real-time access to services and information with just a couple of taps on a screen.

For Grove, CONNECT will initially be available on GMK all-terrain cranes pro-

duced from 2023. It will be offered on all new models and available to retrofit on cranes equipped with the CCS control system.

Benefits include optimized troubleshooting thanks to the real-time availability of crane information. This allows remote technicians to quickly understand the status of the crane, with any error codes displayed through the app. The remote service team can then run root cause analysis and propose potential solutions without the delay of travel or on-site physical assistance.

With simplified and expanded insight into fleet usage, crane owners can adjust their operations to make optimum use of resources or strengthen preventative maintenance programs. A further benefit is the ability to help customers meet their broader sustainability goals. CONNECT’s functionality means that onsite trips to check cranes are reduced as more of this will happen remotely. Improved data ac-

cess also means that any necessary visits are optimized.

Finally, there is much less need for printed documentation as this can be accessed more easily in digital format.

“Grove crane owners can harness the power of data through CONNECT to better understand performance and maximize the return on their investment,” says Patrick Stelter, product manager for all-terrain cranes at Manitowoc. “For so many of our clients, their overall business goals are tied to issues like sustainability, digitalization, and connectivity. With CONNECT they can now advance those goals and reap the benefits.”

For Potain tower cranes, CONNECT will be offered as an option on new top-slewing and self-erecting cranes. In addition, it can be retrofitted on all CCS-equipped cranes. With extensive capabilities available through CONNECT, Potain will discontinue production of its older CraneSTAR Diag tool.

The user-friendly CONNECT solution offers seamless integration between remote diagnostics, advanced analytics, and fleet management to help owners significantly increase fleet utilization while increasing uptime. On the jobsite, technicians and others can use local Wifi to link to the crane via CONNECT. This allows them to easily see the operating system and review performance data.

In the future, Manitowoc plans to enable CONNECT to be embedded into the BIM (Building Information Management) model for a project and allow the creation of digital twins of the crane. This functionality will deliver better optimization, site planning, monitoring, and materials flow on the jobsite, boosting building speed and quality.

As with Grove GMK cranes, Potain owners with CONNECT will enjoy increased utilization through better preventative maintenance. Customers’ sustainability goals are improved too, through the extended service life of cranes that should come through better management.

“CONNECT advances how contractors and rental companies will use tower cranes on jobsites. The platform improves the user experience immediately and opens a world of exciting possibilities in the future,” says Xavier Claeys, director of digital innovation for tower cranes at Manitowoc. “For example, customers can compare expected use versus actual use, with the potential to reframe how pricing and operational models are run. This insight simply wasn’t available before, but we expect it to positively transform how customers approach crane ownership. We’re excited to showcase the new technology at bauma 2022.”

By Andrew Klukas, Path4ward Initiatives Inc.

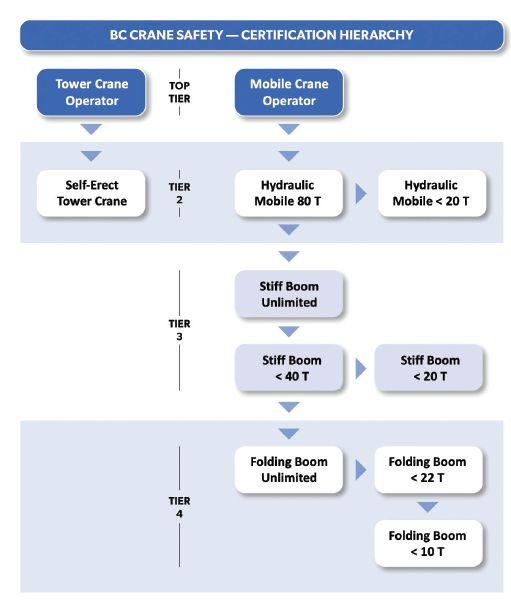

British Columbia’s crane operator certification program addresses in a unique way some of the traditional arguments against compulsory certification.

If a trade is compulsory all work performed must be done by a credentialled journeyperson or indentured apprentice. Historically, this has meant that employers and workers are limited to a single established credentialling process and must keep job roles strictly defined. Credentials have traditionally been tied to hours of experience on the job.

BC Crane Safety’s crane operator certification program is compulsory because WorkSafeBC regulations require that all operators have a credential be certified.

Many employers argue against compulsory trades on the grounds that the heavy up-front commitment of time and money reduces the number of entrants to the trades. Meanwhile, some journeypersons end up performing tasks for which they are overqualified. This is inefficient. The result is fewer people working in the trades and those that do are less productive than they could be.

Is it possible to have compulsory credentials, increased participation, and improved productivity? We think so. A paper

recently prepared for BC Crane Safety argues that, under the right circumstances, it can.

Says Clinton Connell, BC Crane Safety’s Executive Director, “The key to success is to have a certification model that focuses on evaluating people’s competencies instead of relying too heavily on time in trade, or ‘seat time.’

Traditional certification programs that rely heavily on time in trade as an indicator of ability can be problematic in both slow and hot economies.

In a slow economy, a new operator may not get as many opportunities to learn and gain experience on the job. Since time in trade is not clearly defined in Canada it is often calculated in terms of payroll hours and can therefore include other unrelated activities. In this scenario, a candidate can earn their time but still lack some essential competencies. Competency-based models are more responsive to economic conditions and don’t allow this outcome.

In a hot economy there may be ample opportunities to gain needed experience, but formal training requirements can cause delays in obtaining full certification. A competency-based model avoids this outcome as well.

Let’s look at this more closely.

Competency can be described as the ability to meet essential standards of performance for an occupation. When competency is measured against established standards, it can be directly recognized and rewarded. How or where people acquire those competencies –whether it was from formal training, informal learning or experience in related jobs – is less important than the fact that they have them.

Says Connell, “No recruiter needs to confirm whether professional hockey players know how to tie their skates. The ability to put a puck in the net during the game incorporates the relevant competencies without having to test for every detail that contributes to a successful performance.”

This is the kind of assessment process BC Crane Safety and its stakeholders chose for crane operator certification. Candidates have to demonstrate their competence by successfully completing practical assessments that are administered by independent, professional assessors in real-world settings.

Equally important, employers have the responsibility under the Occupational Health and Safety Regulation to ensure their candidates are ready to work independently before they challenge the practical assessment. After a period of on-the-job training operators can challenge the assessments when they and their employers believe they are ready.

Says Connell, “The program has safely expedited the certification process while widening the talent pool and also supporting diversity and inclusion.”

Since operators in training must work under the supervision of an employer, their initial choice of crane is guided by prevailing market conditions as they can only train on cranes that are in commercial use at that time and place. Yet depending on industrial needs in a given region, operators may eventually gain access to their cranes of choice and begin preparing to earn a higher level of certification by challenging the practical assessment on these cranes.

BC Crane Safety’s certification model is tiered and allows people to enter at various levels. Those who choose to certify

at the top tier of the mobile crane class will also be certified to operate any mobile crane or boom truck. Those who choose to certify to operate a boom truck with unlimited capacity will also qualify to operate lower capacity cranes in that class.

Operators are not required to demonstrate competencies they don’t need and can look forward to becoming certified on their crane of choice in a relatively short period of time. The amount of time it takes depends on their individual abilities and the type of crane they are going to operate.

“Most new operators start their careers on cranes in the lower tiers,” says Connell, “but one of the advantages of the tiered system is that operators can gain experience on the job and eventually certify on more specialized cranes by challenging the assessment.”

Conclusion

The identification and applica-

tion of clear standards of competence is a truly reliable way of ensuring that certificate holders have the skills to work according to expectations for quality and safety.

Because it is competency-based, BC Crane Safety’s certification program does not overburden candidates with requirements that don’t apply to them in their work. Candidates who fail to pass the theory or practical tests on more specialized cranes are not lost to industry but can work at the level of their certification until conditions and/or their skills allow them to advance.

This certification model and its development merits consideration by other trades and professions at a time when all are facing growing skills shortages.

Visit www.bccranesafety.ca to read the full paper

Contact: Path4ward@protonmail.com

By George Koch

“The Paramount has been one of the highlights of my career,” says Mike Wurm, Senior Construction Manager with Keltic (Canada) Developments Ltd. “I cannot think of any other project in the Vancouver market that met its schedule this well during this recent challenging period.”

Wurm is speaking of the nearly 600-unit, four-tower mixed-use development in the heart of Richmond, B.C. that was conceived and led by Vancouver-based Keltic and was recently completed and conveyed to strata owners. Being on budget, ahead of schedule and fully sold out, and with a satisfied municipal government, adds up to clear success.

The success of The Paramount, which was initiated in 2017, hinged on careful coordination among the key parties – owner, designer and builder, plus the city, consultants and subcontractors – continuous collaboration and significant use of early contractor involvement. The complex project’s financial viability required not

only maintaining but advancing the schedule from the original target of May 2022, to a phased occupancy approach with Phase I being turned over in October 2021. Achieving Keltic’s vision within budget required value engineering and serious decision-making regarding architectural features and materials. Building in the sea-level environment required strong technical skills. And keeping everything going amidst pandemic constraints followed by intensifying supply chain issues required expert project management and coordination of subcontractors and trades.

The Paramount comprises three 15-storey residential towers totaling 533 for-sale units plus 27 low-income market rental units, a 12-storey office tower and multiple retail units at ground level, built atop a four-level parkade (two below-grade and two abovegrade) totaling 618 stalls, with a gross floor area of 625,000 square feet, all finished to LEED Silver equivalent. The residential units were done at a mid/high-level of design and decor. Notable additional features include a state-of-the-art, $13 million, LEED Gold, 19,000-square-foot early childhood development hub that Keltic donated to the City of Richmond, a large courtyard, a district heating and energy distribution hub, and a spectacular back-painted glass art installation spanning six storeys by Indigenous artist Thomas Cannell of the Musqueam First Nations.

Meeting schedule on The Paramount was a top concern for Keltic in seeking a builder, says Wurm. Graham was selected through negotiation as general contractor for the stipulated sum, $267 million contract. Keltic wanted a partner and regarded one of Graham’s foremost strengths as bringing the sophisticated processes and risk management characteristic of commercial and industrial construction to the residential world. Wurm had grown familiar over his 30-year career in construction with some of these differences. And, he says, it showed. “Midway through the first year of construction, COVID hit,” Wurm recalls. “We didn’t lose anything off the schedule, we worked right through it, and that’s a testament to Graham, how well they staffed their team, and all their subcontractors.” These strengths proved critical when, in March 2020, the schedule was advanced.

Early contractor involvement (ECI) aims to improve process efficiencies and project outcomes by leveraging the builder’s expertise and experience to recognize and resolve construction-related problems before materials have been procured or things have been built. “ECI is a fantastic element because it allows the contractor to get ahead of the curve and mitigate a lot of the problems that could come up during actual construction. By getting the contractor in early, there are fewer surprises,” says Wurm. ECI demonstrated its efficacy in this project. Keltic was so pleased with its benefits, Wurm notes, that Graham is now undertaking ECI on another Keltic project.

Graham’s input on The Paramount was sought when design was at approximately 30 per cent, or still largely conceptual. With its location at Richmond’s main No. 3 Road and Cook Street intersection, across from City Hall and at the terminus of the new elevated CanadaLine LRT, the project’s design team had been “tasked with doing a landmark building, something really memorable, something the city could be proud of,” recalls Amela Brudar, a Principal at GBL Architects. Leaning glass with a dramatic “inward cut” became the office tower’s most prominent aesthetic element, while the residential and retail sections had a number of other features.

“There are different opinions about ECI in the design sector, even within firms, but from my personal experience I think ECI is very valuable, because you are designing with your budget in mind, and there are checks and balances to make sure the things that need to be executed are vetted, and you are working with a contractor who knows the materials and the processes,” says Brudar. “I always suggest this to my clients, from the permitting onward, having the contractor at the table and checking the drawings.” Brudar focuses especially on “the integration of the design with the mechanical and electrical, where we run into the most problems.”

“We were engaged nearly two years before construction was to start, through the Presentation Centre and the demolition and enabling works contract, and this helped us work early on the overall project budget to match expectations with what was realistically achievable and also with what would sell in the Vancouver market,” recalls Jordan Hood, Graham’s Senior

Operations Manager on The Paramount project. Graham’s preconstruction work on several other area projects provided useful insight into market dynamics.

Graham’s ECI effort included 3D pre-modelling to create a constructability methodology, making sure that drawings encompassed all construction issues, and numerous meetings to identify clashes and resolve problems. “The project was highly collaborative among everyone involved,” notes James Cassano, a Senior Project

Manager at Graham. Among other benefits of this approach was generating the confidence needed to start early procurement and stockpile materials nearby, which in turn helped keep construction on schedule.

Perhaps the most important issue ECI raised – and emblematic of the close cooperation that the Keltic-GBL-Graham trio of teams was able to forge – concerned the balcony partitions on the three residential towers. While Keltic had its heart set on achieving a very high-end building, GBL had grown concerned about a mismatch between expectations and likely costs. Graham determined that the envisioned thick balcony partitions, to be clad in very high-end aluminum products, were simply not achievable.

Combining its deep experience, extensive supplier network and value engineering, Graham developed an alternative that was less costly and simpler to execute while maintaining acceptable aesthetics. A subcontractor proposed using prefabricated, stand-alone honeycomb sandwich panels, delivering the required privacy with adequate structural rigidity while dispensing with a heavy wall structure of steel framing and backing. “This saved a

huge amount of labour and cost, many millions of dollars,” notes Hood. “But we did this collaboratively, presenting the design team and client with mockups to consider, rather than just stripping the project of its aesthetics, and thereby finding lower-cost alternatives that still look good and work well.” Brudar agrees. “It was a great team,” she recalls. “We remained friends all along, even when we were disagreeing.”

Before main construction could begin, extensive geotechnical work was required, and Graham also constructed enabling works, including an innovative deep soil mixing (DSM) water cut-off perimeter wall. The City of Richmond is only 1 metre (3 ft.) above sea-level, generating immense hydrostatic pressure in any deep excavation. This system used drilled concrete columns, greatly reducing the amount of seepage and pumping required during construction.

The key challenge during the course of construction itself became advancing the completion date and switching to a phased occupancy. “We needed a multitude of different ideas to accelerate the schedule, amidst COVID, and we needed to get everyone onboard and coming up with smart ideas to do that,” says Cassano. Graham installed a third tower crane, used a separate yard for off-site re-bar assembly to ensure that the concrete teams worked without interruption, hired a logistics software company to synchronize delivery of materials with the use of tower cranes and hoists, and used a new product that provides real-time monitoring of concrete curing, enabling removal of shoring sooner than under the traditional set-time approach.

“Our whole flow mid-way through construction had to change, the tower that had been deemed least priority became first

priority half-way through construction,” recalls Hood. Key to making it all work, says Hood: “We were a cohesive team that was willing to pitch in and meet all the challenges that were thrown at us. We had a fantastic relationship with the client and architects, and this drew everyone in to work collaboratively and deliver on some of the aggressive asks.” Hood praises Keltic for “Fully jumping in and helping wherever they could to achieve their goals.” Among Keltic’s contributions were paying for overtime and renting the aforementioned rebar pre-fabrication yard.

Today, with The Paramount sold out and in full operation, Keltic and GBL look back on the project with great satisfaction. “It was a very positive experience with Graham, and I can’t emphasize that enough, especially because that is not all that common between architects and construction companies,” says Brudar. “They’re well organized, everything we needed to do our job in terms of submissions, they had when we needed, on a very complex project. In terms of execution, it was a very competently run site and an outstanding performance on Graham’s part.”

Adds Wurm: “From a management standpoint the greatest strength of Graham is the agency the company instills in every employee to make things part of their responsibility, to go out and seek solutions to problems, and not let the issue go until they have a solution that benefits the project.”

By Don Horne

Crane and Hoist Canada magazine sat down with Phoenix Truck & Crane’s Vice President Trevor Dick and took the temperature of the current market. Here we dived into how Phoenix dealt with – and are still dealing with – COVID, the current rate of inflation and fuel prices, and how we should reconsider just what we call ‘mini cranes’ here at the magazine, as at Phoenix, they would rather that we refer to it as ‘the mighty crane’ industry.

CHC: COVID hit everyone hard, and it is hard to believe it hung around for two years. What was it like for your staff, and what measures did you take that helped?

Trevor Dick: COVID-19 has indeed affected all of us and Phoenix Truck & Crane had to develop its own COVID-19 Safety Plan which was followed very thoroughly by all our office staff, owner operators and employed crane operators.

We are very lucky to have devoted and dedicated employees, so even though the pandemic has been very difficult on everyone, they stuck by us, they followed our lead, they remained positive and most importantly they adapted to all the changes we had to made and were very open and thankful for it.

We took so many measures to help everyone adjust to the ‘new normal’ back then that it would be hard to list them all, but the main measures that brought us success were clear and ongoing communication with all our personal and trust.

Construction sites are humming again. What is the state of crane rentals right now?

TD: With no shutdowns to job-

sites in B.C during the pandemic, we maintained our workflow and employee base throughout. The construction industry in Vancouver specifically continues to thrive, which keeps our team busy with jobsite assessments and crane rentals.

What new challenges do you see facing the crane rental sector in the months to come?

TD: Retaining drivers and crane operators is our biggest challenge right now, and this isn’t due to COVID-19. Inflation and price of fuel is just one thing that has brought a challenge for our industry.

What new technologies, safety measures have been working well?

TD: Our dispatch and invoicing went paperless this past year which eliminated unnecessary contact or closeness. As a COR-certified company, our safety measures have always been top priorities and are working well for us, with:

• regular maintenance checks

• controlling and reducing risks by identifying any hazards

• by appointing a dedicated Health & Safety Officer

• by providing ongoing training and support to our team

Where is the demand for cranes these days?

TD: Despite the supply chain struggles with shortage of plumbing supplies, lumber, high end products like stones, tiles etc. the demand is still here and high for crane work. We also found ourselves extremely busy with hoisting and placing hot tubs and swim spas.

Is the demand healthy?

TD: It sure is and our clients are staying optimistic.

- Self-Rigging Auxiliary Hoist & Removable Rea r Outrigger Box Allows for Faster Set up & Increases Productivity

- Patented Self-Rigging MegaWingLift System

-297,500 Lb Counterweight with Hydraulic Removal System

-MAXbase Variable Positioning Outriggers Increases Flexibility

-MEGATRAK Suspension System with MegaDrive Hybrid Drive System Impro ve s Traction and Acceleration Speeds

-20 Degree Tiltable Cab with Crane Control System

Mi-Jack Canada is your authorized Manitowoc® and Grove® Distributor in Alberta & Saskatchewan. New and used sales, rental purchase options, unsurpassed customer support, and factory-trained service technicians. As part of the Lanco Equipment Group, Mi-Jack Canada is part of the world’s largest Manitowoc dealer group, and North America’s largest parts inventory, all on-hand and ready to ship.