This edition’s profile, Roy Bouman of Sweet Caroline’s Bakery, descends from generations of Dutch bakers stretching back to the 1800s.

BY LAURA AIKEN

This edition’s profile, Roy Bouman of Sweet Caroline’s Bakery, descends from generations of Dutch bakers stretching back to the 1800s.

BY LAURA AIKEN

It seems the public has been busy tallying up a list of food fears. A recent survey of Americans, conducted by the International Food Information Council Foundation, suggested that chemicals in food outranked foodborne illness as concern. And people die from food poisoning. People also die from having no food. Are priorities becoming misplaced?

NOVEMBER 2015 | VOL. 75, NO. 7 EDITOR | Laura Aiken editor@bakersjournal.com 416-522-1595 1-888-599-2228 ext. 250

ASSISTANT EDITOR | Colleen Cross ccross@annexweb.com 519-428-3471 ext. 261

TECHNICAL EDITOR | John McColl, Puratos Canada jmccoll@puratos.com

}Does the public conversation and popular media focus enough on the plight of the hungry, or the fact that rising grocery bills put real and worsening pressure on households?

I have to wonder if all the fads, the trends turned new normal, and contentious subjects like GMOs, deflect from the gut-wrenching fact that humans prematurely cease to exist every day from starvation, and many more struggle to put food on the table. It is a luxury of the West to be able to have fad diets and debate the viewpoints of GMO-labelling. The world needs to produce at least 50 per cent more food to feed 9 billion people by 2050, reported The World Bank Group in April. Climate change could cut crop yields by more than 25 per cent, predicts the organization, which is mandated with ending poverty. Globally, one-third of all child deaths are attributed to under-nutrition. That’s staggering, really. As a world, we have fundamentally failed to feed our children. Does the public conversation and popular media focus enough on the plight of the hungry, or the fact that rising grocery bills put real and worsening pressure on households? In July, Statistics Canada’s consumer price index reported a 3.2 per cent increase in food prices in the 12 months preceding July, following a 3.4 per cent rise the previous month. Yet talk of alleviating hunger seems a shadow conversation compared to a buzz word like sugar. It is natural inclination to be a local citizen before a global one, after all that is what affects us first. According to United Nations statistics, one in nine people around the world are undernourished, and much of the poverty is in developing nations. It seems very far away. But it’s in our backyard too; on our First Nations reserves, in our food banks, our shelters, our streets and our kitchen tables. Food Secure Canada and Community Food Centres Canada raised alarm bells over a new report on the rate of household food insecurity in Canada released by the PROOF research team. “Household Food Insecurity in Canada 2013” documented that 2.4 million adults and nearly a million children (about 12.5 per cent of households) experienced food insecurity in that year. Statistics Canada defines food insecurity as being within “a household when one or more members do not have access to the variety or quantity of food that they need due to lack of money.”

I hear heart-warming stories all the time of bakeries who donate their leftovers, and share their resources with organizations in their community that help the less fortunate. There are multiple accounts in this issue alone; in our profile on page 23 and in the Final Proof column on page 38. The bakery industry has a vital role to play as a part of the food supply that touches so many.

Doing our part to help reminds us to be empathetic in our views towards a suffering that most of us are fortunate to have never known. It reminds us of the salient fact swimming amongst the many opinions on what we should or shouldn’t be eating, or how we are labelling food, or any of the other heated topics of the day: some people just don’t have enough to eat. And as a big force in feeding the nation, the bakery industry also has the power to be part of fixing that. / BJ

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

ACCOUNT COORDINATOR | Shannon Drumm sdrumm@annexweb.com 519-429-5176 1-888-599-2228 ext. 219

MEDIA DESIGNER | Alison Keba GROUP PUBLISHER | Martin McAnulty mmcanulty@annexweb.com

DIRECTOR OF SOUL/COO | Sue Fredericks

Mailing Address P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710. RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5 Email: subscribe@bakersjournal.com

ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Publishing & Printing Inc.

Subscription Rates

Canada — 1 Year $ 30.00 (with GST $31.50 #867172652RT0001, with HST/ QST $33.90)

USA — 1 Year $ 45.00 USD Best pricing is available online at www.bakersjournal.com

Send your subscription request to: Bakers Journal

P.O. Box 530, Simcoe, ON N3Y 4N5 Tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940 Email: subscribe@bakersjournal.com

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2015 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

Congure the Ford Transit to your exact business specications. Choose from three different congurations for body lengths, roof heights, and powertrains, as well as multiple congurations for towing, payload and cargo capacities up to 461.9 cu.ft.† of space behind the rst row. After all, no one knows how you like to work quite like you.

Wheelbase: 147.6"

Roof Height: 100.7"

Powertrain: Available 3.5L EcoBoost V6 Cargo Capacity: 357.1 cu. ft.**

Towing: 7,000 lb*

Payload: 4,230 lb*

Early Mornings: 365/yr

Late Nights: 365/yr

Avg. Hours Worked: 16 hrs/day

Coffees per Day: 4

Last Day Off: 6/23/2011

briefly | IDDBA elects new officers and board; Two-Bite Brownies seeks sale, say sources; Dr. Oetker debuts Giuseppe Pizzeria | for more news in the baking world, check out our website, www.bakersjournal.com

Bridging the gap between old-fashioned neighbourhood European bakeshops and traditional Asian bakeries, Bake Code, a high-end bakery boutique from Taiwan, has brought their uniquely flavoured, handcrafted baked goods to Toronto.

“Toronto is a multicul tural city at the forefront of global food trends and it made perfect sense to open our first location right here in this great city,” said Thomas Wong, master franchisee for Bake Code in a news release. “We’re part of a global baking renaissance, offering the best of the West, fused with the East. The result is an exciting new world of taste and discovery for Toronto food explorers.”

Bake Code’s open-concept store design offers patrons the opportunity to savour exotic smells and tastes before purchase. With a “Baking Timetable” (posted in-store and online), the bakery ensures fresh product offerings are rotated and available in limited quantities throughout the day. The bakery carries over 60 menu items. Signature

Euro-Asian style baked goods featured daily in the Toronto store include: Gagnam Star, Red Wine Longan Bread, Mentaiko Baguette, Chocolate Surprise and Earl Grey Tea Bread to name a few.

Mi & Stu Foods has opened the doors to a new state of the art allergen-free food facility in Lasalle, Que. The factory is the first in Canada to produce gluten, dairy and peanut-free foods in one place, with many vegan and non-GMO options as well, the company reported in a news release.

“We’re very excited to now be able to undertake large scale manufacturing so that we can reach more people with our products!” said Mimi Bercovitch (the “Mi” of Mi & Stu) in a news release.

Combining both baking techniques and flavours from Europe and Asia, Bake Code aims to shake up the traditional bakery format through the art of fusion baked goods, combining a variety of unique flavours to create artisanal products ranging from soft kimchi and cream cheese-filled rolls to red wine-infused breads.

This modern bakery concept comes to Toronto via three entrepreneurs: Thomas Wong, Kenton Chan and Vincent Lau. The three are also partners and master franchise owners of Chatime, the quickserve tea franchise with 12 locations in the GTA and over 1,000 locations worldwide. Headquartered in Taiwan, Bake Code has international franchise locations in Canada, the U.S., and Malaysia.

Growing consumer demand drove the expansion of Mi & Stu’s small Montreal bakery to factory size, the press announcement stated. With the support of the Business Development Bank of Canada, the company’s new home will also soon be certified HAACP, kosher and gluten-free.

The bakery specializes in allergen-free baked goods such as cookies, cakes, brownies, buns and scones, and also offers bake-at-home gluten-free doughs and batters. The company is looking to provide allergen-free private label options and grow the company in this area, noted the release.

Scott Bieker is the new vice-president of U.S./Canada sales for AMF Bakery Systems. Formerly sales director of Tromp Group Americas, Bieker will lead the U.S./Canada sales team for AMF as it markets automated solutions to commercial bakers. He will also utilize his experience as a baker and AIB trainer to support baking process needs at AMF customer start-ups worldwide.

Bieker brings 26 years of baking industry leadership to AMF, and experience from Tromp Group, Danisco, AIB, Nonni’s, and Earthgrains, where he began his career as a baker.

Continued on page 32

For more news about the baking industry, please visit www.bakersjournal.com.

BY

KAREN BARR

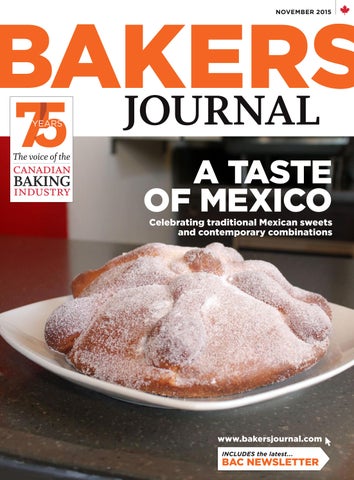

Mexico has always been a celebratory nation and sweets play a major role. Spain brought the people of Mexico their love of pan dulce or sweet breads. Soon, fields of wheat grew outside of Mexico City to keep up with demand. During France’s short occupation (1864-67) there were more than 50 bakeries, 120 chocolate and pastry shops and over a dozen specialty cake shops in Mexico City alone.

Many of Mexico’s holidays include special pastries and desserts meant to be shared at the celebration. Nov. 1 is the Day of the Dead, when Mexican people remember loved ones who have passed. Far from being a solemn day, Mexicans throw a party. Altars are filled with foods offerings for the departed and surrounded by yellow marigolds. The bread for this day is called Pan de Muerto or Day of the Dead Bread. The round, sweet loaf, with orange flavouring, has additional pieces of decorative dough around it shaped into teardrops and bones representing sorrow and death. Small sugar candy skulls are on display, decorated with colourful floral motifs. Chocolate skull sculptures are also popular.

}At Christmas time, Mexicans enjoy buñuelos. The sweet fried fritters are paired with hot chocolate. On the Epiphany, Jan. 6, the ring of the kings bread or rosca de reyes is served. Known as the day the three wise men came to visit the baby Jesus, the sweet bread not only contains candied fruit, but a little plastic doll representing the baby. Whoever finds the doll in their piece of bread throws a party for everyone on Feb. 2.

Figs take on an enlivened flavour with caramel, paired with cinnamon and hoja santa (also known as the root beer plant) brioche with chevre ice cream.

Cinco de Mayo is a celebration of the victory of the Mexican army against the French invasion in the State of Puebla. In the United States, Mexican- American people bake and enjoy corn bread. In Mexico, any traditional Mexican dessert or pastry can be found such as baked flans, empanadas, rice pudding and cookies shaped as pigs.

In Canada, ethnic desserts appeal to consumers’ more adventurous palates. Pancho’s Bakery in Toronto opened its doors in 2009. Today the business has expanded to three locations and two food trucks. Owner Adalberto Aguilar grew up in the industry. His family started their first bakery in Mexico in 1927.

Pancho’s bills itself as the home of the churro – the traditional Spanish creation was adopted by Mexico. “We took the idea and made it better!” Aguilar exclaimed.

In Spain the churro is served plain, but in Mexico it is a sweet dessert. Making churros starts with a cinnamon dough

made in a similar fashion as choux paste, pressed through a star tip, straight into hot oil and fried. Unfilled or filled with chocolate, caramel or jam, the Mexican churro is always rolled in a cinnamon and sugar mixture and served warm.

Poncho’s does a brisk business in empanada sales. The word empanada comes from the Galician, Portuguese and Spanish verb empanar, meaning ‘to wrap’. Each local region of Mexico has its own special recipe for empanada dough.

The pastry can be made with wheat flour, corn flour or yucca flour. Filling can be either savoury or sweet. Popular fillings include meat, chicken, cheese or vegetable. Sweet fillings include pumpkin, sweet potato, yam or fruit.

Aguilar’s favourite pastry is the concha. In traditional Mexican fashion, he eats them every morning for breakfast. The sweet dough buns have a thick topping made with equal parts sugar, flour and

shortening. With the same consistency of cookie dough, the topping is rounded, flattened and placed on top of the concha before proofing. Conchas are decorated with slashes, made by a specialty cutter or created by hand with a plastic bench scraper to represent a seashell. The bakery sells three flavours: plain, chocolate and vanilla.

Other popular desserts are rebandos, which are similar to biscotti but softer because they are baked only once, and orejas, which is the Mexican version of the palmier.

Another item not available from the menu, but made by special order is the tres leche cake or three milk cake. Soaked in a mixture of three milks: homogenized, sweetened condensed and evaporated milk, with the addition of rum, the cake rests overnight to absorb the flavour.

Mexican products are also merging into desserts in a dining setting. Trey Foshee, executive chef and co-owner of George’s At The Cove in the tiny neighbourhood of La Jolla in San Diego, Calif. was inspired to bring Mexican flare to his desserts during a culinary trip to Paris in 2003. His very last meal on the trip, and the dessert served, would change everything.

“It was basically a reconstructed margarita. I realized I should be looking in my own backyard for inspiration,” Foshee said. Soon afterwards desserts like chocolate pot de crème with a churro across the ramekin were on the menu.

At the time, Mexican food did not appear on fine dining menus, even in San Diego, but George’s At The Cove thrives on innovation.

“I’m a big fan of mezcal, but a lot of people have never tried it,” said Foshee, referring to the Mexican spirit made from the cores of the agave plant or piña, which is roasted and smoked in the earth over hot rocks. “If you put it into something like ice cream it makes it more palatable for people to first try it.”

“I incorporate many ethnic ingredients into my dishes, especially Mexican ingredients,” said Lori Sauer, who has been the executive pastry chef at George’s At The Cove for over five years. The mezcal ice cream is used in her mango float with ginger beer and as an accompaniment to deep fried pastries called sopapillas with piña, clove honey

and coriander. Her chocolate ganache is made with guajillo chile and served with avocado and lime. Figs take on an enlivened flavour with caramel, paired with cinnamon and hoja santa (also known as the root beer plant) brioche with chevre ice cream

Foshee’s philosophy is about making the dining experience memorable. He noted that when a customer tries something new or even something familiar served in a different way, they tend to remember it.

Bakers and pastry chefs are often the bookends of the eating experience. Not

only are they creating the first thing the customer eats, be it a breakfast pastry in the morning or the bread served with dinner, but they are also making the last course with dessert. With the rise of interest in ethnic cuisines, traditional Mexican desserts and Mexican products used to heighten flavours may give just the spin to make each bite more memorable. / BJ

For more news about the baking industry, please visit www.bakersjournal.com.

Turn occasional customers into regulars with a proven marketing platform that lets you tailor offers and messages for maximum appeal.

By Tina Kalogeropoulos, Marketing Manager, Vicinity

n the foodservice business, trends come and go along with customers, who may or may not patronize your bakery again after the first time. But as an independent business owner you rely on repeat business because it means you’re retaining customers.

Loyalty marketing helps you retain more customers because it rewards people for buying your baked goods in a way they find relevant enough to return, again and again. Rewards should appeal to different types of customers based on their value and purchasing behaviour; people who shop with you more often earn the best rewards to encourage even more spending.

And cloud-based customer intelligence and marketing tools like Vicinity make loyalty marketing simple and affordable for independent bakeries and small business owners. Here’s how it works:

By building customer relationships.

Nothing feels better as a customer than having your loyalty recognized with a freebie. A loyalty marketing platform makes it easy to send out offers people truly appreciate to encourage them to visit your shop. Things like exclusive invitations to a

“baker’s tips” event, or product sampling sessions can help you to keep your top customers coming back and spending more per visit. Plus it can help you transform already-loyal customers into brand ambassadors who attract others to your business.

By using customer demographics. Loyalty program mechanics are set up to gather detailed customer information and store it in an accessible Customer Relationship Management (CRM) database. Knowing the demographics, lifestyle, and product preferences of your customers helps you engage them with appealing offers and rewards. Vicinity, for example, helps you create your own CRM database full of customer emails, phone numbers, birthdays, and notes about product and service preferences so you can send specific messages to specific customer groups based on demographics and purchasing behaviour.

By appealing directly to specific customer groups.

Relevant, personalized marketing messages have more sway in today’s overcrowded, buzzy marketplace. The more you can

segment customers into groups based on their behaviour, the easier it is to send them appealing offers that they want to redeem. This gets them inside your bakery, where the potential is high for cross-selling and up-selling. Some platforms, like Vicinity, have automated tools that let you pre-set personalized text or email campaigns that are triggered when certain dates (the customer’s birthday; 60 days after their last visit; one week after their first visit; etc.) or purchasing thresholds are met.

Analytics to measure your results.

Most loyalty marketing platforms come with analytics to help you monitor, extract and “marketize” customer data. For example, Vicinity’s platform shows how much revenue each customer generates and displays graphs that help you track customer visits, loyalty program sign-ups, program referrals, and reward points or promotion redemptions. It’s actionable information because you can launch email and text campaigns based on the data within the dashboard. So if you notice that Tuesdays are always slow, for example, you can easily send a text or email campaign (Toonie Tuesdays; two-for-one cupcakes; etc.) to move product.

Tina Kalogeropoulos is Marketing Manager at Vicinity, a complete, customizable loyalty program for small and medium-sized businesses. Vicinity provides an easy, cost-effective way to recognize, communicate with and reward customers to help drive repeat business. Launched in 2013, Vicinity is a division of Rogers Communications. More than 1,500 Canadian small businesses are part of the Vicinity loyalty program, which has more than 1 million cardholders across Canada.

BY DIANE CHIASSON

December is a big month for bakery sales. Ensure that you’re doing all you can to reap and get repeat business this merry time of year.

The holiday rush will be in full force soon, which means it is the busiest time of year for everyone. Non-stop shopping, year-end parties, school concerts, family gatherings, out-of-town guests… the events are endless. As a bakery operator, December is the best month to promote your business, boost sales and generate more interest.

Here are 10 marketing ideas for how you can increase your sales and bring in more customers this holiday season.

}Many businesses may be scaling down their party budgets this year and opting to throw a small party at the office instead of hiring out a ballroom in a hotel. Target all the office buildings in your area, and send them your menu, along with your holiday specials via direct mail, email, Facebook, or fax.

People go to your bakery all year long. Do something to get noticed! Get into the holiday spirit by decorating your bakery inside out. You can decorate without going overboard by sticking to a more natural holiday theme. Put up a decorated tree with real cupcakes, and play some great holiday music. Add a wreath and door mat to the outside of your bakery. This is a fun and festive time, and you want to evoke that feeling and holiday spirit in your bakery.

Save your customers an extra shopping trip by offering some retail products. For example, you could attractively package products that sell well with a beverage and jam to sell to your clients. You could also create your own gift baskets with bakery products, recipe

Small gestures and gifts impress people, and they work to help keep customers loyal and convert prospects into customers.

books, branded t-shirts and aprons, kids’ items or hundreds of other possibilities. Be sure to include a $2 or $5 gift card in each gift basket to ensure that the receiver of the gift basket visits your bakery in the future.

6.

As a token of your appreciation, send all the clients in your database a holiday card with a voucher for free cupcakes or $5 off to thank them for being a loyal customer this year. Small gestures and gifts impress people, and they work to help keep customers loyal and convert prospects into customers.

3.

Gift cards are great stocking stuffers. Make your gift cards visible to customers by keeping a stack next to your cash register with proper POP materials, or have all your staff mention the gift cards to all their customers. Make it worth their while by offering a $5 gift card for every $50 gift card they purchase.

Celebrate the giving season with your clients and customers by handing out free samples. Offering small samples of your Christmas bakery treats will help increase sales and promote a general feeling of good cheer. Offer samples of your cupcakes, loaves, cakes, little cups of hot chocolate or cider, or gingerbread cookies

The holidays are also about helping others. Consider putting together a food drive, whereby you give customers a 10 per cent discount or a free drink to anyone who brings in a non-perishable item. Stack all the items at your store entrance, and put appropriate POS materials to let customers and

passersby know what you are doing. You can also donate a portion of sales to your favourite charity. How about holding a toy drive for local kids?

8. SUPPORT YOUR COMMUNITY

Consider donating day-old breads or left-over products to your local school, sports club, your local Salvation Army, or any other non-profit organization. This will give your bakery a positive image that will in turn improve your customer relationship.

9. USE RECYCLED WRAPPING PAPER

Yo.u can find lots of wrapping papers, ribbons, as well as gift bags and boxes that are made of 100 per cent recycled waste. Think outside the box when you are wrapping something. Use magazines, old maps, wallpaper, old Christmas cards, posters, sheet music, and napkins to wrap a gift.

10. GET THE WORD OUT

Incorporate the 12 days of Christmas to extend your marketing. Email your customers your “super Christmas bakery menu” on each of the twelve days. Make it a simple one paragraph email with a really catchy subject line including an offer they cannot refuse.

Enjoy getting into the holiday spirit and spreading merriment amongst your customers, family and friends. Tis’ the season! / BJ

For more news about the baking industry, please visit www.bakersjournal.com.

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping foodservice, hospitality and retail operators increase sales for over 25 years. She is recognized as an industry leader in providing innovative and revenue-increasing foodservice and retail merchandising programs, interior design, branding, menu engineering, marketing and promotional campaigns, and much more. Contact her at 416-926-1338, toll-free at 1-888-926-6655 or chiasson@chiassonconsultants.com, or visit www.chiassonconsultants.com.

Butter Buds® is both a Functional Dairy Concentrate and a Natural Flavour Alternative Ingredient.

Made from real butter, cream and cheese in strengths of up to 400 times the original, Butter Buds helps improve the flavour and cut costs.

your perfect secret solution for improving and enhancing the flavour of all your products.

• Kosher and Halal certified

• Can be used to create lower fat products

• Long shelf life. No refrigeration required on all powdered products

• Most Butter Buds ingredients can simply be declared as a natural flavour

Celebrating our 20th anniversary in Canada

• Low usage rates=cost savings

• Available in a variety of cheese, butter, cream and milk flavours

• Also available are organic Butter Buds concentrated dairy flavours and non-dairy specialty products including Dried Beer Extract, Butter Buds-Bacon™ and many more

BY JEFF MOWATT

You’ve got a YouTube video gone viral, and it’s bad. Do you know how to handle the media during a crisis?

There are times when being a manager can make you a media target. The larger your organization, the greater the odds of something embarrassing happening that ends up for the world to see on YouTube. Over and over. It could be a spill that causes environmental damage, a defective product that needs recalling, or an employee videotaped sleeping-on-the-job. If you are that manager being asked by a reporter to comment, here are a few tips to ensure that your company’s brand and your personal reputation withstand the barrage.

}them the broken record response. “David, as I just explained, it would be inappropriate for me to comment. I wish I could help you more.” Then sign off.

In my customer service seminars I encourage all employees to identify themselves as a matter of course every time they answer the phone. Otherwise, customers – especially dissatisfied customers – perceive them to be hiding. Similarly, when disaster strikes, senior managers shouldn’t hide behind subordinates. There is a time for presidents, CEOs, and board chairs to be front and center. You need to be perceived by everyone – including your own employees – as being visible and available when the heat is on. Go to the disaster site, talk to the accused employee personally. Get the facts first-hand. And speak using ‘I’ language.

Small gestures and gifts impress people, and they work to help keep customers loyal and convert prospects into customers.

Decide if you are the right person or the right company to make any comment at all. If you are not a senior manager in your organization, or a designated corporate spokesperson, you should refer media inquiries further up the chain of command. There may also be confidentiality issues that prevent you from commenting. If the issue in under legal investigation, if you are working on behalf of a client, or if it concerns your employee’s private life, then chances are, you are not the person or company who should be making a comment.

You’ll sound like a mafia bookkeeper. And you’ll appear to be guilty in the court of public opinion. Instead, if there are indeed reasons why you shouldn’t comment, then explain, “It’s inappropriate for me to comment on this because (give the reason).” Reporters can be relentless, so chances are they’ll ask another question in another way. When that happens, use their name and give

You’ll need it to gather the facts. Explain to the reporter that you are looking into this, and that you’ll have a comment for them at such and such a time. Notice the positive wording. rather than saying, “I won’t comment until...”, instead state, “I’ll have a comment for you as early as…” You’ll be perceived to be upfront and cooperative rather than aloof and defensive.

This is perhaps the biggest mistake executives make when problems happen. They are afraid they’ll be sued if they admit a mistake. The fact is, the mistake has already been made whether they admit it or not, and they may get sued anyway. Learn a wonderful lesson from Johnson & Johnson when they had the tainted Tylenol disaster. They were so up-front about the problem and what they were going to do to fix it, that their brand ended up even stronger than before the problems.

Think of a spouse trying to explain to their husband or wife why they were unfaithful. No matter what the reasons, stating them will only make it look like you’re trying to justify your actions. It makes things worse. Don’t go there.

If one of your employees messed-up, don’t mention the individual by name. Everyone knows that person’s reputation has been ruined. Instead you can refer to ‘the individual concerned’. It shows that you are trying to protect them from more public humiliation. That doesn’t mean they won’t be held accountable. It just means you won’t kick a person when they’re down or embarrass their innocent family any more than they already are.

Explain that you are committed to doing better as an organization. Remind everyone how long you’ve been in operation and your organization’s mission to bring value and improve the lives of the people in your world. Explain how you want to re-earn their trust. Then describe what you’ll do immediately to help the people who were adversely affected. Finally, outline the steps you’ll take to prevent it from recurring.

Bottom line – in every organization there are human beings who will make mistakes and bad choices. No organization is immune. Those brands and individuals who earn the greatest respect are not those who avoid embarrassment: it’s those who learn the skills to best-handle these unfortunate events. / BJ

For more customer service tips, please visit www.bakersjournal.com.

Jeff Mowatt is a customer service strategist, award-winning speaker, and bestselling author. For more tips, training tools or to inquire about engaging Jeff for your team visit www.JeffMowatt.com

Team Canada organized, practiced and baked their way to the Lesaffre Cup. Next stop: Paris. | BY

After years of coming close, the Canadian baking team has finally snagged the Louis Lesaffre Cup. The team is having its best year yet, and members want to maintain that momentum until they are named the world’s best.

The Louis Lesaffre win happened in June in Buenos Aires, Argentina, at the Americas qualifying round –

one of four taking place around the world. Winners qualify to compete in the prestigious Bakery World Cup (Coupe du Monde de la Boulangerie) happening at Europain in Paris from Feb. 5-9, 2016. Our hardworking Canadian bakers will face 11 other teams for a spot on the podium.

To prepare for the Lesaffre Cup, team members worked on a wide range of products, developed new formulas, honed innovative techniques,

made and remade products, always with an eye toward improving the quality, says team member and manager Alan Dumonceaux, chair of the baking program at the Northern Alberta Institute of Technology (NAIT).

The team’s efforts were judged against those of more than 20 other teams in three categories: baguettes and world breads, Viennese pastries and artistic showpiece.

“A large variety and quantity

of products have to be produced,” Dumonceaux says.

The team consists of four members this year: Marcus Mariathas, director of product development for ACE Bakery, who competed in baguettes and world breads; James Holehouse, graduate of the NAIT’s baking apprentice program, who contributed the artistic showpiece; Dumonceaux, who created Viennese pastries; and Elien de Herdt, a graduate of NAIT’s baking

program, who brought her skills to the inaugural “Young Bakery Hopeful” category.

Mario Fortin, bakery consultant and owner of Forma-Lab, is the team’s coach, and Clayton Folkes, NAIT baking instructor, its technical advisor. Former Team Canada members Tracey Muzzolini and Bill Clay also helped prepare the bakers for success in Buenos Aires.

he drew from three types to find out which one he would be required to bake. So he had to practice 12 breads and in the end bake 10.

James Holehouse’s job was

}Success in the competition resulted from a combination of preparation, flexibility and a little luck. The first night involved two hours of preparation; the second day, eight hours. Mariathas, Holehouse and Dumonceaux worked together in one kitchen because team members were encouraged to help one another.

“The judges like to see members communicating,” Dumonceaux says.

For the baguettes and breads division, Mariathus made 10 different types of bread, Dumonceaux says. The day before the competition,

Criteria include weight, correct number of pieces, development quality and aesthetic appeal. Entries that focus on taste and creativity earn the most points,

Judges were impressed with Team Canada’s organizational skills, Dumonceaux says, commenting that they could tell Young Bakery Hopeful de Herdt was from Canada by her methodical approach.

to create a showpiece that was “symbolic of an event that has marked your country’s history.” Holehouse depicted Samuel de Champlain’s discovery of New France, a sculpture that received kudos for being far more detailed than those of his competitors. “It contained more thinned pieces, it was more colourful and creative and of higher quality overall,” Dumonceaux says.

Dumonceaux made 14 products in all, among them panettone, an Italian sweetbread; cramique, a Belgian breakfast loaf; and melon-pan, which he describes as a sweet bun with brioche dough surrounded by cookie dough.

Dumonceaux says. Competitors are penalized if they go over the strict allotted time limit. Cleanliness and proper attire play their part as well.

Because it was winter in Buenos Aires, humidity was not a problem, Dumonceaux says.

However, flour was a big issue. “They gave us the technical analysis on it a month before and the flour we had to use was very weak and very low in protein. Whenever you have low-protein flour, you have to either add more flour or take water out to compensate, because it

doesn’t have the same water absorption power.”

For his entries, Dumonceaux chose to add more flour because reducing the water would have thrown off the yield.

“I added more flour to get to the right dough consistency and then my doughs took double the mixing time that they normally would have in order to get some gluten development. I also gave additional folds to my laminated doughs just to make sure I had enough strength.”

Another big issue they came up against was the absence of bread racks. While practicing they had had 10 racks to use. With only two racks available, they had to improvise by putting product wherever they could: thus, bins were piled up and trays went on top of trays.

Other obstacles included $900 extra in luggage fees to accommodate “a massive pile of ingredients and gear” and the fact that preceding teams were running late, which put those that followed under added pressure.

Despite these challenges, the team prevailed to earn

their tickets to the Bakery World Cup.

Judges were impressed with Team Canada’s organizational skills, Dumonceaux says, commenting that they could tell Young Bakery Hopeful de Herdt was from Canada by her methodical approach.

Canada’s win in the event’s inaugural ‘Young Bakery Hopeful’ division made the team’s victory even sweeter.

Dumonceaux found de Herdt through Skills Alberta. The young baker was preparing to do Skills Canada already, so she happily joined the team and the three senior members took on the task of training her.

Young hopefuls had four hours to create a children’s tea for six- to 10-yearolds gathered to celebrate a birthday. de Herdt put together a spread consisting of four items: sourdough cake pops dipped

Costs attached to competing were considerable, Team Canada manager Alan Dumonceaux says, citing significant additional travel costs to Argentina, the addition of a member and a significant increase in the number of products required by the scope. Fortunately, cash and in-kind donations for Team Canada’s trip to Argentina totalled $47,100. The team wishes to thank the following donors: Ace Bakery (Gold Donor), Northern Alberta Institute of Technology (Silver Donor), Peter Poole (Silver), Lesaffre Yeast (Silver), Forma-Lab (Silver), Ontario Chapter Baking Association of Canada (Bronze Donor), Southern Alberta Institute of Technology (Bronze), Southern Alberta Bakers Association (Bronze), Chef’s Hat (Bronze), Atlantic Chapter Baking Association of Canada (Friends Donor), Baker Tech Inc. (Friends), BC Chapter Baking Association of Canada (Friends), De Herdt Gardens (Friends), Dutch Delicious Ltd. (Friends), InfoPharm Holdings Ltd. (Supporter).

in chocolate (Mickey and Minnie Mouse); croissant cupcakes made with laminated dough, filled with chocolate frangipane and designed to resemble a cupcake; smiley-faced pizzas; and Nutella-style sandwiches featuring laminated dough and hazelnut filling.

Everything had to have yeast in it, she says.

“I made a sourdough Belgian waffle in a cake-pop shape and decorated it as Mickey and Minnie Mouse.”

For the miniature sandwiches, instead of folding in butter to make the pastry layers, she used a mixture of hazelnut filling and batter.

“The fat from the filling made nice layers.”

“It’s fun to come up with different products you wouldn’t see normally. I love being creative,” she says.

Once finished, first stop was the judges’ table, where competitors presented to one judge, who gave them feedback on their creations. “They didn’t really have negative criticisms,” she says. “They really liked the waffle pops; the sourdough in a waffle pop.”

At the convention centre, de Herdt and other competitors cut up and presented the treats to small tables of children on a stage.

“If the kids didn’t like it, everyone could see,” she says with a laugh.

She needn’t have worried, as young partygoers held up plenty of smiley-face signs. Best of all, judges named her the winner.

de Herdt, who graduated from the full-time baking program at Northern Alberta Institute of Technology in 2014, works the night shift at Dutch Delicious bakery in Edmonton.

One thing she learned in Buenos Aires was to be prepared to adjust her recipes to demands of different temperatures.

“There were nine people in that kitchen, all with different oven temperatures,” she says.

de Herdt recommends competing to other young bakers.

“It really opens connections, you learn lots that you can take into the workplace too, like cleaning up after yourself and giving yourself a time schedule.”

They put in “hundreds and hundreds of hours” of practice leading up to Argentina, Dumonceaux says. They held five team practices and did three full practice

runs each, along with countless hours of fine-tuning. Products have to be an exact weight, and have to take into account prebaked weight, baking loss, temperatures and variables.

Competing involves countless hours of preparation. With several team members hailing from NAIT, most practices were held at the college. Four members came from the Edmonton area and two members flew in from Toronto and Montreal. They held the final practice at Southern Alberta Institute of Technology (SAIT).

The team wanted to make sure they practiced outside their comfort zone, he says. For this same reason, they have requested permission to get together at George Brown College in Toronto to prepare for Paris. The team meets once a month through the fall but will meet every two weeks starting in November.

Dumonceaux says one huge challenge in preparing for the Bakery World Cup is the lack of preparation time. Because the criteria – the scope – won’t be provided until November, after the Asia qualifying rounds are complete, the team must prepare based on their best predictions of what will be required. To give you an idea of what they are up against, last year they had nine months to prepare; this year, they have just over two months.

There is a lot at stake, as those who mount the podium in Paris get a free pass to the next Bakery World Cup. After the Louis Lesaffre Cup, the top three or four bakers in each category will be invited back at Europain for the World Masters in 2018, an individual event where 24 bakers compete.

He says financial support from the baking community, allied trades and associations, have been instrumental in the team’s success. Also key is attracting new members: because members are limited to competing twice, de Herdt is the only member who can return next year.

The budget for Paris is approximately $100,000, which includes flights and accommodations for the organizing committee. To follow the team’s journey, visit https://www.facebook.com/ CoupeLouisLesaffre/.

Those wishing to become a member or support Team Canada as it vies for the podium in Paris, can contact Dumonceaux at adumonce@nait.ca or 780-4718693. / BJ

In early September BAC was invited by the Pakistan Consul General and Canada Pakistan Business Council in Toronto to learn more about the Canadian Baking Industry landscape and the potential for bilateral trade opportunities. The meeting was facilitated by the Ontario Ministry of Agriculture Food and Rural Affairs (OMAFRA). BAC has identified areas of interest and is working towards this initiative, especially on the ethnic & specialty ingredients to baked goods manufacturers in Canada. The trade activities are being planned in conjunction with the next Bakery Showcase 2016 trade show & conference.

BAC also had the opportunity to present a Canadian baking industry overview and market potential to the Middle East incoming buyer mission this October. Middle East buyers have expressed strong interest in the Canadian baked goods and ingredients. Canadian bakery sector exports to the Middle East region have been on the rise since May 2014 after the first incoming buyer mission from Middle East visited Bakery Showcase 2014 trade show. More incoming buyer’s missions for Bakery Showcase 2016 are being planned with OMAFRA.

In addition BAC has recently had approved a funding application from the Agriculture Adaptation Council for a market development pilot project that will be supported by 5 member companies. This pilot will seek to promote Canadian baked goods in a number of offshore markets while encouraging imports of new

&

M. Ali, Orient

technologies and ingredients. Canada is a large exporter of bakery products to the United States (U.S.). Key exports include dough mixes, biscuits, pastries/ cakes/desserts, breads, waffles, cookies, gingerbread, puddings, pies, and cereals. According to Statistics Canada, Canada exported over C$2.0 billion worth of bakery products to the world in 2014, approximately 95% of which were sent to the U.S.

& Trading Co. Ltd.

The Canadian baked goods exports to US are the proof that our products are ready for exports globally. BAC has many other export initiatives for 2016 & 2017. BAC member companies that have been involved in exports & imports or have identified a new market please share with Paul Hetherington, President & CEO at phetherington@baking.ca or call 905-405-0288.

by Albert Hill, President, Bryant & Whitford Consultants

The Ontario government has released details regarding the proposed Ontario Retirement Pension Plan (ORPP) which will impact both employees and employers. The ORPP is a new mandatory pension plan proposed by the government of Ontario, with an effective date of January 1, 2017. ORPP is meant to offer employees, without a comparable workplace pension plan, an income in retirement.

The ORPP will operate much like the Canada Pension Plan with equal contributions from employees and employers not exceeding 1.9% (each) on earnings up to an annual maximum of $90,000. A person making the maximum contribution over 40 years would receive $12,815 in retirement.

The ORPP is designed to cover employees without existing comparable pension plans. As a result employers that offer defined benefit pension plans (DB pension plans) with a minimum benefit accrual rate of 0.50 % would be considered to have a comparable plan. Employers that offer defined contribution pension plans (DC pension plans) with an employer contribution of at least 4% and combined employer-employee contributions of at least 8% are also considered to have a comparable plan, and

would be exempt from the ORPP.

Employers that offer DB pension plans or DC pension plans that do not meet these requirements can choose to make changes to their current plan to meet the eligibility requirements and be exempt from ORPP participation. Employers offering other types of workplace savings plan arrangements, such as Group RRSP’s or DPSP’s will have to participate in the ORPP, unless they decide to convert their plans to a comparable plan that would meet the eligibility requirements.

Here are some important factors to consider about the ORPP plan for both employer and employees. There is no death benefit coverage ( for example if you die at 67 years old, the ORPP gives your children/spouse nothing . In addition there is no individual investment choices or retirement income options.

The Ontario government is proposing a phase in period for the ORPP. Larger employers (500 or more employees) will need to comply starting in 2017 while medium size employers (between 50 and 499 employees) will have until 2018. Small employers (fewer than 50 employees) will have until 2019. However, employers and employees with workplace pension plans that are or that could be comparable to the ORPP with

modifications, as of August 11, 2015, will only be subject to the ORPP in 2020.

The Ontario Government has expressed a preference for mandatory expansion of the Canada Pension Plan (CPP) benefits rather than development of a new separate Ontario Retirement Pension Plan.

Mandatory expansion of CPP is not supported by the current Conservative government therefore Ontario has introduced its own program.

Both the Federal Liberals and New Democrats however have indicated they support expansion of CPP benefits. Therefore depending on the outcome of the Federal election Ontario could reconsider its Ontario Pension Plan initiative.

An informative afternoon of baking and demonstrations at VIU in Nanaimo with Wayne Caddy from the School of Artisan Foods in Nottingham UK was held on Wednesday September 23rd.

Wayne is head of the baking program and captain of the UK World Baking Team. He discussed the newest innovations in bread from Europe and demonstrated his pioneering techniques.

The sellout crowd of delegates, which included a group from Vancouver and the mainland, were enthralled by the techniques and products produced by Wayne.

These included: Pain au Levain, Campagne Baguette and decorative breads dough, Orange and Raisin Levain, Olive and Gruyere Bread and Apple and Sultana hot cross buns. Wayne had bread and doughs at various stages of production and participants were encouraged to touch, shape and help in all aspects of the creations.

A supper of artisan pizza, baked in

the BAC sponsored VIU Wood Fired brick oven, by the Diploma baking students was enthusiastically enjoyed, as were the breads and desserts.

The day was a great success, as was Wayne’s work with the Foundation baking students at VIU during the rest

of his visit. The school of Artisan Foods and VIU are exploring the twinning and collaboration of the two institutions.

http://www.schoolofartisanfood.org/ https://www2.viu.ca/baking/

The largest trade show & conference in the baking industryFeaturing baking ingredients, baked goods (fresh, proof & bake, par baked, freezer to oven, thaw & serve) baking equipment, services & technologies.

Ontario Chapter

November 27

Annual Holiday Social

Old Mill, Toronto ON

BC Chapter

December 4

Festive Night at the Races

Fraser Downs, Cloverdale BC

Certified seed, labelled with an official Canada

Certified Blue Tag, is produced by the Canadian Seed Growers’ Association (CSGA) seed growers for sale to farmers to plant their commercial grain acreage.

Not just any seed in Canada can be labelled with the Certified Blue Tag of the Canadian Food Inspection Agency (CFIA). Canada has over 4,000 farms involved in seed production and each seed grower is required to follow stringent production requirements to ensure that quality standards are met right from the start.

Along the way, officially recognized third-party inspectors in the Certified seed fields and processing plants ensure that all quality assurance requirements are met. This involves three main components:

• Varietal purity

• Germination

• Freedom from impurities

In contrast, common seed is multiplied without any officially recognized third-party inspections to confirm varietal purity or quality.

For Canada’s farmers, planting Certified seed provides better quality grains and oilseeds, new marketing opportunities for their crop, risk management, and access to new varieties that are bred for success.

For food processors, using grains and oilseeds produced from Certified seed provides more consistency in processing. The end result will be ingredients that reliably deliver the yield, texture, flavour, nutritional characteristics and appearance that you expect – and that is the foundation of quality food. Having these high standards for purity in your food ingredients means you can reliably deliver:

• High quality, consistent products

• Product differentiation

• Consistency right from the start

• Traceability

BY LAURA AIKEN

Roy Bouman was just “putting the wheels” on his new bread slicer when he answered my telephone call on a sunny day at home in Vernon, B.C. His tone was buoyant, and why wouldn’t it be?

Twenty years ago, with three young sons depending on him, Bouman and his wife Caroline took a leap of faith to open a bakery, and now they have a hoppin’ livelihood to show for it. Before I digress into the generations of Bouman bakers that preceded this particular one’s life at the helm of Sweet Caroline’s, let’s give due pause to say: Happy 20th Birthday! Twenty years in the competitive baking industry is an accomplishment indeed.

Growing up in British Columbia, Bouman did not know the historical length of his baking ancestry in the Netherlands when he got his first job at a bakery as a newly graduated 18 year old in 1978. His first recollection of being initiated into the industry was that of the pre-dawn light.

}“My earliest memory was probably being told ‘Okay, you can start tomorrow and we’ll see you at 3:00 a.m.’ and I was like –what, what time? And they said 3:00 a.m. and I was just out of school then and remember thinking nobody gets up before eight o’clock; what are you thinking, 3:00 am.? So here I was at 2:30 in the morning walking to work and thinking oh my goodness, what have I gotten into?”

‘When we actually opened I think we had 48 customers and probably 45 of them were friends, so I learned I have to adjust pretty quickly and that’s been the game the whole time, the whole 20 years: finding out what everybody likes and sticking with what they want rather than what I think should be out there’ – Roy Bouman

the position with the owner of the bakery. Bouman thought he was going to work in a car wash. What a different future that would have been.

Perhaps there was a glint of the future baker in his childhood, although as a boy he was all about playing with ratios.

Bouman’s products definitely rise properly today, as they surely did for the lineage before him, although he didn’t learn the extent of his family’s roots in baking until he opened his own shop.

It wasn’t so much a purposeful foray into baking, as a pre-determined one. The family was part of a close Dutch community and his parents arranged

“I didn’t get an allowance growing up, so I would say, ‘Can I make something?’ and then I would eat half the batter and my Mom would wonder, ‘Well how come this didn’t rise that much?’ And I’d be there licking my lips.”

The Bouman family has been in the industry since his paternal ancestors opened a bakery in 1888 in Zaandam, Netherlands. The bakery was eventually moved to a newly built location across the street, where the family switched from coal to electricity as a means to power the oven. This became the first electric bakery in Zaandam. And it was here in a room behind the oven, during the second world war, that Bouman’s grandfather and his father’s uncles hid fleeing Jews and helped them safely reach the Dutch underground.

“It was quite something. If they ever got caught, that would have been it. I always tell my boys, ‘Boumans, we don’t

sit back if people need help.’ Must get that from my grandfather and my dad.”

Bouman and his family relocated from Vancouver to Vernon in 1991 when he was offered a job as a cake decorator at Safeway. He was laid off three months later. He dealt with sporadic employment for four and half years, delivering flyers, mowing lawns and generally taking any work possible to stay in Vernon. He didn’t want to uproot his family; quite the opposite. He moved around a lot when he was a kid and really wanted to keep his family in one place no matter what. So when Caroline saw an ad in the paper from Community Futures looking for people interested in being entrepreneurs, it turned out to be the opportunity to settle he had been looking for.

“We had always wanted to start our own bakery, and they really helped us out.”

The program spent three months helping the Boumans get their accounting set-up and empowering their business know-how. Caroline took on the books and staffing, a role that allowed her to be at home with their sons. Bouman took on the task of chief baker.

“It’s been a good balance for both us,” he says.

In 1996, Bouman and his wife officially signed the lease to their new life and opened Sweet Caroline’s Bakery, their from-scratch Dutch-heritage shop.

“How it started off [opening day], I was making lots of bread thinking ‘Oh so many people are going to come in’; I had signs out saying we were coming. I baked like we were in business for 15 years that day, and mostly bread. When we actually opened I think we had 48 customers and probably 45 of them were friends, so I learned I have to adjust pretty quickly and that’s been the game the whole time, the whole 20 years: finding out what everybody likes and sticking with what they want rather than what I think should be out there.”

Fast forward to 2015, and Bouman says Sweet Caroline’s averages around 200 transactions on weekdays, about 300 on weekends, and at Christmastime over 400. The bakery is open from 6:30 a.m. to 5:30 p.m., and is closed on Sundays

and Mondays.

While the first five years demanded the Boumans put in sheer hard work, the second five years marked the seeds of expansion. They needed more equipment, showcases and product. The bakery started off with some tables and chairs for people to eat, but as they grew, those tables ended up outside or gone altogether to make space for product. Bouman started to know what his clients liked, and felt freer to take creative chances. As a baker, he describes himself as “pretty good at everything but I’m not a master of anything.”

Sweet Caroline’s was blossoming.

At the 10 year mark, Bouman said they just kept their nose to the grindstone and kept trying things out. Even after 10 years, he didn’t feel the bakery had the stable customer count that a well-established place would. The locale had the added challenge of being very tourist-centric, meaning a lot of clientele that came and left along with the end of their vacation. It took another five years for the Boumans to see the maturing fruit of their labour.

“We found that at about the 15th year or so, things started to level off and we could really anticipate what we had to make. At Christmas there’s not as much profits because you are spending so much on rich ingredients, so the nice thing about being open for about the 15 year mark is that you can really start to see the pattern so you kind of know from the year before how much you should make, and even though you have new people coming and going, it still seems to work knowing how much to make so we don’t have ingredients left over.”

I ask Bouman if he had a goal for the number of customers he wanted to have.

“No, we just wanted to get out the hole,” he says with a

chuckle. “We wanted to get to the point where we made a profit. It was just [to] see where it went: we put everything on the line, so there was no looking back. We’re taking a step of faith here, we’re going to work as hard as we can, and be as honest and fair as we can, and my goal was to provide for my family basically.”

“I’ll take care of you, but you’ve got to take care of me.” I heard Bouman mention this twice in relation to staff at his bakery, and I figured out why. It underpins his whole approach to caring for the nine employees he has.

Peter Siemens was the person who oversaw his three year apprenticeship, and altered how he thought a boss should lead because he was so kind. Bouman learned how important it was to treat staff well, respect the people you are working with.

“It goes a lot farther when people feel respected and heard and when you take care of them, they will take care of you.”

He credits “the amazing people that I have on staff” with helping the bakery arrive and thrive at the 20 year mark. His primary staff have been with him for over a decade. They know what they are doing and bake a consistent product.

Bouman mainly uses a single base that all products branch from. He says this allows him to be creative and offer customers new things. Bouman takes great pride in his bakery’s products, and wants to ensure his customers can be proud of serving them too.

“The prices go up and people understand that, but I’ve never changed the quality of the product and people still appreciate that.”

Along with consistency, customer service is a cornerstone of his bake-shop philosophy. He strove to ensure that up front was always well staffed so customers weren’t penalized for a

backlog in the kitchen. He says he enjoys that the bakery has allowed him to shake hands with a lot of great people he wouldn’t have otherwise met. He likes to be involved in the community through things like his church and the At the Arbour program, which gives out free food, clothes and haircuts. He speaks with empathy of the hardships faced by the poor, the kind of empathy that comes with knowing what it’s like to struggle. Establishing his bakery was a monumental task that even caused him to black out once from stress while talking to his mother on the phone. But 20 years later, he has three grown sons making successful lives of their own, and a family and bakery with roots deep in the community, just as he wanted.

As my conversation with Bouman comes to a close, he mentions he is about to leave for a vacation to Hawaii. This makes me smile, as knowing how hard bakers work I am sure it is a much deserved holiday. Bouman says he has no worries leaving his bakery in his employees’ hands, and they have never given him a reason to.

“My business plan from the beginning was to work my way out of a job. I’ve seen too many bosses become alcoholics, not delegate, never let go of things; just work themselves to the bone. I want to delegate and let other people do, so I pass on. I don’t hold back; I share what I know.” / BJ

The food industry faces a number of pest concerns, but pantry pests – or stored product pests – are one of its greatest.

As their name implies, stored product pests like to eat and breed in food that is typically found in pantries and kitchen cabinets. Nearly all dry and stored food products are susceptible to pantry pests, and infestations can originate anywhere in the supply chain – in food processing facilities, during shipment, in storage or in the area of use. They devour many types of food and contaminate much more than they eat. Some species secrete substances that alter the flavour of food and can also cause allergic reactions in humans once ingested. So, even the smallest infesta tions can severely damage your inventory and tarnish the reputation of your bakery. Following is a list of common types of stored product pests to help you identify them within your facility.

These pests are small, greyish brown moths with a portion of their front wings being reddish brown. They tend to feed on nuts, herbs, dried fruits, seeds, candies and grain products. They are about 1.5 centimetres long when fully grown and have a life span of one to two weeks. These moths can cause severe damage to food inventory with the webbing that they deposit. Any infested products will have the webbing and frass, also known as moth droppings, on the surface.

Weevils are easily identified by the elongated snouts on their heads, a characteristic that also makes them easily distinguishable from other stored product pests.

feed on a wide variety of stored products ranging from dried flowers to powdered milk. Adults are oval-shaped, brownish and about 2.5 to 3 millimetres long. They have the ability to chew through packaging, making them a nuisance to deal with.

Both sawtoothed and merchant grain beetles are brown, about 2.5 to 3 millimetres long and have flat bodies. Both have six saw-like teeth on each thorax, which is their main identifying feature. They are particularly common within commercial facilities. Their flat bodies allow them to get between tiny cracks and burrow through boxes and packaging. These beetles like to feed on cereals, flour, birdseed, nuts, spices, candy bars and tobacco.

Flour beetles are very small in size: adults are around 3 to 4 millimetres long. They are reddish brown in colour and enjoy flour, cereal products, cracked grains, baking mixes, beans, peas, dried fruits, nuts, chocolate and spices.

Weevils are a type of beetle that are brown in colour and measure up to 3.5 to 5 millimetres in length. They are easily identified by the elongated snouts on

have four pale yellowish markings on wings, forming an X-like mark. Weevils prefer stored grains or seeds such as popcorn, birdseed and nuts. Small holes in grains are a sign of infestation.

Pest management is challenging for any restaurant or food processing facility. The abundance of food, moisture, temperature conditions and harbourage sites creates conditions where pests can thrive.

Maintaining a safe and clean site is critical to tackling these challenges. To reduce the risk of stored product pests invading your facility, apply the following tips:

• Inspect incoming materials for signs of an infestation and to ensure they are free of pests. For suppliers and distributors, trucks should be carefully inspected for pests before any packaging or materials are

Like you, successful bakers know the secret to a profitable bakery starts and ends with high quality, great tasting products. For over 80 years, the American Almond® Products Company has provided successful bakers everywhere with premium quality nut pastes, nut butters, nut flours and a wide range of unique, customer-pleasing ingredients. Let American Almond® help you turn that quality into profits for your bakery.

unloaded and before the products are shipped.

• When storing pantry products, use plastic or glass containers with secure lids to keep food dry and easy to see. Never leave stored products undisturbed for long periods of time. Store products off of the floor, on shelves, racks or pallets.

• Allow for inspection aisles between shelves for inspection and cleaning. If possible, maintain half a metre of perimeter space from wall to allow for inspection and monitoring.

• Eliminate entry points to reduce the risk of an infestation within your pizzeria. Pests often enter under building doors and openings around windows, so make sure everything is closed and sealed properly.

• Inside your restaurant, floors should be in good repair. Be sure to caulk and seal any cracks. Floors should also be free of product and other residue, so address product spills immediately.

• Allow proper ventilation and illumination in storage areas. Ventilation helps keep food moisture down, which discourages pests and mould growth.

• Many female stored product pests use pheromones to attract mates. Using pheromone traps can help you effectively monitor for infestations. Try using non-pheromone based insect glue board monitors or food lures to monitor other crawling pantry insect pests.

Pantry pests can be a pain, but a proactive approach and constant monitoring can save you a lot of hassle in the long run. In the end, your customers will appreciate that you kept these unwanted ingredients out of your restaurant and out of their meal. / BJ

Alice Sinia, PhD, is the resident entomologist, regulatory/lab services, for Orkin Canada focusing on government regulations pertaining to the pest control industry. With more than 10 years of experience, she manages the quality assurance laboratory for Orkin Canada and performs analytical entomology as well as provides technical support in pest/insect identification to branch offices and clients. For more information, email Alice at asinia@orkincanada. com or visit www.orkincanada.com.

From energy efficient ovens to virtual technology and high speed sterilizing, Bakers Journal keeps you “in the know.” for more on new products for the baking industry, check out our website, www.bakersjournal.com

WP Bakery Group showcased a new energy efficient oven at the iba show in Germany. The Rothoterm Green boasts significant energy savings over its predecessor model. The circulating air flow is the same but the heat exchanger has been omitted and replaced by rearranged electric heating elements for better air flow. In combination with the WP Thermopackage insulation concept, energy consumption is reduced up to 25 per cent.

WP also debuted the Riehle ITES high speed oven at IBA. The oven defrosts and cooks frozen baked goods in about 10 to 25 per cent of the time when compared to conventional cooking methods, reports WP in a press release. The Riehle ITES uses specialized infrared (patent pending) technology to quickly defrost frozen baked goods, then bake, toast, crisp and/or brown the product. www.wpbakery.com

PreciBake, an IT company that specializes in the baking and food industry, debuted its Virtual Quality Officer in September. The system is designed to be a highly flexible process monitoring and automation solution for industry customers. PreciBake also highlighted its PB Connect add-on system that acts as a hub and collects all data from connected devices and then sends the data to the BakeIT Cloud without requiring the Virtual Baker.

A new sterilizer from WLD-TEC may assist baking facilities with high-speed annealing and sterilization without the need for a gas flame. The SteriMax Smart from WLD-TEC is designed for laboratories, anaerobic environments and safety cabinets.

This innovative sterilizer uses specifically focused infrared light, which generates an infrared hotspot for sterilizing inoculating loops at a temperature of 750 to 1,000 C in only five to 10 seconds immediately and without any preheating, WLD-TEC said in a press release.

Its features include auto-start through touchless IR-Sensor technology; adjustable sterilization and cool-down timers for two users by front-panel operation; and an annealing tube made of special quartz glass.

The device and annealing tube are designed for easy cleaning. Thermo Control helps promote efficient use of energy and minimal heat dissipation thanks to Cool-Touch housing made of stainless steel and safety glass. www.WLD-TEC.com

B E T T E R P I Z

U G H D I V I D E R

A T R U E S T O R Y : A few years ago, Reiser installed multiple Vemags – each with a multi-outlet cheese extruder –into a customer’s plant The systems extruded cheese onto makeup lines to produce cheese-filled dough products.

After seeing the speed and portioning accuracy of the Vemag cheese extruder, the customer was inspired to ask if a similar Vemag could be used to successfully divide pizza dough Reiser specialists and engineers worked with the customer to develop a solution The result was a new pizza dough dividing process featuring the Vemag. The Vemag Dough Divider was able to produce exact-weight portions while meeting their high output requirements. The savings were so great that the customer converted all of their lines worldwide to Vemag pizza dough dividers

Are you looking for the perfect location to start a bakery, or move one to? Here are a few tips to help you decide whether buying or leasing is right for you.

The most common reason tenants lease space instead of buying a location is supply and demand: 95 per cent of all commercial space is for lease and not for sale.

If you are in the enviable position of being able to purchase property, there are several opportunities available to you: a business condo where you occupy the one unit, a strata title unit, small strip plazas or centres where you’re now a landlord to other tenants as well, or standalone buildings on a small parcel of land.

}When deciding whether to purchase or lease, remember to consider all opportunities – both conventional and unconventional.

Major factors that impact this decision for the average tenant are the long-term commitment of purchasing a building and the ability to obtain the financing.

For those tenants able to purchase, here are a few pros and cons to consider.

Paying a mortgage is better than paying rent. Lease payments are forever, but your mortgage will eventually be paid off. Often, your mortgage payment may be very close to your rent obligation.

In most cases, you will gain equity in your property. Over the course of time, your property may double – or even triple – in value. This increase in value is in addition to the value of your business contained within the property.

You’re in charge. You don’t have to deal with the hassles of a landlord or property manager.

There may be some sacrifice on location, because many of the prime locations may not be available for purchase.

If you’re vacating an existing location, you may be leaving a great opportunity

for a competitor to move into your location.

Being in charge is a con as well as a pro. When you purchase property, you’re the one responsible for all repairs and maintenance a landlord would normally handle.

When making the decision to purchase or lease commercial space, don’t decide to buy simply for the sake of owning real estate. Only consider purchasing a space or property if you would be prepared to lease that same location anyway.

Also, remember to think outside of the box. What we mean here is consider all opportunities – both conventional and unconventional. We live in an “anything goes” or “whatever works” society and that philosophy often applies to business locations as well. For example, a major restaurant chain located near The Lease Coach office went under and the freestanding building was quickly snapped up by a group of orthodontists for their new office. A big-box store can move and be replaced by a sporting goods anchor store. A chiropractor may move in where a fitness facility failed. And so on.

There are both conventional and unconventional opportunities for every business industry. Perhaps a trophy location will make sense for your business? This is a specific unit that outshines all the other spaces for lease or purchase in a property because of its prominence and visibility. Trophy locations do not sell or lease cheaply; however, for some owners, having a trophy location can make their business far more conspicuous.

But do all bakery owners need to be located in the same type of building? Of course not. You need to evaluate every type of building or property that is available because its unique qualities can represent the 20 per cent advantage you need to be successful over your competitors. / BJ

Dale Willerton and Jeff Grandfield – The Lease Coach are commercial lease consultants who work exclusively for tenants. Dale and Jeff are professional speakers and co-authors of “Negotiating Commercial Leases & Renewals For Dummies” (Wiley, 2013). Got a leasing question? Need help with your new lease or renewal? Call 1-800-738-9202, e-mail DaleWillerton@TheLeaseCoach.com or visit www.TheLeaseCoach.com. For a copy of the free CD, “Leasing Do’s & Don’ts for Pizzeria Tenants,” e-mail your request to DaleWillerton@TheLeaseCoach.com.

Get the feeling of fall with this decadent tart that’s sure to please. This recipe is courtesy of Anthony Borgo, CCC, CBS, and a professor of culinary programs at the School of Hospitality, Recreation & Tourism at Georgian College in Barrie, Ont.

INGREDIENTS

Tart

Semi-sweet chocolate 680 g

Unsalted butter 340 g

Whole eggs 6

Raspberries, fresh 1 pint

Pâte sucrée 1 lined 10-inch tart tin (recipe included)

Method

Heat oven to 185 C (365 F)

1. Line tart tin with short crust dough. Bake the shell “blind” for 8 minutes.

2. In medium saucepan, melt semisweet chocolate and butter over medium-low heat, stirring constantly.

3. Beat eggs in small mixing bowl at high speed for 5 minutes, until light and lemony in colour.

4. Fold chocolate mixture into eggs until well blended. Pour into the partially baked shell and return the tart to the oven.

5. Bake at 185 C (365 F) for a further 8-10 minutes; edges will be set and

PÂTE SUCRÉE (SHORT PASTE SWEET)

Chocolate ganache

Semi-sweet chocolate 340 g 35% cream 225 ml

Unsalted butter 225 ml

centre will jiggle.

6. Cool on wire rack for 1 hour; then glaze with ganache.

To prepare ganache:

1. In a small pan over medium heat, bring the cream and butter to a low boil.

2. Add in the chocolate and stir until blended well.

3. Cool to 29 C (85 F).

4. Pour chocolate ganache over the tart and allow to cool.

To serve, cover tart with the fresh raspberries and dust with icing sugar and dark chocolate shavings.

Dennis Meyer started in the pastry business as a clean-up kid at age 15. Who would have guessed that 40 years later, this same hard-working kid would become an award winning pastry chef with the best place in Denver to get a wedding cake?

Meyer, an Indiana native, is the proud owner of Das Meyer Fine Pastry Chalet in Arvada, Colorado—voted best wedding cakes in a Denver poll several years in a row. Though Das Meyer offers a variety of pastries and cakes for all occasions, they specialize in wedding cakes, and make over 1,000 wedding cakes per year.

“The whole family is involved in the wedding business,” said Meyer. “My wife Elaine and two daughters, Hillary and Rachel work with the customers; son Zachary works as a cake decorator; and two granddaughters have joined the business as well. Meyer stated that his success starts with great personalized service, high quality and attention to the details. It has helped the business gain the great reputation it has today.

Each Saturday, future brides can come to an open house to sample a multitude of wedding cakes, and can watch every aspect of a cake’s creation. “With all this variety, taste is everything,” said Meyer. “I use B&V® flavor from International® Bakers Services (IBS) in most of our cakes. The BLOV® flavor is excellent in our home-made butter cream.” He also uses the CINNA-BUTTER in their cinnamon rolls and a whole spectrum of flavors in their gourmet cookies.

PÂTE SUCRÉE - Method

1. Sieve pastry flour and sugar together in a bowl.

2. Add the soft butter.

3. Mix or “cut in” butter to form a crumble.

4. Mix together the eggs, salt and lemon juice.

5. Add them to the crumble all at once.

6. Mix together on 1st speed for 20 seconds.

7. Remove from bowl and cover tightly with plastic wrap.

8. Chill dough before using.

Meyer likes to use IBS flavors because they always offer a natural tasting flavor with no artificial edge. “In this business, a good name is earned—not purchased,” said Meyer. “You have to earn repeat business in the service and quality you provide.”