• 8 - 12% more moisture than traditional methods

• Optimized hydration and oxidation

• Hydrate up to 100% of the flour with uniform moisture

Kaak is the only company that can offer all three state-of-the-art equipment systems to ensure big savings to your bottom line. Using our Rapidojet Premixer in conjunction with the Dough Master Divider and Daub Thermal Oil Oven, you save up to 10% on your flour usage and still get the same weight of finished product. Not only do you save big on flour costs, you can also save on mixing time by pre-hydrating the flour.

North America

351 Thornton Road, Suite 123, Lithia Springs, GA 30122 (800) 367-2504 www.kaakgroup.com

• Shorten mixing time

• Quick processing of sourdough and sponge

• Perfect for Autolyse flour moisturization

• Lowest possible energy consumption, no dough heating

• Quick change-over of recipes

• Designed to handle a wide range of dough products

• Independently driven high accuracy servo drives

• Control of all dividing processes allows the divider to optimize moisture loss

• 2 to 4 % more water retention

– Stress controlled dough divider ideally suited for a large range of dough consistencies

• Very sensitive dough with long resting time and 85% + water can be processed

• Very high accurate dividing

– Every dough piece can be accurately measured by means of a check weigher

• Retains up to 6% more water

• Moisture loss controlled by Daub’s climate separation system

• Precise temperature and moisture loss guaranteed

• Mild and even heat results

• Energy savings of up to 40%

• Very compact Multi Deck systems or traditional tunnel oven configuration

• Longer and better oven-rise

• From rack ovens to large industrial ovens

Healthier profits start here.

Puratos’ new low in Cholesterol cake lets you produce a great tasting product that can qualify for a CFIA Low in Cholesterol permissible claim. This breakthrough technology allows you to command a premium price for a “good-for-you” cake that does not compromise on taste.

Ask us about our entire line of healthier cakes and breads with nutritional benefits today.

Rosie

BY JANE AYER

“When you are through changing, you are through” — Bruce Barton “Change always comes bearing gifts” — Price Pritchett

Change can also, initially at least, be a little bit scary. I suspect most of us remember great moments of upheaval in our lives with a mix of emotions: exhilaration, fear, uncertainty, excitement. Perhaps that first step towards change for you was actually getting into the industry itself: maybe it was an entirely new career path. Pastry chef, bakery owner and TV personality Anna Olson was headed towards a career in banking when she listened to her heart and left the bank vault to go study the art and craft of pastry-making in the U.S. Imagine where she’d be now if she hadn’t taken a risk, left behind the security of the banking world and stepped out into the unknown.

Then there’s Marty Curtis of Marty’s World Famous Café in Ontario’s cottage country. Following in his grandfather’s footsteps, he was on the lookout for a storefront where he could set up an orthopedic shoe business, just like the one he’d worked in with his grandfather, when he stumbled on a building for sale in Bracebridge (about two hours north of Toronto). To help pay the bills, he considered renting out a portion of the store to another business. Speaking to a friend in the ice cream world, realizing what kind of money could be made there and seeing a fit with the cottage community of Bracebridge, Curtis switched business plans and opened up an ice cream shop, eventually expanding that business into a café for the winter months. Well, that café has been raved about the world over for its sweet Canadian classic, the buttertart, and Marty Curtis has just published his first cookbook, Marty’s World Famous Café (published by Whitecap, 2008), giving away the secret recipe for the tart, along with other treats, both sweet and savoury.

}Change can, initially at least, be a little bit scary. I suspect most of us remember great moments of upheaval in our lives with a mix of emotions: exhilaration, fear, uncertainty, excitement.

Perhaps the change for you was taking your business in a whole new direction. Bakery owner, Bakers Journal columnist and member of Team Canada Tracey Muzzolini grew up in Christie’s Mayfair Bakery, her parents’ bakery in Saskatoon, Sask. She couldn’t wait to take flight: to leave the Prairie city for bigger, brighter things. After a number of years of experiencing those bigger and brighter things in the restaurant industry in Toronto, a fellow chef helped inspire an interest in artisan breads. Eventually, she returned home, setting up a small oven in the front of her parents’ bakery to spark curiosity about the work she was doing. That was 10 years ago, and not only has the bakery been reinvigorated with a new clientele who are willing to pay more for the artisan products Muzzolini makes, she’s travelled the world, competing, demonstrating and teaching the craft she’s worked so hard at. She took a risk and it paid off.

Well, the times are a-changin’ here at Bakers Journal too. The first change? Me. I’ll be stepping away from the editor’s desk again this fall as I prepare for the arrival of a second child. The other change should have been fairly obvious to you when you opened your mailbox and picked up this issue. For months now, we’ve been working on a fairly big change: a Bakers Journal redesign. The culmination of months of meetings and musings and discussions about what the magazine means to the industry and what its purpose is, you hold in your hands a cleaner, crisper, more modern version of the magazine. Why the change? Because it was time, because the magazine has looked the same way for a while and we thought it was perhaps just a little tired. And because we believe in that first quote published up there and we never want to be through. It’s our gift to you. Hopefully it’ll help reinspire you; perhaps it’ll encourage you to make change in your business. Let us know what you think. / BJ

OCTOBER 2008 | VOL. 68, NO. 8

EDITOR | Jane Ayer editor@bakersjournal.com 1-888-599-2228 ext. 250

TECHNICAL

EDITOR | John McColl, Puratos Canada jmccoll@puratos.com

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexweb.com 1-888-599-2228 ext. 268

SALES ASSISTANT | Pauline Cecile pcecile@annexweb.com 1-888-599-2228 ext. 273

MAGAZINE REDESIGN | Janice Van Eck

VP/GROUP PUBLISHER | Diane Kleer dkleer@annexweb.com

PRESIDENT | Mike Fredericks mfredericks@annexweb.com

Mailing Address P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710. Return undeliverable Canadian address to: Circulation Department, P.O. Box 530, Simcoe, ON N3Y 4N5 e-mail: sbrady@annexweb.com

Periodicals postage paid at Buffalo, N.Y. (USPS 007-277). US Office of publication c/of DDM Direct.com, 1223 William St., Buffalo, NY 14240. US Postmaster send address changes to: P.O. Box 611, Niagara Falls, NY 14304.

ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Publishing & Printing Inc.

SUBSCRIPTION RATES Canada — 1 Year $ 31.80

(includes GST – #867172652RT0001) USA — 1 Year $ 40.00 Foreign — 1 Year $ 60.00

Send your subscription request to: Bakers Journal

P.O. Box 530, Simcoe, ON N3Y 4N5 Tel: 1-866-790-6070 ext. 206

Fax: 1-877-624-1940

E-mail: sbrady@annexweb.com

From time to time, Bakers Journal may make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2008 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

We say actions speak louder than words. Independent consumer research reveals that 74% of consumers would try a new granola or cereal bar if it contained sweetened dried cranberries.

Consumers have ranked sweetened dried cranberries higher than any other dried fruit in terms of health, color, sophisticated image, unique flavor and low calorie content.

Don’t just take their word for it. Be the first to the

briefly | No slowdown to food inflation; a lemon juice shortage; study shows a switch to a VAT good for Ontario; McCormick Canada at 125 | for more news in the baking world, check out our website, www.bakersjournal.com

TORONTO – Buying food in bulk, purchasing only necessities and turning to food banks are some of the ways Canadians are trying to cope with rising food costs, and many people say baked goods are becoming too expensive.

The price of bread has increased by 87 per cent in the past decade, going from an average of $1.30 in 1998 to $2.43 per loaf, according to a recent study by the Ontario Association of Food Banks.

And, in late August, Statistics Canada reported that food prices jumped by 4.3 per cent in July, led by a 13.2-per-cent hike in the bakery section, as the overall inflation rate rose to 3.4 per cent – its highest level in more than five years.

Rising world prices for grain were the main influence in the rise in prices for bread and other baked goods, Statistics Canada said. The agency also said about 17 per cent of the average family budget currently goes to food. It also reported

that prices of staples such as bread and pasta soared 44 per cent and 36 per cent respectively over the past year.

But food inflation is here to stay, says Douglas Porter, an economist with BMO Capital Markets. “Some of that strength (in grain prices) earlier this year was for real.”

Adam Spence, the Ontario food bank association’s executive director, says the skyrocketing cost of energy is having a profound impact on food budgets.

He said the number of people being forced to turn to food banks to feed themselves and their families is up sharply, with about 89 per cent of food banks across Ontario reporting an increase in the number of people requiring support since the beginning of 2008.

—The Canadian Press

Bakers and canners have been staking out grocery stores these past few weeks in pursuit of an unlikely hot-ticket item – bottled lemon juice. Across much of Canada, the most popular brand of juice concentrate, ReaLemon by Canada Dry Mott’s, has been out of stock since the beginning of summer. Drought and vicious sirocco winds in southern Europe and severe frost in Argentina, California and Arizona peeled back the world’s lemon supply.

Compared to last year, the fruit’s cost has more than doubled.

“A year ago, a case of lemons cost $18,” says Richard Chase, owner of Chasers Fresh Juices in Toronto. “(Now) we’re paying $40 a case.”

—The Canadian Press

TORONTO – Ontario should scrap its outdated retail sales tax (RST) and opt for a made-in-Ontario valued-added tax (VAT) to improve fairness, encourage investment and reduce government and business costs, says a report written by a team of academics and experts for the C.D. Howe Institute.

The report is a based on a study called Growth-Oriented Sales Tax Reform for Ontario: Replacing the Retail Sales Tax with a 7.5 Percent Value-Added Tax, which notes that Ontario is one of five hold-out provinces with outdated RSTs. The authors examine the best road forward for Ontario and make the case for a made-in-Ontario value-added tax (VAT) that would reduce distortions caused by the existing sales tax, encourage investment, improve fairness, and help to reduce compliance and administrative costs associated with tax collection. Their research suggests a 7.5-per-cent Ontario VAT would substantially eliminate the sales tax burden on capital goods and exports, resulting in an increase in real personal income and labour productivity over the medium term. For full report: www.cdhowe.org/index.cfm

LONDON, Ont. – McCormick Canada celebrates its 125th anniversary this year with a plant expansion and new brand acquisitions.

Well known McCormick brands in Canada include Club House; McCormick Gourmet; Thai Kitchen; Simply Asia; Zatarain’s; Fish Crisp; Old Bay; Hy’s; and French’s dry sauce mixes and gravy. Billy Bee and Doyon Honey brands were acquired in February. In August, McCormick acquired another iconic product, Lawry’s Seasoning Salt, previously owned by Unilever.

“McCormick prides itself on a culture that supports its people and delivers business growth through innovation,” says McCormick Canada president and CEO Angie Francolini.

Few other Canadian companies have celebrated the 125th milestone. McCormick joins an elite club that includes Grand & Toy, BCE, Tiger Brand Knitting and E.D. Smith.

McCormick Canada began in London in Canada’s 16th year, 1883, as Forest City

Spice Mills. Its first food products included coffee, baking powder, extracts and spices, with olives added to the line in 1890. By 1905, the company was the largest olive packer in the British Empire, and by the 1930s, the coffee was the official brew of the governor general’s residence at Rideau Hall. The Club House brand was introduced in 1928 as a brand of peanut butter, and within three years was the market leader in that category.

Today, McCormick has become the largest spice, dry sauce, seasonings, extracts and specialty foods operation in the country, employing more than 600 Canadians and enjoying annual sales of more than $250 million.

According to Nielsen’s Top 100 Brands ranking in 2008, McCormick Canada’s largest brand, Club House, is ranked 76th in sales nationally across all categories in Canada. And McCormick continues to grow, with a new 210,000-square-foot warehousing facility slated to open in April 2009 in London.

—McCormick Canada

From healthy breads and granola bars to precision scales and heated merchandisers, Bakers Journal keeps you “in the know.” for more on new products for the baking industry, check out our website, www.bakersjournal.com

Artisan Granola from ACE

With schools back in session, ACE Bakery is promoting its new Artisan Granola as a great way to get the kids and the rest of the family off to the right start. The well-known Canadian brand says Artisan Granola is a healthy suggestion for breakfast or an energy-boosting snack in the kids’ lunchbox. Children and teenagers enjoy thousands of breakfasts and snacks between kindergarten and Grade 12, and healthy eating fuels brain development and learning at all ages. Parents and nutritionists will approve of Artisan Granola’s wholesome, all-natural ingredients such as thick rolled oats, whole almonds, dried cranberries, almonds, raisins, sunflower seeds, pumpkin seeds, flax, maple syrup and honey, while kids, teenagers and adults will love its naturally sweetened, crunchy flavour.

Valor 5000 scale

New Jersey-based Ohaus Corp. has released the Valor 5000 Compact Precision Scale Series as the latest entry in its line of weight measurement products. The Valor 5000 Series of digital portable scales has features that Ohaus believes will be an essential to many food service applications.

The Valor 5000 is a rugged, multi-use scale suitable for a variety of preparation and service applications. It is ideally suited for food portioning and check weighing, with its spill-resistant design, flexible corded and battery powering, and speedy operation. These features make the scale a strong performer in settings such as restaurants, bakeries and food manufacturing facilities.

After 20 years in business, Prefamac has noticed that often there is either a manual moulding machine with enrober belt or an industrial enrobing machine. The semi-industrial chocolatier, with a bigger budget, fell in between – until now.

Prefamac’s new Continua machine allows you to work almost continuously. Its tempering time is less than 10 minutes. The machine is single phased to ensure its usability in smaller companies. Moreover, it is quiet and very user-friendly, thanks to a straightforward PLC screen.

ACE Bakery Artisan Granola comes in boxed packages of 375 grams, priced at $6.99 each.

Hardt

The Valor 5000 is easy to clean and features an ABS plastic housing with stainless steel pan construction; easy-tosee, bright, backlit five-digit LCD display; multiple weighing units and modes; remote tare-foot switch connection; integrated level bubble and adjustable feet. For more information, contact Ohaus Corporation at 973-377-9000 or see www.ohaus.com.

MONTREAL – Hardt is introducing the Smart Zone as the newest addition to its heated merchandiser line at the NACS show in Chicago from Oct. 5 to 7.

The company says the Smart Zone combines visual esthetics and innovative engineering, with a unique curved modern design and angled shelves to grab customers’ attention and give products better exposure and visibility. The compact Smart Zone is ideal for convenience stores as it optimizes store operations by taking up minimal counter space while at the same time achieving maximum profits.

Hardt says Smart Zone uses patented heating technology to keep food constantly at a safe serving temperature; the product’s innovative design allows protein foods such as breakfast sandwiches, burgers, pizza and hot entrees to be merchandised at a safe temperature for convenient “grab and go.”

The Smart Zone is available for customization in an array of size and colour variations and is backed by Hardt’s unparalleled customer service and support. For additional information on the Smart Zone, contact Elif Ozdemir 1-888-848-4408 ext. 276 or see www.hardtequipment.com.

Also, if you are already a Prefamac customer, the Continua does not require additional investments as you can use your own 18cm enrober belt with paper take-off extension or with truffle extension and table. For more information, contact Eva Kenis at eva@prefamac.com.

Canadian company George Weston Bakeries Inc., in conjunction with Cognis Nutrition & Health, a leading supplier of natural phytosterols, is launching new breads containing Heart Choice natural plant sterols scientifically proven to lower cholesterol and reduce the risks associated with heart disease. The breads are making their debut nationwide this month under the popular Arnold and Brownberry brands.

Weston says its new Grains & More Double Oat Hearty Oatmeal Bread was formulated to promote heart health, and contains 0.4 grams of Cognis’ Heart Choice plant sterols. The company’s pitch to consumers says that when combined with a healthy diet and exercise, Double Oat Bread may help lower cholesterol by 15 per cent. Cognis’ Heart Choice logo is prominently displayed on the front package so consumers will know that their bread contains a superior source of heart healthy plant sterols.

For more information about Cognis’ heart health ingredients, visit www.cognis.com or call 1-800-673-3702.

In an industry where consumer tastes are constantly changing, it seems almost inappropriate that most retail displays are so static. They say that, on average, retailers revamp their design concepts every five to seven years. What about those four to six years in between? Wouldn’t it be great to be able to “mix it up” a little and be able to accommodate new products and meet the everchanging needs of your customers? It turns out you can and it’s easier than you think. Below are a few simple tips for building flexibility into your fixtures.

A simple trick for adding flexibility is to make your display mobile. Attaching casters to the bottoms of fixtures opens up the sales floor for interpretation. Whether you want to move sale items to the front, find out that you can increase the sales of one item if it’s placed near another, need more room, or whatever the case may be, displays on casters can be easily wheeled around to create a whole new layout.

If you decide to go the caster route, it’s important to select the right hardware for the job. Take into account your display’s weight as well as what type of flooring your caster will need to roll over. And don’t worry, adding mobility doesn’t mean you have to sacrifice beauty. I’ve seen retailers leave them exposed for a fun, industrial look, but if that’s not the look you’re going for, fixture manufacturers have many tricks up their sleeves for hiding them away.

Modular design is far from a new concept. It’s quite popular with multiunit retailers who have used it to help

their concept fit into different-sized locations for years. At the store level, modular displays continue to afford retailers a great deal of flexibility. Instead of designing your display as one large piece, consider breaking it into smaller units that somehow fit together. No longer limited to just one configuration, retailers are able to reassemble the pieces as needed. Nesting table-type displays are a great example of this. Adjustable shelving is another.

My first two tips have a common theme – mobility – but displays don’t always need to be mobile to be flexible. In fact, my last offering requires no display movement at all and still packs a noticeable punch.

Often, fixtures are designed sans graphics. Considering how powerful graphics can be in attracting attention and communicating information, it’s well worth your while to consider adding some to your design. There are a ton of clever yet stylish frames and holders that not only make it easy to find one that matches your display, but also make it simple to swap out graphics. Now if you have new merchandise you want to promote or just want to make your existing products noticeable again, no problem. You now have an easy and relatively inexpensive way to make it happen.

Just because most retail displays are static and unchanging doesn’t mean yours have to be. Make them mobile, modular and graphic, and be ready for when merchandise and consumer tastes change. Of course, these are only a few of the endless possibilities out there. All it takes is a little flexibility in thinking to come up with some really flexible displays. / BJ

Tim Matey is a retail consultant for F.C. Dadson, Inc., a nationwide fixture management company. The company offers space/floor planning and conceptual design, graphics, POP displays, trade show exhibits, turn-key fixture design and manufacturing along with nationwide installation. You can reach their national sales consultants at 1-800-728-0338 or visit them on the web at www.fcdadson.com.

Pizzey’s Whole-Milled BevGradTM and SelectGradTM flaxseed is an excellent source of Omega-3 fatty acid (22%). Also a good source of dietary fiber and protein, Pizzey's flaxseed does not require refrigeration and is gluten free.

Email: sales@pizzeys.com www.pizzeys.com

BY MICHELLE BRISEBOIS

Navigating the weight loss issue as a bakery can be daunting. Here’s how to sort through the spin and determine what kinds of healthy (waistline-friendly!) options to put into your product lineup

Think back to Grade 5 or 6. Do you remember that awkward, overweight kid in your class? Maybe he or she was bullied but chances are they stuck out like a sore thumb amongst a sea of sprightly kids. Flash forward to today’s school yard and that one overweight kid out of a class of 30 has become about seven or eight portly children. The seventh report of the Standing Committee on Health, Healthy Weights for Healthy Kids 2007, reports that the number of overweight Canadian children has risen from 12 per cent to 18 per cent, and obese children, from three per cent to eight per cent, between 1978 and 2004. That means about one in four Canadian children are overweight or obese. As our society grapples with the notion that 12-year-olds may start developing diabetes and heart disease because of their weight problem, it becomes easy to point the finger towards the food industry. It’s the fault of fast food! It’s because there’s junk in vending machines. Maybe it’s because kids eat too many sweets? Navigating the weight loss issue as a bakery can be daunting. After all, we’re part of the problem right? Not so fast. While the baking industry may be suffering from a wee bit of guilt by association right now, the reasons behind the childhood obesity issue and our options for repositioning ourselves may surprise you.

you can’t necessarily make him drink it if he really wants pop. Many schools are reporting that if kids can’t get their junk food fix on school premises then they simply find sweeter pastures off of school grounds. But schools can do only so much and families have been slow to take responsibility for their own eating habits. “I’m big boned” or “the devil made me do it” are excuses that only go so far. Experts are beginning to realize that the focus needs to begin at home. The most startling statistic to support this argument was unearthed by a 2007 Consumer Reports poll showing that 50 per cent of parents who have overweight or obese children don’t realize their children weigh too much. Many parents are in denial about their children’s weight because they don’t want to have to change their own eating and exercise habits, says Keith Ayoob, a registered dietitian who works with overweight

}Schools can only do so much and families have been slow to take responsibility for their own eating habits. “I’m big boned” or “the devil made me do it” only goes so far.

Since we noticed that generation X was morphing into generation XXL about 10 years ago, it’s been a bit of a witch hunt. Vending machines have been pulled from schools, gym class programs have been re-evaluated and restaurant chains are scrambling to introduce healthy options. The cruel reality remains that while you can lead a horse to water,

children and their families in New York City. A Canadian Medical Association survey found only nine per cent of parents report they have a child who is at least somewhat overweight. If 25 per cent of children are struggling with their weight and only nine per cent of parents feel they have a child who is overweight – the numbers don’t seem to add up. Apparently, if we accept our kids are overweight, it means we have to deal with our own weight issues as well. Denial works both ways. We can ban candy in vending machines, limit advertising of sugary treats to kids and even introduce more physical education in schools, but if parents aren’t ready to come to the proverbial tea party on this topic, how can one bakery tackle this issue in a meaningful way?

Look for many small wins to address the obesity issue. Consider implementing a reward program for customers who bike or walk to your bakery. Why not sponsor a little league team? It’ll be great advertising for your bakery and it will demonstrate your commitment to youth

and their well-being. Create smaller portions of your top-selling bakery items. Mini cupcakes or muffins will provide a great treat with a manageable calorie count. Could your product lineup include more savoury items? Pizza buns, cheese biscuits, and cheddar muffins may offer parents an easy lunch item to pack in place of high-fat processed meats. Reinforce your whole-wheat products along with their health benefits. And don’t forget the humble Angel Food Cake. It can be served many wonderful ways and is fairly low in fat and calories. Why not create a few recipes for customers to take along with the cake to show them how to make it versatile?

As the big food companies bow to public pressure, they’ll shift their product offerings and messaging to healthier options. This will hopefully help families sort through the quagmire of fattening foods – allowing them to get a handle on their handles. The tide is turning and if we continue to stay true to our mandate to give customers fresh, high-quality products, bakeries can continue be a great source for foods that are good for us – body and soul. / BJ

Michelle Brisebois is a marketing professional with experience in the food, pharmaceutical and financial services industries. She specializes in helping companies grow their brands. Michelle can be reached at On Trend Strategies by e-mail at briseboismichelle@sympatico.ca.

BY JOHN MICHAELIDES

What is molecular gastronomy, how is it used by modern chefs and how can it be applied to the baking industry?

The science behind the ordinary practice of cooking, preparing and serving food is generating a great deal of interest lately. Chefs are using this knowledge of basic science to prepare and present new, more exciting dishes in upscale restaurants. This mix of science and cooking is coined “molecular gastronomy” by physical chemist Harve This (pronounced “Tees”) and his colleague, Oxford physicist Nicholas Kurti, in the late 1980s after investigating the scientific approach to many old wives’ tales and various tricks of modern chefs. Their investigations help in proving the scientific basis behind these instructions, which they called “cooking precisions.”

}This, in his PhD dissertation at the University of Paris, presented the five goals of molecular gastronomy as follows: 1) to collect and investigate old wives’ tales about cooking; 2) to model and scrutinize existing recipes; 3) to introduce new tools, products and methods to cooking; 4) to invent new dishes using knowledge from the previous three goals; and 5) to use the appeal of food to promote science.

located in Pollenzo and Colorno in Italy and provides graduate and undergraduate courses in related fields. Their graduates are called “gastronomes.”

It is evident that the precise discipline of science is now merging with the art of cooking and food presentation. The result is the ability to create new and more exciting ways to enjoy food.

The truth is that the discipline of food science has always been involved in these investigations and a lot of what is now applied in the field of molecular gastronomy is well known to the scientist but not understood or put in practice by chefs to create new, exciting presentations or enable them to do more with ordinary or new ingredients.

There is a differentiation between gastronomy and cooking: Cooking means preparing a dish while gastronomy involves all aspects of food as it relates to human nourishment and enjoyment of food.

Molecular gastronomy explains interactions of food ingredients and their behaviour in the complex materials

Maltodextrin … is used to disperse and stabilize high-fat ingredients. It also found its way into chefs’ molecular kitchens as a tool to change oils into powders.

Graduates of the University of Gastronomic Sciences in Italy are called “gastronomes.”

Since the first attempts to shed scientific light into these practices seemed to work, many modern chefs –such as Ferran Adria of El Bulli restaurant in Catalonia, Spain; Grant Achatz of Alinea restaurant in Chicago; and Hest Blumenthal of Fat Duck restaurant in Bray Berkshire, England – are using them in their famous kitchens. Some of the major food manufacturing companies have corporate chefs on staff who are knowledgeable in the field of molecular gastronomy and use this knowledge to market and promote their food products. A university dedicated to gastronomy, the University of Gastronomic Sciences, is

of food matrices. These explanations in turn can help to enhance food preparations to the extent that performance and taste will be substantially improved. The relationship of the gastronomy with the chemistry of ingredients is often well recognized and some of the processes applied are given the names of famous chemists. This, in a European Molecular Biology Organization report published in 2006, gives a few of these examples. Immersing a whole egg in alcohol can achieve coagulation and result in a solid egg without cooking it. The alcohol will infuse through the shell and will coagulate the proteins. This process will take a while (about a month) but the egg will look as though it has been boiled. A coagulated egg prepared without the use of heat is known as a Baume egg after the French chemist Antoine Baume (1728-1804).

Modern molecular gastronomy techniques include spherification, in

which round pearls (spheres) are created by dropping a mix of sodium alginate and flavours into a calcium chloride solution. When the droplets of the mix come into contact with the calcium ions they gel from the outside in, creating the pearls. The longer they remain in contact with the calcium chloride solution the more solid with less liquid centres become. Maltodextrin is a byproduct of starch hydrolysis and is used in the food processing industry to disperse and stabilize high-fat ingredients. It also found its way into chefs’ molecular kitchens as a tool to change oils into powders. For example, highly flavoured oils are blended with tapioca maltodextrin, transforming the liquid oil into powder. This powder oil blends better with water and coats the mouth, releasing the powerful flavours. Some chefs have used the maltodextrin to change peanut butter into a granular form to enhance flavour release. Methylcellulose gum is another tool for this new breed of chefs. This gum has thermo-reversible gelling properties. It transforms into gel as it is heated and when cools reverts back to liquid. This “upside-down” ingredient has found an application in the preparation of hot ice cream which is firm in higher temperatures. Other techniques include the preparation of stable warm gelatin by using seaweed powder (agar).

The use of different gases is also finding its way into the molecular kitchen. For example, certain foams are made from sauces stabilized with nitrous oxide. Liquid nitrogen at temperatures of below –300 F is used for instant freezing of ice

cream, sauces and other foods to create different effects.

Enzymes are great tools in the food processing industry. In the baking industry they have been instrumental in improving the flour performance and the quality of baked goods for years. New enzymes are also finding their way into the molecular kitchen. For example, transglutaminase binds different proteins together and is used in gluing together different meats to create new dishes. One popular application is the cold gluing of bacon to the surface of another meat. Transglutaminase is also a new enzyme for the baking industry and is very useful in strengthening gluten as well having a great potential in the production of gluten-free baked goods.

Molecular gastronomy is not restricted to ingredients but new or modified equipment is being used to create new dishes. Some of these are described in the June issue of Food Technology Magazine. The most interesting one that would have a possible application in sweet baked goods is the “anti-griddle”. This is a normal griddle that is fitted with refrigerant circulating equipment to create instant surface freezing down to –30o F. Such equipment allows the development of dishes that have solid frozen crust and smooth interior.

Chefs are also adopting processes such as Sous Vide to create new and flavourful dishes. Sous Vide is a method of cooking vacuum-packed food in a water bath at lower temperature for a longer period of time. This method allows the retention of juices and flavours while the lower temperature does not change certain properties of the food and its flavour.

}Transglutaminase is also a new enzyme for the baking industry and is very useful in strengthening gluten as well having a great potential in the production of gluten-free baked goods.

Modern chefs are becoming more educated about the chemical and physical properties of the ingredients they use. The techniques, new ingredients (new to the kitchen) and new equipment allow them to be more creative in developing new dishes with enhanced flavours and textures.

One of the major concerns with these new techniques of food preparation has to be the issue of food safety. There is a delicate balance between applying lower temperature in the preparation of food and the danger of food poisoning. It is therefore important to consider this aspect when we begin to explore molecular gastronomy.

In the baking industry there are currently not a lot of applications but as the field of molecular gastronomy is growing it will gradually edge into this sector as well. / BJ

Funding for this report was provided in part by Agriculture and Agri-Food Canada through the Agricultural Adaptation Council’s CanAdvance Program.

For more information, or fee-for-service help with product or process development needs, please contact the Guelph Food Technology Centre at 519-821-1246, by fax at 519-836-1281 or by e-mail at gftc@gftc.ca.

Dr. John Michaelides is director of research and technology at the Guelph Food Technology Centre, www.gftc.ca.

Vancouver’s Butter Baked Goods meets the daily challenges with a smile | BY TUIJA SEIPELL

So many things have come together perfectly for Butter Baked Goods in Vancouver that it is tempting to presume that the little store’s first year has been an easy ride. What could be more fun than opening a cute bakery in the friendly residential Dunbar neighbourhood of Vancouver and baking yummy homemade treats for happy customers?

According to owner Rosie Daykin, many starry-eyed customers have indeed expressed a desire to open their own Butter in their hometown or neighbourhood, having been seduced by their shopping experience. “I let them keep their romantic illusion, but it’s hard work to make it happen,” she says.

Everything at Butter works together and creates the specific Butter charm. In that charming picture, you could imagine entering an old, weathered wooden summer house on the beach, the kind where generations have summered in carefree, casual affluence. Wind, sun and time have caressed every surface with a soothing patina, and the rosy wallpaper and white doilies were selected by the same fictional grandma who, wearing a starched white apron, has just taken a blueberry pie out of the oven.

}Customers have their own individual ideas of what Butter makes them imagine or remember, but most will find themselves thinking of grandma’s kitchen, real or imagined.

Customers have their own individual ideas of what Butter makes them imagine or remember, but most will find themselves thinking of grandma’s kitchen, real or imagined. The sensory harmony at Butter is no accident. Daykin is an interior designer and former owner of an interior design store. Butter’s decor – approachable, nostalgic, unpretentious – is a well-thought-out concept, yet the store does not feel like a “concept” store. It feels as comfortable, “organic” and ever-changing as an old house.

The main colour is a pistachio green and the accent wallpaper is a mix of that green and old-pink roses. The scent of the latest treat out of the oven – perhaps scones or cookies or cakes – wafts from

the back room, and cookies and other treats are displayed on various old-style trays and stands. All aspects of the brand – from the store decor and logo to the packaging, website and business cards –have a hand-made, time-tested charm that exudes quality and care.

The good karma of the neighbourhood and the location might not have hurt either. The 1,000-square-foot space, of which the storefront occupies less than half, has been a bakery for 85 years. Daykin bought the business from its last owner who had owned it for 57 years.

“People know this space as a bakery,” says Daykin, “and they have been so

welcoming and happy to see us here.”

Daykin is elated by the success of the store, and clearly enjoys what she is doing, but she also knows that the quality of the product is what brings customers back and sustains success, not cute surroundings or even good service. Daykin is not a trained baker but she grew up baking and learned from her mother. “This is a dream come true,” she confesses. “I always wanted to open a bakery.”

Daykin has a support team that is also part of the charm of the business. Her mother, Pixie Porcellato, handles the front of the store, while brother Ray Porcellato bakes cookies and other treats and does the heavy lifting. Both are part owners and, like Daykin, work in the store five days a week. The total number of full-time staff is eight.

Ray Porcellato had previously worked for their father’s lumber business, but when Daykin was opening Butter, the

lumber business was slowing down. “Dad suggested I come here to help Rosie and Mom, and I never went back,” he says. He also exudes the customer-friendly attitude that has endeared the shop to the neighbourhood. “One of the nice things about serving customers and being around here is that somewhere else, people could buy a lot of things off you like coffee, or even a house, and still be in a bad mood, but when people walk in here, they are pretty jovial, or become so before they leave,”’ he says. “And the demographic is really cool, too, in that sense that there is no demographic. Kids in a stroller and grandmas with walkers, their eyes get big and they have smiles on their faces.”

}home: from scratch in small batches with the best ingredients. Daykin started with items she had always made herself from recipes she and her mother had used –bars and cookies, muffins, pies, cupcakes and cakes. She now offers close to 50 different products, but not all at once.

[Daykin] now offers close to 50 different products, but not all at once. Certain items are baked on specific days … and seasonal items are part of the rotating inventory.

Certain items are baked on specific days of the week only, and seasonal items, such as hot-cross buns, are part of the rotating inventory.

ones are also now sold in small, transparent bags in the store, and now also in other stores across Canada. The foray into wholesale started shortly after the store opened when Daykin was approached by Whole Foods, which now carries several Butter products. Other wholesale clients include IGA, Gourmet Warehouse and specialty grocery stores, such as Urban Fare and Stong’s in Vancouver and Pusateri’s in Toronto.

At the time of the interview, Daykin was negotiating a lease of additional space into which to move the expanding marshmallow production. Wholesaling in the U.S. is also in the plans and, in the longer term, possibly opening additional stores.

The all-important product quality comes from family tradition as well. Everything is made just the way it was made at

What has turned out to be a true best-seller is marshmallows. Not the tiny squishy pillows you buy in large plastic bags but large cubes of sheer taste with no additives, no preservatives, no food colouring, no fat, no wheat, and no dairy – just delicious fluffy treats sold individually in the store. Somewhat smaller

Looking back at the business’s first year, Daykin is happy. “I’m pretty impressed myself, actually,” she says with a content but exhausted smile. And what, if anything, has been particularly challenging in the first year? “Let’s not kid ourselves,” says Daykin. “It’s all difficult. Some might look at this and think that it appears to have been easy for us, but it is not. It is an enormous amount of work but we are always trying to do it with a smile. And as happy as I am and as fortunate as I think we are, at the same time, no one has handed it to us. We work really hard to do this.” / BJ

For more about Butter Baked Goods, go to www.butterbakedgoods.com.

Packaging, ingredients, emissions and just about every other item that is emitted into the environment or consumed is coming under increasing scrutiny by politicians and regulators across the country. It doesn’t matter if it’s your local city council or federal government of cials, environmental initiatives are becoming more prevalent, resulting in further reporting requirements for industry or in some cases dramatic changes in business practices. Let’s take a look at some of the more recent examples.

There have been numerous initiatives across the country designed to reduce the amount of packaging materials directed to land ll, the most notable are recycling programs either done at the curb side or return to depot. To fund these programs, provinces such as Ontario and Quebec have imposed mandatory packaging levies that generate tens of millions to help fund everything from the actual collection of the materials to promotion and new market development. As a result, industry is paying a signi cant share of the cost to recycle materials rather than have them end up in land ll.

In addition to these mandatory packaging levies, (some have referred to them as a tax) other initiatives are also being actively considering and implemented. One of the most recent high pro le efforts are the bans of bottled water at municipalities across Canada and the US. Cities such as London, St. Catherines, and St John’s have implemented bans on the sale of bottled water in municipal facilities under the premise that the plastic bottles are signi cant contributors to local land ll. Other municipalities such as Toronto, Windsor, Vancouver, Winnipeg and Ottawa have, or are considering, similar bans.

Bans on plastic grocery bags have been or are under active consideration by cities across Canada. The rationale is that these bags end up in land ll.

The City of Toronto is targeting reduction of all forms of packaging including clam shells used

extensively by bakers and even the possibility of bread bags. The Toronto initiative will be considering additional taxation; bans or other means of encouragement to have industry reduce packaging.

In the area of items related to food, the Canadian Environmental Protection Act (CEPA) requires Environment Canada and Health Canada to categorize approximately 23,000 substances for the purpose of identifying those that pose the greatest potential for human exposure or are persistent or bioaccumulative and inherently toxic to humans or non-human organisms. Of this list some 180 substances related to food either as ingredients or packaging (including acrylamide) have been identi ed and require further research to determine rates of exposure, as well as potential environmental and health restrictions.

Lastly, emissions substance use in the workplace are also coming under further scrutiny. The Federal government has its Clean Air Act. Provincially BAC has been consulting with Ontario for a number of years on the matter of ethanol emissions from bakeries. The province has also recently released a new initiative “Creating Ontario’s Toxics Reduction Strategy” with the objective of reducing emissions and release of other substances by requiring materials accounting (for tracking substances), reduction plans, reporting and public disclosure.

In addition the City of Toronto will shortly introduce a by-law requiring similar accounting and public reporting by companies of a list of 25 substances emitted into the environment, including ethanol from bakeries. Where one municipality has gone will others be soon to follow?

Bakers regardless of whether they are retailers, in-store or commercial operators should understand and be prepared for more focus on environmental related issues from all levels of government.

By Laura Pasut, M.Sc., RD and Phillip Lee Wing, Ph.D.

Product enhancement is achieved in two ways:

Either route to making a product healthier is being driven by consumer trends. Key issues for the consumer include:

Program funded by members of the Baking Association of Canada, The Canadian Wheat Board and the Canadian Pasta Manufacturers Association

Part 1 of this information sheet will focus on removing ingredients from your product with particular attention to why, how and the unique challenges resulting from the removal of:

of this information sheet will focus on adding ingredients to your bakery product with particular attention to why, how and the unique challenges resulting from the addition of:

Part 3 addresses labelling opportunities and marketing challenges when you enhance a product.

removing ingredients to make your product healthier

Calories

Why

professionals are now recommending that consumers look for foods that

in most cases. In Canada, one third of Canadians are overweight and 15% are obese and the trend is increasing.

How

Calories come from fat, carbohydrate, and protein, which are also the major ingredients contributing to the overall texture, taste and organoleptic attributes of the finished product. To remove calories in a given product involves the substitution of a higher calorie component with a lower calorie equivalent. For instance, micronized starches have been used to replace fat and have been formulated to act as fat mimetics.

Challenges

Although a calorie reduction may be achieved by replacing fat with starch, the trade off would be both a reduction in taste since most of the flavour volatiles are fat soluble as well as possible changes in the lubricity of the product in the mouth. This apparent dryness creates an added challenge in the shelf life of products and would require humectants to contribute to moisture retention.

Why

Consumers may look for products that are lower in sugar for three reasons:

1. Lower carbohydrate diets with a corresponding higher protein intake may improve satiety and lead to weight loss.

2. Lower sugar products may reduce overall calories from specific foods, such as soft drinks.

be beneficial for people with diabetes. Better blood glucose control may even reduce risk of developing diabetes. A higher glycemic index food, such as sugar, results in a greater rise in blood glucose level, when compared to a lower glycemic index food, such as whole grains. The glycemic index of a food measures how a food affects blood glucose levels.

How

The replacement of sugar may require a multiple substitution approach since sugars contribute to sweetness, texture, aroma and colour.

Challenges

The uniqueness of sugar makes it a difficult ingredient to substitute. As a result, the product may cost more.

a familiar reaction—the Maillard browning reaction—occurs. This reaction, combined with another process called caramelization, imparts the pleasant colour, taste, and flavours we have come to expect with breads and baked goods. As sugars are heated, they change from various glass transition states to a more rigid texture. This influences product viscosity, flavour and aroma and would be affected if the sugars were replaced with non-caloric sweeteners.

Why

risk of heart disease. Not surprisingly, fat content of foods remains the

Canada’s Task Force on Trans Fat recommends elimination or reduction of trans fat from partially hydrogenated vegetable oils so that soft, spreadable margarines be limited to 2% of total fat. For other retail products the trans fat content must be limited to 5% of the total fat.

How

Replacing partially hydrogenated vegetable oils in some products is not a simple task. For example, in spread type cookies simply replacing the fat will alter the finished baked characteristics and dimensions of the product. Reformulation of other ingredients such as gums, fibre, leavening agents and/or liquid components must be examined in order to produce a similar cookie to the original product.

Challenges

Roll-in products layer fat between sheets of dough. In moving to a trans fat reduced or trans fat free non hydrogenated fat, the firm texture of the fat is compromised. A more liquid fat does not facilitate the entrapment of gas between the sheets of dough during the puffing process, leading to a harder less flakier finished product. This area continues to be a challenge for the manufacturer.

Why

to 2400 mg, which is the upper limit of what we should be consuming according to the Dietary Reference Intakes. In 2008, representatives to explore ways to reduce sodium in the diet, specifically from processed foods.

heart disease. In Canada, at least 19% have diagnosed hypertension with an additional 15% having high normal blood pressure levels. As people age, the incidence of hypertension increases.

How

Potassium is a commonly used ingredient to formulate reduced-sodium products. In baking powder applications, calcium bicarbonate has been used to replace the more popular sodium equivalent. It is noteworthy that in the replacement of sodium with a calcium salt, health claims cannot be made unless the calcium source is from a natural source such as dairy.

Challenges

Potassium compounds can impart a metallic aftertaste. Some suppliers formulate blends of sodium/potassium and add flavours to mask this taste. Yeast extract can act as a flavour enhancer and is a potential alternative in salty taste as sodium chloride.

Why

Allium vegetables such as garlic, onions and leeks are used to add flavour to

Report identifies these vegetables as possibly reducing the risk of stomach cancer. As well, garlic may protect against colorectal cancer. Some scientific evidence exists on medicinal roles of spices and herbs. Many spices and herbs are selected for taste, cultural beliefs or perceived benefits.

How

In instances where the addition of a flavour or ingredient would negatively affect the organoleptic attributes—or acceptability—of the finished product, the ingredient could be encapsulated. Certain suppliers have developed proprietary manufacturing processes for the removal of flavours and aromas while keeping the active component functional.

Challenges

The further processing of these spices may lead to increased costs and in the case of some spices unwanted colour may be added as well.

Why

Fibre helps maintain a healthy digestive system and one type of fibre— soluble fibre— has been shown to reduce the risk of heart disease.

The different types fibre include:

Inulin, a common fibre added to baked goods, is a well-known prebiotic. Prebiotics are a food source—often a non-digested carbohydrate—for healthy bacteria in the gastrointestinal tract. Both prebiotics and fibre help the gut.

How

Adding fibre and prebiotics can typically be introduced to products with minimal reformulation and require only slight adjustment to moisture levels and order of addition of ingredients.

Challenges

Fibre has an effect on the water binding capacity of the finished product, fibre competes with other ingredients during the mixing and baking stage and may result in a dryer finished product with an increased bulk density.

Why can help reduce the risk of heart disease, diabetes, cancer and obesity.

How

A variety of whole grains can be incorporated into baked goods and breads. Commercial multigrain blends are usually selected primarily based on nutritional functionality, taste and cost. The availability of the micronutrients in the whole grains is dependent upon the form of the whole grain. For instance, intact whole grains tend to limit access to micro-nutrients unless the grains are cracked or milled.

Challenges

In order to reduce the effect of grains on finished product integrity and density, the grains can be pre-treated to either soften the product by soaking or partial heating.

Why

Probiotics are bacteria such as lactobacilli, bifidobacteria, and yeast. They are commonly found in certain yogurts and other cultured dairy products. Similar to prebiotics, probiotics can improve and/ or maintain a healthy gastrointestinal tract. In addition, there is some evidence that probiotics help our immune system function.

How

Food applications of probiotics to consider are:

throughout the shelf life of the product.

Why to infant brain development. As a result, health professionals recommend the

fatty acids, include soybeans, canola, walnut, flax seed and their oils.

How

baked products are flax seed. Similar to whole grain ingredients, the particle size of seeds is most likely related to the bioavailability of the nutrients. Consequently, flax seed is often crushed or milled to gain better access to the oils in the seed.

Challenges

The down side of crushing the seeds is the potential oxidation of the exposed oils. As a result, this may lead to a shorter shelf life in the storage of some of these sensitive ingredients. Certain suppliers have incorporated anti-oxidants into their products; however, this will have an effect on product cost.

Why

Antioxidants are important because they protect the cells in the body from oxygen damage caused by free radicals. Much of the damage is repaired, but often these damaged cells can develop into cancer or heart disease. Many types of antioxidants exist in foods. The majority are found in vegetables and fruits such as carotenoids and flavonoids. Some, such as vitamin E, are found in whole grains and vegetable oils.

How

reduce effectiveness of the probiotic effect. Therefore, this technology will not work for products that undergo post-process heating.

products using probiotics unless the application is practical, well promoted and is part of a logical substrate.

One way of increasing antioxidants in your product is to add fruit such as blueberries. To facilitate a longer shelf life, some fruits are infused with sugar which will have a preservative effect in binding water.

Challenges

Two apparent outcomes to the infusion process are an increase in calories due to the increased carbohydrates content and an increased cost related to the process.

The Food and Drug Act mandates the addition of vitamins and minerals in white flour, such as replacing the B-vitamins and iron lost during milling and fortifying with folate to reduce neural tube defects. In addition, some nutrients can be added voluntarily like vitamin B6, calcium, pantothenic acid and magnesium. To enhance products, many foods add other such as margarine, are listed in the Act with a specific standard of identity. If vitamins and minerals or other nutrients are added to the product they cannot be identified as bread or margarine; however, these foods can be referred to as a loaf or a spread, respectively.

How

Vitamins and minerals can be added as powdered or liquid mixtures. Other ways to enhance vitamins and minerals in a product is to add ingredients that are high in a particular vitamin or mineral.

Challenges

Typically vitamins will add off flavours (mainly metallic notes) and as a result will need flavour masking.

In the design of a healthy finished product, it is imperative that all ingredients be as “clean” as possible. This includes the elimination of any chemical preservatives in the extension of product shelf life. An interesting approach to addressing this challenge is to depend on a microorganism to deliver natural components in the finished product. This could be in the form of acids produced by the microorganism or other metabolites, which could have an effect on shelf life extension.

It is beneficial to communicate product enhancements to the consumer. Although the information may be evident in the Nutrition Facts tables with lower values of sugars, sodium or fat, front of package information is easier and more readily noticeable by the consumer. In most of these situations, nutrient content claims can be made. For reductions or removal of ingredients, each type of claim (free of the nutrient or lower in the nutrient) must adhere to standard levels as specified by regulations. Examples include:

of

Similarly, when adding ingredients or components to your bread or baked good there are a number of ways in which you can inform consumers about the enhancement. For nutrients such as fibre, vitamins and minerals, the front of package can carry nutrient content claims—“source of…”, “excellent source of…”, etc.

In order to promote the health benefits of spices, antioxidants, probiotics and whole grains, functional claims, also known as biological role claims, can be made. For example, “This food contains probiotics. Probiotics help maintain a healthy gastrointestinal tract”. Biological role claims can make statements regarding the maintenance of a healthy body. These claims cannot refer to a disease state.

A health claim, linking the consumption of whole grains with a decreased risk of cardiovascular disease, is anticipated in the future. This will provide a front-ofpackage added claim that can be used to promote the product.

For a complete listing of permitted nutrient content claims, check out the Canadian Food Inspection Agency’s 2003 Guide to Food Labelling and Advertising, Chapter 7 (http://www.inspection.gc.ca/english/fssa/labeti/guide/tab7e.shtml)

Consider the following two points when launching foods that are enhanced: 1. Are there some food categories that consumer will find difficult to accept as healthy?

2. Are consumers more willing to accept a healthy version of a product that they are familiar with than a completely new innovation that is too new?

Once these questions are answered and you have overcome any formulation challenges, there are key marketing questions that need to be addressed:

find the product?

The health benefits of removing or adding ingredients in baked goods must be balanced with the impact on taste, aroma, safety, shelf life and cost. Changes are possible with appropriate planning and testing. Consumer research can help guide product promotion.

Ultimately, consumers need to be aware of the health benefits provided by the new products. Front of package claims that adhere to government regulations, are an effective way to educate the consumer. In the end, health, value for their money, pleasure (taste and familiarity) and convenience will keep consumers purchasing the new products.

Baking Association of Canada 7895 Tranmere Dr, Ste 202 Mississauga, ON L5S 1V9

Tel: 905-405-0288, Toll Free in Canada & USA 1-888-674-BAKE (2253) Fax: 905-405-0993 E-Mail: info@baking.ca

May be reproduced without permission provided no changes are made and credit is given. Printed August 2008. Visit www.GrainsEssential.ca or www.cwb.ca to download PDFs of this resource.

The Environment and Plastics Industry Council (EPIC) has issued an information sheet “Alert to Retailers on Degradable Plastics” in which it offers advice and direction to businesses considering switching to degradable plastic packaging. Many businesses, responding to growing environmental concerns are considering degradable plastic packaging as an option and may also wish to make certain environmental claims such as -- “biodegradable and recyclable,” “compostable,” “biodegrades in land ll” etc. EPIC offers the following questions for considerations as part of the decision making process:

Where will the material end up at the end of its life? Is there a chance that the material will enter the recycling stream?

• Is the material compatible with current recycling programs for plastics?

• What is the time frame for degradation?

• What are the by-products of

degradation?

• Is there documentation of a third party veri cation that supports any claims about the materials?

EPIC also cautions industry that Canadian regulators are becoming more active regarding compliance with environmental claims to avoid misleading or false statements.

“Environmental claims of degradability should comply with the National Standard of Canada CAN/ CSA-ISO 14021 “Self Declared Environmental Claims and Labels”. The standard requires that: “claims be accurate and not misleading”; “claims be substantiated and veri ed”; “claims be relevant to the product and used in an appropriate context and setting” according to EPIC

In order to provide direction on environmental packaging claims the Competition Bureau within Industry Canada in conjunction with the Canadian Standards Association have created a

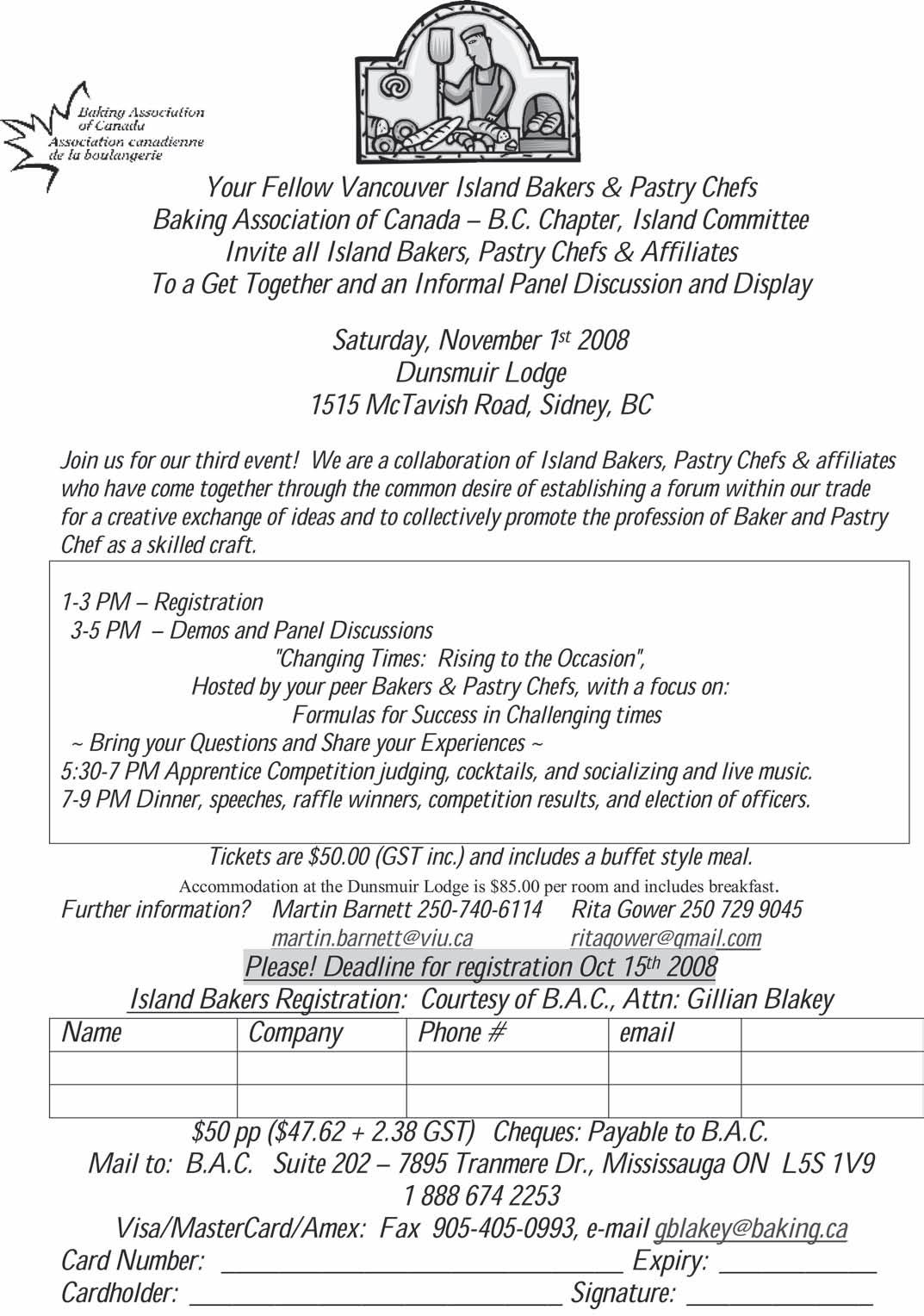

BC Chapter

October 23

AGM Election & Meeting

Vancouver Community College

Vancouver, BC

BC Chapter

Vancouver Island Committee

November 1

AGM Dinner & Social Dunsmuir Lodge

Sidney, BC

Ontario Chapter October 7

Dinner Meeting with Guest Speaker

Valhalla Inn

Toronto, ON

guidance document for Industry. The Guide very similar in format and purpose to the Guide to Food Labeling and Advertising (which the food industry is very familiar with) offers interpretations to ensure that environmental claims are accurate and not misleading. The Guide is available online at: http://www.competitionbureau.gc.ca/ epic/site/cb-bc.nsf/vwapj/guide-forindustry-and-advertisers-en.pdf

EPIC draws attention to a number of statements in the Guide relating to claims in the section dealing with degradables. These include:

“Claims of degradability shall only be made in relation to a speci c test method that includes maximum level of degradation and test duration, and shall be relevant to the circumstances in which the product or packaging is likely to be disposed.”

“It is dif cult to substantiate a claim that a product normally disposed of in land ll is “degradable.”

EPIC urges business considering making a claim of degradability to carefully consider the relevant sections of the Guide. The complete EPIC release on this subject may be found at: http://www.cpia.ca/epic/media/default.

Congratulations To Our Most Recent Correspondence Course Grads!

Peter Storm

Bakery Technology III

A Warm Welcome to our Newest Members

Allen Kirkpatrick Norampac Inc

Kirby Punshon Marcie Cakes Patisserie

The industry comes under fire for continued levels of trans fats in its products | BY

CLÍONA M. REEVES

In July, Health Canada and the Heart and Stroke Foundation of Ontario criticized the baking industry for the levels of trans fats in its products, suggesting some parts of the industry aren’t doing enough work to reduce or remove the fat from the goods they make.

The federal government accepted recommendations from Health Canada’s Trans Fat Task Force in June 2007, asking the industry to reduce trans fat levels to five per cent of the total fat content in food products and five per cent in vegetable oils and margarines. It gave manufacturers and producers two years to comply with the voluntary guidelines, at which point the question of whether to make the guidelines into regulations would be addressed.

Trans fatty acids, or trans fats as they are more popularly known, are produced during a process called hydrogenation.

Oils (which are liquid at room temperature) and certain fats which have a low melting point are subjected to hydrogenation in order to make them more stable, meaning that they develop a higher melting point (and so are solid at room temperature) and a longer shelf life. For a long time in the food industry, this has been an important function and has made it possible to produce food products which are easier to manufacture than with less stable oils, more appealing in flavour to customers, and shelf-stable for longer periods. Curiously, partial hydrogenation produces the highest levels of trans fats, where in fuller hydrogenation, the levels of trans fats fall.

Bakeries, especially smaller ones, seem to be less aware of the health implications of trans fats.

}For a long time, trans fats, which not only had functional advantages, were thought to be a great alternative to animal fats, whose artery-clogging saturated fats were linked to heart disease.

thought to be a great alternative to animal fats, whose artery-clogging saturated fats were linked to heart disease. The irony was that while saturated fats do raise the levels of “bad” cholesterol (low-density lipoprotein, or LDL) in the bloodstream, trans fats are worse. They not only raise LDL, at the same time they lower levels of “good” high-density lipoprotein (HDL) – a double health whammy.

exposure to trans fats. Some food manufacturers have already made significant steps to reduce or eliminate trans fats in their baked goods. One of the quickest was Voortman Cookies Limited, of Burlington, Ont., which reformulated its entire line of cookies. As of April 2004, Voortman’s entire line became trans fat-free.

But the switch to trans fat-free is not just a matter of substituting one ingredient for another. Paul Hetherington, president of the Baking Association of Canada, explains some of the frustration in the industry regarding the move away from trans fats.

For a long time, trans fats, which not only had functional advantages, were

Hence the concern Health Canada has in reducing Canadian consumers’

“In the 1960s and ’70s, the industry was actively encouraged to move away from animal fats and switch to partially

}hydrogenated vegetable fats, which were lower in saturated fats. Twenty years on, issues arise with trans fat, but we don’t yet have suitable alternatives, especially for the functionality in laminated products, such as croissants and puff pastry. Now, the industry is being told to go back to the animal fats they had been criticized for using. Going back to animal fats would mean returning to high saturated fat levels, altered flavours and problems for vegetarians. That being said, the industry has been working hard on reformulations and, so far, has done well. There is more work to be done, and it will take time, innovative thinking and understanding from consumers and groups like the Heart and Stroke Foundation that this is not something which can be magically fixed overnight.”

and Stroke Foundation’s list of trans fat transgressors.

“We’re very concerned, not just about trans fats, but about fats in general,” Lepidas says. “We’re not a primary manufacturer of the mixes we use to make our products. While some of the mixes are proprietary to us, it’s the suppliers who do

“We’re also concerned that the government, in setting these targets and deadlines, has put the onus entirely on the food service industry…”

industry, and not on the supply side. Applying the regulations to both sides would be fairer. Nonetheless, we are committed to removing trans fats. Our objective is to have all Coffee Time and Robin’s Donuts products free of trans fats by the end of 2008.”

Coffee Time executive vice-president Dan Lepidas is concerned about the inclusion of some of Coffee Time’s and Robin’s Donuts’ products on the Heart

the formulations and source the ingredients. We’ve asked our suppliers to remove the trans fats from their formulations, and they’re responding very quickly. It’s not easy, because all fats, including trans fats, perform unique functions, and reformulating to achieve a similar result is a challenge. In some cases, suppliers are even discontinuing certain products which simply cannot be successfully reformulated with other ingredients. We’re also concerned that the government, in setting these targets and deadlines, has put the onus entirely on the food service

Bakeries appear to be having a more challenging time dealing with trans fats, according to Miranda Abolfazli, a graduate student at the University of British Columbia working with the B.C. Ministry of Agriculture. Her study of small and medium-sized bakeries in B.C. shows there are some gaps in understanding between scientists and bakers.

“Generally, the smaller the bakeries, the less likely they were to be aware of trans fats and their health implications,” Abolfazli says. “The medium-sized ones tend to be more aware, and have more resources and people to deal with the cost, time and work needed to develop reformulated products. There are exceptions among the smaller ones, like Red Square Bakery, in Burnaby, B.C., where they have worked hard to remove trans fats. Unfortunately, unless a product contains less than two grams each of trans and saturated fat per serving, you can’t put a ‘trans fat-free’ claim on your product, so there’s little business incentive for bakeries to divert attention from their day-to-day work. Many are understandably reluctant to overhaul their entire business in response to a scientific discovery which may be discredited next year. This does not bode well for the proposed ban on trans fats in B.C. by 2010.”

The solution, she says, begins with building bridges.

“There needs to be clearer communication with bakeries, especially those that are not members of the Baking Association,” Abolfazli explains. “Educational seminars or other programs are needed to help bakers see that getting rid of trans fats is not just a trend. At the same time, before any ban is proposed, government and scientists need to reach out to bakers and understand the business implications of such a huge change.” / BJ

Clíona M. Reeves, MA, is a freelance writer based in southern Ontario, and thinks she can hear a croissant calling her name.

Looking for more contact information about those quoted in this story? Go to www.bakersjournal.com.

A Niagara-on-the-Lake bakery and pastry shop reaches a milestone in sales — and aims for more | BY

KAREN J. AUDET

Even before opening the doors of Willow Cakes & Pastries in Niagara-on-theLake, a sweet, yeasty-cinnamon aroma fills the air. How could customers not file inside to choose from an array of temptations?

Willow Cakes’ proprietor Catherine O’Donnell has been serving up delectable edibles since 2004. Having reached a milestone of

$1 million in sales last year, her philosophy is as simple as the natural ingredients she uses for her culinary creations – “maintaining core business values, personal service, staff excellence, and handmade, quality baked goods.”

Willow Cakes & Pastries is a cozy home-style bakery and coffee bar. O’Donnell’s culinary artistry is apparent with one glance at the display case, which is filled with an array of butter tarts, crois-

sants, cheesecakes, chocolate truffles, quiche, breads, muffins, cakes and cinnamon rolls. O’Donnell’s signature items – White Chocolate Raspberry Mousse, Café Royale, Lindt Chocolate Caramel Cheesecake, Tomato Herb Bread and Pecan & Caramel Crème Brûlée, to name a few – round out the offerings. She remembers the life-changing childhood moment that set the course of her career: the day her “Nan”

took her to Toronto’s King Edward Hotel for tea. Enveloped by the air of the occasion, the beauty of the pastries and the explosion of tastes, O’Donnell immediately knew she was “sold” on a career as pastry chef. She baked apple pies through high school at Chudleigh’s Farm in Milton, enrolled in the Baking and Pastry Arts Management course at Toronto’s George Brown College and invested four months’ more study at

the Callebaut Chocolate Institute in Belgium before donning the official apron.

O’Donnell believes that continuous education helps maintain a competitive edge.

“You get sheltered when you own a business,” she says. “It’s important for professionals to continue to learn and experiment in their trade as new ingredients and techniques emerge.”

amazing (teenage) children who have all bought into the business and who believe in me,” O’Donnell said. “You can sell the best product in the world, but without community and family support, it’s meaningless.”

Situated in the agriculturally rich “banana belt” of Niagara’s wine country, O’Donnell feels lucky to have “seasonal orchard pickings of

instead to find creative internal cost saving measures as they “ride out” the economic roller coaster. O’Donnell also tries to overcome the price mindset by emphasizing the value of fresh and natural ingredients used in her handmade bakery items.

“It’s what sets us apart (from grocery store bakeries). No mixes, no artificial bases. We use the best ingredients and

}Her own learning curve began under the direction of mentor John Higgins and working as a pastry chef under world class chefs Peter Oliver and Stephen Treadwell. Along the way she accepted a position with Vintage Inns in Niagara-on-the-Lake and her love affair with the town began.

“Sitting by Lake Ontario, hearing the birds, being able to ride my bike on the trail and not have the city noise is just paradise,” she said, explaining why she opted to start her bakery business away from metro Toronto. She makes the hour-long drive once a month to get “a fix of the hustle and bustle” but is happy to escape the metropolitan mayhem and call Niagara-on-the-Lake home.

“I have been blessed by a community, a staff and two

“You

get sheltered when you own a business … It’s important for professionals to continue to learn and experiment in their trade as new ingredients and techniques emerge.”

strawberries, cherries, raspberries and peaches right at our doorstep” and is thrilled to participate in the Niagara Culinary Trail, which promotes and supports local foods, businesses, and farmers.

Of setting up shop outside of the city, O’Donnell admits there is a price parity issue.

“We are able to offer New York City or Toronto-quality products but small town communities aren’t as willing to pay the same prices”.

The crunch is further felt as commodity pricing on things like gasoline, chocolate, dairy products, flour and packaging increase. Despite taking a hit to their bottom line, Willow Cakes & Pastries decided not to increase their prices, opting

strive to make everything from scratch.”

As a shop in a tourist town, Willow Cakes & Pastries abides by the peaks and valleys of seasonal business. During the first few months of the year O’Donnell subsidizes the shop by teaching baking to international students who are enrolled in the Niagara-onthe-Lake Chef School. From late spring on, the streets begin to crowd and business stays brisk until the end of September. The winter season is sustained through a regular customer base and an “amazing” Christmas season.

Aside from retailing baked goods, O’Donnell’s business savvy is apparent through