PRINTACTION

WIDE FORMAT RESOURCE GUIDE

PLUS Audrey Jamieson, president of Marketing Kitchen P.10

PLUS Audrey Jamieson, president of Marketing Kitchen P.10

Dramatic printed visual elements illustrate a painful past P.5

As president of Simpson Print, Carla Johanss has ambitious plans for the company P.13

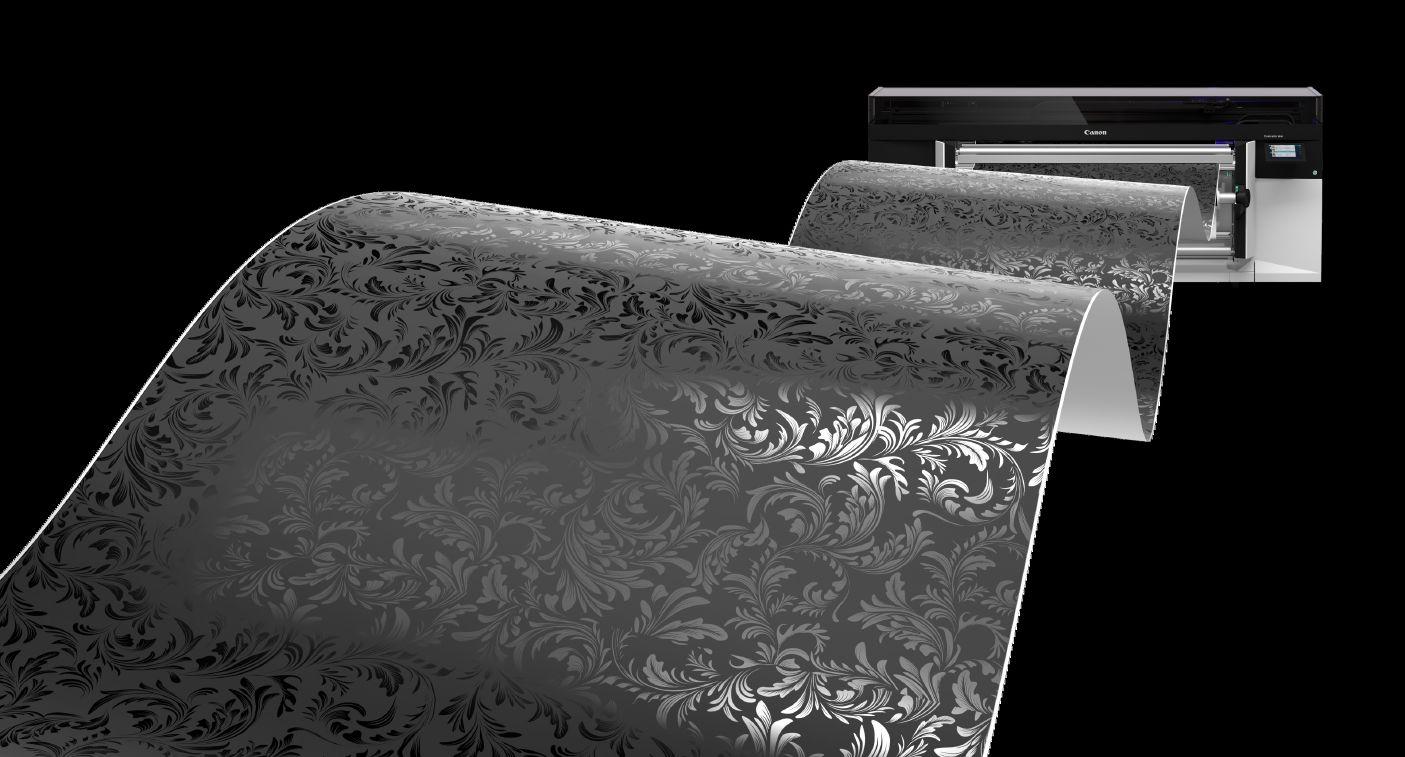

With the FLXfinish technology and the Colorado Series’ UV LED curing, the Colorado 1630 & 1650 have the flexibility to print either with a velvety matte finish, or a smooth mirror-like gloss; all while offering an unusually rich gamut, and maintaining sharp details.

Now, thanks to the new FLXfinish+, we can combine the two curing processes in one step, to enable you to print applications with both matte and gloss finishes, in one go!

www.canon.ca/FLXplus

Reader Service

Print and digital subscription inquires or changes, please contact

Barbara Adelt, Audience Development Manager

Tel: 416-510-5184

Fax: 416-510-6875

Email: badelt@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor

Nithya Caleb

ncaleb@annexbusinessmedia.com

437-220-3039

Media Designer

Lisa Zambri

lzambri@annexbusinessmedia.com

Account Coordinator

Alice Chen

achen@annexbusinessmedia.com

416-510-5217

Media Sales Manager

Kim Barton

kbarton@annexbusinessmedia.com

416-510-5246

VP Production/Group Publisher

Martin McAnulty

mmcanulty@annexbusinessmedia.com

COO

Scott Jamieson

sjamieson@annexbusinessmedia.com

Once

reluctant

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 printaction.com

Tel: 416-442-5600 • Fax: 416-442-2230

Light Visions creates a sensory experience with large-scale graphics

By Nithya Caleb

The show-stopping Mandela: Struggle for Freedom exhibition was produced by the Canadian Museum for Human Rights (CMHR), Winnipeg, in collaboration with the Apartheid Museum in Johannesburg, South Africa. It debuted at CMHR in 2018. In 2019, it began travelling across North America.

Exhibition details

Mandela: Struggle for Freedom takes visitors through the story of South Africa’s first president Nelson Mandela and the struggle of Black and other non-white South Africans for free-

dom from colonial rule and apartheid.

“This was our first blockbuster travelling exhibition since the museum opened. We wanted to create a sensory, immersive experience utilizing scenography and large-scale graphic elements,” explained Rob Vincent,

acting director of design and innovation at the Canadian Museum for Human Rights.

Key visual components of the exhibition were printed and fabricated using HP Latex 3600 technology by Light Visions, a Winnipegbased specialized printing company, in spring

Light Visions used a variety of materials like vinyl, paper, acrylic, wood, steel and fabrics to create textile banners, wallpaper and vinyl wraps.

2018. Light Visions used a variety of materials like vinyl, paper, acrylic, wood, steel and fabrics to create textile banners, wallpaper and vinyl wraps. This contributed to the rich sensory experience featuring dramatic visual elements and original artifacts.

Light Visions printed 280 to 300 image and text panels and large-scale murals. All the panels were uniquely built.

The project comprised 18 murals. The biggest one was 33 x 11 ft. Light Visions also created 71 vinyl wrapped story and text panels. These panels were joined together to create massive panel clusters.

The exhibit included a dramatic “Wall of Laws” that visually illustrated the oppressive rules of apartheid, the system of racial segregation that existed in South Africa until 1994 when Nelson Mandela became the country’s first democratically elected president. The Wall of Laws comprised 74 panels.

The museum’s project team wanted to use materials that were relevant to the time frame and area where the story was taking place. As a result, wood and steel were used throughout the exhibition, as well as vibrant graphics and typographic treatments, explained Vincent.

The exhibition itself was divided into five chapters. The Wall of Laws anchored the “Apartheid” chapter. For the “Defiance” chapter, a living room set in the Sixties showed how people were fighting apartheid. A life-size scale of Nelson Mandela’s jail cell anchored the “Repression” chapter. “Mobilization”, the fourth section, was headlined by a life-sized Casspir tank to show visitors what it was like to defend oneself from tanks with garbage cans. Finally, the last chapter, “Freedom”, was a

celebration of South Africa’s first democratic elections and Mandela’s win.

For each chapter, the curators wanted to create a large anchor with scenographic elements to emphasize that particular section. This approach is exemplified by the Wall of Laws, a tall mural consisting of laws and signs that were used in South Africa at that time to enforce the system of apartheid. The Light Visions project team ensured all signs were printed on the substrates (e.g. plastic, wood, steel) that were used originally to ensure authenticity and potentially transport visitors to South Africa.

Allan Brooks, president, Light Visions, recalls distressing plywood to ensure it looked like the wooden sign panels used in South Africa. The team also deliberately rusted metals before printing on them.

In the end, “the signs we created blended seamlessly with to the original signs” that were also in display, said Brooks.

“The only difference between the installation and the actual artifacts is that the latter are behind plexiglass. Other than that, you would

have a really hard time differentiating the two,” added Vincent.

A lot of the textures used in the exhibition resembled shweshwe, a fabric that was brought into South Africa by Europeans. Though its origin is colonial, the South Africans made the fabric their own by adding more vibrant colours, patterns and textures.

“In the beginning of the exhibition, the colours are quite dull; just black and white, but as the story progresses, you’ll see other patterns

Light Visions created large graphics with scenographic elements to anchor the different sections of the exhibition.

and colours including blue, green, red and yellow. If you look back at exhibition at the end of it, you will see all the colours of the South African flag come together in unity,” described Vincent.

Nearly 90 per cent of the exhibition was printed on HP 3600 with latex technology.

“We can print just about anything on the HP 3600. It has a lot of controls. It is also eco-

The Wall of Laws was direct printed with UV inks.

friendly since it is latex,” said Brooks.

As mentioned earlier, the Wall of Laws was a 17-ft tall wall comprising printed laws, signs and photos. It was a challenging concept. Since the show was travelling, the project team had to create a modular design.The modular panels also had to fit together so that the installed exhibit looked like one seamless piece.

“The Wall of Laws wasn’t just a collection of

The visual elements of the Mandela: Struggle for Freedom exhibition were printed and fabricated by Light Visions on HP 3600 latex printer.

panels stuck on the wall. They all overlapped, and were at different levels. Further, they had to be mounted to plywood panels. It was a really complicated piece. Also, we didn’t want them to look like they were mounted to plywood panels. They had to look like they were literally floating off the wall. It was a tremendous challenge,” recollected Brooks.

One unique feature of the exhibition is that the

large, integrated story and text panels were built to be assembled with the ease of an Allen key to make crating and assembly easier.

“We refer to these panels as monoliths. Each monolith has three or four 1- to 3-in. thick panels, each over 300 lb.We managed to reduce the weight in half by hollowing out the backs of the panels without affecting the overall look. Now, they all had to be assembled and disassembled. So, we came up with a system to assemble them with Allen keys. We even de-

signed custom wall hardware for them because they had to be lifted onto the wall. We wanted to ensure the assembly was easy for everyone,” explained Brooks.

The initial design plan exceeded the budget.

The Light Visions project team had to fit the design vision into the budget.

“One of our biggest challenges at the beginning was figuring out how we were going to produce the exhibit without losing the impact and at the same time stay within budget. I think we were successful in that,” said Brooks.

Typically, exhibition panels will have to be reprinted if they are travelling to several locations due to normal wear and tear. However, this exhibition “is still almost the same as it was, which is phenomenal,” said Vincent.

The exhibition was a huge success for CMHR, which had an increase in visitors. Around 80 per cent of visitors came for the exhibition.

This was the largest and most complicated exhibition for Light Visions since a Jane Goodall exhibit.

“We love working with CMHR because they constantly challenge us with new designs and initiatives. Rob always likes to raise the bar, and my staff loves the challenge,” said Brooks.”

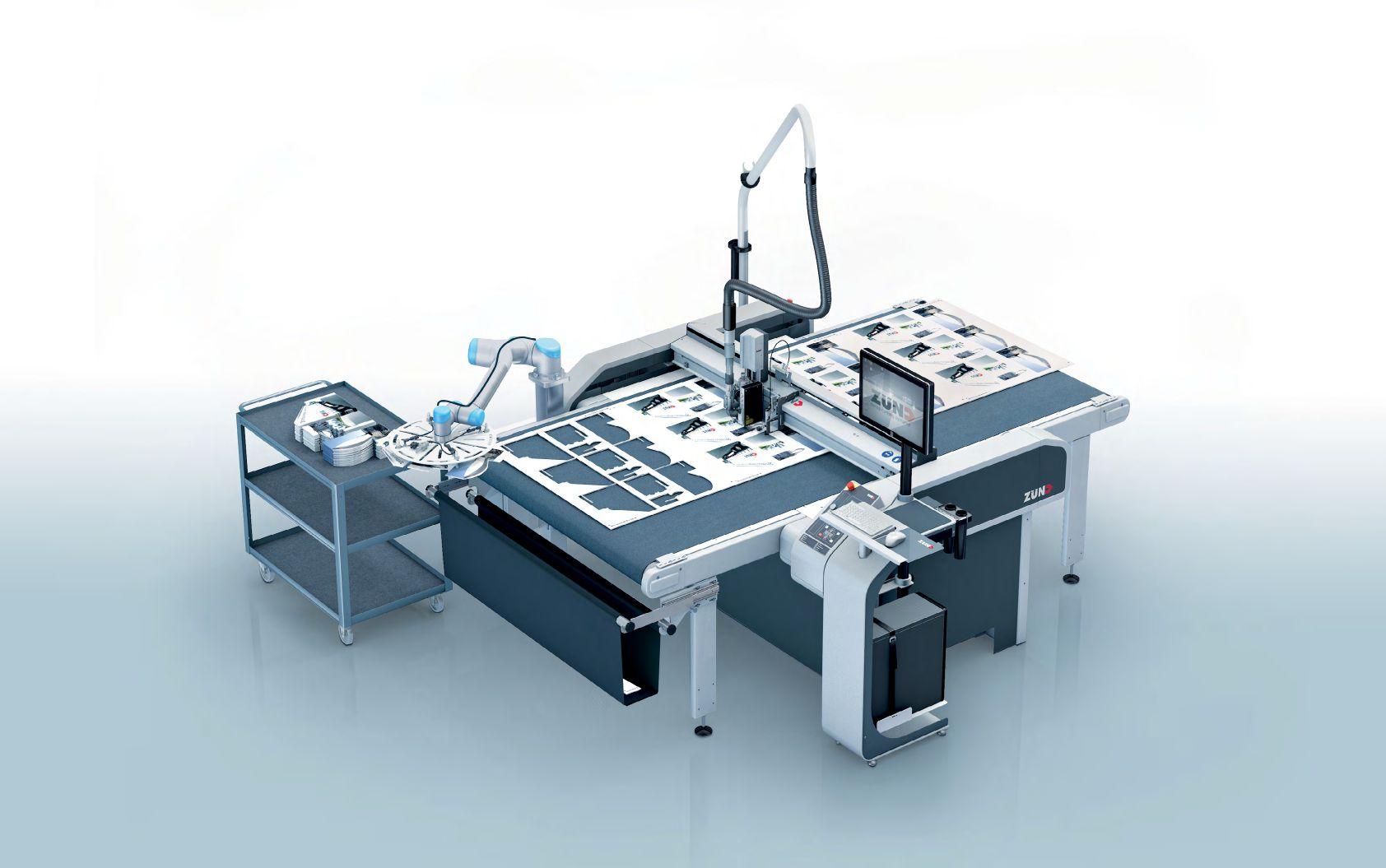

– Prepress and meta-data based production-workflow automation – Continuous productivity monitoring and KPIs with Zünd Connect – Semi- to fully automated/robotic material-handling options

and #Letstalkworkflow!

By Nithya Caleb

Audrey Jamieson is the president of Marketing Kitchen (2014), a direct marketing production company specializing in direct mail and fulfillment. Jamieson founded Marketing Kitchen in 2014, and works out of a 40,000-sf facility in Markham, Ont.

An expert in all things personalized, she fully understands variables, paper, die-cutting and fulfillment. In February 2021, the 53-yearold launched 5am Lemon, a personalized greeting card gift box company.

AJ: I always had a passion for greeting cards, as well as print, paper substrates and shopping (both online and in-person). During the first wave of the pandemic, it was near impossible to send a gift online and couple it with a personalized greeting card. I tried a few times through Chapters/Indigo, and the message was always

printed on the packing slip, which was missed by the recipient. I thought it would be great to order a fully personalized card online and have it accompanied by a small gift or gift card. I had just installed the KM-1 inkjet press that had a 23 x 29 sheet size with full variable capabilities, so I started playing with the sheet.

The next thing I know, my team and I had created a fun and functional greeting card gift box for my daughter’s university graduation. I even took advantage of the side panels, which formed the box, and included pictures of her with her roommates that she could remove and display.

AJ: I think outside of the current supply chain issues with paper, the state of the print industry is strong. Print is an amazing compliment to digital. Print delivers a tangible punch that is

tough to match digitally. Print and direct mail also carry a ton of credibility that is harder to match with digital.

AJ: I started selling advertising for special interest magazines back in the early 90’s. That was my first introduction to the print world, and I have been in love with print ever since.

AJ: I think as an industry we need to show young people how unique and powerful print can be in a digital world.

We know they are super comfortable with everything and anything digital, but may not

feel as comfortable in the tangible world of print. We need to make sure we educate and expose younger generations to the different printing platforms, paper substrates, embellishment opportunities and all the other finishing options available for print communications.

Print is an amazing compliment to digital. Print delivers a tangible punch that is tough to match digitally.

In such a competitive landscape, how can printers win more sales?

AJ: Printers need to go beyond just putting ink on paper. They need to constantly be in consulting mode and assist clients with the creation of their pieces. They need to introduce new paper stocks, finishing ideas and cost-efficient solutions.

are some of the biggest opportunities in the print industry?

As humans, we love engaging in anything we are really good at or know a lot about. The print world can be a scary unknown to younger generations, so we need to introduce them early as well as take advantage of their creative minds.

We always joke with our clients that we have tons of ideas, and some of them are actually pretty good. Today, marketers have more advertising options than ever before and anyone selling print or direct mail need to offer an expertise that goes well beyond knowing paper and ink.

AJ: I see an opportunity for marketers to really stand out in the mailbox using print. The inbox is overflowing, and the digital market can feel a bit saturated. Print offers a refreshing medium that does not interrupt your day, and can be consumed at leisure. Increasing personalization and relevance to a targeted audience is key. When you couple that with good creatives, you have a winning formula.

AJ: Production inkjet printing is definitely

exciting. The ability to offer high-quality, fully variable pieces on unique substrates at an affordable price is really cool. The integration of print with digital will keep getting stronger and it’s going to be great to see how creative marketers are going to use the two media. As an aside, who would have thought it would take a pandemic to make QR codes cool again. I think in the future we will be seeing these codes on much more than just restaurant tables.

Jamieson’s responses were edited for length. For more Q&A Spotlight interviews, please visit www. printaction.com/profile.

Not only does Spicers provide products, services and specialists to support your business goals, we’ll also help you stand out in a competitive landscape. Our National Technical Team uses a tailor-made strategic approach to help customers find efficiences while focusing on their specific business goals and challenges. Get In Touch With Us signanddisplay@spicers.ca 877 790 2335 spicers.ca

Once a reluctant president, Carla Johanns has now embraced the role

By Nithya Caleb

In 2012, when Carla Johanns, president of Simpson Print, Bloomingdale, Ont., moved back into her parent’s home to support a grieving family and stabilize a struggling business due to the tragic death of her brother, she didn’t realize that her life had indefinitely changed.

Until then, Carla, a single mother of two girls at that time, was living in Niagara, Ont., and pursuing her master’s degree. Carla never imagined that one day she would be leading the family business. However, the death of her younger brother, who was the company’s principal shareholder then, propelled Carla into unchartered waters.

“We lost almost $3 million in 90 days. I sat in the hallway and did what comes naturally: sell,” recalls Carla, who was always involved in

sales in some capacity throughout her professional life.

In a hyper-competitive market, Carla, a

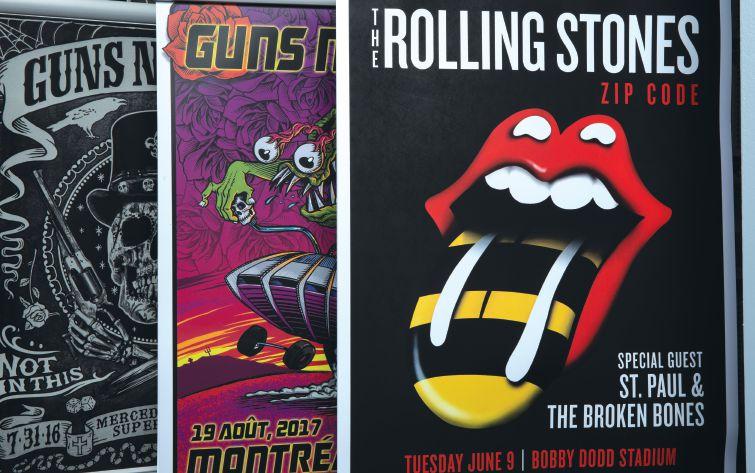

Simpson Print is known for combining art effects with unique finishes on diverse substrates.

goal-oriented individual, managed to successfully turn around the business. Simpson Print posted a profit of $9.7 million last year. This year, it earned $13.1 million. Carla is forecasting a revenue of $15 million for the next fiscal year.

After almost 10 years, Carla is no longer the “reluctant” president of Simpson Print. The 49-year-old has embraced her role as the company’s executive head, and has ambitious plans for the business. She also owns 25 per cent of the company’s shares.

Simpson Print is known for integrating art effects, coatings and unique finishes with special effects and embellishments on diverse and unusual substrates.

We’ve very substrate-savvy. We’re great at merchandising, metallic packaging, obscure postpress, diecutting and finishing, and managing budgets for a Cadillac end-result,” explains Carla.

Carla’s father, Martin Johanns, is the minority

shareholder, chair and founder of Simpson Print. An immigrant from the Netherlands and an aspiring arborist, he discovered his entrepreneurial calling in offset printing.

In 1964, he began a company called Johanns Graphics. This was the heyday of conventional Renaissance printing of annual reports and magazines. Carla remembers watching designers working on storyboards in a 1,000-sf room.

“My father is an extremely passionate ambassador of ink on paper and the craft of print. His enthusiasm and think-ahead mentality carry us even today,” says Carla.

Even though the company was successful, technological changes, such as the introduction of desktop publishing and elimination of film, were starting to emerge. Martin sold the company before the economic crash of 1990.

Two years later, Carla’s mother, Maddy, found, in the middle of another farm field, a screen printing company called Simpson Screen Printing with one client, MTD. The company made $1.3 million in sales of label identification on lawnmowers and other industrial applications.

As an early adopter of an increasingly popular technology, Simpson Screen Printing began to grow. It soon had US clients so much so that 70 per cent of the clients resided south of the border. In 1994, when Martin’s old offset company went into receivership, he bought it along with the building where Simpson Print is currently located.

Carla believes Simpson Print’s biggest strength is diversity.

“I don’t see myself as a screen printer or a digital printer. I view us as an all-under-oneroof print manufacturing and merchandising solutions provider,” says Carla. “Our business is very diverse. Forty per cent of our business is industrial nameplate identification. Another 40 per cent is wide-format solutions from custom through in-store signage programs, and then we have offset, which is actually doing remarkably well. The name of the game is to be diverse,” says Carla.

The company has the capabilities to print spot colour face down; UV litho print with spot UV screen print with specialty inks; different touches, such as textured, powdered and soft; clear; sparkle; tinted; glitter; raised clear with glitter; screen print spot matte; digital print on vinyl, plastic or paper. It can also do custom diecut, folding, embossing, shrink wrapping, laminating, grometting, hemming, drilling, heat bending, heated Platen diecutting, gloss coating and spot reticulation.

“We’re not in the business of conventional prints. When others say no, we say yes. We offer multiple products.We offer still high-resolution screen prints and have an extensive line of wide-formats, digital and UV offset and finishing solutions. In the last few years, I invested around $3 million in new technology and capitol investments. The print industry is

capital intensive, and I do not believe you can remain relevant if you are not continually investing,” adds Carla.

Simpson print is proud to have two screen printers while everybody is eliminating their screen presses. They’re also the largest Canadian client of SwissQprint, which is very dominant in Europe.

“SwissQprint is easy to maintain. I spend $14,000 on maintenance on three SwissQs, and they contribute to 75 per cent of my bottom line. SwissQ is also the most versatile press. They all have varnishes and primers, which means I can print on an unusual amount of substrate, such as tempered glass, building materials, laminate flooring, wood, aluminum and polyethylene. Since it has UV-LED, it is significantly reducing a project’s carbon footprint. It limits the conventional, heavy screen deposit. The fact that I have three of them ensures that I can do small, multiple or 5,000 sheet jobs with an in-store deadline of 24 hours,” explains Carla.

As someone who was taught to work hard and use sustainable practices, Carla is keen on adopting eco-friendly practices in the business.

“Print is naturally a very toxic industry. It generates a lot of waste. In the early days, we used recycling ponds at the cost of $14,000 to

$20,000 monthly to decontaminate water. We also looked at living walls to control dust. We’ve been thinking green because it’s not just about marketing and the end product, but also being lean in our manufacturing workflow by adopting automation. When you’re lean in your manufacturing principles, you’re passing on savings to your customers,” she said.

Carla admits having many sleepless nights in the initial days of the pandemic, but the company was able to pivot quickly.

While some of their clients ( e.g. events) didn’t need printing, others increased their orders. Simpson Print’s label business increased by 20 per cent, and it is still growing.

Carla attributes this resiliency to the fact that the company has seen many ups and downs, especially a big one (the death of its principal shareholder) in 2012, so it was able to navigate the pandemic pretty well. It also helped that Simpson Print had diverse offerings.

“Post-COVID, you’ve got to go back to the basics of great pressing and quality, and on time execution. We recognize it’s going to be the Wild West domestically. [Thankfully] our business is now evenly spread between Canada and the US,” says Carla.

Carla’s main focus is restructuring the com-

pany including finance and operations and maintaining strategic growth either organically or through “sensible US acquisitions.”

Carla is keen on enhancing the company’s digital marketing capabilities to complement its print services.

As indicated earlier, Carla has expanded the company’s inventory to maximize potential and take on new projects.

She’s also expanding space in her print plant by another 20 million sf. “I see my fulfillment and warehouse businesses significantly increasing,” add Carla.

Since Simpson has been in the printing business for 16 years, Carla feels it’s critical for the company to be leaders in innovation and

sustainability as well as to champion the importance of print as a marketing channel.

Carla believes that the industry would soon be shifting focus from the need for speed to software that increases workflow automation.

“The beauty of the industry is you have to commit to change. You have to be creative,” says Carla. Her ambition is to make Simpson Print “omni marketing intelligent.”

As she rightly explains, “You cannot install a press and deliver value; you have to build all silos of the business to be better and to drive innovative solutions that work with your customer base. Print is no longer just about placing ink on paper; it is about the pre- and post-show.”

Roland DGA releases its third-generation inkjets – the TrueVIS VG3 and SG series large-format printer/cutters.

The VG3 and SG3 printer/cutters are suitable for a wide range of applications, including signs and banners, window graphics, labels, decals, floor graphics, vehicle graphics, interior décor, and heat transfer apparel.

glass, stone, metal, acrylic and coroplast. It is powered by iQueue Adobe Postscript/ PDF workflow software.

Ricoh launches the Ricoh Pro TF6251 UV LED flatbed and Ricoh Pro L5160e latex roll-fed wide-format printers.

Ricoh introduces two wideformat printers

Ricoh USA expands its wide-format portfolio with the Ricoh Pro TF6251 UV LED flatbed and Ricoh Pro L5160e latex roll-fed wide-format printers. These solutions are designed to satisfy market demand for affordable output, enabling customers to “pursue ambitious growth plans fuelled by high profit potential, low operating costs and exceptional reliability.”

The Ricoh Pro TF6251 can print

on rigid substrates up to 4.3-in. thick. It can also print on odd-size and pre-cut materials for short-run packaging and promotional products. With two ink configurations and two ink sets to choose from, customers can tailor the system to fit their specific application and production needs.

The Ricoh Pro L5160e is suitable for printing both indoor and outdoor applications from pop-up displays and window graphics to exhibition graphics and vehicle wraps.

Xante releases the latest addition to its UV flatbed printer lineup, the Xante X-55. The Xante X-55 has a large bed size (50 x 55 in.) and doubles the production speeds of the company’s flatbed UV products.

Based on up to four Epson i3200 four channel printheads, the CMYKW X-55 prints on virtually any rigid media including wood,

Drytac announces global availability of Polar Premium Clear and Weathershield

Drytac has announced the global availability of its sevenyear durable Polar Premium Clear permanent polymeric PVC inkjet media and sevenyear durable Weathershield polymeric PVC overlaminating film.

The Roland TrueVIS VG3 and SG series of printers/cutters are suitable for a wide range of applications.

Drytac Weathershield UV overlaminates are 3.2 mil clear polymeric gloss or matte PVC laminating films.

Drytac Polar Premium Clear is a 3.2 mil phthalate-free printable polymeric solvent selfadhesive PVC film with

The Xante X-55 has a large bed size of 50 x 55 in.

a high quality, clear adhesive for optimum performance on a wide variety of substrates.

Drytac Weathershield UV overlaminates are 3.2 mil clear polymeric gloss or matte PVC laminating films that can be used across a host of applications including general signage, window graphics, exhibition and event graphics and POS displays.

The all new Acuity range from Fujifilm...including superwide format

With a track record of pioneering innovations, Fujifilm has helped thousands of sign and display printers transform their businesses. But in a world where change is constant, three years ago we decided to go back to the drawing board to define a new blueprint for UV inkjet print performance.

The result is a brand new range of Acuity printers designed and developed by Fujifilm that redefine price/performance and transform print ROI. They bring new meaning to versatility and value and reset the expectations around ease of use. And being developed by Fujifilm, they come fueled by the best UV ink on the market and a guarantee of outstanding quality and reliability.

The new range of Acuity printers designed and developed by Fujifilm.