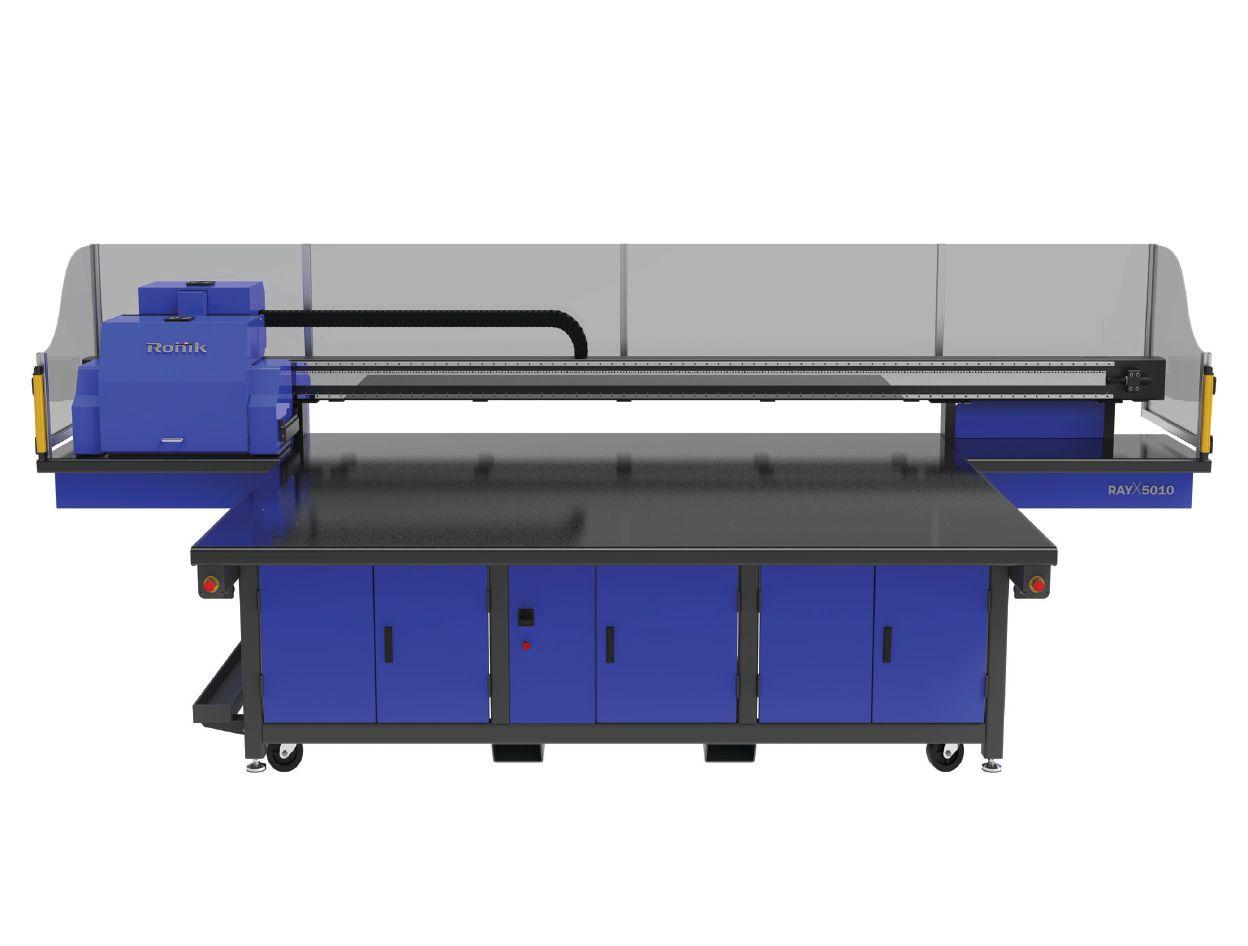

Introducing Ray-X — a new state of the art “Print on Demand” series of printers. A powerful, upgradable print engine with the latest technology that is easy to run and maintain.

Introducing Ray-X — a new state of the art “Print on Demand” series of printers. A powerful, upgradable print engine with the latest technology that is easy to run and maintain.

High speed, grand format flatbed printers for all types of rigid media, signage, and displays.

High speed, grand format flatbed printers for all types of rigid media, signage, and displays.

Introducing Ray-X — a new state of the art “Print on Demand” series of printers. A powerful, upgradable print engine with the latest technology that is easy to run and maintain.

High speed, grand format flatbed printers for all types of rigid media, signage, and displays.

12 Bob Dale and Heather Black Hiring challenges 14 18 22 6

ISSN 1481 9287. PrintAction is published 10 times per year by Annex Business Media. Canada Post Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to: Circulation Department, 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2021 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada.

Future-proof the business by adopting new technologies 18

Eva’s Print Shop offers hands-on training for at-risk youth

GAMUT

5 News, People, Installs

8 Calendar

NEW PRODUCTS

20 Detailing the latest offerings from Kornit Digital, Xaar and Durst

SPOTLIGHT

22 Jaime Campbell, art director at Sherpa Marketing

COLUMNS

FROM THE EDITOR 4 Nithya Caleb Be agile and flexible

CHRONICLE

8 Nick Howard A successful production model

INSIDER

IThe Canadian Printing Awards gala will be held virtually on September 23.

n early June, we hosted a roundtable on “Surviving & Thriving” in 2021 & beyond. The focus was on strategies that can help printers succeed in a post-COVID world. Our panelists— April Burke, VP-operations – Corporate Printed Packaging, Bellwyck; Jay Mandarino, president & CEO, CJ Graphics; and Richard Kouwenhoven, president and COO, Hemlock Printers—shared their experiences and ideas, which I will summarize below.

In his opening remarks, Mandarino laid out the challenges facing the industry. The global print industry prior to COVID had shrunk by nearly 30 to 50 per cent, he said.

“Sales literally in a couple months dropped by 53 per cent and it took over a year to get to 75 per cent, and slowly we are on track to get back to where we were. I believe sadly that 30 per cent of our industry will not survive unless several steps are taken,” he added. Mandarino stressed that “now more than ever I feel our industry needs to come together regardless of competition to make us all successful, and share best practices.”

One of things that all panelists stressed on was agility.

“We need to be agile in our businesses and evolve to adapt. Some segments will return; others will not. We need to look deep into our organizations and determine what we have learned from the events of the pandemic, the positives and the negatives of our business model. Determine if the positives can be made greater and determine if the negatives can become a positive, or do we need to realize it is something we need to address to propel ourselves forward,” said Burke. “The workplace will have a new landscape and businesses will need to embrace to sustain their team or risk losing them to others who are willing to be more flexible in their operating model that brings a greater emphasis to work-life balance that we are all seeking and defining.”

“The pandemic will likely cause permanent changes to our industry—a time when all industry participants need to consider what their business should look like in one, two and five years out and how our businesses will adapt to these changing conditions. As April mentioned, there will be areas of growth and areas of decline and the time calls for creative thinking, being

nimble in all aspects of the business (sales, marketing and operations) and expansion into new products/markets where there is growth potential. It is undoubtedly going to be a challenging 12-24 months for the industry but it is also a time to look at the opportunities to move with the changes in technology and culture and build the business for the future, rather than just focussing on ‘survival’,” added Kouwenhoven.

Labour and attracting young talent were one of the challenges discussed at the roundtable. However, some programs are addressing these issues to the best of their abilities. On pg 18, we highlight Eva’s Print Shop that is training youngsters for jobs in print shops.

Another successful educational program is the Graphic Communications Management program at Ryerson University, Toronto. Every year, they hold an academic and professional networking conference called the Colloquium. The event team had to think out-of-the-box to conduct a virtual conference this year. Colloquium 2021 was a series of firsts for the Ryerson team. By incorporating new technologies, such as Menti, Trello, Zoom and Rally, the event organizers succeeded in atttracting participants from all over the world.

Registrations are open for the 15th Annual Canadian Printing Awards Gala that honour projects, designs, companies and individuals pursuing print excellence and innovation. In challenging times, it is important for us to celebrate our achievements; these events keep the flame of hope burning brightly, so please join us virtually on September 23. Visit https://pheedloop.com/CPA/ site/home to register for free.

I hope to see you all at the awards show. Enjoy the wonderful weather while staying safe and healthy.

Reader Service

Print and digital subscription inquiries or changes, please contact

Barbara Adelt, Audience Development Manager

Tel: 416-510-5184

Fax: 416-510-6875

Email: badelt@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor

Nithya Caleb ncaleb@annexbusinessmedia.com 437-220-3039

Contributing writers

Bob Dale, Heather Black, Nick Howard, David Pittman and Ian Howard

Media Sales Manager

Kim Barton kbarton@annexbusinessmedia.com 416-510-5246

Media Designer Lisa Zambri lzambri@annexbusinessmedia.com

Account Coordinator Alice Chen achen@annexbusinessmedia.com 416-510-5217

VP/Group Publisher Diane Kleer dkleer@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Subscription rates

For a 1 year subscription (10 issues): Canada — $43.00 +Tax Canada 2 year — $70.50 +Tax United States —$98.00

Other foreign —$191.00

All prices in CAD funds

Mailing address

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 Tel: 416-442-5600 Fax: 416-442-2230

Occasionally, PrintAction will mail information on behalf of industry related groups whose products and services we believe could be of interest to you. If you prefer not to receive this information, please contact our Audience Development in any of the four ways listed above.

Annex Business Media Privacy Officer Privacy@annexbusinessmedia.com 800-668-2384

PrintAction is printed by Annex Business Media Printing on Creator Gloss 80lb text and Creator Silk 70lb text available from Spicers Canada.

ISSN 1481 9287

Mail Agreement No. 40065710

printaction.com

NITHYA CALEB Editor ncaleb@annexbusinessmedia.com

Konica Minolta Business Solutions U.S.A., Inc. (Konica Minolta), won the iF Design Award 2021 from the Hannover-based iF International Forum Design GmbH, the world’s oldest independent design forum, for its AccurioPress C14000/C12000 digital production presses.

Also, Konica Minolta Business Solutions (Canada) won the Buyers Lab 2021 PRO Award from Keypoint Intelligence, an independent evaluator of document imaging hardware, software and services. Granted annually, these awards acknowledge the products that gave the best performances in production field testing over the previous year.

Konica Minolta’s AccurioPress C14000 with EFI Fiery IC-319 Controller took top honours in the Outstanding High-Volume CMYK Production Device High-Volume Category and was identified as a trailblazer in the digital production marketplace.

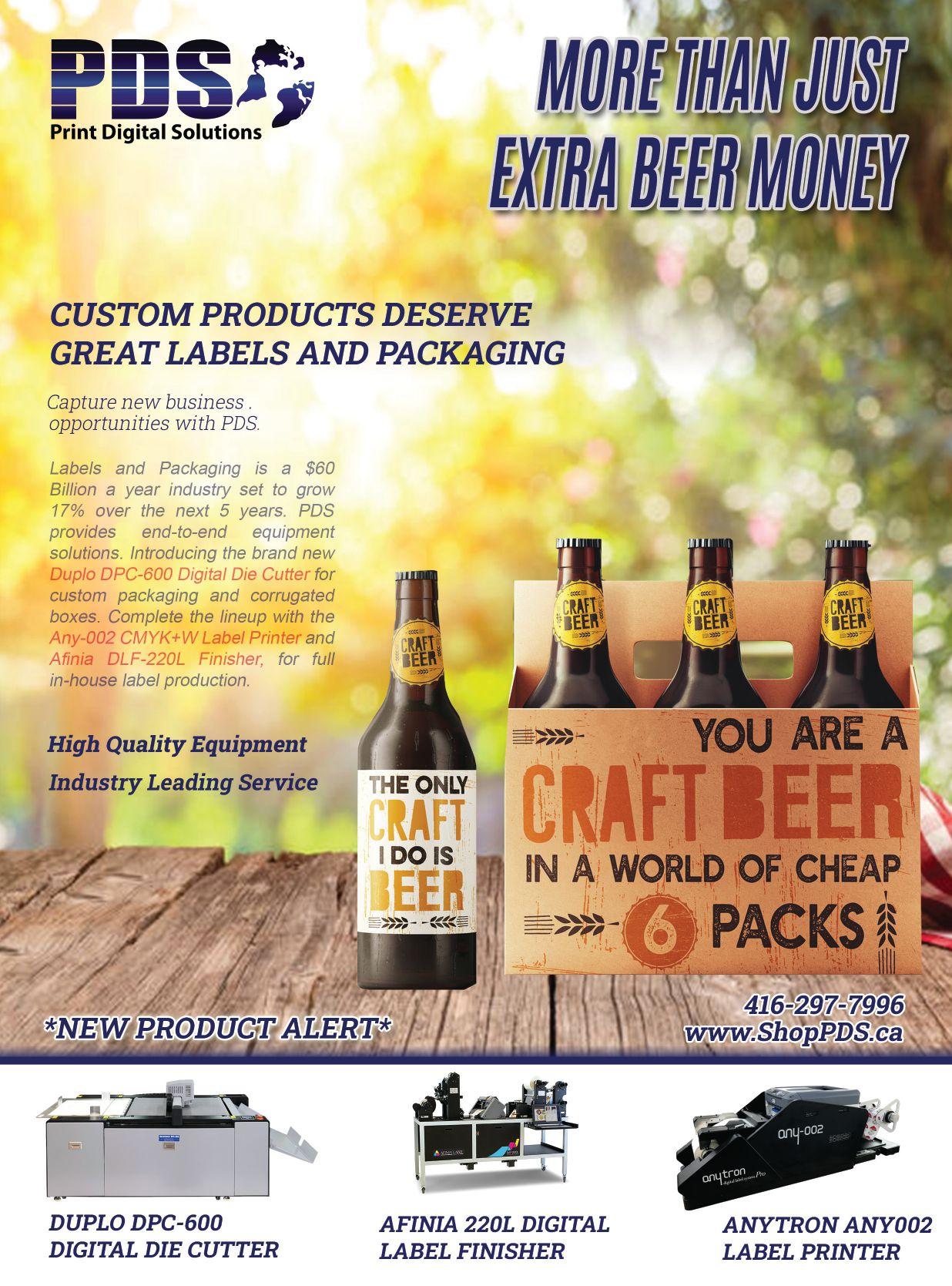

Fujifilm Canada has signed a national distributor agreement with Spicers Canada. Under the terms of the agreement, Spicers will act as nationwide distributor for the graphics division of Fujifilm Canada including its computer-to-plate (CTP) plates and related equipment.

This partnership provides Fujifilm Canada supplementary, full national coverage with the ability to leverage Spicers

Canada’s network of over 600 employees and 25 regional centres that helps with product inventory and logistical co-ordination for faster customer deliverables. Also, Spicers had an interest in increasing available solutions from a well-respected partner in order to best serve Canada’s print industry.

Canon Canada and The Printing House have been recognized as Canada’s Greenest Employers for 2021.

With millions of Canadians working from home the past year, many of the country’s most sustainable companies have responded by helping employees to reduce their personal environmental footprint and make environmentally conscious decisions in their lives outside work. The best of the initiatives were recognized by Mediacorp Canada. Now in its 14th year, Canada’s Greenest Employers is a special designation that recognizes employers who are creating a culture of eco-awareness in their firms.

Quebec-based Empire L.A. has become the first digital prepress and press-ready flexographic plate specialist in Canada to receive the ‘best in class’ certification under the new XPS Crystal Program from Esko.

“We are delighted that Empire L.A. is not just among the first of our global customers to have achieved this accreditation, but the very

first in Canada,” said Julian Fernandez, flexo business development manager with Esko. “The program was developed specifically to recognize those platemaking businesses that consistently produce superior flexo plates, which lead to excellence in flexographic print quality.”

CJ Graphics is the latest member of the Brand iQ Partner Programme. It is now

the master reseller of the Brand iQ software for North, Central and South America. Brand iQ will also be opening an office in Toronto to serve its customers in the Americas.

“The world is evolving and changing so fast [and] we all pivot and change as our businesses develop. The advantage you have with Brand iQ is that it puts you in the game, it puts you in contact with clients,” says Jay Mandarino, CEO of CJ Graphics.

Grimco Canada, a wholesale sign supply company, acquires Cobalt Graphics. Cobalt is a subsidiary of Cansel. It was formed in 2018 to distribute Cansel’s wide-format, offset lithography, flexography, and page-wide printing supplies.

Grimco, with a nationwide fleet of delivery trucks, will continue to distribute its current product lines and add in Cobalt’s printing and signage supplies.

Ricoh USA, Inc., and Ultimate TechnoGraphics enhance their global partnership to offer digital print providers improved upstream workflow

automation. This expanded collaboration between the companies will equate to increased flexibility, control, and visibility over jobs at any point in production for printer service providers.

HP, Inc., and Cimpress sign a multi-year, strategic agreement for a large-scale investment in next-generation HP Indigo digital presses to grow its online market.

Cimpress, HP Indigo’s largest customer globally, will deploy a fleet of new HP Indigo digital presses over the next two years, primarily the B2-format HP Indigo 100K Digital Press. The new technology should provide additional revenue for the company’s brands and improve efficiency across its manufacturing operations.

Cimpress uses the HP technology to deliver personalized print products, such as holiday cards, photo specialty items, gifts, calendars and marketing materials.

Agfa plans to expand its co-operation with the Global Graphics group beyond RIP technology, as its long-term partner in software development now also includes the Hybrid Software Group.

The OEM partnership with Hybrid Software will provide Agfa with access to the group’s specialized technological knowhow and full product portfolio, which focuses on enterprise software for the packaging printing industry.

Sun Automation will be promoting and selling Highcon digital converting solutions for corrugated in North America.

Paul Aliprando, vice-president, digital technologies, at SUN Automation Group said, “We are excited to be adding the Highcon digital converting systems to our extensive range of innovative equipment for corrugated box plants with the aim of increasing production, efficiency and profitability.”

Ricoh appoints Carsten Bruhn as president and CEO of Ricoh North America. A self-described “global citizen,” Bruhn brings more than 20 years of industry experience. He has led global teams that have successfully built digital transformation strategies and implemented services that solve crucial problems for organizations of all sizes—from global enterprises to small businesses.

“The opportunity that lies ahead for Ricoh, our partners and customers is incredible,” said Bruhn. “Customer behaviours, the increasingly changing workforce and the speed of digital transformation are driving toward the need for new business models, including digital services and subscription models, to name a few. And there’s so much to be energized about in North America specifically. We have a tremendous customer base, a passionately dedicated team and a network of dealer partners who share our commitment to solving challenging business problems today and into the future.”

To meet the demands of its growing customer base, Connecting for Results, Inc. (CFR), has hired industry experts Keith Larson, Nicky Milner and Michael O’Connell. Larson will lead their U.S. operations. Milner will assist CFR clients to achieve their business goals in the areas of production technology, operations management and digital media consulting. O’Connell will help CFR clients with profit maximization and performance optimization. The addition of these three new specialists enables CFR to expand its offering by providing leadership expertise, digital media consulting, and operations management services across North America.

After a three-month transition period with his predecessor Herbert Forker, Dr. Nicolas Wiedmann has assumed full responsibility as Siegwerk’s new CEO. He joined Siegwerk on January 1, 2021, and has been intensively involved with the company since then.

Wiedmann continues to drive Siegwerk’s most recent strategic transformation to become a circular and digital packaging solutions company. He will further accelerate company growth with new business models beyond the traditional printing inks. Wiedmann plans to maintain a globally and well-suited network and wants to strengthen Siegwerk’s customer-focused approach through flexible and innovative processes as well as new digital services.

CCL Industries installs the world’s first HP Indigo 35K Digital Press at its CCL Label Healthcare facility in Montreal. The new B2 sheetfed press for cartons and specialty boards offers high-definition printing, security inks and variable data printing for track-and-trace solutions and security elements.

Print 3 of Toronto recently installed a new Memjet label printer and digital finisher. According to owner Abdu Ahmed, the installation allows the company to compete in the fast-growing short to midsized label business.

Lacasse Printing, based in Windsor, Ont., recently purchased their second Agfa wide-format printer, an Anapurna FB2540i LED Printer. Lacasse Printing has been servicing the Ontario market since 1952, offering clients a range of visual communication services.

July 20, 2021

Partners in Printing Expo La Crosse, Wis.

August 12, 2021

OPIA Toronto Golf Classic Brampton, Ont.

August 16, 2021 PrintForward Golf Tournament Surrey, B.C.

August 22-24, 2021

2021 Continuous Improvement Conference Columbus, Ohio

September 23, 2021

Canadian Printing Awards Gala Virtual

September 27-29, 2021

Pack Expo Las Vegas Las Vegas, Nev.

September 29-October 1, 2021

Label Congress 2021 Chicago, Ill.

By Nick Howard

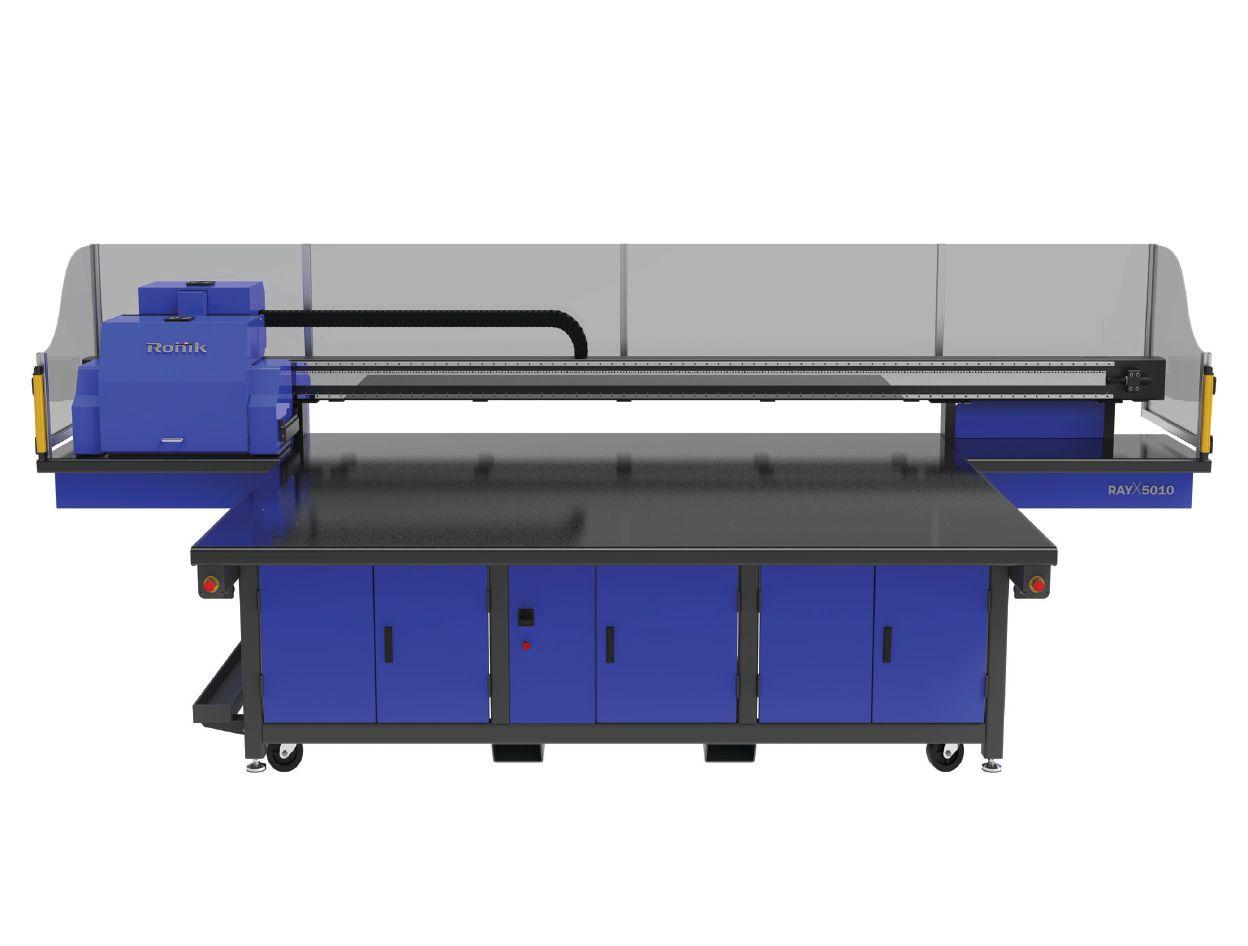

uring my career, I’ve visited China many times. My first visit was in April 1989. I spent two weeks travelling from factory to factory seeking opportunities to import various types of printing equipment. With Chairman Deng Xiaoping’s decree of a new Open Door Policy in 1978, special economic zones were created to relax import and export rules, thereby stimulating western investment and trade. Exports had phenomenal growth in the following decades. Also, imports, especially of used German printing machinery, received a major shot in the arm. European dealers of used printing machines poured into China, and often left with multiple orders.

The Chinese success story is one of resilience and a constant push for more and more.

All business trade was placed under the watchful eye of government agencies, and I was accompanied by a Chinese representative who liked to be called “Jack”. We got along quite well, as Jack was knowledgeable about the global printing industry.

I was shocked by what I saw during those marathon visits. Virtually everything was a duplication of German machines. If it was a guillotine, it looked like a Polar; presses resembled Heidelberg machines; diecutters were a duplication of

Bobst, Gietz or Wupa technologies. Factories were often filthy, and some had dirt floors. It was interesting to note that many cities had new world-class hotels. The divide between a new China and homes and factories with corrugated roofs and ‘bedsheet’ doors was very visible. There was a great deal of head shaking, as I tried to understand how it was possible to rip off a copy of a Heidelberg easily. At the time of China’s great awakening, there was a tremendous need for speed, and what could be easier than simply taking apart a used Heidelberg or Polar, and making patterns from the parts? Intellectual property protection didn’t exist then; its highly flawed even today.

However, the most pressing issue was that none of the equipment I looked at had quality engineering. “Rough” would be a kind description of the state of engineering. I saw a rapidly growing China that had no guardrails to hinder what it decided to do. This was made abundantly clear during meetings with facility owners. The

CEO spoke only Chinese, and often seemed less informed about the technical aspects of what his factory was producing than I did. Men who held key political positions before the open-door era were first in line to take advantage of the new system, and became rich beyond the wildest dreams of average Chinese workers.

The best factory I visited at that time was in Beijing. The Beijing Remin Machinery Co. (Beiren), had been building printing presses since 1952.The facility was making knock-offs of the Man Roland Parva Rekord, in addition to a variety of strange web presses. Years later, Beiren would manufacture inker and deliveries for Mitsubishi Diamond sheetfed and knock-offs of the Harris M300 folder.

With a population (1990) of 1.2 billion people, China held all the ingredients for rapid growth. Armies of low-cost labour were begging the west to do business while offering unbelievably cheap prices. There were no federal watchdogs enforcing laws against pollution: the nearest ditch would suffice to dispose of liquid waste emit-

ting from pop-up factories. Fines were unheard of, and still today not nearly as strict as in western countries. The pet food and infant formula milk scandals of the 2000s are just recent missteps.

Stringent quality protocols for everything from machines to pharmaceuticals were often void of any rigour in those early days.

One of the reasons for poor cast iron at that time was because they typically tossed all types of ferrous products into the pot. During the early 1990s, western buyers flocked to China.These people typically shut down their local factories because it was profitable to buy from China. Why pay taxes and high wages to workers when you could offload the manufacturing of running shoes and other labour-intensive products to China for less than half the cost?

Along with our European colleagues, our company also leaped at the boundless opportunity of selling hundreds of printing and bindery machines to China; and it’s all still going on today.

I made another trip 19 years later, and what I saw then was dizzying. Factories hadn’t changed much, but printing equipment quality had improved tremendously. Unique “Made in China” designs were on full display. It’s no surprise Bobst, Polar and Heidelberg have built factories there that churn out machinery, which is indistinguishable from what is produced in Switzerland and Germany. Heidelberg recently announced more than 33 per cent of all their production emanates from the Shanghai factory, and more models will be produced there going forward. Many other substantial digital platforms ranging from proofers to metres-wide inkjets are growing wildly. Some of you might be surprised at how much of your production equipment is produced in China.

The Chinese success story is one of resilience and a constant push for more and more. They are easy to do business with. They never refuse to climb the mountains appearing on

the horizon. In 1989, the Chinese strategy was to copy and build. Now with a few decades of experience, China, Inc., produces better ferrous and non-ferrous castings, uses quality machine tools, and trains their workers to embrace skills once only found in the west. All this progress happened in the blink of an eye.

Still, the world is wary of China’s single-party system of governance. Life is heavily regulated by government officials in that country. Unless there are political reforms, there will always be friction between democratic countries and China.

The Chinese miracle continues, and the rest of the world is both fearful and envious when dealing with that country.

NICK HOWARD, a partner in Howard Graphic Equipment and Howard Iron Works, is a printing historian, consultant and Certified Appraiser of capital equipment. nick@howardgraphicequipment.com

By Bob Dale and Heather Black

Vacant positions affect productivity, customer satisfaction and profits. Here are some interesting hiring challenges in the industry:

• Young people entering the industry prefer creative or marketing roles instead of traditional industry roles like customer service, operations, estimating or sales.

• Many high schools with technical streams have eliminated printing programs, and only offer design courses.

• Increasing competitive pricing pressure is reducing profit margins, and usually training budgets are the first ones to be cut when profits are low.

• Skilled technical operators are reaching retirement and fewer people are being trained to replace them.

• Industry apprenticeships and formal training programs and facilities are not available.

• With warehousing and fulfillment operations growing rapidly in large urban centres due to the unprecedented increase in online sales, finding staff for these functions is increasingly difficult, and more expensive.

The issues highlighted above affect all companies, and we need to work together to address them. Here are some suggestions to put ‘words into actions’.

There is a perception that “print is dying”. People also assume it’s a heavy hardware industry.

Actions to take

You can spread the message that printing is an exciting technol -

Many companies are struggling to attract skilled labour for printing operations.

Skilled technical operators are reaching retirement and fewer people are being trained to replace them.

ogy-driven industry. Associations must re-instate communication campaigns to promote industry as well as solicit support from industry and government.

A majority of skilled print operators are in their 50s and 60s. Only few young staff members are developing the skills to replace these operators.

Actions to take

• Build succession plans for equipment operators and key operations staff.

• Invest in ongoing internal training programs.

• Cross train staff to ensure critical coverage.

• If located in a small community with a limited talent pool, recruit future talent from larger centres with incentives focused on quality lifestyle instead of financial rewards.

Many companies don’t have dedicated HR staff, and for those that do, recruitment is only one of their duties and responsibilities.

Actions to take

Use recruitment channels that focus on the talent sought. This includes social media and recruitment josites, and industry-specific recruiters.

While it will be easy to ask current operators to train staff, there will be concerns about the quality.

Actions to take

• Develop, document and implement formal processes for training programs.

• Current team members may conduct the training, but they should be monitored by supervisors or HR

As mentioned earlier, the lack of apprenticeship programs has reduced opportunities for technical training.

Actions to take

• Support community colleges that offer fundamental training programs.

• Engage with program leaders; offer support with supplies, facility tours and engagement.

This is a great industry, and regardless of our position or role, each of us can do something to improve the status quo, and make more people aware of the opportunities in the printing world

BOB DALEAND HEATHER BLACK are with Connecting for Results, Inc. They can be reached at info@connectingforresults.com.

By David Pittman

It has been a few decades since the term “digital” first entered the lexicon of the label printing industry. Since then, those at the bleeding edge and adopting when the market was still very much embryonic have been supplanted by a mature customer base deploying tried, tested and refined solutions because digital printing has become quite commonplace.

With the technology evolving— faster speeds, better quality, increased consistency etc.—the market has embraced the opportunities digital printing permits. This has been realised in pressrooms the world over through hardware installations, as printers look to respond to

21st century consumer behaviours, the advent of short runs, personalization and brand owner demands for new business models to provide just-in-time delivery and minimize waste in the supply chain. Due to these factors, many digital adopters in labels are operating multiple lines. They are also embracing the different digital printing technologies and the unique characteristics and capabilities of each to further their ability to respond to today’s business environment, and that of tomorrow.

Increasingly, the end-use is driving the choice of technology, be that:

• challenging substrates as often seen in wines and spirits;

• durable labels that are resistant to various types of environmental factors;

• beer and beauty labels, where achieving the correct look and feel is paramount; or

• food labels, which must be esthetically pleasing whilst meeting stringent regulations for food safety.

For most, digital presses are slotted in alongside flexo and offset machines. There are examples— from the early days—of this approach not providing the most effective route to ROI, with the capabilities and capacities of digital printing undermined by attempts to make the technology work within existing workflows. Today, it is widely acknowledged that to make the most of an investment in digital, the ecosystem around the press is as important as the machine itself. This helps get incoming orders through prepress, onto the print engine, then forward to finishing and converting in the most streamlined and effective way possible.

The starting point is invariably the correct MIS/ERP, designed to handle the greater number of orders and jobs, the complexities of such work and the amount of data involved, whilst being able to keep up with the press and keep it filed with saleable work. Web-to-print business models are now springing up at an increasing rate, bringing the convenience of e-commerce as experienced by consumers on a daily basis to the business-to-business world. While this will not work for all, it is likely that a growing amount of work destined for digital label presses will come from online avenues. This then creates an entirely different business structure for label printers who might be more au fait with established workflows that see orders coming through the door and being processed by the prepress department.

The likely deskilling of the prepress process will result in a need for companies to find new roles for staff. This can be a boon for many, as it creates new opportunities for growth, taps up underutilised resources within a workforce and strengthens

A web-to-print business model will help increase orders for label printers.

The label industry is well placed to embrace the next iteration of digital transformation by coupling its engrained knowledge of digital printing with a capacity to adapt and change.

the personal development roadmap for staff. This may seem scary to some, but it is an inevitable consequence of digital transformation. It should not be feared, but embraced and made a part of corporate strategies for the future.

Similarly, there were concerns about the impact of digital transformation on analogue print processes. Driven, in part, by the digital industry’s excellent marketing activities and loud vocal presence permeating the supply chain, the furore reached a fever pitch. There was a brief point in time when the digital printing industry was having to go on record to state, “We’re not here to kill flexo.”

In recent years, the flexo industry has staged a ‘fightback’ and gone through a technical resurgence of its own, including efficiency gains, automation of press set-up and better standardisation of the process. It has also got more vocal and better at fighting its corner. Its marketing efforts have improved to highlight the strengths of flexo in the 21st century.

As a result, the reality on the factory floor today is that digital and analogue are entirely complementary print processes. This is realised through the growing amount of ‘hybrid’ options—full hybrid, true hybrid, integrated hybrid, etc.—that combine the best of both processes, as well as the capacities that have been freed up and created. By taking the burden off a flexo press to print short runs when implementing a digital printing workflow, for example, label printers can increase the amount of volume work they put through their Gallus/Mark Andy/ Nilpeter/MPS/Bobst press. Similarly, digital presses are now able to take on longer runs, leaving a flexo press free to produce the highest value jobs, perhaps. This maximizes OEE and hastens the ROI for both digital and analogue hardware. For many label printers, this has now opened up new business opportunities and markets they may have previously been unable to service.

One such opportunity has been digitally printed flexible packaging. Flexible packaging is a widely spoken

about goal for label printers. Technical challenges remain in this area, given the greater demands placed on primary packaging, and how it relates to established label printing technologies such as UV. However, work is ongoing in the supply chain to mitigate and alleviate such concerns. Further, a growing amount of hardware is now available to permit fast turnaround of digitally printed flexible packaging constructions, printed using either aqueous inkjet

or toner technologies and suited to ‘print-for-use’ business models. There remains a need for education amongst label printers, as flexible packaging materials and end uses are entirely different. That being said, it’s likely we’ll see more and more label converters moving into flexible packaging as opportunities present themselves.

Adding value is another area of

The look and feel of beauty labels are very important.

opportunity for label printers deploying digital. In the ongoing battle to win at the ‘moment of truth,’ and offer the greatest shelf appeal, more and more systems are being introduced to enhance and embellish digitally printed labels with either post-print analogue processes, or newer digital-native systems that can apply foils, varnishes and other visual effects, as well as haptic elements to appeal to consumers’ desire to touch and feel.

As such, I believe the label industry is well placed to embrace the next iteration of digital transformation by coupling its engrained knowledge of digital printing with a capacity to adapt and change. Rather than being fretful, the label industry is looking forward to how digital can future-proof business, and is ready to embrace all the opportunities this will present.

DAVID PITTMAN is the editor of Digital Labels & Packaging. This article was originally published as part of the Drupa Essentials of Print series.

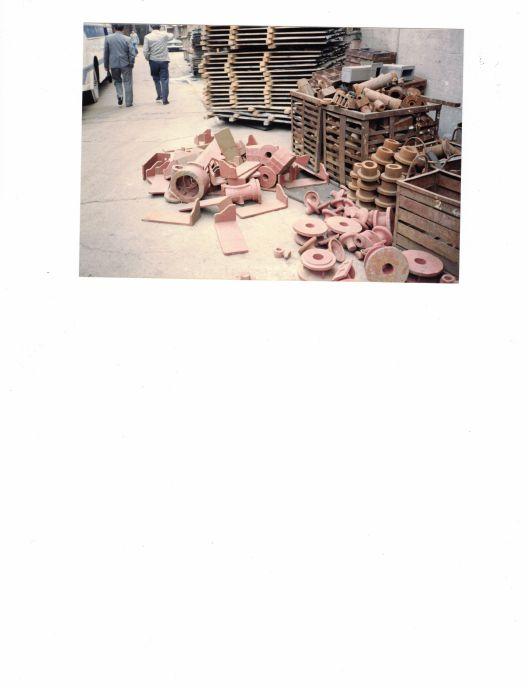

Serving the US market for nearly a decade, RM Machinery (RMM) proudly brings our expertise to Canada’s printing industry. We deliver the highest quality sheetfed o set, digital inkjet, and flexo printing presses by partnering with the finest manufacturers in the industry.

RMM is the premier distributor in Canada for Mitsubishi, RMGT, and Miyakoshi printing presses; Böttcher rollers, blankets, and chemistry; Standard Horizon finishing systems; GEW UV curing systems and TOYO inks.

For years, Mitsubishi set the superior technology standard for Canadian printers. Today, RM Machinery returns that innovation to Canada, but with an even higher standard: Ryobi Mitsubishi Graphic Technology (RMGT).

We are stable, local, and o er the best-in-class technology. We maintain an ample supply of parts, and for as long as you own one of our supported presses, you are guaranteed ongoing service and support programs that are among the best in the industry.

RM Machinery Inc.

905-238-9797 • 1-855-RMGT-123

5250 Satellite Drive, Unit 9 Mississauga, ON L4W 5G5 www.rmmc.ca

Eva’s Print Shop offers hands-on training for at-risk youth

By Ian Howard

Many printing companies are struggling to attract skilled labour.

Further, as explained by Bob Dale and Heather

Black in this issue’s Insider column, skilled technical operators are nearing retirement and fewer people are being trained to replace them. One of the few places training youngsters to enter the printing sector is Eva’s Print Shop.

industry.

Located in downtown Toronto, Eva’s Print Shop is a social enterprise and a digital printing company. The print shop also trains homeless and at-risk youth for jobs in the printing industry. It is a part of Eva’s Phoenix, a transitional housing and employ-

ment training facility. Both of these initiatives come under the umbrella of Eva’s Initiatives for Homeless Youth—formally known as North York Emergency Home for Youth—that was founded in 1989.

“At-risk youth and those experiencing homelessness face additional barriers in accessing education and employment opportunities,” explained Jonathan Gault, manager of Eva’s Print Shop. “Eva’s provides housing and wraparound supports to help our young people break down these barriers and build brighter sustainable futures,” added Gault, who has been the manager for five years. He also has 10 years of prior work experience in the industry.

Eva’s Print Shop offers the Graphic Communications and Print Training Program, a 17week course that’s divided into three sections to help students develop a sense for the craft and be ready for employment.

Each section is the foundation for the next one, and they are divided into:

• work and employment skills training for five weeks;

• six-week training in Adobe Creative Suite; and

• six weeks of real work experience including supervised training in bindery, digital printing, prepress and customer service.

The program serves to give at-risk youth an opportunity to learn and gain work experience while earning a stipend. “All 17 weeks is paid, and participants receive an hourly wage,” said Gault. Eva’s also offers an Adobe training program with stipend for youth who do not want to attend the entire 17week class.

Additionally, the print shop helps students get jobs with some of their employment partners, such as Marquis Books Toronto, Symcor, Inc., and Staples Canada.

“This program helped me a lot. At my first interview, I was

able to express myself and talk about my experience, which led me to obtain a position at a well-established printing company,” said a past participant of the program.

Since the program’s goal is to empower at-risk youth to succeed in the labour market, it offers training in the skills the printing industry needs. The students are trained to operate a digital printing press, wide-format mounting, laminating and trimming of a variety of paper products on a guillotine machine.

“It provides a good combination of soft skills, technical skills and real-world work experience,” said Gault. “The extra time spent problem solving, working with clients and completing hands-on work helps build our participants’ confidence.”

Eva’s, like many companies, has been affected by the pandemic. However, the team managed to continue some aspects of the training.

“The work experience module continued partially online, as well as in-person with small numbers in order to maintain social distancing and keep our staff and participants safe,” said Gault.

Further, by implementing new measures, the print shop has been able to weather the economic downturn.

“New services, such as fully featured neighbourhood mail, personalized mailing, kitting, floor safe decals and stickers were able to make up some of the revenue we lost since the start of the pandemic,” explained Gault. “The continued support of our long-time clients has been essential to our survival as a business.”

As the world begins to recover from the pandemic, Gault plans to strengthen and expand Eva’s Print Shop’s ties with industry leaders and education partners in order to help provide employment options for at-risk youth.

crease without a die, then fold and even glue all on the same machine, up to 30 pt.

3. INTEGRATED MODULAR UNITS — Combined in-line finishing: crease, fold, glue, tipping, envelope inserting, ink jetting (Duplex), clip seal (3 sides), mail prep.

4. SAVE ON POSTAGE COSTS

—As a Certified Canada Post Direct Marketing Specialist, we get contract pricing reductions.

5. RETURN MAIL PRODUCTS — Customized “Return Mailers” created in-line with “U” or “BOX-shape” remoistenable glue, time perfed applications and envelope formation.

6. MINI-BOOKLETS — Saddle-stitch and trim 2-up booklets in-line to the size of a business card. No need to trim off-line, or do 2 passes.

7. HIGH SPEED EQUIPMENT — High speed Tipping, Folding, Saddle-stitching and soft folding ensuring on time delivery.

Kornit Digital unveils a new solution for on-demand apparel production

Kornit Digital has released a new Max technology. A key feature of the technology is XDi, which delivers 3D capabilities for new, high-density graphic decoration that can simulate embroidery, vinyl and heat transfer in a single, wastefree digital process.

Kornit also debuted the ActiveLoad Automation tech-

The Kornit Atlas Max is a carbon-neutral, industrial-scale DTG production system.

nology, a new robotic system designed to ease the burden of manual and labour-intensive media handling in the textile decoration industry.

Xaar, an inkjet printing technology group, has launched its latest printhead, the Xaar Nitrox that provides users with “greater print speeds and uniformity.”

Speed is integral to the Xaar Nitrox, with firing frequencies of up to 48kHz. This enables printing at up to 100 metres per minute.With its ‘plug and print’ capability, printer uptime is maximized.

Durst has introduced the P5 Tex iSub (inline sublimation), which is based on the P5 platform, with a maximum print width of 3.3 m. At the heart of the Durst P5 Tex iSub is the integrated inline fusing for direct printing on polyester fabrics.

The P5 Tex iSub is not limited to direct printing. Transfer papers can also be printed and processed in the usual way. The maximum print speed is 383 m<sup>2</sup>/hour when the 330 cm print format is fully utilized.

A unique feature of the P5

The Xaar Nitrox can print at 100 m/min.

Tex iSub is contactless fusing. The contactless technology ensures colour consistency as well as sharp images and text.

The Durst P5 Tex iSub features an integrated inline fusing for direct printing on polyester fabrics.

Commercial Printing Tabletop

Bindery Equipment. Morgana 52 manual scoring machine. Excellent condition. Lasco Small Corner Rounder with 2 dyes. Good condition.

Aikles 6 Roller Prolam Laminator

Commercial model extra rollers. In excellent condition

Xerox Docucolour 260 Has high capacity feeder and booklet maker. Just off Xerox service. Toners and drums gord this and Xerox Doc 240 available

Antique Rosback Pin Perforator

Late 1800’s model of manual pin/ stroke perforator. Good condition.

Challenge Titan 200 Cutter With full side tables and laser safeties. Extra blade. Excellent condition

Press inks for sale. Large lot of older inks from latter 1990’s and early 2000’s. Oil and rubber based. All kind of different color including gold. All brand name inks. Make an offer.

Contact 506-640-3042. Entityholdingsltd@gmail.com

Heidelberg: K-Line/S-Line/Speedmaster/GTO/MO/KORD64

Komori: 1, 2, 4 or 5 colours & any size

Adast: 714/715/724/725

Mitsubishi: Any model

Ryobi: 2800CD/3200CD-MCD/640K

Itek: 960/975/985

Hamada: 600/700/800/E47/RS34

Shinohara/Fuji: 66/65 1,2 or 4 colours

Sakurai: 1, 2 or 4 colours and any size (newer model)

Polar: any size/older or newer models (66/72/76/78/82/90/92/107/115)

Horizon-BQ: 220/240/260/440/460

Winnipeg-based Sherpa Marketing recently merged with McKim Communications.

Given Sherpa’s expertise in digital marketing, the merger allows Sherpa to grow strategically and creatively. We caught up with Jaime Campbell, art director, Sherpa Marketing, to discuss the merger and the state of the Canadian printing industry.

What does the merger mean for Sherpa Marketing?

JC: We will be operating under our existing brands, but we can now be more competitive when it comes to larger accounts. It allows us to work on complex projects with national and international companies. We are excited to have so many new smart and creative teammates.

What is the state of the print industry today?

JC: In the last few years, digital solutions have taken over print. However, I feel some applications need print to communicate their message. For example, we work with a lot of clients from the agricultural space. They typically working in rural areas where Internet bandwidth is limited; farmers need, and often prefer, a printed piece that they can easily flip through to make purchasing decisions.

What attracted you to the print industry?

JC: My first love was printed design. You really can’t compare the feeling of holding a beautifully printed piece to a digital artwork. The former touches on all of your senses. As a visual person, I’m always drawn to the creative ways marketers use to communicate their brand messages through print. You learn so much about a brand by simply looking at subtle things like the stock used on packaging, typography and colour. It’s been really cool watching brand strategy get embraced across all platforms, such as interior design, retail and social media. Modern-day marketing has changed branding. It now goes beyond the visual, and taps into all of our senses to elicit an emotional response. This is not a new concept, but the evolution of digital platforms has made it more effective.

Campbell was always interested in art and design. She pursued photography after graduating in fine arts from the University of Manitoba. She then went on to study graphic design at Red River College, Winnipeg. After working as a designer in the manufacturing and pharmaceutical industries for a few years, Campbell joined Sherpa Marketing 13 years ago. When not working, Campbell enjoys biking, drawing and attending music concerts (when allowed).

When printers embrace technology and materials that can help shrink their carbon footprints, they show young people the industry is looking out for their future.

How can the industry attract more young people?

JC: While the print industry may be one of the oldest on the planet, it is important that it adapts to today’s needs. Designers want to know if printers think of the impact of their work on the environment. When printers embrace technology and materials that can help shrink their carbon footprints, they show young people the industry is looking out for their future; this allows youngsters to be more perceptive to the industry.

In such a competitive landscape, how can printers win more sales?

JC: It’s important to remember print is viewed as a luxury as things move into the digital landscape. Marketers are looking to catch the eye of potential customers, so showcasing your capabilities for unique finishes and substrates can be the differentiating factor. Additionally, it is important to remember that the needs of customers have changed; they may prefer solutions like print-on-demand.

Over the past decade, I’ve seen our orders for large print runs dwindle. There is more demand for personalized solutions.

What are some of the biggest opportunities in the print industry?

JC: Print is one of those industries where the sky is the limit, and you are only restricted by your imagination. By diversifying the services, staying on top of trends and new technology, being flexible and offering great service, printers can be successful for years to come.

What do you think is the most exciting thing about print today?

JC: I love how the technology on digital presses has evolved so much over the years, and we no longer need to have huge budgets to do special treatments like a spot varnish or foil.

Campbell’s responses were edited for length. For more Q&A Spotlight interviews, please visit www.printaction.com/profile.

The all new Acuity range from Fujifilm

With a track record of pioneering innovations, Fujifilm has helped thousands of sign and display printers transform their businesses. But in a world where change is constant, three years ago we decided to go back to the drawing board to define a new blueprint for UV inkjet print performance.

The result is a brand new range of Acuity printers designed and developed by Fujifilm that redefine price/performance and transform print ROI. They bring new meaning to versatility and value and reset the expectations around ease of use. And being developed by Fujifilm, they come fueled by the best UV ink on the market and a guarantee of outstanding quality and reliability.

The new range of Acuity printers designed and developed by Fujifilm.