BY L Au RA Aike N

BY L Au RA Aike N

Rogers’ Chocolates is celebrating 127 years in the business. That means the company has been at it since 1885. Bakers Journal published its first issue in 1938, just six years after the formation of Allied Trades of the Baking Industry, but it’s just a baby at 74 compared to how long it’s been since Charles “Candy” Rogers was serving up chocolates in the back of his grocery store in Victoria, B.C.

Fast-forward nearly 13 decades and technology, economy and consumers are redefining the chocolate and baking industry at a rapid rate. Yet, some things never change. Bakeries are still born in the backs of stores, the basements of homes and the backs of pick-up trucks. And perseverance is still the defining trait of the forces behind every successful bakery business.

NOVEMBER | VOl. 72, NO. 9

EDiTOr | laura aiken editor@bakersjournal.com 416-522-1595 1-888-599-2228 ext. 250

ASSiSTAnT EDiTOr | stefanie Wallace swallace@annexweb.com 1-888-599-2228 ext. 278

TEChniCAL EDiTOr | John McColl, Puratos Canada jmccoll@puratos.com

nATiOnAL ADvErTiSing MAnAgEr | stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

SALES ASSiSTAnT | sandy Mels smels@annexweb.com 519-429-5176 1-888-599-2228 ext. 219

}Canada is a competitive place for bakers, pastry chefs and chocolatiers because there are just so many fearless, talented and tenacious entrepreneurs in this country innovating the way we eat.

This year’s finalists for the Bakers Journal Business Awards – lead sponsored by Fuller Landau Chartered Accountants & Business Advisors and co-sponsored by Puratos and Hallmark Insurance – were no exception to this rule. Congratulations to Red Square Bakery (Burnaby, B.C.), Kinnikinnick Foods (Edmonton), Curbside Bliss Cupcakes (Mississauga, Ont.), The Cake Box (Kitchener, Ont.) and Dessert Lady (Toronto). All of this year’s finalists are real leaders in what they do. And so is Rogers’ Chocolates, profiled in our cover story. Canada is a competitive place for bakers, pastry chefs and chocolatiers because there are just so many fearless, talented and tenacious entrepreneurs in this country innovating the way we eat. Understanding your competitors is one of the most important aspects of staying in the competition. There are five competitive forces, Bruce R. Barringer and R. Duane Ireland (Pearson Education Inc.) wrote in a case study of Panera Bread and how they positioned themselves as a fast casual bakery café chain. These five forces are rivalry of existing firms (central), threat of new entrants, threat of substitutes, the bargaining power of buyers and, conversely, the bargaining power of suppliers. Within these forces, companies face direct, indirect and future competitors. The authors showed how Panera Bread classified its different types of threats by strength and then systematically reduced the power these threats had in impacting the business while innovating in ways that made it tougher on new competitors entering their space. Getting beyond an awareness of your competitors to a place of analysis is a crucial way to put all the enthusiastic love of your bakery to pragmatic economic use and ensure your bakery stays in the game. In short, tenacity plus analysis is the math that adds up to the kind of long success Rogers’ Chocolates has achieved. Interviewing our business awards finalists and reflecting on our cover profile’s longevity reminded me of these well-known words attributed to American president Calvin Coolidge: “Nothing in this world can take the place of persistence. Talent will not; nothing is more common than unsuccessful people with talent. Genius will not; unrewarded genius is almost a proverb. Education will not; the world is full of educated failures. Persistence and determination alone are omnipotent.”

If you haven’t given yourself a pat on the back lately for simply toughing it out in this tough business, do it now. You deserve one. Stay tuned to read all about the winners of this year’s Bakers Journal Business Awards in upcoming editions of the magazine. / BJ

MEDiA DESignEr | Brooke shaw grOup puBLiShEr | Martin Mcanulty mmcanulty@annexweb.com

prESiDEnT | Mike fredericks mfredericks@annexweb.com

Mailing Address p.O. Box 530, 105 Donly Dr. S., Simcoe, On n3Y 4n5

puBLiCATiOn MAiL AgrEEMEnT nO. 40065710. rETurn unDELivErABLE CAnADiAn ADDrESSES TO: CirCuLATiOn DEpArTMEnT, p.O. BOx 530, SiMCOE, On n3Y 4n5 e-mail: subscribe@bakersjournal.com

IssN 0005-4097

published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, nov, Dec) by Annex publishing & printing inc.

suBsCRIPtION RatEs

Canada — 1 Year $ 30.00 (with gST $31.50 #867172652rT0001, with hST/ QST $33.90) uSA — 1 Year $ 45.00 uSD Best pricing is available online at www.bakersjournal.com

Send your subscription request to: Bakers Journal p.O. Box 530, Simcoe, On n3Y 4n5 Tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940 E-mail: subscribe@bakersjournal.com

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. if you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. no liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. publisher reserves the right to refuse advertising that does not meet the standards of the publication.

no part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2012 Annex publishing & printing inc. All rights reserved. printed in Canada.

Ready to expand your business? At FCC, we’re ready to help. We get to know you and your business. Once we learn how you want to grow, we’ll create a financing package that helps you do it. If you’re ready for a lender who listens, let’s talk business.

www.fccfinancing.ca

briefly | Maize-based nut substitute targets allergen-free market | Study backs addition of fibre to partially baked breads | Price, taste and brand overrule nutrition labelling | for more news in the baking world, check out our website, www.bakersjournal.com

Shrewsbury, Mass. – A new article published recently in the International Journal of Obesity argued there is no evidence to suggest the current obesity epidemic in the United States can be specifically blamed on consumption of high fructose corn syrup (HFCS).

The commentary concludes that after an extensive review of all available HFCS research, there is overwhelming evidence showing HFCS is nutritionally equivalent to sugar. The authors state that while there has been a large amount of debate in the media about the impact of HFCS on obesity levels, the fact is “Sucrose (sugar) and HFCS are very similar in composition . . . and are absorbed identically in the human GI tract.”

“The public discussion about HFCS will likely continue to rage on and more studies will be conducted,” said James M. Rippe, MD, founder and director of the Rippe Lifestyle Institute, and professor of biomedical sciences at the University of Central Florida, who is one of the article’s authors. “However, at this point there is simply no evidence to suggest that the use of HFCS alone is directly responsible for increased obesity rates or other health concerns.”

The article goes on to discuss a number of research trials that have been conducted on the issue of HFCS and obesity, and concludes that at this time the evidence shows no short-term health differences between the use of HFCS or sugar could be detected in humans. Weight gain, glucose levels, insulin and appetite were not adversely affected by the use HFCS over sugar.

The commentary was co-authored with Dr. Rippe by David M. Klurfeld, PhD of the USDA Agricultural Research Service, John Foreyt, PhD of Baylor College of Medicine, and Theodore J. Angelopoulos, PhD, MPH professor and director, Laboratory of Applied Physiology Department of Health Professions at the University of Central Florida.

Richmond, Va. – AMF Bakery Systems (Richmond, VA), Reading Bakery Systems (Robesonia, PA) and Tromp Bakery Equipment (Gorinchen, Holland) have come together to form the Markel Bakery Group. These three companies were all acquired by Markel Ventures, the operating division of Markel Corporation.

Ken Newsome, president of AMF, will also serve as the CEO of Markel Bakery Group. He comments in a news release: “We at AMF have been blessed to be part of Markel Ventures for seven years, so we have already benefited from the support of a partner with significant capital and a long-term horizon. It will be exciting to see how Tromp and Reading flourish under this same umbrella and the formation of the Bakery Group underscores our commitment to a long-term strategy.”

AMF, Reading Bakery Systems, and Tromp will operate as independent companies, but they will benefit from Markel Bakery Group’s international presence. “We have built a strong infrastructure in key markets such as Europe and Asia Pacific,” continued Newsome. “Our plans for expanding this presence into other key international markets will be an advantage for all the Group companies and their customers.”

Cambridge, Ont. – The Alliance of Ontario Food Processors has released its Economic Impact Report, showing a five-year increase in the value of the sector’s goods.

In a time when traditional Ontario manufacturing industries are facing decline, a new report released by the Alliance of Ontario Food Processors (AOFP) and completed by the independent firm of MNP LLP, details food and beverage processing sales of $39 billion in 2010, representing an annual rate of increase of two per cent per year since 2005.

In a comparative analysis with the “motor vehicle manufacturing” and “electrical equipment, appliance, and component manufacturing” sectors from 2005 to 2010, the food and beverage processing sector’s value of shipments increased while the other sectors saw significant decline.

The food and beverage processing sector employs over 126,000 Ontarians. With close to 3000 establishments across the province, in both rural and urban communities, its impact touches every corner of the province. The overall economic contribution to Ontario is estimated at $67 billion annually.

“Ontario’s food sector has been a lynchpin of the Ontario and Canadian economy,” said Michael McCain, president and CEO of Maple Leaf Foods and member of Ontario’s Jobs and Prosperity Council, in a news release. “The tremendous growth of our industry has set the precedent for important new investments that are fuelling jobs and innovation in Ontario and prominent recognition on the world stage for delivering highly sought-after, delicious products.”

Based on the results of this report, AOFP believes that continued and increased investment from both the provincial and federal governments will show solid return on investment for Ontario taxpayers. “Our industry has a proven track record of investment and growth,” said Steve Peters, executive director of AOFP, in a press statement. “We will be telling our story of success. This industry is far more than a little engine that could. It is the engine that can and does and will continue to drive our economy. We look forward to working with our government to ensure that our sector and the province as a whole continues to thrive.”

Canada – A recent survey by Nestlé found that Canadians know very little about where chocolate comes from or the threats to the global cocoa supply that need to be addressed to ward off a future without chocolate.

The study, conducted by Vision Critical for the Nestlé Cocoa Plan, a global initiative to ensure a sustainable cocoa supply and improve the lives of small farmers, found that 77 per cent of Canadians would be upset to wake up in a world without chocolate.

Of the 1,000 Canadians surveyed, 62 per said they could “eat chocolate every day,” while 58 per cent said that if they had to choose their “last meal” it would definitely include chocolate. Meanwhile, 68 per cent confided a friend can “never go wrong” with a gift of chocolate and 39 per cent said chocolate “goes with every meal”!

Still, despite Canada’s national obsession with chocolate, we remain largely in the dark about it – and about threats to the global cocoa supply that could make it an even scarcer luxury. Those include diseased or low-yield crops and ongoing upheaval.

Almost half of survey respondents (42 per cent) thought most cocoa comes from Ecuador, while only 27 per cent correctly identified West Africa as the source of most of the world’s supply. A majority (55 per cent) indicated cocoa comes from a bush compared with the 27 per cent who rightly knew it grows on trees, like coconuts. And 59 per cent mistakenly thought that most cocoa comes from factory farms instead of from small, family-owned operations, where it is grown and harvested, often under challenging conditions.

“There is no question that, while people love chocolate, many have very little idea of how cocoa is grown or of the challenges facing this valued commodity,” said Dr. Sergine Diop, general manager of Nestlé’s Research and Development Centre in Ivory Coast. “Nestlé has partnered with small farmers to improve the quality and sustainability of cocoa crops in West Africa, and has developed and will distribute millions of higher-yielding, disease-resistant plantlets to them, among other proactive, mutually beneficial measures.”

Mast ER-B I lt WE lCOMEs NEW ON ta RIO sal E s REP

Richard Yeomans is the newest Canadian sales representative for Master-Bilt Refrigeration. Yeomans will cover sales for north, east and south Ontario effective immediately. He brings more than 20 years of experience in the refrigeration and foodservice industry. Yeomans has held several executive management positions in sales, marketing and manufacturing, including his most recent position with a company specializing in refrigeration machinery.

Ma Rt INE z a PPOIN t ED l at IN aMERIC aN VP

Federico Martinez has joined Markel Bakery Group (MBG) as vice-president for Latin America. In this new leadership position, Martinez will be responsible for the strategic direction, business development and asset management in the region for the MBG companies: AMF Bakery Systems, Reading Bakery Systems and Tromp Bakery Equipment.

Easyl E as E h IRE s NEW BRO k ER t EaM

Doug Carmichael is the newest addition to the Easylease team. He has previously worked in the telecommunications industry, providing voice and data solutions and offering different finance options to his clients. He has more than 25 years of working experience and will work with Gary Speight. Gary has worked at Easylease for the past four years and holds a masters degree in economics. Together, Doug and Gary are responsible for providing leasing experiences to clients in the foodservice industry.

BY D R . J OhN Mi ChAeLiDeS

Salt plays an important role in many baked goods, and replacing it is no easy task

The debate about the benefits of sodium reduction in our diets rages on. Last year, the Cochrane review of sodium and health concluded that there is not enough evidence to prove that a reduction in sodium consumption lowers our risk of cardiovascular disease. This report was quickly disputed by other scientific reviews and the American Heart Association stated that they are still recommending lowering sodium intake in our diets. The topic is still controversial, but the majority of scientific evidence indicates that reduction of sodium in our diets is a wise choice.

}The main source of sodium in our diets comes from salt. Common salt, or sodium chloride (NaCl), contains 39 per cent sodium. Since salt is widely used in food processing, it is a substantial contributor of sodium in our diet, especially in developed countries where a lot of processed foods are consumed. Salt plays several important roles in food processing. It provides flavour and texture. It is a microbial preservative and a processing aid. Replacing salt’s taste and flavour may be partially achieved with alternatives, but it is hard to find adequate substitutes for its other functional roles. Salt is an inexpensive ingredient, so any replacement adds costs to the product. Furthermore, a reduced-salt product to which consumers add salt at the table would not be beneficial for anyone, so it is imperative that salt-reduced products meet the sensory expectations of consumers. Salt also plays a very important role in the formulation of baked goods. It is considered one of the major ingredients in bread baking, along with flour, water and yeast. Salt affects the taste in baked goods, not with its taste alone, but by enhancing the other flavours. In fact, at the level that is normally being used in the formulation of baked goods, it does not impart a very salty taste. Baking without salt results in bland bread with no

characteristic taste. Salt not only enhances other flavours but also increases sweetness and masks metallic, bitter and other undesirable tastes. For this reason, it is also used in sweet baked goods formulations. Salt helps control and stabilize yeast fermentation in dough. Salt will prevent over-fermentation, which causes dough to have excessive gas and sourness and will leave finished baked goods with undesirable open grain and poor texture. Salt in yeast lowers gas production rate, and therefore results in longer proof times for a goodquality baked good. The effect of salt on the yeast cells is caused by changes in osmotic pressure and a possible direct impact on cell membranes. This is the effect salt has on other microbes as well, which is why it acts as a preservative. Salt is an effective tool in controlling the action of the yeast and gas formation, especially where temperatures cannot be easily controlled in small bakeries. Salt affects the proteins in food. The

Salt is an effective tool in controlling the action of the yeast and gas formation, especially where temperatures cannot be easily controlled in small bakeries.

wheat gluten protein, which is the fundamental component of the baking process (especially for the yeast-raised products), is also affected by the presence of salt in the formulation of baked goods. The salt content in the formula dramatically influences the hydration of gluten, as well as its development and strength. The hydration of flour is achieved at a slower rate when there are low levels of salt in the formulation. This is because salt shields the overall positive charges in gluten, reducing repulsion and allowing the proteins to come in closer contact. This causes a slower hydration rate of the flour, and therefore an increase in the mixing time is required to develop the dough. This is of important consequence because longer mixing time will result in slower rate of production in large bakeries, which increases energy consumption and slows outputs. This problem can be corrected by adding salt at a later stage in the process when the dough no longer sticks to the side of the mixer. In addition, salt may reverse the loss of elasticity in dough that has been over-mixed and lost this characteristic.

Replacing salt’s taste and flavour may be partly achieved with alternatives, but it’s tough to find good substitutes for its other functional roles.

Common salt is known to increase dough strength at its normal level of addition (1.5 to two per cent) in bread formulations. Addition of salt above these levels does not improve the loaf volume of bread. Moreover, salts other than sodium chloride could have a detrimental effect on the loaf volume and other characteristics of the bread.

Salt has a critical effect on both hydrophobic (water repelling) interactions and hydrogen-bonding properties of the gluten proteins, thus affecting the rheology (the study of flow of matter, measured by viscosity, strength and hardness) and the overall development of the dough. Different salts (other than sodium chloride) have different effects on the proteins and some may be suitable as replacements in baked goods. However, the effect they will have on the dough and the yeast is dependent on the type of ions they contain, and this can be a challenge in replacing the common salt.

More research needs to be carried out in understanding what effect alternative salts and their ions (other than sodium) will have on gluten proteins and other important components of the wheat flour. Such efforts will enable us to successfully reduce sodium in baked goods, especially yeast-leavened products. / BJ

For more information, or fee-for-service help, please contact Dr. John Michaelides at John Michaelides & Associates at 519-743-8956, or at Bioenterprise at 519-821-2960 at ext. 226, or by e-mail at j.jmichaelides@gmail.com.

ATRUE STORY: We met a baker who was producing gourmet cookies –heavy, thick cookies with lots of large chunksof chocolate, fruits, nuts and other inclusions. In an effort to increase production, she went from hand-scooping to a wire-cut cookie machine. However, she ran into big problems with the wire-cut machine: she couldn’t maintain portion control; her large chunks were getting cut into smaller, less impressive ones; and the remaining chunks were smeared under the cookie dough.

Then she called Reiser. The solution was our Vemag cookie dough depositor with a guillotine cutoff. Even at high production speeds, the Vemag allowed her to run all of her recipes with precise portioning accuracy. Her chocolate chunks and inclusions came through whole. And the guillotine cutting system actually exposed the chunks and inclusions. Now she is able to produce mouth-watering cookies with great eye appeal that out-sell all the other cookies in the bakery case.

By stEfaNIE WallaCE

Victoria’s beautiful history is on display throughout the city, and Rogers’ Chocolates is a longstanding part of it. Now in its 127th year of business, the southwestern British Columbia staple is known for its gourmet chocolate bars, rich truffles and, perhaps most notably, its luscious Victoria Creams. And much like the city, Rogers’ Chocolates has a rich history to celebrate.

Charles Rogers founded Rogers’ Chocolates in 1885 in Victoria when he began making chocolates at the back of his grocery store on Government Street. Before he knew it, Rogers had unexpectedly found his niche. “Charles found that the chocolates were more popular than anything else he sold in the store,” says Sonia Edwards, marketing manager at Rogers’ Chocolates Ltd. From then on, Rogers produced only chocolates. The entrepreneur moved shop in 1891, but not far – just across the street to the company’s flagship store, which is now a heritage building. “There’s something quite magic about it . . . everything is basically in its original state,” Edwards says. “It’s like walking into an antique boutique. There’s some very cool looking stained glass, the original windows are there and we even have one of the original display cases. The store is a must-see for locals and tourists alike for its beauty and history.” New visitors may be surprised to see a cracked display case though: so the story goes (although no one knows for sure what happened), many years ago, a customer broke the glass with her cane. “We have thought about replacing the glass many times, but we have decided to keep it there as a reminder of the importance of always ensuring our customers are happy.”

The Victoria Creams and squares, hand-wrapped in Rogers’ Chocolates’ signature pink gingham paper, are the company’s most famous treat (opposite); Larry Sullivan, CEO, in the Rogers’ Chocolates factory store (above).

}“i t’s like walking into an antique boutique. There’s some very cool looking stained glass, the original windows are there and we even have one of the original display cases.”

The company has been expanded over the years, but Edwards says it took almost 100 years before major changes occurred in the 1980s, when more stores, resellers and wholesalers were added. Besides its heritage location, Rogers’ Chocolates stores can be found in Oak Bay, Sidney

and a factory outlet in Victoria, and in Vancouver at Granville Island, Gastown and Park Royal. There is also one store in Whistler. “When we open a store, we try to replicate that Victorian feel. We want to give our customers that experience of being in a Rogers’ Chocolates store, instead of just a regular store,” says Edwards. With approximately 300 current resellers (the majority in Canada with a few in Washington state), the business is poised for more growth. “We are a western-based company, still a west-coast secret. We see lots of opportunity to share our story and our products with chocolate lovers in Eastern Canada,” adds Larry Sullivan, president and CEO of Rogers’ Chocolates.

When it comes to choosing new resellers, Edwards says special care is taken to ensure the store is the right fit

for Rogers’ Chocolates. “We’re not looking to have our products in every retail store, but we are trying to partner with retailers who want to tell our story and love our chocolate,” adds Sullivan. The company is dedicated to helping charities and has worked hard to develop its community presence over the years, starting with Leah Rogers, the wife of Charles, back in the early 1900s. After Charles passed away, Leah took over the company. “She was very generous with her time and money,” Edwards says, and was dedicated to helping different not-for-profits and charities. Her good intentions eventually forced her to sell the business, and unfortunately, there are no members of the Rogers family still involved in the business. However, the legacy of Leah Rogers lives on through the company’s commitment to helping the communities that have been so important to Rogers’ success over the years. “We like to get involved in projects that provide direct support to our local communities,” Sullivan says, mentioning an ongoing fundraising project that is set

up to help the navy. “For this project, we have a navy commemorative tin as well as two chocolate bars.” A portion of the proceeds from the tin and chocolate bars is being donated to the CFB Esquimalt personnel support program.

While there are constant changes happening – new products, new seasonal staff, new processes and new fundraising efforts – one thing has always stayed the same. “Today we are using many of the same recipes that Charles Rogers delighted his customers with in 1885,” says Sullivan, noting that modern manufacturing methods are used to meet a larger customer base. Cornell Idu, the company’s master chocolatier, is instrumental in ensuring

the original recipes are honoured. “He leads product development and will bring ideas to the table, and he also makes sure that everything that was created before his time remains the same,” says Edwards.

When it comes to popularity, Edwards says, the classic recipes are the clear winners, but new developments have been well received. The Victoria Creams, hand-wrapped in signature pink gingham paper and available in 45-gram and mini sizes, are what the company is famous for. “Right now we have 19 different centre flavours to accommodate different taste buds, like fruit, chocolate, maple and coffee.” Flavour selections depend on the season, of course, with such options

as gingerbread, eggnog, candy cane and cranberry at Christmastime. Edwards says truffles are also popular among customers. “Over the years it seems like people have developed a palate for truffles,” she says. Classic flavoured and ice wine truffles are hits among customers, and this year, cocktail-inspired truffles were a summer favourite. Popular summer cocktail flavours, such as mai tai, pina colada and mojito, were infused into a truffle centre. “There were a lot of taste tests involved in that development, but in the end we think we found the perfect balance between having a really good cocktail and chocolate taste at the same time.”

The perfect balance is something the company has mastered. Preserving and using classic recipes and evolving naturally over time have proven to be successful strategies for Rogers’ Chocolates. “Authenticity and really doing what’s best for our customers [is the secret to success],” Edwards says. “We have been keeping the same recipes, maintaining our quality and making sure that people like our chocolates over the years. That’s what has kept us in business for 127 years and I think if we keep it up, it’s going to keep us in business for another 127 years.” / BJ

Produced by:

BY Di ANe C hi ASSON

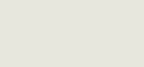

Improve your bakery by getting customers to talk

The best way to develop a good relationship with your customers is through communication. However, communication is not just about you telling your customers what is happening with your bakery. It’s also very important to hear what your customers have to say about your business. But many of your customers will not volunteer this information if it isn’t solicited. Most dissatisfied customers will just walk out your door without saying a word and never come back. Some may even tell their friends or use social media to relay their poor experience.

A successful operation needs to be proactive in constantly improving its business to satisfy its customers’ needs, and the best way to find out those needs is to get feedback. Getting feedback should be ongoing, and not just a one-time project. Once you have received the feedback, it’s also important to take action, and then tell your customers that you have listened and taken action. This will make them feel that you care.

Place a locked box near the exit for customers to drop comment cards into before they leave your establishment.

example, the opportunity to enter a draw for a free pastry or dessert. Today, it is much more common to ask customers to fill out their comments online. If you provide a physical card, make sure that you provide plenty of pens or pencils. Either include either a prepaid self-

}Once you have received the feedback, it’s also important to take action, and then tell your customers that you have listened and taken action. This will make them feel that you care.

Here are some ideas on how to get valuable feedback from your customers.

The best way to build a relationship with your customers is to talk with them. Ask them what they think of your bakery and your products, what else they think you should offer, and how you can improve their shopping experience. Listen to what they have to say, and if they have a good idea, implement it. This will also show your customers that you are truly interested in what they have to say, and willing to take action to please them.

ask thEM tO fIll Out COMMENt CaRDs

Get your customers to fill out a comment card. Provide incentives for them to take the time to write down their thoughts, for

addressed envelope for customers to mail the comment card back to you or place a locked box near the exit for customers to drop the cards into before they leave. This last measure is important to ensure all feedback is submitted; your employees may not submit cards that contain negative comments about their own service.

If you are planning to launch new product items or run a new promotion, consider holding a focus group. Offer free beverages, sandwiches and snacks as compensation. Have the focus group try out your new items and ask them for their feedback. Remember that these are the folks who will be ordering the items, so their opinion counts!

sEND thEM aN E-MaIl

Ask your customers for their e-mail addresses at the point of purchase. Send them an e-mail to thank them for their patronage, and ask them for feedback.

Again, a small incentive may need to be given to obtain the e-mail address, but it is worthwhile.

Always check online to see what others are saying about your bakery. If you receive negative reviews, make contact with the reviewer to try to remedy the situation. Offer an apology and an explanation of how you plan to fix the problem, and invite them back for some free products. Most customers are willing to forgive if you are sincere.

Learn to read the body language of your customers, and react immediately if you sense that a customer is unhappy or dissatisfied with something. Train yourself and your staff on how to deal with a disgruntled guest. Never allow an angry customer to walk out your door.

Communication is at the heart of a great relationship with your customers. Pay attention to what they have to say and you’ll have the chance to truly improve your bakery. / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping restaurant, foodservice, hospitality and retail operators increase sales for over 30 years. Her companyprovides innovative and revenue-increasing foodservice and retail merchandising programs, interior design, branding, menu engineering, marketing and promotional campaigns, and much more. Contact her at 416-926-1338, toll-free at 1-888-926-6655 or by e-mail via chiasson@chiassonconsultants.com, or visit www.chiassonconsultants.com.

Each and every one of us has a unique weak spot when it comes to spending money. Whatever your passion, you will likely opt to spend a bit more to get the calibre and quality of item you covet, even though comparable and less expensive products are available. When we really look at luxury marketing, it becomes clear that people aren’t just paying a premium for the item – it’s the story they buy into. So, you must determine how to train your customerfacing staff to embrace and tell the stories around your products.

Baked goods do fall into the category of luxury marketing. They are considered to be a small indulgence. As such, the same successful tactics used by a fine jewelry shop could easily be adapted for your business too. Consumers are beginning to prefer experiences to products. Rather than acquire more possessions, customers are more interested in spending their money and time on meaningful experiences, making memories and enriching their lives. According to research by the Boston Consulting Group published in 2012,

experiential luxury now makes up almost 55 per cent of total luxury spending worldwide and, year after year, has grown 50 per cent faster than sales of luxury goods. In China, where sales of luxury goods are growing 22 per cent each year, the experiential luxury market is growing at 28 per cent per year. It’s easy to see the financial upside to introducing a little retail theatre, but you may have a customer-facing team of diligent, trustworthy people who find the notion of romancing the product daunting. Is it possible to turn them into showmen overnight?

When you’re hiring customer-facing people, you should look for those who have a natural curiosity and are able to hold a conversation. If they’re too chatty, you run the risk of them being too familiar with the customers. Do they ask questions at the interview? If so, chances are they will enjoy learning about the products and processes. Do they listen when you speak and do they seem to like people? The quieter team members can still be very effective at describing the

Continued on page 28

Howgood are Dunford Bakers’ Double Fudge Chocolate Cake Donuts? Good enough for special request deliveries to the sky boxes at Mile High Stadium during Denver Broncos games. Good enough for private jets to make special stops to pick them up from the bakery. Now known as Dunford Bakers, the company began as the Dunford Bread Company in 1931 in Salt Lake City, Utah. John Stevens, the president of Dunford Bakers, oversees one of the largest wholesale bakeries in the Salt Lake City area. Dunford is in production 365 days of the year. This popular bakery has one retail location, and supplies baked goods to area grocery stores. In addition, it produces many private label brands. While Double Fudge Chocolate Cake Donuts are Dunford Bakers’ most famous product, the Pumpkin Chocolate Cookies have many fans. Mr. Stevens is proud that Dunford Bakers provides 100 people with employment, many of whom are long-time employees.

The secret of Dunford Bakers’ success over the years is the reputation it has built for taking care of its customers by supplying a quality product at a reasonable price. “We put quality into everything we do. We don’t cut corners and we use the best ingredients in order to produce the best product for our customers,” said John Stevens.

To that end, Dunford Bakers uses International® Bakers Services’ flavors such as BLO&V®, B&V®, Raspberry and Pumpkin Pie. “I have known of International® Bakers Services’ flavors my whole life,” said Mr. Stevens. “We are always experimenting with new flavors in order to offer a variety of tasty treats to our customers.”

Whether you are looking for consistent quality in your products or new flavors, turn to International Bakers Services to reach your goals. Contact us toll-free at (800) 345-7175, by fax at (574) 287-7161, or in writing at 1902 North Sheridan Ave., South Bend, Indiana 46628. We have the flavors your customers deserve. ®

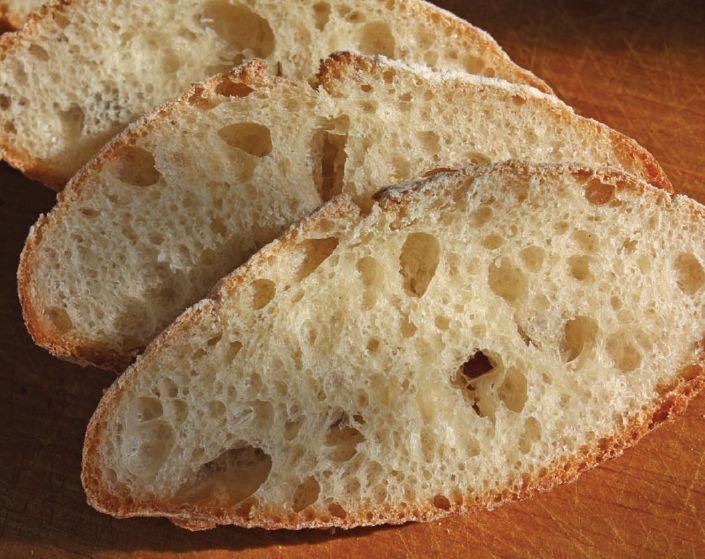

Determining the difference between undesirable holes and alveoli in bread

In the crumb of our artisan bread, we often find big holes, or open crumb. With this in mind, let’s first make the necessary distinction between undesirable holes and alveoli in the bread.

Holes often appear as tunnels. When we cut the bread, we find the same hole on several slices. Alveoli are more evenly distributed everywhere in the crumb. Open crumb for artisan bread is normal whereas holes are not acceptable in the sliced pan bread.

The question concerning artisan bread is whether or not it is normal to have what we call an open crumb that is full of alveoli, or big cells. People commonly refer to these as holes. Their presence in sliced bread is one of the problems that leave bakers and industry experts most perplexed. There are many possible explanations for holes in the breadcrumbs, but the defect may also be a combination of two or more of these causes.

}Open crumb full of alveoli is normal in ciabatta bread, but the presence of alveoli is not acceptable in sliced pan bread.

The intermediate fermentation period between the weighing and the shaping is too long for the strength of the dough. Dough that is too old or too warm may cause this problem, as can improper mixing.

Mostly, bad shaping causes holes:

• If shaped by hand, there may have been insufficient pressure, causing the dough piece to be insufficiently degased.

• The rollers of the moulder machine may be damaged or in bad shape.

• There was an excess of flour during the shaping.

• If the inside of the holes are shiny, it is possible that too much oil was used. Because this divider oil is mineral and does not adhere to the dough it will form a hole.

The intermediate fermentation period between the weighing and the shaping is too long for the strength of the dough. Dough that is too old or too warm may cause this problem, as can improper mixing (dough under- or overmixed).

Lacking humidity in the steam room (proofer) will cause holes. If the fermentation is made in wooden boxes, make sure that boxes are closed well one on the other to preserve the humidity of dough in the box. If the dough gets a dry skin, it imprisons gases and forms holes.

If holes are under the crust it is possible that the proofer is too warm. Dough that ferments too fast will tend to have holes in the finished bread. A too-long fermentation time gives wide alveoli, which we mistake for holes.

Dough that is too hard or too firm will form holes; dough that is very soft and well developed will form alveoli.

Baking bread in an oven with too low a temperature provokes a continuous development, because the yeast rises too long before being seized by the heat thus creating holes.

An abrupt manipulation while putting bread into the oven can cause holes. If the cellular structure of the bread collapses it cannot swell again, which can create a separation of the crust and a big hole.

The use of too much improver or too much oxidizer will make dough more difficult to flush out the tanks during the shaping, which will cause an open crumb.

Pay attention at all stages of manufacturing and you will probably find the reasons for the unwanted holes in your bread. Just remember that people are looking for holes (alveoli) in artisan breads. They expect open crumb or large cells in ciabatta, for example. The high absorption (80 per cent) with good mixing will guarantee you a consistent result in these breads. / BJ

Mario Fortin is an international bakery consultant and owner of FORMA-LAB, consulting services to bakers and suppliers. If you need technical information, send your question to info@forma-lab.com.

BAC has been advised by the Canadian National Millers Association (CNMA) that due to the adventitious presence of priority allergens such as soy and mustard in wheat and other processed

grains, bakers and other flour users can expect to see new precautionary allergen statements for these allergens in the very near future. These allergens, allowed in wheat via Canada’s grain grading regulations, are unavoidably present in unprocessed grains as a consequence of comingling in grain harvest, on-farm storage and movement through the grain handling and transportation system. The practce of the Canadian Food Inspection Agency has been that precautionary statements must be carried through to products made with these ingredients, which will require bakers to apply similar precautionary statements on their own products.

The CNMA has attempted to work with Health Canada over the past 12 months to clarify Health Canada’s allergen labelling policy as it relates to the adventitious presence of soy and mustard in wheat and wheat flour. Compounding the urgency for an expedited resolution to this situation is that the Canadian Food Inspection Agency has been engaged during the same period in product sampling to determine the undeclared presence

of soy in a wide range of wheat based foods. The CFIA product sampling discovered detectable levels of soy, a priority allergen.

BAC and CNMA have both supported a July, 2012 commitment by Health Canada to conduct a targeted consultation on the adventitious presence of allergens in Canadian cereal grains. Unfortunately, at the time of this writing, it was learned that neither preparations for nor scheduling of the consultation is close to completion.

Further complicating the use of precautionary statements is an unprecedented experience by a BAC member company this past summer that was served with an allergen recall notice for the unlabelled presence of oats and barley. While not on Health Canada’s priority allergen list, oats and barley were deemed to be allergens and a recall initiated.

According to the CNMA, the low-level presence of oats and barley along with soybeans, mustard seed, rye and triticale should be expected to be found in wheat flour and other milled wheat products as mills cannot remove 100% of their presence.

BAC is most concerned that the recent oats and barley allergen recall adds a new dimension to the whole matter of allergen labelling and the use of precautionary statements. Firstly, BAC believes it is precedent setting to order an allergen recall for a non-priority allergen which could mean that any ingredient currently not on the priority allergen list may subsequently be deemed an allergen and subject to recall if unlabelled. Secondly, as Canada’s grain grading regulations allow for the comingling of soy, mustard, oats, barley and many other cereal grains, BAC members face an untenable business risk as wheat flour based products could be subject to allergen based recalls at any time.

BAC is currently pressing both Health Canada and CFIA for clear guidance to remove the uncertainty regarding the adventitious presence of both the priority allergens along with oats and barley.

Tuesday February 12th, 2013

Halifax Metro Centre

Wiser’s Lounge - Private Box

Halifax Nova Scotia

Come out and watch the Halifax Mooseheads on the road to the Memorial cup as they play host to the PEI Rockets

Space is limited to 32 seats, please register early!

6:00 p.m. Pre Game reception with Hors D’oeuvres (cash bar)

7.00 p.m. Game time

Please fill in the registration form below and return it before January 31st, 2013

Name:

Company:

Address:

Phone:

Fax:

Email:

Members

x $100.00 ea.Total: Non Members x $125.00 ea.Total: Sub Total: HST 15%:

Please enclose cheque or Money Order Payable to Baking Association of Canada Grand Total:

Visa, Mastercard and AMEX orders please complete the following; a service charge may apply:

Please mail or fax to:Gillian Blakey

Baking Association of Canada 7895 Tranmere Drive, Ste. 202, Mississauga, ON L5S 1V9 Tel (888) 674-2253 x 21 Fax (905) 405-0993

gblakey@baking.ca www.baking.ca

Bakery Congress 2013

Western Canada’s only baking industry trade show & conference featuring almost 45,000 square feet of space.

BC Chapter

November 16

Festive Night at the Races

Fraser Downs

Cloverdale, BC

Ontario Chapter

November 30

Annual Holiday Social

Pavilion Royale

Mississauga, ON

March 21

Night at the Races

Woodbine Race Track

Toronto, ON

Atlantic Chapter

February 12

Hockey Night in Halifax

Halifax Metro Centre

Halifax, NS

By JulIE fItz-gERalD

The sunny skies and pink sands of Bermuda is where Esther Hagen calls home these days.

The Canadian pastry chef jumped at the opportunity to be Fairmont Southampton’s executive pastry chef, heading up the baking and pastry division at the world-famous hotel in August 2011.

For a second career, Hagen has undoubtedly found her calling in life. It was eight years after graduating from the Alberta College of Art & Design in Calgary that Hagen found herself cooking and baking in a small café to supplement her income as a working artist. It soon became obvious that a career change was in order. While Hagen grew up baking intricate desserts like her Swiss father’s favourite Linzer Torte, it had never occurred to her until this moment that perhaps she could make a career out of it.

The pastry-chef extraordinaire knew she needed some credentials, so she complete the Southern Alberta Institute of Technology (SAIT)’s two-year baking and pastry arts program. In addition to her diploma from SAIT, Hagen also pursued four advanced certificates in ingredient technology from the American Institute of Baking in Kansas, providing her with a wealth of knowledge in the world of baking.

With an education under her belt, Hagen landed her first job at The Rimrock Resort Hotel in Banff, Alta., where she worked for four years as the hotel’s pastry chef. She then moved on to the Fairmont Palliser in Calgary for another four-year stint. During this time, the Fairmont chain of luxury hotels was expanding internationally and Hagen had the opportunity to travel to Abu Dhabi in the United Arab Emirates, helping to open the Fairmont Bab Al Bahr. “Never in a thousand

years did I think that Fairmont was literally going to send me halfway around the world!” she exclaims.

The international experience was well suited to Hagen’s personality, providing a change in culture and new challenges professionally. After six weeks in Abu Dhabi, Hagen returned home to Calgary and her position at the Fairmont Palliser. Before too long, this globetrotting Canadian longed for another change in scenery. “I started to get itchy feet. I began looking around and found out that there was an opening in Bermuda. Fairmont’s really amazing about encouraging its colleagues; especially if they get itchy feet, they want to keep them in the company. They provide an enormous amount of assistance when you choose to relocate because the idea is, ‘Why lose a fully trained and valued colleague, when we can just move them to another property?’ ”

Esther Hagen landed the opportunity of a lifetime working as executive pastry chef at the Fairmont Southampton in Bermuda.

The hotel chain facilitated Hagen’s move to the Fairmont Southampton in Bermuda, where she has happily settled into her pristine surroundings. As executive pastry chef, her daily responsibilities are daunting, but it’s a challenge that Hagen is up for. She begins her day at 8 a.m. with a shift briefing to identify what tasks need to be accomplished that day as well as any potential challenges. She then hits the paper, dealing with payroll, daily requests for food, labour reports and e-mail inquiries. Since all food is flown in to the island, taking anywhere from five days to six weeks to arrive, Hagen has to be exact with the timing of orders and quantity of ingredients.

After her paperwork is complete, she walks the floor, observing what has been done, what needs to be done, and if her department is short on any orders. Meetings and tastings usually make up part of the day as well, with Hagen making a personal appearance for VIP clients’ events and wedding tastings to ensure that all expectations are met. Although it’s not unusual to work a 14-hour day, most days are eight hours in duration, culminating with a walk-through of the floor during dinner.

While a good portion of Hagen’s days are eaten up by cheques and balances, part of her job is still reserved for creating scrumptious works of art. “At this level I get the fun stuff. I’m not in charge of making 800 cheesecakes that I need for a Friday night function anymore. Now I’m making the showpiece for that. I’m making the two wedding cakes for next Saturday. I’m making all the chocolate decorations . . . Now I get the really fun stuff, but I have to put up with the paper,” she says laughing.

Although Hagen now lives and works far from home, her inspiration goes back to her days in the classrooms at SAIT where she avidly learned the ropes. “I would say my biggest inspiration was one particular person and that was Volker Baumann at SAIT. He is such a passionate baker, but he’s a passionate educator too and I still hear his voice in my head to this day. He would say to me, ‘Esther, the world doesn’t need more bakers, the world needs better bakers.’ He was always there for the students and the program and was just such a passionate educator and so patient. I don’t know how many times I made that poor man late for a meeting with yet one more question, but he was always so incredibly patient with me and I like to think that I am also now a passionate educator,” she says. “I’m a passionate teacher as well and that certainly rubbed off. He was inspiring. He set a

Even though much of her day is spent doing paperwork, Hagen still prepares showpieces and scrumptious works of art.

standard, not only for my professional knowledge but also for my professional conduct.”

For students contemplating a similar career, Hagen says you should expect to

work hard. She warns that real-life baking is not always how it appears on television, however the industry is extremely rewarding and satisfying, which more than makes up for the odd hours and long days. / BJ

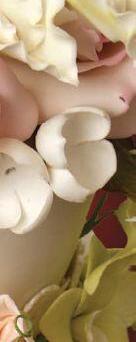

Two slices of bread made with Lallemand Bakers Yeast.

Often overlooked, bread is an important source of daily nutrition. Helping to restore the wholesome qualities of bread, Lallemand offers Bakers Yeast that can significantly contribute to your bread’s nutritional value.

Lallemand Bakers Yeast is a natural and proven source of essential minerals and vitamins, including Vitamin D. Make your bread a non-fortified and vegetarian source of Vitamin D with Lallemand Bakers Yeast. Help yourself!

BY vLAD g uzeNB eRg

Enterprise resource systems help small and mid-sized businesses increase productivity

When most people think of enterprise resource planning (ERP) systems, they think of complex software solutions directed at large, multinational companies with massive budgets. We’ve all heard the horror stories of how complicated ERP systems can be, and the challenges associated with finding and implementing the right system. For this, and other reasons, many mid-sized companies have shied away from ERP systems for many years – preferring to struggle with an array of disjointed systems and masses of spreadsheets, rather than undergo the pain of the implementation of a new program.

}However, today, implementing an ERP system is well within reach for most small and mid-sized businesses. These days, almost all of the mainstream ERP vendors offer some kind of solution directed at helping small and mid-sized businesses increase productivity, reduce costs and transform their business. These systems include best practices and right-sized solutions that are practical and, in many cases, much more affordable than in the past.

A

An eRP system operates with real-time information linking accounting, inventory and production in a way that allows owners and management a consolidated view into overall operations.

visibility into key performance indicators. This is extremely valuable for forecasting and supporting business decisions.

There are several reasons to consider implementing an ERP system for your business. Having an ERP system allows you to:

• Integratebusinessfunctions:

An ERP can help you reduce your operating costs by better co-ordinating various business functions within your organization. An ERP provides a single integrated platform with shared data. Areas such as production, new orders, purchasing, accounting, supply chain management and logistics are all linked together to provide your management with clear

• Get a real-timeviewofyour operations: Knowing where the company stands on a range of issues at any given point in time provides you and your management team with the real-time data you need to make smart decisions. Many small businesses have too little information at their disposal, to make data-driven decisions. Making critical decisions based on gut instinct can be a very dangerous strategy in today’s tough business environment. An ERP system provides the data you need, and today’s systems do so in easy-to-read, easy-to-analyze, drill-down dashboards.

• Betterpredictoptimalinventory: The financial benefit an ERP system can bring your business comes in part from its prediction

capabilities. An ERP system operates with real-time information linking accounting, inventory and production in a way that allows owners and management a consolidated view into overall operations. This allows managers to predict monthly orders in order to maintain adequate inventory levels.

• Improveinventorymanagement: An ERP system can enable you to accurately track all of your inventory, from its arrival at your facility, through production, until final shipments are made. In the case of a bakery, an ERP system can enable you to track ingredients from the vendor to specific batches in production. For example, if you bought flour from a vendor and found out later it might be contaminated, the flour can be specified by batch within the ERP system, allowing you to pinpoint when the bad batch arrived. The goal should always be isolation, so if only one batch is bad, you are able to find it and eliminate it. Batches can be isolated with precision, because an

Continued on page 30

fRENCh MaCaROONs INgREDIENts

• 280 g icing sugar

• 280 g almond flour (fine)

• 5 large egg whites (room temperature)

• Pinch cream of tartar

• 60 g sugar

• 2 drips red food colouring

MEthOD

Sift icing sugar and almond flour. Whip egg whites, sugar and cream of tartar until soft peaks. Add red food colouring and fold in almond mixture. Pipe four-centimetre circles and let dry for 45 minutes. Bake at 135 C (275 F) for about 15 minutes.

ChOCOlatE sORBEt INgREDIENts

• 300 g sugar

• 75 g cocoa powder

• 2 slices ginger root

• 1 l water

• 400 g semi-sweet chocolate

• 115 g milk chocolate

MEthOD

Boil sugar, cocoa powder, ginger and water together. Pour above mixture over chocolate stir to melt chocolate. Strain and allow to completely cool (ideally overnight). Freeze according to ice cream machine manufacturer’s recommendations.

Yield: 24

Source: This recipe is courtesy of Clark Adams, Baking and pastry Arts instructor at SAiT polytechnic. www.sait.ca

ROMaNCINg thE sWEEts

Continued from page 17

product – it’s simply a matter of helping them find their groove within the context of their comfort zone. Tell your team that you need them to not only take orders, but also share their knowledge. It’s about adding value to the customer experience.

The next step is to invest in extensive product training. It can be a challenge to get everyone together when many work part-time on different days, but an hour-long training session once per month to showcase the new products and discuss ingredients could be a great investment in your labour cost. Post a corkboard in the kitchen where you can display labels from ingredients used and write-ups to describe your baked goods. You can send team members e-mail updates with product information as well. Large food companies always have fact sheets that describe the product and give weights, nutritional information and ingredients. You can do the same for your menu.

Put some of the new products out pre-shift and take 10 minutes to conduct structured tastings. If the celebrity ingredient is an exotic spice or chocolate, give everyone a piece of the raw material to smell and feel, asking them to focus on its origin, mouth texture and why it makes a difference to the final product. Ask them to taste together in silence and then to write their own tasting notes as they think about the flavours. As a group, share the notes and see what familiar themes arise. All of these points will provide the base for beautiful stories when talking to customers.

Elements of Persuasion, a book by Robert Dickman and Richard Maxwell, proposes that a story is “a fact wrapped in an emotion that compels us to take an action.” Customers want the story because it enhances their anticipation of a delicious experience to come. The story prolongs the pleasure of the experience. Anthropologists hypothesize that absorbing information via verbal stories is hard-wired into us. For most of our existence on this planet, humans have obtained their most important information, life skills and religion, among other things, through stories. Some experts believe our brain is wired to ensure that storytelling has a much stronger emotional impact than information that’s presented with less emotion. Using the tasting notes your team has already created, you can have them role-play their storytelling at the next staff meeting. Have a contest with a prize to see who can tell the most impactful story about each baked good. The story should revolve around the ingredients (origin, freshness and taste) of the product, as well as how it was created (the artistry). The pièce de résistance should be a description of how it tastes and perhaps a recommendation for a garnish or coffee pairing.

Finally and most importantly, tell your team to enjoy the process and to make sure that their stories are authentic and natural. The stereotypical used-car salesmen get a bad rap because they’re seen as disingenuous. It’s about believability, or, as Mark Twain once said, “Don’t tell fish stories where the people know you; but particularly, don’t tell them where they know the fish.” /

BJ

Michelle Brisebois is a marketing professional with experience in the food, pharmaceutical, financial services and wine industries. She specializes in retail brand strategies.

From natural active dry yeast to gluten-free shells, Journal keeps you “in the know.” for more for the baking industry, check out our website, www.bakersjournal.com

Lesaffre Yeast Corporation’s Red Star brand natural active dry yeast uses a strain of yeast that has not been genetically modified. This natural product is kosher-certified, and is unique in that no processing aids or preservatives are used at the time of drying. The product can be used in all yeast-leavened good with either straight or sponge dough. The Red Star natural active dry yeast is available in 50-pound packages, and the packages do not need to be refrigerated until opened. 800770-2714.

Crown Speciality Packaging recently partnered with International Biscuit and Confections, Inc (IBC) to build unique holiday packaging in the U.S. for Loc Maria, a French biscuit brand, which was sold in club stores across North America during the holiday season. Crown collaborated with IBC to create a shaped metal tin with an embossed design, finished in a rich red colour, creating a luxurious look and feel. Metal is 100 per cent and infinitely recyclable, and once the biscuits have been eaten, the container can be reused for storage or display purposes, extending consumers’ exposure to the Loc Maria brand. www.crowncork.com

Offer your customers a gluten-free dessert with in2food’s gluten-free tart shells. Available in sweet and neutral, in2food’s gluten-free shells can be filled and finished in the oven for 10-15 minutes.

www.in2food.com

A vacuum tube lifter that provides an ergonomically sound alternative to manual lifting for loading and unloading bags and sacks from skids, pallets and conveyors is available from Anver Corp. Developed for production use, this vacuum-operated bag and sack lifter provides a 100 per cent duty cycle, features instant attach and release, and speeds bag handling operations. The Anver VT-Series Bag Lifter is priced from US $4,995 (list), depending upon the vacuum pump size, construction, and vacuum pad attachment. Price quotations are available upon request.

www.anver.com

No mumbo jumbo – just the MIWE condo: • The real hearth baking oven for all types of baked goods such as breads, rolls, muffins, cakes and pies, can even be used for cooking • Standard digital controls with 30 baking programs, 8 of which are direct preset keys • 5 baking phases per program

• Separate top and bottom temperature controls with heat intensity controls for each • Intense steam for excellent crust formulation for all artisan hearth baked breads • Available in so many sizes and deck configurations that for sure we have the right oven for your operation. Sounds charming? That’s what it is! Call us today.

www.miwe.com

ChOOsINg aN ERP systEM

Continued from page 26

ERP system enables you to barcode each batch and track batches through the arrival and baking process. This tracking feature is particularly useful in recall situations.

ChOOsINg thE RIght ERP systEM fOR yOuR BusINEss

There is no question that an ERP system can go a long way in helping you transform your business operations. However, with so many options out there, choosing the right system for your business can be a challenge. Like any type of software, ERP systems can be tremendously different; each one has its own strengths and weaknesses. ERP software selection starts with an understanding of critical success factors, which we define as those things an organization must do well in order to be successful. With this in mind, before investing in a new system, consider hiring a professional, vendor-neutral advisor, to help you conduct ERP software selection in order to help you make the best possible decision. Good ERP system advisors can bring a wealth of knowledge to the table that can prove invaluable as you to sift through the advantages of one system over another. In addition, a strong advisor will help you focus your attention on the key functionality that will have the greatest impact on your business. Although getting help from a professional advisor does represent an additional expense, it’s one that will usually pay for itself very quickly. After all, although there is little doubt that ERP systems are more cost effective than ever before, they are still one of the most important IT decisions you will ever make. / BJ

Vlad Guzenberg is president of the Fuller Landau Technology Group. He has more than 15 years of experience in information technology. Vlad’s background includes systems design and development, technology planning and software selection. He can be reached at 416-645-6544 or by e-mail at vguzenberg@fullerlandau.com.

THE BAKING INDUSTRY Tel: (416) 252-4660 Fax: (416) 252-9993

- 8 Connell Ct., Toronto, ON M8Z 1E8

Manufacturers of NicholsoN Custom Ovens and Proofers, Rack Ovens, Revolving Tray & Tunnel Ovens. Distributors for: ~ Belshaw ~ Lucks ~ Wilton ~ Oliver ~ Bakery Crafts ~ Novelties ~ Bloemhof ~ Decopac ~ Smallwares ~ Gum Paste Flowers & Fondants

Bakery For Sale in BeautiFul kelowna, BC – Wholesale business, family owned and in business since 1949. Potential for growth. Asking $169,000. For more information please call 250762-2277.

Goldmine opportunity – Seldom found chance to escape the city and be your own boss. A meticulous operation and delicious product is the standard for this popular bakery / tea house. The vibrant business has been built over 30+ years. Owner is retiring and willing to train. Only 1 hour from Toronto, the establishment is situated on 1.2 acres in lovely Greenbank, ON. Above the commercial area is a gorgeous 3 bedroom, 3 bathroom, open concept apartment. Built in 1980, renovations were completed in 2000. Out buildings include an oversize double car garage, storage shed and barn/ workshop. to learn more about this wonderful opportunity and financing possibility, contact: keller williams referred realty inc, Brokerage. laura Gray, Sales representative at 416-419-8437, lbgray@ rogers.com or Mark timmons, Sales representative at 416-471-4006, markbtimmons@gmail.com

BY S TePh AN ie O RT eN zi

New regulations bring clarity and safety to bakeries considering gluten-free products

Thanks to an engaging editorial project this spring with Tina Brillinger and her site GlobalFoodSafetyResearch.com, I learned about some new Health Canada labelling regulations that came into effect in early August. These regulations will help put celiacs and gluten-sensitive individuals in a better position when choosing what they can safely eat.

Also, in tandem, I learned about Canada’s new gluten-free certification program that’s endorsed by the Canadian Celiac Association and enforced by the Canadian Food Inspection Agency. This gives the Canadian Gluten-Free Certification Program the kind of authority and general heft that their seal now has in the marketplace.

}baking sector has yet to be seen. Three million Canadians suffer because of gluten, and with such a significant niche market in danger of ill health because of undisclosed gluten ingredients, it must have crossed the minds of many bakery operations –despite dealing day-in and day-out with celiac kryptonite – to seriously consider serving the celiac market.

Surely the baking sector is one that can find its way around gluten, but it involves considerable investment. Getting certified gluten-free requires monitoring operations from the back-end and all along the production line, including the facility. For a baking operation already making products with gluten ingredients, it means spending time and money to make a full production line and facility gluten-free (and, in some cases, establishing a completely new, separate and dedicated production line).

Some big players have already started, but they’re curiously outside the sector.

getting certified gluten-free requires monitoring operations from the backend and all along the production line, including the facility.

As a population, we generally understand that celiacs can’t eat gluten and that gluten can be found in wheat and similar grains. What most of us don’t know is that it’s an autoimmune disease with the only treatment being a completely gluten-free diet. There’s no medicine to take to make it OK to freely eat from the sources most of us take for granted when buying our food.

What the new regulations make clear – especially for those who need to study the fine print that guides the safe packaging and labelling of foods – is the official definition of gluten. Subsection B.01.010.1(1) of the new labelling regulations defines gluten as follows:

Gluten means (a) any gluten protein from the grain of any of the following cereals or from the grain of a hybridized strain that is crated from at least one of the following grains – barley, oats, rye, triticale, wheat – or (b) any modified gluten protein, including any gluten protein fraction, that is derived from the grain of any of the cereals referred to in paragraph (a) or from the grain of a hybridized strain referred to in that paragraph.

How the new labelling will impact the

PepsiCo used four facilities certified gluten-free to produce six varieties of potato chip entitled to the gluten-free seal.

Although that seems a no-brainer, since potatoes are safe (flavourings, though, not so much), what PepsiCo did was identify a sector of that niche market that wants to do what all celiacs want to do, according to one of my sources: to shop where everyone else shops, rather than at a specialty store or along a portion of a grocery aisle that caters to special diets.

This source explained the four submarkets that the certifiers have their eyes on: celiacs, people with gluten sensitivities, the halo group (a great name to identify the shoppers who have a celiac family member and would like to buy gluten-free for the entire family), and finally, people who choose to eat gluten-free because they perceive it as a health benefit.

That last submarket is a giant waiting to emerge. There is so much riding on our culture’s desire to eat a more healthful diet that serious health shoppers are taking a good look at gluten.

Diagnoses of celiac disease are on the

rise. Health Canada says a growing understanding of the impact of gluten on digestive health has put individuals and health-care professionals in a better position to identify the sources of digestive complaints. It has also led to what’s being called the gold standard of celiac disease detection – small bowel biopsy.

Celiac disease is no picnic, which makes it also worth watching to see if gluten goes the way of peanuts and balloons in environments where children spend a significant part of their time. Until then, our industry is awash in the stuff that can drop nearly 12 per cent of our population to their knees.

The guiding principle of whether or not to get into the game is likely to be expense, but maybe there’s something else. Why not leave the specialty products to the specialists? Form alliances with reputable, reliable and certified suppliers that can deliver 100 per cent on dietary safety. Then tell your customers about them, or find a way to safely merchandise them and stock them yourself. Everyone will win. / BJ

Stephanie Ortenzi (www.pistachiowriting. com) is a Toronto-based food marketing writer.

OUR CAPABILITIES:

As a Dawn customer, you have more than 90 years of bakery knowledge and expertise on your side. And as we make changes by adding new products and solutions to our services, we want you to know that you still have our undivided attention. We’ll continue to listen carefully to you and bring you our insights and resources to help you grow your business because we’re committed to helping you succeed. After all, a good partnership is more than just listening to each other, it’s about growing together.