BY MATT JONES

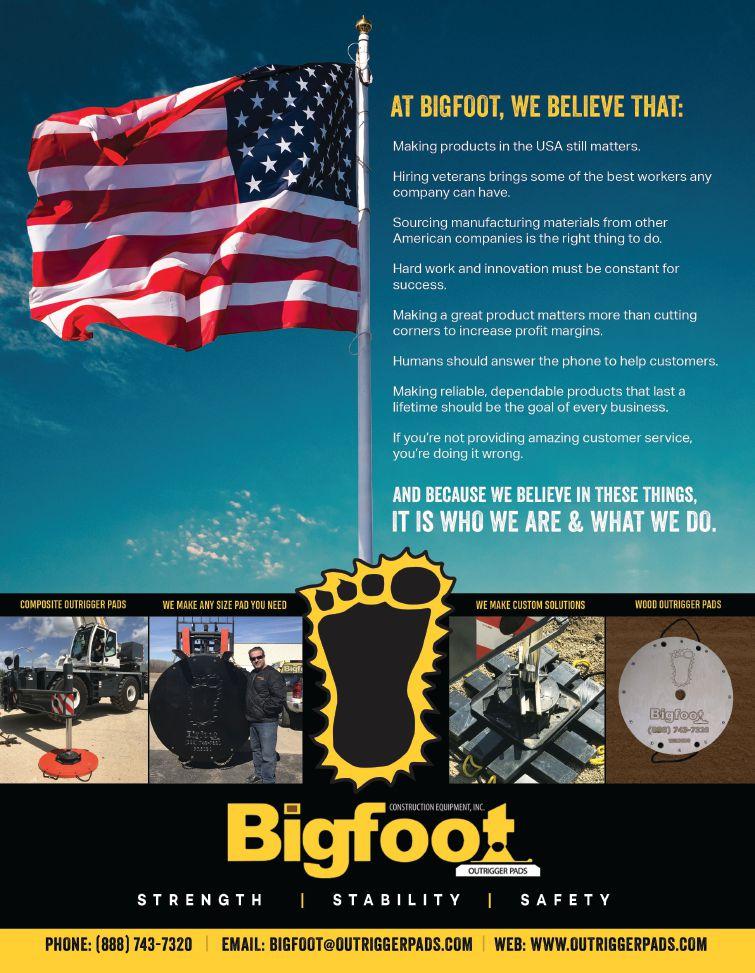

Here in the pages of Crane & Hoist Canada, we frequently talk about the cranes and heavy lifting involved in the construction of facilities such as large arenas. But there’s also some significant heavy lifting that takes place after these venues are up and running. Hoists and winches play an important logistic role in allowing modern entertainment venues to serve sports events, concerts and everything in between.

BY ANDREW SNOOK

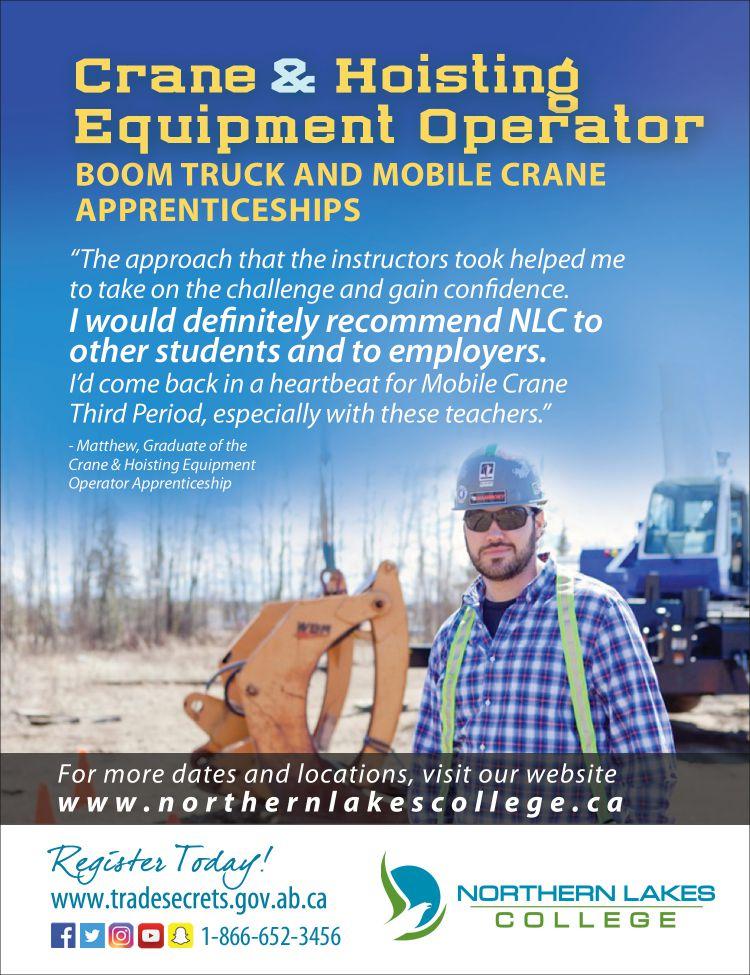

The Crane Rental Association of Canada is celebrating its 21st conference and annual general meeting at the Delta Prince Edward in Charlottetown, P.E.I. from June 5 to 8, 2019.

The conference and annual general meeting will feature the presentation of the second annual CRAC Safety Awards and the Boom Dolly Research Committee Report; as well as featured speaker David Colletto, CEO of Abacus Data, an expert on millennials who produces the largest re-occurring report on millennials in Canada; and presentations on the Amazon effect on the crane industry; Indigenous engagement; detection and prevention of substance abuse in the workplace; and a presentation from Manitowoc Cranes.

< Mammoet Canada’s Tim Sittler discusses the progress of the CRAC Boom Dolly Research Committee during the 2018 CRAC conference in Winnipeg.

Is your site secure? Plan from the get-go, experts say

BY SAUL CHERNOS

Two years ago, a young woman made headlines after she was spotted in the middle of the night atop a tower crane in downtown Toronto. On her own steam, the woman crawled along the boom and reached a pulley block before a firefighter rappelled from the crane’s arm and whisked her to safety.

Then, last summer, a woman was reported to have fallen asleep inside the operator’s cab 50 metres above another Toronto construction site.

While the judgement of these incidents as newsworthy may have been sparked by the gender of the climbers, one veteran Toronto operator told CBC News that, in nearly five years at his prominent high-rise site, he frequently found evidence of rooftoppers and other thrill-seekers breaking in and illicitly climbing his crane.

Experts say incidents like these, along with thefts and vandalism at construction sites, often involve or potentially endanger cranes and suggest protection may need beefing up.

on page 12 continued on page 6 continued on page 14

Editor – Andrew Snook

asnook@annexbusinessmedia.com • 289-221-8946

Account Manager – Amanda McCracken amccracken@annexbusinessmedia.com • 226-931-5095

Media Designer – Svetlana Avrutin

Regular Contributors

Saul Chernos, Doug Younger, Nelson Dewey, Matt Jones, Judy Mellott-Green COO – Scott Jamieson • sjamieson@annexbusinessmeda.com

President & CEO – Mike Fredericks

Circulation Manager – Barbara Adelt • badelt@annexbusinessmedia.com

Subscriptions – Bona Lao – blao@annexbusinessmedia.com Tel: 416-442-5600 • 1-800-668-2374 (CDN) , ext. 3552 Fax: 416-510-6875 or 416-442-2191 • www.craneandhoistcanada.com

Annex Privacy Officer – Privacy@annexbusinessmedia.com Tel: 800-668-2374

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher. A subscription to Crane & Hoist Canada (six issues) is $37 + Tax per year in Canada. For subscriptions in the USA the price is $37 USD. Send cheque or VISA/ Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT.

111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1 ISSN 1923-788X

Next Advertising Deadline: May 25, 2019

Don’t miss the opportunity to be part of this exciting new industry publication. For more information, or to reserve space in the next issue, call Amanda McCracken at our Advertising Department Tel: +1-226-931-5095 • amccracken@annexbusinessmedia.com

Next Editorial Deadline: May 25, 2019 For writers’ guidelines and submission requirements get in touch with the editor, Andrew Snook, at 289-221-8946 Email: asnook@annexbusinessmedia.com

While being able to turn the page on another winter season is favourable to many in our industry, it also means we are nearing the end of one of my favourite times of the year: trade show season.

With hundreds of thousands of members of the construction industry returning to their homes after descending upon Munich for bauma, the largest trade show in the industry, it seemed like a good time to discuss all the advantages that these types of trade shows have to offer.

Over the years I’ve really enjoyed attending all of the massive trade shows and conferences that take place within the construction and resource sectors (particularly between January and March). My first introduction to these shows was as an assistant editor attending World of Concrete back in 2012. I still remember showing up for my first day of the show dressed for the office (silly me), while busting up a chunk of concrete with a Hilti demolition hammer, then jumping into a Case CE 621F wheel loader to take part in one stage of the Case Construction Triple Threat Rodeo Competition, which showcased skilled excavator and wheel loader operators from around the world running obstacle courses. While I was able to successfully complete the course without damaging the wheel loader or any part of the course (with a little guidance assistance from Case’s marketing team), I was almost certainly the slowest operator that day (Fun note: A Canadian operator from Ancaster, Ontario won the competition that year).

While I was excited to see all the various pieces of equipment and technology on display at that show, I remember feeling a little overwhelmed by the sheer size of

it. The combination of having over 50,000 people attend a single show, and the show’s huge footprint really awed me at the time. Then, years later, I was introduced to CONEXPO/CON-AGG. Wow.

The sheer size of shows like the World of Concrete, World of Asphalt/AGG1 (record attendance of 10,063 this year in Indianapolis), the National Heavy Equipment Show (Canada’s largest heavy equipment show, which averages about 13,000 attendees), CONEXPO-CON/ AGG, and bauma and Hillhead overseas, show how much importance professionals within the construction industry (crane professionals included) place on shows like these for making new contacts, catching up with clients, checking out the latest technologies and services for optimizing operations and keeping informed with the latest education sessions.

Although some organizations have attempted online versions of these shows in the past, there really isn’t a replacement for the face-to-face experience you get from a well organized and managed trade show or conference; particularly for the construction sector where being up close and personal with the people and the equipment is so vital. These shows are equally vital for trade press editors such as myself, who want to to stay on top of the latest technologies and projects in the sector and meet with all the great people within the industry. Personally, I’m really looking forward to another CONEXPO/CONN-AGG year in 2020. See you in Las Vegas!

Andrew Snook, editor, Crane & Hoist Canada.

The Ontario Ministry of Infrastructure officially launched the first stream of the province’s $30-billion Investing in Canada Infrastructure Program on March 12. The first stream of the funding, the Rural and Northern stream, is open to cities and Indigenous communities with populations under 100,000. Those communities, about 500 of them, will have eight weeks beginning March 18 to nominate road and bridge projects.

“Our Government for the People is listening and has heard the infrastructure needs of our municipalities,” said Monte McNaughton, Minister of Infrastructure. “This first stream of funding is an invitation to all those communities to get started on the crucial process of project nomination.”

The Investing in Canada Infrastructure Program is a $30 billion, 10-year infrastructure program with cost-shared between federal, provincial and municipal governments. The Province of Ontario will be responsible for upwards of 33 per cent of the funding, or $10.2 billion spread across four streams:

1. Rural and Northern;

2. Public Transit;

3. Green; and 4. Community, Culture and Recreation.

“Our economy, communities, and families all depend on infrastructure. This program will bring major infrastructure investments that people rely on,” said McNaughton. “And when we invest in smart infrastructure, we create jobs and grow the economy, shaping the future for hard-working families in Ontario. Our province is open for business and open for jobs.”

The Grants Ontario website will be a “one-window” source for applicants, handling application intake, review, nomination, reporting and transfer payment management processes – all in one place.

“The Association of Municipalities of Ontario (AMO) welcomes this federal and provincial commitment to infrastructure funding across our province. Rural and northern communities depend on safe and reliable roads and bridges. They are essential to local quality of life and prosperity. Importantly, the ‘one-window’ approach that Ontario and the federal government have put in place will offer Ontario’s municipal governments an efficient means to access infrastructure funding,” said Jamie McGarvey, AMO president and Mayor of Parry Sound.

Source: Ontario Ministry of Infrastructure.

Industry and markets will have greater certainty for making decisions by having production limit information two months in advance.

Alberta continues to increase the amount of oil production allowed. Limits are based on monitoring a number of indicators and recognizing that less diluent is needed in warmer weather for bitumen to flow in pipelines, meaning more capacity.

Production limits in May will increase by 25,000 barrels a day and 25,000 more in June – a 50,000 increase in total to 3.71 million barrels per day allowed, effective June 1. This represents a total increase of 150,000 barrels a day since the start of the production limit policy on January 1.

“As we increase production, we’re providing even more certainty for producers who have been working with us to protect the jobs and livelihoods of thousands of Alberta families and businesses. This temporary policy has been critical to reducing the oil price differential while we move ahead with our medium-term plan to ship more oil by rail and lead the long-term charge for new pipelines as we fight to get full value for the resources owned by all Albertans,” stated Alberta Premier Rachel Notley.

Increasing production limits in May and June will help the province match production levels to what can be shipped using existing pipeline and rail capacity, while also addressing excess storage. The province’s crude-by-rail program is scheduled to begin initial shipments in July, ramping up to 120,000 barrel-a-day shipments by 2020. Alberta will also continue fighting for new pipeline construction both to the United States and Canada’s west coast.

The government will continue to monitor the market and its response to the increases and will work to provide information prior to trading periods for future months.

The first 10,000 barrels per day a company produces remains exempt from any production limits, meaning only 28 of more than 300 producers in Alberta are subject to the production limits.

Monthly production limits, in million barrels per day: • January – 3.56

Source: Province of Alberta.

The Province of British Columbia has selected three pre-qualified bidding teams to participate in the competitive selection process to design and construct the new toll-free Pattullo Bridge that will deliver a safer crossing and easier connections into Surrey and New Westminster.

“The existing Pattullo Bridge is nearing the end of its useful life,” said Claire Trevena, Minister of Transportation and Infrastructure. “The selection of the three teams gets us closer to breaking ground on this project that will improve safety and reliability for residents, commercial vehicles, cyclists and pedestrians.”

The three bidding teams are:

Fraser Community Connectors:

• Respondent: Kiewit Canada Development Corp.

• Design-build contractor: Kiewit Infrastructure BC ULC

• Long-span bridge design contractor: T.Y. Lin International and International Bridge Technologies, Inc.

Flatiron/Dragados/Carlson Pattullo JV:

• Respondent: Flatiron/Dragados/Carlson Pattullo JV (a joint venture of Flatiron Constructors Canada Limited, Dragados Canada Inc. and Carlson Construction Group, Inc.), ACS Infrastructure Canada Inc., Hochtieff PPP Solutions North America, LLC and COWI North America, Ltd.

• Design-build contractor: Flatiron/Dragados/ Carlson Pattullo JV (a joint venture of Flatiron Constructors Canada Limited, Dragados Canada Inc. and Carlson Construction Group, Inc.)

• Long-span bridge design contractor: COWI North America, Ltd.

Fraser Crossing Partners

• Respondent: SNC-Lavalin Capital Inc. and Acciona Infrastructure Canada Inc.

• Design-build contractor: SNC-Lavalin Constructors (Pacific) Inc. and Acciona Infrastructure Canada Inc.

• Long-span bridge design contractor: SNC-Lavalin Inc., Leonhardt, Andrä und Partner Beratende Ingenieure VBI AG, Hatch Corporation, EXP Services Inc. and Acciona Infrastructure Canada Inc.

The $1.377-billion Pattullo Bridge Replacement Project will provide improvements for everyone using the bridge and create thousands of jobs and opportunities for British Columbians. The new four-lane crossing will replace the existing Pattullo Bridge and will have wider lanes and better connections to road networks on either side of the bridge, which will help traffic flow more efficiently. It will provide safer connections for commuters, commercial vehicles and first responders. The new bridge also features dedicated pedestrian and cyclist lanes separated from traffic by a barrier on both sides of the bridge.

The project will be funded and owned by the Province of British Columbia. It will be delivered on behalf of the Province by the Transportation Investment Corporation (TI Corp.). TI Corp. is a Crown corporation with the legislative authority to complete major transportation projects, similar to its role on the Port Mann Bridge project. With tolls now removed on the Port Mann Bridge, TI Corp. will provide oversight and management of the delivery of other major projects throughout the province. Construction of the new Pattullo Bridge will be facilitated by the Province’s Community Benefits Agreement. Community benefits include job and training opportunities for people in the local area and the increased participation of apprentices and workers traditionally under-represented in the construction trades.

The request for proposals for the project will be posted on the project website.

The approved budget of $1.377 billion represents the full cost to complete the project, including procurement, project management, construction, removal of the existing bridge and interest during construction. It is expected to open in 2023.

Source: B.C. Ministry of Transportation and Infrastructure.

continued from cover

Security should be considered at the earliest stages of designing and planning a project rather than as an afterthought following an incident, says John McDonald, a former police investigator who runs Threat Ready, a London, Ont.-based consultancy.

McDonald recommends undertaking a risk analysis and needs assessment to identify factors which might make a site attractive to people looking to break in or otherwise cause trouble. Risks and corresponding protective measures will vary depending on project type and location.

“Are you in a residential area or in a rural setting, are you way up north or in a highly populated area, and who could have access to your site? You need to start by looking at those kinds of things,” McDonald says.

An international bridge project with multiple large cranes, for instance, might seem ideal for conveying a political message.

“If someone wants to make a statement with a flag or banner I can’t think of a better place because you’re going to get lots of media attention,” McDonald says.

A more common problem is theft. While entire machines occasionally go missing — a 48-tonne mobile crane stolen from Stuttgart, Germany in March 2018 was found three months later in Alexandria, Egypt — components and other small items are more typically at risk.

“Copper is a hot commodity right now,” McDonald says, explaining that thieves strip wire from crane cabling as well as from building interiors.

Police occasionally get tips from honest dealers suspicious about materials brought to them.

“It’s taken awhile but police have finally established positive relationships with some of the companies that buy metals,” McDonald says.

Some thieves work from outside, scouting potential sites and learning to recognize stages of development when rolls of wire and other materials are likely to be sitting around. Other times the culprits are insiders who know when valuable items will be available. Organized crime has a hand in some thefts and has been known to ‘probe’ sites by measuring security response to minor incidents such as spray painting, McDonald says.

Once risks are identified and understood, a project team can consider security measures. Fences, barricades and gates can be installed with optimally placed closed-circuit television cameras providing an ongoing, direct feed to security personnel who could be either on or off site. Lighting, alarm systems and foot patrols can also come into play.

In areas where pedestrian traffic is minimal at night, CCTV cameras along the perimeter facing outside might make sense, especially if backed by invisible electronic fencing inside the

perimeter. A communications system could remind anyone approaching a site that they’re being watched or that police have been summoned.

Care must be given to the deployment of security tools. Poorly installed CCTV systems are notorious for capturing the tops of heads so that little is seen beyond baseball caps and hoodies. “Make sure your video system can get the faces of individuals approaching your property and access points,” McDonald says. Well-positioned cameras looking outwards beyond the perimeter can potentially capture images of vehicle and licence plates.

Elliott Goldstein, a litigation lawyer with Epstein & Associates in Newmarket, Ont. says cameras will help security personnel keep watch and provide evidence if a breach occurs but won’t necessarily deter criminal activity.

Goldstein should know — he’s the author of Visual Evidence: A Practitioners Manual, a legal textbook about video and photographic evidence in Canadian civil and criminal courts.

“Video surveillance doesn’t act as a deterrent when people are wearing a disguise, because they don’t care if somebody sees what they’re doing,” Goldstein says. People who are mentally incapacitated due to illness or intoxication or who are suicidal are also unlikely to be deterred by cameras.

“Dummy cameras should only be used as a decoy because sometimes people break into an area and the first thing they do is smash the camera,” Goldstein cautions. “Only use a dummy camera if you’ve hidden the real camera someplace else.”

Video can work well for gathering evidence if an incident occurs, but care must be taken so evidence is considered legally valid and admissible.

“You have to prove who had access to the video from the time it was recorded until the time it was brought to court, and there’s very strict procedures in terms of how to make copies and safeguard them,” Goldstein says. “The main thing is to show that the evidence hasn’t been tampered with.”

There are also legal restrictions. Video cameras cannot be placed in washrooms, change areas or anywhere employees might reasonably expect privacy. In some open spaces where employees may congregate or store personal items, management must post signs indicating video surveillance is in place. Surveillance cameras installed to prevent theft and vandalism, monitor for suspected criminal activity or ensure worker safety generally don’t violate the Criminal Code or privacy provisions of the Canadian Charter of Rights and Freedom, Goldstein says.

However, audio recording is more problematic. Goldstein

says it’s legal if at least one party to a conversation consents to having his or her voice recorded. But this is tricky in group situations, such as in lunch rooms because consenting individuals might not be present at all times and conversation often breaks into smaller groups.

Goldstein adds that signage — multi-language depending on the circumstances — notifying that an area is under video and/or audio surveillance is generally necessary. While the goal is protecting premises and equipment and ensuring workplace safety, Patrick Straw, executive director of the Canadian Security Association (CANASA), says project proponents and contractors also help protect themselves from legal liability.

“The biggest concern isn’t somebody stealing doorknobs it’s somebody falling in an open hole and getting hurt,” Straw says, noting some trespassers might be sober while others may see an open site as a convenient shortcut on the way home from the pub or as an opportunity for adventure.

“If a site isn’t secured properly, it can come back as a lawsuit against a company whose equipment is on-site, or the owners of the site, or the contractor responsible for securing the site,” Straw says. “You have to do your due diligence so that if somebody does climb a fence and gets in you can prove you made every reasonable effort to stop them.”

Ryan Burton, managing partner with Bigfoot Crane Company, an Abbotsford, B.C. sales and rental business, says insurer concerns are valid given cranes vandalized by wire thieves can cost tens of thousands of dollars to repair and lives are at risk if systems are electrified.

“They typically take the main power cable that’s going into the crane,” Burton says. Thieves will also pry open the main control panel to steal smaller wires. “It gets really expensive because rewiring all of that is time consuming.”

Burton, vice-chair of the Crane Rental Association of Canada, says he’s read about barriers used overseas to prevent crane climbers. The device goes around the crane exterior near its base at a modest height, similar to systems used to keep squirrels off bird feeders.

Mike Gallagher, business manager with the International Union of Operating Engineers Local 793 in Ontario, supports physical barriers. “This would probably be a good deterrent. Maybe it’s something manufacturers should consider,” he says.

Gallagher says Local 793 uses a chain-link fence with cameras and a private security firm to protect cranes and other heavy equipment in its training yard. “We’re permanently there, so there may be more unique challenges for contractors and developers.”

BY MATT JONES

Thane Tapley is in his 27th year in the crane industry. From his training in Ontario to the last 10 years working for Irving Equipment in New Brunswick, he’s seen it all – from construction to erecting wind energy farms and everything in between. But none of that could prepare him for his greatest challenge – trying to win stuffed toys from the arcade claw crane at a laundromat in Fredericton, N.B.

“Try to pick up the small one here,” his daughter, Erin, instructs.

“Let’s see if we can grab him by the head,” says Thane, as he deftly maneuvers the claw over a bright blue plush horse. The claw’s pincers grasp the toy around the head but then slide right off.

Claw crane games have a long history, going back to the early 20th century in North America; however, they became much more ubiquitous in arcades and stores in the 1980s. They generally feature a clear plastic enclosure filled with prizes. Stuffed toys seem to be the most common, but jewelry, hats, candy and other prizes are also seen. The claw itself travels along the top of the enclosure on a mechanism similar to overhead travelling gantry cranes often seen in machinery shops.

After paying for a play – two attempts for $1 in this case – the player is given an amount of time to position the claw where they want. Once the time expires or a button on the joystick is pressed, the claw descends, the pincers close, and the claw moves back into position to drop what it has collected into a chute that the player can access. Unfortunately, the claw is most likely to have collected nothing.

“Here’s one of the problems,” says Thane. “The net load is in excess of the clam capacity. The clam won’t remain closed when the load is imposed on it.”

The machine Thane is playing has a variety of different sizes of stuffed toys. However, the larger toys seem to be packed fairly tightly in the centre of the machine. Smaller toys seem to be so far along the periphery of the enclosure that the crane can’t actually reach them.

“The heavy ones are positioned so you can reach them with the crane,” says Thane. “The ones that are actually small enough to pick up with the crane are positioned so you can’t pick them up. For all intents and purposes, there are few options here that you could pick up. Doesn’t really seem fair, does it?”

“It speaks volumes that a crane operator can’t pick up one of these toys,” notes Erin. “I could if they were playing fair, but they’re not playing fair,” adds Thane.

Playing fair is likely not the intention of the game. Claw cranes are designed to get as much money out of a player as possible, like any arcade game. It’s the same reason why

arcade video games like Pac-Man and Donkey Kong just get harder and harder – to inspire a player to keep plunking in more coins. And that certainly is the case here.

“You better start looking for loonies, cause I’m getting this guy,” Thane instructs Erin after going through seven of the eight loonies that Crane & Hoist Canada provided. He adds with a laugh, “It’s the definition of insanity.”

“I’m getting frustrated and I’m not even the one playing it,” says Erin.

Modern claw cranes, like most arcade games, do allow the owner of the device to make adjustments to a variety of features, including claw strength and aperture, motion speed and pick-up strength. It’s unclear how the settings on this machine may have affected Thane’s efforts.

Asked how he would adjust the machine if the point was to make it an effective crane, rather than simply to make money, Thane notes that the main concern is the holding power of the claw.

“You have enough control, but what it’s lacking is the closing power,” says Thane. “It’s insufficient to bring the toys out of the game – which is a reasonable business approach. But that would be the single most important improvement. You know the physics behind it and it does work in the real world, but they’ve tinkered with the physics so it doesn’t work.”

Commuters in the greater Moncton, N.B. area are going to have a variety of new options in the near future. While the project to replace the Gunningsville Bridge continues (see Crane & Hoist Canada’s Jan/Feb 2019 issue for more information on the project), a couple of kilometres up the Petitcodiac River the causeway between Moncton and Riverview is also being replaced. Heavy civil contractor Caldwell & Ross Ltd. completed crane operations for the causeway replacement late last year. The causeway has long been a controversial project. The Petitcodiac was once known for having one of the largest tidal bores in the world, reaching up to two metres in height and moving at up to 13 kilometres per hour. In 1968, the rock-filled embankment and causeway were built in an effort to stop agricultural flooding and to allow a crossing between Moncton and Riverview. However, the restriction of water flows caused significant problems, including large amounts of silt and an enormous downturn in salmon catches in the area.

After decades of outcry from the community, a new bridge is being constructed to allow the water to return to its original flow. Caldwell & Ross were contracted to create the substructure for the 240-metre bridge, including abutments and piers.

“They want to get rid of the spillway and open the river back up to the way it used to be,” says Paul DeMerchant, president of Caldwell & Ross Ltd. “We’re building a bridge on the causeway at this point – we dug out part of the causeway. There’s no water underneath the bridge at all right now. It’s sitting high and dry waiting for other phases of work to be done.”

DeMerchant describes the eventual bridge as being very wide for the area – four lanes across with a four-metre sidewalk. Caldwell & Ross’ work involved driving 2,600 lineal metres of piles between the abutments. They were also responsible for the installation of two large steel sheet pile cofferdams between 40 to 60 feet down in the ground and the placement of form work for cap beams.

“We primarily used two cranes,” DeMerchant says. “One was a new Link-Belt 228 HSL 130-ton crawler. And the other crane on site was a 138 Link-Belt HSL, 80-ton crawler. We bought the new one just to get a little bit more lifting capacity. The other crane, we’ve had for quite some time. You use what you have. We’ve had good luck with Link-Belt products. We’ve got five of them.”

Prior to the actual crane operations, a detour had to be built around the site which involved a significant amount of earthmoving. There were also very poor soil conditions in the area, DeMerchant notes, so the installation of the cofferdams was very time consuming and tedious, including using the cranes to remove mud during the process.

“A sheet pile cofferdam is like a big box,” says DeMerchant. “It was about 20 metres by 10 metres and about 60 feet in the ground down to the rock. Having to support your sheet pile wall, you have to brace everything all the way down. And then between the two of them we poured over 6,000 cubic metres of concrete in those for the footings.”

The project represented over a year of work for Caldwell & Ross – their work on the project started in June 2017 and continued until September 2018.

The Guide to Mobile Crane Safety Management is the most comprehensive reference manual available today. The manual addresses four key areas: risk; lift classification; lift planning; and jobsite issues.

Other details include:

• Criteria for types of lifts

• Site factors

• Pertinent formulas

• Roles and responsibilities

• Equipment inspection criteria

• Safety factors

Plus over 18 useful charts, tables, checklists and inspection lists are included!

OR

BY SAUL CHERNOS

It’s been another long shift, but the setting sun beckons and it’s time to shut down. Requisite switches are pressed, safety controls are enabled and the daily climb-down ensues. For a long-time operator, it can feel almost ritualistic, like putting a tired child to bed. Sleep tight. Pleasant dreams.

Well, you might want to hit the pause button on that dream. Tokyo-based cyber-security firm Trend Micro recently unleashed a team of researchers to test the company’s hypothesis that tower cranes, far from enjoying the calm of a moonlit night, might be at risk from hightech intruders.

Making crane climbers and copper thieves seem like old news, a whole new threat is emerging — hackers.

Trend Micro’s investigation last summer and fall seemed to mix motifs from 1960s counterculture and cheesy sci-fi. In Italy, for instance, two researchers drove a red Volkswagen Polo from construction site to construction site, using high-tech radio systems to crack code and breach the controllers of tower cranes they encountered. With permission from site owners, these decidedly ethical hackers succeeded in their quest.

“If you remove all of the legalities, all the touching base beforehand (to get consent), the actual attacks took less than 30 minutes,” says Mark Nunnikhoven, vice-president of cloud research with Trend Micro.

While actual infiltrations were accomplished with startling speed, the overall endeavour required several years to conceive and prepare. Trend Micro was already probing the security of industrialized robots, autonomous vehicles and so-called smart cities, so tower crane controllers seemed logical to investigate because safety is a serious matter in construction and cranes are capable of considerable havoc.

“All of our research ties into the same theme — things built for one purpose in the physical world quickly colliding with a digital world they’re unprepared for,” Nunnikhoven said.

Working initially from a lab, the researchers scoured manuals and analyzed massive volumes of technical data from sources such as the US Federal Communications Commission, which regulates the broadcast spectrum and sets standards and protocols for electronic devices.

The researchers also tried out controllers from more than a dozen vendors and familiarized themselves with radio controls used to transmit and receive commands. Then, using reverse-engineering techniques and increasingly common and inexpensive software-defined radios able to scan huge swaths of the broadcast spectrum, they probed for access points — potential vulnerabilities where hackers might be able to seize control of a crane from beyond a construction site perimeter.

The Trend Micro team needed to be certain, after all, that when they arrived on-site they would be as prepared and able as actual hackers to swing into action.

Nunnikhoven said the researchers discovered numerous vulnerabilities, including some common across multiple vendors. For instance, vendors generally use fixed codes to pair transmitters with receivers.

“If somebody could discover that code, and it’s relatively easy to do that, then they could send commands to that device,” Nunnikhoven said, comparing the notion of a crane controller to a garage door opener.

“If you remove all of the legalities, all the touching base beforehand (to get consent), the actual attacks took less than 30 minutes.”

“As these technologies get smarter and smarter, more and more computing is added to them, and that’s not being put in on a stable foundation. There’s a challenge here the industry needs to address.”

Equipped with the knowledge and the means, the researchers wanted to apply their findings in real-world conditions. So, working in Italy, they went from project to project, catching site owners and managers perhaps a little off-guard by offering to operate their cranes from outside.

“We’re ethical researchers, so that involved getting consent and legal clearance and to ensure everyone would know what’s going on so nobody would be in danger,” Nunnikhoven said.

When Trend Micro team members used their own laptop computers to move the cranes within a half hour, site personnel were stunned.

Malevolent actors have breached computer systems belonging to government departments, hospitals and business, often demanding ransoms paid in digital crypto-currencies. Yet, Nunnikhoven mused, almost no consideration has been given to the vulnerability of construction equipment.

“We now know these attacks are possible. We haven’t seen them in this particular vertical, but that’s part of the reason behind publishing this research — to get the vendors to help prevent these attacks from happening.”

Nunnikhoven said controller manufacturers need to make changes such as adding layers of security and improving user authentication and encryption so the systems aren’t vulnerable to outside intrusion. “There are fixes,” Nunnikhoven said. “It’s just a matter of having these built in.”

Trend Micro has contacted affected vendors it knows of to explain vulnerabilities particular to their devices. “The good news is everyone we spoke to was eager to implement solu-

tions, very excited to get into building something better and stronger for their customers,” Nunnikhoven said. “The challenge is these are not like your smartphone where you buy a new one every year or two. You invest in one of these things and it runs for 10 to 15 years, so it’s a long upgrade cycle.”

A spokesperson with Hetronic, one of the controller manufacturers Trend Micro cited in its report, said in an e-mail the company has released a new firmware patch to protect all Nova-M series transmitters and compatible receivers from a ‘replay attack’ by malicious attackers.

“Hetronic has been at the forefront in developing and delivering the safest and most reliable industrial radio remote controls on the market,” wrote Kristine Walczak, vice-president of corporate communications with Methode Electronics, of which Hetronic is a subsidiary.

Walczak said Hetronic has recommended all Nova-M users update their radio transmitters and receivers. “The fix is available at any Hetronic office or authorized reseller,” Walczak wrote. “Hetronic has notified its customers and resellers by e-mail of the availability of the firmware patch.”

Ryan Burton, managing partner with Bigfoot Crane Company, a crane sales and rental company in Abbotsford, B.C., said one of his suppliers told him the manufacturer of its remote control systems is working on a fix.

Burton, vice-chair of the Crane Rental Association of Canada and chair of the BC Association for Crane Safety, said he expects this is how remote system manufacturers industry-wide will address the vulnerability.

“My guess is new products will be released with some new software and it will be possible to upgrade old remote control systems or buy new remote control systems in order to avoid the risk,” Burton said, offering the analogy of an automotive manufacturer adding new safety features to successive vehicle lines.

“I wish people didn’t have time in their lives to try and figure out how to make a mess out of something they don’t belong in,” Burton said, adding he is unaware of any

“The fact that somebody could theoretically hack a crane and affect how it moves is scary, we need to ensure everybody gets home safely at the end of the day, and anything that would put that at risk is a serious concern.”

malicious hacks in his region.

John Mollenhauer, president of the Toronto Construction Association, said he wasn’t aware of the vulnerability of crane controllers until recently.

“The fact that somebody could theoretically hack a crane and affect how it moves is scary,” Mollenhauer said. “We need to ensure everybody gets home safely at the end of the day, and anything that would put that at risk is a serious concern.”

said the onus is on manufacturers to correct any vulnerabilities and mitigate any risks that are identified. “I have every confidence that the problem will be treated with a sense of urgency and fixed,” he added.

NOTE: The Trend Micro report is online at: <www.trendmicro.com/vinfo/us/security/news/vulnerabilities-and-exploits/ attacks-against-industrial-machines-via-vulnerable-radioremote-controllers-security-analysis-and-recommendations>.

The conference will also feature a tour of Charlottetown; an in-depth tour of the construction of the Confederation Bridge; the annual golf tournament; annual get-together featuring entertainment by Adam MacGregor & The Foes joined by Cynthia MacLeod on fiddle and Jon Matthews on acoustic and vocals; and the annual Spreader Bar. For more information on the 2019 CRAC conference, or to register, visit www.crac-canada.com.

2:45 p.m. to 3:00 p.m.

WEDNESDAY, JUNE 5

7:45 a.m. to 4:00 p.m. Board of Directors’ meetings

9:00 a.m. to 9:00 p.m.

Pre-registration

Welcome! The pre-registration for the Crane Rental Association of Canada’s 2019 Conference is now open.

8:00 p.m.

The Spreader Bar

The traditional Spreader Bar will be hosted in the Archibald/Campbell/Cartier Rooms.

THURSDAY, JUNE 6

7:00 a.m. to 9:00 a.m.

Breakfast – Coles Room

7:30 a.m. to 3:15 p.m.

The 2018 annual golf event

Departure: 7:45 a.m. Tee-off: 9:00 a.m.

Departure is from the front of the Delta Hotel, arriving at Crowbush Golf Course approximately at 8:20 a.m.

Registration fee is $190. Breakfast, buffet lunch, power cart, bottle of water, sleeve of golf balls, and personalized cart plates, gratuities, and transportation is all-inclusive. H.S.T. is in addition to the price quoted.

9:30 a.m. to 3:00 p.m.

Confederation Bridge Tour

Registration fee is $150 per person. The Confederation Bridge tour, includes an overview of Charlottetown’s rich culture and history, coupled with an in-depth tour of the bridge and its construction and with a professional guide who will provide stories and anecdotes along the way. The fee includes transportation, lunch, and gratuities. H.S.T. is in addition to the price quoted.

6:30 p.m. to 9:45 p.m.

The Get Together – Off-site Brakish

Our Get Together is walking distance from the Delta Prince Edward and what an evening we have in store for you. Entertainment by Adam MacGregor & The Foes joined by Cynthia MacLeod on fiddle and Jon Matthews on acoustic and vocals. A true Maritimes experience!

10:00 p.m.

The Spreader Bar

The traditional Spreader Bar will be hosted every night in the Archibald/Campbell/Cartier Rooms.

FRIDAY, JUNE 7

7:00 a.m. to 9:00 a.m.

Breakfast – Palmer/Pope Rooms

9:00 a.m. to 9:15 a.m.

Opening remarks

9:15 a.m. to 10:00 a.m.

David Colletto – Gray Room

David Colletto, CEO of Abacus Data is an expert on millennials and produces the largest re-occurring report on Millennials in Canada. With 2,000 Canadian Millennials surveyed twice a year they ask them for their thoughts on current affairs as well as track their perceptions on brands, governments, ideas, and lots more.

10:00 a.m. to 10:15 a.m.

Health Break

10:15 a.m. to 10:50 a.m.

J.P. Gladu – Gray Room

Indigenous engagement

CCAB builds bridges between Aboriginal and nonAboriginal peoples, businesses, and communities through diverse programming, providing tools, training, network building, major business awards, and national events.

10:50 a.m. to 11:00 a.m.

Health break

11:00 a.m. to 12:00 p.m.

Dan Demers - Gray Room

Detection and prevention:

Substance abuse in the workplace

Cannabis in the workplace is a rapidly growing and highly contentious issue, especially for employers who operate in safety sensitive environments. The Canadian Government legalized cannabis for non-medical recreational use in 2018. The topic of cannabis accessibility and consumption is sensitive, complex, and highly polarized with issues and implications for health and safety. In this new legal landscape, Canadian workplace safety has to adapt to the age of legal cannabis. Employers have questions about how to respond to this new landscape.

This session focuses on helping employers to understand the changes, the implications for health and safety, and to provide an “urgent response” solution, based on best practices, to the various challenges in safety sensitive industries.

12:00 p.m. to 1:15 p.m.

Lunch – Palmer/Pope Rooms

1:15 p.m. to 2:45 p.m.

David Coletto – Gray Room

David Colletto, CEO of Abacus Data, is an expert on Millennials and produces the largest re-occurring report on Millennials in Canada.

Health break

3:00 p.m. to 4:00 p.m.

Speakers TBA

8:00 p.m.

The Spreader Bar

The traditional Spreader Bar will be hosted every night in the Archibald/Campbell/Cartier Rooms.

SATURDAY, JUNE 8

7:00 a.m. to 9:00 a.m.

Breakfast – Palmer/Pope Rooms

8:30 a.m. to 9:30 a.m.

Annual General Meeting – Gray Room

Annual General Meeting will include the presentation of the second annual CRAC Safety Awards and the Boom Dolly Research Committee Report.

9:45 a.m. to 10:15 a.m.

Klaus Weckenmann, Liebherr-Werk Ehingen GmbH Gray Room

Speaker TBA

10:15 a.m. to 10:30 a.m.

Health break

10:30 a.m. to 11:00 a.m.

Tal Wagstaff - CEO, REDLIST LLC – Gray Room

The Amazon effect on the crane industry: The “NOW” world transition

The game hasn’t changed but the tools used to play are changing rapidly. The incoming workforce is familiar with and expects a “NOW” world and the tools that make this possible. The problems aren’t new but the technology to address them is and continues to evolve. In this presentation we will achieve the following learning objectives: Create awareness of needed transitions in the Amazon World; criteria for screening technology options; and where to start taking advantage of the “NOW” world.

11:00 a.m. to 11:30 a.m.

Manitowoc Cranes – Gray Room

Speaker TBA

11:30 a.m. to 12:00 p.m.

Speaker TBA

6:00 p.m

Closing banquet - Palmer/Pope Rooms

Cocktails will be served in the Foyer at 6:00 p.m.

Dinner will be served in the Palmer/Pope Rooms at 7:00 p.m.

Attire: Formal/Semi-Formal.

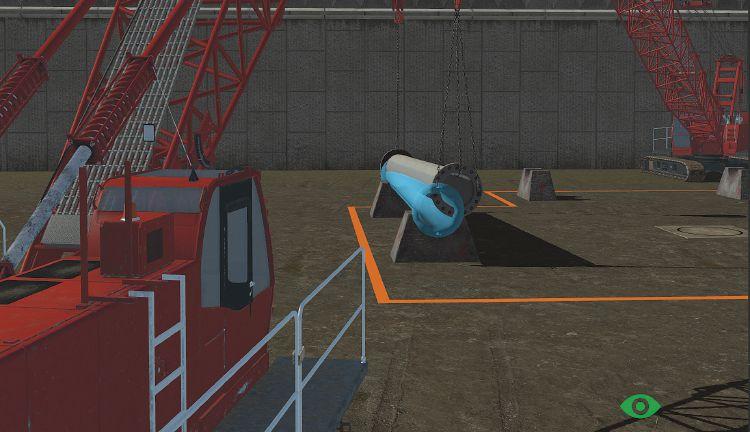

continued from cover

Winnipeg’s Bell MTS Center is home base for the Winnipeg Jets NHL hockey team, but also serves as the venue for a variety of entertainment events throughout the year. Vicepresident of facilities operations for True North Sports + Entertainment Ed Meichsner says the 16,345-seat arena has two hoist systems above the centre-ice position, run by a variety of Cone Drive and Vortek equipment. One hoist is in control of the score clock and video display often used for replays, penalty minutes and other displays depending on the event. Surrounding the top of the score clock is a large, round video board called “the Halo.” The Halo is connected to the second hoist system.

“They’re extremely important,” says Meichsner. “Because of where this video component and this big electronic piece of equipment hangs, it’s 80 feet above the ice surface. We can’t bring large pieces of equipment up there to service the unit. So we need to be able to raise and lower the centre-hung and the ring for service.”

The score board and the Halo can be lowered all the way to the arena floor, so technicians can actually conduct maintenance or repairs standing on the floor. However, the optimal position for the board and the halo for a hockey game will not necessarily be ideal for other events. Large concerts, for example, will often have a lot of lighting, sound and staging equipment of their own to erect and Meichsner notes that they’ll often want to hang them up as high as possible. So the hoists are also used at times to move the roughly 65,000 lb. board and the halo up as high as possible to make room for event riggings.

“They usually like to hang concert grids up anywhere between 50 and 80 feet, and most centre-hung score clocks hang below that or around the 50-foot mark,” says Meichsner. “So one of the challenges in a building like this with a large centre-hung is when you do a show that’s in the centre of your building, you’ve got to be careful. You have to make sure, before you proceed with putting in a new centre-hung, that you take all that into consideration.”

Meichsner says that at one time there were plans to install a large round cap with a Jets logo on the bottom of the clock, but this would have significantly limited the versatility of the potential staging set ups, so an alternate logo display was developed. This allows major events like Kanye West, Metallica, the WWE or UFC to have the space they need for their event riggings.

The two hoist systems require careful operation and maintenance. The addition of a new remote control system makes the actual operation of the hoist easier, but still requires an engineer up in the rafters with the hoists to make sure everything is operating smoothly. They also have a policy that they never operate the hoist the day of a hockey game.

“If the hoist is going to fail, it’s going to fail while it’s moving right?” asks Meichsner, rhetorically. “If we were to lower our centre-hung to do some servicing the day of a hockey game, and for whatever reason that hoist failed and we couldn’t get it back up for the hockey night that could be a disaster.”

Edmonton’s Rogers Place has a similar set up centre hoist system for the score clock. The roughly 20,000 seat home of the NHL’s Edmonton Oilers features a J.R. Clancy hoist system which uses four synchronized drums, all responding to a Raynok remote controller.

“The system was put in in 2016 and it works very well for the score clock,” says Rogers Place director of production, systems and services Keith Hough. “We have some other chain motors that we use for raising and lowering a couple of curtains that we have in the arena. We have a number of chain motors that we can use to lower the truss for that curtain system so we can manage it. We also have a bowl divider curtain system. That operates the same way.”

The J.R. Clancy hoist system allows for much of the same access as the Bell MTS Place system – engineers in Rogers Place need only a short ladder to reach the score clock when brought as low as possible. In this case, the decision of what hoist brand and system would be utilized was under the purview of the company that manufactured the score clock unit itself – Prismview, a subsidiary of Samsung Electronics. The system allows for a significant amount of control and customization.

“We have a computer controller, it’s not like a hand-held pendant where you just push a button to go up or down,” says Hough. “There’s a whole control system that allows us to get really granular with the control of the clock where it sits. It’s nice to be able to have pre-set heights and to be able to enter a target height to set the clock at if we want to do something a little bit other than the norm. Two pairs of drums are mechanically synchronized with a common shaft between them. All four are synchronized through software. So the versatility of the software and keeping track of that is an advantage.”

Hough has been with the Oilers organization since they were in their previous home, the Northlands Coliseum, formerly known as Rexall Place. In that arena, Hough says, there was a hoist system used to raise or lower a mock oil derrick. The large staging piece would be lowered onto the ice each game and players would skate through it.

“That was a good example of using lift technology to be able to raise or lower a set piece for our pre-game opening,” says Hough. “We had lots of lights off of it and we had a lot of effects going on that derrick. It was pretty cool, but times change.”

In 2018, the Avenir Centre opened in Moncton, New Brunswick. The $113-million, 8,800-seat facility is now the new home for the National Basketball League of Canada’s Magic and the Quebec Major Junior Hockey League’s Wildcats. Drew Watson, chief building engineer, says that the arena has the standard hoist used to raise and lower the centrehung scoreboard, but also features a variety of smaller winches, which are used for safety netting on either side of the rink, as well as curtains that can be used to change the scale of the arena.

“Our centre-hung is 16,000 lb.,” says Watson. “So that hoist is rated for one-and-a-half times that, just because of breaking once it’s in motion. The safety nets and the curtain are very, very small. Usually dual drums with one drive motor, and if I was to take a guess those are probably a horsepower or less – very, very small. The safety nets are under 1,500 lb., the curtains, each panel is no more than probably 50 lb. apiece. Really, that’s the only solution. Outside of that, in order to move these things up and down, you’d be looking at using cranes. Every centre-hung I’ve seen has had a hoist and typically those end up being a lifetime item for a building.”

With the hoist being a lifetime item – and one that could be difficult to remove once installed – it’s important to choose the right one for the arena. Watson marvels that newer hoists, like the system in the Avenir Center, are much smaller, more easily serviceable and more reliable than 10- or 15-year-old units he’s seen in other arenas. But that’s no excuse to get slack with maintenance.

“It saves you a lot of down time,” says Watson. “The last thing you want is a hoist to fail at three o’clock in the morning when you’re trying to load a show in. Being that we’re brand new, we institute at least a minimum of an annual inspection where all the limits are inspected, drums, anything for wear. Everything’s greased up as needs to be, gearing systems, etc. And then, typically every five years, that’s where we’ll end up doing some load testing and a little bit more intensive maintenance on all the hoists and what-not.”

Many construction firms are sitting on mountains of data, but have little sense of how to use it

BY JACOB STOLLER

Big data, sometimes touted to as “the new oil,” is one of the most popular technol ogy buzzwords, and also one of the least precise. While there are some familiar examples, such as the gargantuan amounts of personal information retained by the likes of Google and Facebook, there is no accepted definition of what constitutes “big,” nor is there a general understanding of the value it can bring to an organization.

“Like many construction companies, we have a lot of ‘big data,’” says Brian Kmet, senior manager of data and analytics at Edmontonbased PCL Construction. “But I think the term is badly maligned and mis-characterized.”

As Kmet explains, the IT industry likes to describe big data in terms of what are called the four Vs: the sheer volume of data, the velocity with which data is being collected and transmitted, the variety of data types, and the veracity or reliability of the data.

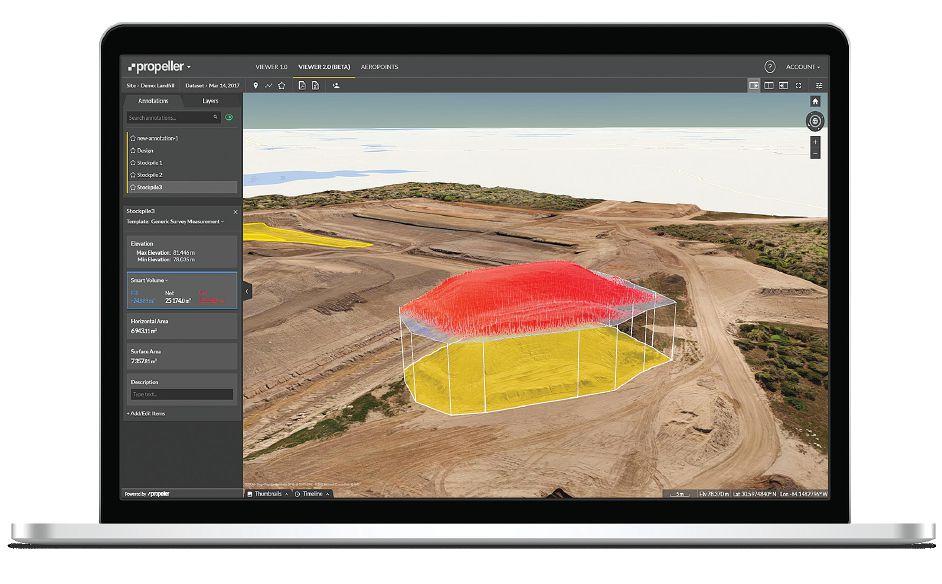

The large amounts of site data now being gathered, on the other hand, are new to contractors.

“If you took a traditional surveyor 20 years ago, he’d go out and if he surveyed a thousand points in a day, that was a good day’s work,” says Alan Sharp, business area director for CEC Software Solutions for Trimble Navigation. “Now these modern day techniques using drones and mobile scanners can store millions if not billions of points an hour. So the volume of the data that you’re processing now is many times larger than the traditional survey approach.”

“In the LIDAR scanning situation, you’re collecting 800,000 points per second, and might be scanning a highway live at 80k per hour, “says Trevor Bergmann, CEO of Beechville, N.S.-based AeroVision Canada, “So you can imagine what the files would look like to scan 100 kilometres of a highway, whether from a drone or ground-based mobile system.”

Making the information useful

Leveraging big data, in general, is about gathering, cleansing and consolidating data into a computing environment, and then applying analytic techniques, including artificial intelligence, to help business owners improve their forecasting, optimize their use of resources, anticipate project difficulties, or compare performance of different crews or regions.

Most vendors to the construction industry now provide data management services through the cloud, allowing users to ramp up quickly without upgrading their IT infrastructure, and also, to use user-friendly tools, often available on a smartphone, to analyze the data.

AeroVision, for example, provides, along with site surveys and other drone-based datagathering services, a cloud-hosted software interface for displaying and analyzing 3D site maps.

Trimble provides, among other software products, a hosted software solution called VisionLink, which brings data together from multiple equipment vendors to enable owners to manage and enhance the productivity of their entire fleets.

On the business data side, the job often involves consolidating data from multiple cloud providers.

“As a cloud-first company, big data for us means the ability to get at data easily and readily,” says Kmet. “Because all of our applications are scattered through various cloud vendors, we have to be able to coordinate that data and get to that data.”

“Those are just characteristics,” says Kmet. “The cause of big data in my opinion, electronically anyway, is that it is in fact cheaper to store data than to throw it away. So in our industry, we often collect a lot of data but do nothing with it.”

Types of data

The technical approach PCL uses, which is similar to many larger companies, is to deploy a series of Application Programming Interfaces (APIs), which allow users to consolidate diverse data sources into a single computing environment.

With demand for data growing “every week, literally” at PCL, Kmet has hired a team of young data experts, typically fresh out of school. In addition to the required data handling skill sets, Kmet looks for people with the right mindset.

“You need people who have a passion for data,” he says, “and are analytically inclined. For me the ideal is not just the technical skills, but the aptitude and the curiosity to see what can be done with data.”

“The cause of big data in my opinion, electronically anyway, is that it is in fact cheaper to store data than to throw it away. So in our industry, we often collect a lot of data but do nothing with it.”

For road construction companies, there are two categories of big data to consider: data connected with running the various aspects of the business, and data related to the GIS, video, and LIDAR-generated data gathered in site surveys, either by drone or groundbased equipment, or by GIS-controlled grading and earthmoving equipment.

“Our industry has always done a lot of record keeping, so our business practices generate very large volumes of data,” says Kmet. “The important thing is, what do you do with that data, how do you make it accessible, and do you even need it?”

The retention of some of this business data, such as health and safety records, is mandatory. Other components include drawings, submittals, RFPs, RFIs, change requests, change orders, and other project-related documents. Construction firms are at various stages of digitizing this information, complicating the chore of managing it.

The interest in site-related information has not been as strong, Sharp notes. Although many Canadian contractors now use machine control, most don’t utilize the data the machines collect, and instead, often send surveyors out to gather the same information, creating unnecessary costs and safety hazards.

“When you have the data coming off the machines, why not use it?” says Sharp. “It uses the same GIS, so it’s just as accurate. And you’re collecting that data continuously as the machine operates.”

Interest in drone surveys of highway infrastructure projects, according to Bergmann, is also at very early stages. However, he notes a recent event that might signal a change in attitudes – the highly successful publicizing of the Big Lift Project, which involved the re-decking of the MacDonald Bridge between Halifax and Dartmouth.

“It was documented like crazy,” says Trevor Bergmann, “and it was shared on social media, with updates left, right and centre. Nothing goes to plan 100 per cent of the time, but as a result of having that awareness, people really seemed to roll with the punches a lot better.”

The fact is, the more people know about a project, the better their relationship to it. As governments seek better transparency in the delivery of public projects, this might turn out to be the best case yet for collecting and sharing site-related big data.

BY MARIO CYWINSKI

The Canadian Truck King Challenge (CTKC) celebrated its 12th anniversary by crowning the 2019 GMC Sierra 1500 Denali as its champion. Sierra beat out five other challengers for the crown, marking the first time that General Motors has won in the half-ton (1500) category. Previously, GM has won the title in the heavy-duty (HD) category, including winning the challenge in 2018 with the Chevrolet Silverado 2500 HD. CTKC is unique in that it tests the trucks using realworld situations. Trucks are driven empty, with payload, and with trailers. The way the trucks would be used in the real world. Also, an off-road course is used to test each truck’s off-road capabilities. All-in-all, the two days of testing allowed for over 4,000 kilometres of total seat time for the five AJAC judges, who then scored each truck using 20 subjective test categories.

“The field of 2019 half-ton pickups was as competitive as ever this year, with brand new trucks from GM and RAM, while the F-150 received major upgrades, including offering a 3.0L diesel engine, that we ran back-to-back with gas engines from RAM, GM, Toyota and Nissan. Towing is where the diesel feels best, but the raw horsepower of GM’s 6.2L V8 is hard to ignore,” said judge Stephen Elmer, TFL Truck. “The performance exhaust on the Toyota Tundra TRD Pro barks when you accelerate, while Nissan’s 5.6L V8 has a strong exhaust note with loads of power. In the end, the GMC Sierra came out on top, and the honours are well deserved for such a smooth riding, comfortable, quiet pickup.”

This year, OEMs that took part were: General Motors with its GMC Sierra 1500 Denali and Chevrolet Silverado 1500 LTZ; Ford with the F-150 Diesel Lariat; FCA with the RAM 1500 Limited; Nissan with the Titan PRO-4X; and Toyota with the Tundra TRD Pro.

Both the Sierra and Silverado were equipped with a 6.2L V-8 engine with Dynamic Fuel Management and mated to a 10-speed automatic transmission. The F-150 was equipped with a 3.0L Power Stroke V-6 diesel engine mated to a 10-speed automatic transmission. Ram 1500 featured a 5.7L HEMI V-8 engine mated to an eight-speed automatic transmission. Tundra offered a 5.7L V-8 engine mated to a six-speed automatic transmission. The Nissan Titan was equipped with a 5.6L V-8 engine mated to a seven-speed automatic transmission. All trucks were 4x4 models.

“As always, the Canadian Truck King Challenge provides the unique opportunity to evaluate the trucks in real-world use. Unlike typical road tests and reviews, this event provides the rare experience of evaluating each entry as a working truck – not simply driving it around empty, but with a hefty payload and significant towing load,” said judge Clare Dear, Autofile.ca. “This year, the format helped reveal characteristics that might otherwise have gone unnoticed, such as the towing capabilities of Ford’s new 3.0L diesel engine and the RAM’s unique load-levelling air suspension. For anyone considering the purchase of a new truck, the findings of the Truck King Challenge are a must-see resource.”

Third-party company, FleetCarma, used data recorders

on each of the six vehicles to measure real-word fuel economy. The recorders sent data to FleetCarma with a final report showing the results for each vehicle under each part of the challenge (empty, payload and towing).

The winner of the Fuel Economy Challenge for 2019 was the Chevrolet Silverado 1500 with 6.2L V-8 that had the best fuel economy of all the trucks.

CANADIAN TRUCK KING CHALLENGE FINAL SCORES:

With trucks that are all new, trucks that offer new engine options, and trucks that offer new packages, there has never been a better time to be a pick-up truck customer, as the differences between them are getting smaller and smaller. The days of one truck being much better than another are over. Today, it’s a matter of fit-for-purpose: what are you going

to use the truck for, and what is of utmost importance to each individual buyer?

“This has to be the most difficult Truck King Challenge ever. I could not find a favourite at first glance,” said judge Éric Descarries, Auto 123. “Each vehicle is really a modern piece of equipment. This time, the winner has to be the consumer.”

Mario Cywinski is the editor of Machinery and Equipment MRO magazine, a member of the Automobile Journalists Association of Canada (AJAC) and a judge for Canadian Truck King Challenge, with more than 15 years of automobile industry experience. He can be reached at mcywinski@mromagazine.com.

With tariffs continuing to take a toll on U.S. businesses, farmers, communities, and families across the country, a new report by IHS Markit outlines the impact of tariffs on the equipment manufacturing industry and the broader U.S. economy.

“This report shows that tariffs continue to take a toll on U.S. equipment manufacturers, who will pay significantly more to manufacture equipment in the United States in the coming years,” said Dennis Slater, president of the Association of Equipment Manufacturers (AEM). “Tariffs on steel, aluminum, and Chinese imports, as well as the potential for additional tariffs, are driving up the cost of production, delaying capital investments, and impeding job creation for our more than 1,000 member companies.”

“While we agree with the Trump administration’s concerns regarding China’s unfair trade practices, including weak intellectual property protections, restrictions on foreign investment, and policies that limit competition, tariffs only hurt America’s businesses, workers, and families,” said John Garrison, chairman of the board, president and CEO of Terex Corporation and AEM board member.

“We urge the Trump administration to negotiate solutions to these long-standing issues with China, de-escalate economic tensions, and remove broad unilateral tariffs.”

The report, “The Economic and Industry Impact of Protectionism Tariffs on the Off-highway Equipment Sector,” estimates the impact of the Trump administration’s Section 232 and Section 301 tariffs. Several of the report’s key findings speak to the significant, long-term impact on the U.S. economy, including:

• Placing tariffs on about $265 billion of imports will hurt the U.S. economy, largely from the direct effect of higher prices, yielding average lost GDP of $29 billion a year for 10 years.

• The effect on employment is negative; the tariffs will

suppress domestic job gains by 260,000 over 10 years.

• Consumers will pay higher prices and reduce their real spending by $23 billion per year throughout the forecast horizon (ending in 2027).

The report also highlights specific impacts on the equipment manufacturing industry:

• Tariffs will increase costs of producing U.S. agriculture and construction equipment by 6 percent; with its higher steel-related product content, the costs of producing U.S. mining equipment will increase 7 per cent;

• Total loss in employment related to diminished output of all off-highway equipment is projected to end the forecast period with a loss of 20,700 jobs.

Equipment manufacturing executives have attributed the increasing costs of manufacturing in the United States to the Trump administration’s tariffs. In fact, Tariffs Hurt the Heartland – a campaign backed by AEM – found that the Trump administration’s tariffs are costing businesses up to $2.7 billion each month and have caused exports of American products to plummet by 37 per cent. Tariffs Hurt the Heartland has also issued state impact reports for several states, including Wisconsin, Pennsylvania, Ohio, Michigan, and Indiana. There are currently tariffs on $250 billion dollars worth of imports from China as a result of the Trump Administration’s use of Section 301 of the Trade Act of 1974. This amount equals half of the total amount of goods imported into the U.S. from China in 2017. Separately, Section 232 tariffs or quotas on steel and aluminum imports have raised the cost of manufacturing equipment in the United States. Equipment manufacturers need free and fair trade, but as a result of tariffs they are currently at a competitive disadvantage in the global marketplace Source: Association of Equipment Manufacturers.

WorkSafeBC has announced that its 2019 high-risk strategy for manufacturing will include a focus on preventing slips, trips, and falls, a widespread cause of injuries throughout the sector.

The conditions that lend themselves to slips, trips, and falls are often not perceived as significant hazards, but they can easily lead to severe injuries; about a fifth of the injuries in this category in manufacturing are defined as serious.

“Contributing factors to injuries are often seasonal — such as slippery surfaces after rain or snow — or are indirectly related to the manufacturing process,” said Dan Strand, director of prevention field services with WorkSafeBC. “We’re tackling complacency around these avoidable incidents by educating employers and workers through inspections, and providing effective resources.”

Those efforts will be reinforced in 2019 with the development of an employer resource and two marketing campaigns, one that addresses slips, trips, and falls generally and another that highlights winter-related risks.

Strand explained that when WorkSafeBC developed its 2018-20 high-risk strategy, it recognized that flexibility would be needed to add other focus areas as required.

Released last year, the Manufacturing High Risk Strategy addresses seven strategic focus areas: safeguarding and lockout, powered tools, hand tools (knives), material handling (falling objects), falls from elevation, falls on the same level, and mobile equipment.

WorkSafeBC’s high-risk strategies identify and target industries and employers with a high risk of serious workplace injury and a significant contribution to the seriousinjury rate. High-risk strategies include four industry sectors: construction, forestry, health care and manufacturing.

More information about the Manufacturing High Risk Strategy, including 2019 deliverables and timelines, is available at worksafebc.com.

igfoot Crane Academy recently announced that its Construction Hoist Operator Training Course has been formally approved by Technical Safety BC.

BBigfoot Crane Academy’s Hoist Operator Training Course is part of Bigfoot Crane Company’s larger entry into the B.C. Construction Hoist and Personnel Elevator business which now covers:

• Rental and service of Fraco construction hoists and personnel elevators;

• Sales and service of permanent construction hoists and personnel elevators;

• On-site service of all third-party hoists and personnel elevators by technical safety B.C.-certified mechanics;

• On-site construction hoist and personnel elevator training; and

• Off-site construction hoist and personnel elevator operator training.

These training programs along with Bigfoot’s other crane and rigger training programs will be managed by Ralf Notheis (2016 Top Trainer for North America). Bigfoot will be installing a permanent construction hoist for training purposes at its Abbotsford, B.C. training facility and along with the ability to conduct on-site construction hoist operator training at all client locations that have a preinstalled construction hoist or personnel elevator. www.bigfootcrane.com

Raimondi Cranes recently announced the appointment of Cristian Badin to the role of sales director reporting directly to Mauro Masetti, chief commercial officer. The company, in parallel, is also releasing its commercial development schema for the coming four quarters, including product and activation tactics.

“Cristian, with more than a decade of sales and business development experience in the tower cranes segment, is a hands-on, solution-oriented heavy lifting professional,” said Masetti, commenting on the appointment. “I have worked closely with him for a number of years, and throughout that time I have noted his ability to carefully address client needs with practical and effective machine solutions. Exceptional sales results have allowed Raimondi’s recruitment drive to continue, and Cristian’s appointment is an important part of this. He is responsible for developing new Raimondi distribution contracts, sourcing new clients, and the coordination of our area managers and our agent roster.”

“Over the course of my career in tower cranes, there are words that I naturally associated with Raimondi Cranes: reliability, history, pride, and passion. Seeing the company’s products perform has helped to nurture a strong respect for the brand, together with its recent innovations in design and engineering. When I realized it was time for me to move forward professionally, Raimondi was the instinctive evolution that I saw would best allow me to grow while drawing on my existing strengths,” added Badin. “The willingness to improve and expand while maintaining focus on the customer base is a top company priority, and this has been a key factor for me in my decision to join Raimondi. I believe I can contribute to the board’s ambitious plans, and I look forward to working closely with Eng. Masetti to realize his commercial aims.”

Prior to his appointment as sales director of Raimondi Cranes, Badin spent his career enhancing his knowledge base through strong and close ties to customers and product end users in the crane sector.

“I am pleased to share that the strategies put into place over the past two years are showing considerable returns and successes – including market share across various geographies that were previously underachieving,” said Masetti. “Raimondi’s progress is almost unmatched amongst our peers in tower crane manufacturing. We are forging forward with three new product releases this year as well as confirming a number of onground activations that we expect to see remarkable results from, and Cristian will play an integral role in our goals for these measures.” http://raimondi.co

Tower crane manufacturer Comansa will be exhibiting in Bauma its latest high capacity model, available worldwide since September 2018. The 21LC1050 flat-top crane can load up to 50 tonnes (110,230 lb.), has a maximum radius of 80 metres (262.4 ft.), and was designed to provide great performance in large industrial or infrastructure projects as well as in construction with heavy precast or steel structures, including PPVC.

The 21LC1050 features high speed hoist mechanisms (up to 300 m per minute - 984 ft.) and capacity for 1,570 metres of wire rope (5,150 ft.), making it also the perfect choice for high rise construction. Thanks to the singledouble trolley system with automatic reeving change, the 21LC1050 crane always has an optimized load diagram. Working with the simple (or front) trolley, the crane improves its tip loading capacity and reaches higher hoist speeds. With the double trolley (front plus rear), the crane can work with the heaviest loads.

A new modular counterjib was designed for the 21LC1050, which allows up to six different configurations to adapt the crane to the needs of each job and increase safety. Thus, when the crane is assembled with a maximum jib length (80 metres - 262.4 ft), the counterjib radius is 31 metres (101.7 ft), being able to reduce to 27 (88.6 ft) when the jib length is 50 metres (164 ft), as it will be shown in the crane at Bauma.

The 21LC1050 is delivered with the new CUBE cab in its XL size, the largest from Comansa, ensuring great productivity thanks to its fully glazed front and providing great comfort to the operator. In Bauma, an XL CUBE cab will be exhibited at ground level for all visitors to see its ergonomic benefits and the spacious distribution of this high-rise office, whose design has been awarded two prestigious prizes: iF Design Award 2018 and German Design Award 2019.

The 21LC1050 flat-top is the latest high capacity crane launched by Comansa, and another step forward in the company’s strategy to adapt its range to the global construction needs. Ten years ago, the company’s catalogue was formed by small and medium size flat-top cranes and three luffers, with maximum load capacity of up to 24 tonnes (52,900 lb). Since then, Comansa has developed a new range of luffers, a new series of medium size flat-tops and all its heavy load range, including a 90 tonne flattop (198,410 lb).

Thanks to such efforts, Comansa offers today 19 flat-top models and 6 luffing-jib cranes for all types of construction projects, and has a leading position in the high capacity range. Besides the new 21LC1050, the company has recently launched the LCL700 luffing jib crane, with maximum load capacity of up to 64 tonnes (141,090 lb), and upgraded the flat-top models 21LC660 and 21LC750 to load up to 50 tonnes (110,230 lb).www.comansa.com

Talbert Manufacturing, a North American leader in specialized heavy-haul solutions, has named Hale Trailer Brake & Wheel, headquartered in Voorhees, N.J. as its top dealer for the 11th straight year. This award recognizes a Talbert dealer for outstanding performance in trailer sales, service and parts. Hale outperformed all other Talbert dealers in 2018 and was also recognized as the top parts seller for the year.

“For over a decade now, Hale has been heavily responsible for the success of Talbert trailers on the East Coast,” Troy Geisler, Talbert Manufacturing vice-president of sales and marketing, said. “With 12 locations from Maine to Florida, their commitment to customer service and knowledgeable staff reflect Talbert’s core values and we are proud to announce their 11th straight year as our top dealer. Accomplishments like this are a great example of what the right partnerships can achieve.”

Hale is a full-service trailer dealership that sells new and used trailers and related equipment. The dealership also rents trailers, sells commercial trailer parts and accessories, and provides general trailer service and repairs.

Talbert also named Reno’s Trailer Sales & Rental of Belle Vernon, Penn. as the most Improved dealer of 2018 and one of the top 10 dealers overall. Reno’s Trailer Sales & Rental is a leader in the open deck market, specializing in flatbeds, drop-decks, lowboys, RGN’s, specialized heavy haul and tag-a-long trailers.

The remaining top 10 dealers, based on 2018 sales, are in alphabetical order below.

• Carrier Centers, with six locations serving southern Ontario, boasts a large inventory of new and pre-owned trailers for sale, lease or rent. As a full-service dealer, they offer financing, parts and service. The company is an award-winning International dealer recognized for their leadership and customer service.

• Coogle Truck & Trailer Sales of Otterbein, Indiana, features a wide selection of new and used trailers for sale or rent and a fully stocked parts department. The family-owned compay also offers custom trailer modifications and full-service repairs.