You don’t need me to tell you these are difficult times to be a baker. You’re facing price increases in everything from the gas you use to fuel your delivery truck, to the flour you put in your mixing bowl, to the eggs you whip up into meringue pies. And with gas prices predicted to reach $1.50 at the pumps before the summer is out, and world wheat stocks the lowest they’ve been in decades, it’s an environment that’s not going to improve any time soon.

“It’s a very, very tight situation,” says the Canadian Wheat Board’s Bruce Barnett of world wheat supplies.

He predicts it’ll be at least 18 months before those supplies can be built up to “comfortable levels” and that’s with a few really good production yields.

So what’s a baker to do?

Well, unfortunately, there’s not a lot you can do to influence flour prices. Wheat flour is a staple in most of the products your customers purchase from you each and every day; you need flour. But there are some actions you can take.

First and foremost, if you haven’t done so already, you need to raise prices. I know, it’s something everyone dreads doing, fearing the worst: the lost customer. Well, maybe you will lose a customer – or two, or four. Perhaps some of your customers will cut back, visiting your shop twice a week instead of three times week. But at least you’ll still be in business. Explain to your customers what you’re doing. One bakery owner in the U.S. has taken to posting the price of flour in her bakery, in a place where customers can’t help but see it. Every time the price of flour goes up, the baker changes the sign. Why not do the same with some of the other commodities you’re using? Show your customers you’re not making any more money than you were months ago.

You can also reduce costs in your bakery. Make sure you know how much it costs you to make each and every product you produce. If you don’t know how much it costs to make a loaf of bread, then you’ll have no idea where to begin when you’re looking for ways to save a little money when you make that same loaf of bread.

Perhaps you need to make your products slightly smaller: consumers are snapping up 100-calorie chocolate bars and pre-packaged, portion-controlled cookies. Why not do the same sort of thing with the products in your display case?

Maybe you also need to consider reducing staff hours, even an hour here and there makes a difference. It’s not a popular decision to make, but be up-front with your staff. Tell them you’re taking preventive action so that you don’t have to reduce their hours by 100 per cent. And if you can’t do that, at the very least sit down with you staff, tell them the situation and ask them for ideas. You’re a team – perhaps as a team you can come up with solutions.

Reduce waste. Have leftover bread at the end of the day? Make a sumptuous bread pudding with it, grind it up into bread crumbs and package those to sell, or make croutons.

Talk to your suppliers; ask them for advice. Your suppliers need you and your business as much as you need some of the products they’re selling.

In the long run, you can get through this. People need and love their bread. And just because they have a little less disposable income doesn’t mean they have more time for doing something like making their own bread.

“Bread is a staple and will survive this crisis,” Ace Bakery’s Linda Haynes told one reporter.

Make sure your bakery survives the crisis too. ❖

Vol. 68, No. 4 May 2008

Editor Jane Ayer editor@bakersjournal.com 1-888-599-2228 ext. 250

Technical Editor John McColl, Puratos Canada jmccoll@puratos.com

National Advertising Manager

Stephanie Jewell sjewell@annexweb.com 1-888-599-2228 ext. 268

Sales Assistant Laura Price lprice@annexweb.com 1-888-599-2228 ext. 219

Production Artist Gerry Wiebe

VP/Group Publisher Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710 RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, PO BOX 530, SIMCOE, ON N3Y 4N5

e-mail: sbrady@annexweb.com

Periodicals postage paid at Buffalo, N.Y. USPS 007-277, ISSN 0005-4097. Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Publishing & Printing Inc. US Office of publication c/of DDM Direct.com, 1223 William St., Buffalo, N.Y. 14240. US Postmaster send address change to P.O. Box 611, Niagara Falls, N.Y. 14304. Printed in Canada ISSN 0005-4097

Circulation e-mail: sbrady@annexweb.com Tel: 866-790-6070 ext 206 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

From time to time, we at Bakers Journal make our subscription list available to reputable companies and organizations whose products and services we believe may be of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2008 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

LetThe GoodFoodRoll. You can’t miss the biggest food show to hit N’awlins in years. You’ll be surrounded by Mudbugs, Po-Boys, King Cakes, and Hush Puppies, plus 8,000 buyers, merchandisers, brokers, distributors, and marketers all looking forward to unmasking the hidden profit potential in dairy, deli, bakery, and foodservice.

TheCrescent City Crawl. Relax, you’re in the Big Easy. You’ll have many opportunities to network and exchange ideas on the Expo Floor, in the Show & Sell Center Merchandising Pavilion, or at one of the many other industry Special Events. And like the Vieux Carre´, the expo floor with over 1,500 booths is always packed with new ideas, products, and services to help you jazz up your business.

A Carnival Of Top Speakers. From inside and outside the industry, you’ll see some top performers address marketing, consumer, and merchandising trends and issues that can affect your business. And this Super Mardi Gras line-up wouldn’t be complete without a recipe that included some of the top chefs in the country.

IDDBA’sShow&SellCenter2008. Once again, an all-new 10,000 square foot merchandising theater brings together the talents of many creative retail merchandising teams. Every year it’s a new showcase for promotional themes, case sets, category merchandising, signage, and special displays. And you can put these original ideas into action using your very own idea resource book .

They came so close. After months of practising and three very long days of creating mouthwatering desserts and chocolates that wowed judges at Le Mondial des Arts Sucres at the end of March in Paris, it all came down to the last five minutes for teammates Jean-Luc Piquemal and Marie-josee Lacombe. As they were assembling the two sugar pieces and the chocolate piece that were the culmination of the team’s three days of work, disaster struck, with one of the sugar pieces partially breaking, followed by the shattering of the second sugar piece. In the manner of true competitors, Piquemal and Lacombe finished assembling and cleaning up their work as best they could, and awaited the judges’ results. After leading in the tasting section of the competition, which accounted for 60 per cent of marks, the team still managed to pull off a fourth place finish (out of 11 teams), behind France, Japan and Russia. Their team spirit and creativity was also recognized with a special

“Coup du Coeur” award.

Team captains Roch Desjardins and Eddy Rosine acted as judges throughout the three days of the competition.

Desjardins says he’s very proud of the team’s accomplishment and says with more support the team could have gone further. Many of the competing teams

had budgets of tens of thousands of dollars, along with high-tech equipment to help them make their showpieces.

“Maybe in two years,” suggests Desjardins optimistically.

The next competition will be held March 6-10, 2010, again at Europain in Paris.

AMF Bakery Systems has signed an agreement to merge with Stewart Systems Inc. The merger closed at the end of March.

“AMF will continue to operate as AMF and Stewart will operate as Stewart,” added Ken Newsome, president and CEO of AMF Bakery Systems. “Stewart and AMF were feeling the same pressure from customers who want both leading technology and integrated solutions. However, it is impossible to be all things to all people. This will allow AMF to focus on dough processing (mixing and makeup) at the front of the bakery as well as the wrap room (packaging and distribution) at the back of the bakery while Stewart will focus on all thermal processing in the middle of the bakery.”

Continued on page 16

Mimac Glaze celebrates 30 years in business.

By Jane Ayer

Every day in Canada, thousands of people bite into a doughnut or Danish, and unknowingly get a sweet taste of some of the products Mimac Glaze makes. The Brampton, Ont.-based business is a small company with some pretty big-name customers. But they’re customers president and CEO Dave Miles prefers not to broadcast, both for reasons of confidentiality, and also for the simple fact it’s just not the way he does business. It’s one of the reasons those big-name customers like working with him. He’s an honest, straightforward, unassuming guy they know they can trust. They also know they can trust the products he makes, which range from icing stabilizers to glazes to cake icings to cream cheese icing to fondant.

“All we do is icing,” says Miles, summing it up.

It all began for Mimac Glaze 30 years ago. After growing up in a bakery run by his father, and eventually going to work for Weston, and then Standard Brands, selling Fleischmann’s Yeast, William “Bill” Miles, Dave’s father, found himself working for an American company selling icing stabilizers to Canadian bakeries. He quickly realized no one else in Canada was making these sorts of products at the time, and, nearing retirement, he saw it as the perfect business venture.

“It was something small he could do as he headed for retirement,” says Dave.

Bill started out with four customers, mixing the stabilizers on the weekend and selling to customers during the week. Dave, who was 28 at the time and working in the baking industry himself, helped out on weekends, while Dave’s mom handled the books for the business.

And then came the advent of frozen dough in the early ’80s, with Danishes and other sweet goods in need of icing cropping up in convenience stores and gas stations across the country.

“That’s when things really started to grow with Mimac,” says Dave. “Not everyone knew how to do icing”– especially not an icing that was shelf stable.

With this new demand, Mimac Glaze

Dave Miles owns Mimac Glaze, a Brampton-based company that makes icings and glazes.

“It’s known in the industry if you’ve got an icing problem, you go to Mimac.”

Ltd. needed more attention than part-time workers and an at-home business could offer, so, in 1982, Bill set up shop in the current Brampton location (just north of Toronto) and Dave joined the business full time.

Thirty years later, the business ships to 19 countries around the world and has five full-time workers, along with a number of self-contractors and consultants who handle everything from sales to accounts payable (which Dave’s sister, Marion, handled until she retired a few years ago), to product development, to food safety. Marion and Dave took over the business from their parents in 1990, a transition that was inevitable, although Dave says he still chats with his father about technical issues.

“We were like Batman and Robin,” says Dave with a smile. “He’s the only other

man I know that I can talk to about the specifics related to the business.”

Once the frozen dough market matured, Mimac expanded into other areas, such as cake icings, fondant, and cream cheese icing for a company that tops its popular cinnamon rolls with it.

But the basics are what Mimac focuses on: they’re what Dave sees as the company’s strength. The fondant they make, for example, comes in three basic colours, which customers can flavour and colour as they see fit. Which doesn’t mean Mimac says no to customers who are looking for something specific. In fact, with a background in product development, Dave is a self-professed “techie.” When customers come looking for a GMO-free icing or a trans fat-free product (which they have), Dave says he’s in his element.

“That’s the kind of challenge I like. I go into the lab, shut the door and start the research.”

But sticking to the basics is what has earned Mimac the reputation as the go-to business for icing.

“It’s known in the industry if you’ve got an icing problem, you go to Mimac,” says Dave. “When all else fails, they come to us, because of our reputation.”

That reputation includes an open-door policy for customers to visit the plant and production area, an 8,800-square-foot, HACCP-certified area. The entire place is immaculate and perfectly organized, flowing from dry production area to wet production area, to storage to packaging.

What’s in the cards for Mimac once Dave retires? It’s something he’s already started to think about. He plans to continue consulting (he’s even started up a consulting business called Paragon) and says he’d also like to teach, perhaps at George Brown College, where he was once a student.

“I don’t see any succession in the business,” says Dave.

In the meantime, Mimac will continue doing what it has done so well (and so quietly) for three decades – and thousands of Canadians will continue licking Mimac icing from their fingers without knowing it. ❖

In light of the recent sale of Toronto’s Ace Bakery to an American private equity firm, we offer a reprint of our 2003 profile of the business.

A formula from the South Korean team competing in last year’s Coupe Louis Lesaffre.

A review of Dominique and Cindy Duby’s latest cookbook, Wild Sweets Chocolate. FULL

From demonstrating to competing to walking the show floor: a number of sights and sounds from the ultimate European trade show.

Another flavourful recipe from the Bakers Journal recipe collection, Baking Over the Decades.

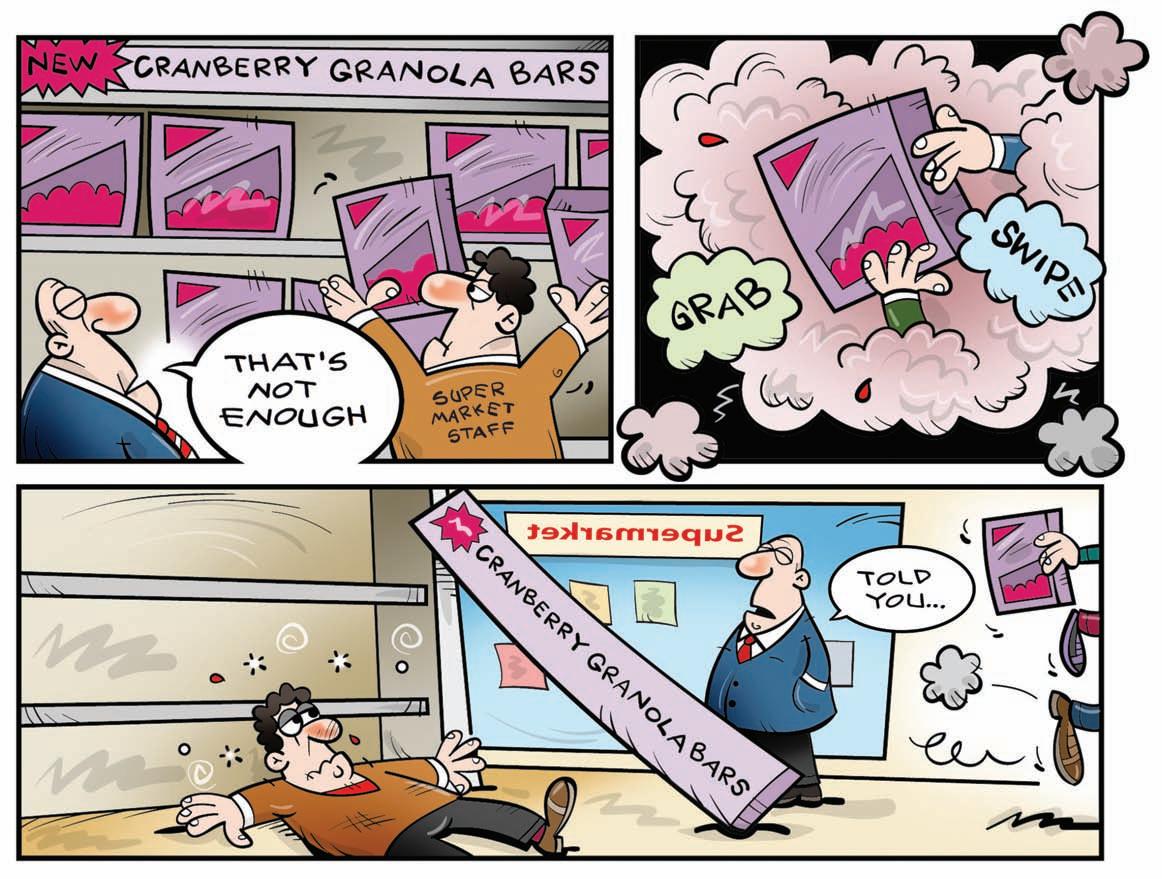

We say actions speak louder than words. Independent consumer research reveals that 74% of consumers would try a new granola or cereal bar if it contained sweetened dried cranberries.

Don’t

Consumers have ranked sweetened dried cranberries higher than any other dried fruit in terms of health, color, sophisticated image, unique flavor and low calorie content.

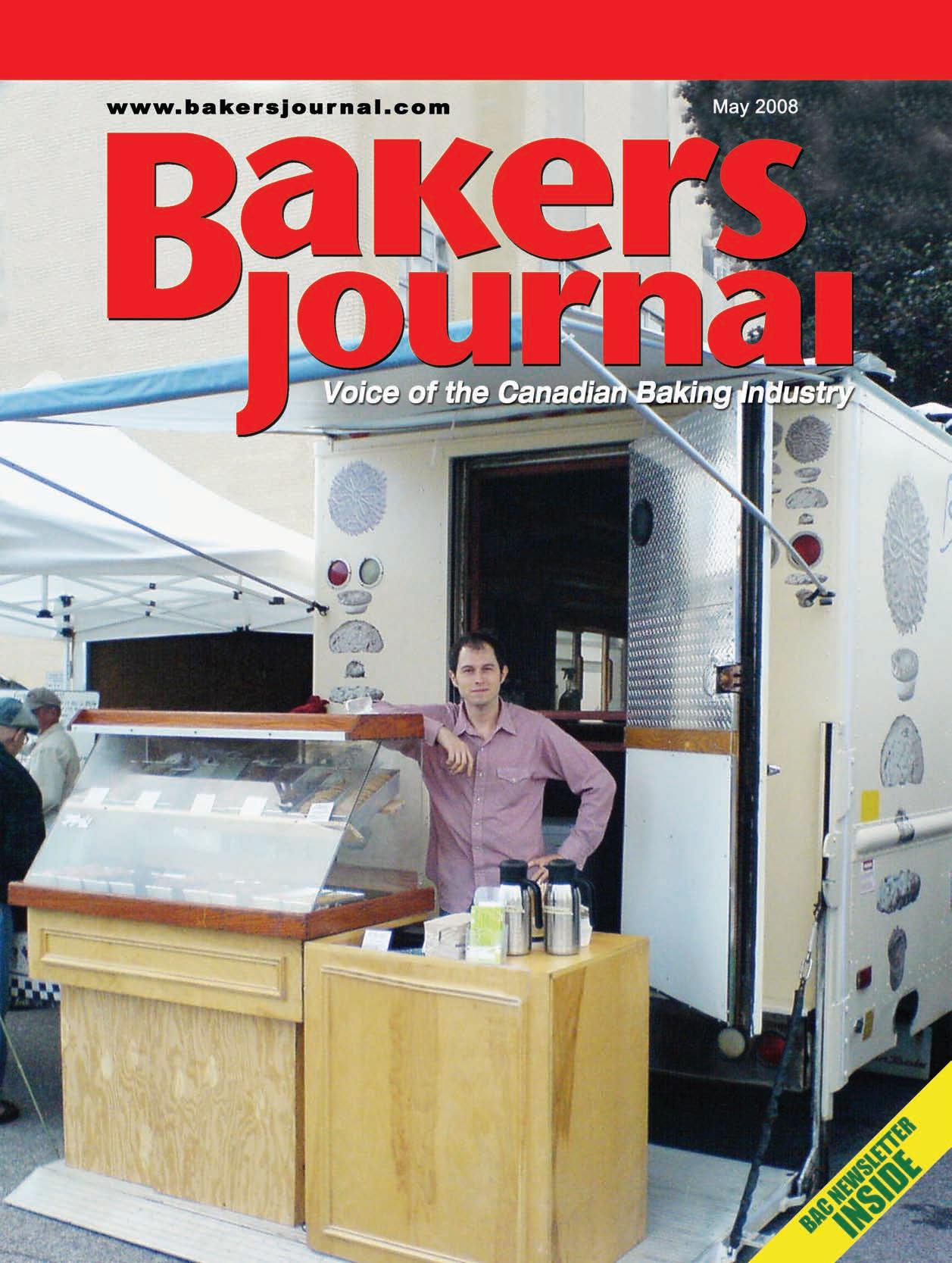

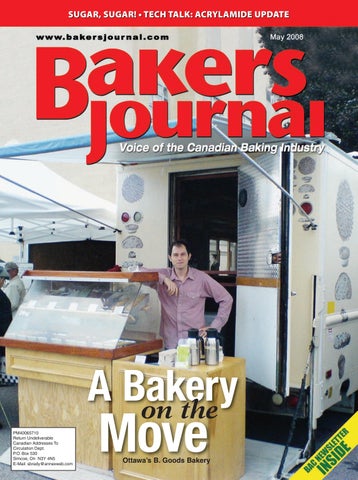

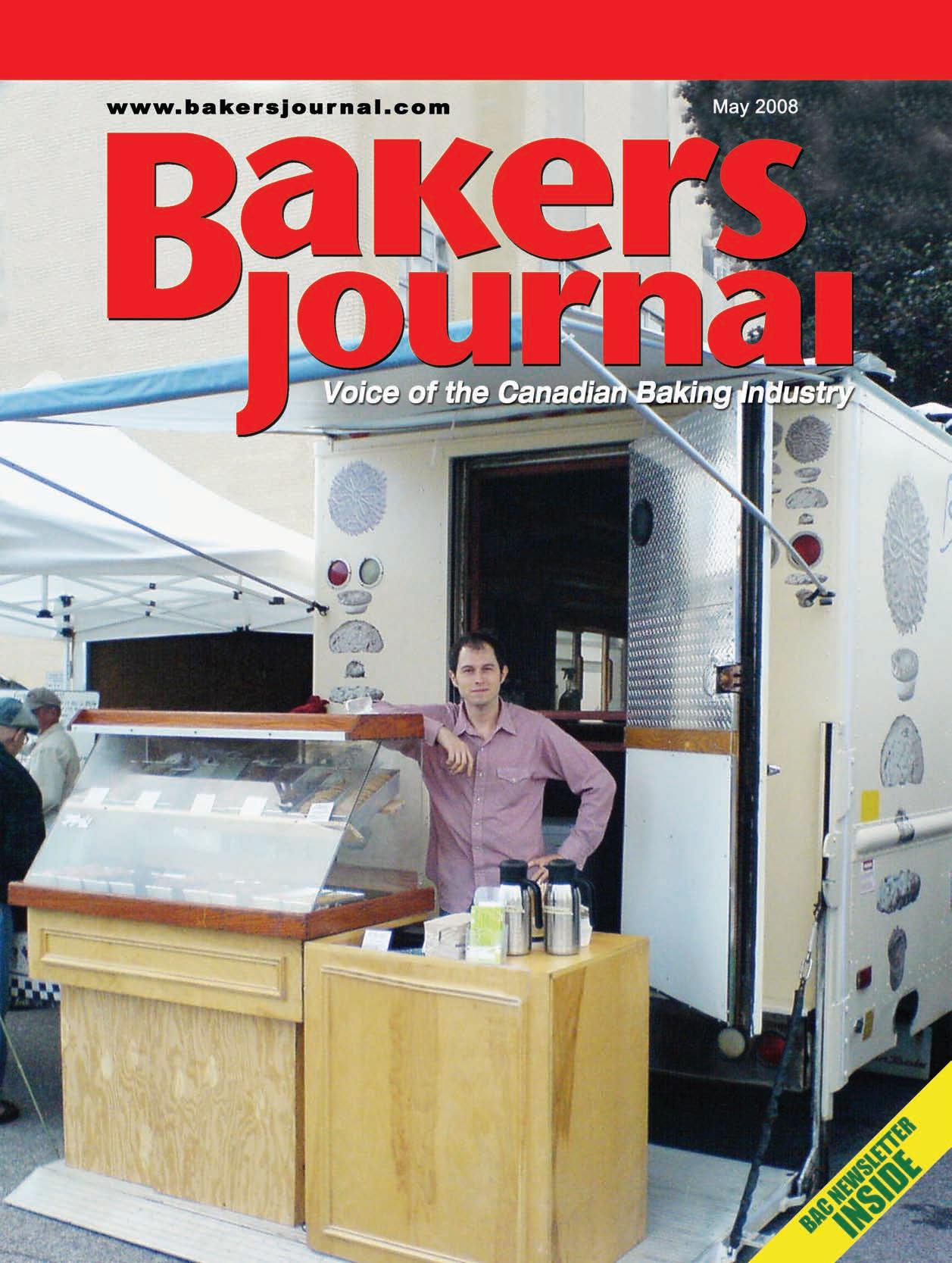

Ottawa’s B. Goods Bakery does it all on four wheels.

By Sarah-Lee Richardson

Walking down busy Rideau Street in Ottawa, past the Shawarma King, the Spring Roll King and Shonn’s Makeovers and Spa, the smell of freshly baked cookies warms the crisp, cool air. The smell is coming from a former Snap-On Tools truck, which, upon closer investigation, is no longer housing wrenches and ratchets, but cooling racks, mixers and bins of flour and sugar. It’s a bakery on wheels.

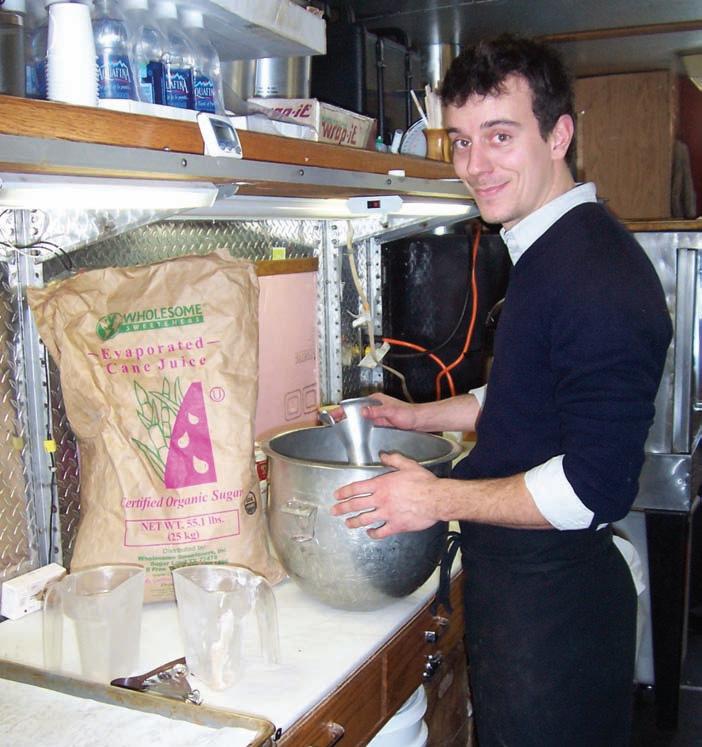

Brad Campeau got his cookie business, B. Goods, off the ground and onto four wheels just last year. He saw a Snap-On Tools truck and immediately knew he could tear out the red shag carpet and the ceiling full of loops for carrying tools, and replace it with a propane convection oven, fridge, double sink, and baking work area. It was just the truck he’d been waiting for.

“Sometimes it’s cramped,” says Campeau, “but if it’s just me, I’ve got plenty of room.”

Everything in the truck is mobile and fully adjustable. Because everything also has to be secure for when the truck is in motion, there are ties to hold down the cooling racks and locking drawers that won’t fly open.

“I wanted to own my own bakery for as long as I could remember,” Campeau says. “I was delivering for another bakery with a sprinter van. I had a moment of realization that I could walk from the driver’s seat to the back. What would stop me from putting a bakery back here?”

A sprinter van would prove to be too small, but by May 2007 Campeau had bought the Snap-On Tools truck. Two months and $30,000 later he was baking and selling his cookies wholesale. By August he was selling retail out of the back of the truck on a downtown street corner in Ottawa. He fitted the truck with an awning over the back door and set out display cases filled with warm, freshly baked cookies.

by Sarah-Lee Richardson

Above: Besides selling retail at festivals and outdoor concerts, B. Goods wholesales its cookies to a number of retailers around Ottawa. The cookies are sold stacked back-to-back in loaf tins with brown bags for customers to fill with their selection.

This past winter, B. Goods set up shop on

Cookies are B. Goods’ specialty, with nine flavours, two of which are gluten-free. Chickpea and rice flours are the bases for the gluten-free varieties – which are very chewy; Campeau pays special attention to making sure the cookies are moist enough so they don’t dry out quickly.

“People allergic to gluten aren’t allergic to fat and sugar,” says Campeau with a grin.

He describes all his cookies as “caféstyle with a healthy undertone.” Campeau uses only organic flours, sugar, and spices when he can find them. He says the organic flour that he uses from Mountain Path has a nicer flavour, is of a higher quality and the price difference isn’t that much compared to non-organic flour.

Campeau made a personal decision early on in life not to eat any dairy or eggs, and as a vegan, his philosophy extends to his business. All of B. Goods’ products are dairy- and egg-free. Campeau use molasses, honey, or a non-butter spread to ensure moistness.

The top two bestsellers are B. Goods’ spelt molasses ginger and chili chocolate cookies. When I ask Campeau which cookie is his favourite, he laughs.

“That’s like asking a father which is his favourite child,” he says.

After thinking about it, he decides his “favourite child” is spelt oatmeal raisin. But then he sighs and says, “the spelt oatmeal chocolate chip is good too.” I guess like all fathers, Campeau has two favourite children.

Campeau pulls a batch of chili chocolate cookies out of the oven for me to sample. The cookie is warm, chewy and full of chocolatey flavour, with a hint of spicy chili that comes through at the end of the bite. Campeau got the idea for this cookie from a chocolate chili truffle that a former employer used to make. Because the truffle was full of dairy, Campeau was frustrated that he could never try it, so he decided to turn it into a cookie. He took the base for a double chocolate chip cookie, took out the chocolate chips, and replaced them with freshly ground pepper, organic paprika and, of course, chili.

From spring through fall, Campeau sells his cookies out of his truck in downtown Ottawa, but his cookies can be found throughout the year at health food stores across the city. The cookies are easy to spot, because they’re sold with as little

Brad Campeau was inspired to create a bakery on wheels while delivering baked goods for another bakery; by the summer of 2007 B. Goods was in business.

packaging as possible, in loaf tins covered with clear plastic bags, and paper bags for customers to fill. This approach keeps the cookies protected, cuts down on packaging for the consumer, and also allows Campeau to deliver them directly in the tins, which means no need for cardboard boxes or any extra packaging.

To make deliveries around town, Campeau relies on a “Virtu-car,” a carsharing service that not only saves on costs, but also lowers his impact on the environment.

The response to the cookies has been good, especially when Campeau hands out samples. When people get a taste of how chewy and moist a spelt, non-dairy, nonGMO cookie can taste, his sales go from 24 to 200 cookies a day. Each cookie at the health food stores sells anywhere from $1.19 to $1.32 plus tax.

Campeau has expansion on his mind and recently purchased a second truck, an old Fire Events truck from Kingston. It still has the Rescue 4 plaque emblazoned on the steering column. His future plans include

using both trucks in downtown Ottawa – the original B. Goods truck will be fired up as the bakery and the second truck will be retro-fitted into a walk-in retail area for customers. This spring, Campeau hopes to capitalize on his success of selling cookies at Ottawa’s Winterlude Festival on the frozen canal, by attending more outdoor Ottawa festivals and offering concert goers a sweet alternative to poutine. And he’s not only adding a second truck, he’s hoping to add more than just cookies.

“Maybe a line of tarts with nice fillings that aren’t all gelatin and sugar, all the fillings would be good stuff.”

The name “B. Goods” means many things to many people – baked goods, Brad’s goods, or “be good” to yourself by eating foods with organic flours and no dairy. Whatever B. Goods means to its customers, one thing is clear; customers see the cookies as a tastier, healthier choice for a delicious snack.

“We don’t want to be known as the healthy cookie, so much as a good cookie for healthy people.” ❖

The finest ingredientsfrom worldclasspartners. A seasonedsupport team. Uncompromisingservice. www.lvlomas.com 800 575 3382 A dairy- and egg-free cookie formula from B. Goods Bakery.

Method:

1. Combine margarine, sugar, cocoa, baking soda, salt, water, vanilla, and all spices and let sit until some of the water has dissolved the cane sugar. Once slightly dissolved, cream together ingredients.

2. Preheat oven to 310 F. Form batter into rounded and flattened balls roughly 50 to 55 g each. Once formed, dip half of one side of the cookie into reserved cane sugar. Space them about two inches apart on non-stick pans or parchment.

3. Bake for 14-16 minutes. Once cool enough to touch, gently remove from baking pan to cool. ❖

Continued from page 8

Traynors

Ontario-based distributor Traynors Bakery Wholesale Ltd. held its annual trade show in Hamilton at the beginning of April. This year, Traynors offered attendees a series of short seminars before the show doors opened, starting off with a talk by Jason Berman of All Gold Imports on the rising price of most commodities. Berman has been in the business for 17 years and he says he’s never seen anything like this.

“It’s everything,” said Berman. Everything from nuts to poppy seeds to cocoa.

Derek Jamieson of New Life Mills continued on the theme of rising prices by tackling the ever-hot topic of flour prices. He predicts prices will eventually go a little lower than the recent all-time highs, but suggests things will never return to where they were.

“I don’t think we’ll ever return to traditional pricing,” said Jamison.

To end on a lighter note, Mel Lopez of DecoPac wrapped things up with an airbrushing demonstration.

To help its customers deal with pricing challenges, Traynors offered all attendees of the show a costing CD to work out precise pricing for the products they make. The company also issued this challenge: raise product prices.

“I had one customer say he’d rather lose one customer due to increased prices than his entire bakery,” said Traynors’ Bill Lloyd.

The owners of ACE Bakery, one of Toronto’s best-known and best-loved bakeries, have sold the business to Glencoe Capital, a Chicago-based private equity firm.

Husband and wife team Martin Connell and Linda Haynes started the business 15 years ago on King Street West, turning a hobby for bread and bread-making into a very successful business with some 300 employees and sales of close to $50 million.

“It was about time to move on,” Haynes told the Toronto Star. “We’re thrilled with the company (Glencoe) and we don’t think anything is going to change.”

Besides having a sense for business, Connell and Haynes also had a heart for community, contributing a portion of ACE profits to Calmeadow, an organization the duo formed to help microenterprises in developing countries. Once Calmeadow became self-sufficient, 10 per cent of ACE profits continued to go towards funding community food banks and kitchens, along with scholarships for cooking and baking, and assistance for organic farmers. It’s not clear if Glencoe will continue the charitable donations.

Connell says he’ll now focus his attention entirely on the Toronto Community Foundation, where he is chairman of the board, while Haynes will focus her immediate attention on finishing a cookbook she’s working on with her 26-year-old daughter. She’ll also stay on as a consultant to ACE in marketing and recipe development.

ACE president and CEO Philip Shaw will stay on in that capacity, as will all the other employees. ❖

BAC’s Board of Directors has requested Federal Agriculture and Agri-Food Minister Gerry Ritz initiate a review to determine the impact the growing biofuels industry is having on escalating agriculture commodity prices. Biofuels include ethanol made from corn, sugar cane, palm oil and other agriculture crops. The biofuels are added to traditional fossil fuels as a fuel alternative and many governments have mandated such additions.

BAC’s request was made in response to unprecedented increases in agriculture commodities such as wheat, which spiked this past February at almost $30 a bushel and is today some 120% higher than last year at the same time. There are numerous reasons for the recent spike in agricultural commodities including droughts in producing countries and increasing demand from emerging countries like China and India.

As well, it is widely recognized that the growing

demand for biofuels has also contributed to escalating commodity prices. A recent media report stated that up to 16% of the wheat and soy crop in the U.S. has recently been converted to grow corn for the biofuels industry. In Canada the Federal government has recently made changes to the grain variety registration criterion that promotes the use of wheat as a biofuel. According to the government’s release these changes “… will allow for the development and registration of new high-yielding varieties of wheat suitable for other uses such as feed and biofuels…”

BAC’s request is for a quantitative analysis on the role the diversion of traditional food crops to biofuels is having on overall food commodity prices. BAC believes such an analysis would then provide transparency to the impact the growth of biofuels are having on food pricing for bakers, customer groups and consumers at large.

On April 8th the federal government introduced the proposed Canada Consumer Product Safety Act and changes to the Food and Drugs Act. The proposed legislation would introduce a general prohibition against the manufacture, importation, advertisement or sale of consumer products that are a danger to human health or safety. The proposed changes would also dramatically increase compliance promotion and enforcement through increased maximum fines up to $5,000,000, and an administrative monetary penalty scheme as an alternative to criminal prosecution.

The amendments to the Food and Drugs Act will also substantially enhance the inspection and enforcement powers of the CFIA and other regulatory agencies.

The proposed FDA amendments will introduce new inspection and enforcement powers that will enable food inspectors to monitor food and take action by allowing the holding and testing of product without seizure and detention, the ability to require removal of unlawful imports and the use of telewarrants.

The amendments also provide new powers to the Canada Border Services Agency (CBSA) and CFIA to stop imports of food; the power to hold and test products; the authority to license or register importers; the power to require importers to establish systems to record the origin and destination of products; and an improved approach to sharing information with other governments.

The proposed amendments will require in some cases enhanced record keeping – including information relating to the origin and destination of domestic or imported foods. They will also provide the CFIA with the authority to require the implementation of preventative food safety controls, such as HACCP (Hazard Analysis Critical Control Points) systems, in areas of highest risk.

The proposed amendments include a framework for a licensing or registration regime. As regulations will be required to implement this regime, interested parties will have additional opportunity for input, before any changes occur.

Yield: 20 macaroons

Basic Macaroons Mix:

Ingredients:

190g almond flour

340g icing sugar

150g egg whites

45g sugar

7g egg whites powder

Directions:

1. Mix together almond flour and icing sugar, sift to remove any chunks.

2. Whip the egg whites until frothy. Add sugar and egg whites powder; whip until stiff.

3. Add a few drops of food colouring to the egg whites mixture according to the flavour being made (raspberry = light pink, pistachio = light green, lemon = light yellow, etc).

4. Gently fold in a third of the almond mixture into the egg whites mixture. The mixture should stay streaky. Lightly fold another third of the almond mixture. Add the final third until combined, leaving a few specks of the egg whites mixture.

5. Fill a pastry bag fitted with a 1/4-inch plain tip with the mixture.

6. Pipe rows of 1-inch kisses, 1/2-inch apart, onto a non-stick, lined baking sheet.

7. Bake in a pre-heated 165°C oven for 11 minutes. Rotate the baking sheet halfway through.

8. Allow to cool.

Pistachio Filling:

Ingredients:

150g cream

50g butter

50g glucose

500g almond paste, 5% (marzipan)

150g pistachio paste

50g kirsch

Raspberry Filling:

Ingredients:

Directions:

1. Whip together the cream and butter until light and fluffy.

2. Add remaining ingredients.

3. Fill a pastry bag fitted with a plain tip with filling.

Lemon Filling:

Ingredients:

150g cream

50g butter

50g glucose

500g almond paste, 50% (marzipan)

300g sweet lemon zest puree

50g limoncello

Directions:

1. Whip together the cream and butter until light and fluffy.

2. Add remaining ingredients.

3. Fill a pastry bag fitted with a plain tip with filling.

500g raspberry filling

60g raspberry alcohol

300g raspberry jam

Directions:

1. Mix together ingredients.

2. Fill a pastry bag fitted with a plain tip with filling.

Assembly:

1. Pipe a 1/8-inch layer of filling of choice onto the flat sides of half of the cookies

2. Make sandwiches by lightly pressing the flat sides of unfrosted cookies to the frosted ones.

3. Refrigerate in an airtight container for up to three days.

Formula reprinted courtesy of the Almond Board of California. Visit www.almondsarein.com for more formulas and information about almonds.

For men who retired years ago, west coast bakers John Evdokimoff, Alex Jmaeff, and George Wagner have never been busier. They are Volunteer Advisers (VAs) with the Canadian Executive Service Organization (CESO) a non-profit, volunteer-sending organization founded in 1967, CESO’s mission is to build capacity in governance and economic development through the transfer of knowledge and skills by VAs.

CESO (pronounced KESSO) offers professional and technical expertise and mentoring services to people and organizations in Canadian Aboriginal and non-Aboriginal communities, developing nations and some of the emerging market economies of Eastern Europe.

A Castlegar, B.C., resident, John Evdokimoff had extensive experience in the baking industry when he retired in 1998. “Being a CESO VA is an exciting way to stay active and share the expertise, skills and knowledge gained throughout your lifetime,” says John, a former Canada Safeway bakery manager and former bakery owner.

“We try to help people help themselves. It’s very rewarding to pass on skills to people who are eager to learn and to help drive the local economy forward.”

Since signing up with CESO in 1999, John has completed 22 assignments, including two in Canada and 20 in Russia, Georgia, Kazakhstan, Ukraine, Armenia, Guyana and Jamaica.

His most recent assignments took him to Ukraine, Russia and Georgia and he has accepted assignments that will involve return visits to Armenia and Ukraine in 2008.

“What CESO does is match the skills of its VAs to the requests from its clients,” explains John. “A typical assignment for me starts when a bakery asks CESO to send a VA to help improve the quality of its products, improve productivity and increase sales. When I get there I assess the equipment and tools, introduce new recipes, train the staff and make recommendations about displays and marketing.”

In Kazakhstan, for instance, he showed the management staff of a struggling bakery how to better organize workloads to improve production flow. He introduced

new recipes for pastries that would prolong shelf life, and made recommendations on marketing products, including point-ofsale decoration and display. His ideas have resulted in a more stable employment situation for the staff, an increase in the volume and variety of bread products and pastries of improved quality.

Also from Castlegar, B.C., Alex Jmaeff is of Russian descent. Russian was Alex’s first language and one he still knows. He is also functional in Spanish. Before retiring in 1994, Alex owned six bakeries of varying sizes and was the owner/operator of Creston Valley Bakery. In 1993, Alex and his wife, Natalia, completeda two-month assignment for the Canadian Human Resource Development Program in Moscow. It was a sign of things to come for two years later in 1995, Alex joined CESO and completed 17 overseas assignments, all but one in Russia.

Alex went to Nicaragua in 2001 to assist a privately owned bakery in Managua improve the quality of its bread and pastry production. The client was very impressed with Alex and said: “Our production personnel were very receptive because of the vast experience demonstrated by the VA. Our productivity has increased.” The client further explained that the most important achievement was the improvements made in the manufacturing process of several products.

The other 16 assignments were in Russia, where Alex’s extensive knowledge of diverse aspects of the bakery industry served him well during his CESO assignments. He helped with starting a new bakery, purchasing equipment, training management and staff, introducing new processes and improving operations, introducing new bakery and pastry production, improving soy bread production, advising on bakery technology, conducting a feasibility study on the integration of a cafeteria, etc.

Alex completed seven assignments with YASNAYA POLYANA, a Hotel-Tourist Complex which was established in 1999 on Leo Tolstoy’s estate and located in Tula, a Russian city just south of Moscow, on the Upa River.

“After many years of planning, the

client has finally opened their bakery. VA Jmaeff’s assistance in planning this venture was extremely important, providing the client with the guidance needed to proceed,” said Paul van der Wel, CESO President and CEO.

The client was so impressed with Alex’s contribution that he was invited to the official opening of the bakery, as a guest of honour. The client said: “The VA has carried out several assignments with us and rendered assistance in all stages of establishing the bakery, beginning with a draft project and finishing by finally putting the bakery into operation.”

George Wagner, of Nanaimo, B.C., will be 66 years old by the time he goes on his next assignment in February, 2008. He joined CESO in June 2002 after retiring as Chef Patissier Instructor at Malaspina University-College, where he worked since 1978.

George has completed an impressive 40 overseas assignments in Asia, the Americas and Eastern Europe and is scheduled to travel to Russia and Georgia this spring on four separate assignments: 1) to help advise an association on pastry producers; 2) to help improve a client’s dessert menu; 3) to help a client expand its dessert menu; and 4) to train a client in sugar, caramel and chocolate production.

When CESO sent George to Honduras on two occasions, the client was Reposteria El Hogar, a bakery located in the capital city of Tegucigalpa. On his first visit, George provided new recipes for bakery products and petit fours, provided recommendations on modern decoration and presentation techniques, helped reorganize the bakery layout and assisted in creating a floor plan for a new production section, provided recommendations on recycling of spoiled products and raw materials, participated in the client’s advertising broadcast on the local TV station, and trained staff in baking techniques.

During the follow-up assignment, George evaluated the production processes and advised on improvements in production, product quality and quality control. He trained staff on the production of a wide variety of yeast products, cookies, cakes, mousses and savoury items. He also

assisted in setting up one of the client’s newly renovated retail stores and café.

Reposteria El Hogar has received CESO assistance over a 10-year period and during this time, the bakery expanded its operations, resulting in 30 new hires, and increased sales and productivity.

The client was very pleased with the assistance provided by George and said: “We were particularly impressed with the VA’s knowledge and working skills. He masters his craft and, therefore, has a natural easiness in transmitting his knowledge and in creating a proper working atmosphere. The VA went along very well with our staff, working conditions and local environment. We are completely satisfied with the assignment.”

As well as English, George is fluent in French and German. His bakery experience is extensive, having worked in the industry for almost five decades. Before joining Malaspina University College, George worked as a pastry chef for 10 years at the Empress Hotel in Victoria, B.C.

He has also worked in France, the Bahamas and Algeria and has been honoured with an extensive list of awards. His studies have taken him from France in 1960, where he earned a Certificate for Patissier-Confiseur-Glacier, to Switzerland and Canada and back to France in 1985 where he studied at the Ecole Nationale de la Patisserie Issyngeau in Lyon. George is a member of the Canadian Federation of Chefs de Cuisine.

John, Alex and George are just three of the 2,700 men and women who volunteer with CESO. “Our volunteer roster has to be one of the biggest resource banks of management and technical expertise in Canada,” says Ruth-Claire Alinas, CESO’s Director, Human Resources and Volunteer Services.

She says about 60 per cent of the VAs are retired from senior level positions in a variety of industries, businesses and academia. “About 18 per cent still work full-time and 24 per cent work part-time,” says Ms. Alinas. “The average age of a VA is 64.”

Typically a VA may spend two weeks to three months on an overseas assignment. In Canada, assignments tend to be shorter, lasting on average from two days to two months.

Ms. Alinas says CESO couldn’t do what it does without funding from the Canadian International Development Agency (CIDA), Indian and Northern Affairs Canada (INAC), as well as support from corporations and foundations and scores of individual Canadians.

She says the volunteers’ airfare, accommodation, meals and local transportation costs as well as a modest, daily stipend are covered, but the CESO travel experience is a far cry from the luxuries of business travel, to which many may be accustomed. Instead, VAs travel economy class, are housed in local accommodations and make their own meals or dine in neighbourhood

You’re never too old to learn something new. Just ask 91-year-old Leo Alho.

This spry, energetic Parksville resident recently completed a two-day workshop in artisan baking offeredthrough Malaspina University-College’s Centre for Continuing Education.

“He’s one of our oldest students,” said Martin Barnett, co-ordinator of the professional baking program. “It was a pleasure to have him in class. Over thetwo-day workshop,he needed no special accommodation and was as spry as the rest of the class. He’s our new poster boy for lifelong learning.”

“I saw the course advertised in a brochure,” Alho explained. “I thought I’d sign up and see what they’re doing at

restaurants, all adding to the interest and the challenge of the assignment experience.

Still, many agree that their involvement with CESO gives them 150 per cent satisfaction and reward.

Are you a baker with management and business skills?

Consider becoming a VA yourself. Besides the satisfaction of sharing your specific expertise with those in need, you’ll be an ambassador for Canada, furthering its strong international reputation. Or, you may help bridge the gap between business and Aboriginal peoples here at home by making your experience available through CESO National Services.

The CESO program is great for people who have been active all their lives, active in their communities, active in their jobs, active in their schools and active in their service clubs. It’s for people who, when retired, don’t want to just sit back and watch the world go by or play golf every day.

CESO provides a means to continue to do what they have been doing successfully throughout their lives, and to continue to contribute to society and to the world in a very meaningful way.

Visit the Web site www.ceso-saco.com and learn more about volunteering and supporting CESO in a variety of capacities.

Also, you may contact Nicole Gold, CESO’s Roster Manager, at 416-961-2376 or 1-800-268-9052 ext. 223, or by e-mail at volunteers.toronto@ceso-saco.com.

Malaspina. Ienjoy trying new things.”

Alhobakes oftenat home,grindinghis own wheat flour and rye flour for baking breads, cinnamon buns and crepes.

“I don’t use white flour at all,” he says.

“They say it’s poison.”

Besides this workshop, Alho signed up for an Elder College course at Malaspina two years ago to learn about opera. He watches for courses that interest him because learning keeps the mind active.

Alho has lived in Parksville for 10 years. He retired in 1991 after a busy career He once owned a bowling alley in Ontario, and then worked for Investors Group. “I did a little bit of everything during my career.That made it interesting ”

Malaspina’s next artisan baking course is May 24 from 9 to 4 p.m. Visit the www. mala.ca website and check out Continuing Education for more information.

By Roberta Tasson, The Magnes Group Inc.

Note: The below captioned claims example was provided by The Boiler Inspection & Insurance Company of Canada

The insured discovered that the compressor had stopped and the temperature in the freezer rose to about 50°F, and the stored food in the walk-in freezer had thawed.

Upon investigation, it was discovered that a rupture in the copper piping from the condensing unit caused refrigerant to escape. This occurrence appeared to be as a result of constant vibration causing the pipe to rub against the casing and a small perforation developed. The pipe was repaired and the unit was re-charged and returned to service.

Final Loss Settlement for this claim:

From the above figures, it becomes evident that the real loss stemmed from the food spoilage, and not the cost to get the unit up and running.

The above claims example also highlights the necessity to carry Spoilage coverage as part of your insurance program should you have a product under cold storage. It is also recommended that a high temperature alarm be installed to avert this type of loss. If the alarm had gone off in the above captioned claims example, the food product could have been saved.

For more information on the above article or other insurance/risk management related queries visit www. magnesgroup.com.

Emilia Doro Occupational Health & Safety

Lei Ma Bakery Technology I

Chandraketubhai Sandesara Bakery Technology III

For information on correspondence courses for baking industry employees and the Certified Bakery Specialist (CBS) program, please contact ext. 21 at the BAC office or check out our website at www.bakingassoccanada.com.

Romina Loten

The Broadmead Bakery

Robert Mattice Harriston Bakery

Boris Petrosian Primex Packaging

Meghan Robins Sweet Twist of Fate

Henry Ruczynski

John Squire

The Kaak Group North America

Peter Storm Niagara College

David Stricker Pfeil & Holing Inc

A look at the functional role of sugar in baking.

By Jenny Gusba

Sweeteners are one of the most important ingredients used in bakery foods. While there are many different sweeteners available, sucrose (or sugar) is perhaps the most versatile.

A large variety of sugars can be produced by extracting and purifying sugar from sugar cane and sugar beet. These sugars may differ in colour, flavour, sweetness, and crystal size. For example, the molasses in brown sugar gives it a different flavour and appearance compared to granulated white. Sugar can also be used in both crystalline and liquid forms. All of these characteristics contribute to the variety of functions performed by sugar in foods. Sugar not only makes foods taste sweet, it also has many other functions.

Sweetness is generally the most recognized functional property of sugar. The preference for sweetness is thought to be innate, appearing shortly after birth. Perception of the relative sweetness of sugar depends on factors such as temperature, pH, concentration, presence of other ingredients, and the difference in individuals’ ability to taste (e.g., detection threshold).

Sugar is an important contributor to flavour by interacting with other ingredients. Depending on the food application, sugar has the unique ability to heighten flavour or depress the perception of other flavours. In breads, for example, the resulting flavour typically is due to two processes that involve sugar: fermentation and crust browning.

In bakery products, sugar is recrystallized as water is removed during baking, resulting in a crisp texture. This crispness is increased by the effects of browning. Two different reactions are responsible for crust browning: caramelization and the Maillard reaction. Caramelization results from the melting of sugars to create a deep brown colour and new flavours. The Maillard reaction takes place when reducing sugars (e.g., glucose and fructose) and proteins are heated together.

The yellow-brown colours that develop

in baked foods can be attributed to the presence of sugar. Sucrose itself develops colour through caramelization.

In addition, sugar can be broken down into its two monosaccharide units (glucose and fructose), which can take part in the Maillard reaction and add to browning. Sugar also contributes to the colour of preserves and jellies through its capacity to attract and hold water. By absorbing water more readily than other components, such as fruit, sugar prevents the fruit from absorbing water, which would otherwise cause colour to fade through dilution.

Sugar acts as an important tenderizing agent in foods such as baked products. During the mixing process, sugar competes with other ingredients for water. In bread-making for example, the affinity of sugar to bind to water will delay the development of gluten, a protein in grains that is essential for maintaining a soft or tender product. Gluten strands, in general, are highly elastic, and this property allows the batter to stretch under the expansion of gases. Too much gluten formation, however, will cause the dough or batter to become rigid and tough. When the correct proportion of sugar is added in the recipe, an appropriate amount of gluten develops and optimum elasticity results. Sugars are also used in bread-making to prevent stickiness.

The physical functions that sugar contributes to foods include its solubility in water, its ability to lower the freezing point and raise the boiling point. Solutions of varying sugar concentrations are important in many food applications, including the production of jellies and jams. Freezing point depression is an important property in ice creams, frozen desserts, and freeze-dried foods to ensure the development of fine crystal structure and product smoothness.

Sugar plays an important role in extending the shelf life of bakery products. Sugar can bind to water molecules, slowing moisture loss and preventing staleness in baked goods. In addition, the glucose/ fructose mixture in invert sugar present in jams and jellies helps to inhibit microbial growth and, later, spoilage.

Fermentation, an extremely important process in the baking industry, is fuelled by sugars. Sugars are used to activate yeast for fermentation. The type and amount of sugar added can increase the dough yield and softness of bread by altering the rate of fermentation. When a hard crust bread is desired, sugars are either omitted or used in lower quantities. In this case, the yeast is activated by sugars formed when starch is broken down by enzymes present in the flour. Sugars remaining after fermentation contribute to the overall flavour, colour, and texture of the final product.

Sugar can act as an antioxidant in some food systems. It is able to block metal ions (e.g., copper, iron) and prevent or slow down oxidation reactions, which cause food to deteriorate.

Sugar can be used in nearly all baking applications, including yeast-based products, chemically leavened products, icings, and fillings. It plays a number of different roles in baking that go beyond the perception of sweetness. ❖

Jenny Gusba is the director of nutrition and scientific affairs with the Canadian Sugar Institute, the national, non-profit association representing Canadian sugar manufacturers on nutrition and international trade affairs. Find out more at www.sugar.ca.

This column is written by Dr. John Michaelides of the Guelph Food Technology Centre.

Question: What new information is available on acrylamide and what is being done to reduce it in processed foods?

Answer: You may remember my acrylamide Technical Talk that appeared in the October 2005 issue of Bakers Journal. In this article we discussed the growing importance of acrylamide in the human food supply; however, since then there have been new developments and information gathered on the subject and we feel it important to revisit the issue. For those who missed the 2005 article, here is a brief synopsis to bring you up to speed.

The first report on the presence of acrylamide in processed foods was published in April 2002 by the Swedish National Food Administration and Stockholm University. They reported the presence of acrylamide in a variety of fried and oven-baked goods. Their report indicated a relationship between the formation of acrylamide, high temperature cooking processes and some high carbohydrate foods. The formation of acrylamide in food products raised researchers’ concern due to the possible carcinogenic potential associated with the chemical. Acrylamide is formed in processed foods by the reaction of the amino acid asparagine and sugar (the major component of carbohydrates). When foods containing this amino acid and carbohydrates are exposed to heat, especially at temperatures above 100 C, acrylamide is formed. Asparagine is found in high amounts in potatoes and cereals. Research findings indicate that trace amounts of acrylamide are formed during boiling (100 C) but the majority of the compound is formed when the food temperature reaches 120 C or higher. The chemical is most likely to accumulate during the final stages of baking, frying or grilling.

Since the discovery of acrylamide in food products, many government institutions, food industry associations, food

industry members, and researchers have been involved in efforts to understand the process of formation and possible prevention of accumulation of this chemical in food products. A joint FAO/WHO Expert Committee on Food Additives report, published in February 2005, reviewed the various studies on acrylamide toxicity, the process of its formation in food products and possible ways to reduce its presence in such foods. It was reported to be prominent in foods containing high amounts of carbohydrates and low protein. Acrylamide is also associated with the Maillard reaction, the reaction responsible for the browning of foods. The FAO/ WHO report, along with other reports and publications, provided information on ways to reduce the formation of the chemical in processed foods. For example, the European Food Industry reported a possible 30 to 49 per cent reduction of acrylamide formation in potato chips by introducing adjustments to chip processing. Significant reduction was also reported by process optimization of crisp bread production. Other suggestions and investigations included reduction or elimination of the amino acid asparagine from the formulation prior to exposing the food to the heat treatment. Experiments in food models at that time have shown success by the use of an enzyme asparaginase which will selectively remove the amino acid from the food materials.

Since the last Technical Talk on

acrylamide in 2005 many developments have taken place to reduce this chemical in food processing. Agencies like the Confederation of Food and Drink Industries of the EU have intensified their research efforts in order to provide guidelines to processors meant to reduce acrylamide formation by modifying the processing parameters. However, through this research, it was discovered that an intricate relationship exists between the formation of acrylamide during the Maillard reaction and flavour development. Reducing acrylamide by controlling processing parameters means a reduction in flavour development. Other suggestions to reduce acrylamide include reformulation and change of the acidity of the food product. However, reformulation could possibly change the organoleptic profile of the product, which will require consumer acceptance evaluations and substantial R&D efforts. Other researchers suggest the addition of compounds to foods prior to processing that will interfere with the production of acrylamide. For example, inclusion of citric acid at a level of 0.39 per cent and glycine at the level of 0.39 per cent was found to reduce acrylamide formation by 40 per cent with minimal effect on the volatile flavour development in potato cakes. Other research from China looks at bamboo leaf extracts as additives to reduce acrylamide in chips and fries. The report indicates that immersion of fries in solutions containing these antioxidant extracts prior to frying allows their penetration into the potato matrix and prevents the formation of acrylamide. Other studies have indicated that immersion of fries into a solution of some common ingredients such as l-cysteine, sodium bisulphide, calcium chloride as well as catechin and ferulic acid inhibits the formation of acrylamide. Of these ingredients the most promising for large-scale manufacturing is calcium chloride. Table salt (sodium chloride) was also suggested as playing a role in the reduction by polymerizing the acrylamide, i.e., changing its form. However, with so many in the industry moving towards salt reduction this option is not viable. Patented technologies of applying different compounds to foods to prevent

the formation of acrylamide have also emerged. A U.S. patent issued in 2007 uses a dry alkaline protein mixture and claims the process will minimize acrylamide formation. Another U.S. patent issued in 2008 uses various cyclodextrins to prevent the formation of acrylamide. However, the most promising solution comes from the commercialization of the enzyme asparaginase which converts free asparagine into aspartic acid that does not form acrylamide during food processing. Two major enzyme companies have introduced enzymes into the market under different trade names. The DSM enzyme which comes from Aspergillus niger with the trade name “Preventase” and Novozymes with “Acrylaway” derived from Aspergillus oryzae. A number of compounds and ingredients are claiming to provide the solution for the acrylamide problem. However, careful consideration should be given before we start using these solutions in food products. We need to make sure they actually work and their function is not affected by the variability of our processing parameters. We also need to know the regulatory status of these ingredients both in Canada and in the countries we intend to export to.

Further research explores storage method and duration impact on acrylamide formation. Research data indicates that concentrations of acrylamide in precooked battered protein foods increases with storage to almost double the original amount when air is present in the package.

Researchers also focused on the development of crop varieties that are less likely to result in formation of the acrylamide when processed into foods. These include the varieties with low asparagine content. The environment in which the crop is grown can also impact acrylamide formation: for instance, changes in the soil conditions from region to region. The soil composition affects the protein levels as well as the corresponding amino acid profile and may increase or reduce the amount of asparagine in the protein of a particular crop.

Researchers continue to explore acrylamide’s connection to human health, especially its carcinogenic properties. Some researchers indicate a positive association of acrylamide and breast cancer based on epidemiological studies. Other researchers found no evidence of acrylamide links

to cancer and specifically colorectal cancer. The research data on the link between acrylamide in our diet and cancer are very scanty and not sufficient to really draw any definite conclusions. However, we should continue our efforts to find ways in reducing or eliminating this unwanted and possibly harmful compound from our foods.

As more data become available on this issue, concerns over the presence of acrylamide in foods will resurface from time to time. In the meantime, the food

industry should be looking into additional ways to prevent the formation of this chemical in food products. ❖

Funding for this report was provided in part by Agriculture and AgriFood Canada through the Agricultural Adaptation Council’s CanAdvance Program.

For more information, or fee for service help with product or process development needs please contact the GFTC at 519-821-1246, by fax at 519-836-1281, by e-mail at gftc@gftc.ca.

If unsurpassed quality and performance are missing from your baking ingredients, choose AB Mauri Dough Improvers from Fleischmann’s Yeast Available in both tablet and powder forms, our extensive line of innovative enzyme-based improvers are designed to maximize baking efficiency, consistency, and quality—including our ABM 310 Gluten and Emulsifier Enhancer, which improves processing while reducing gluten and emulsifier costs.

Plus, our team of Experts can develop custom solutions to optimize your particular dough improver formula applications.

Achieve excellence in your baking processes. Choose AB Mauri Dough Improvers from Fleischmann’s Yeast.

They’re the comeback kids! The first Cabbage Patch Kids were introduced in the early 1980s and were a smash hit. Reintroduced to the market in the early 2000s, these adorable, adoptable dolls are again winning the hearts of a new generation of kids, along with their moms, who have fond memories of the classic collection from their own childhoods.

DecoPac is pleased to be the bakery source for Cabbage Patch Kids cake decorations and cupcake accessories. Check out the Cabbage Patch Kids Creations DecoSet #96398 and a full line of Cabbage Patch Kids products by visiting www.decopac.com or call 1-800DECOPAC to order.

Reiser introduces the Vemag dough divider. Add versatility to every production line, which is perfect for all types of breads, buns, rolls and English muffins. The Vemag is easily adjustable to produce a range of exact-weight portions, dough absorptions and crumb structures. At the heart of the Vemag dough divider lies the pumping element, the double-screw transport system. The double-screw is unique for its positive displacement, which assures gentle and consistent handling of the dough without overworking it, along with exact-weight portions. The double-screw is available in a variety of configurations to handle virtually all types of dough. The Vemag can be easily adjusted with a simple changeover in the double-screw configuration to produce both open-crumb and uniform tight-crumb structure – and anything in between. An optional Vemag 982 developer system can further de-gas doughs in order to produce a more uniform, fine cell structure. The

982 can be added to the line at any time and taken out in minutes to run a more open crumb structure – part of Reiser’s modular approach that preserves your investment and adds versatility to your production line.

Contact Reiser for more information at 781-821-1290 or sales@reiser.com.

Mühlenchemie GmbH & Co. KG now offers its customers two innovative new products for standardizing and improving flours. The enzyme Alphamalt SOX stabilizes doughs while they are being processed. Its benefits lie in its specific effects and its longer storage life as compared to similar enzymes. The second new product, Alphamalt FSR, optimizes the rheological properties of the dough and has additional effects in conjunction with other enzymes, particularly hemicellulases. These synergisms reduce the cost of using enzymes. For more information, please contact Mühlenchemie GmbH & Co. KG through their website at www.muehlenchemie.de.

Horizon Milling has developed three new prototypes that demonstrate how food manufacturers can easily incorporate a concentrated source of essential vitamins, minerals and antioxidants into great-tasting snacks, cereals and bars using all-natural GrainWise Wheat Aleurone: GrainWise cereal flakes; GrainWise bars; GrainWise puffed snack.

GrainWise cereal flakes are an excellent source of fibre; the essential antioxidant

nutrients manganese and selenium; and phosphorus and magnesium. In addition, the flakes are a good source of iron, thiamin, niacin, vitamin B6 and copper.

GrainWise bars with fibre and protein help satisfy consumers’ appetites between meals. They are excellent sources of vitamin E and copper, and good sources of fibre, protein, niacin, phosphorus and magnesium.

All-natural GrainWise puffed snack is an excellent source of fibre, magnesium and phosphorus, and a good source of niacin, vitamin B6 and copper. In addition, it is low-fat, sodium-free and contains zero grams of trans fat.

GrainWise Wheat Aleurone is a concentrated source of essential vitamins, including thiamin, niacin and folic acid; and important minerals, including phosphorus, magnesium, iron and zinc. It includes antioxidants from whole wheat and contains 45 per cent dietary fibre.

To learn more about GrainWise Wheat Aleurone, visit www.horizonmilling.com.

New Double-Mat Wire Shelving from Eagle is specially designed to accommodate merchandise that is difficult to store or display on conventional wire shelving units. Eagle’s new shelving is specially designed for safe storage of items such as soda bottles, round-bottomed containers and small-legged appliances, while continuing to enjoy the advantages of wire shelving including strength, configuration flexibility, and improved air circulation.

Eagle’s shelving design begins with spacing heavy-duty open wires 7/16 inches (11 millimetres) apart for a tighter, more concentrated wire surface. The shelving also features Eagle’s patented QuadTruss system, which maximizes load-bearing weight per shelf. The unique pincer-type design –with the mat wire sandwiched in between the two top truss wires – distributes load weight equally, thereby reducing stress and strain on the welds. Double-mat wire shelving units from Eagle are available in standard widths ranging from 18 inches to 24 inches, and in lengths from 36 inches to 60 inches.

For more information, contact Lynda Donavon at 800-441-8440 or go to the website at www.eaglegrp.com. ❖

Pizzey’s Whole-Milled BevGradTM and SelectGradTM flaxseed is an excellent source of Omega-3 fatty acid (22%). Also a good source of dietary fiber and protein, Pizzey's flaxseed does not require refrigeration and is gluten free.

Joe Puiia began his professional career when he joined father, Vito, in the garment industry. As the industry began to send work overseas, the two sought new business opportunities.

In February 1989, they opened J. P. Bagel Express in Hoboken, New Jersey, which was an immediate success. In June 1989, Joe’s brother, Jerry opened a similar business called Bagel Stop in Vernon, Connecticut. In 1990, Joe moved to South Windsor, Connecticut, to join Jerry in opening a second Bagel Stop. Today, Joe and Jerry own the Bagel Stop Production Company that supplies a variety of baked goods to Joe and Jerry’s newer company, Between Rounds Cafes. Combining several marketing concepts, Between Rounds Cafes offer bagels, gourmet sandwiches, salads and gourmet coffee. Joe and Jerry have a total of six Between Rounds locations in two states, offer catering services for large events and are building a franchise business.

´

´

Email: sales@pizzeys.com www.pizzeys.com

Joe recognizes that a business needs to change in order to grow. ‘‘If you are not competitive in a crowded market, you will lose customers to the next guy,” he said. ‘‘I believe our success comes from our ability to stay competitive, and the work ethic we learned from our father.”

Joe relies on International® Bakers Services (IBS) to stay competitive.

‘‘IBS is the most professional company in terms of meeting their customers’ needs, said Joe. ‘‘They also let their customers know they are appreciated.” For their famous bagels, Between Rounds uses Blueberry Flavor, Maple Flavor, Apple Cinnamon Flavor and seasonally, International’s Pumpkin Pie Spice Blend.

If you want flavors that help you compete in a crowded market, rely on International® Bakers Services

Contact us toll-free at (800) 345-7175, by fax at (574) 287-7161, or in writing at 1902 North Sheridan Ave., South Bend, Indiana 46628. We have the flavors your customers deserve.

Call our Canadian Distributors to request our catalog:

BakeMark of Canada 3202 - 9th Street S.E. Calgary, Alberta T2G 3C3 (800) 663-CAKE (604) 303-1700

Cake Top Inc 151 Carling View Drive, Unit 2 Etobicoke, Ontario M9W 5S4 (800) 584-9883 (416) 798-1777

Catalog Sales Division (800) 428-4413

L & M Bakers Supply Co. 2501 Steeles Ave.W., Unit 1 Downsview, Ontario M3J 2P1 (800) 465-7361 (416) 665-3005

Nicholson Equipment Ltd. 3975 Kitchener Street Burnaby, B.C.V5C 3L9 (800) 668-3722 (604) 291-1901

Nicholson Equipment Ltd. 11640 - 147th St. Edmonton, AB T5M 1W2 (800) 661-9026 (780) 451-6262

Traynor's Bakery Wholesale 191 Victoria Ave.S., Hamilton, Ontario L8N 3C8 (800) 263-9239 (905) 522-2730

Vincent S.Varietes Ltd. 433 Rue Saint Paul LeGardeur, Quebec J5Z 4C7 (800) 263-1687 (450) 585-1687

Vixit Products Ltd.

290 Henri Bourassa Ouest Montreal, Quebec H3L 1N7 (800) 463-8782 (514) 337-0814

(DIVISION OF A & L FOOD DISTRIBUTORS INC.)

SUPPLIER OF FROZEN AND RAW INGREDIENTS

FOR THE BAKING INDUSTRY

Tel: (416) 252-4660 Fax: (416) 252-9993

25 - 8 Connell Ct., Toronto, ON M8Z 1E8

’s (416) 247-7444

“Friends in Business” Suppliers of Quality Baking Ingredients: Flour, Yeast, Shortening, Fruit Fillings, etc.

55 Queen’s Plate Drive, Unit 5 Etobicoke, Ontario M9W 6P2

• BAG CLOSURES & LABELS • BAG CLOSING EQUIPMENT • KWIK LOK TAGS

1039 GRANDE CAROLINE, ROUGEMONT, QUEBEC J0L 1M0

TELEPHONE: (450) 469-2554 FAX: (450) 469-3085 CELL: (450) 531-2002 176 SHELDON DRIVE, CAMBRIDGE, ONTARIO N1R 7K1 TELEPHONE: (519) 623-5140 FAX: (519) 623-1421 1-888 KWIK LOK (594-5565)

Phone 1-888-599-2228 ext. 268 or 519-428-3471 FAX 519-429-3094 or 519-429-3112

Classified rates $1.35 per word. Count each figure or sign as one word. Minimum charge: $75.00 Box Number $10.00

$85.00 per column inch. Only prepaid advertisements accepted. Payment must accompany ad copy. Visa/MC welcome. Bakers

P.O.

530, 105 Donly Dr. S., Simcoe ON N3Y 4N5 Telephone (519) 428-3471, Fax: (519) 429-3094. June Issue classified deadline: May 16th, 2008.

FOR SALE: SOUTHWESTERN ONTARIO Area’s #1

Bakery/Deli operating since 1939 - 7,000 Sq. Ft. retail/ production. Retail sales in excess of $700k. Showing excellent profit. Present owner for last 30 years retiring. Transition assistance. Generous long term lease or property purchase including 4 bedroom. Brick Home. Contact John or Mary at 519-688-2023 or email: marapeaz@hotmail.com

FOR SALE IN EASTERN ONTARIO: Bakery & Cafe; a growing & profitable Turnkey business, located on Main Street; High Exposure. Asking $264,000includes business, equipment and building. For more informataion please call Larry McDowall at Rogers & Trainor Commercial Realty at 613-384-1997 or 1888-384-1997 or email: lmcdowall@rtcr.com.

BAKERY IN KITCHENER FOR SALE: We have taken repossession of our bakery at 300 Trillium Drive. The assets include equipment, retail store display, 2 market locations and business name. This is an ideal opportunity for a family to operate their own, recession proof, business. Owner will help buyer to rebuild customer bas and training in production and sales of the quality of bread, buns and sweets for which we have been known for, for over 29 years. Asking $89,000 Contact Anton and Hildegard Sproll at Phone: 519-5764734 or Fax: 519-576-2357 or email: ansproll@ execulink.com.

FOR SALE: Scratch Bake Shop & all equipment with 3 rented apartments. In a town in need of a coffee shop and bakery. Peak Premier Realty & Auction Inc. Call Helen at 519-291-2299.

SALES/MARKETING COORDINATOR WANTED: $45-60K. Toronto N.W. & E. (on metro). Company seeks creative, analytical, self-starter to watch trends, present info, liaise with clients. 1-5 years experience in food service/retail (broker, distributor, etc) industry. Call Food Industry Recruiters: 416-733-2696 to 11pm.

Product Costing/Nutrition Analysis New! nutraCoster Professional 2.1

- Calculates product cost including labour, packaging and overhead

- Unlimited number of ingredients

- Unlimited number of process steps

- Calculates Gross Margin/Selling Price

- Calculates nutrition content of recipes

- Prints NLEA and Canadian nutrition labels

- Includes 6600 ingredient database

- Accounts for nutrient changes during processing, including moisture loss and fat loss/gain.

- Includes Trans Fats

- Calculates Net or Effective Carbohydrates

- Brand name ingredient data also available Free demo on our web site nutraCoster 2.1 $399 U.S. 45 day guarantee - For Windows Nutrition Analysis Service Also Available

- We can analyze your recipe for you

- $50 per recipe for both Nutrition & Costing Inventory Control! stockCoster 2.1

- Works with nutraCoster 2.1

- Track raw materials and finished goods

- Automatically remove used ingredients

- Print pick lists for production requirements

- Easily identify shortages

- Track aging and expired products and ingredients

- Track vendor quotes stockCoster 2.1 $199 U.S. 45 day guarantee - For Windows SweetWARE (800) 526-7900 http://www.sweetware.com

ext. 219

Michelle Brisebois offers a will and a way for these days of challenges.

For every offence, there needs to be an effective defence. The Canadian food industry has become an interesting landscape these last few years. We’ve emulated the American superstore model; we’ve gone organic, local and healthy. There are, however, several major societal shifts occurring and these changes will impact the Canadian consumer. When it comes to share of stomach are we really ready to do battle for our customer’s hard-earned dollars?

Prices of wheat are increasing. This is partly due to an increased demand from foreign markets such as Asia where economic growth is creating a new middle class. Stem rust, Australian drought and weather problems elsewhere have also caused crop shortages, causing world prices to spike. Many fields previously used to grow wheat are being shifted to corn production for biofuel. This is squeezing the industry hard as bakeries try to avoid passing the costs on to the consumer, but if they’re going to stay in business, they really have no choice. The Canadian Wheat Board sees another 18 months of high prices. Defensive strategy: Diversify your product line by introducing more non-wheat-based products (although some of these products are also facing increased pricing). Portion control and production processes that minimize scrap will help control costs as well. You will be able to command higher prices for artisan breads so look for ways to recoup those costs by adding value to the end product with unusual twists.

Small decadent treats like individual cupcakes become more popular when disposal incomes are suddenly smaller than they used to be.

product line to target in-home entertaining, since restaurant meals may be an early casualty of a tighter budget. Consider developing a series of seminars focused on menu ideas for special meals at home. People often indulge in a small decadent treat when budgets are tighter. Gourmet cupcakes, brownies and chocolate truffles packaged one or two at a time will target this sector nicely.

More Canadians are claiming to have gluten allergies. According to CSPI Canada, it’s estimated that one in 250 Canadians is gluten intolerant (i.e., has celiac disease). For them, ingesting even small amounts of wheat, barley, rye, etc., can cause mal-absorption of nutrients and, increase the risk of a number of diseases. Organic products are posting double-digit growth and functional foods – those that have health benefits – continue to be popular. Defensive strategy: Offer alternative breads and promote the fact that you have wheat-free options. Pilot some organic products on a trial basis to see if they resonate with your customer base. Have fun with exotic ingredients. Chai cupcakes are hot in the Pacific Northwest. Green tea muffins and cookies are popular recipes on sites such as Recipezaar.com.

As of March 2008, gas was hovering around $1.11 per litre. It’s predicted to potentially go as high as $1.40 per litre by summer. We know that gas prices like these keep tourists at home. We also know that it will put pressure on cost of goods and discretionary income for consumers. Defensive strategy: Make sure the people who live within two kilometres of your business know you’re there. According to AC Neilson, 54 per cent of Canadians cite “closest store” as the most important reason for choosing where to shop for food. Eating local is a trend gaining momentum. If you use ingredients that are sourced locally, promote that fact by noting it on your signage and advertising. Place a few ads in the local paper to remind folks that they can walk or ride their bikes to your bakery. Bicycle Product Suppliers Association reports regular “commuter” bike sales are up six per cent for 2007. Show that you’re bike friendly by putting in some bike racks so people can park and lock up their cycles.

Many economists have indicated that the U.S. is already in a recession. Though Canada has a more solid economical footing than the U.S. right now, we still read the same gloomy headlines and U.S. woes have caused many Canadians to think more prudently about where to spend their dollars. A recent joint survey by Harris-Decima and Investors Group indicates Canadian consumer confidence has reached its lowest point in over two years. Defensive strategy: Position your

Everybody is eating each other’s lunch these days. Consumers can pick up groceries at Costco, Wal-Mart and Shoppers Drug Mart. Large chains are expanding into each other’s territory, often building new stores close to each other. Loblaw has responded with deep discounts in an effort to lure customers back to its aisles and this is putting more pressure on margins for all food retailers. Defensive strategy: If you’re a small business, don’t bother trying to compete on price alone – you don’t have the economies of scale. Yes, consumers may want value for their dollar but they’ll consider your signature baked goods a bargain if they are delicious, fresh and attractive. Be clear about your strength as a business and communicate this point of difference through your service, your marketing and your products. Businesses with strong brands are more profitable because they’re able to charge reasonable fees for their products and services.

Clichés about creating opportunity from challenge are as common as white bread. It’s not about being a Pollyanna – it’s about looking for the opportunity presented by the change. Next time you read a headline that causes you to worry, try asking yourself, “What’s great about this problem?” The answer may just be your best defence. ❖

Michelle Brisebois is a marketing professional with experience in the food, pharmaceutical and financial services industries. She specializes in helping companies grow their brands. Michelle can be reached at On Trend Strategies by e-mail at: briseboismichelle@ sympatico.ca.