Editor - Keith Norbury • editor@craneandhoistcanada.com

Advertising Sales - Jeremy Thain • jeremy@capamara.com

free

• Tel. 250.474.3982 • Fax. 250. 478.3979

Art Direction/Production - James S. Lewis • james@capamara.com

Publisher - Peter Chettleburgh • peter@capamara.com

Regular Contributors

Saul Chernos, Jeffrey Carter, Kevin Cunningham, Nelson Dewey, Matt Jones

Subscriptions - Deirdre Chettleburgh • deirdre@capamara.com Tel. +1.250.474.3935 • Fax +1.250.478.3979 www.craneandhoistcanada.com

Crane & Hoist Canada is published six times a year by Capamara Communications Inc. Reference to named products or technologies does not imply endorsement by the publisher. A subscription to Crane & Hoist Canada (six issues) is $34 per year in Canada (including GST) and $36 (including HST). For subscriptions in the USA the price is $36 USD and $45 USD for overseas. Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 4623 William Head Road, Victoria, BC, Canada, V9C 3Y7. Fax orders to +1-250-478-3979. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada, CIRCULATION DEPT. 4623 William Head Road, Victoria, BC V9C 3Y7

ISSN 1923-788X

Next Advertising Deadline: June 2, 2017

Don’t miss the opportunity to be part of this exciting new industry publication. For more information, or to reserve space in the next issue, call Jeremy at our Advertising Department - Toll Free 1.877.936.2266. jeremy@capamara.com

Next Editorial Deadline: June 2, 2017 For writers’ guidelines and submission requirements get in touch with the Editor, Keith Norbury, at 250.383-5038. Email editor@craneandhoistcanada.com

Canada has been chosen as a partner country for the 2019 edition of Bauma, the massive heavy equipment trade show held every three years in Munich, Germany.

Messe München, which organizes Bauma, and Verband Deutscher Maschinen- und Anlagenbau, the German Engineering Federation, announced the honour this March.

Reasons cited for the selection include Canada’s status as the world’s seventh largest market for construction machinery, that construction and mining account for 15 per cent of Canada’s gross domestic product, and the recent free-trade agreement — known as CETA — between Canada and the European Union.

“In selecting Canada, we were not just selecting a very stable sales market but an attractive and dynamic one as well,” Klaus Dittrich, chairman and CEO of Messe München, said in a news release. “I am certain that our exhibitors will find additional business openings here.”

Johann Sailer, chairman of the Construction Equipment and Building Material Machinery Association within the VDMA and chairman of the Bauma exhibitors’ advisory board, added that CETA — which stands for Comprehensive Economic and Trade Agreement — “will lend fresh impetus to bilateral trade.”

Crane operators are among the Canadian professionals who will “potentially” have their credentials recognized in Europe courtesy of the Comprehensive Economic and Trade Agreement, a.k.a. CETA, the European Union’s Commissioner for Trade wrote recently for the Globe & Mail.

“CETA will mean new opportunities for Canadians who want to work in Europe, and vice versa,” Cecilia Malmström wrote in the March 20 essay. “Professionals from architects to crane operators will potentially see their qualifications recognized across the Atlantic.”

Malmström added that the parties have agreed in the deal to strength environmental protections and workers’ rights.

“Trade should mean sustainable development — not a ‘race to the bottom’ on standards,” she wrote.

The commentary was published just weeks before the British Parliament set in motion the article for the U.K. to exit — or Brexit — from the E.U. Even without Britain, the E.U. “will still be Canada’s secondlargest goods-trading partner,” Malmström wrote.

Sailer said his association wants to use Bauma 2019 “and the opportunities afforded by the partner country concept to bind our industries even closer together.”

Despite current weaknesses in mining and oil and gas, Bauma organizers say Canada’s medium-term prospects are positive, citing estimates that the country’s construction industry will grow three per cent annually to 2020. The release also noted major projects such as Ontario’s Ring of Fire mining prospects, as well as billions of dollars in civil engineering projects, such as Montreal hospitals, Vancouver’s airport, a Toronto railway station, and a Calgary cancer treatment centre.

The 2016 version of Bauma attracted a record 583,736 visitors from around 200 countries and featured 3,425 exhibitors from 57 countries. The next Bauma takes place April 8-14, 2019.

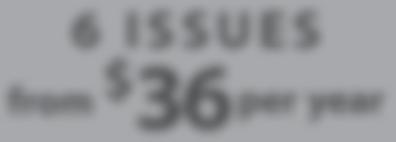

An Abbotsford, B.C.based crane operator trainer will be recognized as North America’s top corporate trainer for 2016 at a crane industry conference in Washington state this May.

The award, to Ralf Notheis, manager of the Crane Academy for Abbotsford-based Bigfoot Crane Co. Inc., was announced late in 2016 by Crane Hot Line magazine.

Notheis received the honour, in the words of the judge, for creating “reward-based safety challenges for his clients and their employees” that show his “ability to gain buy-in and commitment from client management, which ultimately benefits the crane and rigging industry as a whole.”

An article about the award noted that Notheis, who has been with Bigfoot since 2014, has a background that includes positions at the largest crane rental companies in Canada. The piece also cited an example of how he encouraged a student with dyslexia to overcome his lack of confidence and complete his training.

“With over 20 years of experience in the heavy equipment industry, Ralf’s reputation and impeccable safety record speak for him,” said Ryan Burton, managing partner at Bigfoot, in a news release announcing the award. “His combination of practical experience and technical expertise is virtually unmatched and his deep insight into personalities and learning methods have been a game-changer for us.”

The annual Top Trainer Awards are endorsed by the non-profit Association of Crane & Rigging Professionals. The winners will be recognized at the association’s annual general assembly, which takes place May 9-12 in Tulalip, Wash.

2017 Crane Rental Association of Canada conference happens this June at New Brunswick resort

ttendees at the Crane Rental Association of Canada’s annual conference this June will be able to take a virtual busman’s holiday of sorts.

The conference, taking place June 7-10 in St. Andrews, N.B., will offer two opportunities for delegates to test their skills on crane simulators, notes Claire BélangerParker, CRAC’s executive administrator. Montreal-based CM Labs Simulations will bring one of its Vortex simulators to the conference, which happens at the “luxurious and legendary” Algonquin Resort. Meanwhile, Industrial Training International, which has a training facility near Edmonton, will bring its virtual reality crane simulator to the conference.

Both systems were on display at the 2017 ConExpo-Con/Agg heavy equipment trade show in Las Vegas this March.

“I think with Algonquin being a small community we really wanted to have more interaction and more activities,” BélangerParker said. “So the simulators are a great addition.”

The ITI system employs a sophisticated Oculus Rift headset and uses software from Edmonton-based Serious Labs Inc., explained Caleb Steinborn, product manager for ITI’s virtual reality crane simulator, during a demonstration of the equipment at ConExpo. The company officially released the system on March 6, the day before ConExpo opened.

Representatives from CM Labs and ITI will also be among the presenters at the conference. Drew Carruthers of CM Labs is scheduled speak at 10:15 a.m. on Saturday, June 10, while ITI’s Zack Parnell will make his presentation later that morning at 11:30.

“We’re quite excited because at this time last year our numbers were not as high as they are this year. So it gives us great hope to have a great turnout in St. Andrews.”

— Claire Bélanger-Parker, executive administrator, CRAC

New speaker added

A late addition to the program is a presentation by Patrick Lacroix, who is the New Brunswick manager of stakeholder relations for TransCanada Corp.’s proposed Energy East oil pipeline project. In that role, he is responsible for engaging and consulting with municipalities, non-government and environmental organizations, Indigenous communities, and landowners, says his TransCanada bio.

Lacroix’s 20 years of public affairs service also includes working in provincial and federal public service, with non-profits, and

as a director of government relations for J.D. Irving Ltd.

Other speakers on the program include the following:

• Jim Quinn, president and CEO of the Saint John Port Authority, which welcomed two huge gantry cranes to the port last fall and recently announced a $205 upgrade to its western terminals;

• Dan Demers, occupational health operations manager with CannAmm Occupational Testing Services, who will speak about managing medical marijuana in the workplace;

• Jose Perez, export sales manager with Broderson Manufacturing Corp., which is headquartered in Lenexa, Kansas; and

• Aaron Casey, a crane insurance specialist with D.G. Dunbar Insurance Broker Ltd., based in London, Ont.

Early registrations pouring in

With two months to go before the conference, 111 delegates had already registered for the event.

“We’re quite excited because at this time last year our numbers were not as high as they are this year,” Bélanger-Parker said. “So it gives us great hope to have a great turnout in St. Andrews.”

She attributes those high numbers in part to having opened registration earlier this year than in the past. Still, despite that, several current and former directors of the association still hadn’t signed up by the end of March.

They and other latecomers won’t want to wait too long. Those registering by April 30 receive a discount on the conference registration fee. The early bird fee is $850 for members compared with $995 after April 30, and $475 for spouses compared with $500 after April 30.

The conference opens Wednesday, June 7, with a board of directors agenda that includes a directors’ breakfast and lunch, a board meeting, and a meeting of CRAC’s boom dolly committee. Pre-registration for the conference is also open that day from 9 a.m. to 9 p.m. And the Spreader Bar — in

the resort’s Van Horne Ballroom, in a separate building of the main resort — convenes for the first of four evenings, starting at 8 p.m.

Thursday’s program includes the annual golf event, a guided Marine Experience tour of the Bay of Fundy, a visit to Kingsbrae Gardens, and a “Kitchen Party” get-together that evening in the Van Horne Ballroom.

The ballroom is also where attendees will be able to pick up a copy of this issue

of Crane & Hoist Canada for some lateevening reading.

The conference’s charity of choice this year is the Dragonfly Centre for Autism in St. Andrews. Among the centre’s initiatives are “highly specialized music and art therapy summer camp programs, delivered by trained autism specialists, have enriched the lives of many students and families since their incorporation in 2005,” notes a posting on the conference website. For more information, visit www.crac-canada.com.

ne the most startling revelations for a Canadian visitor to ConExpo-Con/ Agg in Las Vegas this March was just how optimistic Americans we spoke with are about the new presidential administration in the U.S.

Now, most of them didn’t mention the new U.S. president by name — although one did quite loudly bellow half in jest that “It’s Trump!” as an explanation for his optimism. By and large, the sentiments ranged from expressions of simple relief that the long presidential campaign was finally over — a veiled indication that optimism would prevail no matter who won — to an expectation that Trump would follow through on his promises in three key areas.

We detected a consensus among those in the heavy equipment industries that they really like the prospect of lower corporate taxes, reductions in regulations, and an increase in infrastructure spending. Nothing else associated with Trump, such as his lack of presidential deportment and propensity for tweeting whatever thought enters his mind, seemed to matter.

Crane & Hoist Canada welcomes submissions of letters, guest columns, short notices, product announcements, press releases, and ideas for articles. Send them to editor@craneandhoistcanada.com.

Letters: Please limit your letters to 250 words. Include your full name, the city or town you live in, and a contact phone number. We do not publish anonymous letters or letters written under pseudonyms.

Guest columns: These can be up to 700 words. Please send a brief note of inquiry first, however, just in case space what you wish to write about has already received a lot of coverage in our pages. Include your full name, the city or town you live in, and a contact phone number.

Short notices: Tell us about individual promotions, appointments, awards, staff movements, plant openings, plant closures, expansions, and other milestones. These short items should be no longer than 100 words.

Product announcements: Are you a supplier to the industry? Has your company developed a new product or process? If possible, attach a photograph.

Press releases: These should have something to do with cranes and/or hoists in Canada. We might publish only part of a press release or use it as starting point for an article by one of our writers.

Story ideas: Maybe you have an idea you’d like us to explore for an article. A good rule of thumb is to limit your story idea to no more than 30 words. If it takes longer than that to describe it, then chances are we won’t be able to take it on.

All submissions are subject to editing and publication cannot be guaranteed. The deadline for our next issue of Crane & Hoist Canada is June 2, 2017. Sooner is always better than later.

With the exception of a taxi driver, now a U.S. citizen but originally from Iraq, nobody we spoke with during ConExpo volunteered that they favoured mass deportations of illegal immigrants from Mexico. Nor did anyone come out and argue that erecting trade barriers are the way to make America Great Again. A few grumbled about the high cost of health insurance in the U.S. but it was hard to tell if those were indictments or endorsements of Obamacare.

Yes, being a Canadian at ConExpo was in many ways to be a stranger in a strange land. Yet while at times ConExpo made us feel like we were on Mars, it also felt very familiar. The U.S. remains a democracy after all. And in a democracy, it’s difficult for a political movement to stay in power indefinitely. Witness the Conservatives in Alberta, not to mention the federal Tories under Stephen Harper.

Canadians no longer wanted a Conservative in charge of Canada just as U.S. voters no longer wanted a Democrat in charge — although for different reasons. Actually, in both cases it was tiny fraction of the electorate that changed their votes — but that’s all it took to effect big changes.

To say that Trump was a change candidate is one huge understatement. To date,

he hasn’t effected many of the changes he promised — including repealing and replacing the Affordable Care Act. But it’s still only a few months into his presidency. So his supporters have plenty of time to hope.

Such hope has made the mood of American businesses much more bullish in the last several months. And that change in mood is, for now at least, more important and forceful than any legislation that Trump and Congress can enact.

It’s so powerful that it has the potential to become detached from politics entirely. For the sake of prosperity, it will need to become detached if Trump and Congress cannot get their acts together.

The economy and industry will thrive, despite politics, once business people fully realize that they have control of their destiny because they hold the levers of technological innovation. Of course, they also need to realize that where innovation is heading isn’t necessarily where Trump is trying to steer it. Actually, indications are that innovation is going in the opposite direction.

Less than a month after ConExpo came the news that the market capitalization of Tesla, the electric car manufacturer, has surpassed that of the Ford Motor Company. That, as Malcolm Gladwell would say, looks like a tipping point. Anyone who has been paying attention knows that Tesla founder Elon Musk — can we call him the Henry Ford of the 21st century yet? — has grandiose plans to transform the transportation infrastructure from gasoline-powered to solar-sourced electrical-powered.

Musk is more than just a planner. He’s a doer — an example to naysayers of that old Chinese proverb, “He who says something cannot be done should not interrupt the person doing it.”

This is all happening while Trump guts environmental rules in a quixotic quest to bring back coal-mining jobs. Unless Trump taxes sunlight, he’s not going to cast any shade on the revolution Musk is leading.

Of course, through his SpaceX ventures, Musk is also pursuing the even bigger prize of colonizing Mars. When that begins — not if — the adventure will need a lot of heavy equipment, including cranes. Who knows, maybe there’ll be a ConExpo on the Red planet in the not-too-distant future. That would really be out of this world.

Nelson Dewey has been a prolific cartoonist for over 50 years. If his work looks familiar, maybe you read a lot of car comic books when you were younger.

In the 1960s, ’70s and ’80s, Dewey was a frequent contributor to those comics, particularly CARtoons. He also drew for Hot Rod Cartoons, CYCLEtoons, SURFtoons and SKItoons. In all, he produced nearly 2,000 pages in those publications.

He has also published cartoons in Cracked Magazine, Oui, Reader’s Digest and Motor Trend, as well as community newspapers and dozens of books. And he shared an Emmy Award in 1988 for his work on storyboards for the Arthur cartoon series on television.

To take a trip down memory lane and see samples of Dewey’s car cartoons, go to his website, www.nelsondewey.com.

Unionized crane operators and related trades people in Newfoundland held a protest in late March over the imposition of emergency supervision over their local, CBC News reported.

Dozens of members of local 904 of the International Union of Operating Engineers gathered outside the local’s office at Mount Pearl on March 27 to show support for business manager John Flaherty who they say has been unfairly blamed for problems that already existed before he was elected to his position in 2015, the news report said.

records of approval for spending $500,000 in 2016 for the local’s training college; the business manager having terminated staff of the local and the college which “created a lack of institutional memory of continuity” and led to litigation from the removed staffers over their severance payments; and failure to make necessary contributions to the general pension plan.

Callaghan appointed Lionel Railton, the union’s regional director for Canada, as the temporary international supervisor effective March 20.

James Callahan, the IOUE’s international president who is based in Washington, D.C., posted an online letter on March 20 explaining why emergency supervision was placed on local 904.

Among the reasons Callahan cited are political in-fighting between the business manager and the executive board that has “created a state of paralysis” that has interfered with the union’s functioning; failure to obtain approval for spending about $93,000 on three new vehicles; failing to provide

Railton himself posted a notice to local 904 members on March 21 saying that a hearing will be scheduled in the near future to determine if self-government will be restored or if the supervision will continue.

Local member Tommy Norman, who helped organize the March 27 rally, told the CBC, “We want to defend our business manager and president who we feel has been doing a damn, fine job.”

The local represents about 2,000 workers in Newfoundland and Labrador.

A former crane operator and union president who represented Hamilton steel workers has died at the age of 83.

Ray Silenzi, who won the presidency of local 1005 of the United Steelworkers of America in 1985 over a controversial incumbent, died March 19, the Hamiton Spectator reported.

Described in the news report as “a crane operator who vowed to get laid-off workers back to work,” Silenzi was a popular vice-president of the local when he defeated six-year incumbent Cec Taylor “in a landslide.” Taylor’s time as president included a 125-day strike in 1981 and a 10-month suspension from office two years later.

Silenzi didn’t harbour any ill will toward Taylor, the Spectator reported, but called his win “a vote for unity” and said he had a different leadership style that believed in teamwork.

Silenzi didn’t seek re-election in 1988 when he retired from Stelco, where had worked since 1957, the report said. However, he remained with the union as a staff representative.

The Association of Equipment Manufacturers will help with managing and co-promoting the annual National Farm Machinery Show starting in 2018.

AEM president Dennis Slater and Jason Rittenberry, CEO of the Kentucky State Fair Board, announced the verbal agreement during the 2017 conference this February in Louisville, Ky.

The exhibition, the largest indoor farm show in the U.S., attracts more than 300,000 attendees each year to the Kentucky Exposition Center in Louisville, the release said.

The agreement would also give the AEM an equity position in the farm show’s future growth.

The 2018 show takes place next Feb. 14-17.

The AEM has more than 900 member companies, about half in the agricultural sector. Association members also include crane manufacturers, such as Manitowoc, Link-Belt, and Terex, as well as makers of

crane accessories, like Columbus McKinnon Corporation, and the Crosby Group.

“This is a first step in a partnership that will benefit all the stakeholders in the National Farm Machinery Show and the Ag industry,” Slater said in the release.

“AEM’s commitment to its core services like public policy and our success in leading trade shows naturally lends itself to our new partnership with the Kentucky Fair Board and the National Farm Machinery Show.”

Rittenberry said the farm show has a wait-list of hundreds of exhibitors each year.

“This partnership will bring new opportunities for current and future exhibitors, and expand the experience for our attendees,” Rittenberry said.

The AEM is best known for putting on the triennial ConExpo-Con/Agg trade show in Las Vegas, and the biennial International Construction & Utility Equipment Expostion, or ICUEE, in Louisville. For more information about the farm machinery show, visit www.farmmachineryshow.org.

Our eet ranges from self-erecting cranes, boom truck cranes up to 35 ton, mobile cranes and rough terrain cranes.

Since each job is di erent, we o er expert personnel to evaluate the customer's need and select the equipment which will complete the job in the most economic, timely and safe manner.

the new four tonne GA 138, which has a 21 metre hook height without tower added and 38 metre jib, maximum 8800 Lbs. And at jib tip capacity of 1,000kg or 2250 Lbs. it will also be sold with a towing axle. Quick assembly crane, smaller foot print , no noise or pollution, they are perfect for congested work sites and urban environments. Radio control, full training and cost effective. Axles for on site towing.

National harmonization still a long way off, however, says Canadian Hoisting and Rigging Safety Council executive director

MATT JONES

In response to concerns from industry and government, work is being done at a national and regional level to harmonize trades training across the country. The goal of the harmonization is mobilization — that, for example, a crane operator trained in Newfoundland can travel to Alberta and have his or her training certification understood and trusted because the standards are the same.

While the Canadian Council of Directors of Apprenticeship, a.k.a CCDA, works towards national harmonization, the Atlantic Apprenticeship Harmonization Project reported last year that harmonization efforts in the region were around 60 per cent complete.

“As a crane operator for many years, I can safely say industry looks forward to having those uniform standards across the country,” said Craig Blatz, a crane operator instructor with the Operating Engineers Training Institute of Nova Scotia. “When they get an operator who’s been trained, they’ll know they’ve been over the same material. That’s the goal, but I know in practice it’ll take a while to get it to shake down the way it’s supposed to. It takes time.”

“If it’s not mandated from above, politically, nothing will occur. And that’s what we’re seeing.”

— Fraser

Cocks, executive director, Canadian Hoisting and Rigging Safety Council

The Atlantic harmonization project formed when the Council of Atlantic Premiers signed a memorandum of understanding and approved joint provincial and federal funding for a 42-month period ending in July 2017. As a result, 10 trades will be harmonized throughout the region — bricklayer, cook, welder, metal fabricator, carpenter, instrumentation and control technician, construction electrician, industrial electrician, plumber and steamfitter/pipefitter. Cranes are not included in that harmonization effort. That’s possibly

“As a crane operator for many years, I can safely say industry looks forward to having those uniform standards across the country.”

— Craig Blatz, a crane instructor, Operating Engineers Training Institute of Nova Scotia

because — as CEO of Nova Scotia Apprenticeship Agency and CCDA chairperson Marjorie Davison explained — cranes pose some unique problems.

Crane trade straddles worlds

“That’s been a particularly challenging one because there are equipment requirements as well that we’ve had to look at,” Davison said. “With this particular trade, it’s a trade that straddles two worlds. It straddles the apprenticeship world where it might be a trade that’s designated in legislation in one jurisdiction and there’s an apprenticeship pathway to certification. But it’s also in a regulated environment, often by what we call technical safety legislation in Nova Scotia. And that type of legislation is really looking at the equipment and making sure the equipment is safe. It looks different across the country, so this is a particularly challenging trade to reach consensus on in terms of harmonization.”

That said, Davison noted that jurisdictions across Canada have agreed to certain guidelines for crane certification — such as three training levels, 5,400 hours of practicum, relevant technical training, and getting a sign-off from both the trainee’s supervising journey person and the employer. The training, however, need not be identical in each jurisdiction.

“There may be an opportunity for a jurisdiction to post what is called a variance if they

“With this particular trade, it’s a trade that straddles two worlds. It straddles the apprenticeship world where it might be a trade that’s designated in legislation in one jurisdiction and there’s an apprenticeship pathway to certification. But it’s also in a regulated environment … so this is a particularly challenging trade to reach consensus on in terms of harmonization.”

— Marjorie Davison, chairperson, Canadian Council of Directors of Apprenticeship

feel that their industry can’t get behind a particular element of harmonization,” Davison said. “Or if they feel that their particular industry can’t provide that training in the same sequence and they have a really good rationale for it, they can keep it a different way. In this case, Ontario has always had a 6,000-hour requirement for the apprenticeship program and they were unwilling to move to the 5,400 hours.”

Representatives for training in all four Atlantic provinces confirmed that harmonization efforts under the Atlantic project are well-underway and on-target.

While those results are encouraging, the road toward national harmonization will still be long and possibly difficult, said Fraser Cocks, executive director of the B.C. Association for Crane Safety and of the Canadian Hoisting and Rigging Safety Council, a volunteer organization of crane industry leaders working toward harmonization.

“Everyone in industry agrees with it, but because you have all these different jurisdictions, these silos if you will, they’re reluctant to make change and it means a lot of work as a result of whatever changes are agreed to,” Cocks said.

He added that the CCDA isn’t really the driver of the process, noting that it oversees the Red Seal apprenticeship program, which he noted is an endorsement or add-on of a crane credential. “They don’t really have the authority to make the change occur,” Cocks said of the CCDA.

While harmonization is mandated from above — Canada’s premiers agreed in principle to work together toward harmonization — the actual implementation falls to ministries within each government’s jurisdiction, Cock said. At that point, it depends on how motivated the minister is to act. Much also depends on the training providers, who might not be interested in changing their processes.

“If it’s not mandated from above, politically, nothing will occur,” Cocks said. “And that’s what we’re seeing.”

Cocks did not dismiss the hard work that Davison and the CCDA have put in toward harmonization. He said the Red Seal program did a very good job of aligning the content for the training outcomes. But he added that the CCDA is limited in what it can do because it wasn’t designed as the vehicle for that purpose.

“Companies are doing work in all jurisdictions — borders are imaginary lines that they cross,” Cocks said. “These are known issues. We’ve known this. This is the reality that we live in and we’re trying to correct it. The process is helping, but it’s not getting it done in terms of what could be done.”

Standard VPC™ machine: 650 t (716 USt)

VPC-MAX™ capacity enhancing attachment: 700 t (772 USt)

Revolutionary Variable Position Counterweight (VPC) and VPC-MAX systems raise the bar on lift capacities with:

•Strongest load charts in class

•Ability to travel, swing and rotate with full capacity

•Reduced ground-bearing pressure

•Fewer loads to transport

•Increased profitability

Get unmatched capacity and value with a Manitowoc MLC650 crawler crane. Contact your Manitowoc dealer today. www.manitowoc.com

Metal Works Ltd., was utilized, as well as a 70-ton Mantis owned by RMI Marine Ltd.

Each crane was responsible for a variety of specific tasks (see sidebar).

The Halifax Regional Municipality began the project in 2014. It is scheduled for completion this fall. The structure has required a significant amount of work, including replacement of the deck and truss of the suspended spans, raising the suspended spans, and reinforcing the towers.

“The Macdonald Bridge is one of two suspension bridges spanning Halifax Harbour,” said Allison Currie, community engagement officer for Halifax Harbour Bridges. “They are major commuter bridges linking multiple communities with a daily average of about 105,000 commuters. The Macdonald is over 60 years of age and, while the bridge remained safe, the deck was wearing out and needed to be replaced. The Big Lift will extend the life of the bridge approximately 75 years and will reduce maintenance.”

Starting near the Dartmouth shore, the bridge deck panels were replaced on weekends in either 20- or 10-metre lengths. A lifting gantry was positioned on the suspender ropes and the existing panels were lowered to a barge in the harbour. The new panel would be lifted into position in the same manner. On the Halifax side, the panels were replaced over land because they were lifted by crane and moved by a self-propelled modular transporter provided by M&J Total Transport and Rigging Inc.

“This is only the second time the suspended span of a suspension bridge has been replaced while open to traffic during the day in the world,” Currie said.

The first time was the redecking of the Lions Gate Bridge in Vancouver in the late 1990s. Halifax Harbour Bridges has worked with the same bridge engineering firm from the Lions Gate redecking project — Buckland and Taylor. ABCC was the contractor for that project as well.

“The Macdonald is over 60 years of age and, while the bridge remained safe, the deck was wearing out and needed to be replaced. The Big Lift will extend the life of the bridge approximately 75 years and will reduce maintenance.”

— Allison Currie, community engagement officer, Halifax Harbour Bridges

On site work on the Macdonald bridge project began in mid-2015. In order to approach the work from the required angles, some of the work was accomplished by setting up a crane on a barge in the river below, said Fergal McKey, a field specialist with ABCC.

“RMI’s 70-ton Mantis was lashed down to the deck of the barge,” McKey said. “The

tracks were restrained from moving. Ballast was added to the tanks of the barge to counter the weight of the crane.”

The Grove RT 540 is the workhorse of the project — it has been in use since May 2015 and will continue until the end of the project. The two large crawler cranes were utilized from October 2016 to February 2017. Other cranes were used periodically as needed.

As of February 2017, all 46 segments of the bridge have been replaced. The remaining milestones left to complete for the Big Lift included finishing and reopening pedestrian and cycle lanes, replacing suspender ropes, finishing paving the Halifax side span, replacing expansion joints, and dehumidifying the main cables.

“RMI’s 70-ton Mantis was lashed down to the deck of the barge. The tracks were restrained from moving. Ballast was added to the tanks of the barge to counter the weight of the crane.”

— Fergal McKey, field specialist, American Bridge Company Canada

The main duties for the SL3800 included lifting heavy structural steel for construction of the expansion and also the installation of a new zero-discharge water-cooling system.

For most of the time, the SL3800 worked in fairly close proximity to a tower crane operated separately, so precautions were needed to avoid any mishaps.

“When we would swing in, we would let the tower crane operator know,” Adam says. “We were in constant communication so he wouldn’t swing into us, or vice-versa.”

It was like a wind tunnel

The biggest challenge, overall, was Alberta’s extreme weather.

“The plant is in a bowl in the surrounding mountains, which acts like a wind tunnel funnelling the wind,” Adam says. “We planned for the risk with a spare super-lift tray but we didn’t expect the winds to be so brutal. Gusts were in excess of hurricane forces, upwards of 110 kilometres per hour.”

A super-lift is a heavy lift attachment that can carry more counterweight, increasing the capacity of the crane.

Asked how such strong winds might affect crane operation, Adam was blunt. “Work is halted. We just don’t lift. Our crew gets the crane to the ground as safely and quickly as possible.”

While crews used wind measurement tools to evaluate conditions, Adam ran a wind finder app on his cellphone to track possible changes in real-time.

“We knew what was coming at us at all times,” Adam says, adding that winds were tricky and would seemingly come out of nowhere, funnelling through the mountains and gaining speed.

Ultimately, the winds impacted the job schedule, causing periodic shut-downs during the peak of construction, Adam says.

While Mammoet bid the job with only one super-lift tray, the company ended up supplying a spare to ensure a quick, agile response when needed.

“This eliminated us having to load up our tray with 150 tonnes each time we had to bring the boom down,” Adam says. “We could cut loose, get into our spare tray, and get the crane down to the ground promptly.”

Jackknife technique avoids gusts

Mammoet is no stranger to wind. The company has experience working on wind farms, and some of the same factors applied to the Exshaw job.

When winds became an issue, crews would jackknife the crawler and bring the jib to the ground to wait things out.

Jackknifing a crawler crane is a standard procedure in high winds. Mammoet says its wind protocol for crawler cranes is for the crawler boom or boom/jib combination to be laid down, or the crawler boom or boom/jib to be placed in a jackknife position, or other such special protective measures.

Adam describes one particularly blustery day where wind speeds exceeded 150 kilometres an hour. “We didn’t have room to lay the crane down (completely) flat, so we laid it down as flat as we could get it.”

Crews only boomed down that way one time. Adam says he received clearance from a Terex representative to do so and also immediately reported the manoeuvre to managers on-site.

“We have wind protocol for our cranes and they all have wind speed indicators fixed to the boom, but for this project it was important for me to be in regular contact with the crane’s manufacturer.”

The key to safety was keeping everyone fully informed. “It was a team effort,” Adam says. “In spite of the wind, we had zero lost-time incidents.”

Adam says he was ably assisted by multiple operators, including Garrett Brophy, Tyler Cottrell, and Ben Snodgrass — while Derek Bland, Dalton Moerike, Riley Novlan, and Len van Rossum provided rigging.

For all their ferocity, the gusts did have their silver lining.

“The wind was always at our back,” Adam says. “If it would have come from any other direction it would have been a nightmare.”

Nelson Manufacturing Company

6448 US Route 224

Ottawa, Ohio 45875

Phone: 419-523-5321

Email: sales@nelsontrailers.com www.nelsontrailers.com

Owner calls for government to help businesses to do more to hire refugees

MATT JONES

ohamad Chikh Neameh never believed that war could come to his native Syria.

“My country is beautiful,” said Chikh Neameh, who is now working for B.C. company and aspires to become a crane operator. “We had a community where everyone was like brother and sister. We loved each other there.”

After the Syrian Civil War did break out in 2011, Chikh Neameh had to flee with his wife and children from their home in Damascus.

“We lost very many people there,” he told Crane & Hoist Canada. “We lost friends. We lost neighbours. That’s why we came here.”

After he and his family spent three years in Jordan, the United Nations High Commission on Refugees offered them a chance to move to Canada.

“I said yes, because I heard Canada was very good and had very good people,” he said.

His first year in Canada was not without challenges. While he was struggling to find work, an apartment fire drove the family and nine other Syrian refugee families from their homes. In the media coverage of the fire, Chikh Neameh made an impassioned plea to the community.

“On the news, they asked me what do you want so people can help you, and I told, we don’t need help, we need work,” he said. “We are coming to here forgetting our lives after war. Give me a chance to begin my life here.”

Bill Dick, owner of Phoenix Truck & Crane, was watching and soon gave Chikh Neameh what he needed — a job, performing a variety of duties in the company’s warehouse. The only barrier truly holding Chikh Neameh back was the language.

“You can tell talking to Mohammed, there’s some language difficulties for our company,” said Dick, whose company is based in Coquitlam, B.C.

Chikh Neameh made an immediate impression on Dick, as did Betul Nebhen, another Syrian refugee whom Dick hired to perform administrative duties and clerical work.

“I’m very impressed with Mohammed, he’s a very nice man,” Dick said. “And Betul is adored by everybody in the community. A very, very strong individual.”

The feeling is mutual. “I am very happy to be working at Phoenix,” Chikh Neameh said. “Mr. Dick is like an angel.

“I am very happy to be working at Phoenix. Mr. Dick is like an angel. He gave me a chance to prove myself.”

— Mohamad Chikh Neameh, Phoenix Truck & Crane, Coquitlam, B.C.

He gave me a chance to prove myself.”

He hopes that other employers will also give Syrian refugees a chance. Back home, many Syrians had good jobs as professionals, however, their chances to find work in Canada are hampered by poor English skills.

Fortunately for him, Dick has been paying for him and Nebhen to attend English classes during company time.

“Mr. Dick offered for me to go to school for my English,” Chikh Neameh said. “My English is not bad. Not very good, but not very bad. But I am going to school and I’m better now.”

Chikh Neameh has since earned a forklift operator’s licence. When his English improves, his goal is to earn a crane operator’s licence and to operate one of the 50 hy-

draulic, all-terrain, folding and stiff boom cranes in Phoenix’s fleet. While the crane job may represent more security for his family, there’s something about the idea of performing big lifts that is very appealing to him.

“I heard a crane is a good job and it’s a lot of money,” he said. “But I love it. I want to learn it.”

Dick is thrilled to help Chikh Neameh with his professional development; however, he says that many other companies may not be able to help the same way Phoenix has.

Help business hire

“We’re very fortunate, we’re in a very secure position. We can afford to do this. We’re willing to fork out the money to help them out, but I don’t know how many companies are in the same position that Phoenix is in, to be able to add on that expense.”

— Bill Dick, Phoenix Truck & Crane, Coquitlam, B.C.

“We’re very fortunate, we’re in a very secure position. We can afford to do this,” Dick said. “We’re willing to fork out the money to help them out, but I don’t know how many companies are in the same position that Phoenix is in, to be able to add on that expense.”

Dick said he contacted the federal government when it was first announced that 25,000 Syrian refugees would be brought to Canada to see if there were any programs or plans that could help businesses hire refugees. He was disappointed with the results.

“Justin Trudeau went to the airport, welcomed the Syrians, gave them a voucher for one year of government assistance and then walked away,” Dick said. “Then the year is up and I’m seeing Mohamad on TV saying he doesn’t want to be on welfare. He wants to work. The government should have some kind of subsidies for businesses to hire the Syrians, but they had nothing there. Give businesses an incentive to hire them!”

from cover

big challenge to find a crane solution that would reach all points. That was definitely a joint effort with Pomerleau, Liebherr and Grues (J.M. Francoeur) combined. It took everybody combined to find a solution.”

Much prep work needed

Each company played a key role in the operation. Morrow and Liebherr supplied the big cranes whiles Grues J.M. Francoeur provided the mobile cranes and crew used to set up the larger ones and Pomerleau brought their expertise in planning and project management. And each needed to work in concert to keep this complicated project moving forward.

The installation of the Liebherr 630 EC-H required a great deal of prep work. First, a Grues J.M. Francoeur-owned Terex Demag CC2800 was employed with an 84-metre main boom and 96 metres of luffing jib. Due to space constraints, the CC2800 was erected and then walked across 6,000 tonnes of compacted soil into the proper position.

“We had pretty close to 300 crane mats to walk the crane from the erection to the installation,” said Pascal Francoeur, director of operations for Grues J.M. Francoeur.

The CC2800 then set to work building the Liebherr 630, an operation that also required special preparations. In order to reach all sides of the tower, the crane had to have its base set up inside the stadium itself. This required careful preparation, utilizing devices to maintain the fabric roof’s tension even after a section was cut out for the crane.

With the 630 EC-H constructed, the next step was the construction of the 710 HC-L. This required the use of a brand new Grues J.M. Francoeur-owned Liebherr LTM 1500-8.1 with 36 meters of main boom length and 56 meters of luffing jib length. The 710 HC-L was to be installed on the curved “spine” of the building, just

above the track for the exterior elevator. Building the crane and its base in that location made the LTM 1500-8.1 the ideal piece of the equipment to utilize.

“We had pretty close to 300 crane mats to walk the crane from the erection to the installation.”

— Pascal Francoeur, director of operations, Grues J.M. Francoeur

“We could get into that small space,” Forbes said of the 1500-8.1. “The advantages were the capacity required. It was a very long radius to erect the 710 HC-L. The HC-L is modular, and it worked perfectly to erect the crane in a small space and then to manage those capacities required to install the 710 HC-L.”

“It was easier to take this crane because of the ease of moving it around the job site,” Francoeur said. “It was easier to use, it’s more mobile and is more flexible.”

The 1500-8.1 will be used to take down the 710 HC-L upon completion of the project as well. Moving forward, maintenance on the project will be split between Morrow, Pomerleau and Grues J.M. Francoeur, along with daily maintenance performed by the crane operators. Such maintenance will be essential as the cranes will see a great deal of use over the next two years.

“We have a very demanding schedule with both cranes and we’re working with all three companies to ensure that they work flawlessly through the entire project,” Forbes noted.

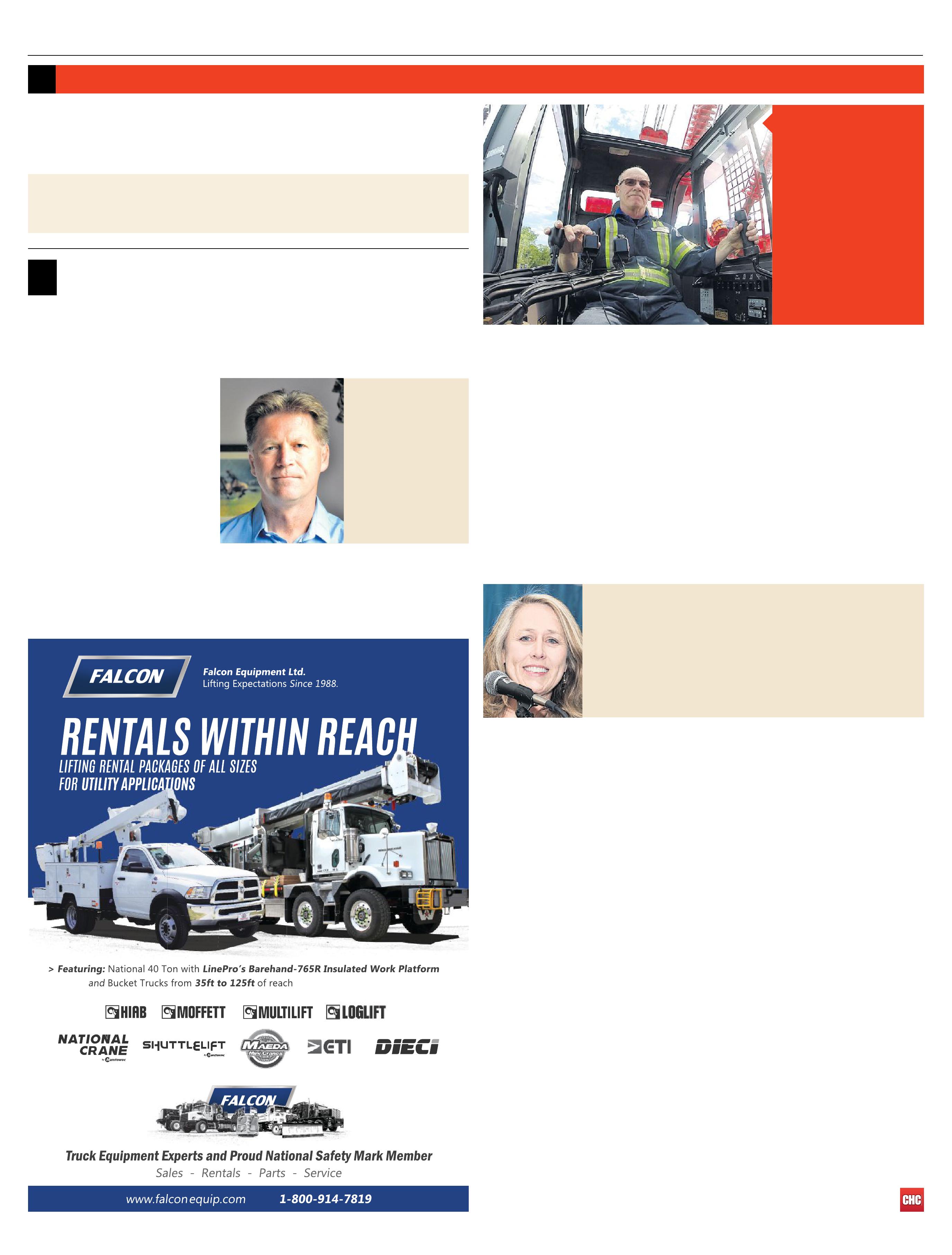

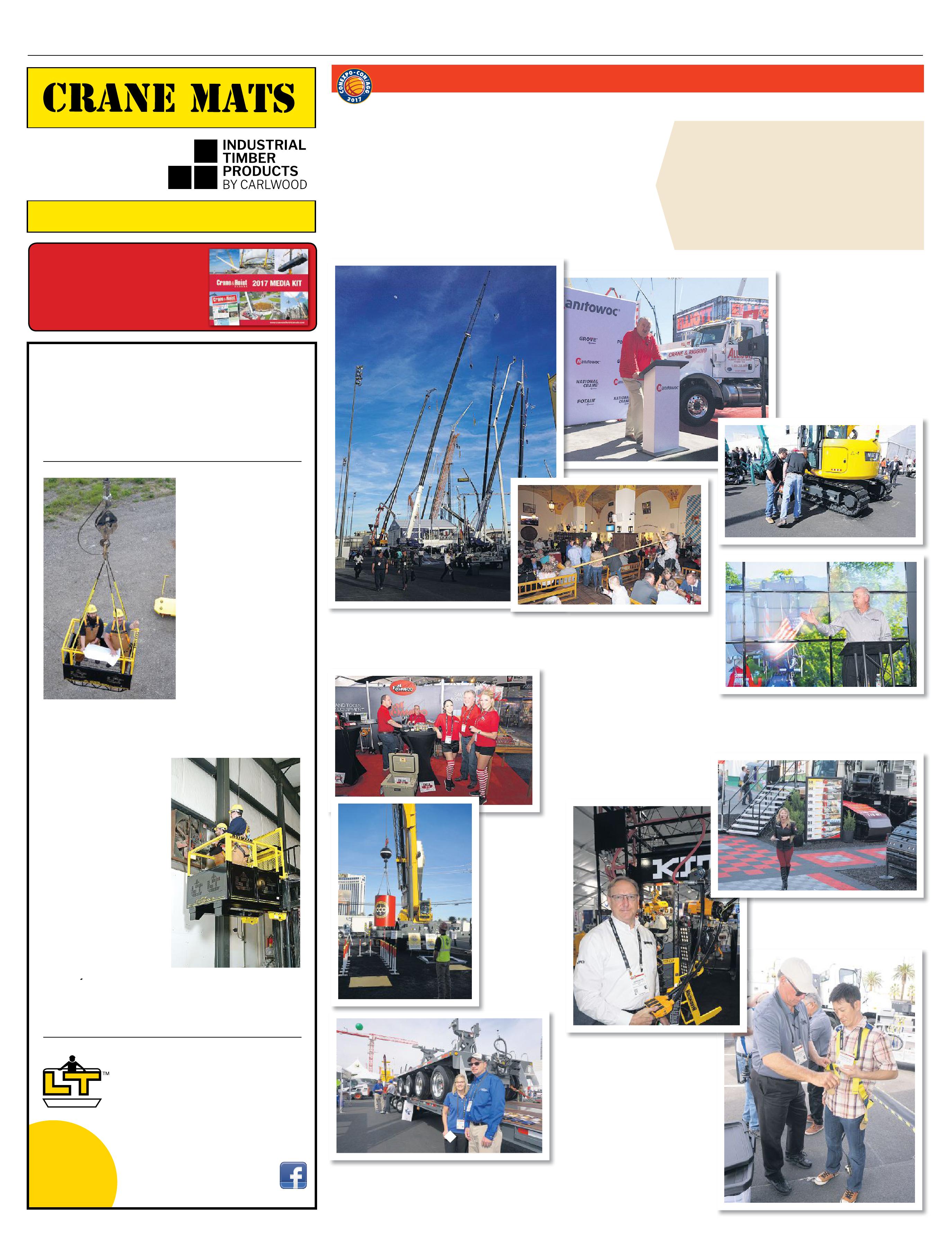

Canadians attending triennial ConExpo-Con/Agg construction equipment trade report that it’s as overwhelming as ever

BY KEITH NORBURY

anadian crane-industry enthusiasts flocked by the thousands to Las Vegas this March for the ginormous triennial ConExpo-Con/Agg heavy equipment trade show.

Despite the loonie fetching only around 75 U.S. cents in a tourism mecca where prices have spiralled upward in recent years, the consensus from Canadians was that

ConExpo 2017 was a great show.

Many of the Canadians whom Crane & Hoist Canada staffers encountered at the five-day event — held March 7-11 at the Las Vegas Convention Center — said the 2017 show seemed busier than during recent incarnations. However, that sentiment wasn’t universal.

“It’s been really great actually, a big improvement over the last show,” said Arnold Free, chief commercial officer for Montrealbased CM Labs Simulations, makers of the Vortex simulators for cranes and other heavy equipment. “We’ve seen a lot more traffic, a lot of really great interest in our products as well.”

2014 more upbeat, says Alberta exec

On the other hand, John Stevens, president and CEO of Alberta-based Entrec Corporation, said during a visit to the Crane & Hoist Canada booth in the Gold hall that the show was good and featured many new products but was not as busy as it was three years ago.

“Still lots of people but it was more upbeat and robust (in 2014),” Stevens said.

pre-engineered,

“You talk to some of the exhibitors, that is kind of their impression as well.”

The economy “was going hard and fast in 2014 before the downturn,” Stevens explained, noting that the price of oil dipped below $50 a barrel the previous day (March 8).

When oil sells above $50, Alberta’s oil patch can do OK, he said, although construction in the province is still “way behind” where it was before oil prices collapsed.

“But there’s other stuff going on,” Stevens said, pointing to power and infrastructure projects as well as Entrec’s business in the United States. Entrec has also hauled “quite a bit of yellow iron” into the Site C hydroelectric dam project in northeastern B.C. and is also bidding on some of the crane work that project will require.

“So yeah Site C will be a good project and we’ll get some work from it,” Stevens said.

“We were really surprised at just how many Canadians we’ve met that were interested in the Zero Emission product and it seemed like the majority of some of the days were Canadians.”

— Steve Kerby, Zero Emission Equipment, Fontana, Calif.

Stevens also noted that a Ritchie Bros. auction in Edmonton the week before ConExpo featured several cranes that fetched “really good” prices. They included a pair of 2015 Tadano GR10000XL 100-ton roughterrain cranes that sold for $775,000 and $710,000, according to auction results on the Ritchie Bros. website.

“So that’s a good sign to see that the prices are good,” Stevens said.

At ConExpo meanwhile, Stevens had a chance to check out some brand new machines that he deemed “pretty neat,” including a Tadano all-terrain crane and a 250-ton Link-Belt telescopic crawler.

First visit proves “amazing”

Also checking out the Tadano offerings was Tanis Loshney, owner of Canlift Crane Inc. of Grande Prairie, Alta. She and her team — husband Ashley Loshney, manager

Terry Kaiser, and his wife Tammy Kaiser — also looked at a new crawler at the Manitowoc booth. “And, of course, Liebherr. We’re a big Liebherr fan, so it’s nice to see them,” said Tanis Loshney, whose company has a fleet of six ATs, RTs, crawlers, and mobile cranes from Liebherr, Tadano, and Terex, as well as some rental machines.

It was her first visit to ConExpo although her husband has been before.

“It’s amazing,” she said. “I can’t believe how many people are here. I don’t think there’s anything missing, that’s for sure.” Even for someone who doesn’t work with cranes — like Tammy Kaiser — the experience was “phenomenal.”

“There’s so much to see. It’s very diverse. It’s a great experience,” Kaiser. “And it’s a little warmer here than it is at home right now.”

During ConExpo, Las Vegas temperatures reached 28 degrees Celsius at a time when in much of Canada temperatures still hovered around zero or below.

Total attendance for ConExpo and the co-located International Fluid Power Exposition was nearly 128,000 for the week, said a news release from the Association of Equipment Manufacturers, which organizes both shows. That was slightly less than the official count of 129,364 attendees in 2014, which was second only to the 144,600 who attended in 2008, just before the global financial crisis.

The AEM didn’t provide an estimate of how many Canadians were at ConExpo 2017. However, the association noted that nearly “26,000 international attendees from 150 countries braved global headwinds including a strong dollar and flagging export markets” to come to the show. The foreigners accounted for nearly 20 per cent of show attendees, down from a 24 per cent share in 2014.

On the other hand, attendance from U.S. buyers jumped over 16 per cent from 2014 with total buyer attendance increasing eight per cent, according to the AEM. Overall contractor and producer attendance was also up, by 10 per cent.

“I think there is a noticeable difference in the attendees at this show, and the difference is their optimism,” an AEM news release quoted Michael Haberman, president of Gradall Industries who chairs the AEM for 2017. “Optimism was on display throughout the show, and the traffic was excellent.”

ConExpo was definitely bigger than ever with a record 2,800-plus exhibitors and over 2.8 million square feet of exhibition space. That new space included the Gold hall where Crane & Hoist Canada had its booth.

“Even though ConExpo continues to increase in size, I was impressed this time with the way in which the different halls and lots were organized into areas of similar products making it easier for attendees to compare and contrast certain types of equipment without having to walk a mile to do so,” said Jeremy Thain, Crane & Hoist Canada’s advertising manager, who attended the show with editor Keith Norbury and art director James Lewis. “It was certainly well worth the trip for the Crane & Hoist Canada team and great fun catching up with readers and advertisers of our publication.”

Thain was also impressed by the number of Canadians at the show, which he estimated outnumbered the Canadian attendance three years previous. “I’m not sure if this was purely a result of Crane & Hoist Canada’s booth being located in a better position this time around,” Thain said.

continued from page 15

U.S. exhibitor notices Canadians too Steve Kerby, sales manager for Zero Emission Equipment, also noticed an influx of Canadians.

“We were interested in meeting some Canadian prospects for distribution,” said Kerby, whose Fontana, Calif.-based company manufactures electric-powered carrydeck cranes. “We were really surprised at just how many Canadians we’ve met that were interested in the Zero Emission product and it seemed like the majority of some of the days were Canadians. So that was really interesting.”

Oil, mining, and nuclear industries are among the industries showing the greatest interest in his firm’s products, Kerby said. However, the cranes are especially popular for indoor use.

“A lot more places are really restricting any kind of emissions indoors,” Kerby said. “Our units are all electric and zero emission. They’ll last a full shift on a single charge when you use them like you usually use a carrydeck.”

Maritimers offer their perspectives

While most of the Canadians at ConExpo 2017 appeared to have come from the western side of the country, a few did arrive from the east.

“There isn’t enough time to see everything, that’s for sure,” said Leo Lafferty, a crane operator based in Riverview, N.B., following a ConExpo educational session on telematics and cranes.

It was Lafferty’s third visit to ConExpo but the first time he had come with an interpreter, Ronald Bourque, a crane operator from Moncton, N.B.

“We spoke with a guy from North Africa yesterday and Ron could translate for me,” Lafferty said. “I only speak English and he can speak English and French.”

It was the first time at ConExpo for Bourque, who commutes from New Brunswick to work for Mammoet at a gas plant in Fort McMurray, where he runs a 100-ton RT.

“There’s a lot of stuff to see,” Bourque said.

Show amazes Quebec exhibitor

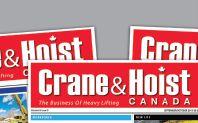

Also coming from the east was Manon Huard, OEM sales manager for Quebec City-based Rayco-Wylie Systems, a manufacturer of crane monitoring equipment.

“The show has been very amazing since the beginning,” Huard said at the company’s booth. “First day started a little slow but, you know, visitors were increasing every day. Yesterday (Thursday) was the best day. This morning is a little bit quieter but it’s Friday and it’s normal.”

Rayco-Wylie made good use of a smartphone app to scan badges by the hundreds of visitors to the booth, which she said produced a lot of good leads.

“So we’re going to have a lot of work to do when we get back,” Huard said.

One drawback was that the company’s booth was tucked behind the wall of one of the big crane stands — not the most optimal location.

“But yeah, we’re happy,” Huard said. “The weather has been great. It’s hot but I’m not complaining.”

“I think the attendance is good. I think the number of exhibitors is right.”

— Gerry Weibe, Bigfoot Crane Company Inc., Abbotsford

Gathering at the Gold lot both shared by Penticton, B.C.-based Brutus Truck Bodies and Italy-based Next Hydraulics are Gerry Turchak, president of Brutus Truck Bodies; Olgher Reverberi, president of Next Hydraulics and Maxilift Cranes USA; Chuck Davis of Davis Transport Excavations of Anchorage, Alaska; and Matt Godard, from Ponsse North America of

“Even though ConExpo continues to increase in size, I was impressed this time with the way in which the different halls and lots were organized into areas of similar products making it easier for attendees to compare and contrast certain types of equipment without having to walk a mile to do so.”

— Jeremy Thain, advertising manager, Crane & Hoist Canada

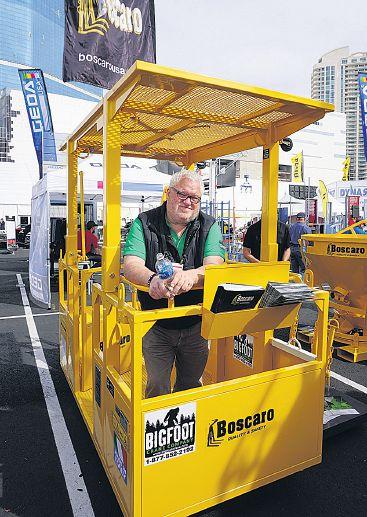

Size is right but tweaking needed

At the booth of Abbotsford, B.C.-based Bigfoot Crane Company Inc., Gerry Wiebe said, “I think the attendance is good. I think the number of exhibitors is right.”

However, he said organizers could take a few steps to make the show even better.

“You’ve got this many people and there’s no wi-fi and in today’s world that’s a pretty big deal,” said Wiebe, who is Bigfoot’s director of business development. “I hear people say don’t drink too much water because there’s no bathrooms. At least out here in the Gold wing, the human facilities are pretty light. Food’s hard to find.”

“So there’s some small things that need to get tweaked out,” added Wiebe, who was attending his fourth ConExpo. “But having said that, I know exactly what I’ll be doing the next time I come to the show is filling some of those needs ourselves so it’ll attract more people to the booth.”

By that time, Bigfoot will have long finished the engineering on its 6500 model derrick crane, which was expected to go into production later this spring. At this ConExpo, Bigfoot was promoting its line of underhook crane accessories from Boscaro, an Italian manufacturer. They included a multi-discharge concrete bucket and a three-in-one style manbasket.

“What’s different about our equipment is we’re really a crane company first,” Wiebe said. “So we’re fixated on where’s the value proposition in this equipment.”

Crosby’s indoor booth was a little busier than the outdoor booth in the Gold lot but Stickel and his colleagues were still introducing visitors to some new products, such as Crosby’s Shurloc-hook with handle, Easy-Loc V2 bolt securement system, and Slide-Loc 150 lifting point.

A chance to put faces to voices At the booth of Edmonton-based Cranesmart Systems, which manufacturers load moment indicators and other crane safety equipment, sales consultant Justin Evans said he has had a busy show.

“My favourite thing to do at this show is to meet people that you talk to over the phone with on a consistent basis,” Evans said. “You meet them in person and get to a put a face to the voice.”

Among the customers he met at this show was Greg Gilchrist of G2 Erectors, a Michigan company with a fleet of 35 cranes that has Cranesmart equipment on some of them. But what about President Trump’s pleas to buy American?

“It doesn’t matter,” Gilchrist said. “It’s what works. Like I said, service for us is everything.”

For Evans, who sits in an office all day and talks on the phone to people around the world about cranes, “it’s nice to actually be in a parking lot full of cranes.”

Seeing ConExpo is believing

Attending ConExpo for the first time was Brian Alexander, assistant director of training and apprenticeship with the Operating Engineers Training Institute of Ontario.

“It’s absolutely massive, just unbelievable. You really can’t appreciate the size and scale of it until you’re here,” said Alexander, who has been a licensed mobile crane operator for over two decades.

“I’d always heard about it, just never had the chance to be here,” he added.

More positive mood noted

Gerry Turchak, president of Penticton, B.C.-based Brutus Truck Bodies and NorMar Cranes, said the mood at this ConExpo was more positive than the last time around. He attributed that to the recent of change of government in the U.S., “whether good or bad.”

Much of the mood change is psychological, he said. “Somebody thinks things are better, they’re probably going to get better,” Turchak said. “You want to come here depressed, you can stay depressed quite easily.”

He has also noticed an attitude change in Canada as well. When oil prices dipped, his business slowed down considerably.

“Now the optimism is coming back. We’re getting busier and hiring,” said Turchak, who has been coming to ConExpo for two decades.

Transportation proves challenging

At one of the Crosby Group’s two booths, Trevor Stickel, Edmonton-based territory manager for western Canada, said this year’s version was the busiest of the four ConExpos he has attended.

“I don’t know if it’s been busier or the transportation’s been tougher,” he said, noting the long lines for cabs, Ubers, and the Las Vegas monorail on the first days of the show.

The OETIO shared a booth with CM Labs, primarily to help the latter promote its simulator systems.

“We’ve got a good rapport with them,” Alexander said. “They do good stuff.”

“One of our best shows”

Arnold Free of CM Labs, who was attending his third or fourth ConExpo, said there’s been a big uptick in business in the last three to five years. He attributed that to ongoing shortages of skilled workers as well as heightened interest in operator training and with introducing more young people into trades like crane operation.

His company brought about a dozen people to ConExpo, who also took time to check out their competitors.

“There’s a lot more simulators this year which I think goes back to that point of looking at the interest in simulation in this industry as a training solution,” Free said.

For CM Labs, ConExpo is “one of our best shows,” he said. It even produces immediate results, such selling demo units right off the show floor, although the company sends the units back to Montreal to make sure they’re in good shape before shipping to the customer.

“We don’t tend to sign contracts but soon afterwards we will,” Free said. “But for sure this show is generating good revenue for our business.”

Bright spots noted — such as big projects in Montreal and B.C. — but slumping oil and gas prices make predictions difficult, say industry execs

Apair of major Canadian projects involving Liebherr cranes were singled out during the Switzerlandbased manufacturer’s press conference that kicked off ConExpo-Con/Agg 2017.

During his presentation, Daniel Pitzer, managing director of Liebherr USA, noted the work of Liebherr cranes on renovations to the tower of Montreal’s Olympic Stadium, and on the Betomix DW 4.5 mixing plant at Fort St. John, B.C., part of the Site C dam project.

A 710 HC-L luffing jib crane, “the largest of its kind on the Liebherr portfolio,” is working with a 630 EC-H tower crane on the Olympic stadium tower, “one of Canada’s most recognized buildings,” Pitzer said during the March 7 press conference at the Liebherr stand on the Gold lot at the Las Vegas Convention Center.

Pitzer also invited attendees to check out a virtual reality simulation of a 710 HC-L at the Liebherr stand.

A few minutes later, Pitzer noted that Liebherr is “proud to participate in North America’s largest production site” — the mixing plant at Fort St. John.

“This is how we like to see a job site picture actually,” he said, referring to a slide in his presentation. “Mixing plants in the front, a mobile crane in the background, and many Liebherr designed components used inside.”

Liebherr USA has about 450 employees while the company employs 320 to 350 in Canada.

Asked about the outlook for the company’s Canadian business, given the worldwide slump in oil prices, Liebherr director Stefan Heisler said that commodity prices seemed to be increasing and that “obviously mining will be back.” However, he

Ontario-based Cropac Equipment celebrated its purchase of a new Potain tower crane during a ceremony at ConExpo-Con/Agg iin Las Vegas this March.

The celebration, which featured a champagne toast, took place at the Manitowoc booth at the triennial heavy equipment trade fair.

The six-tonne self-erecting Igo T 85 A crane “features a slewing mechanism that helps operators improve accuracy,” noted a news release from Manitowoc.

The crane also has a variable height telescoping lattice mast that can be adjusted from 20 to 23 metres.

Based in Oakville, Ont., Cropac also has locations in Nusku, Alta., and Laval, Que. The company’s equipment has been used in such industries as forestry, steel processing, marina storage, transportation, and movement of heavy materials since 1977, the release noted.

Vegas this March.

concluded by saying, “We believe it’s very difficult to predict exactly which direction it (the economy) is going.”

Pitzer added, in answer to another question, that “the main challenge here in North America, that includes Canada, is really for mobile cranes to get them road legal. Whereas in Europe it’s easier because the axle weights are much higher, over here every state almost is different.”

Canadian market “mixed bag”

The next day at rival Terex Corporation’s ConExpo press conference, Terex president and CEO John Garrison was asked about the crane sales outlook for Canada given the state of the energy industry but also the recent approval of major pipeline projects.

“The good news is there has been a change in the southern side of your border and so some of those pipelines projects may be going forward,” Garrison said.

He then turned the question over to Steve Filipov, president of Terex Cranes.

“I was actually just up in Edmonton

not to long ago talking to customers and obviously that area Edmonton and north of there is pretty difficult right now,” Filipov said. “So a lot of our customers are moving fleets of cranes down south where there’s more work. Speaking to another customer around Montreal, actually business is not so bad. And then to your point on the pipeline projects, I think there’s opportunity there.”

Overall, Filipov said, the Canadian market is a “mixed bag” with oil and gas depleted and equipment moving out, but with “other pockets of opportunity.”

North America as a whole is a “tougher market,” Filipov said. A lot of equipment is idle in the southern U.S., particularly for mobile cranes on oil and gas projects. However, the tower crane segment is a bright spot, such as on larger projects on the east coast.

“Not a lot of growth in North America over the last couple of years but I do think that we’ve kind of seen the bottom of the market in North America,” Filopov said.

Cranes dominated the skyline of the Gold lot once again at the ConExpo-Con/Agg heavy equipment trade show in Las Vegas this March. Scenes captured on this page give a sense of just some of the crane-related activity associated with the triennial event, which featured more than 2,800 exhibitors and nearly 128,000 attendees.

an

during a Link-Belt hospitality event at the Las Vegas version of Munich Germany’s famed Hofbräuhaus.

Alison Scheel and Elda Lee flank Pudge Mulloy at the F&M Mafco booth at ConExpo 2017 while Randy Gerken and Larry Kelfhoffer look on in amusement. The Cincinnatibased equipment rental firm still has a property in Alberta but has suspended those operations during the oil price slump.

practical exam for mobile crane operators in the Gold lot of ConExpo.

Meyer of

Greg DeJonghe, of Time Manufacturing Company of Waco, Texas, helps into a harness Hironari Miyake of SK Lease Co. Ltd. of Sapporo, Japan, before the latter ascends 225 feet in a Versalift aerial work platform for a panoramic view of the ConExpo site.

very three years, crane industry snow birds from Canada head south to Las Vegas for the continent’s largest trade show of heavy equipment — ConExpo-Con/Agg. This March was no different.

While the Association of Equipment Manufacturers, which organizes the event, didn’t provide a breakdown of attendees by country, the AEM estimated that nearly 20 per cent of the show’s nearly 128,000 visitors came from outside the U.S.

An educated guess would be that half of those foreign ConExpo visitors came from the Great White North. Quite a few of them dropped by Crane & Hoist Canada’s booth in ConExpo’s Gold hall of the Las Vegas Convention Center.

Photos of some of those fortunate Canucks, and of others we met during the show, appear on this page.

AND

BY SAUL CHERNOS

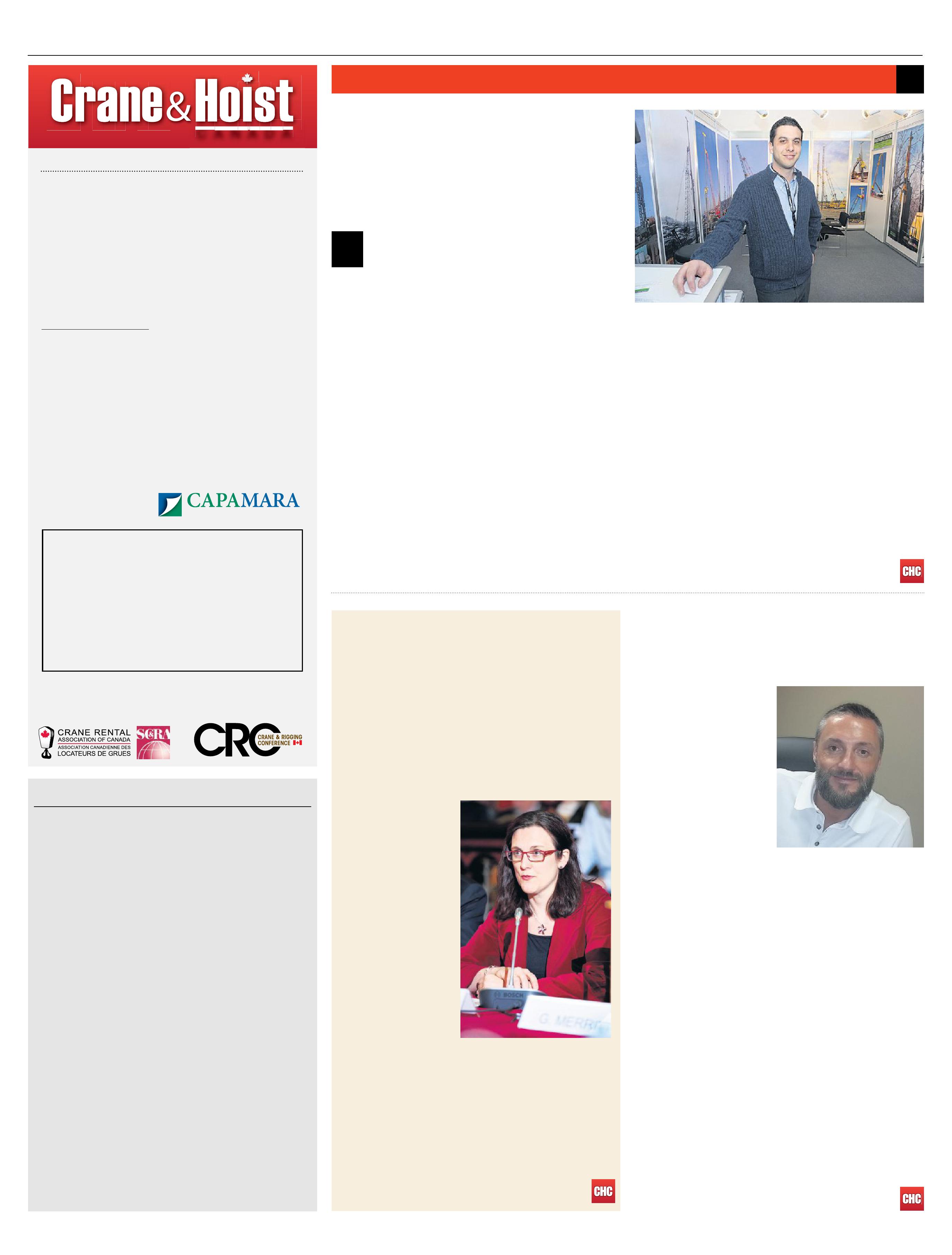

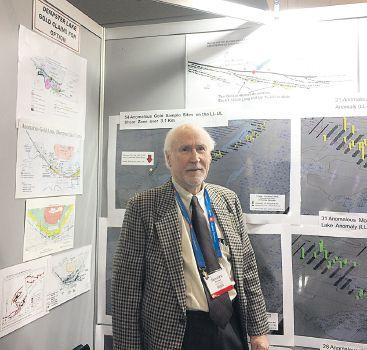

an Simmons, a base manager with Heli Explore Inc., had good reason to smile as he staffed the Quebecheadquartered company’s booth at the 2017 convention of the Prospectors and Developers Association of Canada this March in Toronto.

Thanks to depressed commodity prices and economic and political uncertainty, prospectors and mine developers have found themselves between a rock and a hard place. However, a sense of optimism prevailed at the Metro Toronto Convention Centre, with talk of a slow, gradual recovery.

The annual event attracts thousands of prospectors, developers, mining companies, financiers, analysts and politicians from across Canada and around the world. Technical and business workshops, swanky cocktail receptions and dinners, and an expansive trade floor multiple football fields in size were ripe for networking and speculation about the next big opportunity.

“The last few years have been fairly slow as far as exploration goes,” Simmons told Crane & Hoist Canada

Heli Explore — which has its main base in La Sarre, Que. — supplies helicopter services to an array of sectors across Canada, from forest firefighting to hydroelectric facilities, lifting everything from people to heavy machinery. Helicopters can generally carry up to 2,000 pounds at a time, so for miners and prospectors a 20,000-pound drill rig might be disassembled into 10 loads for transport from an air strip or roadway to an exploration site.

When slow, choppers first to go

Simmons — who manages the company’s secondary base in Sudbury, Ont. — said he’s witnessed the slowdown firsthand.

“If the economy is low, the first thing to go usually is helicopters,” Simmons said. “Helicopters are expensive to operate, and as far as exploration goes helicopter time will probably chew up most of your budget.”

Still, Simmons concurred with the convention’s sense of cautious optimism that markets seem to be recovering.

“It hasn’t been a major jump, but people are starting to invest more into exploration again, which brings the business back for us again,” he said.

Martin Turenne, president of First Point Minerals in Vancouver, expressed hope for his company’s flagship Decar nickel project in central B.C. “We think it’s one of the very few advanced-stage nickel assets that has the potential to go into production in the next up-cycle for the nickel market,” Turenne said.

Asked when this next up-cycle might get underway, Turenne hesitated to venture a prognosis. “That’s crystal ball stuff. At some point in the next several years the nickel price has to go up. The spot price is well below the average cost of production in the industry right now, and the fundamentals are lining up well from a supplydemand balance standpoint that’s going to be positive for the nickel price. But at what rate the nickel price goes up and when that happens — we can’t say.”

Mining action small scale for now

First Point Minerals accesses its Decar site via logging roads, so it’s not a potential helicopter user. And, while cranes are common in the construction and operation of mines, Turenne doesn’t anticipate any action until at least the early 2020s.

“Right now it’s all pretty small scale stuff, pickup trucks and the like,” Turenne said. The company doesn’t even own exploratory drills — it farms this out to specialist contractors. “When we need trucks or equipment we obtain it on a lease or rental basis.”

On the east coast, Toronto-based Anaconda Mining operates open-pit gold mines in Baie Verte and Pine Cove, Nfld., and earlier this year acquired an exploration site located on an old gold producing property in Goldboro, N.S.

“It was discovered in late 1800s and has undergone a couple production exercises,” Anaconda vice-president Allan Cramm said, expressing optimism for gold markets.

“We’ve gone through some record gold prices but it’s been sitting idle. We see an opportunity to apply some of the experience that we have in open-pit and underground mining to make it successful.”

Grove on job in Newfoundland

Anaconda’s Newfoundland operations perhaps typify the modest-size mine’s use of heavy equipment. The largest crane on-site, a Grove rough-terrain of about 80 tons, is used to move materials and components around as needed.

“We’ve also used standard 25-ton truckmounted cranes for routine maintenance, changing out small components, putting in

overhead pipes and general maintenance,” Cramm said.

Like many “junior” miners, however, Anaconda retains outside contractors to supply heavy machinery. “In our case it’s a better utilization of capital,” Cramm said, explaining a desire to avoid risks that come with ownership. “The contractor uses equipment that can be used in the construction industry, so when projects are finished the equipment can find a new life in construction,” he explained.

Ken Lapierre, president of Torontobased Rockcliff Copper, said success with exploration activities near Snow Lake, Man., improved last year. But he acknowledged things remain tough for juniors.

“I remember 2007-2008 before the collapse — these were great times,” Lapierre said. “Right now, the economy could be better. But the base metals are starting to turn around. There’s more money on the

“Mr. Trump’s doing a wonderful job. Every time he lies he creates uncertainty, and he lies at least once a day. And this means that gold will go up incrementally with time.”

street for good properties. People are a lot more upbeat.”

Rockcliff Copper also contracts for heavy equipment. “I don’t like the overhead on it, so I hire them to do the work,” Lapierre explained.

Ring of Fire still simmering

Northwestern Ontario’s Ring of Fire, an exploration zone touted as Canada’s biggest up-and-coming mining hot-spot, is very much the proverbial canary in the coal mine for assessing prospects.

The kettle’s been simmering for more than a decade, never quite coming to a boil as governments, First Nations and com-

panies with stakes in the area grapple with land rights and a complete lack of transportation, electrical and telecommunications infrastructure.

Noront Resources and KWG Resources have stayed the course, exploring for chromium, nickel, copper and other mineralized rock in anticipation that the hurdles will soon be overcome. However, other smaller players have departed, with investors wanting more immediate riches.

Construction of regional infrastructure, as well as crushers, mills and other mine facilities, would create considerable demand for heavy equipment. But, John Mason, mining services project manager with the Thunder Bay Community Economic Development Commission, said it’s a waiting game for now.

“We’ve gone 10 years and time keeps ticking,” Mason said. “I’m an optimist, but risk capital doesn’t hang around forever. Quite often there’s a shelf life to these projects in terms of the willingness to develop.”

Far North holds promise

The far north is perhaps Canada’s most fertile ground for exploration and mining. With four properties in the Yukon’s Dawson Range, Vancouver-based Trifecta Gold is positioning itself as proximate to the country’s most legendary success stories.

“The majors are interested in this area, and we want to make a big discovery and get it to a point where one of them buys it,” said Trifecta president and CEO Dylan Wallinger.

Wallinger and Trifecta have sought to establish strong relationships with First Nations and other stakeholders. He’s also paid attention to the equipment his sector relies upon to get work done. “Two of our projects are road-accessible, but two others are fly-in, only,” he said, detailing the use of helicopters to move heavy drills distances of up to 40 kilometres.

“We work with a couple different companies,” Wallinger said. “They’re busy in the summer, for sure, but they’ve been up there for a long time and it seems like they’re just chugging along.”

This year’s convention came at perhaps a propitious time for a sector with a reputation for brash, wild-west craziness.

Trumpisms bolster gold prospects

“Mr. Trump’s doing a wonderful job,” declared Ottawa-based prospector and geologist Donald Brown. “Every time he lies he creates uncertainty, and he lies at least once a day. And this means that gold will go up incrementally with time.”

Brown, 82 and a perennial at PDAC, was hoping to persuade investors to buy into properties he holds in northwestern Ontario.

“I did some deals five or six years ago but the last few years have been an absolute drought,” Brown said. “But I’m hearing that it’s starting to ease up, that the juniors are starting to raise money. In Val d’Or (Quebec) you can’t find a driller. They’re all busy.”

Timmins, Ont.-based Kerr Crane Services has added a new Demag AC 250-6 all-terrain crane to the company fleet.

The compact six-axle AC 250-6, which has 262 feet of main boom, will give Kerr “better maneuverability in confined working areas and easy overthe-road transportation,” said a news release from Terex Cranes, manufacturer of the Demag brand.

The new crane joins Kerr’s “extensive fleet” of 28-ton to 400-ton capacity mobile cranes, the release noted.

“We wanted a crane that could handle a variety of demanding lifts, was easy to transport between jobs and didn’t require a lot of setup time,” the release quoted Logan Kerr, vice-president of the company. “The Demag AC 250-6 all terrain gives us the biggest bang for the buck. The crane sets up quickly, has user-friendly controls with a simple operation control system, and is cost effective to transport. We save on labour costs, which makes our company a better business partner on future projects.”

Kerr ordered the new unit from Cropac Equipment, a Terex distributor based in Oakville, Ont. “Cropac always makes things easy for the customer,” Kerr said.