THE PERFECT BAGUETTE

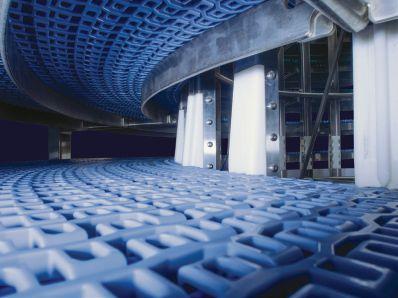

DIRECTDRIVE™ SYSTEM

Increase profitability. Minimize product orientation issues. Enhance production capacity.

Discover how Intralox’s DirectDrive™ System eliminates overdrive and operates with zero slip, transforming our customers’ spiral systems.

Visit us at go.intralox.com/DirectDrive

Dealing

Do

Despite

BY JANINE DRUERY

MY DAILY BREAD

Irecently stumbled across a pile of photographs taken during a European backpacking adventure some 20 years ago. The snapshots were slightly grainy and faded (it was long before a 64GB mobile phone could do the job), but they were, for me, rife with nostalgia and rich with remembrance.

While there were many exquisite shots of European countries in the pile, I lingered over the shots of Paris – one of my very favourite places. For many people, Paris is the “City of Light” or the “City of Love.” But judging from the number of photos in which I am “avec baguette,” Paris was, for me, the “City of Bread.” Sure, places like the Musee d’Orsay or the Arc de Triomphe feature in my photos, but the mighty baguette definitely got its fair share of camera time.

I think that is because, while in Paris, I would head out each morning to a boulangerie with my friends and pick up a warm baguette or two. We would then make them part of our Parisian breakfast, with a bit of butter, jam and either some pain au chocolate or some strong coffee.

Sometimes we’d save them for later in the day when we’d make sandwiches and enjoy them with a glass of vino. And, let’s face it… sometimes we’d eat them straight out of the bag (as we know, a great baguette tastes wonderful au naturel).

Rumour has it that during the 1900s, the French ate almost three baguettes a day per person. While my friends and I never reached that kind of consumption, the baguette was our daily bread – and the ultimate symbol of French culture.

}We would make the baguettes part of our Parisian breakfast, with butter, jam and either some pain au chocolate or an enormous coffee.

It seems fitting, then, that the main topic of this issue of Bakers Journal – my first as editor as I cover for Laura Aiken while she is on maternity leave – is about the beautiful baguette.

In our cover story, called “The Perfect Baguette,” writer Julie Fitz-Gerald delves into what makes the ideal French baguette – from shaping to scoring to baking. The baguette may only include four simple ingredients, but making a great one is a challenge that can try the patience of the most skilled baker. But when it’s done properly, the baguette is beyond delicious. (Speaking of delicious, be sure to also check this issue’s profiles on the sweet successes of Chocklat and Bobbette & Belle).

Of course, I am no longer a young traveller with the ability to linger for hours in European cafés. I am back in the Great White North, I have a family, and life has ramped up to warp speed. But that hasn’t dampened my love of visiting the wonderful bakeries and patisseries in my city. I love stepping into the warm shops, breathing in the delicious aromas and choosing which treats I will buy to share with my family or friends.

Of course, with my new role at this publication, I have firmly decided to make those kinds of outings a lot more frequent – and more far-reaching. It’s all in the name of research, of course!

Do you make the perfect baguette? For that matter, do you make a delicious cupcake, divine croissant or wonderful macaron? I’d love to hear from you and find out about your business, find out what you’d like to read about in the magazine, and discuss “all things baking” as I immerse myself in this exciting industry. Feel free to get in touch with me at jdruery@annexweb.com./ BJ

OCTOBER | VOL. 74, NO. 8

EDITOR | Janine Druery editor@bakersjournal.com 416-522-1595

ASSISTANT EDITOR | Colleen Cross ccross@annexweb.com 519-428-3471 ext. 261

TECHNICAL EDITOR | John McColl, Puratos Canada jmccoll@puratos.com

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

ACCOUNT COORDINATOR | Shannon Drumm sdrumm@annexweb.com 519-429-5176 1-888-599-2228 ext. 219

MEDIA DESIGNER | Brooke Shaw GROUP PUBLISHER | Martin McAnulty mmcanulty@annexweb.com

PRESIDENT | Mike Fredericks mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710. RETURN UNDELIVERABLE CANADIAN ADDRESSESTO:CIRCULATIONDEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5 Email: subscribe@bakersjournal.com

ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Publishing & Printing Inc.

Subscription Rates Canada — 1 Year $ 30.00 (with GST $31.50 #867172652RT0001, with HST/ QST $33.90)

USA — 1 Year $ 45.00 USD Best pricing is available online at www.bakersjournal.com

Send your subscription request to: Bakers Journal P.O. Box 530, Simcoe, ON N3Y 4N5 Tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940 Email: subscribe@bakersjournal.com

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2014 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

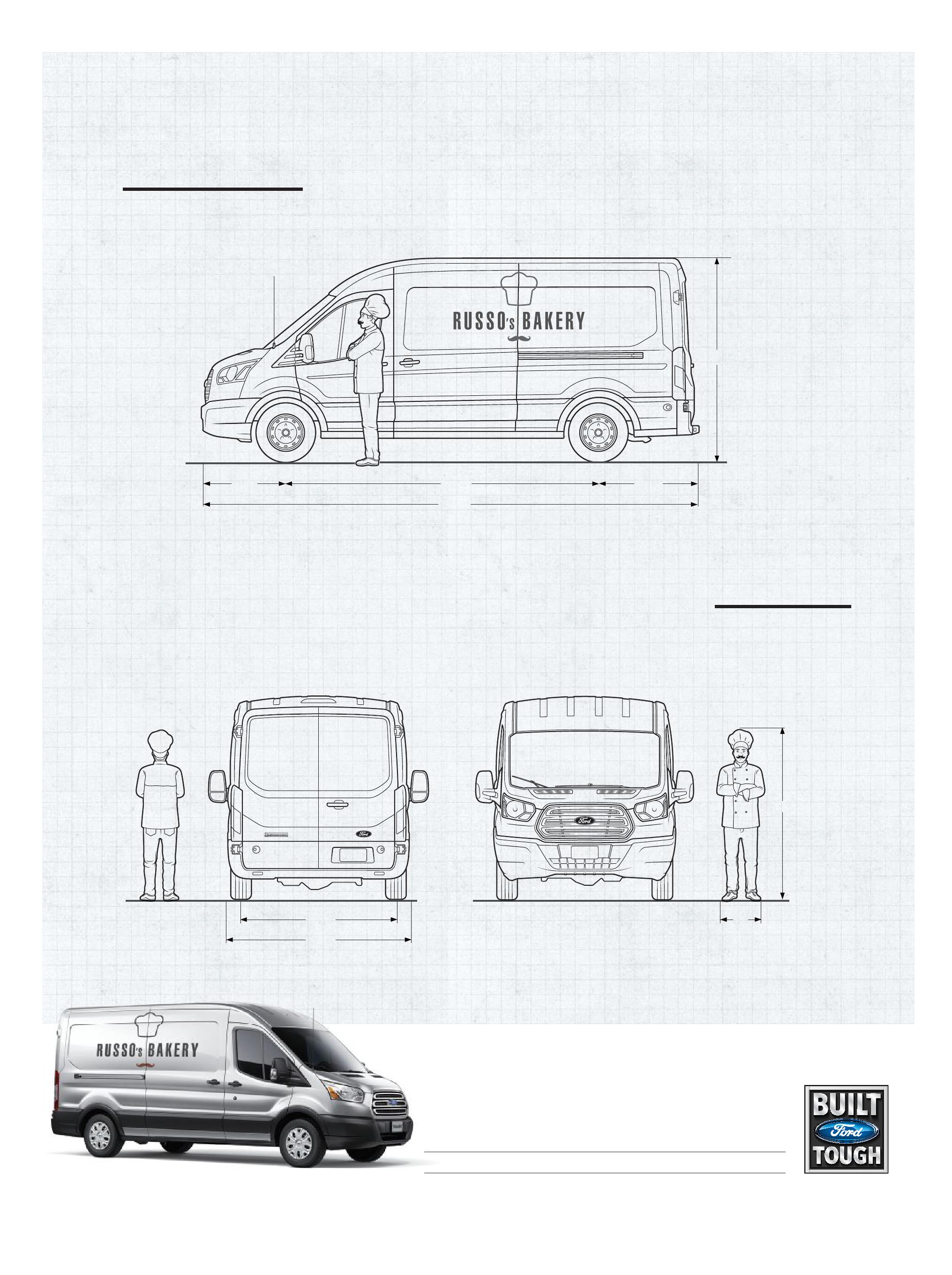

Russo's 2015 Transit

THE 2015 TRANSIT WORKS AS HARD AS YOU DO

briefly | New factory produces whey and lactose; Lesaffre adds culinary centre; Multivac Canada appoints product specialist / FOR MORE baking news, check out our website, www.bakersjournal.com

New factory producing whey and lactose

Production is underway at a new whey and lactose facility – a joint venture between Denmark’s Arla Foods Ingredients and German dairy co-operative Deutsches Milchkontor.

The factory cost upwards of $725 million to build and is operated by ArNoCo, an organization the two companies created to produce high-quality ingredients for the food and beverage industry. Located in Nordhackstedt, Germany, 22 km. south of the Danish border, the new facility is adjacent to an existing factory owned by Deutsches Milchkontor (DMK), which produces 60,000-tonnes/year of mozzarella and semi-hard cheeses such as Gouda.

ArNoCo will use the whey by-product from DMK’s cheese-making operations to produce whey protein concentrate that is ready to be converted into ingredients for the bakery, dairy and nutrition sectors. The new site will also produce 25,000 tonnes of lactose annually, which will be processed and sold as Arla Foods Ingredients’ Dry Blend lactose for infant formula.

“The market for these products is growing faster than the ingredients industry can supply them, so the establishment of ArNoCo in co-operation with DMK is a significant development,” said Hans Jørgen Lauridsen, ArNoCo’s project director, in a news release.

“The construction of the new ArNoCo

Reb M patent application published

Evolva Holdings, in collaboration with Cargill, announced mid-August that a patent application regarding a process to efficiently and sustainably produce sweeteners through fermentation was published.

The patent application, originally filed on Feb. 6, 2013, includes Rebaudioside M (“Reb M”). The ability to produce a Reb M sweetener through fermentation widens the potential to improve the flavour profile of these zero-calorie sweeteners, especially at higher usage levels.

The best-tasting and sweetest parts of the stevia leaf, such as Reb M, make up only a tiny portion of the leaf (less than one per cent), said a media statement from Cargill of Minneapolis and Evolva of Reinach, Switzerland, the two companies collaborating on the product. By producing Reb M using fermentation, the companies can produce the desired sweetness at a scale and cost that is not feasible

through extraction of Reb M from the stevia leaf.

Reb M may enable food and beverage producers to formulate better-tasting products with less sugar, aid them in reaching their product cost targets, and allow for scalability.

“This breakthrough will allow consumers all over the world to enjoy products using Reb M at a commercially viable price,” said Neil Goldsmith, CEO of Evolva, in a news release.

“We are pleased about the prospects of being able to deliver zero-calorie, great-tasting sweeteners,” added David Henstrom, VP for Health Ingredients at Cargill. “At a time when obesity rates continue to rise globally, we are working with food and beverage manufacturers to allow them to formulate a vast array of reduced sugar products with Reb M, which is one of the best tasting steviol glycoside sweeteners.”

factory in Nordhackstedt is part of our quest to fulfil the pledges we make under our ‘Quality starts here’ brand platform, which promises to offer our customers security of supply backed by adequate capacity, logistics and documentation, along with uniform high product quality, supported by strong traceability,” he noted.

Ontario woman wins donut contest

After 76,500 doughnut creations, an eight-finalist showdown in front of a celebrity panel, and a public vote, the ‘Love Reese's to Pieces’ doughnut won the Tim Hortons Duelling Donuts contest.

Created by Jennifer Brown of Glencoe, Ont., the winning doughnut is filled with crème brûlée, covered in chocolate fondant and white dots, and topped with peanuts and peanut butter cup candy.

"I saw firsthand Jennifer's passion for her doughnut, and with that irresistible combination of Reese's Peanut Butter Cups and crème brûlée, I know Canadians made the right decision," said Jason Priestley, one of the celebrity judges.

The inspiration for Brown's doughnut came one night when she couldn't sleep. "I imagined a few doughnut flavours that I would love to try," she said. "A peanut doughnut is an untapped resource – something that's hard to find, but that we all want!"

Lesaffre opens doors to baking centre

A baking centre that will house a formulation lab and culinary centre has been added to Lesaffre’s North American headquarters.

The recently constructed addition, which tacks on 1,500 sq. ft. to the Milwaukee, Wis., headquarters, will be home to both a formulation lab and the first culinary centre in North America for Bio Springer, one of the world’s oldest yeast extract production companies.

The baking centre aims to provide the baking and ingredients industries with expertise in technology and innovation. It offers consultation, training and technical support services in the use, application and development of baking ingredients.

The formulation lab will be home to several of Lesaffre’s experts who will work on the development of baking ingredients such as including dough conditioners and yeast, as well as clean label and organically formulated products. The new lab gives the company development abilities in the U.S., as opposed to in France where Lesaffre’s other lab is located.

“A central goal of the new formulation lab is to be able to more quickly respond to the demands of our customers, so we can remain at the forefront of formulating leading quality baking ingredients for the industry,” said Arnaud Deniaud, director of technical services and new product development for Lesaffre North America, in a news release.

The newly constructed Bio Springer Culinary Center will expand the capabilities of Bio Springer North America, the Lesaffre Group’s global manufacturer and marketer of yeast-derived products for the food, pet and biotech industries. It will serve as a hub for the development and improvement of yeast extract products, training and technical support for the company’s customers.

“A major differentiating factor for our North American Culinary Center is that it shares the space with the Baking Center,” said Jessica Vogel, marketing manager for Bio Springer North America, noting they’d be able to collaborate, share ideas and bring additional resources to their customers.

Multivac Canada appoints product specialist

Sadia Seemeen has been appointed high-pressure processing product specialist for packaging firm Multivac Canada.

Seemeen has a background in biotechnological engineering and post-graduate qualifications in food technology. Her master’s research was focused on high-pressure processing (HPP) at Massey University in New Zealand.

Seemeen worked as a process improvement technologist at a poultry company in New Zealand, where she was project manager for HPP. She assisted in the commercialization of this technology, leading to development of a “clean-label” product and increased export sales in the company.

She also worked at the New Zealand Food Innovation Network, where she developed and tested concept products for several clients as a consultant food technologist.

For the last four years, Seemeen worked in the area of HPP, researching and developing products from concept to commercialization, while also publishing research and presenting at international conferences.

Nestor Plawiuk, president of Multivac Canada, says Seemeen brings a wealth of knowledge and passion to the role. “She is known for her product development skills and food and beverage application knowledge on HPP,” he noted. “I am confident she will add significant value to the novel foods industry in Canada.”

Multivac, a supplier of thermoforming packaging machines, manufactures a range of tray sealers, vacuum chamber machines, chamber conveyor machines, labellers, quality-control systems and automation systems.

The company provides consultation, technical design, sales, distribution and service of its line of packaging systems.

formula ¦

BY CHARMIAN CHRISTIE

APRICOT AND PISTACHIO CRISPS

This apricot and pistachio version of Raincoast Crisps is adapted from Julie Van Rosendaal’s recipe for these double-baked treats. Delightfully crisp, these crackers are bursting with dried fruit, nuts, and seeds. A hint of rosemary makes them the perfect match for cheese at parties. If they outlast the cheese, nibble them plain. Be warned, an entire batch will disappear quickly at soirees, leaving the water biscuits and rice crackers feeling snubbed. Are they sweet? A little. Are they savoury? A titch. Are they addictive? Totally.

Makes about 6 to 8 dozen Commitment level: Done in stages

Ingredients

• 2 cups all-purpose flour

• 2 teaspoons baking soda

• 1/2 teaspoon fine sea salt

• 1 cup chopped dried apricots

• 1/2 cup chopped pistachios

• 1/2 cup pumpkin seeds

• 1/4 cup sesame seeds

• 1/4 cup ground flax seed

• 1 1/2 tablespoons chopped fresh rosemary

• 2 cups buttermilk

• 1/4 cup packed brown sugar

• 1/4 cup honey, melted

Instructions

1. Preheat oven to 350 F. Spray two 8- x 4-inch or 9- x 5-inch loaf pans with non-stick spray, or grease liberally with butter and dust with flour.

2. In a large bowl, stir together the flour, baking soda, and salt. Add the dried apricots, pistachios, pumpkin seeds, sesame seeds, flax seed and rosemary, and toss to coat evenly with the flour. Stir the brown sugar and honey into the buttermilk, making sure they dissolve. Add to the flour mixture and stir until just combined. Pour the batter into the prepared loaf pans. Bake for 35 to 45 minutes until golden and springy to the touch. Remove the loaves from the pans and cool on a wire rack. The bread is easier to slice when cool, so bake it the next day or pop it in the freezer to cool it down.

3. Preheat the heat to 300 F. Using a serrated knife, slice the loaves as thinly as you can. Aim for no thicker than 1/8th inch thick. Place the slices in a single layer on an ungreased baking sheet and bake them for 15 minutes. Flip them over and bake for another 10 minutes or until they are crisp and deep golden brown.

Tip: These are so addictive you might want to slice and bake one loaf and put the second loaf in the freezer (well-wrapped, of course) for when the crisp craving strikes. / BJ

Charmian Christie is a writer, recipe developer and cookbook author specializing in approachable, from-scratch recipes. The former baking columnist for recipes.ca and voice behind themessybaker.com, her work appears in various national publications including the Globe and Mail and Canadian Gardening. Her book, The Messy Baker: More than 75 Recipes from a Real Kitchen, was published by HarperCollins Canada in August.

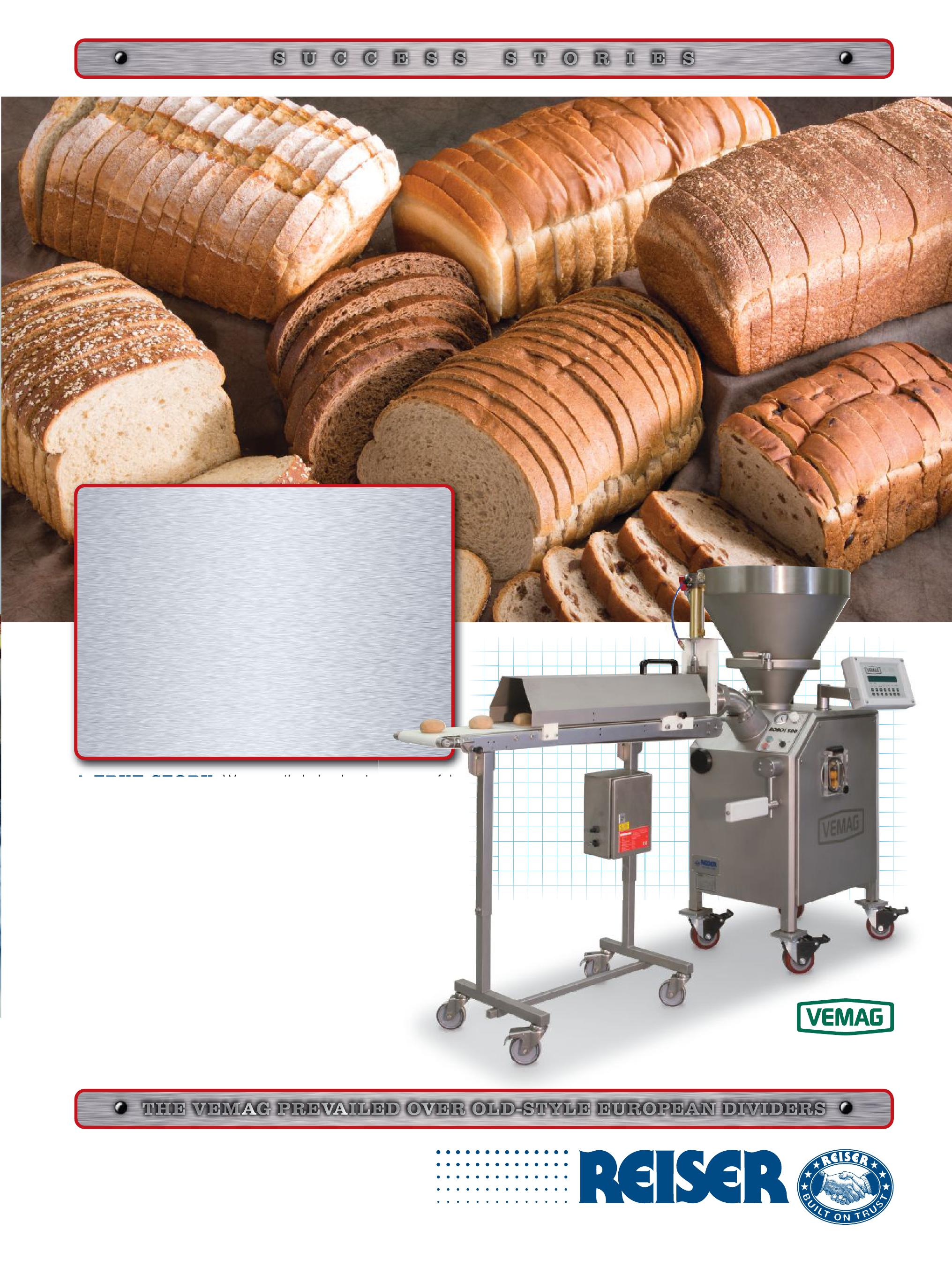

A T R U E S T O R Y : We recently helped out a successful, high-end bread producer. He discovered that his European dividers were wearing out and needed to be replaced. He tested other dividers, but none were able to duplicate the quality of his European and American breads. He was also concerned ab out the drawbacks of simply buying the same units again – the lack of dividing accuracy, the expense of mineral oil, and the frequent service that the units required. He decided to try our Vemag Dough Divider on his products Working with our on-staff Reiser bakers, this customer was able to equal or exceed the quality on all of his breads He was absolutely delighted with the Vemag and he now runs five Vemag Dough Dividers – all producing the highest quality breads with excellent weight control, no mineral oil, and Reiser service and support just a phone call away

A combination of time, skill and feeling |

BY JULIE FITZ-GERALD

THE PERFECT BAGUETTE

BAGUETTE

The quintessential French baguette speaks of time, care and craftsmanship. It’s caramel-coloured, crumbly crust and fluffy middle rippled with airy holes is a testament to skilled bakers who spend years honing their ability to shape, fold and score the dough to perfect proportions. Despite the simplicity of its four ingredients – flour, water, salt and yeast – the fermentation and baking process is complex, requiring the baker to take into account the weather outside, the temperature within the bakery and the feeling of the dough.

Once an unstoppable staple in France, the baguette has taken a hit in recent years with the average French person eating only half a baguette a day compared with nearly a whole baguette in 1970 (and more than three a century ago). Despite dipping sales in its homeland, the baguette’s versatility has made it a fan favourite around the world. Whether it’s served as an accompaniment to soups and salads, paired with fine cheeses, or used as the foundation for deserving sandwiches, the baguette is beloved by consumers and has earned its place on bakery shelves.

IT’S ABOUT TIME

}The most important component in achieving the perfect French baguette is time. For the past 18 years Louis Andre Joyal has been crafting noteworthy baguettes at La Petite Boulangerie, a Montreal bakery that he co-owns with wife Sylvie Boissonneault. The bakery makes between 1,500 and 1,700 baguettes per week.

For many bakers, the process of creating baguettes has as much to do with “feeling” as with following a series of steps. Each day may call for a slight alteration to the process.

“I make the dough the day before I’m using it for cooking,” says Joyal. “This way is better because I’m using less yeast and longer fermentation time. The baguettes stay in the fridge at eight degrees Celsius for 16 to 18 hours and that’s what gives more flavour.”

Cliff Leir, proprietor of the popular Fol Epi bakery in Victoria, B.C., agrees that time is crucial when it comes to ba-

guettes. “We have a 15-hour fermentation time,” says Leir. “This allows for enzyme development which breaks down starch structure. In that breaking down there are various labour components – wild yeast, lactic acid production – so, in short, it’s flavour and texture development.”

If one is tempted to rush the process, be warned, the result will be a dense baguette that’s seriously lacking in flavour. Bonjour Brioche in Toronto, Ont., has been serving up mouth-watering French baguettes for 17 years. Henri Feasson co-owns the bakery-restaurant

with his wife Lori and they sell about 240 baguettes on an average Saturday.

“The inside of the baguette should be fluffy with some holes and when you taste it you should taste the flavour and the time,” explains Feasson. “You can see the bread has been rested. If you see holes in the dough when you cut it then you’ve done a good job. If it’s too dense then it hasn’t been proofed enough and had the time to relax. It’s basically all about time.”

TAKING SHAPE

Gluten is an important component in a great baguette and is also the reason why baguettes must be shaped twice.

“You can’t just shape it because the gluten will shrink back like an elastic band, so you have to shape it twice and then put it on the trays,” says Feasson.

Cliff Leir (opposite) of Fol Epi bakery with some fresh baguettes; Preparing the dough (this page, top); Rolling the dough (bottom)

“The flour has to be a strong wheat flour that’s rich in glutens. That’s what makes your baguette beautiful. Technically, I don’t think anybody can make a baguette or French bread without gluten. It wouldn’t rise; it would only be flat bread.”

Leir uses Red Fife wheat, a type of wheat that set the standard for Canadian wheat cultivation back in the mid-1800s. Sourced from a farmer in Saskatchewan, Leir mills the wheat at his bakery, which is indicative of his “slow food” beliefs and only adds to the flavour of a great product.

“Baguettes are one of the harder breads to learn to fold,” Leir explains. “It always takes a couple months of doing baguettes every day for people to get the right technique. Mixing it to just the right point, having the right kind of flour. While the dough is fermenting we fold it and dump it in one large piece instead of stretching and mutilating it. It needs to be in an oblong shape without breaks so there’s no break in the gluten structure.”

TAKING SHAPE

Shaping the dough into its characteristic oblong shape requires time, patience and practice. Each baguette should measure 350 grams before baking, which will fall to roughly 300 grams after baking. Joyal’s step-by-step process for achieving one of the top-rated artisanal baguettes in Montreal (as determined by the Montreal Gazette) is this: “When we arrive at 12 a.m. we put the dough out for one hour. Then we cut it into a rectangular shape just a little bit. We take the top of the rectangle and put it at the bottom just to make a nice tube and then we let it rest for 30 minutes. After 30 minutes we continue to make the shape of the baguette. The rectangle is folded in one, and the second time we put it in two and make it a bit longer. At that point we let it rest for 45 minutes or until it’s ready, depending on the temperature of the bakery and if it’s winter or summer. It’s not us who decides when the baguette should be cooked; it’s the baguette that decides.”

Before going into the oven, the baguette must be adorned with its signature scoring marks. It is here that bakers can express their style.

“The cuts are the signature of the baker,” says Joyal. “Some make three, some make five or even seven cuts, but

The proofing stage

Slashing the baguettes

JANINE DRUERY

A SWEET COLLABORATION

At 2:00 p.m. on a Wednesday afternoon, the large, airy retail storefront and café of Bobbette & Belle Artisanal Pastries is buzzing. A group of women laugh and talk over slices of cake; two young men grab lattés at the counter; and customers saunter in to buy the shop’s infamous macarons and other treats.

It’s a good thing the proprietors, Allyson Bobbitt and Sarah Bell, are so animated, or they’d never be heard above the voices and the constant hum of the espresso machine. But their

speech is lively and their laughter easy as they tell of how they got into the business.

“I didn’t come from a family of fine epicureans,” says Bell with a chuckle. “My mom was a terrible baker – my cakes always rose higher than her cakes did.”

That aside, Bell always had a passion for food, and she decided to study cooking and then baking at George Brown College in Toronto. She then went to work for Oliver and Bonacini, where she rose to head pastry chef at the acclaimed Canoe at a very young age. She then decided to try a new path and became a

chocolatier at Soma chocolates.

Bobbitt’s road into the business was perhaps more atypical. Although she grew up with a grandmother who was a wonderful baker, she didn’t follow in the family footsteps at first. She pursued a science degree and then became a teacher. Eventually though, she decided to pursue her passion for art and for baking, and started up a cake business part-time.

“When I stumbled upon creating cakes about 10 years ago I just fell in love with it,” Bobbitt says. “I had always done a lot of art. So it was the perfect

melding of the artistic and the culinary.”

Bobbitt and Bell crossed paths when they both taught at the Bonnie Gordon College of Confectionary Arts in Toronto. By that time, Bobbitt was running her cake business and had earned the Canadian Wedding Industry award for Cake Designer of the Year.

“Allyson would bring pictures by the school of the cakes she was making, and I thought she was just as crazy as I was in terms of dedication,” laughs Bell.

Bobbitt approached Bell about the possibility of working together and they launched

Allyson Bobbitt (left) and Sarah Bell of Toronto-based Bobbette & Belle

Bobbette & Belle as a French macaron shop, starting out in a basement before moving into a smallish storefront space and expanding their products. When orders became too much for them to complete there, they knew they had to make the next step – and take a large leap of faith.

IF YOU BUILD IT

The big, bright space features a wide variety of pastries, cakes, cupcakes, tarts – and their infamous macarons and acclaimed cakes. They also produce a line of packaged products like cookies, toffee and flavoured marshmallows. Everything is baked on the premises, using fresh, whole, high-end ingredients that include Lindt chocolate and

but we want it to be the best carrot cake you’ve ever eaten and the best butter tarts you’ve ever eaten.”

They have also made a complete commitment to customer service, knowing that you can always get somebody in the door once. “But, if you are not really standing behind your product and making a quality product, you cannot get them

accolades. Their signature wedding cakes sell for between $1,000 and $2,000, but their custom cakes can run up to $15,000.

}The pair opened a 3,000-sq.-ft. artisanal pasty shop in Toronto’s hip Leslieville district, complete with a retail space, a café, a place to display cakes and a giant baking area in the back. It was certainly a bold move, going from a tiny shop to a large, chicly designed store in a stylish neighbourhood.

“I think the feeling was that ‘failure is not an option,’” notes Bobbitt. “And not to be cliché, but if you build it they will come.”

When they started, there were only three of them baking in the back; Bobbitt’s father sat up front, yelling back whenever a customer would enter the store. Today, the establishment has 20 staff, including bakers, cake decorators, administrative people and front counter staff.

Bobbitt and Bell’s ability to finish one another’s sentences, expand each other’s ideas and think along the same lines has made them a team in the true sense of the word.

Boiron fruit purées.

“We kind of walk a fine line between classic French pastry and more rustic North American-style pastry,” says Bobbitt. And while the products are simply beautiful, it’s about so much more than good looks.

“Our mission is to create the best baked goods you can find in Toronto” – in a beautiful but approachable space,” says Bell. Adds Bobbitt: “There is a lot of classic pastry out there that looks great and it is so tempting to buy it and it tastes like nothing. We’re not trying to reinvent the wheel – we do carrot cake, we do butter tarts,

back in a second time,” says Bobbitt.

Adds Bell: People always talk about location, location, location. For us, its consistency, consistency, consistency.”

LET THEM EAT CAKE

The duo mainly sell their products in their own store, but have chosen a few choice places to share their goods; they are in Holt Renfrew, McEwen and O&B Artisan. They also have a display outside of Kleinfeld bridal boutique at the Hudson’s Bay store in the city’s downtown to showcase their wedding cakes, which have won them many

What does $15,000 buy you? Well, for First Canadian Place, it was a five-ft. exact replica of its building. And cakes for corporate clients and discerning brides and grooms can run that high – creations that have appeared in a variety of magazines across the country.

It can take Bobbitt a month to create one of her couture cakes with all the elaborate sugar flower work that is involved. Sometimes she becomes so attached to the cake, it’s hard to let it go.

“If I go on delivery, I don’t like to leave the cake,” she notes. “I feel really sad leaving it behind. I’m glad I’m not there for the cutting part of it.” Bell merely laughs at this and adds: “Good riddance.”

OVERCOMING HURDLES

While everything is falling into place for the duo, they aren’t shy about admitting the bumps they’ve had to smooth out and the hurdles they’ve had to jump over along the way.

In addition to the long hours

The front counter at Bobbette & Belle is chock full of cakes, macarons, cupcakes and other heavenly delights.

and learning how to stretch a dollar, they’ve had to struggle with the difficulties of finding dedicated staff, and learn to juggle their business with their personal lives. They’ve also learned that they can’t do it alone.

“We’ve had to learn to realize when we don’t know something, and to form a team around us who do know what they’re doing,” notes Bobbitt.

And they have learned that they can’t jump on every opportunity that comes along. For instance, while they’ve been the baking experts on the Marilyn Denis show for the last four years, they decided against doing their own show.

“We didn’t get into this business to be celebrities,” says Bell. “We got into it to be entrepreneurs and business owners.”

MOVING FORWARD

Bobbitt and Bell are not really involved in the baking aspect of things any longer. They only jump in for the bigger things now, like recipe development, large custom projects,

and ideas for growing the business. They really want to stick to the retail side of things and hope to eventually open multiple locations across the city.

For now, they have enough on their plates to keep them busy, including a contract with Penguin to produce their first cookbook and a partnership with Roots for that company’s general store. Most exciting, perhaps, is their new store that is opening the first week of October in Toronto’s Lawrence and Yonge area. It will be smaller than their Leslieville digs, but will have a café, retail section and a basement in which the baking will be carried out.

Their many years of hard work have left them in an enviable position – and made them a rock-solid duo. Bobbitt and Bell’s ability to finish one another’s sentences, expand each other’s ideas and think along the same lines has made them a team in the true sense of the word.

“I’m the right side and Sarah is the left side,” jokes Bobbitt. “Together we make one whole brain.” ! / BJ

Sarah Bell (left) and Allyson Bobbitt stand by their amazing wall of cakes.

We’ll help your dough rise

A happy staff is a productive staff and a productive staff is a profitable one

Don’t let inertia stunt your company’s growth. Standard Life group insurance and group savings & retirement programs are the answer to your business needs and employee wants. Our programs are designed for small businesses to help them attract and retain talent. The result is a more motivated and engaged workforce.

Need the facts? We’ve developed a site dedicated to small businesses to show you how group solutions can help your business grow.

Simple group solutions to get your business moving at standardlife.ca/mySME

¦ concepts for success ¦

BY DIANE CHIASSON

HOW TODAY’S CONSUMER SHOPS

People are more focused in their shopping habits these days. Here are five things you should know.

The recent recession has changed the way today’s consumers shop and spend. Despite the fact that the economy is on an alleged upswing, more than one-third of consumers still feel they are in some kind of financial distress and are not willing to spend like they used to. Consumers are very focused on exactly what they buy and where they spend their hard-earned dollars – and they will not spend recklessly. If you run a bakery, it is important to know your customers, track their spending habits, be on top of what consumers are looking for, and adjust your business accordingly in order to be successful. Here’s a look at five ways average consumer spending habits are changing, and how these could affect the way you operate your bakery:

If you run a bakery, it is important to know your customers and track their spending habits.

}Great customer service must be at the top of your list of priorities when it comes to customer retention.

spending is being donated to a charitable organization. It affords them a simple way to be charitable without having to get fully involved.

3.

THEY ARE SMART AND SAVVY

1. POOR CUSTOMER SERVICE IS A DEAL-BREAKER

In a recent poll of consumers with a higher-than-average annual income, 90 per cent of respondents said they would walk out of a store if they received bad service. Great customer service must be at the top of your list of priorities when it comes to customer retention. There is more competition out there than ever before, so if consumers don’t like the way they are being treated in your store, they can easily walk out the door and shop down the road.

2. TODAY’S CONSUMER CARES ABOUT THE COMMUNITY

Consumers today are much more civic-minded and they care about their communities. People are much more willing to shop within their community to help out small businesses than shop at big-box retail stores. They are also willing to make a purchase if part of their

With so much information available on the Internet, today’s consumers are more likely to be destination shoppers, make more considered purchases and do their homework before they head out to shop. They are able to compare prices, read reviews and get opinions on products online. When they walk into your bakery, they probably already have an idea about your signature products and price range. It is important for you to monitor what others are saying about your operation online and to consistently check what your competitors are doing so that you stay relevant.

4.

THEY LIKE NEW STUFF

Today’s consumers are always looking for new things to try (new sensations, new products) and are willing to spend money on something if it offers them a novel experience. Make sure you renew and refresh your offerings at your bakery regularly – things like specials, guest chefs, custom breads, cakes and cookies, seasonal products, flavour profiles and

new technologies. You might even consider opening pop-up locations at various places in your city to increase your visibility during festivals and events.

5. CONSUMERS WANT TO FEEL SPECIAL

Today’s consumers are not as loyal as they used to be. There are a lot more options out there these days, which translates into much more competition for customers’ time and money. The one way for your bakery to create customer loyalty is by making your customers feel special. Even a simple gesture like remembering their names will make them feel like they have a unique connection to your bakery. Special perks and access to insider knowledge will also make them feel important and give them an opportunity to talk about your bakery with their family and friends. As we all know, word-of-mouth advertising never hurts! / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping foodservice, hospitality and retail operators increase sales for over 30 years. She provides innovative food and retail merchandising programs, interior design, marketing and promotional campaigns, and much more. Contact her at 416-926-1338, toll-free at 1-888-926-6655 or chiasson@ chiassonconsultants.com, or visit www.chiassonconsultants.com.

Healthy Grains Institute Tackling the Anti-Wheat Message

For the past 10 years the media landscape has been inundated with gluten-free and anti-wheat banter. The conversation has largely been driven by the launch of popular diet books that use emotional narratives and testimonials, versus science, to promote the merits of eliminating wheat from one’s diet.

As a response to the onslaught, the Healthy Grains Institute (HGI) was created. This not-forprofit Institute, guided by an independent Scientific Advisory Council, was created with partners such as the Baking Association of Canada (BAC) to use rigorous scientific research to combat the gluten-free trend among the non-gluten intolerant Canadians.

The team at HGI has been working hard for the past two years to generate awareness of the important role grains play in the Canadian diet and is seeing significant results in shifting the conversation away from fad diets and misinformation. And given recent media coverage, it seems going gluten-free as a diet strategy is finally attracting consumer scrutiny.

• A surge in visits to healthygrains.ca and interest in HGI produced materials on the website

• 44% growth in Facebook following and a 52% increase on Twitter

• A presence at speaking engagements and conferences including FarmTech 2014, The Calgary Stampede, Western Canadian Wheat Growers, Farm & Food Care Ontario farm tour, Grain Industry Symposium, Baking Association of Canada Bakery Showcase, and The Dietitians of Canada Conference

• Registered Dietitian communications, spearheaded by a quick and easy whole grains meal recipe contest with Dietitians of Canada

In year three, the HGI will look to:

• Raise awareness with consumers of the health benefits of wheat and other grains

• Promote the truth and defend the science supporting the role that wheat and grains play in maintaining a healthy and balanced diet

Christine Lowry, Healthy Grains Institute “ “

We want to help inform and educate Canadians on the health benefits of whole grain…We can no longer ignore this anymore. We have got to get engaged and defend our industry”

Research into consumer behaviour has revealed the popularity of gluten-free and wheat-free diets can largely be attributed to an emotional decision, meaning that there is a lack of rationalization involved. The research showed that consumers still believed in the goodness of grains and are now looking for permission to return to them. This is where the HGI plays a critical role. Its focus on leading a rational argument has helped to educate consumers and make a connection with them.

This past year the HGI membership has seen some impactful results of their efforts, including:

• HGI-driven media coverage totaling 24,573,976 media impressions worth over $500,000 in advertising value

This year the HGI team will continue to turn the conversation back around to favour wheat and grains as part of a healthy diet. A large part of that will be to work with the BAC again and continue the joint-mission to defend the reputation of wheat and grains together. The HGI’s website includes a number of free resources such as fact sheets and research studies to assist Canada’s baking industry in responding to consumer questions regarding wheat-based foods. Visit www.healthygrains.ca to see everything the HGI has to offer. The public can keep up-to-date on the latest progress of the HGI by subscribing to the Institute’s newsletter at info@healthygrains.ca

Adding Real Business Value For Bakers

Provision’s One-Stop Online Sustainability Portal

Icannot believe the portal is a free resource made for food and beverage processors.” Tony Ngo, Environmental & Sustainability Coordinator at Oakrun Farm Bakery and his Facility & Environmental Manager, John Vanden Broek, are reviewing the tools and resources in Provision’s Online Sustainability Portal. They’re planning to make the portal their go-to-site in order to monitor and track the performance of Oakrun’s baking facility, using it to demonstrate a strong business case for implementing new projects. Their first step? Conducting an assessment using the portal’s Self-Assessment Tool to help them identify the current stage of their sustainability journey and aim for the next level in the continuum using the ‘how-to’ integration framework.

Reduced production costs and improved margins, a smaller environmental footprint and minimizing the risk of regulatory non-compliance are just a few of the key benefits the Oakrun Farm Bakery team and many other food and beverage manufacturers are realizing by integrating sustainable practices into their business strategy, operations, culture, and decision making. Manufacturers are also facing increasing demands from consumers and retailers for sustainable production information and verification, but meeting these needs can prove challenging for many small and medium-sized businesses.

Provision’s Online Sustainability Portal (www.provisioncoalition. com) is a one-stop source of innovative, web-based sustainability tools and resources designed specifically to help food and beverage manufacturers assess, monitor and improve their sustainability performance. And best of all, it’s free to all manufacturers.

Once registered in the portal, manufacturers will find valuable tools to help meet their customer and business needs. The SelfAssessment Survey provides a comprehensive evaluation of a facility’s economic, environmental and social performance, identifying strengths and gaps in operations. With the Key Performance Indicator (KPI) Scorecard, users can enter and crunch production data with energy, water, waste and emissions generated, to develop KPIs that can be used to establish, monitor and track performance targets. Manufacturers can also assess their facility’s compliance with Ontario’s environmental regulations and legislation using the Environmental Benchmarking Tool. Facilities receive a prioritized report suggesting action items to

help address potential compliance gaps. Other helpful resources include the comprehensive funding and consultant/ vendor databases, plus a Library of articles and food and beverage case studies.

Manufacturers ready to begin or expand on their sustainability journey can register in the portal today at www.provisioncoalition.com. You’ll need your business registration number and NAISC code to get started. Provision is also making house calls to food and beverage manufacturers who might like a helping hand. Contact the Provision team (info@provisioncoalition.com) and request an on-site visit and/or portal demonstration.

ABOUT PROVISION COALITION

Quick Case Study:

Sons Bakery in Brampton, Ontario, began using the web-based tools and resources in Provision’s Portal in 2012. The result?

• A 12% reduction in electrical consumption

• A 6% reduction in natural gas usage and 4% reduction in water consumption

• Annual cost savings of $45,000 being used to help fund further energy and water conservation activities

• Zero waste-to-landfill status

• A fresh business vision, mission, and goals that encompass the organization’s commitment to sustainability and align with customer expectations

The Baking Association of Canada is a member of Provision Coalition. The leading voice on sustainability for the food and beverage industry, Provision consists of 11 member associations that represent the sustainability interests of manufacturers and input supply sectors across Canada. We are committed to helping our member companies enjoy the economic, environmental and social benefits that come with operating in a sustainable manner.

This program carries top-of-the-line news on what’s happening in the industry with governments, services, BAC activities, etc.

The E-Bulletin is ONLY available to BAC Member companies and their employees. Don’t miss out on receiving time-sensitive news.

If you’re not currently receiving the E-Bulletin please email info@baking.ca to be added.

2014 Festive Night at the Races

A fun-filled evening & Christmas celebration with friends from the Baking Industry

Friday, November 7 th, 2014

Fraser Downs - Clubhouse Restaurant

17755 60 th Ave, Cloverdale BC

6:00 pm Cocktails | 6:30 pm Buffet Dinner | 7:00 pm 1st Race Tickets $45.00 (includes GST)

Reserve your Tickets ASAP!

Mail cheque and registration form to:

Or send form with credit card information to: BAC (Attn: Gillian Blakey) Fax: (905) 405-0993 Suite 202 - 7895 Tranmere Dr.

Email: gblakey@baking.ca Mississauga, ON L5S 1V9 Phone: 1 (888) 674-2253 ext. 21

Cheque Payable to BAC Tickets to be picked up at the door

____________________________ 7895 Tranmere Drive, Suite 202, Mississauga, Ontario L5S 1V9

Tel: (905) 405-0288, 888-674-2253 Fax: (905) 405-0993 Email: info@baking.ca Website: www.baking.ca

Corbion

Designed by science, powered by nature and delivered through dedication

Better food. Richer life.

At Corbion Caravan, we provide food solutions that nourish the world. Our innovative ingredients o er unsurpassed freshness from creation to consumption, initiating a love a air between your products and consumers. With more than 100 years of dedicated service to the bakery industry, Corbion Caravan has the proven expertise and scientific creativity required to develop industry-leading bakery products that ensure quality and consistency. As always, our future-focused thinking helps you deliver the products your consumers want. Nobody keeps your best interests or your bottom line at heart like Corbion Caravan.

INTERESTED IN FRESHNESS SOLUTIONS?

Our broad bakery portfolio includes functional ingredients, emulsifiers, bread mixes, specialty bases, frozen dough, vitamin and mineral premixes and flour enrichment.

Together we create enhanced freshness and safety solutions.

COLLEEN CROSS

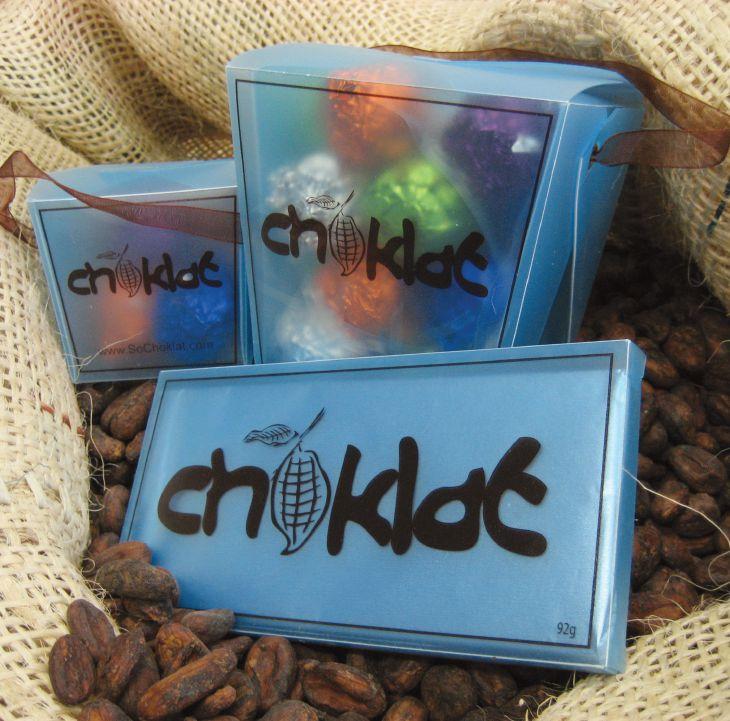

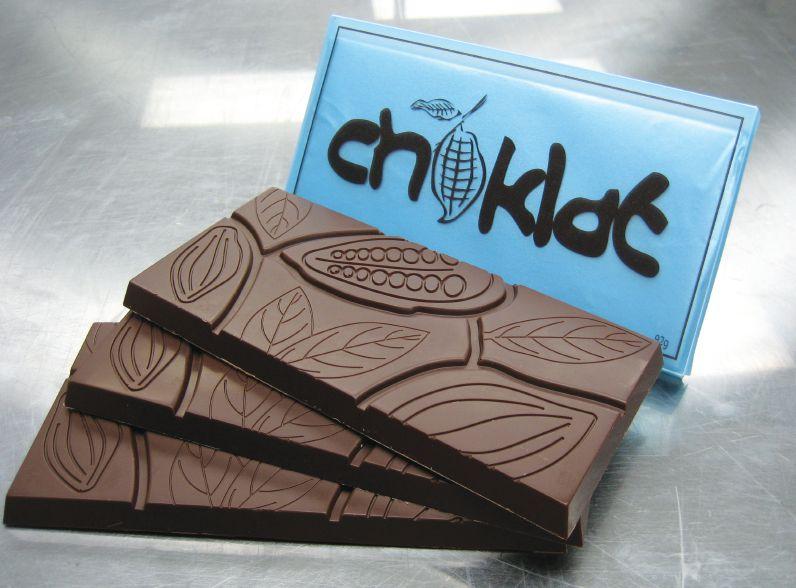

CELEBRATING CHOKLAT

Brad Churchill is not afraid to get in your face about chocolate.

Describing himself both as an “upstart nobody” on Canada’s foodie scene and the “bad boy” of the industry, he won’t rest until he has educated his customers about how their favourite indulgence should taste – and he has freed them from preconceived notions.

A software engineer and dot-com developer by profession, Churchill, owner of Choklat, became obsessed with making high-quality chocolate from scratch in 2005 after learning an expensive box of chocolates he’d purchased was not made by the seller as advertised. What he saw as a dearth of freshly made chocolate in the market (and a lack of integrity in marketing), sparked both a business model and a passion.

He started making chocolate in his kitchen, using friends as test subjects. When he came up with a product they agreed was good, he decided to take it retail. It took three years and some 3,000 hours of research, reading and experimenting to develop his product and his approach, but, in 2008, he opened his first shop in Calgary. A second store soon followed in that city and a third opened in Edmonton this year.

}With so many irons in the fire, Churchill still manages to feel passionate about his products and the comforting experience they offer people.

He asks a lot of questions. For example, he wonders, ‘Why can’t the chocolate market be more like the coffee market, which has exploded in recent years with a wealth of options?’ According to Churchill, chocolate is going the way of coffee in that consumers demand it be customized.

EDUCATING PEOPLE AND PALATES

The nuances are processed out in most chocolate, contends Churchill. He has made it his mission to create chocolate

that celebrates the cocoa bean like great wine celebrates the grape. His goal is to educate customers about differences in the quality of the chocolate.

“We make single-origin, and in some cases single-plantation, chocolate. The difference is so drastic it’s startling,” reads a quote on the company’s web site, which is full of chocolate facts.

Churchill says that when asked what kind of chocolate they prefer, many people state a preference for dark chocolate. However, it should not be chalky and bitter. The chalkiness comes

from astringency.

“We’ve been encouraged to accept these characteristics,” he says, adding that he believes most people want the perceived benefits of dark chocolate along with the taste of milk chocolate.

THE CHOKLAT EXPERIENCE

Chocklat’s mainstays are moulded chocolate bars, and hand-rolled and molded truffles, complemented by fruit and nut bars, cupcakes, brownies, hot chocolate and gift baskets.

In the store or on the website, chocolate lovers are faced with an abundance of choice. When ordering a truffle, for example, they’re asked to choose from 25 fillings, among them Espresso Buttercream, Pumpkin Spice and spicy Hot Diggity. That centre will

then be dipped in either 70 per cent Dark Choklat or 48 per cent Milk Choklat. It may then be set off with toppings like sprinkles, toasted coconut or Skor toffee bits.

Churchill, who did extensive research before opening, says his modus operandi is to watch customers everywhere he goes to determine what they like and what they actually buy. This helps him choose flavour combinations. For example, he has noticed people gravitate to comfort foods and coffee flavours. Before opening, he did much testing and provided samples to thousands of people to get their feedback. Although there are no samples in his shops now, he has hit upon a creative and profitable way to take his chocolate to the public. Believing word-of-mouth to be the most powerful form of advertising, Churchill launched a series of tasting events called “Choklat Snobbery 101.”

The idea was to establish himself as a “trusted source” of chocolate expertise by hosting events where customers could sample the wares and up their chocolate IQ. The tastings run as often as four nights a week and can accommodate 10 to 12 people at a cost of $40 each. They have proven popular for special occasions, particularly bachelorette parties.

These sell-out events, which include chocolate education and wine pairings, also provide a way to donate to charity. Churchill can present an event’s worth of tickets to local charities, which then auction off tickets.

“So now it’s a win-win,” says Churchill. “The $400 to $600 would be donated to a non-profit and I get an audience of 10 or 12 captive for two hours. Suddenly that works out a whole lot better than a silent auction item or gift basket.”

He has offered a few workshops, but the logistics of running them from a 1,500-sq.ft. kitchen, as well as food safety considerations, prompted him to put them on hold. He hopes to expand and is designing a new facility with lab and event areas where he can hold chocolate-making, confection-making, caramel and truffle workshops.

HANDS-OFF OPERATION

Churchill designed his business to be managed hands-off. He set up the roasting, enrobing and other processes, then trains staff to operate them independently.

It’s all about efficiency. He wrote the software system that runs most aspects of his business, including inventory tracking, point-of-sale and credit-card payment functions. The software also helps identify trends. Products are broken down by ingredient; for example, he can see exactly how much amaretto chocolate is required. That helps him streamline his processes and reduce his food waste.

The system is built into a website, which provides employees and customers with user-friendly access. Most of the year, there are one or two employees in each of the three locations, but in the weeks leading up to Christmas and Valentine’s Day, this number may rise to 20 people.

Staff masters the processes quickly and learn to use the equipment easily. But, Churchill says, customer service is the toughest skill to teach. It’s important to relate to and educate customers, and surprisingly few people have those skills.

RAMPING IT UP

His current challenge is finding money to build a larger factory he is designing to house larger processing equipment. The goal is to sell into grocery stores. “That step is over a million dollars,” he

says. As someone who has raised money for a dot-com company in the past, Churchill knows there are significant challenges to raising that amount.

“Buying into a retail venture, such as chocolate, that is very cyclical in nature is not something that is easily sold to investors,” he says. “Even to people who’ve invested in the food industry in the past. They say, ‘If your chocolate is so good, let’s ramp it up and sell it to restaurants wholesale.’ But then you’re making pennies on the pound and that’s far riskier than doing a retail deal. Many investors don’t understand that.”

With so many irons in the fire, Churchill still manages to feel passionate about his products and the comforting experience they offer people.

“My daughter really summed it up when she said, ‘The fancy confections are fine, but when you do a chew-andshow it all looks the same,’” he reflects. “So just focus on taste. And that is so true. The bottom line is a person will buy with their eyes once, but if that product doesn’t live up to their expectations, they will never buy it again!” / BJ

The shop's mainstays are molded chocolate bars (above) and hand-rolled and molded truffles (opposite page).

BY MARK BORKOWSKI

AFTER YOU SELL

So, you’ve sold your business?

Here are 10 things you need to do...

Arecent survey, entitled the National Survey of Canadian Business Sellers, revealed that selling a business was an exhausting ordeal that left people with little time to think about themselves or their new circumstances.

The survey, conducted by investment firm Newport Partners, polled 500 Canadian entrepreneurs who had sold businesses. The research objective was to better understand the challenges and needs of entrepreneurs through the entire sales cycle.

One of the more significant findings was that fewer than 25 per cent of the business owners had pre-planned the sale of their business. Those surveyed also confirmed that the selling process was both distracting and tiring. Given the circumstances, it’s no surprise that many of them needed considerable time to re-engineer themselves and their money after the sale.

As a result of the research findings, ten practical suggestions were developed:

The sale of your business often creates a void that will take time to fill.

1. TAKE A BREATH, A VERY LONG BREATH

The sale of your business can create a void that will take time to replace. It can take a year or more before you declare yourself “ready” for the next challenge. The management of your funds needs to reflect this new plan.

2. RECOGNIZE YOUR NEW REALITY

You are not any wealthier than you were prior to the sale. However, your balance sheet has changed dramatically. And, if you are working for the new owner, your wealth is no longer lodged at your place of work. It is at the bank and is not getting the same attention it received before the sale.

3. SEEK PROFESSIONAL CASH MANAGEMENT

The survey confirmed that a large proportion of business sellers “park” their funds in cash for three months to a year. Bank branches are for “retail” clients. And there are several layers between the branches and the wholesale money market. Ensure you are dealing with someone with direct access to the money market and can get you the rates you deserve.

4. DRAW UP A NEW BALANCE SHEET

There’s no better time than now to take stock. Your affairs are probably more complex than you would like. You need funds to live and you need to understand which funds are best accessed from a tax perspective. You may be surprised to learn that the funds in the family trust belong to the beneficiaries i.e. your spouse and kids. A detailed balance sheet will help you identify issues that require immediate attention.

5. GET ORGANIZED

Your money may be in several places, such as a family trust, a holding company and several family accounts. Many business sellers find themselves overwhelmed with the paperwork. You might want to consider hiring a part-time bookkeeper. That person will more than pay for themselves at “tax time”.

6. COMMUNICATE YOUR NEW REALITY

Many business sellers emphasized the importance of communicating their new reality with key family members. So much has changed and misunderstandings can easily arise. Recognize this possibility so you can avoid the unpleasant consequences. After all, the sale is a positive event.

7. GET AN ESTIMATE OF THE TAXES OWING

You must obtain an estimate of your tax liability. It may be due over several years and some of it may be deferred indefinitely. There are many strategies available, including insurance and philanthropy. Focusing on these issues may be the best way to increase your net worth in the short term.

}details. You have moved up their list and they will now be soliciting you for a large commitment. Again, recognize your new reality and be prepared. Many entrepreneurs find it helpful to have a gatekeeper who will handle these types of requests for them, so they don’t have to.

10. DEVELOP AN APPROACH FOR LOANS

You may be asked for a loan by a family member or a friend.

If you are working for the new owner, your wealth is no longer lodged at your place of work. It is at the bank and is not getting the same attention it received before the sale.

8. DO AN AUDIT OF YOUR CURRENT ESTATE PLAN

It is very likely that your estate plan including your will and insurance do not match your new circumstances. Does your will include provisions dealing with shares of a private company now sold? Are your current executors capable of handling the complexity of your new affairs? In our view, these are “immediate concerns”. We suggest you make the necessary changes so that your current plan works. More sophisticated changes can wait.

9. DEAL WITH CHARITIES

Yes, charities know you’ve sold. And they probably know the

Do you take security? Or document the loan? Will it set a precedent? These are sensitive issues. A simple solution? Buy yourself time by telling them that your money is tied up with your advisors. BJ

Mark Borkowski is president of Mercantile Mergers & Acquisitions Corporation. Mercantile is a mid-market mergers and acquisitions brokerage firm (www.mercantilemergersacquisitions.com).

Newport Private Wealth is one of Canada’s largest independent full-service wealth management firms serving high net worth individuals. To download the business seller survey visit www.newportprivatewealth.ca

BY DR. JOHN MICHAELIDES

THE LOW-DOWN ON GLUTEN

Making sense of the gluten-free marketplace – and the new rules that will affect us all.

The development of gluten-free products is the food product manufacturers’ attempt to satisfy the needs of those suffering from Celiac disease. This disease is the chronic intolerance to some cereal gluten forming proteins found in wheat, rye, barley and some other wheat-related cereals.

The term “gluten” is basically the result of various proteins from wheat, barley, rye and other related grains that combine during dough development to form the structure that is important in the baking process. The main two proteins in these grains are gliadin and glutenin. The celiac-toxic component, which is present in alpha, gamma and omega-gliadins (wheat), hordeins (barley) and secalins (rye), is the main cause of disease.

}Self-diagnosis is common due to the multitude of symptoms CD is known to cause, such as severe cramps, inflammation, fatigue, anaemia and weight loss.

It is estimated that one in 100 to 300 people worldwide is diagnosed with Celiac disease. Although the number of individuals diagnosed with Celiac disease is growing due to better and faster diagnosis techniques, this portion of gluten-free (GF) consumers represents a small number in the market.

There is also a growing number of self-diagnosed consumers who are influenced by media and other information sources. Self-diagnosis is common due to the multitude of symptoms Celiac disease is known to cause. These include severe cramps, inflammation, chronic diarrhea, abdominal distension, fatigue, neurological symptoms, anaemia, osteoporosis, skin rashes and weight loss.

Although it currently may appear to be niche, there are indications that the market is moving into the mainstream. There is no doubt the actual number of cases is increasing, but one needs to be careful with these figures because of the

uncertainty of the self-diagnosed portion of consumers. However, the core audience for gluten-free products will always be those genuinely suffering from Celiac disease and who have an adverse reaction to consuming gluten.

And the audience is also potentially broader. While a dairy or gluten-free diet was once used only by those suffering from illness or intolerance, many ‘free-from’ products are now seen as foods that can improve general health. The wheat-free diet recently caused a lot of controversy and confusion to the general consumer. Free-from foods must credibly communicate the broader benefits rather than simply relying on the ingredients they exclude.

The entrance of GF food products in the market will continue to evolve with new technologies and with ingredients that enable manufacturers to develop products that closely resemble, in structure and taste, those that contain gluten.

The GF market is currently enjoying substantial growth, which is a good portion of the total intolerance market. North America and the EU are the most developed markets with a number of new GF products appearing annually.

As a result of the growing market and consumption of GF food products, many countries and jurisdictions are looking to ensure that consumer health is protected and products are correctly labelled. For this reason, definitions of what constitutes a gluten-free product had to be developed.

Most countries have developed labelling rules on GF food products based on the Codex Alimentarius definition. This definition states that gluten-free foods can be made from naturally gluten-free ingredients and/or ingredients containing wheat, barley, rye, or crossbred varieties of these grains that have been specially processed to remove gluten with a gluten level not exceeding 20 milligrams per kilogram (20 parts per million).

Health Canada’s position on GF states: “Based on the available scientific evidence, Health Canada considers that gluten-free foods, prepared under good manufacturing practices, which contain levels of gluten not exceeding 20 ppm as

The core audience for gluten-free products will always be those suffering from Celiac disease. PHOTO: FOTOLIA

a result of cross-contamination, meet the health and safety intent of B.24.018 when a gluten-free claim is made.”

Based on the enhanced labelling regulations for allergens and gluten sources, any intentionally added gluten sources, even at low levels (e.g. wheat flour as a component in a seasoning mixture which makes up a small proportion of the final food), must be declared either in the list of ingredients or in a “contains” statement. In these cases, a glutenfree claim would be considered false and misleading.

“If, however, a manufacturer using a cereal-derived ingredient includes additional processing steps which are demonstrated to be effective in removing gluten, then the food may be represented as gluten-free.”

Last August, the U.S. FDA issued a final rule defining the term “glutenfree” for voluntary use in the labelling of foods. The compliance date for the final rule was August 5, 2014. The rule states: “In general, foods may be labeled ‘gluten-free’ if they meet the definition and otherwise comply with the final rule’s requirements.”

More specifically, the final rule defines ‘gluten-free’ as meaning that the food either is inherently gluten free; or does not contain an ingredient that is: 1) a gluten-containing grain (e.g., spelt wheat); 2) derived from a gluten-containing grain that has not been processed to remove gluten (e.g., wheat flour); or 3) derived from a gluten-containing grain that has been processed to remove gluten (e.g., wheat starch), if the use of that ingredient results in the presence of 20 parts per million (ppm) or more gluten in the food. Also, any unavoidable presence of gluten in the food must be less than 20 ppm.”

This year the EU, recognizing the increased consumption of GF foods, has moved the gluten-free labeling laws into the Food Information for Consumers (FIC) regulations. This has allowed these products to be better represented in the mainstream food categories.

Many analytical tests are available for testing the presence of gluten in foods. Some of these are quick, involving immunoassays as well as other new technologies. These tests can be performed by food manufacturers for

screening their own products. In addition, various laboratories are now providing more accurate analytical services.

Scientists are also continuing their efforts to find the actual cause of Celiac disease. Recent studies have shown that a specific human protein plays an important role against the inflammatory reaction relating to Celiac disease. Continued research investigations may eventually result in a better treatment for those who are suffering. / BJ

For more information, or fee for service help with food technical and processing issues and needs, please contact Dr. John Michaelides at John Michaelides Consulting. He can be reached at 519.743.8956, at Bioenterprise at 519.821.2960 or by email j.jmichaelides@ gmail.com. Bionterprise is a company of experienced professionals that coach and mentor emerging agri-technology companies from planning to start-up to profitability and beyond.

From custom cake circles and prune purée to the latest software and tracking systems, Bakers Journal keeps you “in the know.” for more on new products for the baking industry, check out our website, www.bakersjournal.com

Boards of all shapes and sizes

New Method’s FDA-approved Celebration boards are available in a variety of circle and sheet sizes. The boards can include customprinted logos or be in standard four-colour process designs, making them suited to graduations, birthdays and other occasions.

Constructed of single-wall corrugate, they are also available in double-wall design.

Custom-printed cake circles are available with the same sturdy base and custom printing. Both sheets and circles are available in low minimum-order quantities.

“We’re excited to introduce the Celebra-

tionboards,”saidJonRay,thecompany’snationalsales manager. “They are another example of our customer-focusedapproach.We’rebigenoughtobe competitiveandversatileenoughtodevelopproducts for specific customer needs.”

The company also has a line of PET-lined trays that are bakeable, disposable, and constructed from a corrugate board that is both heat-resistant and waterproof.

The high-gloss laminate, designed for easy

release, is available in kraft, black, white and silver finishes. PET, which is available in E, B or C-flute, provides a moisture and grease barrier and can tolerate a temperature of 425 F for up to 30 minutes. The trays are available in standard sizes, including quarter-sheet, half-sheet, and full sheet, in addition to custom sizes.

New Method also offers bakeable and disposable corrugated circles that are designed for bake-in applications such as bake-and-ship cheesecake.

www.newmethodpackaging.com

Prune purée lowers glycemic index

Sunsweet Indgredients’ Prune Purée is a blend of prunes that have passed through a fine mesh screen and prune juice concentrate. Available in 55-gallon drums and five-gallon pails, the product is shelf stable at cool storage conditions and does not require refrigeration.

The purée is designed to lower the glycemic index to 29, versus that of a normal sweetener at 60, and helps reduce sugar and fat in breads.

It is used to replace fats and oils in bakery products, and as an inclusion in drinkable supplements and yogurt.

www.sunsweetingredients.com

ActiveTrack aids oven band tracking consistency

Ashworth’s ActiveTrack Baking Band tracking system, designed for consistent bidirectional tracking of your oven band, aims to improve product quality and extend band life.

The tracking system employs the use of high temperature, self-cleaning, non-contact sensors to collect and analyze band speed and position data in order to make

Software integrates weighing data

Mettler Toledo has new software that allows weighing terminal users to integrate weighing transaction data into PC databases.

Called WeighSync DC, the software can be configured for industrial process requiring easy data management. It allows users to collect data to create reports and meet compliance tracking and tracing requirements.

WeighSync DC is compatible with Windows 7 or 8 and collects weighingtransaction data from multiple terminals in a Microsoft SQL Express database. Weighing transactions are automatically updated to the WeighSync database. Pre-defined templates within WeighSync enable quick connection to a broad variety of the company’s industrial weighing terminals.

The product will also define custom data structures, which allows users to create custom templates for connection to a broad variety of other devices that may be attached to the PC running WeighSync.

In addition to providing real-time transaction data, Mettler Toledo terminals that store data in tables can be used for scheduled data transfer using a calendar function within WeighSync. Collected data can be utilized to create reports in MS Excel or other programs or for tracking and tracing purposes.

The WeighSync network can use a serial connection to communicate with older generations of terminals, but it is designed for Ethernet-enabled products.

www.mt.com/IND-WeighSync

small and consistent bidirectional adjustments and track an oven band to within +/- 1/8 of an inch.

To help ensure optimal performance, ActiveTrack is equipped with an integrated alarm system and utilizes external heavy-duty bearings and rollers with an adjustable centre roll. The system consists of three rollers on the return path and two rollers for the load path of the oven.

www.ashworth.com

Like you, successful bakers know the secret to a profitable bakery starts and ends with high quality, great tasting products. For over 80 years, the American Almond® Products Company has provided successful bakers everywhere with premium quality nut pastes, nut butters, nut flours and a wide range of unique, customer-pleasing ingredients. Let American Almond® help you turn that quality into profits for your bakery.

Call your distributor today or dial 800.8ALMOND for a distributor near you. Visit www.americanalmond.com for more information and profit building recipes.

Nutmeats and Nut Flours Crunch

THE PERFECT BAGUETTE

CONTINUED FROM PAGE 12

for me, to have a nice development of the baguette, three to five cuts are good.”

Leir explains that proper scoring adds a depth of flavour, making the baguette crunchy and delicious: “It’s a technique with a curved razor that runs parallel under the surface of the baguette. It’s shallow and there are usually five cuts and each slash should overlap the other one by a third.”

With the lengthy process nearing completion, the baguette is ready for baking. Depending on the oven, baking temperatures range from 240 to 260 degrees Celsius for approximately 20 minutes. During the first five minutes of cooking time, the bread must be steamed in order to get a delightfully crunchy crust.

“For the first five minutes of cooking we put humidity inside to allow the baguette to expand,” says Joyal. “The humidity wets the dough to make the baguette expand and then the water with the dough will make the caramel colour. Then we open the door of the oven to let the humidity out and make it dry so the crust will finish.”

FEELING YOUR WAY

For many bakers, the process of creating baguettes has as much to do with “feeling” as with following a series of steps. Each day may call for a slight alteration to the process. For Joyal, even emotions can have an effect on the final product.

“It’s a question of feeling: feeling the dough, feeling the

temperature, how you are feeling when you’re making it. When we’re baking, the end product is an extension of our mind,” he explains.

Even for an experienced baker like Joyal, things can sometimes go awry. “It’s a surprise every day when we make bread. It’s not because we don’t know what we’re doing. It’s because a baker needs to be on his toes every day. When we open the fridge to pull out the dough, it’s a surprise. When we put the bread in the oven, it’s still a surprise. After 18 years, it’s still a surprise. I don’t know any baker who says, ‘My bread will be perfect when I cook it.’ We have to be on our toes.”

Feasson agrees that baguettes can sometimes have a mind of their own. “You’re going to make a lot of bad baguettes before you make good ones,” he says. “Even us now, we have days where things go wrong and you have to go back and figure out what happened. The problem with the baguette is that you don’t know until it’s baked. If I had one word it would be ‘time,’” says Feasson.

Perhaps that’s the allure of the baguette. The crunchy, crumbly crust and cream-coloured centre rife with airy hollows can sometimes elude even the most skilled baker. It’s a daily challenge that, when done right, can have the most scrumptious results. / BJ

Julie Fitz-Gerald is a freelance writer based in Uxbridge, Ont., and a regular contributor to Bakers Journal.

toronto_bakery_jan14.indd

& New Machinery

L4K 2K1 E-mail: sales@torontobakery.com

Manufacturers of: Depositors, Transfer Pumps, Metal Detector Conveyors, Conveying Systems, Custom Built Equipment, Baking and Proofing Racks and Used Equipment.

and Service 381 Bradwick Drive, Unit #1

905-660-4040 Concord, Ontario L4K 2P4

E-mail: info@megartsystems.com

Website: www.megartsystems.com

905-660-1930

ALBION

BAKERY SUPPLIES

(DIVISION OF A & L FOOD DISTRIBUTORS INC.)

SUPPLIER OF FROZEN AND RAW INGREDIENTS

FOR THE BAKING INDUSTRY

Tel: (416) 252-4660 Fax: (416) 252-9993

25 - 8 Connell Ct., Toronto, ON M8Z 1E8

• BAG CLOSURES & LABELS

• BAG CLOSING EQUIPMENT • KWIK LOK TAGS

PIERRE GENDRON

Regional Sales Manager

254 Rue De Thebes, Laval, QC H7M 5P2

1-888-KWIK LOK (594) 5565

Cell: (514) 710-9364 • E-mail: pierreg@kwiklok.com

176 SHELDON DRIVE, CAMBRIDGE, ONTARIO N1R 7K1

TELEPHONE: (519) 623-5140 FAX: (519) 623-1421

1-888 KWIK LOK (594-5565)

Dutchess Bakers Machinery Co.

Model JN Semi-Auto Divider/Rounder

4-in-1 machine capability, 36, 18, 9 & 6-part heads

Heads can be removed or interchanged without tools in seconds

NSF & UL certified, Made in America

2-Year parts & labor warranty.

Heads can be washed in a sink or dishwasher.

High production rate - low maintenence

Easy to train and operate.

Model BMIH-36/18 Dough Divider

2-in-1 machine capability - 36 & 18-parts 1oz up to 8oz each piece scaling range.

Mounts to a Portable Stand for mobility (Optional)

Divide many types of dough including sticky pie and cookie dough in addition to bread and bun doughs. Contact our Canadian Representative @ eric@bloemhof.com

www.dutchessbakers.com - sales@dutchessbakers.com

-

-

-

Amy’s Bre A d: Artis A n-style B re

Amy’s Bread is a legendary New York institution that serves some 50,000 customers every month and supplies bread to more than 300 restaurants and stores daily. Long out of print, Amy’s Bread shares Amy Scherber’s recipes and techniques for everything from basic loaves to artisan breads. Now fully revised and updated, this full-colour edition includes more than fifty recipes for bakers at every level of experience.

Amy’s Bread starts with the basics like Big Beautiful White Pan Loaf and French Baguette before progressing to more complicated recipes like Whole Wheat Sandwich Bread with Oats and Pecans and Semolina Bread with Apricots and Sage. But there’s more here than just bread — recipes for pizzas, sandwiches, and sweet treats are also included.

EquipmEnt for SalE: 80 Quart Hobart Mixer with 3 sized bowls and 8 attachments: asking $5,500. Masterbuilt 17 pan glass door proofer/warmer on wheels: asking $900. Oliver Bun divider on cart: asking $700. Refrigerated right rotating round showcase on wheels: asking $800. All equipment in excellent condition. Dunnville, ON. please contact ross at 289-6844442.

BY JANE DUMMER, RD

SORGHUM: THE ‘NEW’ ANCIENT GRAIN

While sorghum is one of the world’s most familiar foods, it is largely unexplored in North America.

Is sorghum the next ancient grain to take on the baking industry? I’ve been writing about quinoa, amaranth, millet, chia and hemp, but I was unaware of sorghum’s potential until this past summer at IFT 2014 in New Orleans when I was invited to a superb education and culinary event called Sorghum 360.