DISPLAY YOUR WAY

Features include:

Headless HMI

With the C-more headless HMI, you can display your factory oor data how and where you choose. The EA9-RHMI has all the powerful functionality of the C-more Touch Panel HMIs, but without display size restrictions. This HDMI-enabled device works with televisions, monitors, projectors, and most any other HDMI display device or use the C-more Remote HMI mobile app and/or the embedded Web Server if you prefer no local display at all. The choice is yours!

• HDMI Video/Audio output with multiple resolutions

• VGA 640x480, SD 720x480, XGA 1024x768, HD 1280x720

• Compatible with ELO Resistive Touch screens

• Multiple connections

• Ethernet and RS-232/422/485 serial ports support programming and device connections

• USB-B port for programming, monitoring and configuration

• USB-A port for USB HID devices such as pen drives, touch screen displays, keyboard, mouse and bar-code scanners

• SD card slot for log files, project memory or graphic media

• Get control on-the-go with the C-more Remote HMI mobile app and embedded Web Server

• 82MB of user memory

Now with FREE software!

C-more HMI design software can now be downloaded free-of-charge. Get started on your project today or take it for a test drive.

Download as often as you need. No license or key needed.

Get your copy now at: www.go2adc.com/cmoresw

Orders over $49 get FAST FREE SHIPPING

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

the mould

Ro-Matt implements robotics and automation solutions, from the traditional to the unconventional By

Karen Smock

A look at new approaches that can be used to automate safety in manufacturing plants By

Treena Hein

Ransomware attackers are better resourced and more brazen. Unwitting manufacturers have become a prime target By

Jacob Stoller

How DC power for industry is an opportunity in the making By Jon DeSouza

FROM THE EDITOR

BY KRISTINA URQUHART

Building a stronger community

There is power in community. Last year, our communities stepped up and supported us at the onset of the pandemic. Family, friends, colleagues, yes – but also our wider networks. For manufacturers who had spent years developing relationships within the sector, that meant when it came time to switch gears and get PPE out the door, the right tools and partners were just a few calls away.

Recently, I was talking with Jeanine LassalineBerglund, the new president of Automate Canada, MA’s association partner, about building community. Jeanine’s mandate is to support the automation industry and manufacturing supply chain through advocacy – and to look at ways to recruit the next generation of workers. Among her goals are increasing access to programs that attract youth, such as Manufacturing Day (or MFG Day as it’s better known), which takes place every year on the first Friday in October.

The U.S.-based initiative showcases modern manufacturing careers with a doors-open format that sees students, teachers and local residents tour through plants across the country. MFG Day has been gaining ground in Canada – for example, the Workforce Planning Board of Waterloo, Wellington and Dufferin has participated for several years, staging bus trips and in-person plant visits. On Oct. 1, they’ll post video tours of area manufacturers online.

But thus far, MFG Day programming in Canada has been fragmented. Lassaline-Berglund says there needs to be a more concerted community effort across industry to make MFG Day a must-participate event for both industry and students – and, in the spirit of supporting a sector that accounts for more than 10 per cent of the country’s GDP, there should be support from the government to make it happen.

We’re acutely aware of the need for talent in manufacturing. The workers are there – the industry just needs to reach them. There are some reports that Generation Z (people born up to 2012) will eclipse the Millennial generation in size. If you haven’t thought much about Gen Z, it’s time you do – and here’s where that community-building comes in. Opening your doors with events like MFG Day can show Gen Z the diverse career paths and workplace environments available in advanced manufacturing.

EDITORIAL ADVISORY BOARD

There is, of course, other work to be done internally to ensure Gen Z views your company as a viable place to be. “To attract Gen Z, employers must be ready to adopt a speed of evolution that matches the external environment. That means developing robust training and leadership programs, with a real and tangible focus on diversity,” say Tiffany Mawhinney and Kimberly Betts of Deloitte Consulting in a recent article. This is your future workforce. The latest generation of teens are digital natives. They spot inefficiencies and make innovative suggestions, and they care about the environment more than ever. They’re not afraid to hold leaders accountable. For a manager who loves the status quo, that sounds scary. But the best leaders don’t – just ask columnist Paul Hogendoorn, whose first post-retirement missive appears on p. 8.

Gen Z wants technology? Show it to them. Wants to reduce waste? Take them on a gemba walk around the plant. Wants to know how they can make a difference? Show them how your business serves the community by creating jobs and giving back. If the future workforce doesn’t know how companies operate, and what options are available to them, they’re not going to feel connected to the sector. That means they’re not going to consider manufacturing when choosing their post-secondary path.

Together, we must show students that this is a community worth investing their lives in. And there have been some excellent programs over the years that are doing just that. NGen’s new CareersoftheFuture.ca site comes to mind, and CME celebrates Manufacturing Month in October with stories from across the sector. We need more. MA plans to do its part – over the coming months you’ll see a number of new initiatives focused on bolstering the manufacturing automation community. There are exciting things in store for 2022. On that note, it’s been a wonderful few years connecting with the industry, but this is my final editor’s note as I move on to a new challenge at MA’s publisher, Annex Business Media. I’m pleased to welcome Sukanya Ray Ghosh as our new editor. To our readers, thank you for showing me the power of a well-connected manufacturing community, and all the very best as you continue to build it. | MA

AL DIGGINS, Chairman of the Board, Treasurer and General Manager, Excellence in Manufacturing Consortium

DAVID GREEN, Technology and Business-to-Business Consultant

SHELLEY FELLOWS, Chair, Automate Canada

KARIN LINDNER, Founder and Owner of Karico Performance Solutions

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Support Systems Developer, KINITO Support Systems

Your resource for Canada’s industrial automation news

Reader Service

Print and digital subscription inquires or changes, please contact:

Urszula Grzyb, Audience Development Manager

Tel: (416) 510-5180

Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR

Kristina Urquhart kurquhart@annexbusinessmedia.com Tel: 437-220-3031

ASSOCIATE PUBLISHER

Kathryn Swan kswan@annexbusinessmedia.com Tel: 647-339-4880

GROUP PUBLISHER

Paul Grossinger pgrossinger@annexbusinessmedia.com

MEDIA DESIGNER

Graham Jeffrey gjeffrey@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com Tel: 416-442-5600 ext 3221

COO

Scott Jamieson sjamieson@annexbusinessmedia.com

CONTRIBUTING WRITERS

Alena Barreca, Jon DeSouza, Treena Hein, Paul Hogendoorn, Maxime Lacouture, Karen Smock, Jacob Stoller

Manufacturing AUTOMATION is published seven times a year by:

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 Fax: 416-442-2191

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

SUBSCRIPTION RATES

Canada — $43 per year

United States — $75.50 (US) per year

Foreign — $86 (US) per year Students — $20.50 per year

ANNEX PRIVACY OFFICER email: privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Manufacturing AUTOMATION will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Manufacturing AUTOMATION are © 2021 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Association Partner

AUTOMATION UPFRONT

PRODUCTION

Mitrex opens new Ontario factory

Mitrex, a manufacturer of building-integrated photovoltaic technology (BIPV), has opened its new production factory in Toronto.

The new facility is the largest building in the world to date incorporating Mitrex’s patented solar solution, including solar cladding, windows and railings.

The facility, which will also act as the company’s head office, will allow Mitrex to localize its production in the Canadian market while ramping up product offerings into other markets including the United States.

The plant is comprised of a uniquely designed 3D outer wall of the company’s cladding technology, spans an area of over 100,000 square feet, and has a fully automated production line that will manufacture 25,000 square feet of solar-integrated panels per day.

The facility will help Mitrex establish itself as a player in the North American and global markets, with its R&D efforts, manufacturing capabilities, and new supply chain capacity, the company says. This factory structure will then be used in future facilities throughout Canada, the U.S., and globally.

ROBOTICS

NGen invests $4.2M in mushroom-picking robots

A robotics project led by Mycionics to automate mushroom harvesting will receive nearly $4.2 million in funding by Next Generation Manufacturing Canada (NGen).

Mycionics, in partnership with Whitecrest Mushrooms and Piccioni Brothers Mushroom Farm, will deploy and demonstrate the commercial viability of the Mycionics robotic harvesting system.

The entire harvesting process will be optimized through the application of data analytics, machine learning and artificial intelligence. Mycionics will be the first company in the world to successfully automate the end-to-end mushroom harvesting process for the fresh market.

As a complete system, Mycionics robotic harvester will increase the yield of a growing room

Mitrex has opened a solar technology production facility in Toronto. system to pick each mushroom at the optimal time instead of being restricted to harvesting

through a “smart graze harvesting” strategy, picking over a 24-hour period and allowing the

AUTOMATION UPFRONT

only during normal working hours. Additionally, the ability to harvest robotically and the use of data analytics will increase food safety, traceability and disease detection.

Based on the farmer’s harvesting requirements, such as desired mushroom sizes, stem length, quality and harvesting schedule, the Mycionics mobile robotic harvester scans the mushroom beds, picks the desired mushrooms, trims the stems, and intelligently packs the mushrooms into boxes where they can be retrieved by the farm operators.

NETWORKS

PI North America to promote IO-Link technology

PI North America, the trade association for industrial networking technologies, will represent the

IO-Link community in Canada and the United States.

The non-profit organization has signed a contract with IO-Link facilitator PROFIBUS Nutzerorganisation (PNO) to become a Regional IO-Link Interest Group (RIOLIG).

PI North America will promote IO-Link technology, offer member registration services, organize seminars and workshops, technical training, and trade fairs, and manage the related product test and certification services and other technical support for North America enterprises and users.

IO-Link is an international standard for industrial communication at the device level, developed in cooperation with a wide range of automation technology manufacturers.

The technology, also known as the “USB of Automation,” helps users to create simple configurations and flexible applications

Reliable Motion Feedback

Encoders designed for industrial automation Contact us to nd out more.

in components and software for automation systems. Due to the openness, which is unique in the industry, integration into existing and new automation systems is guaranteed.

EXPANSION

ECM Global Measurement Solutions enters Canada

East Coast Metrology, now known as ECM Global Measurement Solutions, is moving into Canada through a partnership with Precitech Metrology.

relationship with Precitech Metrology, and we are excited to advance this to the next level,” says Gary Confalone, CEO of ECM Global, in a statement.

ECM has also launched a dedicated Canadian website focused on portable measuring equipment calibrations.

3D PRINTING

U Waterloo to establish AM network

Precitech, a 3D metrology and precision alignment company based in Montreal, supplies rental laser trackers and arms as well as inspection and alignment services.

In collaboration with Precitech, the U.S.-based ECM is now able to offer customers in Canada an ISO/IEC 17025 Accredited Calibration Certification for all portable new or pre-owned measuring instruments including laser trackers, laser scanners and portable CMM arms.

The company currently operates locations in Michigan, Massachusetts and California and services a range of global manufacturing industries, including automotive, aerospace, power generation, architecture and construction.

“Over the years we have developed a strong working

The University of Waterloo will establish the Additive Manufacturing Alliance (AMA) with $8.2 million in funding from the federal government.

The alliance will leverage the school’s Multi-Scale Additive Manufacturing (MSAM) Lab, a research and development facility for metal additive manufacturing that also works with manufacturers to test new technologies.

A collaboration between post-secondary institutions and major industry partners, the AMA will help businesses across southern Ontario overcome barriers to adopting cutting-edge advanced manufacturing technologies by providing access to the MSAM’s specialized metal 3D printing equipment and expertise.

Using the funding from FedDev Ontario, AMA will help companies grow and move their technologies from prototype to production-ready. It will also facilitate industry connections

ECM Global Measurement Solutions has expanded to Canada.

to integrate businesses into established supply chains, and develop a talent pool of additive manufacturing workers through training and upskilling.

AMA will connect participants from academia, government labs, as well as companies from the aerospace, energy, defence, nuclear, automotive, communications and other sectors.

The project will support more than 90 businesses to commercialize nearly 30 advanced manufacturing technologies, create and maintain over 275 jobs and provide training and outreach opportunities for about 1,500 students, research associates and industry personnel.

DEAL MAKERS

Weidmüller acquires Ont. connectivity company

Electronics specialist Weidmüller has acquired Emphatec in Markham, Ont., allowing the company to expand its PLC migration and Class 1 Division 2 solutions.

Emphatec, which specialized in the engineering of customized connectivity solutions for the process industry, will now operate under the name Klippon Engineering Canada, and continue to offer engineering and service expertise.

The Detmold, Germany–based Weidmüller recently named its process industry

division Klippon Engineering. The arm has its own sales team, application experts, affiliated production and assembly sites to develop, certify and implement product and application-specific solutions.

ABB to sell Dodge division for $2.9B

ABB plans to sell Dodge, its mechanical power transmission division, to RBC Bearings Incorporated for $2.9 billion in cash.

The deal, expected to close by the end of 2021, will create a manufacturer of highly engineered bearings and motion control components.

For more than 140 years, the Dodge business has specialized in the design, production and marketing of mounted bearings, enclosed gearing and power transmission components.

It offers a wide range of mechanical power transmission products in the market, selling to industries such as surface mining, aggregates and cement, warehousing, and food and beverage.

Dodge has roughly 1,500 employees worldwide and posted revenues of approximately $600 million for the last 12 months ending June 30, 2021, of which more than 90 per cent were generated in the Americas.

Björn Rosengren, ABB CEO, says an update is forthcoming on the sale of ABB’s turbocharging

business, as well as on speculation that the company may list its e-mobility division.

Rockwell to acquire Plex for $2.2B

Rockwell Automation will acquire Plex Systems, a cloud-native smart manufacturing platform, for $2.2 billion.

Plex is a single-instance, multi-tenant SaaS manufacturing platform operating at scale, and includes advanced manufacturing execution systems, quality and supply chain management capabilities.

Plex’s software capabilities will benefit from Rockwell’s global market access, complementary industry expertise, and ability to turn real-time data into actionable insights, the companies say in a statement.

Plex will be reported as part of Rockwell’s Software and Control operating segment, which provides hardware and software offerings for the design, operation and maintenance of production automation and management systems. As a part of the acquisition, 500 employees will join Rockwell Automation.

The acquisition is expected to close in the fourth quarter of Rockwell’s fiscal year.

ATS acquires German engineering company

ATS Automation Tooling Systems has acquired BLSG AG, a consulting company that specializes in process engineering and operational excellence.

The financial terms of the deal were not disclosed.

BLSG, which is based in Munich, Germany and employs 12 consultants, will join ATS’ Process Automation Solutions (PA) business.

BLSG specializes in discrete processes and serves customers in automotive, logistics, medical device and food and beverage sectors.

ATS Automation is headquartered in Cambridge, Ont.

MOVERS & SHAKERS

Lenze, an automation company for the machine-building industry, has named Steve Markham as president of Lenze Americas.

Markham brings to the role experience leading U.S. and international firms in rapid growth. He also has experience in management and consulting services, continuous improvement and business transformations. With his expertise in supply-chain, operations, production and international business, Markham will make expansion of the Lenze brand in North America a top priority. He has held executive leadership positions at Musent LLC (Interim Management and Consulting), Schaefer Container Systems North Americas and BLG Logistics. “It is an exciting time to be joining Lenze as we work to make a dramatic expansion in the Americas,” says Markham.

ALS Mechatronic, a British automation engineering company, is expanding to North America and has appointed a new vice-president, business development for the region. Jim Humphreys joins the ALS Mechatronic team to oversee growth in Canada and the U.S. ALS Mechatronic was set up in 2002 and specializes in the design, build and installation of bespoke factory automation systems, control systems, container handling machinery, vision inspection systems and robotics. A veteran in manufacturing automation, Humphreys has more than 30 years’ experience, initially developing and executing automation projects before moving into sales and management.

The Klippon Engineering team, formerly Emphatec, in Markham, Ont.

Steve Markham

Jim Humphreys

INDUSTRY WATCH BY

PAUL HOGENDOORN

Paul Hogendoorn co-founded FreePoint Technologies with the goal of giving manufacturers the benefit of information technologies that inform, empower and motivate their most critical asset – their people. He can be reached at hogendoorn.paul@gmail.com or at linkedin.com/ in/paulhogendoorn.

Leading for success: Best practices learned over a 40-year career

I’ m a half-dozen weeks into “non-employment,” which is a new and interesting condition for me.

I’ve been writing this column for 16 years now, typically writing about the business stresses and challenges that kept me awake most Sunday evenings and opportunities and ideas that kept me going to back to work on Monday mornings anyway. Building a business or running a plant is not easy; there is a relentless pressure to deliver something “tangible” every day, week, month and year.

Many others in the organization have different degrees of separation in their lives; the longer-term, big-picture objectives can be deferred to others, and shorter-term objectives can be delegated. There is an “off switch” they can apply, and even though many opt to leave it on most of the time, that option is still theirs.

But, if you are the leader, there really is no “off switch,” unless you have the company running very smoothly like a flywheel spinning on its own momentum – but in that case, you likely have effectively delegated the leadership to another person, and that person relates

Your business will only ever be as good as your people can make it; a good coach will make your people better, and your people will make your company better.

to what I’m saying here.

I’ve been asked to continue writing this column for a while longer, and its something I’m glad to do. I’ve had the privilege of visiting hundreds of manufacturing plants all over the world, spending time on the floor, working with people and on machines (I loved that part), planning, executing, failing and succeeding, and always growing. It would be tempting to add “improving,” or “continually improving,” but I’ll be frank – that wasn’t always the case. In the next few columns, I’ll share some of the best learnings from both the good and bad experiences, and key lessons other leaders taught me along the way.

Tip #1: Don’t make a big production out of it.

If you want to be innovative, or try something really different, do it quietly and on a small scale. “Under radar” in other words. Most people resist and even oppose change. (I’ll deal with this more in a book I’m writing). They may clamour for change, but they really just want to be heard and considered.

When it comes right down to changes actually being discussed openly,

resistance builds on the floor (fueled by natural skepticism), and through the ranks of management (fueled in part by career defensiveness). In both cases, change disrupts their sense of security.

The best way to avoid the near-certain resistance and opposition to your idea is to prove it first in a small, non-threatening way. If it works, you have tangible evidence – “certainty,” to combat doubt.

It’s still early enough to let others buy in to the idea and adopt and embrace it, and be part of it as it gets planned for larger rollout. If the small project fails, its not an “epic fail” that gets in the way of future ideas and initiatives you might bring forward.

Remember, manufacturing is largely filled with “tangible and tactile” people; they like to see, feel and experience. They are not as likely to buy in to things that are still abstract, or feel like “marketing,” sales or slogans. Do it small and succeed or fail under radar. If the small project works, consider that the official starting point. Achieve “undeniability” first and then it can’t be resisted or opposed by people on the floor or in the management ranks.

Tip #2: You and your people are the smartest people in the room.

O ver the years, I developed a healthy skepticism towards consultants, government-sponsored funding programs, and people being positioned as specialists and “experts” in their field. There is an army of people lined up to tell you or your people how to do your or their job better. They have a vocabulary that only they understand, and they use it to quickly tilt the conversation to where they become the smart ones and you and your people need them to really improve your operation.

Achieve “undeniability” first and then it can’t be resisted or opposed by people on the floor or in the management ranks.

T he truth is, you and your people are the smart ones; you are the people that built the business, run it successfully, and have figured out how to get things done, day in and day out. They need to be learning from you before they can offer you any insight of value at all. There are good ones, and there is a place for them, but always remember that your people know your company, plant and product far better than third parties ever will.

The best they can do, in my opinion, is bring in a good project process, help you be accountable to the goals you set, and “coach” you and your people to be the best they can be. Your business will only ever be as good as your people can make it; a good coach will make your people better, and your people will make your company better. The consultant, or government funding programs, or “experts” can’t. Only you and your people can.

“Training” is one thing, “teaching” is another, but what you and your people would likely benefit most from is “coaching.” You can train people to follow a process – perhaps a refined

process – but it’s a process nonetheless. Teaching is what expands their knowledge.

With the Olympics freshly in mind, every successful athlete needs quality coaching in order to achieve an identified goal. Training and teaching are part of coaching, but they can (and should) go on indefinitely. The goal of coaching is to achieve an identified significant goal. Coaching helps your

people achieve their potential, making sure the hours, dollars and energy invested in teaching and training pays off in a tangible, definitive way.

T hose are my first two big tips on how to achieve your goals, as I look back and share the best things I’ve learned working with hundreds of successful manufacturers and their amazing, often unheralded people.

Feel free to send me a note at hogendoorn.paul@gmail. com if there’s a specific topic or question you’d like me to address in a following column. M anufacturing created and continues to sustain our socioeconomic wellbeing. We are in it together! | MA

Looking for more Industry Watch columns? Visit automationmag .com/topic/opinion

MONEY MATTERS

BY ALENA BARRECA

eligibility for grants and tax credits, visit mentorworks.ca.

Financial support for manufacturing jobs and growth

The COVID-19 pandemic caused the worst economic recession since the Great Depression and has affected businesses in every sector, including manufacturing. To help recover from these recent significant instabilities, the newly announced federal government funding program known as the Jobs and Growth Fund (JGF) is investing a total of $700 million to help Canadian businesses achieve long-term growth opportunities, including the retention and creation of many new jobs across the country.

Upwards of $70 million from the JGF is exclusively being set aside for small business applicants established after January 2020 and that meet the program’s eligibility criteria. This is a valuable commitment, as most government funding programs cater to mature businesses established for longer periods of time — thus, there is typically less funding support for start-ups and entrepreneurs.

Government funding support is more important now than ever before as the country reopens to a world that continues to endure COVID-19. Canadian businesses should stay aware and updated about accessing grants and loans available to help them succeed.

The JGF financial support is being administered federally by Canada’s regional development agencies (RDAs), including FedDev Ontario for Southern Ontario applicants, FedNor for Northern Ontario applicants, and Western Economic Diversification Canada (WD) for applicants in Western Canada. Applications are now being accepted on a continuous intake basis until Mar. 31, 2024, or until funding is fully allocated.

The following information will provide your manufacturing business with insight about application details and eligibility criteria to determine whether the federal JGF financial support is right for you.

Eligibility and timeline

In relation to manufacturing industry businesses, the Jobs and Growth Fund will support projects that contribute to job creation and long-term economic growth to focus on rebuilding the Canadian economy following negative impacts of COVID-19.

Funding amount

• Eligible industry businesses, including manufacturers, could receive interest-free repayable contributions for up to 50 per cent of authorized costs

• Eligible not-for-profit organizations could receive non-repayable contributions for up to 90 per cent of eligible costs

• Eligible Indigenous organizations may receive contributions for up to 100 per cent of eligible project costs

• Project contribution amounts cannot normally exceed $10 million

Applicant eligibility

• Small and medium-sized businesses, including co-operatives

• Not-for-profit organizations and community economic development partners

• Indigenous organizations

Project eligibility

To be eligible for the Jobs and Growth Fund, manufacturing projects must:

Foster an inclusive recovery by:

• Increasing the participation of underrepresented groups in the economy by supporting not-for-profit organizations that provide funding, business services, training, etc. for a more equitable workforce

• Supporting businesses owned or majority-led by underrepresented groups

Preserve Canada’s competitiveness and future-proof SMEs through digital adoption by:

• Investing in technologies that help scale businesses, enhance their capabilities, and increase resilience

• Supporting the development or adoption of digital and technological solutions (i.e. Industry 4.0) to increase and promote business productivity

Strengthen the capacity in sectors critical to Canada’s recovery and growth by:

• Developing emerging areas of global

competitive advantage

• Supporting scale-up and market expansion activities

• Supporting supply chain adaptation and diversification opportunities in critical sectors such as food production, medical supplies, and biomanufacturing Support the transition to a green economy by:

• Helping communities and businesses plan and drive clean, sustainable economic growth

• Partnering with organizations to catalyze the development of green regional clusters

• Supporting the development and adoption of clean technology

• Working with organizations supporting businesses to transition to a green economy

Program timeline:

• Applications will be accepted on a continuous basis until all funding is allocated

• Certain costs may be eligible on a retroactive basis up to 12 months before the receipt of the project application, but no earlier than Apr. 19, 2021

• All projects must be completed prior to Mar. 31, 2024

Even though most Canadian provinces are no longer in COVID-19 lockdown mode thanks to Canada’s vaccination rates being higher than any other country, many manufacturing businesses are still on a challenging road to recovery following a year and a half of significant delays and impacts brought forth by COVID-19. In addition to the new Jobs and Growth Fund (JGF), there are a variety of other government programs dedicated to providing Canadian manufacturers with funding support to get through this time. |

Alena Barreca is a marketing coordinator at Mentor Works, a business support organization specializing in Canadian government funding. To find out your business’s

LEARNING 4.0

Maxime Lacouture has 15 years of manufacturing industry experience and is a national sales manager at Javelin Technologies –A TriMech Company. Javelin is a provider of additive manufacturing and SOLIDWORKS 3D CAD software solutions. maxime.lacouture@ javelin-tech.com

Additive manufacturing continues toward highervolume production

From a single 3D printer in a classroom or design studio to rows of production machines on a factory floor, additive manufacturing continues its rapid evolution, becoming an increasingly important tool in the manufacturing mix.

Previous barriers to widespread adoption – including cost, speed, size, volume and material choice – are falling quickly. Industrial 3D printing is no longer niche or nice-to-have It’s a viable method of production.

Preparing for the future

To improve access to the latest technology, and to keep building a future full of additive manufacturing specialists, students, faculty, and small businesses have access to Javelin – A TriMech Company through on-campus research and innovation centres across Canada, including at the Barrett Centre for Technology Innovation (CTI) at Humber College in Toronto.

The Barrett CTI is home to Humber’s Advanced Manufacturing Skills Consortium, a group of nine industry partners. Javelin is the lead partner for additive manufacturing and supports the Centre’s two Stratasys Fortus 450mc 3D printers, along with various other printers across the campus.

In the Barrett CTI, access to real-world additive manufacturing equipment, combined with the other Industry 4.0 technologies available on site, promotes rich learning in STEM fields, equips our future workforce and supports the start-up and small business community. Students and industry can turn their designs into reality, using technology they wouldn’t otherwise be able to access.

Variety of materials

The 450mc is ideal in both educational and industrial environments for advanced prototypes, jigs and fixtures, and end-use parts that require engineered thermoplastics.

Material examples include the tough FDM Nylon 12 (with chopped carbon fibre), which can replace metal in some applications; the chemical-resistant Antero 800NA; and Ultem 1010, which withstands temperatures as high as 421°F (216°C).

No special facility requirements are needed, offering the flexibility to install Fortus printing systems anywhere. Operators also learn and work fast.

At the Barrett CTI, even with public health

seen with previous large-format systems.

Students and industry can turn their designs into reality, using technology they wouldn’t otherwise be able to access.

restrictions, the two printers have been valuable. At the outset of the pandemic, staff used additive technology to produce protective face shields to support the local healthcare community. Post-secondary students completing industry capstone projects can access the printers, and the Barrett CTI supports a STEM outreach team that inspires thousands of local middle school and high school students.

The Stratasys Fortus 450mc also prints components for Humber’s automated guided vehicle (AGV). The Humber Hawk is built by third-year electromechanical technology students under the leadership of the Barrett CTI director and with partner support.

Increasing productivity

The Stratasys F-series family continues to grow to meet the needs of engineers and manufacturers. The new F770 makes large-format FDM 3D printing more accessible and economical. With a build chamber sized 39” x 24” x 24”, you can print one or several large parts or make many small parts to increase productivity.

It builds accurate parts from batch to batch, overcoming repeatability challenges

The advanced technology driving the new Stratasys Origin One (Programmable Photopolymerization or P3) and the Stratasys H Series Production Platform (Selective Absorption Fusion) controls the print process to allow production of tens of thousands of end-use parts from a variety of high-performance materials for high heat, high impact, or medical certification. Components meet the quality standards of injection-moulded parts.

Printing in metal is gaining popularity, even in small shops. Office-friendly ExOne 3D printers quickly create metal, ceramic, and composite production parts with excellent dimensional tolerances. The Xact Metal XM200C makes metal powder-bed fusion 3D printing affordable for educational institutions, labs and small-to-medium businesses that need prototyping and tooling.

Overall, as the pace of change keeps accelerating, advances in medium- to high-volume production are happening fast.Manufacturers in all sectors will continue to find new ways to advance their design process and digital workflows, improve time-to-market, and make complex, custom parts in larger numbers. Exploring additive manufacturing in a post-secondary environment is a good way to test technology before bringing it to scale. | MA

BREAKING THE MOULD

How machine builder Ro-Matt helps manufacturers implement robotics and automation solutions, from the traditional to the unconventional

BY KAREN SMOCK

Steven Del Duca, president of Ontario-based automation builder RoMatt International Inc., recalls how daunting the learning curve was when his company first started working with robotics.

“In the beginning,” Del Duca admits, “it was very intimidating seeing and working around robots.”

When Ro-Matt first started over 30 years ago, the cost of robotics compared

Riveting

In a fastening technology first in North America, Ro-Matt implemented a robotic riveting process that accommodated different orientations.

to automation or skilled workers was prohibitive, and finding programmers was difficult.

However, as the cost has come down and skilled workers are in short supply, robotics have become a more attractive option. “We’re glad that we made the move to embrace robotics in the beginning and have been able to experience and enjoy the evolution. Learning about the technology and the ever-increasing capability unlocks new potential every day,” says Del Duca.

Now, the company shares the knowledge gained from robotics implementations when designing and building automation, custom machinery and material handling solutions for clients in Canada, the United States, Mexico, Europe and Asia.

Robots

gain ground

D el Duca says there are two main drivers for companies to implement robotics: a shortage of skilled workers, and the additional benefits of robotic solutions. Many Ro-Matt clients are in industries that have traditionally been labour intensive. For example, fabricators need hundreds of welders to make their products – but their current welders are retiring, and not enough people are entering the workforce to replace them. The net result is a serious shortage of people

Ro-Matt’s robotic riveting cell

“Robots are as common in manufacturing spaces as coffee machines are in office kitchens. It’s an absolute necessity to have this technology integrated,” says Del Duca.

available to do the work.

Extra benefits such as improved productivity, enhanced safety and flexibility with manufacturing processes make robotics attractive. Robotic systems are proving to deliver on their claims, with increased cycle times, greater productivity, more consistent quality, and the capacity for redeployment.

“Now, robots are as common in manufacturing spaces as coffee machines are in office kitchens. It’s an absolute necessity to have this technology integrated into manufacturing, to keep up with production and quality demands,” says Del Duca.

Welding advances, robotics evolves O ne area that Ro-Matt now specializes in is robotic welding and assembly solutions, as well as the design and manufacture of custom hydraulic cylinders. Del Duca explains the evolution was because many companies that make stamped components also have sub-assembly work, and need robotic welding to supply their customers with further-completed components and assemblies.

Welding has gone through many technological advances, such as laser welding, fusion welding and cold metal transfer. The automotive industry is now hot-stamping high-strength, lightweight parts. With these advances, traditional welding methods don’t work, so new types of welding systems must be created.

Del Duca credits robot producers including ABB, FANUC, KUKA, Yaskawa Motoman, Kawasaki, Nachi, Yamaha and others for asking, “What would you like to see robots do next?” and listening to the market. Just because there isn’t a robot doing something now doesn’t mean it

can’t be done.

To meet the specific needs of the systems and manufacturing cells that they create, Ro-Matt designs and builds the equipment – starting from the production process through to the capital equipment, automation, fixture and tooling, including end-of-arm tools, piping, wiring and controls programming. “We’ve done crazy things like mounting a robot on the end of a robot,” says Del Duca.

He says a low-capacity robot could theoretically be used to do welding because there’s not a lot of payload and it’s a dedicated process. But when you need a long reach, a standard dedicated weld robot won’t suffice – you need a large robot to give you the reach.

For a client that needed extra-long reach for a particular project, Ro-Matt proposed mounting a smaller robot onto a larger robot to provide the necessary reach alongside the dexterity required from the actual welding robot. Del Duca explains that the application can go even further by taking those two robots and mounting them on a seventh or eighth axis or sliding unit. By mounting the two robots on a shuttle, these can move from point A to point B in a linear direction so the robots can access more features and the equipment can be more productive.

The advent of vision systems has allowed robotics to do more with better precision. Del Duca says that vision systems for robotics are especially useful for tasks like seam welding. The vision system can go ahead of the welding operation and gives feedback to the robot so that it follows exactly where it needs to go.

In a fastening technology first in North America, last year Ro-Matt implemented a robotic riveting process that accommodated different orientations. Typically, riveting is performed

in one orientation on a stationary unit that comes down like a press – putting the rivet in the hole and popping the rivet. To rivet in different orientations, Ro-Matt found a way to allow the robot to turn and orient rivets like it would for a welding application.

Improving job safety with robotics

Del Duca stresses that the idea of robotics taking jobs is a myth. In addition to a shortage of skilled workers driving the need for robotics, the implementation of robotics does not decrease the workforce. Companies are using robotics to do unsafe and repetitive work that people shouldn’t be doing, and they’re bringing in staff who can program and maintain the robotic systems. By using automation to perform tasks such as clamping and manipulating, operators are left with safer jobs such as loading, unloading, packaging, and machine operation and maintenance.

“ We want the operators to be the smart part of the system, to use their brains and to use what they’re good at – the decision-making ability – and let the machinery do the mundane, repetitive work,” says Del Duca.

Expanding to other industries

The lack of skilled workers isn’t a problem limited to manufacturing. Del Duca says that in addition to the need for welders and machinists in manufacturing, the construction industry is experiencing a shortage of bricklayers, framers and carpenters. That shortage is driving the construction industry to use automation in a sector that traditionally wasn’t a pioneer in robotic implementations.

A recent construction project Ro-Matt worked on was for a client making large 3D volumetric structures out of steel. Operators were placing heavy pieces in a large fixture and welding everything manually. Ro-Matt assisted in developing a large, automated production weld cell using robotics to load all of the material in place according to the CAD design, and then to weld everything in the structure. Operators only had to cut the material, load racks and put them into the cell. The cell took care of everything else, and the new robotic process allowed the client to more than double productivity.

Achieving success with robots

For manufacturers looking to implement robotic solutions, Del Duca advises setting up a team internally before starting to bring in technology. The infrastructure needs to be in place from the beginning, built from the top down so that the system can be properly run, operated and maintained.

Del Duca explains that there are some very creative things companies can do with the wide range of robots available with different capabilities to do a variety of tasks, so find an automation partner that can think outside the box.

“Systems are getting smarter and safer. Artificial intelligence is making its way into the manufacturing space and robotics are starting to do things that people are unable to do,” says Del Duca, noting that it’s time for manufacturers that haven’t yet automated to take the leap. “Robotic automation is here to stay, and every year, will become more and more technologically advanced,” he says | MA

A dial table moulding line

GET SMARTER ABOUT SAFETY

A look at new approaches that can be used to automate safety in manufacturing plants

BY TREENA HEIN

While automation has been transforming manufacturing plants for decades, automation of safety is now coming into its own.

By automating paper-based and manual safety-related processes using a variety of technologies and approaches, workers in plants are much better protected. And, because they save time, these automated approaches also boost plant productivity. Here are the current broad trends in safety automation, along with a glance to new technologies and future outlook, from some leading industry experts.

Integration of safety

Safety in manufacturing used to be focused on manual “point solutions,” where for example, the safety of each machine is handled separately, explains Pierre Van Neste, global director of sales, plant and personnel safety and risk reduction software at Honeywell Process Solutions.

“Individual machines, safety training, personal protective equipment, etc. –handling these things individually is inefficient and involves silos of data that are disconnected, so it’s very difficult to access and analyze the data,” he says. “Now it’s becoming common practice to have most or all aspects of worker safety integrated with overall plant digitization. The growth in understanding of the power of integrated solutions has been slow across manufacturing, but it’s coming along now.”

Chris Morgan and Eric Haapamaki, applications engineers at Sudbury, Ontario-based Ionic Mechatronics, are also seeing increasing uptake of

integrated safety solutions. “We’ve been doing presentations about this for over 10 years,” says Haapamaki, “and now, safety analysis and implementation of integrated systems is 25 per cent of our business.”

Van Neste says how safety can be integrated with equipment assets, workforce management and site security. Employee badges (employing radio-frequency identification and/or other technologies) help ensure only authorized personnel are on site, but the integrated system also validates that the correct individuals are “safe” to work in a given area of the plant.

“If the required certification is not up-to-date for a particular worker, the system will simply not allow entry,” Van Neste says. “Before such a system is put in place, there was either an inefficient paper-based system and/ or siloed computer records where, for example, the dates for which given employees needed to do recertification courses were kept, and hopefully it was all accurate.”

It has also been left to workers to do proper lockout before approaching a machine, which has led to solutions to automate the process. “From my observations over the years, proper lockout takes time and it’s very rare that all procedures are followed, such as checking that there is no voltage running to that machine,” Morgan says. “Everyone is relying on the worker to do things correctly, and we know that if procedures take a lot of time, things will get skipped even if there is a safety risk. If you leave a situation to procedure, an accident will happen at some point.”

Ionic now offers an automated remote lockout system called SafeBox

where a worker or supervisor requests entry into a given area and the system does the lockout, saving time and ensuring better safety.

Automation vendors are working to develop artificial intelligence systems that do predictive modelling –this can help to prevent spills, map out emergency responses and more.

Another way safety is being automated involves virtual reality (VR) technology, explains James Findlay, solution consultant at Rockwell Automation. “We offer several VR systems such as Vuforia with our partner PTC that allow new workers and contract workers to understand plant layout and safety hazards before they arrive onsite,” he explains.

“ This technology has been used in aerospace industries for years and it’s starting to come into other sectors. Then, when workers are onsite, we can switch to an augmented reality system, where you can have a module, for example, where a worker who’s been there for years can virtually show a new worker in the real environment of the plant how to use a machine and do the overall job in the most safe and productive way.”

Contractor safety Integrated systems for contractor management also provide significant safety and efficiency value. “The contractor ahead of time shows that

“An automated system can monitor for falls [and] allow workers to alert the system quickly and easily by pressing a panic button,” says Van Neste.

the workers who will arrive have the required certifications and access,” Van Neste says. “The work permit is requested ahead of time, so it’s ready when the workers arrive.” This system also provides a significant bonus, he adds, of being able to track “time on tool.” That is – geo-location is used to verify that the contractor was working at the correct machine, and, at inspection, that the inspector was present.

Automated accounting

Accounting for all workers at an emergency muster point is another situation where safety is being automated (and greatly enhanced) through integration with a digitized site management system.

Without such a system, a designated person must manually record who is or is not at their designated meeting place. Now, digital badge systems can account for everyone automatically and can immediately locate anyone not present, guide workers to a safe

zone, and so on.

“ It also provides that critical situational awareness for emergency operations,” says Van Neste. “Supervisors not on site can understand what is happening and make the best decisions. Without this, it can be very dangerous, for example, to send someone to try and find a worker who has not reported, and there have been many cases where workers get really frightened and leave the site but don’t tell anyone they’ve gone.” He adds that there should be a cloud-based component to data management because on-site computing power could be affected by the emergency.

Technology keeping pace

Yet another area of safety automation is the use of IoT and sensors that prevent dangerous situations in the first place. “An example in a paper plant would be speed monitoring on a paper winder,” says Morgan. “Changing the speed has traditionally been done by a worker with a selector switch but

with automated speed monitoring on the drive, the winder is automatically slowed or stopped if it’s going too fast.” Morgan and Haapamaki also point to new radar-based sensors now available that are not affected by dust, smoke, fluid spray and other airborne materials the way traditional light/ laser sensors are affected. Haapamaki adds that if a given sensor system produces a lot of false trips, employers will simply rip it out.

And different types of worker-focused sensors are already in use. The badges offered by Honeywell, for example, automatically alert spoton personnel when a worker hasn’t moved for a given period of time or has fallen. “In today’s world, we have an increasing number of lone worker situations,” adds Van Neste, “and an automated system can monitor for things like falls but also allow workers to alert the system quickly and easily by pressing a panic button.”

Tech also already exists, he says, to detect if a worker has donned all the protective equipment required, and developments related to ergonomics are coming (for example, alerting workers when they aren’t lifting an item properly). Biometrics are also already included in some automated workplace safety systems, which can detect if a worker’s heart rate has changed or stopped, for example. “These systems can respond to events such as a heart attack that happens to occur at work,” says Van Neste, “and therefore go beyond work-related safety issues.”

Looking forward, Findlay believes artificial intelligence (AI) systems will play a greater role in plant safety. Rockwell is working with PTC to develop AI systems that do predictive modelling, for example, to prevent spills, map out emergency responses and more.

In terms of what company leaders should do to start taking safety automation to the next level, Findlay notes that the amount of technology available can make the process feel overwhelming. “Contact a reputable company,” he advises, “one capable of doing a full analysis of your needs and that will create a suitable digital transformation plan.” | MA

Treena Hein is an award-winning freelance writer based in Ontario.

CONFRONTING THE RANSOMWARE THREAT

Bolstered by recent success, ransomware attackers are better resourced and more brazen. Unwitting manufacturers have become a prime target

BY JACOB STOLLER

Keeping ransomware attackers at bay is somewhat analogous to avoiding getting eaten in the jungle, notes Yogesh Shivhare, senior analyst at research firm IDC Canada.

“If you’re in the jungle and a lion is chasing you, you don’t have to outrun the lion – all you have to do is outrun the other people,” says Shivhare. “The key point is that you have to make your organization a little more difficult to attack than others.”

Ransomware-as-a-Service (RaaS), as it is sometimes called, is now a well-established criminal undertaking where “bad actors” invest in technical resources and then seek out targets that will provide the best return. Recent incidents range from a high-profile attack on Canadian manufacturing giant Magna to smaller-scale attacks on SMEs. “This is one very organized industry,” says Shivhare. “Now the tools are so readily available that anybody can attack anybody.”

Manufacturing appears to be a particularly lucrative hunting ground – an IDC survey found it was the most frequently attacked industry in Canada in 2020, and that manufacturers are attacked at twice the national average.

“ There are a couple of elements in manufacturing that make it a very good target for attackers,” says Daniel Clayton, vice-president, global security operations and services at Texas-based cybersecurity firm Bit Defender. “They have to deal with not only the downtime from the incident, but with the knock-on impact on the supply chain. Furthermore, the interconnected nature of manufacturing supply chains means that you’ve got a lot of industrial devices and networking devices that

are exposed to the internet.”

Manufacturers are noted sometimes for having weaker defences. “There is a view that manufacturing organizations are not always very mature from a security perspective,” says Clayton. “In cases where this is true, there are likely to be old operating systems in the environment, and unpatched systems.”

RaaS

Ransomware-as-aService is a criminal activity where bad actors invest in technical resources and then seek out targets that will provide the best return.

The pandemic has increased this threat. “A lot of organizations had to adopt remote work but were not ready for it,” says Shivhare, noting that implementing such programs normally takes six to 12 months. “That opened up a lot of vulnerabilities.”

Pinpointing the vulnerabilities

Today’s hackers have upped the ante. No longer content to encrypt a company’s data and then demand a hefty ransom to unlock it, they combine this threat with double extortion, where they threaten to expose data, often publishing samples online to prove their point.

Typical incidents occur in two

phases. The attacker first gains access and then trolls the host network to locate critical data, assess its sensitivity, disable backup and security systems, and estimate what the victim will be willing to pay. This is frequently automated with software tools that have become readily available on the dark web.

Technology can help reduce these risks. Endpoint Detection and Response (EDR) solutions, for example, use analytics to establish profiles of security incidents over time to speed threat verification and elimination from environments and improve defences.

“ We manage over half a billion endpoints globally, which means that we have eyes all over the world,” says Clayton. “We see attacks as they happen and we can very quickly develop signatures that will block those attacks and protect our customer base.”

M any defensive strategies, especially older ones, are focused on preventing attacks at the perimeter, but today’s attackers are often able to circumvent those defences. Often,

they do so by exploiting what is too often the weakest link – unwary employees.

“Phishing is the tried-and-true method, and the number one attack vector,” says Kevin Magee, chief security officer at Microsoft Canada. Fake ads for unbelievable discounts, free software or posts about a favourite sports team are common bait.

Bitdefender combines security analytics with cyberthreat-hunting to scour customer networks for signs of intruder-like activity. “What our analysts are able to do is develop a very detailed picture of the way a device in that environment normally operates,” says Clayton. “If a user credential, or system, is not operating in the way it normally does, we can identify it and if necessary, shut it down.”

Clayton warns, however, that companies should focus on security best practices like multi-factor authentication, reduced access rights to sensitive data, hardening of systems to ensure that all versions and patches are up to date to protect their credentials, their networks and their businesses. Much of this is aimed at blocking intruders from moving laterally within the network once they have gained access.

These measures are detailed

“In a manufacturing environment, there are so many computing devices that keeping everything updated and patched is really difficult,” says Baumgartner.

and time consuming. “In a manufacturing environment, there are so many computing devices that keeping everything updated and patched is really difficult,” says Kurt Baumgartner, principal security researcher at global cybersecurity firm Kaspersky. Baumgartner also recommends segmenting the manufacturing network, with its many sensitive devices, from the rest of the corporate network.

The rise of IoT, edge computing and robotics has increased the scope of these chores dramatically. “If you’re the security professional, you might be managing 20 to 30-year-old equipment that’s now connected to the Internet but was never designed to,” says Magee. “But you also might be managing some cutting-edge operational technology that is brand-new and still evolving.”

The rapid evolution of Industry 4.0 technology has increased the urgency of breaking down the divisions between plant engineering and IT. “The CIO has never been trained to secure

OT (operational technology) edge computing resources,” says Magee. “I would love to see a plant engineer or plant manager brought onto the security team to give that perspective.”

“I also think we’re not training technical managers to lead technical teams that cross over into electrical and mechanical engineering,” adds Magee. “I think we as an industry really need to do more in the coming years to close those gaps.”

Another important requirement is planning what to do in case of attack. Companies are now augmenting their disaster recovery plans to include ransomware incidents. Added measures might include establishing relationships with specialty firms that handle negotiation with and payment to attackers. While ransomware is an unsavoury topic for many executives, this is not a conversation that should be taking place when the clock is ticking.

Future outlook

Announcements by U.S. President

Biden and other leaders have raised hopes that cyber criminals will ultimately be tracked down and put out of business. “I’ve seen some positive things,” says Baumgartner. “It was good to see the FBI claw back millions of dollars in Bitcoin from one of the ransomware operators after it was paid out. That was incredible.”

But Baumgartner is guarded in his optimism. “At this point, the ransomware operators have stolen enough money to not only grow their own organizations, but to continue doing so for years,” says Baumgartner. “This is a problem that’s going to get worse before it gets better.”

“One of the reasons why ransomware is so popular and still growing is that in a large part, it’s successful,” says Jean-Philippe Racicot, manager, strategic threat assessments, CSE (Canadian Centre for Cyber Security).

CSE hopes to make Canada a tougher hunting ground. “It’s not like we’re going to completely eradicate cyber criminals from across the world,” says Racicot, “but if you take simple effective actions to make yourself a harder target, they’re typically going to go elsewhere.” | MA

Jacob Stoller is a journalist and author who writes about Lean, information technology and finance.

MAKING A DIRECT IMPACT

How DC power for industry is an opportunity in the making

BY JON DESOUZA

In Hollywood’s depiction of the War of the Currents ( The Current Wars, 2017 ), alternating current (AC) achieves a decisive victory over Edison’s direct current (DC) when the Westinghouse interests win the right to electrify the 1892-93 Chicago World’s Fair. In truth, a more defining moment was the August 1895 start-up of the world’s first large-scale AC generating complex at Niagara Falls, N.Y. Early 20th-century utilities leveraged the AC advantage: the ability to step up power from large generating complexes to very high voltages and transmit it over hundreds of kilometres, then step it down to voltages suitable for running a printing press or toaster. Over time, centralized AC grids supplying power from huge generating sites became ubiquitous, here and abroad.

O f course, direct current never disappeared. It’s powering our smartphones, laptops, smart TVs and LED light strips. Plug-in adapters convert AC to low-voltage DC; we don’t give that a second thought. Anything battery powered is DC-powered. In industry, direct current is preferred for many applications. The speed of DC devices such as servo and stepper motors and brushless motors is directly proportional to the voltage supplied, which makes them the most efficient choice for many jobs.

Every time AC is converted to DC at a field-level device, there is a small energy loss. Switching to a plant-wide DC grid eliminates such conversions, reducing consumption by two to four per cent.

Now, trends reshaping the global energy sector assure DC a much greater role in industry – from opportunity as much as necessity. With widespread electrification and the eventual retirement of conventional thermal generation capacity, where will the power come from to assure uninterrupted supply at stable rates? Optimists believe solar and wind power, coupled with high-capacity storage, will indeed suffice. They are cost-competitive now, faster and easier to design and build, and are beginning to disrupt our heavily centralized and regulated AC grid architecture. They also generate DC power.

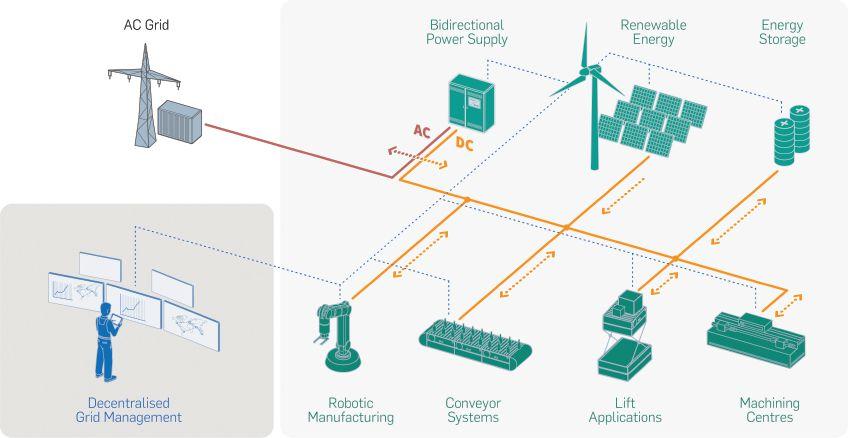

For industrial users, DC presents two macro possibilities: 1)

to rethink their relationship with external sources of electricity, potentially gaining some autonomy and even pricing leverage, and 2) to convert their internal grids to DC. The potential benefits include material gains in energy efficiency and reduced exposure to surges, blackouts and utility-ordered brownouts. An internal DC grid can be bi-directional, recuperating waste (braking) energy from production systems for additional savings. Recuperated power could be stored and used as backup or peaking power, or turned into a revenue stream. Each facility can be its own microgrid, drawing power from multiples sources, even DC from rooftop solar panels, making that plant independent of

or interdependent with its current utility, rather captive to it.

The global beer industry is a notable proponent of supply hybrids. Heineken has a portfolio of 16MW of internal solar – some 12,800 panels – on its installations worldwide. Anheuser-Busch InBev and SABMiller, and Miller Coors boast some on-site solar as do many craft brewers. Amazon, Target, Wal-Mart, Apple, Intel, Macy’s, IKEA – among others –have installed rooftop solar.

M icrogrids can be created by companies, communities, campuses, industrial parks, cooperatives, etc. As a learning exercise, Hydro-Quebec and the City of Lac-Megantic have created a microgrid with 2,200 solar panels on six downtown buildings – 800kW of generation capacity, connected to 700 Kwh of battery storage. In a blackout, the microgrid, which has its own control system, can supply 30 downtown buildings with power for several hours. Or surplus power

The microgrid concept with decentralized management of an internal DC grid gives industry more control over energy supply and new opportunities to increase energy efficiency.

can be sent to the Hydro-Quebec grid. The microgrid also feeds an electric vehicle charging outlet.

Such hybrid sourcing can facilitate a switch to internal DC grids in the manufacturing and process sectors.

Multi-stakeholder research collaborations such as Germany’s DC-Industrie and its follow-on, DC-Industrie2, are describing and testing topologies and infrastructure – hardware and software – for smart in-house DC grids. Standardization of relevant aspects will follow.

DC-Industrie’s focus on the “industrial power supply of the future” is exploring how to connect all of a plant’s electrically powered functions, even offices, to a smart DC grid that is more energy efficient and stable than AC mains, also open, scalable and flexible.

DC Industrie2 continues until 2022, focusing on the benefits for the DC grid, modularity and the spatial extension of the infrastructure throughout entire factories in conventional and Industry 4.0 environments. DC infrastructure is being tested in model plants and distribution centres at the various partners.

Every time AC is converted to DC at a field-level device, there is a small energy loss. Switching to a plant-wide DC grid eliminates such conversions, reducing consumption by two to four per cent. Other gains are in recovery of waste energy, easy integration of external DC sources (including

COMPLEX

Harting’s proposal for an industrial DC connector with AC/DC power, signals, Ethernet/data and autonomous interlock.

rooftop solar), reducing peak time-of-day usage using stored power and by turning surpluses into revenue streams. An internal energy management system can optimize internal energy usage and juggle multiple external power feeds for best costs.

Waste energy recovery is essentially the same principle as regenerative braking on a car:

Excess kinetic energy is captured when decelerating and stored for use when accelerating. With a DC grid, energy recovery in a plant becomes practical. Take, for example, a large injection moulding machine with electrical-powered drives, spindles, clamps, lifting apparatus, etc. Their waste energy can be recuperated.

DC grid material costs are lower – up to 30 per cent lower for cabling because DC cables need only three conductors and less insulation. Shop-floor components for converting AC to DC or line filtering aren’t needed. (Less expensive inverters can be used for powering legacy AC devices). There are few interference concerns; equipment can be more compact. High power

electronics can be mounted closer to a motor, even integrated into it, doing away with expensive shielded motor cables.

Each sector will find its own opportunities to economize. For example, Japanese telecom NTT claimed a 15 per cent power saving at a new data centre by replacing AC-to-DC converters at each server with more efficient centralized inverters. Among the improvements – a DC feed generates less waste heat; servers require less cooling.

S uppliers are developing products for internal DC main grids. The voltage can be slightly higher than the typical 400-600V AC grid – in a range of 650-800V DC. Throughout Harting’s history, the company’s principal focus has been heavy-duty industrial connectors.

With any power connector, there is a risk of sparking if the unit is accidentally (or maliciously) disconnected under load. With AC connectors, passive solutions such as blocking plates or padlocks are used to deter or prevent disengaging under load. With

direct current, extra protection is recommended. DC connectors will require active locking – literally an actuator incorporated into the unit for that purpose, says my colleague Norbert Gemmeke, managing director of Harting Electric GmbH. “This can be by an autonomous interlock in the connector, or by the connector’s integration into the control system of the plant or system technology.

“We currently see two possible versions of a future DC interface: They differ in the design of the plug face and in the control system for plugging and unplugging. One version contains contacts for both DC/AC supply plus Ethernet. In the second, contacts are provided for DC/AC power and signals, Ethernet and pneumatics as well as for linking the sensors/ actuators to an external control system, either a PLC or a higher-level cloud/IIoT system. Both solutions offer the required level of safety and protection.”

While widespread internal DC deployment by industry won’t happen overnight, the trends energizing it are clear, persistent and accelerating. Businesses are embracing rooftop solar or sourcing DC power externally, creating the basis for their own microgrids. As such, DC for industry ought to be viewed as on-the-horizon rather than over-the-horizon technology. | MA

Jon DeSouza is president and CEO of Harting Americas

CAN communication over wireless

Since its launch five years ago, the Anybus Wireless Bolt has provided industrial applications with wireless Ethernet access with its bolt-on-machine mounting. HMS now launches the Anybus Wireless Bolt CAN, featuring CAN-based communication to the host equipment. The new version enables CAN-based, heavy-duty machinery and applications to transfer CAN data over a robust wireless link. Wireless communication is

ENCLOSURES

Ready-to-roll enclosures

Rittal has launched the readyto-roll TS IT Pro enclosures. The cabinets are ideal for a range of applications – from small to large-scale deployments, to high-density cooling and cabling solutions. The new TS IT Pro ships with a perforated single front door and split rear doors keyed alike, levelling feet, casters, roof with brush baffle cable access channels, and vertical cable walls with dual PDU mountings. Fullheight rear accessory channels allow for installation of power distribution, cable management, and additional mounting locations for toolless accessories. The cabinets are built to handle

established either over a fast Wi-Fi connection or a reliable Bluetooth link. The CAN data is transported over a TCP/IP link that enables other standard Wi-Fi infrastructure to also connect to the wireless link if desired. Anybus Wireless Bolt CAN is fully transparent when it comes to transporting CAN data, meaning that it works with any CAN-based protocol, including CANopen. This opens the possibility to create mobile automation islands in any manufacturing process. hms-networks.com

Managed Ethernet switches

Antaira Technologies has redesigned its LNX-2012GN-SFP switch and is introducing its LMP2012G-SFP and LMX-2012G-SFP series of switches. Antaira’s LMP-2012G-SFP and LMX-2012G-SFP series are industrial-grade equipment, Ethernet ready to fulfill edgelevel networking applications in harsh environments such as manufacturing automation. Antaira’s LMP-2012G-SFP Series industrial PoE switch provides eight PoE ports (30 watts) for security applications and 12 fibre-optic interfaces for long-range connectivity (one metre to 100 kilometres). The SFP port will allow connectivity beyond the 100-metre limitation

of copper cable and permits connectivity through areas where electromagnetic interference may cause issues found on factory floors. If you are looking for a switch with the same spec, without PoE functionality, the LMX-2012G-SFP series supports 12~48VDC power input, which is ideal for applications where only low volts of DC power are readily available. Features such as SNMP Traps, Syslog, and port mirroring help to reduce issues causing outages. Additional features that were not included in the predecessor, like the ERPS (both LMP and LMX-2012G-SFP series) and PoE functionality (LMP-2012G-SFP series only), provide versatility. antaira.com

MACHINE TOOLS

Cooling for CNCs

heavy loads – the sturdiness is a result of both structural design and reinforcements in key areas. This flexible and scalable network and server rack solution can be deployed quickly to address a variety of needs, enabling companies to adapt their IT infrastructures to the growing demand for more complex challenges at higher speeds. rittal.com

POWER SUPPLIES

Buffer and redundancy modules for DC power

The new PS9xxx buffer and redundancy modules extend the universal 24/48 V DC power supply series from Beckhoff. The PS90xx buffer modules prevent disturbances caused by voltage dips and fluctuations in the electrical grid or by peak loads, so that the power supply units and connected loads can operate reliably. For this purpose,

168 Manufacturing, a brand of Precision Tool Technologies, has debuted the FS40 series of FullShop Automated Coolant Management Systems. Optimized for the most common CNC machine shop sizes, one FS40 system can automate a few CNC machines or expand to accommodate up to 40. Like the flagship

FS120 system, the FS40 series monitors and replenishes all CNC sumps with optimized top-off ratios. This system consists of a centralized pumping station, controller, distribution manifolds and level sensor that drops into the machine tool sump. Compared to the FS120, which has a footprint of 50 by 60 inches, the new FS40 is more compact. 168mfg.com

the buffer modules store energy via maintenance-free electrolytic capacitors and release it as required. In this way, power failures, for example, can be

effectively bridged. The buffer modules require no control wiring; they can be added in parallel to the load circuit at any point. In addition, multiple modules can be connected in parallel to provide more power or further increase the power failure bridging time. The PS94xx redundancy modules create a redundant fail-safe supply network. beckhoff.com

Flexible feed-throughs for connectors

binder USA has introduced control cabinet feed-throughs for its M12 and M12 Power connectors (Series 713, 813, 814, 823 and 824). These flexible new feed-throughs enable the dependable flow of signals, data and electrical power between modules in the control cabinet and automation components in the field. The combination of plug or socket and coding on each connection side supports a variety of configurations, including the complex implementations found in Industry 4.0 smart factories. binder’s M12 and M12 power connectors allow signal, data and supply cables to be connected using circular connectors of the same series. The feed-throughs are equipped with an M12 locking thread and an M16 mounting thread. binder-usa.com

Data cables for industrial environments