PROTECT ELECTRICAL EQUIPMENT FROM DISRUPTION

OPTIMIZE BELT AND CHAIN DRIVE LIFE

KPI QUIZ - A PULLOUT POSTER FOR TRACKING EFFECTIVENESS

HOW MISALIGNED EQUIPMENT HINDER RELIABILITY

DRONES TAKE OVER PLANT INSPECTIONS

PROTECT ELECTRICAL EQUIPMENT FROM DISRUPTION

OPTIMIZE BELT AND CHAIN DRIVE LIFE

KPI QUIZ - A PULLOUT POSTER FOR TRACKING EFFECTIVENESS

HOW MISALIGNED EQUIPMENT HINDER RELIABILITY

DRONES TAKE OVER PLANT INSPECTIONS

When Dodge® created the Type E bearing in 1943, it quickly became the industry standard. And, after 74 years of improving and expanding the Type E, it has become the most widely used, reliable industrial bearing in the world.

Designed with innovative features to improve bearing life, reduce maintenance costs and simplify installation, our Type E family of bearings meets the needs for the most rugged, wet and dusty applications and environments. When you choose genuine Dodge Type E bearings you’ve chosen the original, unequaled bearing in the industry.

baldor.com 479-646-4711

• Introduced in 1943

• Proudly Manufactured in Marion, NC and Rogersville, TN

• Complete Inventory, Sales and Support

• Reliable and Safe for the Toughest Environments

SEPTEMBER 2017

Volume 33, No. 4

Established 1985 www.mromagazine.com www.twitter.com/mromagazine

Rehana Begg, Editor 416-510-6851 rbegg@annexweb.com

Contributors

Philip Chow, L.(Tex) Leugner, Douglas Martin, Jonathan Mosterd, Peter Phillips, Jeff Smith, Matthew Walker

Jim Petsis, Publisher 416-510-6842 jpetsis@mromagazine.com

Jay Armstrong, Sales Manager 416-510-6803 jarmstrong@mromagazine.com

Mark Ryan, Art Director

Tracey Hanson, Account Coordinator 416-510-6762

Beata Olechnowicz, Circulation Manager 416-442-5600 x3543 bolechnowicz@annexbizmedia.com

Tim Dimopoulos, Vice-President tdimopoulos@annexbizmedia.com

Ted Markle, COO tmarkle@annexweb.com

Mike Fredericks, President & CEO

Machinery & Equipment MRO is published by Annex Business

Media, 80 Valleybrook Dr., Toronto, ON Canada M3B 2S9; Tel. 416-442-5600, Fax 416-510-5140. Toll-free: 1-800-268-7742 in Canada, 1-800-387-0273 in the USA.

Printed in Canada

ISSN 0831-8603 (print); ISSN 1923-3698 (digital)

PUBLICATION MAIL AGREEMENT #40065710

CIRCULATION

email: blao@annexbizmedia.com

Tel: 416.442.5600 ext 3552

Fax: 416.510.5170

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

Subscription rates.

Canada: 1 year $61.50, 2 years $97.95. United States: 1 year $105. Elsewhere: 1 year $120 Single copies $10 (Canada), $16.50 (U.S.), $21.50 (other). Add applicable taxes to all rates.

On occasion, our subscription list is made available to organizations whose products or services may be of interest to our readers. If you would prefer not to receive such information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

privacy@annexbizmedia.com, 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2017 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

To be an expert one must master the basics. That’s the mantra we use when we decide whether an article is topical and fits with our maintenance and reliability focus. Whether we’re reporting on breakthrough technologies, or publishing democratized ideas for business and processes, we’re constantly taking stock so we can reinforce our competence at helping manufacturing leaders deliver greater maintenance effectiveness.

And while we’re confident in our position to bring best-in-class information to subscribers, the search for model maintenance case studies can conceivably distort the view of what actually happens in the field. Along with the incentive to be an authoritative voice comes the constraint to consider current practices (as opposed to best practices) and to acknowledge that not all maintenance departments measure the state of their maintenance practices with the same rigour.

This reality is made clear in this issue’s Maintenance 101 column (page 30) in which contributor Peter Phillips describes the frequency with which he has observed slipshod levels of cleanliness at various plants. He shares real-world photographs and notes that the issue is affecting tradespeople and supervisors alike. The problem raises red flags because poor housekeeping practices in maintenance shops add labour hours, and contaminate components and assemblies even before they reach the machinery they need to be installed on.

Regardless of the level of maturity of a plant’s maintenance program, maintenance work should remove the risk of failure from the plant (including equipment, people and processes). Between the extremes of world-class maintenance and passable performance, maintenance leaders need to set benchmarks against realistic goals.

A good place to start is to research maintenance performance values and follow through by setting key performance indicators that are both relevant and sensible for the circumstances.

Get the ball rolling by checking out our maintenance quiz (“Lead or Lag,” page 24). Contributor L. (Tex) Leugner has conveniently isolated useful maintenance KPIs and explains the logic behind each value. Presented in the centre of the book, the quiz is a nifty tool that can be detached and shared with colleagues. Post it on noticeboards, make copies for teammates and share it at the next association meeting.

Then, build momentum into your efficiency program by reading how next-level technologies are shaping the future of plant inspections. Our feature on drones (“Take to the Sky,” page 36) takes a look at how unmanned aerial vehicles (UAVs) are making inroads in industrial markets. Armed with sensors and data integration technology, drones are a game-changer for uncovering cost efficiencies.

Keep in mind, however, that while adopting new technology is an advantage and essential in the current landscape, it’s not a magic bullet. Whether your plant’s maintenance effort teeters between basic cleanups and embracing change through disruptive innovation, you’re only as effective as your ability to perform basic tasks that are fundamental to the skill.

SKF Certified Rebuilder

Facing another repair? Go from continual Repair to constant reliability with one of SKF’s Certified Rebuilder’s.

Motors are among the highest in reliability incident reports. 40% to 70% of motor failures are related to bearings. For many companies, that leads to a continual cycle of costly repairs and unplanned downtime.

How parts in the motor are installed, lubricated, handled, stored, aligned, transported, and maintained is of critical importance. Trust a SKF Certified Rebuilder to keep your equipment running at the highest level.

» Pumps

80% of pump failures relate to bearings and mechanical seals. A thorough understanding of what it takes to maintain industrial pump system performance is vital. SKF’s Certified Rebuilder’s are trained to repair to the highest standards.

» Large Gearbox

SKF is specialized in repair and refurbishment of large gearboxes –350 hp and above. Make your gearbox perform like new –or even better! SKF takes a systems approach, drawing on knowledge developed from designing bearing systems for all types of rotating equipment for many OEMs and our expertise in bearings, gears, seals and lubrication.

Why scrap large bearings unless you really have to?

Bearing service life can often be significantly extended by SKF’s proprietary process in our Canadian facility. In fact, a bearing with only 30% left of its calculated service life can be worth remanufacturing.

» Large Gears

SKF can help you with any gearing issue which will assist to streamline production, shorten time-to-market, increase torque, decrease operating temperatures and reduce noise levels. Ring gears, gear wheels or even larger applications up to 8 meter outside diameter are manufactured from high quality alloy steel or casting material. Gear design verification, and eventually upgrade, is done when a new gear pair is manufactured.

For all these services contact your SKF Authorized Distributor

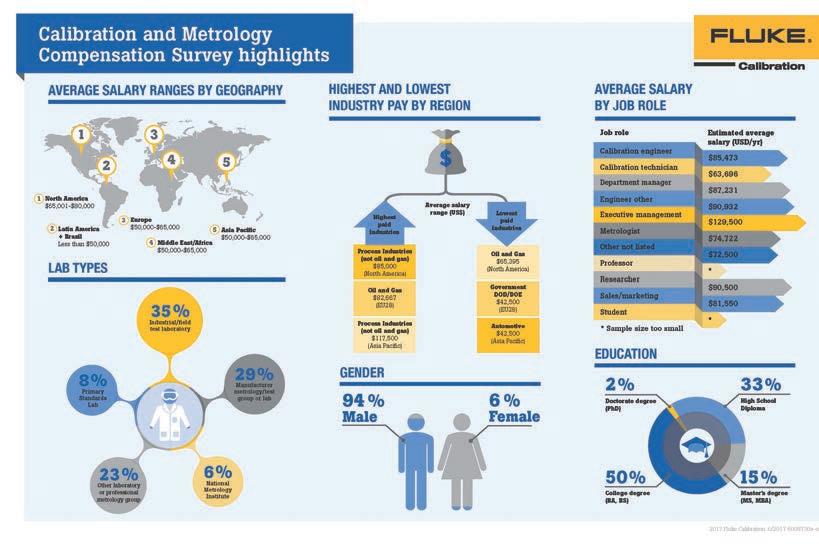

Everett, Wash. – Fluke Calibration released the results of its first annual Calibration and Metrology Compensation Survey. Data collected in this survey shows median annual base salary information across multiple industries and disciplines in the field of metrology and how those incomes differ between educational backgrounds, gender, years of service, job titles, and more. The largest cohort (35 per cent) reported that they work in an Industrial or Field Test Laboratory. Canadian respondents earned an average salary of $62K.

Read the results at http://us.flukecal.com/metrology-compensation-survey.

Mississauga, ON – FLO Components Ltd. is celebrating its 40th Anniversary with a Giveaway Contest.

The company is giving away three lubrication product packages to lucky LinkedIn users over three draw periods. Participants who enter in the earlier draw periods are

automatically entered in subsequent draws from September to November.

To enter, simply fill out the contest entry form and follow FLO’s LinkedIn page using a valid LinkedIn account. No purchase is required.

The three prize winners will be selected in random draws in Mississauga, Ont.

• On October 1, one entrant will be selected for a Lincoln 1864 PowerLuber and a Lincoln 5900 PowerLock coupler pack (value at $1,100).

• On November 1, one entrant will be selected for a Lincoln 1864 PowerLuber and a Lincoln 5900 PowerLock coupler pack (valued at $1,100).

• On December 1, one entrant will be selected for a choice of one of either a Lincoln 1864 PowerLuber and a Lincoln 5900 PowerLock coupler pack (approximate value $1,100), or a FLO Components 18-point Automatic Lubrication System in a Box (valued at $3,025).

For full contest details and to enter draw, visit www.flocomponents.com/40th/

Global automotive and industrial supplier Schaeffler presented its strategic direction and longterm growth perspectives at this year’s Capital Markets Day in Bühl, Germany, on July 20.

Klaus Rosenfeld, CEO of Schaeffler AG, explained the cornerstones of Schaeffler’s strategy, “Mobility for tomorrow,” with its three key opportunities for the future – E-Mobility, Industry 4.0 and Digitalization – which are to develop into important growth drivers. He said that the Schaeffler Group intends to create an independent E-Mobility business division as of January 1, 2018 to bring together all the products and system solutions for hybrid and pure battery electric vehicles. The company has also decided to set up a competence centre for E-Mobility in China, alongside the existing German units, to accommodate the increasing importance of the Chinese market in the field of E-Mobility. In the Industrial division, all mechatronics business, plus the digitally driven service business opportunities are also to be combined in an independent organizational unit “Industry 4.0” from January 1, 2018 to tap additional growth potential.

Dr. Stefan Spindler, CEO Industrial, reported that the Industrial division, alongside the component business, systems and mechatronic products gain more and more importance. In addition, the company sees a steadily growing market for Industry 4.0 applications. For more information, visit www.schaeffler.ca.

Windsor, ON – Precision machining specialist Reko International Group Inc. has announced its plans for the construction of a new manufacturing and innovation facility. The building, which will encompass over 40,000 square feet of production space, will be adjacent to its current premises on Silver Creek Industrial Drive in Lakeshore, Ont.

Construction is expected to cost approximately $5.5 million and should be complete early in 2018, allowing Reko to expand its offerings of automation equipment, moulds and machining services to current and new customers.

Source: Reko International Group Inc.

Gothenburg, Germany – SKF inaugurated its Sven Wingquist Test Centre in Schweinfurt, Germany, an investment totalling EUR 40 million. The centre is the first in the world that is able to test large-size bearings under actual operating conditions.

The centre has two testing rigs. One rig is designed for the testing of wind turbine main shaft arrangements. The second rig will be used for testing bearings used in other industrial sectors, including mining, construction, steel manu-

facturing and marine transport.

Combined with SKF’s continued development of diagnostics, condition monitoring and simulation methods, these rigs will contribute to reduced testing and product development lead-times and provide deeper insights into bearing performance.

The test centre has received funding from the Bavarian Ministry of Economic Affairs, Media, Energy and Technology and the German Federal Ministry for the Environment, Nature Conservation, Construction and Reactor Safety.

For more information, visit www.skf.com.

Chicago – Grainger reported results for the 2017 second quarter ended June 30. Sales of $2.6 billion increased two per cent versus $2.6 billion in the second quarter of 2016. There were 64 selling days in the 2017 second quarter, the same as the 2016 second quarter. Net earnings for the quarter of $98 million were down 43 per cent versus $173 million in 2016. Earnings per share of $1.67 declined 40 per cent versus $2.79 in 2016.

“The second quarter was in line with our expectations, as we saw continued volume growth from our strategic pricing initiatives in the United States,” said chief executive officer DG Macpherson.

“Outside the United States, we took aggressive action to streamline our portfolio and focus on profitable businesses, as we announced the wind-down of the business in Colombia and previously announced the closing of 59 branches in Canada this year. Based on our confidence from what we are seeing, we are reiterating our guidance for the year.”

The company reiterated its 2017 sales and earnings per share guidance of sales growth of one to four per cent and adjusted earnings per share of $10.00 to $11.30. The company’s previous 2017 guidance was communicated on April 18, 2017.

Second quarter 2017 sales for the Canada segment decreased 3 per cent in U.S. dollars and increased two per cent in local currency. The two per cent increase consisted of two percentage points from volume and a two-percentage point ben-

efit from the favourable comparison related to the Alberta wildfires in 2016, partially offset by one percentage point from lower price and a one percentage point decline from the timing of the Easter holiday.

For more information, visit www.acklandsgrainger.com.

The power quality equipment market is expected to grow from an estimated US$ 29.74 Billion in 2017 to US$ 40.85 Billion by 2022, registering a CAGR of 6.56 per cent, from 2017 to 2022, according to a report issued by research firm Markets and Markets.

The report, “Power Quality Equipment Market by Equipment (UPS, Harmonic Filters, Surge Protection Devices, Power Conditioning Unit, Static VAR compensator, and Power Quality Meters), Phase (Single and Three Phase), End-User, and Region – Global Forecast to 2022,” provides an in-depth understanding of the competitive landscape and includes the profiles of some of the top players in the power quality equipment market.

The industrial and manufacturing segment led the power quality market in 2016, and is projected to dominate the market during the forecast period. The Industry 4.0 initiative is being applied to vehicles and electrical machinery in order to facilitate remote diagnostics, remote maintenance, and remote data capture. Such initiatives have increased the need for data centres, servers and communication systems.

For more information, visit www.marketsandmarkets.com/.

News and views about companies, people, product lines and more.

• Birmingham, Ala. – Motion Industries, Inc., a wholly owned subsidiary of Genuine Parts Company, has entered into a definitive agreement to acquire Numatic Engineering. Execution of the transaction will occur on August 1, 2017. Numatic Engineering has over 60 years of experience selling and supporting automation components, ranging from pneumatic automation to electrical motion controls, PLCs, VFDs, machine vision, sensors and industrial communication.

• Calgary and Houston – Shell has launched a methane detector pilot at one of its shale gas sites near Rocky Mountain House in Alberta. The pilot test is part of a wider

multi-stakeholder initiative called the Methane Detectors Challenge, a partnership between Environmental Defense Fund (EDF), oil and gas companies, U.S. government agencies and technology developers to test next-generation methane detection technologies.

• Saltcoats, Sask. – EMW Industrial welcomes Dave Link, a food industry veteran with more than 27 years of experience, to their team as chief executive officer (CEO). Link most recently was product line manager for Cargill Texturizing Solutions, in Minneapolis, MN. At EMW, Link succeeds Ewen Morrison as CEO, who had led the company since 1971.

• Kingsey Falls, QC – Cascades Inc., a leader in recuperation of recyclable materials and in manufacturing of green packaging products and tissue paper, announced an investment of US$80 million for the construction of a new containerboard packaging plant in Piscataway, NJ. The plant will create 120 jobs, and will manufacture corrugated packaging products. Operations will begin in the second quarter of 2018.

• Oakville, Ont. – Siemens Canada announced the appointment of Faisal Kazi as president & CEO of Siemens Canada Limited, effective September 1. Kazi replaces former president & CEO and current chair of Siemens Canada Robert Hardt, who left the company in June to take on the role of Catalyst Partner at next47, Siemens’ separate unit for startups.

• Exeter, N.H. – Anvil International has acquired the Grin-

nell Mechanical Product suite for the North American mechanical business, including grooved couplings, fittings and valves, G-Press Systems, and the Anniston, Alabama foundry. Johnson Controls will retain the Grinnell Fire Suppression business globally. Anvil International manufactures pipe fittings, pipe hangers and piping support systems. The company offers product solutions for plumbing, mechanical, industrial, mining and oil and gas.

• Pittsburgh, PA – Industrial Scientific, a leader in gas detection and safety-as-a-service, has signed a definitive purchase agreement to join the Fortive family of industrial technology companies as a member of its Field Solutions platform. The new ownership will provide Industrial Scientific with additional capacity to accelerate the company’s vision of eliminating death on the job by 2050. MRO

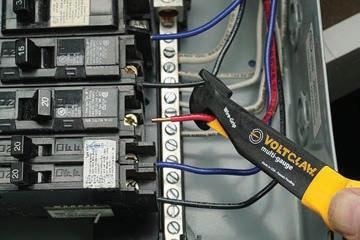

Does your facility have a game plan to remain operational during an unexpected outage?

BY PHILIP CHOW AND MATTHEW WALKER

Stories of mass disruptions caused by electrical power outages make front-page news. We hear about extreme weather events, such as Hurricanes Katrina (2008) and Sandy (2012) and the Ontario Ice Storm of 2013 that cause widespread power outages due to damaged electrical utility infrastructure. International airlines have experienced disruptions with a multitude of stranded passengers due to electrical outages in the data centres that manage bookings. Cybersecurity and physical security have also become prevalent subjects with the continuous expansion of networked systems and recent acts of hacking and terrorism around the world. While difficult to quantify, executives understand the impact power outages have on corporate revenue, restart costs and poor public image with customers.

In the event of an unexpected electrical power outage, does your facility have a game plan to remain operational and restore systems? Does your operations

group have a program that maintains emergency preparedness for electrical outages?

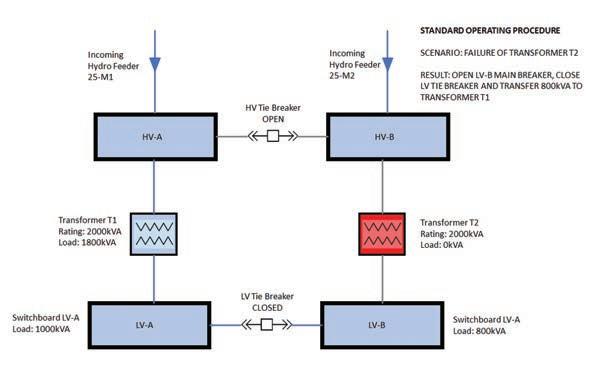

Internal power outages originating within a facility can be both short-term and long-term events. Short-term outages typically result from nuisance tripping, where overcurrent protection de-energizes a circuit due to an abnormal event, an increase in electrical load, the addition or replacement of equipment with new ratings, or incorrect protective settings. In most instances, short-term outages do not result in any significant equipment damage, and power is restored after the cause is identified and subsequent diagnostic tests are performed. Long-term outages can result from a variety of causes and typically result in permanent equipment failures and damage that renders a portion of a distribution system inoperable. When a long-term outage occurs, facilities fortunate enough to have redundancy built into their distribution system can rely on alternative feeders, transformers or circuits with spare capacity to restore pow-

er in the interim. Without the luxury of built-in redundancy, temporary solutions and temporary equipment rentals may be required, while replacement equipment is being manufactured (a process that can take upwards of 20-plus weeks). In order to fully appreciate the possibility and impacts of unexpected internal power outages, let’s consider a few case studies.

Electrical work can create the potential for electrical hazards, accidents and associated power outages. In this case study, an electrical contractor was expanding on a newly installed 15,000V (15kV) distribution system. A dedicated electrical-service space was being constructed in a critical, process-based facility in British Columbia. The contractor was in the process of running a 15kV feeder circuit to connect an existing load to the new distribution system and new medium voltage cables had been run in anticipation of an upcoming shutdown to make the final connections. Prior

to the shutdown, the contractor was performing some final checks within the 15kV switchgear and accidently energized the 15kV circuit. The new MV cables, which were left unterminated and coiled together, became energized and created a three-phase bolted fault. The accidental energization resulted in a short-circuit event of about 10,000A and was near the maximum fault level stipulated by the local utility. Multiple medium voltage circuit breakers tripped as a result of the fault, including a main breaker in the service entrance switchgear for the site. The facility’s standby generators came online, due to the tripped circuit breakers and powered the facility for a number of hours, until a procedure to properly isolate the circuit was implemented and utility power was restored. Fortunately, no injuries occurred and a subsequent assessment revealed that no damage to equipment or cables occurred, with the exception of the cable ends, which were cut back several inches.

Facilities often rely on service groups to perform routine electrical tests, circuit

Cable ends had to be removed after MV cables became energized and created a three-phase short circuit.

switching and isolation requests. The exact switching procedure is typically left up to the service group and they are responsible for operating distribution equipment. In this case study, a service contractor was manually switching between utility power and standby generator power via a set of 480V circuit breakers. The system was placed into manual operation, utility power breakers were opened, standby generation was brought online and generator breakers were closed to provide power to the switchboard. When it came time to return to utility power, the utility

power breaker was inadvertently closed, while the standby generators were still powering the switchboard. The switchboard did not have any synch-check protection, paralleling equipment or interlocks. The individual generator breakers tripped open several seconds after the unintended paralleling condition was created. Unfortunately, large magnitude currents had circulated within the distribution system, before the generator breakers tripped. These large magnitude currents created significant magnetic forces, which damaged bus work in a dry-type transformer that was close

An unintended switching operation resulted in two sources being paralleled out of phase. The high magnitude currents created significant magnetic forces, which bent energized bus work into contact with transformer’s grounded steel frame.

coupled to the switchboard. The bus work was bent outwards and insulating paper covering a portion of the bus was dislodged, creating a condition where uninsulated bus was bent into contact with the grounded steel frame, supporting the core and coil assembly. The resulting line to ground fault melted the entire bus connection, until the phase to ground fault was eliminated and the bus connection was no longer in contact with the steel frame. Fortunately, proper safety procedures had been followed

and no one was injured in this incident. The switchboard was supplied with power from a redundant transformer and the damaged transformer was permanently removed from service. The facility subsequently shifted downstream loads to other distribution within the building, to further offload the remaining transformer.

Electrical failures can also occur unexpectedly within a distribution system,

A dry-type transformer failed due to a latent installation deficiency. Low voltage control wiring for power metering had been installed in close proximity to uninsulated 5kV bus work and a flashover had occurred due to the insulation rating of the wiring and insufficient physical clearance.

without any precipitating factors such as electrical work or switching operations. A variety of recent cases come to mind, with causes that include latent installation defects, utility supply issues and failures related to aging electrical infrastructure. A critical facility, in the Greater Toronto Area, experienced a localized extended power outage for several weeks, when a dry-type transformer unexpectedly failed. The dry-type transformer provided essential power to both occupied areas in the building and critical process-based loads. The transformer had been recently upgraded to a new energy-efficient model and the replacement core and coil assembly had been site installed, due to space limitations and access requirements for a newly manufactured unit. The failure analysis confirmed that low-voltage control wiring for power metering had been installed in close proximity to uninsulated 5kV buswork and a flashover had occurred due to the insulation rating of the wiring and insufficient physical clearance. Operations were shut down in the affected area until a refurbished transformer was sourced and installed. In another example, an Ontario- based electric utility experienced an outage to one phase in a distribution circuit, when parallel fuses for one of the phases in a disconnect switch unexpectedly blew. The utility replaced the blown fuses and restored power within several hours. However, by this time the facility had determined that several 30 hp motors, critical to the central plant’s chilled water and condenser water system, had burned out due to the single-phasing condition and inadequate motor overload protection. Mechanical services were interrupted for 15 hours while motors were replaced. In yet another example, an underground 5kV distribution cable, in an institutional campus, unexpectedly failed after approximately 25

years in service. Temporary generators were brought in for a week, until a portion of the failed cable could be removed and re-fed with replacement cable. While the cable had not yet reached statistical end-of-life conditions, it was determined that the early failure was attributed to physical damage, which had reduced the cable’s anticipated life expectancy.

How can an operations manager plan

for an unexpected electrical outage in their facility? To start, a well-structured preventative maintenance program and an infrastructure review can help diagnose potential risks. Is equipment being maintained and are recommended diagnostic tests being performed? Equipment should be reviewed for age and reliability. Consideration should be given for redundancy in the power distribution system and how the failure of a particular component could affect

continued operation. Taking meter readings on a frequent basis will confirm if there has been any load growth and how load is segmented throughout a distribution system. If metering is unavailable, consideration should be given for installing permanent metering or taking readings with a portable meter. Operational data can be used to expand on a facility’s electrical single-line diagram and performing a detailed review can determine options for supporting load

in emergency situations. Emergency scenarios should include how critical loads are supported during an extended utility outage, how load can be supported during equipment failures (transformers, switchboards, panels and main feeders), points in a distribution system for connecting a temporary generator and options for interlocked tie connections. Abbreviated single line diagrams for modes of failure and electrical load data can be used to create a standard operating procedure (SOP), in the event of an unexpected power outage. A well-developed SOP will include detailed, step-by-step operations to help diagnose an electrical outage, isolate faulted equipment if applicable and restore power using alternative means, if available. Photographs of equipment should be included and operating switches, buttons and HMI screens should be identified. Having a guide readily available will increase response times and decrease downtime.

place, identify any shortcomings with existing practices and provide opportunities for improvement. Creating documentation for SOPs, MOPs and training will typically involve a detailed review of existing systems, creating a site-specific set of procedures, and drawing upon industry standards and best operational practices. By investing in a plan for emergency preparedness, operations managers can equip their staff with the knowledge to deal with the next electrical outage, thereby increasing response times, decreasing downtime and ensuring their facility remains operational.

MRO

Philip Chow, P.Eng., P.E., is a senior project manager and electrical engineer at H.H. Angus & Associates Ltd. who specializes in electrical infrastructure projects and construction in mission critical facilities. Reach him at Philip.Chow@hhangus.com. Matthew Walker, P.Eng., a senior electrical engineer at Telus Communications Inc., specializes in emergency preparedness and infrastructure projects in mission critical facilities. Reach him at Matthew.Walker1@telus.com.

To complement the effectiveness of standard operating procedures, any work performed on a power distribution system should be subject to a detailed method of procedure. A typical MOP will outline a step-by-step procedure for work being performed and includes information on demarcation of work (who is doing what?), the duration of tasks, a back-out plan to deal with the unexpected occurrences and a list of emergency contacts. A dry-run of switching operations and load transfers should be performed in advance of a planned shutdown, especially when a number of complex switching operations and load transfers are involved. Operations staff should actively participate in the process, as this will further develop familiarity with a power distribution system and mitigate risk when electrical work is being performed. Consideration should also be given to providing regular training sessions on electrical systems for operators. Training should focus on the topology and equipment in the distribution system, facility procedures (SOPs and MOPs), preventative maintenance requirements and general troubleshooting practices. Having well-trained operations staff will not only ensure that a facility’s first responders can effectively deal with issues when they arise but also ensure outside contractors follow an approved procedure before commencing work.

Unexpected electrical outages in a facility can be caused by a variety of factors, including electrical work, routine switching operations, issues with the incoming utility supply, or aging infrastructure. A proactive approach to managing an electrical power distribution system and maintaining emergency preparedness should include: a well-developed preventative maintenance program; the creation of SOPs to identify an approved response to emergency scenarios and to troubleshoot issues; MOPs for all electrical work, including preventative maintenance and isolation procedures; and having regular training sessions for operations staff. Undertaking a detailed needs assessment will help a facility review procedures currently in

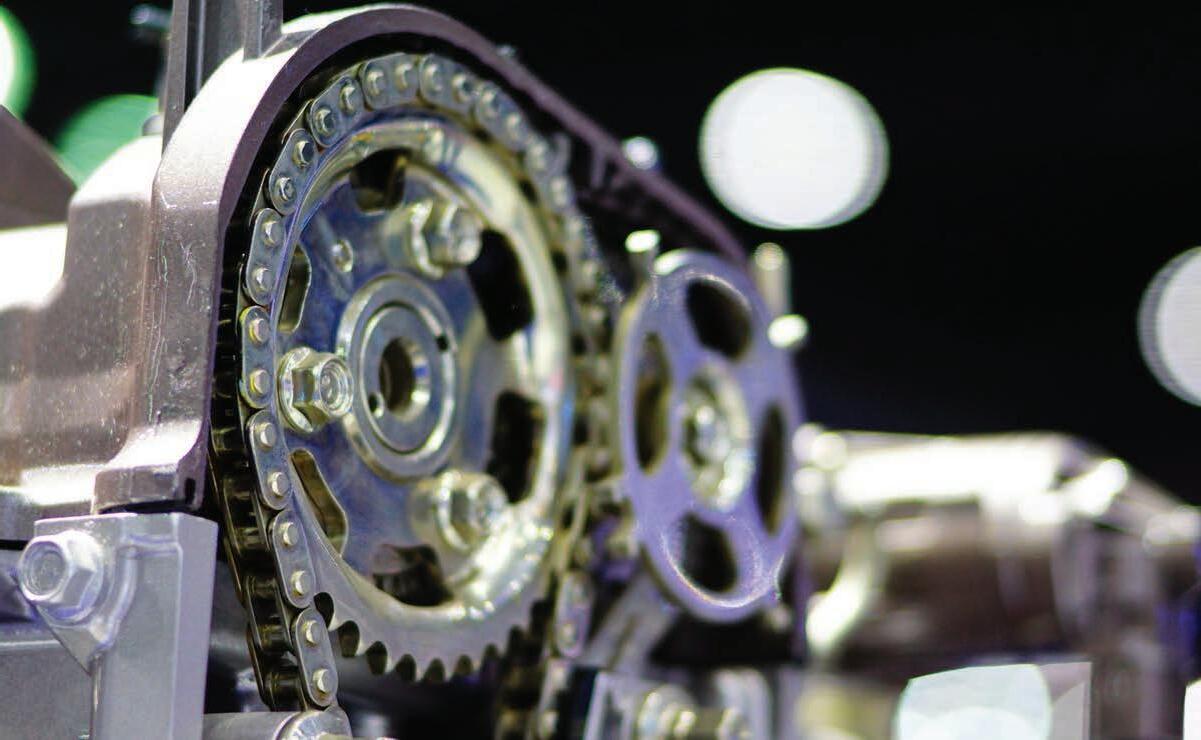

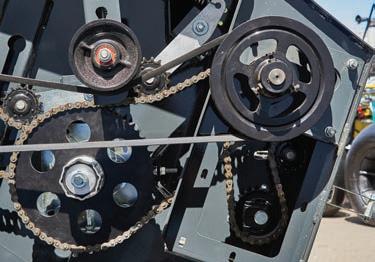

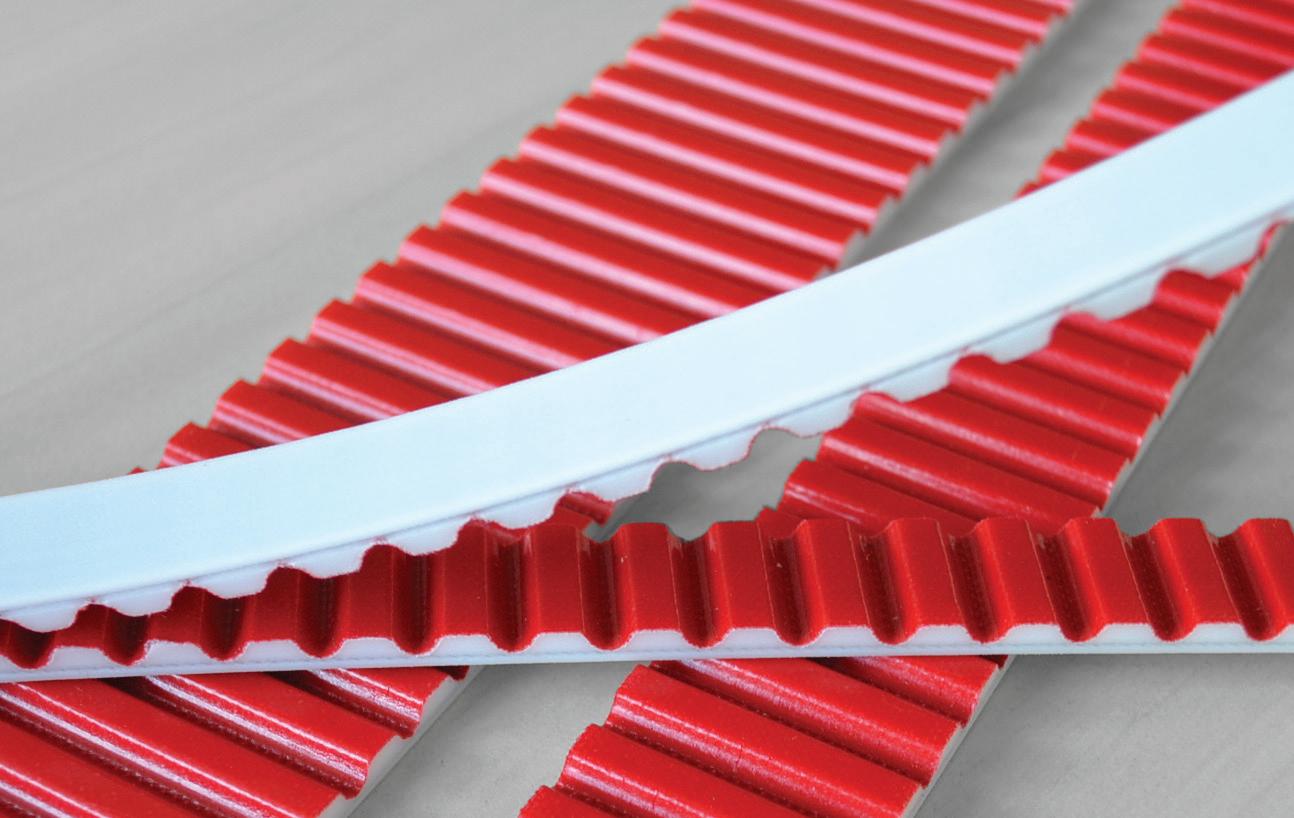

Optimizing belt and chain drive life.

BY JEFF SMITH

Snow plowing a Fernie, B.C. driveway on five acres, located 15 minutes from a major ski hill is not a minor task. The massive snowfalls on some days are a threeshift strategic feat. This particular day of snowfall, I used a John Deer lawn tractor with a two-metre snow blower. The key was not to let it get too deep. With the snow that was falling I would have to clear it about four times that day. I geared up with snow pants, a heavy jacket, gloves and a toque. I easily started up the tractor and went to clear my first path. About 100-hundred metres down the driveway the tractor stopped. Not a gradual stop, not a stop in blowing snow, just an instant stop! The snow stopped flying and the engine was no longer running. Silence. I soon realized the auger drive chain had failed and jammed between the drive gears and shock loading the system. I looked at the dry, excessively worn chain. My first thought: “Where am I going to get a new chain?” My second thought: “Some reliability expert you are – you never oiled, aligned, inspected or maintained this chain at all!” What is that they say about the cobbler’s children?

Chains and belts seem to cause more trouble than they should. They are not complex and they don’t have a multi-

tude of integrated components, yet they seem to jump out of a multitude of reliability Pareto graphs as bad actors. In hindsight I wish I had tracked the downtime I had encountered due to “avoidable” failures of drive chains and V-belts. Having made a career of setting up inspections programs, I tend to naturally observe things as I walk through a facility. I have seen countless belts dragging on the side frames from misaligned rolls, or obviously loose drive belts flapping happily until failure. Why?

As with many assets, let’s consider the key stages that impact reliability: Selection, Storage, Installation, Operation, Maintenance and Disposal.

In many cases the selection of a drive chain or belt has been made by the manufacturer, but to follow RCM logic, your operating context may differ, therefore your chain or belt may not be adequate for the current loading you are experiencing. (Loading could be under-loading, overloading, shock loading or environmental loading.) To select a chain or belt the following must be understood:

1) What is the horsepower that is going to be transmitted? And, what is a realistic service factor? If the system will be subject to hard stops and starts or intermittent overloading, we need to include a service factor in our calculations.

Service factor x required horsepower = design HP

An example of a service factor would be an AC motor driving a centrifugal pump continuously and would use a service factor of 1.2

Tip: Use your supplier’s subject matter experts; they will help.

2) What is the required ratio between drive and driven? Remember, in belt systems, it is only theoretical as slippage will happen. So over-speeding slightly is a good practice. This does not apply to chain drives.

Selecting the right drive is imperative not only for initial construction but should be revisited if drive or driven speeds or loads have changed. If it is a problem drive, one of the first considerations should be: Can this drive handle what we want it to do? (CAN>WANT).

Time to Save

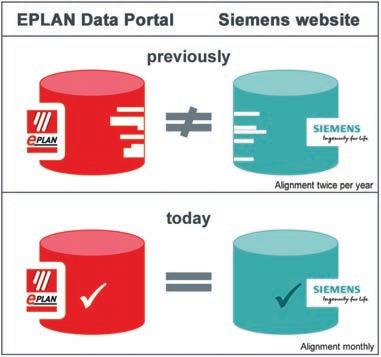

Time is money. Switching to EPLAN Electric P8 from CAD software typically reduces project time by 40% or more right out of the box – as much as 80% when using the feature-rich EPLAN portfolio to its fullest.

Time to Automate

EPLAN automates time-consuming data creation and verification functions CAD users must perform manually, often repetitively: like device tagging, generating wiring, parts and connection lists and performing crossreferencing and error-checking. Ready-to-use, vendorcertified datasets can be imported from a selection of almost 1,00,000 components via the EPLAN Data Portal.

Time to Plan Ahead

EPLAN has virtually unlimited scalability for managing the increasing electrical content designing for the IIoT/Smart Factory environment. The bigger the assignment, the more EPLAN excels. CAD can’t do that.

Time to Switch

EPLAN is the future of engineering. It’s freedom to concentrate on what matter’s most – engineering – so you or your team can quickly create high-quality machinery and plant documentation.

Value destruction can and does happen in storage, it is often driven by moisture, dust, sunlight, chemical attack, mechanical damage or mislabelling. When storing chains or belts, keep them in a clean, dry area. Do not mishandle them. Try to limit the stock needed on hand when Min/Max quantities are automated. I have seen scenarios where there is a drive issue that requires the use of multiple belts in a short time, but once the issue is resolved, the stock levels have been driven up and the storeroom ends up with a 10-year supply of belts. There is also the fire sale mentality that dictates the purchase of chain in bulk “because it was such a deal!” Store what is actually needed and take care of it. As with any parts, ensure your BOM (Bill of materials) is correct for the assets; slight pitch differences can be easily overlooked and create chain-eating machines.

How tight is tight? Deviation tribal wisdom provide an astounding number of answers to this question: ½” deflection per foot; you should be able to twist the belt over; there should be no chain sag at all, etc. But let’s start the installation at the beginning.

For more information or for a free 30-day trial, contact us at: 1-847-240-4667 www.eplanusa.com info@eplanusa.com

www.eplanusa.com

Inspect the driven shaft and look for any deformation or cracks in the key slot using magnetic particle inspection, if possible. Look for any signs of torsional stress. Is the shaft worn? Use your calipers and check the fit between the shaft and the sheave/sprocket. Remember, drives should last for years; take the time to ensure a proper fit. Also check the key slot, with the new key of correct hardness. Remember to balance; fill half the exposed key slot with the key.

Install the drive sheave or

gear in a position that centres it. I have seen way to many guards worn through. If it is a key and set screw, tighten it correctly. If it’s a taper lock, make sure it has sufficient contact. Prussian bluing isn’t just for hard-hat liners.

Follow the steps above for the driven sheave/sprocket, then align them. There is a multitude of belt or chain alignment tools on the market, so don’t use guesswork here.

Install the drive belt/chain and tighten. How tight? I will let you in on a little secret: there is no definitive answer. I have had different settings from two manufacturers for the same drive system. Some systems are not sensitive to tightness but for other systems it’s critical. If you are the purchaser, have the suppliers’ SME give you specifications for how tight the drive should be and any special instructions for installation. If you’re the planner, translate the tightening instructions into the job plan. If you’re the tradesman, read and follow the instructions. One last thing: Do not close the jobs until the run in retightening has been done. Installing drives is worth doing right.

If possible, try to avoid shock loading the drive systems. In many cases this can be accomplished with automation and control. For example, soft starts or fluid clutches. Ensure the systems are controlled to avoid loaded starts. If you have a problem drive system that keeps failing and with no mechanical issue, investigate the system loading. Also ensure your process has sequential startups, starting from the last machine first.

The first requirements in maintaining drive systems is to retighten or inspect after installation. Things do stretch and wear in. This is a simple but often overlooked task. As the drive system progresses through its life, make sure the criteria that are life limiting is understood, such as the limiting acceptable pitch increase between pins or acceptable wear measurements for belts. If we define the criteria that establishes end of life we can maintain prior to failure. Follow the drives specifications for lubrication type and method.

dynamic inspections. Dynamic drive inspections are conducted with a strobe light slightly offset to the belt/chain pass frequency. This enables a very clear view of each inch or link. Inspect belts for cuts, glazing, separation, contamination and wear. Inspect chains for roller damage, evidence of side loading (worn sprocket sides), elongation, contamination, adequate lubrication and wear.

Another key point in drive-system maintenance is the fact that many drive-system failures are not associated with the drive system itself. As the system is inspected, look for evidence of leaking seals or process spills on the drive. Inspect for mounting looseness or excessive movement of the drive and driven units. Ensure there is adequate housekeeping around the system and don’t be surprised if a drive buried in woodchip fails.

I utilize dynamic inspections for belts and chains. The drive system must have a guard but if the guard is fully enclosed, plants tend to run the drive to failure. We don’t fix what we can’t see. Use doors or expanded metal windows to enable

In reliability improvement projects, asset disposal is a consideration. Do we use parts? Do we run out assets by allowing degradation? You get the picture. So what would I have to say about simple drive system disposal? Dispose the used stuff! How many of you have an old fan belt for emergencies? (OK, that may just be old guys like me). Don’t keep old parts for emergencies if you feel you need replacements – stock new parts. It’s not worth the downtime to reuse a worn belt or sheave. I have seen some cases where disassembling requires substantial effort, so an extra set of belts are placed over the rotating assembly to speed replacement. If following best practices, replacing them like this is unnecessary. But if you sleep better with them there, make sure they are protected from the elements and secured. MRO

Jeff Smith is a reliability subject matter expert and the owner of 4TG Industrial. His work spans a cross section of industries, including oil sands, mining, pulp and paper, packaging, petrochemical, marine, brewing, transportation and synfuels. Reach him at smith@4tgind.ca.

Taking the next smart step with your VFD.

BY JONATHAN MOSTERD

As variabl frequency drivess continue to inhabit the industrial and commercial landscapes around us, there comes a time when everyone realizes the finite lifecycle of their investment. Far too often this recognition happens during an unplanned failure or fault. Most experts in the field will agree that after 10 years of service, the average VFD with electrolytic capacitors is heading for the home stretch – when it will no longer be able to contain the smoke within it. Often people will ignore this truth or hope that good maintenance and possibly the odd repair will somehow stretch the life of their product. Yet there is a proactive approach that could help increase reliability, while saving money and time.

In being proactive, you can create plans to upgrade your equipment before it fails, based on calculated life expectancy. In fact, many VFD manufacturers and service organizations have created such programs to assist users and partner with them. These smart step programs seek to find cost-effective ways for owners to upgrade their equipment to newer models. The biggest benefit to being proactive is that you are given the time to come up with a plan. This plan can include a budget and allow you to invest in newer technologies. When a product fails unexpectedly, we are forced to become reactive. In

doing so we spend more money and time and may not always get the product that we want installed. We become subject to whatever solution we can quickly locate and end up doing whatever we can to simply make it work. In creating a plan, you can reduce these unexpected costs and perform upgrades in a timely manner.

A good retrofit plan or program will seek ways to reduce costs, downtime and help to modernize your process. Instead of reacting to a problem, it’s possible to be proactive and have a chance to consider all options. This could include, for example, starting to plan or implement a new building control system or set up new communication protocols. Further, take the time to consider how the Internet of Things is affecting your business, or seek out ways to increase efficiency and product life. There are many reasons why spending time on this now will pay out dividends into the future.

One of the biggest reasons is to prevent unexpected failures, especially in a world of tight budgets and high production efficiencies. No one is happy when equipment fails in an unscheduled manner. Not only does upgrading give you an opportunity to make your process better, but it also provides you with confidence that the process will continue without interruption.

Knowing why it is important to plan for a retrofit is the first step. There are still the questions of who will do it, what product to install, where to install it, when to do it, and how it will be done. By addressing the classic who, what, where,

With a product and a plan in place, the next step is to secure someone to perform the work.

when, why and how of the entire project, you can build a plan and business case and justify the upfront costs. Further, with proper planning you can spread these costs over a few years and thus reduce the overall budgetary costs.

What. To start off a retrofit you need to define a preferred product. Often, the best way to do this is to step back in history and consider if the current drive product has met your needs or if it needs to be improved. One of the things to consider

is the installation environment. Maybe you have a UL type 1 unit and, due to contamination, should investigate using a UL type 12 or type 4x instead. Other questions to consider are auxiliary components, such as contactors or sensors, which may also need to be updated. On top of this, newer VFDs often have some PLC functionality built in, so you may want to consider eliminating some smaller controllers or possibly adding functionality to existing systems. By taking time to talk with your local distributor, electrician or supplier, you can gain the insight required to select the best item for your needs. You can also learn more about new technologies and possibly improve your process and reliability, and save on energy.

Where. Once a product has been selected, the question of where to install it can take shape. Do we simply remove the old product and insert the new one, or is there a newer, more optimal place to put it? The new product may be shaped differently and not fit in an existing space. Many VFD manufacturers are aware that real-estate in a cabinet is a premium, and thus have found ways to reduce the overall footprint of their equipment. Often this means that drives are no longer flat and wide, but rather tall and narrow. Also, if your future plans involve integrating this drive into a new control system, or using some of the onboard functionality of the VFD, a user may want to move the installation to a more practical location. The environment and cooling requirements are also important. Be sure to consult the technical specifications for a new unit before installing it, so that it will operate as it was designed to, for a long period of time.

When. As the plan comes together for upgrading, the “when” portion of this retrofit plan comes into place. When can mean many things. It may relate to scheduling work to be done during low demand, or maintenance intervals. It can also be a calculated risk of how many years do you think you have left in the old unit, before it requires a retrofit. Often, there could be a large quantity of VFDs that are approaching the end of their lifecycle and as such a strategic plan could be put in place to retrofit them in a timely manner over a number of years. This allows for downtime and costs to be spread out over a number of budgets, rather than in one lump sum. A multi-year plan seeks to target the units with a higher probability of failure first, and then move onto the rest. Determining when a retrofit will happen requires diligent planning, as it often involves and affects a number of different people and processes.

Who. With a product and a plan in place, the next step is to secure someone to perform the work. Many VFD manufacturers have authorized installation and commissioning partners, often local to larger markets. Having the correct people in place to perform the work will decrease the installation and commissioning time. It will also allow you to build relationships with the people who are authorized to perform warranty and repair work. If an unfortunate event were to occur in the future, you can rest assured knowing that the same people who installed the product are also authorized by the manufacturer to fix it. Plus, by having trained people to perform the work, you can trust that the product is being installed according to manufacturer’s guidelines and that it will meet warranty guidelines. Having the right people for

the right job is sometimes the difference between a successful retrofit versus a non-successful one.

How. Lastly, there is the “how” portion to the retrofit. This portion is the easiest, as it has already been addressed throughout the process of asking who, what, where, when and why. By taking the time to do your research and talk with your sales and service channels, you will have already figured out how you will get your product, how it will be installed and how it will operate. Yet, this is still an important step in retrofitting as it allows you to review your plan. By stepping back and looking at how everything will happen, you can double check your approach and ensure that all the pieces are in place.

Retrofitting equipment, especially VFDs, takes time and money. Naturally, both are hard to come by in the world we live in. However, when a retrofit is done correctly, it will ultimately help to prevent unexpected costs and lost production time. Unplanned failures are expensive. They often involve paying for things such as overtime and expediting fees and, most importantly, can halt production. When you can plan your strategic upgrades in a controlled fashion, even if it involves large quantities, you are able to enhance your processes and increase overall efficiency. Retrofitting your VFD installation is a great way to keep these silent workhorses operational and saving you both time and energy. MRO

This article was submitted by Jonathan Mosterd, Canadian Service Manager, Danfoss Drives. For more information, visit http://drives. danfoss.us.

Track the effectiveness of your Asset Management Maintenance Program.

BY L. TEX LEUGNER

In a truly proactive maintenance organization, the focus must be on monitoring equipment condition in order to preserve and protect critical assets. Maintenance work is performed to prevent equipment deterioration and failures and both maintenance and production personnel take responsibility for initiating necessary maintenance. But to achieve the highest level of equipment reliability possible, it is first necessary to recognize and correctly apply the most useful maintenance performance indicators. In selecting and applying these KPIs, the primary questions must include: What must be measured?

How do we measure it? Why should it be measured?

Keeping these three questions in mind, let’s begin our quiz:

1

Assuming that you have carefully reviewed your PM program to ensure that only those tasks necessary are carried out and at the correct intervals, do you monitor PM backlogs? PM backlogs should be no longer than seven days. LOGIC: Deferring PMs to increase production should never be done unless absolutely necessary.

2

Every necessary task on a PM work order must be carried out when it’s due. Do you monitor PM task compliance? LOGIC: Compliance should be 100 per cent. If it’s not, why not?

3 Rework, whether for PM tasks or repairs, should be zero. Do you monitor all rework? LOGIC: Rework reflects such things as improper standards or specifications, lack of training, improper tools, rushing work due to time constraints, inadequate job plan task instructions, carelessness, inadequate or no root cause failure analysis prior to repair. EFFICIENCY

4

The MTBF (mean time between failures) is a measure of machine’s reliability (or a component of that machine’s reliability). Do you measure the MTBF on all critical equipment? LOGIC: A short MTBF could indicate a design deficiency, improper operation, inadequate PMs or training deficiencies. Extending MTBF is a direct reflection of improved machine reliability, improved maintainability and elimination of recurring operational problems.

5 The MTTR (mean time to repair) is a measure of how long a repair task or PM action takes to complete. Do you measure the MTTR on all critical equipment? LOGIC: Reduced MTTR reflects improved maintenance efficiency, and/or improved operator knowledge. It may also reflect shortened response time, improvements in job plans or maintenance methods and is a direct reflection of improved maintainability.

6

Maintainability is directly related to the ease and/or simplicity of carrying out maintenance or operational tasks on critical equipment. Have you determined maintainability on all critical equipment? LOGIC: Improved maintainability can be as simple as moving an oil filter to a more accessible location or moving a critical pressure gauge to a location directly into the operator’s view.

7 Many machine component failures are accepted as normal, particularly if the same failure has occurred several times. Do you carry out a root cause failure analysis on all critical machines (or components of that machine)? LOGIC: Any recurring failure or stoppage that directly affects production or causes higher than acceptable repair costs should undergo a root cause analysis with the objective of preventing recurrence.

8 Predictive Maintenance techniques such as vibration and oil analyses are used to monitor machine condition or component deterioration. Do you regularly monitor the condition of critical machines or do you permit “failure progression?” LOGIC: Some operations adopt a “let’s see what happens” philosophy. For example, a

rotating machine failure might include the following progressive stages: misalignment determined by an ignored vibration analysis, may be followed by a deteriorating bearing, in turn causing shaft damage, ultimately resulting in catastrophic housing failure. Never permit the deterioration to advance past the first stage.

9 Higher than normal maintenance overtime is often a reflection of PM non-compliance, excessive PM backlog or ineffective repair tasks. Do you measure maintenance overtime and the reasons for it every month? LOGIC: Maintenance overtime should be no more than six to eight per cent of total labour costs. If it’s not, why is it not?

10 Design defects are often the direct cause of machine stoppages and failures. Do you record these failures or stoppages and determine if a design problem was a potential cause? LOGIC: Design deficiencies are often blamed on inadequate maintenance for which the maintenance department may have little control. No amount of maintenance can overcome design deficiencies. These must be determined.

11 The efficiency and effectiveness of tradespersons is directly related to time spent waiting for parts, inadequate work order instructions, poor communication between operations and maintenance, waiting for another trade to complete work (in union shops), starting late, or leaving early. Do you regularly compare productive time with lost time? LOGIC: It is a statistical truth that in many plants trades personnel may lose up to 60 per cent of their productive tool time in any eight-hour shift.

12 In manufacturing plants, overall equipment effectiveness (OEE) is critically important. Do you regularly monitor OEE in your facility if it’s applicable? LOGIC: An acceptable 85 per cent standard includes measuring availability (which should be 90 per cent, including breakdowns and setups), performance efficiency (which

13

should be 95 per cent, including reduced speed and minor stoppage problems), and quality levels (which should be 99 per cent, including process defects and reduced product yield).

Finally, if you have an effective PM program, it is unrealistic for management to demand that critical equipment be available 100 per cent of the time. Availability (uptime) is a function of machine reliability, maintainability and how well the machine is supported by the operating organization. To ensure 100 per cent reliability, allow time for effective PM work that prevents machine deterioration. Do you measure availability (uptime) and how “scheduled” PM downtime affects it? LOGIC: Measure availability (uptime) as it relates to reliability and maintainability as follows:

Assume that the period under observation is one month, where operations are 24/7, or 168 x 4 = 672 hours of potential availability (A), where 32 hours (MTTR) were applied to return the machine to service caused by stoppages and minor repairs during the period and 8 hours were scheduled for scheduled preventive maintenance.

Therefore:

672 – 32 – 8 = 632 A = __________________ = 94% 672

You can see how important equipment reliability and maintainability are to production and process success. Many plants tend to defer preventive maintenance instead of removing the causes of 32 hours of downtime. If the 8 hours are deferred in our example, the availability for the measured period would be over 95 per cent, making production look good temporarily (until the deferred PM creates even more unexpected downtime).

MRO

L. (Tex) Leugner, the author of Practical Handbook of Machinery Lubrication, is a 15year veteran of Royal Canadian Electrical Mechanical Engineers where he served as a Technical Specialist. He was the founder and operations manager of Maintenance Technolgy International Inc. for 30 years. Leugner holds an STLE lubricant specialist certification and is a millwright and heavy duty mechanic. He can be reached at texleug@shaw.ca.

BY JEFF SMITH

While working at a major brewery, part of the job entailed fighting reliability issues. One issue involved the Hi-Cone (the machine that puts the plastic around a six pack) and the Nigrelli (a machine that loads the six packs into a tray in groups of four). There was a curved conveyor between the two machines that transferred the six (or eight) packs between the two machines. When we were setup for six packs the machine ran OK but eight packs constantly jammed. We struggled with this issue for a bit and I asked Dean Luff, the brewery packaging SME, how it was that other breweries did not seem to have this issue. His answer was actually quite simple: “Other breweries have the Hi-Cone and Nigrelli in line; they don’t have a 90-degree curve to deal with.” Pardon?

We eventually solved the issue, but why was the line constructed that way in the first place? After further investigation I understood that the brewery had been at its location for more than 100 years, so the constraints of the building were fixed. The old equipment had been exchanged with a new state-ofthe-art can line. The engineer had taken

the floor plan and the dimensions of the equipment and setup locations for the equipment. Then it was a simple matter of drawing lines to connect the blocks, phone “conveyors are us” (not a real company, it’s a joke), order the conveyors and the rest is history.

So that’s how the problem was created. Not to place blame, but I was once asked by an engineering class: “Shouldn’t all engineers understand asset reliability?”

To which I responded, “If they did, we wouldn’t need reliability engineers.”

How could this have been avoided? Any production line or system should be subjected to a RAM (Reliability, Availability and Maintainability) study. A RAM study will assess production systems capabilities and identify the possible causes of production losses and examine possible system alternatives. Even if a RAM study was not conducted, simply facilitating a discussion on your design choices with the internal SMEs and vendor representatives can avoid a lifecycle of reliability issues. As much as I like to think we can improve things, most issues are inherent by design.

So what types of issues are found in misaligned equipment and how does

this impact reliability? Let’s consider piping. Most petrochemical systems look like a bowl of spaghetti with pipes going everywhere. Considering every turn or twist is a wear point and level changes require additional energy to overcome, there should be substantially more consideration of optimal piping, placing the equipment as required, positioning the equipment, then considering the flow. (Is the tail wagging the dog?) This same argument applies to the building your production line is housed in. We seem to have a habit of constructing a square box and then cramming in the equipment. Have we ever considered designing a process-flow optimized system, then considering the tin it takes to cover it?

Here is a challenge: Look around your production facility – pulp mills, refineries, processing plants – and think about asset positioning and process flow. I guarantee that you will see things that should never have been positioned where they are and have caused reliability issues in the product transfer flows. Product transfer flows could be pipes, blow lines, chain conveyors and augers. Equipment alignment should be opti-

mized in several ways, and, yes, this tends to be a design issue but, as with coupling alignment, there are things that don’t require redesign. Let’s use a log conveyor feeding a saw box for example. The logs are fed into the saw box at a high rate of speed to be cut into dimensional lumber.

If the in-feed conveyor were to incline away from the saw box, it would result in additional energy to move the log in an upward motion; therefore, the cut would not be optimized as the wood could be wasted because the entry point is fixed and the cut would taper off.

If the in-feed conveyor were tilted toward the saw box there would be less energy to move the log, but it would run away. This would impact loading the saw blades as it hit, potentially jamming the log. It would also result in a less than optimal cut.

If the saw box were misaligned vertically to the in-feed conveyor, the blades would be side loaded as the log travelled through the saw box, resulting in blade damage and a bad cut.

If the mounting of the saw box is worn and loose, the movement of the box will result in jamming, excessive blade wear and poor cutting quality. Basically, the things that matter to conduct a coupling alignment are similar issues that matter when equipment is aligned to each other. There are also additional considerations of level and flat. They are not the same things! Level means the asset is parallel to the earth, which is generally a good thing as it corresponds with gravity, thereby enabling oil to get to both bearings in a pump. Flat means that whatever point matters is on the same plane as the other point. Yes, flat can be a vertical plane or any other plane.

Let’s use another brewery asset, such as a can filler and seamer to explore this concept.

A can filler is a large bearing that has filler valves. It rotates and the cans are filled. The cans then pass over a transfer table to have the lids installed and seamed. If there is too much spillage, then the almost full cans are rejected and crushed. To ensure the optimal fill, it

requires the filler ring to be level to the earth (level) for the complete circumference of the circle (flat). If it is not level, it will spill and the turning of the bearing will induce splashing. If it’s not flat, it will induce wear on the bearing and bounce the cans as it turns, inducing splashing. If the transfer of cans to the transfer table is not smooth, it will induce spillage, and if the cans do not enter the “seamer” correctly, it will misalign lids and cause a “seamer” jam. (This is all serious stuff! After all, this is beer we are talking about.)

So how would we align a dynamic unit like this? First, we deal with the filler

and use a level line system to ensure the filler was level and flat. Then the jacking bolts (legs) of the filler are secured.

With the initial section true, we could then level the transfer table and finetune the transition with the use of a high-speed camera. After all, this unit produces over 2,000 cans per minute. This fine-tuning effort results in a substantial increase in production and a decrease in shrinkage (manufacturing term for lost product).

The primary consideration of asset alignment should always be product flow. Most assets take something in,

When it comes to critical applications, reliability is everything. But not just any chain can withstand the nonstop stress of high speeds and harsh conditions. That’s why Tsubaki designed its Titan chain to deliver superior durability in challenging environments. Specially coated pins, solid lube groove bushings* and a patented ring-coining process increase fatigue strength while minimizing wear. The result is a significantly longer wear-life, even in extreme environments. So go on, hold your chain to a higher standard — the Titan gold standard.

add value and move the value-added product to the next asset. The value add may just be the transfer of the product or altering the size or shape but there is always some additional value. There will be issues with the product flow that create value destruction, such as abnormal wear or reliability issues. One example of this was at a hammer mill. Hog fuel was fed into the hammer mill and smashed down to a burnable level for the incinerator. The mill was constantly going out of balance and the hammers were wearing prematurely. The vendors and engineers were looking to make indestructible hammers through tungsten hardfacing. It only took one glance at the hammer to see the wear was uneven, and another at the conveyor feeding the hammers to see that all of the material was falling into one side of the hammer mill. With a quick conveyor realignment, and installation of a sweeper bar to spread the bark out over the conveyor, the indestructible hammers were no longer required. It’s funny how that works. MRO

A few points to consider on asset alignment:

• It’s the product flow you are aligning, therefore, consider the product the centreline.

• All level changes and horizontal turns are bad; if you use them, make sure there is a reason. (“Because it looks nice on the drawing” is not a reason.)

• Ensure that in-feed is fed evenly and constantly

• Soft foot is not just for electric motors; ensure assets are mounted securely.

• Understand the importance of asset alignment. In some cases it’s critical, but not all.

• The path of least resistance always uses the least energy.

• Assets in some cases can and should be repositioned.

Jeff Smith is a reliability subject matter expert and the owner of 4TG Industrial. His work spans a cross section of industries, including oil sands, mining, pulp and paper, packaging, petrochemical, marine, brewing, transportation and synfuels. Reach him at smith@4tg-ind.ca.

Poor housekeeping practices stem from “the good enough syndrome.”

BY PETER PHILLIPS

Afocal point for this issue of Machinery and Equipment MRO is severe service and preparing to execute maintenance in this environment.

Let there be no question about the relationship between implementing a new ERP system and severe service. The importance of keeping a clean house as a way to prevent premature equipment and process failure cannot be underestimated.

In recent months at the ERP implementation with a Canadian building manufacturer, we have been working diligently at organizing our maintenance storerooms in order to upload our parts into the MRP section of software.

During an ERP implementation, every part needs a Bin location, effective labelling and barcoding, and cycle counts must be carried out on a regular basis.

Every plant needs a well-organized storeroom. We developed a Basic Store -

room Development Guide that every plant has been following to ensure the same guidelines are implemented from plant to plant.

Many of the plants’ storerooms were a complete disaster and looked more like a dumping ground for old equipment and parts. Of course we have worked through these issues and we have purged old parts and equipment and designed proper storeroom layouts and security systems to restrict access to the

storeroom and parts.

One thing we have been developing is sustainability guidelines so our new stores continue to maintain their new structure.

As I thought about this sustainability and visited some other facilities, I noticed some very poor maintenance practices that will not help maintain our new storerooms.

I noticed in many maintenance shops the majority of tradespeople are not following good housekeeping practices. (The evidence is in the images.)

Benches are cluttered with tools, parts and rags. Personal lockers are overflowing with everything, from PPE to empty buckets.

After seeing this same scenario at several plants I questioned why the maintenance management team allows this type of unprofessional behaviour. But then I noticed the same clutter in the maintenance supervisors’ offices. No one seems to mind the mess and disorganization. The shop and tradespeople’s standards seem pretty low to me, but are accepted as normal practices to everyone else.

I have named this “the good enough syndrome.” If it’s good enough for our maintenance supervisors’ offices to look like a pigsty, then it’s good enough for the tradespeople. The untidy benches and tools scattered around the maintenance shop is normal for everyone. I have to wonder what standards are being followed in the repair and maintenance of the equipment.

I recently presented some of the pictures seen in this article to a group of plant managers to help them understand and explain the cultural change they need to make in their organization and why they need to encourage the maintenance people to step up their game.

Good enough will not get them to world-class maintenance practices or improve the reliability of the equipment.

It’s true that much of heavy industry has this problem. We see it across the board in many industries. But how does this impact maintenance activities?

In severe and harsh environments, where airborne dust, dirt and other forms of contaminants are part of life, it takes effective standards to maintain

housekeeping at an acceptable level.

Just the routine task of removing parts can force grease into equipment, and contaminate tools, benches and shop areas. Poor housekeeping practices in maintenance shops and storerooms will add labour hours to every job. It increases the opportunity to contaminate new parts and assemblies before they even reach the equipment they will be installed on.

In some industries, such as food processing, there are stringent standards for housekeeping and cleanliness. There are internal, external and regulatory procedures that must be followed. There are government inspections and internal audits performed on regular schedules. SOPs (Standard Operating Procedures) are followed to the nth degree. Parts and tools need to be accounted for after every maintenance job is completed as it ensures objects don’t end up in the food chain. Work areas need to be cleaned and sanitized before production resumes. Work orders and documentation need to be completed immediately following the work.

If we think about it, why shouldn’t ev-

ery industry follow these standards?

In severe environments, where there is raw and partly processed material laying on top of equipment, losing tools and parts can happen easily.

For example, a wrench left in a screw conveyor or mill can cause a lot of damage on startup. So tracking parts and tools becomes just as important as it does in the food industry.

Developing world-class standards relates to every industry. We can implement it at a level that fits the environment we work in and move our maintenance people to a new level of professionalism. Clean and organized work areas are pretty basic principles.

Each facility needs to decide whether they will allow and live with the “good enough syndrome” or take the time and effort to change the culture in their maintenance departments.

One thing is for sure: whatever we accept is the best we will ever get. MRO

Peter Phillips of Trailwalk Holdings, a Nova Scotia-based maintenance consulting and training company, can be reached at 902798-3601 or by email at peter@trailwalk.ca.

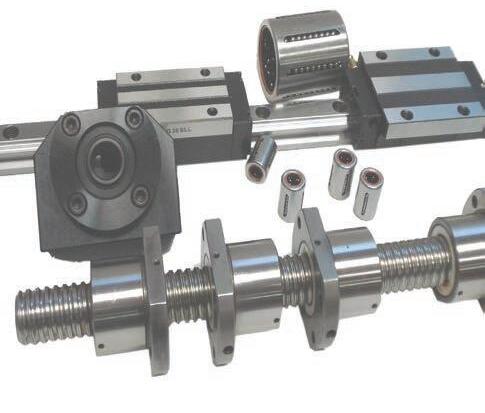

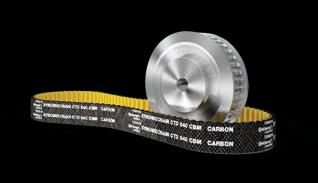

Global Bear Inc. is pleased to announce the addition of our latest products:

Our extensive stock of belts and pulleys are competitively priced. We have also invested in cutting machines which will allow us to cut “non-standard” as well as standard dimensioned belts.

Aluminum Metric Timing Pulleys (T5-T10-AT5AT10) with stock bores available from stock.

It will be our pleasure to respond to your requests.

Global Bear Inc., striving to service the needs of industry, through distribution. www.globalbear.ca

Eaton’s Diamond Advantage hydraulic hose series is engineered to optimize pressure, temperature and abrasion while maintaining hose flexibility, fluid compatibility and ease of hose assembly. Pairing Eaton’s Diamond Advantage hoses with over 550 Eaton Z-Series hose fittings make it an excellent choice for your engineered hose assembly needs.

And, you can find Eaton Diamond Advantage hydraulic hoses at your local Motion Canada branch. Our sales and service specialists are experts in providing application and technical solutions, with the choices and expertise you need to stay up and running.

BY DOUGLAS MARTIN

There are many severe applications in the world and some are specialized to certain industries. When it comes to bearings, most companies are split into business units that generally serve three main industries: Aerospace, Automotive and Industrial. There is no question that aerospace applications are the most severe and most demanding, however, industrial applications have a stake in the servere service category, too.

The term “severe service” could mean a lot of things to a lot of people. So, to qualify this, it’s useful to discuss a “bearing design” that has been successful in severe-service applications. In this case, “bearing design” refers to the materials used in the bearings, as opposed to some unique geometry.

There are three key materials that have made a standard bearing geometric design suitable for severe service. Of note, these materials were first introduced and proven in the aerospace and automotive (F1 racing) industries before being introduced to the industrial market.

Those materials are:

1 – Ceramic Rolling Elements (Silicon Nitride)

2 – High Nitrogen Chromium Steel (HNCR) for the bearing rings

3 – Polyether ether ketone (PEEK) as a cage material.

Ceramic Balls have been around for a while. By the end of the 1980s they were

Build a Connector and Calculate Cost Savings With HARTING’s Industrial Connector Configurator and Savings Calculator App

being commercially promoted. However, the manufacture of ceramic rollers is still not available as mass-produced components. A degree of manufacturing development is still required. Ceramic rolling elements have several advantages but the most important one (in terms of servere service) is the ability to operate under marginal lubrication conditions. When the “severe environment” degrades or prevents the lubricant from doing its job, the ceramic rolling elements can cope with the poor conditions (better then standard bearing steel).

HNCR stainless steel offers greater material “cleanliness” than standard bearings steels, with almost no presence of sulfides, aluminates, silicates or globular oxides. The absence of these non-metallic contaminants contributes to extended bearing service life, as does the extremely homogeneous structure. They are very resistant to aggressive media.

PEEK as a cage material is relatively new. PEEK is a semi crystalline thermoplastic with excellent mechanical and chemical resistance properties that are retained to high temperatures and high levels of resistance.

The Connector Configurator lets users create a custom modular connector and send it to a HARTING expert for feedback.

The Savings Calculator shows how using a connector can save money over time as compared to hardwiring the system. DOWNLOAD THE APP NOW AT: HARTING-usa.com/hartingapplications/

In sour gas compressors, a standard compressor (often refrigeration units) is typically used. With sour gas, the H2S (the gas that makes natural gas “sour”), condenses in the compressor and contaminates the lubricating oil and forms sulfuric acid, which then corrodes the bearing.