BY CARROLL MCCORMICK

Learning how to survive a helicopter ditching into the ocean is best done under realistic conditions. In aid of this goal, Survival Systems Training Limited (SSTL) in Dartmouth, N.S. dunks trainees in a helicopter trainer, suspended from a specially designed hoist. Its designers left no room for failure.

This hoist is suspended under the roof of a 43-metre by 27-metre building, completed in 2014, called the Marine Aviation Survival Training facility (MAST). Mounted on a beam and girders, it can maneuver SSTL’s Helicopter Underwater Egress Training simulator, or HUET, over portions of the poolside deck and the 25-metre by 14-metre by 5-metre deep pool itself. The hoist sits roughly 13 metres above deck level and 14 metres above the pool’s surface.

BY MATT JONES

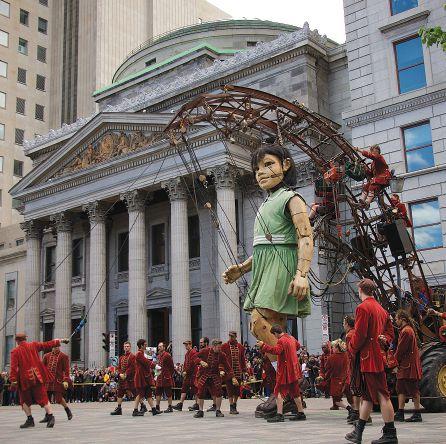

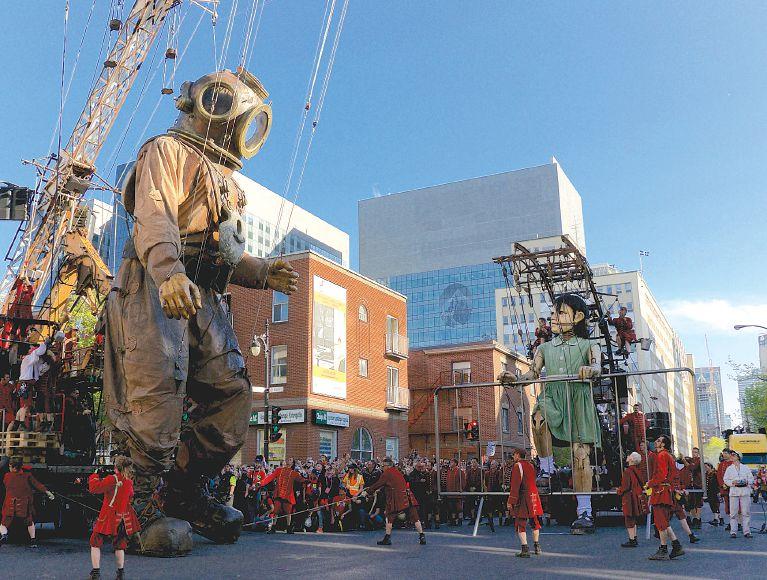

uring Montréal’s 375th birthday celebrations last year, two visitors to the city stood out among all others – a pair of 10-metre-tall marionettes called the Deep Sea Diver and the Little Girl Giant. The puppets come from the Royal-De-Luxe street performance troupe from Nantes, France. The giants’ gestures and movements are controlled by a bevy of puppeteers who maneuver them by swinging on control ropes like pirates in a swashbuckling movie. Heavily customized mobile cranes keep the marionettes upright and move them around through the city while the puppeteers provide the illusion that the puppets are moving by themselves.

BY SAUL CHERNOS

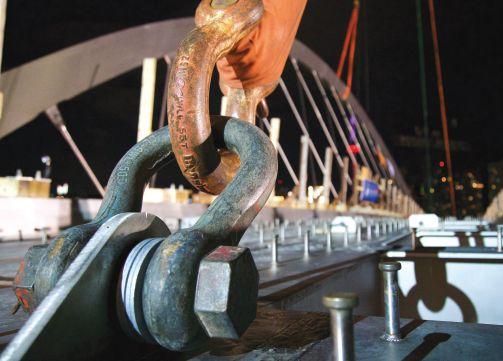

stainless steel pedestrian bridge construction project nearing completion in downtown Toronto has called for two of North America’s biggest crawlers.

The new bridge is a result of ongoing efforts to build infrastructure for pedestrians and cyclists. In 2001, city council adopted the Toronto Bike Plan which includes a network of bikeways, and Toronto’s official plan supports links between parks and open spaces. In this case, Garrison Crossing will connect Trinity Bellwoods and Fort York, neighbourhoods long divided by two rail corridors extending westwards from Union Station.

“This major infrastructure project will not only create a new connection with great vantage points for the local neighbourhoods around King Street West, Liberty Village and Fort York, it will offer new ways for pedestrians and cyclists to move across the city,” said Mike Whelan, vice-president of major projects with CreateTO, which is overseeing the project on the city’s behalf.

Editor – Andrew Snook

asnook@annexbusinessmedia.com • Tel: 289-221-8946

Account Manager – Amanda McCracken amccracken@annexbusinessmedia.com • Tel: +1-226-931-5095

Art Director – Svetlana Avrutin

Regular Contributors

Saul Chernos, Carroll McCormick, Nelson Dewey, Matt Jones

Group Publisher – Scott Jamieson • sjamieson@annexbusinessmeda.com

President & CEO – Mike Fredericks

Circulation Manager – Barbara Adelt

badelt@annexbusinessmedia.com

Subscriptions – Bona Lao • blao@annexbusinessmedia.com

Tel: 416-442-5600 • 1-800-668-2374 (CDN) , ext. 3552 Fax: 416-510-6875 or 416-442-2191 www.craneandhoistcanada.com

Annex Privacy Officer – Privacy@annexbusinessmedia.com Tel: 800-668-2374

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher. A subscription to Crane & Hoist Canada (six issues) is $36 per year in Canada. For subscriptions in the USA the price is $36 USD. Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO:

Crane & Hoist Canada. CIRCULATION DEPT.

111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1 ISSN 1923-788X

Next Advertising Deadline: November 23, 2018

Don’t miss the opportunity to be part of this exciting new industry publication. For more information, or to reserve space in the next issue, call Amanda McCracken at our Advertising Department Tel: +1-226-931-5095 • amccracken@annexbusinessmedia.com

Next Editorial Deadline: November 23, 2018 For writers’ guidelines and submission requirements get in touch with the editor, Andrew Snook, at 289-221-8946 Email: asnook@ annexbusinessmedia.com

Unless you’ve had your head in the clouds – possibly some particularly smoky clouds that have caused you to crave unhealthy amounts of pizza and nachos – then you’ve heard about the upcoming changes coming into effect related to recreational marijuana use across Canada.

On October 17, the Government of Canada will legalize recreational marijuana use and allow for citizens to purchase upwards of 30 grams of the drug per sale.

Since the news of marijuana becoming legalized, many companies have had their human resources professionals working overtime re-writing their hiring practices and work guidelines and rules. This is particularly true in the construction industry, where many employees are entrusted with the operation of potentially dangerous heavy equipment.

Will the changing legislation allow employees to smoke a joint then jump into an excavator or a crane and go to work? Absolutely not. But marijuana isn’t the same as alcohol. Effects from the drug can carry on from the night before and impact someone’s performance on a jobsite. So how do companies manage their employees using a legal drug recreationally on their own time? Some companies will need a new approach. According to Cann Amm Occupational Testing Services senior manager Dan Demers, that approach should include a fit-for-duty program that includes policy, training and compliance measures.

During the 2017 edition of the Crane Rental Association of Canada’s annual conference, Demers told the crowd that these types of programs “cover all of the marijuana considerations; including considerations to current legal access for medical purposes and potential

recreational accessibility in safety sensitive workplaces.”

Construction work zones certainly qualify for safety sensitive workplaces. But where some companies were used to arguing that marijuana was illegal to the general public (without a prescription), hence, illegal in the workplace, the waters do appear to be muddier. So how do ensure that your company is properly prepared for the legalization of marijuana? Get informed. Talk to lawyers, human resources professionals, workplace consultants and anyone else that might be able to provide answers to a clear legal path for dealing with this new law.

Not sure where to start? Well, thanks to Crane & Hoist Canada’s sister publication OHS Canada, there’s an informative forum set up to help address your pot problems. On November 14, OHS Canada will host its symposium, “Marijuana in the workplace: Best practices for your company and employee expectations.”

The symposium is for occupational health and safety leaders and decision makers across all industries and will bring together a panel of experts and industry leaders who will address hot-button issues regarding the legalization of recreational marijuana and its implications on workplace safety in Canada. The event will offer attendees insights on compliance, rights and learn best practices in ensuring fitness for duty, manage worker expectations and balance compliance/enforcement with employee privacy.

To learn more, visit www.ohscanadasymposium.com, and make all your worries surrounding marijuana legalization go up in smoke.

Have photos of unique cranes and hoists?

Email a photo and brief description to editor Andrew Snook at asnook@annexbusinessmedia.com.

BY MATT JONES

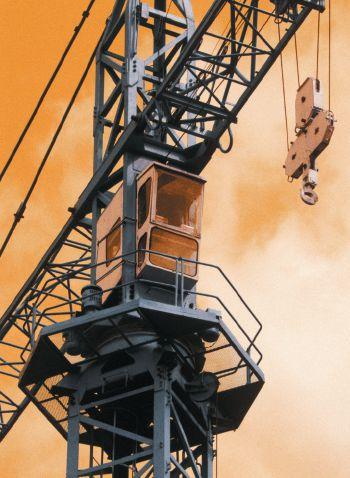

For the third consecutive reporting period, Toronto has been listed at the top of the Rider Levett Bucknall (RLB) Crane Index for Q3 2018. The Crane Index monitors crane activity in major cities. Calgary was also listed in the top 10 of the list (No. 7), which includes 12 major American cities such as New York, Los Angeles and Seattle. Calgary and Toronto were the only Canadian cities included in the study.

“It’s a topic of interest,” says RLB quantity surveyor Joe Pendlebury. “Politicians seem to refer to the cranes during elections to show how much their cities are growing and I think it represents an indicator of the confidence in the market and how much money is being invested on larger scale projects. We think it’s a good visual indicator of the activity going on in a city at a given time.”

Pendlebury says that Toronto has been very busy with crane activity (97 active tower cranes according to the RLB July 2018 report) and at some points the Greater Toronto Area (GTA) had more cranes than all the U.S. cities combined. While Calgary also showed an increase in activity (26 active tower cranes in the same report), its lower ranking on the list reflects a slow recovery from the impact of a drop in the price of oil.

The Crane Index only measures tower cranes, not any other types of cranes.

“There’s lots of mobile cranes around, but the identifier we chose was tower cranes, which usually indicate a larger scale project or a high-rise project,” says Pendlebury. “We actually physically go around to the sites in Toronto and identify which sites have them and how many cranes are on each site because there’s so many cranes.”

Other major Canadian cities, such as Vancouver or Montreal, could deserve a position on the Crane Index, and in fact could be highly rated. However, the reason that Calgary and Toronto are included is that RLB have offices in those cities and are able to collect data there. Pendlebury says RLB are interested in expanding to include other Canadian cities but they have to be mindful of logistic concerns.

“We have to be careful that its markets that we have familiarity with and that we have people on the ground who can actually do the work. That’s really our limiting factor right now.”

Pendlebury notes that one interesting statistic regarding Toronto’s performance is that the location of the cities activity has shifted in recent years. Though the overall crane counts have been increasing, the percentage in downtown Toronto has dropped. At one point, 55 per cent of the crane activity was in the downtown core but it has now dropped to 39 per cent. This indicates most of the increase has been in other parts of the GTA.

BY MATT JONES

On the morning of Aug. 16, Toronto emergency services rescued a woman who had climbed a construction crane. Lindsey Flockhart, 34, climbed the crane in the Lake Shore Blvd. W. and Bathurst Street area and, according to media reports, was sleeping shirtless in the cab when she was discovered.

“Toronto Fire Service (TFS) prepared for a rope rescue and we talked to the woman for approximately 30 minutes waiting for the Toronto Police Service (TPS) emergency task force,” says TFS

tain David Eckerman. “The

she was

and

Eckerman says that emergency services were able to stage on the ninth floor of the building the crane was working on at the time for the rescue. Flockhart was able to climb down to the ninth floor by herself and then took the stairs the remainder of the way down. TFS received a call about the incident at 6:35 a.m. and Flockhart reached the ninth floor at 8:41 a.m. The reasons for her climb are unknown, but Eckerman says she would fall into the general category of an “emotionally disturbed person.”

Flockhart is alleged to have damaged the crane and rendered it inoperable. TPS media relations officer Caroline de Kloet confirms she was arrested and charged with two counts of mischief and failing to comply with a probation order.

While the incident calls to mind the well-publicized “crane girl” rescue from 2017 (see Crane & Hoist Canada July/August 2017), Eckerman hesitates to say if crane climbing incidents are on the rise.

“I can’t definitively say if we’re experiencing more of these than in the past, but more of them are being brought to my attention for further information by the media,” says Eckerman. “There’s a greater media interest, for sure.”

Eckerman says that two significant challenges with a rescue like this are assessing the subject and maneuvering the required equipment into position.

“I’ve never climbed a crane, but I would think the framework surrounding the ladders would make for pretty close quarters while carrying bulky ropes and bags and carabiners and anchors and all the things we require,” he says. “We had the Stokes Basket – it’s basically a backboard that wraps around the body a bit more – on the ninth floor. We didn’t have to take that up the crane, but that would have been a huge challenge if she had been incapacitated in some way and we had to stabilize her.”

Hiab recently announced that Andreas Öhman from Sweden has won the World Crane Championship (WCC) held on Sept. 22 and 23 in connection with the IAA exhibition in Hannover, Germany. Among 15 finalists, Öhman won the championship final with a time of 2:32:89. Jani Väisänen from Finland came in second place with a time of 2:38:95, and Tim Hansen from Denmark came in third place with a time of 2:33:18 after winning the bronze final. In the finals of the third World Crane Championships, the crane drivers got to operate the Hiab X-HiPro 232 mid-range loader crane. The competition tested the contestants’ skills and ability to move water cans along a predefined path in the shortest possible time.

“I was very nervous during the competition, I had a high heart rate during the whole time, but now it feels so good,” Öhman commented after the race. “The WCC competition was very well arranged and a lot of fun. You meet people from all over the world.”

Öhman will return home with the title of World Crane Champion, a EUR 5,000 travel cheque and a EUR 20,000 voucher to purchase of a new Hiab loader crane.

Lotta Sjöberg, the global marketing manager of Hiab loader cranes, congratulated Öhman on the championship title.

The first-ever World Crane Championship in 2015, sponsored and organized by Hiab, launched a new tradition in the industry, giving crane operators from around the world the chance to showcase their skills and measure their abilities against those of their peers. This year, the finalists came from Austria, Belgium, Denmark, France, Finland, Germany, Israel, Italy, the Netherlands, Norway, Poland, Sweden, Spain, the U.K. and Slovenia.

“I want to warmly congratulate Andreas Öhman for the win and all the finalists for a great competition,” said Joakim Andersson, senior vice-president of Hiab Cranes. “Andreas put up a stunning show at the World Crane Championships. The national qualifiers leading up the finals were truly amazing, with hundreds of professional crane drivers taking part. We at Hiab are thrilled to have hosted this event for the third time, where the industry’s best drivers have proven that they really have what it takes. We look forward to the next championship final at the IAA 2020 exhibition in Hannover!”

Source: Hiab.

Tel: 780-440-4010 Fax: 780-440-4787

Contact: Kevin Maguire kmaguire@essltd.com

Terex Cranes distributor for Atlantic Canada, Cropac Equipment, is broadening product offers with new models of Terex tower cranes and expanding its territory to include all of Eastern Canada. Already one of the largest distributors of Terex and Demag cranes in Canada, Cropac Equipment has recently added more than 35 new Terex tower cranes to its inventory. Cropac Equipment’s new crane models include a variety of Terex flat top, hammerhead, and luffing jib tower crane models, and are available through any of the dealer’s four locations.

“Our customers are thrilled to see us bolstering our tower crane inventory,” said James Graham, business development manager for Cropac Equipment. “With a more diverse and expanded Terex tower crane line, we’re better able to meet the specific needs of contractors in our territory. And, we know our customers will be happy with the quality and innovation built into every Terex tower crane we sell.”

Over the past year Cropac Equipment has doubled down in the busy Canadian tower crane industry, which is a tremendous advantage for contractors working in Atlantic Canada because it reduces the wait times on projects. Cropac Equipment has also grown its parts inventory to further ensure they can be responsive to all of their customers’ needs.

“Cropac Equipment has been a wonderful partner for Terex Cranes and their customers,” Dean Barley, vice-president and general manager of Terex Cranes. “We’re happy to play a role in their success and admire their commitment to the companies they serve. They do a great job.”

Source: Terex Cranes.

Association of Equipment Manufacturers (AEM) president Dennis Slater issued the following statement about the announced United States-Mexico-Canada Agreement (USMCA).

“The United States-Mexico-Canada Agreement (USMCA) is a step in the right direction,” Slater said. “Trade agreements provide better access to customers across the globe and help us add to the 1.3 million jobs our industry supports in the United States. We urge this administration to continue working closely with the Canadian and Mexican governments to enact policies that promote continued economic growth for our industry.”

Nearly 30 per cent of all equipment produced in the U.S. is intended for export and Canada and Mexico are the first and second-largest export markets for both U.S. construction and agricultural equipment. Since the creation of NAFTA two decades ago, the equipment manufacturing industry has benefited greatly from duty-free access to our industry’s largest two export markets: Canada and Mexico.

AEM is the North American-based international trade group representing off-road equipment manufacturers and suppliers, with more than 1,000 companies and more than 200 product lines in the agriculture and construction-related industry sectors worldwide. The equipment manufacturing industry in the United States supports 1.3 million jobs and contributes roughly $159 billion to the economy every year.

Source: AEM.

SC&RA is seeking subject matter experts to speak at the 2019 Specialized Transportation Symposium being held from Feb. 19 to 22 in Houston, Texas. The annual event brings together specialized transportation professionals and government permitting officials to discuss a variety of topics, including permitting harmonization, safety, regulations, compliance, and the most pressing topics in the industry.

The Symposium Task Force will be accepting speaker and topic proposals focused towards specialized transportation professionals, with an emphasis on safety and permit issues, and regulatory and legislative updates. Interested individuals should submit a topic idea with description, learning objectives, and a brief biography to Steven Todd by Sept. 21.

The task force will then review the proposals and make final topic and speaker selections by early October and notify speakers via email. For more information, contact Todd at stodd@scranet.org.

Consulting Engineers of Ontario (CEO) held its annual general meeting at Blue Springs Golf Club in Acton ,Ont. on Sept. 14, announcing a new board of directors who will lead the organization for the year ahead.

Special guests among the 35 attendees included: Michael Snow, Association of Consulting Engineering Companies (ACEC) chair elect; Martine Proulx, ACEC vice-president, programs and member services; Jonathan Hack, Ontario Society of Professional Engineers (OSPE) president and chair; Sandro Peruzza, OSPE CEO; and Dave Thomson, Ontario Association of Certified Engineering Technicians and Technologists (OACETT) CEO.

Jeremy Carkner, Morrison Hershfield principal and director, business development, has been appointed Chair of the CEO Board of Directors. Rex Meadley, C. C. Tatham & Associates Ltd. president, chief engineer becomes past chair of the CEO Board of Directors.

It was announced that Peter Mallory, Jacobs vice-president, Americas director of projects, has retired from the board. Karen Freund, Jacobs vice-president, was elected to fill the position.

The Board of Directors for 2018-2019 are as follows:

Officers:

• Jeremy Carkner, Morrison Hershfield Principal and director – Chair;

• Christine Hill, Cole Engineering Group Ltd., business development leader, water practice – Chair Elect;

• Bill Allison, Dillon Consulting Limited Partner – Governance Chair;

• Joe Sframeli, WSP Canada Inc. Executive Vice President, Infrastructure – Treasurer;

• Rex Meadley, C. C. Tatham & Associates Ltd. President & Chief Engineer – Past Chair;

• Bruce Matthews, CEO Chief Executive Officer – Corporate Secretary.

Directors:

• Steve Dyck, SNC-Lavalin Inc., vice-president Ontario, government relations;

• Khaled El-Dalati, HDR Inc., vice-president;

• Karen Freund, Jacobs, vice-president;

• Don Holland, Stantec Consulting Ltd., vice-president, water;

• Steve Pilgrim, McIntosh Perry, assistant vice-president, transportation;

• Tom Richardson, R.V. Anderson Associates Ltd., chief structural engineer;

• Brian Ruck, GHD Group Ltd., Principal, vice-president, transportation; and

• Ron Scheckenberger, Wood Principal, senior water resources engineer.

Source: CEO.

continued from cover

“It is certified as being fit for purpose and was the first and, at the time of install, the only designed-for-purpose HUET hoist in the world. We worked closely with SCX engineers so the system was designed in such a way where we would not need to ever replace the hoist in the MAST, that our clients would feel safe sending their personnel for training, and that the hoist would be the new standard for hoists needed for underwater escape training all over the world,” says Jacob Elliott, acting maintenance and operations supervisor with SSTL. SCX Special Projects, a division of U.K.-based Street Crane, designed and manufactured the HUET hoist, including the electrical systems. Seftec, a manufacturer and provider of training equipment, including HUET and firefighting simulators, originally contracted SCX on behalf of SSTL.

The hoist is certified by Lloyd’s Register as being fit for the purpose of conducting HUET operations. The hoist meets, and generally exceeds, regulations and requirements in Canada, the industrial sectors serviced by SSTL, and industrial best practices.

SSTL also uses the hoist for other aircraftspecific underwater egress training programs, with a client list that includes Environment Canada, the Canadian Coast Guard, the Department of Fisheries, the Canadian Armed Forces, Canadian/HNZ Helicopters, and TRS Canada, among many others.

For example, SSTL can add hardware to the HUET to replicate the inside of a Sikorsky S-92 Search & Rescue helicopter, complete with seats, hoist, communications systems and powerful fans that create a wash like that of helicopter blades. Configured in this way, TRS Canada leases MAST time to train search and rescue specialists in a realistic ocean environment.

With a safe working load (SWL) of 5,000 kilograms, the 2,357 millimetre-wide by 5,452 millimetre-long hoist has a 30 kW primary hoist gearbox, type X2FS100B; a 12kW recovery hoist gearbox, type X4FS120B; and a 400VAC, 57-A primary hoist motor, DRE200L4BE32HR/FF/TF.

SEW-Eurodrive manufactured all three.

“The hoist has two side-by-side reels on one wire rope system. The rope is anchored at both ends, on each reel, and the wire is fed through a four-point trolley for more stability and to minimize or eliminate any horizontal movement,” Elliot says.

The hoist operator can move the hoist a maximum transverse speed of five metres per minute. Its maximum lower speed is 30 metres per minute, and its maximum raise speed is 12 metres per minute.

From the primary operating station above and to one side of the pool, the hoist operator has full control of the hoist, as well as the MAST environmental effects, including wind, rain and waves.

“SSTL hoist operators must complete a comprehensive training program, which

Designed & Manufactured in Western Canada, Purpose-Built for the Oil & Gas Sector

includes numerous supervised practice sessions and various emergency response scenarios,” Elliot notes.

The hoist has several key safety features: mechanical overload tops out at 110 per cent of the SWL. In the event of an overload, only the hoist lower function can be used. There is no single point of failure throughout the hoist arrangement, including the wire ropes and block.

One of the features of the HUET is its ability to roll upside-down, recreating what top-heavy helicopters are prone to do after landing on water. As trainees are at their most vulnerable at this point in a training session, SCX built in a batteryoperated backup system that the hoist operator can use if there is a power failure at exactly the wrong moment: It will raise the HUET and return the trainees to a safe area.

The auxiliary lifting system consists of 10 deep cycle gel-filled batteries in a box mounted on the hoist.

“If there were a total power loss in the building, SSTL can still raise the system

out of the water with a fully redundant hoist cable and evacuate any trainees and instructors that would be underwater during a session,” Elliot explains.

The backup hoist cable also ensures that if there is a main hoist failure or power failure, it cannot drop the simulator or trainees at any time.

O’Brien Material Handling, based in Memramcook, N.B., assisted in the installation of the girders along the long walls of the MAST, the transverse beam that travels along the girders, and the hoist itself. O’Brien is also the OEM-specified maintenance and service provider for the hoist system. This includes supplying replacement parts, and visiting SSTL to inspect the hoist’s electrical and mechanical systems in the MAST, and for the other HUET hoist SSTL uses in its other training building. Some components are inspected quarterly and others annually.

Some SSTL staff are also trained to carry out inspections before each training session, and to do monthly visual and function tests of the hoist systems.

continued from cover

Kevin Donnelly, chief of events for the city of Montréal, says his department was in charge of working out the logistics of all the performances and events that took place as part of the festival. The Royal-De-Luxe performance proved to be one of the most significant challenges he’s faced.

“The cranes themselves and the vehicles that were used to carry around the puppets, they were vehicles that they used for all of their events,” Donnelly says. “They’re from Europe – they’re obviously not made for the Canadian market – so they don’t have license plates, and they had a few questions related to emissions and stuff like that. So we had to deal with that to make sure that we would allow them to be rolling on the streets.”

The route the puppets took through the city had to be carefully planned as well –during the spring when the festival took place, certain roads in Montréal cannot be used by heavy equipment to prevent damage during the thawing process.

“The height of the puppets themselves meant that the routes had to be very well determined in advance, because in certain places, we had to remove wiring and move lamp posts,” Donnelly says. “We had to deal with certain bridges that they were going over and something they called ‘Mission Impossible.’”

The Mission Impossible lifts, presumably named for the famous scene in the 1996 movie where Tom Cruise infiltrates a vault while suspended on wires, involved separate

cranes waiting at key areas, which would lift the puppets over the obstacles while RoyalDe-Luxe’s cranes travelled underneath. Once both puppet and crane were on the other side, they would be reattached to RoyalDe-Luxe’s crane. There were three Mission Impossible lifts throughout the path of the puppets, which were performed by a 110-ton Grove TMS9000E with a 75-foot radius supplied by Montréal’s Guay Cranes.

Donnelly says that one of the most interesting aspects of the performance was that there was limited promotion before the arrival of the puppets on the Friday. While media buzz obviously built over the course of the weekend, it could have made for some very interesting interactions early on.

“It’s quite fascinating and basically you could be on the fourth floor in an office building, look out and you had these big eyes looking in at you. It is a bit of a surprise.”

Donnelly says that even after working on the logistics of the performance for quite some time beforehand, he was stunned when he first saw one of the puppets stand up in person. Even as a large crew worked different aspects of the puppet, it was easy to lose yourself in the performance.

“I was really amazed to see how something so huge could be so fun. One thing that I found personally surprising is even though the big diver is about four- to five-floors high, the kids weren’t scared,” he says. “The kids were always in the forefront of the crowd, always moving to try to see it. As

opposed to other events – the kids get a bit nervous and they move back. In this case it was very different. I found it quite magical. That would be the best way to describe it.”

During the festival, the puppets told a story all weekend about the girl and her dog

searching for the diver, her long lost uncle. They reunited on the Saturday evening and spent the Sunday wandering the city together. The giants have performed around the world, but this was their first performance on North American soil.

continued from cover

City politicians approved the project in 2013 and construction started in 2016, with Dufferin Construction Company responsible for design and construction.

The bridge features two separate spans. The first runs 52 metres from the South Stanley Park Extension to Ordnance Triangle Park, crossing the Kitchener rail corridor on the site’s north end. The second runs 49 metres from Ordnance Triangle Park to Garrison Common on Fort York grounds, crossing the Lakeshore West corridor on the site’s south end.

While the concrete decks and wooden handrails are fairly conventional for pedestrian bridges, the rest is made of stainless steel.

“Duplex stainless steel was chosen because of its exceptional mechanical properties,” Whelan said. “Aside from its unique and beautiful appearance, it is highly durable, lightweight, corrosion and weather resistant, requires less maintenance, and provides reduced life-cycle costs.”

The steel structures are relatively lightweight for bridges, but the totality of each of the two lifts — 130 metric tonnes for the north section and 125 metric tonnes for the south one — called for 600-tonne hoisting capacity.

Because the lifts were scheduled nearly three months apart and cranes this size are few and far between, the team landed different, though similar-sized machines for each lift.

On July 28, to lift the north span, Sterling Crane supplied a Liebherr 1600/2 with a suspended 771,000-lb.

counterweight tray, a 295-ft. maximum boom length, a 198ton capacity hook and block, a 160-ft. pick radius, and a 296,934-lb. pick weight/work load capacity.

The south span was scheduled to be hoisted into place Sept. 22 but this was postponed until Oct. 13, weather permitting, in order to coincide with other work being done in the rail corridor.

For this second lift, crews plan to use a Demag CC2800 (SSL) with a similarly sized counterweight wagon, boom length and hook and block. The pick radius will measure 170 feet and the pick weight/work load capacity will be 266,720 lb.

Janine Turner, moved from WSP Canada to Stantec during the project and is vice-president of major projects, overseeing the bridge’s engineering, design and construction. She said the large crawlers are needed to hoist the spans and provide a 35-metre reach.

“Using a crane of this size eliminates railway corridor closures that would have taken place for several hours each night over several months,” Turner said. “It also eliminates preparation work which would have been required to enter the rail corridor.”

One of the biggest challenges has been preparing for the lifts. Each crane requires 32 transport trucks, four needing permits for wide/heavy loads, to transport its components from Sterling’s yard in Sarnia, in southwestern Ontario.

“Delivery to the site required significant and careful

coordination that included planning the delivery route, arranging for police escorts, and coordination with surrounding development activities and ongoing events in the city,” Turner said.

The components of each span were assembled and welded off-site, with a smaller crane placing them on temporary abutments, to produce one arch and one deck for each span.

For the July lift, crews spent a little over a week on site using a 350-ton hydraulic crane to assemble the crawler. They followed up with several days of rigging checks and test picks in order to make sure the span’s pick points were correctly positioned and to adjust rigging lengths with custom extender plates and lift shackles.

“The bridge was lifted with one end being intentionally 25 millimetres low for a controlled ‘touchdown’ during erection,” said Steve Matthews, area manager with the structural steel and bridge division of E.S. Fox. “To the naked eye the bridge seemed to be lifted in a level state.”

Matthews said his firm and Harbourside Engineering Consultants did considerable pre-engineering to determine how the two loads would be safely and optimally handled.

“A full 3D independent model using material characteristics of stainless duplex steel, actual shop drawings with as-built material thicknesses, and inserted weld material masses were created to determine the precise centre of gravity locations of each bridge [span],” Matthews said, noting that centres of gravity varied because the spans are asymmetrical and the north one is slightly heavier than the south one.

The advantage of hoisting the structures from the centre ordnance is that it minimizes disruption to train traffic in the corridors, Matthews said.

“A shut down of the rail corridors is only necessary during the actual super-lift operation, one per bridge,” he said. “There is no need to install track level protection in each corridor, which can only be done on shutdowns. It also eliminates any risks of damaging the rail structures.”

The July lift began at the stroke of midnight. It took the crane approximately one hour to pick it up. The swing took about 30 minutes to occur, placement on the abutments took another hour and placement on the deck panels continued through the night. Crews needed favourable weather conditions and, with clear skies and a full moon, the lift was completed by sunrise.

A similar schedule is planned for the Oct. 13 lift, and Garrison Crossing is expected to open to pedestrians and cyclists in December. Photos: CreateTO.

BY ANDREW SNOOK

Hundreds of professionals from the crane and rigging industry flocked to the Louisville Marriott Downtown for the Specialized Carriers & Rigging Association’s 2018 Crane & Rigging Workshop, which took place from Sept. 26 to 28 in Louisville, Ky.

The annual workshop featured keynote speaker Anne Mahlum, the owner and CEO of [solidcore], who discussed her work with Back on My Feet, a non-profit organization combatting homelessness through the power of running. Mahlum shared her personal story with the crowd, her work with the non-profit organization, and her advice for moving out of one’s comfort zone to create significant life changes.

The workshop also offered attendees breakout sessions on a variety of industry-related topics including the hazards of service providers; how to successfully use synthetics; calculating sling angles and hardware selection; practical ways to protect your company from lawsuits; bridging the gap between compliance and choice; tackling jobs better with tool management; mobile cranes on the move: using new OS/OW rules to your advantage; tips on how crane and rigging companies can boost their OSHA compliance efforts and minimize their risk; and essential elements for preparing engineered lift plans.

The SC&RA’s Leadership Forum also took place during the conference. The one-day forum is designed to offer the industry’s best and brightest young minds an opportunity to build connections and discuss industry trends.

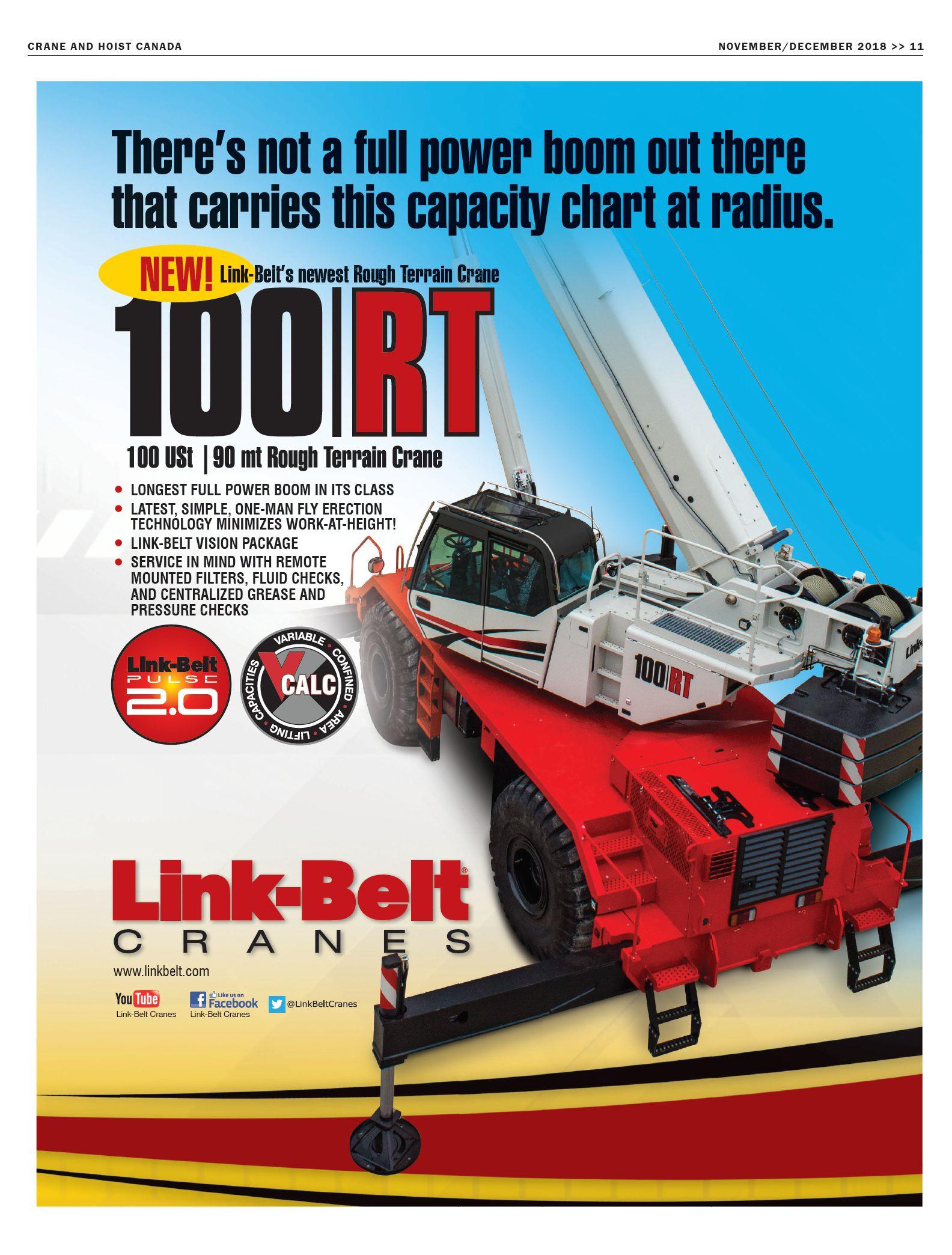

Other highlights of the workshop included a factory tour of Link-Belt Cranes’ 770,000-sq.-ft. factory in Lexington, Ky.; the awarding of the 2018 Rigging Jobs of the Year; and the annual SC&RA Exhibit Center, which features 90 of the industry’s top manufacturers, software and training providers, insurance representatives, and media partners.

The Specialized Carriers & Rigging Association’s 2019 Crane & Rigging Workshop will take place from Sept. 18 to 20, 2019 at the Renaissance Phoenix Glendale Hotel in Glendale, Ariz.

BY SAUL CHERNOS

Tree cutters have long used truck-mounted knuckleboom cranes connected to saw-wielding felling grapples to do their work. It’s considered safer, generally, than using a lift bucket or climbing trees. Still, it can be challenging to judge the weight of a load to ensure the crane stays within capacity. But that could improve thanks to a new computerized system that tracks lift weights in real time using a load pin designed for tree felling.

Treezilla is the brainchild of Timberland Trucks, a company in Bassett, Virginia that outfits custom-built trucks with knuckle-boom cranes and other tools of the trade for arborists.

While cranes usually come equipped with load sensors, these often indicate only what percentage of the lifting capacity has been reached, Timberland owner Jack Lippett told Crane and Hoist Canada

“If you’re boomed out and at 90 per cent capacity, it just tells you 90 per cent,” Lippett said. “It doesn’t give you the weights in pounds or kilograms. It just tells you what stress the crane is under.”

Lippett’s interest in tree felling might stem from the fact he’s Canadian, born and raised in Ottawa. He met his future wife, an American, and they eventually moved to New Jersey, then to Virginia’s Blue Ridge Mountains. Working initially in steel fabrication, Lippett veered into work-truck assembly and latched onto the arborist market when a customer asked him to outfit a truck with a knuckleboom crane, grapple, and other tools for tree cutting.

Lippett established relationships with various crane manufacturers, including Hiab, and it soon occurred to him arborists might benefit from being able to measure the precise weight on the end of their boom.

In scrapyards, for instance, he recalled loading steel and other materials onto trucks, and using load pin-based systems to retrieve data stating the current load. He could even keep a running tally.

While most cranes are equipped with load sensors, these tend to simply indicate when a particular load is either safe or possibly exceeding its limits. This is fine when picking up a known weight — say a package of materials on the ground. But in tree cutting the weight of limbs is generally unknown because wood weights vary by species and a tree’s condition isn’t always obvious.

“Cutting down trees is completely different from probably any other crane operation you can imagine,” Lippett said.

A load pin lets arborists measure precisely what they’re cutting, letting them judge whether they might safely increase the sizes of limbs they’re removing in order to increase productivity, or whether it might be wiser to back off a bit for safety’s sake.

While load cells are widely available commercially, Lippett wanted ones specifically designed to fit onto the rotators of the felling grapples that attach to the Hiab knucklebooms he mounts onto trucks.

Lippett worked out parameters for his ideal load pin, researched potential manufacturers, and settled on Straightpoint, a company based in Hampshire in southern England.

“We actually contacted several companies,” Lippett said. “Some didn’t take it seriously or weren’t interested in doing something unusual, but Straightpoint was interested right from the beginning.”

Lippett supplied his preferred dimensions and Straightpoint developed a prototype that fits into rotators without any modification required.

Straightpoint president David Ayling said other manufacturers produce load pins, but it’s the blue box and its accoutrements that are attached that makes the product truly unique.

The load pin uses a tiny wireless transmitter to send data to a remote control that’s either attached to the operator’s belt or is worn around the neck, and the blue box protects the technology from the elements.

Load pins are usually used for crane sheaves or for more traditional lifting projects, so Timberland’s order was clearly a departure from the norm. “It’s a great match of raw power and cutting edge technology,” Ayling said. “We love to see these different and varied applications.”

While Straightpoint supplies Timberland with load pins on a regular basis, the company markets them internationally through its network of about 80 distributors. “We manufacture dozens of custom load pins alongside our more standard products across the world,” Ayling added.

Peter Gerstenberger, senior advisor for safety, compliance and standards with the Tree Care Industry Association, says weighing loads makes sense.

“In tree removals, one cannot ignore the need to carefully estimate pick weights beforehand and to make conservative picks,” Gerstenberger said. “Once the cut is made, you own the load and it’s too late to put it back.”

Based in the U.S., the TCIA sells a green wood weight chart for estimation purposes, and free mobile apps are available for the same purpose, Gerstenberger said.

“Members have been using load cells with Bluetooth connectivity in rigging situation for a few years now.”

DOUG YOUNGER, WORKSAFEBC

It should come as no surprise to anyone in this industry that the second most common type of serious tower crane incident reported to WorkSafeBC in the last decade relates to contact with overhead power lines. Unwanted contacts – between two cranes or between tower cranes and power lines – have caused 15 reported close calls in B.C. since 2015 alone, and that number doesn’t account for all those potentially disastrous incidents that have gone unreported.

While none of these reported incidents resulted in injury or death, several caused temporary power outages for thousands of nearby businesses and homes, many resulted in lost time or materials and damage to costly machinery, and all 15 had the potential for serious injury, death, or catastrophic equipment failure. As per the regulatory requirement, tower cranes and ancillary equipment involved in the incidents all had to be inspected, repaired if necessary and re-certified for use.

This statistic has helped guide WorkSafeBC’s provincial crane inspection team in developing its three-year Tower Crane Strategy, one element of which is a focus on raising awareness of the value of digital zoning and anti-collision devices. Slew-limiting technologies have advanced steadily over the last 20 years. Sensors, interfaces and the software used to analyze the data have become very reliable, making the benefits for safe and efficient operation indisputable.

This advancement in technology is leading a trend that is seeing manufacturers install these devices as original equipment. Additionally, aftermarket systems are available to tower crane owners that can be retrofitted onto older cranes by qualified firms.

Worldwide, anti-collision technology is increasingly being treated as compulsory. In California and France, its use on tower cranes has been mandated by law for years, and the rest of Europe will introduce similar requirements in 2019. In B.C., the technology is becoming more common and is frequently an option on new cranes. The obvious benefits of these systems make it worthwhile for industry to explore retrofitting older equipment wherever possible.

Ultimately, when employers use qualified, experienced operators, combined with safe-work procedures and the technology of the anti-collision devices, they should be able to effectively mitigate risks to workers and improve a worksite’s efficiency and productivity at the same time. By taking this approach, especially when it comes to complex, multi-tower crane installations, the construction industry should feel more confident about avoiding costly and possibly deadly incidents.

To encourage employers in this direction, WorkSafeBC has revised Guideline 19.24.1 – which describes the minimum approach distance to electrical conductors – accordingly. Typically, where the minimum required distances between equipment and conductors cannot be maintained for any reason, an employer must provide written assurance that certain safeguards are in place, detailed in the guideline. With this change, operations that use a zone-limiting device to prevent such contacts are now exempted from the need to provide assurance in writing.

The relevant section now reads:

In cases where possible or theoretical movement of a piece of equipment into the minimum approach distance is prevented by a system such as a zone limiting device, section 19.25 does not apply and an assurance in writing is not required.

For instance, a tower crane may be positioned so that it is possible for the load line of the tower crane to travel within the limits of approach of a high voltage distribution line. However, the owner of the tower crane may put systems in place that prevent the tower crane from operating in an area that is in violation of the required limits of approach. In that case, section 19.25 does not apply and an assurance in writing is not required.

For additional resources on crane safety, please visit worksafebc.com.

Doug Younger is an occupational safety officer and member of the Provincial Crane Inspection Team for WorkSafeBC.

how tough it was and he told me that one of tests they had subjected it to was loading a snowmobile with a steel-pick studded track into the truck bed, starting it and then pinning the throttle – spinning that track – in place, with those hardened two-inch steel picks tearing at the floor. This uniquely Canadian-ish torture test did not damage the material. Personally, I can tell you I have shredded steel, aluminum and bed-liners doing the same thing – well, actually trying not to.

For power – this is where GMC and Chevy do share –new versions of the 5.3L and 6.2L V8 engines will be joined by an all-new 3.0L inline-six turbo diesel engine (very late availability). The 6.2L and 3.0L engine will be paired to a 10-speed automatic transmission. But past the usual updates GM has unveiled a new fuel saving system called Dynamic Fuel Management. This industry-first technology enables the engine to operate in 17 different power patterns (using from two to eight cylinders) all governed by demand. DFM will be available on both the 6.2L and the 5.3L V8.

Driver-assist technologies are new and found throughout the new Sierra. Key among these is an electronic trailering system called ProGrade. Included in its features is a hitchview camera with zoom feature for hooking up; side-view cameras to see down the side of the truck and trailer; also an auxiliary camera may be mounted on the back of the trailer for an in-cab view of what’s behind you. A nice touch is a new Auto Electric Parking Brake Assist which automatically applies the parking brake as you shift into park; preventing that one-inch lurch that takes you off the ball. Also part of the package are wireless tire pressure sensors that when installed on the trailer wheels relay tire pressure and temperature information to the in-cab trailering screen. A new trailer light test and diagnostics system is included too.

Inside the Sierra offers another industry first. A 3-in. x 7-in. heads-up display projecting vehicle info onto the windshield within the driver’s sight-line. The standard 8-inch infotainment screen offers a new Smartphone-like experience, faster responses and improved voice recognition. This screen also stitches various camera angles together for a bird’s-eye view of the truck.

Also new is Adaptive Ride Control (offered on Denali). Using real-time monitoring of road and driver inputs it reacts (in milliseconds) adjusting shock damping on-the-fly for the smoothest ride.

No conversation about a Sierra would be complete without talking about the Denali trim package. Since its debut in a 2001 Sierra it’s taken on a life of its own. This organic marketing coup happens only occasionally in the automotive world; GM knows it and is working to exploit it. They are pumping even more upscale styling and materials into the truck and expanding its stand-alone character by including a prominent Denali nameplate on the tailgate.

For the off-road crowd GMC has decided to add a new Sierra spin-off; the AT4. It is billed as a premium vehicle that holds its own off the beaten path. To that end it gets a 2-inch factory lift, upgraded Goodyear DuraTrac tires (up to 20 in.) and an overall look that can best be described as “blacked-out”. These cues come on top of the standard off-road features of Sierra; namely, Rancho shocks, locking rear diff, 2-speed transfer case, skid plates, traction select system and hill descent control.

Pricing for the new 2019 GMC Sierra has not been released yet. It’s due in showrooms late this fall.

BY ANNE RAMSAY AND PETER BERVOETS

The safe operation of mobile and tower cranes in Ontario continues to be a major concern for the construction industry, its stakeholders, and the public.

In the past few years, there have been a number of serious incidents and close calls in crane operations. Some of these incidents occurred when cranes overturned, when the crane or its load came in contact with overhead live powerlines, or when the cranes or the material that they were lifting struck or crushed workers when the load was dropped on, or swung into them.

Outdated and inadequate training can lead to incidents like those above. Without proper qualifications and training, workers may fail to properly inspect or use a crane, fail to test the overload protection devices for accuracy, inadequately assess the work area around the crane, work with unknown load weights, work with an incompetent crane signaller, etc.

Proper training, including refresher training, is a key component of reducing hazards and preventing incidents in crane operations. Despite the risks, however, some employers continue to push the envelope. Some of them de-rate cranes so that a less qualified operator may be used. Others provide only enough training to be compliant with the legislation instead of providing the kind of training that will be most effective for worker safety. It’s not enough just to get a Proof of Training certificate — operators must receive the proper training on the cranes they will be using and the hazards they will be facing.

Effective training for worker safety includes theory and practical training. Workers must also be tested on their knowledge to ensure that they understand the training. Theory training includes topics such as crane types and components, basic hydraulics, operators’ responsibilities, load charts and overload protection systems, and crane safety; practical training includes site-specific hazard analysis and how to control those hazards, pre-use crane inspection, installing manual boom extensions, load weight calculations, basic crane maintenance, and other practical crane operation topics.

Training requirements for crane operators under the Occupational Health and Safety Act (Ontario)

Under Ontario’s Occupational Health and Safety Act (OHSA), crane operations fall under the Construction Projects regulation (O. Reg. 213/91) for construction operations or section 3 of the Industrial Establishments regulation (O. Reg. 851) for industrial operations.

Specific crane operator qualifications are spelled out in section 150 of the Construction Projects regulation. It states that:

no worker shall operate a crane or similar hoisting device unless the worker holds a certificate of qualification issued under the Ontario College of Trades and Apprenticeship Act, 2009, that is not suspended, or the worker is an apprentice and is working pursuant to a training agreement registered under that Act, that is not suspended, in the trade of,

(a) hoisting engineer — mobile crane operator 1, if the worker is operating a crane1,2 or similar hoisting device capable of raising, lowering or moving any material that weighs more than 30,000 pounds;

(b) hoisting engineer — mobile crane operator 1 or hoisting engineer — mobile crane operator 2, if the worker is operating a crane1,2 or similar hoisting device capable of raising, lowering or moving only material that weighs more than 16,000 pounds but no more than 30,000 pounds; or

(c) hoisting engineer — tower crane operator, if the worker is operating a tower crane. O. Reg. 88/13, s. 1

In crane operations, a worker who operates a crane or similar hoisting device capable of moving material that weighs more than 16,000 pounds requires a hoisting engineer certification under the Trades Qualification & Apprenticeship Act. A worker who operates a crane or similar hoisting device capable of moving material that weighs less than 16,000 pounds requires written proof of training in the safe operation of the crane.

In Ontario, the Ministry of Advanced Education and Skills Development (MAESD) has a voluntary 0 to 8 ton crane standard, P930030. Because it is voluntary, most training providers don’t align their curriculum to this standard, so it’s important to be aware that qualifications among crane operators can vary.

The Construction Project regulations define a “competent worker” as a person who is qualified because of knowledge, training, and experience to perform the work. A competent worker is required to be familiar with the OHSA and the regulations that apply to the work, and have knowledge of

all the potential or actual danger to health and safety in the work.

A certified crane operator is considered a competent worker. As such, they are required to inspect all mechanically-powered vehicles, machines, tools, and equipment (i.e., cranes) rated at greater than 10 horsepower to determine whether they can handle their rated capacity and to identify any defects or hazardous conditions (O. Reg. 213/91, s.94(1).

Refresher training

In the OHSA, there are no specific requirements referenced for refresher training for crane operators. However, providing training only to be compliant with legislation instead of being effective for worker safety is not a way to reduce hazards and preventable incidents on the worksite.

In the OHSA section 25(2)(h), it states that the employer must take every precaution reasonable in the circumstances for the protection of a worker, and appropriate refresher training would be considered part of such a precaution. Best practice may be for employers to require refresher training every three years in order to keep workers’ knowledge and skills sharp and everyone on the worksite safe.

Otherwise, operator follow-up or retraining may be required when the following conditions occur:

• Training certificate is expired

• A different type of crane is used

• There is a modification or an update in the equipment operated

• Operators are observed operating a crane improperly

• An incident occurs during the crane use

• Employer’s H&S program stipulates retraining

• On-site contractor stipulates retraining

• MOL sends operator for retraining

This article was submitted by Infrastructure Health & Safety Association (IHSA). IHSA can help businesses and crane operators in Ontario access the resources and training that are required under OHSA. Visit ihsa.ca/chcmcm to learn more about IHSA’s training and product offerings for cranes.

1 Crane capacity will determine qualifications of mobile crane operator 1 or 2 or hoisting engineer, not the weight of the lift being lifted.

2 Crane here is also not limited to just mobile cranes. The only crane exempted here is tower cranes, see 213/91 150.(2)(c)

Anne Ramsay is a communications writer for the Infrastructure Health and Safety Association (IHSA) in Ontario. Peter Bervoets is a health and safety training consultant for IHSA that specializes in crane training and safety.

www.craneandhoistcanada.com

Signifying the importance of the luffing jib tower crane design to the Terex equipment offering, Terex Cranes introduces the new Terex CTL 27218 luffing jib tower crane that boasts a 10-per-cent increase in jib length over the previous class model. The new Terex model features a 61 m (200 ft.) maximum jib length, 270 ton-metre load moment and maximum full-length load of 2.6 tonnes (2.9 U.S. tons). The crane’s unique Terex Power Plus feature can temporarily increase the maximum load moment under specific and controlled conditions (e.g. reduced dynamics) by 10 per cent, giving the operator extra lifting capacity.

Seven different jib configurations from 30m to 61m (98.4 ft. to 200 ft.) on this new Terex crane give contractors the flexibility to meet a range of jobsite reach needs. Equipped with an independent safety line, all jib sections of the new CTL 272-18 crane deliver safe work at height, plus galvanized jib walkways provide longlasting and dependable service life. The crane’s 5.8 m (19 ft.) counter jib boasts multiple job angles to meet demanding in-service and out-of-service conditions.

The new control system found on the CTL 272-18 crane delivers efficient set-up of expanded crane configurations needed to meet a variety of jobsite demands. The large, 18 cm (7 in.) colour display with antiglare screen displays operating and troubleshooting data to the operator. In addition to Terex Power Plus, Terex Power Match enables the operator to choose between operating performance or energy efficiency to adapt to lifting needs. The new

crane offers the choice of hoisting with one to four pull lines, affording the flexibility to choose between lifting speed with lighter loads or power and precision when placing heavier objects. Its auto-levelling feature automatically maintains the same hoist block height while luffing the jib. Since efficient crane assembly is important, the new CTL 272-18 offers a competitive, 84.4m (276 ft.) maximum freestanding height. The flexible tower design can be configured using a combination of the 1.9m (6.2 ft.) H20, 2.3m (7.5 ft.) HD23 and the 2.37m (7.8 ft.)

TS212 tower masts, allowing customers to efficiently manage tower section inventory

The Maxi Transmitter is Scanreco’s most advanced and versatile transmitter with a 4.3 in. highperformance colour display, and room for many control elements as well as function labelling. The ergonomic housing comes in two basic versions, with linear levers or joysticks. The Maxi Transmitter has a modular design and offers a bundle of both standard and optional settings and features to improve the operator experience. The maximum speed of proportional movements can be easily adjusted using a “turtle/rabbit” toggle switch in five steps. The stop function conforms to performance level “e” (PL e) as specified in EN ISO 13849-1, a legally binding standard for safety-critical components of control systems.

Maxi Transmitter features include:

• 1 to 8 linear levers or 1 to 4 joysticks;

• Operator feedback options;

• Colour display (4.3 in.) with 480 x 272 px;

• Monochrome display (2.5 in.) with 128 x64 px;

• LEDs;

Aand cost-effectively meet tower needs at multiple sites. Tower masts are equipped with durable aluminum ladders and optimized for transportation to the jobsite.

Stemming from in-depth operator feedback, the new Terex cabin on the CTL 272-18 luffing jib tower crane includes a comfortable work space for the operator, including a fully adjustable comfort seat. The cabin’s joystick controls feature a short stroke length to reduce arm movements and operator fatigue. Standard heating and air conditioning keep the cabin at convenient temperature, regardless if operating during cold winter months or the heat of summer. Large windows give the operator a panoramic view of the jobsite for excellent visibility. In the event of a broken glass pane during operation, it can be replaced from the inside.

The crane’s counter jib with winches and electrical panel powering all crane movements are located at cabin level for convenient access. A service derrick located at the counter jib with 1.25 tonne (1.38 U.S.-ton) lifting capacity conveniently hoists parts to jib-level for maintenance activities.

The new CTL 272-18 luffing jib tower crane can be equipped with several advanced options to give more flexibility to the owner for crane configuration. It is ready-equipped for the installation and setup of zoning and anti-collision system and cameras. The crane is compatible for the next generation of Terex tower telematics, which reports machine operation and service data back to the office. www.terex.com

• Frequency bands: 433-434 or 902928MHz (other frequencies available on request);

• Operating range greater than 100m;

• Cable control: Standard length 10 metres;

• Operational temperature: -20°C to +70°C; and

• Protection category: IP65.

Scanreco’s automatic frequency management allows for continuous operation without any interruptions caused by radio interference from other wireless equipment. The Maxi Transmitter communicates with the corresponding receiver using a protocol and a unique identity code. This guarantees that no other Scanreco transmitter, any other product, can unintentionally activate the machine. www.scanreco.com

November 2018

Nov. 7-8, 2018

Buildex Calgary Calgary, Alta. www.buildexcalgary.com

Nov. 14, 2018

OHS Canada: Marijuana in the Workplace Vancouver, B.C. www.ohscanadasymposium.com

Nov. 15-16, 2018

SHCA Annual Fall Convention Regina, Sask. www.saskheavy.ca

Nov. 26-28, 2018 CCA Fall Board Meeting Ottawa, Ont. www.cca-acc.com

Nov. 28-30, 2018 The Buildings Show Toronto, Ont. www.thebuildingsshow.com

December 2018

Dec. 6-8, 2018

BCRB AGM & Winter Celebrations Victoria, B.C. www.roadbuilders.bc.ca

January 2019

January 22-25, 2019

World of Concrete Las Vegas, Nev. www.worldofconcrete.com

February 2019

February 13-14, 2019

Buildex Vancouver Vancouver, B.C. www.buildexvancouver.com

February 19-22, 2019

SC&RA Specialized Transportation Symposium Houston, Texas www.scranet.org

March 2019

March 28-29, 2019 National Heavy Equipment Show Mississauga, Ont. www.nhes.ca

April 2019

April 6-14, 2019 bauma 2019 Munich, Germany www.bauma.de

April 23-27, 2019

mong their many in-house fabricated products, Unirope manufactures a torpedo style mobile crane button for non-rotating wire rope. Each button is type tested to destruction and subjected to the same rigorous 75,000 cycle test demanded under EN-13411. After installation onto the rope each button is proof-tested to 40 per cent of the rope’s minimum breaking strength. The button is permanently stamped with a unique serial number and a test certificate is issued for each button installed. www.unirope.com

SC&RA Annual Conference Carlsbad, Calif. www.scranet.org

June 2019

June 5-8, 2019

CRAC Annual Conference Charlottetown, P.E.I. www.crac-aclg.ca

bauma, Munich, April 8–14, 2019

More than an exhibition: The entire market

All key players, innovations and trends. bauma is more than the world’s leading trade fair: it is the heartbeat of the industry. Because it dynamizes the market and highlights new potentials together with its partner country Canada. 600,000 participants and even more space make it the largest – and the most relevant – international meeting place for the industry. Business at its best.

LRT 1090-2.1: 47 m / 154 ft full power boom

LRT 1100-2.1: 50 m / 164 ft pinned boom

Safe & Strong High lifting capacities with a maximum of safety due to VarioBase®

Globally uniform load charts conform to ANSI, EN and further standards

Safe access points and flat deck

Comfortable Simple and easy to operate

Operator friendly extra wide and tiltable crane cabin

Sales and service directly from the manufacturer

Liebherr-Canada Ltd.

1015 Sutton Drive

Burlington, Ontario L7L 5Z8

Phone: +1 905 319 9222

E-mail: info.lca@liebherr.com

www.facebook.com/LiebherrConstruction www.liebherr.ca