Universal Analog Modules

NEW! BRX Programmable Controller Universal Analog I/O Modules

Starting at just $159.00

Forget using multiple expensive analog I/O modules to handle di erent signal types - the BRX PLC o ers low-cost universal analog I/O that accepts all standard analog signals. Read and/or write 0-5VDC, 0-10VDC, +-10VDC, +-5VDC, 0-20mA, +-20mA, or 4-20mA all from the same analog module.

BRX Universal Temperature modules allow each input channel to be independently con gured for thermocouple, RTD, thermistor or millivolt signals. Temperature Combo modules have both universal temperature inputs and discrete, relay or universal analog outputs, allowing one temperature module to perform two jobs at once!

The BRX universal analog/temperature modules will easily conform to any process application while keeping more money in your pocket - where it belongs.

BX-4UT4TR

All-in-one Temperature

Combo Module

Input:

• Thermocouple

• RTD

• Thermistor

• Millivolt

Output:

• Form A (SPST) relays

Orders over $49 get FAST FREE SHIPPING

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

5

14

The

Joel Blit, University of

10

Before you buy a cobot

16 Deconstructing data

An AI-backed application makes sense of disparate data by reorganizing it into universal manufacturing concepts

By Kristina Urquhart

20 Retool and recover

Faced with the threat of closure due to COVID-19, a Torontobased SME rallied area manufacturers to make face shields – and found a way to save its century-old business By

Lindsay Broadhead

22 Automate to innovate

Five steps to plan and pay for automation in the coronavirus era, from our first-ever virtual summit

By Kristina Urquhart

24 A real-time view

Process management platforms streamline work processes and boost communication during shift handovers By Andreas Eschbach

COVID-19 PRODUCTION

Ontario invest $2M in PPE sanitizing device

The Ontario government is providing $2 million in funding to help scale up the manufacture of a device that sanitizes personal protective equipment (PPE) for reuse.

The Clean Flow Healthcare Mini device, created by Clean Works Medical and Pure Life Machinery, can decontaminate up to 800 N95 masks per hour, along with other PPE.

The device is a Health Canada–approved innovation based on existing technology designed to disinfect fresh produce. The technology uses UV light, hydrogen peroxide and ozone to decontaminate surfaces.

The technology can destroy up to 99.99 per cent of pathogens and viruses on surfaces, making them as sterile as an operating room.

“This is an incredible success story about an Ontario apple farmer taking technology used to decontaminate produce and converting it into a device that can decontaminate personal protective equipment,” said Premier Doug Ford in the announcement.

Clean Works is a joint venture between Moyer’s Apple Products and Court Holdings Ltd., a global manufacturer.

The company will use the funding to scale up the production of its portable disinfectant device to nearly triple its current capacity.

The investment, made from the province’s $50-million Ontario Together Fund, will support 19 new jobs and the purchase and installation of metal fabrication, equipment assembly and facility modifications.

Since its launch, the Ontario Together web portal has received more than 28,000 submissions for COVID-19 projects.

Eclipse receives over $1.4M for N95 production

Eclipse Innovations, the incubator launched by Eclipse Automation earlier this year, is receiving over $1.4 million from the Ontario government to scale up its manufacture of N95 masks.

The company, based in

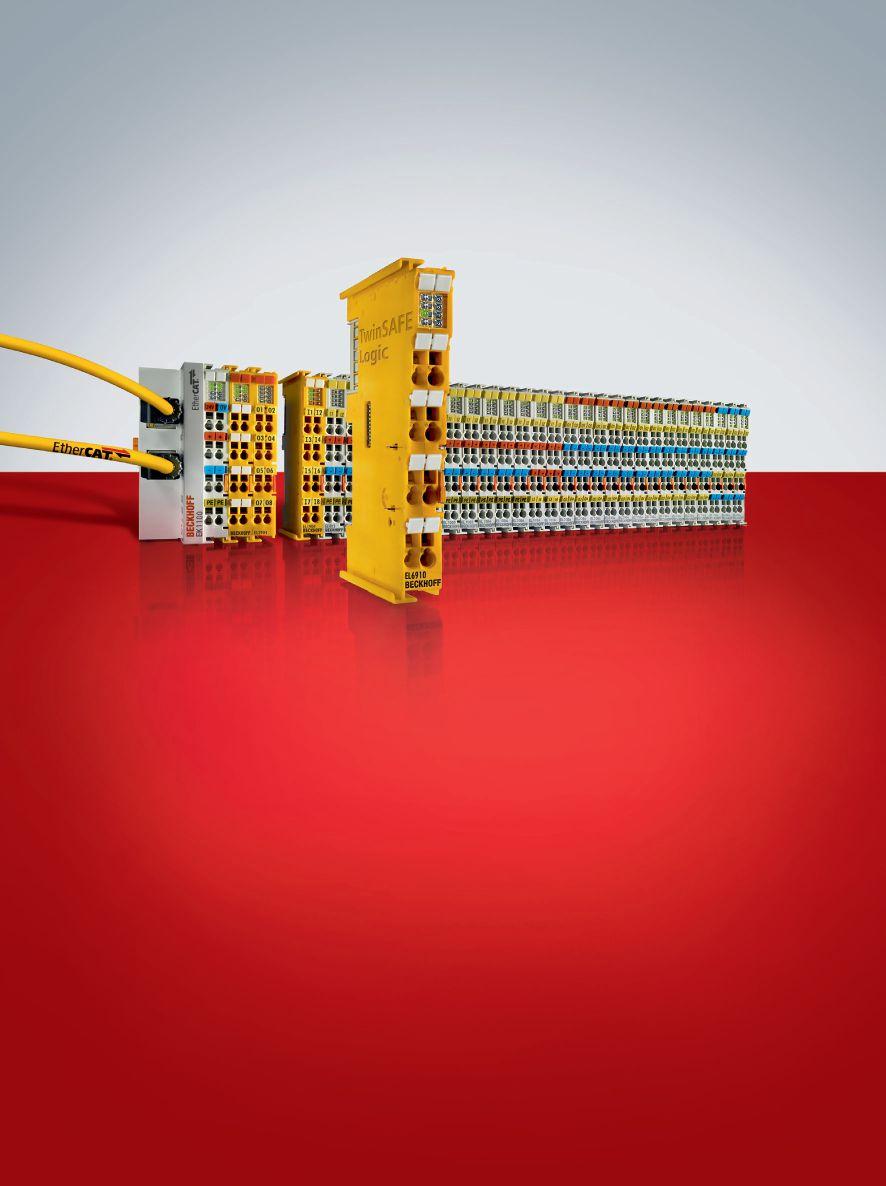

Integrate automation and safety on one platform: TwinSAFE

Premier Doug Ford announced $2 million in funding for an Ontario-made PPE-sanitizing device produced by Clean Works Medical.

Cambridge, is receiving $1,408,475 from the $50-million Ontario Together Fund to increase the capacity of Ontario-made PPE.

N95 respirators filter 95 per cent of airborne particles, making them highly effective in protecting the wearer from airborne pathogens, such as viruses and bacteria that could damage the respiratory tract.

By adding this new capacity, Eclipse Innovations will be able to make one million N95 respirators per week.

“Eclipse is a company that does not stand still, especially at a critical time like now. We are nimble and ready to take action, and that’s exactly what we did when we established Eclipse Innovations,” says Steve Mai, CEO of Eclipse Innovations, in a statement.

When the outbreak of

COVID-19 hit, Eclipse quickly pivoted its business and collaborated with global players IREMA and Harmontronics to create a solution to design, produce and distribute N95 respirators for the domestic market.

This investment will also allow Eclipse to develop a range of different mask sizes and styles, such as horizontal and vertical fold, providing multiple options for an optimal fit.

Eclipse also has a partnership with Conestoga College for the development of a N95 predictive

fit testing software using facial scanning technology.

The company has 450 Ontario-based employees and this project will include the creation of 17 new permanent full-time jobs at Eclipse Innovations.

PPE maker launches automated surgical mask production

The Canadian Shield, a Waterloo, Ontario–based personal protective equipment (PPE) manufacturer, is expanding its production line to include disposable surgical masks.

These masks are in addition to the reusable face shields and cloth masks already being manufactured by The Canadian Shield.

The company has built two automation lines for surgical mask production that will be running 24/7 to ensure the company meets its production quota of one million surgical masks per week.

For Motion Feedback in Industrial Automation,

By mid-September, The Canadian Shield’s annual capacity will grow to more than 200 million surgical masks annually.

Non-rated disposable surgical masks are now available for consumer pre-order online through The Canadian Shield’s website.

Pending further testing, the company will also be releasing ASTM Level 1, 2 and 3 disposable surgical masks for consumer sale.

The Canadian Shield has also recently launched a line of cloth masks, while continuing to grow its capacity to manufacture reusable face shields. The company now produces more than 200,000 face shields per day having just launched in March 2020.

The company will also begin manufacturing isolation gowns, with an anticipated capacity of six million gowns per year.

JMP Solutions lands ventilator contract

JMP Solutions has partnered with Vexos Inc. to fulfill a contract for the production of 10,000 ventilators for use in Canada.

JMP Solutions, a systems

integrator and engineering services provider based in London, Ontario, is part of Ventilators for Canadians, a consortium of manufacturers and solutions providers working to ensure Canada is equipped with sufficient supply of ventilators to aid in the fight against COVID-19.

Ventilators for Canadians was borne out of the need to quickly develop an agile team of industry professionals with complementary skills, technical expertise and access to fit-for-purpose supply chains and manufacturing environments.

As part of the Ventilators for Canadians consortium, JMP has been working with an international team of scientists and engineers from Canada, Italy and the United States named the MVM (Mechanical Ventilator Milano) Collaboration, the team responsible for the product engineering, design and testing of the MVM Ventilator.

The global team was able to bring the MVM Ventilator from concept to FDA approval in a span of six weeks.

The team has submitted for Health Canada approval under the provisions of the Interim Order in regard to medical devices for use in relation to COVID-19.

JMP Solutions has partnered with Vexos, an electronics manufacturing services provider in Markham, Ontario, to manufacture the mechanical sub-assembly, which will then be sent to Vexos for electrical assembly and testing.

“We feel very fortunate to have the opportunity to step-up and do our part to support our fellow Canadians during this crisis,” says Scott Shawyer, president and CEO of JMP Solutions.

COVID-19 CONCERNS

Canada and the Canadian Association of Mold Makers indicates a rebound is underway among manufacturers, despite difficulties still facing the industry.

For the second month in a row, 98 per cent of survey respondents say they have resumed their business operations. At the peak of the crisis, almost 20 per cent of respondents had temporarily closed their business.

Responses are voluntary and primarily from companies in the Southwestern Ontario region, which has a significant manufacturing, moldmaking and industrial automation cluster.

Having progressed from a reactionary mode early in this crisis to more long-term planning, the associations say that the July survey shows manufacturers are now putting plans and actions in place to ensure the long-term sustainability of their businesses.

The top concerns for manufacturing, based on the responses to this survey, are cash flow and a return to profitability in the face of declines in demand from their customers.

This is also supported by the employment numbers reported in this most recent survey. While hiring has resumed, permanent and temporary layoffs have also increased as manufacturers adjust staff numbers and skills of employees to align with demand. When the survey closed on Jul. 10, respondents had reported having 408 employees on temporary layoff, which was up over the previous month.

“We are a resilient industry. We have gone through tough times and this pandemic is no different,” says Mike Bilton, chair of CAMM. “We know we still have tough times ahead so we are working as an organization

to build on how as a team we can move forward.”

The survey has shown the newly extended Canadian Emergency Wage Subsidy (CEWS) has remained the most popular financial support program for businesses from the federal government.

Employers also report improvements in health and safety practices in the workplace, flexible work from home arrangements and collaboration among employees.

Difficulties getting employees successfully into the U.S. has been a continued challenge for the mold making, tool and die, and industrial automation companies that are under pressure to resume projects with their U.S. customers. The border restrictions have impacted almost one-fifth of respondents.

The CAMM and Automate

Canada boards continue to meet regularly, including twice a week as part of the Windsor-Essex COVID-19 Economic Task Force.

INVESTMENT

CME launches local manufacturing program

Canadian Manufacturers & Exporters (CME) is launching Ontario Made, a new program to promote goods made across the province by helping consumers easily identify, access and purchase local products.

The program is being supported by the Ontario government with an investment of $500,000.

“Ontario has always been Canada’s workshop, and our products are recognized as the gold standard across the country and around the world,” said Premier Doug Ford in

Innovative Automation Solutions

SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

CARLO GAVAZZI has the solution for your application needs, whether it’s our industry leading solid state relays, energy meters, contactors, motor controls, monitoring relays or sensors, now available with IO-Link communications.

Contact us today, and one of our field sales representatives will show you why we are one of the fastest growing automation companies worldwide. We’ll even provide a free evaluation sample to qualified customers.

a statement. “Promoting locally made products will be essential to building a strong, self-sufficient province and key to our economic recovery.”

Funding for Ontario Made is coming from the government’s Ontario Together Fund. It will be used to create a new Ontario Made logo that manufacturers can use to help consumers identify their made-in-Ontario products, launch a new SupportOntario Made.ca website that will connect consumers and supply chain partners to manufacturers of madein-Ontario products through one directory, and promote Ontario Made through a digital newsletter to raise awareness of Ontario products.

CME will also meet with major retailers to promote Ontario Made products in-store and increase visibility for customers.

“As consumers increasingly want to buy local, it’s important that we help them make informed decisions and find local manufacturers,” said Dennis Darby, president of the CME. “Ontario Made will help raise awareness of what is manufactured right here by our neighbours, friends, and families.”

TRAINING

Industry 4.0 centre opening in Quebec

A new knowledge sharing centre will help Quebec manufacturers initiate or accelerate their digital transformation.

Longueuil’s industrial expertise centre (IEC) is now known as DigifabQG and is accessible online or in person.

“The integration of new technologies, artificial intelligence, automation and robotization have become essential to manufacturing companies that wish to increase their efficiency and productivity,” says Pierre Fitzgibbon, minister for the economy and innovation, and minister for the Lanaudière region.

“Competition is fiercer than ever on the world stage, and Quebec must have the ability to seize

business opportunities quickly.”

The IEC adopted the name DigifabQG (a contraction of “digital” and “fabrication,” or manufacturing, and “QG” for “quartier général,” or headquarters), following consultations that sought to illustrate the sector’s desire for digital intelligence within the production process.

Digifab belongs to a network that includes four IECs in Longueuil, Saint-Laurent, Drummondville and Quebec City.

The centre includes three distinct areas: the discovery zone,

STANDARDS

Survey: Engineers weigh in on automation standards

About two-thirds of automation engineers believe that industry standards will be “extremely important” in the future, according to a recent survey conducted by the International Society of Automation (ISA).

The ISA surveyed 290 people in the automation engineering field to evaluate how they view industry standards.

Sixty-three per cent of respondents say they believe that standards will be “extremely important” in the future, and 33 per cent believe they will be “important.”

operators, salespeople, marketers or other roles.

3D PRINTING

GM uses 3D printing to ramp up tooling

General Motors has added 17 production-grade 3D printers over the past several months to make tooling that will help optimize speed, weight reduction and cost efficiency on its production lines.

At the end of 2019, the automaker started adding Stratasys FDM 3D printers to its fleet, which have since helped to manufacture ventilators and personal protective equipment used in the fight against COVID-19.

featuring success stories and existing technologies that could provide solutions; the demonstration zone to test software and technologies before use; and the interaction zone, to provide interactive experiences that replicate real-world industrial situations for companies that are ready to purchase digital solutions.

Coaching is provided by four experienced specialists in artificial and business intelligence, robotics, advanced automation, manufacturing optimization and business strategies.

Siemens Canada is the first official partner of Quebec’s four IECs, and has provided $6.5 million in state-of-the-art equipment to assist manufacturers in their digital transformation.

Desjardins invested $500,000 to help set up Digifab. These funds have been earmarked for equipment purchasing, leasehold improvements and technology integration that will help propel factories into the future.

The site’s inauguration has been scheduled for September.

Survey respondents suggested that standards are essential to maintaining excellence in their work. In general, respondents have a positive outlook about standards, and they believe that standards will continue to be just as critical, if not more so, in the future.

Most respondents (87 per cent) say they believe that industry standards make processes and facilities safer.

Eighty-one per cent say they believe that industry standards help companies prove compliance to regulations. Sixty-seven per cent indicated that industry standards make it easier to train and cross-train people in technical jobs. And 63 per cent said that industry standards make processes and facilities more cyber-secure.

Conducted in June 2020, the online survey received responses primarily from the United States, Europe and Canada.

Forty-two per cent of respondents described themselves as engineers, 21 per cent as consultants, 15 per cent as managers, and eight per cent as executives. The remaining 14 per cent reported as a mix of technicians,

“With the pace of change in modern industry accelerating and business uncertainty increasing, 3D printing technology is helping us meet these challenges and become more nimble as a company,” says Ron Daul, GM’s director of additive manufacturing, in a release.

“We’ve been on this journey for more than 30 years, but 3D printing is becoming even more widespread at our company, with more than 700 employees now trained to use the technology. Additive manufacturing is consistently providing us more rapid and efficient product development, tooling and assembly aids.”

An April 2020 study by SME Media found that 25 per cent of U.S. manufacturing professionals were planning to change their supply chains in response to the pandemic, and 3D printing was the top choice (along with robotics) of 11 manufacturing technologies for post-COVID investment.

The technology can be used to 3D print spare parts, produce end-use parts closer to assembly, help manufacturing lines retool faster, and develop new and better prototypes more quickly.

GM is moving quickly to gain competitive advantage. The company has used 3D printing since 1989 for prototyping. Seventyfive per cent of the parts in the

DigifabQG, a new Industry 4.0 training centre, has opened in Quebec.

prototype of its 2020 Chevrolet Corvette were 3D printed, and GM now has 3D printers installed in many production facilities around the world.

The company is increasingly moving beyond prototyping to production-related applications such as tooling.

A big test of this application came in April when GM entered into contract with the U.S. Department of Health and Human Services to deliver a 30,000-unit order for critical care ventilators, in conjunction with Ventec Life Systems, by the end of August.

The company reverse-engineered part data for tooling fixtures from the original ventilator manufacturer, and started 3D printing them the next day.

NEW DIGS

Taylor Fluid Systems opens robotics lab

Taylor Fluid Systems (TFS) has opened its first proof-of-concept (POC) laboratory in Ontario, highlighting robotics from Omron.

The new lab features a variety of robotic applications that use advanced technologies designed to help customers improve accuracy and flexibility while minimizing complexity for common applications like part feeding.

The new lab provides customers verification of proposed part feeding solutions within two to four days.

DEAL MAKERS

Motion Industries inks double acquisition

Motion Industries, a U.S.–based distributor of maintenance, repair and operation replacement parts, has acquired two new businesses – including TRC Hydraulics, a supplier of hydraulic products and services headquartered in Canada. The deals took effect on Aug. 1.

In business since 1986, TRC Hydraulics is a distributor of T-slotted aluminum extrusion components and serves the Atlantic Canada region.

In 2019, TRC Hydraulics expanded by opening a facility near Spartanburg, South Carolina.

Along with distributing many lines of hydraulic products, TRC designs, manufactures and maintains hydraulic components and systems.

TRC also engineers customized hydraulic and mechanical solutions.

Motion Industries’ other acquisition, F&L Industrial Solutions, is based near San Diego, California. The company has served the southwest U.S. with aluminum extrusion components since 2002.

“We are pleased to welcome these outstanding organizations, TRC Hydraulics and F&L Industrial, to the Motion family,” says Randy Breaux, president of Motion Industries.

“TRC gives us the opportunity to expand our hydraulics business in the Atlantic Canada markets. And with its aluminum extrusion niche, F&L will nicely supplement our Mi Automation Solutions Group.”

Rittal gets new representation in Quebec

Franklin Empire, an independently owned electrical distributor, has expanded its partnership agreement with Rittal Systems Ltd. to represent Rittal in Quebec.

Franklin Empire has represented Rittal in Ontario since 2017.

The company has over 500 employees in Canada and an inventory investment exceeding $35 million. In Quebec and Ontario, Franklin Empire operates 23 branch locations and five assembly and repair shops.

Rittal, part of the German-owned Friedhelm Loh Group, is a producer of enclosures, heating and cooling systems, power distribution and IT solutions.

MOVERS & SHAKERS

Handling Specialty, a manufacturer of custom material handling equipment, recently announced two job moves at its Grimsby, Ontario–based offices.

Marek Cybula is leaving his post of supervisor of Handling Specialty’s professional services group to join the sales department as senior technical representative.

As head of the professional services group, Cybula was responsible for moving technicians and parts around the world servicing and maintaining material handling equipment.

LAPP North America has announced the appointment of Jay Lahman as the organization’s new chief executive officer. Lahman will be responsible for the North American region and will report directly to Georg Stawowy, LAPP’s chairman of the board of directors. Lahman has 25 years of experience in the cable industry including electrical, industrial, utility, OEM, data communication and specialty markets. Prior to joining LAPP, he served as senior vice-president of electrical raceway sales at Atkore International and spent 14 years at General Cable U.S, including a role as vice-president and general manager for General Cable in Barcelona, Spain. Lahman began his career with positions at Belden Wire and Cable, Thomas & Betts and ADC Telecommunications. “The talented team at LAPP is devoted to helping our customers meet the challenges of increasingly automated and networked manufacturing environments,” says Lahman. “I’m excited to be part of that team as we join our customers in building the factories of the future.”

Mobile Industrial Robots (MiR) has appointed Søren E. Nielsen as the new president of the Denmark-based company. Nielsen, who has served as MiR’s chief technology officer since January 2018, takes over the responsibilities of MiR co-founder and CEO Thomas Visti. Teradyne, which acquired MiR in 2019, made the change at Visti’s request as he pursues a new career. Nielsen brought his background in mechanical engineering to his role at MiR, along with the experience gained from more than 25 years of managerial positions with major international corporations such as Danfoss and Siemens. Workers build production ventilators for General Motors with 3D-printed tooling.

An authorized Omron distributor, TFS offers automation products and experienced specialists that work with customers and system integrators to deliver automation solutions. TFS is headquartered in Stratford.

Mi Automation Solutions Group offers control panels, conveyors, machine vision, motion control, pneumatics, robotics, sensing I/O and other automation-related solutions.

“Handling Specialty is excited to welcome Marek into this role and [we] look forward to many more years of our mutually beneficial partnership,” the company says in a statement. Taking Cybula’s role as supervisor of the professional services group is Rob Hicks, who has been with Handling Specialty for over 12 years.

“Everyone is excited to see him excel in his new position,” the company says.

with, and that person is not part of the executive team that shares all the interrelated responsibilities to the company’s stakeholders (i.e., its customers, suppliers, staff and investors).

As part of that research, FreePoint developed a “value-to-vision persona chart” (pictured above). Roles on the left are very tactile, and in the present. On the far right, the C-suite scope of view is far longer term, and the metrics are financially, and sustainability, focused. In the middle, you have department and plant management roles. The two positions missing on the valueto-vision connecting line are the IT manager and CTO. Although very important positions, they are often not directly in the line connecting

the value-adding activities on plant floor with the vision – and accountability – to the stakeholders.

This, in my opinion, is why many manufacturing companies remain slow to adopt new technologies. There are exceptions, but in most of those cases, the exceptions are the ones where the CEO has a strong personal interest and inclination towards technology.

There are several ways to close this gap. One way is to make sure IT is not considered a “service” to be run as an independent, standalone department, or that “advanced manufacturing” is considered a research or development project. They need to be connected to the company’s vision directly, and to the accountability to the stakeholders.

With our modular safety gate system you can build an individual safety gate solution optimally tailored to your application!

• Configurable safety controller PNOZmulti 2: Modular and compact solution as flexible as your application

• Safety gate system PSENslock: Safe position monitoring with process guarding in one system

• Pushbutton unit PITgatebox: Simple operation of your safety gate system

• Safety gate system PSENmlock: Safe interlock and guard-locking in one product with optional escape release

Pilz Automation Safety Canada L.P. - Mississauga, ON - www.pilz.ca - info@pilz.ca

Modular safety gate system: Your gate. Our system. Your safety.

Another way is to be aware of potential candidates within your organization that have a good sense for your company’s business and a strong personal inclination towards technology, and then encourage and support them to develop and advance their technology skills. And another is to investigate programs such as the CME’s Technology Assessment Program (TAP) to help you get started.

Technology adoption needs to start at the top. It can be delegated to a champion, but to make sure the right goals get accomplished for the company, the CEO needs to stay involved. Effective delegation requires communication, goals, checks and balances. Anything less is abdication, not delegation. | MA

Many companies are slow to adopt – the exceptions are the ones where the CEO has a strong personal inclination towards technology.

The value-to-vision persona chart, as described below, demonstrates the technology adoption gap.

In a new study, JOEL BLIT, professor of economics at the University of Waterloo, determined that Canada’s post COVID-19 economy will see more automation in manufacturing. Here’s why

Manufacturing Automation: Using data from the Labour Force Survey, you’ve determined there’s a link between recessions and a subsequent increase in automation due to the loss of routine jobs, like office support or parts assembly (ed. Read more on p. 4). What got you thinking about this connection during the coronavirus crisis?

Joel Blit: When COVID hit, I think we all tried to figure out how we can contribute to the effort to overcome this crisis. So I started reading on the topic and I was seeing that a lot of productivity increases seem to happen during recessions. It seems that right now, there are two things happening.

One is we’re going to be involved in a recession very much like all the previous ones. And in all the previous recessions since the beginning of the ICT (information and communications technology) revolution – so the last three – we’ve seen a lot of automation and reallocation happen towards the end.

Over the last 30 years, there’s been a big decrease in the number of routine jobs per capita and a big increase in the number of non-routine jobs. But that drop in routine jobs hasn’t been a steady one. Fundamentally, they’re steady, and then a recession comes along and there’s a big drop, and those jobs never recover. That’s consistent with the story that during recessions, firms are taking the opportunity to reorganize and re-examine their processes. Maybe they get rid of workers and then say if we automate, we don’t have to call them back.

The other thing that’s happening is what I call a reallocation. During recessions, there’s a lot of pressure on firms. The ones that are already more productive – which [usually] are the ones that employ automation more strongly – tend to have lower costs, and so they survive. The ones that are higher cost –that use more labour, less automation – very often will either see their revenues decrease or they’ll go bankrupt altogether. Then that market share is taken up by the bigger, more productive, more upgraded firms. Whether it’s firms directly investing in automation, or whether it’s reallocation of market share resources from less automated firms, the outcome is the same.

MA: What about COVID-19 makes this different?

JB: Stacked on top of this story is that there’s now a health incentive to automate as well. If you have a production line, and you have workers that are all next to each other, that’s a risk to the operation. So you want to automate at least some of these processes, so that you get more individual-to-robot interactions. That not only protects workers, but it also is going to mitigate some of the risky operations. Because you have these two stacked factors on top each other, I suspect that we’re going to see a massive amount of automation coming out of this recession.

The other point of the study was to try to get a sense of which industries were going to see the biggest automation impact. And it’s those industries that both have strong incentives to innovate – i.e., to automate because of health incentives, because workers have to work closely with other workers – and that have lot of these routine jobs that could be automated. Manufacturing was one of those that came up there, and so was retail.

MA: In what ways could policy help to support manufacturing companies through this transition to more automation?

JB: First, there’s the question of how to support the companies themselves. Right now, we’re supporting them with a program (Canada Emergency Wage Subsidy) that is pushing them towards hiring more people and not using technology. The context of this, of course, is that over the last 20 years, Canada has been complaining that our productivity gap with the U.S. is increasing. With lower productivity, wages stagnate and eventually the standard of living of Canadians falls behind, which we’ve already seen.

Now that we have this tremendous opportunity to actually increase productivity and make Canada richer, we’re putting in

place policies that are slowing it down. We could help firms in ways that are neutral – like with loans, because the firm can use that loan in any way they want.

Or it could be a support that is actually positive towards technology. It could be something like any firm that invests in automation is going to get a partial subsidy or tax break from the government.

MA: Cash flow is pretty low right now because of everything that’s happened with COVID-19. How does a company jump into this transformation in a timely manner given their current financial restraints?

JB: This is an excellent point of why the government needs to step in. Through the central bank they are pumping out so much money into the economy, so I suspect capital is going to be relatively accessible.

There could also be joint programs with the government’s help, like with loans that are specifically designed for technological upgrading. But a lot of firms are suffering. They don’t have the cash flow right at the time or maybe the cash flow to invest in the future. Can we step in as a government, as a society and make those investments for the future? It’s of course going to be hard, because right now they’re trying to protect jobs, and to invest in something that is actually going to get rid of jobs but make us better off in the long term is difficult.

With the smaller firms, it’s often a problem [of] knowledge. They’re often not aware how robots can be implemented, or how AI can be implemented. [We need to] partner these firms up with the knowledge that we’ve got at our universities to mobilize for the better of all of Canada.

At the University of Waterloo, for example, we have an AI Institute, and we have the RoboHub, both of which work closely with industry. When things get developed at the university, we want to make sure that firms are using that technology.

Read our full interview with Professor Blit, which addresses how many jobs he estimates will be permanently eliminated because of the COVID-induced recession, at automationmag.com

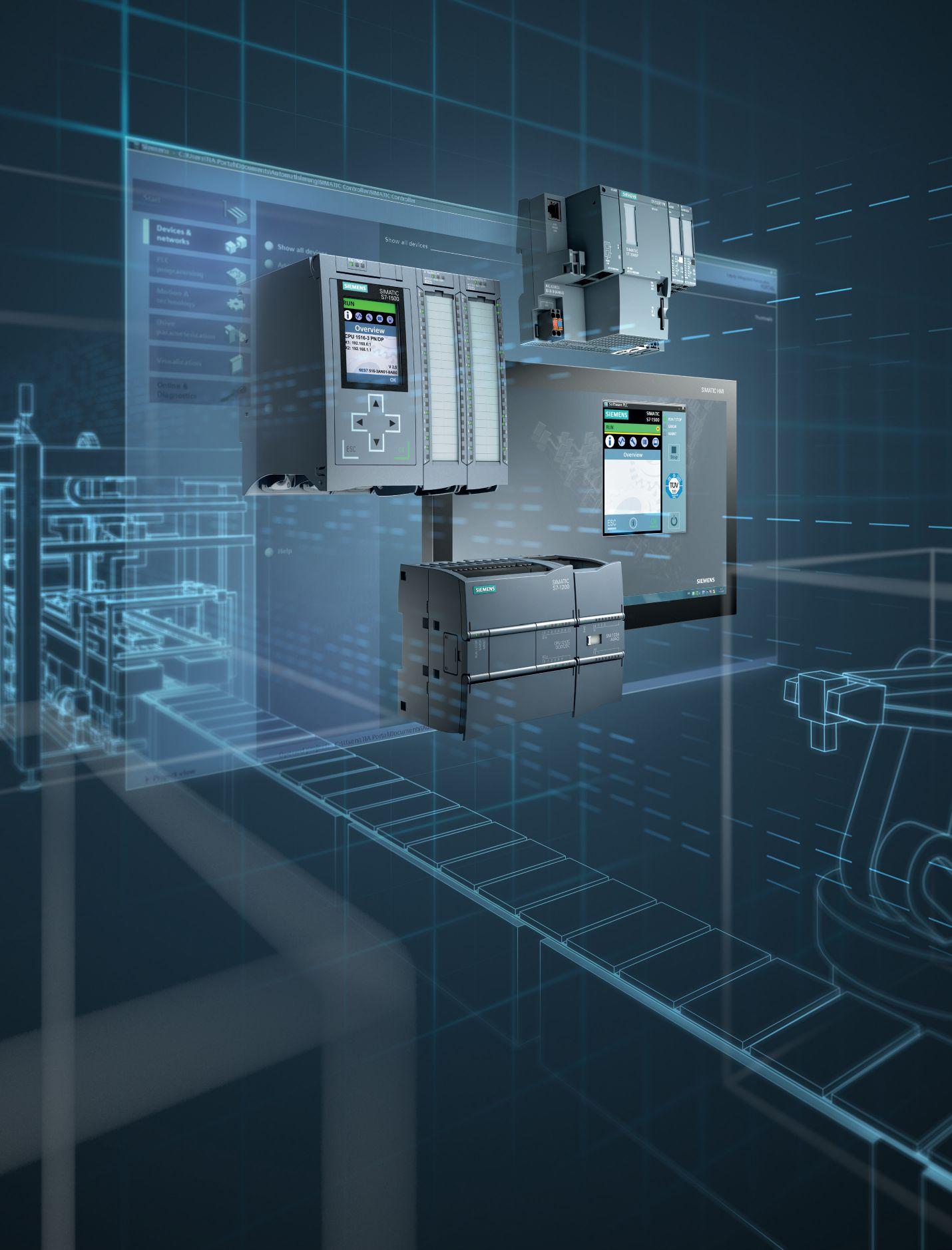

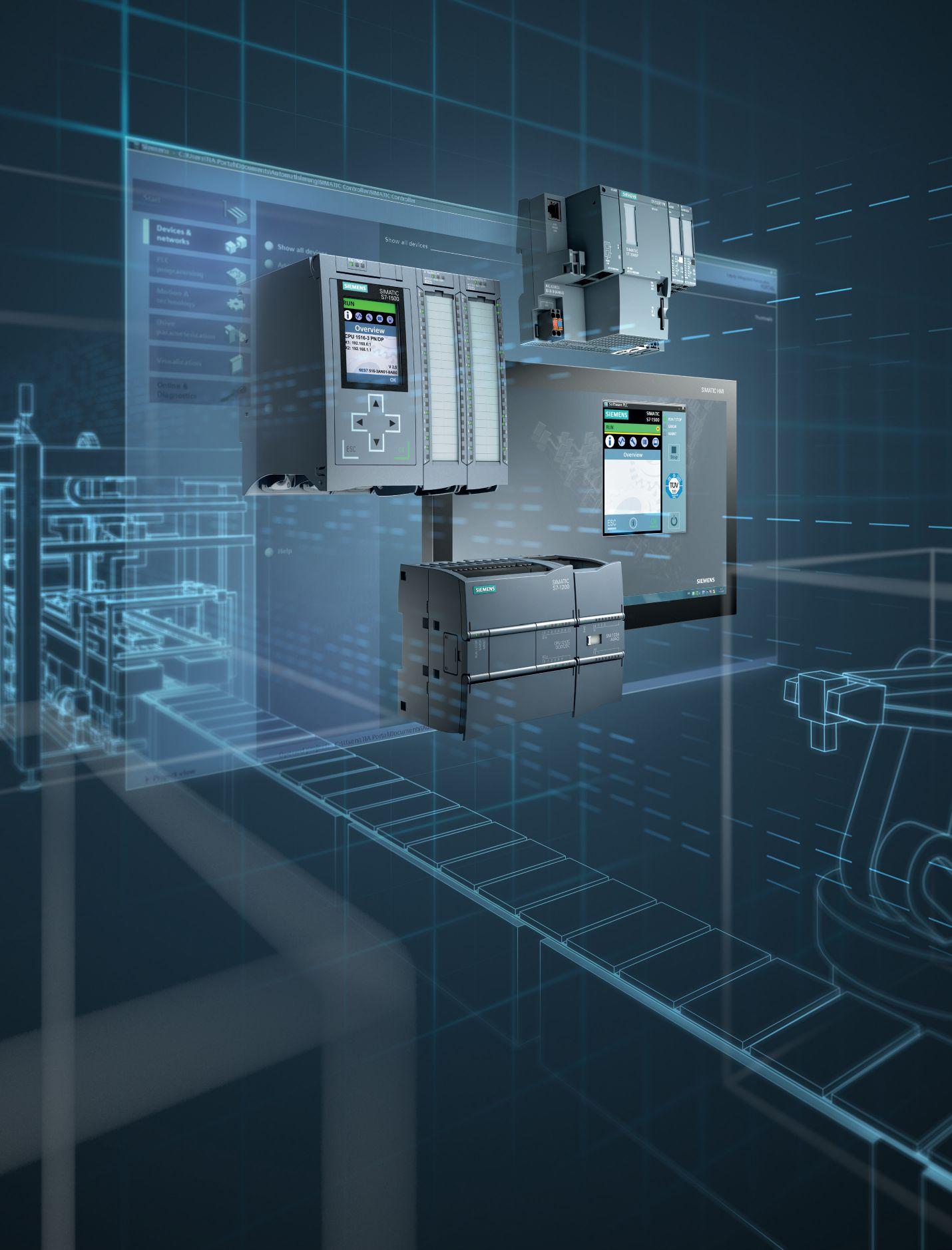

Engineered with TIA Portal

The intelligent choice for your automation tasks

SIMATIC Controllers

The SIMATIC Controller portfolio convinces through highly scalable and integrated system functions. It comprises Basic, Advanced, Distributed and Software Controllers. The Basic Controllers SIMATIC S7-1200 are used in small to medium-sized applications, the Advanced Controllers SIMATIC S7-1500 in medium-sized and complex applications, the Distributed Controllers SIMATIC ET 200 in distributed applications, and the SIMATIC S7-1500 Software Controllers in PC-based applications.

DECONSTRUCTING DATA

An AI-backed application makes sense of disparate data by reorganizing it into universal manufacturing concepts

BY KRISTINA URQUHART

Over the past several years, there’s been what Jon Sobel, CEO and co-founder of a manufacturing data platform called Sight Machine, calls an “explosion” of Industry 4.0 technologies.

“Everybody’s trying to get out of pilot land and get to scale and impact – to some outcomes in the business that matter,” he says.

As a result, the market is teeming with apps promising to use artificial intelligence to improve plant performance. But unless there’s a way to correlate data from different sources in a common language that can be interpreted by the AI, these products may be watered-down solutions to complex manufacturing

goals such as avoiding downtime, reducing maintenance costs, improving operational efficiency and predicting asset failure.

Another goal tied to Industry 4.0 became increasingly urgent as the COVID-19 pandemic gripped the sector earlier this year, paralyzing supply chains and forcing many plants into temporary shutdown: manufacturers need real-time visibility across the entire enterprise in order to respond to – and even potentially predict – crises.

Gaining visibility is not as simple as streaming data and analyzing it to spit out some dashboards on the computer. What really makes the difference, Sobel says, is a deep knowledge of the people who need to use that information every day, and the ways humans and machines

can collaborate to maximize the production efficiency of an operation.

“The technology by itself won’t get the job done,” he says. “You’ve got to understand the needs of the people.”

Making data consumable

Sobel is one of five co-founders of Sight Machine, a Michigan-based start-up established in 2011 that raised nearly $90 million in venture capital to build an analytics platform. The funding went largely toward initial engineering and then the evolution of the product over the last nine years.

The team, who had 15 years of experience in internet, big data and manufacturing, worked with clients to understand need as they continued to develop the platform, which blends data computation with real-time visualization and predictive analytics. They discovered that while all manufacturers share common goals, there are many of them. The Sight Machine platform would have to address all of those needs, and also allow for quick scaling across many plants – even

though every factory within a given company has a different set of data requirements.

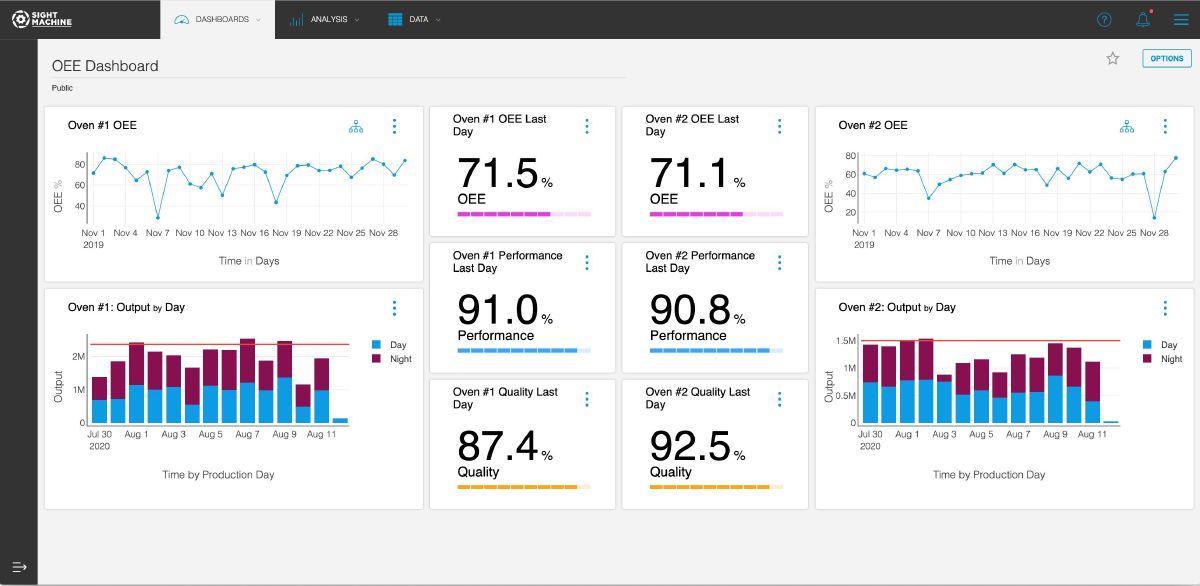

“[Manufacturers] all measure OEE, but it’s highly variable from plant to plant and it’s difficult to get a consistent, accurate, real-time view of things,” says Sobel. “Every manufacturer wants to increase uptime. They want to decrease quality issues. They want to manage energy.”

Sight Machine is built on a common technology platform that can be used in any manufacturing vertical – and it’s been used in at least 15 sectors, including automotive, packaging, pulp and paper, food and beverage, medical devices, electronics and glass, in more than 10 countries. The company is currently concentrating on growth in the enterprise manufacturing realm, but the system can be applied to plants of any size.

“There’s a lot of process data that’s being captured and consumed, or even not consumed at all,” says Alexander Soave, Sight Machine’s senior customer success manager. “We want to make [plants] consume it in a reasonable and fast manner.”

The platform aims to help operators and managers make improvements by streaming data from a variety of information sources in a plant, including, but not limited to, historians, quality systems, MES, ERP, PLCs, SQL, MTConnect, spreadsheets and raw sensor data.

All of these information sources structure their data differently, so the mere act of pulling them together for analysis isn’t enough. Data from a historian and data from a DCS, for example, can’t “talk” to each other. “Simple things that you think would go together, like quality and process data – it’s very hard for companies to blend [them] in any systematic way,” says Sobel.

The missing link is a process that restructures the data into a common language. “As the data is being generated, it’s pulled off of the assets and run through our product, almost like an EKG,” explains Sobel.

Laying the foundation

As the Sight Machine system

“If you get your data in shape, then you have an endless array of analytical techniques you can apply,”

says Sobel. “Get the foundation to the house right, and it’s easy to build the house.”

acquires data – either via an edge device or the plant’s own cloud, if the company is already sending its data to the cloud – it begins to translate the information, re-tagging it and adding metadata to get it ready for API input. From there, the information gets aggregated into what’s called a data lake – essentially a cloud-based repository for information – which is where Sight Machine organizes the data into useable analytics.

“If you get your data in shape, then you have an endless array of analytical techniques you can apply,” says Sobel. “Get the foundation to the house right, and it’s easy to build the house.”

The technology creates a “digital twin” of the plant, which combines process and product data to form virtual representations of areas such as machines, products, cycles, downtime, assembly and defects.

$100M

Then, artificial intelligence and machine learning begin to assess anomalies and create analytics to produce real-time visualizations for the manufacturer, from quality reporting, to engineering diagnostics, to production activity over a period of time, to KPIs on asset performance. Users can design their own reports that illustrate correlations between areas, root causes for problems and recommendations for optimization.

It results in a user experience that, due to a flexible query and visualization layer, feels very customized.

“If you look at what we can do on Google today, you and I can search for anything,” explains Sobel. “There’s an engine under there that finds whatever we want […] but it’s actually driven by a deep product architecture.”

The platform is open, so if a plant is already running factory information systems, Sight Machine can feed processed data into existing software. It also facilitates access to the data for various users across the

organization – data scientists may want to look at tables, machine operators can receive sensor information for production lines and individual machines, plant managers may require insight into every line and machine, and corporate managers can access higher-level KPIs across plants and supplier networks.

For example, a glass manufacturer using the system for two months has built 100 different dashboards, for a variety of users across the enterprise.

Alerts allow for operators to be notified if any number of controls are amiss, like if a machine is not operating within spec limits, or if data is for some reason not being streamed to the system due to unexpected downtime.

By corralling data from so many disparate sources, the subscription-based service is also highlighting issues that companies may not have known they had.

“One of the customers we started with had just 10 problems that they wanted to solve, and now we’re in 35-plus problems by the end of the implementation,” says Soave. “They just keep thinking of more and more problems that they want to solve with this data they have now.”

Improving performance

In December 2019, a global magnet wire producer with some operations in Canada tapped Sight Machine to improve overall equipment efficiency (OEE) by a measurable and clearly defined increment at one of its plants in Latin America.

As a continuous improvement leader and Six Sigma black belt, Soave works with clients to problem solve in a way that is familiar to them. Pre-COVID, he would meet with customers in person, do a Gemba walk on the floor, then review the plant’s biggest challenges and how data could solve them.

About a month after the factory was fully online, the COVID-19 crisis hit. Part of the plant was locked

Sight Machine raised $100 million in venture capital to develop its manufacturing data platform.

down, some staff were furloughed, and, as a result, Soave and the Sight Machine team worked remotely to fine-tune the analytics.

While the client thought they had been accurately measuring OEE before the implementation, Sight Machine’s data ingestion and modelling showed they hadn’t been doing it correctly, nor did enough people in the plant have access to the results to even make a measurable impact.

As the manufacturer emerged from shutdown, the plant saw a four times improvement in OEE against the agreed-upon baseline over the span of two months, far exceeding its original goal. Eighty per cent of the plant’s ovens, which are used to cure the magnet wire, saw a seven to nine per cent improvement in performance.

With that done, the manufacturer has turned to a new problem: reducing scrap. The price pressure and low market demand precipitated by the pandemic underscored the need to demonstrate to customers a tight control on quality.

The Sight Machine team identified over a dozen variables that can affect the amount of scrap when producing magnet wire. To respond, Sight Machine built what it calls a

defect prediction analytic, which forecasts when a machine may produce a defect over a 10-minute window, and then highlights why that defect might be occurring.

“If you look data you already have, it tells you how to be as good as the best day you ever had,” Sobel says. “But if you want to be better than you’ve ever been, you’ve got to build a model that predicts when there’s issues and how to avoid them, that goes outside of your past data.”

Finding the right leader

Getting clients to trust the data and its accuracy is one of the most challenging parts of moving clients to AI-based technology, says Sobel.

But the COVID-19 crisis is helping to push manufacturers in the right direction because of new and urgent requirements for remote access and visibility. In order to be a trailblazer in this space, Sobel says manufacturers need to think about how to amalgamate information from activities that were once separately managed.

“The integration of production data with other data in the enterprise is clearly the next frontier,” he says. “And that’s true for the automation providers as well. Many of the machine builders are

moving from, ‘Let’s help our customer understand this machine’ to, ‘Let’s help our customer understand materials usage associated with the machine, or how the fleet of machines is performing, or how everything else in relation to the machine is performing.’”

Integral to making this kind of change happen at any company is somebody who can see the possibilities. Sobel credits the plant leader at the magnet wire factory in Latin America with being the catalyst for change across that whole company.

The magnet wire supplier has more than a dozen facilities around the world – and when senior executives contracted Sight Machine to do the first implementation, it was for a different plant. At Sobel’s encouraging, the company reassigned their test case to the factory that housed the most dynamic leader, who in turn assembled a group of staff eager to dive in.

“Your best plant leader may not have the best plant – but if you get an influential leader who the other plant leaders respect, who cares about progress […] that is a huge key to success in these initiatives,” says Sobel.

“What’s really needed is not technology, but leadership.” | MA

An example of a Sight Machine dashboard

As the manufacturing industry restarts, are you struggling to maintain social distancing? Perhaps you’re spreading employees across multiple shifts, leaving gaps in your operation? Time to consider collaborative automation to fill those labour gaps while improving productivity.

Quick and easy to program, cobots are less than half the cost of traditional industrial robots, and handle a wide range of tasks, including machine tending, assembly, packaging and palletizing. Request a cobot demo

Call 844-462-6268 or ur.na@universal-robots.com www.universal-robots.com

RETOOL AND RECOVER

Faced with the threat of closure due to COVID-19, a Toronto-based SME rallied area manufacturers to make face shields – and found a way to save its centuryold business

BY LINDSAY BROADHEAD

As far as the quintessential COVID-19 Canadian-business story goes, Toronto Stamp is right out of central casting.

It’s unlikely you have heard of the company, but Toronto Stamp has been a small, family-run business since 1907. Based in Toronto, the latest owners are the Williams family – a first- and second-generation Chinese-Canadian team of Rosita Lee and two of her sons, Jimmy and Rich. The boys grew up in Brampton, Ont., playing hockey and they now help their mother run the business after she bought it four years ago. Many employees have been with the company for over 20 years.

The core business has remained largely unchanged, focusing primarily on manufactured signage, nameplates, tags and various custom products made out of acrylic. Toronto Stamp was also the manufacturer of Ontario’s first license plates.

The company enjoyed nearly 113 years of successful service until February 2020, when the first whispers of a virus called COVID-19 started to

circulate around the region.

Soon those whispers became a continuous drumbeat of news streams and conversations. And then quickly there was silence at Toronto Stamp. Orders from long-time customers started to drop off and the phones stopped ringing. Quite literally overnight, the future of the business hung in the balance.

“There was one late night at work when I sat at my desk and couldn’t see a way forward – I didn’t know how to keep the business going,” says Jimmy Williams, general manager at Toronto Stamp. “How do you save and rebuild a business when there is no market, anywhere?”

Innovation is a lofty word. It implies very learned people purposely sitting down to “innovate,” as if that were possible with the urgency imposed by COVID-19. But ideas are borne from experience, exposure and, often, necessity. As Toronto Stamp faced a hit from which it seemed the company might not recover, a chance conversation happened.

Williams (left) and his brother Jimmy (right), run the day-to-day operations of Toronto Stamp alongside their mother.

“I spoke with my friend Dr. James Mather, family physician at Middlesex Clinic,” says Williams. “He was telling me about how he and his colleagues weren’t prepared for what was to come. The doctors and nurses needed personal protective equipment (PPE) quickly. I asked for more details of exactly what that meant and how it might work and felt incredibly motivated to help out.”

From there, Williams called an old hockey friend who knew about masks and mask design.

“It seemed like overnight,” says Dr. Mather. “Jimmy and the team came back with a prototype for a face shield. I couldn’t believe it. We didn’t have access to the equipment yet and here is my old friend who sent me exactly what would work.”

A new opportunity

From here, the story moves fast.

It has been widely reported that in the early days of COVID-19, Canada had very little capability or capacity to manufacture PPE domestically. The

Rich

country relied on international supply chains, which required manoeuvering through difficult diplomatic hoops to acquire products in demand.

Seizing this opportunity, Williams reached out to dozens of other Ontario-based manufactures to gauge their interest in being part of a project to develop an end-to-end supply chain that would design, test, manufacture and deliver made-in-Canada face shields. Over 20 companies from across the province jumped on board and many retooled their operations to produce the PPE.

The Toronto Stamp–led network of businesses, called Unitum Consortium, for “united community,” secured a contract with Health Canada to deliver four million face shields in two months. Within weeks, deliveries of PPE for domestic use started to arrive in Ottawa, following the contract that was signed in early April.

The team remained heads down and focused on meeting the order, but there were also a few reminders of the significance of what was being done. Toronto Stamp had developed a previously non-existent supply chain that would help to protect Canadian frontline workers, and the company was mentioned by Prime Minister Justin Trudeau during three of his daily news conferences.

Toronto Stamp’s network to build an end-to-end supply chain included these businesses from across Ontario:

• 3G Packaging Corp.

• Baysquare Technologies Pvt. Ltd.

• EM Plastic & Electric Products Ltd.

• Maverick Exhibits

• Pattison Sign Group

• Piedmont Plastics

• Sherway Group

• Spectra Advertising and Signs

• Swift Components Corporation

• Threadfin Business Solutions

• Trotec Laser Canada Inc.

A need to automate

“Once COVID-19 arrived, the needs of our customers changed, and so did our operations. When we had to deliver a large number of units over a short period of time, it forced us to reevaluate,” says Williams. “Everything from inventory management to quality assurance was challenging.

We were working on multiple spreadsheets, at multiple locations, and it was immediately clear that we needed to automate.”

company’s ability to come up with viable solutions in difficult scenarios.

Toronto Stamp led a network of manufacturers that won a federal government contract to produce four million face shields..

Now, only a few months later and with the initial order fulfilled, Toronto Stamp is taking the necessary steps to automate each step of its stamp manufacturing process. Automation, Williams says, will allow for better customer service, new capabilities and the opportunity to co-innovate with clients. “After 113 years, we will finally be able to automate some of our short-run, custom products,” he says.

“In hindsight, one thing is certain,” Williams continues. “When we found out we won the government contract, we knew we were never going to be successful alone – industry in Canada was going to get this done.”

Getting to this point wasn’t easy. The primary barrier Toronto Stamp faced was that very few understood its true capabilities or potential. The company had always been recognized within the rubber stamp industry, but it was not consistently at the top of the list when people were looking for solutions to their unique situations outside of Toronto Stamp’s primary product line. Pivoting to deliver four million face shields demonstrated the

Looking to the future, Toronto Stamp is fully invested in offering in-house and vertically integrated automation. The company is currently in a 7,000-square-foot facility and has found a 49,000-square-foot space that will be operating at full steam in a matter of months.

The building will occupy a growing team and a full suite of new machines, including a Davis-Standard multi-layer film extrusion line, a Mark Andy flexo press, injection molding machines, an inverted flow wrapper, Trotec CNC lasers, a multicam CNC router and robotic arms for pick-and-place applications.

With uncertainty of what is still to come and a possible second wave of COVID-19 on the horizon, Toronto Stamp says it is committed to helping ensure there is a domestic supply chain of PPE to protect Canadians.

The retooling has also opened up new international markets for the company in Europe and Asia – and, perhaps most importantly, it means this small business gets to see its 114th year. | MA

“We were working on multiple spreadsheets, at multiple locations, and it was immediately clear that we needed to automate.”

Lindsay Broadhead is a Toronto-based communications strategist.

Toronto Stamp pivoted to produce face shields during the COVID-19 pandemic.

AUTOMATE TO INNOVATE

Five steps to plan and pay for automation in the coronavirus era, from our first-ever virtual summit

BY KRISTINA URQUHART

In the May issue of Manufacturing AUTOMATION, we discussed the impact COVID-19 is going to have on the sector. The following month, we looked at how supply chains are going to change because of the crisis. The resounding sentiment from industry experts, association representatives and senior executives was that implementation of automation is going to ramp up much more rapidly than previously expected, because labour shortages, increased safety measures and supply and demand fluctuations now require it for businesses to stay competitive. So we know what will happen, but how do we make it happen? That was our question when we partnered with our colleagues at Canadian Plastics to stage the Automate to Innovate Virtual Summit on Jul. 29. After months of

manufacturers being in crisis management mode, we wanted to get the automation conversation reignited – or, in some cases, started – for small and medium-sized businesses, in the context of COVID-19. “Senior management has gone from simply reacting to this crisis [to] thinking longer-term,” said Shelley Fellows, chair of the Automate Canada association, in a panel discussion. “They’re thinking recovery; they’re thinking investment into their operations where automation has a role.”

The virtual event was all about the “how” of automation, with the first set of sessions exploring how to plan for and install it, and the second set focusing on how to pay for it. In total, there were four presentations and two panel discussions in the live event, plus an on-demand session. Here are five key takeaways:

1. Assess your problem

Think about what tasks could be automated easily and that will bring high value to your company. It might be a dangerous job on the factory floor, a repetitive data entry function or a task that would free up a skilled worker to do more complex work.

“My advice would always be – preCOVID but maybe now even more in COVID times – just know the problem you’re trying to fix and the objectives of your project,” said Blair de Verteuil, vice-president, operations, life sciences at ATS Automation. “Whether it’s cost-centric – unit cost reduction, a reduction in changeover time – your competition is edging you out.”

Assessing your problem will also help to pinpoint what is most necessary to start with as your business recovers from COVID-19 shutdowns, the panelists said. A poll held during the event indicated that 40 per cent of attendees were most concerned about low cash flow over recent months as a barrier to implementation.

David Jeffrey, regional vice-president, Central Canada at Salesforce, advised that once SMEs identify the problem they need to solve with automation, they must quantify it. “You don’t want to be solving a $10 problem with a $100 solution,” he said. “Cash flow obviously is a difficult thing to get over, but we see status quo as being the strongest gravitational force. The ability to […] understand the problem and have a vision about what you’re going to do to change that, and how it might impact everyone, is very critical.”

Rather than coming at the problem by trying to find automation that fits your current cost needs, figure out the appropriate solution first. Automation integrators and OEM suppliers are there to help manufacturers develop solutions, and often won’t charge for consultations, de Verteuil said. “They may even help you build a TCO model. And then you can start to seek your financing options. It’s really difficult to convince anyone – internal to the organization, lenders, grant decision makers – to pony up cash unless you know what you’re solving and you have a really solid business case.”

2. Develop a funding plan

Once you know your problem, the funding route becomes clearer, said Bernadeen McLeod, president of Mentor

Works, who gave a 20-minute presentation on how to select and leverage federal government funding. She emphasized that knowing your business challenges will help you divvy up the funding opportunities into manageable pools.

“Identify your project. Is it assessment and analysis money that you need, is it training money that you need? Is it consulting and implementation and execution money?” she asked. “Once you identify where you want to work with a vendor, then the program from the government is so much easier to identify.”

McLeod pointed out a number of programs for capital investment, training and implementation. For manufacturers who need to stabilize their business after COVID-19, there’s the Regional Relief and Recovery Fund, which offers the opportunity for a $500,000 loan if a business shows its operating expenses and shortfall.

“I want you to get in the habit of picking a federal program and then stacking it with a provincial program that is a lookalike,” she advised.

3. Set up a phased approach

“If done right, financial returns on automation can be absolutely enormous,” said de Verteuil. “My recommendation would be to be ambitious with that big-picture thinking, but start small. Think scalable automation, phased approach – consider, is this new technology to the company?”

Shelley Fellows of Automate Canada recommended a digital simulation as a cost-effective way to test and determine whether an automation application will work before making a major investment.

She said the automation companies that have a good controls team can conduct a virtual representation to show how concepts will work, “so the customer has a really strong sense of what capabilities the equipment is going to attain before one single piece of wire is purchased or one single robot is placed on the floor.”

4. Expand with data

Once you have a plan, think about how you can use data to gain insight into your operation, which will help you achieve the perennial goals of reducing cost and waste, said Asghar Rizvi, director of automation and motion for Siemens Canada. Artificial intelligence and machine learning are big terms that can feel intangible, but ultimately, they are tools that, when used correctly, help drive a profit.

“As more data is available, as computing capabilities increase, it’s really going to open up the way that we work with automation, and not just use automation to replace the work

For more insights from the Automate to Innovate Virtual Summit, visit automationmag.com/virtual-events/manufacturing-efficiency-emerging-fromcovid-19/ to register and watch the recordings for free.

that we do,” said Michelle Chrétien, director of the Centre for Advanced Manufacturing and Design Technologies at Sheridan College. The challenging part for SMEs, however, may be bringing their legacy systems into the Industry 4.0 era. Some machines may only require an IoT-enabled sensor, but for others, connectivity may be more complicated. “There isn’t one solution to rule them all, and right now what predominates is bit of a piecemeal approach in terms of patching together things,” Chrétien said. “That’s an incredibly time-consuming operation, which basically puts it out of the realm of possibility for many SME manufacturers who just don’t have the time or the staff or perhaps even the expertise to approach that.”

Santiago Olmedo, customer solutions engineering manager at Festo, reiterated this. “If you consider an older automation system running an outdated protocol – for example, DeviceNet – unless we could integrate a gateway to transfer the data to a more modern fieldbus, say Ethernet/IP, it may be rather expensive to try to overhaul the entire system to work with Ethernet/IP devices.”

In the past, this daunting challenge has often led to a throwing-up-of-the-hands for SMEs and a return to status quo, but COVID-19 has changed the game.

“It’s always been a matter of time and money,” said de Verteuil. “Now, it’s a recognition that change is necessary.”

5. Consider your customer Embracing that change is crucial to satisfying the customer – and amid all of the planning

for automation, the panelists stressed to never lose sight of that.

“Manufacturers are [now] working in an environment where production runs are high mix and low volume,” said Michael Phillips, pre-sales engineer at Universal Robots, citing the move to online shopping as a major factor for the shift.

“Manufacturing lines themselves have to become a little bit more agile and able to respond to information that they pull down from higher-level systems,” he said. “This in turn means they’re much more flexible. They can execute any of the product lines that the customer may want.”

David Jeffrey of Salesforce said the effect of the COVID-19 crisis on the supply chain has highlighted the increasing expectations of business-to-business customers when it comes to price, value, service and other measures of competitiveness. “Now’s not the time to create a worse customer experience,” he said. “So, if your supply chain and technologies don’t support the customer expectations, especially now when those are so critical, you’re really exposing yourself.”

Whether an SME’s plan initially involves automating factory processes or tracking product lifecycle data to adjust production on the fly, be mindful of how all processes will eventually integrate. “We need to understand how to make our customers’ lives easier,” said Rizvi. “This pandemic will pass, but it will change how our executives will review their readiness for real-time events. Real-time data will play a very important role.” | MA

A REAL-TIME VIEW

Process management platforms streamline work processes and boost communication during shift handovers

BY ANDREAS ESCHBACH

As the Industrial Internet of Things (IIoT) has evolved over the past 20 years, the focus has been on interconnecting sensors and devices with industrial applications. This allows for a high degree of automation and the ability to use cloud computing and artificial intelligence in the next-generation of process control. Thus, the shift to the IIoT has effectively expanded computer technology beyond the confines of IT to the shop floor and beyond.

However, this first wave of the IIoT has largely ignored the human element, an important factor in the execution of any industrial process, regardless of the degree of automation employed. Production teams can become more efficient due to the ability of IIoT networks to capture, exchange and analyze data instantly. But without access to IIoT infrastructure, these gains will be difficult to realize.

The next wave of IIoT must promote collaboration between people and machines, particularly for personnel directly involved in production, to best exploit its ability to respond quickly to changes in the operating condition of an industrial process.

The upheaval caused by the COVID-19 pandemic underlines the need for seamless integration between human intelligence and machine data collected through legacy systems and IIoT. Production team members who need to work remotely need access via the public internet to assist on-site colleagues in solving process upsets. For

24/7 production, each shift team relies on this information for rapid response to adverse operating conditions, making remote work more difficult if the access is not available for the night or weekend shifts. Therefore, as IIoT becomes more pervasive in production processes, this access will need to be open for everyone within a shift operation, not just technical specialists.

A real-time view of plant operations

Plant process management (PPM) is a system that gives manufacturers the ability to manage, monitor and optimize plant operations around work activities and production assets. A fully implemented PPM system provides a real-time view of work procedures and tasks, including recording and status of any incidents or outliers to normal plant operation.

With many plants running continuous operations on regular shift changes, it is imperative that the current shift is made aware of any issues that may have arisen during the previous shift. This means there is a critical need for communication at shift changes to alleviate any missed details at the handover. A lack of quality communication can have a direct impact on the ongoing safety of the workforce, as well as on plant efficiency and production quality. The requirements met by PPM apply to any type of plant, regardless of the amount of IoT instrumentation, machine learning (ML) or predictive maintenance in place. Knowledge can be ingested and analyzed from

86%

The percentage of respondents who said safety incidents at their organization in the past year have stemmed from a lack of communication, in a recent study conducted by 451 Research.

any human contact point in a process. As the pandemic has demonstrated, consistent capture of team-to-team communication has shifted to a “must-have” capability. Irregular work patterns are the new normal for individuals due to isolation and social distancing measures, which have put added pressure on safe operations.

Process management becomes priority

New research findings for process industry manufacturers show that IT and OT collaboration using a PPM solution has become an investment priority. The survey was conducted by 451 Research, part of S&P Global Market Intelligence on behalf of eschbach. While OT and IT may have different perspectives and priorities in the journey to digital transformation, safety is cited as the top use case for shift data in both groups, followed closely by process optimization. A significant majority of survey respondents – 86 per cent – indicated that one or more safety incidents recorded in the past year were related to a lack of communication.

When looking at shift management challenges, 36 per cent of IT respondents identified the inability to consume or share captured data is the greatest challenge they face in terms of shift management. On the

OT side, 34 per cent of respondents stated that the inability to reconcile shift data with machine logs is their greatest challenge in terms of shift management.

The top-ranked priorities cited by IT/OT respondents for a PPM investment included capturing and sharing best practices for worker safety, broader collaboration and communication among production teams and managers, and gaining a platform to record real-time incidents for reporting and corrective action.

A case in point

Roche Pharma, a developer of cancer treatments, deployed a PPM solution

Cameras and Software

If you want to detect the smallest errors in the production process, you must take a close look and fully utilize the potential of the images. Machine Vision from Balluff makes it easy. With our intelligent software, the precise cameras are simple to set up and intuitive to operate – minimum experience required.

just prior to the pandemic. They benefited greatly from the software’s ability to support their production teams as they re-adjusted their work practices, instituting remote monitoring and shift handovers.

“We have transitioned from multiple tools and applications to just the one solution, making communication much easier. This has allowed us to feel more confident and comfortable during this crisis,” says Mathias Gerchel, manufacturing technician at Roche Pharma.

Manufacturers like Roche Pharma who were already using a PPM approach were able to respond quickly after the lockdown. They transitioned more easily to the new normal by lowering shift-to-shift contamination and enabling employees to work remotely. Outgoing teams have been virtually connected to incoming teams and are able to easily conduct digital handovers. Engineers in remote offices can read the notations and observations as well as see supporting photos or videos. During shift runs, remote operators can record observations in real-time via mobile devices. They share this information with the board operators and supervisors – with no personal face-to-face contact.

Establishing critical communications

These critical transitions are a key focal point for essential human communication to keep core processes running well. Knowledge management and maintaining the integrity of any knowledge capital are essential

when continuous processes are in place. The need to maintain production at its optimal state should not be impacted by missing information as workforce members hand over to one another between shifts.

While process industries may be somewhat behind the curve on the digital transformation journey, according to research findings, a focus on worker safety appears to be a unifying driver for change.

Without repeatable procedures in place where human communication occurs, a potential gap is created for incidents to happen. As expensive installations of equipment and resources are run and maintained by a human workforce, the correct tooling and equipment – including those enabling clear communication and collaboration around details – are essential.

Big bang or step-by-step?

It is possible to implement PPM without a full IIoT roll-out. Replacing whiteboards, ad hoc conversations and checklist sheets with an OT-focused system, run in an IT-friendly way, can be a significant start to a successful digital transformation. For general process optimization and to maintain a high level of overall equipment effectiveness (OEE), plant operations can be improved through the application of IIoT instrumentation and AI/ ML analysis.

To reap the benefits of IIoT instrumentation, the human workforce in the system needs to be well informed.

LEARN MORE: balluff.ca/vision

Andreas Eschbach is the founder and CEO of the software company eschbach.

NEW PRODUCTS

CONNECTIVITY

Gateway for EtherNet/ IP

HMS Networks has unveiled the second-generation Anybus Communicator gateway for serial to fieldbus and industrial Ethernet, 20 years after the original release. The first version for EtherNet/IP is now available and it will be followed by versions for Modbus TCP, PROFINET and PROFIBUS. All second-generation communicators are powered by the award-winning Anybus NP40 industrial network processor used in all HMS embedded solutions. Depending on use case, data cycle times are up to 10 times faster than with the first-generation communicators thanks to the new hardware and software. Up to 1,448 bytes can be transferred from the connected PLC to the gateway, as well as from the gateway to the PLC. In order to meet current and future security challenges, all products are equipped with a security chip. A secure boot ensures that the firmware has not been tampered with. hms-networks.com

I/O modules for safe connections in hazardous areas

Rockwell Automation has released the Allen-Bradley 1718 Ex I/O modules for connections to devices in hazardous areas. The safe distributed I/O modules provide EtherNet/IP connectivity to field devices in Zone 0 and Zone 1 hazardous areas. The 1718 Ex I/O modules can reduce

wiring in industrial applications because they can be mounted in Zone 1, closer to field devices in hazardous areas. The I/O modules can also save space with a compact, chassis-based I/O design that contains the primary power supply and an optional redundant power supply in the chassis. Different chassis options and slot sizes allow users to scale the 1718 Ex I/O modules to meet a wide range of system requirements. A dual-port EtherNet/IP adapter that enables a Device Level Ring (DLR) topology can help improve network resilience. rockwellautomation.com

I/O connectivity outside the cabinet

WAGO has introduced the I/O System Field, which is designed to meet the requirements of modern decentralized production facilities to provide highlevel connectivity. This system is IP67 rated and offers two types of housings: cast zinc housings with encapsulated electronics for harsh environments, and non-encapsulated plastic housings with low mass for mobile applications such as robots. The cast zinc housing devices have input and output power ports for use with daisy-chained modules, and are PROFINET based. Future releases will be able to support EtherNet/IP and EtherCat protocols. These modules are also designed for the time-sensitive networking (TSN) standard, support OPC UA and MQTT communications and can be configured via smart device app using Bluetooth technology. The non-encapsulated lightweight modules are IO-Link hubs for connection to an IO-Link master. These hubs come in either eight or 16 configurable DIO ports and

each channel is configurable for a 24 VDC digital input or output rated at two amps per channel. wago.com

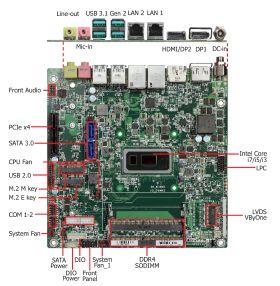

IoT gateway for cloud communications

WIN Enterprises has released the MB-50050, a mini-ITX SBC to serve as the basis for a flexible, general-purpose IoT gateway. The board features an 9th/8th-generation Intel Core processor for factory-process visualization support and communications from factory

line to cloud. Additional expansibility for device and sensor support is also provided. Because IoT gateways need to provide rich serial communications capability to handle factory line input and communications, the MB-50050 was designed with robust serial communications that includes four COM, four USB 3.1 Gen 1 and four USB 2.0, plus up to four expansion interfaces. The MB-50050 supports dual independent displays with one of these being high resolution (i.e., 4096 x 2304) to enable sophisticated process visualization of the factory-line processes. The MB-50050 provides memory, storage and connectivity for communicating with the cloud, with two times the DDR4 to process the raw factory-line data into information, two times SATA 3.0 for storage, and two times Intel GbE LANs for communications with the cloud and other IoT elements on the network. win-ent.com

ENCLOSURES & WORKSTATIONS

Portable cobot workstation

Applied Manufacturing Technologies (AMT) has introduced the jobHopper, a flexible, portable collaborative robot workstation. jobHopper is a customizable collaborative robot system that allows manufacturers to use a single portable robot for a variety of applications on the plant floor. Its fenceless workstation permits side-by-side work with human operators. jobHopper features FANUC’s

collaborative robot and controller to achieve a balance between productivity and flexibility. The hand-guidance capability and flowchart-style operating system with touchscreen interface allow for quick deployment to complete a variety of tasks, including pick-and-place applications, machine tending, inspection and more. appliedmfg.com