Three former chairs of the CRAC reflect on their careers, growing up in cranes, and their experiences as women in a male-dominated industry

BY MATT JONES

ranes and heavy construction have long been stereotyped as “men’s work,” and the demographics of the industry could enforce that perception. The industry is fairly dominated by men. But that perception is changing, as more and more women are establishing themselves as driving forces within their companies and within the industry as a whole.

We spoke to three such prominent women about their experience growing up around family-owned crane businesses, their terms serving as chairperson of the Crane Rental Association of Canada, and their experiences as women in the crane industry.

SHEENA BAKER

CANADIAN CRANE RENTALS

“I’ve been exposed to the crane industry since a very, very young age,” says Sheena Baker. “Growing up, most people had Tonka toys, I had real life-sized heavy equipment and that’s where my love for the equipment started.”

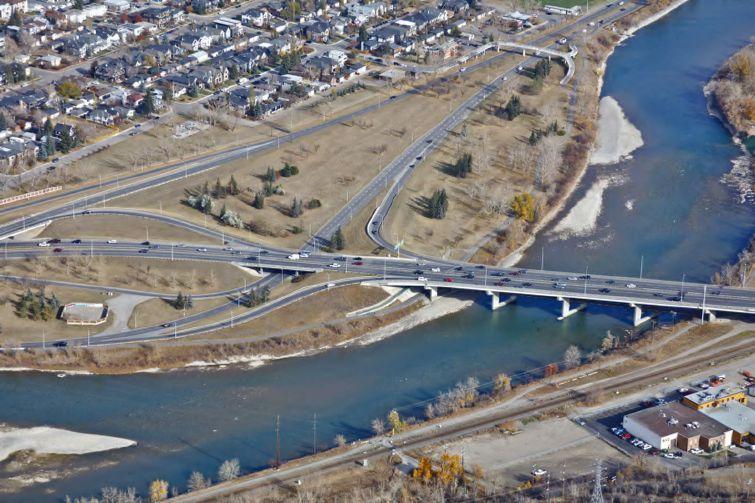

BY SAUL CHERNOS

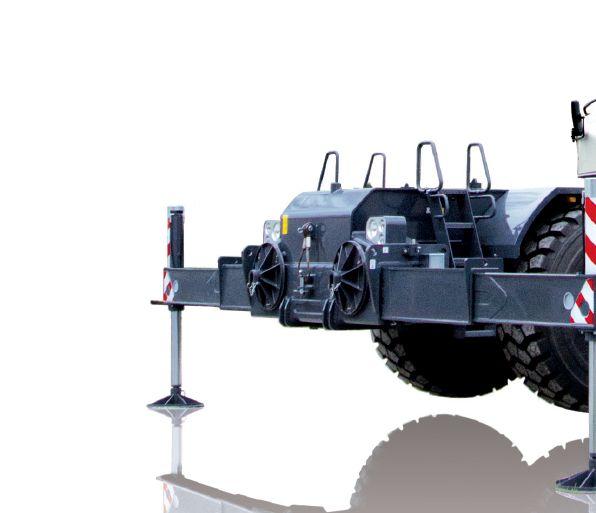

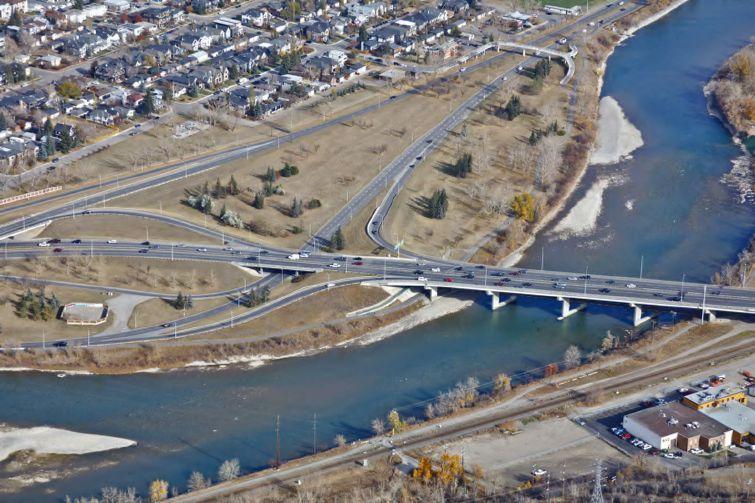

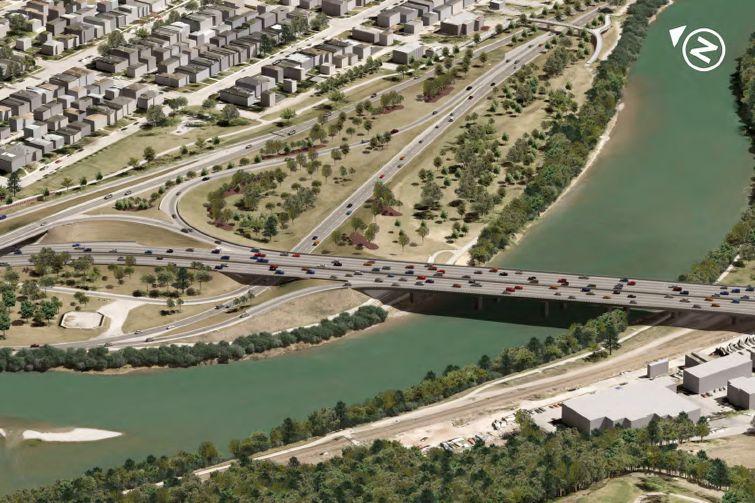

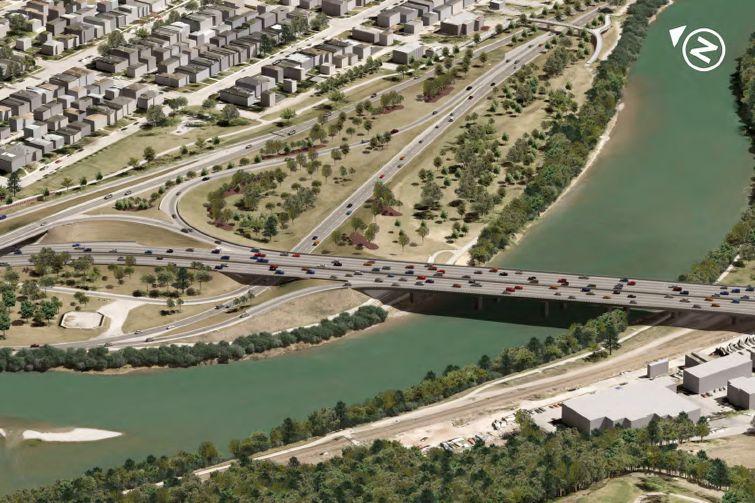

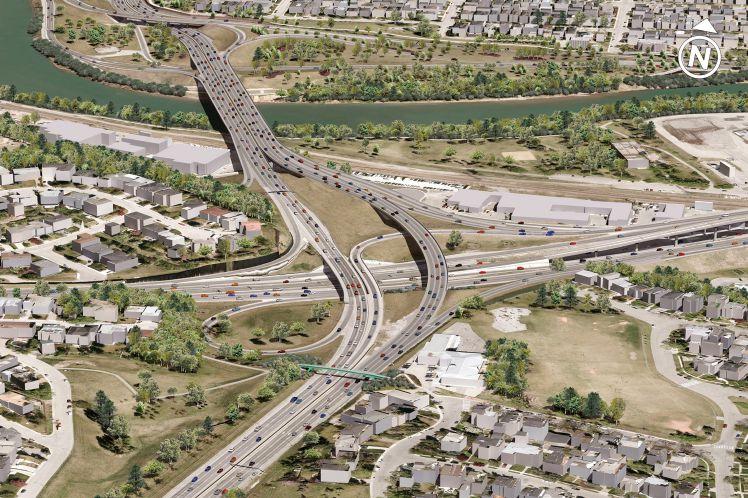

ranes will be modest in size, but hard working, when crews refurbish four bridges on Crowchild Trail, a major roadway in Calgary over the next two years.

The pier-and-girder bridges, all connected and flowing into one-another, cross the Bow River, two rail lines, smaller roadways and walking paths. But, built in the 1960s, they have weathered significantly.

“You can see the concrete starting to deteriorate and there’s some exposed rebar,” Jeff Baird, a senior City of Calgary transportation engineer who is managing the project, told Crane & Hoist Canada. The bridges also needed expansion, given

BY LAURA SUTTON, ALL-WEST CRANE & RIGGING, LTD.

Canada’s abundant natural resources are just beginning to be tapped, and, as a greater exploration of mineral and energy sources ramps up, the country will have a need for more heavy construction equipment, including cranes, crane trucks, and related equipment.

One recent project that illustrates the need Canada’s growing mining industry has for industrial machinery is the Brucejack Gold Mine, a major mining project in British Columbia with proven reserves of about US$2 billion in gold in the main body of the mine. Pretivm Resources, the company in charge of the Brucejack mine, says that the mine likely has four times that much gold altogether, along with a huge deposit of silver. Substantial funds have been spent to develop the mine, but it is expected to provide an excellent return on investment.

Big projects require big equipment, and All-West Crane & Rigging, Ltd. played a major role in the Brucejack project, providing cranes and staff to help in the construction of mine facilities. The company began work on the project in June 2016 with two

Editor – Andrew Snook • asnook@annexweb.com, 289-221-8946

Advertising Manager – Jeremy Thain, jthain@annexweb.com

Tel. +1-250-474-3982, Toll-Free (North America) 1-877-936-2266

Media Designer – Brooke Shaw

Regular Contributors

Saul Chernos, Jeffrey Carter, Nelson Dewey, Matt Jones

Group Publisher – Scott Jamieson • sjamieson@annexbusinessmeda.com

COO – Ted Markle • tmarkle@annexbusinessmedia.com

President & CEO – Mike Fredericks

Circulation Manager – Barbara Adelt

badelt@annexbusinessmedia.com

Subscriptions – Bona Lao – blao@annexbusinessmedia.com

Tel: 416-442-5600 • 1-800-668-2374 (CDN) , ext. 3552

Fax: 416-510-6875 or 416-442-2191

www.craneandhoistcanada.com

Annex Privacy Officer – Privacy@annexbusinessmedia.com

Tel: 800-668-2374

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher. A subscription to Crane & Hoist Canada (six issues) is $36 per year in Canada. For subscriptions in the USA the price is $36 USD. Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT. 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1 ISSN 1923-788X

Next Advertising Deadline: March 23, 2018

Don’t miss the opportunity to be part of this exciting new industry publication. For more information, or to reserve space in the next issue, call Jeremy at our Advertising Department - Toll Free 1.877.936.2266 jthain@annexweb.com

Next Editorial Deadline: March 28, 2018 For writers’ guidelines and submission requirements get in touch with the Editor, Andrew Snook, at 289.221.8946. Email: asnook@annexweb.com

Staying safe out there? Then get recognized for it!

More than ever before, companies in the crane sector are expected to manage time constraints and penalties for not meeting deadlines, that in many cases, have never been more severe. This puts additional pressures on companies to perform efficiently, and leaves open the possibility of things beings missed during the rush to get the job done that can lead to unsafe workplaces.

That said, surely almost everyone working in the sector puts safety as a top priority – who wouldn’t want all their people going home safe at the end of the day? But the reality is not all safety procedures across all companies are created and managed equally.

And now, for the first time, the Crane Rental Association of Canada (CRAC) is accepting submissions for its first ever Safety Awards, which will be part of the association’s festivities during its 20th anniversary celebrations at the 2018 CRAC Conference taking place from June 6 to 9 at The Fort Garry Hotel in Winnipeg, Man.

WHO CAN APPLY, YOU ASK?

The CRAC Safety Awards are open to member crane rental companies. Companies receiving the awards will be listed on the CRAC website and covered in partner publications (including Crane & Hoist Canada).

WHAT ARE THE CRITERIA FOR THE AWARDS?

1. All Crane Rental members of CRAC who are voting members in good standing as of Dec. 31 of the contest year and of the application date may apply for the Safety Award;

2. All entries must be received at the CRAC association office no later than March 31 of the year following the contest year to be considered;

3. All information submitted including reports on injuries, illnesses and lost time days will be kept confidential by

CRAC staff and not shared with other CRAC members;

4. Requested information must be calculated from January 1 to December 31 of the contest year;

5. Only companies with statistics for the full twelve (12) months will be eligible for the competition;

6. The company shall not have had a fatality in the year of the contest;

7. The company shall have a Workers’ Compensation Modification Rate of 1.0 or less and a Total Recordable Incident Rate of 1.75 or less. Entrants must submit a completed application form along with the following documents:

i. Workers compensation board injury reporting form for each province the company does business.

ii. WCB Premium rate report for each province the company does business.

8. TRIR (“Total Recordable Incident Rate”) will be the primary method for deciding award. When calculating incident rate, recordable incidents and man hours worked should be included for all applicant company WCB registrations. TRIR = [(number of recordable injuries and illnesses)*(200,000)] \ [person hours worked]. Recordable Injuries Illnesses is defined as, “every occupational death; every non-fatal occupational illness; and those nonfatal occupational injuries which involve one or more of the following: loss of consciousness, restriction of work or motion, transfer to another job, or medical treatment (other than first aid).”

9. At the discretion of the CRAC’s Safety Awards Committee, entrants may be required to submit verification of their application information.

10. At the discretion of CRAC’s Safety Awards Committee, serious property damage incidents may disqualify the company from winning an award.

MORE QUESTIONS?

Contact Claire Belanger-Parker at: claire@crac-aclg.ca; or call 306-585-2722.

The criteria and application form for the CRAC Safety Awards can be found on the CRAC website: www.crac-canada.com.

Good luck to all of the entrants of the inaugural CRAC Safety Awards, the team here at Crane & Hoist Canada look forward to touching base with many of you in Winnipeg. Stay safe out there!

BY MATT JONES

he Halterm International Container Terminal at the Port of Halifax in Nova Scotia announced it would invest $10 million into capacity enhancements over the next 12 months – including the addition of new rubber-tired gantry cranes (RTGs) from Konecranes.

The new RTGs will replace three shipto-shore cranes, which were installed in the 1970’s.

Halterm utilizes a variety of equipment for stacking, including Konecranes ReachStackers and toplift forklifts. They will add three ‘1 over 5’ RTG cranes in 2018; which be able to reach over six lanes and can stack up five containers in import and export zones. The new cranes will increase yard capacity by 160,000TEU, or 40 per cent overall. The first crane will be installed in February with the next two arriving in October.

Halterm reps say that all their currently active five ship-to-shore cranes are still in excellent working order; however, following increased container traffic in 2016 and 2017, the new cranes will be necessary to keep up with rising consumer demand. The investments will provide carriers congestion-free operations over more than a kilometre of quay, at three berths between 14 to 16 metres draft.

Halterm is the only facility in Eastern Canada capable of handling ‘Ultra’ class container vessels. The enhancements will also include new reefer capacity, with an increase by 25 per cent to over 600 reefer plugs.

anitowoc Cranes has appointed Mi-Jack Canada as the newest dealer of Manitowoc and Grove cranes in Alberta and Saskatchewan. The Leduc, Alta.-based company offers full sales, rental purchase options, aftermarket parts and service support in both provinces. The move strengthens Manitowoc’s dealer network in the region.

Alan Swagerman, regional manager for Mi-Jack Canada, said that the company is uniquely positioned to bolster Manitowoc’s success in Canada.

“Mi-Jack has achieved success over its six decades in business by maintaining a benchmark of service response and aftermarket support, assuring equipment reliability in the field,” he said. “We share those qualities with Manitowoc Cranes, which is why we’re so excited to offer Manitowoc and Grove cranes throughout Alberta and Saskatchewan.”

Mi-Jack Canada is a member of the Lanco Group of Companies and is closely tied to two North American Manitowoc distributors: Riverdale, Ill.-based Walter Payton Power Equipment; and Fontana, Calif.-based Western Pacific Crane & Equipment.

“We’re very excited to partner with Mi-Jack Canada,” said David Hull, vice president of Americas sales for Manitowoc. “Manitowoc’s customers expect velocity, product innovation and outstanding customer service, and Mi-Jack Canada will deliver on those expectations.”

Mi-Jack Canada will service the region from its offices at 7609 42nd Street, Leduc, Alberta T9E 0K5, Canada. Customers can reach the company at (780) 986-1001.

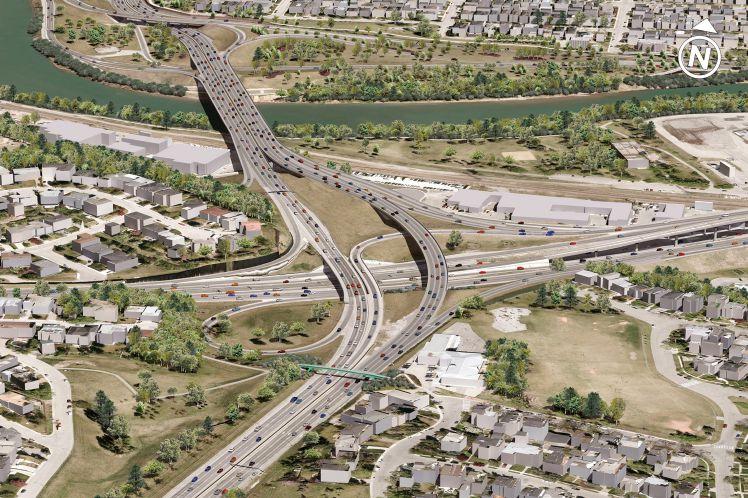

WIKA Mobile Control (formerly Hirschmann MCS) of Chambersburg, Penn. has awarded Crane Warning Systems, Inc. of Lakeland, Fla. the Top Sales Award for 2017.This is the ninth year in a row that Crane Warning Systems has received this award.

“Our success is due to the amazing teamwork we have here. Great customer support, technical experience, and the relationship we have with our customers is what makes us who we are today,” says Randy Dickinson, president of Crane Warning Systems Inc.

Crane Warning Systems has been a dedicated Premier Dealer since 2002 and offers the entire line of PAT, Krueger, and

Hirschmann branded crane operator aids including wireless and hard-wired indicators, load moment indicators (LMI), and A2B systems.

inshofer recently announced it has acquired the Doherty Group, a New Zealand-based excavator attachment manufacturer. Under the terms of the agreement, Kinshofer acquired 100 per cent of the Doherty Group. The entire Doherty management team will stay with the company and Doherty Group co-owner and managing director Jeremy Doherty will remain as its managing director.

“Kinshofer continues its strategy of providing the industry with a ‘one-stop-shop’ solution of outstandingly engineered products to increase efficiency and, more importantly, the profitability of its customers,” said Thomas Friedrich, Kinshofer Group president and CEO.

Doherty, a family business established in 2001, focuses on developing and marketing attachments and equipment that enhance the effectiveness and versatility of carriers. The acquisition adds additional product segments to Kinshofer’s range, including quick couplers, buckets and other excavator products.

Doherty will continue to develop and sell its products globally. Anticipating increased opportunity and demand, Doherty and Kinshofer will expand their sales and production staff to ensure swift integration of the products throughout both organizations.

“The concentration of knowledge and competence between our companies

provides a platform and expertise that will enable rapid and responsive product development to meet new customer challenges,” said Doherty. “In addition, our customers will benefit from continuing to be able to buy from the team they know and trust.”

Kinshofer and Doherty employees are working on rapid integration to provide customers worldwide with their comprehensive range of products and services.

Founded in 1946, Equipment Sales & Service Limited (ESS) is a third-generation family business that has been designated as one of Canada’s best-managed companies since 2011. Their distributor agreement with Link-Belt Cranes for the territory of Alberta dates back to 1978. ESS will provide comprehensive sales, parts, and service coverage from Delta, B.C. (Vancouver area) and two locations in Alberta.

“ESS is extremely excited about the opportunities expansion into British Columbia brings,” said Mike Smith, ESS vice-president and general manager. “We take pride in delivering a personal standard of service to our customers based on our core values of hard work and integrity. Increasing our footprint with the sales and service team we are putting into place will be a benefit to Link-Belt customers in British Columbia.”

Baker represents the third generation of her family to work in the crane industry. At 10 years old, Baker began by doing cleaning and other types of grunt work for her family’s business – Canadian Crane Rentals in Wingham, Ont. After leaving the industry briefly to pursue an education, she was drawn back in her early 20s.

“We also had a pumping division, so we were running a significant amount of equipment at that time, so we needed extra help,” Baker recalls. “I came back just to temporarily help out for a little bit and rekindled that interest in heavy equipment and running a business; and learning more about what goes on in the field of a construction site, multi-site projects, that type of stuff. I started there and built on that to what I do today.”

Baker worked on the safety side of the business initially and slowly added more and more skills – learning what size equipment would be needed for which projects, dispatching, managing employees, overseeing the shop floor and overseeing the operators. Today, she serves as operations manager.

Her brother technically works underneath her, but there is no sibling rivalry.

“He’s running the equipment but he has no interest in actually managing the business,” she says.

There were no gender roles in their household growing up – if her father needed help fixing the car it fell to whoever was handy. They were both treated the same and exposed to the same things.

Baker is also an owner and instructor for Huron and Bruce Safety Training. Grown out of her experiences focusing on safety within Canadian Crane Rentals, she saw a need for training options that were more affordable for smaller businesses.

“I understand the risks that they’re being exposed to. So, from an instructor standpoint, I don’t just have a book that tells me, I actually have hands-on experience,” says Baker.

Canadian Crane Rentals has been associated with the CRAC since the beginning. Her father is currently serving his third term on the board and was also president. Baker herself served on the board for six years and was president last year.

“I was very grateful that they accepted somebody, relatively very young in the industry,” says Baker. “I was only in my

mid-20s when I was nominated. There was no, ‘I’m older, I’ve been around longer. Can we trust you?’ It was very well diversified between anyone on the board –everybody’s opinion mattered.”

One of Baker’s proudest achievements with CRAC was putting an enhanced focus on the safety aspect of the business – getting information about what’s happening in the field, what the trends are, and getting the forum to discuss how to deal with those issues. She was also very happy to provide a voice to smaller companies in the industry, such as Canadian Crane Rentals.

SHAWNA BOREEN SARENS

“My father owned a crane company and I drew the short straw,” jokes Shawna Boreen.

At a young age, Boreen was extremely interested in business.

“Even as a young kid, I would read the business section of the Edmonton Journal, totally nerdy,” she says.

After finishing her university degree, Boreen worked for her father’s company, King Crane Service Ltd. There, she worked in the office and came to understand the basics of what her family did.

The biggest lessons she learned from her experiences working with her father were about decision-making and leadership – how it’s not about always

being right, but about being able to make a decision that helps the team get to where they need to go. Her father entrusted her with responsibility early on and was adamant that she develop the skills she would need.

“One of my first tasks in the crane industry was to get a loan for my dad to buy a crane,” says Boreen. “I had to go to the bank manager and said, ‘Mr. Simpson, I’m here to get a loan’ and he said ‘I don’t deal with you, I deal with your dad,’ and he sent me away! So I came back to my dad and he’s like, ‘Get back there, you’re the future. You’re going to learn how to get a loan from a bank.’ I had to go back to see Mr. Simpson and I said, ‘I’m more afraid of my father and going back without a loan than anything you can do here.’ And I got to write a check with more zeroes than I’d ever seen in my life.”

She remained with King Crane Service until its closure. Following that she did some freelance work for other crane companies on specific projects, from the opening of a new branch, to helping with health and safety aspects, to managing rough terrain crane fleets. During a lull between jobs, she was approached by Sarens and became their special projects manager. Currently, she is based out of Nisku, Alta. serving as senior project manager and site manager for the company.

In the early days of the CRAC, her father was asked if he would like to sit on the board – he declined, but suggested Boreen would be a good fit. She became a board member and would go on to become chair in 2006. She did a lot of community and committee work with the association. She will finish her third tenure on the board this May. She says she was particularly proud of the CRAC conference she was in charge of in Kelowna, B.C. in 2006.

“What I bring is a sense of collaboration and communication. I think those are my strengths as a leader,” says Boreen. “We helped to really establish the spousal program with regards to having some value for the spouses who attend, men or women, and we really developed that. We were really diligent in ensuring that the speakers we bring are informative, are relevant to the times and can speak to the issues that are of a nation instead of just specific areas.”

VALERIE

BRENNAN

AMHERST CRANE RENTALS LTD.

Brennan took a brief sabbatical in her early 20s, working in the Caribbean islands. When she returned, she began working for Amherst as a bookkeeper and developed further skills in other aspects of the industry.

“It was all just continuous learning and an enjoyment of working with the people in the industry who I find very creative,” Brennan says. “Art and music and cultural things have always been a big part of our lives. My parents were like that and taught us that. So the construction industry sort of follows suit – the people that you need in this business are builders. They always have great ideas and strong conviction, so they move ahead and build. I enjoy that environment, so I’ve made myself a big part of it.”

Today, Brennan says she touches on all aspects of the business – perhaps not as an expert, but well-versed in all of it. She has participated in the development of education for crane operators and has sat on committees with the government for regulatory bodies. She manages the office and staff, and helps with legal issues while also being a capable crane operator, and able to cover for a dispatcher, if need be.

“I was one of the oldest, so the kids all got involved in helping right from the get-go in one way or another,” says Valerie Brennan. “I began to do invoices for my mother when I came home from school and I helped her with some of the bookkeeping. It was a family business, no question about that.”

Brennan’s father started his company – Amherst Crane Rentals Ltd. – in Scarborough, Ont. in the early 1960s as a one-crane operation. Brennan began working in the company’s office, but started getting very hands-on with the equipment shortly after her father bought a full shop.

“I liked to be outside, so I got into the shop and got involved in watching what they do and why they need things and what broke down and learning a lot about it,” Brennan says.

Brennan, and Amherst, joined the CRAC in its second year of existence. Brennan thought it would be wise to join it as a social club and networking opportunity, to get to know people in the industry who had the same type of machinery, the same concerns and the same dealings with manufacturers. Eventually that social club evolved into what the CRAC is today.

“Now it’s becoming more of a voice,” says Brennan. “Obviously, there are projects that are more connected in Canada, so it’s more sophisticated than it was 15 or 20 years ago. It’s been a great asset to already have that base.”

Brennan is particularly proud of the work she was able to contribute to with CRAC, including Red Seal training and a current project looking at law surrounding heavy machines and their impact on the road. She was also very proud of the CRAC conference in Toronto during her time as chair, where they brought in elephants and other animals from the Bowmanville Zoo, based on an incident where cranes were used to rescue elephants that had slid down an embankment at the zoo.

The goal is to change habits before they lead to incidents.

BY JEFF THORNE

Behaviour is one of the most common denominators for every organizational performance issue. It certainly is when it comes to safety. So often we see repeatedly poor safety performance and there is no sustainable change in behaviour because the focus is on the action and not the behaviour that led to the action. To curb the non-compliant behaviour we discipline without ever realizing what led to the behaviour. This makes it difficult to achieve desired changes in safety performance.

When organizations take the wrong approach to changing safety behaviours in the workplace, often all the time and effort spent in creating and implementing a behaviour-based safety program has been wasted as the program doesn’t yield the desired results. The focus remains on the process and the sequence of a behaviour-based safety program where the focus should be on safe behaviours.

For the implementation of a behaviour-based safety program to be successful, there are five key things that need to occur.

1

Identify the objectives and outcomes of a behaviour-based program. The main objective of a behaviour-based safety program focuses on making safe behaviour a habit. Many incidents arise from the repeated at-risk behaviour of the worker. The worker has worked unsafely for years and avoided injury, so assumes there is no need to change their behaviour. A major objective of your program is to replace unsafe behaviours with automatic safe work habits. To do this, all parties must be able to understand and apply basic principles of behaviour change effectively so everyone is working towards the same goal.

2

Application of positive reinforcement. We’ve all done it, we’ve all taken risks. Often we take risks because there is a positive result. Risk-taking may result in saved time, effort, and resources. The unsafe behaviour that we exhibit occurs and is maintained because of the perceived positive results that follow. Therefore, management needs to focus on positively reinforcing safe work habits to replace unsafe habits. A little training in how to effectively apply positive reinforcement goes a long way.

Tel:

3

Applying the program to everyone in the company, not just the front-line workers. All too often these programs are targeted at yard staff, mechanics and drivers only and they may grow to feel like they are the ones putting in all the effort to make the process work. For change to be sustained, the program must apply to management and office staff. Workers’ safe behaviour must be reinforced, as should the managers and supervisors for supporting and reinforcing the workers’ safe behaviour.

Training – just do it. Provide the same type of training to everyone. All parties –managers, supervisors and workers – should be trained in core behaviour principles and the objectives and outcomes of the behaviour-based safety program. Desired behaviours and roles and responsibilities should all be clearly defined so that everyone can accept their role within the program. The training must focus on safe behaviour, not the process.

5

Create a program that fits the needs of the organization. Many organizations take the same approach where their behaviour-based safety program focuses on a specific action sequence: meetings about what to observe, detailed observation, data collection and review, and more meetings, with very little focus on changing the behaviour. A well-planned and designed program does not require significant amounts of time offline to complete training, complete paperwork, perform observations and attend meetings. The program should not affect key performance indicators such as service and production. If you’re implementing a behaviour–based safety program, it should be custom-tailored to fit your needs. Keep observations short, no longer than five minutes. Focus on two or three behaviours, not an extensive list, and be prepared to implement changes quickly. Behaviour-based safety is more than observation. It’s about understanding how and why people do the things they do. When we have an understanding of how to change behaviours and properly reinforce desired safety behaviours, safety performance will improve.

Terex Crane’s largest Canadian distributor Cropac Equipment Inc. – with locations in Ontario, Québec, Alberta, and B.C. – is already the official tower crane partner for Ontario and Quebec. With the addition of Atlantic Canada, they now service all of Eastern Canada.

“Cropac is committed to expanding our product offerings in all regions, this is an opportunity to better serve our existing customer base in these areas, as well as tap into some new markets,” said Bill Finkle, president of Cropac Equipment.

“We are excited for this opportunity to develop the Atlantic Canadian tower crane market, and we know our customers will not be disappointed with the Terex product or Cropac’s expansion into these areas,” added James Graham, business development manager for Cropac Equipment.

Over the past year, Cropac has doubled down in the busy Canadian tower crane industry, and are stocking new units for sale. This is a huge advantage when serving its client base because many times a buyer cannot wait for production or shipping time from the manufacturing facility located in Fontannafredda, Italy. By stocking machines on the ground in Oakville, Ont.

they can often eliminate most of this delay for their clients, which could mean the difference between winning or losing a project bid. Current stock orders include the Flat Top CTT332-16, the Luffing CTL260-18, and the Hammerhead Terex/Peiner SK415.

Another area Cropac anteed up to support their commitment to Terex tower cranes is parts inventory. Cropac will now be stocking spare towers, fixed anchors, motors, gear boxes, slew bearings and electronic parts. Cropac has also hired a new tower crane dedicated parts representative to strengthen their team and serve customers more efficiently.

Cropac’s appointment as Terex’s official tower crane partner in Atlantic Canada has already paid dividends, as Cosmos Developments recently took delivery of a new Terex CTT132-6 Flat Top Tower Crane in Halifax, N.S.

The crane was erected in January 2018 at the Gradhaven Estates (Phase 2) in the Clayton Park West area of Halifax, a luxury residential project owned and operated by Cosmos. The crane will serve to drastically speed up material handling duties on the jobsite as well as reduce labour costs by performing all the heavy lifting. After Phase 2 is complete it will move over to start on the final phase.

The Crane Certification Association of America will hold its annual educational conference from March 18 to 20 in Tulsa, Okla.

The conference is held every year for crane inspectors, engineers and surveyors with presentations by peers, engineers and safety officials.

Topics for this year’s conference include:

• Federal OSHA crane regulation updates

• Validity of inspection and test reports

• Overhead limit switches

• Repair documentation or “The anatomy of a welded repair”

Speakers will include Nick DeAngelis (OSHA); Donald O’Rourke (National Crane Repair); and John Groce (WireCo World Group).

A plant tour of Paccar Winch and Crosy’s Tulsa plant are included in the conference admission. The conference will be held at the Hyatt Regency Tulsa in Tulsa, Okla. To register, go online to: www.cranecertification.org.

I’m very happy with the Crane & Hoist program through Northern Lakes College, all the equipment is state-of-the-art, so you are being trained on the equipment you will be working with in the field.

– Vance, graduate of the Crane & Hoisting Equipment Operator - Mobile Crane Apprenticeship 3rd Period

Northern Lakes College offers a unique mobile delivery where training is provided in locations across Alberta where apprentices are working. Bringing the classroom to you!

For dates and locations please visit us on our website www.northernlakescollege.ca or call 1-866-652-3456.

rane companies with operations in British Columbia are gearing up for renewed activity on the Site C dam following a provincial government decision in late 2017 to proceed.

Crews had built roads, camps and other infrastructure to support construction of the large-scale, earth-fill hydroelectric dam on the Peace River near Fort St. John in northeastern B.C.

However, with strong opposition to planned flooding of land and soaring cost projections, Premier John Horgan’s NDPGreen coalition government sent the project to the BC Utilities Commission for review.

With that review completed in December, Horgan declared the dam back on.

While two Treaty 8 First Nations launched legal action in January to stop construction, crane service providers are readying for potential business and economic spin-off activity from a project now pegged at $10.7 billion.

With a planned peak production of roughly 1,100 megawatts of electricity and an annual output of 5,100 gigawatts, Site C stands to become B.C.’s fourth-largest electricity producer.

“A project of that magnitude will require cranes for various stages,” says Jerry van Halderen, owner of AllWest Crane & Rigging. “Construction of the powerhouse buildings and some of the other infrastructure and feeder power lines that come off of it would definitely use cranes.”

Still, van Halderen said the province’s largest crane companies seem best poised to gain the key contracts and he doesn’t expect much if any work from the project.

“We’ve quoted to a couple of contractors for the steel erection on the powerhouse — that’s where we’ve been involved in it so far,” van Halderen said. “But we haven’t

received notice that our contractors were successful or not successful.”

Certainly, the project is high-stakes. “We’re an intermediate-size crane company,” van Halderen said. “Often, on projects similar to this size, we don’t know we’re going to realize work until we get a call from one of the subcontractors who are smaller suppliers who end up being awarded parts of the work.”

Dan Patton, who owns Advantage Crane in Victoria, described similar circumstances. “About a year ago I looked at a small segment with one contractor who was trying to do a conveyor system up there. But he was unsuccessful, and I haven’t looked at anything else since.”

Distance from Site C is a factor — Advantage Crane is based over 1,000 kilometres away. “There’s so many cranes in that neck of the woods,” Patton said. “If I was going to go up there I’d need to be able to service my equipment.”

But company size is also key.

“We have 10 cranes, anywhere from 28-ton boom trucks to 275-tonne all terrains and we work on pulp mills, refineries and bridges — we’ve even done a wind farm,” Patton said. “But in that area you have Northern Crane, ENTREC, Mammoet, Sterling, LaPrairie and Sarens. Those six companies combined probably have, worldwide, 4,000 cranes.”

For now, these larger companies are holding their cards close to their chest.

“Preference would be to not talk about Site C due to the competitive nature of this project,” ENTREC Corporation president and CEO John Stevens wrote in response to a request for comment.

Ted Redmond, president & CEO of NCSG Crane & Heavy Haul (Northern Crane), also declined comment, calling it “a competitive situation.”

Crane companies that are retained stand to keep busy if one of Canada’s other big hydro megaprojects is any indication.

The $12.7-billion Muskrat Falls Project on the lower Churchill River in Labrador has both concrete and earthen structures, yet it has many of the same features Site C will have, including a spillway and powerhouse. With Muskrat Falls slated for completion by 2019, Brian Doyle, crane and rigging manager with general contractor Astaldi Canada, says a wide variety of cranes have worked on site.

“The cranes that have proven most productive and beneficial have been the tower cranes,” Doyle said, listing models such as Potain MD560 and MD365. Other signature cranes have included a Manitowoc 14000 crawler, a Manitowoc 16000 crawler, a Manitowoc GMK6250L, a Manitowoc 2250, a Grove RT9150, a Tadano ATF 220 and two 80-ton Terex RT780 machines.

The tower cranes handled formwork, rebar and various large materials, while the mobile cranes loaded and unloaded materials, moved trailers, and set up a warehouse, mechanic’s shop and other buildings.

A project in the B.C. Interior might expect some challenges similar to those faced in Labrador, where crews laboured through cold, snowy winters. As construction progressed, crews disassembled one of the cranes from the spillway and moved it to the powerhouse. “We took it down, disassembled and reassembled it,” Doyle said.

Astaldi purchased many of its cranes, renting only those it wouldn’t need for long. As the need for particular cranes ends, the company either auctions them off or transfers them to another company project. The Manitowoc 14000, for instance, is Miami-bound.

At the peak of construction, Astaldi maintained

roughly 80 crane operators, with 26 for each of three shifts. “The primary operators came from Newfoundland, though we did have some tower operators from Ontario and a father and son duo from Alberta,” Doyle said. None of the tower crane operators were local. “There was no training at the time,” Doyle said, explaining locals had first option on jobs through the union and some local apprenticeships were earned.

Doyle’s advice for crane and service providers wanting to maximize their chances of work at Site C?

“Bid the job honestly and fairly. If you can get your foot in the door and supply good service, then you’ll be the go-to person for the extra cranes or the extra work or the next job down the road.”

Brian Cochrane, business manager with Local 115 of the International Union of Operating Engineers, in B.C., said a handful of cranes have helped with earth moving and infrastructure development, but the go-ahead means work for several hundred crane and other heavy equipment operators.

“It’s been a while since we’ve seen a megaproject in British Columbia,” Cochrane said, recalling Rio Tinto aluminum smelter facilities in Kitimat, B.C.

Cochrane said the IOUE plans to engage First Nations and other local communities in training, certification and career development opportunities.

“That was part of the approval process, and we’ll be doing everything we can to make sure that mandate is supported and this becomes a legacy project that creates long-term lasting benefits for not only the Fort St. John area, but for the entire province.”

While the larger crane companies may be best poised for the bulk of the work, there could be a ripple effect for companies not partaking directly in Site C.

“When the large crane companies get work on projects like this, it takes their focus away from some of the smaller jobs and that allows us increased [activity] on more of the intermediate and smaller-size projects,” said All-West Crane & Rigging’s Jerry van Halderen.

Van Halderen said the approval, coupled with likely pipeline work, bodes well for B.C.

“It’s going to keep construction moving forward over the next couple years,” he says. “As long as we don’t see an economic crisis, the crane industry is poised for an upswing.”

BC Hydro was unavailable for comment.

Superior lifting capacities, on-line load chart calculation

Great variety of boom configurations

Quick and easy assembly

Easy and cost-e ective transportation

Liebherr-Canada Ltd.

1015 Sutton Drive, Burlington, Ontario L7L 5Z8

Phone: +1 905 319 9222

E-mail: info.lca@liebherr.com www.facebook.com/LiebherrConstruction www.liebherr.ca

Calgary’s strong growth in recent decades. The project will see two lanes added, one in each direction, bringing the total to eight. “Calgary has outgrown not just the bridge but the whole stretch of road (Crowchild Trail) to which the bridge connects,” Baird said.

Most of the initial work will involve replacing damaged, worn-out concrete and other components. Crews will encase piers and foundations in concrete to extend their service life, expand hammerhead supports atop piers, replace weathered expansion joints as well as some bearing plates and systems used for girders supporting the deck, and rehabilitate bridge decks, with one deck getting a high-performance concrete running surface.

“We’re doing about 1,500 square metres of surface rehabilitation on the substructure alone,” Baird said, estimating this at roughly one-fifth of the overall bridge and pier surface area.

While there will be some overlap in activities, the widening component will follow, with steel dowels installed to provide reinforcement and help the new concrete bond to the old.

“That would be the unique part of the

project,” Baird said. “Really, how the bridge is getting widened is putting in a lot of extra reinforcing steel. The dowels will be drilled in from work platforms underneath the bridge deck or from the ground supported by scissor-lifts or scaffolding.”

Crews will also relocate access ramps and install noise barriers along the roadway.

The considerable volume of work calls for a strong complement of heavy machines, including cranes. However, overall project demands add a layer of complexity that will directly impact cranes on the project.

To start with, crane sizes will be limited due to weight capacities imposed by existing bridge girders.

“All cranes used on the bridges during construction have had to be assessed for their impacts on the existing girder and deck systems,” Baird explained.

A variety of mobile cranes, supplied by Mammoet, will be on-hand. The largestcapacity include two 110-ton Liebherr LTM 1090 4.1 machines running in tandem on the bridge for demolishing the old girders and installing the new ones, and a

The Bow River is 645 kilometres long and intersects with Banff, Canmore, Cochrane and Calgary. It is one of the most managed rivers in Alberta.

open from 5 a.m. to 9 p.m. Monday to Friday to avoid commuter chaos.

This is what ultimately necessitated the work platforms. While traffic is in full play during these peak hours, crews will work from underneath the structure. Then, at night and on weekends, when traffic volumes ease off, crews will put signs in place and close lanes as needed while construction continues.

The decision to allow traffic during critical hours will impact the use of cranes. Crews will need to position cranes carefully so as not to interfere with traffic, and most lifts performed from the bridge deck will be conducted during night shifts to minimize impacts to traffic.

assist with project falsework and help erect the temporary work platforms underneath the bridge.

As well, a 55-ton Liebherr LTM10553.2 will help with temporary formwork support, and an assortment of smaller cranes, from 30-ton machines down to picker trucks, will handle beams and other materials going underneath the bridge to support the temporary platforms.

Those temporary platforms are necessary from the get-go because working from berms directly in the Bow River is not permitted.

Graham, the project’s main contractor, was tasked with designing the platforms and their set-up underneath the bridge. The platforms need to be able to handle loads safely, and an existing pedestrian footbridge beneath the main bridge deck also needs protection even though it’s offlimits to the public for a portion of the project’s duration.

Working with consultants Allnorth, Graham verified the structural capacity of the existing girders and deck, and crews used the 65-ton Liebherr to position temporary steel girders, fabricated in pairs, to create working platforms for widening

existing hammerheads that sit atop four piers in the river.

Martin Dobby, senior project manager with Graham, said the platforms were placed on hangers, suspended from the existing hammerhead, and then winched into position until the beams reached jacks, which were dowelled into the existing piers. Once the two sides were installed and spliced, the aluminum-beam platforms could then be installed.

Each lift for this project segment required careful engineering planning and approval.

“The outrigger positions are critical, and the path of the load has to be prescribed to ensure outrigger loads are not exceeded,” Dobby said. “The slinging arrangement and lifting-eye positions required specific attention, as the restriction of the existing edge beam meant the beams had to be eccentrically lifted.”

On the southernmost bridge, a boxgirder construction, Graham is developing a rail and trolley system to improve production on the installation of the working platforms.

“This is necessary due to the number of road crossings and the LRT (one of two

rail lines), where working windows are extremely limited,” Dobby said. There are additional considerations. All lifts need to consider obstructions posed by bridge infrastructure and hydro wires as well as entities below the bridges such as the river, rail tracks, roadways and a pedestrian bridge that crosses the Bow directly underneath the traffic bridge. Traffic will be a constant issue for crews. Because Crowchild Trail is a skeletal road carrying more than 100,000 vehicles daily, project planners opted to keep all lanes

“Each crane set-up on the bridge requires traffic management,” Dobby said. “The major lifts using the 110-tonne cranes can only take place once the traffic is shifted to [the other] side of the bridge, which can be achieved once the first side is widened.”

The $87 million projected price tag includes the various environmental and safety measures the project requires, in part due to the Bow River and other naturalized areas underneath.

The corridor study also proposed medium and long-term recommendations, so additional work could happen down the proverbial road. But the city’s Jeff Baird said the long-term plan to replace bridges and build new ones has yet to be funded and is still 30-plus years out.

BY ANDREW SNOOK

or more than a century, the Vancouver Public Library (VPL) has been dedicated to offering free access to reading materials to residents in the Vancouver area, while promoting the joy of reading and learning to all.

Although the mediums through which people learn and access information have changed somewhat over the years, the VPL has kept pace with the needs of both young and old. Last year alone, the VPL had more than 6.8 million visitors across its 21 locations, with close to 9.4 million physical and digital items borrowed by residents.

As part of continuing to keep pace with the needs and changing learning experiences of residents, the VPL decided to expand its Central Library, which included the renovation of the building’s top two floors to include a reading room, new community event and meeting space, exhibit spaces, a theatre and a ‘garden in the sky’ public garden, among other enhancements.

Construction on the two floors began in the spring of 2017 and was preformed by Vancouver-based contractors Smith Bros. & Wilson (BC) Ltd. (SBW) of Vancouver. The doors to the new facilities are expected to open to the public this spring. The expansion will add another 35,000 square feet to the library.

One of the biggest challenges facing SBW was planning out how to perform the necessary lifts in the congested area surrounding the Central Library, located on the busy West Georgia Street in the city’s downtown. The moving of demolition and construction materials onto the 8th and 9th floors required a well thought-out plan of attack.

“All the demo material had to be removed and the library only had service elevators to get material from the top floors to street level,” explains Tyler Brown,

o further reduce project costs, SBW’s plan for the CTL 43024 crane included a freestanding tower that wasn’t tied into the library’s structure. Originally, SBW planned on using an undercarriage strut mounting for the tower section. However, the optional base’s availability was limited and not available in western Canada.

SBW put its century-plus concrete fabrication experience to work and consulted with engineering firm, TNAI Engineering Ltd. of Vancouver, to construct a custom concrete base to serve as a tying point for the crane’s tower. TNAI came up with an ingenious way to

anchor the crane in a manner that would not require it to be secured directly into the building’s foundation.

Anchoring to the foundation would require cutting through the street-level membrane and closing the three-level underground parking structure.

“You don’t know what type of utilities and electrical components you will run into when cutting into the membrane, and this could lead to significant expense and delays,” explains Arsene.

TNAI’s engineering team came up with a “floating” 32.8- x 32.8 ft (10 x 10 m), X-shaped concrete base.

“When reviewing the parking lot’s

drawings, we found columns supporting the library’s parking structure that were built at a 32.8- x 32.8-ft (10- by 10-m) spacing, so we tied directly into those columns,” adds Arsene.

The columns served as the anchor conduit to the foundation below the parking structure.

The concrete anchor measured 6-ft (1.8-m) wide, and height along most of the cross section was 6.5-ft (2.0-m) tall. The outside 4-ft (1.2-m) end segments of the structure anchoring into the columns were 8.5-ft (2.6-m) tall.

“This, in essence, gave us 2-ft (0.61m) spacing between the concrete end

general superintendent for SBW. “During the tender phase, we saw the need to hoist many items, including large-span escalators to get people up to the green space. It was quite a challenging prospect.”

Adding to the project’s challenges was the building’s unique architecture, which required additional pre-planning during the bidding phase. To help find the right lifting solutions for the project, SBW sat down with Leavitt Machinery, based out of Surrey, B.C.

“The library is designed after the Roman Colosseum and surrounded by an elliptical wall on the east side,” says Dean Arsene, crane rental and sales representative for Leavitt Machinery. “We started discussing the project with SBW in late 2016, and all options were reviewed.”

SBW initially considered using mobile cranes to perform the heavy lifting from street level, but after identifying drawbacks to this plan of attack the company decided to pursue other options.

“The structure’s shape required a minimum of a 500-tonne (600-ton) capacity class mobile crane to hoist large materials to and from the upper floors because it would be boom bound,” explains Brown, adding that the possible set-up locations for a mobile crane at the site did not offer capacity to lift many of the objects at the required boom lengths and working radii. “This meant we would have had to shut down an entire street, and mobilization costs would have been high. By the time we counted everything that needed to be hoisted, it was cost-prohibitive to use a mobile crane.”

With mobile cranes out as an option, SBW decided it would look at using tower cranes for the project, reviewing flat top, hammerhead and luffing jib designs.

“The job required a 180.4-foot (55metre) boom radius, and the flat top and

segments and grade at the center of the X-shape to create the floating base required to properly disperse the load,” explains Arsene.

By employing the ingenious solution, SBW saved time, lowered costs and allowed the parking structure to remain open during the year-long reconstruction project.

“It was a pleasure working with SBW on this project,” concludes Arsene. “They have the expertise to find the solutions to successfully complete a challenging project like VPL, and they don’t shy away from them.”

Source: Terex Cranes.

hammerhead cranes didn’t offer the capacity we needed for the escalators without breaking them down,” Brown says, adding there was a more pressing issue, as the crane would be placed about 50 feet from an adjacent structure.

“Those booms were too long, and they didn’t have the freedom to slew without hitting a structure, so these designs were not an option,” explains Arsene.

In the end, SBW decided the right crane for the project was a luffing jib tower crane, and opted for the Terex CTL 430-24; which met the project’s reach and capacity requirements.

“Through our discussions with Leavitt, we calculated the luffing jib as the most economical hoisting logistics solution for us,” Brown says.

SBW rented the 26.5-ton (24-tonne) class Terex luffing jib tower crane from Leavitt for six months. Its tower required seven HD23 22.6 segments to reach the needed jib base height of 147.6 ft. (45.0 m). To cover the entire site, the CTL 43024 was equipped with a 180.4-ft. (55-m) jib. A 15-degree in-service radius was used throughout the project to lift materials to and from the rooftop.

“Using the luffing jib allowed us to position the tower closer to the library structure, but, even still, most of our lifts were made close to tip radius of the 180.4-ft. (55-m) jib,” says Brown.

“When the crane was not in service, the jib was set to a 65-degree radius to allow it to slew without hitting any of the adjacent structures,” adds Arsene.

Thanks to careful planning, Leavitt and SBW were able to install the crane without any major issues over a weekend in June.

The City of Vancouver permitted the closing of the adjacent Homer Street to allow for the installation.

“Using a 300-tonne (350-ton) capacity mobile crane, we installed the tower, counter jib and apex on day one,” recalls Arsene. “On day two, we installed the jib and counterweight. It was a very smooth set-up, and we were done in about 1.5 days.”

The crane was used daily during the demolition phase of the operation for the removal of large structural pieces and concrete from the rooftop. During the reconstruction phase of the project, the crane is being used to hoist building materials and full concrete buckets from street level to the 8th and 9th floors. The largest and heaviest planned lifts were for two 12,000-lb. (5.4-tonne) escalators that were hoisted into position without disassembly to save time and money.

The luffing jib tower crane hadn’t been taken down yet at the time of this issue’s publication, but Arsene says there are plans for it to be disassembled sometime in February, on a weekend when they are able to shut down the surrounding busy streets.

With everything moving according to schedule, the inhabitants of Vancouver’s downtown will be able to enjoy the new facilities at VBL’s Central Library in the very near future.

With files from Terex Cranes.

BY STAFF REPORT

Liebherr’s LR 1500 delivers the load capacities of the 500tonne crawler crane class throughout its operating range whilst having the dimensions and component weights which have previously been normal in the 400-tonne class. It can be transported around the world without restrictions with a transport weight of just 46.7 tonnes. The overall concept of the new crane is designed for simplicity in all areas and great economy. The criteria of simplicity and economy also had the highest priority in the development of the LR 1500. The new Liebherr crawler crane cannot just be transported easily and at a low cost, but is also simple to set up and operate. The powerful main hoist gear with its line pull of 180 kN can handle all hoists up to the maximum load capacity. This makes crane operation easier since it means that there is no need for a second winch for

lattice boom simpler and therefore more economical. The designers have come up with a particularly smart solution to increase economy with the central ballast. It consists of just a few concrete sections which can be set up quickly and easily and whose top section forms a safe catwalk for the undercarriage.

www.liebherr.com

The CK3300G-2, CKE3000G and CKS3000 debut as the largest models of Kobelco’s multi-purpose crawler crane CK / CKE / CKS series. Along with the recent increase in weights and dimensions of construction materials and heights of high-rise buildings, mobile cranes are required to have a higher lifting capacity as well as improved productivity and safety. In order to respond to such needs, Kobelco recently developed these “All Rounder” cranes

the super heavy lift configuration, including luffing jib, for the heaviest lifts. Kobelco designed these cranes taking into consideration maximum compatibility, such as jibs and pallet weights, with our other models.

The North American model (CK3300G-2) has a standard maximum lifting capacity of 661,300 lb. x 18.1 ft.; standard maximum boom length of 295 ft.; standard maximum fixed jib combination of 256 ft. + 100 ft.; standard maximum luffing jib combination of 197 ft. + 217 ft.; and standard heavy fixed jib combination of 236 ft. + 98 ft.

www.kobelco-cranes.com

The GTC-800 (88 US-ton capacity) features a five-section, 141.1-foot main boom, plus a 58.1-foot bi-fold jib. The crane has automatic switching load charts for operation at up to four degrees out-of-level. The level ground charts for Tadano Mantis are for slopes to 1.5 degrees. The GTC-800 boasts the Tadano AML-C rated capacity indicator with OPTI-WIDTH (Tadano Mantis’ system allowing asymmetric track positioning in reduced width configurations), HelloNet Telematics and a Cummins 310hp QSB6.7 Tier 4f engine.

The full power, hydraulic boom is designed to perform exceptionally well for lift work, while also being capable of out-of-level, pick-and-carry, and foundation work. The round boom is manufactured specifically for the Tadano Mantis telescopic boom crawler cranes by Tadano Japan. The main boom is complimented with a 33.1 ft./58.1 ft. (10.1m / 17.7m) bi-fold jib that offsets at 3.5°, 25°, and 45°. The maximum lifting height with the jib erected is 198 ft. (60.4m). An optional 8.2 ft. (2.5m) heavy lift jib with a maximum capacity of 23.5 US ton (21.4t) that offsets at 3.5° and 30° is also available. The GTC-800 design project was managed by Tadano Mantis and included collaboration with Tadano, Ltd. in developing the purposedesigned, Tadano built telescopic boom and the integration of Tadano winches, jib, hydraulic cylinders, AML-C and Hello Net telematics. The GTC-800 is CE marked and available for global sales.

www.tadano.com

Link-Belt Construction Equipment recently released its new 250-ton (227-mt) 298 Series 2 lattice crawler crane. The new boom design is the capstone of the 298 Series 2 and allows the working combination boom tip section to remain in place when transitioning from conventional mode to luffer with a maximum combination of 180 ft. (54.8 m)

of luffing boom and 195 ft. (59.4 m) of luffing jib. In order to provide quick conversion from conventional style lifting to a luffing configuration, assembly has been simplified with the advent of the following: semi-bore weldments for pin locations; point-of-use storage provisions for all components; and stop bolts for quick pin alignment. A new luffing jib transport package with lifting lugs simplifies and expedites luffer assembly. The rear post will scissor into place by means of alignment links. The transport package also comes assembled with nylon rope reeving to assist with initial luffing jib wire rope hoist reeving. Once the rear post is in working position, all luffing jib pendant connections are made and the luffer is ready to be raised for work. All assembly is done from the ground with no work at height exposure. The 298 Series 2 also features a new base section and 12 in. (30.48 cm) wide boom walkway. Bar pendants with storage brackets replace dual wire rope pendants. A newly designed retractable auxiliary lifting sheave has a capacity of 25-ton (22.67-mt) and offers two parts of line. Conventional boom length will remain the same as the 298 HSL at 60 ft. – 290 ft. (18.2 – 88.39 m). The maximum tip height of boom and jib [250 ft. + 90 ft. (76.2 + 27.43 m)] is 342 ft. 3.2 in. (104.32 m). The 298 Series 2 will come with a Cummins QSL 9 Tier 4 engine. Greater fuel efficiency is just one of the benefits offered with the ECO winch system.

When activated by the operator, ECO hoist provides maximum line speed with lighter loads all with the engine under 1,000 RPM. Also, standard equipped is operator-selectable auto-engine shutdown. The crane operator is assisted by an on-board high-resolution rear view camera that helps monitor jobsite conditions. An audio/visual travel alarm system informs crew members on the ground. The RCL monitoring system provides the operator all lift information, is extremely intuitive and allows the operator to set swing and other control parameters creating virtual walls with audio, visual alarms and function kick out.

www.linkbelt.com

The Demag CC 3800-1 offers a 650t (715USt) capacity at a radius of 12m (39.4 ft.). Highlights include a load moment of 8484 tm; erection of wind turbines up to 117m hub height without superlift; erection of main boom 114m with 12m LF and hook block mounted, without superlift mast and without assist crane; and erection of wind turbines up to 170m hub height with super lift. It offers best-in-class ergonomics for

operators and is suitable for worldwide operation. Optional Boom Booster Kit is available.

Terex Cranes’ HC 285 crawler crane offers a maximum lift capacity of 285 tons. The crane offers power up/down as standard and optional free fall on main and auxiliary drums. It is built with a quiet, comfortable operator’s cab with excellent viewing range. The shockless stop system gradually retards operating speed to reduce shocks when the crane approaches lifting load or boom limits. Twospeed travel allows the operator to select the best speed and power control for any condition. The HC 285 also offers superior transportability with a 10.5-ft width and a 12-ft. height. Its hydraulic counterweight removal system simplifies installation and removal.

www.terex.com

offers Unsurpassed , led by the best , the most knowledgeable , all backed by North America’s leading equipment group. As a part of the Lanco Equipment Group, along with Walter Payton Power Equipment and Western Pacific Crane & Equipment, we are now part of the World’s Largest Manitowoc Dealer group.

and cranes and Knuckle Booms. They are part of North America’s and

sales along with , we are your source for on the full line of Manitowoc, Grove and PM cranes.

BY HOWARD J ELMER

hevy recently partnered with John Deere at its world headquarters to show off its newest version of the HD Silverado pickup. The reason? A work-related backdrop is vital to understanding the needs of the HD truck owner; and frankly, what looks better than some spanking new construction equipment towed by shiny 2018 Chevy’s!

CSo, while this setup created the right visual, the actual towing of up to 20,000 lb. highlighted not just power but a new trend in safety that has the OEMs tying existing on-board technologies together electronically.

These are known as driver assist features. This is a new phrase that is becoming more common when describing the innovative electronic features found in today’s pickup trucks. I bring this up first when looking at the 2018 Chevy Silverado HD because the traditional newsworthy trifocal of towing, payload and power are fast becoming secondary to this new headline – driver assist features. I, for one, am just fine with that. Frankly, with the exception of a new hood scope design, the tin on the 2018 has not changed and yet the truck has changed so much for the better.

Today’s pickups, particularly the HD versions, have so much capacity and power that driver’s need help in managing these loads. GM recognized that first in 2015 when they

incorporated a cruise control system that stopped overspeeding on long downhill grades. At the time I wrote:

“On the new 2015 the cruise control computer is also integrated with the exhaust brake, transmission shifter and trailer sway control. What’s that all mean? Net result – down a 7% grade the truck did not pick up speed; the brakes did not come and it never upshifted; all I did was steer. So, don’t all HD’s do this? Straight up, no. GM is the first to pull all these systems together and have the computer take care of it all. And, this is what inspires confidence – the speedometer didn’t budge off 90 km-h even with all that weight pushing the truck downhill.”

For 2018, the trend towards more electronic helpers continues, as does the quest for HD weight supremacy –after all that is still the name of this game.

Looking at the growth of these numbers, just in the GM family, it backs up what I’m saying – drivers need help managing these loads. In 2011, Chevy’s max HD numbers were: payload 6,335 lb. (3,009 kg); conventional towing 17,000 lb. (7,711 kg) and for fifth wheel towing 21,700 lb. (9,843 kg) (up from 16,500 lb. on the 2010).

The next benchmark was 2015. Weight capabilities increased to a max payload of 7,374 lb. (3,345kg). Conventional towing climbed to 19,600 lb. (8,890 kg). Fifthwheel and gooseneck towing rose to 23,200 lb. (10,523kg).

For 2018, the max numbers are once again hiked. Now the max payload is 8,070 lb. (3,661 kg), while conventional towing has risen to 20,000 lb. (9,072 kg) and on the fifth wheel, again, up to 23,300 lb. (10,569 kg).

So, for 2018 this last set of numbers demands a truck that can handle them power-wise; and more importantly, safety-wise.

The new 6.6L V8 turbo-diesel has been redesigned with a new cylinder block and heads. Oil and coolant flow capacity has been increased and the turbocharging system is now electronically controlled. Horsepower has increased to 445 and torque now reaches 910 lb-ft. Ninety percent of both numbers are achieved at just 1,550 rpm. A new

patent-pending feature is a redesigned air intake system. Using an integrated hood scoop (on 2018 HD Silverado and Sierra) this setup has a trap for snow, sleet and rain, allowing cool dry air to get to the engine without clogging up the intake.

A new two-piece oil pan makes the Duramax quieter and also houses an integrated oil cooler with 50% greater capacity than found on the current engine. Of particular interest to Canadians will be the new Duramax coldweather performance. With microprocessor-controlled glow plugs the engine requires less than three seconds to preheat in temps as low as -29C. These new ceramic glow plugs adjust current to each plug based on outside temperature. This new engine continues to be coupled to the Alison 1000 six-speed automatic transmission which has a stellar reputation.

This mechanical update, to this Duramax diesel engine, now officially starts it building sales into its second generation. The original Duramax sold over 2 million copies since its 2001 introduction.

So that covers power, but moving loads safely requires all the trucks systems to work together “smartly”. GM’s HD trucks get a number of system upgrades this year to build on the trend it started in 2015. A new Digital Steering Assist improves road handling. A new tire pressure monitor system now includes a tire fill alert. All full driver alert packages include lane departure warning, forward collision alert, safety alert seat and front and rear park assist. GM’s longtime StabiliTrak stability control system has been updated to include rollover mitigation technology, a tie-in to the trailer sway control and hill start assist. Visual help is found in the Chevrolet MyLink with an eight-inch-diagonal touchscreen. Of particular interest is the camera system that broadcasts on this centre mounted touchscreen (now standard on all models with cargo box). It shows reversing images that make hooking up easy – whether it’s to the bumper hitch of the in-bed fifth wheel. An around–the-truck view assists in parking maneuvers. While driving the signals now activate cameras in the mirrors showing images down the side of the truck, highlighting the blindspot (I also noted that you can see right down the side of any towed trailer as well). Other improvements include: and an available Gooseneck/Fifth wheel trailering prep package will include a spray-in bedliner. Electronic upgrades include wireless phone charging and remote locking tailgate. These are the types of driver assist systems that I see coming into the mainstream. These will help prevent collisions and in general make the operators job that much easier and that is the future. The OEM’s have built a generation of highly competent HD trucks – load wise – now they have to help make them easier to drive and safer in general. From what I saw in Iowa, GM is well on its way to this goal.

The ALL Family of Companies is expanding its fleet with the purchase of eight cranes from Manitowoc. The package includes two each of the MLC650 crawler, Grove TMS760E truck-mounted crane, and Manitowoc 999 crawler, plus two more truck-mounted units: a Grove TMS800E and the all-new Grove TMS9000-2. Upon receipt, the cranes will be deployed across the company’s network of branches, targeting markets where they are in the highest demand.

When ALL initially acquired two MLC650s last fall, the large-capacity crawlers proved extremely popular with customers, providing impetus for the acquisition of additional units. The MLC650 has a 716-USt capacity and features Variable Position Counterweight (VPC) technology that automatically positions the crane’s counterweight to match lifting demands. VPC helps reduce the operating footprint, minimizes ground preparation, and reduces matting, adding up to a potential savings of thousands of dollars per month on longer-term projects.

“This capacity — 700 to 900 USt — is in high demand across all geographies and in multiple sectors,” said Rick Mikut, crawler crane division manager for the ALL Family of Companies. “The MLC650’s large capacity and site-friendly ground bearing pressure will ensure these new units will be deployed almost immediately for energy-related projects, including refineries, petrochemical installations, and power plants.” Manitowoc developed the TMS9000-2 with the input of customers and dealers to create a crane that delivers in realworld applications. It is a 115-USt capacity truck crane that is significantly lighter than similar models, making it easily configured for local roadway weight limits. It has a longer 169-foot main boom with jib options available. Strength was boosted by five per cent across the load chart.

“Our truck cranes are an important part of our taxi rental fleet — the in-and-out work that is really important to our business — and Manitowoc is doing a great job reinventing these TMS units to keep them strong and increasingly more roadworthy,” said Michael Liptak, president of ALL. “And our crawler division is booming right now, perhaps seeing the highest demand in a decade. Our new ‘triple 9s’ and MLC650s are a direct response to this need. We will continue to define our response to this demand by our commitment to a modern, technologically advanced fleet,” explained Liptak.

BY MATT JONES

runside, Nova Scotia’s R&D Crane Rental has obtained a Manitowoc Grove TMS9000-2, becoming the first company in Canada to do so. The new model is an evolution of the previous TMS9000E and features an increased capacity, which has already been a benefit to R&D Crane Rental’s operations.

“I think they just redesigned it and got more capacity out of it, because there are no additional counterweights for it,” says Alex Jenkins, operations manager for R&D Crane Rental. “But the biggest selling feature is the length of boom. The TMS9000E only has 142 feet of main boom. The TMS9000-2 has 169 feet of main boom, which makes it a lot easier. When you roll into a site, you’ve got a lot more options before you get into putting your swing-away jib on.”

Jenkins says that the new crane fits nicely into a gap in existing crane options in the region. Most truck-mounted cranes lift between 50 and 110 tons, and all-terrain cranes can cover 120 tons and up, however there are other costs related with utilizing all terrain cranes. With a 115-ton capacity, the truck mounted TMS9000-2 achieves additional capacity without incurring those costs.

“When you get into the all terrain crane, you sometimes have to get into additional permit costs, additional escorting, more counterweights, and they only run certain periods of the year,” says Jenkins. “This 115-ton crane is mounted on a truck body and you can run it all year long. You get that additional boom, it’s cheaper to move from point A to point B because we don’t have to pay for additional permit costs or escorts.”

The TMS9000-2’s versatility has already paid dividends for the company – a customer had a crane on site breakdown and getting in an equivalent replacement would mean a significant work delay. The TMS9000-2 additional capacity meant it could handle the load and could easily be moved to the jobsite without any special preparations.

“It was able to leave that minute and bail that customer

out rather than delaying their job by waiting four or five days for a special move permit from any other crane company in the city,” says Jenkins. “There was no crane company in the city that could get a permit for a crane to do that lift that quickly and keep costs down. But we didn’t have to, because that crane doesn’t need a permit and we were able to do the lift. Instead of talking about reach, for a change, we’re talking about all boom shoved in max capacity lift. The 115-ton crane really did the job. It gives us that competitive edge.”

The most significant operation R&D Crane Rental is currently utilizing the TMS9000-2 for is the construction of a new Marriot hotel in Halifax, N.S. R&D is doing the formwork for the building, which will eventually reach up to 112 feet. While at some point in this project, they will have to utilize the swing-away jib, the TMS9000-2 will allow them to put off that step until later.

“We can get up to the sixth floor without putting the swing-away jib on when any other competitors can only get to the fifth floor,” says Jenkins. “It keeps costs lower for the customer for a longer duration of time and keeps them on budget.”

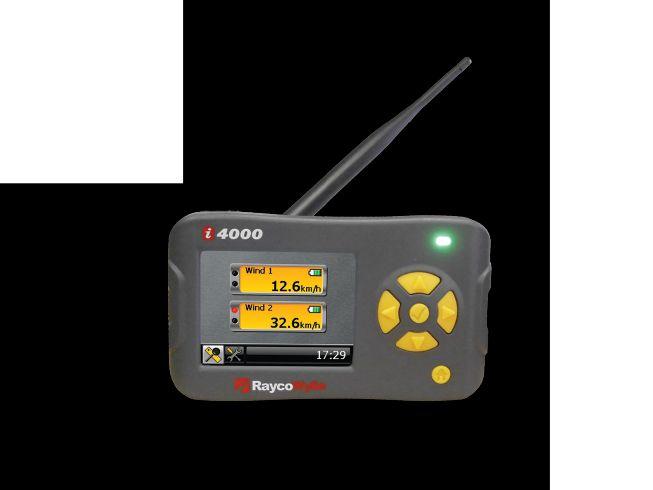

anitowoc has announced the newest addition to its line of Grove Hydraulic Crawler (GHC) cranes: the Grove GHC30. The new 30-tonne (30USt) crane is the smallest in the GHC line and its compact dimensions will enable exceptional maneuverability. As with previous models in the series, the GHC30 is the result of a partnership with Germany’s SENNEBOGEN Maschinenfabrik.

The GHC30, like others in its range, offers the ability to pick-and-carry at 100 percent of its load chart on inclinations up to 4°, and it can swing loads a full 360°. It has a compact footprint of 10.6 m (34.7 ft) x 3 m (9.8 ft) x 3 m (10 ft), and a tail swing of only 3.3 m (10.8 ft). Being the smallest of the GHC cranes, it can work on job sites with tighter working quarters that require precise movement.

Companies with applications in utility work, alternative energy applications, tunnel construction, barge work and storage tank construction will find the crane especially useful, as it fits easily onto a variety of job sites. With its full-power, three-section 25.2 m (83 ft) telescoping boom, operators can easily handle a variety of lifts at various radii without setting up on outriggers like traditional hydraulic boom cranes.

The GHC30’s crawler tracks easily navigate tough job site conditions, such as swampy or mountainous terrain. The undercarriage is driven by powerful, two-stage hydraulic traction motors that provide best-in-class gradeability and mobility. The track side frames can be hydraulically extended and retracted, providing three track spans with lifting capabilities at each span.

The crane transports easily in one load, and once it reaches the job site, it can roll off the truck and immediately begin work with minimal setup. In-cab amenities include a large, air suspension heated seat; a climate control system for added comfort; a 178 mm (7 in) screen for viewing the hoist, rear and right side camera feeds; an intuitive, graphical RCL system; and precise load-sensing joystick controls. A 15° tilting cab is another added benefit not often seen on cranes in this capacity class, providing added comfort when doing high-boom angle work.

The crane can be outfitted with one of two engine options: a 173 hp Cummins QSB 4.5 L Tier 4 Final or a 160 hp Tier 3 model.

www.manitowoc.com

New enhancements to the yourKONECRANES.com customer portal allow customers to monitor crane condition with improved organization of data.

Hiab, part of Cargotec, has launched a revolutionary new oil tank using cyclone technology, which reduces oil usage, weight, space and running costs.

The patented technology, the first of its kind in the industry, introduces a new generation of efficient hydraulic oil tanks. The tank uses a cyclone system to remove air from the hydraulic oil returning to the tank, which is up to ten times more efficient than standard systems.

The technology allows oil to be circulated and filtered more often, so that the size of the tank can be significantly reduced. This means that the volume of oil required is also significantly reduced, plus the slight over-pressure in the system’s outlet prevents cavitation in the oil pump, leading to a longer operational lifetime for the pump, oil and hydraulic system.

“Our new cyclone oil tank is a gamechanging accessory for use in a truckmounted or crane-mounted application,” explains Markus Sjöqvist, Hiab’s product

manager of loader crane accessories.

“Because the cyclone removes air from the oil up to ten times more efficiently, we can work with a much more compact oil tank. So, for example, instead of the 250- or 300litre oil tank you would expect to find on a standard truck mounted with a Loader crane or Forestry Crane, we can now fit a 100-litre cyclone tank. This reduced size and weight allows the truck to reduce its fuel consumption, and lower its CO2 emissions by up to 600 kg a year. The tank size and weight reduction also gives additional cargo capacity, plus the advantages of lower oil usage of up to 60 per cent, and a more durable hydraulic system, so operating costs are reduced too.”

The cyclone oil tank can also be mounted directly onto the crane, and will be included in the crane’s warranty package. The higher mounting position on the crane enables better operating conditions for the pump, and installation costs are lower than the truck-mounted option.

The robust nature of Profi TI series air hoists from J D Neuhaus (JDN) ensures their suitability for a whole host of general industrial applications. JDN’s Profi TI series is extensive, but models from TI 3 to TI 25 (providing 3 to 25 metric ton lift/load capacity) are ideal for general purpose use, even in continuous working processes. These units can be outfitted with many accessories to meet end user needs. Some of these accessories are various control systems (including remote control) for precise positioning of loads, and a variety of trolleys available to meet specific demands.