Faba

BY BRIAN HARTZ

Faba

BY BRIAN HARTZ

Does Canada’s baking industry need more competitive events? I mused on this topic in my blog at BakersJournal. com and got an enthusiastic “yes!” from readers. The question originated at a meeting of the Canadian Pastry Chefs Guild in mid-September. Guild members were discussing ways to boost attendance at meetings and the topic of competitive cooking shows came up.

The weekend before the meeting, I attended a Food Networksanctioned, “Iron Chef”-style contest at the Hot & Spicy Food Festival in Toronto and was impressed with not only the superb production values, but also the attendance. It was a standing-roomonly crowd as chefs battled each other and the clock to plate the best dishes for a panel of culinary experts. The cameraman was constantly darting around, providing excellent shots of the action that were then projected onto a screen behind the stage. The single-camera setup made it a little disorienting at times and points of view shifted back and forth, but latecomers standing near the sides and back of the auditorium were surely appreciative.

Meanwhile, the emcee did a great job mixing commentary and updates on what the chefs were doing with explanations of the rules and brief chats with the judges. And in true “Iron Chef” fashion there was even a mystery ingredient – fresh Ontario beets – revealed dramatically right before the contest began.

Mentioning this at the guild meeting stirred some talk about how Canada’s baking industry could capitalize on the competitive cooking craze. I don’t have enough space to recap the discussion, but here are three responses to my blog post on the subject:

}Being a young pastry cook, I find it difficult to find solid information on how to get involved in the pastry world. There isn’t a lot of information about even such popular events as Coupe de monde de la Boulangerie or even how to enter the World Skills competition. I have asked teachers about both events and no [one] knew of them. Showcasing pastry chefs and bakers in a new light will really help new and young people to become more interested in the field. – Stephanie Blackmore

Pulling off a live match-up involving all stages of food creation will be significantly more complex, but there’s no reason it can’t be done with proper planning and support.

I am a recent graduate of the professional baking program at Vancouver Island University and completely agree with the need for more baking competitions. I competed in Skills Canada this past year and had a blast and can’t wait to do it again. I would also be interested in doing other competitions as well but I can’t seem to find any. What can we do to get the word out? I want to gain more experience and I think [taking part] in competitions would be terrific. – Tara Devine

I would suggest groups like the Canadian Pastry Chefs Guild get their feet wet at the college level with an “Iron Chef”-style competition, and offer some real meat as the reward (pay a chunk of tuition or something like that). Get local media involved, and sponsors will line up, although some might need to be coaxed to the altar a little bit. It takes legwork, time, dedication, commitment and most of all passion, and it certainly can be a very rewarding success. – Mark Floerke, project leader, Food Oil Applications Bake Lab, Archer Daniels Midland Co.

Canada, it’s time to step up and get those competitive juices flowing. The Bread Bakers Guild of America has assembled its nine-member team that will train for the Louis Lesaffre Cup at the International Baking Industry Exposition in Las Vegas next September. Meanwhile, Team Canada, at the time of this writing, was still looking for a third member to compete at the Cup –the qualifier for the prestigious Bakery World Cup in 2012.

To be fair, Bakery Showcase in May 2010 will have two competitions – cake decorating and decorative bread – each with professional and student divisions. These fall under the type of contest in which the work is done in advance and the finished product is brought to the show for judging; pulling off a live match-up involving all stages of food creation will be significantly more complex, but there’s no reason it can’t be done with proper planning and support.

Happy reading,

NOVEMBER 2009 | VOl. 69, NO. 8

editor | Brian Hartz editor@bakersjournal.com 1-888-599-2228 ext. 250

teChniCal

editor | John McColl, Puratos Canada jmccoll@puratos.com

national advertising Manager | stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

sales assistant | Barb Comer bcomer@annexweb.com 519-429-5176 1-888-599-2228 ext. 235

ProduCtion artist | Brooke shaw grouP Publisher | Martin Mcanulty mmcanulty@annexweb.com

President | Mike fredericks mfredericks@annexweb.com

Mailing address

P.o box 530, 105 donly dr. s., simcoe, on n3y 4n5

PubliCation Mail agreeMent no. 40065710. return undeliverable Canadian addresses to: CirCulation dePartMent, P.o box 530, siMCoe, on n3y 4n5 e-mail: lmorrison@annexweb.com

IssN 0005-4097

Published ten times per year (Jan/Feb, Mar, apr, May, Jun, Jul, aug/sept, oct, nov, dec) by annex Publishing & Printing inc.

suBsCRIPtION RatEs

Canada — 1 year $ 31.80 (includes gst – #867172652rt0001) usa — 1 year $ 40.00 Foreign — 1 year $ 60.00

Send your subscription request to: bakers Journal

P.o box 530, simcoe, on n3y 4n5 tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940 e-mail: lmorrison@annexweb.com

From time to time, Bakers Journal may make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. if you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

opinions expressed in this magazine are not necessarily those of the editor or the publisher. no liability is assumed for errors or omissions. all advertising is subject to the publisher’s approval. such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

no part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2009 annex Publishing & Printing inc. all rights reserved. Printed in Canada.

In September, a white chocolate version will be available on the market.

Here it is, life size

Small and beautiful as beads of caviar, delicious as only chocolate can be: that’s the new Crispearls™ in a nutshell. The biggest surprise comes when you taste them. With their crunchy heart of toasted biscuit, you can even mix them in chocolate mousse, ice cream… Crispearls™ are your new tool for creating taste, texture and decoration.

briefly | Charles “Matt” Matheson Tatham: Nov. 21, 1957-Sept. 12, 2009 | New competition to debut at Europain 2010 | for more news in the baking world, check out our website, www.bakersjournal.com

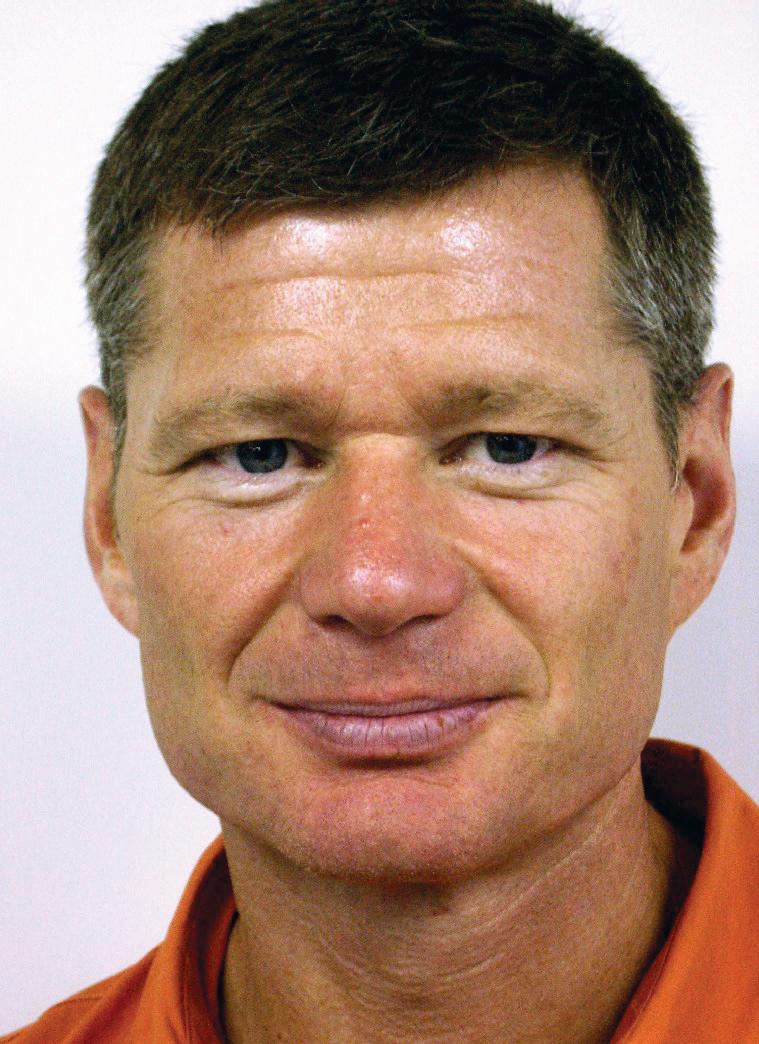

Charles “Matt” Matheson Tatham died unexpectedly on Sept. 12, 2009, after completing the Wasaga Beach Triathlon in Wasaga Beach, Ont.

Born Nov. 21, 1957, in Woodstock, Ont., Matt was active in the Baking Association of Canada, whose members are shocked and saddened by his passing. He began his career in baking while in high school, working part time at a bakery. He graduated from the University of Guelph with a degree in food science and went to work at Marks & Spencer with responsibility for cakes and cookies. He prospered over the next 25 years, becoming a highly respected professional in the North American bakery industry, and at the time of his death he was enjoying great success as business manager at Nealanders International Inc.

Matt was a world champion triathlete who successfully defended his title in Copenhagen this year. He was also a

gardener and horticultural society award winner. Matt’s many other hobbies included photography; composing and performing his own music; stamp collecting; and making, flying and fighting kites.

He is survived by his companion of 24 years, John LaRocque; his parents, Sid and Marnie Tatham of Woodstock; siblings Robin, Paul (Nancy), Bill (Janna), Mary Ellen Rennie (Dan), and Ian (Edie); and 12 nieces and nephews.

A service to celebrate Matt’s life was held Sept. 19 at Morley Bedford Funeral Home in Toronto. In lieu of flowers, donations may be made to the War Resisters Support Campaign www. resisters.ca).

VANCOUVER – Vancouver Community College baking and pastry arts student

Caitlin Mayo competed against the world’s best at the 2009 WorldSkills in Calgary – and she won her just desserts, bringing home a medallion of excellence and the people’s choice award.

Mayo, a 20-year-old Langley, B.C., resident, had been training full time since January to prepare for this event.

“I practiced all day, five days a week,” she says. “I love the challenge of competing against my peers.”

Her preparations paid off. Mayo represented Canada against 13 other countries in the confectioner/pastry cook category and was awarded a medallion of excellence for receiving more than 500 points during the recent four-day competition.

Mayo had to create everything from marzipan to chocolate and plated desserts to cakes during the international competition. She plans to continue learning her craft to achieve the inter-

provincial Red Seal certification. Her future dreams include opening her own business.

“I love what I do, and that is what keeps me motivated,” she says.

WorldSkills International 2009 hosted 1,000 competitors from 50 countries with a mandate to promote vocational and skilled trades training.

Europain 2010 will feature the show’s first individual bakery competition – the Bakery Masters. This new event promises to “bring together the best of the bakers who competed in the Louis Lesaffre Cups and the Bakery World Cup,” says organizer Christian Vabret.

“The aim … is to unearth, from among the 6,000 bakers we have met all around the world in the past few years, the real gems who will be able to represent their trade at an international level. By enabling bakers to prove themselves as individuals and to evolve as professionals, contestants in the Bakery Masters will be striving on behalf of our trade, raising standards ever higher.”

The competition will include three categories: bread, viennoiserie and artistic creation. Eight individuals will compete to become the three bakery world champions. The 24 competitors are between the ages of 18 and 55 and hail from 17 different countries throughout Europe, the Americas, Asia and Africa.

The competitors have all taken part in the 2008 Bakery World Cup and the Louis Lesaffre Cup international selections, held in 2006 and 2007. Eighteen were selected based on their scores from these competitions. Another six are wild-card competitors who were unable to demonstrate the full scope of their talent and knowledge when working with their teams during these competitions.

International Bakery Union president Peter Becker will preside over the Bakery Masters judges’ panel, which will consist of three master bakers from each category. The names of the judges will not be disclosed until the start of competition in order to guarantee impartiality during the contest.

The Bakery Masters is sponsored by the Lesaffre group, with technical support from EKIP, the association of food equipment manufacturers and owners of the Europain exhibition.

For more information about Europain 2010, visit www.europain.com.

CALGARY – Calgary foodies gathered at Southern Alberta Institute of Technology (SAIT) Polytechnic in late September to celebrate the opening of a new gourmet food store – the Market Place at SAIT.

The store, thought to be the first of its kind on a post-secondary campus, serves as a live classroom for SAIT Polytechnic’s School of Hospitality and Tourism students.

“Students will have the opportunity to gain valuable experience, this time in a retail setting. They will translate customer service theory into real-world application,” says Tom

Bornhorst, dean of SAIT’s School of Hospitality and Tourism. “

The Market Place at SAIT integrates 100 students from three programs: Baking and Pastry Arts, Professional Cooking, and Meat Operations and Management. The students work together in the space, selling their products, just as they would when they go to work in the community.

Features include a deli counter that sells meat cuts, a bakery counter displaying artisan bread (delivered fresh twice daily) and fresh baking, and coolers featuring to-go

BRAMPTON, Ont. – Saputo Inc. of St. Leonard, Que., and L.V. Lomas of Brampton, Ont., have reached an agreement in which L.V. Lomas will supply and distribute the Saputo’s line of dairy ingredients to the Canadian food market, a move that will

complement Saputo’s existing sales force in Canada.

BRAMPTON, Ont. – Embassy Flavours Ltd., a manufacturer of flavours for bakery applications, is now a distributor of Nielsen-Massey vanillas. Nielsen-Massey has been producing premium pure vanilla products since 1907.

Embassy’s customers will be able to order the renowned Madagascar Bourbon Vanilla along with many other flavours.

OAKVILLE, Ont. – Continental Ingredients Canada Inc. has successfully completed its HACCP registration with the Canada Food Inspection Agency (CFIA). The Oakville, Ont.-based company is committed to offering customers safe, quality food ingredients, and the HACCP designation confirms the company’s dedication to achieving this goal.

For more information, call 905-815-8158 or visit www.cic-can.net.

The ingredients will include whey powder, skim milk powder, WPC 35, WPC 80, WPI and lactose. In addition, several modified milk ingredients – made available through advancements in whey protein technology and complex physical treatment – will be marketed through L.V. Lomas.

style main course and side dishes. The facility will also sell specialty culinary items such as veggie chips, almond paste, rolled fondant and specialty oil and spices.

A column (“Star Power,” August/September 2009) said Anna Olson is Home Depot’s kitchen expert. She will be working with Home Hardware.

In our 2009 Recipe Collection, quantities for Purple Wheat Cranberry/ Walnut Bread were incorrect. The formula calls for 7.8 kg of water and 0.3 kg of yeast.

A caption in “Back to School” (October 2009) failed to identify AIB vice-president Kirk O’Donnell, who was seen awarding a certificate to baking student Joe Isenhart Bakers Journal regrets these errors.

BY MICHELLE BRISEB

Recession or no recession, formulating, introducing and marketing new products should always be a top priority for your business.

Ask any retailer what question they get most from customers, and the answer will most likely be: “What’s new?” Indeed, there’s a little bit of magpie in all of us as we are often unable to resist shiny new things.

William Pollard said, “The arrogance of success is to think that what you did yesterday will be sufficient for tomorrow.” One doesn’t have to be a large corporation to follow a formal protocol when launching a new product. In fact, smaller operations have the advantage of speed and flexibility when bringing new concepts to market. It’s not about skipping steps or flying by the seat of your pants; it’s about following the same steps as the big companies but in a less formal way.

}2. tECHNICal assEssMENt

Once you have a new product in mind, look at your production and sales capabilities and see what it would take to get in the game. Does the new product require special equipment to make it or unique delivery systems to serve it? Do you have the manpower or expertise on staff to make and sell it? Sweet Flour spent months perfecting its two-minute bake time and through extensive testing it was able to determine where it could customize and where it had to stay the course.

“We do get some customers who will request a larger cookie,” says owner Kim Grans. “However, we’ve established a certain size, weight and formula of the base dough that makes an optimal cookie at the desired cook time so on that point – we don’t deviate.”

Customizing is a huge trend moving forward so if you can figure out a way to

Customizing is a huge trend moving forward so if you can figure out a way to do it, yet still maintain efficiencies, technological innovation will be a key to your success.

1. assEssINg NEEDs aND tRENDs

Where are there unmet needs that your business can fill? This is a high-level view so look at economic conditions, culinary trends and what competitors are doing. Is there a customer segment you’re missing? If your customer base contains young and old but is missing 36- to 49-year-olds, then you might want to find out where they’re eating instead and why.

What new trends are emerging in “sister segments” of the food industry that might have applications for the baked goods category? Starbucks lets you build a latte with the flavours and milks you want – why not cookies? Sweet Flour Bake Shop in Toronto does just that by allowing customers to pick a base dough then choose the mix-in that appeals to them. It could be anything from chocolate chunks to Snickers bar pieces. Ice cream parlours offer mix-ins, too, proving that really good ideas can cross many categories.

do it, yet still maintain efficiencies, technological innovation will be a key to your success.

3. sOuRCE-Of-suPPly assEssMENt

Where will the ingredients come from? Are there seasonal challenges, or political, environmental or currency fluctuations that may affect supply or cost of the final product? If you’re using branded ingredients such as chocolate bars or candies – make sure you know what the rules are for using trademarked names and logos.

4. MaRkEt REsEaRCH

Who will this product appeal to? Will you pull customers from afar or are you fishing in the radius of a few kilometres around your operation? Look at the demographics of your market area and compare them to your target group for the product you’re introducing. Try to gauge how many potential consumers live there and what percentage of them

Developing innovative new products is a complex process, but you can’t afford to stand still and not plan for the future.

would be interested in your new product.

Sweet Flour established that the core customer for its customized fresh baked cookie would be busy moms. The company made sure women in this demographic were well represented in terms of the research they conducted and the product testing. Sweet Flour developed a fitness cookie made from dark chocolate, almonds, oats and blueberries after noticing that many of their fitness-oriented customers were eating nature bars with similar ingredients. Watch your market and take note. Sometimes they’ll tell you with their choices and actions instead of words.

5. PRODuCt CONCEPt tEstINg

Once you have the recipes and ingredients on hand, try different variations and hold blind sampling sessions where customers can vote for their favourite. This is consumer involvement in the process and it’s a great way to engage your market up front. How long does it hold, stay fresh and how does it taste served cold the next day? Try to use the product yourself as the consumer would to

The Vemag Dough Divider produces uniformly spaced dough portions onto the conveyor, eliminating doubles and downtime It can be easily converted to a two-lane set-up to produce up to 200 cuts per minute

What makes the Vemag Dough Divider so special? Versatility and weight accuracy. The Vemag Divider adds versatility to every production line and is perfect for all types of breads, buns, rolls and English muffins. It features a positive displacement double screw system that is the most gentle extrusion divider on the market The Vemag is easily adjust able to produce a range of exact-weight portions, dough absorptions and crumb structures

See for yourself – c all us today for a free DVD or to set up a demonstration.

Batch after batch, the Vemag consistently produces precise weight portions at 1% standard deviation

The Vemag does not require mineral oil, saving thousands of dollars annually while eliminating product air pockets and surface blisters.

The Vemag is easily adjustable to produce a wide range of portion sizes – from 5g to 20kg

The Vemag is easily adjusted to produce b oth open-crumb and uniform tight-crumb structures

The Vemag can handle absorption rates from 45% to 95% – from stiff bagel doughs to soft English muffins

BY Jo HN M ICHAELIDES

Continuing our series on the basic ingredients for baking, what are functional foods, what functional ingredients are available to be used in baked goods and what are the challenges of incorporation of such ingredients in baked goods?

}Consumers are taking their healthy eating habits very seriously and are seeking to enhance their health through food rather than medication alone. Thus, there is a great market demand for foods that deliver health benefits to the consumer. The foods that have this capability are called functional foods. These foods are defined as any foods that may provide a health benefit beyond the traditional nutrients they contain. In addition to functional foods, consumers might use isolated components from plants, animals or microbes to further enhance their health. These natural health products can best be described as substances that can be considered a food or a part of a food and provide medical or health benefits. These can be isolated nutrients, dietary supplements, herbal products, etc.

such as juice and skins, which have resveratrol; and asparagus, containing rutin. The main health-delivering components in fruits and vegetables are powerful antioxidants that contribute to heart health and prevent cancer, diabetes and numerous other chronic diseases. These compounds are present in almost all fruits and vegetables.

Fruits and vegetables as ingredients can be used whole, dried or ground into powders. Also, extracts from fruits and vegetables are available as ingredients to be used in the manufacture of functional foods and beverages.

Grains, pulses and other seeds are powerhouse functional ingredients. Again, they can be used whole, ground into flour or used for the extraction of other functional ingredients. Soybeans

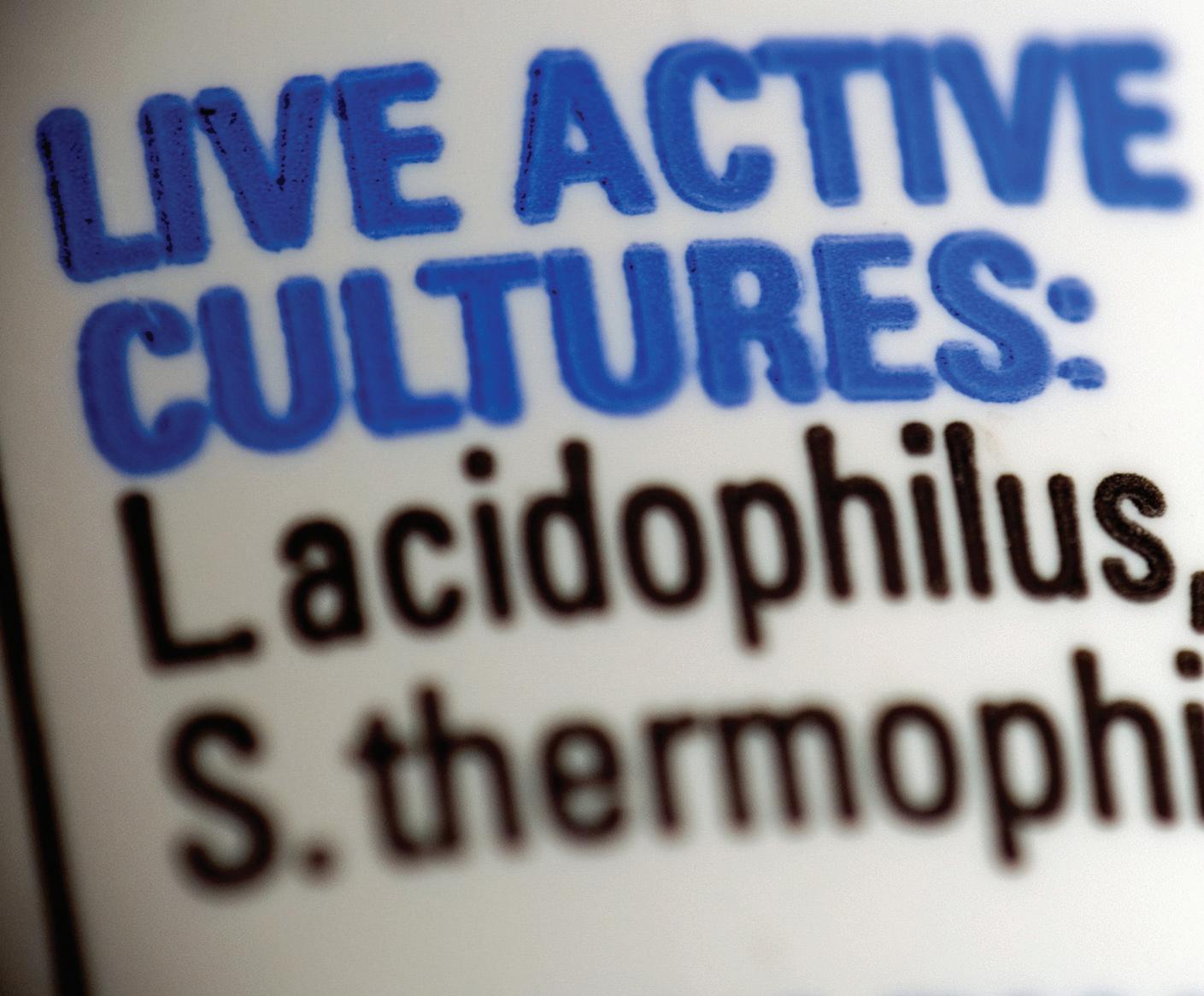

Prebiotics are functional ingredients that can be incorporated into … baked goods. They are beneficial in supporting gut micro-flora (probiotics) and contributing to overall gut and immune system health.

Functional ingredients such as probiotics –gut-beneficial bacteria – are increasingly being incorporated into many food products.

We need functional ingredients to manufacture functional foods, and functional ingredients are substances that are shown to possess health and wellness advantages. They can be isolated components or whole foods that can be used as ingredients.

In this technical talk we will mainly deal with functional ingredients, and I’ll describe a few examples that will represent a good range of what is being used today.

fRuIts aND VEgEtaBlEs

Practically all fruits and vegetable contain substances beneficial to human health. Examples include tomatoes, which contain lycopene (researchers at the University of Guelph are working on improving the lycopene content of tomatoes); red grapes and grape products

are well documented for their powerful phytoestrogens – known as isoflavones. Oats and barley are characterized by their soluble dietary fibre beta-glucan, which is recognized for its important role in heart health (heart health claims for oat and barley beta-glucans are permitted in the United States). Flax and sesame seed contain substantial amounts of omega oils but, more importantly, plant lignans. These lignans are converted in the human large intestine into mammalian lignans (phytoestrogens) and extensive research has shown that they are instrumental in the prevention of breast and other hormonal-related cancers.

Insoluble and soluble dietary fibres are the main components of grains, pulses and other seeds that contribute to health benefits of human diet. I discussed the various benefits of dietary fibre in the August/September 2009 issue of Bakers Journal. The many fibre ingredients available in the market was also discussed.

However, it is important to mention

the benefits of soluble fibres as prebiotics. Prebiotics are functional ingredients that can be incorporated into many foods and beverages, including baked goods. They are very beneficial in supporting the gut micro-flora (probiotics) and contributing to overall gut and immune system health. Many prebiotic ingredients are now available in the market and come from a variety of sources. Fructo-oligosaccharides such as inulin come from chicory root or Jerusalem artichoke tuber. Other short chain fructo-oligosaccharides are manufactured from starch and sugars.

aNIMal aND MICROBIal ORIgIN

Fish oil containing DHA, conjugated linoleic acid, omega-3 eggs and egg ingredients are functional ingredients that can be incorporated into food products. Galacto-oligosaccharides produced from the modification of milk sugars are prebiotics and can be incorporated into many foods and beverages.

Probiotics are also functional ingredients of microbial origin. They are those gut-beneficial bacteria that colonize the human large intestine, fermenting prebiotics and producing substances that contribute to a healthy colon and overall health of the body. They are incorporated into many food products and attempts are being made to expand their use in many other foods.

aND BEVERagEs

Functional ingredients need to deliver health benefits to the consumer at the

point of consumption and beyond (probiotics). So, they need to survive all processing steps and be viable at the end of the shelf life of the food product. Current and past practices in food processing are focused on providing safe food and therefore rigorous processing conditions are in practice. These conditions quite often will reduce or completely eliminate the health benefits. Recognizing this issue, many new technologies are now available or being researched to provide gentle processing environments that are also effective in ensuring food safety for the consumer.

Other challenges of incorporation of functional ingredients in food products deal with the taste and flavour of these ingredients, which might be good for you but might also taste bad. For example, fish oil is difficult to incorporate in many foods because of this reason. New technologies of masking taste and flavours such as micro-encapsulation not only overcome this problem but also provide additional protection to functional ingredients. Protection is also necessary to avoid issues of oxidation (fish oils) and ensure viability of ingredients such as probiotics.

REgulatORy IssuEs

Food regulations regarding functional ingredients are strict in Canada. As formulators of functional food products we should always use ingredients permitted in Canada and in the case of exports adhere to the regulations of the targeted country. We should also always adhere to Health Canada regulations in regard to making any health claims relating to these functional foods.

The Canadian Food Inspection Agency has more information about the regulatory aspects of functional ingredients. Visit the CFIA website at www.inspection.gc.ca. / BJ

Funding for this report was provided in part by Agriculture and Agri-Food Canada through the Agricultural Adaptation Council’s CanAdvance Program.

Dr. John Michaelides is Guelph Food Technology Institute’s director of research and technology. For more information, or fee-for-service help with product or process development needs, please contact GFTC at 519-821-1246 or gftc@gftc.ca.

Beans, peas, lentils and chickpeas are at the forefront of ingredient innovations | By

BRIaN HaRtz

Canada is one of the world’s leading producers and exporters of pulses – beans, peas, lentils and chickpeas – and these crops are increasingly being looked at as healthful, functional ingredients for baked goods.

In 2009, this message has been taken to the food manufacturing community with new vigour thanks to groundbreaking research into the nutritional benefits of pulses and pulse ingredients such as flours and starch fibres. At a February symposium in Toronto, Pulse Canada unveiled the results of seven human clinical trials conducted from 2006 to 2008 at universities here and in the U.S., with major benefits reported in the areas of cardiovascular health, weight management, diabetes and gut health. Pulses were also found to be good sources of fibre, folate and iron, and low in fat.

“Pulses are an under-utilized ingredient in North America and around the world,” Pulse Canada market innovation director Peter Watts told Bakers Journal. “For food companies looking to create new, healthier products or reformulate existing products, we see a big opportunity for pulses but we see a low level of awareness of the ingredients.”

Watts says about 90 per cent of Canadian pulses are exported, but domestic food producers should consider their long list of benefits, because “when people see ingredients such as bean flour in a bread or pastry product, they think healthy.”

Pulses also fit nicely into food trends popular with consumers, Watts adds.

}“They’re Canadian grown. They’re essentially a local product, not exotic. And they’re natural, unmodified, and gluten-free. There’s also the sustainability aspect – environmentally it’s an area that’s going to have some potential.” More on that later.

A University of Alberta employee harvests crops (opposite) at PUREnet research plots near St. Albert, Alta.; University of Alberta student Christina Williams, foreground, and her professor, Dr. Jane King, explain the pulse crop research they’re conducting.

Pulses play an important role in controlling blood sugar, with most having a low glycemic index between 40 and 50. They’re low in fat and high in fibre – about eight grams per 250-millilitre serving.

But, Watts says, “This is an emerging industry. Sure, other ingredients are going to be more cost-competitive on the surface, but what kind of benefit are you

getting? [Domestically], the pulse flours aren’t yet in as good supply as wheat [flour]. But pea fibre is a great example of a cost-competitive product that’s on the market right now. It can be used as a source of dietary fibre in a food product and can be very cost-effective compared to say, inulin.”

To further stimulate awareness of

pulses, Pulse Canada and the Alberta Pulse Growers sponsored a first-hand look at western Canada’s pulse industry, inviting chefs and media – including Bakers Journal – from Canada, the U.S., Mexico and the U.K. to Edmonton to take part in their three-day “Healthy People/ Healthy Planet” tour.

faBulOus fOOD

The tour’s first stop was Fabulous Food Creations – the Nisku, Alta., kitchen studio of Lovoni Walker, a celebrated chef, cookbook author, food stylist and host of the TV cooking series Simple,

Fresh, Delicious. As she efficiently went to work on a pulse-themed menu, Wendy Benson, R.N., of the Alberta Pulse Growers highlighted some of the other nutritional aspects of pulses – and their benefits to food producers.

“Pulses play an important role in controlling blood sugar,” she said, “with most having a low glycemic index (GI) between 40 and 50. They’re also naturally low in fat and high in fibre – about eight grams per 250-millilitre serving.”

Benson reported that pulses are an excellent source of protein for vegetarians and vegans, and are also good for people with celiac disease, as flours milled from these crops are naturally gluten-free. However, despite all these benefits, the consumption of pulses in North America continues to be much lower than desired.

“Americans eat about half a cup of pulses per week,” Benson said, “and Canadians eat about a quarter of a cup.”

U.S. Dietary Guidelines recommend eating three cups of pulses per week, and Canada’s 2007 Food Guide to Healthy Living urges regular consumption of them as a way to reduce saturated fat while still getting protein.

“All these food guides recommend more pulses in our diets,” Benson said. “But people have lost touch with how to use them in everyday meals.”

That wasn’t a problem for Walker, who presented a truly fabulous lineup of dishes, starting with a Yellow Split Pea Soup with Chilies and Goat Cheese and ending with a batch of Speckled

• Join 4,250 industry professionals including bakers (retail, wholesale, commercial), grocery and foodservice outlets

• Visit the trade show - over 200 companies in 35,000 sq.ft. showcasing ingredients, equipment, services, technology and baked goods (fresh, proof & bake, par-baked, freezer-tooven, thaw & serve)

• Learn at the informative seminars and workshops

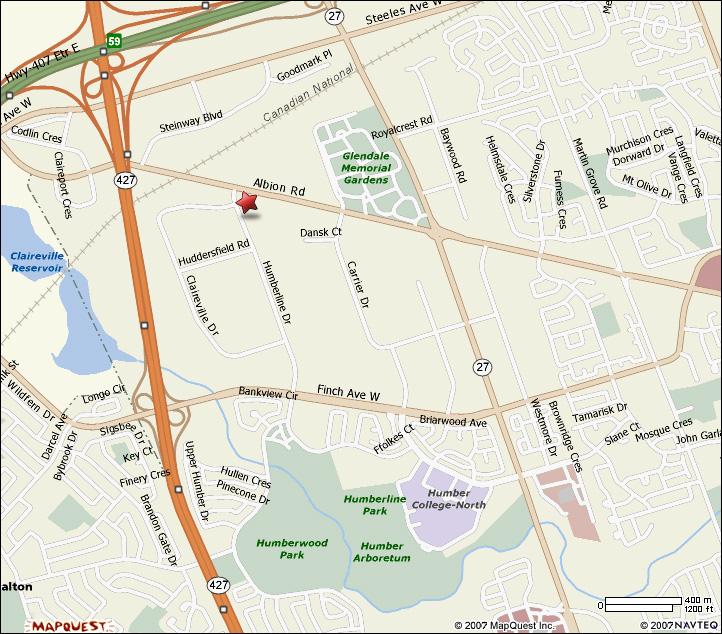

• Located in the Toronto area, the facility is easily accessible by public transportation (Mississauga Transit & GO Trains), major highways, 5 minutes from the Toronto International Airport and provides plenty of free parking

• NEW Show Features

Held every other year, it is the only baking specific event produced in Canada

If you want an easy life, don’t buy a bakery. If you do buy one, and still think you would like an easy life eventually, you do not run it the way husband and wife Mark and Valerie Engels are running their twolocation Bubby Rose’s Bakery & Café in Victoria, B.C.

As avid learners focused on ingredient and product quality, they work constantly at improving and perfecting their products and operations. It’s not the easy way, but it’s the right way for them.

An article in a Victoria newspaper about Bubby Rose’s a couple of years ago was appropriately headlined “‘It’s good’ is just not good enough.” In the article, Mark was quoted as saying: “I don’t let people get away with ‘It’s good.’ I don’t feel comfortable with anything less than ‘great!’ If it’s just good, we want to know what would make it better.”

With around 90 items in regular production and each ingredient and preparation method constantly under the owners’ scrutiny and subject to change for better, there is never a dull moment. Since the day they entered the bakery business in 2002, the Engelses have sought to improve every aspect of every product – taste, appearance, nutritional value, healthy qualities, consistency and ease of preparation.

Before becoming bakery owners, Valerie worked in early childhood education, while Mark’s career was in restaurant and hospitality management. In 2002, Valerie was ready for a career change when the Rising Star Bakery, a neighbourhood bakery with a good following, came up for sale in their home neighbourhood of Fairfield, a well-established residential area within walking distance of downtown, seashore and parks.

}When dealing with organic ingredients and individual bakers, you do not get a factory-produced look. It looks homemade, because it is! The quality is always good, but it may not always look the same.

Valerie and Mark bought the business and entered a permanent learning experience. The first thing they wanted to change was the name of the 879-squarefoot bakery. “We created lists of attributes that we wanted to promote – natural,

nurturing, homey, comfortable, loving, relaxed – and we kept coming back to Bubby Rose’s,” Valerie says. “Mark is Jewish and ‘Bubby’ is the Jewish grandmother, and Rose runs in both families: Mark’s mother is Rose, my middle name is Rose and my grandmother is Rose.”

Bubby Rose’s transformation continued with changes to the ingredients of many products, from baked goods to sandwiches, soups, chilis and pizzas. Whenever possible, they switched to more wholesome, organic

and natural ingredients.

Four years later, they needed more space, especially freezer and storage space. They expanded by opening another Bubby Rose’s in September 2006 in a 1,550-square-foot former video store seven blocks away.

Today, they operate the healthy two-store business with 32 staff members. About eight per cent of their revenue comes from wholesale, mostly to local cafés. The product range is still wide – too wide, the owners feel. Bubby Rose’s offers baked goods such as cookies, bread and pies, plus lunch items ranging from soups and sandwiches to pizza, quiches and lasagne. Coffee is also one of Mark’s passions, so a fine selection of espresso drinks made of local Discovery Roasters coffee is also available. Many items are vegetarian,

organic, Jewish or specialty – flourless, gluten-free – products. Mark is diabetic, and specialty items catering to diabetics are in the mix.

“We counted a few years ago and, unfortunately, the total number of items was around 110,” Mark says.

“I’d like to think it’s at around 85 now, and I want to see it at around 65, but every time we cut something out, it’s like cutting a toe,” he adds with a laugh. “We don’t feel right about taking something out that the customers expect to find.”

Improving ingredients is Mark’s passion. Anyone in the bakery business knows that changing a single ingredient in a single product is no small feat. To achieve a croissant, cinnamon roll or chocolate chunk cookie that not only wins awards in local publications’ “Best of the Island” reader surveys, but also has the most wholesome ingredients, looks good and turns out consistently well, is a complicated and time-consuming task.

The learning continues on both sides of the counter. “We also try and educate the customer about why the product does not look exactly the same every day,” Valerie says. “When you are dealing with organic and natural ingredients and individual bakers, you do not get a factory-produced look. It looks homemade, because it is! The quality is always good, but it may not always look the same.”

One method for educating customers is an in-store newsletter that Mark produces. In short-paragraph format that is easy to read while enjoying a snack or standing in a line, it talks about the ingredients –what’s happening in the world of wheat or what’s happening to honeybees – and profiles team members, preparation methods, news and other goings-on. Another successful education and marketing tool has been the website, www.

bubbyrosesbakery.com. It has brought new business and has a lot of potential, which is why a complete overhaul of the site was underway in October.

The Engelses have divided their duties along what comes to each of them naturally. Mark oversees production and marketing, while Valerie is in charge of human resources and esthetics. A front-end manager and an assistant manager divide the daily in-store duties at both locations. Valerie does not bake, but is responsible for some specialty ingredients such as the vegetarian mincemeat for the Christmas season. Mark bakes daily only if a baker is on vacation.

“Otherwise, I get to ‘play’ whenever I can, experimenting and developing new products from time to time,” he says. “Baking is a most wonderful activity for me.”

Expansion is not in the books in the near future. “Our focus is on improving our bottom line and business infrastructure,” Mark says. “We must operate more smoothly before expansion can be considered. We have been tempted many times by enticing offers to open in different locales, but we have decided to keep our heads down and improve what we already have – for now.”

Things are looking good for Bubby Rose’s even though customers are paying more attention to their money. This can be good for a bakery such as Bubby Rose’s that invests so much in quality.

“If you are going to indulge, make sure that what you indulge in is really something very good,” Valerie says. “And if it isn’t, you’ve got to tell us, so that we can improve it!” Mark adds. / BJ

Tuija Seipell writes about business, retail, design, architecture, branding, trends and travel. Follow her at twitter.com/TuijaSeipell or e-mail tseipell@telus.net.

determine where there are opportunities for improvement.

“We tested the cookies extensively for months,” Gans says. “We kept lots of notes from the consumer testing to ensure we had a solid sense as to the consumer’s preferences. Even now I have a suggestion box in the store so customers can share their wishes for new mix-ins.”

6. PRODuCt DEfINItION

What will you name the product? What is its final direct cost? How will you package and advertise it, and what price can you charge for it to strike that balance between volume and profitability? Will this be a signature product around for the long haul or a limited time offer? Consumers count the days until Starbucks launches its pumpkin latte and the coffee retailer shrewdly keeps it as a limited time offer to enhance the mystique.

7. BusINEss aND fINaNCIal aNalysIs

Now that you know the product cost, price and estimated sales volume, determine what the gross and net profit will be on the item. Is it still a good idea to introduce it? Even if the product isn’t as profitable as others on your menu, it might still help you draw in new consumers who will purchase other key items as well. Establish the cost for the various raw materials and make sure that you can sell the finished product at a reasonable price point.

Innovation isn’t a “nice to have”; it’s a “must have.” Food Processing Magazine reports in its May 2009 issue that 48 per cent of companies this year list new product introductions as their most important focus. They know the secret to success: When times are good, good companies plan for the future. When times are bad, great companies still plan for the future. / BJ

Michelle Brisebois is a marketing professional with experience in the food, pharmaceutical and financial services industries. She specializes in helping companies grow their brands and can be reached at briseboismichelle@ sympatico.ca.

Pizzey’s Whole-Milled BevGradTM and SelectGradTM flaxseed is an excellent source of Omega-3 fatty acid (22%). Also a good source of dietary fiber and protein, Pizzey's flaxseed does not require refrigeration and is gluten free.

While Fair Trade has its roots in coffee (which remains the dominant commodity and employs the greatest number of farmers in the Fair Trade sector), the variety of Fair Trade Certified products has grown exponentially in the past five years to areas well beyond coffee. The baking industry appears to be the next big sector to see an influx of Fair Trade ingredients.

Fair Trade is a system of trade based on the principles of respect, transparency and dialogue between all actors in the trading relationship. More than one million farmers in 58 developing countries – typically small-scale farmers organized into democratically run co-operatives – benefit from the standards established by Fair Trade Certified.

These benefits include a floor price below which the prices paid for their products will never fall; a Fair Trade premium, which is an extra amount farmers can use for purposes of their choosing (such as improving roads, access to clean water, health clinics, schools, business development, etc.); an additional premium if their products are organic; advanced contracts of at least a year to allow more effective financial planning; and pre-financing of those contracts should the farmers request it.

loyal to Fair Trade. A global consumer survey on Fair Trade conducted by GlobeScan indicated shoppers increasingly expect companies to be more accountable and fair in dealing with producers in developing countries. There is a shift occurring in consumer demands toward ethical consumption and understanding the origin of products, including the labour practices behind it.

Email: sales@pizzeys.com

There are environmental standards for Fair Trade production as well, such as creating a plan for improving sustainable production, no use of genetically modified seed and an immediate ban on chemicals proscribed by the UN Food and Agriculture Organization, the World Health Organization and the Pesticide Action Network.

Despite difficult economic circumstances, it seems consumers are staying

The GlobeScan survey of 14,500 people in 15 countries, including Canada, found that almost 75 per cent of people believe it is not enough for companies to do no harm, but that they should actively support community development in developing countries. A similar percentage looks to independent third-party certification as the best way to verify companies’ claims.

The participants also clearly stated they would think better of companies whose products are Fair Trade Certified. This is supported by a recent

study by A.C. Nielsen that indicates 70 per cent of consumers worldwide are interested in contributing to Corporate Social Responsibility (CSR) through the purchase of ethical products. Consumers are calling for a new model of trade in which justice and equity are integral parts of the transaction. “Active ethical consumers” make up more than half the population (55 per cent) in the countries surveyed.

These shoppers have higher expectations of companies’ social, economic and environmental responsibilities. Their shopping habits and decisions tend to reward (or punish) companies that meet (or do not meet) their expectations, and they influence others with their opinions.

These attitudes are fuelling support for Fair Trade as more consumers come to recognize and identify with the values behind it. Half of the public (50 per cent) in the 15 countries surveyed are now familiar with the Fair Trade Certified Mark, and of these people, nine out of 10 (91 per cent) trust the mark. Among all respondents, 64 per cent believe Fair Trade has strict standards, a quality that also closely correlates to consumer trust. Almost three-quarters of shoppers (72 per cent) believe independent certification is the best way to verify a product’s ethical claims.

An important basis for Fair Trade’s success is revealed by the survey – people learn about new products and concepts from their own social groups and contacts. Alongside conventional promotion activities, its unique marketing strength comes from its loyal grassroots base. Thirty-two per cent of people learn

about Fair Trade through family, friends and work colleagues, and a further 16 per cent hear about it through education, community and faith groups. Broadcast and news media account for how 33 per cent of people learn about Fair Trade.

Canadian consumers who have purchased Fair Trade Certified products are more likely to recommend them to others than the average among Fair Trade consumers in the 15 countries surveyed. Almost three-quarters (72 per cent) of Canadian Fair Trade purchasers say they are “very” or “somewhat likely” to recommend Fair Trade Certified products to others.

The five top products that are most widely recognized to carry the Fair Trade Certified logo in Canada are coffee (76 per cent), cocoa/chocolate (38 per cent), tea (23 per cent), rice/ quinoa (21 per cent) and cotton products (16 per cent).

The products showing strong growth in the baking sector include sugar (cane sugar, demerera, icing sugar), molasses, honey, cocoa, chocolate products and dried fruits.

Estimated retail sales of Fair Trade products in Canada topped $200 million in 2008 and growth continues in this sector despite the recession. Fair Trade is more than a trend. It’s transforming the way that companies do business and consumers’ understanding of what’s behind the products they purchase. / BJ

Tia Loftsgard is TransFair Canada’s business development manager. E-mail her at tia.loftsgard@transfair.ca.

At Mimac Glaze Limited, we believe in being innovative. When Trans Fatty Acids first became an issue to the Baking Industry, we wasted no time in finding alternative ingredients to make our products compliant with Health Canada’s Trans Fat Regulations as instituted by the Trans Fat Task Force.

Not only did we reach that goal, but in fact, we surpassed it! We are proud to offer our customers a wide array of products, including Icings, Glazes, Stabilizers and Rolled Fondants that are completely Trans Fat Free.

Another hot topic in the industry today is the term “Clean Label”. Clean label generally refers to going back to basics. Consumers today are very knowledgeable in that they read the label first They want to know what they are eating. On a “clean label”, you will find no artificial colours nor artificial flavours, no preservatives, no hydrogenation, partially or otherwise.

Developing products for the industry that can make this claim can be a daunting task to be sure! However, once again, Mimac Glaze rose to the challenge and we now have numerous “Clean Label” products to offer.

BakeMark of Canada 3202 - 9th Street S.E. Calgary, Alberta T2G 3C3 (800) 663-CAKE (604) 303-1700

Cake Top Inc. 151 Carling View Drive, Unit 2 Etobicoke, Ontario M9W 5S4 (800) 584-9883 (416) 798-1777

Catalog Sales Division (800) 428-4413

L & M Bakers Supply Co. 2501 Steeles Ave.W., Unit 1 Downsview, Ontario M3J 2P1 (800) 465-7361 (416) 665-3005

Nicholson Equipment Ltd. 3975 Kitchener Street Burnaby, B.C.V5C 3L9 (800) 668-3722 (604) 291-1901

Nicholson Equipment Ltd. 11640 - 147th St. Edmonton, AB T5M 1W2 (800) 661-9026 (780) 451-6262

Traynor's Bakery Wholesale 191 Victoria Ave.S., Hamilton, Ontario L8N 3C8 (800) 263-9239 (905) 522-2730

Vincent S.Varietes Ltd. 433 Rue Saint Paul LeGardeur, Quebec J5Z 4C7 (800) 263-1687 (450) 585-1687

Vixit Products Ltd. 290 Henri Bourassa Ouest Montreal, Quebec H3L 1N7 (800) 463-8782 (514) 337-0814

At age 20, owner Gordon Arthur Evans offered to work for free if he could apprentice with a baker who had started out in the 1930’s. Gordon took the older man’s baking secrets to his father’s business, Art’s Grocery & Bakery. Art’s, half deli and half bakery, has served the Erie, Pennsylvania region for 55 years.

Mr. Evans’ father, Arthur Gordon Evans, ran the deli side, while Gordon handled the bakery. Perhaps best known for elderberry pies, Art’s chocolate chip cookies have also been rated the best in the region by local newspapers.

Mr. Evans cites raising four children as his greatest accomplishment, but his business accomplishments are also impressive. Three years ago, Mr. Evans replaced the old Art’s building. And, despite competition from several new supermarkets, Art’s has doubled its business.

For Gordon Evans, International® Bakers Services’ flavors are a key to consistency. “I’m really sold on flavors from International®. They are really top notch. I like BLO&V®, and Butterscotch is my favorite.” Using butterscotch morsels in his butterscotch cookies didn’t work, so Mr. Evans turned to Butterscotch Flavor. The cookies became a big hit and their sales doubled. Mr. Evans offers this advice to other bakers: “The customer respects two things, price and quality. The customer will buy product for a good price but will come back for good quality.”

According to Mr. Evans, consistency is very important in the bakery business. “Your product can’t vary,” he said. “And that comes down to consistency in ingredients.”

Let International Bakers Services help keep your customers coming back. Contact us toll-free at (800) 345-7175, by fax at (574) 287-7161, or in writing at 1902 North Sheridan Ave., South Bend, Indiana 46628. We have the flavors your customers deserve. ®

BY N ADINE S INGH

This is a great Fair Trade Certified recipe to enjoy on a cold winter day in front of the fire with a warm blanket and your favourite book.

Nadine Singh is a Toronto-based chef, recipe developer and aspiring food stylist. She can be reached at 416-763-2274 or nadinesingh@rogers.com.

Yields: 24 large cookies.

1 cup black strap molasses

1 cup demerara sugar

1 cup unsalted butter

1 tbsp. baking soda in some water

1 egg slightly beaten

1 tsp. vanilla extract

1 tbsp. ground ginger

Bring molasses to a boil, add sugar and remove from heat. The demerara sugar adds a wonderful texture to the cookies. Add butter and baking soda. When cool, add egg and vanilla. Combine dry ingredients and add to wet ingredients. Refrigerate until chilled.

To assemble: Take two tablespoons of mixture and form small cup in palm of hand. Add one square of chocolate in the center and cover to enclose

1 tsp. ground cloves

1 tsp. ground cardamom

1/2 tsp. ground nutmeg

1 tsp. ground cinnamon

1 tsp. salt

2 3/4 cups unbleached flour

1 dark chocolate bar

chocolate and form a ball.

Heat oven to 375 degrees F. Place cookies on parchment paper one inch apart and press down slightly. Bake for 10 to 12 minutes. Cool on wire rack. Serve warm with thick and creamy hot chocolate made with half and half cream and chopped dark chocolate, and infused with cardamom seeds. No need to sweeten. Top with whipped cream and cinnamon stick. Sit back, relax and wait for the snow!

Health Canada is approaching the baking industry and potential individual baking companies to request they voluntarily reduce the salt used in breads and other baked goods as part of a national effort to reduce overall consumer consumption of sodium in the diet. Health Canada is making similar requests of other food manufacturers regarding the products they produce.

Health Canada is proposing to consult with bakers and other food industry companies over the next six months with the objective of establishing voluntary reduction targets in sodium use. A similar initiative underway in the United Kingdom since March, 2006 has the objective of reducing overall salt to no more than 6 g/day (2400 g sodium) by 2010. The targeted sodium content for bread in the U.K. is 430 mg/100 g.

The Health Canada request is a result of the three pronged strategy developed by the Federal Sodium Working Group which was established to propose means to reducing Canadian consumption of sodium to between 1,200 mg and 2,300 mg/ daily from the current level of 3,500 mg/daily. Excess sodium consumption is considered a major contributor to hypertension which is itself a major contributor to coronary heart disease, stroke and other diseases.

The strategy developed by the Sodium Working Group includes a major public awareness campaign on the health problems caused by excessive sodium consumption, research, and voluntary commitments by the food industry to reduce salt in processed foods which have been identified as contributing some 75% of sodium in the diet.

Charles “Matt” Tatham passed away suddenly on September 12 after completion of a local triathlon. Matt was a well respected professional in the Baking industry for the past 25 years, most recently as the Business Manager at Nealanders International. He was also a dedicated volunteer to the industry having served on many committees such as the BAC Ontario Chapter and Bakery Showcase.

Rizzo Hall

Program:

Cocktails: 6:00 – 7:00 pm

Plated Dinner Service: 7:00 pm

Entertainment: 8:30 – 11:30 pm

PrizesthroughouttheEvening

Registration Fees:

$40.00 per member

$45.00 per non-member

Pre-Register By November 30th

Reservations for tables of 8 accepted Vegetarian Meal Requests must be provided in advance

FEATURING:

Come out to an evening of dining and dancing or just listening to the music of the 60’s and beyond

Rizzo Hall, 1941 Albion Rd, Toronto

Please note allregistrations receivedafter Nov. 30th willrequire a creditcardpayment. No refunds willbegiven. Please list names of all attendees: (attach separate sheet if necessary) Name _________________________________________________

Fax completed form with payment to: Baking Association of Canada, 7895 Tranmere Drive, Suite #202, Mississauga, ON L5S 1V9 Tel: 905-405-0288 ext 21 Toll Free: 888-674-2253 Fax: 905-405-0993 info@baking.ca www.baking.ca AconfirmationbyemailwillbesenttotheCompanyContact

BAC has conducted a study of leading sliced breads in the Canadian marketplace. In total the sodium values of 212 breads were identified and then weighted by their respective market share.

The results summarized in the chart show the average sodium in white bread and whole grain breads to be almost 30% lower than posted in the Canadian Nutrient File. The survey did show that there is a wide range of sodium levels in breads depending on taste and product characteristics. The mean sodium level of all breads, taking into consideration each category’s respective market share, was some 472 mg/100 g, or within 10% of the voluntary target of 430 mg/100 g that was established in the U.K.

BAC will be using the studies findings as part of its discussions regarding voluntary sodium reduction targets.

From Lunar foam gloves to DecoPac’s latest Petite Signature Cake, Bakers Journal keeps you “in the know.” for more on new products for the baking industry, check out our website, www.bakersjournal.com

MONROE, Ohio – West Chester Holdings’

Lunar foam nitrile palm dip gloves are well suited for food and beverage processing and handling applications. Part of the PosiGrip brand, these gloves sport a white or salt and pepper nylon shell dipped over the palm and fingertips with full-saddle coverage. This gives them extra grip on wet or oily materials, and better surface adhesion on dry applications. In addition, antibacterial surfactants prevent odours and bacteria from forming. Machine washable and silicone free, PosiGrip gloves are available from most safety distributors throughout North America. For more information, visit: www.west-chester.net.

Flexicon’s new Tip-Tite drum dumper seals drums against a discharge cone, tips the drum, mates the cone against a gasketted connection, and discharges bulk material dust-free through a slide gate valve. The dumper accommodates drums from 30 to 55 gallons (114 to 208 litres). Its drum platform is raised by a hydraulic cylinder, creating a dust-tight seal between the rim of a drum and the underside of the discharge cone. A second hydraulic cylinder tips the platform-hood assembly and drum, stopping at dump angles of 45, 60 or 90 degrees with a motion-dampening feature. The vertically oriented cone mates with a gasketted inlet port fitted to the lid of an optional hopper with integral flexible screw conveyor or pneumatic pick-up adapter, or to existing process equipment. For more information, visit www.flexicon.com.

C. Cretors and Co.’s Echols slaw shredder and food slicer is ideal for deli counters and food preparation stations in grocery stores and supermarkets. It can process up to a gallon per minute of vegetables and hard cheeses, and can also process hard or frozen ingredients for bakeries. The Echols shredder/slicer is built to last, with cast aluminum construction, stainless steel blades and a 1/2-horsepower, 1,725-rpm motor. For maximum convenience and safety, a removable clean-out cap has a safety interlock to prevent accidental startup during cleaning. It fits a Model 113 panelled counter stand, Model 114 open counter stand, Model 512 floor stand with bucket, or Model 515 floor stand with caster. For more information, visit: www.cretors.com.

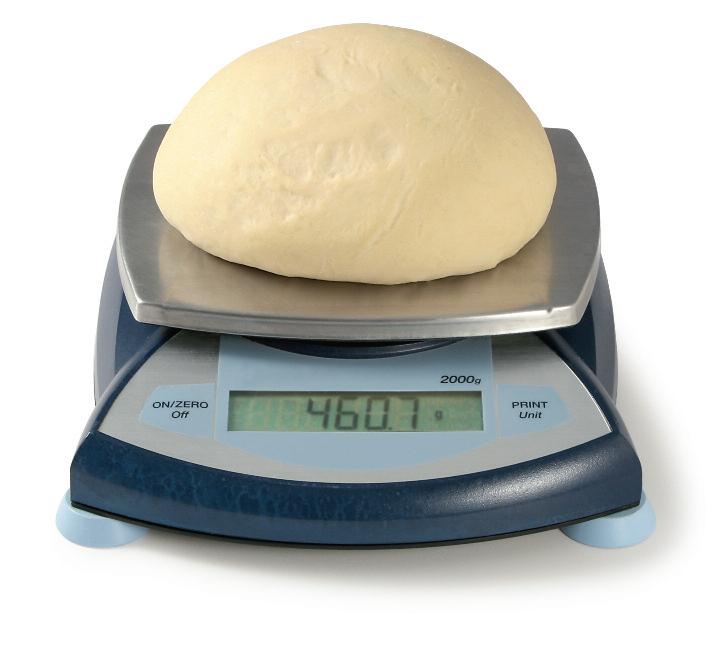

The OHAUS FD food portioning scale is gaining popularity in pastry and dessert instruction. For weighing out dry ingredients, the FD’s capacity range and precision have made it a popular piece of equipment in instructional kitchens. Specifically designed for use in food preparation where cleanliness is a must, the OHAUS FD is available in capacities and readabilities of 6 lb x 0.001 lb (3 kg x 0.5 g), 15 lb x 0.002 lb (6 kg x 1 g) and 30 lb x 0.005 lb (15 kg x 2 g). The FD provides fast and accurate results within two seconds, which is quickly readable via the large backlit LCD display. To meet stringent cleanliness requirements in food preparation, the FD features a stainless steel top and bottom housing as well as a removable stainless steel pan. For more information, visit www.ohaus.com.

Case packing and palletizing can transition to smart automation with the Schneider stainless steel HCP-10 horizontal case packer. It features data acquisition monitoring and reporting for overall equipment effectiveness (OEE) and has energy monitoring options to improve overall sustainability of operations. In combination with a case elevator to improve ergonomic operations, it can reduce floor space and solve logistical limitations. The HCP-10 indexes and horizontally accumulates the prescribed number of stacked product in any packaging combination, packs cartons into cases, and is ideal for food or other applications that require an easy clean. It has programmable memory, which stores various configurations allowing different products to be easily case packed without extensive changeover. For more information, visit www. schneiderequip.com.

DecoPac’s newest addition to its Petite Signature Cake line is Disney Fairies Petites. Featuring a cake specifically designed for each Disney Fairy – Tinker Bell, Fawn, Iridessa, Rosetta and Silvermist – they are an ideal size for the birthday girl or as an extra treat for any special occasion. For more information, visit www.decopac. com.

By J lyNN fRasER

Selling a bakery business is a major decision that some might be considering as the economy transitions from recession to recovery.

It’s a choice that involves valuing your business’s tangible and intangible assets, your employees, possible liabilities and tax issues. And it’s important that the sale price you set for your business matches the expectations of the marketplace.

“Reasons for selling a bakery usually centre around retirement, the long hours, loss of skilled employees and very high capital expenditures,” says Mark Borkowski, president of Mercantile Mergers and Acquisitions Corporation.

Your next step, according to Steven Hacker of the accounting firm Meyers Norris Penny, is to “prioritize objectives and consider exit alternatives” from your business.

You can choose to work with your accountant and then bring in an additional professional, Borkowski suggests.

“A business valuation can be done informally,” which will help keep down costs, he says.

If you choose to work with a business valuator, ask for references from their clients who sold businesses similar to yours in terms of size, assets, customers and number of employees.

“It may take a year to put best practices in place,” says Hacker, explaining that this involves ensuring tax planning has been done, to reduce liabilities. “First you have to understand your objectives for making the sale and allow market exposure time in the hopes of exiting at the highest price.”

If the business is sold to a family member to ensure family harmony and to minimize tax liability for all parties involved, an accountant should be consulted prior to the sale. A plan should be in place if the seller remains involved financially with the business, such as through a retiring allowance. Planning for a retirement savings plan (RSP) and to find out if the seller qualifies for a $750,000 capital gains tax exemption is

The typical buyer, according to Borkowski, is a strategic buyer who “knows their business and knows what they are buying, such as the process, the equipment, and the supplies. They are the logical choice [for a seller].”

The second most common is the private equity buyer, and the “least preferred” is the individual buyer. There are many methods to value a business. Your business valuator should discuss the pros and cons of each one with you

and answer all your questions.

The “valuation by financial statement” method will base value on your company’s financial statements, examining the cash on hand, equipment, real estate, debts and investments, and obligations. The liabilities will be subtracted from the total assets to establish the business’s theoretical value.

This method may not take into consideration the current values of assets and instead assign them their costs at the time they were acquired. These are the “historic costs,” says Hacker. Another disadvantage is that intangible assets such as your brand, trademarks, copyright, trade secrets such as recipes, customer lists, employees and their contracts, and lease agreements are not considered. They are only considered if they were purchased from another business and thus appear on the business’s financial statement at their historic cost.

A second method called valuation using multiples or comparable company analysis looks at what public companies similar to your own are being traded for. This method for valuing businesses is best applied to larger businesses, such as George Weston Ltd., rather than smaller owner-manager businesses.

The disadvantage here is that no two companies are completely alike in terms of products, size and growth potential. If your business produces a specialized product or service this can also make comparisons difficult.

This method is an approximation of the similarities between businesses and affects the business valuation’s accuracy; thus, two sub-methods can be used.

A business valuation can be done informally with your accountant, or you can bring in an outside valuator.

The first is the price-to-earnings ratio (P/E). This sub-method requires that the price of a share of the business’s stock be divided by the business’s earnings for a share.

The second sub-method uses the enterprise value to earnings before interest, taxes, depreciation and amortization (EV/ EBITDA). Enterprise value (EV), Hacker says, “refers to the business operations,

and does not include debt, excess cash and redundant assets.”

EBITDA represents the business’s cash flow (before required capital expenditures) that would be paid out to shareholders. Hacker notes that when applying an EV/EBITDA multiple, “the art of it is in choosing the right variables, earnings level and multiple.”

Another available method is the comparable transaction method, which looks at recent sales and purchases of

similar but privately owned businesses. The business valuator will determine which businesses are appropriate to use as a comparison to yours and will apply valuation methods such as P/E or EV/ EBITDA to determine your company’s value. Due to the differences between your business’s characteristics and those of the business to which it is compared, the valuation might be affected.

Creating a projection of what cash the business can produce at a future date is

another possible valuation method. The business valuator, Hacker says, will create this projection with the “assistance of the business owner.”

Discounted cash flow analysis is a fourth method that can be applied. As the value of the cash received in the present is not the same as cash received at that future date, the cash flow must be discounted to assess the cash’s current value. This is a complicated process and is best applied

The City of Toronto’s Environmental Reporting and Disclosure Bylaw begins January 1, 2010.

This means that some businesses and facilities will be required to track and report the use and release of certain toxic chemicals.

Find out by coming to a free breakfast seminar for food and beverage manufacturers in early December 2009. Dates and locations are listed at toronto.ca/chemtrac.

Guest speakers will discuss:

• the bylaw and how it affects food and beverage manufacturers • the resources and tools available to help you

Plus, test out program tools and give feedback on how we can better meet your needs. For more information or to reserve your seat, email chemtrac@toronto.ca or call 416-338-7600.

BRIaN HaRtz

Lisa Bugeja has a sense of humour – and not just because she opened her new business, Flour Confections in Pickering, Ont., on April Fool’s Day this year.

The George Brown College-trained cake designer has to keep things light to successfully manage her multifaceted enterprise, which on any given day can see her baking, designing, decorating and delivering cakes; teaching classes; selling sugar-craft and cake-decorating supplies; entertaining celebrity guests from the world of cake design; or working on her next entry for international cake and pastry competitions.

She completed George Brown’s baking and pastry arts program with intentions of a career in the industry, but after a couple of years in the workplace she became pregnant and then a full-time, stay-at-home mother.

“But I always wanted to do something like this,” she says. “In 2004 a cousin asked me to do her wedding cake, and it kind of snowballed from there.”

She went on to create a kitchen for her work in the basement of her Ajax, Ont., residence, but eventually she needed more space to meet demand. So she set up shop in a nondescript light industrial park at the end of Plummer Street in Pickering, conveniently located just south of the 401.

Doing so has not only been convenient for Bugeja, her husband Scott and their daughter Isabella, 7, but it has also allowed the business to flourish. In just a few short months, Flour Confections has become a way for its proprietor to give back to amateurs and home-based businesses, to give support to the people who are coming into the industry from the ground up, like she did.

“It seemed like all of the cake-supply shops were located in [Toronto’s] west end. As someone who started with a home-based business, believe me, it can be very frustrating if you’re based out here or in Scarborough,” Bugeja says. “We’ve already exceeded our business plan in six months, and it seems like we have a new customer every day. I’m supposed to have Mondays off, but I

“Cascading Roses,” a wedding cake by Lisa Bugeja.

haven’t taken one in quite a while.”

It’s no wonder she stays busy: From the most basic, unassuming cookie to ornate, multi-tiered wedding cakes, every Flour Confections product is strategically hand-designed. The popularity of her products can certainly be attributed to Bugeja’s artistic talent and work ethic, but the array of flavours she uses is also impressive. These include Vanilla Orchid, Midnight Chocolate and Calypso Coconut, and customers also have the option of choosing butter-cream fillings and fresh fruit.

“We’re retail-only at this point, and everything is made to order,” Bugeja says. “Our primary clients are people who want to have a highly customized and person-

Lisa Bugeja’s prize-winning sugar mask from the 2009 Oklahoma Sugar Arts Show.

alized cake – something they can’t find at the grocery store. We offer full consultation on the design in person, over the phone, or via e-mail.”

Bugeja’s creations, as well as her tireless dedication to nurturing the industry, have caught the attention of cake decorating stars such as Bronwen Weber, who taught a standing-figure class at Flour Confections earlier this year; Toba Garrett; and the Food Network’s Elisa Strauss. Brides magazine also took notice, selecting her entry in the 2008 Oklahoma Sugar Arts Show, titled “The Language of Flowers,” for its March/April 2009 issue. Her cake was one of only 10 chosen for the spread and was featured quite prominently.

The Oklahoma Sugar Arts Show, now in its 17th year, takes place every October in Tulsa and is one of the largest in North America. Bugeja has been competing in it for years. When we spoke with her in late September, she was getting ready to make the 20-hour trek once again. She returned with two first-place ribbons, for her baby cake and cookies, as well as a second place for her sugar mask. In the event’s Grand National Wedding Cake Competition, she was a silver finalist.

“I wanted these other avenues of income so I could still focus on the competitions,” she says, adding that she also competes in Canadian Society of Sugar Artistry events.

Their daughter Isabella is also into cake decorating, and won second place in the children’s division (age 6 and under) at the 2008 Oklahoma show. This year she’ll be competing in the event’s 7- to 12-year-old division.

On the rare occasion when Bugeja is away, someone has to mind the store, and that duty falls to her husband. Plus, with so many aspects to the business, she needs the help.

“Scott has a background as a sales consultant, and he’s the IT guy and my right-hand man,” she says, adding that he was essential to getting Flour Confections’ online presence off and running.

“We ship our merchandise all over North America, including Mexico, and as far away as Saudi Arabia,” she says. “Locally, orders can be placed online for pickup, as well, if you know you’ll be in the area and want to save money on shipping.”

Now that the busy summer weddingcake season is over – Bugeja says she had to hire an intern to cope with the demand – Flour Confections can get back to hosting classes. From the basics of Flour Power to the enticing education of Cake Couture, her students come away with a newfound knowledge and appreciation of what really goes into the fabulous treats they indulge in at parties, weddings and other social occasions.

“The classes are open to people of all skill levels, and I like to keep them small, so everyone can have the proper handson experience and personal attention,” she says. “For the classes with a celebrity guest, we’ll host up to 20 students, but I like to keep the normal classes small – about eight to 10 people.”

Flour Confections provides all utensils and other materials to class participants.

“It can be a real headache if someone forgets something or can’t afford something,” Bugeja says.

Being an educator alongside her myriad other roles has its benefits in that it allows her stay on top of all the trends in the industry.

“We’re doing lots of custom cookies for favours at weddings and baby/bridal showers,” she says. “And of course we’re doing a lot of cupcakes and cupcake wedding cakes. In the past I’ve some -

times done more cupcake cakes than normal cakes.”

When asked about how she’s been able to transition so smoothly from a homebased operation to a full-fledged retail storefront, Bugeja says she’s “developed a brand. Having a good web presence helps, but I’ve been doing custom cakes for about five years now and worked with a lot of wedding planners, so that’s helped me develop referrals through good word-of-mouth.”/ BJ

Chocolate Chip Cookies made with black bean flour. She handed out the recipes to the tour group so we could follow along as she cooked, and they didn’t seem too complex or difficult to this untrained eye. For more information, contact Walker at 780-9553841 or lovoni@fabulousfoodcreations.com.

Next up was the Food Processing Development Centre (FPDC) in Leduc, Alta., near Edmonton International Airport. Agribusiness is a cornerstone of the Alberta economy – pulses alone bring nearly $200 million per year to the province – and this government facility is designed to strengthen and expand the industry through application of new technology and the development of new or improved products and services.

Founded in 1984, the centre is a hub for cutting-edge research and development, stocked with the latest food-processing equipment and staffed by scientists and engineers specializing in dairy, meat, cereals, vegetables, small fruits, packaging, bakery, extrusion technology, condiments and sensory evaluation. These experts work with food processors, entrepreneurs, industrial or commodity groups, university researchers, federal and provincial agriculture personnel and suppliers of equipment, ingredients and packaging.

They can help guide a new product from initial technical consultation to the final pre-production phase, including packaging and consumer evaluation. Then, companies can make use of FPDC’s pilot plant for up to a year to put these new products into full-scale production – giving them time to evaluate the product’s performance in test markets before moving them into their own production facilities.

Start-up companies and business ventures without a proper production facility can make use of the adjoining Agrivalue Processing Business Incubator (APBI). APBI contains 32,000 square feet of processing area divided into eight privately accessed, fully serviced processing suites – ensuring security and confidentiality.

Crop scientist Jay Han, PhD, is FPDC’s resident pulse specialist. He has been working on a couple of interesting projects using pulse flours: a gluten-free chickpea cracker and chickpea dog treat. He has also developed an extruded meat analogue product using chickpea flour, and an ongoing project is the development of gluten-free pastas using a high percentage of pulse fractions.

“I’ve found the pulse ingredients with the most promise are chickpea flour, pea starch, pea protein and pea fibre isolates,” he said, showing us a finished carton of the gluten-free chickpea crackers, which were produced in collaboration with Edmontonbased Kinnikinnick Foods. “In the end, I chose chickpea flour for commercial scale-up and production.”

Han’s findings, as reported in the journal Food Research International, said: “The compositional and nutritional profiles of the crackers were very similar to existing cracker products on the market with the exception of the percentage daily values per serving of iron that were three to six times higher in the chickpea crackers than existing products on a per serving basis. The pulse-based, gluten-free cracker products investigated in this project have well-developed potential to appeal to consumers and impart health benefits.”

The potentially lucrative ramifications of Han’s work have not gone unnoticed, as Stephen Daniells of NutraIngredients.com reports: “The findings could lead to enhanced products for the

blossoming gluten-free food market, worth almost $1.6 billion last year, and experiencing a compound annual growth rate of 28 per cent over four years.”

For more information about the FPDC and APBI, visit: www. agric.gov.ab.ca/fpdc.

Ironically, the tour wrapped up where the process of turning pulses into delicious baked goods begins: the seemingly endless golden fields of Alberta.

We were treated to a barbecue lunch at Pathfinders Western Ltd., the 2,200-acre family farm of Paul and Annette Gabbey, just outside Edmonton.