MAINTENANCE AND THE ENVIRONMENT

Increases employee safety

Condition monitoring For mechanical components

Improves productivity

Eliminates unplanned stops

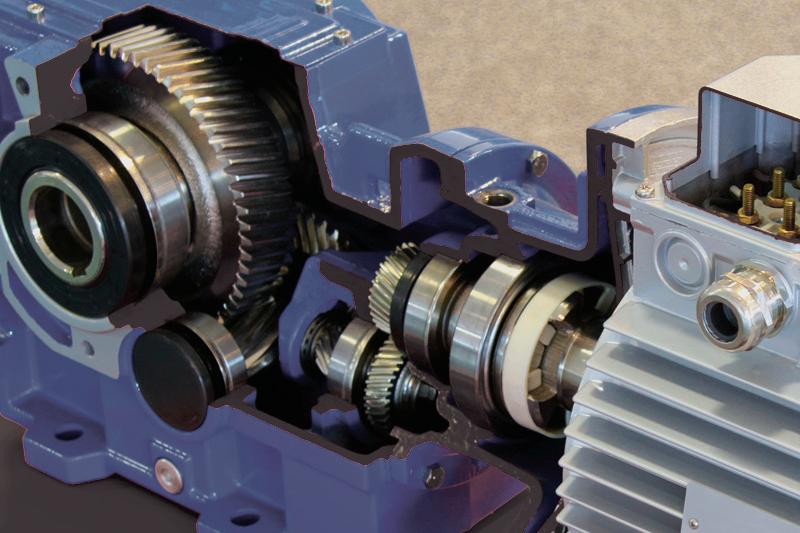

The ABB AbilityTM Smart Sensor for mechanical products is an easy-to-use, wireless sensor which monitors the health of mounted bearings and gear reducers. The sensor provides warnings when health status declines, reducing the risk of unplanned downtime. In addition, connectivity and trend data allow maintenance to be planned proactively instead of reactively, and remote monitoring capabilities keep employees away from areas that are difficult or dangerous to access.

Operate safely. Reduce downtime. Improve reliability. new.abb.com

MACHINERY AND EQUIPMENT

NOVEMBER 2020

MONTH 2019

Vol. 36, No. 5

Established 1985

Vol. 35, No. X Established 1985 www.mromagazine.com

Maintenance Industry Events Go Digital

www.mromagazine.com

Twitter: @mro_maintenance

Twitter: @mro_maintenance

Instagram: @mromagazine

Instagram: @mromagazine

Facebook: @MROMagazine linkedin.com/company/mro-magazine

Mario Cywinski, Editor 226-931-4194 mcywinski@annexbusinessmedia.com

Contributors

Mario Cywinski, Editor 226-931-4194 mcywinski@annexbusinessmedia.com

Bryan Christiansen, Ted Cowie, L. Tex Leugner, Douglas Martin, Doc Palmer, Peter Phillips, David Rizzo, Brooke Smith

Contributors

This time last year, in MRO Magazine’s November issue we covered a large cross-section of live in-person events. They included: the 2019 PEMAC MainTrain Conference, which was held in Edmonton, Alberta, and included an MRO Roundtable; the 2019 Canadian Manufacturing Technology Show (CMTS), which is held bi-yearly, and alternates with the International Manufacturing Technology Show (IMTS); Excellence in Manufacturing Consortium held its Advantage Through Excellence conference; and The Canadian Wind Energy Association (CanWEA) held its 35th Annual Conference and Exhibition.

Michael King, Publisher 416-510-5107 mking@annexbusinessmedia.com

Rehana Begg, Gary Einarson, John Lambert, L. Tex Leugner, Douglas Martin, Peter Phillips

Paul Burton, Senior Publisher 416-510-6756 pburton@annexbusinessmedia.com

Mark Ryan, Media Designer

Barb Vowles, Account Co-ordinator 416-510-5103 bvowles@annexbusinessmedia.com

Jason Bauer, Media Sales Manager 416-510-6797 jbauer@annexbusinessmedia.com

Beata Olechnowicz, Circulation Manager 416-442-5600 x3543 bolechnowicz@annexbusinessmedia.com

Ilana Fawcett, National Account Manager 416-829-1221 ifawcett@annexbusinessmedia.com

Tim Dimopoulos, Vice-President tdimopoulos@annexbusinessmedia.com

Mark Ryan, Media Designer

Flash forward to 2020, PEMAC held its first ever virtual MainTrain (page 10), which was shortened to two days, and was held entirely online. IMTS was cancelled for 2020, with CMTS hopefully returning for 2021. And the CanWEA is now the Canadian Renewable Energy Association, and it is putting on the Canadian Renewable Energy Forum: Wind. Solar. Storage virtually this year in November.

With the pandemic still ever-present, virtual events are the way to go. For many, the virtual nature of the events are welcome, as it reduces costs associated with travel and accommodations, as well as time away. It does feel different; however, reporting on events that you cannot take photos of, and attend is person. Maybe I'm just old fashioned. Looking at how things stand, it may not be until MRO’s next November issue that we will have in-person event to report on again. Let’s hope it is sooner.

Scott Jamieson, COO sjamieson@annexbusinessmedia.com

Barb Vowles, Account Co-ordinator 416-510-5103 bvowles@annexbusinessmedia.com

Mike Fredericks, President & CEO

Machinery and Equipment MRO is published by Annex

Beata Olechnowicz, Circulation Manager 416-442-5600 x3543 bolechnowicz@annexbusinessmedia.com

Business Media, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1; Tel. 416-442-5600, Fax 416-510-5140. Toll-free: 1-800-268-7742 in Canada, 1-800-387-0273 in the USA.

Printed in Canada

Scott Jamieson, COO sjamieson@annexbusinessmedia.com

ISSN 0831-8603 (print); ISSN 1923-3698 (digital) PUBLICATION MAIL AGREEMENT #40065710

Mike Fredericks, President & CEO

CIRCULATION

E-mail: bolechnowicz@annexbusinessmedia.com

Machinery and Equipment MRO is published by Annex Business Media, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1; Tel. 416-442-5600, Fax 416-510-5140. Toll-free: 1-800-268-7742 in Canada, 1-800-387-0273 in the USA.

Looking at the environmental theme in this issue, MRO’s former editor Rehana Begg, speaks with Aaron Weston, hydraulics specialist and owner of ASW Enterprises in Stratford, Ontario. In her article Smaller Footprint: Extend the Life of Hydraulics, which looks at how energy efficient components and training initiatives help to maintain hydraulic systems (page 12).

Tel: 416-510-5182 Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Printed in Canada

Subscription rates.

ISSN 0831-8603 (print); ISSN 1923-3698 (digital)

Canada: 1 year $65, 2 years $110 United States: 1 year $110

PUBLICATION MAIL AGREEMENT #40065710

CIRCULATION

Elsewhere: 1 year $126 Single copies $10 (Canada), $16.50 (U.S.), $21.50 (other). Add applicable taxes to all rates.

E-mail: bolechnowicz@annexbusinessmedia.com

Tel: 416-510-5182 Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Subscription rates.

On occasion, our subscription list is made available to organizations whose products or services may be of interest to our readers. If you would prefer not to receive such information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

Privacy@annexbusinessmedia.com, 800-668-2374

Canada: 1 year $65, 2 years $110. United States: 1 year $110. Elsewhere: 1 year $126. Single copies $10 (Canada), $16.50 (U.S.), $21.50 (other). Add applicable taxes to all rates.

Our special green news section (page 8) looks at how Ford Motor Company of Canada, along with the Federal and Provincial governments are investing in Ford’s Oakville Assembly Complex, to make it a battery electric vehicle manufacturing hub. We also look at how the Ontario Main Street Recovery Plan will include an Act that if passed will enable Community Net Metering demonstration projects that will help local communities develop things like net-zero or community micro-grids. And finally, SANY is introducing battery electric truck mixers to its fleet, which helps to reduce emissions produced on its regular truck mixers.

On occasion, our subscription list is made available to organizations whose products or services may be of interest to our readers. If you would prefer not to receive such information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2019 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

Annex Privacy Officer Privacy@annexbusinessmedia.com, 1-800-668-2374 No

Our Mr. O - The Practical Problem Solver tip (page 30) looks at how to sustain the environment with maintenance. James Reyes-Picknell discusses how maintainers are the key to achieving good environmental performance.

If anyone has any story or theme suggestions for an upcoming issue of MRO, be sure to send me a note.

Good day,

Machinery

Mario Cywinski Editor

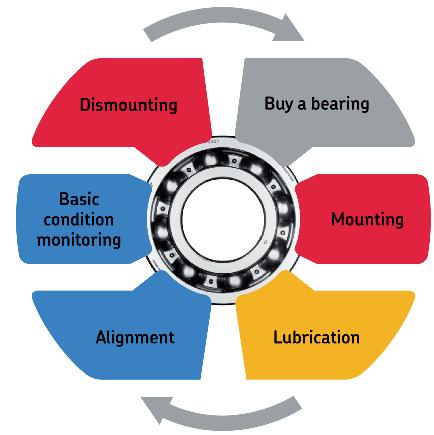

SKF TOOLS HELP KEEP YOUR MACHINES RUNNING

Improve your efficiency with solutions from SKF

» Bearing fitting kits TMFT Series

Poor fitting, usually using brute force, accounts for 16% of premature bearing failures. SKF’s TMFT Bearing Fitting Tool Kits are designed for quick and precise mounting of bearings, while minimising the risk of bearing damage.

goo.gl/WrkTMQ

» Shaft Alignment Tool TKSA Series

» SKF EasyPull mechanical puller TMMA series

The patented SKF EasyPull is one of the most user-friendly and safe tools on the market. The series is equipped with spring-operated arms and a solid design.

Avoid damaging the shaft with improper removal techniques, the TMMA series will assist you in the secure way to remove your bearings.

goo.gl/BL26Qo

The TKSA Series are easy to use laser alignment solutions for achieving accurate shaft alignments. With two wireless measurement units, large sized detectors and powerful lasers, the instrument performs in even the most challenging conditions.

By applying the right maintenance practices and using the correct tools in all stages of the bearing life cycle, you can considerably extend your bearing’s service life and thereby increase plant productivity and efficiency.

More at: goo.gl/o2cwdF

» SKF Portable Induction Heater TIH series

The TIH series combines high heating capacity with portability. Heat is used to expand the bearings inner ring before placing on the shaft, as the bearing cools a stronger interference fit is the result.

goo.gl/TOSupQ

» SKF SYSTEM 24 Single Point Automatic Lubrication

Continuously delivers precisely measured amounts of lubricant to desired points via a gasdriven pump. It is ideal for lubrication points difficult or unsafe to reach manually, or where there are a large number of lubrication points where manual greasing would be less effective.

goo.gl/1gpzZZ

Smaller Footprint: Extend the Life of Hydraulics / 12

Energy efficient components and training initiatives can help maintain hydraulic systems.

What’s Up Doug / 18

Bearing quality, service life and fatigue life. What does the user want? What does the machine designer want?

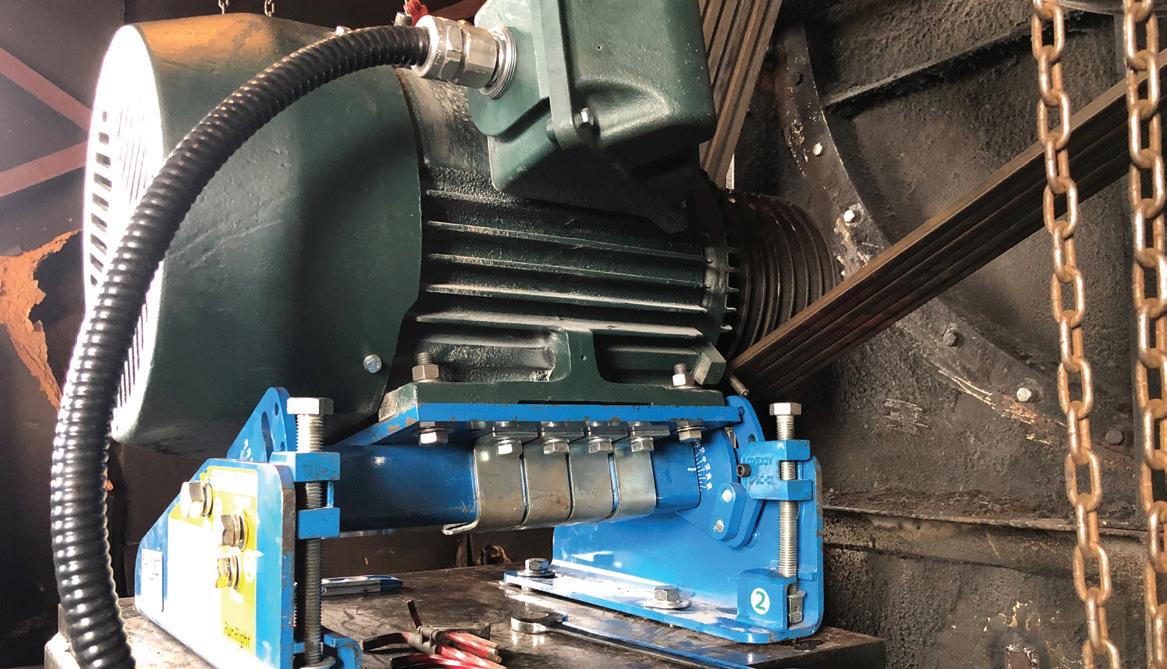

Belt Alignment / 22

It’s about time we treat belt driven machines with more respect.

MRO Quiz / 16

Troubleshooting using common testing and measurement tools.

Maintenance 101 / 20

Preventive and predictive maintenance are two important elements of any equipment maintenance program.

Case Study / 26

How to detect pump valve failures in positive displacement pumps.

Editor’s Notebook / 3

Industry Newswatch / 6

Green News / 8

Resource Sector News / 9

Mr. O / 30

MainTrain Conference Goes Digital / 10

Product News

What’s New in Products / 29

ABB Partners with Lion Electric

ABB has partnered with Lion Electric to help strengthen the transition to zero-emissions in the future in North America. ABB will offer its charging equipment product line to Lion Electric, to be sold under Lion Electric’s new Lion Energy division, making the Quebec-based company a service partner for ABB.

Lion Energy packages charging infrastructure design and review, project management, utility coordination and customized consultation to customers. Lion Energy helps to ensures infrastructure installation is accomplished

in tandem with the vehicle purchasing process, allowing customers to meet their charging needs for now and the future.

ABB will supply the full range of solutions to support the Lion Electric fleet, which ranges from small buses to 300kw battery trucks. Lion Electric will be trained to undertake the servicing of ABB’s EV charging solutions. ABB’s charging hardware and software are designed to meet the needs of e-buses and trucks.

ABB also supports the end customers’ installation of the charging equipment. MRO

Field Support for Hydro One Workers

Safetyscope has a new three-year contract with Hydro One to provide confined space rescue services.

Services to be offered will include confined space attendant/rescue, along with consulting services, and assistance in developing custom rescue plans as identified in Hydro One’s Confined Space Management Program.

“We have worked with Hydro One in the past on a project basis providing confined space rescue services and program support employing our experienced crews with extensive knowledge of Confined Space Rescue,” said Gary Spencer, President, Safetyscope. MRO

General Motors Invests in St. Catharines Plant

General Motors Canada and its partners are investing $28 million at its St. Catharines Propulsion plant. St. Catharines Mayor Walter Sendzik, Niagara Regional Chair Jim Bradley and Local MP Chris Bittle, were on hand for the announcement at the plant.

The co-generation program is expected to reduce net greenhouse gas emissions by approximately 70 per cent, and protect the plant from rising electricity and carbon costs.

The 6.4-megawatt co-generation project uses renewable landfill gas delivered by pipeline from a landfill to generate electricity from newly installed engines at the plant. GM will also recover thermal energy to power and heat the plant.

Partnerships with Alectra Utilities, Integrated Gas Recovery Services, and Ontario Centres of Excellence, have allowed the project to be the first complete renewable landfill gas industrial co-generation system in Ontario delivering renewable landfill gas from an off-site source. MRO

OACETT Names CEO

The Ontario Association of Certified Engineering Technicians and Technologists (OACETT) has named Cheryl Farrow as its new CEO.

Farrow’s will help put OACETT’s strategic plan into action and connecting with stakeholders, partners, and members. She will also focus on better understanding how members have been affected by the COVID-19 crisis, and working with staff to provide support to members coping with disruptions in their organizations.

Farrow has over 20 years of experience in not-for-profit management, including governance transformation, amalgamation and credentialing. She has been CEO of the Canadian Bar Association, President and CEO of the Supply Chain Management Association, Executive Director of the Canadian Grocery Human Resource Council, and President of the Ontario Tourism Education Corporation. She has an MBA from the University of Toronto’s Rotman School of Management, and holds the Certified Association Executive designation. MRO

Ford of Canada Invests in Oakville Plant

Ford Motor Company of Canada, along with the Canadian and Ontario governments are investing a total of $1.8-billion to make Ford the first auto maker in Canada to build BEVs. Both levels of government will invest $295 million.

"With the support of the federal and provincial government, Ford of Canada is investing in the future of its Ontario-based operations, solidifying its commitment to providing thousands of well-paying jobs in Ontario and becoming the first automaker in the country to build full battery-electric vehicles while delivering operational improvements that will maximize production flexibility to ensure we remain operationally competitive," said Dean Stoneley, Presi-

dent and CEO, Ford.

Ford will retool its Oakville Assembly Complex from an internal combustion engine site to also become a BEV manufacturing facility, beginning in 2024. Ford also plans on introducing a new engine program at its Windsor plant.

"Today's announcement is a testament to Canada's attractiveness as a destination for clean technology, talent, and infrastructure in the automotive industry," said Prime Minister Justin Trudeau. "Companies like Ford are helping accelerate our transition to a low-carbon, cleangrowth economy, which will help protect our environment, drive innovation, and create many good middle-class jobs."

The Oakville plant will be modernized with a flexible manufacturing system, allowing for multiple BEV models, as well as installation of a battery-pack assembly line. Ford plans to have its first BEV from Oakville roll off the line in 2025. The Oakville plant is planned to be one of the highest volume BEV plants in North America.

Ontario’s Main Street Recovery Plan

Hon. Prabmeet Sarkaria, Associate Minister of Small Business and Red Tape Reduction unveiled Ontario's Main Street Recovery Plan, and plans to introduce proposed legislation (Main Street Recovery Act, 2020).

The Act (if passed) will enable Community Net Metering demonstration projects to help support local communities to develop innovative community projects like net-zero or community micro-grids.

“There are many Ontarians who are keen to have their homes and businesses powered by solar energy but do not have the roof space on-site to install this technology. A community net metering framework would enable more people to benefit from solar energy deployment within the community while also creating local jobs and investment”, said Nicholas Gall, Director of Distributed Energy Resources, Canadian Renewable Energy Association.

The plan includes:

• A one-time grant of up to $1,000 for eligible main street small businesses — in retail, food and accommodations, and other service sectors — with two to nine employees to help offset costs of PPE;

• Ontario's small business COVID-19 recovery network, which links 47 small business enterprise centres across the province;

• Digital main street squads;

• Mental health supports for families, frontline workers, young people, children, and Indigenous communities; and,

• Ontario's small business recovery web page.

"Ontario's small businesses were hit hard by COVID-19, but they were the among the first to step up and demonstrate the best of the Ontario Spirit by bringing forward their innovative ideas and solutions in our time of need," said Vic Fedeli, Minister of Economic Development, Job Creation and Trade. "Building on the steps we took at the outset of the pandemic to provide urgent economic relief to struggling small businesses, Ontario's Main Street Recovery Plan will help get more and more small businesses back on their feet as we continue down the path to economic recovery together." MRO

“By making this investment in Ford Canada, we are ensuring our province continues to lead North America and the world in automotive manufacturing and innovation, while boosting our competitiveness in this key sector," said Premier Doug Ford. "We are also securing thousands of good-paying jobs, not just at the facility in Oakville, but across the province. This project will help support our auto parts sector and other suppliers and service providers." MRO

Sany Battery Electric Truck Mixers

Sany has unveiled a battery electric version of its truck mixers. The model is equipped with permanent magnet synchronous motors with maximum 350kW in power output and 2,065 foot/pounds (2,800 Nm) of torque.

High-energy-density LFP batteries supply, offer a driving range of 250 kilometres. The power source is augmented with thermal management technology, an anti-rollover structure, and fire-proof protection system.

Other features include self-heating function for low temperatures, and advanced cooling system for high temperatures. Truck Line provides real-time monitoring, performance analysis, and remote diagnosis.

The trucks have been delivered to and commissioned to strategic Sany partners in China. MRO

TransAlta Renewables WindCharger Begins Operation

TransAlta Renewables Inc., WindCharger battery storage project began commercial operation in October.

WindCharger is Alberta's first utility-scale, lithium-ion energy storage project, utilizing Tesla Megapack technology. It has a nameplate capacity of 10MW and total storage capacity of 20MWh.

This technology can be fully charged in approximately two hours, and will be powered by TransAlta’s Summerview II wind farm. The project, acquired from TransAlta Corporation in August, has a total capital cost of approximately $14.5 million, with approximately 50 per cent funded through Emissions Reduction Alberta.

As part of the acquisition, TransAlta will pay a fixed monthly capacity charge for the right to operate and dispatch the battery in the Alberta market.

Schneider Electric and Semiotic Labs Announce Partnership

Schneider Electric and Semiotic Labs have signed a partnership agreement, that will broaden Schneider's managed service offering. It will now support monitoring of rotating equipment.

Integration of Semiotic Labs' predictive analytics into Schneider's EcoStruxure Asset Advisor platform helps to predict upcoming failures up to six months in advance. The expanded service offers a unified user experience and remote expert service team.

EcoStruxure Asset Advisor powered by SAM4 analytics provides Schneider customers with asset reliability. SAM4's machine learning algorithms provide performance and energy insights with improved asset management efficiency and effectiveness. MRO

Stelco Completes Blast Furnace Upgrade

Stelco Holdings Inc., owner of operating company Stelco Inc., announced the successful completion of the Lake Erie Works blast furnace upgrade and reline project, and commencement of production.

It’s expected the upgrades in the blast furnace will result in improved quality, increased hot metal production (up to 300,000 net tons per annum), and a corresponding $30 per net ton reduction in costs to produce steel coils. MRO

MAINTRAIN CONFERENCE GOES DIGITAL

BY MARIO CYWINSKI

PEMAC Asset Management Association of Canada held its annual MainTrain conference recently. The conference goes to a different location in Canada every year, with Ottawa and Edmonton being the two most recent destinations. This year, the event was to take place in St John, New Brunswick; however, as a result of COVID-19, it became a virtual conference for the first time. Therefore, in a way, you can say that its destination for 2020 was all of Canada.

“MainTrain 2020 successfully enabled PEMAC Asset Management Association of Canada's members to connect, learn and contribute across a wide range of maintenance, reliability and asset management topics,” said Susan Lubell, President PEMAC. “Over 50 per cent of participants attended for the first time in this online event forum and were rewarded with networking opportunities with other practitioners across the country.”

Over 200 attendees took in the 21 presentations that included 35 speakers, two keynotes, networking sessions, an exhibit hall, and an awards presentation.

Keynotes

Cut down to two days for 2020, the event still packed a lot of information. Two keynotes began each day of the conference. On the first day Daisy Foster, Managing Director, Atlantic Infrastructure Management Network, spoke about Municipal Asset Management in Atlantic Canada, while day two kicked off with a keynote from Brett Plummer, Vice President Nuclear and Chief Nuclear Officer, NB Power, who spoke on Recovery of Asset Management.

Sessions

Through the two days, learning sessions were divided into three streams, asset management, reliability, and maintenance management. Each time slot provided attendees the choice of attending a session from each of the streams.

The maintenance management stream featured sessions by James Reyes-Picknell, Conscious Asset (Getting Your Point Across), Iqbal Singh Biln and Gregory Palmer, St. Lawrence Seaway Management Corp. (Maintenance Excellence at SLSMC),

Cliff Williams, Erco Worldwide (Getting to the Bottom of Things - Removing Causes), among others.

The reliability steam offered sessions by James Kovacevic, Eruditio LLC (Asset Hierarchy and the Link to Reliability Improvements), Andre Ferrari, Enbridge Pipelines (Reliability Engineering Analytics Explained), Conrad Greer, SPC Results Inc (Bad MRO Material Master Identities Are a Root Cause of Your Business Process Challenges. A Fixable Problem), and more.

Finally, the asset management steam looked at Operations Readiness – An Often Forgotten Part of the Asset Management Lifecycle (Christopher Biel, PPAIP Consulting), The Organization-Wide Physical Asset Management Approach (Dharmen Dhaliah, Town of Halton Hill), Asset Management Effectiveness Begins with the Right Plans - Are You Planning and Delivering the Right Capital and O&M Work? (Roopchan Lutchman, SLBC Inc), and others.

Panel Discussions

Two panel discussions ended each day of the conference. On day one technology was the topic of discussion. It was moderated by Len Middleton, Asset Management Solutions, and featured Koleya Karringten, Absolute Combustion; Sepideh Rajaeirad, Seeq; and Chi-Guhn Lee, University of Toronto. The day two panel focused on Creating a Culture for Asset Management Excellence. Moderated by Cliff Williams, and had a panel with Rob Lash, The Regional Municipality of York; David Albrice, Asset Insight Management Ltd.; Dharmen Dhaliah; and Andy Thorne, Cameco Corporation.

As PEMAC is keeping the MainTrain virtual portal open after the event, all the streams, as well as on-demand content, are available to those who registered for the event.

Exhibitor Hall

A big part of the MainTrain conference in previous years has been the exhibitor hall. This year a virtual exhibitor hall was created and allowed attendees to view company information (including PDF files, social media links, videos) and contact representatives from each exhibitor.

Photo: Pemac

Networking

Two final aspects of the conference were the networking capabilities and a lobby. The former was used to great effect, as it allowed attendees to message each other, create group chats, video chat, and comment on sessions. The latter was as the landing page or jumping off point for attendees.

Award Winners

PEMAC ended the first day of the MainTrain conference with its 2020 Virtual PEMAC Awards Ceremony.

“PEMAC congratulates all of the 2020 award recipients, and thanks to everyone who participated in the nomination and review process,” said Alan Cox, Chair, PEMAC Awards Committee. “We are proud of the work members are doing to accelerate excellence in maintenance, reliability, and asset management throughout Canada and around the world.”

Seven awards were given out this year, including two new awards in the asset management category. The winners were:

Member Awards

Life Member

Dr. Andrew Jardine

Excellence in Practice Awards –Maintenance Management

MMP Capstone Award: Ryan Berg, MMP

Sergio Guy Memorial Award: Susan Lubell, P.Eng, MBA, MMP, CAMA

Maintenance Team of the Year Award

Regional Municipality of Halton

Excellence in Practice Awards – Asset Management

AMP Capstone Award

Lorena Mueller, CAMP

Asset Management Leadership Award

Cliff Williams, CAMP CMRP MMP CRL

Asset Management Achievement Award Cowichan Valley Regional District

The awards were created to encourage excellence in maintenance, reliability and asset management across industries as professionals connect, learn and contribute to their organizations and the asset management community. MRO

SMALLER FOOTPRINT: EXTEND THE LIFE OF HYDRAULICS

Energy efficient components and training initiatives can help maintain hydraulic systems.

BY REHANA BEGG

Scarcity of resources and the impact of climate change is a megatrend that drives the need to shape responsible attitudes to protecting our natural resources. This lynchpin behind the growing emphasis on energy efficiency and sustainable technologies challenges manufacturers to step away from a takemake-waste extractive industrial model in favour of a circular economy approach, which aspires to decouple from consuming finite resources while designing waste and pollution out of the system.

The phrase “reuse, prevent and repair” is unambiguously associated with environmental efficiency, but could serve as a mantra for a conscientious aftermarket. Typically, the opportunities to save energy and reduce operating costs across industrial MRO markets are tied to overall energy consumption at the plant or on the shop floor. The choice to be intentional about energy efficiency and cost

savings begins with selecting equipment and components that take advantage of various energy sources, while limiting the waste associated with the processes that transform that energy.

Take modern hydraulic systems for example. A hydraulically powered machine using “smart” and energy-efficient components (including valves, seals, filters) not only reduces the damaging effects of fluid friction, but also creates value and rapid ROI (return on investment), argues Aaron Weston, hydraulics specialist and owner, ASW Enterprises in Stratford, Ont.

Weston highlights research on global applications of electric motors in industrial settings that shows that about 60 per cent of electrical power generated is consumed by electric motors. This consideration throws light on increased production costs and pollution and motivates industry to optimize

energy efficiency.

Fixed displacement pumps, for example, waste energy by either dumping over a relief valve or bypassing fluid when pressure exceeds its setting.

“That is wasted energy,” said Weston. “If you’re driving these pumps at 1,800 rpm, that’s hydraulic horsepower that’s not being utilized. It’s turned into heat energy. If you can lower the rpm, you can reduce the heat energy and reduce the waste.”

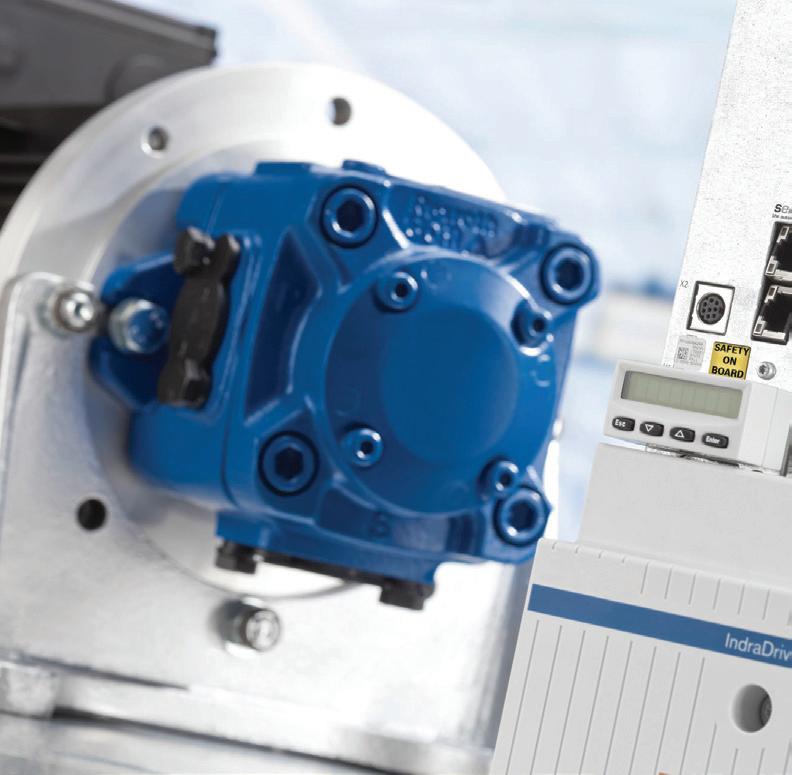

Weston, who researches market technologies, cites Bosch Rexroth’s Sytronix as just one example where variable frequency drive (VFD) servo motors are being used.

“Instead of having motors run and pumps compensating and wasting energy, they’re starting to lower the rpm and react to the demand of the system,” said Weston. “So, there’s been significant downsizing in the hydraulics; the load

Photo: Bosch Rexroth

has been brought down.”

In an interview with Machinery and Equipment MRO, Weston acknowledges the extent to which electrification has impacted a mature hydraulics industry.

“You can say it’s negative and that servo and electrical components are more capable with higher forces, but you’re always going to need hydraulics for highforce outputs,” said Weston.

“Hydraulics is its own animal” and demand endures for technical knowledge on hydraulic systems and for innovative ways to lower its footprint, suggests Weston, who delivers courses ranging from Principles of Hydraulics and Maintenance, Repair & Commissioning of Hydraulic Systems, to Piston Pumps & Motor Controls, Servo & Proportional Hydraulics, Design Considerations, and Mobile Hydraulic Systems.

Currently supporting Bosch Rexroth Canada with hydraulics instruction at sites across Canada, Weston also points out there are few colleges in Canada that offer training for hydraulic specialists.

“Centennial College used to offer courses and Mohawk College has a little bit, but it’s just not focused enough. As a result, aftermarket companies like Rexroth or Vickers or Parker or Siemens have to do training, because nobody specializes and there is no special field for it per se in the educational system.”

MRO: How are best practices evolving across the hydraulics industry and its aftermarket as enterprises strive for more sustainable practices?

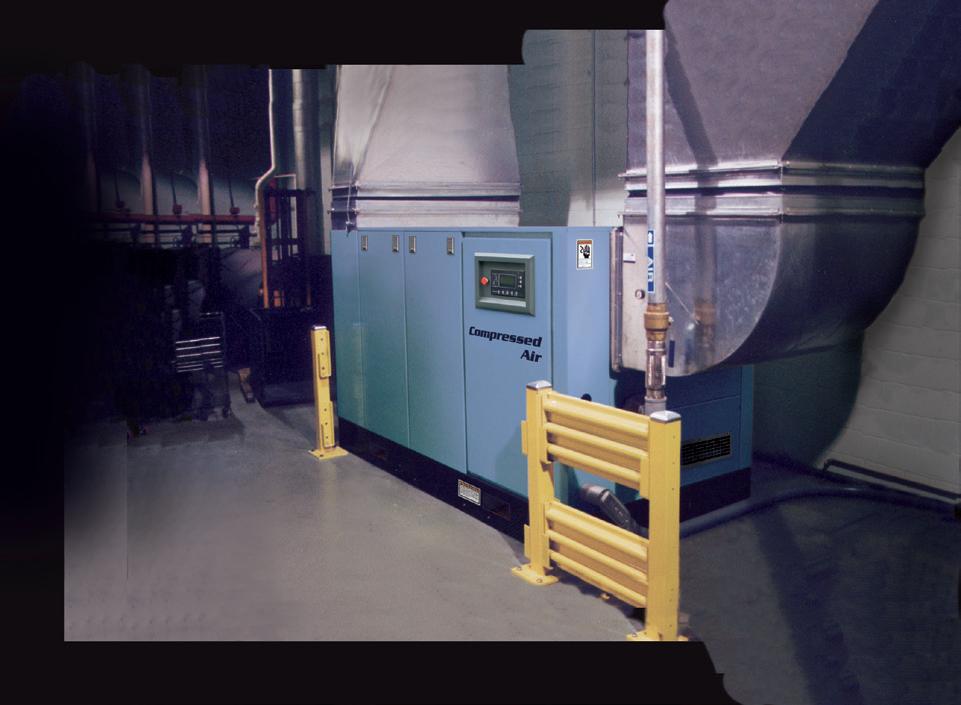

AARON WESTON: Electrification is here, and with respect to the hydraulics industry and its aftermarket, more and more hydraulics companies are developing and implementing hydraulic systems utilizing variable frequency drives and servo motors. Having variability with the prime mover (the VFD motor or servo motor) now means less complication with the hydraulic pump.

Therefore, depending on the pressure/force requirements, the hydraulic pump used can

now be a less expensive vane or gear pump. This does put a bit more expense on the electric motor and control side. However, this has been the direction companies who build air compressors and water supply systems have moved over the past 20 years.

From a sustainability standpoint, both knowledge and aftermarket components for the electrical side of the control are more widespread. From an energy perspective, there is a lot less kilowatt usage, because during idling and when holding pressure, the prime mover (motor) can slow down to 200 to 300 rpm. When flow is required the prime mover can speed up rapidly to 1800 to 2200 rpm. This presents significant energy savings.

MRO: Hydraulic pumps and motors were traditionally designed to be workhorses for mobile machinery, particularly in combination with diesel engines. These days, manufacturers look for energy efficiency solutions through electrification. Can you elaborate on how the trend towards electrification impacts hydraulics? What kinds of efficiencies do we gain and what do we lose?

WESTON: The overall advantage of electrical energy is that it is less wasteful than hydraulic energy. The law of energy simply states you can neither create nor destroy the energy, only change its form. With hydraulic energy, if something is not being moved, either linear or rotary, or a combination of both, there is waste, and that wasted energy is transferred to heat energy.

With the ability to control the electrical energy, utilizing only the pow-

er required to do the work, efficiency solutions through electrification have become the trend. With that said, this means less use for linear and rotary solutions with hydraulics if electrical solutions can perform the work at a cost-competitive advantage.

MRO: The hydraulics assembly process can generate a variety of waste materials, such as scrap hose and couplings, and other rubber and plastic materials. From field experience and observation, can you provide examples of waste? What should be the approach to handling waste or leakage at the plant level?

WESTON: With respect to old hoses, damaged pumps, and discarded components, I believe the industry does a good job with recycling materials, considering much of the material recycled is steel, brass or bronze and rubber, which often yield a decent return when recycled.

With respect to oil leaks, and leakage, not a lot is done overall to repair or prevent leaks. Many companies are under tremendous constraints to produce their products and often the cost of replacing the oil, unfortunately is easier than allowing the downtime required to find and repair leaks.

MRO: Can you provide a few pointers on how industrial plants can optimize MRO strategies in support of sustainability?

WESTON: Really invest, utilize and believe in reliability centred maintenance. With the advent of Industry 4.0, and the Internet of Things (IoT gateways), so much has been developed to signal to industry the health of their hydrau-

lic systems and all the components involved. Thermal imaging technology is cost-effective, and with heat signatures prevalent in hydraulic systems, heat signatures can tell an end-user a lot about how their system is operating, often indicating when components are headed to failure mode.

Oil analysis, vibration analysis, pressure values, flow values, positional information, among many other inputs, can give very important information before critical failures arise, and the cost of these systems has become favourable in recent years.

MRO: Arguably, addressing some of the sustainability issues requires a deep understanding of basic processes in fluid mechanics, heat and mass transfer and materials science, and more. What role should hydraulics instruction play in educating industry on sustainable best practices? Are there any standards to reference? What is your personal approach to instruction?

WESTON: Unfortunately, hydraulics instruction is not covered with any great deal of detail at either the college or university level. In-depth knowledge required to address some of the sustainability issues is lacking in the industry because of the lack of understanding of basic fluid principles. Hydraulics instruction, beyond the college and university level, has become crucial for those who design, build, install and service hydraulic systems—especially with the marriage of electrical systems into hydraulic systems, that is, electro-hydraulics.

My personal approach to instruction, first and foremost, is safety. Hydraulic technology is a very dangerous technology with system pressures sometimes registering well over 5,000 psi (350 bar). Beyond that, understanding the basic fundamentals of fluid power (energy, horsepower, heat, torque, pressure, flow, etcetera), understanding the inputs (pumps), understanding the outputs (actuators—motors and cylinders), and understanding all of the controls in between (pressure control, flow control, directional control). MRO

Rehana Begg is a Toronto-based freelance editor. She has spent the past decade in the trenches of industrial manufacturing, focusing on engineering, operations, asset performance and management. Reach her at rehanabegg@rogers.com.

Photo: imantsu / Getty Images

WHY WEBINARS?

You’ve got valuable information/expertise to share with the Canadian MRO world but need a qualified audience and a way to reach it effectively. A targeted webinar, hosted and moderated by MRO, is an important part of the solution.

OPPORTUNITY

Develop a single or series of webinars around issues that are relevant to your business and MRO’s readers — your customers and prospects.

FORMAT

FREE to participants

45 minute presentation with 15 minute Q&A

MRO assists with content development

MRO hosts and moderates

MRO promotes registration

MRO co-ordinates technical elements

ROLES AND RESPONSIBILITIES

MRO markets event online to drive registration (e-newsletters, direct email, banner/button advertising)

MRO coordinates logistics of conference call

MRO provides a list of all attendees post-event for follow up

MRO records event and hosts on website for 12 months

Sponsor can provide speaker(s) and presentation content

TROUBLESHOOTING USING COMMON TESTING AND MEASUREMENT TOOLS

BY L. (TEX) LEUGNER

Monitoring equipment condition has been around since man created the wheel. When the wheel squeaked and the wheel hub began to burn, man learned to grease the wheel with tallow. As the application of the tallow became more precise, the mean time between potential failures of the wheel was extended, and the concept of preventive maintenance was established using the senses of sound, sight, touch, and smell.

Sensory perceptions; however, are subjective and imprecise, and condition-monitoring techniques using common tools have been developed and applied for industrial equipment. Substantial evidence exists that the intelligent use of common testing and measuring techniques may provide as many benefits as the use of costly technologies.

By definition, the use of any testing and measurement tool requires that data be collected on an on-going basis. To establish repeatable trend data using common tools, the data must be obtained at regular scheduled intervals, gathered when equipment is at operating temperature and taken at the same point on the machine component each time it is collected. These test and measurement techniques are common, easily applied, and only require that operations and maintenance personnel have a sound knowledge and understanding of their equipment and its operation.

How would you determine the condition of lubricant without an analysis?

Logic: Common oil analysis techniques such as spectroscopy and particle counts can measure wear rates and contaminant levels respectively, but common sense suggests that simple on-site tests can be very cost effective. If an operator suspect’s contamination, a sample of oil

can be obtained in a glass jar, which is then allowed to sit overnight. When the jar is turned over, any contaminant will remain visible on the bottom surface of the jar. A decision can then be made if further laboratory testing is required. Water contamination in the lubricant can also be determined very quickly by placing a few drops of used oil on a hot plate. If the oil drops crackle or sizzle, there is excessive water present.

How can you determine the effectiveness of oil filters?

Logic: Every time an oil filter is replaced, the old filter should be cut open, the filter media spread on a bench and using a magnifying glass or microscope, contaminants and wear metals will be obvious. Further testing can be applied by placing a magnet under the filter media. All ferrous materials will move on the surface of the filter media as the magnet is moved. If machine damage is suspected, or the level of contaminant or wear metals has increased since the last filter inspection, an oil analysis should be carried out immediately.

How can you easily determine the operating temperature of any rotating machine component?

Logic: the operating temperatures of industrial equipment are often unknown or ignored and frequently never considered until after a failure has occurred. The first step taken for any piece of equipment is to determine the operating temperature under normal conditions after the equipment is first placed into service. Record this standard in the maintenance files and investigate any change in that standard during the life of the equipment and temperatures should not exceed those listed below during operation.

Rolling element bearings – 71ºC (160ºF), this is the temperature at which lubricating oil or grease begins to oxidize.

Hydraulic systems – Bulk oil temperature at the exterior of the reservoir should not exceed 60ºC (140ºF).

Gear drives – Operate best in a temperature range of 49ºC to 60ºC (120ºF–140ºF).

Worm gears – Operate best at oil temperatures of about 60 to 65ºC (140–150ºF).

V-belts – Should not operate at temperatures higher than 60ºC (140ºF) and should only be covered by a wire mesh safety shroud to ensure airflow.

Gas turbines – Oil temperatures should normally be in the range of 54ºC to 71ºC (130ºF–160ºF).

Electric motors – There are four classes of motor winding insulation, with a corresponding maximum temperature rating.

Photo: Yaraslau Mikheyeu / Getty Images

The temperatures listed include combined ambient temperature and temperature rise. For every 10ºC increase in temperature above the rating, the service life of that particular motor is reduced by 50 per cent. Various studies suggest that 40 per cent of all electric motor problems are directly caused by excessive heat. Common and inexpensive methods of testing temperature conditions include the use of infrared thermometers and digital temperature indicators. The actual operating temperature of internal components will be about 20ºC higher than the recorded temperature.

How do you monitor equipment conditions such as fluid leaks, steam trap

leakage, rotating bearing condition, electrical system arcing, corona discharge, or determine how much grease is required in a bearing without sophisticated equipment?

Logic: these conditions are common in machines of all types and a common inexpensive tool that can be used to monitor these problems is a hand held acoustic ultrasonic device that can easily determine if these problems exist.

How can you determine if a rotating machine has a vibration without the use of a sophisticated vibration analysis device?

Logic: every piece of equipment contains moving parts causing potential sources of vibration such as unbalance, misalignment, bent shafts, defective bearings or gears, mechanical looseness, and electrically induced problems. There are simple devices available today that can be used to determine if a vibration exists within a piece of rotating equipment. They include the following test and measurement tools.

• Stroboscope - can be used to determine the vibration phase and is a useful tool when measuring unbalance and its correction.

• Shock pulse measurement - devices emit shock pulses pressure waves generated in the contact zone between the ball or roller and raceways in bearings. Shock pulses are measured on a decibel scale and compared with severity against the ISO Standard 2372 that provides vibration tolerance limits.

• Vibration pen - can be used to assess rotating machine condition in the 600–12,000 RPM range. The device measures vibration severity in either (mm/s), RMS or (in/s) peak. The vibration severity can then be compared to ISO Standard 3945.

• “SEE” pen - incorporates “spectral emitted energy” to monitor bearing condition. The SEE device measures very high frequencies relating to poor lubrication, damaged bearings, or overloading. The device is recommended for use in conjunction with the low frequency vibration pen described above.

• Marlin condition detector - a handheld device that can be used to gather velocity and acceleration vibration data, as well as temperature monitoring for all types of rotating equipment. It can incorporate bar-coding, oil analysis data, and can be used with many of the common computerized maintenance management programs available today.

• Video probe borescope - is a handheld device that can be used to obtain 3D scans of internal components of any machine, allowing inspectors to visualize the shape and characteristics of areas of wear, including the depth of the wear or pitted condition of component surfaces.

This article only scratched the surface in describing the many inexpensive testing and measurement devices and simple methods that can be applied to increase equipment productivity and reliability. MRO

L. (Tex) Leugner, the author of Practical Handbook of Machinery Lubrication, is a 15year veteran of the Royal Canadian Electrical Mechanical Engineers, where he served as a technical specialist. He was the founder and operations manager of Maintenance Technology International Inc. for 30 years. Tex holds an STLE lubricant specialist certification and is a millwright and heavy-duty mechanic. He can be reached at texleug@shaw.ca.

BEARING QUALITY, SERVICE LIFE AND FATIGUE LIFE

What does the user want? What does the machine designer want?

BY DOUGLAS MARTIN

These are the questions that a bearing manufacturer needs to address to satisfy customer requirements.

What does a machine designer want?

Very often the machine designer is governed by a customer or a technical society’s specification, that defines a calculated life of the machine being designed. For the bearing in that machine, this specification asks for “L10 life” of so many hours (revolutions), are achieved.

L10 life is a calculation that uses the applied load from the application and another ISO governed value, the Bearing Dynamic Capacity (Cdyn) to determine the number of cycles until the onset of sub-surface fatigue.

The difficulty with using the L10 life and dynamic capacity to determine a service life, is that it does not include important factors that influence service life. For the basic “life” calculation, there is no adjustment for the delivered quality of lubrication and cleanliness of the application. There has been “Adjusted L10” calculations that do address these factors, but despite being around for over 30 years, a basic L10 life calculation is still often asked for in machine design.

In terms of the calculation of Cdyn, there are several manufacturing qualities benefits that are not quantitatively defined, and are not equally expressed in the bearing Cdyn tables published by manufacturers.

Meaning a machine designer or governing body who does not take into consideration an adjusted L10 life, is missing an opportunity for more efficient machine design. Also, selecting a Cdyn only, may exclude manufacturers who have a better product for their application.

What does a machine user want?

Machine users want the longest service life between breakdowns or a longer running time before a planned maintenance shutdown. In some cases, the machine users will ask for a bearing (brand) by name that they have had positive experience with, and have a perception of reliable rotation.

In these cases, they are looking for a long service life. Unfortunately, service life is not expressed by an L10 formula, but by a “modified” L10 formula that considers the lubrication conditions including contamination.

What have some bearing manufactures done to bring this to the attention of the bearing users? They have created marketing tags for their products to indicate that these bearings have improved features. These tags are names such as “Explorer” and “X-Life” and are unique to specific brands.

What are the properties that these tags could define?

Cleaner steel – over the past few decades there has been a reduction of the percentage of oxygen in some manufacturers bearing steel. With less oxygen, there is fewer carbides that build up on the grain boundaries of the steel structure. It is these anomalies that serve as the initiation point for sub-surface fatigue, which is the failure mode that L10 life predicts. However, there is no standard by which steel cleanliness is factored into the Cdyn formula.

Rolling element diameter tolerance –element to element – another feature that extends service life is the tolerance of the actual difference between the diameter of each rolling element relative to each other in a single bearing. When

there is differences in rolling element diameter, then the load is not shared evenly. The larger rollers will carry a higher load than the smaller rollers. This leads to a higher stress under the largest roller and it is the magnitude of this load that governs how quickly the fatigue will initiate.

Cage design – the design of the cage can play a number of roles including proper guidance, creating a reservoir for grease, avoidance of lubrication being scraped off the loaded area of the roller, and the ability to accommodate rolling element speed differences in different places in the bearing at any instant.

Some in the industry may argue that there is a performance factor that can be adjusted when publishing a dynamic capacity, and this is true; however, this

Photo: Llgorko / Getty Images

value does not have a defined method of calculation, and some companies may take liberties at determining this value in their calculation of Cdyn.

Misuse of the quality perception

One misuse of the quality levels of bearings is the marketing of “skate wheel” (roller blade) bearings. Some companies have targeted the aftermarket with “ABEC 5” quality bearings. The problem with the ISO and ABEC tolerance levels is to call the bearing an ABEC 5 or P5 means all dimensions are to that precision level, including the bearing width. In many applications, the precision of the width does nothing, so why make a bearing P5 width tolerance when it does not need it.

As a result, one cannot get “ABEC 5” roller blade bearings from the major manufacturer, as they realize that

to call a bearing P5 ISO or ABEC 5, the width tolerance has to be held to a tight tolerance.

What is more important is the running accuracy of the bearing, i.e. the run-out of the ring. What has happened is that skateboard / roller blade makers have tried to capture the market by selling “ABEC 5” bearings as better bearings, but in reality that much accuracy in a skate wheel bearing is wasted. The major manufactures do make this size bearing with tighter tolerances, but only where useful such as the bore, OD and radial runout. They do not hold an “ABEC 5” width tolerance, so they cannot be labelled as such. Also, major manufactures focus on true quality factors, and raceway smoothness, which is not specified with “ABEC 5.”

Not all bearings are made the same.

Some meet the most basic ISO or ABEC standard, others exceed this standard with features that are not part of the standard but directly address service life, as opposed to a simple L10 life formula. Some manufacturers will tag their products to show consumers that this is truly a better bearing.

In the strive for better service life, one must go beyond the bearing capacity and L10 life and understand how the added features from premium manufacturers can provide the longest service life of the bearing and the machine that contains it. MRO

Douglas Martin is a heavy-duty machinery engineer based in Vancouver. He specializes in the design of rotating equipment, failure analysis, and lubrication. Reach him by email at mro.whats.up.doug@gmail.com.

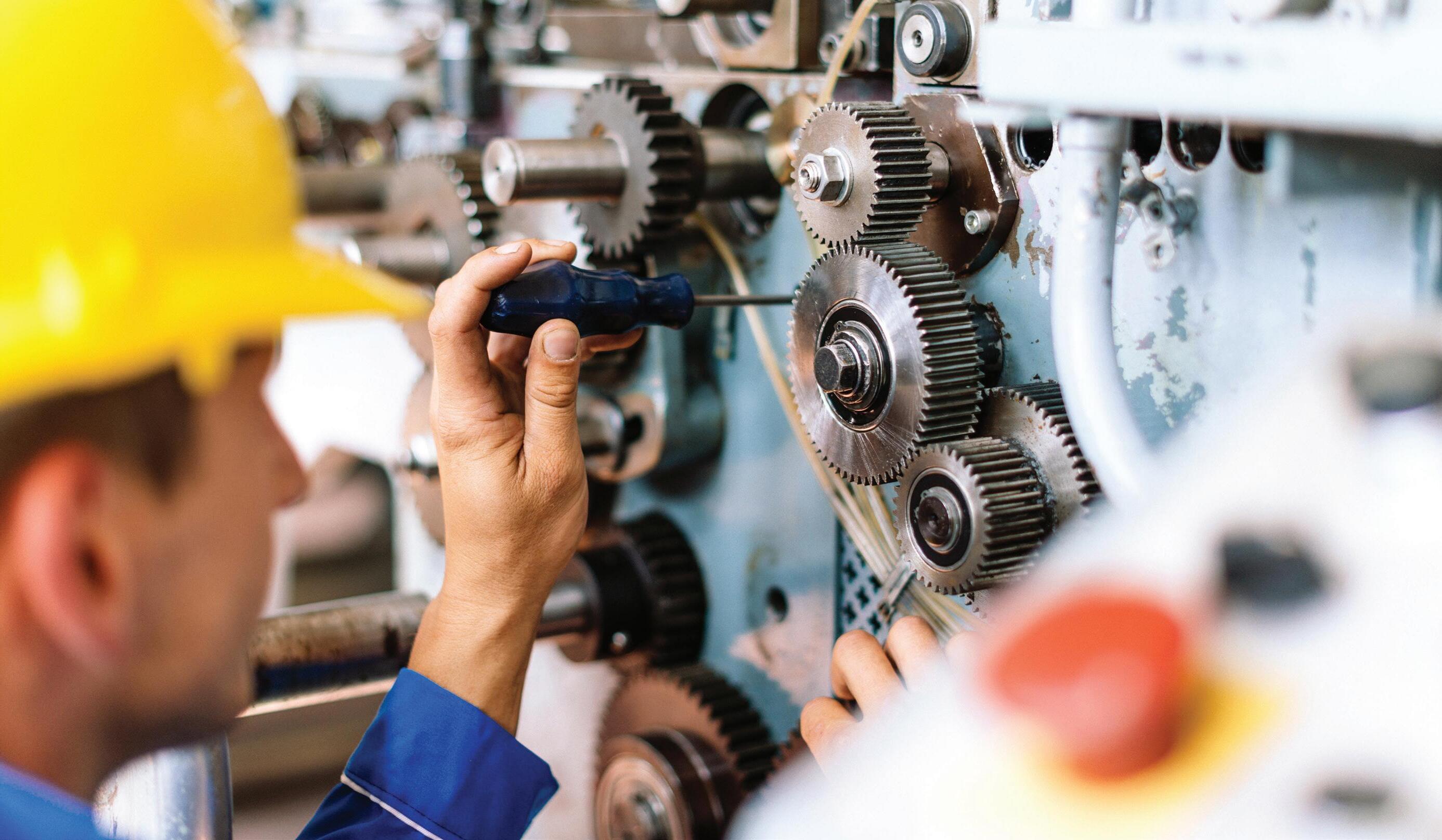

PM REGIMES

Preventive and predictive maintenance are two important elements of any equipment maintenance program.

BY PETER PHILLIPS

Considering PM activities make up approximately 70 to 80 per cent of our time, it only makes sense that those hours are spent wisely, as the effort put into PM activities directly affects equipment reliability. Poorly written and executed PMs can easily be identified as seen through unplanned equipment downtime and decreased equipment availability.

As equipment becomes more complicated, the days of generic PM instructions and leaving equipment maintenance to the discretion of tradesperson has long passed. People maintaining the equipment need specific guidance to perform effective PMs that leaves nothing overlooked due to lack of detailed instructions. Therefore, bullet proof PM regimes need to be developed to improve and maintain equipment performance. What exactly is a PM Regime? They are detailed PM programs that include all necessary documentation, resources, skills, and knowledge needed to perform specific and detailed

preventive maintenance on a single piece of equipment. There are three key PM regimes that need to be developed.

Lubrication PM regime

A properly developed lubrication program determines the specific type of lubricant to use, and when and how to apply it. Well-designed lube programs ensure the proper lubrication frequencies, type of lube, and the amount and method of application, to ensure equipment does not fail due to the lack of lubrication. However, there is more to a lubrication program than just applying lubricants. They need to be stored and handled properly to prevent contamination, from the time they enter the facility until applied to the equipment. Lubrication storage areas need to be organized and clean to protect the lubrication products while they wait to be used.

An effective lubrication PM regime needs to include

• Storage and handling procedures for all lubricants;

• Stocking the right lubricants prescribed by the equipment manufacturer;

• A lubrication plan and map that includes the instructions of when to lube, where to lube, amount to apply, and how to apply it; and,

• Lubrication training for all trades people and equipment operators.

Time Based Preventive Maintenance Regimes

Every piece of equipment requires inspection to evaluate the state of its wear components. Mechanical drives, belts, chains,

Photo: Denys Yelmanov / Getty Images

and gearboxes, need periodic inspections. They need to be written with the appropriate information to ensure the equipment is reliable between scheduled inspections. Often, it is assumed that tradespeople, because they are trained and certified as industrial mechanics and electricians, know everything about their profession.

This is far from the truth. People are trained on the basics, and over years of instruction and experience they learn how to be good at what they do. Tradespeople cannot be expected to know about every piece of equipment and its specific maintenance needs. Tradespeople need training and specific instructions to objectively evaluate and maintain the health of the equipment.

Time-based PM regimes need to include

• Specific and detailed equipment inspection list that include manufacturer recommendations, and plant equipment knowledge;

• Documents, SMPs, and specific equipment details available during inspections, component replacement, and rebuilds;

• Wear components stocked in the storeroom;

• Continuous review of the PM program;

• Monthly equipment reliability reports to determine the effectiveness of the regime; and,

• Periodic training for tradespeople and operators on new equipment and maintenance best practices.

Predictive maintenance regimes

Equipment that falls into the category of critical or hard to access, usually get special maintenance attention and evaluation using technology. Condition-based monitoring has come a long way in recent years, and the availability of cost-effective solutions have made this technology more attractive and affordable. In the past, we have depended on technicians, internal or external, to take periodic condition monitoring readings, and then waiting for the analysis. This type of monitoring is quickly being replaced with permanently mounted sensors on the equipment that provide continuous readings and analysis of the equipment’s health and performance. There are several vendors that specialize in remote sensing and are willing to assist with installation, set up, and analysis.

Other technology such as machine learning and Internet of Things (IoT), is changing how condition monitoring and predictive tools are used to sustain equipment reliability. Industry and Maintenance 4.0 implementations are gaining favour in plants around the world and include maintenance technologies that are vastly improving equipment reliability.

Predictive maintenance regimes need to include

• Selecting the equipment to use equipment monitoring;

• Partnerships with remote condition monitoring vendors;

• Removal of redundant time-based maintenance tasks from the maintenance schedule (CMMS); and,

• Training of staff on new monitoring technologies.

Considerable time, effort, and cost are associated in the development of ironclad PM regimes. They need to be planned and executed on time, because backlogged PM regime work orders will jeopardize the results, and the regimes will start to crumble. In most manufacturing plants, PM hours outweigh the number of available labour hours and equipment availability to perform PM regimes.

Therefore, the design of the PM regimes must take these

constraints into consideration. Apply estimated hours to every PM regime and develop the PM program based on available time and resources. Effective regimes encourages smarter maintenance planning and execution, because missed or poorly done PMs directly affect reliability.

To be successful with effective PM regimes

• Choose the right combination of PM regimes for the equipment;

• Match PM regime required hours with available resources;

• Develop specific detailed regimes for each type of equipment;

• Maintain the necessary parts and resources to complete the regime;

• Train people to understand their responsibilities and how to perform the PM regime; and,

• Measure the change in reliability using monthly graphs and KPIs.

PM regimes that are properly developed and executed are now a best practice in every manufacturing plant wanting a higher percentage of equipment availability. Breakdowns may still occur, but at significantly less frequency, and repair times will fall dramatically, and more time can be spent on PM regimes. MRO

Peter Phillips is the owner of Trailwalk Holdings Ltd., a Nova Scotia-based maintenance consulting and training company. Peter has over 40 years of industrial maintenance experience. He travels throughout North America working with maintenance departments and speaking at conferences. Reach him at 902-798-3601 or peter@trailwalk.ca.

Serious Jack s

Joyce jacks and systems lift and precisely position your loads in the most extreme environments

• Machine screw jacks

• Ball screw jacks

• Bevel gear jacks

• Stainless steel jacks

Adapted for:

• High or low temperatures

• Corrosive environments

• Custom requirements

IT’S ABOUT TIME WE TREAT BELT DRIVEN MACHINES WITH MORE RESPECT

Belt driven machines are the Rodney Dangerfield of the maintenance industry –“they don’t get no respect!.”

BY JOHN LAMBERT

Belt driven machines do need a little bit more TLC than they currently get. Two innovations will greatly improve your maintenance efforts on these highly efficient drives. Also, the general way in which we work with belt drives is a good example of what keeps reliability unachievable for many.

Some individuals/organizations really understand the value

of doing this work right. Gary Burger wrote an article on improving the efficiency of belt drives. He says that he “expects to get three to five years from a belt that is running 24/7.” He gets that, and you can too. Keep in mind that this is not a roof fan that will spin forever, it is a working machine that needs sizable horsepower to turn it over.

The reason these drives do not get the respect they need is

Photo: Easy-Laser

experience. Like many of you, I’ve seen belts pried off, and a new set pried on; large sheaves installed with air guns and never checked for run-out, so they vibrate in the axial plane; string used for alignment or a length of angle iron from the steel rack used as a straightedge for alignment. Air guns have been used to tension a belt so tight that the belt would not defect, even if you walked on it; belt dressing, which used a can at a time to try and stop the belt from squealing. All of these are not acceptable if you plan on doing the job right. The first time.

What is belt misalignment?

The number one reason why belts fail prematurely is heat. Heat dries the belt out, which leads to cracking and slippage and the end is not far off after that. The heat is from friction caused by misalignment. To correct misalignment, we must correct the offset and angel errors in both the horizontal and vertical planes.

• Angular misalignment in the horizontal plane. (Toe-out and toe-in)

• Parallel (offset) misalignment in the horizontal and vertical planes.

• Angular and parallel (offset) misalignment in both planes. This is what we are normally trying to `correct.

One of the reasons why it is difficult to correct this misalignment is because you are constantly correcting the alignment as you tension the belt. If you have ever worked with an adjustable motor base that has one central adjusting bolt allowing the motor to pivot as you tighten it, it is a challenge. These bases are lightweight, flexible, and cheap. The inexpensiveness is why they are used but there is a hidden cost. You do a lot more maintenance work with this type of base so there is no savings. The frustration comes from the fact that you are unaware the bases are flexing until it’s too late. This is because it is not something you can see when using a straightedge to align the sheaves. You still must compensate or adjust the alignment as you tension the belt.

Innovations Effecting Belt Alignment

Two of the same style bases used to drive reasonably sized fans. They are taller than common bases and that is because the motor can pivot forward and back to allow for tension-

For any maintenance operation, those are the goals. And NSK is the partner of choice.

NSK High Capacity bearings are designed to deliver higher loads, higher speeds and longer life in pumps, motors, drives and equipment critical to optimizing plant capacity. For consistently improved machine efficiency and lower total cost.

Download the case study at NSKamericas.com/Pumps

SOLUTIONS FOR PROCESS MACHINE EFFICIENCY

NSK High Capacity Deep Groove Ball Bearing

Run right motor baser.

ing. The pivot point is square tubing that has a rubber insert, which creates resistance. This has an effect of spring loading the belt tension. It reduces the stress on the motor bearings because of over doing the tensioning. The base is solid and does not flex but allows for angular movement. Simple to install, but you still must check for soft foot or distorted footings as you normally would.

It separates the two critical components of the installation of the belts. The alignment and the belt tensioning. You align the sheaves in the normal way by moving and shimming the base. Then simply tilt the motor back to tension the belt. The tensioning will not affect the alignment as the motor comes straight back. The alignment is maintained and has no effect on the tensioning. It’s easy and efficient, provided you used the right tool to do the alignment.

With all advances made in the maintenance world, some are still using a string or straightedge to do alignment. This is still the common form of belt alignment today. Using a piece of string to align two sheaves should be left in the past. A laser should be used.

Why? When you measure with a laser you can measure the horizontal from three to nine o'clock and at the same time measure the vertical from 12 to six o'clock. To try and do all of this with a straightedge is exceedingly difficult, if not impossible, and that is where the saying “that’s close enough” comes in.

Photo: Easy-Laser (Top) / Mike Moschella, (Bottom)

The Alignment Process

Begin with the vertical plane from 12 to six o'clock and adjust by adding or removing shim from the base. We do the vertical plane first with the shimming. If you started with the horizontal plane first, moving the motor side-to-side, and then did the shimming in the vertical plane, you would inadvertently disturb the horizontal alignment adjustments you already did. It’s always best beginning with the vertical, and shimming the motor as necessary.

Next, correct the horizontal plane (toe-out and toe-in). This will remove the angle from both planes. Lastly, adjust the offset sliding the sheave/pulley forward or back on the shaft. This is the same process that you can use with a visual/optical or digital laser system.

One trick used is placing the laser transmitter on the station ary machine, a fan for example. The laser beam will point to the motor. The beam will pass the motor and will be seen on a fixed item such as a pipe or a wall. If you mark where the beam is hitting and watch it as you ap ply the tension to the motor. If the beam moves off the mark it means the stationary machines base is flexing.

For me, the best feature is that you can create an as Found and an as left report in a PDF for mat. You can e-mail this report from the display or from your phone to the customer, boss, or planner, who can attach it to the machines history.

belt drives can put production down. If you wanted to im prove the asset reliability in your plant and decided to do some breakdown analysis after losing a belt, without the docu mentation, you would be guess ing at what happened.

belt drive installations and the maintenance of them is an ex ample of why asset reliability is un-achivable. That is because we use poor installation proce dures. For example, a belt drive squeals at start-up. A work or der is made to tighten the belt. Is the belt loose? Or is the sheave the wrong size? Many OEM ma chines have the minimum size sheave that are good when new, but when a little worn they slip. That is because there is limited belt rap on the small sheave. If this is the case, the repair is to replace the sheave with a larger

size so that the belt has more area to grip. In my experience, what happens is the belt gets “re-tightened,” which is another way of saying it gets overtightened.

If tradesmen are still using string or a straightedge to align sheaves, the statement we are making is “close enough is OK.” The perception that a v-belt is a rubber band and can handle misalignment is wrong.

It is not just belt driven machines that are poorly installed. It is a fact that the biggest influence in a machine’s life expectancy is the installation. Therefore, the reliability of the asset is also affected. MRO

John Lambert is the President of BENCHMARK PDM. He can be reached at john@ benchmarkpdm.com.

Grasp your Industrial performance

HOW TO DETECT PUMP VALVE FAILURES IN POSITIVE DISPLACEMENT PUMPS

Yara Belle Plaine is a Nitrogen Fertilizer Plant located in Saskatchewan. Predictive maintenance technologies (PdM) were employed during the commissioning of the equipment in 1992, and are actively used today. Highly skilled and experienced management, and employees with PdM backgrounds were available to startup, operate, and maintain the plant.

BY GARY EINARSON

Over time, knowledge and experience with PdM technologies grew exponentially. In the early 1990s, portable vibration monitoring was advancing, but there were only a few vendors to choose from. Vibration technology is predominantly used to monitor the typical assortment of rotating equipment found at industrial plants; such as pumps, fans, motors, compressors, turbines, conveyors, and gearboxes.

Photos: Gary Einarson

Reciprocating positive displacement pumps (Figure 1) operate in many different industries worldwide. Reciprocating pumps move fluid using one or more oscillating pistons, plungers, or membranes (diaphragms), while valves in the pump-head restrict fluid motion to control the desired fluid direction.

During the suction stroke, the plunger retracts, decreases the pressure in the chamber causing the suction valve to open resulting in the fluid entering the cylinder. In the forward stroke, the pressure in the chamber increases, and the plunger pushes the liquid out through the discharge valve, and into the discharge pipe at a high velocity and high positive pressure.

The Yara Belle Plaine Plant contains a number of tri-plex plunger pumps of various sizes that operate at very high pressures. The plungers, seals, discharge valves, and suction valves all come into contact with the fluid being transferred, and the material choices are based on the fluid transferred.

Typically, industrial plants use vibration analysis to monitor the condition of the rotating equipment with respect to bearing faults, looseness, alignment, imbalance, plus many other mechanical issues. Looking at how vibration analysis was used to determine the condition of the suction and discharge valves in the pump-head of tri-plex positive displacement pumps; more specifically, whether these pump valves were passing.

The Problem

Early on, valves were failing often in mid-size pumps. Vibration data was collected every two weeks on the pumps, but the valve condition wasn’t found in the vibration data. Overall vibration (velocity), spectral data (velocity and acceleration), overall high frequency envelope data (HFE) (spike energy), and time waveforms (acceleration and velocity) were collected to try to discover an indication that the valves were failing.

This persisted for a few years, and the pump valves continued to fail in the mid-size pumps due to premature wear and catastrophic failure. In most cases, the valve disc and seat were becoming wire drawn, which caused a leak path (Figure 2).

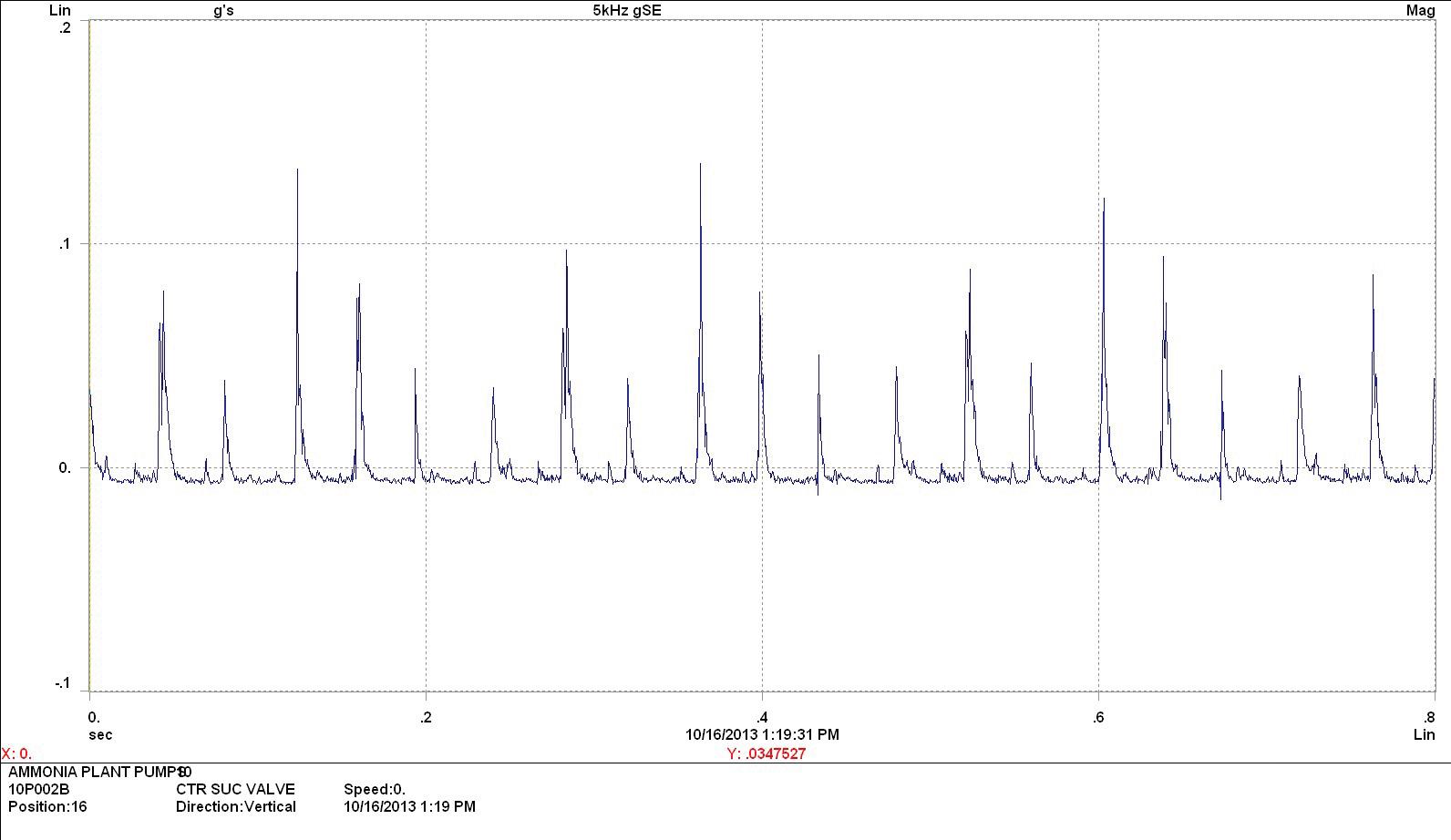

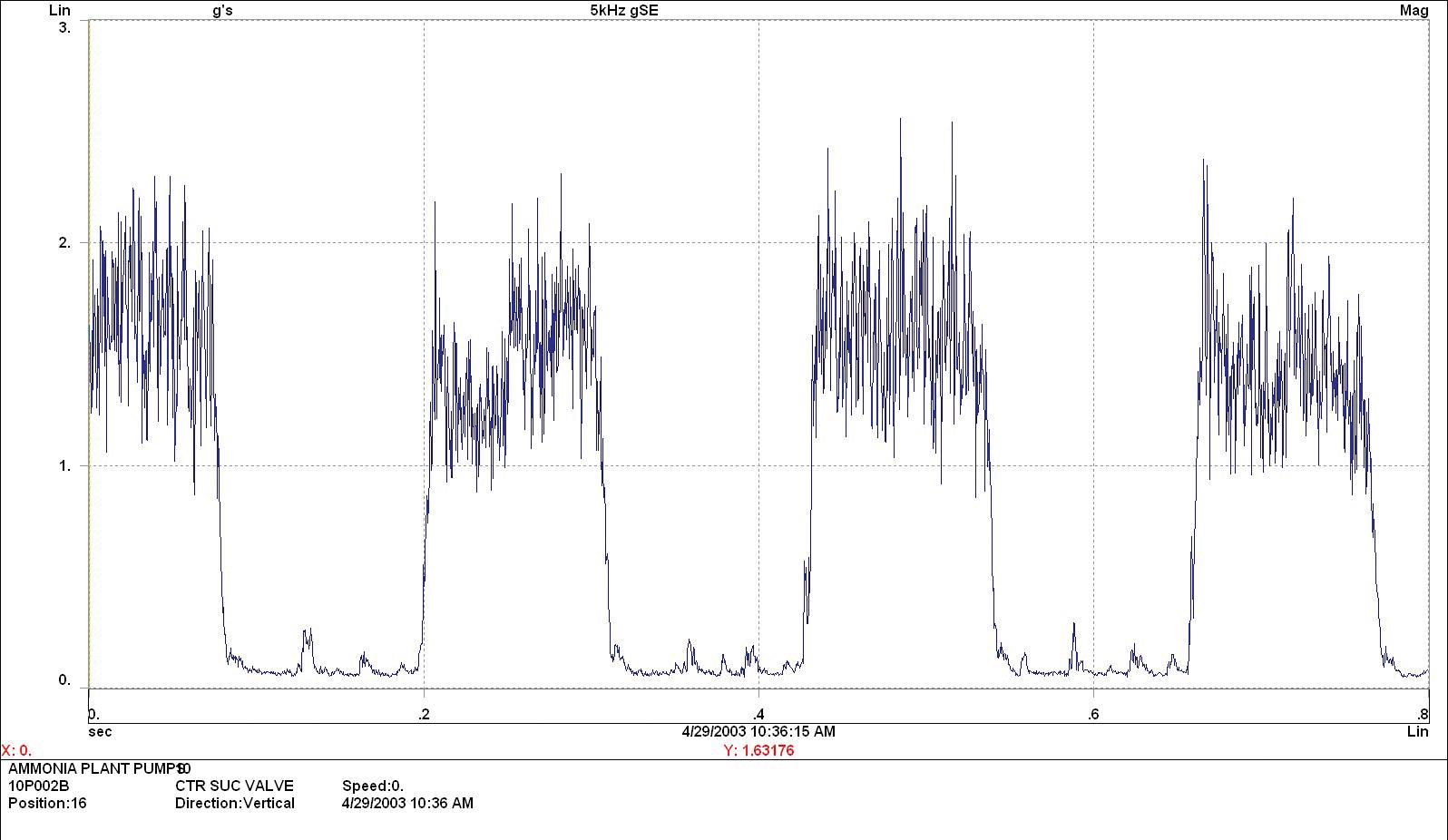

Spike energy (gSE) measurement was developed in the late 1970s and has been used in various industries for machinery condition monitoring and fault diagnosis. Compared to other filtered high frequency enveloping methods, gSE has a unique signal filtering and detection process. In addition to the traditional gSE overall measurement, spectrum, and time waveform (TWF) were developed and used for vibration analysis.

As understanding of vibration analysis evolved, we learned that the gSE TWF could clearly identify bearing fault frequencies in rotating equipment. The gSE TWF was a rectified waveform in the positive domain, which was ideal for detecting non-synchronous frequencies in the ultrasonic range.

Confidence using gSE motivated us to try this measurement on process valve leaks. There were issues in the process plant isolating a piping system for a hydrotest. The system had a number of isolation valves, but some valves were passing, preventing us from completing the hydrotest. The theory, if a process valve was slightly open, it should emit high frequencies, or possibly ultrasonic frequencies. The smaller the opening, that the liquid or air had to pass through, the higher the frequency. Overall gSE was tried because it was a measure of ultrasonic vibration frequency. This was unsuccessful because there needed to be a baseline measurement to compare with, in order to know for sure if the process valve was passing. Only the gSE TWF could show the frequencies needed for analysis.

Going back to the pump valves and the collection of gSE TWF was added to the two-week vibration routes on the midsize tri-plex pumps. The difference was that by collecting data multiple times, there was baseline data when the valves were in good condition. The next valve failure allowed us to study the historical data collected to find out if this new measurement was helping.

Before a failure occurred, we delved into what the pump valves were doing. There was sliding motion between the sealing disc and valve stem along the bushing; spring action; impacting when the disc landed on the valve seat; looseness; and liquid was flowing through the valve openings. The valve disc travelled from a fully closed position resting on the valve, to fully open, at some distance away from the valve seat.

It was concluded that flow induced high frequency vibration should be the greatest when the valve disc was as near the fully closed position as possible, but still allowing fluid to pass by the sealing surfaces.

gSE TWF Discovery

An accelerometer with a magnetic base was attached to the trigger nozzle on an air hose in the maintenance shop (Figure 3). With the data collector in live mode measuring overall gSE, the nozzle was triggered open and closed. The change in the overall spike energy level was observed. Once this reaction was confirmed, the data collector was set to

Figure 1: Mid-sized tri-plex plunger pump.

Figure 2: Failed pump valve from one of the mid-size tri-plex pumps. Wire drawn leak paths.

Figure 3: Accelerometer attached to air nozzle for testing spike energy theory.

store the gSE TWF using various collection filters, until the best parameter was found.

When the air passed through the air nozzle, the rectified gSE TWF clearly displayed a unique pattern. The plateaus in the TWF for the time duration of the leak. We were able to associate a vibration measurement to the pump valve condition. Whether liquid or air was passing through a small opening, the results remained the same, ultrasonic vibration frequency was generated.

Vibration readings were collected from each pump valve location. Three suction plus three discharge valves. TWF when the pump valves were in good condition (Figure 4). The narrow spikes in this gSE TWF represent the smallest of openings when each valve is nearest the

fully closed position.

TWF when a valve was passing (Figure 5). It consists of normal ultrasonic emissions from the valves opening and closing, separated by plateaus of high ultrasonic vibration. The time duration of the plateaus was equal to the time elapsed by the plunger stroke in one of the directions (suction or discharge stroke). Equivalent to one half revolution of the pump shaft.

Attention was focused on the mid-size pumps before moving to smaller and larger plunger pumps. There were more valve failures on the mid-size pumps. Seeing the failures occurring, there was a greater understanding of the level of unreliability and the failure modes. This led us to discussions with the pump vendor for ways to improve the reliability. The

vendor offered the option of installing upgraded designed valves. The new design proved successful and rarely failed. We were confident with the results to add vibration measurement to the route readings collected on all the other triplex pumps on-site. The valve failures on other pumps was less frequent, but this failures mode could be seen as it progressed along the P-F curve.

Benefits:

• Time to plan repairs and organize parts, labour, and tools required;

• More accurate records in the CMMS;

• Operations had less disruption to the process;

• Valve replacement could be combined with other work on the same equipment;

• Data to support RCA and FMEA; and,

• Safety and environmental concerns could be addressed.

The condition of the valves within positive displacement pumps can be monitored. Learning how vibration technology could be used in this application took years to accomplish, but the rewards were worth the effort. How to think outside the box, and use a common PdM technology in a non-standard application, was learned.

Benefits of knowing when pump valve defects have begun can range from economic to safety. Planning and scheduling are improved. There could be RCA and FMEA activities that result in design or operational changes. Production loses and not meeting commitments to customers, could be avoided. Depending on the level of hazardous product flowing through pumps, safety and environmental issues may be avoided. Positive displacement pumps are often high pressure, high flow equipment. The more known about the condition of the pumps, the more they can be operated safely and reliably.

MRO

Gary Einarson is the Vibration Technologist at Yara Belle Plaine. He has 40 years of experience in the mining and petrochemical industries, and has devoted nearly 30 years to the setup, development, and promotion of the condition monitoring program. He is a mechanical engineering technologist and is a certified technologist with the Society of Applied Science Technologists and Technicians. He is a certified reliability leader, certified maintenance and reliability professional, and has completed Level 4 vibration analysis, and Level 1 thermography. He can be reached at: gary.einarson@yara.com.

Figure 4: Rectified gSE Time Waveform when the pump valves were in good condition.

Figure 5: Rectified gSE Time Waveform when a pump valve was passing.

Photos: Gary Einarson

WHAT’S NEW IN PRODUCTS

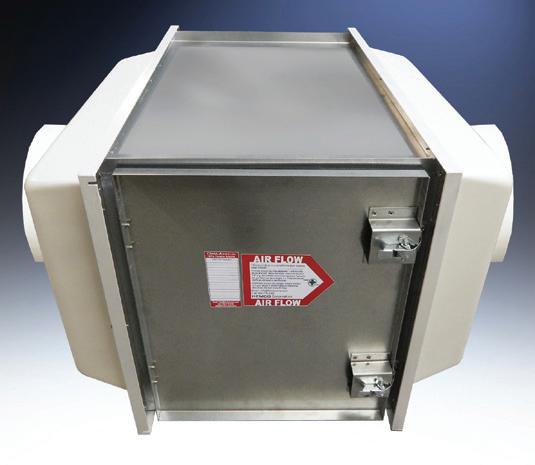

HEPA and Carbon Filter Packs

CleanAire HEPA and Carbon Filter packs mount inline in the exhaust ducting from a fume hood or contaminant source up to 1,500 cfm. The pack includes a galvanized steel housing with hinged and gasketed access door for filter change out, and molded composite resin inlet and outlet plenums, with duct connection collars sized to specification.

Pfannenberg PY L-S LED Signaling Device