Mini cranes report p.16 Ontario seeks to overhaul safety rules for tower cranes p.20

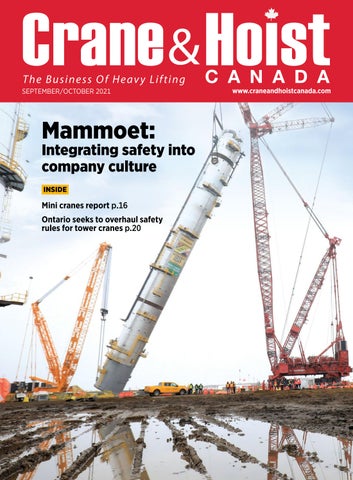

Mammoet

A

FROM THE EDITOR

BY ANDREW SNOOK

Mini cranes report p.16 Ontario seeks to overhaul safety rules for tower cranes p.20

Mammoet

A

BY ANDREW SNOOK

Does the recent rash of accidents call for nationwide action?

Ihave no doubt that the overwhelming majority of professionals in the heavy lifting industry place safety as a top priority over almost everything else.

That said, the recent rash of tower crane collapses is a major concern, and it calls for major action to be taken.

There have been tower crane collapses written about in several major cities from coast to coast across Canada over the past 24 months, including most recently, the tragic collapse of a tower crane in Kelowna, B.C., which resulted in the loss of five lives (additional information about the accident can be found on p. 18 of this issue).

While this accident is still under investigation, the likely causes determined for several of the more recent tower crane collapses by provincial safety authorities have included improper disassembly procedures and welding failures.

In response to these accidents, some cities and provinces have stepped up to push for further guidelines and rules related to the assembly, disassembly and operation of tower cranes.

In Vancouver, BC Crane Safety, WorkSafeBC, the IOUE and other industry representatives worked together to revise the current assembly/disassembly checklist to make completion of the list not only mandatory, but to also better coordinate street usage needs such as: street closures; traffic control; pre-planning operations and responsibilities; and discussion of issues like being how to better keep workers safe during assembly process, some cities not allowing road closures, and not

being able to take cranes down during reasonable hours.

Operating as a pilot project within the City of Vancouver, this new Tower/SelfErect Crane Pre-Assembly Requirements Checklist has been set up to accompany permit applications (for more information, check the cover story for Crane & Hoist Canada’s July/August 2021 issue).

Under its Occupational Health and Safety Act (OHSA), the Province of Ontario is currently looking at modernizing and clarifying the existing requirements relating to the use of tower cranes. The proposed changes are wide-reaching and include 20 recommendations across six areas (For more on this story, turn to page 20).

While tower cranes are obviously not the only types of cranes that require a strict focus on safety, the nature of their use for heavy lifting applications in highly populated urban areas for the construction of condominiums and skyscrapers does add additional potential for danger to workers and the people walking around the streets below and working in adjacent buildings.

I tip my hat to all the municipalities, safety associations and industry professionals across the country that are working hard to improve the guidelines and rules for assembly, disassembly and operation of tower cranes.

That said, would nationwide rules and guidance for the assembly, disassembly and operation of tower cranes be at all helpful? Email me at: asnook@annexbusinessmedia.com. I’d love to hear your thoughts. Stay safe out there.

Reader Service

Print and digital subscription inquiries or changes, please contact Urszula Grzyb,

Audience Development Manager

Tel: (416) 510-5180

Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

INTERIM EDITOR | ANDREW SNOOK asnook@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER | LAURA GOODWIN lgoodwin@annexbusinessmedia.com • 289-928-8543

MEDIA DESIGNER | SVETLANA AVRUTIN savrutin@annexbusinessmedia.com

ACCOUNT COORDINATOR | KATHRYN NYENHUIS knyenhuis@annexbusinessmedia.com

REGULAR CONTRIBUTORS

Saul Chernos, Matt Jones, Judy Mellott-Green

GROUP PUBLISHER | TODD HUMBER thumber@annexbusinessmedia.com

COO | SCOTT JAMIESON sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues)

Canada: $37.00 + tax per yea • USA: $37.00 USD Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-5106875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT. 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

PRINTED IN CANADA ISSN 1923-788X Publications Mail Agreement #PM40065710

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

The contents of Crane & Hoist Canada are copyright ©2021 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Advertising Deadline: August 27, 2021 Don’t miss the opportunity to be part of this exciting new industry publication. For more information, or to reserve space in the next issue, call Laura Goodwin at our Advertising Department Tel: +1-289-928-8543 lgoodwin@annexbusinessmedia.com

Next Editorial Deadline: August 27, 2021 For writers’ guidelines and submission requirements get in touch with the editor, Andrew Snook, at asnook@annexbusinessmedia.com

MEMBER OF: MEDIA PARTNER: RANERENTALASSOCIATIONOFCAND AS TO A D D O

7

• Crane Control System (CCS)

• New wider full vision cab with 20° cab tilt

•

The global crane and hoist market is expected to grow from $26 billion in 2021 (all figures U.S.) to $33 billion by 2026, according to a forecast report from ResearchandMarkets.com.

It is expected to grow at a compound annual growth rate (CAGR) of 4.8 per cent from 2021 to 2026. The key factors driving the growth of the crane and hoist market are significant demand from the construction industry, expanding mining industry, increased use in the shipping industry.

The mobile cranes’ segment is expected to continue to hold a larger market size during the forecast period.

The growth of the mobile crane segment of the crane and hoist market can be attributed to their features such as high mobility, high traveling speed, and the requirement of less time to set them up on construction sites. The use of mobile cranes in the mining, construction, aerospace, shipping and material handling industries has gained popularity, where lifting and lowering activities require extensive displacements of objects, materials, or equipment.

The hydraulic operation segment is expected to continue to hold a larger market size during the forecast period.

The use of hydraulic technology ensures efficient use of energy and reduces the need for power.

Hydraulic cranes are widely used for hoisting and moving heavy materials in warehouses and industrial workshops. Moreover, hydraulic cranes are used in the transport, manufacturing, and construction industries. The retraction length of hydraulic cylinders is 20 per cent to 40 per cent of the fully extended length. Therefore, telescopic hydraulic cylinders are ideal for limited mounting space, and a long stroke is required. The use of hydraulic cranes is increasing owing to the space constraint in different

industries, such as construction and shipping & material handling, and assembly lines. The COVID-19 pandemic has affected the growth of the overall crane market, which has consequently hampered the growth of the hydraulic-operated crane market.

The construction industry is expected to hold the largest market size during the forecast period.

The construction industry has undergone substantial changes in recent years because of the global recession, which has led to the downsizing of the industry in developed markets. However, the investments regarding construction in most emerging markets have continued to grow at a moderate rate despite the global crisis.

Earth-moving equipment is mainly used for construction works such as digging the earth, lifting, loading and unloading weight, and leveling. Applications of cranes in earth-moving equipment include heavy loading, high cycle rating, and accurate movement.

The COVID-19 pandemic has affected the global construction industry by delayed projects and decreased investments in the infrastructure sector.

With the development of vaccination against COVID-19, the real estate and infrastructure projects across the globe are expected to slowly gain pace and lead to the growth of the construction industry. China has already launched the “New Infrastructure” campaign to offset the economic impact of the COVID-19 pandemic. These factors are expected to result in a high growth rate of the crane market for the construction industry.

The Asia-Pacific (APAC) region is expected to hold the largest share of the crane and hoist market during the forecast period.

APAC is the most rapidly growing market and offers high opportunities for the construction industry, which is driven by the growing population. Construction and material handling industries have boomed rapidly and consequently have driven the market for cranes in India, China, and Australia.

The growing awareness related to automation and the increasing emphasis of leading economies such as China and Japan on construction and material handling industries are some of the primary factors contributing to the largest market share of APAC.

Besides, the rapid growth of the automotive, construction, and aerospace and defense industries in emerging economies,

such as China and India, is also supporting the growth of the crane market in APAC.

The Ontario government is investing more than $3 million to create a virtual training hub that will help construction supervisors learn the skills they need to mentor and train their team.

The funding will also go toward the creation of an online job bank that will help up to 200 laid-off and unemployed workers find good jobs in construction.

“Construction workers build the houses we call home, the hospitals that care for us and the communities where we come together,” said Monte McNaughton, Minister of Labour, Training and Skills Development. “There is a growing demand for these skilled workers and our government is proud to invest helping more workers start and build their careers in this in-demand sector.”

This initiative will support Merit Ontario, an organization that supports contractors who employ both unionized and non-unionized workers, in developing and running a virtual training and resource hub that helps 225 small, medium and large construction companies bring their training programs online. The hub will also offer courses and resources to train supervisors so they can provide improved skills and safety training for their workers.

“On behalf of the hundreds of Merit Ontario members and thousands of employees in the construction sector across Ontario, we thank the Government of Ontario and Minister McNaughton for this historic investment in training,” said Mike Gallardo, President and CEO of Merit Ontario. “This funding will ensure that underrepresented communities can fully participate in training and be part of the jobs of the future. Jobs in the construction sector are in high demand and we must do everything we can as employers and governments to ensure we can meet that demand. This funding will go a long way in meeting that goal.”

In addition, the project will create an online job bank where employers who are looking for new talent in the construction sector will be able to post job ads. The job bank will also help job seekers assess their skills and recommend additional training where needed. It joins other resources, including the newly launched ConstructionJobSite.ca.

We believe in the power of integration. That is why at Strongco, a Nors Group Company, we take pride in offering industry-leading crane equipment, parts, service – and certification –all in one place. Our product line includes Manitowoc National and Grove cranes, the innovative Fassi machines, and global, leading Konecranes industrial lifting equipment.

No matter your crane needs, you can trust Strongco to deliver.

888 542-2202

This funding is part of the government’s $115-million Skills Development Fund to address hiring, training and retraining workers because of the COVID-19 pandemic.

The Manitowoc Company, a global manufacturer of cranes and lifting solutions, has entered into an agreement to acquire the crane business of H&E Equipment Services, one of the largest rental equipment companies in the U.S.

Under the terms of the agreement, Manitowoc is expected to pay about US$130 million funded by a combination of cash on hand and existing debt availability. The transaction is expected to close in the fourth quarter of 2021 and is subject to customary closing conditions and regulatory approvals.

The acquisition of H&E’s crane business will expand Manitowoc’s ability to provide rentals, new sales, used sales, aftermarket parts, and service to a variety of end market customers, it said in a press release. H&E’s crane business operates with 11 full-service branch locations.

“Over the past few quarters, we have communicated that our intent is to grow through four strategic priorities, one of which is acquisitions focused on aftermarket. The purchase of H&E’s crane business is the next step in our journey to grow the less cyclical part of our business. H&E has a long history and excellent reputation for serving the lifting

The Crane Rental Association of Canada is pleased to announce the appointment of Mark Danderfer as Chair of the Boom Dolly Research Committee (BDRC). Danderfer is president of Radius Crane & Rigging Inc. and has a long history in the crane rental industry.

Mark Danderfer began is career in the industry as a crane operator over 20 years ago and has invested a great deal of time on personal growth and skill development. He understands every single position to run a successful crane rental company from mainten-

industry, and we look forward to welcoming the H&E crane team to Manitowoc,” said Aaron H. Ravenscroft, president and CEO of The Manitowoc Company.

The New Brunswick government is partnering with employers, labour representatives and others to maximize employment and economic development opportunities expected to result from the Port Saint John modernization project.

“The modernization project is expected to significantly increase the demand for workers in the Saint John region in the very near future,” said Post-Secondary Education, Training and Labour Minister Trevor Holder.

The primary objectives of the workforce partnership are to develop and implement a recruitment and training strategy that supports and aligns with the needs of all potential employers associated with the Port of Saint John; and to develop and refine a

ance, through safety, human resources, and management. Further to serving on the Board of Directors of the CRAC, he is also a member of the Edmonton Executives Association and a director of the Nisku Business Association.

“I am honoured to have the opportunity to lead this committee and this initiative through the western provinces. A lot of work has been done by past Chair and committee members and I look forward to bringing all interested members back together as we plan for the year ahead” said Danderfer.

The Boom Dolly Research Committee has a three-pronged approach: Advocate for changes to provincial regulations; develop best practices and research technical solutions.

The Crane Rental Association of Canada’s members are crane rental companies, manufacturers and suppliers of cranes and equipment, and supplier of

workforce partnership model that targets and accelerates strategic workforce recruitment.

The provincial government has committed up to $450,000 through WorkingNB for the creation and operation of the partnership.

The workforce partnership will begin its work immediately and will be chaired by Allen Bodechon. Other members of the partnership include Envision Saint John: The Regional Growth Agency, employers, union representatives and the Saint John Learning Exchange.

“The International Longshoreman’s Association Local 273 is looking forward to the role that it will play within the workforce partnership to meet the future labour demands in the longshoring industry due to the modernization project attracting new business,” said Terry Wilson, local president of the International Longshoreman’s Association.

“A skilled workforce plays a critical role in growing the port and in advancing our business model at DP World Saint John,” said Matthew Leech, chief executive officer and managing director for DP World Americas.

“We are excited to be a part of this important workforce partnership and look forward to seeing how these highly trained workers help strengthen Port Saint John and the overall community.”

The Port Saint John modernization project is expected to be completed in 2023. It will expand cargo business and allow New Brunswick businesses to export and import more competitively.

services used in the specialty crane rental business in Canada.

On June 8, the CRAC hosted its CRAC Standard Terms & Conditions Webinar. This initiative was led by Gijs Verdeijen, a past Chairman of CRAC.

The webinar recording is available via YouTube at: https://youtu. be/41S04hjB94k.

CRAC launched its Member Portal in June. Association members now have access to a wealth of information, networking opportunities, calendar of events, and more. Each committee also has a workspace to share documentation and best practices. For more information, contact CRAC executive director Claire Bélanger-Parker at: Claire@crac-aclg.ca.

In an effort to add to our large range of below-the-hook lifting devices, Caldwell is proud to introduce the Dura-Mod Modular Spreader Beam. Our new product will come in a variety of sizes that allow the user to configure a spreader beam suitable for different projects and applications depending on the desired capacity and spread.

Lightweight in comparison to fixed/multiple point beams.

Easy to transport & store; single longest component is only 20’!

Two end units, drop links, and spreader sections make it fully customizable.

Distributors are able to keep them stocked, offering customers quick ship access to certified spreaders.

World-renowned Caldwell brand name on a modular spreader system.

Components can be added and bought separately; take what you need now, add later!

Dura-Mod can be used with corner fittings to create box and rectangular configurations

All of the Dura-Mod spreaders conform to ASME B30.20, BTH-1, DESIGN CATEGORY B, CLASS 0.

For additional Dura-Mod information, contact Caldwell or scan the QR code!

While much was made of how the clean up and removal dragged on for weeks after the 2019 tower crane collapse in Halifax, the legal proceedings resulting from the collapse could drag on much longer. As the construction company’s lawsuit against the owner and operator of the crane continues, business owners impacted by the collapse have shifted strategies from a class action lawsuit to a mass tort.

The lawsuit filed by Fares Construction and W.M. Fares Family Inc. against Lead Structural Formwork alleges that the crane “had

suffered from a variety of structural defects which included, without limitation, rust, corrosion, breaks, splits and cracks in the steel components intended to give it its vertical, compressive, tensile, and torsional structural integrities, and broken, cracked, and deficient welds in those same steel components.”

Lead Structural Formwork’s defense stated that the company had followed instructions from the Fares companies and accused them of contributing to the collapse through negligence, the design of the apartment complex itself and that the crane needing to be at such a high elevation exposed it to stronger winds.

The Nova Scotia Department of Labour’s investigation determined that welding failure was the likely cause of the collapse.

Attorney Ray Wagner, who is representing the affected businesses in their suit, says the decision to move to a mass tort was made as new potential defendants emerged, including engineering firms that had been involved.

In a mass tort, all plaintiffs, often from the same geographic area, are still treated as separate individuals, as opposed to class action suits where all members are treated as one plaintiff. Wagner notes that while his plaintiffs may be involved as part of discoveries, document disclosure and other functions, moving to a mass tort likely puts their suit in a secondary position to the suit between the construction and crane companies.

“There are other, bigger players, in terms of their finances, and that will likely be taking more of a lead,” says Wagner. “We’re not dropping the litigation, but we probably won’t be leading it as we started to appear to be when we were doing the class action.”

Michael Smith, co-owner of Twiggz shoe store and one of the plaintiffs in the mass tort, says that businesses like his were left with little support following the incident. Business interruption insurance, he says, was unhelpful due to the technicality that the crane had fallen on another building even though owners and customers were unable to access their businesses for some time.

“It turns out, none of this was covered,” says Smith. “What we got was a percentage of our profits, but its not profits I care about, its operating costs – power, labour, rent, the cost of goods.”

Smith says this incident should drive a conversation with the government about supports for businesses in such situations, such as a bond that could be used to support smaller companies in the interim.

“We need a cleaner mechanism,” says Smith. “We can’t allow this big Hunger Games-like legal battle at the back end. That’s not how it has to be. That just marginalizes the most vulnerable of the group. The last to get paid and they have the least means to litigate. If that’s what we’re going to do, it’s not a fair and balanced society if it comes down to rights for the mighty.”

Smith noted the possible need for a review of standards for how and where cranes are erected, as tall towers in Halifax can create a wind tunnel where wind speeds are greatly increased. Smith was also critical of Mayor Mike Savage’s response to the incident, noting that he had never visited with the impacted businesses.

“You’d think by talking to business owners, you may have learned something about how complex recovery efforts work, which could have made you more aware of how to prod your bureaucracy to do better. There’s the Halifax Wanderers soccer club, any time they want to do promotion the Mayor is on camera wearing their shirt. But a crane falls and nearly kills people and destroys businesses and livelihoods? Nothing. He’s a great mayor but no one is perfect. You’ve got to do the work.”

The office of Mayor Savage did not respond to a request for comment.

By Saul Chernos

When tragedy occurs in crane operations, it’s only common sense to think about lessons learned in order to prevent reoccurrences – after a respectful period of time has passed, of course. But can good ideas be gleaned from operations that are recognized as safe year in and year out?

Mammoet Canada Western received its fourth consecutive Crane Rental Association of Canada Safety Award in June, cited for outstanding safety standards. Mammoet was among 14 companies receiving the award for 2020. The list also includes ABCO Crane Services, Amherst Crane Rentals, Canlift Crane, Canadian Crane Rentals, Canuck Concrete Pumping & Crane, Energy Crane Service, Irving Equipment, Myshak Crane & Rigging, Myshak Sales & Rentals, NCSG Crane & Heavy Haul Services, Radius Crane & Rigging, RKM Services, and Sterling Crane.

“The Safety Awards support our work for a stronger, safer industry,” says CRAC executive director Claire Bélanger-Parker. “Small and large companies can apply for an award as long as they meet the criteria set forth by our awards committee.”

Nominees are asked for Worker Compensation Board reports and other safety related data, including claims for damage. Companies experiencing even one fatality in a given year are ineligible, and serious property damage incidents can also disqualify a company.

Gijs Verdeijen, vice-president and general manager for Mammoet Canada Western, and 2019-2020 chair of CRAC’s board of directors, called the recognition an honour and issued a statement noting that company personnel across the region worked under especially challenging conditions last year. He praised them “for planning and executing each and every job with their and their colleagues’ safety at the forefront.”

Marie Aitken, who manages safety, health, environment and quality — known internally as SHE-Q — for Mammoet Canada Western, told Crane & Hoist Canada that the key to creating a company-wide culture of safety is making safety the cornerstone of all operations rather than relegating it to a program or department.

SHE-Q is highly involved in everything, whether it’s sales meetings, operational meetings, branch management meetings or HR, Aitken says.

“SHE-Q is not just the subcategory of a department that only goes out to the field. Our field staff are the ones who have to work with our policies and procedures, and if those aren’t relevant and aren’t working, we have an open door, open-ended conversation.”

Mammoet Canada Western’s territory includes British Columbia, Alberta, Saskatchewan, Manitoba and the Yukon, with additional responsibilities in parts of the U.S., including the Dakotas, and Aitken’s SHE-Q team has a hand in pre-bid packages, visits job sites, checks in on programs, addresses concerns that arise, and conducts regular audits to maintain core operating certificates.

Of course, on any job site, Mammoet is just part of an overall equation. Any kind of incident could potentially be attributed in whole or in part to the actions or directions of a client or fellow contractor.

Mi-Jack Canada is your authorized Manitowoc® and Grove® Distributor in Alberta & Saskatchewan. New and used sales, rental purchase options, unsurpassed customer support, and factory-trained service technicians. As part of the Lanco Equipment Group, Mi-Jack Canada is part of the world’s largest Manitowoc dealer group, and North America’s largest parts inventory, all on-hand and ready to ship.

AUTHORIZED DISTRIBUTOR IN-STOCK FOR IMMEDIATE AVAILABILITY

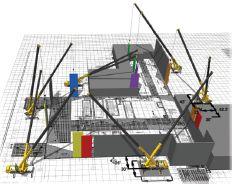

“You get into positions where clients say they want something moved or lifted, and it’s never been done before and can be challenging to do safely,” Aitken says. “You’re lifting or transporting massive items that can be complex and diverse, and this requires a lot of teamwork. It requires a lot of input that has to be streamlined, it has to be direct, it has to get out to the field in a proper manner, and the field has to agree with it and be able to work with whatever we’re doing.”

Mammoet likes to take on difficult, highly unique projects, which requires meticulous planning. “How do we ensure we have the right, competent, trained individuals,” Aitken asks rhetorically. “Do we need to reach out to our global group who may have done this before? Do we need simulator

training? Do we need to get certain pieces of equipment from certain places?”

When it comes to moving massive bridge girders and ultra-heavy equipment such as splitters, Mammoet personnel collaborate intensively with municipal engineers, police escorts and other personnel, often under challenging conditions.

“We do our heavy lifting predominantly in the winter so we’re dealing with the cold, and the cold can present itself with many additional hazards not present in the summer,” Aitken says.

Memorable challenges include hoisting massive coke drums using a PTC ring crane.

“It’s one of the largest cranes in the world and we have to see where it’s booked and get it here,” Aitken says, describing transport using multiple sea cans and compli-

cated assembly and disassembly. “We work hand-in-hand to understand how we’re going to move or hoist something. We work on the logistics of where the crane is, the best location on-site to ensure the ground-bearing pressures, how we’re lifting something, how we’re rigging it, how we’re moving it, and we work on hazard analysis. That’s how we do things well — we involve every department that needs to make that lift or that transport successful.”

While the lifts themselves might seem precarious, ring cranes have the benefit of even weight distribution, which lends itself to safety. Instead, what does present the highest degree of risk of serious injuries such as crushing is the meticulous assembly and disassembly massive cranes require.

Keys to safety include following procedures to the letter, engaging crews who are thoroughly trained, competent and familiar with the machines, and ensuring all personnel, including clients and contractors, function as a team steeped in a culture valuing safety. Aitken says hazard assessment documents are shared between contractors, and crews are meticulous in their respective roles.

If something unexpected arises or a client or contractor wants to do something that isn’t in the plans or doesn’t conform with procedures, Mammoet has a no-rushing policy, communicated with all new personnel when they join the company, directing personnel to discuss requests with their supervisor and come up with a plan.

“A client isn’t allowed to dictate where a crane goes without going through the right channels,” Aitken explains.

Thankfully, Aitken says, clients are safety conscious and tend to be problem solvers rather than sources of trouble. Typically, they’ll designate a liaison to deal directly with contractors and mediate should site needs change or plans need reworking.

“They respect that we’re dealing with cranes and critical tasks and need room,” Aitken says.

In spite of all preventative efforts and a zero-tolerance policy for unsafe behaviour, incidents do occur. Even when there are no significant consequences, the entire procedure is reviewed from planning through to execution.

“We look at how it was initially planned and not just what happened in the field,” Aitken says. “We understand that, right down from our sales people to the people in the field, everyone is accountable when something happens.”

By Andrew Snook

When it comes to what contractors are looking for in mini cranes, OEMs and dealers seem to have a solid handle on what their customers want. An increased focus on low-emission fuel sources, improved durability, and enhanced lifting capacity, top the most wanted list for contractors continuously utilizing these machines for an increased number of applications.

“The big trend right now in a lot of major cities is the buildings going up, whether they’re condos or skyscrapers, which reduces the space you’re able to work in. I think we’re all seeing that,” says Jose Perez, international sales manager for Broderson Manufacturing Corp. “We’re having to keep our packages small, whether that’s width or length. Reach is another thing customers are wanting, to reach higher but keep the same footprint.”

Cristina Da Frè, marketing manager for Jekko, says that her company sees the current and future trends for mini cranes continue to shift towards electric power.

“In the area of electric power, Jekko has always been ahead of the game, offering battery-powered models and now switching to lithium-ion batteries to ensure constant power and precision while working,” she says. “We have always offered the possibility of having bi-energy mini cranes, fitting an additional electric motor to the diesel engine versions as well.”

Pacific Northwest-based Leavitt Cranes general manager Erick Zampini says the trend towards use of lithium-ion batteries as opposed to LP/gas or diesel systems and telemetry systems to diagnose the cranes remotely are the main technological advancements in the mini crane market in recent history.

“Keeping up with the trends in green technology, that would be the main one,” Zampini says.

Jekko is also focused on continuously improving the ease of use and durability of its mini cranes.

“Our attention is also focusing on making it easier for the operator to use the machine and on the reliability, two factors that for us are fundamental in the development of all the machines we design,” Da Frè says.

Low-emission fuel sources, improved durability, and enhanced lifting capacity, top the most wanted list for contractors.

There is also an increasing demand for telematics from contractors and rental houses, Perez says.

“You can access it from your phone and tell where a crane is. You can see diagnostics, how long it’s been ran, and get all those service intervals. You can know how hard and long your asset is running. This helps make financial decisions on whether you want to invest more in that product,” he says.

Zampini says that mini cranes are being used for a larger number of applications on construction sites than in the past.

“The primary application for this unit is in the glazing industry. But we’re seeing more of the larger units being utilized as a Swiss Army knife for various construction sites,” he says. “We’ve seen it in concrete applications, stripping forms and steel placement.”

Jimmy Latta, sales representative for Up and Down Lifting Solutions in Ayr, Ont., says that glazing is still the most common application for mini crane rentals at his company, but he is also seeing them used for tacking less traditional projects.

“Glass is always the busiest for us, but were definitely seeing more in other areas,” he says. “Structural steel; landscaping for moving large stones in backyards; we’re also working with arborists to remove some trees with the larger cranes.”

For the most part, mini cranes are being used to reduce manual labour and improve efficiencies, especially in glazing applications where glass panels continue to get heavier and heavier.

“Where they have six, seven, eight, nine or 10 guys lifting the glass, now they have a crane and a few guys lifting the glass,” Latta says. “They’re improving the efficiencies on sites. Lots of companies are using these mini cranes because it’s much safer, more efficient, quicker and easier. It’s a time saver.”

Zampini says that the COVID-19 coronavirus pandemic did have some impact on the mini crane rental business, particularly, earlier on, but he already sees the market bouncing back.

“For the most part, it’s been fairly consistent. Utilization year-to-date has been roughly 60 per cent on the smaller stuff and 70 per cent on the larger stuff. It’s impacted us a little bit,” he says. “There is increased activity in all aspects of the crane business, not just the mini cranes, so we forecasted that utilization will be up in the next six months and have forecasted a positive 2022.”

“The initial lockdown when they limited construction, we slowed down a bit. But after that it’s been steady,” Latta adds. “We’re seeing it growing from different industries.”

By Matt Jones

Atragic scene unfolded in Kelowna, B.C. on July 12 when a tower crane collapsed, landing on two adjacent buildings and claiming five lives. The crane was in the process of being dismantled when it collapsed but no official cause for the incident has been released as investigations by WorkSafeBC continue.

As the community have come together to support the families of the victims, representatives of the B.C. crane industry have also begun lobbying for increased safety measures, particularly surrounding the assembly and dismantling of tower cranes.

Four of the victims were construction workers on site – Jared Zook, Cailen Vilness and brothers Eric Stemmer and Patrick Stemmer. The fifth victim, Brad Zawislak, was working in the office building next door.

Hundreds of people gathered in Kelowna later that week for an emotional memorial.

“I thought I was processing it better than I was but when I got down here it really hit home,” Michelle Kienas, who was in one of the buildings next to the site, told CTV News regarding the memorial.

Frank Carr, business representative for the International Union of Operating Engineers Local 115, says that the union has been advocating for stronger safety measures and regulations for years – calls for action which have only intensified since this incident.

“After the Seattle incident, we went on the record and we’ve been requesting that mandatory training and certification for workers involved in assembly and dismantling of tower cranes be implemented,” says Carr. “As well, we’ve been calling for setting out minimum qualification standards and establishing a registry for individuals who work in the industry. Now we’re calling on the B.C. government to mandate it after this tragic incident.”

Carr says that he’s been heartened by the willingness of municipalities to listen and adapt standards. The union, along with industry members, the BC Crane Safety Association (BCCSA), regulators, training authorities and other stakeholders, have worked with the City of Vancouver for the past 18 months, to develop a pre-assembly and disassembly procedure and scheme. The plan involves pre-site meetings with the city inspector and regulator where plans are reviewed to ensure all due diligence is in place.

“In the City of Vancouver, that’s become conditional on issuance of a crane permit – you can’t put a crane up or down without following that process,” says Clinton Connell, executive director of the BCCSA. “So, one of the things we did immediately was get [this plan] into the hands of every health, safety and environment manager for every single municipality in the province.”

Carr notes that Vancouver also adopted recommendations including giving crane crews longer timelines for erection and dismantling and closing off more generous sections of city streets to provide larger staging areas. He notes, however, that a public education campaign on this topic may be required. Smaller staging areas and shorter windows for erection and dismantling can be driven by public pressure not to disrupt traffic flow, business hours or access.

“The pressure is from the public and we need to educate them about the dangers above them and around them,” says Carr. Connell says that he has been in close contact with Carr and the union and that the two groups are aligned in their response to the incident.

“We’re in full support of moving forward with any initiative that’s going to improve safety in the industry,” says Connell. “There’s a big difference, jurisdiction to jurisdiction, how assembly and dismant-

ling is handled. [We support] anything we can do in the province to better formalize that process.”

One effort that could improve crane safety is national harmonization of standards. Connell says that incremental improvements have been made in this area but there is still a wide gap between provinces.

“There’s a lot more work to be done,” says Connell. “One of the simple examples is where we split the lines on tonnages. Certain provinces have a handful of crane type categories. We have 11, some draw the line at 8 tons, others at 22. The minimum/ maximums are different. The training schematics are different from province to province as well.”

Connell notes that the industry is broadly in support of strengthening regulations and standards.

“Whenever there’s roundtables about safety standards or regulation changes, all this sort of competitiveness gets dropped,” says Connell. “Everyone pulls together. You can imagine, an incident of this nature sparked a lot of activity in conversation. My phone was ringing off the hook the first couple of weeks. A lot of activity took place behind the scenes in terms of industry not waiting for government or the regulator to come to them. By the time the regulator concludes their investigation and have some findings and details to share, industry is going to be ready.”

Kelowna City Manager Doug Gilchrist describes the collapse as a “sad and horrific event for our community.” While Gilchrist declined to speculate on potential regulatory and standard changes while the investigation is ongoing, he noted that the city and community have come together to attempt to support the families and businesses that were affected by the incident.

“I know the developer of the site is really wanting to step up and do the right things,” says Gilchrist. “What that ends up being, I don’t know. There’s been GoFundMe pages that have been set up that have raised money for the families. That’s certainly not going to mitigate but hopefully it’ll help them out to some small degree.”

Connell, executive director of the

Association, says there has already been discussion among the industry about where regulations and standards could be strengthened in response to the collapse.

for minimum qualification standards and establishing a registry for individuals who work in the industry. Those calls for action have only intensified since this incident.

International Union of Operating Engineers Local 115 has been advocating for stronger safety measures and regulations for years – calls for action which have only intensified since this incident.

Ontario is proposing to modernize and clarify existing requirements relating to the use of tower cranes under its Occupational Health and Safety Act (OHSA). The changes contemplated are significant and wide-ranging, and require close scrutiny by professionals.

There are 20 recommendations being made in six key areas including:

• Introducing new notification requirements relating to the use of tower cranes;

• Clarifying requirements for design, installation, maintenance, and inspection requirements including record keeping;

• Referencing the Professional Engineers of Ontario’s practice standard for tower crane review and clarifying the role and responsibilities of professional engineers in the design, erection and inspection of tower cranes, including certifying tower cranes as safe to use after repairs or following fault diagnosis;

• Introducing new, and updating existing, references to relevant national and international standards relating to the design and operation of tower cranes;

• Updating and introducing new training requirements for crane operators; and

• Addressing advances in technology by adding new and specific requirements for self-erecting tower cranes.

Some of the proposed changes would also impact provisions related to the operation of mobile cranes, it said.

The Ministry of Labour, Training and Skills development recently released a proposal to look at the Construction Projects Regulation (O. Reg. 213/91) and the notice and reports under regulations governing fatalities, critical injuries, occupational illnesses and other incidents.

“The proposal takes into consideration recommendations made to the Minister by the Provincial Labour-Management Health and Safety Committee (PLMHSC) and the Prevention Council,” the province said. “It also includes other changes intended to clarify, modernize and update the provisions to reflect current standards in the operation, use and maintenance of tower cranes. Opportunities to reduce regulatory burden in the requirements were also considered.”

The ministry said it recognizes some of the proposed changes may require equipment upgrades and will consider the timing of implementation to provide the industry with time to comply with the proposed provisions, if approved.

A look at key details in the proposal

You can view the entire 42-page proposal at https://www.ontariocanada.com/registry/showAttachment.do?postingId=38147&attachmentId=49945.

But here’s a quick overview of some of the changes:

Self-erecting tower cranes

Self-erecting tower cranes are not currently defined in the regulation. The ministry proposes to define them as “a tower crane that

is capable of being erected without the use of ancillary equipment.”

The proposed definition is intended to differentiate between conventional tower cranes and self-erecting tower cranes.

This proposal introduces specific provisions related to the use of self-erecting tower cranes such as operator qualifications and inspections. The proposed definition is adopted from Canadian Standards Association (CSA) Standard Z248-17, Code for Tower Cranes.

If a suspended load is dropped from a crane, there could be potentially catastrophic consequences to the health and safety of workers, it said. The proposed amendment would require that a constructor give written notice of an accidental or uncontrolled movement of a load, or part of a load, or any failure of rigging suspended from a crane.

The written notice would need to set out the circumstances of the incident and the steps taken to prevent a recurrence (as required by subsection 4(3) of the regulation) and must be submitted to the ministry and to the joint health and safety committee, health and safety representative or trade union, if any, within two (2) days of the occurrence as required by section 53 of the OHSA, it said.

The proposed notice requirement would provide the ministry with the ability to follow up on occurrences to determine whether they involved any violations of the Regulation.

Excavation equipment used to place pipes into a trench is not a

mobile crane or tower crane and, therefore, the current subsection 150(1.1) is redundant and should be deleted, it said.

“The proposed new operator qualification requirements for self-erecting tower cranes clarify the qualifications required to be held by the operators of self-erecting tower cranes depending on the rating of the crane,” it said.

It is also proposed that all operators of self-erecting tower cranes would be required to successfully complete the relevant modular training program for self-erecting tower cranes in addition to holding one of the prescribed certificates of qualification.

The ministry is proposing to require the rated load carrying capacity for a tower crane to be determined in accordance with the current CSA Z248-17, Code for Tower Cranes to reflect current technology and standards.

The ministry is also proposing to update references to standards for mobile cranes.

The ministry proposes to replace “load rating plate” with “load rating chart” to align with clause 4.7.3 of CSA standard Z248-17, and to use “load rating chart” consistently throughout the Construction Regulation for clarity.

Adding a requirement for cranes operated by remote control reflects the current technology used on Ontario construction projects and will ensure that operators have the information to safely operate cranes whether by remote control or more traditional methods.

The proposed amendment reflects the changing technology of tower cranes since the initial introduction of this requirement in the construction regulation. Industry experience indicates that most new luffing tower cranes have digital boom angle indicators at the operator’s controls. Older luffing boom tower cranes that do not have boom angle indicators may need to have them retrofitted in order to comply with this requirement.

The ministry proposes to amend section 152 to provide clarity regarding the creation and maintenance of the written record of a crane’s inspection and maintenance history.

The proposed requirements for Operator Crane Log to be kept at a project would codify current industry practice respecting the retention of crane inspection and maintenance records by crane owners and operators at projects. These requirements are consistent with clause 6.2 of CSA Standard Z248-17 Code for Tower Cranes, and they are intended to standardize and clarify what information is required to be kept in the Owner Crane Log and Operator Crane Log.

Section 19 of the construction regulation currently requires a constructor or employer to keep a project record for at least one year after the project is finished. Under this proposal, the log book would continue to be a record required to be kept in accordance with section 19.

The constructor or employer would be required to keep the Operator Crane Log for at least one year.

It would also require them to provide a copy of the log to the owner of the crane to be transferred into the Owner Crane Log.

The proposed amendments clarify that an owner of a crane would be required to provide the crane log to not only a constructor as currently required, but also to an MLTSD inspector, the employer or any persons designated by the constructor or employer (such as a professional engineer) in addition to the current requirement to provide these records to the constructor.

The proposed amendments to subsection 153(1) and subclause 153(2)(b)(iii) clarify the intent of the current provisions which is to ensure the platform is adequately connected to the boom of the crane whether it is connected by means of:

• rigging with more than one suspension line or support; or • directly attached to the boom.

The proposed amendment clarifies the existing provision and would not change the current intent of the requirement. It would require that a revised loading chart must be prepared specifically for the hoisting of workers on a platform connected to a crane.

It would also require that the revised loading chart must take into consideration the load restriction set out in subclause 153(2) (c)(iii) (i.e., the crane must not be loaded in excess of 25 per cent of its maximum rated load).

Crane operators would have to be provided with the revised loading chart and would be required to use the revised loading chart whenever a crane is used to hoist a worker.

The current location of this requirement could be interpreted so that the requirement is only applicable when cranes are hoisting workers. The proposed amendment clarifies the ministry’s intention that the requirement applies during all crane operations.

The proposed change clarifies that the notification requirement relates to a hoisting operation of workers only for the first time at a specific project rather than any time at a hoisting operation.

The proposed amendments regarding inspections of cranes used to lift persons are intended to ensure consistency with the other proposed inspection requirements for tower cranes under this proposal.

Cranes except tower cranes would still be required to be inspected by a professional engineer using non-destructive testing to ensure structural integrity of a crane used to hoist workers. A tower crane that is used to hoist a person must have all of its structural, mechanical, electrical and hydraulic components and systems inspected by a professional engineer before hoisting a worker. The performance standards specified in O. Reg. 260/08 are meant to provide professional engineers with the minimum basis for making an assessment on whether the tower crane is ready to operate.

It is proposed that a tower crane that complies with the general inspection requirements under Recommendation 15 of this proposal would be in compliance with the inspection requirements for tower cranes used to lift persons. The proposed schedule for inspections for cranes used to hoist workers and the proposed schedule for general tower crane inspections are consistent.

The ministry’s proposed requirements for tower cranes where the emergency procedures required to be established by section 17 include the use of a tower crane to move a worker or workers in a platform, basket, stretcher or other rescue device suspended from the tower crane are what the ministry views as essential to the safety of workers being hoisted in an emergency.

The proposed requirements are similar to the existing requirements in section 153 that apply to all cranes but are separate and distinct requirements for tower cranes hoisting workers in an emergency in accordance with emergency procedures. Under this proposed section, the constructor would not have to notify the ministry prior to the emergency hoisting operation.

The proposed amendment would include the term “climbing” to clarify that subsection 154(1) applies to the activity of “climbing” that may be performed on cranes including, for example, internal climbing and telescoping.

The proposed new subsection is intended to address a common safety concern related to the use of tower cranes.

Failure to accurately weigh and mark these components can result in incorrect balancing, decreased stability, overturning and/or overloading of the tower crane.

Any of these situations can be hazardous and potentially fatal to both workers and the general public if the project is near a public way.

The proposed notification requirement is similar to the notification requirement for suspended work platform systems under section 7.1 of the construction regulation.

It is intended to strengthen enforcement by alerting the ministry about projects where a tower crane, except a self-erecting tower crane, will be placed into service and will be dismantled.

The ministry proposes to introduce new design specification requirements for tower cranes (including self-erecting tower cranes) to ensure that cranes are adequately designed for its intended use and will not endanger workers. The proposed requirements would

apply to all tower cranes used in Ontario, including cranes that are imported into the province. This recommendation would be supported by a revised and more rigorous inspection regime.

“According to industry representatives, tower cranes are routinely designed to the European standard BS EN 14439,” the ministry said. “The ISO standard is intended to provide guidance in the design and assessment of control systems.

“The proposal would ensure that cranes used in Ontario have reliable and safer control system for tower cranes.”

It also clarifies that if a crane is in service at the time the proposal comes into force, the motion control contactors can be replaced after the crane is dismantled but before the crane is re-erected at a project. This will allow cranes in use at the time the Regulation comes into force to avoid in-service delays while attempting to change out contactors.

This would assist industry with compliance by allowing them to continue to use the older cranes, while still enhancing the safety of the cranes that are operated in Ontario, it said.

The proposed amendments to sections 158 and 159 would expand the prescribed inspection of the structural elements/components of a tower crane to include the inspection of the electrical, mechanical and hydraulic components and systems, and control systems.

The inspection would need to be performed in accordance with the performance standards for inspecting a tower crane prescribed by section 6 of the Performance Standards Regulation (O. Reg. 260/08) under the Professional Engineers Act.

The performance standards prescribe how professional engineers are to conduct reviews of tower cranes on construction projects before and after the cranes are erected and before they are put into operation which would ensure that inspection is conducted in a consistent manner. It would also provide compliance clarity and guidance to the engineering community and the construction industry.

This ministry also highlighted self-erecting tower cranes – which are erected and dismantled frequently, and in some cases daily.

“As such, these cranes are more prone to being damaged than conventional tower cranes and should be inspected periodically when they are in service to ensure they are maintained in good condition,” it said.

Improper maintenance of a tower crane can lead to catastrophic failures of the equipment. As such, in addition to Recommendation 15A above, the ministry proposes to introduce new comprehensive inspection requirements to ensure that tower cranes used in Ontario are thoroughly inspected at prescribed intervals.

The proposed requirement would require a tower crane manufactured ten or more years before the coming into force date (if any) to be inspected every 10 years (or earlier). These requirements for older cranes would involve a higher level of scrutiny of the crane components to ensure they can handle the rated capacity and to identify any defects or hazardous conditions. If the crane undergoes an inspection in accordance with this proposal within the 10 period (e.g., because of a major overhaul) the next inspection would need to be 10 years after the last inspection.

The ministry posted the information on July 14, 2021 and comments are due by Sept. 13, 2021.

Comments can be emailed to WebHSPolicy@Ontario.ca.

Jekko works with Belgian army to develop a mini-crane for parachuting

By Andrew Snook

The versatility of mini cranes has been expanding rapidly over the past decade. Once largely considered a tool for glazing installations, these small cranes have been becoming popular for a wide variety of applications including construction, landscaping and more.

Jekko, a leading mini crane manufacturer based in Italy, recently designed one of their cranes for an entirely new application: air transport and parachuting.

“The cranes will be used to do service on the new Airbus A400M military cargo planes. When an airplane has a breakdown in a

foreign country, the cranes will be transported by another A400M to assist on repairments and maintenance. Of course, they will also be used on the military airfield in Belgium when there are service or maintenance jobs to do on the airplanes,” says Davy Bintein, Rentalift sales manager and official Jekko dealer for Belgium.

The company worked with the Belgian Defence Forces to create the Jekko SPX1280. This mini crane features compact dimensions, cutting edge stabilization and hydraulic systems, a maximum lifting capacity of 8 tons, and a 2-ton Pick & Carry.

Jekko’s technical department worked with Belgian equipment

dealer Rentalift and the Belgian Defence Forces (Air Component) over a two-year period to design the first-ever mini crane for air transport and parachuting.

“The most important thing that was adjusted is the chassis: instead of a three-part chassis, these cranes have a one-full chassis, provided with anchor points regulated to the NATO STANAG regulations – in order to cope with G forces when the plane is taking off, landing or turning. The windmeter on top of the boom, the special designed towing points, the customised extra air filter make this crane suitable for this type of customer,” Bintein says.

“This adaptation of the crane is characterised by the chassis, which in this case consists of a single element and by the addition of an anemometer that allows the wind speed to be read on the display of the remote control. In addition, we have also fitted a cyclone filter with a clogging sensor to further filter the engine air in dusty environments. In this case, the configuration of the machine was with main boom only, in order to be able to operate by winch,” adds Marco Zava, Jekko’s research and development technical director.

The SPX1280’s frame is built with several anchor points for securing the mini crane on a plane and for parachuting the unit, if required.

“The aim was to adapt a normal crane to be transported by an aircraft. It was therefore necessary to check and modify the frame and anchor points so that they could withstand the loads and accelerations of the aircraft during take-off, turning and landing. In addition, it was also necessary to secure all those components that are not fastened during normal transport,” Zava explains.

The unit also features a cold-weather kit for starting the engine, and filters for working in dusty or sandy environments. The SPX1280 is designed to work in any environment ranging from the freezing temperatures of the arctic to inhospitable heat of the desert.

Bintein says this mini crane should do well in the military sector.

“I believe there is a market for these cranes, especially in the military sector, because lots of countries are ordering or buying the A400M, and this crane is, until now, the only mini crane fitted and approved for air transport,” he says.

No matter how challenging your needs, BKT is with you offering a wide range of OTR tires specifically designed for the toughest operating conditions: from mining to construction sites.

Sturdy and resistant, reliable and safe, able to combine comfort and high performance.

BKT is with you, even when work gets tough.

For info: Western Canada 604-701-9098 Eastern Canada 514-792-9220

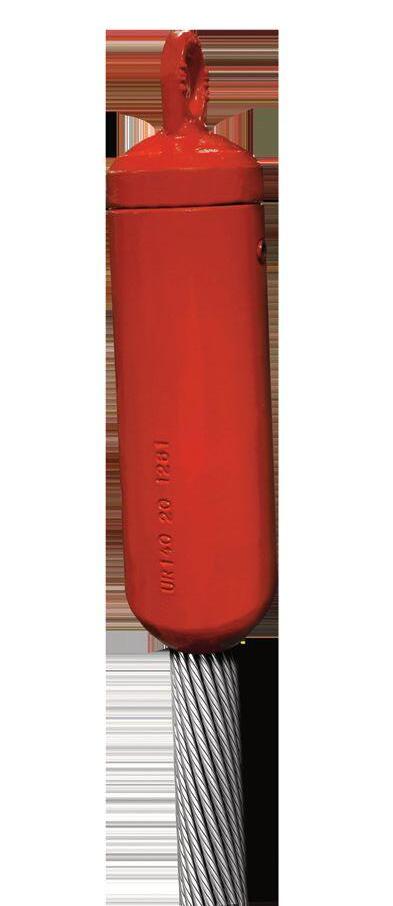

Mobile crane manufacturer Tadano is betting on being on the cutting edge of things, and so the company recently decided to upgrade more than just the name of its four-axle and five-axle cranes in the 110 USt to 130 USt class. The maneuverable AC 4.110-1 now has a larger lifting capacity despite there not being any changes to its total weight – all thanks to a new and stronger boom that is also part of the five-axle AC 5.120-1. The latter continues to make a compelling case in day-to-day work with a convenient 22,000 lb. axle load. As part of its reorganization efforts, Tadano will be standardizing the names of its mobile crane models throughout the year. The new AC 4.110-1 and AC 5.120-1 come with updated names right out of the gate.

The pivotal point of both crane models is the new and stronger main boom. With it, Tadano offers greater lifting capacities: The two models can now lift 11 USt with the main boom fully extended, which corresponds to a lifting capacity increase of 37% in comparison to the preceding ATF-100-4.1 and ATF-120-5.1 models.

The boom extension means that the two cranes now have a larger work area. A smaller minimum radius, larger lifting height, and 82° boom angle make it possible to work closer to the crane. This makes both crane models even better suited to tight work sites and work at large heights.

In addition to the larger lifting capacity, the AC 4.110-1 and AC 5.120-1 benefit from an updated main boom extension. This extension can be set up particularly quickly as a result of reduced complexity. The ATF-100-4.1 and ATF-120-5.1 main boom extension, including a runner, will continue to be available. Both main boom extension versions now benefit from a reduced minimum radius in the 0° position.

Tadano offers the AC 5.120-1 with a modified wheelbase specifically for the US market. With this modification, the crane conforms to current US approval regulations. www.tadano.com

Manitowoc will display three of its strongest new offerings for the utilities market at The Utility Expo this year: the National Crane NBT60XL boom truck; the NBT45-2, a compact 45-ton model from its new NBT40-2 Series; and the Grove GHC110 telescoping crawler crane that just launched in July. It’s the first time the public will have a chance to see these cranes at an in-person trade show.

This year’s Utility Expo will be held in Louisville, Ky. at the Kentucky Exposition Center from Sept. 28 to 30. The event will cover more than 30 acres, and Manitowoc will occupy outdoor booth number E843.

Show visitors will have a chance to check out the National Crane NBT60XL boom truck at Manitowoc’s booth for the first time since its launch in late 2020. This versatile crane is particularly well-suited for the utility sector, boasting a 151-foot main boom with class-leading load charts and practical transportability.

The NBT60XL features 16,000 lb. of hydraulically removable truck crane-style counterweights. This trayless design allows for the counterweight slabs to be stacked in any order quickly and efficiently. The NBT60XL also comes standard with a host of operator-centric features, such as the deluxe tilting cab (up to 20) with heated seat and a Bluetooth/AM/FM radio and speakers.

Also on display at the company’s booth will be the new NBT45-2 boom truck, one of two models in the NBT40-2 Series. The crane is also offered in a 40-ton version. Both the 40-ton and 45-ton configurations offer 127-ft. and 142-ft., five-section boom options with load charts boasting double-digit percentage increases over predecessor models, with no change in gross vehicle weight (GVW).

The NBT40-2 Series is ideal for work in utility sectors, due to its versatile boom lengths and excellence in close charts or capacity at reach. The tree service industry will find the crane suitable for its rugged design and when needing 200 ft. plus of platform height.

Also making its debut is the new Grove GHC110, a machine just added to the upper size range of Manitowoc’s growing telescoping crawler product line. Featuring an impressive 110 USt capacity, the GHC110 joins the larger GHC140 to bring another robust option to the utility market.

The GHC110 is fully self-rigging so it can get to work quickly after being unloaded. Its undercarriage offers several advantages in terms of reducing the need for site prep. The 36-in. triple bar grouser shoes are standard with the option to choose flat tracks. The wide stance produces enhanced stability, with the hydraulically tracks offering a choice of three spans in symmetrical or asymmetrical positions without pinning the tracks. www.manitowoc.com

Simon Meester has been appointed president of Genie, effective Aug. 1, 2021.

John Garrison, Jr., chair, president and CEO of Terex, made the announcement. Meester will continue to report to Garrison and join the company’s executive leadership team.

Meester currently serves as COO of Genie. Meester joined Genie in 2018 from Eaton Corporation, where he was vice-president and GM of the Industrial Control Division. Previously, he held senior roles at Caterpillar and Sandvik. Meester will continue to be based in Genie’s Redmond, Wash. headquarters.

“Simon’s leadership has kept Genie team members safe during the pandemic, while leading key strategic initiatives to deliver quality and value for our customers,” Garrison said.

Meester commented, “Genie has committed team members, strong customer relationships, and a passion to innovate and grow the business. I am honored to lead Genie and build on our momentum as we continue to position Genie for the future.” www.terex.com

DICA will showcase products for utility contractors from its Outrigger and Crane Pad, Ground Protection, Cribbing and Blocking, and Rigging product lines during The Utility Expo. The show will be held Sept. 28 to 30, 2021 in Louisville, Ky.

“DICA products help contractors get ready to get to work, and have long been a staple of equipment stocked on utility trucks,” said Kris Koberg, CEO of DICA.

Among the company’s newest products, which will be featured at the show, are FiberTech Outrigger Pads, ProStack SlotLock Cribbing Blocks, and LiftGuard Sling Protectors.

DICA Outrigger Pads provide unbreakable strength, safe handling, and easy setup for use with aerial lifts, digger derricks and mobile cranes.

FiberTech Outrigger Pads are an ideal solution when extra rigidity is needed and weight is a concern.

ProStack Cribbing Blocks are designed to provide height in situations where you need to crib up.

Slot Lock Cribbing Blocks have a rated capacity of 100,000 lb., and are suitable for use with aerial devices, digger derricks, concrete pumpers and smaller cranes.

LiftGuard Sling Protectors prevent damage to slings caused by contact with abrasive edges, corners, or protrusions from loads being lifted. They also keep the sling away from other significant contact points during lifting operations. Visit DICA at booth N1331. www.dicausa.com

• New operator aids with kickout

• Free swing modes

• Simple interface with large touchscreen

• Wi-Fi enabled to update and service remotely

• Calculate outrigger positioning

• Real-time 360°charts

• Live preview mode

• Incorporated swing arrest

• Anti-skid paint on allowable walking surfaces

• No trip points

• Large walking area

• Guided, sequential, fail-safe fly erection

• Control fly assist and boom hoist cylinder from the ground

• One person operation

• Minimal ladder climbs

• Swing around at 0°

• Pivot-point & boom head speed screws

• Heated back-up, winch and right-side cameras with night vision

• LED working lights

• Outrigger lights

• 20 degree tilting cab

• No helper crane needed to install counterweight

• Transport weight of 95,000 lbs

• 6 Points of Access

• Large grab handles

• Deep, sturdy steps and ladders

• Working platform with guardrails