Two

BY NAOMI SZEBEN

Two

BY NAOMI SZEBEN

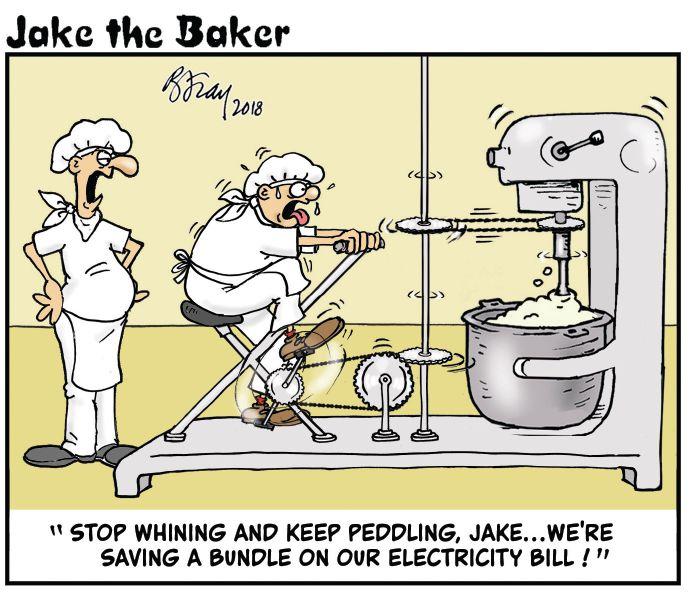

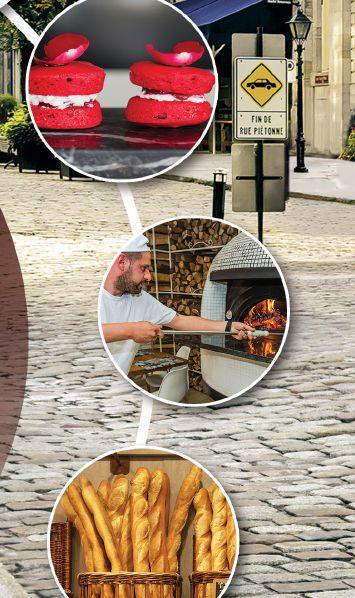

The future of bread seems to lie in the past: Consumers and bakers are now asking where their wheat is cultivated, how is it processed, what is added to the dough, and what methods are used to bake it. “Traditional baking” is the future of artisanal breads, and this issue looks at how chefs are following ancient recipes and using old fashioned wood fired ovens to satisfy our appetite for good quality, home made bread.

Four hundred years ago, we would wake up, stoke a fire, and begin to bake bread to start our day. Without insulation or a way to regulate the flames, house fires were frequent and many professional village bakers suffered from smoke inhalation due to constant proximity to their ovens.

Today, we wake up, and buy something in a store. Health concerns for us are high cholesterol, or obesity from too much processed food laden with sugar. For commercial bakers, the electric oven presents no threat with its even, steady temperature and built-in safety measures. Chef Thorsen Pannek wants the next generation of chefs to connect with the ancient ways of making bread. He teaches tomorrow’s chefs using yesterday’s tools: By bringing them to a working nineteenth century kitchen he shows them both the quirks and the benefits of a wood-fired oven.

There’s no comparison between a loaf cooked in an electric stove and bread that has a smoky, woody fragrance still clinging to its crust. Once the students have conquered their fear of playing with fire, they are hooked. From pizza, bagels and flatbreads to rounded loaves of sourdough, each slow-rising, full grain loaf is complemented by the smokey kiss of flames. Aside from chefs like Pannek, you’ll read about Greg Wade, Jeffrey Finklestein, Kevin Mathieson and Jan Campbell-Luxton, chefs who are all passionate about the quality of their bread. None of them are slaves to trends, but they adamant about using clean-label, all natural ingredients. These chefs are simply following recipes that are centuries old, but the current market for easy to read, simple ingredients seems like a current fad.

The public is starved for good quality bread. Mathieson and Finklestein are Canadian bakers who saw an opportunity to provide rich, healthy and flavourful bread to an eager public, and profited well from it.

While the public is concerned about clean label, all-natural ingredients and high fibre products, artisanal baking did that all along. Sourdough is likely the most natural of loaves, with only three ingredients: Water, flour and naturally occurring, airborne yeast. You can’t get a cleaner label than that.

The public is starved for good quality bread. Mathieson and Finklestein are Canadian bakers who saw an opportunity to provide rich, healthy and flavourful bread to an eager public, and profited well from it. Wade learned quickly that providing wide array of bread is a mixed blessing: Though he knows how to make a dazzling variety of all-natural breads, he learned quickly that variety is not the answer. A smaller, more focused inventory was what made Publican Quality Breads’ name.

It’s hard for bakers to try to gauge what clients might want. Do they want to indulge or are they concerned with a more healthful option? Bakers can provide both, but it can take its toll on profits when food and efforts are wasted. The answer may lie in a bread that satisfies both health concerns and the indulgent mouthfeel of a crispy crust and a fluffy interior studded with grains or fruit. Today’s bread lover wants a sumptuous mouth-feel, a decadent treat -- but one that’s ethically sourced, plant based and/or healthy.

We’re finding tomorrow’s trends in ancient diets. Whether it’s healthy, tasty or a rare combination of the two, we’ll gladly break bread with our friends and neighbours. / BJ

NOVEMBER 2018 | VOL. 78, NO. 9

EDITOR | Naomi Szeben editor@bakersjournal.com 416-510-5244

TECHNICAL

EDITOR | Philip Oxford, Puratos Canada foxford@puratos.com

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexbusinessmedia.com 705-826-2254 1-888-599-2228 ext. 268

ACCOUNT COORDINATOR | Shannon Drumm sdrumm@annexbusinessmedia.com 519-429-5176 1-888-599-2228 ext. 219

MEDIA DESIGNER | Curtis Martin

CIRCULATION MANAGER l Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-442-5600 ext. 3543

GROUP PUBLISHER | Martin McAnulty mmcanulty@annexbusinessmedia.com

PRESIDENT & CEO | Mike Fredericks

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710.

ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Business Media.

CIRCULATION

lmalicdem@annexbusinessmedia.com

Tel: 416-510-5187

Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Subscription Rates

Canada — 1 Year $ 30.00 (with GST $31.50 #867172652RT0001, with HST/ QST $33.90)

USA — 1 Year $ $55.50 USD

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbusinessmedia.com Tel: 800-668-2374

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2018 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

briefly | HostMilano features new “macro-areas”; A pilot plant is built for bakers looking to experiment with edible oils| for more news in the baking world, check out our website, www.bakersjournal.com

Preparations are underway for HostMilano, a professional hospitality event that highlights bread, pizza, pasta, coffee, ice cream, tableware and food technology.

The trade show, organized by Fiera Milano every two years, is set for Oct. 18-22, 2019.

Nearly 1,000 companies have confirmed their participation, about half of which come from more than 40 foreign countries.

The show is divided into three sections, or “macro-areas”: Professional Catering –Bread, Pizza and Pasta accounts for 48 per cent of all exhibitors; Bar, Coffee Machines, Vending Machines – Ice Cream, Pastry Shops – Coffee and Tea represents 23 per cent, and Tableware, Furnishings & Technology accounts for the remaining 18 per cent. In partnership with ITA Agency, more than 1,500 buyers from 80 different countries are brought to Host 2019.

HostMilano will feature at least 500 workshops, presentations of figures and studies, tastings, educational initiatives and contests. The trade show is designed to be

a multisensorial experience with presentations at corporate stands, cooking shows by award-winning chefs, culinary creations of pastry chefs and cake designers, and performances by top baristas and bartenders.

In partnership with POLI.design, organizers will identify and promote innovation in products, services and formats. In partnership with ADI - Associazione per il Disegno Industriale, SMART Label will recognize innovative products and display them in a hall of winners.

Some of the key features of the show include the Cake Designers World Championship, and The World Trophy of Pastry Ice Cream Chocolate.

The European Pizza Championship, the event that gathers together pizza chefs from all over Europe every two years, returns to HostMilano for a two-day event dedicated to the most popular, most eaten and most interpreted Italian dish in the world. This trade show promises to educate all levels of food experts around the world.

Cargill’s global edible oils business commissioned a new pilot scale lab specifically for bakery shortening development and production.

The shortening pilot lab, located in Minneapolis, was designed to accelerate their product development and commercialization efforts. The lab gives Cargill the ability to produce small-batch quantities of shortenings and similar products for bakery applications. It also allows for swifter access to prototypes and samples and to make real-time adjustments to production parameters.

The new pilot lab has state-of-the-art computer controls that allow for very specific and efficient process adjustments to meet bakery customers’ needs. These controls also track and record process data, giving visibility to settings and changes throughout the production process. This can help deliver the quality product needed when bringing it to full production scale.

Cargill feels that this product can provide feedback for all sizes of bakeries and production plants. The applications can be used for ready-made “instant” mixes, breads, cakes, and pastries.

Samantha Liebhard, the PR lead for Cargill, states that the pilot plant is promises a practical way to test new products in an economic and effient manner, and can impact both large and small bakeries.

From hygienic grocery pallets to new automated cake decorating systems Bakers Journal keeps you “in the know.” for more on new products for the baking industry, check out our website, www.bakersjournal.com

The Orbis XP Grocery Pallet ORBIS®, an international reusable packaging corporation, has introduced a new pallet to its XpressPal® family. The XpressPal (XP) Grocery pallet is designed to ship finished goods from distribution centers to retail in grocery supply chains. As grocery and food service industries continue to evolve, the XP Grocery pallet is a versatile and reliable pallet option.

“Our latest addition provides a nestable, fully hygienic pallet option that features a new design and innovative features for handling high-demand products, such as fresh food,” said Ryan Roessler, plastic pallets product manager at ORBIS Corporation in a press release. “Fresh food is a highselling category for grocers, and the new XP Grocery pallet is a safe, cleanable and reusable option to ensure products are delivered to retailers in

good condition and with minimal hassle.”

The new legs on the XP Grocery pallet are round, making the pallet compatible with similar pallets on the market and increasing the pallet’s impact performance in rugged grocery environments. In addition, the XP Grocery pallet’s legs are now 18 inches apart. This gives forklifts maximum room to remove stacked pallets without the pallets sticking together, allowing for easier material handling.

The XP Grocery pallet’s top deck includes a moulded-in texture to minimize load shifting. The texture increases friction, so goods are less

Unifiller Systems released its newest cake decorating system, the CakeStation, at this year’s IBA event.

With the bakery industry currently facing a shortage of skilled labour due to an ageing workforce, fewer people entering the trade, and economic restrictions, the CakeStation presents bakers with an automated solution.

This all-in-one system was designed specifically to address the needs of cake manufacturers looking to do more with their equipment. Bakers will be able to deposit batters, assemble cakes, mid-fill, ice sides and the tops of cakes, and decorate with rosettes or borders – all on one machine.

Stated in a press released, Jason Du Toit, product manager at Unifiller Systems said, “The CakeStation’s PLC touch screen control system with recipe storage will drastically reduce change over time compared to other similar machines in the market.”

Featuring a manual touch-up setting that’s triggered at the touch of a button, the CakeStation has 4 programmable modes for decorating, depositing, icing and bordering.

The CakeStation also features a swing-away servo-controlled turntable and an automatic 10.16 cm lifting mechanism for greater icing accuracy. Capable of icing up to 7 cakes or 120 deposits per minute, the system’s portion accuracy helps to reduce product waste thereby lending itself to controlling raw ingredient costs.

The CakeStation includes a patented SV product valve, a 14-gallon conical hopper, and adjustable pins for finishing round cakes from 15 to 30 cm. The CakeStation works as a stand-alone machine, however, a height adjustable frame and slave-mode settings allow it to be configured into an automated system.

likely to slip off the pallet. In addition, the XP Grocery pallet’s top deck includes ergonomic handle holes so the pallet can be manually moved or un-stacked, making it an applicable option for manual and automated systems. For additional anti-slip friction, rubber grommets are available.

For increased function and safety, the XP Grocery pallet is a one-piece fully hygienic plastic pallet. The one-piece construction gives the pallet a high strength-to-weight ratio and the ability to withstand rugged handling. The pallet’s flow-through design eliminates areas where contaminants, such as dirt, dust and liquid, can collect.

specifications

• Dimensions: 40 x 48 x 6.5

• Weight capacity: 2,800 pounds

• Trailer capacity: 1,140 XP Grocery pallets fit in one truckload

Cereals Canada welcomed the announcement of a modernized North American Free Trade Agreement, which will be known as the U.S.-Mexico-Canada Agreement (USMCA).

“Achieving the agreement will ensure ongoing stability in agricultural trade within North America,” stated Cam Dahl, President of Cereals Canada in a press release. “Agriculture in all three countries has benefited from freer trade. Preserving these benefits was a key objective in these negotiations.”

USCMA will also modernize the agreement in critical areas, including chapters on biotechnology and new plant breeding techniques and addressing issues of low level presence. These updates will help bring the agreement up-to-date with modern technology.

Dahl added, “This is a modernization that addresses issues that did not exist when the original NAFTA was drafted. The Canadian value chain supports these changes.” Dahl further noted that “there was some concern that the adjustments to the grading system would undermine Canada’s classification system for wheat. This is not the case as the agreement continues to allow both countries the ability to develop national policy.”

Cereals Canada thanks all the Canadian negotiating team who have carried out this work in order to accomplish the agreement. This includes Minister Freeland and Minister MacAulay who have been engaged throughout the negotiations.

More information about the USCMA can be found online: https://international.gc.ca/trade-commerce/trade-agreementsaccords-commerciaux/agr-acc/usmca-aeumc/index.aspx

BY: CAMERON’S PALE ALE

Cozy up this fall with a warm pie and Cameron’s Auburn Ale. Thanks, OCB and Cameron’s Pale Ale!

PIE DOUGH - INGREDIENTS

443.5g all-purpose flour, 291g unsalted butter, cut into 1 inch cubes, 79.99 g ice water, and a pinch of salt.

Add flour, butter and pinch of salt to the mixer, until mix is coarse. Add ice water, remove dough from mixer and form into a flat ball. Wrap in plastic wrap and chill for at least one hour. When dough has chilled remove from freezer and roll onto a lightly floured surface until it is 1/3 of an inch thick. Place the pot pie baking dish on top of the dough and trace with a knife half an inch from the edge of the baking dish. Keep pie crust covered with plastic wrap in the refrigerator while you prepare the filling.

2.73 kg cooked turkey breast, diced

480 g Cameron’s Auburn Ale

960 g turkey or chicken stock

Kosher salt and freshly ground black pepper

72.75g unsalted butter

2 carrots, peeled and cut into a large dice

1 rutabaga, peeled and cut into a large dice

1 parsnip, peeled and cut into a large dice

1 purple-topped turnip, peeled and cut into

a large dice

1 onion, diced

153.6 g wild mushrooms

18.9 g tablespoons all-purpose flour

2g chopped fresh thyme leaves

2g chopped fresh flat-leaf parsley

1 egg

Preheat oven to 350. In a large roasting pan, bring beer to a simmer and cook for three minutes. Add stock and bring back to a simmer. Transfer liquid to a saucepan, boil to reduce to 2 cups. Melt 3TB of butter in the liquid and add the all the vegetables. Cook vegetables until tender. Transfer vegetables to a plate and pour liquid into separate bowl. Melt rest of butter over medium heat, add flour and stir, for 5 minutes. Add the liquid (without vegetables) bring to boil, lower the heat and simmer for 15 minutes. Add turkey, vegetables and herbs; Mix thoroughly. Set aside to cool.

Fill a dish with mixture. Brush edges of the dish with egg wash. Top with egg washed pie crust and bake at 375 degrees for 40 minutes or until golden.

Searc h i n gfora

Getting into gluten-free has never been easier than with the versatile Vemag.

A single Vemag will prove to be the most flexible machine in your plant The Vemag incorporates a variety of innovative attachments that allow it to produce all types of gluten-free products It can easily handle the st fluid gluten-free doughs and batters. The Vemag’s modu allows it to be used as a dough divider, cookie dough depositor, brownie sheeter, bar extruder, batter depositor and more As your product mix changes, the Vemag can adapt with y

The Vemag’s double-screw pumping technology sets the standard for portioning accuracy, speed and product quality while never overworking the product. And its stainless steel construction and an easy-to-clean design with total access to the product path allows complete sanitation of the Vemag, whil eliminating any cross-contamination risks. Test the Vemag for yourself –schedule a demonstration at the Reiser Customer Center today

BY BRAD WOLFF

7 Steps to stop falling behind your competition, and gain a competitive advantage

Doesn’t it seem that business is more competitive than it used to be? ABC, a company that previously dominated their marketplace, suffered staggering losses in their previous fiscal year. It became blindingly apparent that what had worked in the past was no longer effective, and the company president had no idea how to fix things. It was time to use proven techniques for achieving a competitive advantage. ABC engaged a firm that identified the root causes of their problems. After two years, sales and profits dramatically increased. The results came from a seven-step process based on sound principles that put a focus on leveraging their internal talent. If you find your business falling behind, you can follow ABC, Inc.’s lead by putting these seven steps into practice.

1. EMPLOYEE ALIGNMENT

When assigning duties performed by employees that don’t fit their characteristics or core nature, they won’t perform well, like making people with poor detail orientation doing work that requires high detail. Training and development, management encouragement and other well-intended efforts will not fix these issues. As Peter Drucker said, “A manager’s task is to make the strengths of people effective and their weaknesses irrelevant.”

}3. ALIGN EMPLOYEES WITH YOUR COMPANY’S MISSION AND VISION

Human beings have an innate need for meaning and purpose in what they do. This means that they need to care about how their efforts affect the world outside themselves. For example, take assembly line workers that produce incubators for premature babies. In one scenario the workers are only told to mechanically perform the prescribed duties. In the other scenario they are crystal clear about the importance the quality of their work has on the survival of infants. Which workers do you think are more motivated? Engagement and performance are directly affected by people’s connection to the outcomes of their work.

4. ALIGN EMPLOYEES WITH YOUR COMPANY’S CULTURE AND VALUES

People need to feel that they fit in with their social groups. Employees who are out of sync with an organization’s culture and values will never contribute their best. Being aligned is the point, since diversity of thought and behavior allow a culture to adapt and thrive. It’s important for leaders to consider whether they should change their culture, like when it’s become toxic, or when there’s shrinking population of workers who fit the current culture.

It’s important for leaders to consider whether they should change their culture, like when it’s become toxic, or when there’s a shrinking population of workers.

Without the ability to attract and retain needed talent, organizations will fail.

5. ALIGN ROLES AND TO STRATEGIES AND GOALS

its vulnerable side. We’ve been taught to hide or deny our weaknesses despite how obvious they are. Our ego’s impulse to protect our self-image is normal but counterproductive. When leaders openly and honestly acknowledging “challenge areas,” this sets the example for others.

Studies on human potential and positive change demonstrate that self-awareness is the first step, but it’s not the last. Committing to take baby steps and doing them generates positive habits that create lasting positive change. Changes intended to meet the needs of your environment create a flexible, adaptive organization poised to thrive despite the torrent of unpredictable or unwanted change. Your willingness to acknowledge change that you don’t like, openly discuss it and consistently take the actions required to adapt will stregnthen you. At the end of the day, leaders are simply making choices that define the present and future of themselves and their organizations. There’s nothing magical about the most effective leaders. They’re just making more effective choices. These choices encompass how they decide to see the world, their openness to challenge their beliefs and their willingness to experiment with innovative ideas. Equally important choices include their willingness to objectively look at themselves and take actions to grow in areas. They choose to become a greater, more effective version of themselves. Leaders know that what they demonstrate (not what they say) is what has the greatest impact on the entire organization. / BJ

2. CREATE A CULTURE OF

Personal growth results in professional growth, creating a greater capacity to handle life challenges, accomplish long-term goals and work well with others. Personal growth and development includes an increased awareness of self and others, the ability to manage one’s ego, ability to manage emotions and development of innate talents to maximize productivity and effectiveness.

In today’s environment, organizational goals and strategies must change to adapt. Frequently, roles and supporting job duties don’t adequately change to align with these shifts. Think of a company that changes its strategy to shift most customer communications from telephone to email, yet the employees’ duties and training continue to focus on telephone communications.

6. ASSESS YOUR WEAKNESSES, STARTING FROM THE TOP

It’s impossible to have a strength without

Brad Wolff specializes in workforce and personal optimization. He’s a speaker and author of, People Problems? How to Create People Solutions for a Competitive Advantage. As managing partner for Atlanta-based PeopleMax, Brad specializes in helping companies maximize the potential and results of their people to make more money with less stress. His passion is empowering people to create the business success they desire, in a deep and lasting way. For more information on Brad Wolff, please visit: www.PeopleMaximizers.com

The baking industry is always in flux—with new trends, techniques and tastes making it increasingly di cult to stay one step ahead of the competition. That's why we're always more than willing and able to help you apply a little—or a lot—of science to whatever challenges and opportunities come your way.

Our motto? When art meets the state-of-the-art, innovative sustainable solutions are never far behind.

Dry ice cleaning is similar in concept to sand, bead and soda blasting, in that it cleans surfaces using a media accelerated in a pressurized air stream. But, dry ice cleaning uses solid CO2 pellets or MicroParticles, accelerated to high velocities to impinge on the surface and clean it. The particles turn from a solid to a gas upon impact, lifting dirt and contaminants off the underlying substrate without damage.

Traditional cleaning methods are time consuming, labour intensive and costly. Manual scraping or scrubbing with wire brushes and water or chemicals can consume many hours and result in extended downtime. It can also cause damage to equipment, shortening asset life and/or making it less productive.

Dry ice cleaning can make cleaning easier, more thorough and enables food-processing facilities to quickly and easily clean a number of different surfaces and get them back into production immediately.

ice is EPA, FDA and USDA approved for use around food processing.

Utilizing dry ice cleaning can result in cost savings, improved productivity, the extension of equipment life and improved worker safety.”

Cleaning with dry ice reduces water usage. It sublimates (turns from solid to gas) upon impact with the surface being cleaned, which means no secondary waste, no residue and no moisture is being generated. This eliminates the added costs of extra cleanup, disposing of secondary waste streams and additional cleaning preparation, such as masking delicate sensors or wrapping electronic components prior to cleaning.

The cleaning process does not use water, which allows equipment to be cleaned while online and still operating. Because it is non-conductive, dry ice cleaning allows for electrical equipment to be safely cleaned.

Dry ice is a very soft media and can clean sensitive electronic equipment, such as printed circuit boards, without etching, profiling or changing surface dimensions.

It is a food grade media and is EPA, FDA and USDA approved for use around food processing. Dry ice colorless, tasteless, odorless and non-toxic. It allows for the elimination of environmentally harmful cleaning chemicals and eliminates worker exposure to hazardous cleaning agents. It also does not produce any toxic waste that must be disposed of.

Utilizing dry ice cleaning can result in cost savings, improved productivity, the extension of equipment life and improved worker safety.

Dry ice cleaning can reduce cost by using significantly less time than conventional manual labour. This enables a cleaner clean even in situations that are difficult or unpopular to clean by hand with conventional methods.

Dry ice cleaning helps to reduce shut down times, as equipment can be cleaned while hot and online. By cleaning equipment in less time, facilities are able to get more production cycles from existing equipment. Preventive maintenance or spot cleaning can also be done more frequently without impacting production.

This method is non-abrasive and non-conductive. This means it won’t damage equipment and is safe for most surfaces, including electrical components.

The Safe Food for Canadians Act (SFCA) and Regulations

BAC E-Newsletter Promo

Bakery Showcase 2019 Exhibitor Prospectus

have substantial positive trade balance wit h t he U.S.

T he f ollowin g are the openin g comments o f BAC’s President & CEO

Paul Hetherin g ton’s September 20, 2018 appearance be f ore the Senate of Canada’s Standin g Committee on Ag ricu l ture an d Forestry

Th ank you for the introduction a nd t he invitat ion to be wit h you this mornin g . The Bakin g A ssoc i at ion of Ca n ada i s a n at ion a l not-for-profit trade association r epresentin g the country’s $ 8

bi ll ion b a k in g sector. Ou r

i ndependent r etail, in-store

a nd commer c i al baker member s produce a wide ran ge of

nut rit ious br eads

a nd roll s, a lon g with indul gent pro ducts suc h as ca kes a nd pastries. T h is is

usually when I get asked if I brou g ht samples; I did not The Committee’ s focus on how t he

v a lue -added f ood sector cou ld be more competitive in glob a l markets is timely. Canadian bakers have g rown exports on bread and b a kery products, alon g with cookies and crackers, f rom $1.5 billion in 2013 to almost $2.8 billion in 2017. So f ar this year, exports are up an add itiona l 17 per cent. T h is trade is a l most exc lusivel y wit h t he United States, which consumes some 96 per cent of our exports. For reference, imports in t hese categories was $721 million in 2013, growing to slight ly less t han $1 billion in 2017. Again, t he vast majority of that is coming f rom the United States So as you can see, we

Not surprisingly, t here are issues wit h t his trading relationship and challenges to growth. U.S. tariff rate quotas on sugar-containing products limits certain bakery exports. T he new U.S. Food Safety Modernization Ac t requires new regulatory compliance to maintain market access. T hese issues are well k nown and, where possible, are

But t he reality is t hat t hese are issues not within the control of Canadian legislators or government departments and agencies. I would instead like to focus on areas wholly under the control of Canada. In our view, the priority is to have a refocus on evidence-based regulatory development wit h clear and measurable objectives.

A lready submitted to t he Committee is t he Treasury Board submission by t he Baking Association of Canada and the Canadian National Millers Association in response to the Government of Canada’s regulatory review of the agri-food sector. This submission outlines in detail our concerns. Chief among t hose is t hat we see a creeping reliance on empat hy, not evidencebased regu latory development and we refer to Health Canada’s Healthy Eating Strategy as an example.

Canadian bakers have four sodium targets that have all been issued by Health Canada

The Baking Association of Canada supported the voluntary removal of trans fat from the food supply.

The Baking Association of Canada supported mandatory fortification of refined flour with folic acid

And we would clarify it is not that the problems such as obesity and related chronic diseases aren’t real and supported by evidence. The issue we have is that the proposed policy and regulatory solutions to these problems don’t have such foundations.

As identified in our paper, we now have regulations or regulatory proposals that are:

• Not based on science but instead a rule of thumb or, in some cases, literally criteria that are unique to the regulator’s authors.

• Regulatory proposals that are in contradiction with our major trading partners.

• We also have multiple overlapping regulations and policies. Do you know that Canadian bakers have four sodium targets that have all been issued by Health Canada?

We also have proposals that have not taken into consideration unintended consequences. As an example, under the proposed restrictions on marketing unhealthy foods to children, almost all bread will be deemed unhealthy for children. Health Canada has not, to our knowledge, identified the impact of unintended folate, fibre and other nutrient deficiencies that may occur in children as a result of such a declaration. Bread is a major source of all these essential nutrients, along with other grain-based foods.

In addition, what will be the adverse effect on trade once the Government of Canada declares to the world that Canadian breads are unhealthy for children? Our critique of these recent regulatory proposals should be taken into consideration that we have a long history in supporting evidence-based policy and regulatory development with some of the highlights including:

• The Baking Association of Canada, the Canadian National Millers Association and the Canadian Pasta Manufacturers Association, supported first the voluntary then actively lobbied for the mandatory

fortification of refined flour with folic acid even though this was resisted by Health Canada. We have estimated that this initiative has saved more than 5,000 children and their families from the nightmare of birth defects with the corresponding estimated savings to Canadian health care of up to $4.5 billion in direct costs, not including billions more in indirect and opportunity costs.

• The Baking Association of Canada supported the voluntary removal of trans fat from the food supply, which was 97 per cent trans fat-free before the government brought in regulations banning its use.

• We have also been supporters of sodium reduction, even though it’s an essential ingredient in the baking industry. Bakers have reduced sodium levels in pantry breads by some 14 per cent. Based on these efforts and others, we believe now that Canada is a world leader in population sodium reduction, as demonstrated by Health Canada’s recent sodium report.

• Lastly, we need to return to evidence-based policies and regulations with clear and measurable objectives, as they put a real cost burden on industry, a cost that inhibits growth and competitiveness. Agriculture and Agri-Food Canada’s food processing round table has estimated that compliance with Health Canada’s Healthy Eating Strategy for the labelling and packaging changes would be some $2 billion. This estimate does not take into account product reformulation costs, loss of market share, et cetera.

In summary, bakers have made substantial investments in supporting past public health initiatives. We simply ask that demands for future investments of limited financial resources be evidence-based with clear and measurable policy objectives. Thank you for your time.

Find out what your business will require to follow the SFCA initiative at the links below.

The publication on June 13, 2018 of the Safe Food for Canadians Act regulations in the Canada Gazette Part II was a positive step in the modernization of Canada’s food safety regulatory regime. This major initiative took more than 10 years to develop and combines fourteen separate regulations into a new approach. The new consolidated regulations will require food businesses that import or prepare food for export or to be sent across provincial or territorial borders to have licences, as well as preventive controls that outline steps to address potential risks to food safety. They will also help reduce the time it takes to remove unsafe food from the marketplace by requiring businesses to trace their food back to their supplier and forward to whom they sold their products.

The timelines for complying with licensing, preventive controls, preventive control plan and traceability requirements vary by food and activity. http://www. inspection.gc.ca/food/sfcr/timelines/all-other-foods/ eng/1527610633553/1527610633758

To find out if and when the new requirements apply to your business: http://www.inspection.gc.ca/food/sfcr/timelines/eng/1528199762125/1528199763186

You may require a licence for some of your business activities, while not for others. Find out if your business requires

a licence by answering a few simple questions. It only takes about 5 minutes. The specific sections of the Safe Food for Canadians Regulations (SFCR) that outline the requirements are indicated where applicable. https://na1se.voxco. com/SE/93/SFCR_licence/?&lang=en

Learn about the requirements for licensing and review guidance to help you comply. Find out if and when you need a licence and how you can apply for one. http://www.inspection.gc.ca/food/sfcr/general-food-requirements-and-guidance/licensing/eng/1523876882572/1523876882884

Some parts of your business may require a written Preventive Control Plan (PCP), while others may not. Find out if your business requires a written PCP by answering a few simple questions. It only takes about 5 minutes. The specific sections of the Safe Food for Canadians Regulations (SFCR) that outline the requirements are indicated where applicable. https://na1se.voxco.com/SE/93/SFCR_ PCP/?&lang=en

Learn about the requirements related to preventive controls and review guidance on how you can put these measures in place in your business. http:// www.inspection.gc.ca/food/sfcr/general-food-requirements-and-guidance/preventive-controls-food-businesses/ eng/1526472289805/1526472290070

Learn about the preventive control plan requirements. Find out if and when you need to have a written preventive control plan and review guidance on how you can build and implement one. http://www.inspection.gc.ca/food/sfcr/ general-food-requirements-and-guidance/preventive-control-plans/eng/1512152894577/1512152952810

Some parts of your business may have traceability requirements, while others may not. Find out whether you need to prepare and keep traceability records, and what type of information you require by answering a few simple questions. It only takes about 5 minutes. The specific sections of the Safe Food for Canadians Regulations (SFCR) that outline the requirements are indicated where applicable. https://na1se.voxco.com/SE/93/traceability/?&lang=en

Learn about the traceability requirements and find out how they apply to your business, when you have to have them in place and review guidance on how you can meet them. http://www.inspection.gc.ca/food/sfcr/ general-food-requirements-and-guidance/traceability/ eng/1526651817880/1526651951357

The SFCR consolidates all food labelling, standards of identity and grades requirements from the former Consumer Packaging and Labelling Act, Canada Agricultural Products Act, Meat Inspection Act, Fish Inspection Act, and their respective regulations. In addition, requirements on standards of identity and grades have been included in documents incorporated by reference. http://www.inspection.gc.ca/food/sfcr/general-food-requirements-and-guidance/labelling-identity-and-grades/ eng/1526652006909/1526652007189

Find out which documents are incorporated by reference in the Safe Food for Canadians Regulations. Documents incorporated by reference have the same force of law as the regulation in which they are incorporated. http://www. inspection.gc.ca/about-the-cfia/acts-and-regulations/list-ofacts-and-regulations/documents-incorporated-by-reference/ eng/1518625951131/1518625952071

New consolidated regulations will require food businesses that import or prepare food for export to have licences, as well as preventive controls.

CFIA has published a few guidance documents and they can be found at:

1. Conducting a hazard analysis http://www.inspection.gc.ca/food/sfcr/general-food-requirements-and-guidance/preventive-controls-food-businesses/hazard-analysis/ eng/1513283555932/1528205368359

2. Incoming ingredients, materials and nonfood chemicals http://www.inspection.gc.ca/ food/sfcr/general-food-requirements-and-guidance/preventive-controls-food-businesses/incoming-ingredients-materials-and-non-food-chemic/ eng/1523628204236/1528209219187

3. Supplier Food Safety Assurance Program http://www.inspection.gc.ca/food/sfcr/general-food-requirements-and-guidance/preventive-controls-food-businesses/sfsap/eng/1523365528734/1528208259725

Ensure you are up to date on the latest happenings in the baking industry!

If you work for a Baking Association of Canada member bakery or supplier company, you are entitled to receive the bi-weekly complimentary BAC E-Newsletter. For more information or to be added to our distribution list, please email info@baking.ca

Trade Shows Hours: 11:00 am - 5:00 pm daily Conference/Seminars will be prior to 11:00 am

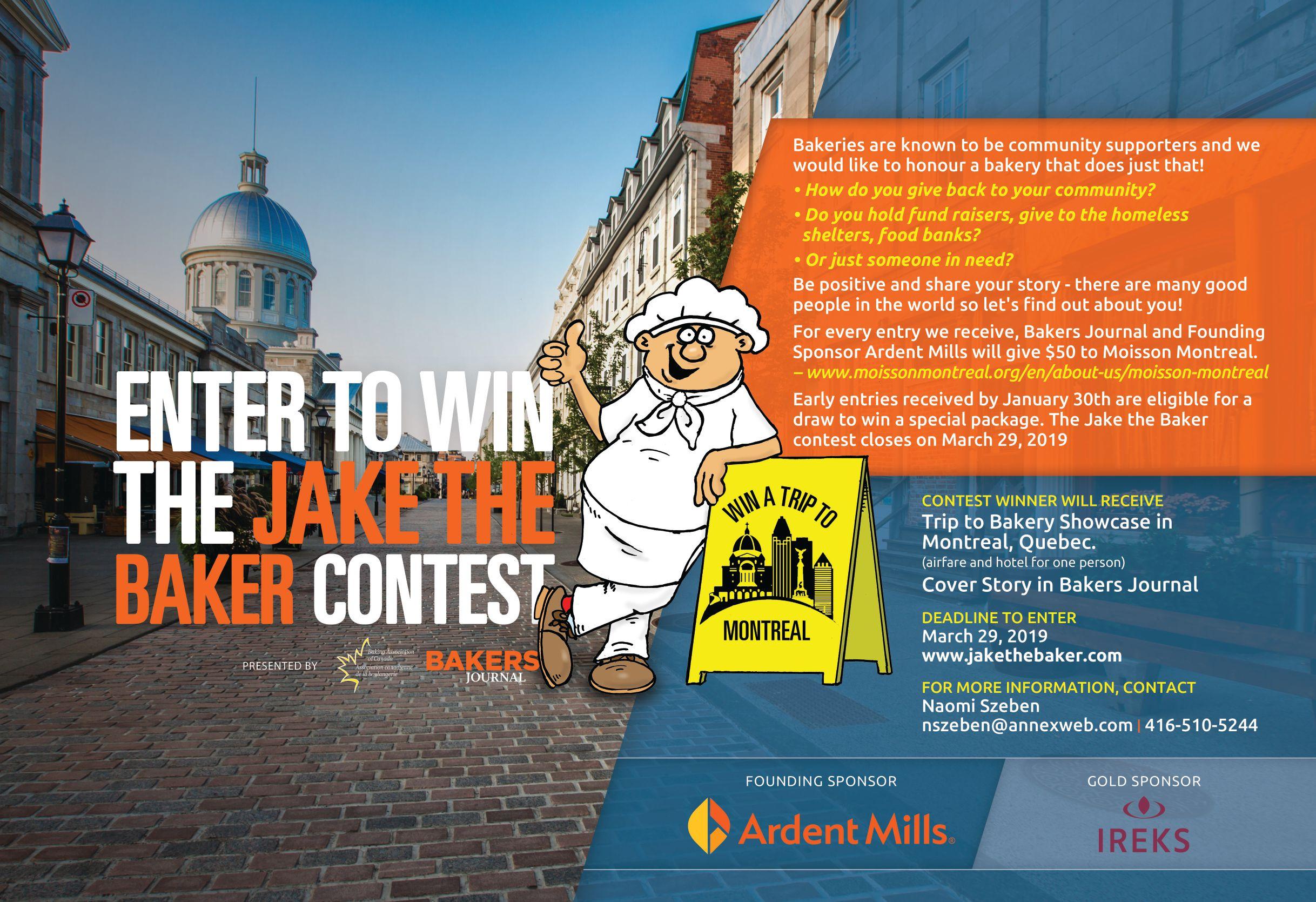

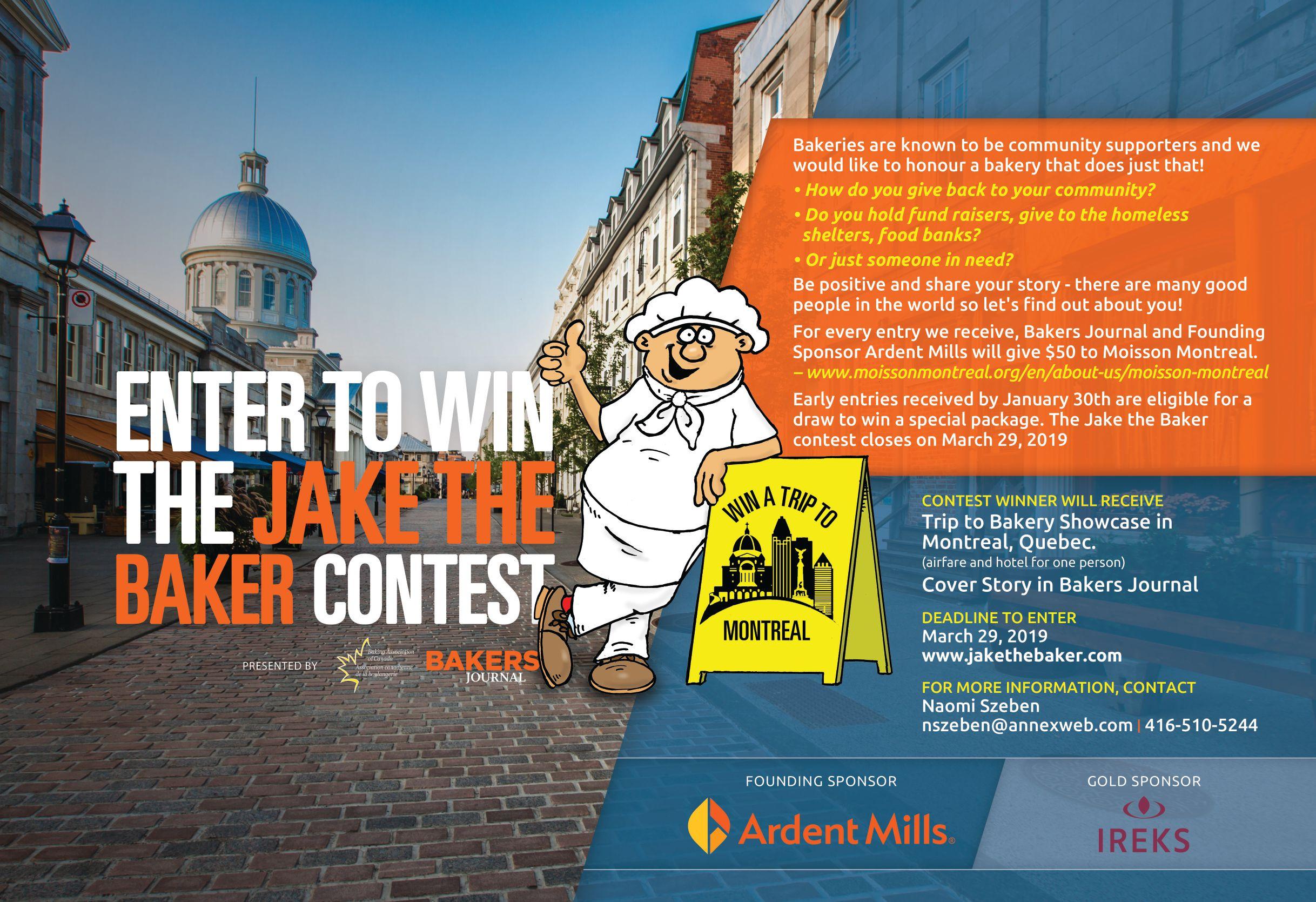

BAKERY SHOWCASE 2019 is the baking industry trade show & conference featuring almost 50,000 sq. ft. of space showcasing the latest baking ingredients, equipment, services, technology and baked goods (fresh, proof & bake, par-baked, freezer-to-oven, and thaw & serve).

buyers, increase brand awareness, launch new products & services, write orders, and network with the industry

Produced by:

Bakery Showcase 2019 trade show and conference is in Montréal

May 5 & 6. The Montréal event was last held April 2015 and we are expecting greater success in 2019.

The 2 day event at the Palais des congrès de Montréal is almost 50,000 sq. ft. of trade show floor offering products & services for the baking industry.

Companies that manufacture, market, distribute, and broker, baking ingredients, baked products (fresh, proof & bake, par-baked, freezer-to-oven, thaw & serve) baking equipment, supplies, and technology and services.

EXHIBITOR

Bakery Showcase 2019 will provide the best selling opportunity of the year. For attendees, the decision is just as clear – when all the best ingredients, products, equipment, services and innovations are in one place, at one time, there’s no better place to shop around. That’s why allied trades and bakers rely on Bakery Showcase 2019 for the complete picture of the latest trends.

As an exhibitor you can:

Meet industry professionals from Canada.

Do business… book orders, make new deals, develop new

Provide samples of your products to show how good they taste or demonstrate how well your equipment or services work.

Launch new products, new merchandising programs and new promotions to get sales moving.

Attract new customers, cater to existing customers and win back former customers.

take a measure of new trends

Bakery Showcase 2019 is the place of business for Canada’s baking industry

Hold your annual sales meeting during Bakery Showcase

important industry event

Wholesale & commercial bakeries (intermediate and large volume), retail bakeries (independent & franchise), patisseries, grocery chains / mass market / supermarket in-store bakery, c-stores, foodservice establishments (restaurants, cafes, hotels, caterers), specialty bakers, brokers, baking profession schools, consultants, government buyers, local and international trade missions.

Bakery Showcase 2019 will be actively promoted regionally, nationally and internationally through extensive campaigns directed at key industry segments.

Event promotional coverage will be achieved through:

Direct mail promotions, e-mail broadcasts and telemarketing campaigns to key industry segments

Media and trade journals will receive timely press releases and a targeted advertisement campaign will be implemented.

Networking through BAC Chapter meetings.

Communication through allied event partners.

ask yourself these questions:

Do you want to meet retail bakers, in-store bakers, foodservice bakers or wholesale / commercial bakers / manufacturers?

Does your company do business or are you considering doing business with the baking industry?

Does your ingredient, product, service or equipment effectively?

Is your company concerned about the rising costs of

If your answer is YES to any of these questions, commercial and retail bakeries and food service establishments will want to meet with you at Bakery Showcase 2019 trade show

Located in Montréal’s downtown core, the Palais is a safe and bustling venue. A hub of activity straddling the city’s business centre, international district, Old Montréal and Chinatown, it is near Montréal’s main attractions, and 4,000 of which are directly linked to the Palais via indoor passageways. For more information on the venue: www.congresmtl.com

Exhibit space rates: (prices are excluding applicable taxes)

Minimum exhibit size is 10’ x 10‘ = 100 sq.ft.

Single In-Line Booth (10’ x 10’ unit) $2,100 - BAC/CBQ members only $1,900 Corner premium (exposure on 2 sides) additional $250

Exhibit space cost includes the following:

Draped booth – 8’ high x 10’ wide backwall, 3’ high railing drape to aisle

24 hour perimeter security coverage

5 exhibitor badges per 100 sq.ft. (up to a maximum of 25 badges)

Materials handling from loading docks to booth. *Includes: dollies, pump trucks and forklift with maximum capacity of 5000 lbs per unit/item. Exhibitors requiring special handling/equipment beyond that provided by Show Management will be responsible for all fees incurred.

10 complimentary attendee registration discount codes per 100 sq.ft. exhibit space (up to a maximum of 100 discount codes)

A $200 discount on every 100 sq. ft. of space

A $50 Discount on hot link to company web-site

Additional 10 complimentary attendee registration discount codes per 100 sq. ft.

As per schedule

Conseil de Boulangerie Québec (CBQ) (CTAC)

BAC is the industry association representing Canada’s over $8 billion baking industry. BAC’s mandate is to further the interests of Canadian retail, in-store, commercial and wholesale bakeries through advocacy and effective programs at the regional and national level. For more information visit www.baking.ca

the majority of businesses from baking and pastry sector and their suppliers whose products are manufactured or distributed in Quebec. For more information visit https: //conseiltaq.com/association/boulangerie-quebec/

exhibit

Dry ice cleaning eliminates exposure to toxic cleaning materials. The process also eliminates repetitive motions of hand cleaning or scrubbing, chiseling or activities that require pounding, sanding or scraping.

A Texas bakery was seeking a solution to its cleaning problem. In the company’s 11612.88 square meter baking facility, there were many issues for its quality assurance (QA) manager to worry about; from general maintenance and equipment repair to shelf life and product contamination. Keeping the facility and equipment clean was one of the most important tasks, but it was labourious and time consuming.

The bakery’s biggest cleaning project included a mile long bread cooler, which moved baked goods from the oven to an area for cooling and packing. The cooler was cleaned regularly by hand. Because of the plant’s constant operation, the conveyor and surrounding equipment were coated with layers of mineral oils and bread crumbs that had accumulated over time.

The plant used a combination of traditional cleaning methods, such as pressure washing and detailed hand scraping. When the cleaning crew performed a deep cleaning of the cooler it took 25 people more than ten hours to clean the entire length of the conveyer.

After the deep clean, regular cleaning included pressure and hand washing, conducted by five labourers working 8-10 hour shifts. The regular cleaning has helped keep the surface of the stainless steel pins and rollers, the guides and the wear strips clean. Unfortunately, the general maintenance does not clean deep enough to completely remove the layers of residue from the other parts of the cooler, proofer, grids, baggers and floors. In addition, the pressure washing and manual wiping removes important mineral oils from the conveyor which must be reapplied following the cleaning to ensure the conveyor is properly lubricated—a process which adds at least two hours of downtime.

The use of the pressure washer also required the company to wrap all electrical components prior to cleaning and then designate a few crew members to collect the water. The crew must remove all secondary wastewater and ensure that the equipment is completely dry before the parts can be reassembled and production could begin again.

“No matter how hard you try, water gets everywhere, and even after trying to remove the water, moisture remains,” said the QA manager. “In a baking environment, we are highly concerned about the long-term quality and shelf life of our products. Where there is moisture or build-up, there is a greater chance of a biological [mold] growing.”

Since implementing a dry ice cleaning system, the Texas bakery has seen an immediate return on investment. Cleaning the bread cooler and mile-long conveyor now takes two people less than six hours. Facility managers noted that they were also able to reduce their staffing in the sanitation department while the remaining crew is now able to focus on areas of the plant that the company hadn’t been able to clean previously. They estimated that by reducing the amount of people and time required to clean the equipment by hand, they were able to recoup 24 to 30 hours per person per week that can be allocated to other cleaning and maintenance projects.

The cleaning process is soft enough that it doesn’t peel paint, impinge electrical conduit, damage the laser

and infrared photo eyes used in production, or remove the mineral oils on the conveyor, yet is powerful enough to remove several years of built-up residue from production line machines.

The QA manager commented, “We simply did not have downtime to clean some pieces of equipment to our standards, but because of the speed and effectiveness of the dry ice system, we now have the time and resources to attend to a variety of other areas of the plant. Much of the equipment in a high-speed baking plant is simply not designed to be cleaned easily.”

With the dry ice system, the plant does not have to worry about water residue. Crew members no longer have to bag the electrical components, and they have also reduced the possibility of harmful biologicals. The QA manager noted, “We do significant testing to determine how clean our equipment is after cleaning, and with dry ice cleaning, we are able to do more than simply removing debris. We are actually sanitizing our machines, which will have a positive impact on the long-term quality of our products and the life of our equipment.” / BJ

Tyson Marlowe is the vice president of global training & development at Cold Jet. He has been involved in researching, testing, and implementing dry ice cleaning in many different industries for over 16 years. He is also heavily involved in product development and improvement, as well as global business development.

Artisan breads are all the rage. Prefermentation, the process of using bread dough made hours in advance, to add to the final dough, is the new norm. Think biga, poolish, sour dough and levain. Mix in a vast variety of grains and seeds to really ramp up flavour and basic white bread just can’t compete.

Two Canadian bakers Jeffrey Finklestein, owner of Hof Kelsten in Montréal and Kevin Mathieson owner of Art Is In Bakery, in Ottawa have found success through their bread.

Finklestein, at thirty years old, was broke and living with his mother in Montréal. He started to experiment with breads, in their tiny, shared apartment kitchen. This would become the start of his bakery. With years of experience working in both the savoury and sweet sides of restaurant kitchens throughout Europe, Finklestein thought up a savvy business plan. “I saw some of the best restaurants in the world buying their bread,” he says. “I decided I wanted to bake bread for chefs.”

}After a decade in business, 60 restaurants in Montréal now buy bread from Hof Kelsten. Initially, Montréalers were only able to enjoy the bread when dining out. Today, there is a retail bakery and café with 19 seats.

Setting up a booth at the local Ottawa Farmers Market at Lansdowne Park set sales soaring. “That’s when things exploded!” exclaims Mathieson.

Finklestein’s philosophy is simple, “We want you to taste the grains,” he says “Our breads focus on four ingredients; Grain, water, a rising agent and salt.

The top selling bread is the pain au levain. The levain is made with about one-third parts each of white flour, whole wheat flour and rye flour. Made the day before, 90 per cent of the levain is added to fresh dough made from more of the same three flours. “The other 10 per cent of the levain is added into the new levain,” says Finklestein. “It keeps refreshing itself that way.”

The end result is a 600 gram round

bread. “We like our breads to be dense and compact. The more holes there are in bread, the more it is exposed to oxygen and dries out.” Dense bread is especially beneficial for his restaurant clients who will not serve it for a few hours after it is delivered. It is then pre-sliced and sits again prior to service.

The signature bread is the Jewish rye. “This is the bread of my childhood, before it became destroyed in today’s market. In this bread, we try to add as much rye as possible, while still keeping it fluffy.” Olive oil, a bit of honey and caraway seeds are also added.

Two breads that have become popular with customers are the kamut bread and the spelt bread. The kamut is made with a starter of white flour,

while the spelt is made with a starter of spelt making it a 100 per cent same grain bread.

The pumpernickel bread that regular customers love is available only on Fridays. “It’s black. And the colour comes from the slow bake --16 hours in an oven that is turned off over night-and the caramelization of the molasses.” The bread is made from 80 per cent rye flour and contains whole grains and rolled grains. The loaf weighs two kilograms, and because of its high moisture content, it keeps for three days.

Kevin Mathieson, owner of Art Is In Bakery in Ottawa, started his business in 2006. It too, started out as a home-kitchen based business. He quickly needed space, when restaurants in the Byward Market area of the city started enthusiastically purchasing the bread.

A local catering company allowed Mathieson the use of their kitchen during off-hours and the graveyard shift, between 6 pm to 6 am. “I didn’t

have any money at all to start a business. But they gave me the space for very low rent.”

Setting up a booth at the local Ottawa Farmers Market at Lansdowne Park set sales soaring. “That’s when things exploded!” exclaims Mathieson. Soon everyone, including the media, was singing his praises.

Today Art Is In Bakery has 14000 square feet of space, with a licensed café. Mathieson’s wife Stephanie takes care of the administrative work, human resources and customer service, while their daughter Emma runs the retail side on things. The menu has been expanded to include breakfast pastries, savory items and desserts. While Mathieson’s bread is still sold to restaurants and appears at local farmers markets, the company has expanded into grocery stores, such as the local Farm Boy chain.

He still sells the two original stiff levain raised breads, the Dynamite White and Whole Grain Fennel, made from a levain of 90 percent organic white flour and 10 per cent organic whole-wheat flour. Creating this bread is a three-day process. But, it’s the latter of the two that is more finicky to make. Mathieson says. “It needs more attention to detail and requires gentle folding and shaping. The bran and germ are very rough. It can puncture the gluten structure.”

Grains play a big part in the breads at Art Is In Bakery. “I’m a big fan of bread with grains. I love to eat it toasted,” enthuses Mathieson.

The Crazy Grain bread starts with a biga.”It’s a stiff dough starter that gives a real strong yeast flavour, with a floral fragrance.”

A pre-mix of crushed grains including wheat, rye, millet, spelt, flax, oats, kamut, cracked corn and alfalfa, along with the flour, soaked in water and buttermilk, mixed with black strap molasses and left to autolyse—or soak for 30 minutes. This helps to soften and hydrate the grains and slow fermentation, while increasing flavour. “The dough has a lot of moisture, so it’s almost like a pancake batter. It thickens as it sits. Then, we mix it for 20 minutes.”

Additional popular breads at Art Is In Bakery include the Cheddar Chive Jalapeño and the Garlic Rosemary. These breads begin with a poolish of equal parts water and flour. The next day fresh flour is added, along with olive oil, milk, yeast, and salt resulting in a bread of 80 per cent hydration. “We ferment it all day and then process it from there.”

Bread fans continue to rise and artisan breads give customers more choice than ever before. In a market full of unique combinations bread variations can be endless. / BJ

With ADM, you don’t have to navigate multiple suppliers for your baking business. We offer an extensive range of on-trend flours, baking mixes and more. And our strong geographic footprint in the U.S. and Canada means you can count on an uninterrupted supply, cost efficiencies and support.

Learn more at ADM.com/milling

James Beard Foundation Award nominee, Chef Greg Wade of Publican Quality Bread is modest, but pleased with the nod from the American Who’s Who in culinary excellence. “It’s nice to be thought of and recognized as one of the best bakers in the country, and I’m hopeful for next year…it’s just pretty cool. It’s a pretty wild experience,” says the young chef.

Chef Wade attributes his success to how strongly he feels about quality. His driving force is knowing about the source of his ingredients, and being able to provide high-quality bread that is as good, if not better than bread found in Europe. “I think the best thing you can do is to find something that you’re actually interested in, find something that you’re passionate about and that you can do to make money.”

}Starting out at the critically acclaimed, Girl and Goat, then later Little Goat, he was introduced to Paul Kahan, of Publican Quality Meats. Wade remembers the informal interview well. “He asked me, ‘what do you want to do?’ I said, ‘I want to do natural fermentation, and I want to focus on sourdough, and I want to feature local farms, small grains.’ And he said, ‘perfect. Let’s do it.’

“Just do one or two things and do them extremely well. Just knock ‘em out of the ballpark and have it be something special.”

have been posed prior to opening: “What do we want to do, and what do we want to do really well?”

need to be in every restaurant in Chicago. That’s not the point.” Wade explains. “For me, in five or ten years, I do a retail bakery and café for Publican Quality Bread. But I don’t want to see ten locations of PQB locations. I want to keep it manageable, I want to keep it successful, but I also want to keep it special.”

“We started off with just doing the one-off location...so it was like seven or eight accounts, and initially we were tied into Publican Quality Meats’ revenue stream, so we weren’t broken out as an entity. Overall, we were able to do many more things. We were able to do naan, and pita and pretzels, and our sourdough and bagels and what have you. It just a product list about forty or fifty items long. It was pretty crazy.”

However, the chef soon learned that the saying, “you can’t please all of the people all of the time” applied to bread baking as in life. Having a wide-range of products looked good on paper, just not on their monthly ledger.

“We were haemorrhaging money. It was really rough on everyone involved.” The bakery and the partners all took a step back to ask the one question that should

“Do I want to be known for the best hamburger bun in Chicago?” asks Wade. “Absolutely not. Do I want to be known for the best sourdough? Yes! So, that’s what we decided to do, we limited our product list to only ten different mixes and re-examined our pricing structure and then we started making money. That’s when we actually grew. Especially at the onset, we weren’t charging the one-off location for full price, it was like half off, or something like that. We decided that in order for the bakery to be successful and be its own thing we needed to charge everybody the same and just pick a small amount of things and do them really, really well.”

The bakery took off after that decision. “I just tallied up our accounts the other day, and we’re just over a hundred. Now we just do over a hundred locations in Chicago, mainly restaurants, and we’re hovering around 12 thousand pounds of dough being produced.”

“Quality” for Wade means keeping his production relatively local. “I don’t think I

“I think as you grow, you lose a lot of what you started out with. It takes somebody like myself to be there, consistently, to be able to feel the dough, to be in production and to be able to train, teach and mentor bakers.

“I don’t want to see it become this giant behemoth that I’ve got to run between ten locations and everything is doing “just okay.” I want to do it really well. Just make one or two things and do them extremely well. Just knock ‘em out of the ballpark and have it be something special.”

Wade is optimistic about the quality of bread in the United States, in light of the wider variety of natural flours and grains that are being introduced to commercial baking. “I think that we will see people using better flour, fermenting it, doing more whole grain, that’s where I think bread is going.

“I think we have a very talented group of American bakers these days, that we can try to turn the tide of “Americans don’t have good bread” assumption throughout the world.” / BJ

• Kosher and Halal certified

• Can be used to create lower fat products

• Most Butter Buds ingredients can simply be declared as a natural flavour

• Long shelf life. No refrigeration required on all powdered products

• Low usage rates = cost savings

• Available in a variety of cheese, butter, cream and milk flavours

Buds

BY DIANE CHIASSON

5 easy tips to entice customers off the street and into your bakery

Bakery merchandising can be a simple and cost-effective way to enhance your customers’ shopping experience, and most importantly, boost your sales. Give passing pedestrians a chance to see something they might not have seen before: Turn your bakery into an experience, not just the to buy treats. Before we begin, you must first put yourself in your customers’ shoes to get a better understanding of what you are currently doing, and ask yourself how you can improve on it. Go outside and take a good, long look at what you see, and ask yourself these questions:

• What does my storefront display tell me about my bakery?

• Is the entrance open and inviting?

• Are my windows clean?

• Do my signs tell me exactly what I am going to find inside?

• Are the promotions up to date?

• Does the space outside my bakery smell good?

• Do I want to come in and stay?

• Is my place child-friendly?

}eye-catching, symmetrical and smell enticing, and delivered with excellent customer service.

Here are a few quick and easy tips you can use, and watch your sales multiply immediately!

First, an affordable way to entice local foot traffic through your bakery doors is to place a colorful chalkboard panel in front of your door or on your patio. A great window display will be the first impression your customer has of your bakery; consider it a “teaser trailer” for your bakery. It’s a great place to show customers your new products, your best sellers, and what’s on sale. Third, use scents to get your customers in the door. Did you know that Cinnabon strategically places ovens near the front of its stores so the smell of baking cinnamon rolls wafts outside?

2.

All your signage should be consistent in size, layout and typeface, and should complement your bakery’s image and brand. Use signs to give your customers the information they need, but might be too shy or busy to ask. Mention the unique way in which it

Did you know that Cinnabon strategically places ovens near the front of its stores so the smell of baking cinnamon rolls wafts outside?

To find where your bakery is missing out on sales opportunities, walk through your shop as though you never saw it before. Consumers tend to favour their right-hand side when they enter a store, and continue walking along the perimeter when buying. Stand in front of your displays and look at them as if you were a customer. Walk all around your bakery, and look at all of your equipment, seating arrangements, display and shelves. How does it look, feel, smell and sound?

You should always bring your fresh products right up front, near the cash. Make sure these treats are

was made, and try to also offer nutritional information. Always make sure every item is priced appropriately to avoid surprises at the cash register.

3.

People love free samples! I cannot stress how beneficial sampling can be for your bakery. Giving customers a chance to taste your products and opportunities to ask questions is the best way to make a sale. Sampling also gives your staff an opportunity to educate customers. It is probably the best marketing tool a bakery could use.

Your goal is to sell fresh bakery and other food products and the food should always stand out in order to generate impulse sales. Always envision your displays full of products. Colourful displays are not only very attractive to the eye but colours play a major role in luring a would-be customer into your bakery.

Creating displays with different heights and depths is a key merchandising point. For baked goods, this can be achieved by using a variety of different platters, twoand three-tier display units, and cake stands with pedestals. Avoid using large, commercial-looking plates. Your dishes should be small enough to look full when you place your pastries on them, but big enough so that they don’t seem crowded. Place your most eye-catching cakes on pedestal cake stands, so that they attract attention from far away. Cross-merchandising baked goods is also an excellent opportunity to upsell by pairing the right items together. Tiered shelving and glass shelves greatly enhance baked goods, and is a great place to suggest pastry pairings. Avoid routines: Try to mix things up on a regular basis.

5. PAY ATTENTION TO PACKAGING

Presentation is essential to your bakery; your packaging will boost your brand, and will make your products stand out from the crowd. It should be part of your merchandising. Your products should display yourbakery’s logo, slogan, and website. as they say when it comes to bakery products, we eat with our eyes first! / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping foodservice, hospitality and retail operators increase sales for over 30 years. She is recognized as the industry leader in providing innovative and revenue-increasing foodservice and retail merchandising programs, interior design, branding, menu engineering, marketing and promotional campaigns, and much more. Contact her at 416-926-1338, toll-free at 1-888-926-6655 or chiasson@chiassonconsultants.com, or visit www.chiassonconsultants.com

Hailed as a “revelation” when it first appeared in 2004, Jeffrey Hamelman’s Bread is a legendary resource praised by baking luminaries from around the world. Explaining complex techniques with simple and helpful illustrations, the book includes recipes for a vast array of breads, including sourdoughs, brioche, authentic rye breads, flat breads, French breads, and much more.

• Features nearly 150 detailed, step-by-step recipes, along with vivid drawings and photographs showing techniques and finished products

• Written by Jeffrey Hamelman, one of fewer than 200 Certified Master Bakers in the United States and a recipient of the Golden Baguette Award (2005), the highest honor bestowed by the Bread Baker’s Guild of America

• Fully updated to include the latest techniques, methods, trends, and bread

As Canadian consumers continue feeding their appetites for low carbohydrate, reduced sugar, and gluten-free foods, bakers such as Chef Jan Campbell-Luxton bake on, unburdened by the latest food trends.

Campbell-Luxton creates organic, artisan breads and pastries from his original bakery, De la Terre bakery in Jordan, Ontario using his “hundreds-yearold style of bread.”

He and his staff supply 15 to 20 wholesalers and 12 farmers markets between Niagara-on-the-Lake to Toronto.

“I don’t want to lose creditability by reacting to the latest craze. I just do what I do naturally. I’m committed to foregrounding locally produced foods and their producers, as well as encouraging consumer support of organic and sustainable agricultural practices,” he said. “And what we do with our traditional techniques and ingredients just happens to overlap with the current market trends.”

Looking towards the future, CampbellLuxton believes bread consumers will continue to place emphasis on natural sweeteners, plant-based foods, convenience, waste reduction, and gut health. His primary concern is the “market surge about gluten-free products and consumption.”

}“People need to take into the account the ‘process’, because many products claiming to be gluten free use a process that includes high quantities of commercial yeast, salt and sugars,” he said, warning consumers that some bakers’ methods may undercut nutritional quality.

Deliberately fermented foods are becoming all the rage with evidence suggesting that their consumption has a positive impact on our digestive health.

involved in one thing. The other is trying to dispel myths and have people embrace real bread. You have to wonder how natural is a loaf of bread that can last up to two weeks?”

Further, he says his mission is to educate the public against pop culture headlines –genetically modified food (GMO) being a big one. “Canadian-grown wheat is GMO-free. Working with customers to try and get them to understand the process and labour

Other emerging trends to which De la Terre bakery already aspires, are authenticity and sustainability. Baked goods are all natural, with no dairy or animal products with the exception of the Honey Walnut or Honey Butter breads. Campbell-Luxton states that “vegan is becoming less of niche trend and more mainstream.”

With consumer interest in the sustainability of our food systems and environmental stewardship, he says they use biodegradable and compostable take-out containers, cutlery, and napkins. “We are trying to normalize environmental factors as a way of life.” This includes waste reduction by sending scraps to the pig farmer, making bread donations to charity, composting and recycling to reduce garbage, and repurposing bread products to make crostini, bread crumbs and croutons.

He has a true passion for connecting people with their food, helping educate about where it comes from and how labour transforms it to become food.

“There’s a rupture between producers and

consumers of food that can have negative consequences,” he says, as in the case of clean label product trends.

“I find it needs to be stewarded with more care. It’s disconcerting the way words which are meant to demonstrate cleanliness and health consciousness are so widely marketed, making them lose meaning and intent.”

Asked whether he thinks most people view bread as an indulgence or a staple, Campbell-Luxton says the market is split. “There are those who view carbs and breads with suspicion, thinking it’s a poor health decision (based on fads like Atkins, Wheat Belly, South Beach diet), and those who are more educated.”

“Food fads will episodically scare people off bread,” he said. “It’s one of many foods that have long endured cycles of public misunderstanding. But it will continue to be a leading bakery segment. It’s central to how people nurture themselves and it can be a part of a healthy, balanced diet.”

His fare of time-honoured, labour intensive artisanal products include organic whole wheat, cheese and herb, honey and walnut, multigrain, multi-seed,

sourdough, olive, spelt, and rye breads. With innovations stemming from an increased interest in whole grains and long slow fermentation, Campbell-Luxton is excited for the resurgence of products based on flavour and slow fermentation. “It’s exciting. It goes a long way of dismissing the hyperbole about grain consumption,” he said.

Deliberately fermented foods are becoming all the rage with evidence suggesting that their consumption has a positive impact on our digestive health. Campbell-Luxton believes they will continue to gain in popularity and is excited about an idea he’s been ‘fermenting’ in using old bread and beer, along with other experimental baking of potato sour dough, beet bread, sweet potato bread, tomato and sage breads.

Another area of interest is that of sprouted and heritage grains. “I’d love to see this take off and expand our own product lines,” he said, adding that he finds it “interesting to work with a flour that contains a much more dynamic enzyme activity and interesting taste profiles.”

While the bakery purchases flour and produce from small independent farmers where possible, he would love to mill his own grains where it not for the debilitating factor of too little working space. However they are “working closer with supply chains to find a mill we can work with, using my dad’s spelt and rye from the family farm that will be able to match our volumes and provide consistent distribution.”

With his own son suffering a wheat allergy, Campbell-Luxton has worked with many millers and growers in an attempt to find alternative grains. In the meantime he and his staff are dabbling with innovative experimentation using a host of original grains including Red Fife and Emmer, to name a few.

Commodity pricing, environmental change, and economic shifts all impact spending habits. Not being one to “trend hop”, Campbell-Luxton will go about baking his daily bread based on a decades-old tradition. “My basic way of thinking is, whatever way you slice it, bread is made to be enjoyed.” / BJ

¦ classified Ads ¦

Phone 705-826-2254 | 1-888-599-2228, ext. 268 Fax 1-866-810-8111 (secure line)

BY JANE DUMMER

How Keto diets change the low- sugar bakery market

Over the years, the very low carbohydrate, high protein diet has been marketed and rebranded. In the course of my twenty-plus year food and nutrition career, I’ve seen it go from Atkins to keto.

Today’s trend, the keto diet focuses on high fat, moderate protein and low carbohydrate aimed mainly at the fitness and weight loss market. It’s call the keto diet because ketones are the source of energy that the body uses when it’s burning fat.

In the short term, low carbohydrate diets can be helpful for weight loss. However, the health effects of maintaining ketosis for long periods of time are unknown, especially on the gut microbiomes and should be supervised by a health professional like a dietitian. That being said, I’ve observed a surge of “keto-friendly” products in the mainstream market over the past two years including the baking sector.

}to table sugar (sucrose.) This makes it tricky to create a low carb bread or baked good. I’ve seen some baking disasters because the sugar in the recipe has been meddled with.

A few baking companies are specifically focusing on the keto market. Nui Foods in Southern California is one of them. They specialize in keto cookies. The founders were both living the keto diet and wanted to create a snack that was ready to eat at home, work, and at the gym. Juan Altamirano, Research and Development Manager describes the kitchen to commercialization process: “Perfecting our cookie for large scale production took roughly three months and over 50 recipe tests. The biggest hurdle that we overcame when transitioning to large scale production was dough machine-ability. Our dough would separate due to its high fat content (Keto Ratios) and it

“We are on a mission to make saying no to sugar easy, tasty, fun, but like all bakers know, sugar plays a very important role in a cookie’s flavor and texture.”

would result in an overly dry dough that would feed into the cookie depositor.”

Ketogenic baking often uses coconuts for flour, milk and fats.

Ian Graham, founder of Global Food Alliance agrees. “I hear about the keto diet daily. The UK is quite concerned about sugar consumption and has declared a ‘War on Sugar’, so it’s not surprising people are gravitating towards these low carbohydrate products. Keto Genius is a subscription service available for people living in the UK. Monthly you receive a supply of keto friendly snacks delivered to your home. Some UK mainstream supermarkets have devoted aisle(s) to keto food products making it easier to get all your items in one location.”

We all know that sugar is essential for the sweet taste in baking. However, sugar goes beyond sweetness and is an important ingredient for function including colour, texture, and fermentation. When I say sugar, I’m referring

Even substituting maple syrup or honey for table sugar creates new interactions that will not behave the same as sugar, resulting in very different outcomes, just like using low sugar sweeteners.

Altamirano, who has a baking and culinary background, agrees. “Other baking hurdles that we experienced include the no added sugar/low sugar, gluten-free and low carb. We are on a mission to make saying no to sugar easy, tasty, fun, but like all bakers know, sugar plays a very important role in a cookie’s flavor and texture. It has led us to use a mixture of nut flours which don’t bind as well as traditional flour does. We use a combination of erythritol and monk fruit extract. Overcoming these hurdles was amazing. Our cookies shelf-life is four months, and we want to increase that to one year. Day by day, we move closer to it.”

Altamirano goes on to explain, “Our top flavour is peanut butter. I believe it’s our top seller because of its taste, texture, and because it’s an iconic flavour. We plan on expanding with more flavours as well as our reach; we want to make it as easy as possible for everyone to indulge in something greater.”

Another company, SoLo Carb Bread in Wisconsin has created three breads with only 3 grams of carbohydrates per serving. They describe their formula as, ‘two years in the making.’ Finding the right balance of low carbohydrate for bread and baked goods takes time, science and precision. However, with the move of mainstream interest in the keto diet even though the long-term health effects are still unknown, there seems to be opportunities for the baking industry to explore and innovate in this space. / BJ

Jane Dummer, RD, known as the Pod to Plate Food Consultant, collaborates and partners with the food and nutrition industry across North America. www.janedummer.com

Pour toute information sur les espaces d’exposition, les commandites et les conditions de participation :

For exhibit space, sponsorship & attending information:

www.baking.ca | info@baking.ca