FAR-SIGHTED VISION:

Complete Systems starting at: $610.00 (100w)

Starting at $610.00 (100W system with cables and I/O breakout)

LS Electric servo systems provide the most requested featuressetup wizards, auto tuning, built-in indexers and more - in an extremely cost-effective package:

• 5 standard servo systems from 100W to 1kW

• 200-230VAC single-phase input power on all systems

• Control via high-speed pulse train, analog speed or torque signal, or internal indexing

• Use with AutomationDirect CLICK, Do-more BRX, or Productivity Series PLCs; or any other host controller

• Auto-Tuning and FREE setup software (with built-in o-scope function)

• Fully digital with up to 1kHz velocity loop response

• 30-day money-back guarantee

• Two-year warranty

L7C System Selector Tool

Use our L7C Servo Selector Tool to size your system, and to specify all the required and optional accessories for YOUR application. Get all the parts you need on the first order! www.automationdirect.com/ selectors/ls-servo

LS Electric® MSS Series Inline Planetary Gearboxes

Starting at $264.00 (96200004)

Pre-matched LS Electric gearboxes offer easy mounting to the servo motor. Use these gearboxes to increase the available torque or to solve inertia mismatch problems.

• 5:1, 10:1 and 20:1 gearbox models perfectly matched to each motor size

• Increase the available output torque by 5x, 10x or 20x

• Full motor output torque allowed for all pairings

• Reflected inertia of the load is reduced by the square of the reduction ratio!

• Mounting hardware included

8

Canadian manufacturers lag behind their peers in other advanced economies when it comes to technology adoption. Turning that situation around is not a simple matter.

By Jacob Stoller

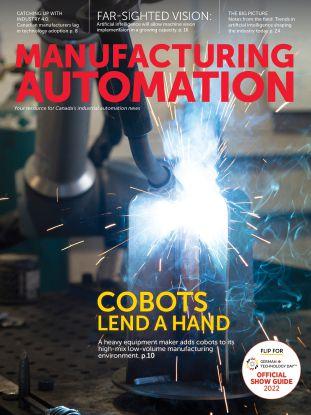

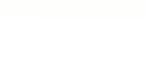

A heavy equipment manufacturer adds cobots to its high-mix low-volume manufacturing environment.

By Jacob Stoller

Artificial intelligence will allow machine vision to be employed in a growing capacity within the manufacturing world. By Jack

Kazmierski

Flip the magazine for the official show guide for the 2022 edition of

Technology Day.

BY SUKANYA RAY GHOSH

he conversation on the benefits of adopting automation is an old one. For over a decade now, experts have been explaining how automating factory floors intelligently can help manufacturers build stronger futures. The Canadian manufacturing industry has already embarked on its technology adoption journey. However, not all manufacturers can adopt technology that can help them reach their full potential.

Cost is a major barrier for manufacturers looking to add automation technologies to their facilities. Interestingly, some of the latest advancements in technology are focussing on democratizing automation to ease the pocket pinch. The idea is to create pathways that equip shop floor employees with the ability to install and maintain automation technology.

side-by-side and compare them to figure out the best fit. While browsing through, they can also take the time to discuss each viable option with vendors to narrow down their choices.

This Fall, German Technology Day (GTD) is returning for its fourth edition, presenting such an opportunity. Launched in 2019 with four exhibiting companies, the event showcases the latest advanced manufacturing technologies that mid-sized German companies have to offer. Successful since its first year, the 2022 edition is the biggest one ever with 15 exhibitors. GTD 2022 will take place in Toronto and Montreal. Don’t forget to flip this issue to browse through the official show guide for the event.

Submission forms for the Canadian Automation Awards close on Oct. 14. Visit the MA website to apply today.

Advanced automation technologies designed to achieve specific objectives currently abound in the market. A significant challenge for manufacturers is to be able to choose the right product or service that can add value to their company. And the number of options available to them can be quite overwhelming. In a recent poll on Manufacturing AUTOMATION’s website, respondents indicated that having too many choices is actually a significant barrier in their automation adoption journeys.

Overcoming these challenges and selecting the right option to begin the journey is not easy. In my previous editorial, I talked about the existing support system that manufacturers can access to take that step forward. Tradeshows and technology showcases are a major part of that support system. With COVID-19 restrictions mostly gone, the industry has returned to such shows with full force throughout 2022.

Seeing automation systems and technologies in action can help make the selection process easier. Technology showcases offer the perfect opportunity to look at multiple options

Going back to the results of the poll, respondents also shared that unsatisfactory ROI on previous technology implementation is a barrier in their ongoing automation journey.

While ROI can be realized only after the system is integrated, there is no harm in taking a look at what has worked successfully for other manufacturers. An example is the cover story in this issue that discusses how cobots changed the game for Carriere Industrial Supply.

Manufacturing AUTOMATION has now officially launched the Canadian Automation Awards. The two categories are Canadian Systems Integrator of the Year and OEM of the Year. The awards will highlight automation implementations in discrete manufacturing facilities that are successful and bar-raising. The winning application stories will be featured in the magazine and on AutomationMag.com.

This is a great chance to understand the implementation journey, the different types of challenges that manufacturers can face and how they can overcome them. The awards also present the opportunity to carry the technology conversation forward. Seeing successful digital transformation and automation journeys can often motivate industry peers to take the plunge. If you have an exemplary story to tell, visit AutomationMag.com and submit your application for the awards. The deadline is October 14| MA

CONNECT @AutomationMag srayghosh@annexbusinessmedia.com /company/automation-mag

EDITORIAL ADVISORY BOARD

AL DIGGINS, Chairman of the Board, Treasurer and General Manager, Excellence in Manufacturing Consortium

DAVID GREEN, Technology and Business-to-Business Consultant

SHELLEY FELLOWS, Chair, Automate Canada

KARIN LINDNER, Founder and Owner of Karico Performance Solutions

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Support Systems Developer, KINITO Support Systems

Your resource for Canada’s

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: 416-510-5113

Fax: (416) 510-6875

email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

EDITOR

Sukanya Ray Ghosh srayghosh@annexbusinessmedia.com Tel: 416-510-5225

ASSOCIATE PUBLISHER

Kathryn Swan kswan@annexbusinessmedia.com Tel: 647-339-4880

GROUP PUBLISHER

Paul Grossinger pgrossinger@annexbusinessmedia.com

MEDIA DESIGNER

Svetlana Avrutin savrutin@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com Tel: 416-442-5600 ext 3221

AUDIENCE DEVELOPMENT MANAGER

Urszula Grzyb ugrzyb@annexbusinessmedia.com 416-510-5180

COO

Scott Jamieson sjamieson@annexbusinessmedia.com

CONTRIBUTING WRITERS

Paul Hogendoorn, Jacob Stoller, Jack Kazmierski and Stephanie Holko

Published by Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 • Fax: 416-442-2191

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

SUBSCRIPTION RATES

Canada — $43 per year

United States — $75.50 (US) per year

Foreign — $86 (US) per year

Students — $20.50 per year

ANNEX PRIVACY OFFICER

email: privacy@annexbusinessmedia.com

Tel: 800-668-2374

Occasionally, Manufacturing AUTOMATION will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. The contents of Manufacturing AUTOMATION are © 2022 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Whatever rolls your way, our uniforms and services experts have you covered, so you can work harder, smarter, and safer.

Explore our offerings like Red Kap ZeroSkratch,™ OilBlok Technology, and classic ripstop fabric.

Scan the code or call (888) 831-1787 to get started on your custom uniform program.

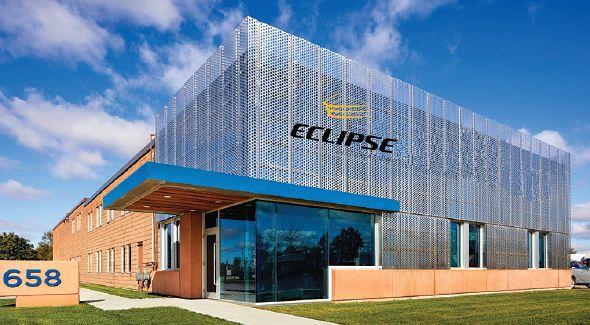

Accenture is acquiring Cambridge-based Eclipse Automation, a provider of customized manufacturing automation and robotics solutions. Eclipse Automation’s 800 professionals will join Accenture’s digital engineering and manufacturing service, Industry X.

“For two decades, we have been leaders in delivering advanced automation solutions and hightech manufacturing know-how to clients across multiple industries. By joining Accenture, we can also bring the advantages of data, AI and the cloud to our clients’ facilities at a scale that no other company can offer them,” said Steve Mai, CEO of Eclipse Automation.

With this acquisition, Accenture will offer automated production lines that leverage the cloud, data and artificial intelligence for smart and connected factories.

Founded in 2001, Eclipse Automation has offices in Canada, the U.S., Hungary, Germany, Switzerland and Malaysia. The company makes automated manufacturing systems to

produce sophisticated products for life sciences, industrial equipment, automotive, energy and consumer goods companies. Its technologists and engineers design, build, integrate and service advanced automation solutions for producing components and devices such as electric vehicle batteries and wearable blood-glucose monitors.

Eclipse Automation’s product offerings include automation control systems, production machines and robots, with critical customized tooling manufactured in-house.

“Globally recognized as a leader in the robotic technology field, we are very pleased to add the Epson FA product breadth to our robotic solution offering,” said Dave Lawson, president of Advanced Motion & Controls. “Leveraging the Epson FA portfolio will provide our growing customer base access to this excellent product mix and expand our presence in leading industries throughout Canada.”

Epson’s line of industrial robots can be used for a wide range of automation applications, including assembly, pick and place, part transfer, material handling, packaging, kitting/tray loading, machine tending, screw-driving, dispensing, palletizing, laboratory analysis and testing, inspection, material removal, surface finishing, and grinding.

Advanced Motion & Controls is offering three categories of Epson robots to its customers in Canada:

• SCARA robots: Epson manufactures more than 300 models from which customers can choose for their specific applications.

“Many companies are bringing production back home to Canada and the U.S. due to global supply chain disruptions. This gives them a unique opportunity to reinvent manufacturing with digital technologies and advanced automation. With Eclipse Automation, Accenture will provide technology and training capabilities that our clients need to develop a digital industrial workforce in markets where manufacturing skills are scarce,” said Jeffrey Russell, president of Accenture in Canada.

Advanced Motion & Controls has teamed up with Epson FA, expanding its product lineup. Epson manufactures industrial robots, which are now available in Canada through Advanced Motion & Controls.

• Six-axis robots: These compact, high-performance units work in confined spaces easily.

• All-in-one robots: These units combine SCARA and six-axis features, with space-saving design, ease of use and a builtin controller.

new Boston office

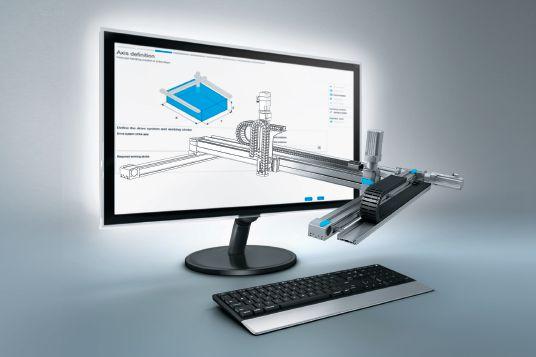

Vention, a cloud-based manufacturing automation platform (MAP), recently expanded its operations in North America with a new office in Boston, United States. This is the second expansion this year by the Montreal-based company, after opening its European headquarters in Berlin, Germany.

“Having a local presence in the United States will bring us closer to our American clients and business partners,” says Etienne Lacroix, CEO and co-founder of the company.

Montreal-based Vention has been offering its services to manufacturers looking to automate their production floors. Its manufacturing automation platform (MAP) allows manufacturing professionals to design, automate, order and deploy automated equipment and robot cells through an integrated cloud environment. The company’s customers can drive their industrial automation projects by combining 3D design, code-free industrial programming, next-day e-Commerce logistics, and a library of more than 1,000 modular automation components.

In a release by the company, Vention noted that its North American customers already using its manufacturing automation platform (MAP) will benefit from enhanced coast-to-coast support from a dedicated client team. The expansion will also enable Vention to tap into the pool of Boston’s robotics and engineering software talent to accelerate the development of its platform.

ATS Automation Tooling Systems announced that its industrial automation business has received an initial order booking valued at approximately US$70 million (or approximately C$90 million at current exchange rates). The order is from an existing global automotive customer. The company is to provide fully automated battery assembly systems for the customer’s Canadian and U.S. manufacturing operations.

“This booking allows us to continue to leverage our experience and successful track record in the EV market, and further demonstrates our ability to deliver solutions to meet the needs of customers,” said Andrew Hider, CEO of ATS. “With accelerating customer and consumer demand, we are able to leverage our ATS Business Model and commitment to continuous improvement to evolve and expand our offerings as technology

and needs continue to change.”

The company stated in a release that this initial order is part of a multi-phase enterprise program that includes the design, build, and installation of turnkey battery assembly systems. These systems are critical components of the customer’s electric vehicle (EV) strategy. ATS states that this further establishes its position as a leader in this growing space.

POSITAL names Andy Zou as its ‘new face’ and ‘new man’ on the ground in Canada. Zou is now responsible for developing stronger ties with customers and distribution partners in Canada and Latin America. “My aim is to help build awareness of FRABA’s POSITAL and UBITO brands in these important markets,” says Zou. “We have an exciting range of products for the manufacturing and process industries, and I am eager to help customers find ways of using them in their products and production facilities.” | MA

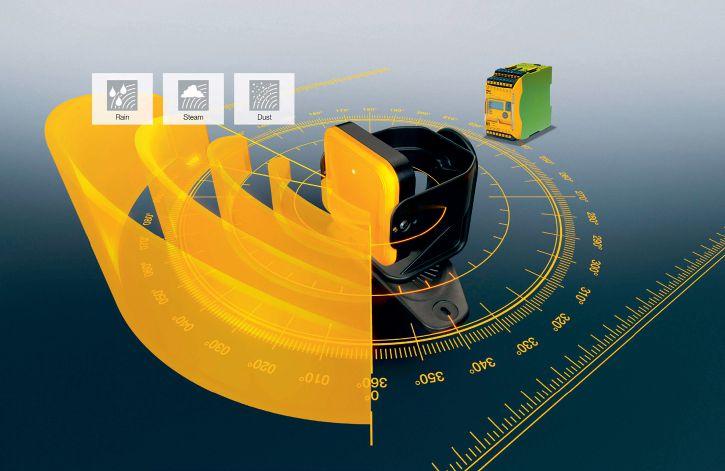

Safe protection zone monitoring in rugged conditions!

Canadian manufacturers lag behind their peers in other advanced economies when it comes to technology adoption. Turning that situation around is not simply a matter of investing in and implementing technology solutions.

BY JACOB STOLLER

In the 2022 Federal Budget, the Government of Canada singled out “innovation and productivity” as the “Achilles heel” of the Canadian economy.

The issue is not a lack of brainpower –Canada is home to Nobel-prizewinning tech scientists and some of the most respected technology companies in the world. Canadian companies in most sectors, however, have been slow to adopt these technologies compared with their peers.

“This is a well-known Canadian problem –and an insidious one,” reads the Foreword to the budget. “It is time for Canada to tackle it.”

Planned countermeasures include the creation of the Canadian Innovation and Investment Agency, designed to draw on international best practices to give Canadian companies “the tools and incentives they need to create and invent, and to produce more with less.”

For manufacturers, however, the tech adoption problem is intertwined with a perennial shortage of skilled workers. According to the Canadian Manufacturers Association (CME) Survey on Supply Chains which was issued in

March, having enough skilled workers is the biggest concern for manufacturers, with 71 percent including this in their top three and 52 percent including the cost of labour.

“There were about 80,000 job vacancies in manufacturing and our unemployment rate in manufacturing is 3.3 percent, which means we’re in a really tight labour market,” says Dennis Darby, CME president and CEO.

Automation helps companies produce more with fewer resources, but only if companies can recruit and retain the workers to operate that technology.

“The one thing I really worry about is the fact that companies are saying, ‘I’m not even going to invest in robotics or automation until I can be sure I can get the staff to run it,’” says Darby.

Workers will need a broader range of skills to thrive in increasingly digitized environments. On one hand, they will have to understand existing manufacturing processes, and on the other, develop competencies in handling a new generation of digital tools.

“What we need is workers’ time to be used more efficiently, and that’s where machines

can help,” says Darby. “If you can have an operator assembling more parts with robotics, that improves productivity and makes us more competitive.”

Accordingly, collaborative robotics, where skilled employees work side-by-side with robots that execute physical tasks such as lifting and transporting, is the fastest-growing segment of the robotics industry.

The need for workers with high-tech skills will force manufacturers, already facing a tight market, to compete with other sectors for talent.

“Those skill sets are very transferable across a number of different sectors,” says David Adams, president of Global Automakers of Canada, “so I think we’re going to continue to see a highly competitive workspace for those people.”

“Our members have told us that the top challenge in attracting qualified people is competing against big tech firms and the growing distribution industry,” says Chris Gardner, senior vice-president of operations at Automotive Aftermarket Suppliers Association (AASA).

Colleges are evolving their industrial training programs rapidly to keep pace with these trends. “Our faculty are continually asking the industry how we need to evolve and upgrade our labs and our shops,” says Melissa Groves, associate dean, Electrical, Transportation and Innovation at Mohawk College in Stoney Creek, Ontario.

The automotive sector’s transition to electric vehicles is a major change driver. “Everything is very electrical now,” says Groves. “When we talk with our automotive partners, they no longer just want somebody who is good with a wrench – they want electricians and people who can go onto a computer and log onto that technology. So, the demographic and the skill sets that are required are definitely shifting.”

“Electrical vehicle production, for all intents and purposes, probably requires fewer people, but people with different skill sets than factories that were producing internal combustion engines,” says Adams. “I think the reality is that you’ll need people with the same skill set of a diagnostician as opposed to an assembly line worker.”

A complicating factor is that manufacturing environments typically host a blend of new and older technologies. “Mohawk College is looking at how we can continue to advance our manufacturing labs so we can simulate those automation and instrumentation systems with older and newer digital technologies working together,” says Groves, “because that’s what we consistently hear from our industry partners. They don’t necessarily have the newest high-end technology, so we have to teach our students to work on both.”

“People think that with skilled trades, you can just walk in there and take an apprenticeship course, but it doesn’t work like that,” says John Breslin, Unifor.

As the work of skilled trades becomes more technical, the interaction between engineers and operators is also increasing. “We’re seeing an integration of engineers and skilled trades,” says Groves. “There’s so much more in terms of cross-functional teams in manufacturing organizations in sectors like steel, energy, and automotive. So we’re really trying to ensure that our students are ready for that.”

Schools can’t fill the gap alone, however. Many of the skills required can only be learned in a live manufacturing environment. To this end, the Canadian government supports the Red Seal apprenticeship, which blends classroom learning with extensive on-the-job training. However, according to John Breslin, national director of skilled trades for Unifor and a board member of the Canadian Apprenticeship Forum, the need for hands-on training is often under-appreciated.

2020-Nema-Electric-Motors-MANUFACTURING-AUTOMATON-third-page.pdf 1 11/6/2020 9:52:35 AM

“People think that with skilled trades, you can just walk in there and take an apprenticeship course, but it doesn’t work like that,” says Breslin.

One of the barriers is a widely-held bias against skilled trades as a profession. “There’s a stigma around skilled trades today that if you can’t go to college and you can’t go to university, you pick up a trade,” says Breslin. “That’s totally false and we need to change that.”

In Europe, especially Germany, attitudes are very different. “In Germany, skilled trades are treated like doctors,” says Breslin. “There’s professionalism attached to that, so people are proud to be in the trades. Companies are going to need these people.” Germany is, notably, among the world leaders in technology adoption.

Mohawk College initiated the Apprenticeship Community Hub, which works to dispel some of the myths about skilled trades. “When people see how much math is required, and the kind of precision these tradespeople have to work with, those myths are easily dispelled,” says Groves. “So, we’re working very hard to get that message out to younger people – we’re currently looking at going into the elementary schools.”

While acknowledging the challenges ahead, Darby sees a bright future for skilled tradespeople. “I would highly recommend anybody coming into the workforce,” he says. “This will be a very vibrant sector for years to come. And if you go into an automotive assembly plant, by and large nobody’s doing heavy lifting anymore. They’re using automation to move things around, and the humans are coordinating to make sure it all works.” | MA

Jacob Stoller is a journalist and author who writes about Lean, information technology and finance.

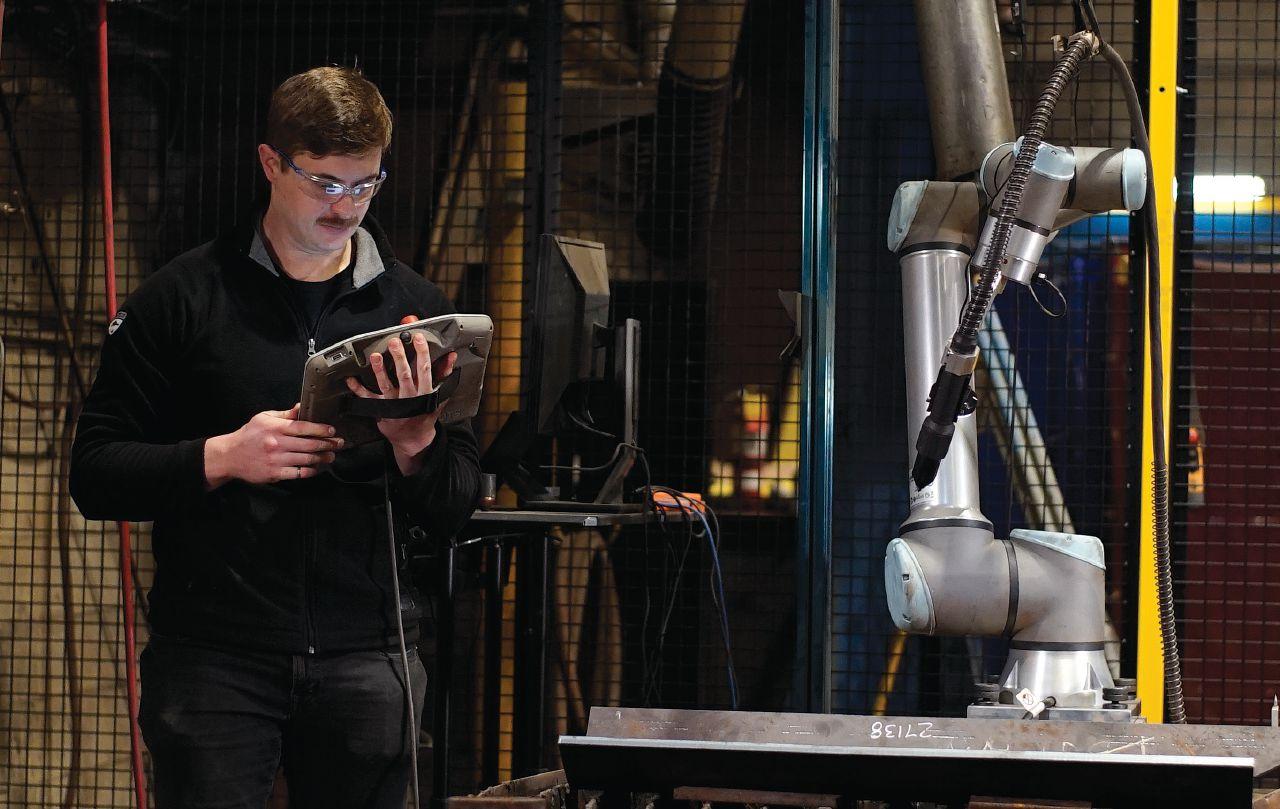

Robotics has evolved to meet the challenges of high-mix low-volume manufacturing. The new collaborative robots are safe, versatile and user-friendly for human work environments.

Until very recently, Marc Sauvé never imagined he’d be teaching his team members to program robots. “I would never even have thought about a robot,” he says. “That was something for car manufacturers.”

Sauvé is process leader for steel processes at Carriere Industrial Supply (CIS), which manufactures heavy equipment and wear parts for mining and other applications in its plant near Sudbury, Ontario. His involvement with robotics exemplifies how the latest generation of robots could transform the day-to-day work in Canadian manufacturing facilities.

Like many Canadian manufacturers, CIS has been affected by the perennial shortage of skilled workers. Last November, a Canadian Manufacturers & Exporters (CME) survey reported that 77 percent of manufacturers rate attracting and retaining a quality workforce as their biggest challenge, and 42 percent claim they have lost business or paid penalties due to a lack of skilled employees in the past two years.

Large mass-producers such as automakers have responded by increasing their investment in automation, but that has been difficult for companies like CIS. While traditional robots are extremely fast and effective, their setup times and relative inflexibility make them unsuitable for much of the low-volume

high-mix work that is the lifeblood of the typical Canadian manufacturer.

The robotics industry has met this challenge with the development of collaborative robots or cobots. While not as fast and powerful as their predecessors, cobots can operate safely in proximity to human workers, allowing them to share a low-volume high-mix workload with humans in a collaborative environment.

Cobots leverage the enormous technology investments that have occurred over the past decade. Current generation artificial intelligence (AI), for example, allows cobots to quickly learn new tasks, make decisions, and most important, identify conditions that could pose a safety risk for a worker only inches away. Advanced vision and control systems, combined with a plethora of task-specific hardware and software options, enable phenomenal versatility and dexterity. User-friendly interfaces make it practical for shop floor workers to program and be informed by cobots.

The result is a paradigm shift. Instead of exporting manual work processes to segregated robotic cells, companies like CIS are starting to bring robotics onto the shop floor to share the work with existing workers in a complementary fashion.

Contrary to what some believe, the push is not to replace employees with machines but

BY JACOB STOLLER

to augment the existing workforce.

“Everybody’s having difficulty hiring or retaining employees,” says Joe Campbell, head of Americas marketing and application development for Universal Robots, Ann Arbor, Michigan, “especially skilled operators such as welders, and even people who do things like tend CNC machines. So, what we’re recommending to our customers is that they focus on the tasks that are least desirable for operators, that is, tasks that are, to quote the old cliché, dull, dirty and dangerous.”

Welding and machine tending are the fastest-growing areas for cobots, Campbell notes.

In a nutshell, cobots allow companies to optimize their workflow by dividing the work according to what’s suitable for humans and machines respectively. “Humans and robots each have their strengths and weaknesses,” says Dr. Alexander Wong, University of Waterloo engineering professor, Canada Research Chair in the area of artificial intelligence, and a founding member of the Waterloo Artificial Intelligence Institute. “There are some tasks that it’s not even safe for a person to do, and in some cases, humans can’t work to the required level of precision. In other situations, robots might not have the level of dexterity to deal with a particular task. Here, humans and robots are complementing each other.”

You’re gonna want SOME CUT OFF DISCS, grinding wheels & EYE PROTECTION

First steps

CIS began its cobot initiative when a team visited the Universal Robots (UR) booth at the 2019 Fabtech trade show in Chicago. CIS was no stranger to robotics. It has operated a robotic welding cell for over a decade, powered by a Fanuc long reach welding robot, for projects such as the welding of mining buckets, which require a very large number of welds.

The technology, however, is not suited for much of CIS’s workload. Setup times precluded many of the small runs that the company does, and it was impossible to get some of the larger workpieces into the cell.

The team was impressed with the ability of the UR robots to operate side-by-side with workers to reduce their risk. Another deciding factor was the user interface, which makes it practical for an operator or tradesperson to instruct the robot.

Follow-up conversations with UR, and with local integrator Advanced Motion & Control of Barrie, Ontario, concluded that plasma cutting was the most promising opportunity. Here, operators were spending an inordinate amount of time cleaning up after cuts. The company decided to purchase a UR 10e cobot for plasma cutting.

Mason Fraser, a junior programmer at CIS, was assigned the task of creating the software interface. Because of UR’s open approach, Fraser found himself on familiar ground.

“The back-end language that the API is written on is Java, which is something I’ve been writing in for close to ten years now,” he says. “There was definitely a learning curve around their scripting platform, but the documentation got me up on my feet pretty quickly.”

Fraser also notes that UR’s online learning tools made the tasks easier. Once the code was written, a simulation platform allowed him to do trial runs in a virtual environment before testing the cobot in real life.

Perhaps the biggest challenge was learning to understand plasma cutting. “I got quite a bit of help from Marc and some other shop people to teach me how plasma works,” says Fraser. “I’d never touched a plasma cutting application, so that was a bit intimidating. But now I feel a lot more familiar with it.”

Sauvé found the interaction useful as well. “You get a lot of engineers and technical people that come into the job and know the computer and the coding side of it, but they don’t see the physical part of it,” he says. “Showing Mason how this all works is better for me, better for him, and better for the company.”

With the system up and running, CIS operators “teach” the robot to make a plasma cut by guiding the robotic arm with the tool to indicate the starting and end points of the cut, and the correct angle to hold the tool.

“It’s surprising how easy it is for shop users to run this,” says Sauvé. “You tell it to trim a cut between point A and point B, and it will do that all day long. You can give it two points, or a thousand points – whatever the part requires.”

Sauvé notes that the cobot now fits naturally into the workflow. “It doesn’t change what we do – it just makes it easier,” says Sauvé. “Operators can use the robot to trim a workpiece and at the end of it, there’s little to no cleanup required. Doing it by hand, there would be some grinding and touch-ups.”

When it came time to assess the project, the numbers added up. The company estimates that the trimming work on mining truck bodies was reduced from 50 to 12 hours per truck, saving a total of 1000 hours. Furthermore, freedom from the drudgery of cleanup has allowed operators to experiment with different angles to improve the overall quality of the cuts.

Based on the success of the plasma cutting application, CIS decided to take on the MIG welding process that is frequently used. To accomplish this, the company purchased a UR10e cobot for MIG welding.

To provide the required versatility, the team built a welding skid that can be moved by forklift to the workpiece.

The potential targets for this automation are wide-ranging. Safety is a number one priority. For example, deploying a cobot is ideal for long welds that pose ergonomic challenges for operators.

An early success was using the welding cobot to assist an operator in attaching ribs to a mining truck body. In this scenario, the worker and the cobot work side-by-side, each attaching alternate ribs in a leapfrog fashion. This reduced the completion time by half.

Small tasks are another area. “A lot of small welds we do vary drastically,” says Fraser. “That’s where the low-volume high-mix comes in – in situations where you need to constantly reprogram it, the UR is a big bonus for us because we can teach it a new welding program quite easily.”

The company is also experimenting with more complex tasks. One is the process of layering, where, for example, a wear-resistant cladding might be welded onto a workpiece.

CIS’s work with cobots is just beginning. Fraser expects the company will use cobots to further optimize its welding operation, freeing workers to undertake value-added tasks such as improving the visual appearance of welds.

Looking to accelerate these goals, CIS sees great potential in applying cobot technologies more broadly in its manufacturing operations, now that it has joined Scotland-based Weir, an engineering firm that specializes in the development of highly engineered wear parts for mining and infrastructure markets.

“Alongside our skilled workforce, this is a great solution for us,” says Fraser. “I definitely think cobots are going to be the up-and-coming thing – we’re going to see a lot of them in the future and they’ll be hard to ignore.”

“Robotics is going to be increasingly more critical in manufacturing, especially now with labour shortages,” says Wong. “But another point is that there are things that humans can’t do and there are things that robots can’t do. If we can put humans and robots together, it’s much better.” | MA

Breaker Health Diagnostics

Monitors and communicates breaker health status, enabling predictive maintenance to avoid costly, unscheduled downtime

Standardized ARMS Functionality

Enhanced and consistent functionality of industryleading solution to reduce arc flash energy released during maintenance operations

Scan to learn more about Eaton’s Pow-R-Line Xpert panelboards and switchboard

Integrated Metering Capabilities

Current, voltage, and power metering integrated into the trip unit simplifies installation without need for external devices

Embedded Communications

Built into the trip unit creates cost savings by eliminating the need for separate hardware and associated wiring

In a recent episode of MA’s podcast Machine Language, Jeff Burnstein, president of the Association for Advancing Automation discusses the latest trends in industrial robotics, what is next in the human-machine collaboration space and what manufacturers should consider when implementing robotics. An edited transcript is below. To hear the full conversation, visit automationmag.com/podcasts.

Manufacturing AUTOMATION: What trends in industrial robotics do you see governing the North American manufacturing in the near future?

Jeff Burnstein: There are a lot of trends that we’re currently seeing in robotics. One of them is the transition into a wider range of industries. When I got involved in this nearly four decades ago, the automotive industry was the largest user by far. For the first time in 2020, we saw non-automotive customers

comprise a larger share of robot orders. That’s the current overarching trend. In terms of the technology itself, robots have become easier to use. You have companies offering no code robots or robots that can be controlled more easily or controlled by hand. You have collaborative robots that are working side-by-side with people. And then, there is a trend toward mobile robotics.

MA: Industry 5.0 is already here with a focus on human-machine collaboration. What is next in this space?

JB: First of all, we’re not getting people out of the equation. People are critical to the success of the adoption of robotics. So, what we’re seeing is people doing better, safer and higher paying jobs. They’re not

walking six miles in a warehouse anymore, or lifting heavy boxes. The jobs that are open require a different set of skills. We need to do a better job of educating people for the jobs of the future and the jobs of today; a better job of retraining the current workforce. And we need to make sure that we’re creating jobs that anybody can benefit from.

MA: North America is facing a labour shortage crisis at present. How can the latest advancements in robotics help?

JB: There was a time when everyone was talking about robots replacing people. The current problem is that you can’t find people. I talked to a leading aerospace company recently and they said that they would actually buy more robots if they had a trained workforce that could implement them and

adapt them. You talk to the companies who do welding and they say, we can’t find welders. We have to have robots that have to do the welding. Every situation is the same. The situation has flipped.

MA: We’re seeing this trend of robot-asa-service, smaller-sized robots, and other different ways to aid small and medium businesses adopt these technologies. How do you see this helping adoption within the industry?

JB: Cost and return on investment are always major considerations. So, these new models are pretty exciting. I know in the warehousing field, if you need to ramp up to get a whole fleet of robots, you don’t want to make the capital equipment expense. A lot of companies can afford to just write such huge checks. So leasing is becoming popular. Robots-as-a-service is really starting to have an impact. A company in Michigan is developing a four-robot system to change tires because tire shops can’t find enough people to change tires. Now, a four-robot system can do it faster, more accurately, with data to show to what

level it was torqued and so on. Anybody can operate that system and they’re planning to charge by the tire they change. Now that’s an interesting model that can be applied to all kinds of industries.

MA: Safety is an important part of the conversation when implementing robots.

JB: Safety has been a top priority for our association since the 1980s. We have to make sure that the standards are kept up-to-date. We also have to make sure that companies are following the standards and understand how the technology has evolved and what is safe.

focused on developing standards for mobile robots safety as we’re seeing an explosion in this space.

Robots understand the role they have to play but they do not have an understanding of the context. They don’t see the big picture.

A long time ago, robots had to be behind a fence and you had to keep people away. Now we’re working side-by-side with robots. So you really have to do a very careful risk assessment. You can put a small robot next to a person and it could hit them. It’s not fine if it’s holding a knife or is holding some toxic vial in its gripper. You really have to understand what you’re doing when you put these machines next to people. We’re also

MA: Robots have sensory capabilities that make them ideal workers. What are your thoughts on this?

JB: Technology is getting smarter. Sensory capabilities are better. A robot today sees better and understands how to pick up an object better. All that is true. But it doesn’t understand the context of what we are trying to do. The robot only knows and sees what it has been programmed to do; what the AI is allowing it to learn from its experiences. But people have a sense of awareness that machines just don’t. They understand the role that they have but don’t understand the big picture. I am optimistic about the role of people. Going forward. I don’t think we’re going to be able to implement technology successfully without the people not only in the loop but in charge of these processes. | MA

SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

CARLO GAVAZZI has the solution for your application needs, whether it’s our industry leading solid state relays, energy meters, contactors, motor controls, monitoring relays or sensors, now available with IO-Link communications.

Contact us today, and one of our field sales representatives will show you why we are one of the fastest growing automation companies worldwide. We’ll even provide a free evaluation sample to qualified customers.

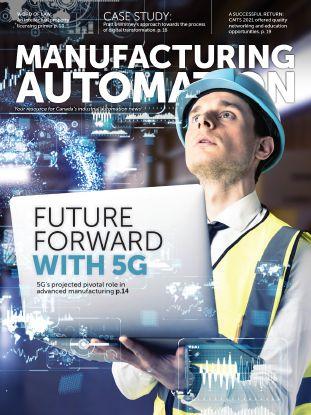

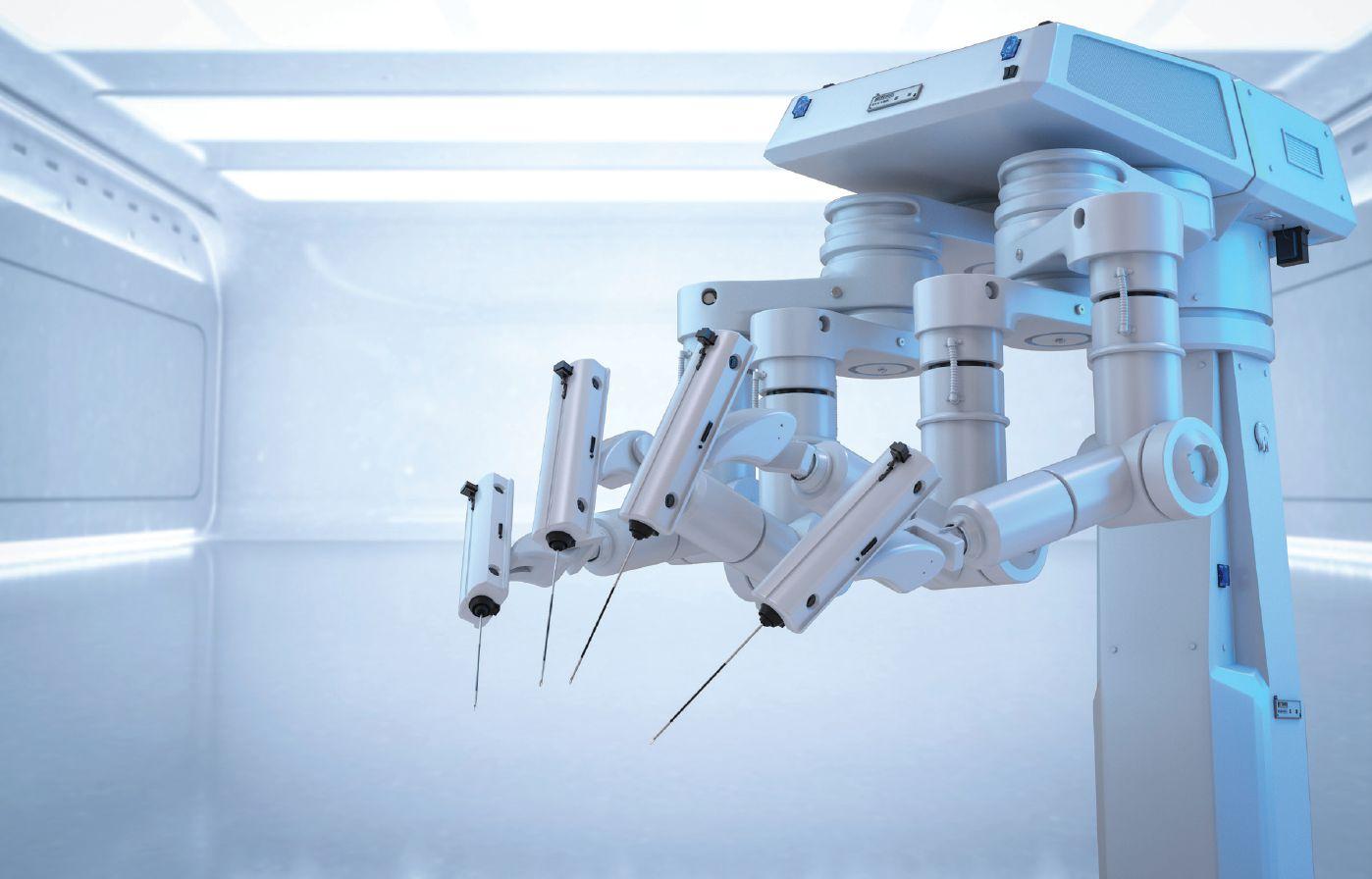

Rising costs, a broken supply chain and a human resources situation that has been complicated by the pandemic have made it a challenge for manufacturers to stay competitive in today’s changing world. In order to limit risk and boost profitability, some are turning to machine vision automation to cope, as well as prepare for tomorrow’s business landscape.

“Staying competitive,” says Donato Montanari, vice-president and general manager of machine vision at Zebra Technologies, “is really about the cost of the product and access to labour.”

Montanari explains that machine vision can help manufacturers tackle these challenges by automating some of the labour-intensive aspects of the manufacturing processes. He offers the example of a parts manufacturer

dealing with elevated costs, exacerbated by a shortage of certain parts, having to deal with imperfections or mistakes that result in a defective end product that needs to be discarded because it can no longer be sold.

“This is where inspection and quality control become more and more important,” he says. “With the old approach, quality control was done by a person at the end of the line. Today, the problem is you don’t have access to those people anymore. Those people don’t scale, and that labour is among the most specialized and most expensive in your company, because that’s where the value is.”

The solution could be machine vision, which is scalable, which can be as specialized as necessary, and which once trained can work around the clock and never take a day off.

JACK KAZMIERSKI

The importance of quality control, and the importance of track and trace, which are the two predominant applications of machine vision, have become increasingly significant today. “And this is how machine vision can help discrete manufacturing, enabling them with automation,” Montanari explains.

Abhishek Sarkar, lead data scientist at Siemens Advanta Solutions agrees, adding that machine vision can do what the human eye sometimes can’t. “You need very well-trained labour to inspect parts in manufacturing and discrete industries,” he explains. “If you have an untrained eye, you might miss a lot of defective parts, so that’s where AI [Artificial Intelligence] can come into the picture.”

Sarkar notes another advantage machines have over humans. “When

Breakthrough compression technology that’s smart, clean & delivers high volumes & unmatched efficiency - quietly.

• Small footprint - 25% less square footage than an average HPU

• Less power consumption than hydraulic & air-driven boosters

• Easy maintenance with quick access & visual diagnostics

• Clean compression

• Quiet operation (<77dBA), infinite controllability

• Energy efficient, 100% duty cycle

• Environmentally friendly

it comes to manual inspections,” he explains, “they cannot be done 24/7. A human will only take samples every few minutes or hours, and there’s a high chance they will miss a lot of defective parts. So that’s where machine vision comes into the picture. You can have 24/7 monitoring so that the chances of missing a defective part and figuring it out later on when that part has already gone through a downstream process and it’s too late [is minimized].”

As practical as machine vision may be, historically, it’s been expensive and time-consuming to implement. Much of the cost has to do with the need for a machine learning engineer, working with a subject matter expert, to program the system to recognize defects so that the system understands what it’s looking for.

“You need a lot of what we call in the machine learning language, label data,” Sarkar explains. “So, you have to feed the algorithm a lot of images.”

The system has to understand what a defect looks like, but unlike a human, it needs a lot of examples to fully comprehend what it’s being asked to look for and recognize.

“So, let’s say we want it to look for a crack on a part,” Sarkar adds. “You have to give it thousands of images, not only of the cracked part, but you have to also label or annotate that there is a crack in those images. That is a very labour-intensive task, unfortunately.”

To make the process less time-consuming, companies are working on solutions that will automate the learning process, reduce the need for human intervention, and therefore cut the costs associated with incorporating machine vision into a manufacturing facility.

For example, Siemens’ new SynthAI is a technology that generates thousands of annotated computer-generated synthetic images and then employs them to train the system on what it needs to look for.

Dave Wilson, vice-president of sales at Siemens Digital Industry Software for Canada explains, “The basis of SynthAI is to train the machine learning model by feeding it those images. So in effect, we’re trying to empower the customer. Whether they have a data science staff or not, those skill sets can still be contracted in. But when it comes to the actual teaching of the model, and feeding it all of that data, this solution helps take some of the complexity and manual tasks out of the equation.”

Zebra Technologies recently announced the acquisition of Matrox Imaging, which Donato Montanari says will allow Zebra to make machine vision more accessible and more affordable for manufacturers thanks to Matrox Imaging’s focus on ease-of-use and AI.

Montanari explains how AI is making machine vision more affordable to implement. “All machine vision software is something called ‘rule-based,’ which means a programmer has to write the rules of the defects you’re

looking for,” he explains. “That’s why it’s so expensive. You need a programmer who spends, hours, if not days, in your production line, setting up the system.

“With the introduction of artificial intelligence, it’s going to be very different. The camera will be shown components with defects, and it will learn what a defect is. Nobody has to code anything. This will allow discrete manufacturers to be able to deploy the solution virtually by themselves, which would significantly lower the total ownership cost. It would also allow them to really leverage this technology, by using it not just at the end of the production line, but at different points. If we make it cheap enough, you can use it to look at work-in-progress.”

Tasks and applications

The potential applications of machine vision seem almost limitless. “There are tons of examples of use cases,” Siemens’ Sarkar says. “Think of human beings and what they’re watching or keeping an eye on. In all these cases, the eyes are simply being replaced by cameras.”

Applications include looking for defects in parts, tracking lot numbers, sorting SKUs, sorting parts, monitoring employees to make sure they’re wearing the proper protective gear, or even whether an employee is operating equipment they’re not trained on, etc. If a human eye can see it, monitor it, track it or record it, then machine vision can probably do the job faster, more accurately, and around the clock, without taking a break. Sarkar adds that infrared cameras can also be employed, which means the system can be taught to look for hotspots that might mean there’s a problem with a part or a component before it’s shipped.

Whether machine vision automation is the right fit for an organization is a question eachl manufacturer must answer for

themselves. However, with the benefits this technology can offer, it’s certainly worth a closer look, especially if costs come down.

“With cost pressures today, automation represents the biggest opportunity to minimize the labour inputs and control those variable costs,” concludes Dave Wilson from Siemens. “Machine vision technologies are one of a plethora of advanced

technologies that manufacturers should be exploring as part of their digital transformation endeavours to identify whether or not there are use cases that could drive value for them.”

As costs come down, thanks in part to advancements in AI, we’re likely to see machine vision employed in a growing number of applications. “This is not a new technology,” stresses Zebra’s

Montanari. “People in the quality control and manufacturing businesses understand the value of machine vision. But sometimes it’s not feasible for them, because it’s too complex, and complexity translates into cost and time. So, the easier machine vision becomes, the more we can expect it to become a predominant technology.” | MA

The ultra-compact ELM72xx EtherCAT Terminals: full-fledged servo drives in an I/O terminal with robust metal housing increased output current of up to 16 A at 48 V DC metal housing for optimum heat dissipation at high outputs directly integrated in the standard EtherCAT I/O system increased performance and added functionality optimal shielding in case of electrical interference convenient connector front end and One Cable Technology (OCT) selectable safety range: STO or comprehensive Safe Motion function package

BY PAUL HOGENDOORN

Paul Hogendoorn co-founded FreePoint Technologies with the goal of giving manufacturers the benefit of information technologies that inform, empower and motivate their most critical asset – their people. He can be reached at hogendoorn. paul@gmail.com or linkedin.com/in/paulhogendoorn.

When I started this series, I set aside one of the most significant tips as the last one to round it up. However, I realize that I should have shared the other one (tip 9) a while ago, especially in light of the recent pandemic.

TIP #9: “Don’t forget to take vacations, weekend getaways and days to rest.”

It’s more than just looking after your mental and physical health, your family and maintaining a healthy life balance. It’s also about giving your mind time to be creative, to pursue thoughts and crazy ideas and to let your imagination run a little wilder than you usually allow it to. Your next breakthrough idea may be buried behind a nearly impenetrable wall of day-to-day and month-to-month issues that dominate your available mind space. Sometimes it’s not new ideas that suddenly come into mind but simple, fresh solutions to old problems you were looking at the wrong way. Think of “recreation time” as a critical “time to re-create”. Don’t try to squeeze it in later. Refresh your mind by getting out of your standard daily routine. It’s an important ingredient for success. It also helps you find, or re-discover, your inner compass – which takes us to tip 10.

TIP #10: “Don’t ignore your inner compass”

A friend of mine lent me a book that covers this topic very well – The Bomber Mafia by Malcolm Gladwell. Although the book uses WWII as a backdrop and speaks specifically about how technology can alter the course of human life, it identifies the unique critical elements required for invention, radical innovation and technical advancement.

The book outlines three key concepts. One is having a clear picture of something that’s not yet in existence “in your mind’s” eye. I call it “vision”. The second is having the tenacity, or as Gladwell refers to it, “obsessiveness” to see something through to completion despite a world of barriers and a legion

No one gets to lead by following.You have to do something significatly different to differentiate yourself. Being able to sense what that is, is where the “internal compass” comes in.

of naysayers. I call it “entrepreneurship” – the ability to create something tangible and beneficial from nothing. The third one is the ability to attract and engage others in your dream as wholeheartedly as you are yourself. I’d call that “leadership”.

I haven’t finished the book yet, but each new page delivers another “aha – that’s it!” example of this special ingredient that I suggest is the primary differentiator between good companies and great companies. The best companies I had the pleasure of working with over the last 40 years had leaders that understood the importance of consensus, delegation, operational discipline, effective communication and team building. But more importantly, they had leaders that trusted their inner compass.

Think of it in another way. No one gets to lead by following. If you’re the best adherent of a policy or the best practitioner of a proven practice, you can get medals pinned to your chest and move up in the ranks. But will that change the course of history or create the next technology? No, it won’t. If you want to differentiate your company, you can’t just aim to do everything as well or better than all your competitors. You have to do something significantly different. Being able to sense what that is, is where the “internal compass” comes in.

One of the most influential people in

my (business) life recently shared with me why he never did patent searches and never looked at his competitors’ products, literature or websites. If he was setting out to do something new and different, he didn’t want to be influenced by decisions and directions others had chosen to take. He saw something “in his mind’s eye” that he wanted to apply himself to thoroughly, without being unwittingly pulled off course. If you are perfecting what others had done, you are still “following.” The best companies I observed weren’t doing their own thing purely out of a smug sort of arrogance of “not following anyone.” They were (and still are) following an internal compass that is pointing to their true north.

To be an exceptional company, doing exceptional things and accomplishing exceptional goals, takes more than that. It takes people that are willing – and able – to follow their internal compass, even though all the maps aren’t yet complete.

Reflecting on the first nine of the top 10 tips I shared in this series, I think many of them may seem counter-intuitive. However, most of the leading companies I gleaned these tips from were following seven, eight or even all nine of them. To me, this indicates that they are companies that aren’t just following an approved playbook. They are in the habit of always paying close attention to their inner compass. | MA

MISUMI components can cover up to 90% of your bill of materials with material certification available upon request.

Choose the material, surface treatment, dimensions and alterations of a component, and see instant pricing and lead time. Configured components have a unique globally-recognized part number, allowing easy re-ordering anywhere in the world.

Learn more about MISUMI’s offerings for Medical Industry.

Connectors with levers

WAGO released the new 2734 series Multi Connection System Mini (MCS Mini). The new products in the series are equipped with levers designed to provide rapid connections in the field. In addition to the intuitive lever operation, these connectors feature a versatile locking system, offering an extra layer of safety and protection against mismating. The MCS Mini PCB connectors are suitable for several applications, including those with small cross-sections from 26 to 14 AWG and a pin spacing of 3.5 millimetres. One of the added benefits is that extra board space is not required, giving this system the edge for device connections such as drive controls. wago.com

Emerson introduced its first pneumatic valve system with integrated Open Platform Communications Unified Architecture (OPC UA) – the Aventics series advanced valve systems. The new series is a digital twin solution that solves interoperability challenges. A valve system with integrated OPC UA functionality simplifies communication with upper systems since data and analytics are received via the valve system

and communicated directly to upper systems, no gateway necessary unless deeper analysis or local dashboards are required. The AES is simple to integrate and connect to new or existing applications and machines and provides easy access to data and analytics without changing the programmable logic controller (PLC).

emerson.com

Extended reach robot

Yaskawa’s extended reach GP8L robot is designed to operate in compact production spaces. This six-axis robot is well-suited for high-speed bin picking, induction and packaging tasks. The robot supports applications for assembly, dispensing, material handling and machine tending as well. A single cable connects the manipulator to the controller, resulting in easy setup. Cables and air lines are routed through the robot base to upper arm to increase cable life, enhance safety and reduce teaching time.

A cable installation tube facilitates fieldbus routing through the S-axis. The GP8L features an IP54 body and offers an eightkilogram payload capacity, 1,636 millimetres horizontal reach and 2,894 millimetres vertical reach. It can be floor-, wall-, tilt- or ceiling-mounted. Brakes are included on all axes.

motoman.com

Harold G. Schaevitz Industries introduced its new LPPS-36B linear potentiometer position sensor with rod end joints. The product is used to monitor and track the linear motion or position of a target from 350 millimetrs up to 700 millimetres. The ruggedized sensor is ideal for use in industrial and laboratory applications. It consists of a resistive potentiometric element made from conductive plastic. With swivel rod ends that allow for self-alignment and easy mounting, the swivel rod can be rotated up to 360 degrees. The LPPS-36B series sensor is made from industrial duty materials for resistance to dust, temperature, shock and vibration. hgsind.com

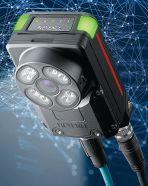

Vision sensor with built-in AI

Keyence’s IV3 series vision sensor features built-in artificial intelligence. The sensor automatically determines imaging conditions and detection conditions with its AI specifically designed for presence and difference checking. Installation and operation are simple. Users determine the part to focus on and register a minimum of one OK and one NG image. The all-inone design includes a lens and illumination. Setting operations are performed using a small amplifier with a built-in high-performance CPU, eliminating the need for a separate high-performance PC. The ultra-compact head supports a range of installation distances from 50 to 2000 millimetres, and the maximum field of view of 1822 × 1364 millimetres allows for detections from wide angles. keyence.ca

BY STEPHANIE HOLKO

Stephanie Holko is the director of project development at Next Generation Manufacturing Canada (NGen). She loves connecting emerging technologies with existing manufacturing problems and believes the future of manufacturing is in the adoption of new ways of working. Stephanie is a licensed Professional Engineer in Ontario.

Artificial Intelligence (AI) is touted as a panacea by many. The truth is always more nuanced than that, but AI is a remedy that is a powerful tool if applied correctly. When technology reaches critical mass, there are tools and strategies to support widespread adoption that ease the transition. In this article, I highlight some trends in artificial intelligence technology for manufacturers that are paving the way for widespread adoption and impact in this area. While none of these ideas are theoretically new, they are being applied on a wider scale and at economically attractive price points that make AI accessible in an exciting new context. The solutions in development are across the manufacturing value chain. AI can be seemingly small, embedded in process inputs via sensing technologies. AI can be overarching, providing optimization across multiple operations.

At the input level, AI is now consistently used in sensing applications to mimic human sensing, processing and meaning-assignment. These could be vision solutions – telling you what kind of product or defect is present and then deciding what kind of actions or procedures to implement, just like noticing the pizza you put in the oven needs a few extra minutes to come out perfectly cooked. These can be auditory, picking up on those noises that a seasoned operator or tradesperson could pick up when walking around the plant and alerting personnel to an irregularity. The sensing applications can be olfactory, such as deciding a batch of beer is done and needs to be decanted to the next process step. It’s the integration of these sensors into a wider process that is changing how things are made, saving money, reducing waste and minimizing human intervention when not required.

At the plant optimization level, AI augments existing technology. An IoT-based plant advisor system could be even more effective with AI models that can optimize over time for a better

process outcome. AI can predict maintenance failures earlier and schedule a diagnostic or repair at a convenient, or non-bottleneck time. It can afford operators the ability to be unceasing eyes and ears (and nose) on the plant and it frees them up for higher-level tasks. AI technology can provide a similar level of diligence without the operator standing over the machine full-time.

Making AI usable is allowing average process specialists take advantage of its power.

AI plant models can be stand-alone. The model optimizes for one outcome, such as uptime or quality or cost. What is emerging is how multiple optimization models can be interlinked and the entire process optimized based on a system of constraints. For example, while you may want perfect quality, that may trigger a cost constraint. It may make business sense to achieve 95 percent quality to minimize the costs of rework. So, 95 percent should be the constraint on the quality model and once that threshold is reached, you can optimize for increased production speed instead. The interplay between AI models at this level is an exciting trend that is just starting to take off.

In the past, one limiting factor of AI adoption was the access to AI development experts who not only know the theory of model development but can code and integrate systems. This bottleneck is prohibitive for many companies for a variety of reasons. Many companies do not have a large

enough employee base to justify a full-time resource to support AI development. Luckily, there are several ways that technology is changing that make AI approachable. One way is the development of low-code or no-code solutions that integrate with existing data architectures that allow users with a good understanding of theory to create and tune models for a variety of process and maintenance applications. For example, one solution is an add-on module that connects directly with the plant controls and allows the process specialist to drag and drop data representing good or poor operations into a model. The software trains the model on how to predict issues specific to that plant and recommends actions without having to code anything. This democratization of AI model tuning makes it easy for an average process specialist to take advantage of the power of AI.

AI is a powerful tool that is transforming our manufacturing processes and ways of working. Making AI approachable and usable by plant experts is a fantastic way to meet in the middle of manufacturing expertise and technology with some truly inspiring results on the horizon. Next Generation Manufacturing Canada (NGen) is working to support manufacturers and technology providers in AI innovation. Please connect with us to learn more at info@ngen.ca. | MA

Email:

Phone:

ManufacturingJobsite.ca is Canada’s premier online job portal for the growing manufacturing sector. A laser focus on the right people across the country’s largest manufacturing media audience means you get the right applicants the first time. No more massive piles of unqualified applicants, just professional employers reaching qualified professionals.

Powered by the top manufacturing media brands in Canada, the reach to over 500,000 industry professionals on ManufacturingJobsite.ca is amplified by:

Website advertising to 185,000 qualified monthly site visitors

A comprehensive and magnifying reach across multiple associated job boards

Email promotion and job alerts to 131,000 industry emails using Canada’s largest CASL-compliant direct access to manufacturing professionals

Social media promotion to all brand networks on Facebook, Instagram, Twitter and LinkedIn

The Future of Automation: Digital. Sustainable. Efficient.

Toronto | Thursday, October 20, 2022 | 8:00 am – 4:00 pm ET | Humber College

Montreal | Thursday, November 3, 2022 | 8:00 am – 4:00 pm ET | Plaza Centre-Ville

A warm welcome to all participants of German Technology Day 2022!

As we gather for the fourth event of this kind we can already call it a tradition! I am very grateful to Andreas Sobotta of Pilz and his colleagues at Eplan, Rittal and Wago for initiating this yearly conference in April 2018. Since then, it has evolved into the exhibition of the best of German technology for industrial automation and advanced manufacturing in Canada. Small and medium companies are the backbone of our economy. Many are world champions because they realise that by joining forces they achieve better results on the Canadian market. This year, fifteen prominent companies are hosting the annual German Technology Day. This is a new record and a great example of cooperation and collaboration.

I am convinced that, in 2022, the German Technology Day will profit from the new dynamics in German-Canadian relations created by the recent visit of Chancellor Scholz to Canada. Plus, it is finally back as a full in-person event. Participants in Toronto as well as in Montreal will have the chance to visit an impressive trade show and discuss various aspects of the future of automation. I thank the organizers and wish you all a very successful event!

It is my great pleasure to introduce you to this special edition presenting the fantastic line-up for the fourth German Technology Day! I have been a staunch supporter of this extremely important initiative from the very beginning. During my entire diplomatic career I have never ceased to be impressed by the ingenuity of the German Mittelstand. Many of these are medium-sized enterprises, some from quite small towns throughout Germany. They have managed to become world leaders in their respective fields through innovative thinking and technical expertise. That is precisely why this event that started in 2019 with only four exhibitors managed to attract 130 visitors right from the start, and has grown almost threefold during the pandemic! As you will see over the following pages, we are expecting 15 exhibitors this year: The crème de la crème of Industry 4.0, some of them even direct competitors working together to showcase the excellence of German automation to a North American audience. Needless to say, we will have a fantastic event this year and I cannot wait to welcome you there!

My very special thanks to my dear friend Andreas Sobotta, who brought this event to life and has grown it beyond any expectations over the last four years!

German Canadian companies in collaboration

We invite you to join us in a newly reimagined version of the showcase that offers interactive pathways for participation. It is time for all of us to work collaboratively and build up a wealth of best practices so we can better serve our customers in Canada.

We look forward to continuing to share more about what innovation means to us as the GTD event comes to a city near you. Whether this is your first GTD or your fourth, we are looking forward to collaborating with each of you as we count down to a great showcase event together! Register today!

This year we are excited to offer a host of deep-dive experiences through our Innovation Hub and technology workshops.

October 20, 2022 Humber College, BCTI 205 Humber College Blvd.

Toronto, ON

November 3, 2022

Plaza Centre Ville, 777 Blvd, Robert Bourassa

Montreal, QC 8:00 am to 4:00 pm

Opening messages

Invitation to attend

Agenda for the day

From the founding four

Meet the exhibitors

German Technology Day in photos

What you will learn and more:

German Technology Day is back in 2022 with the latest solutions and technologies from German automation and advanced manufacturing companies. This year’s event promises a full-day of presentations and technical sessions across three rooms, running in conjunction with the exhibition.

Visit germantechnologyday.com to register for the event you would like to attend. Registration is currently open. The event is FREE to attend.

Visit the Innovation Hub

Challenge-driven innovation methodologies, sparking innovative ideas, utilizing speed, agility and efficiency all with seamless integration

The German Technology innovation hub is a collective workspace of collaborative innovations by our exhibitors. The idea is to spark creativity for customers and show how a variety of applications and solutions can work in a cohesive environment with agility, efficiency and safety at the core. A showcase of how technology and automation companies can collaborate to help their customers succeed by removing barriers to new ideas in the factory, plants, or facility.

Network in the Exhibition Hall

Where the industry meets to do business

With 15 exhibitors confirmed for this year’s show, the largest showcase to date the GTD2022 will be the place to see the latest technology releases from leading German companies in the Canadian marketplace. From the latest in AI, machine learning led tools, to the solutions in manufacturing, automotive, robotics, building automation, smart city automation, safety and more that solve the biggest challenges facing the industry today, GTD2022 in Toronto and Montreal will have it all.

The Exhibition Hall will feature factory, logistics and process automation and will be open the entire day to all registered attendees. Technical representatives will be onsite to answer any questions about your applications and solutions. Be sure to come by and check out the latest innovations that can help your business succeed.

• Embedded AI in smart positioners providing prescriptive maintenance

• Unlocking the full potential of sensor intelligence.

• Workforce development

• Decentralized installations

• Digital factory now

• (RTM) Real Time Maintenance

Toronto: BCTI @ Humber College, 205 Humber College Blvd. Toronto, ON October 20, 2022

The Barrett Centre for Technology Innovation (BCTI) is designed to inspire innovation, support skills development and promote science, technology, engineering, art and math outreach with industry and community partners. Located at Humber’s North Campus, it builds on Humber’s expertise in areas such as automation, robotics, systems integration, user experience testing, applied research and work-integrated learning.

Montreal: Plaza Centre-Ville, 777 Blvd Robert-Bourassa, Montreal, QC November 3 ,2022

In the dynamic business district of Montreal, the Plaza Centre-Ville brings world class technologies to your fingertips. Enjoy the modern settings that include interactive technology zones, open concept gathering spaces for demonstration areas for new products and technologies.

8:00 a.m. - 9:00 a.m.

Registration, breakfast and tour of innovation booths

9:00 a.m. - 9:25 a.m

Opening Remarks –A greeting from the Consul General, Federal Republic of Germany, Toronto, Thomas Schultze.

9:30 a.m. - 10:15 a.m.

Room 1: Real Time Maintenance (RTM)

Room 2: Industrial network connectivity made easy

10:20 a.m. - 11:05 a.m.

Room 1: Unlocking the full potential of Sensor Intelligence

Room 2: PITmode: Unlocking your access management and security potential

Room 3: Decentralized gear motor installations: Digital, sustainable & cost efficient

12:00 p.m. - 1:25 p.m.

Lunch, innovation booths and Collaborative Automation Hub workshop

1:30 p.m. - 2:15 p.m.

Room 1: Revolutionizing automation technology

2:20 p.m. - 3:05 p.m.

Room 1: Embedded AI in smart positioners providing prescriptive maintenance

Room 3: Decentralized power distribution for manufacturing: Best practices

11:10 a.m. - 11:55 a.m.

Room 1: Key technological advancements in robotics

Room 2: The integrated Rittal-Eplan value chain: Digitalization in switchgear and panel building

Room 2: The easy way to industrial internet of things: From data to value

Room 3: Digital factory now

Room 2: Benefits of the Rittal-Eplan value chain: From smart to digital to collaborative

Room 3: Filling the training gap with workforce development 3:10 p.m. - 4:00 p.m. Trade show and social hour

Room 3: IIoT remote monitoring simplified

October 20, 2022 | Humber College BCTI | 205 Humber College Blvd. Toronto, ON November 3, 2022 | Plaza Centre-Ville | 777 Blvd. Robert Bourassa, Montreal, QC 8:00 am to 4:00 pm

In 2019, Andreas Sobotta, CEO and General Manager at PILZ Automation Safety Canada; Andre Bousette, President of Rittal Canada; Juliano Matias, President of WAGO Canada; and Roland Younk, President of EPLAN Canada put together the first edition of German Technology Day. They created a game-changing event to familiarize the Canadian manufacturing space with German technology offerings.

Andreas Sobotta, CEO and General Manager at PILZ Automation Safety Canada

Andreas Sobotta finished at Christian-Albrechts-University of Kiel, Germany with a Master of Physics degree. His entire professional life he was employed by automation companies. In 1998 he moved to Canada and since then gained experience in different industries. Employers included Phoenix Contact, Siemens, Festo and Hammond Manufacturing. For six years, he has been CEO and General Manager of PILZ Automation Safety Canada L.P. Andreas is also vice-chairman of the Canadian mirror committee of ISO TC199, the technical committee that globally works on improvements of standards around safety of machinery.

“After the initial discussions with the Canadian German Chamber of Industry and Commerce back in 2018 we were able to conduct the first GTD back in 2019, which was a great success. We started with four companies and over the years I was able to convince other companies to join the GTD. This year the target was 15 participating companies, and we have 15 companies! I am very excited to welcome some fine mid-size German companies, which are the heart and soul of Germany’s industrial automation. The GTD is an excellent opportunity to show customers the capabilities of the companies and how several mid-size companies can work together on very large automation challenges.”

André Bousette has been with Rittal Limited, Canada for 32 years. He joined Rittal in 1990 as an Outside Sales Representative in Montreal and surrounding area. Rittal’s strong market position in Eastern Canada is a tribute to his vision, leadership, dedication and hard work. In his most recent position as Regional Sales Director for Eastern Canada, he has achieved record sales growth while lending his considerable knowledge and expertise to the functional areas of TSG and Modification as well as product management for Rittal’s industrial solutions; in particular power distribution and climate control. André has over 37 years of experience in the manufacturing and automation fields. He holds a Bachelor of Commerce Degree from Concordia University and post-grad qualifications from McGill University.

“I am very happy to participate in the 2022 GTD as it showcases innovation and efficiency all in the same place. The GTD is the best vehicle to showcase how a multitude of products all work harmoniously well together as they are all built on the same globally accepted standard. It also explains how the user can benefit from the quality in terms of time and cost saving. Lastly it gives an encompassing view on possibilities that would not be as clear if seen on an individual basis.”

Born to a family of German immigrants, Roland Younk was raised on a farm and learned to speak German before he was even old enough to go to school. By college, he sought an apprenticeship in Germany at a CNC manufacturer, where he learned his electrical skills. He later came back to Montreal where he earned his degree in electrical engineering. Having developed a passion for the field, Roland discovered EPLAN, a Computer Aided Engineering software for panel building and schematics. For over 30 years, he has devoted himself to introducing colleagues, clients and customers to platforms and practices that lead to a focus on efficient engineering. The German Technology Day is an extension of this mission.

“The concept behind the GTD has always been to showcase the natural collaboration between German companies and their technology. When German companies work together, we allow each other to do more, work faster and require less resources. It’s sometimes difficult to see for us Canadians, because we are used to brands that are established in North America, but there are ways to enable our industry to be a lot more efficient. The German Technology Day helps spread that message and each year more people get to hear it.”

Juliano Matias, President of WAGO Canada

Juliano Matias is the General Manager for WAGO Canada Inc. In 2015 he joined WAGO as a National Sales Manager where he grew in his role and led the Canadian team to a new beginning in the electrical and automation business. From his electrical engineering background, Juliano transitioned into a leadership role, ultimately mentoring his sales team which has shaped the backbone of the values that WAGO is built on today. Juliano has a passion for people to make connections through the automation industry. With over 26 years of experience, he has been leading the way for industrial innovation.

“We love being a part of GTD because we thrive off the collaboration of this community which centers around automation. This type of event allows us to showcase our products and our expertise in one location giving us a chance to bring ideas together. We will continue to open this event to those who seek building stronger connections. WAGO will be alongside our partners and show that these complementary products work towards achieving a full solution. We have seen in the past an amazing turn out with more and more attendees joining. As we grow, the industry grows and develops modern innovations of manufacturing and automation.”