For more than 140 years, professional bakers have trusted Fleischmann’s Yeast to “rise to the occasion” in their bread, rolls, buns, donuts, and pizza formulations.

Backed by the global expertise and resources of AB Mauri—a world leader in yeast and bakery ingredients—Fleischmann’s Yeast is committed to offering the world’s best fresh and dry yeast ingredients—and extending its record of service in providing superior technical expertise and service support to the Canadian baking industry.

Optimize your formulations. Ask your AB Mauri representative or distributor for Fleischmann’s Yeast.

GFSI (SQF ) Certified Production Facilities Montreal, Quebec · Calgary, Alberta

Alan Dumonceaux’s search for better croissant techniques yielded a wealth of tips for your bakery.

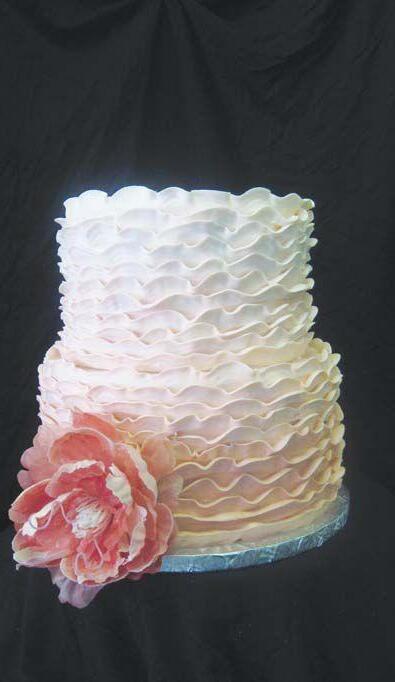

This example of the elegant, hushed simplicity this year’s brides and grooms seem to favour is courtesy of Brenda Walker at Cakeworks. For more on what wedding cake makers are creating this year, see full story on page 10.

The

This

BY LAURA AIKEN

The general public is proving a cynical lot that doesn’t trust what’s put on their plate from Big Food. It’s not surprising there is mistrust. The commercial food industries, and particular ingredients such as wheat, have been crucified in popular culture. But why has it been so easy for consumers to trust nutritional arguments made in books by doctors, authors who by standard training really have very little nutritional background?

For one thing, they do not perceive the author to be having backroom handshakes with industry. That alone may be enough to cause a failure in critical reading. At the Baking Association of Canada’s (BAC) recent myth-busting seminar, an audience member commented on the fact that two large commercial bakeries were funding the Healthy Grains Institute; this would cause cynicism and why shouldn’t it? In the U.K., experts who advise the government on sugar intake came under fire recently after it was revealed they received research funding that included money from large confectionary companies. There are many systems around research that invite criticism – from competitive peer-review processes to activist organizations leading the agenda – but none seems to offend as much as the thought that a researcher and its subject may somehow be in cahoots.

If only all the funds could come from sources with no conflict of interest in the results. In 2004, industry represented a 27 per cent share in health research expenditures by source of funding in Canada (Statistics Canada). Private funding seems a significant and essential source of financial support.

}Perhaps it is the scientist who should be the next rock star. Perhaps it is the scientist whose motivations and credibility need to be better communicated.

I hope a scientist would not fudge results for a conclusion that favours a financial backer. Scientists are bound by a professional code of integrity and have reputations to consider. There will always be rogue members of the profession. No industry escapes its bad apples, and there are also peer review and academic institution ethics to be accountable to. But sometimes industries need to help get research underway. A lot of people have a stake in finding out the truth about wheat, and as Paul Hetherington, president and CEO of the BAC, said in his closing remarks on the topic of industry partnering with the Healthy Grains Institute: “If we don’t do it, who will?”

To which, it would be easy to respond that the scientists have been bought, so how can any research be accepted as well founded? Industry funded research should be scrutinized but not disregarded as without merit. Publication in a peer-reviewed journal is a big confidence booster. So is transparency. If where the money is coming from is out in the open, then it is certainly easier to place trust than if sources of funding are later exposed. Perhaps even more beneficial would be more public education on the scientific research process. In the Canadian Journal of Infectious Diseases, Dr. R. Saginur wrote of the public cynicism in medicine, “The border between the medical lobby and the pharmaceutical lobby is obscure to the public, and there is neither knowledge of, nor interest in, ethical guidelines of professional and industry associations…We live increasingly in a participatory democracy. The cynicism of which I spoke is directed against closed door dealings, of what are perceived to be self-serving groups in positions of power.”

If it is true that the public has no interest in the ethical guidelines, then education will need to reach the public in a way that resonates. In the food industry, farmers have been looked to as the next heroes to capture the public imagination. The farmer is the next rock star, I once heard celebrity chef Michael Smith say. Perhaps it is the scientist who should be the next rock star. Perhaps it is the scientist whose motivations and credibility need to be better communicated. Popularizing science is a perennial challenge, but we all have a stake in gaining a better understanding. / BJ

MARCH | VOL. 74, NO. 2

EDITOR | Laura Aiken editor@bakersjournal.com 416-522-1595 1-888-599-2228 ext. 250

ASSISTANT EDITOR | Karly O’Brien kobrien@annexweb.com 905-713-4358

TECHNICAL EDITOR | John McColl, Puratos Canada jmccoll@puratos.com

NATIONAL ADVERTISING MANAGER | Stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

ACCOUNT CO-ORDINATOR | Shannon Drumm sdrumm@annexweb.com 519-429-5176 1-888-599-2228 ext. 219

MEDIA DESIGNER | Brooke Shaw

GROUP PUBLISHER | Martin McAnulty mmcanulty@annexweb.com

PRESIDENT | Mike Fredericks mfredericks@annexweb.com

Mailing Address P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

PUBLICATION MAIL AGREEMENT NO. 40065710. RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5 e-mail: subscribe@bakersjournal.com

ISSN 0005-4097

Published ten times per year (Jan/Feb, Mar, Apr, May, Jun, Jul, Aug/Sept, Oct, Nov, Dec) by Annex Publishing & Printing Inc.

SUBSCRIPTION RATES Canada — 1 Year $ 30.00 (with GST $31.50 #867172652RT0001, with HST/ QST $33.90)

USA — 1 Year $ 45.00 USD Best pricing is available online at www.bakersjournal.com

Send your subscription request to: Bakers Journal

P.O. Box 530, Simcoe, ON N3Y 4N5 Tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940

E-mail: subscribe@bakersjournal.com

Occasionally, Bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2014 Annex Publishing & Printing Inc. All rights reserved. Printed in Canada.

Easy in and out from either side. If you’re installing custom cabinets for urbanites, you can spend less time in the van getting your tools and supplies and more time using them. You always have a door on the side with the best access to your job site too.

out custom cabinets s for ur u banites, can spend less your them. You have a door on the side with

Our latest addition to the available EcoBoost line of proven engines features an impressive 178 horsepower* and great fuel economy.** If you have a shuttle full of travellers with ights to catch, you can whisk them to their terminals reliably and economically.

to line of features an impressive 178 horsepower economy y have a e l r catch,you n whhisk them to their terminalls s reeliably y and economically

Got a load of heirloom tomatoes to deliver?

competitor. That translates 120 more tomatoes trip payl of 1 ,710 lb, those

The Transit Connect van can hold 8 more cubic feet of them than its closest competitor.‡ That translates into roughly 120 more tomatoes per trip. And with a best-in-class maximum payload rating of 1,710 lb,† those tomatoes can be really heavy.

the

s

r witith h c carggo s spac ac e that’s easily cus stoomized to suiuit t your neeeds s and n pre r fere r nces, whetheer r yoou’re re a mu m siician n instrummennts and p or a fishhin i g gu g ide wi w th annd tacackkle.

Outside, it’s easy to wrap the Transit Connect any way you like to create your very own sleek, modern mobile business card. Inside, you can have your choice of the wagon, with the most exible seating in its class.^ Or choose the van, with cargo space that’s easily customized to suit your unique needs and preferences, whether you’re a musician with instruments and amps or a fishing guide with anglers and tackle.

O MA M TH : t wo

SO DO THE MATH: No two businesses are exactly alike, but the new Transit Connect adds up for all of them with best-in-class horsepower* with the available 1.6L EcoBoost engine and the most con gurations in its class ^ / in a compact, nimble package. Throw in reliability that’s earned the Built Ford Tough® badge, and you’ve found the van with all the answers.

Connect adds up for all of them with best-in-class horsepower available 1.6L EcoBoost and in its clas s in a compact, nimble Built Ford Tough foundthevanwithalltheanswers

EARLY 2014

briefly | DDW has purchased Danicso USA’s food colourings; A new survey indicates that Quebecers want the agri-food industry to make eating healthy easier | for more news in the baking world, check out our website, www.bakersjournal.com

A new CROP survey suggests that Quebecers want the agri-food industry to help make it easier to eat healthy.

Roughly six out of 10 of those surveyed said they are making efforts to limit their intake of ingredients such as fat, sugar and salt.

Some of the obstacles that the Quebec residents polled said they currently face are a lack of will, diligence and the time needed to cook meals. According to the CROP survey, which was carried out for Melior, 95 per cent of Quebecer residents recognize that it’s important to eat well even when they lack the diligence to do so.

Those surveyed self-reported that they reward themselves with small snacks (cookies, chips, chocolate) almost every day of the week. CROP is a marketing and research company. Melior is a program of voluntary commitment that helps agri-food industry businesses increase the nutritional value of their products.

The survey indicates Quebecers are looking to be better informed, with

DDW has purchased Danisco USA’s food colouring product line and related processing equipment from DuPont.

Danisco has been a part of DuPont Nutrition & Health since 2011. The financial terms of the transaction were not disclosed. The Danisco food colouring product line consists primarily of various carotenoid colourings and blends offered as food industry solutions in the yellow to orange spectrum. They are supplied to the dairy, dessert, bakery/snack, culinary, flavour, beverage and other industry sectors.

The equipment and inventory will transfer from the DuPont plant in Madison, Wis., to DDW’s GFSI-certified operation in Port Washington, Wis., to supply domestic and export customers.

three-quarters of consumers polled saying they read the ingredient and nutritional labels of the foods they purchase and consume.

“A growing number of Quebecers want to better manage their lives. Eating better helps them feel that they are in control of their health,” said Youri Rivest, CROP vice-president, in a media release.

The survey indicated that 86 per cent of respondents believe the industry is responsible for providing them with healthy choices that help improve their health, such as products with reduced salt, fat and sugar.

Additionally, the survey found that 53 per cent of respondents find it difficult to reduce food portions. Nearly six out of 10 Quebecers polled want their favourite chocolate bar available in a smaller size. Of these, 55 per cent are even willing to pay proportionally more for a smaller size.

Ninety per cent of those surveyed said they want to know if a product has been improved in order to make a conscious

decision for their health. Nearly threequarters (74 per cent) of respondents said they would reward companies that improve their existing products with greater brand loyalty.

“The survey results are very clear. People want to eat better, but they also need the support of the food industry,” says Annick Van Campenhout, CEO of the Council for Food Progress Initiatives (CFPI), the body that governs Melior, in a media statement.

Seventy-five per cent of the Canadian workforce will be made up of millennials in 2028; a generation driven less by financial success and more by securing flexible and fulfilling careers, indicated the Canadian Youth Business Foundation (CYBF).

The organization said that millennials are eager to turn their passions into reality and twice as likely to open a small business. As a result of these indicative findings, CYBF has launched the Owners Wanted initiative to help potential owners get their business started.

“A large number of the businesses opened in Canada are by a younger demographic and this is only expected to grow as the millennial generation takes a dominant place in the workforce. This is a new generation of small business owners who want something that is more than

just a job. They want to do something that is personal and matters to them, and they’re not afraid to take that leap,” said Julia Deans, CEO of CYBF, in a prepared statement. “Lots of Canadians have business ideas, but may let their nerves and fears stop them from taking the first step, which is exactly why the Owners Wanted campaign was created.”

Pre-launch coaching, mentoring, business resources and low-interest financing of up to $45,000 are some services that the organization offers.

“I had a business idea that related to my passion for the arts, but without any experience, I had no idea where to go and how to get started,” said Samantha Chan, owner of Paintlounge, in a press release. “CYBF and my mentor worked with me to further develop my idea, create a business plan, and secured my financing. Today, my business is thriving and I was just able to open a second location in the GTA.”

L.V. LOMAS WELCOMES TWO NEW EMPLOYEES

Martin Rolland and Dianne Worrell have landed new positions with L.V. Lomas.

Rolland joined the team on Jan. 13 in the position of technical sales representative of food for the Quebec and Maritimes territory.

Rolland has many years of sales experience and significant knowledge of the food industry.

Previously, he was at Elanco Animal Health, where he was servicing the animal nutrition market as a sales associate. Rolland has a bachelor’s degree from McGill University in microbiology and immunology, and a master’s degree in food science from Laval University.

Worrell began her new position on Jan. 13 as marketing manager of oils. She will have a product portfolio responsibility that includes food-grade oils, value added blends and other select commodities. She is joining the company from Givaudan where she

has been working as a senior account executive.

Bohm is the new national service manager at Globe Food Equipment. He joins the company with more than 15 years of service experience in industrial equipment support.

He most recently worked as service manger with Baumer HHS Corporation. Baumer manufactures industrial gluing and quality control equipment for the packaging and corrugated industries. During his 15-year tenure with Baumer, he also served as field service engineer and technical support.

Previously, he served in the U.S. navy for six years. He graduated from the nuclear propulsion program and was stationed on a fast attack submarine for four years in San Diego.

As Globe’s national service manager, Bohm is responsible for all aspects of the after-sales support, which includes managing field service companies and coordinating technical support and

CYBF has invested in more than 5,600 young and emerging entrepreneurs across Canada.

parts distribution operations. He will report directly to Globe’s president, Hilton Garner.

Jim Anderson is Corbion’s new national sales manager of industrial solutions. He will lead the industrial group. Anderson has been with the organization for five years.

Corbion also recently promoted Thomas Douglass to category director of the food market unit.

Douglass joined Corbion recently as fortification director. In his new role, Douglass is responsible for supporting sales through the development and execution of category growth strategies for the food market unit.

Corbion promoted David Meggs to vice-president of meat and culinary market unit. Previously, Meggs held the position of director of business development of food for 10 years with the company.

“FCC is key to our company

When you talk financing with FCC, we’ll listen

Ready to expand? We learn how you want to grow, then create a financing package that helps you do it. Work with the leading lender to agriculture, agribusiness and agri-food in Canada. Let’s talk business. fccfinancing.ca

Some Canadian cake designers are seeing a dramatic shift in wedding cake trends this year, with clients toning down their matrimonial indulgence. The elaborate designs and bold colours that embodied last year’s cake trends are being replaced with a simplified, vintage feel. Two-tiered cakes with soft, muted colours and vintage lace designs will be particularly hot this season. Add a dessert table into the mix, and this year’s wedding season is shaping up to be a simple, yet sweet, affair.

In Calgary, Cakeworks is a bustling cake shop that specializes in buttercream icing and recently celebrated its 20th anniversary. Brenda Walker, who co-owns Cakeworks with business partner Brian Klassen, says their clients are asking for a more simplified look.

}“This year’s trend has a vintage feel, where the cakes are back to being simple. The ornate cakes with bright colours aren’t in style as much now. Instead, we’re seeing a lot of texture: a ruffled look, a homemade look like grandma used to make,” she explains. “Because we work with buttercream, we’re finding clients want a lot of texture like ruffles, lace and string work. We’re going back to basics.”

colours

more requests than the over-top, whimsical cakes of yesteryear.

“The ornate cakes with bright colours aren’t in style as much now. Instead, we’re seeing a lot of texture: a ruffled look, a homemade look like grandma used to make.”

Yvonne Zensner, owner and operator of The Cake Box in Kitchener, Ont., is seeing the same trend with her clients in Southern Ontario.

“In previous years the trend was very glitzy, with a lot of metallics, golds and coppers, but this year we’re seeing the opposite with a lot of vintage laces,” she says. “Last year I found there were laces, but they were more of the expensive French laces. This year we’re going for more of a handmade, crocheted, doilytype of lace that is still classy but simplified.”

With the glitz and glam of last year’s wedding season being pared down into a more simplified, romantic style, the number of tiers and colours are following suit. Instead of towering cakes with bold

colours, Walker says many couples are opting for two-tiered versions in hushed tones. “I’m noticing that we’re doing a lot of muted colours, like blushes, off-white and white. I advise my clients to incorporate colours with the flowers so that it’s not too much. But definitely we’re seeing more of the subtle champagne colours, off-white and white,” she says.

Zensner agrees, although it’s not quite the colour scheme she was hoping for.

“This year everything is still ivory, but it’s earthy. It’s really soft tones, which surprises me. I thought it would be more vibrant – the trendy new blues, the bright greens – but brides aren’t going in that direction at all. I really wanted that turquoise, the emerald greens and teals, but I think those colours may come later on in the year,” she predicts.

Adding to the scaled-back romantic theme is an earthy, natural look.

“We’re going back down to a very nature-like feel: very woodland, very easy,” explains Zensner. “There’s going to be a lot of wood being used in the cakes,

in the sense of wood-like cake stands and platters. We’re seeing a lot of the birch bark-type cakes with buttercreams. A lot of people are having an outdoor-feel to their venues, so we’re doing cakes that fit with that style by using mosses, branches and barks. It also ties in with an old vintage feel. Some of the venues are old churches and barns.”

In the same vein of vintage, but with a little more pizzazz, is The Great Gatsbythemed wedding cake. While this style rose in popularity last year with the release of the movie by the same name, cake designers are seeing it carry over into 2014. The art deco style may be bolder than the muted colour trend of the year, but Zensner says quite a few of her clients are still opting for the Roaring Twenties-inspired style, with its golds, creams, blacks and coppers.

Accompanying the smaller wedding cakes this year is a growing number of sweet tables and dessert bars. The cupcake and cake pop craze that has been building for several years now has only added to the sweet table’s popularity.

“Almost every other wedding that we do we provide a sweet table,” explains Zensner. “They usually contain an

BY DIANE CHIASSON

Five reasons why instructing staff members over the Internet may be a good future bet

Hiring and training your employees properly is a must-do for any successful business, especially in the foodservice and retail industries. Today, many foodservice operations are turning to online training to help in this area.

There are a few different ways to set up online training for your bakery. You could either build your own training website from scratch or use a web-based service called a learning management system (LMS) that allows customers to upload their own training materials to a proven platform.

Training staff members online also eliminates a great deal of expense, as there is no need to constantly print and reprint training materials.

}Online learning platforms, however, should never replace the need for person-toperson guidance. It is still essential to your bakery’s training program to create a dialogue and relationship with all of your employees, and offer praise and constructive criticism at all times.

displays – since trainees can review the material over and over again until they understand and pass the test. Visual training components are also very handy,

This is especially important if you are hiring young people to work in your bakery, as youth are now attached to their digital devices. It makes sense to train them digitally as well.

Here are five reasons why training your employees online might be the way to go in the future.

People are always on the go. Online training allows your new employees to train on their own time using their mobile devices. This is especially important if you are hiring young people to work in your bakery, as youth are now attached to their digital devices. It makes sense to train them digitally as well.

With an online training program, you can ensure that all of your employees are learning the exact same materials. It is especially ideal for teaching technical skills – such as how to use the POS system, how to prepare products and how to set up

especially in the foodservice industry. Online training also allows you to use videos, which can be much more effective especially when training on how to use new equipment, new products and safety issues. With consistent training, it is easier to maintain certain levels of standards that you may have in your bakery operation.

It is also much easier to update materials using an online training program. Any addendums, changes or additions you want to make to your training program can be done within seconds, keeping it relevant at all times. If you have any new materials you wish your employees to see or review, you can send them a text message to let them know that there is new information they need to review.

A computer-based training program offers immediate results since all of the testing is completed online. This allows for employees to remedy their errors right

away instead of waiting hours or days for results to come back in. Your training program can also include interactive games that could make the training more fun and entertaining.

Owners and operators can monitor each employee’s training and receive test results automatically. Most training platforms have a reporting mechanism that allows managers to monitor the progress of each employee’s training and has the ability to see employees’ scores and results. Some platforms will also show which areas each employee had difficulty with. This allows owners and operators to work on that area with the individual employee on a more intimate basis.

It may be an initial investment in time and/or money to get a customized online training program set up for your bakery, but the results could mean a better-trained staff. / BJ

Diane Chiasson, FCSI, president of Chiasson Consultants Inc., has been helping foodservice, hospitality and retail operators increase sales for more than 25 years. She provides innovative food and retail merchandising programs, interior design, marketing and promotional campaigns, and much more. Contact her at 416-926-1338, toll-free at 1-888-926-6655 or at chiasson@chiassonconsultants.com, or visit www.chiassonconsultants.com.

This cake, from Brenda Walker at Cakeworks, is an example of the trend of two-tiered cakes being used for photographs and complemented by dessert bars.

CONTINUED FROM PAGE 11

assortment of customized cupcakes, French macarons, little pastries, mini tarts and mini pies, as well as jars of meringue kisses and sugar cookies that are either very simple like grandma makes or super elaborate with chocolate cameos on them. Everything can be very matchy-matchy or classic looking.”

Walker has noticed this trend in Alberta as well, with two-tiered cakes being used for the bride and groom’s photographs, while cake pops and cupcakes, along with other goodies, make up tantalizing dessert bars.

When it comes to flavours, traditional vanilla or chocolate bases with cream fillings remain popular choices; however, Zensner is seeing a new trend emerge in her shop.

“A lot of clients are asking for European-style cake flavours, like hazelnut ganache and almond buttercake. And of course tiramisu is another popular European flavour. Our clients usually want at least one or two tiers to be one of those flavours,” she says.

This year is shaping up to be a romantically blissful wedding season, with cakes revealing soft hues, vintage lace patterns and scaled-back tiers. Enchanting, nature-inspired themes will add to the understated yet beautiful feel of this year’s nuptials. / BJ

Julie Fitz-Gerald is a freelance writer and regular contributor to Bakers Journal.

For more on trends, visit the business section of www.bakersjournal.com

Recognized the world over for consistency, workability and taste, Satin Ice fondant offers an extensive range of colours with beautiful cake-decorating characteristics.

There is no consensus on the gluten-free debate, except that it’s here to stay | BY LAURA

AIKEN

Gluten-free is still the heavyweight champion of the Canadian baking industry when it comes to the reigning topic in nutrition myth busting,. On Jan. 21, the Ontario chapter of the Baking Association of Canada (BAC) held a technical seminar promoted as a myth-busting discussion among an esteemed panel on the subject of glutenfree and other topics such as fibre and non-GMO. With only so much time in one afternoon, gluten-free and its related conversations decidedly took centre stage. It all culminated in a bottom line for bakers that the panel largely agreed on: Gut health is BIG. And gluten-free is not going away.

The panel was composed of mostly registered dietitians working in various roles, and although there was some inevitable overlap of gluten-free information, each presenter

brought unique information to the table.

Jennifer Sygo, M.Sc. and RD, works as a sport nutritionist with the Cleveland Clinic of Canada and in private practice. She is a nutrition columnist with the National Post, and has authored the soon-to-be-released book Unmasking Superfoods, which takes a critical look at the superfoods trend. Her presentation focused on separating gluten myth from fact, drawing largely on the arguments made in Wheat Belly There is conflicting nutritional information out there, she has found, and she said the world of nutrition is at a “tipping point where science is re-evaluating what has been accepted for a long time.” The popularity of gluten disdain, driven by books, celebrity, alternative medicine, word of mouth and some

scientific evidence that is being actively debated, has prompted more research into the area. This means we will see more studies on gluten being published in the future.

Wheat Belly alleges that gluten causes disease, various ailments and weight gain, and that the protein is also present in our food in higher amounts than in the past. The first point she addressed, and the one she said author Dr. William Davis raises a valid inquiry about, was whether or not genetically altered (not modified) wheat has taken issue with the human body. The alteration in question centres on research that began in the 1940s and led to high yield, very resistant wheat; a scientific achievement that Norman Borlaug won the Nobel Peace prize for in 1970 as his contribution was credited with bringing more world peace through increasing the food supply. Has the altered wheat

increased the gluten content? And if we are eating more gluten, is that a problem? This is an area she said needs more research.

As far as Davis’ other gluten blames in the book are concerned, Sygo was quick to bust myth from what she believes are the scientific facts. Davis proposes wheat is an appetite stimulant, but she said the fact is that there is no scientific evidence to support this assertion. On the claim that wheat makes one fat, she said the fact is that obesity causes are multifaceted and to “lower to one cause is being an evangelist.” On Davis’ argument that people were skinnier in the 1950s and 1960s and now we are not, so it must be caused by wheat, Sygo pointed to the fact that people in that era did a lot more demanding housework and that sitting is a defining problem of the current era.

She cautioned to be wary of what you read. As the author of

The perception that gluten-free automatically means a product is healthier is one of the myths the Health Grains Institute is focused on dispelling. A treat is still a treat, gluten-free or not.

a soon-to-be-published book, she said no one “fact checks your work.” It’s not a peerreviewed journal. Data in Davis’ book is hand picked and there is potential for authors to select views that are favourable to the messaging. It is much easier to present a biased position when writing a book for public consumption as opposed to publishing in a scientific journal.

She wrapped up her myth busting with a challenge to Davis’ argument that gluten is a problem for all people. Her bottom line is this: There is no convincing scientific evidence that gluten is problematic for 93 per cent of the population, but about seven per cent really have a problem (the 1 in 133 who have celiac disease and the estimated six per cent of the population who have gluten sensitivity). Celiac disease is an autoimmune condition where damage is done to the intestinal lining when gluten is consumed. Gluten sensitivity is not an autoimmune disease; damage is not done to the intestines, but the condition can present as a number of other physical maladies. The number of people with gluten intolerance or celiac disease is three times the number of people with anaphylactic food allergies, she said, so there is definitely a market there. Her last point segued into some market opportunities she sees for the bread industry in general. She sees market potential for bread makers to incorporate ancient grains or other non-wheat grains and artisan bread that focus on quality, story and process. Clean labels, “your grandmother’s bread” –in essence “going back into the past to change the future” – is one way industry may be able to re-establish the trust that’s

been broken by what’s been published in the popular press.

During the afternoon Q and A session, Sygo identified awareness of gut health in general as being a big trend, and said she believes fermented foods will go “hog-wild.” She recently came across research that took a look at people who had what seemed like an inability to lose weight despite best efforts, and the results suggested that the participants all exhibited shared traits of poor gut health, insulin resistance and chronic inflammation in the body.

When asked what she felt the next big thing would be, she noted vitamin K2, found in animal fat, is an emerging area of research. Vitamin K2 tells calcium where to go in the body, and if you don’t have enough it seems to go to your arteries instead of your bones. As more studies come out, it could signal a return to full-fat cheese and butter.

Christine Lowry, M.Sc. and RD, is the nutrition and policy advisor for the Healthy Grains Institute. Her presentation focused on what the young organization’s mission is and on what successes they have had so far.

The Healthy Grains Institute, a Canadian non-profit, was formed to bring balance and influence to the public conversation on gluten-free and grains.

“Consumer consume headlines,” said Lowry. “Then take it as gospel truth.”

The institute encompasses more than nutrition, she said. It enters the spheres of gastroenterology, cardiology, pediatrics, plant breeding and grain science. The

organization rests on the backbone belief in the science that shows people who eat three or more portions of whole grains per day experience a decreased risk of colorectal and pancreatic cancers, diabetes, cardiovascular disease and abdominal fat.

While Sygo discussed the impact of Wheat Belly in North America, Lowry told a tale of a pre-emptive strike that softened the negative impact of Grain Brain by Dr. David Perlmutter on the media and public perception.

The organization sent out a press release about the publication of the grains-positive book Mindfull by Dr. Carol Greenwood around when Grain Brain hit the shelves.

The purpose of this was to force the media to hear two stories. Lowry cited a CBC report that interviewed Perlmutter and Greenwood for equal amounts of time as evidence of the efficacy this strategy had with the media. They also prepared other associations, such as the Dietitians of Canada, the Canadian Diabetes Association and the Heart and Stroke Foundation, for the publication of Grain Brain with key positive messaging to distribute through their social media and other public-facing channels.

In the end, Perlmutter still got plenty of airtime (making it all the way to Dr. Oz), but she said the institute’s efforts helped the book have less impact on the Canadian media than Wheat Belly did. Lowry introduced a chart that showed the number of headlines given to Grain Brain versus positive grain messaging and it was indicative of a measure of balance brought to the coverage.

The key issues the institute is fighting are what she termed the concept of FrankenWheat, Wheat Weight and Gluten Free=Healthy. The non-profit’s next campaign may focus on the farmer as a hero and the farm-to-table movement.

The Healthy Grains Institute is guided by an independent and multidisciplinary scientific advisory council but is financially backed by industry partners, including the Canadian National Millers Association, BAC, Canada Bread, Weston Bakeries, Grain Growers of Canada, Alberta Wheat Commission and Grain Farmers of Ontario.

Rob Kowal is the president of Kriscor & Associates, a company that helps food manufacturers add ingredients that increase the nutritional profile of their products. This involves much research into what consumers are looking for in their food, and his presentation set out to answer the question of whether or not gluten-free is here to stay (yes it is, he said, but there are other things

Kowal first told a personal story of reading Wheat Belly, identifying with the symptoms described in the book and deciding to stop eating gluten. He has been on an gluten-free diet for over a year and says it has remedied his ailments. He identifies as gluten-intolerant, and was never tested for celiac disease. He became somewhat of the prime example during the afternoon of anecdotal evidence that the scientific community should not ignore, and stood as proof that there are many other people who have found relief from physical and mental symptoms by not eating gluten.

“There is something to some of this gluten-free [debate] in that we don’t know what we don’t know,” he said, pointing to new research out of Australia suggesting that perhaps as much as 50 per cent of the population studied has gluten sensitivity markers in their genetics. Kowal predicted that the gluten-free market will continue to grow at double-digit rates for the next five years before it potentially plateaus.

Kowal identified three overarching global consumer trends: health/freshness, convenience and value. Global obesity and its associated diseases is still an enormous challenge societies are grappling with. The baby boomers still have a lot of purchasing power and they are primarily interested in gut health, disease prevention and anti-aging products.

“The digestive gut health category is huge,” he said, and noted the yogurt manufacturers as leaders in capitalizing on this with probiotics. There is also a big interest in low-glycemic products.

Baby busters (people born between 1966 and 1971 as defined by Statistics Canada) also can influence through decisions to become vegetarian or to follow other specialty diets.

Consumers are more educated these days because of all the information on the Internet, he said. Sometimes they get it right and sometimes they don’t. Either way, they lack trust and confidence in Big Food. Kowal’s research indicates that consumers do not feel the food industry is doing a good job of giving them the healthy, safe, fresh food they are looking for. The characteristics consumers are seeking seem to be high fibre, whole grains, gluten-free, low carbohydrate, pre- and probiotics, low sodium, low sugar, natural (organic) and value/cost. Yet, of course, taste is still king, he said. One of the barriers to healthy eating is still the perception that it won’t taste good.

Big Food has been under attack, he said,

and the media doesn’t help but rather hinders by continuing to confuse consumers with headlines that are out of context. He points to this rather comedic example from the Telegraph: “EU bans claim that water can prevent hydration.”

You wouldn’t want to take that headline at face value.

Sue Newell is an education and communications consultant for the Canadian Celiac Association (CCA). The CCA is a consumer advocacy group and endorses the GlutenFree Certification program for food manufacturers.

Newell, who has celiac disease, shared that gluten-free shoppers are a very loyal group but making their products is not to be taken lightly. It’s a significant commitment that requires proper procedures to ensure a safe food supply.

She outlined some of the recent research the CCA is looking at. Research in Finland is suggesting that two per cent of seniors have celiac disease, and this has raised the question of whether there is an age

component to developing the condition. Celiac disease is found worldwide, except in Japan where she said they don’t seem to have a genetic basis for it.

The CCA found that diagnosis rates are still “abysmal,” with 10 to 12 years being the average time. Sometimes early onset osteoporosis leads to a diagnosis, because celiac disease interferes with the way the body absorbs calcium. Iron absorption is also a concern for this group. Importantly, she advised that parents should not put their children on a gluten-free diet without having them tested for the disease first. If a test is not done, the damage will have to be recreated later by consuming gluten to make a diagnosis.

There has been debate about people with other conditions such as autism or other autoimmune conditions responding well to gluten-free diets. The links are “tenuous,” said Newell, and there is “something interesting going on, but we don’t know what.”

Newell wrapped up her presentation by reviewing the changes to the

CONTINUED ON PAGE 38

L

nutrition in every loaf.

Arthur Gunn carries on the traditions of 76-year-old Gunn’s Bakery | BY

KARLY O’BRIEN

Arthur Gunn, co-owner and chief baker at Winnipeg’s Gunn’s Bakery, knows all of the ins and outs of kosher baking.

The word kosher means to satisfy the requirements of the Jewish laws written in the Torah, which dictate how food is cooked, eaten and sold. Kosher requirements say that Jewish people can’t eat dairy and meat together. A practising Jewish person is required to have a waiting period, which can be as long as six hours, between the consumption of dairy (milchig) and meat (fleishig).

Because the bakery is fully certified as kosher, Gunn and his staff must be sure that all kosher milk products come from kosher animals and do not contain non-kosher additives. Milk products cannot contain meat products or derivatives (for example, various cheeses are manufactured with animal fats and this would not be allowed). Bread is not allowed to contain meat or dairy (pareve). Bread is without either because bread is a staple food in many Jewish households and usually paired with dairy or meat. The eggs of suitable birds like chickens, ducks and turkeys are permitted as long as they do not contain blood. Therefore, eggs must be individually examined.

}Dave Shambrock (on left) of the Manitoba Food Processors Association presented Bernie and Arthur Gunn (to the right) of Gunn’s Bakery with the 2012 Company of the Year award.

Because the bakery is fully certified as kosher, Gunn and his staff must be sure that all kosher milk products come from kosher animals and do not contain nonkosher additives.

This is just a fraction of what a kosher bakery is required to do. Two of every tool, such as scissors, slicers, bowls and boards, are needed and kept separately. Each culinary device is colour coded to indicate which can be used to create dairy and non-dairy baked goods. The product showcase teasing customers with mouthwatering creations separates the dairy from the non-dairy.

To adhere to these rules, Gunn’s Bakery purchases products that are certified by widely accepted kosher organizations. The most common certifying bodies that Gunn comes across

are B.C. Kosher, Montreal Kosher and Kashruth Council of Canada. There are also other organizations that certify products as kosher, but it depends on where that supplier is located. A supplier in Toronto, for example, would use the Kashruth Council of Canada to certify the company’s products as kosher. On top of that, the bakery employs a rabbi who works for one of the certifying bodies. The rabbi will ensure that the bakery makes no mistake in cross-contaminating dairy with non-dairy and follows the rules that are set out in the Torah.

There are many specifications to producing kosher baked goods, but for

Gunn’s Bakery, this is the day-to-day routine and a standard the bakery committed to when it first opened in 1937.

“I can tell you that if you were just starting out to be a kosher bakery it would be an astronomical headache for you,” says Gunn. “An expensive headache at that.”

His team of staff is a mix of Jewish and non-Jewish people, so kosher rules may be new to an employee who joins the company. Gunn tries to make it as easy as possible to learn so that his staff can focus on baking.

“I have to say that I am so proud of my staff here because it’s not a Jewish staff, but they adhere to the rules. It is unbelievable. If they are making something with dairy in it then they bring out the special tabletops and the special pans. If you go into the back, it is just seamless.

INNOVATOR OF THE YEAR 2014

Are

Once again, Bakers Journal will honour its Innovators with the fourth annual Bakers Journal Business Awards.

For

DEADLINE:

It’s fantastic.”

Like his staff, he attracts a mix of Jewish and non-Jewish clientele.

“Some people come into our bakery and they have no idea what the word kosher even means,” says Gunn with a laugh.

When the bakery first opened, there was a large Jewish community in Winnipeg. Over time, the immigrants that resided in Winnipeg moved to southern Manitoba, Toronto and the United States.

In the last few years, the Jewish community has been revived with the arrival of hundreds of newcomers, especially from South American countries like Argentina, Brazil and Venezuela.

“We’ve actually had a large influx of Jewish people from South America. A lot of them have moved up here for better opportunities for their families and they have become a part of our community.”

The family business began with his father, Morris, a baker’s son who immigrated to Canada from Poland in the mid-1920s.

He started out as a baker at Buchwald’s Bakery, saving every penny until he could bring his sweetheart and soon-to-be wife, Florence Grodenczik, to Canada in 1930.

Seven years later, he started his own business – a one-man operation with a bakery storefront and his family living in the back quarters. At the time, he and his wife had a daughter, Betty, and a son, Bernie. Five years later, Gunn was born, and Morris’ business had outgrown the space. The family moved out of the bakery and moved the business to a new location just a few blocks from the previous location on Selkirk Avenue, where it currently resides and remains a fixture in Winnipeg.

As a child, Gunn was always interested in baking. At the bakery, he watched his father turn raw ingredients into delectable baked goods. His father taught him everything he knew; that is how he learned the processes and rules of baking kosher. But Gunn also liked to experiment on his own.

“You get instant gratification by turning out something that looks good, tastes good

and that people enjoy to eat,” he says.

In 1987, Gunn earned his Master Baker certificate from the Retail Bakers of America Association (RBA), and later joined the board of directors. He then became active with the board of directors of the Baking Association of Canada (BAC).

Bernie was not immediately interested in the family business and became an accountant. After his father passed away in 1973, Bernie joined Gunn’s Bakery full time to help with the financial functions of the business like payroll and taxes.

Their sister Betty never joined the business, although, she did create a bestseller called Betty’s Chocolate Almond Commish. The bakery still sells this treat, which is similar to biscotti.

Gunn, who is in his 70s now, still loves to bake and come up with new recipes to add to the product lineup.

“I love creating new products. I watch things on TV and on the Internet and just sort of take things from what I see there and adapt them to what I think will be a winner for us,” says Gunn, who has now accumulated more than 50 years of industry experience.

Some of these winners have been the feta cheese horn, the pizza bagel and multigrain sourdough.

“He’s very good with trying different things,” says Krista Senkow, assistant manager at Gunn’s Bakery since 1998. “He’s not afraid to try something new… he’s actually more willing than me sometimes to go out on a limb and try new things.”

Today, Gunn and his brother carry on the tradition of running the kosher bakery that employs more than 60 staff members. The bakery has also expanded into the wholesale and catering markets, and offers a full line of ethnic European goods spanning from bagels and breads to cakes and cookies.

“The bakery is something that I’ve undertaken with a lot of delight knowing that we produce top-quality products that people seek out,” says Gunn. “People always come back to our store and say that they can’t find anything close to what we make, and that gives me a lot of satisfaction.” / BJ

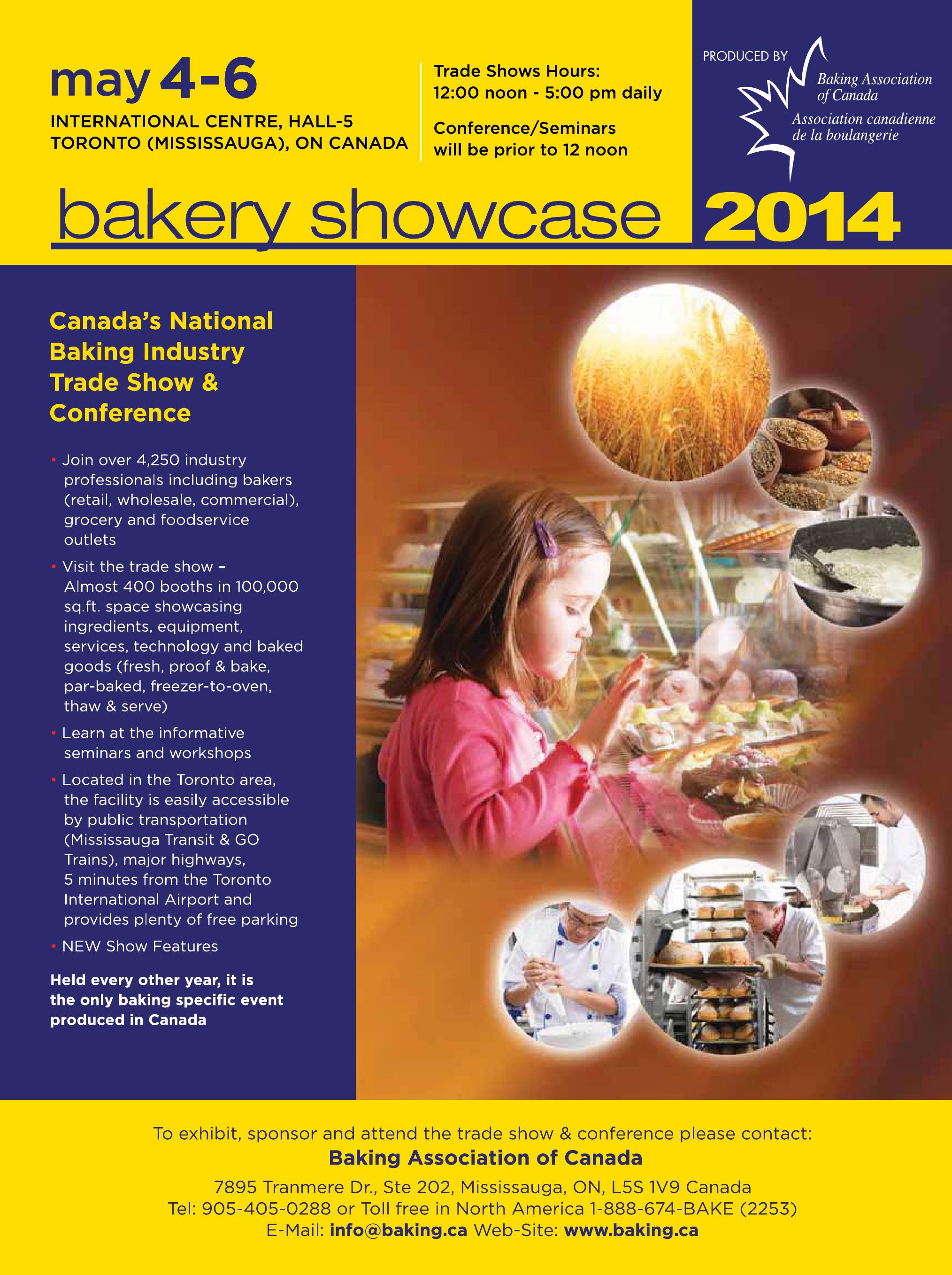

may 4-6

INTERNATIONAL CENTRE, HALL-5 TORONTO (MISSISSAUGA), ON CANADA

Trade Shows Hours: 12:00 noon - 5:00 pm daily

Conference/Seminars will be prior to 12 noon

Canada’s National

Baking Industry Trade Show & Conference

Join over 4,250 industr y professionals including bakers (retail, wholesale, commercial), grocers and foodser vice personnel

Visit the trade show – Almost 400 booths in 100,000 sq.ft. space showcasing ingredients, equipment, ser vices, technology and baked goods (fresh, proof & bake, par-baked, freezer-to- oven, thaw & ser ve)

Learn at the informative seminars and workshops

Located in the Toronto area, the facility is easily accessible by public transportation (Mississauga Transit & GO Trains), major highways. It is only 5 minutes from the Toronto

International Airport and provides plenty of free park ing NEW Show Features

Held every other year, it is the only baking specific event produced in Canada

To reg i ste r to atte n d vi s i t www. b a k in g.c a Entr y to all seminars are included in the trade show pass.

nderstand your business. Visit the trade show floor to see unlimited possibilities in ingredients, equipment, ser vices, tec

h, much more! To v

May 4

Jack and Jill, Hickor y Dickor y Dock , and Humpty Dumpty are just some of your favorite nurser y rhymes that will be featured by student teams from George

Brown, Niagara and Centennial Colleges as they compete in this year’s College Creative Challenge. This friendly competition will feature the design sk ills of students in massive 3D visuals of some of the

e winner w

Free Admi

Limited seating: Available on a first come, first ser ved basis

SUNDAY MAY 4, 2014

9:45 AM – 10:45 AM

BAC ANNUAL GENERAL MEETING

(Members and non-members invited to attend)

The annual meeting of members provides a review of the Association’s activities over the past year as well as direction for the future. This year’s meeting will also include a presentation and request for approval of by-law changes required for BAC to come into compliance with the new Not-For-Profits Act. Please note: only BAC members are eligible to vote.

11:00 AM– 12:00 Noon

1 HOUR - 3 MINDS: THE STATE OF THE INDUSTRY

ADDRESS YOU CAN’T AFFORD TO MISS

Three industr y leaders, spanning the perspectives of large commercial, midsize commercial, and independent retailers, will share how they are managing the challenges and opportunities facing their sectors of the bak ing world. Don’t miss this first- ever opportunity to see these four minds on one panel, and participate in what is sure to be a memorable Q&A.

SPEAKERS:

Marla Kravice, President of Baker Street; Maria Liang, President of Weston Bakeries; Thierry Schmitt, French Master Pastr y Chef and O wner of Patisserie La Cigogne.

MODERATOR:

Laura Aiken, Editor, Bakers Journal Magazine Entr y to all seminars are included in the trade show pass.

MONDAY MAY 5, 2014

10:00 AM – 12:00 Noon

CFIA REGULATORY MODERNIZATION FOR BETTER FOOD SAFETY OUTCOMES

The Canadian Food Inspection Agenc y is strengthening food safety and consumer protection by undertak ing significant changes in current regulator y and inspection approaches and tools. These changes will have major implications for Canada’s bak ing industr y and its suppliers including mandator y licensing of all businesses that import, export or ship food or food ingredients across provincial borders. CFIA’s goal in this session is to help you understand how the new legislative, regulator y and inspection changes will impact your business and what you need to do to ensure compliance.

Presented by Canadian Food Inspection Agency (CFIA)

TUESDAY MAY 6, 2014

10:00 AM – 10:45 AM

RESOURCES TO SUPPORT YOUR BUSINESS DEVELOPMENT

The presentation will highlight the prime focus of the

Business Development Branch (BDB) of the Ontario

Ministr y of Agriculture and Food (OMAF). Who we are, what we do and how we can help the baker y sector, which is one of the most successful, globally competitive and market responsive sectors in the province, is the focus of this presentation.

It will also address government assistance and support in order to help retain, expand and grow your business, including resources on Export

Development, Food Safety and Traceability

Presented by the Ontario Ministry of Agriculture (OMAF)

10:45 AM -11:15 AM

EXPORTER ALERT: UNDERSTANDING THE U.S. FDA FOOD SAFETY MODERNIZATION ACT (FSMA) PROPOSED RULE: PREVENTIVE CONTROLS FOR HUMAN FOOD

The U.S. FDA Food Safety Modernization Act (FSMA) was signed into law with the aim of providing safe food to consumers. If you ship product, ingredients or pack aging to the U.S., you will need to comply with FSMA requirements. Under FSMA, all registered facilities will be required to conduct a hazard analysis, implement preventive controls and develop a food safety plan. During this FSMA over view, learn about the requirements of the FSMA Proposed Rule for Preventive Controls for Human Food and what you need to do to bring your current food safety system (HACCP, BRC- or SQF- certified) into conformance.

Jennifer McCreary, Technical Manager, Training Services, NSF-GFTC

11:15 AM -12:00 Noon

WHAT THE TREND IS GOING ON?

How are bakers coping with balancing ever changing

trends in order to meet both consumer needs and required formulation changes? Health and wellness is always present in consumers’ minds and bakers

need to stay on top of the science as well as the art of bak ing. Gluten-free and clean label challenges and strategies will also be highlighted. Hear from a product development expert about

the latest industr y trends, technical information and insight on how bakeries can capitalize on these opportunities.

Karen Technical Manager,

Karen McPhee, Technical Manager, Product and Process Development Services, NSF-GFTC

AB Mauri Fleischmann’s

ABI Ltd

ADM Milling Company

Air Liquide Canada

Alfa Cappuccino Imports

All Gold Imports

Alpha Poly Pack aging Solutions

Amazing Fruit Products Ltd.

American Almond Products Co. Inc.

Amoretti

Apple Valley Foods Inc.

ATESCO Industrial Hygiene Ltd

Auralite Panel Products Ltd

BakeMark Canada

Bakers Journal

Baker y Crafts

Bak ing Association of Canada

Barr y Callebaut

Belcolade Real Belgian

Chocolate

Bettendor f Stanford Inc.

Bizerba Canada Inc.

Blodgett Oven Co.

Bunge Canada

Burnbrae Farms Ltd

Business Improvement Group

Caldic Canada Inc.

Canada Bread Company Limited

Canadian Food & Grocer y Guide

Canadian Grocer

Canbrands Specialty Foods Inc.

Carmi Flavors

Carmichael Engineering Ltd.

Chemroy Canada Inc.

Chicago Metallic Bakeware

Compass Food Sales Co. Ltd

Contemar Silo Systems

Continental Ingredients Canada

Corbion Caravan

Crown Custom Metal

Spinning Inc.

CRS Vamic

As of February 10, 2014

CTP Imaging

Daiya Foods

Dakota Specialty Milling Inc.

Dawn Food Products

Dealers Ingredients

DecoPac

Design & Realisation

Doyon/Nu-Vu

Drader Manufacturing

Eckert Machines

Embassy Flavours

Everspring Farms Ltd

Evolupak

Fanc y Pokket Corporation

Farinart Inc.

Farm Credit Canada: Agribus.

& Agri-Food

Fiera Foods

Foley ’s Candies

Food in Canada Magazine

Forpak

Fortress Technology Inc.

France Décor Canada

Francis Pack aging Inc.

G Cinelli - Esperia Corp

Gay Lea Foods

GDI Integrated Facility Ser vices

Global Egg Corporation

Gloco Accents

Gourmet Baker Inc.

Grain Process Enterprises Ltd

H & A Health Products Inc.

H Moore Printing Ser vices

Handtmann Canada

Harlan Bakeries - Edmonton L.P.

Har vest Corporation

Hobart Canada

Horizon Milling

Intralox LLC

J.J. Marshall Inc.

JBNT Marketing Inc.

JVR Food Pack aging Solutions

Kaak Group

Kerr y Ingredients & Flavors

King’s Pastr y

KLR Systems

Kwik Lok Corporation

L & M Bakers Supply

L V Lomas Limited

Lallemand

Lantic Sugar

Legumex Walker Canada Inc.

Lentia Enterprises

Lesaffre Yeast

LorAnn Oils Inc.

LVO Manufacturing Inc.

Magna Industries Inc.

Magna Mixer Co.

Malabar Super Spice Company

Margarine Golden Gate –

Micha Inc.

Margarine Thibault

Marsia Foods

McCormick Canada Inc.

MFG Tray Company

MIWE Canada

Natunola Health Inc.

Natu’oil Ser vices

Novelis Foil Products

NSF- Guelph Food

Technology Centre

Nutriart Inc.

Oak run Farm Baker y

Ontario Ministr y of

Agriculture & Food

P&H Milling Group

Parmalat

Petra International Picard Ovens Inc.

Polar Pak

Port Royal Mills

Powertank Cleaning

PreGel Canada

Prime Pastries Inc.

QPC Pack

Quadra Ingredients

Reiser Canada

RF Baker y Equipment

Rich Products of Canada

Richardson Oilseed Limited

Richmond Traders Inc.

Rondo Inc.

Sampla Belting Canada

Sandvik Process Systems

Sani Marc Inc.

Satin Fine Foods

Sensient Flavors Canada Inc.

SEW-Eurodrive

Seydaco Pack aging Corp

Signature Fine Foods Ltd.

Sik a Canada Inc.

Somersert Industries

Southern Champion Tray Spectra Foods Ltd

Spectrim Label & Equipment Inc.

Spraying Systems Co.

Stirling Creamer y Ltd

Supreme Egg Products Inc.

Texture Technologies Corporation

The Original Cakerie

Toufayan Bakeries Inc.

Unifiller Systems

Unipex Solutions Canada Inc.

University of Guelph – Agri. & Food Lab

Vale Pack aging Limited

VC999 Ltd

Vegfresh Inc.

V-Tech Engineering, Inc.

Weber Mark ing Systems

Westcan Marketing Inc.

Weston Bakeries Limited Zeppelin Systems USA

Employees of exhibiting companies (booth personnel and general attendees) who qualify in the “Supplier” category are encouraged to be added to their company’s Exhibitor Badge Order in order to avoid paying the Supplier rate.

Solicitation by non-exhibitors is strictly prohibited and violators will be evicted.

ADVANCE REGISTRATION ENDS ON APRIL 28

Registrations received after this date will not be processed –register on-site at the International Centre May 4-6.

ONSITE REGISTRATION FOR BAKER/RETAILER/ FOODSERVICE: Applies to owners or employees of bakeries, retail grocers, food distributors, restaurants, hotels, foodservice operations, accredited schools and enrolled students. Proof of qualification is required for on-site registrations which may include: business card, business license, white/yellow page business listing, company web site, company invoice, payroll stub (white out $), student card. Qualification criteria may be extended to group registrations at BAC’s discretion.

Print clearly and use one form per person Registrations will not be processed without full payment and will be confirmed via email. All badges will be held for pickup on-site. BAC reserves the right to refuse a registration request to anyone. BAC must verity your registration eligibility. Refund Policy: Written cancellation must be received no later than Thursday April 4 th . A $20 service fee will be applied. Refunds will occur after the event. Cancellations after April 4 th are non refundable. Badges are required for admittance. Altering your badge in any way (including inserting a business card), misrepresenting information on the registration form, loaning or giving your badge to another person is strictly prohibited and will be cause for eviction.

to

BAC does not sell, share or transfer your personal information to any third parties for reason(s) other than communication that is required by BAC through approved vendors. Check this box if you do not want to receive information on future

In 10 years of running an online cookie delivery company, Alan Zelcovitch has come across every imaginable problem. Through software development, he has made them all go away.

Zelcovia Cookies is Toronto based and keeps its owner busy year round, with Christmas being the peak season when he brings in a few extra hands. Adding labour, however, isn’t how Zelcovitch says he wanted to solve the challenge of managing increased sales in a growing company that has unique challenges, most pressing of which is a short delivery window for online perishable food sales. Instead, he turned to his computer background and made a big investment that has paid him back in spades.

He first figured out that 50 to 60 per cent of time spent on any given order had nothing to do with baking or packaging. Baking the product was not the largest part. There were many other tasks that took even more time, and that is if nothing went wrong, like a bad credit card. Here is what else took more than half the time.

• Talking with a client on the phone

• Using the terminal to key in the credit card details

• Using QuickBooks to provide an invoice

• Logging into the courier website to type all the details of the order to be picked up

• Calculating what to bake on any given day

• Writing a gift card for the recipient

• Writing an address label for the package itself

• Numerous other miscellaneous tasks

At least 50 per cent of his time on paperwork, and he wanted to eliminate this without adding more labour. He began using Excel to standardize his administration. Step 2 was quite a bit bolder. He spent $30,000 on a customized online ordering system and back end management solution. This was a boon for the business, and he says his paperwork time became three to five minutes per order rather than 15 to 20

minutes per order. There were still hiccups along the way and work to be eliminated. His programmer advised him it would take another $10,000 to make the administrative work go away. However, like a home renovation, it never goes quite how you planned it. By the time Zelvovitch added all the bells and whistles to it, like the ability for clients to add their own logo or photo to the card, he had spent double the original estimate. He says he paid the whole bill in the three weeks at Christmas just by being able to produce more orders because five hours of paperwork a night disappeared. He had the software so finely tuned that, he says, “We disallowed the customers to complain.” By that he means that any error that they make because they didn’t take the time to input proper addressing information is well documented in the order form so that he can go back to them and prove they didn’t do it right and if required charge an additional fee to re-deliver.

The system is simply built to know all the problems of online ordering. It’s also built to help Zelcovitch make more money when demand is high. It is set up so that Zelcovitch can enter a percentage and all products will decrease or increase by that amount, which is great on holidays or if you are having a sale. It can also modify special single-day and specific time frame shipping charges. For example, you could charge on Valentine’s Day when demand is high. These two features work well for sales, but what he says he loves is how much of a boost to the bottom line it can be. On Valentine’s Day, increasing the price of the product and shipping across the site earns him an extra $5,000, he says. And that is only for orders that come in on the 14th. He can adjust prices so customers are rewarded for advance orders, but pay more for rush deliveries. At one time he found himself losing money on deliveries and solved this problem by having the system do customized charges by postal code. He also found that customers often need to specify the

time of delivery, so while he includes 9-5, he also allows them to pay more for delivery in a smaller window, such as 9-12.

On the back end, the system communicates directly with the courier and the bank, who are made aware of orders in real time. It recognizes out-of-town shipping and is so smart it doesn’t try to submit those to the local courier. The system prints the shipping label and inscription card with pristine colour laser quality on special perforated paper to make adding it to the basket lightning fast. It is so smart it is impossible for Zelcovitch to accidently deliver an order a week early if he accidently file it incorrectly. When the order is delivered, it lets the sender know it has arrived by e-mail (and even lets them know who signed) within two minutes of delivery, he says. It takes five seconds per order for the software to produce a label, card and courier slip for each address. The system also invoices the client and deposits money directly into the company account.

The system incorporates other, more subtle, sales-generating tactics for Zelcovia. It automatically e-mails senders of a birthday or anniversary gift a coupon 51 weeks later asking if the client would like to reorder. It automatically e-mails senders a survey two days after delivery, then e-mails coupons and a Facebook link if the customer rated their services well. It also has a built-in loyalty program that automatically enrolls everyone by using their e-mail address.

The software addresses client communication needs. Zelcovia can leave a special message on a specified date, which is useful if there is poor weather and extra time is needed for deliveries. For example, during the holidays when someone selects a certain date and knows his orders are nearing capacity, he can have a message pop up that says “We are getting close to capacity, may we suggest Thursday to order if that is not an issue for you?” He can also put up an order block that helps manage workflow. He can prevent people from ordering when he is booked solid by graying out certain times of day, or entire days.

The system is also intelligent about the baking aspect of the business. It calculates Zelcovitch’s bake list, basically telling him what to bake, and it knows how long it takes to bake and cool the cookies, which assists him in time management.

From a user perspective, the order form allows the customer to fill out all the needed details and add their own logo to the inscription card, which is handy for corporate gifting. People can also add a photo to the card instead of a logo and choose to add a balloon.

All in all, Zelcovitch’s customized system has 336 features that help him run his small online business at peak efficiency. Investing in the software has, he says, made the ordering mistakes he

was making go away and cut his labour time required for each order by 50 to 60 per cent. It was designed to eliminate an employee and make him more money, which he says it has done successfully.

“I used to not want to spend money, now I will spend whatever it takes to make the problems go away.” / BJ

For more profiles, visit www.bakersjournal.com

COLLEEN CROSS

Joanna Schultz was motivated to open Pikanik, her gluten-, wheat-, nut-, dairy-, soy- and sometimes egg-free bakery, by the disappointment and frustration she felt on entering bakery after bakery that offered gluten-free products only to find a very limited selection of items that were safe to eat.

Her two daughters, Frances, 6, and Gisela, 3, are intolerant to gluten and dairy. Schultz herself is gluten-intolerant.

“I thought, this can’t be all there is,” she says.

A baker “four careers ago,” Schultz had been doing her own baking for years, experi-

menting and developing recipes. When she realized what a demand there was for safe, delicious baked goods in the food intolerant and allergen market, along with the luxury of choosing freely from a menu, she set about developing and honing recipes for breads, buns, cakes and other treats in order to fill that niche.

She says her “classic sandwich bread” took two years to develop and entailed a challenging process: “I baked 20 loaves before I even had a glimmer of hope.”

In October 2012, she left the corporate world of labour relations to become an

entrepreneur and opened a storefront location near her home in White Rock, B.C., a suburb of metro Vancouver where the multi-allergy clientele was underserved.

She started the business as a bakery and lunch counter offering nut-, gluten- and dairy-free products, and then added soy- and egg-free products. The popular lunch spot has since given way to a straight bakery, where the demand for product and demands on her time have made it necessary to focus on developing and making products.

Although not formally

trained in business, she says she is comfortable in this new venture.

“I feel like this is what I was always meant to do,” she says.

Pikanik’s four staff members include Schultz, two bakers and a full-time manager of customer service. Schultz does most of the business administration herself, with help from her husband, Patrick Gibson, who is co-founder of a software development company and an amateur photographer.

Operating a shop that is “everything free” means there is no chance of cross-contamination. Production efficiency wasn’t even a consideration,

The shop offers a menu of breads, rolls, scones, muffins, cream puffs, cookies, squares and specialty cakes that changes daily.

says Schultz, because she couldn’t take the risk. But focusing on a niche market has helped her streamline marketing efforts. She posts her menu in the store and on Facebook every day and is able to drive home the message that the bakery is a safe environment for people sensitive to certain foods, without letting taste take a back seat: “We only mention it because you’d never know,” says the Facebook page.

Schultz describes the shop’s ratio of fresh to packaged goods as about 85 to 15, but increasing all the time. Most of what they sell are freshly baked goods: breads, rolls, scones, muffins, cream puffs, cookies, squares and specialty cakes made to order. She also has a ready-bake line that includes cinnamon rolls, burger buns and dinner rolls. All goods are freezable, she says. Customers appreciate having access to products seven days a week and baking with family when they feel the impulse.

When she brought home a three-inch-thick manual for the cash register and handed it to her husband, he quickly came up with another option. He downloaded a program called Shopkeep and set it up to run the POS system to run from an iPad.

“This system has helped me know when the key times are to schedule staff, track patterns in sales, identify top sellers, track inventory and more,” Schultz says.

It allows staff to change menu items at any time, do a sales analysis and pull reports, which is useful for figuring out customer traffic patterns. She says the Cloud-based system takes the guesswork out of making decisions and gives her some data to work with.

Shopkeep can serve as a database of customer lists for marketing e-mails and has recently added a built-in

customer loyalty program feature, features Schultz plans to use to their full potential.

A customer web app Gibson created and a tiny computer called a Raspberry Pi allow her to feed information simultaneously to the website, Facebook, Twitter and an in-store projector.

On the wall of Pikanik’s clean, bright shop, in full view of the customer lineup, Schultz projects the daily menu, advertises products and highlights customer feedback.

“I enjoyed a wedding cake made by you over the weekend! One of the best I’ve ever had, and I’m not even trying to avoid gluten,” read one of the featured comments.

“Customers love to see their comments projected in the shop, and seeing other people’s testimonials as they are standing there thinking about whether to buy something really impacts folks – especially people in our shop for the first time,” says Shultz.

Social media (Facebook in particular) is integral to the bakery’s mission. Schultz, a finalist in the Bakers Journal Business Awards, put it best in an e-mail to Bakers Journal: “The key underpinning of my business is customer engagement. In this day and age, when bricks and mortar businesses need to compete with webbased sales, customer loyalty is critical. There is no better way to build customer loyalty and brand recognition than with customer engagement – my customers are as passionate about my business as I am. Not a day goes by that I don’t have customers thanking us from the bottom of their heart for doing what we do, committing to spread the word, taking business cards to hand out to their friends, even posting our

“It’s really when I want to communicate with our customers or I want to engage them in something,” says Joanna Schultz of Pikanik’s social media strategy.

brochure in their apartment buildings! I’m so proud of that.”

She focuses her efforts on Facebook because of the demographic it provides. “Not only does Facebook allow us to share what’s going on in the shop, promote new products, etc. – it provides so much more,” she says. “People get their hands on our products faster by messaging us . . . and, critically, the more people that ‘like’ our page, the more insight we gain about our customer base.

“You can also build anticipa-

tion about product development. One day I posted a photo of a pizza we made in the shop and it went viral. It was obvious from the numbers and comments that a fantastic gluten-free pizza dough needed to move up in our development list. Since we’ve launched that pizza dough, it’s become one of our best sellers.”

On days she is swamped, readers might see only one post – that day’s menu by 10 a.m. – but when she has more time

Many bakers shy away from making their own laminated products because they feel that it takes too long to make and it’s too expensive, or, when they make their own croissants, Danish, and puff pastry products, the results are mixed and inconsistent. Buying frozen seems to be the logical solution.

The great news is that with new laminating techniques you can make excellent and consistent products with less than one hour of actual hands on time, and in some production techniques you can get from mixing to baked products in less than four hours.

But first we must take a step back and discuss the common problems with laminating and the solutions. For the purpose of this article, we will focus exclusively on croissant production, however most of the rules apply to Danishes as well and with a few modifications, puff pastry too.

Yes, our great Canadian high protein baker’s flour is not ideally suited for croissant production. Most baker’s flour has protein ranges from 12.5 to 13.2 per cent. This is too strong for making great croissants. The crumb will be tight and closed versus open and very flakey.

As I was preparing for the Louis Lesaffre Cup in 2010, I was already well versed in new and quick ways of laminating, but the crumb of my croissants was always closed. I began to source weaker flour and flours with no treatments. Unbleached all-purpose flour was a good first option, but still not ideal. I then began to work with an untreated winter wheat, which in the end provided the best results for the flours that were easily accessible in Alberta. Lower protein winter wheat with no treatments (i.e. ascorbic acid, azodicarbonamide) is the flour that I find most suitable for croissant production. For your market try and source a lower protein flour, anywhere from 11.5 to 12.8 per cent. Improvements were coming in the crumb,

but still not to the level that I wanted. This is when I began to add pastry flour to weaken the flour further. The long awaited improvement that I was looking for finally arrived! A weak winter wheat with a blend of pastry flour at 20 to 25 per cent seemed to provide the best crumb.

Coming to this conclusion made a significant improvement in the final product.

The butter used in France has higher butterfat content (84 to 86 per cent) and the process in which it is made enables the butter to remain more plastic in nature. Our regular Canadian butter has more water and only 80 to 82 per cent butterfat. The lower butterfat and higher water content poses challenges in laminating, as the process requires the dough to be placed in the freezer, causing the butter to freeze and then fracture through the laminating and make up process.

This hurdle was causing inconsistencies in the final product. Fortunately, early on I

received a great tip from Mario Fortin (the coach of Baking Team Canada). He suggested warming the butter to at least 9 C before laminating. Then Peter Yuen, who was a guest instructor at Nait Bakes 2012, talked about tempering butter as if you are tempering chocolate, so that you get the fat crystals in the correct alignment so they remain plastic in nature. He demonstrated a technique of sheeting the butter between resinite films. Yeun suggested that once the butter is in a plastic state it will remain there. This may hold true to higher butterfat butters, but not the regular lower butterfat butters you purchase from your supplier.