BY MATT JONES

Newfoundlanders Derek Tucker and Gina Jesso first found love together, now they’ve found a career path together as well. The couple attended and graduated from the College of the North Atlantic’s (CNA) Mobile Crane Operator program at the Bay St. George campus in Stephenville, Nfld. Now, they’ve relocated to Grand Prairie, Alta., to start a new life in their chosen field.

“We’re both outdoors people,” says Tucker. “We love camping, we go hiking, we walk, we do whatever it takes to be outside, and that’s where I met her. I went for a ride on a dirt bike one day and she was camping by herself and we got talking, and here we are.”

Jesso says she was initially looking at pursuing a general heavy equipment training path, but, much like meeting Tucker, another random encounter changed things.

“I bumped into a couple of friends of mine who did the course and they steeped my curiosity,” says Jesso. “I just thought it was really interesting and I wanted to experience it.”

< Derek Tucker and Gina Jesso

BY SAUL CHERNOS

When it comes to hoisting HVAC and other heavy rooftop components onto downtown Toronto office towers, the lifts themselves take just a day or two. What makes it all work, however, is months of planning.

A case in point: In late May, Amherst Crane Rentals placed mechanical equipment atop a 22-storey building on Yonge Street, between Adelaide and Richmond streets, in the heart of downtown Toronto’s business core. With a 15,000-lb. cooling tower the heaviest lift, and a relatively narrow area to work from, Amherst brought in one of its heavyweights — a 500-ton Liebherr LTM 1400 all-terrain crane.

Initial tenders released for modernization project

BY ANDREW SNOOK

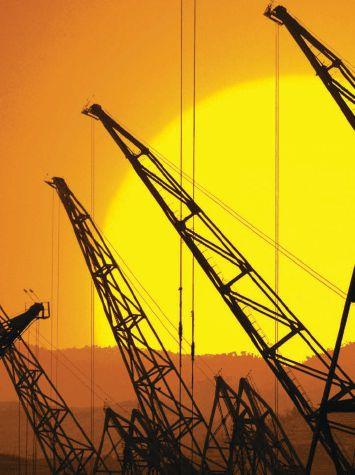

ork on Port Saint John’s modernization project is underway with the initial tenders for the project released this summer. The massive project will expand the port’s annual container yard handling capacity from 125,000 TEU to 330,000 TEU. The project will also allow the port’s rail handling capacity to grow exponentially from 75,000 TEU to 330,000 TEU.

In 2010 the then new CEO of Port Saint John, Jim Quinn, recognized that in order to remain in the container business, the Port would have to modernize its facilities in order to keep up with the rapid changes that were occurring in that sector.

“Containers are an important business for Port Saint John, and it was clear we needed to have facilities that could handle lager vessels,” Quinn said. “This lead to the planning of the West Side Modernization Project which gained the support of the federal and provincial governments. Together we will equally fund the $250 million project that will be completed by 2023.”

Editor – Andrew Snook • asnook@annexbusinessmedia.com. Tel. 289-221-8946

Advertising Manager – Jeremy Thain, jthain@annexbusinessmedia.com

Tel. +1-250-474-3982, Toll-Free (North America) 1-877-936-2266

Art Director – Svetlana Avrutin

Regular Contributors

Saul Chernos, Grant Cameron, Nelson Dewey, Matt Jones

Group Publisher – Scott Jamieson • sjamieson@annexbusinessmeda.com

President & CEO – Mike Fredericks

Circulation Manager – Barbara Adelt

badelt@annexbusinessmedia.com

Subscriptions – Bona Lao – blao@annexbusinessmedia.com

Tel: 416-442-5600 • 1-800-668-2374 (CDN) , ext. 3552

Fax: 416-510-6875 or 416-442-2191

www.craneandhoistcanada.com

Annex Privacy Officer – Privacy@annexbusinessmedia.com

Tel: 800-668-2374

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher. A subscription to Crane & Hoist Canada (six issues) is $36 per year in Canada. For subscriptions in the USA the price is $36 USD. Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875.

Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT.

111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1 ISSN 1923-788X

Next Advertising Deadline: September 28, 2018

Don’t miss the opportunity to be part of this exciting new industry publication. For more information, or to reserve space in the next issue, call Jeremy at our Advertising Department - Toll Free 1.877.936.2266 jthain@annexbusinessmedia.com

Next Editorial Deadline: October 3, 2018

For writers’ guidelines and submission requirements get in touch with the editor, Andrew Snook, at 289.221.8946. Email: asnook@ annexbusinessmedia.com

If you’ve got a chance to get away from the hustle and bustle of your business for a few days, I suggest a trip to Louisville, Ky., this September.

The Specialized Carriers & Rigging Association (SC&RA) is hosting its annual Crane & Rigging Workshop at the Louisville Marriott Downtown and it is packed full of interesting sessions and great networking opportunities.

The sessions offer great learning options for industry professionals. The topics include:

• Practical ways to protect your company from lawsuits;

• Bridging the gap between compliance and choice;

• Tackling jobs with better tool management;

• Calculating sling angles and hardware selection;

• How to successfully use synthetic fibre ropes and slings, and how they differ from steel wire and round slings;

• The hazards of service providers;

• Playing offence with OSHA from an attorney’s point of view; and

• The essential elements of preparing an engineered lift plan, from A to Z.

Have photos of unique cranes and hoists?

Email a photo and brief description to editor Andrew Snook at asnook@annexbusinessmedia.com.

There will also be the awarding of the 2018 Rigging Jobs of the Year; a keynote presentation by Anne Mahlum, owner/CEO of [solidcore], who will discuss her personal story and work with “Back on My Feet”, a non-profit organization combatting homelessness through the power of running; the opportunity to tour Link-Belt Cranes’ 770,000-sq.-ft. factory in Lexington, Ky.; and an exhibit centre showcasing 90 of the industry’s top manufacturers. If you’ve never been to the SC&RA Crane & Rigging Workshop before, there is also a First Timers’ Briefing that will offer you an opportunity to meet with SC&RA officers, staff and other first-time attendees, to network, and learn more about the event.

The fact that the hotel is a 10-minute walk from the Louisville Slugger Museum is an added bonus for any baseball fan, myself included. So sign up and check out a fantastic learning and networking opportunity that is sure to be a home run. See you in Kentucky!

For more information on the 2018 SC&RA Crane & Rigging Workshop, visit www.scranet.org.

At a recent Doors Open event in Toronto, where the public toured buildings that are often off-limits, visitors to the R.C. Harris Water Treatment Plant in the city’s east end might have noticed an overhead crane. Plant manager Gord Mitchell says the 20-ton capacity overhead travelling crane gracing the ceiling of the massive pump room was installed in 1936 in conjunction with construction of the roof trusses. By 1938, the crane was fully operational, and it was used to help install the pumps. Today, the crane remains active, used primarily to maintain pumps, valves and piping. Recently, it has been extensively used in the removal, rehabilitation and installation of cone valves. The crane’s label reveals that it was supplied by the Dominion Bridge Company, a Quebec-based steel bridge constructor. Canadian General Electric supplied additional electrical equipment for the crane.

According to the latest rental revenue forecasts from the American Rental Association (ARA), Canada’s rental revenues are projected to be $5.4 billion in 2018, up 4.4 per cent; and are expected to grow an additional 4.8 per cent in 2019; 4.7 per cent in 2020; 3.8 per cent in 2021 and 2.7 per cent in 2022 to reach $6.159 billion. Canada’s construction and industrial segment is expected to make up $4.3 billion in 2018.

In the U.S., the ARA, for the second quarter in a row, is projecting larger increases in revenue almost across the board for the equipment and event rental industry than it did in the previous five-year forecast released in May.

The July 2018 forecast from ARA Rentalytics calls for total U.S. rental revenue of $53.04 billion in 2018, up 7.6 per cent, and then growing 5.8 per cent in 2019, 5.9 per cent in 2020, 5.1 per cent in 2021 and 4.7 per cent in 2022 to reach $65.4 billion.

The May forecast called for total U.S. rental revenue of $52.3 billion in 2018 growing to $64.1 billion in 2022.

“ARA’s second quarter forecast shows continued strong growth in rental revenues over the forecast period. Growth rates for 2018 and 2019 look particularly strong in all segments of the equipment and event rental industry with growth rates forecast at more than double the rate of GDP [gross domestic product] growth,” says John McClelland, Ph.D., ARA’s vicepresident, government affairs, and chief economist.

While the near-term outlook is particularly strong, McClelland said the out-years of the forecast could be subject to change due to the potential impact of tariffs on the economy and construction projects.

“Coupled with the increases in equipment prices that are almost inevitable after the imposition of tariffs on steel and aluminum, the equipment and event rental industry could face a challenging economic climate beginning in 2020 and beyond,” McClelland says.

According to ARA Rentalytics, construction and industrial equipment rentals continues to account for the bulk of revenue in equipment and event rental and now is expected to reach $37.15 billion in 2018, up 8.3 per cent over last year. General tool rental revenue in 2018 is forecast to be $12.49 billion, up 5.4 per cent.

ARA also forecasts total investment in equipment by rental companies to reach $13.9 billion in 2018, up 7.8 per cent over 2017.

Source: ARA.

Hiab recently announced that it is purchasing the Effer loader cranes business from the CTE Group for an enterprise value of EUR 50 million. Hiab stated that the acquisition will complement its loader cranes portfolio and expand its range of heavy cranes, in particular in the greater than 100-tonne segment.

Effer will continue to operate as part of Hiab under its brand and through its dealer network.

“I am happy to welcome Effer to the Hiab family,” stated Hiab president Roland Sundén. “This acquisition is a bold step in line with our growth strategy to be the global leader in on-road load handling and in particular in loader cranes, the industry that Hiab founded nearly 75 years ago.”

Effer, founded in 1965, has over 50 years of experience in developing and manufacturing knuckle-boom cranes, with its product range encompassing truck cranes with a 3- to 300-tonne lifting capacity, special application truck cranes, and marine cranes. Effer S.p.A. is headquartered in Minerbio, Italy and has about 400 employees. Distribution is managed through a network of more than 100 dealers covering 60 countries. Effer’s sales in 2017 totalled EUR 71 million and generated an operating profit of approximately EUR 6.1 million.

“Through its size and global scale, Hiab offers the most optimal opportunities for continued growth for Effer and I am delighted that Effer is becoming part of an organisation with an equally proud past, passion for quality and reliability, and drive for innovation,” says Lorenzo Cipriani, CEO of Effer.

“With a comprehensive crane portfolio and a strong global sales and service presence in complementary geographies, Hiab and Effer will jointly become a stronger partner for our customers, helping them reach their full potential,” adds Joakim Andersson, senior vicepresident of cranes at Hiab.

The acquisition is subject to regulatory approvals expected to be received in the second half of 2018. Effer’s results will be consolidated into Hiab from the closing date.

ransport Canada recently announced it will invest $7.5 million into a project at the Port of Thunder Bay in Thunder Bay, Ont. that will improve the port’s infrastructure. The project will include adding tracks and laydown areas for cargo staging and transshipment to respond to increased demand, and building a 4,645-sq.-m. multi-purpose heated facility to suit requirements of terminal users, according to a recent statement from Transport Canada.

T“Our government is investing in Canada’s economy by making improvements to our trade and transportation corridors,” stated Minister of Transport Marc Garneau. “We are supporting projects that will efficiently move commercial goods to market and people to their destinations, stimulate economic growth, create quality middle-class jobs, and ensure that Canada’s transportation networks remain competitive and efficient.”

The project is designed to reduce bottlenecks and capacity constraints while offering shippers more options for meeting their requirements; and improve the port’s resiliency to “a changing climate and its adaptability to new technologies and future innovation.”

“Transportation and distribution of goods are a vital part of our local, regional and national economies,” stated Minister of Employment, Workforce Development and Labour and MP for Thunder Bay—Superior North Patty Hajdu. “The investment announced here today will make our transportation system stronger by addressing urgent capacity constraints at the Port of Thunder Bay and fostering long-term prosperity for our community.”

BY MATT JONES

In early June, a crane tipped over at the Muskrat Falls hydroelectric project on the lower Churchill River in Newfoundland. The companies involved and local government continue to conduct investigations into the cause of the incident.

“Our sub-contractor Capital Crane was completing work to dismantle a crane. The crane that the operator was using to dismantle another crane tipped over on its side,” said Astaldi Canada country manager Don Delarosbil in a media release. “The operator was taken to the Labrador Health Centre in Happy Valley-Goose Bay for an assessment. At this time the person’s injury is not classified as serious.”

Astaldi is contracted for construction work on the project by Nalcor Energy which stated in a release on the incident that the day shift had been suspended and that a full investigation had been launched.

“Immediate action was taken by our Lower Churchill Project site team and Astaldi Canada to address today’s incident,” Nalcor’s statement read. “Astaldi’s suspension of their day shift is a proactive step to ensure the necessary steps are taken as the incident is investigated. We will ensure a full safety investigation is completed and that the contractor and its workers implement all safety recommendations that might be identified following this incident.”

Meanwhile, local authorities are also carrying out their own investigation into the incident. A spokesperson for Service Newfoundland says that when an incident occurs, investigations are carried out by trained occupational health and safety officers, whose mandate is to identify the cause or causes of the incident.

“The primary goal of the provincial government’s occupational health and safety legislation is to protect the health and safety of workers,” said the Service NL spokesperson. “The investigation is ongoing, therefore, we cannot comment further at this time.”

This is the second construction incident to occur on the site. In 2016, a structure to support concrete that was being poured collapsed, covering seven employees with wet concrete and sending another to the hospital with minor injuries.

After many years using the Linden Comansa brand name, the tower crane manufacturer has decided to focus its efforts on a single overall brand, to be used throughout the group, by returning to its original name: Comansa. This change will be implemented gradually right across the product range and at the company’s facilities in Spain (headquarters), the U.S. and China.

“Combining the names Linden and Comansa in a single brand was initially important as we looked to open up markets, as it gave us recognition on markets where Linden had been a major player and the benefits of its products were widely appreciated,” said Alberto Munárriz, CEO of Comansa. “However, Comansa has been developing and improving this system for 35 years, and has been actively present in the market for over 50 years. The fact that we continue to be a benchmark in the tower crane industry today is not due to the name Linden in our trademark, but rather thanks to all the work we have put in over many years, allowing our products to be renowned for their quality. In fact, we are widely known on the market as Comansa, meaning the change is very natural. Moreover, the company’s situation has changed a great deal over recent years, having set up in China and embarked on significant commercial expansion. This change aims to bolster our strategy at group level by having a single, uniform image on the market.”

This change means that cranes manufactured in Pamplona, Spain, previously marketed under the Linden Comansa brand, and cranes manufactured in Hangzhou, China, distributed under the name Comansa CM, will all be know from now on as Comansa.

Each crane model will keep its current name, using the letters LC or CM to indicate the product range, thus avoiding any confusion on the market. Model name 21LC750 therefore indicates that it is part of the range previously known as Linden Comansa, while model name 21CM550 indicates that it is part of the former Comansa CM range.

Source: Comansa

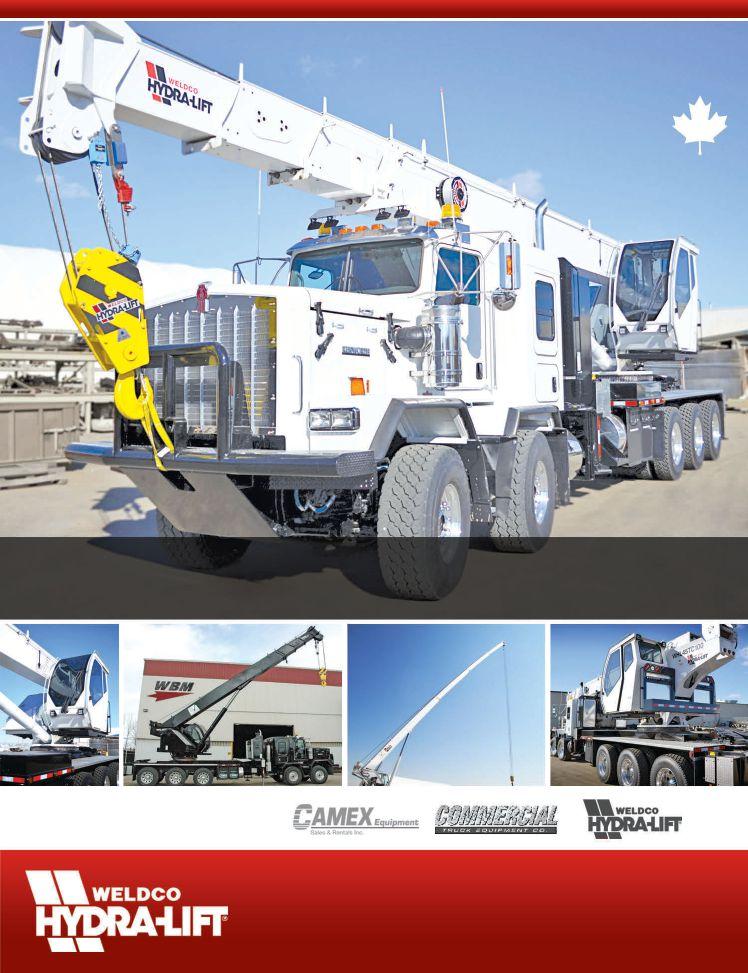

Designed & Manufactured in Western Canada, Purpose-Built for the Oil & Gas Sector

“We’ve

– Pascal Francoeur, Director of Operations, Grues JM Francoeur

continued from cover

The project is expected to take seven years to complete with the first tenders being released throughout the summer, the main tenders are scheduled to be released this September.

“We’re currently in the 85 per cent range in detailed engineering and completing the environmental permitting,” added Tyler O’Rourke, port engineer for Port Saint John, during a meeting with Crane & Hoist Canada at the offices of Port Saint John in Saint John, N.B.

The modernization project will include the construction of deeper berths that can accommodate the Super Panamax vessels that are becoming more common in the container trade. Right now routine maintenance dredging is performed using a 210tonne high duty LIMA Dredge, but the port will likely need some additional dredging horsepower for the project.

“There will probably be larger dredges brought in for expansion, also for some channel dredging down to 9.5m from 8.4 m to accommodate larger vessels” O’Rourke says.

Tel: 780-440-4010

The expansion will increase the depth of the main channel from 8.4m at low tide and 16.9m at high tide, to 9.5m at low tide and 18.8m at high tide. The depth alongside the container terminal will grow three metres, from 12.2m at low tide to 15.2m.

Prior to the initial work getting underway, DP World Saint John – the terminal operator and stevedore for the Rodney Container Terminal and Navy Island Terminal – brought in two 1998 Paceco electric drive cranes to accommodate the expansion. The cranes have a 50- to 60-ton capacity, depending on whether a spreader bar or a project cargo hook is used; and an outreach of 145 feet. The new cranes will allow the port to accommodate 16 container-wide, 6,500 TEU capacity vessels while working throughout the Saint John tidal cycle. Currently, the existing cranes have a much smaller window around high tide.

To accommodate the new cranes that will service incoming and outgoing Super Panamax vessels, the project includes the installation of new electrical substructure that can handle 12.5kV or larger voltages as well as 100-gauge gantry rails. The cranes are currently sitting on 60-gauge, 60-feet-wide gantry rails on an electrical substructure that can handle 4.1kV.

The container growth alone is expected to double direct and indirect jobs across the region from 500 to more than 1,000, not including economic growth spin-offs. Over the course of the seven-year project, more than 1,400 person-years of direct and indirect employment are expected to be generated. Photos: Port of Saint John.

Superior lifting capacities, on-line load chart calculation

Great variety of boom configurations

Quick and easy assembly

Easy and cost-effective transportation

Liebherr-Canada Ltd. 1015 Sutton Drive, Burlington, Ontario L7L 5Z8

Phone: +1 905 319 9222

E-mail: info.lca@liebherr.com www.facebook.com/LiebherrConstruction www.liebherr.ca

continued from cover

“In this configuration we had 276 feet of luffer and around 220,000 pounds of counterweight with the [Liebherr TY guying] heavy-lift attachment,” Amherst Crane Rentals vice-president Mark Welstead explained.

Key to matching the LTM 1400 with this particular job was the fact the telescopic boom is attached and doesn’t need launching each time it’s needed.

“You have a great lifting capacity without having a major operation like launching a boom, so this speeds things up and makes the whole job more productive,” Welstead explained. Because the LTM 1400 is versatile and can readily adapt to an eclectic mix of hoisting jobs, it isn’t sitting around if only smaller jobs come calling.

“Where it excels is in its capacities for all the work we do, whether it be for [erecting] tower cranes or for mechanical work like this,” Welstead said. “If we don’t have a 500-ton job for a few days we can rent it out as a 250, 300 or 400 with relatively ease. This gives us more productivity and use out of the crane. We can use it for smaller jobs very easily without a big cost.”

The truck-mounted crane’s compact nature makes it relatively easy to transport it from job to job. To travel to the Yonge Street site from its yard in the suburb of Brampton, Ont., the crane simply motored down major arterial routes, taking up a single lane, travelling at the cityapproved 40 kilometre per hour speed limit and avoiding sensitive overpasses.

“The crane is permitted for the City of Toronto, but there’s lots of roads and bridges we’re not allowed to go over,” Welstead said, singling out the Gardiner Expressway, which for much of its length is an overpass that is aging and showing signs of deterioration. To reach its downtown destination, the crane and its convoy of support trucks drove down Highway 427 and then took Lakeshore Blvd. eastwards. While the set-up and job itself were fairly straightforward, the project itself required months of logistical planning. As soon as its customer came calling, Amherst contacted City of Toronto work zone coordinators

and affected parties such as the Toronto Transit Commission (TTC) to sort things out.

“It starts with the customer and what they require,” Welstead explained. “We figure out what kind of crane we need and how we’re going to do it, then we decide whether or not we need to shut a road down.”

Logistics are normally arranged months in advance. Transit routes can be affected, and while Toronto’s subway system is underground downtown, bus and streetcar routes are impacted by street closures. Just as motorists and pedestrians will be redirected for a job’s duration, the TTC also needs to plan alternate routes.

Because there are subway tunnels, hydro infrastructure and other amenities underneath Yonge Street, Amherst and city engineers needed to ensure the area where the crane was set up could tolerate the weight.

Crews set up on mats, with engineered heavy point loads calculated to accommodate the 190,000-lb. crane. “We provided them with all the crane loadings and came to agreement as to where the crane could sit on the road,” Welstead said.

It also took time to arrange for permits, paid-duty police officers and other supports. With a significant amount of on-site staging work, and numerous components needing to be hoisted, Amherst avoided chaos by scheduling the project for the Victoria Day long weekend.

“We had to take some of the older equipment out and put up some steel and other components to accommodate the new equipment up there, so there were multiple smaller lifts as well as a heavy lift,” Welstead said. “We’d hoist stuff down, put new stuff up. Then they would be fabricating and we’d start working on other stuff — taking down older frames and things like that.”

On more modest jobs, crews might normally arrive on a Friday evening to assemble the crane so it’s ready to hoist Saturday morning, and then wrap up and leave midday on the Sunday. The extra day afforded by the long weekend offered wiggle room, though crews were gone by mid-

morning on the holiday Monday.

“If we’d had to interrupt traffic for a whole other weekend to finish, it wouldn’t be in the city’s best interests,” Welstead said.

While the customer brought in two other contractors to handle other components of the job, Amherst relied as much as possible on its own equipment and services, opting not to sub out anything it was responsible for. “That way we can ensure being on time and everything’s working properly and we don’t get a let-down,” Welstead said.

This included trailers, secondary equipment and services, and a second crane — a Liebherr, LTM 1055 all-terrain machine — to set up and dismantle the main crane.

While severe weather can put best-planned timing in jeopardy, crews endured nothing more than light showers on the Saturday.

“High wind and lightning can be a challenge if we have all of this set up ahead of time,” Welstead said.

Graham Morrison, the crane operator Amherst assigned to the job who also served as site supervisor, said the lift had its challenges but was mostly straightforward.

“We had five different trades working all at the same time in the same confined space,” said Morrison, a member of the International Union of Operating Engineers (IUOE) Local 793. “There were only three companies, but we were dealing with pipefitters, electricians, millwrights, welders and crane operators.”

Morrison described the rigging, which he oversaw, as standard, with nylon belts, steel chokers, steel beams and spreader bars used to help protect the load from potential damage.

Morrison concurred with Welstead that the LTM 1400’s compact nature and its ability to avoid a boom-launching manoeuvre played a major role in getting the job done within a tight time frame.

“By 10 o’clock Monday morning we were gone and the street was reopened. We were right on schedule,” he said.

BY ANDREW SNOOK

Courageous conversations with loved ones was the focus of the Crane Rental Association of Canada’s (CRAC) keynote speaker during the association’s 20th Annual Conference and AGM recently held in Winnipeg.

Insurance expert and financial advisor Jane Blaufus discussed the importance of preparing yourself, your family and your business for worst-case scenarios; to help mitigate risks related to one’s financial security.

Blaufus is the author of “With the [STROKE] of a pen: Claim your life,” which is recognized as one of the most comprehensive, actionable, personal and financial planning resources available today for families, individuals and business owners alike. She has more than 25 years of insurance expertise as a financial advisor, sales manager and executive. Today she is the principal of The Blaufus Group Inc., based in Ancaster, Ont.; and is a highly sought after international keynote speaker, a frequent guest expert on both national and local TV and radio, and a contributor to the Huffington Post

Blaufus tackled the topic of worst-case scenarios with great eloquence and passion as she told the crowd the story of her life before and after the sudden passing of her husband – a pilot, who lost his life when his plane crashed in a tragic accident that took the lives of him and three passengers. Following the accident, Blaufus was hit with lawsuits from the families of the victims of the crash, and spent 10 years in the courts in financial uncertainty, awaiting decisions from the courts.

“Why do you think I travel around and tell people my story?” Blaufus asked the crowd. “I do it because I was in the business and I thought if anything happened to me I would be able to handle it better than anyone else… I was wrong.”

Understandably, Blaufus was in extreme emotional distress after losing her husband so suddenly. She said having a solid insurance policy in place really helped her throughout her grieving process.

“The life insurance my husband put in place proved to be a safety net,” she said. “It was a gentle place for me to fall until I could find the strength to get back on my feet again to build a new normal for me and my child… if I had to pick myself up financially in addition to everything else, I wouldn’t be here today speaking to you.”

Blaufus stressed the need to have “courageous conversations” with yourself and family members about your finances, guardianship for your children (if they are under the age of majority), and your desires related to your medical needs and funeral wishes, and to engage the appropriate planning professionals when getting your financial house in order.

“It’s really important that you have the proper documentation in place,” she said. “Having a will in place that is drawn up by a lawyer, and that is up to date, is worth its weight in gold.”

Blaufus also encouraged people to introduce their children to their financial planner, and to take a great deal of time and thought when selecting an executor for your estate, and make sure they know your wishes in great detail.

“Share your wishes for raising your children, and share your wishes for disbursement of your estate,” she said, adding that people need to make sure they ask the person they choose as an executor if they will willingly take on this responsibility, and have it recorded in a signed document.

Blaufus discussed the importance of business continuation in the case of a medical emergency or death, and how owners and their businesses can be adversely affected. She said that every company has employees that are key people inside an organization, and everyone should have a plan in place, in case those people (including yourself) are no longer able to work.

“Do you know how things would affect you if a key employee was taken out for a while? What would happen if you became critically ill or required long-term care for yourself, or someone you love was ill?” she asked the crowd. “If you suffered from a long-term disability, is there a long-term disability buyout in place? What’s ‘Plan B’? If God forbid, you were going to die, is there a funded buy-sell agreement in place where all the parties have signed… or is the business you’ve spent your life building going to become a fire sale?”

Blaufus said that, as a business owner, it is vital to have a wealth team in place made up of a financial advisor, accountant and lawyer.

When wrapping up, she reiterated to the crowd the importance of having these courageous conversations.

“Talk with your loved ones, and talk with the necessary professionals,” she said. “We have an obligation to ourselves, and to those we love, to make sure we leave this world in an organized manner. None of us can deal with the emotional loss and try and wade through the financial chaos afterwards, and neither should you have to.”

For more information on The Blaufus Group and her book, “With the [STROKE] of a pen: Claim your life,” visit www.theblaufusgroup.com.

Customers from more than 80 countries experienced two world premieres at the Customer

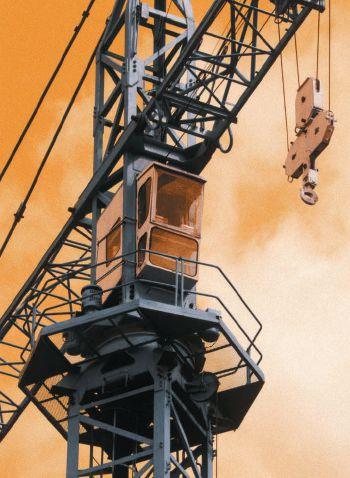

he theme for Liebherr-Werk Ehingen GmbH’s Customer Days was, “Strongly connected,” which was an apt choice as it drew customers from more than 80 countries to Ehingen, Germany.

The event attracted 3,000 customers to the company’s plant in Southern Germany on June 13 and 14, 2018. During the festivities, Liebherr unveiled new crane models from its crawler and mobile crane division.

During an open house day on June 16, Liebherr invited employees’ families and friends and presented impressive mobile and crawler crane demonstrations. International visitors had the chance to tour the production site, with more than 35 mobile and crawler cranes being presented. Highlights were the presentation of the two new crane models.

“We received very positive feedback from our customers,” stated Christoph Kleiner, managing director of sales at Liebherr-Werk Ehingen GmbH. “Both crane presentations of the new crane models LTM 1230-5.1 and LR 1800-1.0 were a huge success. Our innovation park’s ‘Hands-on technology’ were well attended as visitors could experience our technology themselves.”

New mobile crane LTM 1230-5.1

The new LTM 1230-5.1 was the final element of the mobile crane presentation. It is the successor model to the globally successful LTM 1200-5.1. In its development work, Liebherr pursued the objective of increasing both the boom length and the lifting capacity of its predecessor. The result: the LTM 1230-5.1 delivers an extremely long telescopic boom and sets new standards in terms of lifting capacity. With lattice extensions, the maximum hook height has been increased by 10 metres to 111 metres. The new Liebherr LTM 12305.1 is an ideal crane for working on steep gradients and large hook heights, for example, for erecting tower cranes or maintenance work for wind turbines.

To illustrate its flexibility during the crawler crane presentation, technicians set the new LR 1800-1.0 up in front of the spectators within 45 minutes. The LR 1800-1.0 extends the Liebherr range of crawler cranes in the class below 1,000 tonnes, particularly for industrial work such as power plant construction and jobs in the petrochemicals industry. This type of work generally requires luffing jibs and derrick systems. The focus of the product development work on the new large crane was to achieve maximum lifting capacities for these applications; whilst also ensuring low cost transport around the world. The new LR 1800-1.0 is currently the most powerful crawler crane on the market with a basic machine just three metres wide. It is particularly rigid because of the increased design height. A quick connection to raise the superstructure for transport is standard.

Liebherr has been organizing Customer Days in Ehingen since the 1990s. For 15 years, Liebherr has hosted its Customer Days in a regular sequence of every three years. Since the Soccer World Cup in Germany in 2006, the company associates a motto with the Customer Days. From “Stay on top of the game with Liebherr” in 2006, to this year’s motto of “Strongly connected.”

For more information on Liebherr’s Customer Days, the new 800-tonne crawler crane LR 1800-1.0, or mobile crane LTM 1230-5.1, visit www.liebherr.com.

Liebherr-Hydraulikbagger GmbH marked the first construction phase of a new logistics centre for production on June 11, 2018 with an official ground-breaking ceremony. Liebherr will invest a total of around 35 million euros in the project. The project is planned to be completed at the end of 2020.

“With the restructuring and the optimization of the material flow, the logistics centre for production will make an important contribution in the future to efficient and high-quality production,” stated Matthias Herzog, production manager at LiebherrHydraulikbagger GmbH.

Following completion, the new logistics centre for production will have an overall dimension of around 245 x 96 x 22 metres. In the first construction phase, which should be completed by the end of 2019, a new incoming goods area with a highbay warehouse will be built. The planned air lock for lorries with a 20-tonne crane system will greatly facilitate the acceptance of goods. In the second stage another highbay warehouse and logistics areas for order picking, consolidation and packaging are to be erected. The workstations will be set up with modern technical systems and

the complex logistics requirements will be supported by a warehouse management system. For day-to-day work modern picking vehicles with a driving assistance system are available to the employees.

The big challenge of the project lies in the fact that the demolition of the existing warehouse and the construction measures are taking place during ongoing operations. In order to be able to guarantee the material supply in production, the construction is realized in two stages. In addition, Liebherr is currently using several outdoor areas for the storage of production material.

Kirchdorf an der Iller is considered the birthplace of the Liebherr Group.

Hans Liebherr founded the company there in 1949 on the basis of his parent’s construction business. Today, LiebherrHydraulikbagger GmbH develops and produces a comprehensive range of highquality hydraulic excavators, material handlers and articulated dump trucks in Kirchdorf. The company produces approximately 3,000 machines a year and is one of the leading manufacturers in the world in the area of wheeled excavators.

Source: Liebherr

BY JUSTIN BROWN

nyone that has ever dealt with a wire rope supplier has surely heard the old cliché that wire rope is a machine. As overused as it may be, the cliché is true. A wire rope consists of hundreds of components that must move and interact in unison to bend and support massive weights. Like any other machine, a good maintenance program will yield significantly longer life.

AAlthough the subject is much broader and longer than a short magazine article will allow, touching on some of the key points of wire rope maintenance is at least a good start.

A significant part of good rope maintenance is ensuring that the equipment it works with is also in good order. For the rope that mainly means checking the sheaves. Sheaves must move freely to avoid undue abrasion and run true without wobbles to avoid vibrations that can fatigue the rope. Next, the groove must be suitable for the rope being used. It is recommended that the groove be 1% larger than the maximum rope diameter including its allowable tolerance. That means for a typical wire rope with 0 to +5% tolerance, the groove should be nominal rope diameter +6%. Worn and undersized sheaves lead to deformations from forced twist while larger tolerances can lead to damage caused by a lack of support. Corrugation in the groove will both twist and wear the rope. Finally, inspection of rollers must be regarded to be as important as inspection of the sheaves, and also need to be free of corrugation, wear and stuck or worn bearings.

Among the most misunderstood aspects of crane rope maintenance is lubrication. When a wire rope is bent, the individual wires and strands have to slide relative to each other and the rope itself glides within the sheave. Without proper lubrication, friction increases and the rope life is drastically reduced. Checking the lubrication and periodically applying a thin coating of maintenance lubricant is key to any maintenance program. As a rule of thumb, ropes require maintenance lubrication every six to 12 months. When it comes to maintenance lubrication there are a few lesser-known things to keep in mind.

First, the lubricant must be compatible with the original lubricant otherwise, through intermixing, the two products can form a totally different lubricant with different technical properties. Second, a lubricant designed only for wire rope is a must. Wire rope lubrication performs a very specific function with very specific properties; which generally cannot be met by multi-use products such as a typical gear, chain and rope lubricant. Third, the lubricant must be able to penetrate inside of the strands to cover each component uniformly. A product that just sits on the outside does not help the wire rope life; plus it can inhibit inspection (see the photo below).

A common wear area of running ropes on construction cranes is at the drum. Since the rope is wound in multiple layers, it is subjected to abrasion and crushing at crossover points between rope wraps and change in layers. In order to get optimal life from the rope it must be sufficiently tensioned on the drum to five to 10 per cent of working load limit during installation. When a wire rope is sufficiently tensioned it tightens and gains lateral stability enabling it to resist crushing from the incoming loaded rope. When it is not tensioned it will crush much more easily. It is important to note that tensioning is not a one-time event. Over time, unused lower wraps and layers slowly lose this tension and therefore ropes need to be routinely tensioned as part of the crane maintenance program.

But even with perfect tension, wire ropes will eventually wear at the aforementioned crossover points. Another method to extend the lifetime is by cutting a length equal to 1-1/4 drum wraps from the drum end in order to move the wear points. In order for this method to be effective it must be done at intervals that occur prior to these sections showing more wear than the rest of the rope. Three or more times over the ropes lifetime is recommended.

For tower cranes, the problem is usually compounded. The crane starts at a base height and climbs during the job leaving lots of unused rope in the lower layers on the drum, not to be used until the crane is climbed to is final working height. These lower layers at the start of the job cannot be practically re-tensioned or shortened until the rope climbs high enough to fully spool the rope off. Unfortunately, by the time the rope at these lower layers is needed it may already be damaged. The solution is to plan to use a different length of rope for each stage of the job. This ensures that there aren’t any unused, low-tension layers becoming damaged before seeing any useful life and in most cases the ropes can be used again at the next job. Following these steps can greatly increase the total lifetime of wire rope and thereby lower the total cost of ownership and that is the key indicator of any good maintenance program.

Justin Brown is the product manager for wire rope at Unirope Limited.

Take your business to the next level with the new Demag AC 300-6. It delivers class-leading reach combined with strength, including the ability to lift 15 t on a fully telescoped 80 m boom. To allow for high versatility, the AC 300-6 can be adapted to the needs of a variety of jobs and is the smallest crane in the Demag AC range with a luffing jib. The HAV and many components are shared with Demag 5-axle cranes — increasing your return on investment and reducing the amount of spare parts you need to have on hand.

BY HOWARD J. ELMER

uiet. That word describes, perfectly, the new 3.0L Power Stroke diesel just introduced by Ford. I’ve driven it, stood beside it while idling and floored it uphill while towing – it is eerily quiet. This trait, plus the power it makes, now available in the F-150, makes this introduction a true milestone in the history of the F-series. And, as of today, you can order this diesel engine in your new half-ton – a first in the 70-year life of the brand.

QIf you do, here is what you’ll be getting.

This new engine (under development for several years now) uses V6 graphite/iron block architecture; a variable geometry turbocharger; 29,000 psi injection fuel rail and aluminum pistons. It displaces 3.0L and makes 250 hp at 3,250 rpm and 440-lb.-ft. of torque at 1,750 rpm. It does use DEF (diesel exhaust fluid) along with a particulate filter and highpressure cooled exhaust gas recirculation technology to reduce emissions.

Ford’s SelectShift 10-speed automatic transmission is the other half of this new powertrain. It’s already in use with several of Ford’s engines and has been getting good reviews. This non-sequential transmission is also part of the fuel economy improvements that Ford is seeking. This effort also includes the auto stop/start feature that is now standard on all F-150’s; gas or diesel.

Ford is claiming a fuel consumption number of 10.8L/100km city and 8.0L/100km on the highway for the 3.0L. So, while these numbers are light, the capabilities of this diesel-equipped truck won’t be. To start with, the published torque number is currently best-in-class as is the towing (up to 11,400 lb.) and the payload (up to 2,020 lb.). With this new Power Stroke in the stable, the F-150 now offers customers an unequalled choice of six engines.

The recent first drive of this diesel was as impressive as the numbers suggest. I found it strong, efficient and very well paired with the SelectShift transmission. I towed with it and drove it with payload – the quiet, as I already mentioned, was impressive. But then so was the vibration and harshness – as there wasn’t any. The torque comes on as soon as you start to roll and pulls strong and straight through the gears. The strength here is evident, not just from the feel, but also from how the transmission handles the power. With 10 gears you might expect the tranny to hunt or drop several gears when the accelerator is mashed. Not so. Even during floorboard acceleration it drops at most two gears, most often just one – it’s that strong. As for backpressure, it too is even, quiet and strong; holding just about any gear while coasting down long grades. As for the fuel numbers, I beat them. Driven gently this engine can easily best the numbers that Ford is claiming. Overall, this introduction and my first drive of it, was a smile-inducing success. I suspect that the truck-buying public will also feel the same way about this newest F-150 engine option.

So, while Ford’s new small diesel is certainly welcome, it does beg the question – what took them so long? Watchers of the brand (like me) have been pestering Ford about bringing in a small diesel for years. Normally, in trucks, they lead in the trends. First with

an aluminum body; first with a 10-speed transmission; first with a flat rear floor; first with an integrated tailgate step; first with a factory trailer brake controller; and the list goes on.

Yet in this one area they let Ram, GM, and even Nissan, do it first. Those companies have been offering small displacement diesels in 1500-series trucks for several years now –and doing very well with them.

The F-series sold a total of 896,764 units in 2017 (everywhere). It’s the single most popular pickup truck in Canada for over 50 consecutive years. Looking at just these numbers and even without knowing much about the auto business you can easily see trucks are Ford’s bread, butter and dessert. So, why take so long to bring the small diesel to market?

My personal opinion – EcoBoost. After its introduction in 2011, Ford repeatedly said that the “future” was all about EcoBoost. They felt that this high compression, turbo heavy, gas engine technology would set them apart. Well, yes, EcoBoost has its place, but as they have now finally acknowledged, so does diesel.

On the other hand, this late arrival may have more to do with the long journey this engine has had to make. For starters it’s built in England, and also shares a design history Jaguar/Land Rover.

Ford’s Dagenham plant, outside London, has produced over 10 million cars and

37,000,000 engines since Edsel Ford turned the first spade of dirt beginning its construction back in 1929.

Today its primary business is building engines, which includes a contract with Jaguar/ Land Rover (once owned by Ford but sold to Tata Motors in 2008). This 3.0L F-150 diesel started out as a clean-sheet design that would power vehicles from both companies, then owners changed and times changed. In the end, speculation aside, it’s a story that ends well. This new engine is impressive.

If, like me, you’ve been waiting for Ford to join the new age of small diesel you may well decide to head down to your dealer and order one. However, as the rollout begins, the new diesel will only be available as part of the more expensive trim packages.

Customers can choose this engine option for 2018 F-150 Lariat, King Ranch and Platinum edition SuperCrew trucks with either a 5.5-foot or 6.5-foot bed configuration, and SuperCab trucks with a 6.5-foot bed. Pricing, with this restriction in mind, will then start at $51,449.00 and walk up through $77,979.00

Now for fleet customers, 3.0L Power Stroke diesel engines will be available on all F-150 trim levels with SuperCrew 5.5-foot or 6.5-foot bed configurations and SuperCab trucks with a 6.5 foot bed. That means the entry price for Fleet will be $36,749.00

The construction industry has seen steady growth over the past decade, fuelled by significant building and infrastructure projects. However, finding skilled crane and heavy equipment operators has proven to be increasingly difficult. For example, a 2017 poll indicated that over 75 per cent of construction firms were having trouble finding skilled equipment operators.

There is no argument that operators need to be trained; however, training can be a risky activity that can’t be taken lightly. Vehicle/equipment accidents are the leading cause of workplace deaths on construction worksites, and placing inexperienced operators on machinery can add unnecessary risk to the student, the instructor and the worksite in general.

Aside from the risk of injury, the cost of construction equipment training can be substantial. One company interviewed noted that renting equipment to train student operators costs between $8,000 to $10,000 per month. After adding wages, fuel, insurance, and maintenance, the annual cost of training can top $100,000 per piece of equipment.

The use of computer-generated simulation for training purposes has a long history in the flight industry. Saving flight time, fuel costs, and wear and tear on planes, not to mention avoiding risk, simulation has been the defacto standard for commercial pilots since the 1970s.

In the late 1990s and early 2000s, companies focusing on the simulation of mechanical vehicles and earthworks started to appear, offering training simulators for construction scenarios.

These terrestrial simulators share similar benefits with flight simulators — lowering both the operating costs and the risks involved in a novice training on the real equipment.

The investment in simulation-based training can not only help to fill employee and training gaps, but do so in a costeffective, efficient, and safety conscious way.

This paper reviews the traditional costs of training, the savings that simulation can provide, and additional benefits of integrating simulators into training programs.

It also shows how two organizations have successfully implemented simulation-based training programs and highlights key considerations when determining how to evaluate if simulation fits into your training program.

THE TRADITIONAL COSTS OF TRAINING

Training recruits into worksite-ready crane and heavy equipment operators is essential for a safe construction industry. Conducting training programs on machinery has both direct and indirect costs; implications to consider when evaluating the costs of your current training.

Direct costs

Equipment: Crucial to any training program is having the machinery on hand. The price tag on construction equipment can be quite substantial; full-sized backhoes

range between $50,000 and $80,000, motor graders can cost between $200,000 and $500,000, and tower cranes can stretch into the $1 million to $2 million range. Even with discounted long-term rates, rentals of the same machinery can end up costing even more.

Fuel: Cranes and heavy equipment need fuel to power their engines and motors. For every hour of use, there will be a fuel cost that adds up quickly. For example, a new wheel loader, burning 3.75 gallons of fuel per hour, could cost between $18,500 to $22,500 in diesel per year.

Maintenance: In general, machines need to be kept in good working condition, with costs including replacing lubricant and tires, the parts required for repairs and the field-rate for mechanics.

Wages: A certified, qualified, and trustworthy operator needs to be on hand during training to offer mentoring and supervision. Their wage is a cost of training that can add up quickly.

Insurance: Operators need to be insured against damages to protect both them and your organization.

Productivity: Along with paying an instructor to provide training, there is an additional “opportunity cost” as that particular operator’s work isn’t contributing to the completion of a project. Similarly, equipment being borrowed from the worksite to offer training could have been used toward progressing the job.

Injuries: Inexperience is a major factor in workplace injuries; therefore, student operators present an added risk. Injuries add significant costs to a worksite, with each workplace injury costing an average of $38,000 in direct and indirect costs. These can include: Lost/decreased productivity; production downtime; administrative costs; unwarranted negative media attention; potential OSHA penalties; attorney fees; damage to equipment, machinery, and facility; higher Worker’s Comp premiums; reputation loss; degraded client loyalty and support; managerial costs including inspections, investigations, meetings, and administration; loss of employee morale; and slowed work pace due to other employees fear of injury.

Simulation holds some key advantages when compared to traditional training. While simulation is noted as a “risk-free” training experience, it also offers a cost-reduced tool that can provide an experience transferable to the jobsite. Some areas of differentiation have been highlighted below:

Equipment: While simulation does have a cost, the digital nature of it makes it much more affordable. With construction simulators ranging from $10,000 to $100,000plus, based on features, simulation can fit in many budgets at an investment lower than most machinery. Some simulation vendors have also developed hardware (simulators) that allows for interchangeable training modules. Equipment

costs can be shared across multiple training programs, useful for larger organizations that previously required the rental or purchase of numerous machines.

Fuel: Aside from electricity and networking costs, fuel is not required for simulation-based training.

Maintenance: The cost of repairing a simulator is much less expensive than labor-intensive repairs needed on real equipment. As well, by lowering use time and therefore wear-and-tear on the equipment, items like tires and lubricant last longer and need to be replaced less often.

Wages: With trainees requiring close supervision on real machines, instructors are limited to working in a one-to-one ratio with students. However, simulation is less risky, meaning that oversight can be spread among students, and one instructor can train multiple students at a time. Similarly, training can be pre-programmed and recorded, meaning students can access the simulation without an instructor on hand, and their performance can be assessed and evaluated at a later, more convenient time.

Insurance: While student operators will need to be insured to use real equipment, less time spent on machines may positively affect premiums.

Productivity: Instruction is important; however, simulation can be used as a self-directed exercise for student operators. With instructors being freed up during these self-directed sessions, and fewer instructors required in general, experienced operators can return to productive work. Similarly, machinery can be put back into productive rotation.

Injuries: One of the key benefits of simulation is its safety. Time on the simulator is time that is injury free.

THINGS TO CONSIDER WHEN EVALUATING SIMULATION

Like any other purchase, it’s important to evaluate how simulation will affect your budget and your processes. The following are some key considerations to keep in mind while you’re looking at simulation providers:

• Your current training costs are an important figure to know. Having this number on hand lets you compare as you gather information on simulation;

• Only accurate simulation is transferable to the worksite, so ask vendors specific questions and have experienced operators test the simulation;

• Enquire about the simulation platform and the ability to run multiple machines from one simulator. This can help defer the costs, especially when training a large fleet of machinery;

• Think about how simulation would affect your current training costs: For each hour of training shifted to simulation, there are savings in terms of fuel, maintenance, and rental costs;

• Training on a simulator can be concentrated, as weather and time of day do not affect simulators;

• Instructors can manage more than one simulator simultaneously, which may increase student throughput; and

• If certain training exercises are more prone to causing accidents or injuries, these are ideal exercises to move to simulation ASAP.

Written by Myles Carter, content manager for CM Labs.

Manitowoc has revealed the newest addition to its award-winning range of crawler cranes: the Manitowoc MLC100-1 crawler crane. The company debuted the crane at its Crane Days event in Shady Grove, Penn., showing how it’s the quickest crane to erect and decommission in its class, saving lifters valuable time on the job site.

The MLC100-1 has a 100t (110 USt) capacity and a maximum boom length of 61m (200 ft.). The new-model crawler crane has an impressive load moment of 371 t-m (2,680 ft.-kips) and is powered by a 300-hp Cummins 6.7 L Tier 4 Final engine.

The crane will save customers time on the job site because of its self-assembly hook, which enables the operator to install the counterweight without any outside assistance. During assembly, the crane uses a single segment of hoist line with a button termination, which is routed through sheaves in the boom butt. This eliminates the need to assemble the boom top and enables operators to get to work faster when compared with competing cranes in the same class.

The MLC100-1 has an improved, wider cab design, with easier access to the cab made possible by additional grab bars and a movable left-hand console. In addition, the cab’s high-back seat with head rest and electronic seat controls combine with improved HVAC performance for best-in-class comfort.

The crane allows for easier service than ever, with high-visibility sight glasses and quick drains on every gear box. The main valve is also easily accessible. The crane operates via Manitowoc’s Crane Control System (CCS), which can be used in conjunction with the company’s new Diagnostic Code App to quickly analyze diagnostic screens.

End users can customize the MLC100-1 with numerous options to suit their specific job site needs. These include a free-fall option, a third-drum option with a 22-m (72ft.) wire rope, generator-powered boom lights and a cold weather package for high performance in the toughest climates.

Joining the MLC100-1 on display at Crane Days is the MLC300 crawler crane. The MLC300 is outfitted with its new 3.5 m- (11.5 ft-) wide boom inserts and extended upper boom point, which provides an off-set lifting point for wind maintenance or other jobs that require a higher hook height. www.manitowoccranes.com

The fabrication and attachment of wire rope end fittings onto a wire rope is a core competency of Unirope. With incomparable expertise and accumulated engineering experience in this space, Unirope can provide anything from a simple flemish eye splice which, forms the basics of a lifting sling, to complicated purposedesigned fittings for highly engineered lifting solutions.

Unirope’s fabrication shops are specifically designed to provide custom solutions while their wire rope department, with a total of 11 rope swagers ranging from 35- up to 1,500-ton capacity, enables fittings to be swaged up to 3” rope diameter and socketed up to 6” rope diameter. www.unirope.com

Manitex International, Inc. recently announced the expansion of its industrial crane line with the addition of the Manitex CD110 industrial carry deck crane.

The CD110 Industrial carry deck crane provides 11-ton base rated capacity; 35-foot, three-section boom and 53-foot maximum reach when equipped with optional jib. This machine fits the needs of refineries and manufacturing facilities with its versatility and strength. Along with the CD110, Manitex’s strong line of industrial cranes includes models ranging in capacity from 10 to 30 tons.

“The CD110 is designed around input from rental fleet owners to suit refineries and petrochemical applications,” stated George Pocock, industrial sales manager for Manitex. “This model’s compact design is also well suited for work in manufacturing maintenance and retooling projects. With 35 feet of boom, excellent on rubber capacities, along with two-position out/down outrigger configurations, this unit offers best in class load chart while remaining simple to use and cost effective.” www.manitex.com

Strongco Corporation has appointed Oliver Nachevski, formerly vicepresident, Construction Equipment, to the position of vice-president and chief operating officer (COO).

“Over the past several years, Strongco has undergone significant change in an effort to reposition the business and focus on our core strengths. The creation of the COO role will provide more centralized leadership, with the goal of delivering greater operational excellence during the next phase of stability, sustainability and strategic growth,” said Robert Beutel, executive chairman of Strongco. “Oliver’s many years of service at Strongco, combined with his demonstrated leadership, make him well suited to propel our operating initiatives across all of the business units. On behalf of the Board of Directors, I look forward to him bringing this experience and commitment to his new post.”

JD Neuhaus (JDN) has further enhanced its remote control capabilities with three remote control models that are now available.

The RC-X, RC-S and RC-SP are each comprised of a transmitter and receiver and all can either be integrated in existing JDN solutions or directly combined with a new JDN hoist.

One of the many advantages of the new JDN receiver is its rigid and extremely compact design.

As vice-president and COO of Strongco, Nachevski will oversee all operations, including construction equipment, cranes and finance, and will play a key part in coordinating and integrating the business for maximum efficiency and reward.

“This is an exciting time for Strongco in terms of the strategic transformation of the company,” said Nachevski. “In collaboration with our strong team, I look forward to the opportunity to drive the business forward.”

Nachevski joined Strongco in 1996, and since that time he has made a significant impact on many facets of the business. He has held many titles, such as controller, Western Division, where he earned a CGA designation in Alberta. In 2004, he accepted a position at head office as assistant controller and national credit manager, and later director, National Credit and Inventory. In 2008, Nachevski became operations manager of the Cranes and Material Handling Division, and in 2012 was promoted to lead the implementation of Strongco’s new SAP computer system as director of dealer management system implementation. In 2013, he was appointed regional vice-president, Case, and in 2016 was promoted to vice-president, Construction Equipment, which centralized leadership for both Strongco’s Case and Multiline/Volvo divisions.

Sept. 10-13, 2018

ACPA Conference

Saint John, N.B. www.acpa-ports.net

Sept. 11-12, 2018

Oil Sands Trade Show & Conference

Fort McMurray, Alta. https://oilsandstradeshow.com/

Sept. 16-18, 2018

BCRB Fall Conference Kelowna, B.C. www.roadbuilders.bc.ca

Sept. 26-28, 2018

SC&RA Crane & Rigging Workshop Louisville, Ky. www.scranet.org

Oct. 23-25, 2018 CanWEA Annual Conference & Exhibition Calgary, Alta. www.canwea.ca

NOVEMBER 2018

Nov. 7-8, 2018

All components are housed in a space-saving, shock-resistant GRP (glass-reinforced plastic) casing featuring protection class IP65 (dust and water protected). A breathable membrane guides any condensation away from the interior to the exterior.

The design also offers seawater-resistance for offshore applications. The radio remote control model RC-X is even suitable for the use in potentially explosive environments rated up to ATEX zone 2/22.

Consideration has also been given to ease-of-installation. Even existing JDN hoists and cranes can be retrofitted thanks to the standardized interface of the JDN RC.

The receiver can be mounted directly on the hoist or the trolley, or individually at site. The compact design of the receiver makes it even suitable for hoists with low carrying capacity.

Individual solutions according to specific customer needs are available. Up to 20 hours of use is possible before recharging of the portable transmitter is required.

Perfect for covering long distances between hoist and operator, the JDN RC represents a sensitive alternative to applications with long control hoses.

In addition, the JDN RC can be used in hard-to-reach places and for simultaneous control of multiple hoists. www.jdngroup.com

Link-Belt Cranes recently introduced the all-new 348 Series 2 300-ton (273-mt) lattice crawler crane. Over the years, Link-Belt’s 348 class of lattice crawler has been job-proven on projects from Prudoe Bay, Alaska to Miami, Fla. Crane owners and operators will have a lot to like about the new 348 Series 2 300-ton (273-mt) lattice crawler crane. First shipments of the new 348 Series 2 will begin fourth quarter 2018 following final testing in Lexington, Ky.

Manufactured and assembled in North America with support around the globe, Cummins QSL 9 350 hp Tier 4 Final and Tier III engine options are both available and deliver efficient power to a Kawasaki pump and motor package for fast, responsive, fingertip control providing simultaneous operation wherever it is needed.

Dual swing motors provide dynamic control for the incredibly smooth free swing all Link-Belt HYLABS are famous for having. The operator can also dial swing speed up or down with volume speed controls in the cab. Matching hydraulically driven main and auxiliary hoist drums utilize LinkBelt designed gear drives for either straight power-up/power-down auto brake mode, or can also incorporate an optional “wet clutch” free fall feature, if required. www.linkbelt.com

Buildex Calgary Calgary, Alta. www.buildexcalgary.com

Nov. 15-16, 2018

SHCA Annual Fall Convention Regina, Sask. www.saskheavy.ca

Nov. 26-28, 2018 CCA Fall Board Meeting Ottawa, Ont. www.cca-acc.com

Nov. 28-30, 2018 The Buildings Show Toronto, Ont. www.thebuildingsshow.com

Dec. 6-8, 2018

BCRB AGM & Winter Celebrations Victoria, B.C. www.roadbuilders.bc.ca

JANUARY 2019

Jan. 22-25, 2019 World of Concrete Las Vegas, Nev. www.worldofconcrete.com

FEBRUARY 2019

Feb. 13-14, 2019

Buildex Vancouver Vancouver, B.C. www.buildexvancouver.com