BY LAURA AIKEN

Hello Canadian bakers! I’m back at the editorial helm after a wonderful year at home with my daughter, and looking forward to catching up on what’s new in the baking industry.

At first glance, it seems that much of what was newish at my departure in 2014 has become even more mainstay now. Glutenfree, GMOs (or lack thereof), sugar-free, low sodium, natural, local, organic, clean label, whole grain…these are, in no particular order, the conversation of yester-today.

I suppose what’s changed is they just don’t seem to be specialty anymore. Most bakeries are on board with some facet of these trends. Consumers demand, the industry gives. Such is the nature of the business beast.

Offering a clean label, artisan (in actuality or feel), free-from product won’t give the edge it once gave the grassroots. It has become necessity to innovate in the realm of these trends to stay competitive. There is no “if you build it they will come” – not anymore, and perhaps there never was.

This begs the unabating questions that rob the winks from the night: How am I to keep my customers, get them to spend more, and find new ones? How do I get more word of mouth? The lack of easy answers ought not to stall the search. You’re already in one good place to forage! For 75 years, Bakers Journal has helped the industry grow their businesses, and I am committed to continuing that tradition in my new-old post.

On that note, I offer a few sentiments gathered during many moments of stroller-strolling reflection. Yes, people want healthy, convenient food. They are demanding it. But giving it to them doesn’t make them tell their friends about it. Even if it was deliriously delicious, they may not tell a soul. Their experience, from the first encounter with your brand to the last bite, must evoke enough emotion to compel the telling.

}Offering a clean label, artisan (in actuality or feel), free-from product won’t give the edge it once gave the grassroots. It has become necessity to innovate in the realm of these trends to stay competitive.

Food has a lot of power to stir the heart, but not near the capability of people. It’s your hands, your heart; your passion sifted in flour that brings your customers back. It’s the friendliness and helpfulness of your staff that cements the connection. Writers, of fiction or non-fiction, all know that stories are about people or you haven’t got a story at all no matter how elaborate your plot of details. The story of your bakery is really about people too. Perhaps finding ways for your customers to get to know you and your staff better would foster the kind of connection you want to forge for repeat business. Sharing expertise and knowledge is one way to allow people to get to know you, for you can only deliver it in the unique way that makes you, you. Encourage conversation and time spent with customers who seem eager for it. The more time they spend with you, the more they will spend (not counting the laptop/one coffee/many hours lot).

I have some experience with being a new customer lately. I recently moved to a new neighbourhood, and have the spent the last couple months ferreting out new haunts, which include several bakeries for various items. There are many highly regarded cafes where I am, but I have only tried one and gone back several times since. I was too impressed with the gracious, knowledgeable staff and the excellent coffee to bother with anywhere else. Therein lies a great goal for any bakery: be so good that your customers don’t even care to try your competitors. It is my goal for Bakers Journal to help you reach that potential. It’s good to be back in touch, and if there’s anything you’d like to see in your industry magazine, please reach out to me at 416-522-1595 or laiken@annexweb.com. / BJ

OCTOBER 2015 | VOL. 75, NO. 7 EDITOR | Laura Aiken editor@bakersjournal.com 416-522-1595 1-888-599-2228 ext. 250

ASSISTANT EDITOR | Colleen Cross ccross@annexweb.com 519-428-3471 ext. 261

TECHNICAL EDITOR | John McColl, Puratos Canada jmccoll@puratos.com

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

ACCOUNT COORDINATOR | Shannon Drumm sdrumm@annexweb.com 519-429-5176 1-888-599-2228 ext. 219

MEDIA DESIGNER | Emily Sun GROUP PUBLISHER | Martin McAnulty mmcanulty@annexweb.com

DIRECTOR OF SOUL/COO | Sue Fredericks

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710. RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5 Email: subscribe@bakersjournal.com

ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Publishing & Printing Inc.

Subscription Rates Canada — 1 Year $ 30.00 (with GST $31.50 #867172652RT0001, with HST/ QST $33.90)

USA — 1 Year $ 45.00 USD Best pricing is available online at www.bakersjournal.com

Send your subscription request to: Bakers Journal

P.O. Box 530, Simcoe, ON N3Y 4N5 Tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940 Email: subscribe@bakersjournal.com

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2015 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

briefly | Nisshin expanding Chilliwack flour mill; Quebec baker creates birthday cake for Kylie Jenner; U.S. egg farms recovering after AI | for more news in the baking world, check out our website, www.bakersjournal.com

On Oct. 5, Lallemand increased the price of its fresh and dry bakers’ yeast. Fresh yeast prices went up by five cents per kilogram and dry yeast prices by 11 cents per kilogram.

“The Canadian dollar has fallen substantially against the U.S. currency and economists do not expect it to rise significantly in the near future,” Lallemand

vice-president Michel Dion said.

“Since most of our costs are on a U.S. currency basis,” Dion explained, “we have suffered a significant increase of our costs. Your business is important to us and it is our objective to keep servicing it to the best of our abilities; thus in order to keep doing so, we must remain financially sound.”

Ardent Mills acquired the Mondelez Canada flour mill located in Mississauga, Ont. The mill produces hard and soft wheat flour for its Canadian bakeries and a number of food manufacturing customers.

According to Ardent Mills, the Mississauga mill will add to its capabilities to serve food manufacturers across Canada, and will support the company’s vision of being a trusted partner in nurturing its customers through innovative and nutritious grain-based solutions.

“Acquiring this mill is consistent with

our strategies for growth and our desire to help our customers win,” said Dan Dye, chief executive officer of Ardent Mills, in a news release. “We want to nourish this facility and its people as we serve our Canadian customers, and ultimately consumers, with safe, nutritious, grainbased products.”

Ardent Mills has milling operations in Saskatoon and Montreal, as well as a bakery-mix facility in Burlington, Ont., and an administrative and sales office in Brampton, Ont.

The new sales team at Baker’s & Us. From left to right: Sylvie Laroche, director of sales; Karen Reissmann, account manager; Denise Stemmler, technical support, sales; and Fernando Lopes, sales representative.

Baker’s & Us has added an express truck to its delivery fleet that will handle small- to medium-sized deliveries in the Greater Toronto Area. The goal is to improve manoeuvrability in high-traffic areas as the truck is smaller than the traditional large trucks out on the roads, said Alex Létourneau, who heads up communications and projects at the company.

The truck is capable of delivering controlled temperature products, which is a new service for the company. It will also serve as an emergency delivery vehicle and be used for deadline-driven situations.

Baker’s & Us also announced a new sales team consisting of Sylvie Laroche, director of sales; Karen Reissmann, account manager; Denise Stemmler, technical support, sales; and Fernando Lopes, sales representative. The team is looking forward to meeting all of our friends in business,” Létourneau said.

In our August/September edition, we incorrectly identified the photo on page 9 accompanying the article “Canadian Road Trip”. The image is not staff from The Artisan Bakery, but students in a baking class that The Artisan Bakery was involved in. The story also indicated that The Artisan Bakery sells crab cakes, and they do not. Also, the story incorrectly reported that Theo Korthof was retired when he was in Mississauga.

Why shell out so much for eggs?

Egg prices are high and availability is limited. Corbion Caravan is here to help. Choose from our portfolio of proven solutions, including Cara-Eg, Bro-Eg and Function Plus™ to reduce or eliminate fresh, frozen or powdered eggs. The only difference you’ll notice? A sweeter bottom line.

Together we create enhanced freshness and safety solutions. Reduce, replace or extend the use of fresh, frozen or powdered eggs. Now that’s something to crow about.

INTERESTED IN EGG REPLACERS?

BRANDI COWEN

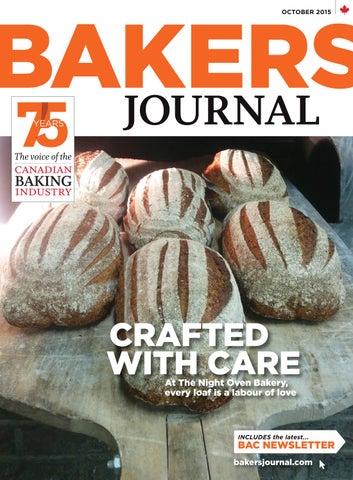

There’s no question Bryn Rawlyk had his hands full when The Night Oven Bakery opened for business.

In addition to managing day-to-day operations at Saskatoon’s newest production bakery, Rawlyk was also faced with the challenge of perfecting processes to keep his operation stocked with wood-fired breads made from flour milled in-house.

The Night Oven, which celebrated its first anniversary earlier this year, is located in Saskatoon’s North Downtown neighbourhood. The bakery draws many regular customers who work in the area; walk-upon customers are rare. At first blush, the location may seem a little unorthodox, but step through the door and one of the reasons behind the choice soon becomes clear: “The building was suitable for the wood oven I wanted to build,” Rawlyk explains.

He’d been drawn to the idea of baking with fire for a while, and had already built four Alan Scott-style ovens for backyard and community projects. When he decided the time was right to open a bakery, Rawlyk knew he wanted to bake his goods in a wood-fired oven. He sought advice from Cliff Leir at Fol Epi in Victoria, who helped troubleshoot design ideas and offered practical insights based on his experiences baking with a wood-fired oven.

}“One of my not-so-subtle goals is to really let people know where their food is coming from, both ingredients-wise and in terms of the labour that goes into making it.” – Bryn Rawlyk

Today, Rawlyk’s oven, with its ninefoot dome and two-foot arch in the middle, is a showpiece in the bakery. The oven can be fired from an external firebox, or from a fire inside the oven itself. It holds approximately 42 loaves of bread at a time.

On Friday nights, that oven also churns out delicious wood-fired pizzas. The weekly “Night Pizza” event was inspired by customer requests for pies to enjoy on their lunch breaks. Rawlyk explains that, from a heat management standpoint, making pizza right after baking the day’s breads wouldn’t work

well; cooking up pies just before beginning the Saturday bake is a much better fit. The pizza nights have been a hit, giving existing customers another reason to stop by the bakery and introducing The Night Oven to a new clientele.

“It’s definitely a different crowd on Friday nights, but that’s great because they want to know what the bakery is all about,” Rawlyk says. “They turn into customers who then stop in during the week.”

The Night Oven’s open concept design allows customers to watch as staff prep and bake every morsel. They can also see The Night Oven’s mill in action, as grain grown by local farmers is transformed

into the flour that is key to the bakery’s mouth-watering goodies.

A few years ago, during a trip to the Salone del Gusto and Terra Madre slow food expo in Italy, Rawlyk and his wife met food producers from around the world. Bakers from places such as California and Australia bemoaned their ongoing struggles in sourcing quality, locally produced grain. These conversations opened Rawlyk’s eyes to the possibilities offered by a place like Saskatoon, with its proximity to countless sprawling grain farms.

“I realized that we have such an amazing resource; these farmer are growing all of this grain that usually gets shipped off. Why not showcase that and use that product right here?” Rawlyk says. “I’ve developed connections with those farmers and have great sources for a variety of different grains.”

The Night Oven typically mills a couple bags of wheat every few days. Although he tries to stay ahead, milling a day or two before the flour is needed, Rawlyk admits there have been times when a staff member is measuring out freshly milled flour for a recipe as the mill is working the grain.

“It’s a dynamic product and consistency isn’t 100 per cent sometimes, but it’s a variable I’m willing to put up with because of those relationships,” he adds.

Both the mill and the wood-fired oven have sparked a lot of curiosity in customers. They’ve proven to be good jumping off points for conversations about the product the bakery puts out, and how that product gets made. Pulling back the curtain on production processes dovetails nicely with one of Rawlyk’s aims in establishing The Night Oven.

“One of my not-so-subtle goals is to really let people know where their food is coming from, both ingredients-wise and in terms of the labour that goes into making it,” he says.

“That’s one of the challenges that we have with our customer education. We do everything by hand, we use fire to heat our oven and we use freshly milled flour, so there are times when those variables don’t necessarily line up as nicely as we may want. Bread may be late or we may not have some pastry because the oven was too hot or too cold. I see that as an opportunity to share with

people: ‘I hear you, and this is why. I want the bread to be out on time too, but the oven was too hot.’ It’s a good conversation starter with those customers.”

Rawlyk’s dedication to unique production processes and specific ingredients (he prioritizes organic options) isn’t just attracting curious customers – it’s also attracting great staff. In fact two staff members, both interested in working at a bakery where they could do innovative things, packed their bags and moved to Saskatoon to join The Night Oven team. And so, at a time when other businesses are struggling to find staff, eager and engaged prospective team members are reaching out to Rawlyk about employment opportunities.

“I’ve been really privileged that way – that people have come to me expressing an interest in wanting to work here rather than having to search people out,” he says. “We have a really great team right now.”

Establishing connections and building relationships is an important cornerstone of The Night Oven’s philosophy, and, perhaps more importantly, of Rawlyk’s approach to business. He’s a big believer in the value of sharing information within the industry, and isn’t shy about striking up a conversation to pick another baker’s brain about the systems and processes in place in their businesses.

And, as word spreads about what Rawlyk and The Night Oven staff are doing in the heart of the country’s breadbasket, he’s paying that willingness to share forward.

“A lot of people are curious about milling their own flour and there isn’t a whole lot of information out there about what the options are and what works. Having done all that research myself, I love sharing with folks,” Rawlyk says.

Interest has far surpassed what he anticipated back when The Night Oven Bakery was still just an idea. Balancing the hands-on demands of the baking with the day-to-day managing of the business has been challenging at times; bringing great staff on board has helped with that. Still, if Rawlyk could go back and give himself one piece of advice prior to opening the doors, it would be to plan better.

“I talked with lots of bakers before I opened and they said to plan for getting busy and plan for having staff. I thought, ‘Sure, I have a plan,’ and I did have a business plan that I had written out. But in that business plan, I had ‘think about hiring a staff member at six months’ and two months in I was sleeping at the bakery and working all the time. I needed to hire people,” he explains. “I would say to plan for even moderate growth better than I did.” / BJ

For more profiles, visit www.bakersjournal.com

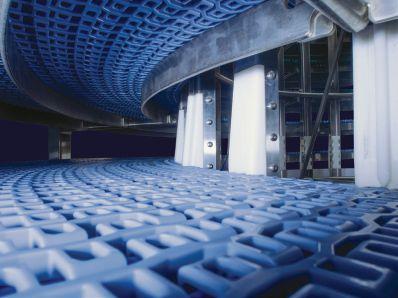

Increase profitability. Minimize product orientation issues. Enhance production capacity.

Discover how Intralox’s DirectDrive™ System eliminates overdrive and operates with zero slip, transforming our customers’ spiral systems.

Visit us at go.intralox.com/DirectDrive

YVONNE DICK

Bakers in the near future may have another resource at hand to help them in the kitchen.

Imagine having ingredients pre-measured and being able to toss them into a recipe, package and all. Or working with smaller amounts of fresh products like balls of cheese or dollops of yogurt, package and all. This is one vision of how things may be if big companies get on board with the idea of edible and dissolving packaging for food products. Monosol is one of several companies entering the dissolvable/edible package market. Other names include Dr. Oetker and popular yet lesser-known retail brand

WikiCells. These manufacturers and retailers have sensed an opportunity to reduce packaging and target a market that is for the most part forgotten: baking ingredients in custom sizes for industrial and commercial kitchen use.

A quick primer: think about the individual laundry and dish detergents that come in small squares and dissolve as they clean. Now imagine them with food or ingredients inside, and you can eat the bag they are contained in as well.

A division of Monosol known as Vivos is working on food-grade packaging. Not packaging that is safe to use for food, but packaging that could be used as food. Due to various confidentiality agreements, Sumeet Kumar,

senior manager of strategic marketing for MonoSol, is unable to say which companies may be working with Vivos to produce food items in packaging that disappears into the food. He does confirm that several large brands have shown interest, and offered a few examples of how the Vivos edible packaging works.

“It could be used for baking where there are a number of ingredients, and they must be measured out in precise amounts,” Kumar says, “This would achieve a batch-tobatch consistency with the finished product.”

The edible film is designed so that it does not change the viscosity, odour or taste of the food that has been packaged. Ingredients that must be kept

away from light can be tinted; however, Kumar says that often customers like the idea of seeing exactly what is in the package. He notes that it is practically tamper-proof because it isn’t meant to be opened and removed before using the contents. The film does not reseal; once open it is obvious that the ingredients are compromised.

Wondering what this may be made of? Don’t worry, it’s not science – exactly.

“This is not a new molecule or something like that. It is existing ingredients used in new ways. We can customize the packaging for kosherfriendly, gluten-free, nonGMO with a certificate, et cetera. It can be used on a small scale or a very large

Single-serve packets of oatmeal, hot chocolate or soup, and industrial-sized batches of pre-mixed ingredients are among examples of products that make natural edible packaging contents.

These packages are not meant to be resealed, which means they are virtually tamper-proof.

one,” Kumar says.

Another benefit Kumar sees to digestible packaging is the reduced amount of food waste and spilling – single-serve items could be encased in the film and then put into one box rather than packaged separately with layers of plastic and foil, as is done now.

Examples of products that make natural edible packaging contents are food colourings, enzymes, spices, flavours, sweeteners, singleserve packets (oatmeal, hot chocolate, soup), industrial sized batches of pre-mixed ingredients, and some condiments.

}A Harvard professor has also taken up the challenge of reducing waste and encouraging simplicity in food preparation and consumption. Professor David Edwards and designer François Azambourg created a product known as WikiCells. Likened to a grape’s skin keeping the grape encased, WikiCells offers a variety of cooking and baking options including a wine “skin” with edible packaging. Other examples include ice cream and dairy products. Whatever is in the secret recipe for WikiCells, it is food-grade quality and palatable too. The outer packaging is set to enhance whatever is inside using complementary flavours. Edwards went a step further, conceiving the idea

of making the outer packaging dissolving or edible as well.

Edwards’s initial outer shells included ingredients like caramel, bagasse (the fibre left behind after sugar is extracted from sugar cane), tapioca or rock candy. This would make the external shells edible, but there would still need to be a further package of some sort. Imagine a bag of chocolate chips that was in an edible outer box, sitting in a grocery store aisle. Edwards correctly ascertained that people were

combination by a baker in the early-morning hours each day without the need for measuring, sifting and pouring and the cleanup of multiple kitchen implements.

One of the company’s newer products, WikiPearl, packages two-bite concoctions, including cheese, chocolate mousse, ice cream, and specially prepared fruits and vegetables as snacks, inside the edible outer skin.

The most immediate impact that edible packaging may have on a bakery near

Some critics of edible packaging focus on the packaging aspect, claiming that in order to have digestible packaging a whole new layer of packaging is being created.

not interested in eating the external box. On the other hand, a compostable and natural outer box could be made of non-food grade tapioca or bagasse. Food trays are now being made by a number of companies using these (non-edible) ingredients.

According to Harvard University, WikiCell packaging can be made by anyone who owns a WikiCell machine. Bakeries that want consistent cakes might package large batches of a mix into smaller ones for storage and near-future baking. These packages could contain dry or wet ingredients. For instance, in a cake recipe one bag could hold the moist and another the dry for

you comes from German baking company Dr. Oetker. Like a thin wafer, the cupcake cases come in pink or blue, and can be baked on a flat tray. After they are cooked, the cupcake and its outer case can be eaten. Currently available in the U.K., each package contains three blue and three pink cupcake cases.

Some critics of edible packaging focus on the packaging aspect, claiming that in order to have digestible packaging a whole new layer of packaging is being created. For instance, with edible package films, an outer container must be used to keep the items dry and clean – hot chocolate powder in an edible package could not sit

on the shelf and then be used in a mug of cocoa due to food-safety concerns.

On the positive side of non-toxic dissolvable packaging is the science: some types of edible packaging actually assist in keeping food items fresh longer than the usual plastic and preservative methods.

But is there a demand? Vivos film is still in development. Though WikiCells have been around for approximately three years, thus far a limited number of Whole Foods stores located in Massachusetts are the only places WikiCell packaging can be found. WikiPearls are much more of a speciality item, available at Whole Foods but also a single Cambridge, Mass., cafe called the WikiBar. The Dr. Oeteker line is exclusive to the U.K. and consists of one item.

The questions remains: will the food industry come to embrace the new, more environmentally friendly packaging solutions that are available?

While edible packaging is now available for retail purchase in select areas, only a future expansion will tell this community whether or not the edible packaging market is here to stay or a gone-in-twobites novelty of the week. / BJ

For more on ingredients, visit

BY DR. JOHN MICHAELIDES

Staling as about more than bad taste. Ensure food safety and quality by using the correct additives.

Baked goods, like all other foods, must be safe when consumed. At the same time, they need to deliver excellent taste and texture. Over the many years of producing such foods, the baking industry has relied on a multitude of ingredients to ensure safety and good quality.

My last column discussed the safety of baked goods, including microbiological contamination as well as the danger of chemical contamination with natural toxins, such as mycotoxins. Preservatives do not necessarily mean that they function as antimicrobials alone. They can usually be grouped into: antimicrobials (which are described above and act against bacteria), moulds or yeasts; and antioxidants, which slow the oxidation of fats and lipids (a process that, in turn, leads to rancidity. Natural and synthetic antioxidants can be used to prevent rancidity of processed grains as well. Grain products such as oat flakes, oat flour and bran as well as wheat germ contain high amount of lipids which oxidize quickly due to inherent enzymes or exposure to oxygen. Application of heat can stabilize (deactivate the oxidizing enzymes) but added antioxidants will further extend their shelf life by preventing spoilage due to exposure to atmospheric oxygen.

harder, tougher and crumblier appearance and feel.

These processes are accelerated when the bread is stored at refrigeration temperatures and quite reversible when it is exposed to heat. We may want to store bread at low temperatures to slow microbial growth but this practice will result in accelerated staling.

More and more large manufacturers are moving towards centralizing their production of bread and other baked goods. As a result their distribution expands to greater geographical areas and the products taking longer to reach the consumer. For this reason the longer shelf life is paramount otherwise the economic impact will be quite substantial. Shelf life extension of baked goods by prevention of staling can be achieved by the inclusion of various ingredients, improving production processes and packaging.

}The use of lecithin may be revisited as the demand for natural ingredients is increasing and consumers are looking for food products that are more natural and organic.

Mono and diglycerides may also be classified as natural since they are found naturally in fats and oils. However, modified ones such as ethoxylated mono and diglycerides, will not be considered natural.

Lecithin, a naturally occurring compound, was one of the first emulsifiers to be used extensively in the baking industry. The use of lecithin may be revisited as the demand for natural ingredients is increasing and consumers are looking for food products that are more natural and organic. Additional anti-staling ingredients such as enzymes are very effective in preventing staling and extending the shelf life of many baked goods. A number of anti-staling enzymes are available in the market and approaching the suppliers of such ingredients will help you. These enzymes act by breaking down the gelatinizing starch during the baking process and therefore need to be active at the baking temperatures

This column will discuss staling of baked goods. Bakers also must contend with staling of baked goods, particularly bread products. Staling of bread is a complex issue and has been extensively investigated. Crust staling results in a soft and leathery appearance and loss of aroma as well as the development of bitter taste. Crumb staling, on the other hand, is more concerning and results in

Ingredients used in the normal formulation of these products can be optimized and thus reduce the staling effect. Optimizing the use of common ingredients such as water, fat, oxidizing agents, gluten and others will result in softer crumb, which in turn will delay the staling process. In addition anti-staling agents are readily available for this purpose. Several ingredients are available that can be added to formulations in order to prevent staling and extend the shelf life of baked goods. For example, emulsifiers and surfactants result in crumb softening by forming complexes with the gelatinizing starch and thus prolong the shelf life of baked goods by retarding the staling process. Mono and diglycerides and sodium stearoyl – 2 – lactylate (SSL) are effective crumb softeners. Many emulsifiers are available to be used for different functional effects in the production of baked goods. Most of these emulsifiers are synthetic chemicals.

In attempting to use these ingredients, either to preserve quality or ensure safety of food products, we need to make sure they are permitted for use in foods in Canada and any other country to which we are planning to export the finished products.

Processing parameters and conditions such as mixing and fermentation will influence the structure of the crumb and if optimized will result in the delay of the onset of stailing.

A factor of the onset of staling is also the migration of water from the crumb to the crust. The use of packaging material that will reduce the moisture loss of the bread will result in less staling and a longer shelf life. / BJ

For more information, or fee-for-service help with food technical and processing issues and needs, contact Dr. John Michaelides at John Michaelides Consulting at 519-743-8956 or j.jmichaelides@gmail.com, or at Bioenterprise by calling 519-821-2960. Bioenterprise is a company made up of experienced professionals who coach and mentor emerging agri-technology companies from planning to start-up to profitability and beyond.

BY DIANE CHIASSON

In tough times, the last thing you want to do is cut your marketing budget. Here are easy-to-do ideas to help your bakery.

During difficult times, businesses should not be decreasing their marketing budgets, but increasing it! Take this opportunity to get ahead of your competitors with simple, inexpensive ideas that are easy to implement.

1.

Send information like an e-newsletter or a printed newsletter with photos of yourself and your staff. You can also send a thank-you card; a personalized, hand-signed customer appreciation letter to your best customers; or a postcard at least every 21 days to contacts in your database.

}If you haven’t collected any names, start today. Leave a guest book or a fish bowl for dropping business cards next to your cash register, and encourage customers to leave their information. You can also collect email addresses via your own website. Make sure you ask permission to add them to your mailing list.

expenses. They could provide you with co-op dollars to help defray the cost of mailings, food samples and giveaways.

4.

Have your bakery name and logo professionally painted on the side of your car, so that when you drive around town, you are acting as a moving billboard to advertise your establishment.

5. CALL EVERYONE YOU KNOW

Make a personal phone call to invite your friends, family, regular customers, and/or old business acquaintances to see how they are doing and remind them of upcoming specials and promotions. Telephone calls are a great way to let your customers know they are valued and also a great reminder of your establishment.

6. SHOW YOUR FACE IN TOWN

Build your business by networking and

Invite a local radio or TV host in for a complimentary “dessert extravaganza” and have them talk about your bakery on their show.

attending your local Chamber of Commerce, Rotary Club or local associations’ meetings to meet potential customers. Check online to see what conventions are coming to your area.

7. BARTER WITH YOUR SUPPLIERS

Use sampling events to highlight new bakery menu items and create excitement.

greater exposure. Invite a local radio or TV host in for a complimentary “dessert extravaganza” and have them talk about your bakery on their show.

10. MOTIVATE YOUR STAFF

2. BE TRUE TO YOUR PLAN

Create a marketing plan and include a monthly calendar of activities with upcoming events such as Oktoberfest, Halloween and Christmas. Include your monthly budget and deadline for these promotions as well as who is responsible. Remember that having an ultimate plan is the key to any successful campaign.

3. INVITE CUSTOMERS TO COME IN

Send a postcard or an invitation to announce special events and promotions such as an appreciation night, baker’s demo or cooking classes. Create a buzz and excitement in your community, and give customers something to look forward to. Involve your vendors in sharing your advertising and promotional

Exchange services with your suppliers. For example, you can barter some of your printing costs in exchange for a few free cakes and pies.

8. GET OTHER BUSINESSES INVOLVED

Do cross-promotions and co-op advertising with non-competitive businesses. For example, work with your local movie theatre for a “Divine Desserts and a Movie” promotion. You could also sponsor a sports team from the local high school or an adult league. Print your name and logo on their team shirts.

9. FREE PRESS

Take advantage of your local paper by sending the editor press releases and brochures, or write an article to gain

Train your staff on suggestive selling and upselling – from dessert for one to dessert for two. Always reward your staff members by organizing special celebrations for them and inviting your local community and regular customers as well. You should always recognize a job well done.

11. GIVE OUT FREE SAMPLES

Use sampling events to highlight new bakery menu items and create excitement. / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping foodservice, hospitality and retail operators increase sales for over 25 years. She is recognized as an industry leader in providing innovative and revenue-increasing foodservice and retail merchandising programs, interior design, branding, menu engineering, marketing and promotional campaigns, and much more. Contact her at 416-926-1338, toll-free at 1-888926-6655 or chiasson@chiassonconsultants. com, or visit www.chiassonconsultants.com.

In its submission to Health Canada’s Nutrition Labelling in Gazette 1, BAC has offered its support for many of the Department’s evidence based proposals but also taken it to task in other areas where the proposed regulations were not supported by science, but motivated apparently by public opinion.

Scientific evidence and consistent approach.

BAC applauded Health Canada’s withdrawal of its original proposal for the declaration of added sugar in the Nutrition Fact Table (NFt). In BAC’s original comments, the association stated that “there is little evidence to suggest that added sugars have health effects independent of the effect of total sugars.”

BAC is also pleased to see a five year transition period for compliance as it will allow members to better manage conforming to the new regulatory requirements. Other changes proposed by Health Canada and supported by BAC include:

• The updated Table of Reference Amounts for Food that replace Schedule M.

• The serving size for bread that reflect that most people eat 2 slices of bread at one time.

• The use of population coverage approach in the proposed Daily Value for vitamin D.

• The listing of all components of carbohydrates together so that consumers understand that total sugar and fibre are both components of carbohydrates.

• The status quo on saturated and trans fat declaration in the NFt, which is a testament to the success of the voluntary approach to remove trans fat in the marketplace.

Benchmark and rule of thumb replacing scientific evidences.

BAC has again criticised Health Canada’s proposed daily value (DV) for sugar for its lack of scientific evidences. Health Canada suggested that excess sugar intake may lead to overconsumption of calories and thus to obesity and chronic diseases. BAC pointed out, the current DVs in Canada are based on two sets of accepted values, including the Recommended Daily Intake for vitamins and minerals and Reference Standards. The proposed DV for sugar is not based on any of these sets of values but

rather it is a consumption benchmark.

BAC also took issue with Health Canada’s proposal to remove the DV for dietary fibre. Dietary fibre has been shown to provide a multitude of health benefits, such as reducing the risk of heart disease, diabetes and cancer. Furthermore, diets high in fibre have been linked to reduced weight gain overtime, which is why Canada’s Food Guide (CFG) recommends to choose food that are high in fibre, because “fibre rich food can help people feel full and satisfied”. But apparently these evidences are insufficient for Health Canada.

BAC opposed Health Canada’s proposed mandatory footnote explaining %DV benchmark levels. BAC made the point that there is no scientific evidence to support the statement “5% DV is a little and 15% DV is a lot“ as proposed by Health Canada.

BAC also demonstrated that Health Canada has moved away from an evidence-based approach with their proposal to:

• Use of bullets to separate ingredients in the ingredient lists.

• Use a thick black line to separate sodium and potassium declaration in the NFt.

• Group various source of sugars in the ingredient list and not sources of other nutrients such as fat and sodium or grain/fibre component where Canada Food Guide encourages people to choose foods lower in fat, sugar and salt and to make half of their grain choices whole grains.

Inconsistencies in Health Canada approach.

In its submission, BAC found Health Canada’s approach not only lacking scientific rigour but also inconsistent and conflicting. One of the many examples BAC used was the removal of the DV for fibre and when considered against the proposed DV for sugar. Health Canada’s stated goal in enhancing sugar labelling was to decrease Canadians’ consumption of sugar. BAC was confused as to why then Health Canada did not apply the same logic they used for sugar to increasing Canadians’ fibre intake.

Members wishing more information regarding BAC’s submission should contact Johanne Trudeau at the BAC office 905-405-0288, ext. 26 or jtrudeau@baking.ca.

may 1-3

THE INTERNATIONAL CENTRE TORONTO (MISSISSAUGA) ONTARIO, CANADA

Trade Shows Hours: 12:00 noon - 5:00 pm daily Conference/Seminars will be prior to 12 noon

Join almost 5,000 baking & food industry professionals from retail, wholesale, commercial bakeries, grocery stores & foodservice outlets.

Bakery Showcase 2016 trade show and conference May 1- 3 is the three day Canadian national baking industry event in Toronto (Mississauga), Ontario Canada.

The event will be held at The International Centre, Hall-5 and will comprise almost 400 booths in 100,000 sq. ft. of trade show floor.

Companies that manufacture, market, distribute, & broker, baking ingredients, baked products (fresh, proof & bake, par-baked, freezer-to-oven, thaw & serve), baking equipment, supplies, packaging, technology and services.

As an exhibitor you can:

• Meet baking and food industry buyers & professionals from across North America.

• Conduct business ... place orders, make new deals, develop new markets and meet qualified buyers in the baking & food industry.

• Provide samples of your products & services, demonstrate your equipment or services.

• Launch new products, new merchandising programs and new promotions.

• Attract new customers, cater to existing customers and win back former customers.

• Raise your corporate profile, size up the competition, and take a measure of new trends.

• Hold your annual sales meeting during Bakery Showcase 2016 and your whole staff benefits from Canada’s most important baking industry event.

Bakery Showcase is the Canadian baking industry marketplace where bakeries (commercial, wholesale, retail & in-store) and food service industry professionals meet to see, feel, touch & taste the newest products and services for their businesses.

Market Overview: Canadian baking industry is currently over 8 billion dollars

Wholesale & commercial bakeries (intermediate and large volume), retail bakeries (independent & franchise), patisseries, grocery chains / mass market / supermarket in-store bakery, c-stores, foodservice establishments (restaurants, cafes, hotels, caterers), specialty & artisanal bakers, brokers, baking profession schools, consultants, government buyers, local and international trade missions.

Event promotional coverage will be achieved through:

• Direct mail promotions, e-mail broadcasts and telemarketing campaigns to key industry segments.

• Media and trade journals will receive timely press releases and a targeted advertisement campaign will be implemented.

• Networking through BAC Chapter meetings.

• Communication through allied event partners.

ask yourself these questions:

• Do you want to meet retail bakers, commercial bakers, in-store bakers, foodservice bakers ?

• Does your company do business or are you considering doing business with the baking industry?

• Does your ingredient, product, service or equipment provide bakers with the tools to compete efficiently and effectively?

• Is your company concerned about the rising costs of maintaining a sales force or are you finding it increasingly challenging to speak with bakers on a regular basis?

• If your answer is YES to any of these questions, commercial and retail bakeries and food service establishments will want to meet with you at Bakery Showcase 2016 trade show.

6900 Airport Road

Mississauga, ON Canada www.internationalcentre.com

The International Centre is located minutes from Canada’s busiest airport, Toronto Pearson International (YYZ). A network of freeways and public transit all provide fast access to downtown Toronto. The airport area is home to over 40 different international hotels with over 10,000 available bedrooms; plenty of choices to make your stay more comfortable. The venue has free parking for over 5,000 vehicles.

Exhibit space rates: (prices are excluding 13% HST)

• Single In-Line Booth (10’ x 10’ unit – 100 sq. ft.) CAD $2,175 – BAC members pay only CAD $1,875.

• CAD $200 discount per 100 sq. ft. for bulk space available for 400 sq. ft. or more size booths.

• Corner premium (exposure on 2 sides) additional CAD $250.

Minimum exhibit size is 10’ x 10’ = 100 sq. ft. Various sizes and configurations can be accommodated.

Baking Association of Canada members will receive the following benefits:

• CAD $300 discount on every 100 sq. ft. of space.

• CAD $50 Discount on hot link to company web-site.

• Additional 10 complimentary attendee registration discount codes per 100 sq. ft.

• Up to 30 cu.ft. of complimentary refrigerated or freezer storage space (a $200 value) if ordered in advance.

Exhibit space cost includes the following:

• Draped booth – 8’ high x 10’ wide backwall, 3’ high railing drape to aisle (only for in-line booths).

• Company listing in Official Show Guide published by Bakers Journal Magazine (if contracted and paid by printing deadline) or in On-Site Addendum (if contracted after Official Show Guide printing deadline).

• Materials handling from loading docks to booth*, (uncrating, assembly & spotting available at additional charge).

• 24 hour perimeter security coverage.

• 5 exhibitor badges per 100 sq.ft. (up to a maximum of 25 badges).

• 10 complimentary attendee registration discount codes per 100 sq. ft. exhibit space (up to a maximum of 100 discount codes).

*Includes: dollies, pump trucks and forklift with maximum capacity of 5000 lbs per unit/item. Exhibitors requiring special handling/equipment beyond that provided by Show Management will be responsible for all fees incurred.

Bakery Showcase 2016 trade show & conference is produced by the Baking Association of Canada (BAC), the industry association representing Canada’s over $8 billion baking industry. BAC’s mandate is to further the interests of Canadian commercial, retail, in-store and wholesale bakers through advocacy and effective programs at the regional and national level.

To reserve your exhibit space please contact:

of Canada 7895 Tranmere Dr, Ste 202, Mississauga, ON L5S 1V9 Tel: 905-405-0288, 888-674-2253 Fax: 905-405-0993 E-Mail: info@baking.ca • www.baking.ca

Holiday Social

Friday, November 27th, 2015

Old Mill Toronto 21 Old Mill Road

Toronto, ON

www.oldmilltoronto.com

Cocktails: 6:00 pm Dinner: 7:00 pm

Entertainment & Prizes: 8:30 pm

CASH BAR

REGISTRATION FEES:

$109 per member

$129 per non-member

Pre-register by November 13th 2015

Reservations for tables of 8 accepted

Event is limited to 130 Guests! Book Early to Avoid Disappointment!

Friday, November 27th, 2015

Friday November 28th 2014

Please note all registrations received after Nov. 13th will require a credit card payment. No refunds will be given.

Please list names of all attendees: (attach separate sheet if necessary)

Event is limited to 130 Guests! Reserved Table of 8 for Company Sign Main Contact Information:

A fun-filled evening & Christmas celebration with friends from the Baking Industry

FRIDAY, DECEMBER 4TH, 2015 at FRASER DOWNS

Fraser Downs Clubhouse Restaurant

17755 60th Ave, Cloverdale BC

Tickets $45.00 (includes GST)

Fantastic Door Prizes

✻ 6:00 pm Cocktails

✻ 6:30 pm Buffet Dinner

✻ 7:00 pm 1 st Race

All guests must be 19 yrs of age

Event Information Contact Nicole Higgins – 604-838-0727

Reserve your Tickets ASAP!

Mail cheque and registration form to:

BAC (Attn: Gillian Blakey)

Suite 202 - 7895 Tranmere Dr. Mississauga, ON L5S 1V9

Cheque Payable to BAC

Send this form with credit card information to:

Fax: (905) 405-0993

Email: gblakey@baking.ca

Phone: 1 (888) 674-2253 ext. 21

Tickets to be picked up at the door

Contact: Company: Phone#

Email: # Of Guests x $45.00 = $

Includes GST, Tax #887064798

Cheque Please charge my: Visa MasterCard Amex

Card Number:

Cardholder:

Expiry Date:

Signature:

7895 Tranmere Drive, Suite 202, Mississauga, Ontario L5S 1V9

Tel: (905) 405-0288, 888-674-2253

Fax: (905) 405-0993

Email: info@baking.ca Website: www.baking.ca

BRANDI COWEN

Customers are curious about what you do, how you do it, and how they can execute some of your tricks of the trade at home. Just look at the programming line up on Food Network Canada, the abundance of food and drink magazines lining the checkouts at your local grocery store, and the buffet of websites, blogs and social media accounts catering to self-proclaimed “foodies.” This curiosity presents a powerful opportunity to build stronger relationships with your existing customers and catch the eye of people who might otherwise pass your bakery by. The secret? Offering workshops to share some of your expert knowledge and start building relationships with these inquisitive consumers.

Gerda Korthof and her husband, Theo, have been offering workshops from their London, Ont., bakery for just over a year now.

“From day one, The Artisan Bakery had it in mind to offer workshops for the community, to educate the public about the bread baking process and to make the scope of our services complete,” Korthof says.

}Teaching classes to children can be a profitable new avenue for your bakery.

Korthof recommends asking staff about their hobbies and hidden talents, and then matching them with workshops best suited to their interests and skills.

“When the customers asked many questions about the process and ingredients, the time seemed ripe. Why not offer it to the public and get paid for it?”

The Artisan Bakery has hosted workshops on everything from sourdough bread baking and canning to themed classes such as “An Evening in Indonesia” and “An Evening in Paris.” Free kids workshops have also been popular, not to mention an effective way of encouraging parents to visit the bakery.

So far Korthof says that the introduction to bread baking class has been their most popular offering. Each student pays $85 for a five-hour class that includes instruction, materials and a luncheon.

Classes are taught by staff. Korthof recommends asking staff about their hobbies and hidden talents, and then matching them with workshops best suited to their interests and skills. At The Artisan Bakery, Theo teaches the themed cooking classes, while another staff member who loves children leads the

kids’ cooking classes, and an avid canner on staff shares her knowledge with curious customers. Instructors are paid $25/hour for teaching time, as well as for the time it takes to set up ahead of class and clean up afterwards. So, for example, an instructor teaching the introduction to bread baking class will be paid for seven to eight hours of work.

To make the math work, Korthof says The Artisan Bakery aims for a class size of between eight and 10 students.

That’s a considerably larger group than you’ll find taking a class at Halifax’s Le French Fix Patisserie. Geoffroy Chevallier says workshops at his bakery are usually capped at four students. The bakery has been offering classes for about two years now and, after experimenting

with different days and times throughout the week, Chevallier set Wednesday afternoons from 1 p.m. to 3:30 p.m. as the regular workshop date.

“We did some on the weekends and found it doesn’t really work, and after hours makes for a long, long night,” Chevallier explains. “When we do them on Wednesday afternoons, sometimes we get a full class and sometimes we don’t.”

Workshops are promoted on the bakery’s website, and on its social media channels. Students also help spread the word about Le French Fix’s workshops, posting about their experiences and sharing photos of their creations on social media.

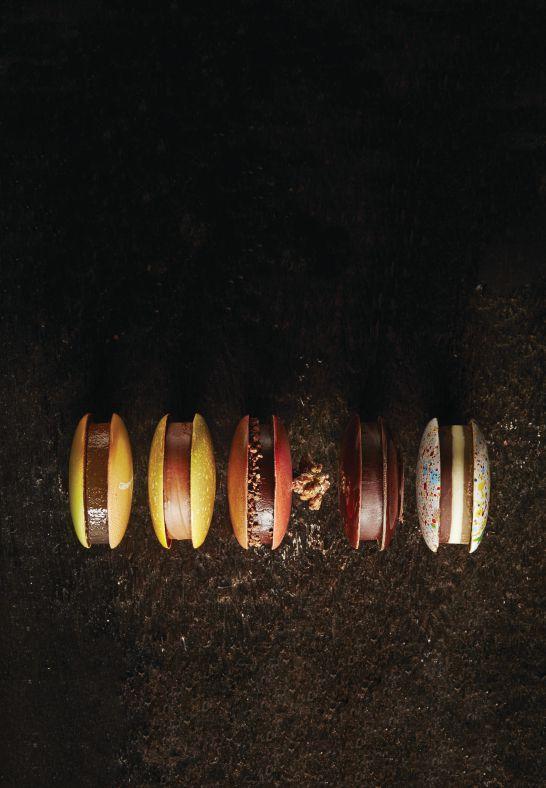

During the course of a class, students learn the techniques they need to execute the recipe. They leave with the finished product and a copy of the recipe they can prepare at home. Given the tight time frame, its important to pick a recipe that even a beginner can complete and then scale that recipe properly. That’s a lesson Chevallier learned during the bakery’s first class, teaching the art of making a perfect macaron.

“Based on the recipe, in the first class we maybe did too much,” he admits. “Those people did get to bring a lot of stuff home, but we should have managed it a bit better to get the right amount for the recipe.”

To set prices for the workshops, Chevallier scouts online to determine what others are charging for their classes, both in Halifax and outside the province. He currently charges $65 per person.

Neither Le French Fix nor The Artisan Bakery offer the tools

or equipment used during workshops for sale to customers, although Korthof says she would “highly recommend” this to other bakeries.

At SweetSalt bakery in Vancouver, owner Emma Tolliday is encouraging kids to stretch their culinary muscles. Tolliday took over SweetSalt from the previous owner earlier this year, and has spent many Sunday afternoons since hosting birthday party cooking classes.

During a two-hour party, children make pizza dough, sweet dough animals, and a small three-layer cake measuring three-inches in diameter. That may sound like a lot to pack into one afternoon, but there’s a good reason for the full agenda –especially when working with very young children.

“They don’t have the patience to sit there and entertain themselves while their pizza dough is baking, so as soon as something goes in the oven, the table has to be cleared and another activity has to go on the table,” Tolliday says. “Keep it moving: that’s my advice.”

1. Pick a date, time and topic for your workshop – Consider who your customers are, what your goals are in offering the workshop and how the rest of your business will be affected. Will you need to close your bakery early or schedule extra staff to work during the class? Use this information to help calculate an appropriate rate to charge.

2. Make a plan – What materials will students need to participate in the class? Will you need to invest in extras so each student has their own toolkit? If a lot of specialty tools are required, it may be a good idea to include the cost of the toolkit in your price calculations. If students get to take their projects home at the end of the class, will you have to provide packaging to transport their work? Factor this into your pricing calculations too. Developing a clear plan will ensure your workshop runs smoothly and prevent last minute surprises from taking a bite out of your bottom line.

3. Promote your workshop – Spread the word through in-store flyers, promos on your website, and on your e-newsletters and social media channels. Don’t forget about other businesses in the neighbourhood that can help cross-promote your class. The yoga studio down the street may be a good place to post a flyer about your upcoming healthy baking workshop.

4. Prepare for the big day – Make sure all staff understand what needs to be done (both in the class and in the rest of the bakery) and assign clear roles for everyone. If you’re teaching the workshop yourself, assign a number two who has the authority to handle any situations that may arise during the class. Remember: your students are customers too. They deserve their instructor’s full attention for the duration of the workshop.

5. Collect feedback about the workshop – What did students most enjoy about the class? What could use some improvement? Are there other topics they’d like to explore in future workshops? And don’t forget to ask staff for feedback too. They may have some ideas to make a great workshop even better!

How smoothly the class runs can depend not just on the children, but on their parents. Tolliday hosted a party for a group of children whose parents were very keen to be involved and get creative. That class was a breeze, with plenty of adults to lend the kids a hand with their creations. The next party, she says, was attended by 13 children whose parents preferred to sit off to the side and chat over coffee. Tolliday says keeping activities age appropriate is key to successfully leading both types of classes. Having an assistant on hand to pitch in doesn’t hurt either.

Another key to keeping things running smoothly is to be prepared. Tolliday learned this lesson during her first class, when it came time for the children to assemble their dough animals. “I had four pairs of scissors and I should have had 10 pairs,” she says. “For a class like that, expecting the kids to share is a nice idea but it’s not my lesson to teach.”

How smoothly the class runs can depend not just on the children, but on their parents.

Under Tolliday’s ownership, the price tag on a birthday party at SweetSalt has increased from approximately $200 to $300. The higher cost is, in part, to compensate for the bakery’s earlier closing time on party days. Instead of the usual 4 p.m. close, the bakery closes at 2 p.m.; parties run from 2 p.m. to 4 p.m. “This is something we started because we decided to give the whole café over to the class. I find it’s a much better experience for everyone,” she says.

The going rate for similar services was also a consideration in setting the price. Birthday parties have been generating a lot of repeat customers for SweetSalt. Tolliday says many families with children who have attended parties at the bakery are now familiar faces in the shop, stopping in for special treats on the weekends. One family even goes out of its way to swing by for some banana bread on the way to weekly swim lessons. So far each party has also generated at least one new booking. One child has already attended three baking parties since May.

“The kids know me,” Tolliday says. “There’s definitely a community connection that’s been built.”

In the coming months some moms

and dads may find themselves stopping by SweetSalt without the kids. After a number of requests from parents, Tolliday is looking into adding some baking classes for adults into the mix. She’s already in the process of applying for a liquor license so the bakery can offer a baking with bourbon class. Tolliday hopes the adult classes will deepen relationships with existing customers while forging ties with new ones.

She believes these customer relationships reflect the evolving role businesses play in their communities. “It’s the new model: when you go someplace, it offers more than one service. I think that’s what you have to do to be competitive now. It’s very hard to build connections with people otherwise.” / BJ

ACADÉMIE CULINAIRE

Montreal, QC

Evening and weekend continuing education classes in desserts, pastries, decorating and more www.academieculinaire.com

ASSINIBOINE COMMUNITY COLLEGE

Brandon, MB

Evening and weekend continuing education classes in types of cuisine and hands-on courses www.assiniboine.net

BAKING ASSOCIATION OF CANADA

Mississauga, ON

Certified Bakery Specialist designation, plus correspondence courses www.baking.ca

BARRY CALLEBAUT CHOCOLATE ACADEMY

Montreal, QC

We are proud to present the 2015-16 course program at the Chocolate Academy™ Montreal, located in one of the most dynamic neighbourhoods in this gourmet city: the Technôpole Angus. This Chocolate Acadamy™ centre in Montreal offers classic, specialized and innovative classes in both French and English for artisans, culinary professionals and those passionate about international gastronomy. 4820 Molson St. H1Y 3J8 1-855-519-8676 www.chocolate-academy.ca

BONNIE GORDON COLLEGE OF CONFECTIONARY ARTS

Toronto, ON

Certificate & Diploma programmes in Artisanal Baking & Pastry Arts, Cake Decorating and Design

Full & part-time programmes. Continuing Education 416-440-0333 www.bonniegordoncollege.com

CAMOSUN COLLEGE

Victoria, BC

FOODSAFE Level 1 offered (oneday, weekend class) www.camosun.ca

CANADORE COLLEGE, SCHOOL OF CULINARY ARTS

North Bay, ON Correspondence and online courses offered, including nutrition, sanitation and safety, food preparation and communication and customer service www.canadorec.on.ca

CENTENNIAL COLLEGE

Toronto, ON

Correspondence and online courses offered, including nutrition and health, sanitation and safety, kitchen equipment and food preparation, and workplace communication www.centennialcollege.ca

COLLEGE OF THE NORTH ATLANTIC

Newfoundland and Labrador

9-month Baker program (fulltime) offered at Bay St. George campus

9-month cook program (full-time) offered at several campus locations Marine Cook program also available www.cna.nl.ca

CONESTOGA COLLEGE

Waterloo, ON

Continuing education courses in food processing supervisor and advanced sanitation practices Distance learning courses in creative cooking and food service worker

www.conestogac.on.ca

CONFEDERATION COLLEGE

Thunder Bay, ON Evening, on-campus classes in cake design www.confederationc.on.ca

CREATING OCCASIONS

Victoria, BC

Continuing education classes: chocolate/classic baking, cake decorating, specialty, savoury, sandies www.creatingoccasions.com

DURHAM COLLEGE

Whitby, ON

• Advanced Baking & Pastry Arts

• Culinary Management

• Hospitality ManagementHotel, Restaurant and Tourism

• Special Events Planning

905.721.3000 www.durhamcollege.ca/cff

FANSHAWE COLLEGE

London, ON

Full time Baking and Pastry Arts Management Program and part time Advance Bake Patissier Program.

For a full list of our culinary, tourism and hospitality programs fanshawec.ca/tourism.

FLEMING COLLEGE

Peterborough, ON

Online and on-campus continuing education courses in advanced food safety training, quality food preparation, communication and the food service worker and cake decorating www.flemingcollege.ca

GEORGE BROWN COLLEGE CHEF SCHOOL

Toronto, ON

Continuing education programs and courses in baking arts, baking and pastry management, culinary management and culinary arts. www.georgebrown.ca/chefschool

GEORGIAN COLLEGE

Barrie, ON

Continuing education programs and courses in bake theory, patisserie, techniques and baking. www.georgianc.on.ca

INSTITUT DE TOURISME ET D’HOTELLERIE DU QUEBEC (ITHQ)

Montreal, QC

Part-time, on-campus classes in restaurant management and hygiene and food safety www.ithq.qc.ca

KLARA’S SCHOOL OF CONFECTIONARY AND PASTRY ART

Cambridge, ON

Continuing education: Cake decorating/baking/sugar art/ chocolate classes www.klarajohnsons.com/index.html

LAMBTON COLLEGE

Sarnia, ON

Part-time food service worker program, offered online www.lambton.on.ca

LE CORDON BLEU

Ottawa, ON and international (France, U.K., Spain, Australia, Japan, Korea, Mexico, Peru)

Short-term (one-day) courses at Ottawa and international campuses on varying subjects

Continuing education classes at Paris campus, including master of food and food cultures and Hautes Etudes du Goût www.cordonbleu.edu

LETHBRIDGE COLLEGE

Lethbridge, AB

Continuing education classes in food safe sanitation www.lethbridgecollege.ca

NEW BRUNSWICK COMMUNITY COLLEGE

Moncton, NB

One-evening on-campus classes available in cooking and candy making www.nbcc.ca

NORTHERN ALBERTA INSTITUTE OF TECHNOLOGY (NAIT)

Edmonton, AB

NAIT is a leader in culinary education, with full-time, part-time and apprenticeship options:

• Culinary Arts diploma

• Hospitality Management diploma

• Baking certificate

• Retail Meatcutting certificate

• Baker and Cook apprenticeship training

• Numerous evening/weekend courses

1.877.333.6248 | www.nait.ca

NOVA SCOTIA COMMUNITY COLLEGE

Dartmouth, NS

Short-term, on-campus continuing education classes in pies and tarts, croissants and danishes, fondant and cake decorating for beginners and restaurant desserts www.nscc.ca

PACIFIC INSTITUTE OF CULINARY ARTS

Vancouver, BC

Short-course cake decorating and specialty cuisine classes www.picachef.com

PASTRY SCHOOL VANCOUVER

Vancouver, BC

Continuing education classes in artisan bread baking, pastry training, chocolate training, cake decoration www.pastrytraining.com www.vancouverpastryschool.com

PREGEL CANADA

Toronto, ON and Vancouver, BC

International Training Centres Fundamentals and advanced classes in gelato, soft serve and frozen novelties www.pregelcanada.com/en/training/

RAW FOUNDATION CULINARY ARTS INSTITUTE

Vancouver, BC

Continuing education classes in desserts and chocolate www.rawfoodfoundation.org

RED RIVER COLLEGE

Winnipeg, MB

Food services management continuing education program (some courses available by distance delivery) www.rrc.mb.ca

SAIT POLYTECHNIC

Calgary, AB

Join us for evening and weekend continuing education culinary courses, including Introduction to Baking, Cake Decorating, Fondant, Butter Cream Basics, Chocolate, Viennoiserie, Artisan Bread, Assorted Buns and more. 403.284.SAIT culinary.campus@sait.ca culinarycampus.ca | sait.ca

SASKATCHEWAN INSTITUTE OF APPLIED SCIENCE AND TECHNOLOGY (SIAST)

Saskatoon, SK

Distance education options for food service worker and food nutrition management

Evening and weekend on-campus cooking and baking classes, including European pastry and torte preperation www.siast.sk.ca

ST. CLAIR COLLEGE

Windsor, ON

Part-time classes in kitchen management and culinary skills and techniques www.stclaircollege.ca

ST. PIUS X CULINARY INSTITUTE

Montreal, QC Day and evening classes in professional cooking www.emsb.qc.ca

VANCOUVER COMMUNITY COLLEGE

Vancouver, BC

Continuing education/part-time programs and courses in baking and pastry arts www.vcc.ca

VANCOUVER ISLAND UNIVERSITY

Nanaimo, BC Professional Baking and Pastry Dept.

Foundation, Apprentice and Leisure Courses in Artisan Baking, Viennoiserie, Decorating and Wood Fired Baking. https://www2.viu.ca/baking/

Do you want to learn French patisserie?

Join this specialized French food and culture postgraduate program. Learn from the experts here in Canada and then live, learn and get work experience in France! Find out more: georgebrown.ca/patisserie

The federal government will provide up to $10.1 million in funding to strengthen the food and beverage sectors in southern Ontario.

George Brown College’s Office of Research and Innovation will receive funding of up to $7 million to expand its Food Innovation and Research Studio (FIRSt) and establish new labs for research and development to support product and process improvement for the food and beverage industry.

Federal Economic Development Agency for Southern Ontario’s (FedDev Ontario) contribution of $7 million will leverage additional funding of $4.7 million from George Brown College, $2 million from industry partners and $500,000 from the Natural Sciences and Engineering Research Council of Canada.

Furlani’s Food Corporation, a privately owned manufacturer of specialty garlic bread products, was allocated $3.1 million

From left to right: Deep Virk, controller, Furlani’s Food Corporation; Jonathan Kawaja, chief operating officer, Furlani’s Food Corporation; Wladyslaw Lizon, MP for Mississauga East−Cooksville; and Anne Sado, president of George Brown College, after the funding announcement for Furlani’s Food Corporation and George Brown College.

in federal funding to improve its efficiency and productivity and boost its production capacity of specialty food products.

The company will be investing in

advanced production equipment and a building expansion to add 21,900 square feet of freezer space. In addition to increasing production capacity, the adoption of new technologies will allow the company to develop a new line of breadstick products and expand its existing line of products. This is expected to enhance the company’s competitiveness in global markets.

The project is expected to create up to 74 full-time equivalent jobs by 2017 and an additional 34 full-time equivalent jobs in the two years after project completion. It will also leverage close to $8.8 million through private sector investments.

The funding is a repayable contribution made through FedDev Ontario’s Investing in Business Growth and Productivity initiative.

Ontario has the largest food and beverage processing industry in Canada. The sector accounted for 14.7 per cent of manufacturing jobs in 2013.

Using hashtags to help grow your brand can be an easy and effective way to make the most of your social media messages.

Not so many years ago, people paid little attention to that pound sign on the computer keyboard. You know, the one that looks like this: #.

Then along came Twitter, and what we have come to call the “hashtag”, and social media marketing was changed forever.

Yet not everyone takes advantage of hashtags the way they should, and that’s unfortunate. If you are not using hashtags, you are missing out on exposure for you and your brand.

}When you are on social media sites such as Twitter or Instagram, your goal should be to become part of the conversation. The hashtag allows more people to find your contributions to that conversation. Without them, you miss out on lots of eyes that could be viewing your content.

happened a few years ago when McDonald’s, apparently hoping for a flattering conversation about the restaurant chain, introduced #McDStories on Twitter. #McDStories went viral, but not in a good way, as the Twitter world had a field day tweeting unflattering tales of their alleged bad experiences with the restaurant.

Don’t let such cautionary tales deter you, though. March boldly into hashtagging, but as you do keep in mind these suggestions for getting the most out of your efforts.

Use proprietary hashtags: One of the advantages to a proprietary hashtag, such as the “Orange is the New Black” hashtag, #OITNB, is that it is linked directly to your brand. These hashtags typically are not used as widely as a more generic hashtag, but the goal is to brand yourself through the hashtag with the hope it could go viral.

If you are a local company that depends mainly on local clientele, a hashtag that links to your location works well.

For example, let’s say 1,000 people follow you on Twitter. Not counting retweets, only 1,000 people will see your posts if you don’t use a hashtag.

Add the hashtag, though, and you start picking up momentum because the post has the potential of being seen – and retweeted – by any number of people. A common hashtag, such as #love, can position your post to be seen by potentially millions of people.

But be warned. While there are great benefits to hashtags, there also are pitfalls. Hashtags don’t come with exclusivity. Anyone can use them, so a hashtag can become a weapon that works both for you and against you. Critics of your brand, or just the usual assortment of Internet trolls, may attempt to hijack your hashtag, putting you or your business in a bad light.

A prime example of a hijacked hashtag

Don’t overdo it: A post littered with too many hashtags can be difficult to read, so your message might become obscured as your followers see what appears to be gibberish. Perhaps you saw the skit Justin Timberlake and Jimmy Fallon once performed in which they spoofed the device’s overuse by lacing their spoken conversation with seemingly endless hashtags. It was hilarious and annoying all at the same time.

Twitter itself suggests using no more than two hashtags per tweet: Certainly, three should be the very maximum on Twitter.

A different etiquette exists on Instagram, though, and most Instagram followers will tolerate excess hashtags.

Meanwhile, although hashtags can be used on Facebook, there’s little reason to include even one. That’s not the way people use that social media site. Think geographically: If you are a local company that depends mainly on local

Add a hashtag and you start picking up momentum because the post has the potential of being seen – and retweeted – by any number of people.

clientele, a hashtag that links to your location works well. Hashtags such as #Seattle or #Bangor drop you into numerous conversations about your hometown.

Since social media has become such a vital element of any comprehensive marketing strategy, understanding all of the nuances is critical.

A hashtag may not look like much, but it’s really a powerful tool that is a double-edged sword. If used correctly it can greatly bolster your marketing reach. Used incorrectly, it can have adverse effects or unintended consequences. With social media, your hashtag is your brand, so use it wisely. / BJ

Jay York, senior digital marketing strategist for EMSI Public Relations (www.emsincorporated.com), is an Internet marketing expert with extensive experience in social media marketing dating back to the early days of MySpace and LiveJournal. Since graduating from the University of South Florida Business School, Jay has worked as marketing coordinator for an international IT training company; business development and branding manager for a startup restaurant management group; and CEO of his own social media management firm.

From sourdough starters to digestive enzymes to egg white replacers, Bakers

Ingredient manufacturer Beneo launched its next-generation sugar, Palatinose, at the recent IFT Food Expo in Chicago. Derived from beet sugar, Palatinose was formulated to deliver energy in a balanced and sustained way naturally.

Beneo commissioned research indicated that consumers are looking to gain energy in a natural way, without the boost and crash delivered by commonly known sugars such as sucrose, high-fructose corn syrup or maltodextrin. Palatinose is a low glycemic sugar that assists with better fat oxidation during physical activity. www.beneo.com

Cambridge Engineered Solutions’ proprietary measuring system, Tug Tester, is designed to help customers obtain tension readings on turn and spiral cage conveyor belts commonly used during the cooling and freezing stages of bakery and food processing. The system uploads data and tracks changes on a PC and provides daily plant monitoring. Tug Tester measures tangential tension by tier as belts cycle through systems. www.cambridge-es.co

FlatTech manufactures a range of table base systems designed to avoid that irritating wobble. The feet remain locked until the table is moved or the surface changes when it instantly adjusts the feet.

Styles with varying shapes, finishes, sizes, colours and materials are available.

The PAD and table base are purchased together; the connections located underneath the table base are required to attach the PAD and to ensure functionality.

The PAD systems are available through Canadian sales director Peter Tichband, based in St. Catharines, Ont., and foodservice and hospitality distributors across Canada. www. FlatTech.com

The Function Plus 150W egg white replacer from Corbion Caravan is being touted as a cost-effective solution for replacing egg whites in sweet baked goods as egg costs continue to rise.

Function Plus 150W is capable of replacing 50 to 100 per cent of egg whites.

The company’s first egg white replacement, Function Plus 150W is an addition to its existing egg replacement portfolio, including whole egg replacers and egg extenders.

The product is not designed to be a high-whip solution for angel food cakes. In testing, the solution’s formulation of specialized whey proteins, gums, enzymes and emulsifiers proved successful in a variety of sweet baked goods, including cakes and chemically leavened batters. www.corbion.com

BackNatur Lepold introduced a new dry, direct sourdough starter that may be stored at length without refrigeration and allows bakers to produce several kinds of sourdough without changing the starter.

BackNatur Trockenferment aktiv, which comes in powder form, lets bakers start aromatic and mild-sour sourdough in a singlestep process over 12 to 15 hours. It may be stored for up to six months without refrigeration.

The starter, which works on rye, spelt or wheat flours, is designed for companies that would like to produce several kinds of sourdough without changing the starter, the company said in a press release.

Because its natural ingredients are harvested organically, the starter can be used in organic bread and rolls as well. www. backntur.de

Searc h i n gfora

Getting into gluten-free has never been easier than with the versatile Vemag.

A single Vemag will prove to be the most flexible machine in your plant The Vemag incorporates a variety of innovative attachments that allow it to produce all types of gluten-free products It can easily handle the stickiest and most fluid gluten-free doughs and batters. The Vemag’s modular design allows it to be used as a dough divider, cookie dough depositor, brownie sheeter, bar extruder, batter depositor and more As your product mix changes, the Vemag can adapt with you

The Vemag’s double-screw pumping technology sets the standard for portioning accuracy, speed and product quality while never overworking the product. And its stainless steel construction and an easy-to-clean design with total access to the product path allows complete sanitation of the Vemag, while eliminating any cross-contamination risks. Test the Vemag for yourself –schedule a demonstration at the Reiser Customer Center today

(DIVISION OF A & L FOOD DISTRIBUTORS INC.)

SUPPLIER OF FROZEN AND

Tel: (416) 252-4660 Fax: (416) 252-9993 25 - 8 Connell Ct., Toronto, ON M8Z 1E8

4-in-1 machine capa bilit y, 3 6, 18, 9 & 6-pa rt h ea ds

Heads can be removed or interch anged without tools in seconds

NSF & UL cert if ied, Ma de in America

2-Year parts & la bor warranty

Heads can be washed in a s ink or d ish washer

High production rate - low maintenence

Eas y t o t ra in a nd operate

Model BMIH-36/18/9 Dough Divider

3-in-1 ma chine capa bilit y - 36 ,18 & 9-parts

1oz up to 16oz each piece scaling range

Mounts to a Porta ble Stand for mobilit y (Optional)

Divide many types of dough including s tick y pie and cook ie dough in a ddit ion to bread a nd bun d oughs

Conta ct our Canadia n R epresentat ive @ eric@b loemhof com www dutchessbakers com - sales@dutchessbakers com

bakery for sale: Long established, successful Bakery for sale in the Tri-city area of Ontario. Revenues $250K+, Profits $80K+ Owner must sell due to out of country relocate. Price $160K Contact: dwayne.mitchell@sunbeltnetwork.com