From sheet-to-sheet and fold-to-fold, we equip Canada’s printers with solutions to outpace, outperform and outlast.

Printers looking for an edge turn to RM Machinery for unparalleled print and finishing performance. That’s why we’ve paired the unstoppable RMGT 10-Series B1 presses with the flexible Horizon AFC-746F B1 Pallet-Feed Folder — delivering a duo that defies expectations.

RMGT 1060LX PERFORMANCE PACKAGE

is a fully loaded press configuration for commercial and packaging printers that delivers real-world, measurable productivity improvements to yield more output and better printing performance for your operation.

✔ SimulChanger Parallel Automated PlateChanging and Washup System helps you complete an extra job per shift.

✔ Improved Front-Lay and Side-Lay Detectors accommodate thicker stock up to 1.00 mm.

is a robust finishing solution that provides 6-buckle folding with with integrated knife/ buckle cross folding with quick changeover and simple operation.

✔ 20 pre-set fold patterns and programmable memory for up to 200 di erent jobs.

✔ Achieve production-class speeds for knife folds up to 240 meters/min

RM Machinery is your partner in productivity, from expert installation of RMGT and Horizon equipment to industry-leading service and support, backed by our fully stocked parts and consumables warehouse. Plus, with strategically located field technicians in Ontario, Quebec, and across the provinces, experience the local advantage for in-person maintenance and remote response.

Join the ranks of Canada’s print market leaders — those who don’t just reach their milestones but multiply them with RM Machinery.

21

On the cover: Mitchell Press printed the posters on the cover as part of a self-promotional kit to showcase nanographic printing.

ISSN 1481 9287. PrintAction is published 6 times per year by Annex Business Media. Canada Post Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to: Circulation Department, 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission.

© 2024 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada.

12

A unique approach is redefining how businesses bridge physical, digital realms

deep dive into the PELT program 21

It’s been a bumpy ride for packaging

The print industry is showing increasing confidence despite economic headwinds

26 Print Panther bets on

Company president discusses the role of embellishments in marketing

GAMUT

5 News, People, Installs

11 CALENDAR

SPOTLIGHT

30 Jennifer McConnell, director of operations, Royal Printers

FROM THE EDITOR

4 Nithya Caleb Brand marketing 101

BYTE BULLETIN

8 A.J. Rai

Tech and print: Friend or foe?

INSIDER

11 Bob Dale

The future of print

CHRONICLE

10 Nick Howard

The irony of a tsunami

TECH REPORT

28 Angus Pady

Brand colour matching 12 26 30

In this issue, we’re launching a new column that focuses on digital solutions printers can successfully employ in addition to print in their quest to reach new market sectors. Authored by A.J. Rai, VP-sales, Mitchell Press, I hope you find the information helpful. Check out Pg. 8. In his first column, Rai talks about the need to educate our customers about the benefits of print. It’s simply because we have a new breed of print buyers, who being largely digital natives are unaware of print.

Did you know it only consumers take only five seconds to choose a product.

A 2023 survey by Printing United Alliance found the recent crop of print buyers belongs to multiple generations with varied work experiences as well as many job responsibilities; there’s intense pressure for ROI on mar-comm plans; and they’re exposed to several options that go beyond print. Their job responsibilities may include specifying print, selecting vendors, creating marketing strategies, recruitment, budget preparation, developing products or services, policy development, and investing in workplace technologies. Given these multiple responsibilities, it’s not surprising there’s a knowledge drain about print among buyers, which needs to be addressed.

A respondent to the 2023 Printing United Alliance survey said, “We continue to focus on automation and the need to teach clients commercial printing. Many designers have no clue how to convert from the screen to paper or other substrates. The ad agency print production manager is a dinosaur and commercial printers are having to fill the void.”

The survey found that print customers mainly learnt about print trends from online sources (52 per cent), vendors/ suppliers, e-newsletters (51 per cent), trade magazines (46 per cent), and social media (43 per cent). It’s true that print providers try their best to educate clients by providing relevant content, but it’s not enough. Print users need more education and access to more samples to understand how printed products can help their business.

Conversely, print service providers must adopt the world’s lingo. As Rai mentions in his column, digital means a whole lot than just digital printing. Think con-

sumer data, artificial intelligence, online advertising, web development, augmented reality etc. Digital tools can be used effectively in target marketing, which is focusing on a specific group of people with common characteristics. “Companies use target markets to thoroughly understand their potential customers and craft marketing strategies that help them meet their business and marketing objectives,” as described by Coursera.

Hubspot adds, “A target market can be segmented by different variables. Consumers can be split by demographic, geographic, and behavioural factors.” You have to choose the variable thats appropriate for your campaign. Mitchell Press has been helping their clients target market successfully by extrapolating data, such as demographics, age, gender, time spent on website and pages visited, and combining that with their print solutions. As you’ll read in Pg. 14, this 360-degree approach has increased sales to pre-pandemic levels at Mitchell Press.

Another trend is the increasing use of embellishments in printed products. Print Panther Direct, a commercial printer in Oakville, Ont., realized this a few years ago. In 2018, it installed a Konica Minolta Jetvarnish 3DS embellishment press, and last year, it added a MGI Jetvarnish 3D Evolution. As shared on Pg. 26, Christine Yardley, Print Panther Direct’s president, firmly believes embellished print is next-generation print and can help shape consumer behaviour and drive brand success.

Yardley references the five-second rule. Conceptualised by author Mel Robbins, this idea is widely used in marketing. Robbins believes consumers take only five seconds to choose a product, underscoring the need to create product, which “trigger memories, ideas, or semiotic associations that in turn ignite emotions.”

What steps are you taking to educate clients about the power of print? Are you thinking of using digital solutions to elevate your offerings? How are you using embellishments? I’d love to hear from you.

NITHYA CALEB Editor ncaleb@annexbusinessmedia.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal 416-510-5113 apotal@annexbusinessmedia.com Fax: 416-510-6875

Mail: 111 Gordon Baker Road, Suite 400, Toronto, ON M2H 3R1

Editor Nithya Caleb ncaleb@annexbusinessmedia.com 437-220-3039

Contributing writers

Bob Dale, Nick Howard, A.J. Rai, Robert Seay, and Angus Pady

Associate Publisher Kim Barton kbarton@annexbusinessmedia.com 416-510-5246

Media Designer Lisa Zambri lzambri@annexbusinessmedia.com

Account Coordinator

Julie Montgomery jmontgomery@annexbusinessmedia.com 416-510-5163

Audience Development Manager Urszula Grzyb ugrzyb@annexbusinessmedia.com 416-510-5180

Group Publisher/VP Sales Martin McAnulty mmcanulty@annexbusinessmedia.com

President/COO Scott Jamieson sjamieson@annexbusinessmedia.com

Subscription rates

For a 1 year

subscription (6 issues): Canada — $43.86 +Tax Canada 2 year — $71.91 +Tax United States — $99.96 Other foreign — $194.82 All prices in CAD funds

Mailing address

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 Tel: 416-442-5600 Fax: 416-442-2230

Occasionally, PrintAction will mail information on behalf of industry related groups whose products and services we believe could be of interest to you. If you prefer not to receive this information, please contact our Audience Development in any of the four ways listed above.

Annex Business Media Privacy Officer Privacy@annexbusinessmedia.com 800-668-2384

PrintAction is printed by Annex Business Media Printing on Creator Gloss 80lb text and Creator Silk 70lb text available from Spicers Canada.

ISSN 1481 9287

Mail Agreement No. 40065710 printaction.com

The Assiniboine Community College’s Centre for Creative Media (CCM) in Manitoba receives a $100,000 donation from the Leech Group and family, who will soon be commemorating their 100th anniversary. This contribution that has been made by the print and digital media company in Brandon, Man., and the Leech family includes $75,000 toward CCM and $25,000 to support financial awards for students in Digital Art and Design, and Web and Interactive Development programs. The college has also named a space as the Leech Group Collaboration Classroom on behalf of the donor.

Xerox unveils a new operating model and organizational structure. “The evolution of Xerox’s reinvention aligns our resources in three key areas –improvement and stabilization of our core print business, increased productivity and efficiency through the formation of a new Global Business Services organization, and disciplined execution in revenue diversification,” said Steven Bandrowczak, CEO at Xerox. The company has redesigned and realigned its executive team to support the new operating model. Effective immediately, John Bruno will lead the enterprise alignment of Print, Digital Services, and IT Services businesses. Louie Pastor returns to Xerox as chief

transformation & administrative officer, charged with overseeing the Xerox Reinvention Office and the newly established Global Business Services organization. Flor Colon has been appointed chief legal officer and corporate secretary.

Pantone introduces Pantone 13-1023 Peach Fuzz as the 2024 Colour of the Year. Pantone describes Peach Fuzz as “a velvety gentle peach whose all-embracing spirit enriches mind, body, and soul.” The introduction of Pantone 13-1023 Peach Fuzz also marks the 25th anniversary of the Pantone Colour of the Year program. First introduced by the Pantone Color Institute in 1999, the Pantone Colour of the Year captures the global zeitgeist, serving as an expression of a collective mood and an attitude on the part of the consumer.

Alberta-based Burke Group of Companies acquires Capital Colour Press and Priority

Printing, two printing companies with rich histories in the Edmonton market. The integration of Capital Colour Press and Priority Printing into the Burke Group family brings together a wealth of experience, technology, and a highly skilled team of professionals. The Burke Group can now offer an even more comprehensive portfolio to its clients including offset and digital printing, mail services, wide format printing, and signage.

Greenpeace Canada and Auriga Nusantara, an NGO in Indonesia, urge the Forest Stewardship Council (FSC) to recognize the connection between Paper Excellence and Asia Pulp & Paper (APP)/ Sinar Mas Group, the parent company, and disassociate itself from it. FSC disassociated itself from APP in 2007. According to its policy for association, FSC proscribes businesses related to disassociated companies from obtaining certification.

Müller Martini AG acquires Hunkeler AG. The management of Hunkeler AG under the leadership of Daniel Erni will remain responsible for day-to-day business. The name Hunkeler, the Hunkeler products and services as well as

the Hunkeler Innovationdays will remain unchanged. The Hunkeler location in Wikon and its employees will be retained. The current day-today business continues unchanged. Müller Martini intends to continue business with other finishing companies that are currently partnering with Hunkeler.

Raddar, a thin leaflet, is TC Transcontinental’s newest flyer solution.

TC Transcontinental expands distribution of the Raddar flyer across Quebec as well as in areas of Ontario and British Columbia. Raddar is a thin leaflet folded in four that combines flyers from various retailers into a single printed product. It is distributed via Canada Post and has a digital version. It’ll replace the flyer bundle service called Publisac in Quebec, which has left local newspapers in a limbo.

Icon Digital Productions, a visual communications agency in Markham, Ont., appoints Alex Christopoulos as its new CEO, effective January 1, 2024. Christopoulos took over from co-founder Juan Lau, who decided to retire. Lau is still the board chair. Co-founder and CCO, Peter Evans said, “Alex has been an integral part of our success as a company and we’re confident in Alex’s ability to lead.” Lau added, “Alex has served as CFO and a key member of my executive team for the past 16 years and, I can’t think of anyone more capable and deserving to succeed me and continue our legacy.”

Canon Canada appoints Mikio Takagi as president and CEO. Takagi began his career with Canon in 1989. Over the past 35 years, he has worked in various regions and held progressively more senior roles. He has worked for Canon companies in Japan, Hong Kong, China, and the United States. He became president of Canon Mexicana in 2019. Since 2021, he has been president and CEO of Canon Mexicana, Canon Panama, and Canon Latin America North Zone. Takagi earned a bachelor’s degree from Aoyama Gakuin University, majoring in international politics and emerging market economies. Takagi succeeds Isao “Sammy” Kobayashi, who has assumed the role of president and CEO of Canon USA.

Calgary-based Mountain View Printing invests in an Epson SurePress L-6534VW UV digital label press to scale up business.

Mike Suter as business strategy and people development specialist. An experienced financial planning executive, Suter is a hands-on, results-driven management executive. He has worked in print and financial services helping teams with strategic planning, sales process enhancements, human resources, and team building. He is also skilled in capital improvements, negotiations, and workflow efficiencies and has extensive experience in succession planning.

Monadnock Paper Mills appoints Daniel J. Burke as its new chief financial officer and treasurer. Burke assumes the role following the retirement of Andrew Manns. Burke is a CPA and brings more than 22 years of financial management experience in the manufacturing and distribution industries. Most recently, he served as corporate controller at Velcro Companies, where he managed an international team of 60 accountants across the globe. Before his tenure at Velcro, he held the position of vice-president of finance at Iredale Cosmetics.

Minoh, a print and signage fabrication company in Etobicoke, Ont., installs a Canon Colorado M-series printer.

Simpson Print, Bloomingdale, Ont., invests in a SwissQprint Kudu printer. Simpson is the first Canadian company to acquire this printer.

By A.J. Rai

hy does the second oldest industry in the world have a tough time staying relevant?

How is it that print can date back hundreds of years and withstand many new inventions but come to a standstill as soon as the digital era exploded? I asked myself these questions several times before entering this industry.

Now, don’t get me wrong; the industry has made great investments and strides into assembling some of the greatest and coolest technology out there. From new advancements in sheetfed printings to short-run digital print, variable capabilities, web-to-print, and expanded colour gamut, the list goes on. But how do we perceive these advances against what’s happening in other industries that are inhabited by our (as well as potential) clients? Print lovers who have lived in our industry over the past decades will tell you there is still a place for print in the world, that it means something to folks and can still be useful to organizations outside the publication sector. But do we really agree with that? More importantly, do our future customers and partners agree with that? Do we know our future customers? Why is it that we, as a collective group, only see advancements in technology as a way to better serve our current crop of customers, a group that is constantly dwindling due to market variables. Have we thought about the lack of knowledge regarding print in the digital-native generation, which includes millennials and the groups that came after them. With the age of AI (artificial intelligence) upon us, how will we, as an industry, shift

By unifying

focus to educate the world on print.

In the 1440’s, Johaness Gutenberg invents the printing press, thus heralding the printing revolution.

It’s time for us to not only look at print technology, but also how we can incorporate print into existing tech. Online privacy laws have become much more restricted with stricter ad-blocks for digital advertising and a need for opt-in-consent of emails. As a result, organizations will lose the ability to reach out to the masses and generate revenue. Variable printing is an attractive option in these times. It is extremely powerful and has a higher success and open rate than traditional printed pieces, but let’s dig a little deeper.

Our clients have powerful CRM software that houses a lot of data about their customers. They might not understand how to target market different segments of that information to maximize their objectives. They may understand that they have data, but at the same time, they might be purchasing new leads lists because they want to grow by X per cent year over year. How about helping them better understand their own data? What if you could show them that 60 per cent, for example, made it to the checkout page and only 18 per cent made the purchase. What can we do with that information? Well, for starters, we take the time to help clients understand the metrics behind variable print—explain to them variable printed pieces have an open rate of 79 per cent, per my company’s internal

data metrics, and if you sent an individually messaged note to more than 10,000 prospects, there’s an eight/10 chance for them to make a sale or garner more attention to their physical or online storefront. The key is to incorporate digital data the client has and automate it into a print process. If we can unify these two worlds, then we will have a two-pronged approach to generate revenue. This will open doors to new markets.

I bet you’re wondering what the ROI is on these types of personalized notes. However, what’s more important is to understand what that ROI means to a customer and where it can be seen along the sales process.

Is there a place in this world for print? Absolutely. Can the industry be perceived as cool and fun in the global marketplace? Yes, no doubt. There is a place for print to be more functional, a place where we can intertwine it with the latest technologies and provide our industry with a different set of product offerings. These solutions will continue to educate people on the relevance of print for generations to come and in a world where we stand as tall as digital.

The bottom-line is that print is here to stay, so let’s get creative albeit in a different way.

A.J. RAI is the vice-president of sales at Mitchell Press, Burnaby, B.C. He can be reached via email at ajrai@mitchellpress.com.

By Nick Howard

On December 26, 2004, a tsunami wreaked havoc in parts of South and Southeast Asia. It not only caused catastrophic costs, but also killed 228,000 people. Just the word, “tsunami,” alone evokes strong emotions, whether one survived or saw the aftermath on TV. What is ironic is that if you were relaxing on a boat far from land when the underwater earthquake began, you’d only notice a slight rise and fall of the sea, but it’s a different story on land—disaster awaits on the shore.

The Oxford Dictionary also defines tsunami as “an arrival or occurrence of something in overwhelming quantities or amounts.” There are hundreds of words that have dual, often opposite intents, just as futuristic technologies often carry equally painful and joyful outcomes.

Recently, a raft of industry news signalled hope for some offset press manufacturers—photos of customers with toothy grins standing before their new investments on social media and trade magazines. Most of the recent installations are B1 (40 in.) and often have unique configurations. Late last year, Heidelberg announced the installment of the world’s largest offset press, a Speedmaster 106 with a whopping 20 units, at a Westrock plant in Poland. It’s as if we took the last 15 years of stagnation, wrapped it up in a beach towel and buried it someplace: Did the printing industry’s struggle against the internet ever happen? This rejuvenation is only an illusion; declining print use is the reality. Print service providers must do everything faster and at less cost to keep afloat.

The recent resurgence of traditional offset press sales is exciting, even with print’s decline. New equipment makes mincemeat of older presses that have become obsolete overnight. But I still wouldn’t bet on the long-term future of offset. Other new digital technologies are making huge, tsunami-like moves to replace the old guard.

As if the HP T250 HD to a perfect bound book—sans signatures— wasn’t enough, the same HP runs roll-to-roll. Then the printed rolls are sent to another line, encompassing a Hunkler sheeter, an MBO eight-page folding section and finally into a Müller-Martini Prinova stitcher. The Prinova collects each folded signature until the book is complete, then sends it along where a cover feeder can fold and feed a cover. One operator for the whole line. There are no skids of signatures awaiting the entire book to be printed. Printing and binding are in real-time with few personnel and drastically lower costs. Run lengths vary from a few thousand to well over 30,000 copies.

The 40-in. sheetfed, mainly used for cover work (also equipped with UV), hasn’t seen a job in months, with all the work transferred to a few recently installed toner cut-sheet digital presses.

10/2023

Heidelberg installs the world’s largest offset press, a Speedmaster 106 with 20 units, at a Westrock plant in Poland. The HP PageWide T250 HD inkjet press can print up to 500 ft per minute.

A client in New York recently contacted me with big news. This 100-year-old business and longtime offset commercial printer wanted to sell all their offset equipment and go 100 per cent digital. This is no small operation. The pressroom held two 16-page webs and a six-colour 40-in. press. I’d never encountered a situation as significant and evolutionary before, and as I travelled, I assumed the company’s president wasn’t completely serious. I held onto that notion until I walked into the area that used to house their offset webs. It was all true; this company had overnight transitioned from typical old-school printing methods to a shiny new HP T250 HD inkjet rollfed press. As I stood and watched, the HP, with only two operators (it looked as if one was enough), hummed along at close to 500 ft per minute from paper rolls through to a bespoke ribbon-deck finishing line that folded and then collected complete products ready for (in this case) perfect binding.

The owner likes to say he grew up making “signatures.” Now, no longer. The plant also doesn’t need a battery of traditional folding machines, as pages are printed in order and bound.

With such a long, successful history, this printing firm had to overcome two world wars, a global depression and fierce competition in the transactional and book printing segments. Today, they have accomplished something few thought feasible: a completely digital process from workflow to delivery.

This isn’t the first HP T250 HD or HP T485 HD installations and Hunkler and Müller-Martini aren’t new to collaboration. Twenty years ago at Drupa 2004, these two were running with Koenig & Bauer’s RotaJet. HP has been marketing the web lines for over 10 years. Transitions of this kind continue to spread. Whether it be Ricoh’s ProZ75, Canon’s ColorStream or Xeikon’s SX30000, choose a partner, as there are many. What has changed is the frequency of these new technologies taking the lead away from old-school offset. The tsunami is already here. Discover it soon.

NICK HOWARD, a partner in Howard Graphic Equipment and Howard Iron Works, is a printing historian, consultant, and Certified Appraiser of capital equipment. He can be reached at nick@howardgraphic.com.

By Bob Dale

We all could benefit from knowing the future, however the best we can do is plan and be prepared.

At a recent meeting hosted by the Atlantic Printing and Imaging Association meeting in Halifax, there was a lively discussion with students enrolled at the Graphic and Print Production program at Nova Scotia Community College.

The session started with a lighthearted review of printing from the past and included an overview of the printing and publishing activities of Benjamin Franklin. He established the Pennsylvania Gazette, wrote several books, and published several columns. He is credited with printing innovations that improved clarity. Franklin also contributed to the development of the postal system. It’s interesting that the first post office in what is now Canada was opened

in 1755 in Halifax, with Ben Franklin as the deputy postmaster for the Colonies. The key message shared was that Franklin diversified from print to include technology improvements, content creation and distribution services to meet customer needs.

The speed of technology changes has shifted from decades to months. Today’s printers need to be aware of the changes and gauge the impact on their business. They must also understand market needs as they evaluate print technology and capabilities, such as offset, dry toner, UV inkjet, water-based inkjet, HP Indigo LEP, and the recently introduced nanography printing by Landa.

Successful commercial printers have embrace diversification, just as Ben Franklin did. According to a recent study by Printing United, “Fifty-six per cent of commercial printers are moving into adjacent print markets” including signs and graphics, packaging, direct mail services and promotional print and apparel. In part to overcome labour challenges and to

improve efficiency, robots and robotic capabilities have been added to print and finishing equipment, which has decreased production time and the amount of labour required.

For many, the use and application of artificial intelligence (AI) is in the future, but it has become a part of our daily lives. AI features are embedded in many of the business and communication applications we use daily and in the advanced workflow tools and processes.

AI can automate prepress, file analysis, colour correction, image enhancement, order management, job routing, scheduling, and quality control to reduce turnaround time, minimize errors, and to ensure a smoother production process. Integrating AI into print management software tasks such as estimating, quoting, and job tracking can automate these jobs, thus reducing manual labour and saving time.

In my experience, successful companies from past, present and future need to be ready for ongoing change. This requires strategy, action, execution and monitoring to ensure you’re on

February 6, 2024

Futures Edge Summit | PAC Global Awards 2022 New York City, N.Y.

February 12-14, 2024 Printing United Leadership Summit Palm Beach, Fla.

March 12-14, 2024 TAGA 2023 Annual Technical Conference Dallas, Texas

March 18-24, 2024 PACK Expo East Philadelphia, P.A.

March 19-22, 2024

FESPA Global Print Expo Amsterdam, The Netherlands

March 20-22, 2024

AWA Global Release Liner Industry Conference & Exhibition Amsterdam, The Netherlands

April 10-12, 2024 ISA Sign Expo Orlando, Fla.

May 5-8, 2024

FTA Forum, Infoflex 2024 Kansas City, M.O.

May 15-16, 2024 SmartMTX Red Deer, Alta.

May 28-June 7, 2024 Drupa Düsseldorf, Germany

The first post office in Canada opened in 1755 in Halifax.

The future belongs to those who prepare for it today. –Malcolm

the right track. Successful leaders will have a combination of business and technical skills required to succeed. Companies that understand markets, customer and employee needs, and deliver value will continue to grow.

BOB DALE is vice-president of Connecting for Results, the premier management consulting company focused on the graphics communications industry. He can be reached at b.dale@cfrincorporated.com.

Mitchell Press’s unique micro data approach

is redefining

how businesses bridge physical and digital realms

By Nithya Caleb

In 2023, one of Canada’s leading print companies, Mitchell Press, had a rebrand; it dropped the word ‘Press’ from all client-facing logos. As explained at that time by the company’s executive vice-president Scott Gray, “While our legal name remains Mitchell Press, we removed the word ‘Press’ from our client-facing mark because today our services are so much broader than print alone. While print remains an integral part of our business, we prefer a non-traditional approach by empowering print through data analysis, web development, graphic design, print management tools, and sustainable production solutions.”

The Mitchell Group consists of Mitchell, its digital marketing division, Project28, which focuses on web development, CGI renderings, and augmented reality, and Pacific Bindery and trade services. It was founded in 1928 by Howard T. Mitchell as a financial newspaper. The company, which is now in its third generation of family ownership, has evolved with the times from being a financial newspaper and web offset printer to digital printing and now, a comprehensive visual-communications solutions provider.

As the print industry goes through a tectonic change brought about by the Internet of Things, many com-

panies have been diversifying, actively future-proofing themselves. In the last few years, Mitchell has also engaged in this exercise. The question uppermost in the minds of senior leadership has been, “How do we prepare the business for another 90 years of success?”

As part of this resilience strategy, the company hasn’t hesitated to seek advice and talent from outside traditional print corridors to help create a new vision for Mitchell. One such hire or find was A.J. Rai, VP-sales, Mitchell, who won the 2023 Emerging Leader of the Year Award at the Canadian Printing Awards late last year. Not to downplay the role played by others at Mitchell, Rai has been pivotal in the company’s active adoption of digital solutions. I spoke to Rai about how Mitchell is successfully merging the physical and digital worlds and the perspective shift required among printers for the industry’s long-term success.

In June 2017, Rai, who has zero print experience, joined Mitchell as

Scott Gray, executive VP, Mitchell Press, at the 2023 Canadian Printing Awards.

the company’s first digital media specialist. Born and raised in Richmond, B.C., Rai’s background was in tech strategy. A mutual friend introduced Rai to Mitchell’s executive team. During the initial meeting itself, Rai began to see gaps around how the print industry views digital vis-à-vis the rest of the world. In the print industry, digital often refers to digital printing whereas ‘digital’ is far deeper and complex than that; it can refer to innumerable tools and soft-

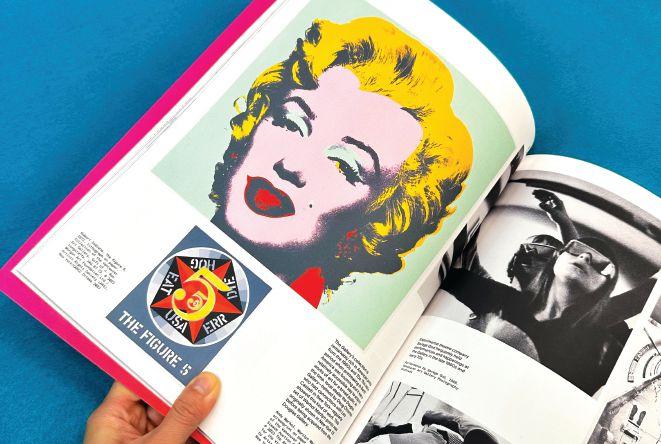

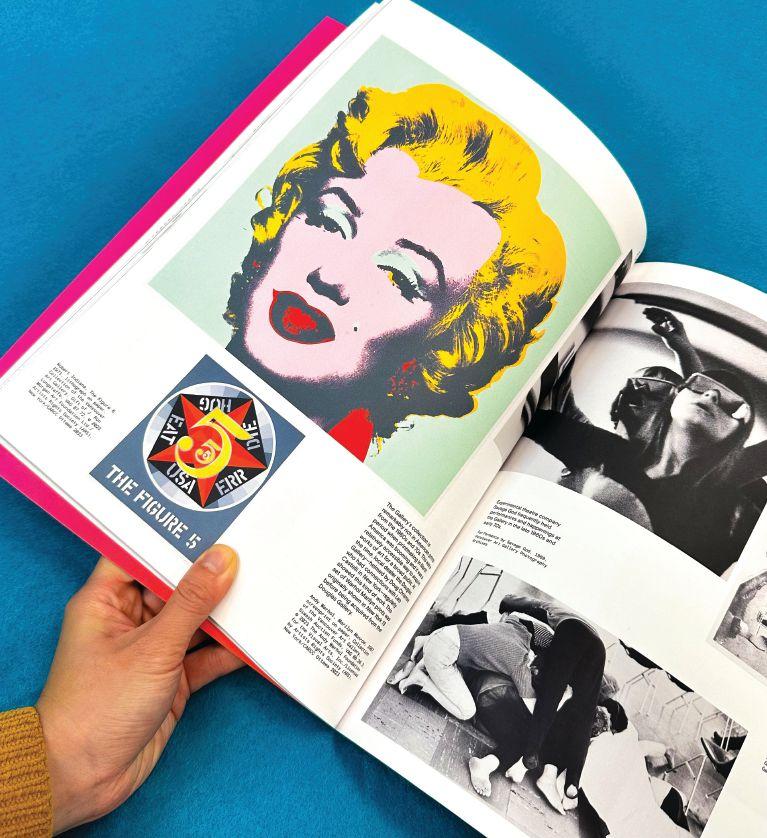

The Vancouver Art Gallery’s Incomplete History of the VAG 1931-2023 is a perfect bound book containing imagery ranging from archival BW to professionally shot artwork.

ware that can support a business process, Rai explained.

“Print is the only industry where we use digital to mean print and not digital like it’s perceived by the rest of the world. When we talk digital, it always means digital printing, shortrun, machine, equipment. This is great but when we look at it from the perspective of the rest of the world, it’s confusing,” he said. For instance, a prospective client may seek your help with digital advertising after

The Hip Trip Kit showcases the strengths of nanographic printing. It comprises a custom folding carton container, journal/sketch book, mini art prints, and custom baggage tags. Print

is the only industry where we use digital to mean print and not digital like it’s perceived by the rest of the world. – A.J. Rai

seeing ‘digital’ as one of your services. However, you’re only offering digital printing. These genuine gaps in communication make us wonder what the industry is missing by not combining the physical and digital worlds.

Rai came on board with the confidence that while print may have lost its power, it’s possible to use modern technology (read digital) to grow the overall business where print plays a significant role.

Rai’s first responsibility was to launch Mitchell’s digital solutions division. A consultative approach and in-depth knowledge of IT helped Rai understand Mitchell’s clients (old and potential), delve into the data in their CRM systems and how that could be used to address pain points in their businesses.

To understand this better, let’s look at real estate mailouts. Typically, developers send mass mailouts about a new property to residents in a specific postal code. Rai is suggesting a more targeted approach. Since developers have been in the business for decades, they must have data indicating which consumer is looking for what type of property. So, if a developer is looking to sell a 2BHK condo, they can, if needed, send personalized mailouts to consumers who are looking for a similar property. Such personalized, targeted mailouts would naturally generate a higher ROI than mass mailouts.

Another issue that Rai realized Mitchell could help their clients with was website development. Many clients either didn’t have a website or the site wasn’t user-friendly. By optimizing the website, Mitchell helped improve brand engagement.

“Your website is your first tool for sales and marketing. Through our own unique IPs, we’re able to watch people’s ‘behaviour’ on a website. We can map out how they’re interacting with the website. We can take this a

little bit further as well by running it through our AI IPs where we record the data, look at the interactions and how it impacts creative. This data will allow us to decide the best places to include a call-to-action button to improve engagement and what colours/fonts/styles to use, as well as product positioning. We identify the metrics that need to be captured for our customers. This allows us to have a better understanding of the client’s goals and objectives and can help determine which Mitchell product can be offered to help the client,” he explained.

The obvious corollary to the above discussion was the type of data that was being captured. Mitchell’s inhouse term for that is micro data.

“It’s concise, intuitive, day-to-day data, actionable and readily accessible to anyone. Through Mitchell’s Project 28 discovery process it can be used immediately in an impactful manner, allowing you to maximize ROI,” Rai explained. “The data we’re collecting allows us to merge the physical and digital worlds and target consumers in specific ways.” Remember the real estate mailout example that was mentioned earlier?

In a nutshell, micro data refers to consumer behavioural data like demographics, time spent on website and pages viewed, purchase history, etc. Mitchell’s Project28, a joint venture with Toronto-based software firm Hypekraft Digital, focuses on capturing and interpreting that data at a granular level.

Mitchell’s 360-degree approach didn’t pigeonhole them into one silo of the marketing conversation. Thus, they were able to convince customers to use Mitchell’s core business of ‘printing’ to achieve things like unboxing a brand-new shoe, customized packages, etc.

The Landa Nanographic Press is also playing a key role in Mitchell’s digital transformation plan.

In 2022, Mitchell became the first Canadian printer to invest in the Landa S10P Nanographic Printing Press. At that time, Gray said, “The Landa digital press pushes us to re-imagine print. Rather than producing 500 of one book, let’s create 500

In 2022, Mitchell became the first Canadian printer to invest in the Landa S10P Nanographic press.

Mitchell invested in Canada’s first Landa S10P Nanographic Printing press in 2022.

books of one – completely personalized, with an incredibly high bar for quality. While mass customization was once a dream, today it’s a cost-effective reality.”

The Landa is allowing Mitchell to elevate its variable data printing capabilities. It has proven invaluable in Mitchell’s ability to blend digital technology and print.

“Landa allows us to take the metrics we’re getting from the web development, CRM, and ERP and transition them towards these [print] initiatives. We’ve done short runs for events and packaging for tea manufacturers. While sheetfed is great, Landa has simply automated the process,” explained Rai.

Thanks to Mitchell’s company-wide focus on digital solutions and Rai’s vision to let data inform Mitchell’s client’s marketing decisions, the company’s overall sales volumes increased to pre-pandemic levels by early 2022, a fact that Gray highlighted in his application to nominate Rai to the Canadian Printing Awards program.

The team is now “adept at bridging the gap between print manufacturing and the digital realm. Leveraging data metrics and cutting-edge technology is helping the company transform the industry,” he added.

MARCH 6, 2024

https://www.automationmag.com/virtual-events/women-in-manufacturing-2024/

A look at the innovative PELT program of B.C., which has a success rate that begs for national adoption

By Treena Hein

Practical, useful, truthful, eye-opening – those are just a few ways that graduates of the B.C.based PELT (Print Entry Level Training) describe the program.

Take Gerald Rath, who took the free 10-week program in mid-2023 and is now a production operator at Hemlock Harling in Richmond. He reports that while he enjoyed the basic overview of the print industry through “studying the excellent textbook and lectures, I relished being able to talk to seasoned professionals.”

Rath describes these professionals (who gave tours of their operations to

PELT participants) as “very honest” about their businesses and the future of the printing industry as well. He reports that he and his fellow students asked many tough questions about starting pay, highest possible eventual pay, whether there are typically layoffs during slow times of year, and much more, and he says all questions “were answered honestly and succinctly, so as to not give students an unrealistic view.”

Another PELT graduate, Hossein Hosseinian, explains PELT confirmed for him that a career in the print industry would be an exciting opportunity for him to put his cabinet-making experience to good use.

“As I learned more about printing, I saw it matched my skills,” says Hosseinian, who is now working in production at Great Little Box Company, also in Richmond. “It felt like a good change for me. I learned about different materials and how to design.”

PELT, now entering its fourth year, is offered through PrintForward Printing and Imaging Association of B.C. and its Next Generation Task Force. Funding is provided by the federal government through the Canada-B.C. Workforce Development Agreement, under the Ministry of Post Secondary Education and Future Skills through the Community Workforce Response Training Grants. PELT is delivered by the NorthWest Skills Institute (NWSI), which offers a wide range of vocational certificate programs and health and safety training.

With over 40 graduates and a job placement rate of 85 per cent, PELT continues to be a highly successful way of easing recruitment pressures and bringing new vitality to B.C.’s print industry. According to PELT program director Jennifer McConnell (who’s also director of operations at Royal Printers in New Westminster, B.C.), the program model has the potential to be replicated across Canada.

This model, a free, honest, and jam-packed introduction to the sector, requires participants to apply for full-time print industry jobs at

graduation. It also provides job application training and assistance with job application submission. Rath explains that “revising my resume, coaching me on how to ace job interviews and even how to act after being hired ( e.g. attend all social events held by the employer; don’t be anti-social), was all invaluable information. I credit this to NWSI having direct contact with those employed in the printing industry for several decades. NWSI did not just give general advice.”

Rath also very much appreciated that he didn’t have to demonstrate the reasons why he was seeking job retraining in order to be accepted to PELT. Incidentally, Rath’s reason for taking PELT was to try something

new, and because, as an experienced graphic designer and operator in the sign industry, he was frustrated. “No matter the position for which I was hired over the past few years, I was soon transferred to installation,” he says. “This is because most sign installers have long since left for the far more lucrative careers in the construction industry.”

Hosseinian was looking for a new career where he could apply existing skills and thought PELT looked interesting. Some students like Rath are also able to access financial support through WorkBC, free transit passes and more.

Rath strongly valued the help with job applications, which led to him being employed very soon after PELT

completion. “I very much appreciated that the NWSI applied for several jobs within the local printing industry on my behalf,” he says. “These jobs were based on my past work experience, and on in-class cleanliness, attendance, punctuality, and comprehension of class material. Thus, the potential employer was getting the real picture of my capabilities, while I felt confident the potential employer was not a flash in the pan or only interested in hiring temporary employees for the busiest season.”

NWSI senior program manager Cormac O’Reilly applauds the Next Generation Task Force and PrintForward team for leading the charge with this program in order to address the looming print industry labour shortage. “As part of curriculum development, the NWSI team visited and spoke with a number of PrintForward employer members to understand their needs, and the skills

required for a person to start work within this sector,” he says.

From “this invaluable insight and input,” PELT was born. It covers all aspects of the industry right from the history of print, print production processes and planning, bindery, printing presses, creative suite prepress skills, packaging and mail, safety, Kaizen, and as mentioned, job readiness. Guest speakers are an important aspect of PELT, along with weekly tours to local printing companies that expose students to different print environments and how their training would be applied in real-life situations. “The tours were also a great way to help students see what type of printing company or opportunity they would like to get into following completion of the training,” says O’Reilly.

PELT has also evolved over its three iterations, incorporating feedback from students and employers.

“As a result, more tours, more handson projects and more guest speakers

The 2023 cohort of PELT with advisors and instructors.

have been included,” O’Reilly reports.

Further, excellence in instructors continues to be a critical part of PELT. Sarah Dakiniewicz, owner of Stationery Bike Designs, is PELT’s newest. “My hope is to imbue my passion for print onto the next generation of print industry leaders,” she says. “I am looking forward to lending my experience and expertise to help fill in gaps we’re currently experiencing in the workforce. PELT is an integral component for our industry to not only survive, but to also thrive.”

The PELT program was launched in

2020.

The potential employer was getting the real picture of my capabilities, while I felt confident the potential employer was not a flash in the pan or only interested in hiring temporary employees for the busiest season. – Gerald Rath

With the print industry’s current labour state, no one could argue that a successful program like PELT would be useful across Canada. “We know the B.C. printing sector is not the only province facing challenges,” says O’Reilly. “With a proven training model, there is an opportunity to help expand the program nationally and ensure the amazing skills of experienced professionals are passed down to the next generation before they retire.”

Rath and Hosseinian are also in full support of the program going countrywide. Hosseinian notes that “my journey from cabinet making to printing underscores the potential for individuals from diverse backgrounds to find their niche in this industry. A national program would not only bridge skill gaps, but also encourage career transitions and foster a more diverse and skilled workforce.”

print must add new value and improve cost structure to compete with optimized analog processes to get large orders.

It’s been a bumpy ride on the digital highway for corrugated packaging

By Robert Seay

Digital print has been promising broad transformation in corrugated for a long time. Significant progress has been made, but digital print still only represents and addresses a small subset of corrugated print needs. New approaches are needed to broaden the reach and value of digitally printed corrugated packaging. Digital print transformation in the corrugated industry has been a promise waiting to happen for many years. Part of the reason for the delay could be the industry has been perceived as having one monolithic set

of needs and digital print has been promoted as one generic solution to fit all of those needs. However, all corrugated needs and digital print solutions are not the same.

The reality is much more nuanced. There has been some progress in several use cases and sub-markets including high quality graphics, samples, mock-ups, displays, short-run, large format, double-sided print, and supply chain efficiency including turn-around time, but there are still a few other use cases like personalization and variable data that haven’t yielded transformation. Digital print still only addresses a fraction of the overall market for printed corrugated

packaging. For this to change, we must address the existing gaps in the overall solution set. Digital print solutions do not adequately address all substrate, board combinations, and form factors. Special requirements of the printed product like ink holdout, colour, overprint varnish, coefficient of friction, durability, and gluability play a part in what can or cannot be done by any given digital print solution. Specific press limitations might mean something can be done in limited quantities or certain situations but cannot be done at scale and remain cost effective.

Digital print was and still is supposed to simplify, streamline, and accelerate the overall graphics, print process, and product development for the corrugated industry. Digital print in corrugated has been most successful in areas in need of disruption including samples, mock-ups, displays, and ultra short runs. However, to get at the bulk of the market, digital needs to contend with what analog printing does well day-in and day-out.

Analog has been incrementally fine-tuned to provide the quality, productivity, reliability, equipment life expectancy, and cost structure that the market recognizes today. Digital print must do something better or different to provide more value than analog.

Finally, digital printing must consider the macro trends and needs of tomorrow. These macro trend requirements are fast turnaround, short run lengths, supply chain efficiency, e-commerce, lightweighting, sustainability, and automation.

The predominant issue with digital print is the production costs for a given run length compared to the analog alternative. For digital to win more broadly, it must look beyond just consumables cost and at reducing overall value chain costs including running costs, maintenance, capital, useful life, and any other steps or parts that can be streamlined.

It is encouraging to see there is a next generation of solutions being developed that will hopefully help make some of the necessary improvements to expand the segments of the market where digital can add value.

For those of us who have been championing digital print and what is possible to transform the corrugated industry, the pace of progress is both encouraging and disappointing. There are pockets of great success, but there is also a lot of work to do to get us to the full transformation that all members of the value chain need.

ROBERT SEAY is the vice-president of digital print strategy and growth at Georgia-Pacific. This article was originally published as part of Drupa’s Essential Series of Print.

The ninth Drupa Global Trends Report indicates commercial printers are starting to plan ahead with more confidence.

The print industry is showing increasing confidence despite economic headwinds

By PrintAction Staff

The ninth Drupa Global Trends Report, published in November 2023, is a clear statement of increasing confidence across almost all regions and markets. Printers and suppliers alike forecast 2024 will also be better than 2023.

The report tracks key economic and market developments across the print industry globally, regionally and within markets. The findings come from an in-depth survey, run in spring 2023 by Printfuture (U.K.) and Wissler (Switzerland) with over 600 printers and suppliers from the Drupa expert panel of senior decision

makers. Globally, 32 per cent more printers and suppliers described their company’s economic condition as ‘good’ compared with those that reported it as ‘poor’. Amongst printers, almost all regions and markets were more buoyant than 2019 (i.e. before COVID). It is clear the old saying, “Adapt or die,” applies as printer and suppliers alike seek new ways to grow. It is not all good news, though. Germany was downbeat at +12 per cent, the same as 2022. Yet the Rest of Europe was +34 per cent. North American (N. America) sentiment softened to +50 per cent from the peak in 2022. However, South/Central America (S/C. America) +24 per

cent, Africa +34 per cent, Middle East +52 per cent and Australia/Oceania + 56 per cent, all recovered well from previous lows. Looking ahead, all regions, except Australia/Oceania, expect better performance in 2024, although Germany, at just +4 per cent, is far more cautious than most.

Richard Gray, operations director

at Printfuture, said, “While positive forecasts might be expected from packaging and functional printers, what was pleasing was the increasing confidence amongst commercial and publishing printers.”

It would appear that commercial and publishing printers have weathered the worst of the impact of digit-

ization and are starting to plan ahead with more confidence.

Suppliers were a little more cautious than in 2022 at 32 per cent, down two per cent. N. America, S/C. America and Asia were up, with Europe down five per cent. All markets were fairly flat in 2023, but all showed great confidence for 2024.

The source of such confidence across most markets is clear from the financial performance figures provided. Globally, 50 per cent more printers raised prices in 2023 than lowered them, sustaining the pattern of last year, after the previous seven years of falling prices. Better revenues and margins have followed. The pattern was not universal, with Europe and S/C. America reporting a more mixed situation. Suppliers reported a similar upbeat assessment.

Commercial pricing is strong, net balance average +57 per cent for 2022-23 compared with an average of –21 per cent 2013-2017. Publishing is also an average +57 per cent 2022-23; average –18 per cent 2013-2017.These figures suggest the beginnings of better times for both market sectors.

The resilience of sheetfed offset print volume across all markets is remarkable, matched amongst packaging printers by growth in flexo. Digital toner cutsheet colour print volume tops digital print technologies. Globally, the digital adoption—printers claiming more than 25 per cent of turnover in digital—is growing from 26 per cent in 2014 to 29 per cent in 2023. At first sight this is only a modest growth. However, various industry sources show volumes have grown significantly since 2014 even though the digital adoption rate appears to be slowing down.

Twenty-five per cent of the total printer panel reported having web-toprint installations in 2014. The figure for 2023 is still 25 per cent. Some regions have less e-commerce for cultural, technical and other reasons but the figure is flat almost everywhere. Those operating web-to-print enjoyed a surge in demand from that source over the COVID period, but demand has fallen back this year almost to pre-COVID levels. The exception is packaging where the major growth of

2022 has been largely maintained.

Employment numbers amongst printers are flat in the developed economies but show significant growth elsewhere.

Labour shortages are reported by both printers (47 per cent) and suppliers 39 per cent. Conventional press operators and finishing staff are hardest to recruit for printers and manufacturing and technical support staff amongst suppliers. Supply chain issues have loomed large for both printers (63 per cent) and suppliers (73 per cent), although all expect issues to be less this year.

Capital expenditure tumbled during COVID, recovered a little in 2022 and accelerated in 2023 with 27 per cent more printers investing more in 2023 than those who reduced expenditure; a better global figure than any year since 2017. An even higher investment rate is forecast for 2024, by both printers and suppliers. In general, print technology and finishing remain the most popular targets, with sheetfed offset and digital toner cutsheet colour being the most popular technologies globally, though there are significant variations by market.

Strong industry growth forecasts must, of course, be balanced by recognition of stiff economic headwinds. Socio-economic issues loom as large as ever over all regions. The risk of economic recession is the top concern at 47 per cent, knocking the impact of pandemics into second place (41 per cent). However, beyond the top two issues there were major variations across almost every region. For example, S/C. American printers were concerned about political instability (52 per cent), African printers highlighted currency issues (51 per cent), Australian printers pointed to environmental issues (33 per cent), Asian printers commented on trade wars (23 per cent) and N. American printers worried about standards of living (32 per cent). Opinion is divided between those that think market forces are more important (43 per cent) and those who prioritize socio-economic forces (46 per cent). For commercial markets, the key

Globally, 50 per cent more printers raised prices in 2023, per Drupa’s ninth Global Trends Report. 50%

takeaway is the advantages of diversification in both markets served and services offered. The proportion of publishing printers in the survey sample has halved since 2014 (from 30 per cent of the total 2014 to 15 per cent in 2023). The mix of markets they serve has also changed, with fewer in the newspaper, magazine, and catalogue markets but more offering varying book printing options. Packaging printers report increasing demand for added value packaging (e.g. interactive print. The search for more environmental alternatives to plastic packaging is a major focus for many, particularly for flexible printers of course. While Drupa’s sample of functional printers is small, the survey

clearly shows a shift to inkjet print from screen and toner.

Sabine Geldermann, director Drupa and global head print technologies at Messe Duesseldorf, commented, “Printers and suppliers know they must innovate to succeed in the longer term. I am confident Drupa 2024 will be the ideal opportunity to explore how best to achieve this objective.”

Drupa has been surveying print service providers and suppliers since 2013 to shed light on industry and global megatrends, market potential and innovations in all key areas of the print industry. For more information on the Drupa Global Trends Report, visit www.drupa.com/en/Press/ Global_Trends_Reports.

Print Panther Direct’s president

Christine Yardley discusses the role of embellishments in

By PrintAction Staff

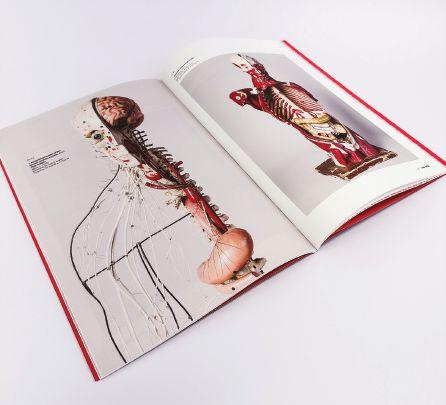

Late last year, Print Panther Direct, a commercial printer in Oakville, Ont., invested in a Konica Minolta Business Solutions Jetvarnish 3D Evolution press. This was five years after it installed a Jetvarnish 3DS embellishment press. The new press has a sheet size of 29 x 47 in.

“The acquisition of our new Konica Minolta MGI Jetvarnish 3D Evolution with its larger sheet size opens up exactly the kinds of opportunities we like to seize, and our clients like to take advantage of. Brands will always be about their emotional pull as well as their physical appeal

and the two should be inexorably linked,” says Christine Yardley, president, Print Panther Direct.

“Just as their emotional appeal must keep abreast of the latest consumer insights so the physical appeal has to communicate its relevance with its contemporary look and tactile feel. We live in an age where people expect change and ‘newness’ to keep them engaged. Packaging designs trigger memories, ideas, or semiotic associations that in turn ignite emotions. The technology we now have with our new Konica Minolta MGI Jetvarnish 3D Evolution press builds on our core mission statement of printing print that

matters, creating more meaningful interactions between consumers and the physical presence of the brands we serve,” she adds.

Eight years ago, Print Panther Direct evolved and decided to focus on embellishments. At that time, “we were not thinking about tactile engagement, emotional connection, perceived value, or packaging psychology. We just knew our clients wanted more. Technology was a great place to start in wanting more for the printed page,” she recalls.

After numerous projects and awards, Print Panther Direct better understands the science behind the power of embellished print.

“We can help shape consumer behaviour, drive brand success, and by using eco-friendly printing practices, appeal to environmentally conscious consumers as well,” Yardley explains.

She talks about the five-second rule, which is widely used in marketing. Conceptualised by author Mel Robbins, the idea is that consumers take only five seconds to choose a product. This decision is “often influenced by various factors, including product familiarity, brand recognition, and prior experiences. While the ‘five-second rule’ may not be an exact measurement of the time consumers spend on product selection, it underscores the importance of capturing attention, communicating value, and instilling trust in our choice. “Embellished print is for me, next generation print,” shares Yardley.

Investing in new technologies like embellishment costs money, so printers must ensure a good return on investment.

Yardley agrees and shares, “Embellishing the printed sheet is not new. What is new is that it can be done digitally. Being able to provide embellished print digitally opens doors to more business. The opportunity to improve profits on a print job exist with digital embellishment. But more importantly to me than per page profit, is the recurring revenue when you supply a product that is unique.”

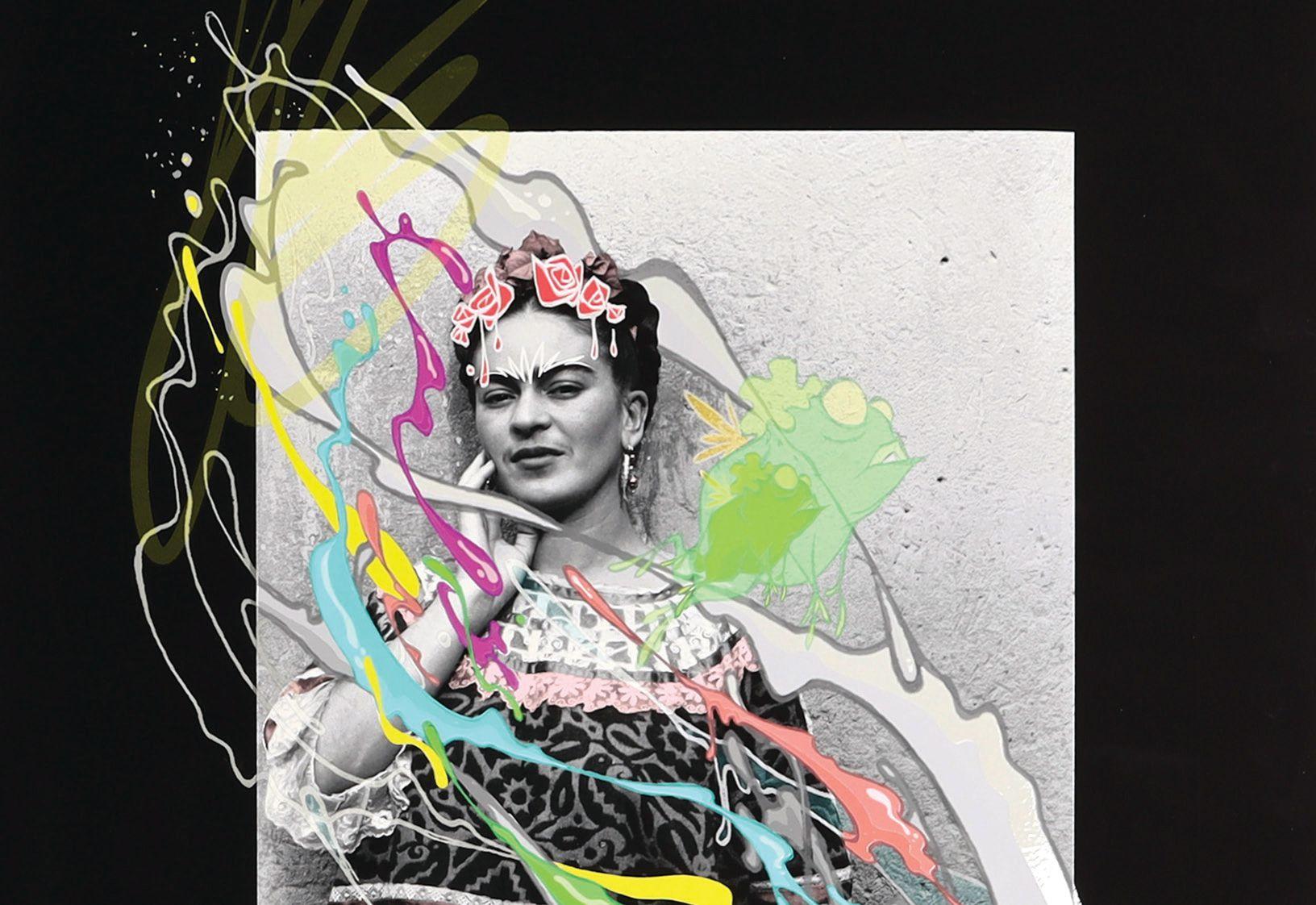

In 2023, Print Panther Direct won a Canadian Printing Award in the Specialty Effects category for “Freida - Giclee and Digital Embellishment on Fine Art Piece,” which was a giclee print of famed artist Freida Kahlo. The project was printed on an acid-free, PH buffered, 100 per cent cotton rag, matte stock.

“Giclee prints are extremely high quality, archival grade, digital prints that use an ultra-fine inkjet printing process to produce images. In giclee printing, no screen or other mechanical devices are used and therefore there is no visible dot screen pattern. The image has all the tonalities and hues of the original painting. The Giclee printing process provides better colour accuracy than other means of reproduction. Archival quality ensures that the prints are light-fast and not water soluble. The spot varnish brings a depth to the intense color of the artwork,” explains Yardley.

Print Panther Direct is one of the few printers marrying giclee print with digital embellishment. Yardley is excited about the opportunities this combination presents.

“The world of art and design often pushes the boundaries of what’s possible with print. We work with artists and designers who continually explore embellishment techniques to create visually stunning, thought-provoking pieces,” she adds.

By Angus Pady

In the world of branding and marketing, colour is a powerful tool that conveys emotions, sets the tone, and creates lasting impressions. Whether you’re designing a business card or billboard, or you are a brand owner, getting your brand colours right is crucial.

When it comes to brand colour matching in print, you’ll come across several options: CMYK, RGB, Hexadecimal, CIE Lab, Pantone and Spectral. There are a few factors to consider when determining the best option for a project.

CMYK is device dependent, meaning every CMYK build is specific for a particular output device. If we print Coca-Cola red on a digital device that has an accurate ICC profile, the RIP will convert CMYK values so that the red visually matches the incoming CMYK values. If we print the same colour on an offset press, the plate curves will dictate the final CMYK values. As we can see, specifying a colour in CMYK is not going to work when you have more than one device as each machine needs a unique CMYK build.

RGB is great for pictures but does not work for brand colours, as the colour consists of additive colours and still needs to be converted to CMYK.

Hexadecimal is fine for specifying web colours. However, it’s a terrible choice for brand colours.

Pantone is a great choice when it comes to spot colours. In our industry, we have adopted this process. It is also well established with ink vendors and brand owners. These standardized ink colours ensure your brand colours remain consistent across various media. If you are working in packaging, check out Pantone Live.

2015

In 2015, ISO adopted X-Rite’s Colour Exchange Format version 3 as a global standard for colour data exchange and verification.

Let’s say you’ve chosen a vibrant shade of orange for your logo. With Pantone, you can specify the exact shade (for instance, Pantone 165 C) to your printer. The press will use a specific ink formulation to match that orange consistently. However, the same Pantone 165 C sent to your digital device with only CMYK inks is going to look dull.

Brand colours, often expressed as Pantone colour names, are generally specified using CIE Lab values. The Lab value describes how the spot colour looks under certain lighting conditions (D50). It does not describe how the mid-tones should behave nor provide any information about what the colour looks like under other lighting conditions. This lack of lighting information may cause metamerism, a phenomenon where colours look different when light source changes.

ly across different printing technologies and substrates. In contrast, CMYK and Lab colour models are dependent on the characteristics of the specific inks, devices used, and substrates, making it harder to achieve consistent colour reproduction. Spectral data can help mitigate metamerism. By specifying colours in spectral terms, you can choose ink formulations that minimize metamerism, ensuring your brand colours remain consistent in various environments.

When you think of the terms, “Lab,” and “Spectral,” remember that Lab is a single measurement on a specific substrate. Spectral covers the full spectrum of colours on any substrate, and that is the key.

The

Colour Exchange Format is defined in a completely open way so that all aspects of a colour can be communicated.

Spectral colour definitions are device independent. This means that they aren’t tied to a specific output such as a press and stock. Spectral colour data provides an extremely precise description of colour properties. This accuracy ensures the desired colour will be reproduced consistent-

Capturing and implementing spectral data is a bit more challenging. Measuring Lab is easy and fast—one can type the Lab values into an email. You can’t do that with a spectral definition. That is where a CxF (Colour Exchange Format) comes in. CxF is defined in a completely open way so that all aspects of a colour can be communicated, even when the application and the colour communication features required are unknown. This means that every software vendor implementing and supporting CxF can easily and accurately extend the information throughout global workflows. This is indeed the future of brand colour communication.

ANGUS PADY is a G7-certified expert that has helped customers resolve colour management challenges for over 30 years. He can be reached at angus.pady@fujifilm.com.

Jennifer McConnell has been in the printing industry for almost 25 years. She spent most of these years at MET Printers. In October 2023, McConnell took up the role of operations director at Royal Printers in New Westminster, B.C. Established in 1932, Royal Printers is a family-owned company. McConnell’s focus at Royal Printers is to maximize overall efficiencies of the plant, foster an empowering staff culture and assist in creative solutions that’ll set up the company for long-term success. McConnell is also passionate about creating meaningful career pathways for students interested in the print industry. Here’s an excerpt from an interview with her.

What is the state of the print industry today, in your opinion?

JC: I think the print industry is being challenged more than ever. Pushes for new technology to produce high quality work in shorter turnarounds keep our equipment vendors on their toes. Supply chain issues are constantly changing accessibility to materials and supplies. Finding individuals interested in learning the machinery is challenging, as most high schools do not actively promote print-related trade work. The sustainability of our industry relies on individuals who favour building long-term careers, but we are seeing more turnover as the newer generations have different priorities. If employees are not being engaged or supported, they move on and not always within the industry; we are losing them altogether. Having said all this, I strongly believe print is not dead. Although digital media and marketing have grown immensely, consumers are getting tired of the countless spam emails, and pop-up ads. Print can be used quite effectively along with digital marketing. I believe our industry has a huge opportunity (and responsibility) to educate our clients and provide meaningful solutions that include print.

What attracted you to the print industry?

JC: My father owned a print shop in White Rock, B.C. When I moved to Vancouver from Toronto, it only made sense that I would work for him and see where things went. I never expected to fall in love with print, but here I am.

This industry has become my life, and the print community has become my second family (possibly even my first!).

How can the industry attract more young people?

2023

In October 2023, Jennifer McConnell joined Royal Printers as its operations director.

JC: There needs to be a collective effort from print and vendor companies to create a plan that includes opportunities for apprenticeship, internships, succession plans and mentorship. We have made headway with the Print Entry Level Training (PELT) program, but we need do more.

In such a competitive landscape, how can printers win more sales?

JC: It doesn’t matter what you’re offering, there is a market for it. Take the time to get to know your clients, fully understand their needs, challenges, and budgets, and then provide them with appropriate solutions. Be knowledgeable, helpful, and cost-effective. Stay in your lane, build up a solid foundation of customers and build off those relationships over time.

What are some of the biggest opportunities in the print industry?

JC: The biggest opportunity I see and the only one I really want to talk about (because I truly believe it is the most

important one) is to create mentorship programs and succession plans to help our industry bridge the gap between the baby boomers who are now retiring and their replacements. Many expert technicians and trades people are planning to retire and have told me they don’t have someone coming in to take their place. I know there are considerations around the equipment aging out, but it’s the commitment and passion for the trade that I’m most afraid of losing. The skill that these folks bring to the table isn’t taught in schools, and we are about to lose a treasure trove of knowledge unless we, as an industry, act.

What do you think is the most exciting thing about print today?

JC: The most exciting thing today is the advancements in technology and the improvements we are making in both quality and efficiency. Some of the newer machines practically run themselves. That being said, it still takes a skilled press operator to create print perfection.

Jennifer McConnell’s response was edited for length. For more Q&A Spotlight interviews, please visit www. printaction.com/profile.