BY MATT JONES

his May, Calgary’s historic 12th Street S.E. Bridge was removed. e “Zoo Bridge”, which leads to an island in the middle of the Bow River, was constructed in 1908 as part of an agreement between the Federal Government and the City of Calgary. Since the age of the bridge began to become a signi cant logistic challenge, Mammoet were contracted, via Pomerleau/Westpro, to remove the bridge to make way for a replacement.

“Back in 1908, we weren’t really using cars here in Calgary, more horse and buggy,” says Katherine Hikita, project manager with the City of Calgary. “It was a fairly narrow carriage way, a 2.6-metre wide lane. We had a 4.5-tonne restriction on the bridge for a number of decades. Physical condition is really what was dictating it from an asset management point of view.”

In 2012, the 120-tonne bridge was identi ed in future planning reports for replacement, due to issues

BY SAUL CHERNOS

As Canada moves towards legalizing marijuana for recreational use, cranes are poised to gain a foothold in a budding new industry. In a statement announcing plans for a giant cannabis grow facility in Alberta, Aurora Cannabis said it would deploy cranes and conveyors speci cally designed for indoor agricultural settings.

including a signi cant amount of rust, lost side view mirrors on cars due to the narrowness of the lane and ood concerns. Following a 2013 ood, there was an interest in replacing the bridge with one that would be better suited to help deal with ooding.

BY ANDREW SNOOK

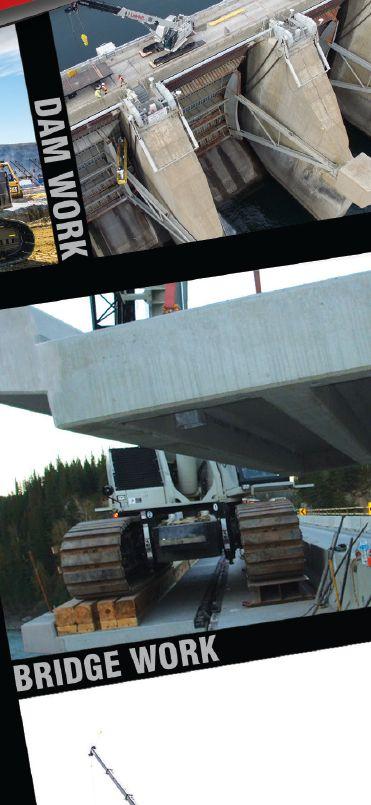

t took three construction seasons, but the Upper Cambie Bridge has been replaced. The $7.7-million project began in May 2015, involving the replacement of the aging bridge located on the summit of Highway 3 (Crowsnest), east of Allison Pass, and west of the Manning Park Resort, about 60 kilometres east of Hope, B.C.

“This bridge replacement was necessary because the previous bridge at this site had reached the end of its service life, and a stron-

Health Canada issued its rst medical marijuana permits in 2002, and Aurora burst on the scene in 2014 with a small grow facility in Cremona, Alta. Now, with recreational legality just around the corner, market opportunities stand to grow signi cantly and Aurora has mainstream production in mind.

“ ere isn’t enough supply even for all the medical patients out there,” says Joel Fuzat, senior project coordinator with Aurora.

“Our Cremona facility is already maxed out at just over 19,000 patients, and with recreational coming on-market there’s going to be something to the e ect of at least 7.5 million users in the rst year of legalization.”

Publications Mail Agreement #PM40065710 RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 80 Valleybrook Dr., Toronto, ON M3B 2S9

PS Cranes has announced that it has entered into a definitive agreement to acquire American & Ohio Locomotive Crane Co. (AOL Crane).

According to a recent statement from AOL Crane, the merger will “enable IPS Cranes to achieve its mission to provide customers with a greater range of services that will give them the ability to sustain and maintain their fleet of American Hoist and Ohio locomotive cranes and American Hoist crawler cranes. It also will manufacture excavator bodies and offer line boring services related to locomotive crane repairs and rebuilds.”

AOL Crane is a global leader in material handling on rail for all railroads, steel plants, dock loading, the scrap recycling industries, material handling yards, railroad

fined $95,000 after worker fatality

Toronto Crane Service Inc. has been fined $95,000 after pleading guilty to the offence of failing to ensure that the measures and procedures prescribed by section 46 of Ontario Regulation 851/the Industrial Establishments Regulation were carried out in the workplace, contrary to section 25(1)(c) of the Occupational Health and Safety Act (OHSA).

The court also imposed a 25-per-cent victim fine surcharge as required by the Provincial Offences Act. The surcharge is credited to a special provincial government fund to assist victims of crime.

Toronto Crane Services Inc. carries on business setting up, servicing and maintaining tower cranes, mostly at construction sites, and stored a number of decommissioned cranes at its Innisfil, Ont. facility.

contractors and concrete pipe companies.

“We are extremely excited for this acquisition, as it allows us to create the industry’s broadest and deepest range of crane manufacturing, services, and resources,” stated Jackie O’Connell, president and CEO of IPS Cranes.

North American Equipment Sales (Canada) Ltd. was the Canadian manufacturer’s sales representative for AOL Crane prior to the IPS Cranes acquisition.

“We will continue that representation in the same manner our customers have come to expect from us, but with all of the new and innovative products and services offered by IPS,” said Paul O’Shell, president and CEO for NAES Canada Ltd.

NAES Canada Ltd.’s head office is located in Binbrook, Ont.

The incident occurred on June 22, 2016 when a worker had been assigned the task of cutting a tower crane into smaller sections, for disposal. The crane’s jib consisted of two sections - a heel section and a jib section.

The worker made several cuts to the jib section, which disconnected the upper portion from the lower portion, then began to cut the jib section away from the heel section, making a last cut to the remaining structural member that connected the two sections. Once the jib section was no longer connected to the heel section, it lost stability, tipped over and fell on the worker, who suffered fatal injuries.

Section 46 of the Regulation for Industrial Establishments prescribes that “machinery, equipment or material that may tip or fall and endanger any worker shall be secured against tipping or falling.”

Toronto Crane failed to ensure that the crane was secured against tipping or falling as required. This is contrary to section 25(1)(c) of the OHSA.

Source: Ontario Ministry of Labour.

ger, more robust bridge was needed to cross the Similkameen River,” stated Minister of Transportation and Infrastructure Claire Trevena.

Emil Anderson Maintenance Co., which performs regular highway and maintenance work in the area, was awarded the contract for the four-lane, 95-foot single span BC MoTI Type IV Pressed I-Girder bridge, which included improvements to the bridge approach areas, a higher clearance above the water to better withstand flood events and ice flows, a wider bridge deck and wider shoulders to better accommodate traffic, cyclists and pedestrians, according to the B.C. Ministry of Transportation and Infrastructure.

Ten 85-ton girders, built by Armtec and transported to the site by Triton Transport, were lifted into place to build the new bridge. To complete the lifts, Emil Anderson Maintenance Co. relied on a combination of a Grove 50-ton rough terrain crane from its fleet, and a second crane they outsourced.

“We used a Grove 50-ton rough terrain (RT) 650E and a 60-ton Link-Belt rough terrain,” says Brian Atwell, senior project

manger for Emil Anderson Maintenance Co., adding that EcoWest Crane & Rigging out of Abbotsford, B.C. supplied the second crane.

The two cranes were also used to install the bridge’s 125 2,000 lb. pre-cast concrete deck panels.

Although the replacement of the small bridge was not overly complex, the project still required three construction seasons to complete due to its remote location.

“It’s at the summit of a pass of one of the highways,” Atwell explains, adding that the harsh weather at the summit creates a shortened construction season. “You only have a six-month season out there… it’s at the summit and is the highest structure on that highway. The girders’ transportation, which were manufactured in Richmond, going through the mountain pass is always interesting when moving 100-foot loads.”

Apart from the bridge’s remote location, no big challenges popped up that needed to be overcome over the course of the project. The lifts, like the rest of the project went very smoothly, much to Atwell’s delight.

“It was very straightforward, that’s how we like them,” he says.

More crane rescues conducted in wake of April “crane girl” incident

PHOTOS BY JOHN HANLEY

BY MATT JONES

Toronto emergency services continue to deal with situations involving people climbing cranes on construction sites in the city. Late on the night of Aug. 2, Toronto Fire Service (TFS) and Toronto Police Service (TPS) responded to an incident where a man broke into a construction site in the Dundas Street East/ George Street area, climbed a large tower crane and was threatening to jump. The incident follows one, which took place in April, where the rescue of a woman who climbed up a crane and down the main hoist line onto the pulley drew national media attention.

“I was fearing the worst,” says TFS Platoon Chief Donald Beam, who was among the crews who responded to the Aug. 2 situation. “He was jumping up and down; you could see the crane arm move. It did not look good there for a while.”

officials arrived on the scene, the man was yelling incoherently and threatening to jump from the jib of the tower crane. A TFS aerial truck, Tower 333, was brought into position and luckily the tower was the right height to bring a police negotiator to the top of the jib.

“The police negotiator was doing a fantastic job talking to him, trying to keep him calm,” says Beam. “He did become calm when we gave him cigarettes and water and some food. There was a restaurant nearby so we sent some chicken and potato wedges... and he ate some. That always seems to calm people down.”

After the uniformed negotiator calmed the man, a psychiatrist who works with the police in such incidents was brought in.

“He wasn’t up there very long and he convinced the guy to get into the basket by saying things like, ‘We’re all concerned about you, we don’t know what’s wrong,’” says Beam. “He got kind of emotional, he said, ‘You mean all these people really care about me? Who’s that guy in the white shirt?’ That was me, he kind of lied to him, he said ‘that’s the Deputy Police Chief, he came from home because he was so concerned about you.’ That really calmed him down, that got to him. They have to use whatever tactics they use to get people to respond, but it all worked out well. It’s part of their negotiation training, the psychiatrists know how to read those people better than I would.”

Media reports of the incident say the man was arrested under the Ontario Mental Health Act. TPS confirmed that the man had been apprehended and brought to hospital, but did not specify whether he had been charged with a crime.

The incident reminded many of the so-called “crane girl” incident the morning of April 26, when Marisa Lazo was rescued from the pulley of a crane. In that

case, an officer with the TFS had to climb up above the pulley and rappel down to reach the woman.

Platoon Chief Kevin Shaw was on scene and says that while the logistics for the April rescue were more challenging, it was a far different situation because Lazo was not what they would deem an EDP – an emotionally disturbed person.

“I think it was a misadventure for her,” says Shaw. “When our guys got there, she was trying to shimmy her way up that cable. She probably went down 40 to 60 feet on that cable to where she was sitting. There was no way she was climbing that cable so she could climb back down the crane. I heard later, there’s a lot of whackjobs around here who get up on construction sites and up on the roof and take selfies, but I do not believe she even had a phone with her.”

Lazo was charged with six counts of mischief by interfering with property. Whether the charges serve as a deterrent against others remains to be seen. While the Aug. 2 incident was obviously a different type of situation, TFS Captain William Bygrave says that the frequency of such incidents is trending up – he noted an incident where thrill seekers climbed a crane and fled into the night before officers could reach them had occurred just days before he spoke to Crane & Hoist Canada in September.

“It’s not common – it’s not like every day that people are climbing these things,” says Bygrave. “But 10 years ago it was unheard of. If it’s the selfie thing, I don’t know, but it’s definitely more common than it was 10 years ago.”

For a closer look at the mindset of a thrill-seeking crane climber, see “His Life In His Own Hands,” Crane & Hoist Canada issue Nov/Dec. 2016).

• 130ton (118mt) Lattice Crawler Crane

• 281ft (85.6m) max tip height (Tube)

• 44,565 lb (20,214 kg) max line pull

• 536 ft/min (163m/min) max line speed

• 89,000 lb upper Ctwt / 26,500 lb lower Ctwt

• Cummins QSB 6.7 Tier 4 Final

Division 2111-80th Avenue Edmonton, AB, T6P1N3 1-800-319-7787

Tel: 780-440-4010

Fax: 780-440-4787

Contact: Kevin Maguire kmaguire@essltd.com

416-249-8912 Contact: Drew Paton dpaton@essltd.com since 1946 www.essltd.com

Nelson Dewey has been a prolific cartoonist for over 50 years. If his work looks familiar, maybe you read a lot of car comic books when you were younger. In the 1960s, ’70s and ’80s, Dewey was a frequent contributor to those comics, particularly CARtoons. He also drew for Hot Rod Cartoons, CYCLEtoons, SURFtoons and SKItoons. In all, he produced nearly 2,000 pages in those publications. He has also published cartoons in Cracked Magazine, Oui, Reader’s Digest and Motor Trend, as well as community newspapers and dozens of books. And he shared an Emmy Award in 1988 for his work on storyboards for the Arthur cartoon series on television.

To take a trip down memory lane and see samples of Dewey’s car cartoons, go to his website, www.nelsondewey.com.

Crane & Hoist Canada welcomes submissions of letters, guest columns, short notices, product announcements, press releases, and ideas for articles. Send them to editor@craneandhoistcanada.com.

Letters: Please limit your letters to 250 words. Include your full name, the city or town you live in, and a contact phone number. We do not publish anonymous letters or letters written under pseudonyms.

Guest columns: These can be up to 700 words. Please send a brief note of inquiry first, however, just in case space what you wish to write about has already received a lot of coverage in our pages. Include your full name, the city or town you live in, and a contact phone number.

Short notices: Tell us about individual promotions, appointments, awards, staff movements, plant openings, plant closures, expansions, and other milestones. These short items should be no longer than 100 words.

Since the federal government announced that it would be decriminalizing marijuana for recreational purposes in July 2018, a mixed reaction has come from the provinces and territories, and across the public and private sectors.

While the feds have claimed that all levels of government will benefit from a new source of tax revenues that will be generated through the legal selling of the drug, some provinces (particularly Quebec and Alberta) have voiced concerns about the costs of managing the decriminalization of marijuana. Some provincial representatives stated in recent news reports that they only expect minor windfalls once costs of rolling out new programs are included (the federal government would collect half of the revenues from an imposed federal excise tax on the sale of recreational marijuana, if Prime Minister Trudeau’s proposed levy gets approved).

As for positive responses to the decriminalization news, the most public pro-marijuana province, currently, is New Brunswick. The province has expressed excitement about potentially being a leader in the production and distribution of marijuana as a means to stimulate its economy and create much-needed jobs in the province.

Like many of my fellow Canadians, I find myself with mixed feelings about the coming legislation. On one hand, I feel like decriminalization has the potential to increase tax revenues on what would essentially be a luxury item, which I am fine with, while creating new employment opportunities for struggling communities. It also has the potential to relieve a little pressure from some of the country’s more thinly stretched and under-budgeted police services, allowing them to focus on more serious crimes; while allowing government agencies to control the supply helping prevent the tragic deaths and addictions that have stemmed from street dealers lacing marijuana with other more addictive and destructive substances. That said, decriminalization should be done with a great deal of planning and coordination between the feds and the provinces and territories to ensure it is efficiently implemented; and this feels very rushed to me.

While Canadians debate the usefulness of this legislation, and the provinces and territories wrestle with how to roll out programs in time for the July 2018 deadline, many industries have been in panic mode looking for solutions to managing their workforces under the new rules. The construction industry as a whole has been very vocal in its concerns related to the announcement, and rightfully so! With the amount of heavy equipment operators working in the sector, it would be crazy for companies not to be concerned.

As Cann Amm Occupational Testing Services’ Dan Demers pointed out at the 2017 CRAC annual general meeting (for coverage of the event, check out the 2017 July/August issue of Crane & Hoist Canada), most crane companies will need to change their current policies related to job site intoxication to deal with recreational marijuana users.

In the article he stated that, “scientific research and both Canadian and international authorities have made it abundantly clear employers should not support allowing cannabis use – even off the job – and complex dangerous work to mix for any reason.”

Demers went on to explain that a new approach to drug policies would be needed for many companies, since an employee who smokes marijuana recreationally could suffer from the affects of the drug longer than its actual high, and that could affect their ability to perform their job effectively and safely. He believes companies will need a fit-for-duty program, including a policy, training and compliance measures. As things stand, companies will not always be able to know if an employee is feeling the affects of recreational marijuana use on the job, since drug testing won’t always be effective. So, what’s the answer? I think in positions where the safety of employees and the public is potentially at risk, whether in the crane industry, construction sector or otherwise, companies will need to take a hard stance on recreational marijuana use for heavy equipment operators and just say “No”, whether the drug is legal or otherwise.

Product announcements: Are you a supplier to the industry? Has your company developed a new product or process? If possible, attach a photograph.

Press releases: These should have something to do with cranes and/or hoists in Canada. We might publish only part of a press release or use it as starting point for an article by one of our writers.

Story ideas: Maybe you have an idea you’d like us to explore for an article. A good rule of thumb is to limit your story idea to no more than 30 words. If it takes longer than that to describe it, then chances are we won’t be able to take it on.

All submissions are subject to editing and publication cannot be guaranteed. The deadline for our next issue of Crane & Hoist Canada is November 28, 2017. Sooner is always better than later.

By any agricultural measure the Cremona operation is small potatoes, at 55,200 square feet. Aurora is also opening a 40,000-square-foot facility in the Montreal suburb of Pointe Claire, but that, too, is relatively modest.

It’s a new 800,000-square-foot greenhouse in Leduc, Alta. adjacent to Edmonton International Airport that will use cranes in everyday production. Fuzat says the facility, known as Sky, should be up and running later this year.

Because of its sheer size, Sky will be highly automated, partly to optimize greenhouse equipment and also to help avoid some of the more backbreaking work that comes with greenhouse growing.

Aurora plans to use two small overhead cranes manufactured by Netherlands-based Codema Systems Group to work with robots to handle up to 400,000 plants that will be growing at various stages at any given time.

Plants will mostly grow in small individual cubes and sit in rows on tables, with robots helping ensure they’re appropriately spaced.

As the plants grow, the tables holding the plants need to be moved from zone to zone, and that’s where the cranes t in. “All that transportation takes place via the overhead crane system,” Fuzat explains.

e cranes will work from overhead tracking and rely on software to know what needs hoisting. Using tines and safety-like harnesses that reach downwards, the cranes will grasp and cradle the 6-by-15-foot tables, which can weigh roughly 1,000 pounds with product, and move them where they need to go next.

When a table-load of plants matures and is harvested, the cranes will carry the empty tables to an automated washing centre for their eventual clean reintroduction into the growing cycle.

“ e whole idea of the cranes is to eliminate back-breaking labour and speed things up,” Fuzat says.

Automation is key to the whole process, and the crane systems will do more than lift. e cranes will carry sensors and operational software, with RFID tagging, to

keep track of the plants so management and sta know which plants are where and in what number at any given time.

Fuzat says Aurora also wants to minimize the use of chemicals, so the company plans to attach small visioning, data-capturing and logging systems to spot diseases and poor plant health.

“Cannabis is a very sensitive plant,” Fuzat explains. “ ere are any number of pests and diseases that, once they get a hold of cannabis, can ourish very quickly. So those cranes are doing double duty in also being a guard, observing our crops and alerting us if there are insects or microbial damage.”

e system also consists of conveyor belts, which Aurora will use to move harvested plant material in one direction and residual waste in another.

While Aurora sourced the overhead cranes directly from Codema, Tava Systems, based in Beamsville, Ont. with its parent Zwart Systems, serves as Codema’s North American distribution partner. Isaac Van Geest, Tava’s sales and project manager, says the cranes can be attached to I-beams located on a ceiling, as in Aurora’s case. But the cranes can also work from a stand mounted at ground level, with I-beams still located overhead. It all depends on the facility they’re used in, Van Geest says.

Tava supplies an array of products, including conveyors and irrigation systems, to a broad greenhouse market, and cranes are nowhere near the distributor’s top seller at this time. Van Geest says Tava had just two other crane-deploying customers at press time, including a grower of succulent plants, also in Beamsville, and a potted mums supplier in Abbotsford, B.C.

Van Geest concedes Tava’s earliest cranes sales were partly driven by “a cool factor… where you bring buyers through your greenhouse and you have automation. ere’s also a comfort feeling that you can produce — that’s really the reason why the rst ones were sold.”

ese days the driver is cost, following a trend that began a quarter century ago in the Netherlands.

“ e Netherlands is the agricultural hub of the world,” Van Geest says, o ering that the European country has a half-dozen agricultural crane manufacturers and 12,000 greenhouse operations — roughly the same number of greenhouses as in all of North America.

“ e need there is higher mainly because of high labour and land costs,” Van Geest says. “In North America land and labour have been cheap, but that’s changing.”

While the price tag ultimately depends on features such as lifting capacity and accessories, the cranes and the hardware they’re attached to cost roughly $250,000, Van Geest says.

As with many investments, the potential savings are long term. Van Geest estimates a fully automated system could save close to 45 per cent on labour costs, alone.

he does think the systems make sense for anything on the scale of Sky.

“We’re just on the beginning of cranes in Canada,” Van Geest says. “I think we’re going to see a lot more of them due to labour rates — it’s really the only consideration at this moment.”

Joel Fuzat doesn’t see installing cranes at Aurora Cannabis’ two smaller facilities, but

“As we continue building these larger types of greenhouses in the future we’ll continue using this automation, with solutions smarter and smarter as we learn from each project.”

Hikita says that they knew during the design phase that the removal of the bridge would be complicated by its size, its lead paint coating and concerns about the condition of the foundation.

“ e wind proved to be a challenge and delayed the lift until conditions improved,” says Mammoet crane supervisor Chad Hendry. “With the deteriorated condition of the bridge there was some uncertainty with its structural integrity.”

After the wind delay, Mammoet utilized a Liebherr LR1350 crawler crane to perform the lift, which was chosen primarily due to scheduling concerns. Hendry says they had access to a number of cranes that could have performed the work, but the LR1350 made the most sense for scheduling. e lift and setting of the bridge took approximately one hour.

“A small jetty was installed by Pomerleau in order to assist in the positioning of the crane for the placement of the new bridge and the removal of the old bridge,” adds Hendry.

“Westpro – a division of Pomerleau – is very proud to have carried out this project as the prime contractor,” says Bryan Buis, project director with Westpro. “Overall, we are excited to be working on more and more projects such as the 12th Street S.E. Bridge replacement project, all of which

are contributing to our continued growth in civil works and infrastructure coast to coast.”

Hikita says that some elements from the old bridge were salvaged; including portals from either end of the bridge. ose elements have had their lead paint stripped and the intention is to install them into the landscape to help commemorate the old bridge.

“We had a lot of interest in the bridge,” says Hikita. “We actually held a farewell party for the bridge before we took it down and we had at least 200 spectators sitting on the banks to watch the bridge removal.”

Construction on the replacement bridge has nearly been completed – as of press time, workers were nishing o the deck and prepping it for waterproo ng. It is expected to open this fall.

Our eet ranges from self-erecting cranes, boom truck cranes up to 35 ton, mobile cranes and rough terrain cranes.

Since each job is di erent, we o er expert personnel to evaluate the customer's need and select the equipment which will complete the job in the most economic, timely and safe manner.

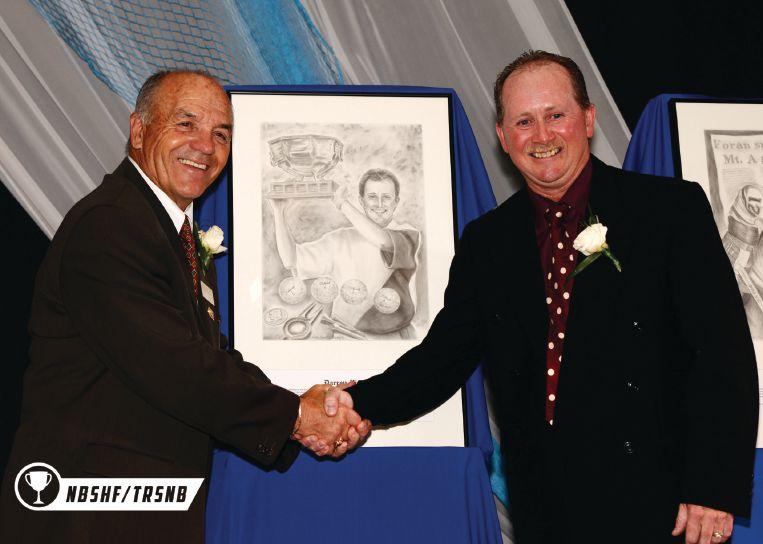

Darren Ritchie is a Canadian golf champion and, as of June 2016, a member of the New Brunswick Sports Hall of Fame. When operating the cranes on job sites with Irving Equipment, however, he says he’s just another guy in a hard hat.

says one of his favourite aspects of the job is how quickly it changes and how every day he might be operating a different type of crane, depending on what’s needed. And he gets to utilize some of the same natural talents that served him well on the links.

Gru, ITALIAN SELF ERECTING CRANE

Quick assembly crane, small foot print, no noise or pollution, perfect for congested work sites and urban environments. Radio control, full training and cost effective. Axles for on site towing. Call us for more details!

Exclusive Canadian Distributors for FB Gru, ITALIAN SELF ERECTING CRANE

“I like being just one of the boys and they accepted me as I am,” Ritchie says. “My golf is totally separate. I was very fortunate to be as successful as I was, but I want to be just as successful with my crane job as I was with golf.”

Ritchie’s path to golf started when his father put a golf club in his hand at age five. He played his first full round at age seven.

“At 13, there was a golf tournament and a baseball game at the same time,” Ritchie recalls. “I chose the golf tournament and never looked back, I guess.”

The highlight of Ritchie’s career was winning the 1992 Canadian Amateur Championships, besting future Masters champion Mike Weir in the process. Ritchie was also a member of Canada’s 1992 World Amateur Team, won the New Brunswick Amateur Championship in 1996 and 1997, and won over 40 invitational tournaments around his home province. However, as his children were getting older, he decided he needed a change and he found it in training for a career in heavy lifting.

Career change in order

“I took a little sabbatical as my kids were growing up; they were my priority,” says Ritchie. “It was weird going back to school at 40. You apply yourself a little bit differently. But I’m thankful they gave me the opportunity and it was a great career change.”

Currently working for Irving Equipment at a refinery in Saint John, Ritchie

“Hand-eye coordination was certainly a great help to becoming a crane operator,” says Ritchie. “You use it to make your lift better, of course. I love what I do. I love going to work every day. It’s amazing what these machines will do.”

Ritchie says one of his favourite tasks is a lift with a man in the bucket. It’s a great source of pride for him to have the trust and responsibility of performing such a lift.

Lifting also requires teamwork

“It’s amazing, the most critical lift you could ever do, having somebody in the basket and placing them within millimeters of where they need to be,” Ritchie says. “But you’re only as good as the guy giving you signals as well. No question, we work with a great bunch of people. It’s a great team to be a part of.”

It was also great to be part of the New Brunswick Sports Hall of Fame in Fredericton.

“Not too many golfers from our province are chosen. It was a great feeling. This province has put out many great athletes and to be recognized among them is truly amazing.”

effective. Axles for on site towing.

Now that his children are a little older, Ritchie has begun picking up the clubs again. After nine years away from playing in individual tournaments, his wife talked him into playing again in June.

“I ended up winning the tournament. It was great to have her support. It felt just like old times. It’s funny, the butterflies were back in my stomach and they hadn’t been there for a long time. It felt really good to do that again.”

I was concerned about the math prior to coming. The approach that the Instructors took helped me to take on the challenge and gain confidence.

I would definitely recommend NLC to other students and to employers. And I’d come back here in a heartbeat for Mobile Crane Third Period, especially with these teachers.

Northern Lakes College offers a unique mobile delivery where training is provided in locations across Alberta where apprentices are working. Bringing the classroom to you!

For dates and locations please visit us on our website www.northernlakescollege.ca or call 1-866-652-3456.

Manitex International, Inc. recently announced that Steve Kiefer has been named president, North America, for Manitex International.

Kiefer has held senior roles with Manitex and affiliated companies since 2015, and brings with him more than 25 years of experience within the industrial equipment sector, from new product development, sales and marketing to business development, operations, and P&L management. He began his career at Eaton Corp., a public company, where he spent seven years in various new product development roles, playing a key role in the growth of the Eaton Supercharger Division. He additionally spent over 10 years at Hendrickson International, where he held numerous senior-level positions in new product development, program management, and sales and marketing. He was vice-president of sales for Pettibone Heavy Equipment Group, a privately held group of heavy equipment companies for five years, prior to joining Manitex at Manitex-Sabre Industrial Tanks and Equipment.

“I am pleased to continue serving our customers, shareholders and employees in this expanded role, and continuing to contribute to the growth of the company,” Kiefer said. “Our market leadership position with Manitex boom trucks and accel-

erating growth of PM in North America makes this a very exciting time for us, particularly given the improvements that are occurring in the construction end-markets. It is imperative that we deliver exceptionally reliable and high-value products every day that are supported by some of the best dealers and employees in the heavy equipment industry.”

Cropac Equipment Inc. announced that it is moving into the British Columbia market. To lead the expansion, the company has hired James Graham of Abbotsford, B.C.

Graham has spent his entire career in various facets of the crane industry.

“James has amassed a strong knowledge base working with many crane types and manufacturers. He started out building swamp pads, progressed to become a journeyman mobile crane operator and then moved into operations and fleet management. James eventually evolved into sales where he has thrived by utilizing an honest, consultative and customer focused approach with his clients and their requirements,” the company stated in a recent release.

The crane dealership already services the crane markets across Eastern Canada and Western Canada through its full service branches in Laval, Que., Oakville, Ont. and Nisku, Alta.

In related news, Cropac Equipment is now the Terex Cranes authorized dealer in B.C. for the complete line of Terex Mobile Cranes and is also the authorized Manitex dealer in B.C.

The address for the company’s B.C. branch will be announced in the near future.

SUBMITTED BY ALL WEST CRANE & RIGGING LTD.

ranes are essential for large-scale construction projects in Canada, providing lifting power that makes the construction of roads, big buildings, and other major projects possible. Crane injuries and deaths happen in unfortunately high numbers each year, and almost all are preventable. Crane truck and crane operators can drastically reduce the likelihood of crane-related injuries by observing some best safety practices recommended by experts.

Canada is currently enjoying a construction boom in many parts of the country, with cranes being a common sight in growing cities around the country. As a result, mobile crane rentals and crane operators are in big demand.

Best safety practices

Safety experts believe the vast majority of crane accidents are caused by human error, meaning that most are preventable. Compliance with government and industry standards will help companies that use cranes avoid injuries to workers or bystanders. Creating a culture of safety on job sites is also important to reducing injuries and deaths. Safety experts recommend these best practices:

• Become familiar with standards for crane use – Crane operators and labourers working around cranes should know relevant OH&S standards for their equipment. For example, regulations require crane operators to set up their cranes on firm ground that has been drained and graded to specifications. The government also requires the use of blocking, pads, and crane mats. By providing your employees with proper safety training regarding OH&S standards and enforcing these standards on the job, employers can avoid accidents and injuries, as well as potential fines for non-compliance.

• Make careful preparations before moving a load – Good planning will help crane operators avoid most problems with their equipment. Before moving a load, crane operators should ensure the load is not heavier than the crane’s maximum capacity. All loose materials that might fall from the load should be removed from it before lifting. Workers should also ensure any slack from slings or hoisting ropes be eliminated prior to the lift. Before starting the lift, an audible alarm or bell should be sounded to advise workers and others to clear the area.

• Smooth and steady – Workers should operate their crane smoothly, avoiding sudden jerky movements. Operators should ensure that nothing catches on the load when it is being raised and that nothing obstructs the movement of the load. The operator should keep the load under control. If the braking system stops working properly, the operator can lower it by reversing the crane’s hoist controller. Crane operators should also take care to follow signals from the slinger in charge of the lift.

• Equipment safety – Make sure the cranes you are using are well-maintained and appropriate for the job. Ensure that important safety features such as emergency disconnects and safety latches on hooks, hoists, and boom angle indicators are present. Also, ensure that the crane you are using is rated to lift more than the load you are lifting. Equipment should be regularly load tested.

• No guesswork – Crane operators need to know the exact load rating for their equipment and that of the load they are lifting. Loads should be rigged with properly sized cable and slings. The use of 3D Lift Plan in the planning of the lifts greatly reduces the margin for error and ensures the safety of the lift.

• Avoid sharp edges – When rigging a load, sharp edges on the load should be padded to avoid damage to the rigging.

• Don’t allow crane loads to pass over street traffic – The possibility of injury to pedestrians or motorists and the consequences of these accidents are too great to chance. If re-routing isn’t feasible, crane operators should, instead, close off streets when loads must pass over streets and pedestrian areas.

• Avoid passing loads over workers – This should go without saying, but it’s important to reiterate. Loads should never pass over workers on the ground. The risk from falling objects is too great.

• Carefully monitor every job – Accidents happen when supervisors aren’t paying attention. Monitor every lift and end the lift at the first sign of trouble. When using large equipment like cranes, there is little margin for error. It’s better to call off a lift and try again later than risk injury to workers, not to mention damage to the crane or equipment.

• Turn the phone off – Mobile phones can be a huge distraction to crane operators. Lifting a load is serious business and requires the full attention of the crane operator. While in the cab, crane operators should turn their phones off and focus only on the task at hand.

• Avoid leaving loads unattended – A qualified person should keep an eye on

the controls at all times when a load is suspended in the air. Lots of things can cause a crane to tip over or a load to fall, so having a competent person at the controls at all times during a lift is important.

• Encourage employees to “follow their gut” – Create a workplace culture where employees feel empowered to point out concerns or problems they may have regarding safety. Also, encourage employees to be vigilant about safety and to stop work until perceived problems are resolved.

Safety lapses carry huge consequences

Failure to maintain good crane safety practices can result in injuries and deaths, and it can also result in huge fines for companies. For example, in 2009, contractors building the rapid transit line in Vancouver were fined more than $315,000 by WorkSafeBC for negligence and safety violations related to the death of a crane operator. The crane operator, a 22-year-old man, was crushed to death after his crane tipped over. WorkSafeBC found that insufficient supervision and training contributed to the accident. The human and financial consequences of crane accidents are very real. That’s why it is important for contractors seeking mobile crane rentals or cranes for sale to purchase their equipment from a reputable dealer that makes after-sale support a priority.

This article was submitted by All West Crane & Rigging, Ltd. The company has more than two decades of experience providing cranes and equipment for hire to clients in British Columbia and Alberta. All West Crane & Rigging recently won BCCSA’s Certificate of Recognition for Health and Safety Management System.

BY ANDREW SNOOK

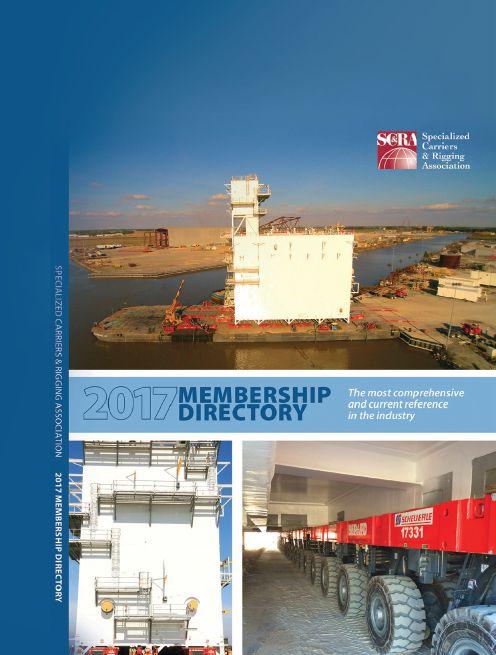

The Specialized Carriers & Rigging Association (SC&RA) drew more than 630 attendees to Kansas City, Mo. for the SC&RA’s 40th annual Crane & Rigging Workshop, which took place at the Sheraton Kansas City Hotel at Crown Center.

Terry Young, SC&RA president (Construction Safety Experts) and Mike Vlaming, chairman of the SC&RA Crane & Rigging Group, welcomed the record-breaking number of attendees to the milestone event.

Vlaming discussed the various natural disasters that recently took place, including the devastating hurricanes in the U.S. and his pride that the industry took a significant role in helping rebuild communities affected by the natural disasters.

“I don’t know about you, but I take great pride in the knowledge that it is our industry that stood poised and ready,” he told the crowd.

Attendees were treated to variety of education sessions tackling topics such as electronic logging devices (ELDs); wire rope challenges for crawler cranes; the physics of a move; virtual and augmented reality related to the future of work; litigation preparation; crane matting; lift director qualifications; and below the hook lifting.

The workshop also featured open houses of Versa-Lift’s forklift manufacturing and WireCo WorldGroup’s wire rope production facilities; the 2017 Rigging Jobs of the Year; a trade show featuring 90 exhibitors; and special presentations by keynote speakers Dewey Bozella, the 2011 Arthur Ashe Courage Award Winner and Stephen Sandherr, CEO of the Associated General Contractors of America, on the future of America’s infrastructure.

The 2018 edition of the SC&RA Crane & Rigging Workshop will take place from Sept. 26 to 28, 2018 at the Louisville Marriott Downtown in Louisville, Ky.

featured 90 exhibiting companies from the industry including manufacturers, software and training providers, insurance representatives and media.

Attendees battle for top spot during the PuttPutt Challenge, which took place at the SC&RA Exhibit Center.

SC&RA workshop attendees watch what not to do during session, “Unbreakable laws: Physics of a move,” presented by Hydra-Slide president

The Crane Rental Association of Canada’s Conference is scheduled for June 6 to 9, 2018 at The Fort Garry Hotel in Winnipeg, Man. The 2018 CRAC Conference will include technical presentations, keynote speakers and proceedings. Abstracts for this national conference are being sought now for presentations to be offered at the event.

CRAC 2018 will feature technologies from manufacturers that help the mobile crane industry to compete more effectively in today’s global market.

The CRAC technical program promotes the transfer of knowledge by providing a national forum for presenters to share ideas, experiences and knowledge of the industry. Members are invited to submit an abstract for consideration.

CRAC Conference programs are developed by Selection Committee members representing crane rental companies and their associated suppliers.

Presentations and best practices on any of the following topics:

• Health and safety

• Environmental

• Computer applications

• Project and construction management

• Material handling

• Cranes

• Transportation and logistics

Presentation submittal deadline: October 31, 2017

The first step is to submit an abstract for the Selection Committee to review. The subject matter should be of current interest to those in the crane industry and should present new developments, methods or applications. Please limit your abstract to 100 words and include the following information:

• Title

• Contact

• Company affiliation

• Complete mailing address

• Phone

Letter of invitation to selected presenters: December 15, 2017

If your abstract is selected, CRAC will send you a formal letter of invitation. This letter contains necessary information, including registration requirements for accepted paper. If your abstract is not initially selected, we will retain it in case of cancellations in the program.

Final presenter acceptance: January 5, 2018

To verify your acceptance and commitment to present, we require a response to our letter of invitation.

Presenter conference registration deadline: April 30, 2018

This is the final date for presenters to register for the full conference in order to present at the conference.

Presentation draft due: March 15, 2018

A total of 30 minutes is allotted for each presentation. (20 min. plus 10 min. for Q&A).

BY ANDREW SNOOK

uring the Crane Rental Association of Canada’s (CRAC) 2017 annual general meeting this past June, Ted Redmond was named the new chairman of CRAC.

Redmond is the president and CEO of NCSG Crane & Heavy Haul Services Ltd. based out of Acheson, Alta. NCSG is a large lifting and specialized transportation solutions provider that offers crane and heavy haul services to various industries such as oil and gas, utilities, forestry, mining and wind energy. The company has more than 1,000 employees and currently serves Alberta, Saskatchewan, B.C., Manitoba, and the Northwest Territories in Canada; and the Montana, Idaho, North Dakota, Utah, Wyoming, Washington, Oregon, Louisiana, and Texas markets in the U.S.

To learn more about the new chairman, Crane & Hoist Canada caught up with Redmond to learn about how he got into the industry and to learn more about his plans as the new CRAC chairman.

Industry introduction

Redmond was introduced to the industry a little over seven years ago while working with customers at an energy and utilities business.

“I ran a number of companies in the energy services space,” Redmond says. “NCSG’s investor group was looking for a CEO and I was approached to join the company… it looked like a really interesting business. We basically build and move the world in the crane and heavy haul business. You do lots of cool and interesting things so I thought it would be a really interesting industry to get involved in.”

Since heading up NCSG, Redmond has dedicated a great deal of his time to expanding his knowledge base about the crane industry.

“Luckily we’ve had great, experienced managers and employees at NCSG that helped me learn the business,” Redmond says.

And NCSG has definitely benefitted from Redmond coming on board. The company has grown substantially under his leadership.

“When I first joined the company we were doing about $120 million in revenue, now we do about $300 million,” he says. “We’ve made acquisitions, significantly grown the business and gone from seven branches [when he was first hired] to about 25 branches today. It’s probably about a 20 per cent compound annual growth of the business.”

CRAC relationship

Redmond got involved with the CRAC shortly after coming into the industry.

“When I first got into the business I wanted to get to know people in the industry. It’s a very close industry and people are very

friendly and helpful; getting involved with the industry association was something I thought would be a good idea,” he recalls. “At the time Dean Schmied was on the board of CRAC [a former vice-president at NCSG] and he encouraged me to get involved… so I started going to the meetings. When Dean finished serving his board term in 2013 he got me involved on the board.”

Redmond has continued serving on the CRAC board since that time, and was nominated two years ago to go through the executive roles on the board.

“CRAC is a great organization,” he says. “We’ve got members from all over the country, from large crane companies to small crane companies. We’ve got all the suppliers involved as well, so there are lots of educational learning opportunities. It’s been a great organization to be involved in and has helped me learn a lot about the crane industry.”

As chairman of the CRAC, Redmond plans on continuing to grow the value of the association for its members.

“The key initiative we’re working on as the executive and with Claire [BélangerParker] is to keep finding ways to add value to our members,” he says. “This year we’ve introduced the safety award program so that the companies with a total recordable incident rate under 1.75 can apply for a safety award and they’ll get a certificate and logo to put on their website showing that they’re one of the safest crane companies in Canada.”

The CRAC has also formed a committee to work on making boom dollies easier to use.

“We’ve also tried to increase the amount of educational content at our annual meeting,” Redmond adds. “It’s all about how we can give our members more benefits and more services – things that they can take back and use to grow their business. We want to add more content and more value while maintaining all the networking opportunities.” For

The temperature outside wasn’t the only thing running hot in early October in Louisville, Ky. Attendees and exhibitors at ICUEE – the International Construction and Utility Equipment Exposition - agreed that the show exceeded their expectations with specialized exhibits, hands-on test drives, interactive product demonstrations and lots of activity and leads in the booths.

Commencing Oct. 3 to 5, the 2017 installment of the Demo Expo was the largest in the show’s history with 28-plus acres of exhibits (nearly 1.24 million net square feet) of the latest utility and construction equipment, products and technologies and more than 1,000 exhibitors, of which 25 per cent were new to the show.

Tracking close to the 2015 recordbreaking attendance, nearly 18,000 registered attendees from all 50 U.S. states and more than 50 other countries worldwide perused the exhibits, raised money for the Red Cross Disaster Relief and the Call of Duty Endowment, and took advantage of all that the show had to offer. Attendee demographics in the utilities category was up six per cent over 2015 and the utility construction category was up three per cent over 2015 totals.

“We had a great turnout and participation at ICUEE 2017,” said Rick Rodier, vice-president, Sitework Systems Division of The Toro Company and 2017 ICUEE chair. “It was inspiring to see the enthusiasm of so many utility and construction professionals networking and sharing ideas, and finding the product innovations and solutions that will help them grow their businesses.”

Exhibits and equipment “Test Runs”

ICUEE 2017 featured specialized exhibit pavilions for fleet management, safety and green utilities, Chinese and Korean exhibit pavilions, and the Lift Safety Zone from the National Commission for the Certification of Crane Operators (NCCCO).

Hands-on equipment test drives and interactive product demonstrations included a two-mile Test Drive Zone for on-road equipment and technologies.

Over the roar of the Super Witch, a demo vehicle with an 850 horse power 502 Chevy Engine, Tucker Dotson, Ditch Witch regional sales manager for the Eastern United States, shared that the show has been going great for the enduring ICUEE exhibitor.

“Telecom is hot and it’s a big deal for us to be here at ICUEE,” said Dotson. “We’ve been coming to the show since its inception and 2017 has proven to be another great show for Ditch Witch. It’s been steady in the booth and it’s a great opportunity for us to meet with customers and prospects and show our equipment in one location.”

Liz Kendrick, project sales manager for Man Lift, a new exhibitor to ICUEE, echoed Dotson’s comments.

“We are looking to make our mark in the industry and shows like ICUEE help us do that,” said Kendrick. “We couldn’t be happier with the experience. Our president came down in 2015 to walk the show and at that point we knew this was the way to go to get out to market.

We’re busy and we’re very happy with the results.”

Representatives from Ditch Witch and Man Lift said they plan to return to the next ICUEE, in 2019.

ICUEE 2017 education focused on utility and construction “hot topics” presented by industry experts to help attendees enhance their safety knowledge, increase efficiencies and reduce downtime on the job.

New Field Classroom sessions highlighted industry best practices first hand with equipment on the show floor, and the indoor ICUEE Demo Stage expanded the show’s outdoor equipment demo component with more product innovations in action.

Another new feature, ‘Tomorrow’s Topics Today’ sessions from show owner and producer Association of Equipment Manufacturers (AEM), explored industry trends and emerging technologies.

Rounding out ICUEE 2017 education were popular returning programs: the iP Utility Safety Conference and Utility Fleet Conference plus industry certifications.

In response to the unusual number of natural disasters, a new ‘Disasters Taskforce: Preparing for What’s Next’ program tackled disaster preparedness in the aftermath of the current hurricane season, with a former FEMA advisor.

Gretchen Bakke, author of ‘The Grid: The Fraying Wires Between Americans and Our Energy Future’ was the featured speaker in the new ‘Diversity in the Grid’ luncheon brought to you in partnership with Terex Utilities and AEM.

The ICUEE Industry ‘Give-Back’ Auction returned with the goal of connecting military veterans with quality jobs. All proceeds again went to the Call of Duty Endowment, the nonprofit organization founded by Bobby Kotick, CEO of Activision Blizzard. The auction, plus onsite donations, to benefit the organization raised over $37,000.

The endowment helps military veterans secure high-quality employment and works to raise awareness of the value vets bring to the workplace.

A new “Discover ICUEE” walking tour before show opening offered a behind-thescenes look at the exhibition, and ICUEE 2017 closed with an enhanced ‘Bourbon, Beer & Bites’ networking reception.

The biennial ICUEE is also known as The Demo Expo and is the leading event for utility professionals and construction contractors seeking comprehensive insights into the latest industry technologies, innovations and trends, owned and produced by the Association of Equipment Manufacturers (AEM).

escribing the Ram Power Wagon as “new” is peculiar; even though the 2017 model is just that. This truck’s basic design is over 70 years old. Mind you the terrain it’s meant to conquer is much older than that; so in this case the “new” is irrelevant.

The Power Wagon is unique in that it’s a specialized pickup truck right out of the factory, versus trucks being modified by upfitters across the country. For many “off-road” industries it’s often the perfect fit right off the dealer’s lot.

The Power Wagon is a product of the Second World War. More than 255,000 of these 3/4-ton 4x4 trucks saw service. These trucks were so successful at navigating European and Pacific battlefields that after the war Dodge engineers used this truck as the basis for their civilian Power Wagon models. Introduced in 1946 with a new cab and a purpose built 8-foot cargo box, it rode on a 126-inch wheelbase chassis and featured a 230 cubic-inch flat head six-cylinder engine, a two-speed transfer case, a four speed transmission and also had power take off (PTO) capability to operate auxiliary equipment. It was produced (with very little change) till 1968 when new light-duty truck safety regulations in the United States made the almost 30-year old cab obsolete; though production for export

continued for almost another decade. Of note for collectors, in 1966 a short-lived Crew Cab model was added – now those are rare.

Fast-forward to 2005 at Chrysler’s Chelsea proving grounds in Michigan where an earthen presentation podium blows apart to reveal a new Dodge Ram Power Wagon. It roared out onto the presentation carpet covered in dirt and sporting a name that hadn’t been riveted to

a Dodge fender in over 25 years. This was the rebirth of the modern Power Wagon. Since then it has dropped the Dodge name – it’s now part of the Ram standalone brand – but the purpose of this HD truck remains the same – go where no other factory built truck dares.

A Power Wagon starts with a stock 2500 series HD frame. Ram then adds locking front and rear differentials, twospeed transfer case, an electronically disconnecting sway bar, high-pressure Bilstein monotube shocks, heavy front and rear springs, skid plates and underbody protection, special 33-inch off-road tires, an integrated 12,000 lb. electric winch and, of course, increased ride height.

For 2017 the standard engine is a 6.4L V8 Hemi that makes 410 hp and a peak torque of 429 lb-ft. A unique feature of this engine is an electronic calibration that softens the throttle response when in 4WD-low, yet raises the idle speed by 100rpm to increase low-end torque.

Driving this truck through the Nevada desert inspired an almost reckless confidence in my ability to climb obstacles that would make a goat sweat. Even through the soft sand the aggressive tread of tires floated the truck, though that’s when I appreciated the 6.4L’s torque that churned out of these traps. Sharp rises and deep gulleys didn’t impede the truck either; its height (14.3-inches of clearance) and steep approach (33.6 degrees) and departure (26.2 degrees) angles prevented hang-ups. Then again, that’s why it does have an integrated front mounted winch and massive tow hooks.

After pushing the truck through worsening dry washes, I was thinking I couldn’t find a spot that would get it stuck. I’m sure there was one but I never did find it. However, a word of caution, just don’t drive it fast! Unlike the Ford Raptor, which is designed to cover rough terrain quickly, the suspension on the Power Wagon is setup for slow and steady – at speed it’s rough. But then speed is not its purpose; this stiff setup lets it climb steep, jumbled rocks with a surefooted ease; while carrying a crew and substantial payload. Hence, the reason it’s a favourite of forestry and fire services throughout North America. It features a payload of 1,510 lb. and a tow rating of 10,030 lb.

During our off-road drive (in a publiclands designated off-roading area of the desert) the only other vehicles we met with were heavily modified Jeeps and ATV’s. It’s a compliment to the Power Wagon’s engineering that it can keep up to this company off-road; yet at the end of the dusty day it drives home, comfortably, on the highway.

So, while the core engineering of this truck changes little over the years, there are new esthetics and comfort features.

For instance, a selection of standard and optional equipment includes: power folding mirrors and power rear-sliding window with defrost. Also, one-touch, central locking includes the RamBox cargo management system and tailgate. Power seats, heated wheel, backup camera, dualzone HVAC, nine Alpine speakers and satellite with Bluetooth are other options. Spray-in bedliner, LED bed lighting, front and rear park-assist system, poweradjustable pedals and remote start are also available.

The 2017 Ram Power Wagon shows off its “ultimate off-road truck” claim with a new exterior design that incorporates styling cues found in the Ram 1500 Rebel. This starts with prominent silver “RAM” letter badge. Surrounded by a blackedout grille it’s bookended by bi-functional projector headlamps with LED marker lights. The domed vent-stamped hood sports a Gloss Black graphic.

In fact the entire truck shows very little chrome. Instead primary colour schemes are set off with front and rear bumpers that are matt-coloured and powder coated. The exception is the 17-inch forged, multisurface aluminum wheels with Silver outer and Matte Black inners.

The blacked-out theme continues on the flanks, where wheel-arch mouldings, badges, mirrors and lower body panels create a distinctive appearance. At the rear a 324-point bold original font “RAM,” is stamped into the tailgate with blacked-out lettering. A black “Power Wagon” decal crosses the bottom of the tailgate. With this package there will be no question of what you’re driving.

From what I saw in Nevada, today’s Power Wagon is also following the current pickup trend of packing more and more upscale content into trucks. That’s fine for many buyers, however it should be noted for those that value ability more than luxury Ram does offer the Power Wagon as a base Tradesman Crew Cab 4x4 model. Although this option does not include the same interior and exterior design elements, it does include the same unique off-road equipment, including the winch, lockers, larger tires, electronic disconnecting sway bar, suspension and under-body armor. Monotone paint covers this package. The grille-surround and inserts are from the Tradesman model and are colored Black as are the headlamp filler panels and wheel flares.

The 2017 Power Wagon pricing starts at $58,945. A leather and luxury option package can be added for $4,995. These trucks are available at dealers now.

iebherr USA, Co. continues its expansion in the U.S., with the opening of its newest location in Lodi, Calif. to better service customers in the western region. The Lodi facility operations will include sales, service and repair of new and used mobile, duty cycle and lift version crawler cranes, as well as piling and drilling rigs.

The new Lodi branch will bring Liebherr equipment specialists closer to existing customers and provide localized service to customers in the western region. It is located at 880 South Beckman Road, Lodi California; and will serve as a hub to provide technical assistance, field service, yard storage for consignment cranes, stock and replenish parts, perform equipment repairs, stock inventory for sale and deploy rental fleets. The new facility includes service bays, a warehouse and office building. Liebherr USA will have two divisions operating out of the Lodi facility, Mobile and Crawler Cranes and the Crawler Cranes and Foundation Equipment divisions. This cooperation will derive further advantages to Liebherr crane customers in the western region of the United States, enhancing the level of customer service and product support, and offering a greater selection of cranes.

The facility in Lodi is located in California’s Central Valley, about 84 miles east of San Francisco and about 36 miles south

owa Mold Tooling Co., Inc., an Oshkosh Corporation company, recently introduced four new articulating crane models and revisions to its current articulating crane lineup.

“After evaluating the market, we developed four new articulating crane models to meet the growing lifting demands of our customers,” said John Field, articulating crane product manager at IMT. “We also increased lifting capacity on current radio-remote articulating crane models to improve upon the high-performance and economical lifting solutions the IMT crane line offers.”

New models include the 610, 710, 810 and 910. The four new models will replace the 5/33, 6/39 and 7/48 articulating models in the IMT portfolio. The new articulating cranes offer versatile increased lifting capacities in the 40,000 ft.-lb. to 70,000 ft.lb. range. The new models share the same features offered on all IMT articulating cranes, such as over-bending, which ensures the working area between the main boom and the jib is no less than 195°.

Also available on the new cranes is the Electronic Vehicle Stability (EVS) system. Implemented to prioritize operator safety, EVS monitors the crane stability and warns the operator when the tilt of the truck’s chassis approaches a pre-set angle. The EVS system integrates with the Rated Capacity Limiter (RCL), a key safety component that monitors the crane’s load

moment, operation and function. Together, the EVS and the RCL create an integrated system that ensures truck stability, so the crane can be used at available capacity in any vehicle setup — without jeopardizing safety. Additional new features include internal hose routing, the “j” stow hook and improved lift to weight ratio on all models.

“Between the increased lifting capabilities and the EVS and RCL, customers can maximize their productivity without worrying about safety — the system monitors what is happening for them,” said Field.

“These new models will significantly impact the productivity capabilities of operators.”

of Sacramento. In terms of logistics, this allows Liebherr to respond to customer inquiries quicker and accelerate the distribution of parts and services in this region.

“A lot of effort and dedication went into preparing this location for success. The Lodi branch will tremendously improve our abilities to service and support our local customers in their respective time zone,” says Tobias Haemmerle, divisional director of Liebherr USA, Co. Crawler Cranes and Foundation Equipment Division.

The opening of the Lodi location and the joint venture with the Mobile and Crawler Cranes and the Crawler Cranes and Foundation Equipment Division is the latest development in support of the manufacturer’s rapid growth in the U.S. under the newly formed mixed sales organization and a benefit to Liebherr customers. This allows Liebherr USA, Co. to support the company’s overall goal to strengthen customer support and equipment distribution across the United States. The new location had a small opening ceremony on Tuesday, September 12, 2017.

Liebherr USA, Co. Crawler Cranes and Foundation Equipment division in Lodi will offer a product range of crawler cranes, duty-cycle crawler cranes, piling and drilling rigs as well as attachments, such as rotary drives, hammers and vibrators. The Mobile and Crawler Cranes division will offer a wide range of mobile cranes with telescoping or lattice booms on wheeled or crawler-tracked undercarriages. These cranes are powerful, maneuverable and feature ultramodern technology that satisfies combined road and off-road operating requirements on construction sites of all kinds. They range from 40 US ton to 3,000 US ton.

Fulford Log Books & Manuals: Resources to make your work better

Fulford Logbooks combine National Safety Code and Provincial and State inspection requirements into one book with mechanics’ repair tracking sheets. They are customized to most jurisdictions in Canada. USA states coming soon.

“Where have you been hiding these? These logbooks are so good our operators actually want to use them!”

Fulford Manuals give you the technical information you need to improve your and your team’s rigging competence. Rigging Manual, Marine Pedestal Mount and Overhead Crane Manuals available.

Part of a complete training solution for you to use in-house to increase the skill of your people.

adano has extended its product range with the GR-1200XL/GR-1100EX, its largest two-axle rough terrain crane in their rough terrain crane line-up. The crane boasts a maximum lifting capacity of 120 US tons (110 metric tons), and a boom measuring 183.7 feet (56m).

This product was developed specifically for North America for industrial, commercial and energy sites applications. These construction and maintenance sites require high maneuverability, durability, and lifting performance under tough conditions. In addition, there is a need for cranes in the 100 US ton - class to have higher reach capabilities, longer boom lengths and larger lifting capacities. To meet these kinds of customer demands, Tadano has developed the GR-1200XL/1100EX to be both compact and high performing.

(several locations) and Montreal, QC.

Education and Certification Secondary School required.

Hosting Engineer - Mobile Crane Operator Branch 1 and 2 required.

Skills and Experience

Qualified candidates must have experience (more than 10 years) instructing managers and supervisor on the regulations and set-up of lifting equipment and on routine maintenance work, and experience instructing operators and apprentices on hoisting and jacking equipment.

While working as an operator the candidate must be able to set-up and operate foundation equipment cranes with pile driving or drilling equipment from American, Ohio, Terex, Manitowoc, Grove, Link Belt. The Instructor/Operator must have experience with tandem lifting of large vessels including bridge spans, experience working with cranes on barges sitting in fresh and salt water for setting bridge spans, and must have a strong mathematical background.

The GR-1200XL/GR-1100EX has the largest maximum lifting capacity in Tadano’s two-axle rough terrain crane product line. It has a strong and light high tensile steel formed boom that features a single telescopic cylinder. The crane has a 184-foot (56.1m) lifting height and a maximum 144.3-foot (44.0m) working load radius. Extra reach is provided by a jib, which extends the lifting height to 241.4 feet (73.6m), with a boom only load radius reaching to 153.8 feet (46.9m).

The GR-1200XL has a compact carrier with a similar size as Tadano’s GR1000XL. This compactness provides high maneuverability and transportability. With conventional cranes, outriggers extended to their maximum length provide uniform, circular rated load capacity footprint over 360° of slewing angle. However, thanks to Tadano’s newly developed Smart Chart, a safety device and control system, the crane can achieve a square-shaped rated load capacity footprint, with extended “corners” over the outriggers that increase the load radius depending on the degree to which the outriggers are extended.

The GR-1200XL comes equipped with Tadano’s state-of-the-art fuel monitoring system; Eco-Mode, which reduces fuel consumption when the crane is being operated; and positive control, which reduces fuel consumption when the crane is on standby.

Using Hello-Net telematics, customers can monitor their crane activity, work history, machine position data, and maintenance information with computers and mobile devices.

Ben-Mor recently announced that it has acquired two companies in the rigging and lifting industry: Saturn Industries Ltd. and Roughrider Rigging. e acquisitions, which became o cial as of Sept. 30, 2017, will allow Ben-Mor to expand its range of specialized lifting equipment with exclusive products. Saturn Industries is located in Winnipeg and Roughrider Rigging is located in Regina and Saskatoon. Saturn Industries is also specialized in the manufacturing of custom trailers. e two companies combined employ 50 people. Ben-Mor stated that things will be “business as usual” and that the two companies will continue to operate independently. www.saturnind.com www.rrrigging.com

ombining a great look with productivity and comfort in a single product is not normally a simple task, especially when it comes to construction machinery. However, the new CUBE cab in Linden Comansa’s tower cranes combines these three qualities, while bearing in mind that the cab is a work space and, as such, productivity should always be the No. 1 requirement.

Proper visibility of the site and the working area is assured from the front of the crane’s CUBE cab, all of which is made of glass, not only at the front but also on the sides and at the floor, and even at the roof when installed in luffing jib cranes. Thanks to the optimum visibility of the load and working area, the crane operator has greater control over the operations and the surrounding area, which also means greater safety.

In terms of the external appearance, the aim is a modern and innovative design that gives Linden Comansa’s cranes a distinctive look. Inside, all of the elements have been designed to convey warmth and comfort to the user, through their materials and good quality finishes.

The cube-shaped design of the cab with flat glass panes not only looks good, it also aims to make maximum use of the space, which is not possible with curved front panels or tilted windows. Thanks to this cube design, all of the elements of the cabin are distributed in a more intelligent way and there is extra space for operator ergonomics, and there is even room to comfortably fit a second person in the largest cab.

Linden Comansa’s cranes are operated across the world, so the design of the CUBE cab has taken into account extreme thermal requirements, both hot and cold. Facili-

tating maintenance was also one of the goals during the design of this work space. As a result, the window panes are easy to replace when necessary and they can be bought anywhere in the world as they do not require a mould.

The new cab will be available in two sizes, L and XL, and it comes as standard with most Linden Comansa cranes. The smaller range, i.e. the 11LC132 and 11LC90 models and the models from the LC500 range, will be keeping the current, smaller cab for now. The new L and

XL cabs are slightly bigger than the current ones, so they cannot be installed on tower cranes that have already been delivered.

Linden Comansa’s new CUBE cab offers users a number of ergonomic benefits including: complete visibility of the working area; optimal access to the digital indicators and the multifunction touchscreen; improved positioning of the seat; and improved posture for the crane operator.

The ALL Family of Companies has strengthened its fleet by adding two versatile Manitowoc MLC650 crawler cranes, as well as four new Grove GRT8100 rough terrain cranes.

The large capacity MLC650 has a 717-ton (U.S.) capacity and features the Variable Position Counterweight (VPC) technology that automatically positions the crane’s counterweight to match lifting demands. ALL went in big with VPC technology in 2014 when it purchased 10 of the smaller MLC300s, battle-testing the then-new technology and acting as an incubator for improvements. Because the counterweight is movable as needed, VPC helps reduce the crane’s operating footprint, minimizes required job site ground preparation, and reduces often by as much as half the matting required to distribute the crane’s weight. In all, these reductions could save potentially thousands of dollars per month on longer-term rentals.

The MLC650 strengthen ALL’s fleet in critical industries, especially for energy-related projects, including refineries, petrochemical installations, and power plants, as well as infrastructure applications. The smaller footprint plus the VPC system enable the cranes

to easily move around a job site, and a VPC-MAX capacity enhancing attachment allows increased capacity for heavy lifts that would usually require a wheeled-type lift enhancer. The MLC650 maximum capacity increases to 770 tons (U.S.) with the VPC-MAX installed.

The Grove GRT8100, meanwhile, was designed with input from crane owners and operators to incorporate some of the most-requested features for a rough terrain crane. Built for today’s market, it features 100 USt capacity and a 154-foot, five-section, full-power Megaform main boom with sequenced, synchronized extension capability. This reach and versatility combines with a user-friendly interface, tilting cab, impressive load charts, and extensive component testing to offer unparalleled productivity.

“The addition of these machines demonstrates our continued commitment to putting the right equipment in the hands of our customers,” said Rick Mikut, crawler crane division manager for the ALL Family of Companies. “Although meant for very different jobs, what these two cranes have in common is versatility. It’s what today’s jobsites demand, and ALL is responding to that reality.”

Terex Cranes recently introduced the newest addition to its growing tower crane family, the Terex CTT 472-20 flat top tower crane. This new Terex 20-tonne (22-U.S.-ton) class crane expands maximum jib length to 80 metres (262.5 ft.) and increases load charts over previous models offering the same lift capacity on the whole jib length, with a maximum load at the full length of the jib tip of 4 tonnes (4.4 U.S. tons).

“Fresh off the introduction of our new hammerhead tower crane at CONEXPOCON/AGG, we offer our customers the new CTT 472-20, an extremely versatile and robust flat top tower crane with great features requested by our customers. The CTT 472-20 gives the market a flexible solution to meet complex lifting challenges,” says Marco Gentilini, vice-president and general manager for Terex Tower Cranes. “With Terex fully committed to the tower crane business, we are accelerating new tower crane product development to meet our customers’ needs. This includes a new tower crane cabin that will advance operating efficiency and comfort for our new CTT 472-20 crane.”

Offering a 470 ton-meter load moment, the new CTT 472-20 crane delivers extremely high lift capacities throughout its load chart and 11 different jib configurations from 30m to 80m (98.4 to 262.5 ft.) to meet varying jobsite needs. Its hoist, slewing and trolley speeds allow operators to quickly and precisely move and position heavy loads. All jib sections come preassembled with a life line for quick, safe installation at height, while galvanized jib walkways deliver long-lasting quality.

The CTT 472-20 can be configured with H20, HD23 and TS212 Terex mast section or thanks to the transfer masts with the combination of them. “Here, Terex offers superior value for the customer, as

onecranes Training Institute has raised the level of its game in a major way with a move from the original location of 43 years to a new 13,000-square-foot facility adjacent to Konecranes service branch in New Berlin, Wis. Konecranes also has its nuclear and modernization groups located nearby.

According to general manager Jim Lang, the new campus represents the next generation of technical capability for an organization that trains more than 10,000 crane professionals every year. Improving safety at customer facilities is at the forefront of the curriculum at Konecranes Training Institute.