MAY/JUNE 2021 www.craneandhoistcanada.com

MAY/JUNE 2021 www.craneandhoistcanada.com

Mother and crane operator gets the job done PG 21

Spotlight on Modern Crane PG 15

Ergonomics: Cab fatique PG 26

FROM THE EDITOR

BY JAY KOBLUN

Report says hopeful recovery for Canadian construction industry

Good news – BuildForce Canada published its labour market forecast at the end of March and said construction across the country is expected to rebound in 2021 and rise through the next 10 years as the industry recovers from the COVID-19 pandemic.

An industry recovery is not going to happen overnight, but it is great to see a professional report say 2021 could be a year of progress considering the 2020 that we all just witnessed. It also makes sense that a successful rollout of vaccines in Canada will affect each province’s recovery speed.

BuildForce Canada’s 2021 to 2030 Construction and Maintenance Looking Forward national report says the strength and speed of recovery will look different for each province and will be affected by the rollout of COVID-19 vaccines, the recovery in consumer and business confidence, the global demand for Canadian exports, and the lifting of restrictions on international travel. It will help the industry if the country is vaccinated and we can get back to regular hours, more in-person gatherings and events.

of negative construction growth in years. Declines in residential growth may cause employment levels to drop slightly.

Saskatchewan and British Columbia are expected to see the steepest growth of the provinces. Broad-based recovery is expected to take hold in Saskatchewan, as education, health care, utility, and mining investment combine to boost growth. And British Columbia will add more than 11,400 non-residential workers through 2022. By 2030, employment is expected to increase by 9,900 workers compared to 2020.

All-in-all the industry should be proud of itself for sticking with it and working hard to keep the country getting built.

Alberta was hit hard by the pandemic and the report says could see even more challenges. With continued uncertainty in the energy sector and the cancellation of major investments have significantly tempered expectations for a strong near-term recovery. All-in-all the industry should be proud of itself for sticking with it and working hard to keep the country getting built. From cranes to pavers, to dozers and general engineers, we owe the industry a lot of thanks.

Reader Service

Print and digital subscription inquires or changes, please contact Urszula Grzyb, Audience Development Manager

Tel: (416) 510-5180

Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | JAY KOBLUN jkoblun@annexbusinessmedia.com • 519-410-0600

NATIONAL ACCOUNT MANAGER | LAURA GOODWIN lgoodwin@annexbusinessmedia.com • 289-928-8543

MEDIA DESIGNER | SVETLANA AVRUTIN savrutin@annexbusinessmedia.com

ACCOUNT COORDINATOR | BROOKLYN VAN DYK bvandyk@annexbusinessmedia.com

REGULAR CONTRIBUTORS

Saul Chernos, Matt Jones, Judy Mellott-Green

GROUP PUBLISHER | TODD HUMBER thumber@annexbusinessmedia.com

COO | SCOTT JAMIESON sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues)

Canada: $37.00 + tax per yea • USA: $37.00 USD Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-5106875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT. 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

The report says Newfoundland and Labrador are expected to see a modest recovery in 2021. New Brunswick and Nova Scotia are going to be bolstered by in-migration trends (people moving into a new area in their country) and PEI was the only province of the four to experience a rise in construction employment in 2020, and that increase is expected to continue.

Quebec’s market is expected to grow through 2024 on the strength of private-sector spending and strong levels of government investment. Ontario’s recovery will be driven by a growing pipeline of major infrastructure projects across all regions. In 2020, Manitoba experienced its first year

Part of that success comes directly from those the industry honoured and celebrated on March 8 for International Women’s Day. Crane & Hoist Canad a magazine partnered with several other industry-leading construction publications to shine a light on successful women in construction and barriers they still face in the industry during our Women In Construction Virtual Event. The event was a look inside parts of the industry that need to be talked about more. Celebrating International Women’s Day and women in construction is just one part of the work that needs to done.

PRINTED IN CANADA ISSN 1923-788X Publications Mail Agreement #PM40065710

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Advertising Deadline: May 28, 2021

Don’t miss the opportunity to be part of this exciting new industry publication. For more information, or to reserve space in the next issue, call Laura Goodwin at our Advertising Department Tel: +1-289-928-8543 lgoodwin@annexbusinessmedia.com

Next Editorial Deadline: May 28, 2021

For writers’ guidelines and submission requirements get in touch with the editor, Jay Koblun, at +1-519-410-0600 Email: jkoblun@annexbusinessmedia.com

MEMBER OF: MEDIA PARTNER:

Offering a full line of equipment from the industries top manufacturers. Including Manitowoc, Grove and National Boom Trucks. Western Pacific has the crane to get the job done.

Anchorage, AK

6720 Arctic Blvd (907) 331-4876

Bakersfield, CA 3521 Alken Street (661) 578-5854

Fontana, CA

8600 Calabash Ave (562) 286-6618

Tracy, CA

275 W Larch Road (209) 597-3824

Kapolei, HI 91-210 Kalaeloa Blvd (808) 682-7263

Portland, OR 8912 Northeast Vancouver Way (971) 202-4002 Arlington, WA 19602 60th Avenue Northeast (253) 254-7950

By Crane & Hoist Canada

BuildForce Canada released a labour market forecast explaining construction requirements across the country are expected to rebound in 2021 and rise through the next 10 years as the industry recovers from the COVID-19 pandemic.

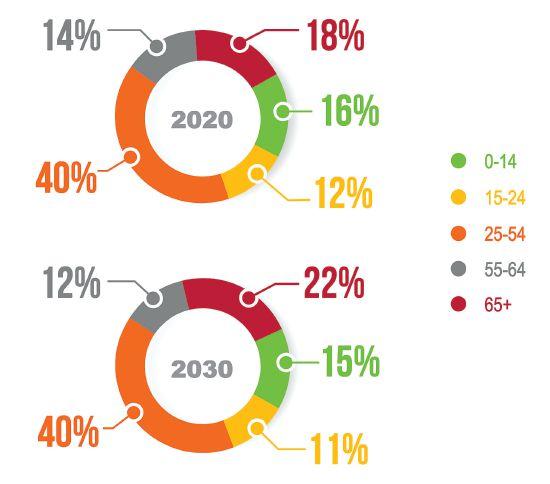

The 2021–2030 Construction and Maintenance Looking Forward national report forecasts construction employment to rise by 64,900 workers over the next decade. This represents an increase of six per cent over 2020 workforce levels. While the outlook forecasts much of that growth to take place through 2025, by the end of the decade, the respective provincial industries will have to cope with the need to replace nearly 259,100 workers, or about 22 per cent of the current labour force, due to retirement.

The strength and speed of recovery will look different for each province and will be affected by the rollout of COVID-19 vaccines, the recovery in consumer and business confidence, the global demand for Canadian exports, and the lifting of restrictions on international travel.

“Canada’s construction outlook is strong for 2021 and well into the middle portion of the decade thanks to gains in the residential and non-residential sectors,” says BuildForce Canada Executive Director Bill Ferreira.

BuildForce Canada anticipates that the non-residential sector will lead industry growth between 2021 and 2023 and be driven by a large list of public transit, health care, education, roadwork, and other civil infrastructure projects. Overall, non-residential employment is projected to increase by more than 39,800 workers between 2021 and 2025, and another 5,000 to 2030. The sector is expected to end the decade up 44,800 workers (+8%) compared to 2020.

After a mixed year in 2020, the

10-YEAR WORKFORCE OUTLOOK FOR CANADA

SOURCE: BUILDFORCE CANADA

22%

44,800

residential sector is expected to see strong growth post-2021. Low lending rates and renewed immigration levels are expected to drive a moderate up-cycle in new-home construction to 2024, while renovation work is projected to grow steadily. As a result, total residential employment is expected to peak in 2024 before ending the decade with an increase of nearly 20,100 workers, a four per cent growth, compared to 2020 levels.

260k

Activity across the Atlantic provinces is expected to vary. Newfoundland and Labrador will see a modest recovery through 2021, but long-term growth will be constrained. The forecasts for New Brunswick and Nova Scotia, meanwhile, will be bolstered by in-migration trends, the process of people moving into a new area in their country to live there permanently. The report says Prince Edward Island was the only province of the four to experience a rise in construction employment in 2020, and that increase is expected to continue through 2022.

Quebec’s market is expected to rebound from the pandemic in 2021 and grow through 2024 on the strength of private-sector spending and strong levels of government investment.

Ontario will be driven by a growing pipeline of major infrastructure projects across all regions. An additional recovery in commercial and industrial investment will bring labour demands to a peak in 2026.

In 2020, Manitoba experienced its first year of negative construction growth in several years. Declines in major-project requirements and lower levels of institutional and residential growth may cause employment levels to drop slightly, by one per cent, over the forecast period.

A broad-based recovery is expected to take hold in Saskatchewan in 2021, as education, health care, utility, and mining investment combine to boost growth across most construction segments to an expected peak in 2023.

In an effort to add to our large range of below-the-hook lifting devices, Caldwell is proud to introduce the Dura-Mod Modular Spreader Beam. Our new product will come in a variety of sizes that allow the user to configure a spreader beam suitable for different projects and applications depending on the desired capacity and spread.

Lightweight in comparison to fixed/multiple point beams.

Easy to transport & store; single longest component is only 20’!

Two end units, drop links, and spreader sections make it fully customizable.

Distributors are able to keep them stocked, offering customers quick ship access to certified spreaders.

World-renowned Caldwell brand name on a modular spreader system.

Components can be added and bought separately; take what you need now, add later!

Dura-Mod can be used with corner fittings to create box and rectangular configurations

All of the Dura-Mod spreaders conform to ASME B30.20, BTH-1, DESIGN CATEGORY B, CLASS 0.

For additional Dura-Mod information, contact Caldwell or scan the QR code!

SOURCE: BUILDFORCE CANADA

The report says Alberta was one of the provinces hit the hardest by the pandemic and could see further challenges ahead. Ongoing uncertainty in the energy sector and further deferrals and cancellations of major investments have significantly tempered expectations for a strong near-term recovery. A more material expansion is expected after 2023.

Finally, British Columbia is poised to enter the steepest period of growth in its forecast period. The province will add more than 11,400 non-residential workers through 2022, before shedding as many as half of those gains through 2026, before renewed growth later in the period adds new jobs. By 2030, employment is expected to increase by 9,900 workers compared to 2020.

The development of skilled tradespersons in the construction industry takes years and often requires participation in a provincial apprenticeship program. As such, replacing retiring workers typically requires several years of pre-planning to avoid the creation of skills gaps. By 2030, overall hiring requirements in the industry are ex-

228,100

First-time new entrants aged 30 and younger from the local population, leaving the industry with a possible retirementrecruitment gap of 31,000 workers. 2030

Employment is expected to increase by 9,900 workers compared to 2020.

pected to exceed 309,000 due to the retirement of some 259,100 workers (or 22 per cent of the current labour force) and growth in worker demand of 49,900.

Based on historical trends, Canada’s construction industry is expected to draw an estimated 228,100 first-time new entrants aged 30 and younger from the local population, leaving the industry with a possible retirement-recruitment gap of 31,000 workers.

The report says an ongoing commitment to training and apprenticeship development will be necessary to ensure there are sufficient numbers of qualified tradespeople to sustain a skilled labour force over the long term. What is yet unclear is how the pandemic will impact registration rates going forward. Limited data collected to date suggests that the pandemic has resulted in a steep decline in new registrations relative to employment across the country.

BuildForce Canada is a national industry-led organization that represents all sectors of Canada’s construction industry. Its mandate is to provide accurate and timely labour market data and analysis, as well as programs and initiatives to help manage labour force requirements and build the capacity and capability of Canada’s construction and maintenance industry. Visit www.constructionforecasts.ca.

Tadano announced that Toshiaki Ujiie, executive vice-president and representative director, will replace Koichi Tadano as Tadano president and CEO effective April 1.

“Today, it is my pleasure to announce the new leadership of Tadano to our valued stakeholders. It has been my honour to serve as president and CEO of Tadano Ltd. for 18 years. For your support in helping me reach this milestone day, I offer my humble thanks to all of our stakeholders and each and every one of the employees in the Tadano Group,” said Koichi Tadano.

Ujiie said he is humbled to be given the opportunity to serve as president.

“I am humbled and honoured to be given the opportunity to serve as president and chief executive officer of Tadano Ltd. I joined the company in April of 2019, less than two years ago, but I am surrounded by some of the world’s greatest crane experts. I look forward to honing my understanding of cranes and the inner workings of the company by working closely with them. I also hope that the experiences and knowledge that I bring from the world outside of the crane industry can combine with their expertise to bring about dynamic change and transformation.

“Mr. Tadano has remarked to me that ‘Innovation is brought about by the young, the foolish, and the outsiders of our world.’ While my age precludes me from claiming the first of these characteristics, I certainly possess the other two. By working together with the young and energetic talent in our company, I will strive from day one to expand the Tadano brand, which my six predecessors have built in their turns as CEOs of the Tadano Group.”

Link-Belt Cranes appointed Andrew Soper as product manager for telescopic trucks, and all-terrain cranes. Soper joined Link-Belt in 2014 as

marketing specialist for lattice and telescopic crawler cranes. In 2017 he moved to the same role for telescopic trucks and all-terrain cranes.

Before joining Link-Belt, he had manned and maintained crane rental experience as a project manager and sales estimator.

“Andrew has a detailed understanding of the crane industry. Not only that, but over time he has built strong relationships within our distributor network, providing a great link between our products and our customers,” said Pat Collins, director of marketing at Link-Belt Cranes.

Soper has a bachelor’s degree in economics from the University of Kentucky and is scheduled to complete his MBA this spring.

Gary Lane was named manager of North American sales for Link-Belt Cranes on February 1. Bill Stramer, senior vice president of marketing, sales, and customer support, made the announcement at Link-Belt’s headquarters in Lexington, Ky.

Lane is a 15-year veteran of the crane business and is well respected among crane industry professionals. He originally joined Link-Belt Cranes as a district manager in 2008 covering the Central U.S., and he has spent the last nine years heading up the crane sales efforts for Link-Belt crane dealer General Equipment and Supplies Company, Inc. based in Minneapolis, Minnesota.

Gary holds a Bachelor of Science degree in Business Administration from the University of Nebraska.

“Gary’s strong background with crane distribution and end-users provides him all the necessary skills for his new role,” said Stramer. “Gary’s management experiences will aid him in continuing the legacy of successful leadership of Link-Belt’s North American sales team.”

When not working, Lane enjoys spending time with his family and a variety of outdoor activities including hiking, fishing and canoeing.

Link-Belt Cranes appointed Amy Maddox as manager, marketing promotion in December 2020. Maddox will oversee all promotional, publicity, trade show, logo standards and business gifts endeavours.

Maddox has more than 20 years of experience in marketing promotion, with nearly half that time spent as corporate communications manager with Link-Belt’s sister company, LBX Company. She comes to Link-Belt from Toyota North America where she served as its production engineering communication lead.

“The timing for Amy’s return to the construction equipment industry perfectly coincided with Tonya Creasman’s retirement and I am confident that the same level of professionalism and service will continue,” said Bruce Kabalen, manager, marketing and technical communications. “Amy’s experience and abilities at LBX and other positions in her career make her a great fit for our Link-Belt team.”

Gary Lane, Link-Belt’s manager of North American Sales, announced the company’s top five distributors for 2020. These distributors are based on overall performance in marketing and sales of Link-Belt cranes.

Link-Belt’s top five distributors for 2020 in alphabetic order:

• Atlantic & Southern Equipment LLC – Lake City, Georgia

• HOLT Crane & Equipment – Houston, Texas

• Mardian Equipment Co. Inc. – Phoenix, Arizona

• Nixon-Egli Equipment Co. – Ontario

• Pinnacle Cranes – Charlotte, North Carolina

“Our distributor partners are a vital link between our products and our end-users, and we are grateful for their hard work and commitment through a year of exceptional challenges,” said Lane. “Our top five distributors represent the ‘best of the best’ in terms of product support and customer service, and we know that Link-Belt crane owners will benefit from their dedication for years into the future.”

The Caldwell Group launched its new website and rebrand at caldwellinc.com. The site features the specialist lifting equipment manufacturer’s new brand and logo.

Caldwell, a provider of standard and custom lifters, has been working on the relaunch for almost a year, having set out last spring to position the business even closer to end-users, distributors and potential partners. The new website also captures Caldwell’s status as a ‘Lifting Solutions’ provider, which is the tagline of a revamped logo.

At the heart of the site, powered by web developer WeCreate, is Caldwell’s full catalog of below-the-hook and other lifting equip-

ment, and SmartSpec, a digital tool that allows distributors to configure products. SmartSpec resembles other advanced product configurators but is unique in giving customization options to dealers specifically looking for non-standard equipment.

“As an organization, we have been putting a lot of emphasis on evolution, whether it be through our products or our internal culture. The website needed to better reflect that same mindset. Also, we keep talking about improving the customer experience—how can we make our partners’ lives easier? The website was a big part of that. The pricing and quoting aspect built into the site will ultimately help customers become more efficient, whether it’s dealers logging in to view standard catalog pricing or source custom solutions,” said Darrin Noe, director of sales at Caldwell.

“If you want a catalog product, it’s right there in front of you. If you want something a little more customizable, you can simply click a button to take you to SmartSpec. And if you’re hunting for a full-blown, one-off system, you can contact our sales staff from that same window. We want to be the worldwide leader in providing lifting solutions and the old website didn’t reflect that. The new one does,” he added.

Noe explained that the new logo’s colour theme represents the continuity of the

brand’s identity, while also indicating a new era and direction for the company. He credits Jose Pelaez, a Minnesota-based designer with the ‘slung C’ concept, versus the more tightly cradled look of the old logo. Pelaez provided a rendition of the logo that was slightly edited into what it is today. The modernized sling look originated from his work, however.

“Lifting Solutions is what we do and who we are. Whether it’s a simple pipe tong or a complicated lumber lifter, we provide solutions for your lifting issues. The new website and brand collectively chime with that ethos,” said Noe.

Crane Industry Services (CIS) now offers monthly open enrollment training and written and practical exams for NCCCO Mobile Crane Operator certification. CIS is authorized to deliver practical exams for NCCCO Telescopic Boom (Swing and Fixed Cabs) and Lattice Boom Truck Cranes.

The NCCCO Mobile Crane Operator Training program is specifically designed to prepare experienced operators for the successful completion of NCCCO Written and Practical Examinations. This program includes a CIS Study Guide, which is authored and copyrighted by CIS on an annual basis, interactive classroom exercises, and hands-on practice time on CM-Labs simulators.

“We strive to offer our customers a choice when it comes to qualification and certification of workers,” said Debbie Dickinson, CEO of CIS. “In addition to these new classes, CIS offers rigger and signalperson training, NCCER Basic Rigger and Advanced Rigger written and practical testing, and courses for crane site safety, lift directors, and safety managers.

To see the full open enrollment training and certification options visit, centeredonsafety. com/events.

offers Unsurpassed , led by the best , the most knowledgeable , all backed by North America’s leading equipment group. As a part of the Lanco Equipment Group, along with Walter Payton Power Equipment and Western Pacific Crane & Equipment, we are now part of the World’s Largest Manitowoc Dealer group. and cranes and is part of North America’s and

sales along with , MI-JACK CANADA IS your source for on the full line of Manitowoc and Grove cranes.

Your Authorized Distributor in Alberta and Saskatchewan for Manitowoc and Grove, Sales, Parts and Service visit us at Call us at:

We encourage interested sellers to contact us today to take advantage of the strong market.”

Close to 10,000 bidders from 67 countries registered for the three-day Toronto auction. Approximately 93 per cent of the equipment in the auction sold to Canadians, including 73 per cent sold to Ontario buyers, while the remaining seven per cent was sold to international buyers from as far away as Singapore, Peru, and the United Kingdom.

• Gross Transaction Value: $49 million

• Total Registered Bidders: 10,000

• Total Number of Lots: 4,300

• Total Number of Consignors: 700

Liebherr maritime cranes is looking back on the business year 2020 for their mobile harbour crane product segment.

At the beginning of 2020, Liebherr Mobile Harbour Cranes was able to rely on a strong order backlog, which was already built up in 2019. The first quarter of 2020 was also very positive with several incoming orders. At the beginning of the second quarter of 2020, a decline in orders was noticeable. This was strongly linked to the corona pandemic and the resulting global lockdown.

However, current projects were not cancelled but postponed. A certain amount of uncertainty was felt in the market, but in this never-before-seen situation, this behaviour was quite understandable and comprehensible. These delayed decisions led, positively speaking, to an extended summer break but not to a drastic downturn. In addition, Liebherr was able to maintain the production operation in compliance with all the required hygiene rules and in constant communication with the local health authority. During this period supply chains could be maintained.

Despite the slight drop in sales in the course of the worldwide lockdown, Liebherr equipment continued to operate at ports around the world. Although the flow of goods declined for a short time, ports are systemically important, so service and support from the Liebherr customer service continued to be in demand. The worldwide well-positioned Liebherr service network has helped a lot during this time and through local mixed sales companies, dealers and partners Liebherr was always on site at the customer’s location. Trade fairs and customer visits that were cancelled due to travel restrictions were also well compensated by online trade fairs, online webinars

Liebherr sold LHM equipment on every continent in the fourth quarter 2020 and ended the year with an order intake slightly above the level of 2019. PHOTO: LIEBHERR

and online talk shows. In this way, the sales staff were able to maintain contact with customers, although online offers naturally do not replace personal contact. A strong fourth quarter

The Mobile Harbour Crane market was lively throughout the entire period. Liebherr sold LHM equipment on every continent in the fourth quarter 2020 and ended the year with an order intake slightly above the level of 2019.

“This development gives grounds for optimism and provides a good base to start in 2021. A stable order intake will be the goal and a challenge in the coming year – especially due to the restrictions imposed by the corona pandemic. If we manage to achieve this, we should also achieve an increase in sales compared to 2020 – all in all, a positive forecast,” said Andreas Müller, sales director of Liebherr mobile harbour cranes and reachstackers.

Procore released the results of its annual customer technology report, Unlocking the ROI of Construction Technology, which looks at how leaders in the construction industry are driving positive results in their business during a year of unprecedented challenges, with the use of Procore technology.

This year’s report surveyed 4,784 Procore customers from Canada, the U.S., South America, Asia, Europe, Australia and the Middle East. Some key findings include:

• Respondents had a notable focus on communication after a year of navigating the pandemic. The word “communication” was mentioned in 548 responses.

• 79 per cent reported improved communication for a remote workforce. This was consistent across businesses of all sizes, including; 80 per cent of general contractors surveyed; 77 per cent of owners surveyed; 76 per cent of speciality contractors surveyed.

• 89 per cent said they have more standardized processes.

• 71 per cent said they met or exceeded profit goals.

Canadian respondents make up more than 10 per cent of the total surveyed. Procore’s results show the Canadian respondents said Procore helps manage change orders, that Procore helps them own their project data, and that the platform’s financial tools have improved transparency between project management staff and accounting.

“This year’s global ROI report, Unlocking the ROI of Construction Technology, helps codify what many in the industry have experienced,” said Jas Saraw, vice-president, Canada, Procore. “In construction as in many other sectors, ‘communication’ has been the watchword since the pandemic began. The industry has unique challenges in connecting field and office workers, and we believe the shift to modern solutions has been accelerated.”

By Matt Jones

Mark Williams is the third generation in his family business – his grandfather founded Ontario-based Pumpcrete in the 1960s and his uncle and father were both involved in the business before him. Williams himself started with the company in 2001 and in that same year, company leadership saw cranes as a significant expansion opportunity and acquired a crane business called Modern Crane.

“We saw cranes as a world commodity,” says Williams. “You always need something hoisted; you always need something lifted. Installing a hot tub in your backyard to erecting a tower crane. There’s all kinds of different work. There’s always a need for cranes. And no matter where you are or what job it is, there’s only so much human muscle power that you can lift with.”

Today, most of Modern Crane’s work is taxi-style, providing both a crane and an operator for specific lifts. But the company is also available for specific lift planning and, on rarer occasions, bare rentals in cases where a competitor might have a licensed operator but lack the appropriate crane for a particular job. They employ between 150 to 170 operators (depending on seasonality) in four locations between London and Niagara Falls, Ont.

“We try and get the Greater Toronto Area to Golden Horseshoe area coverage,” says Williams. “That way you diversify, and you

No matter how challenging your needs, BKT is with you offering a wide range of OTR tires specifically designed for the toughest operating conditions: from mining to construction sites. Sturdy and resistant, reliable and safe, able to combine comfort and high performance.

BKT is with you, even when work gets tough.

For info:

Western Canada 604-701-9098

Eastern Canada 514-792-9220

can make travel time between a lot of the job sites around an hour, two hours. The majority of the equipment is in Milton, that’s our main ‘hub’ and the head office where everything is done paperwork-wise is in Niagara Falls.”

Williams says that Modern Crane has a varied customer base – as of late there has been a lot of road building and infrastructure maintenance work around the 401 highway but work with hydro companies is also very common. Williams says Modern Crane will take on any job that makes sense. And to serve that varied base, the company keeps a variety of cranes on hand.

Operating in and around Toronto, which has been a hotspot of tower crane activity in recent years, mobile cranes that can facilitate tower cranes are a particular focus.

“One of our latest purchases was a Demag AC 300,” says Williams. “That machine has a real nice chart, 262 feet of main boom and has tons of capacity for tower crane erection and dismantling.”

Even with cranes being a relatively new avenue for the Pumpcrete parent company,

Williams notes that he has already seen significant evolution in the crane sector and the machines that drive it. Cranes these days have a lot more main boom capacities and are constructed out of much lighter materials.

“The tensile strength in the actual boom systems and the construction of the cranes have changed a lot over the years,” says Williams. “The other interesting thing I’ve noticed is the amount of computerization. For example, the AC 300 that we have and a few other cranes that are starting to come out now. The computer automatically calculates the chart based on what your outrigger positions are. That is really, really helpful.”

For a company called Modern Crane, obviously keeping up on the modern advancements of the crane industry is particularly important.

“You’re always looking for the next biggest thing or next niche thing or the next beneficial thing for your customers,” says Williams. “Especially when it comes to tight jobs like overhead crane erection. We do a fair amount of that as the city-class

cranes come into play as well. You need to be able to identify your customers’ needs. It’s changed a lot and you have to stay on top of everything. There’s a lot of involvement that goes into studying charts and doing a lot of comparison amongst the manufacturers. ‘We’re going to be running these scenarios, which crane really has the strongest chart in this scenario.’”

One of the company’s most unique lifts came in 2012 when famed tightrope walker Nik Wallenda crossed Niagara Falls – Mod-

ern Crane was contracted to hold the wire in place for Wallenda’s death-defying stunt. Another significant job was erecting transmission lines from the Bruce Nuclear Power Plant to a station in Milton, which took about four years. Williams says it was very satisfying to safely execute a job of that complexity and duration.

“I’m a firm believer that everyone has to go home safe at the end of every day,” says Williams. “No matter what, safety is the absolute most important thing to us. I never want something like that under my belt, we want everyone to be safe. We’re quite extensive training our people – we don’t just hire people, we put them

through quite the training process.”

The COVID-19 pandemic has been a significant challenge for companies in almost any sector, but Williams says that Modern Crane adapted quickly, writing a policy for new procedures early in 2020. From his perspective, adapting to the pandemic was just another extension of their commitment to safety.

“When we started seeing the first cases, we acted very fast,” says Williams. “We’ve been managing it well. We have not had any outbreaks. That’s terrific.”

Williams says the company is also committed to fostering an interest in the heavy equipment sector in young children. It’s important for the company to bring pumps and cranes to schools when the opportunity presents itself in order to demonstrate how the equipment works and how heavy equipment can be a lucrative and rewarding career.

“Some of the best guys that we have came through a high school co-op program and worked their way through the shop, got their licence and worked their way up through the ranks,” says Williams.

BY JUDY MELLOTT-GREEN

COVID-19 has gripped industries throughout the world. Perhaps because we did not understand the risks at the beginning, there was little thought as to how it would radically change the way businesses will move forward in the future. Due to the economic impact of lockdowns, the day-to-day operational requirements of many companies have forever changed. We have survived a worldwide attack of a virus that has had a catastrophic effect on the way businesses will continue in the future.

The most amazing thing is, when our backs are against the wall, societies and industries worldwide get busy. We are now in the process developing ways to continue operational requirements under these kinds of situations, should they reoccur in the future.

Before this, we have been quite comfortable in the daily operations of our companies, factories and industries worldwide, never giving a thought as to “What if” something was to happen, how would we deal with it? Well, that day has come, so how do we move forward from here?

Just in this past year, people worldwide are now wearing masks and taking sanitation, sterilization, and social distancing far more seriously. I am now automatically putting on my mask and using sanitizer after handling my car keys before I go to work and get home in the evening. Most everywhere we go there are signs warning us: “Wearing of facemasks and use of hand sanitizer is mandatory on these premises.”

Companies are now also asking for your company policies, procedures and instructions as to the operations for those people coming on to their jobsite, such as exposure, social distancing, masks, gloves etc. Luckily, we have found effective ways to continue to promote and conduct our business in this new economy, but for every success story, there are several businesses that are indeed struggling to cope.

This “new normal” appears to be here for some time, and we will need to continue to find new and inventive ways to continue doing business, as well as ensuring worker safety on our jobsites.

Many platforms offer different solutions for contacting customers and allowing remote conferencing, reducing the risk of exposure. We have been able to take advantage of this new technology in regard to our own training products, offering our clients a more flexible option to satisfy their training needs.”

Judy Mellott-Green has almost 30 years of experience working in the overhead crane industry and was the recipient of the 2016 CSA Award of Merit in recognition of exemplary goal-oriented leadership. As president of the All Canadian Training Institute Inc. (ACTi) in Edmonton, Alta., Judy continues to participate on provincial, national and international safety committees to assist in improving standards and workers safety for those who utilize this type of equipment.

By Jay Koblun

When working towards a Mobile Crane Red Seal certification it’s uncommon to complete the written portion before filling in the required hours, but that’s what Apprentice Crane Operator at Irving Equipment Rachel McCoy has done.

“I wrote the block in 2020. I don’t have the hours to qualify for Red Seal yet but I’ve passed the exam, so the hard part is over,” says McCoy. “It’s not common to go this route, but because there are such few people in the trade, especially women, it could be another three or four years before there another exam, so it’s nice to have out of the way.”

McCoy completed a Mobile Crane Operator course in 2014 at the Miramichi campus of New Brunswick Community College. The 14-week training service was designed to develop certified Mobile Crane Operators with the knowledge and skills necessary in the rigging and hoisting activity associated with the construction industry. She found her way to Irving Equipment through Irving’s New Boots program. A program aimed to attract, support, and retain underrepresented groups in non-traditional skilled trades.

“Rachel is an apprentice from the community college. As part of our efforts to grow opportunities with underrepresented groups in the workforce, we partner with New Boots which is focused on skilled trades for women. Rachel is part of that program. Typically, the challenge for new operators is getting the hours to complete ‘blocks’ towards an ultimate Red Seal designation,” said Mary Keith, vice-president of communications at Irving. “Rachel came recommended with a very enthusiastic vote of confidence from the managers at Irving Equipment for her professionalism.”

“She’s a very good ambassador for women in construction and trades, presenting herself in a way as if gender doesn’t enter the equation. It’s about someone’s skill set and capabilities,” said Keith.

McCoy operates a lot of picker cranes and has had training on boom trucks,

completed a

Crane

rough terrain cranes, and crawler cranes— including mobbing and demobbing.

“I really enjoy mobbing and demob— setting up and tearing down of cranes when and where they’re needed. A goal of mine is to someday operate one of those entirely by myself and be in charge of a crawler crane.”

McCoy says it would be great to see more women in the industry and not to shy away from trying it out for yourself.

“It’s never really bothered me that there aren’t more women in trades, but it really would be amazing to see more women take their interests as I did and just go for it,” she said. There are less than 10 certified female crane operators in the province so McCoy said she would love to see more, adding that drawing attention to and promoting more women in construction is the best way to see that happen.

“Things like this; profiles, interviews. Anything to really get it out there for more women to see crane operating and trades as a viable and great career path. The biggest challenge I hear from women about joining the industry is how hard it can be to find work at times in New Brunswick.

Sometimes you may need to travel, so it’s understandable that it doesn’t work for some lifestyles.”

McCoy has two children, five years old and two years old, and when she isn’t working or travelling to and from work, she loves to spend time with her family outside or inside baking with her kids. “I’m quite busy, driving an hour and a half every day for work, but I’m still able to find time to spend with my family. I worked while pregnant with one of my children up until four days before the due date. Anything is possible if you’re willing to work for it and put your mind to it.”

When asked what advice McCoy would give to a friend considering joining the industry, she says to just go for it.

“Go for it. Give it a try. You’re not going to lose out. If anything, you’re going to gain valuable experience to take with you wherever you end up in life,” McCoy.

“Being in construction with young children can be difficult. With me, I don’t know exactly where I’m going to be working every day, or how long a job will take. It all comes down to your support system. If you have the right people supporting you it makes the job and all the challenges that come with it much easier.”

By Jay Koblun

More than 500 industry professionals registered for Crane & Hoist’s Women In Construction Virtual Event held on International Women’s Day and listened to six of the Canadian construction industry’s top voices discuss issues women still face today in their sectors.

Three of those voices; Stephanie Hnatuk, operations manager at Prairie Crane; Jennifer Green from Skills Ontario; and Nancy Chadwick, senior HSE director at Graham Construction, took questions from viewers and shared insight into what the construction industry is doing well to support women in the industry and also what it could be doing better.

One of the biggest takeaways from the panel that all three women agreed upon was that whether on a construction site, in the office, or operating a machine— women have a place in construction.

“Knowing where to start to get your foot in the door, and that there is a place for women in construction is the most difficult challenge to overcome,” said Hnatuk. “Once you’re in the industry, it’s quick to realize and learn there are a lot of people who have changed their ways and have accepted women in the industry.

Chadwick said there are several barriers women face in construction, but honed in on the fact that most facilities still operate with personal protection equipment (PPE) designed for men.

“The majority of PPE we ask our folks to wear is designed by and made for men. We come to projects and we are forced to sort of conform to what is provided to us. If you don’t have the right fitting gear that

“When I moved into operations manager from a junior position, I was in the position of directing our crew. Primarily middle-aged men. Also dealing with clients who are primarily men. What do I do? Do I put on my tough face and say ‘this is how it is and how it’s going to be’? How else am I going to gain their respect?”

Hnatuk said she quickly learned she needed to just be herself and allow her work to speak for itself and in doing so she has made a lot of great relationships with her employees and clients.

Green said one thing she continually ran into was that most men had never worked with or under a woman before. To work around this Green said she became very used to saying “I’ll meet you halfway because I’m here to stay.”

“One of the big things I learned was how to handle situations tactfully. Figure out how to read the room when colleagues or superiors are constantly answering questions for me, or doesn’t allow me to finish thoughts. Someone who is not licenced or is less trained, trying to tell me how to do something,” she said.

‘How can you decide on what to do as a career if you don’t know what’s out there?’ is a question Green asked during the panel. “Students and young women need to know what’s available and out there,” she said, continuing on to say the first step for women interested in the field is being curious.

“Ask questions to make that decision yours. Step one, pure exploration,” she said. “The next step is companies. Letting the public and women, or those that identify as a woman, know there are programs and inclusion groups in place that show you are welcome.”

A tip she suggested for companies is to promote it on your website that your company has inclusion and diversity groups or programs.

can be a big risk to people as well,” she said, adding that the industry is beginning to expand on this but it currently is a very real challenge and barrier.

Hnatuk is operations manager for Prairie Crane in Saskatoon. It is a family business and she started right out of high school doing administration work and odd jobs in the shop. She said her greatest challenge when she entered the industry was remembering to be herself.

Chadwick said it’s important to connect women interested in a career in construction with organizations that support initiatives like those listed above. “Support them in a way that makes sense to you. If you can give back to somebody, whether it’s just a conversation or advice or guidance on their career, there are lots of ways to do it and have an impact.”

To celebrate International Women’s Day, eight of Canada’s leading construction media brands teamed up to deliver an exclusive virtual event. You can view the content ondemand, and stay on top of news throughout the year, at women-in-construction.ca.

PLATINUM SPONSOR

GOLD SPONSORS

SPONSORS

SPONSOR

PRESENTED BY

By Matt Jones

Speaking with Merv Baker about his life in the crane industry is an opportunity to learn about the past. It can also be stunning to see what was considered normal in those days.

“I left school in grade eight,” says Baker. “I got the last beating from my teacher that just about half killed me. And I went to work. And I’ve never looked back.”

A schoolteacher dealing out corporal punishment would be a major scandal today, but it was a fact of life in Baker’s youth. A less horrifying artifact of the times is the fact that Baker then walked on to a construction site, was hired and trained on the job with no certification or classwork. That led to an opportunity for an apprenticeship with Ontario-based Canadian Crane Rentals (CCR). Baker earned his crane ticket in 1965.

Ten years later, he purchased the company outright.

Running Canadian Crane Rentals

“I’d work for Ontario Hydro eight hours a day,” says Baker. “Then I’d go to a [CCR] crane job at night. And if I had a guy that wanted to pour concrete or needed a crane for some lifts, there wasn’t anything up here. So, it was a pretty big market. Within a year after I bought the first crane, I ended up buying another one.”

Baker was eventually laid off by Ontario Hydro, so CCR became his main focus. He worked a few large-scale projects but mostly kept to smaller jobs that wouldn’t keep him tied up for too long.

Members of the Crane Rental Association of Canada are invited to attend the Annual General Meeting for a year in review report.

Les membres de l’Association canadienne de location de grues sont convoqués à l’Assemblée générale annuelle et la présentation du rapport annuel. May 26, 2021 / 26 mai, 2021 10 am MT / 12 noon ET To register / Pour s’inscrire www.crac-aclg.ca

“My theory was if you work with small contractors, you’re always available because you can say ‘I can be there tomorrow,’” says Baker. “But if you’re on a job for a week or two weeks or three weeks, you lose that customer because he goes somewhere else. So, I just kept rolling.”

Over time the business flourished. Canadian Crane Rentals acquired more cranes and continued to expand. Working long hours can drain your energy – particularly for an owner and operator as fastidious about maintenance and repairs as Baker.

“If you own the business you don’t have much of a life,” says Baker. “If you’re not big enough to hire a mechanic, on Monday morning when those four or five cranes have to roll, somebody had to fix them all day Saturday and Sunday. You work, work, work and it’s not a good home life if you don’t get to see your kids.”

Fortunately for Baker, he moved the lot for Canadian Crane Rentals next to his home. Once his son Sheldon was of age, he could spend more time with him as his son helped fuel, wash and repair the cranes. He also got his daughter Teri to help with lettering on the cranes when he could.

“I used to get so mad at her. I’d get a crane in, clean it all up and get it set up for her and then she wouldn’t show up to come put the name on the crane boom,” says Baker with a laugh. “I still tease her today. ‘Oh, the artiste isn’t in the mood.’”

Sheldon; however, did take to the crane industry. Baker remembers bringing a 12-year-old Sheldon with him to jobs in the summers, such as setting steel with a company out of Orangeville.

“I’d take him along with a 25-ton Grove crane I had,” says Baker. “He could run that crane better than I could at 12 years old. He was with me all summer.”

Eventually, Sheldon purchased CCR from his father and today serves as company president. Sheldon’s daughter Sheena serves as operations manager and is also an owner and instructor at Huron and Bruce Safe T Training. Another grandchild, Dustin, also operates a crane for CCR.

With Sheldon at the reins of CCR, Baker left the company and the industry. However, about a decade ago, he purchased a small company called Ontario Crane Rentals. His initial plan was just to sell off the assets of the company, but it didn’t work out that way.

“I bought it and, unbelievably, I landed a three-month job,” says Baker. “Then that led to buying a better crane and then I landed another job. So, I had to buy another crane. Same old story.”

Doing small jobs with Ontario Crane Rentals is rewarding and allows him to pick and choose jobs he’d like to do.

Looking back, Baker says the changes in the industry in his time have been unbelievable. The first crane he ran, with a 12-ton capacity, was considered a huge crane in the 1960s. The advances in size, capacities, durability, and the introduction of computers have radically changed the game.

“It’s something you’ve got to keep up with,” says Baker. “The whole crane business is like day and night from when I started to what it is today.”

While Baker appreciates the modern advances in crane technology, he does feel that something has been lost in the process as well. While computer technology has advanced crane work, he feels it could be a crutch for crane operators who might not be able to run the crane without it. The reliance on high technology could prevent them from developing their own judgement as well.

“What happens if the outrigger sinks? I asked two guys that question here a while ago. I said if suddenly that back outrigger starts to sink and you’ve got 80 feet of boom out and a load on it, what are you going to do? They both looked at each other and said, ‘I guess we’d be upside down.’ I said ‘wrong answer.’ You try to save the crane, you boom up, lower the load and swing it away from that outrigger.”

About two weeks after that encounter, Dustin was telling his grandfather about a situation where the outrigger started to sink on him.

“I said ‘what did you do?’ and he said ‘I remembered some grumpy old guy that showed me this one day.’ And I said ‘well, thank you, but I’m not that old yet.’”

Asked what advice he might give to someone looking to start a crane business, Baker advises not to focus strictly on growth and expansion saying you don’t want your reach to exceed your grasp.

“It’s like a baby. A baby learns how to crawl. Then it learns how to walk, and then it learns how to run,” says Baker. “So, when you start your crane business, don’t bury yourself in debt. Get yourself financially set so you know how much you can bring in and have a few dollars in case you need it. If you’ve had a few good years, now you can look at expanding.”

He also emphasizes that the freedom that comes with being your own boss comes at a price. Often in the form of working 12- to 14-hour days for six or seven days a week.

Baker turns 75 years old this year. And while retirement is an enticing prospect for most people in his age group, he still enjoys the satisfaction of a job well done.

By Jay Koblun

Crane operators work long hours sitting in the same spot for most or all of the day. Canadian healthcare professionals say construction workers and operators can be at risk for postural issues if they are not getting up and moving frequently enough throughout a shift. But how many times a day can a tower crane operator climb down from their cab for a quick stretch? Not many.

Alex Bramley, a physiotherapist in Vancouver, B.C., said your hips, low-spine, spine, shoulders and neck are all areas of the body that are likeliest to experience stiffness and pain.

Long and short term issues

“Hips, low-back, spine, shoulders and neck. Depending on your job, other areas may be involved as well,” Bramley said. “Low back pain can arise from sitting in the same position for a long time especially if not in a good ergonomic setup.”

Aside from those mentioned, sedentary operators are also at risk for degenerating disc disease, sciatica, aggravated arthritis, carpal tunnel from operating controls all day, and hand tension.

“Chronic low back pain, muscle weakness especially in your glutes, poor circulation, stiffness in your neck shoulders and hips, and headaches are all possible effects from sitting in these conditions. On top of that, low mood and energy are often attributed to those who work in positions where they are sitting in the same position for long periods at a time,” said Bramley.

“Even the proper setup does not make someone exempt from issues if they’re not repositioning and stretching every so often.”

In Hamilton Ont., Registered Massage Therapist Alison Pretty said prolonged sitting in that position shortens the quad muscles and hip flexor muscles and it can cause problems in hips and lower back pain. Tight muscles in that area will pull on the pelvis and create low back pain. Pretty said consistent massage therapy can be a great tool for maintaining healthy muscles and joints.

“Massage kind of works like exercise. It’s muscle memory. You train the muscles to be relaxed. The more you teach them to relax the better off you will be,” she said.

Pretty said that consistently does not have to mean often. It just means to develop a pattern and schedule of therapy that allows your body to get used to treatment and adjustment. In the meantime, she shared some exercises and stretches a crane operator can do in their crane cabs anytime during a lull in their shift.

Before jumping right into a new exercise, Pretty said when holding a stretch, it is important to hold it for a good 30 seconds.

“Hold for more than 30 seconds per stretch or exercise,” she said. “Anything sudden or under 30 seconds and your body thinks your muscle is being attacked or about to be ripped off, so it can tighten and hold on, not allowing for the deep stretch you need. When you hold a stretch for 30 seconds your body understands that this is good and begins to make room for a deep healthy stretch.”

Wrist stretches

Flexion

• Extend arm in front of you.

• Bend wrist pointing fingers down.

• With opposite hand add pressure to the stretch by pulling down on your fingers.

Extension

• Extend arm in front of you.

• Bend wrist pointing fingers up.

• With opposite hand add pressure to the stretch by pulling your fingers toward your body.

Neck stretches

• Sit straight with your head forward.

• Bring right ear down to right shoulder and hold stretch for 30 seconds.

• With your head in position lift your nose to the sky and then bring it down towards your armpit and hold for 30 seconds.

• Repeat on opposite side.

Hips and lower back

• Take your right ankle and put it on your left knee.

• Lean forward slightly.

• Repeat on opposite side.

“You don’t have to lean forward a lot on this one. Most operators are likely going to already have quite tight back and hips so even just shifting an inch forward is going to be enough to feel a stretch,” said Pretty.

Honour your limitations

It’s important to honour your body’s limitations no matter what your activity level is. Pretty said it’s common to see people pushing themselves too hard or too fast.

“Honour your limitations. If you don’t, it only aggravates your muscles if you push farther than you can. Unfortunately, we live in a society where people think it’s healthy to not use their vacation time, and overwork, and put in way too many hours, and that’s not doing anything good for your body and muscles. No stretch should be exceedingly painful. If it is, dial back to a comfortable point where you are still getting a stretch but aren’t in pain.”

For a long career in the job you love, Pretty said to take care of yourself now so you can be healthy enough to enjoy your retirement when it comes.

“Be consistent. That is what will improve the situation if you’re already noticed some restricted movement and pain. And be proactive. Start doing these stretches now and see a massage therapist consistently. Again, that doesn’t have to be often, once every three weeks or once a month is great,” said Pretty.

For step-by-step instructions with images head to www.crane&hoistcanada.com.

By Saul Chernos

It’s been another long shift, but the setting sun beckons and it’s time to shut down. Requisite switches are pressed, safety controls are enabled and the daily climb-down ensues. For a long-time operator, it can feel almost ritualistic, like putting a tired child to bed. Sleep tight. Pleasant dreams.

Well, you might want to hit the pause button on that dream. Tokyo-based cyber-security firm Trend Micro unleashed a team of researchers to test the company’s hypothesis that tower cranes, far from enjoying the calm of a moonlit night, might be at risk from high-tech intruders. Making crane climbers and copper thieves seem like old news, a whole new threat is emerging. Hackers.

Trend Micro’s investigation in 2019 seemed to mix motifs from 1960s counterculture and cheesy sci-fi. In Italy, for instance, two researchers drove a red Volkswagen Polo from construction site to construction site, using high-tech radio systems to crack code and breach the controllers of tower cranes they encountered. With permission from site owners, these decidedly ethical hackers succeeded in their quest.

“If you remove all of the legalities, all the touching base beforehand [to get consent], the actual attacks took less than 30 minutes,” says Mark Nunnikhoven, vice-president of cloud research with Trend Micro. While actual infiltrations were accomplished with startling speed, the overall endeavour required several years to conceive and prepare. Trend Micro was already probing the security of industrialized robots, autonomous vehicles and socalled smart cities, so tower crane controllers seemed logical to investigate because safety is a serious matter in construction and cranes are capable of considerable havoc.

The researchers also tried out controllers from more than a dozen vendors and familiarized themselves with radio controls used to transmit and receive commands. Then, using reverse-engineering techniques and increasingly common and inexpensive software-defined radios able to scan huge swaths of the broadcast spectrum, they probed for access points — potential vulnerabilities where hackers might be able to seize control of a crane from beyond a construction site perimeter.

The Trend Micro team needed to be certain, after all, that when they arrived on-site they would be as prepared and able as actual hackers to swing into action.

Nunnikhoven said the researchers discovered numerous vulnerabilities, including some common across multiple vendors. For instance, vendors generally use fixed codes to pair transmitters with receivers.

“If somebody could discover that code, and it’s relatively easy to do that, then they could send commands to that device,” Nunnikhoven said, comparing the notion of a crane controller to a garage door opener. Equipped with the knowledge and the means, the researchers wanted to apply their findings in real-world conditions. So, working in Italy, they went from project to project, catching site owners and managers perhaps a little off-guard by offering to operate their cranes from outside.

“We’re ethical researchers, so that involved getting consent and legal clearance and to ensure everyone would know what’s going on so nobody would be in danger,” Nunnikhoven said.

FRICTION – PROTECT COMPONENTS – IMPROVE EQUIPMENT LIFE

FOR OVER 15 YEARS, LUBE-A-BOOM HAS BEEN THE MOST TRUSTED NAME IN LUBRICATION

IDEAL FOR CRANES, FORKLIFTS, AERIAL LIFTS, TELEHANDLERS, TELESCOPIC BOOMS, HYDRAULIC EXCAVATORS, WRECKERS AND TOW VEHICLES AND SO MUCH MORE…

When Trend Micro team members used their own laptop computers to move the cranes within a half hour, site personnel were stunned.

“We now know these attacks are possible. We haven’t seen them in this particular vertical, but that’s part of the reason behind publishing this research — to get the vendors to help prevent these attacks from happening.”

Trend Micro has contacted affected vendors it knows of to explain vulnerabilities particular to their devices. “The good news is everyone we spoke to was eager to implement solutions, very excited to get into building something better and stronger for their customers,” Nunnikhoven said. “The challenge is these are not like your smartphone where you buy a new one every year or two. You invest in one of these things and it runs for 10 to 15 years, so it’s a long upgrade cycle.”

John Mollenhauer, president of the Toronto Construction Association, said he wasn’t aware of the vulnerability of crane controllers until recently.

“The fact that somebody could theoretically hack a crane and affect how it moves is scary,” Mollenhauer said. “We need to ensure everybody gets home safely at the end of the day, and anything that would put that at risk is a serious concern.”

Mollenhauer said the onus is on manufacturers to correct any vulnerabilities and mitigate any risks that are identified. “I have every confidence that the problem will be treated with a sense of urgency and fixed,” he added.

On November 23, 2020, a crane collapsed near Eglinton Avenue and Mount Pleasant Road in Toronto. One employee of All Canada Crane Rental Corp. sustained a minor injury, but there were no serious injuries.

The crane collapse was said to be caused when a sinkhole opened up due to water erosion, at which point the 70-tonne Link-Belt crane tumbled into the crevasse. Crosslinx Transit Solutions (CTS) spokesperson Kristin Jenkins told media that the crane operator had to jump from the crane to safety.

Roads in the area were closed off as a second crane was utilized to stabilize and recover the one that collapsed. A spokesperson for the Ministry of Labour, Training and Skills Development (MLTSD) declined to comment on the specifics of the incident as the investigation is ongoing. However, they did confirm that an MLTSD inspector and engineer attended the scene the evening of the incident. That night they issued requirements (a request for further information to determine compliance) to both CTS and ACCRC. In the days that followed, seven further requirements were issued. CTS was also issued three orders (an order that a potential Occupational Health and Safety Act or regulatory violation be addressed).

MLTSD could not disclose the details of any of the orders or requirements.

• New operator aids with kickout

• Free swing modes

• Simple interface with large touchscreen

• Wi-Fi enabled to update and service remotely

• Calculate outrigger positioning

• Real-time 360°charts

• Live preview mode

• Incorporated swing arrest

• Anti-skid paint on allowable walking surfaces

• No trip points

• Large walking area

• Guided, sequential, fail-safe fly erection

• Control fly assist and boom hoist cylinder from the ground

• One person operation

• Minimal ladder climbs

• Swing around at 0°

• Pivot-point & boom head speed screws

• Heated back-up, winch and right-side cameras with night vision

• LED working lights

• Outrigger lights

• 20 degree tilting cab

• No helper crane needed to install counterweight

• Transport weight of 95,000 lbs

• 6 Points of Access

• Large grab handles

• Deep, sturdy steps and ladders

• Working platform with guardrails

Tadano’s new GR-1300XL-4 rough terrain crane was specifically designed with high-pressure situations in mind where reliability can’t be compromised. The narrow and confined spaces of refineries, active urban environments with strict safety requirements, and bustling commercial construction sites are where Tadano’s GRs perform best.

The GR-1300XL-4 includes the longest main boom in the 130 USt RT class, AML-E2 crane-control system and the high-performance 280hp Cummins B6.7 engine. This new powerhouse Tadano RT transports easily with two trailers, increasing productivity and value for owners and renters. Additionally the GR-1300XL-4 offers one of the best operator experiences in the industry. Innovative features, such as the Tadano View System--a multi-camera system created to increase visibility and obstacle detection--enhance safety on the way to and at the job site.

Call 1-833-TADANO-1 or visit www.tadanoamerica.com to learn more about the Safety, Performance and Value of Tadano’s new GR-1300XL-4.