CASE STUDY:

CYBERSECURITY:

Building

p.

CYBERSECURITY:

Building

p.

Systematix offers solid support to client Leggett & Platt Lakeshore throughout its automation journeys and beyond. p.10

Our process sensors give you

Starting at $12.50 (FLS-VM-100)

Level sensors monitor the level of liquids, pellets, powders, and other similar products in tanks and process systems.

• Ultrasonic level sensors

• Float, capacitance, and vibration level switches

• Rotating paddle level switches

• Guided wave radar level sensors

• Differential pressure level transmitters

Starting at $19.00 (THMJ-B01L06-01)

Temperature sensors provide accurate and reliable feedback for temperature control and monitoring applications.

• NEW! Optris infrared pyrometers

• Temperature switches and transmitters

• Digital temperature switches/transmitters

• Thermocouples, RTDs, and thermowells

Starting at $190.00 (VCST-25-1000)

ProSense VCST switches and transmitters provide overall vibration monitoring of typical industrial machinery, allowing for early detection of potential problems, improved predictive maintenance strategies, and a reduction of costly downtime.

Starting at $84.00 (QPSL-AP-42)

Pressure sensors measure pressure at a specific point in the process and transmit the measured value or trip point to a control device.

• NEW! Winters pressure accessories: siphons, snubbers, and isolation needle valves

• Pressure switches and transmitters

• Digital pressure switches/transmitters

• Differential pressure transmitters

Starting at $63.00 (FG1W-100PP-28)

Flow measurement devices monitor liquid media and provide reliable flow indication, detection or measurement.

• Mechatronic flow switches and transmitters

• Magnetic-inductive flow meters

• Thermal and vortex flow sensors

• Variable area mechanical flow meters

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

Systematix and Leggett & Platt Lakeshore have grown a mutually beneficial partnership of trust and respect.

By Sukanya Ray Ghosh

A roundup of the latest technology and market trends for 2023

By Treena Hein

A custom machine builder improves performance specs promised to its customer with the support of its vendor.

By David Gersovitz

Examining the top challenges to cybersecurity adoption and the strategies to address them.

By Syed Belal

BY SUKANYA RAY GHOSH

The Canadian manufacturing industry is not untouched by challenges, such as skilled labour shortages and supply chain constraints. Manufacturers are trying their best to navigate the tough market conditions within Canada and also at a global level. Investing in automation technologies is the oft-recommended expert solution to tackle the various challenges that manufacturers have to face regularly. In our May/June 2022 issue, Stephanie Holko, in her column “The big picture,” wrote at length why investing in technology during economic downturns could actually be a blessing. However, it is not an easy decision to take the plunge, especially when economic uncertainties constantly loom in the horizon.

This October, I had the opportunity to attend the Toronto edition of 2022 German Technology Day. It was thrilling to see the show floor buzzing with action throughout the day. Out of curiosity, I asked several exhibitors what solutions or products were the customers (manufacturers) looking for at the event, and in general. They shared that their customers were looking for automation solutions that would help them tackle their problems. The ask was not for rigid automation products. Customers wanted technology that could tell them where to spend their resources. An exhibitor mentioned that their customer was most interested in parts for their automated machines. Having built lasting relationships with their clients, the exhibitor shared that they felt comfortable sending them to competitors if they themselves did not have the part in question at the moment. This helps them maintain their relationship of trust. Some exhibitors shared that their customers were looking for digital, data-driven solutions as opposed to the conventional automated systems.

In general, manufacturers were approaching the exhibitors to build solid partnerships to help them for the long-term. These relationships can indeed be valuable. In this issue, our cover story focuses on one such long-term partnership between a systems integrator company and its customer. Systematix, the winner of Manufacturing AUTOMATION’s inaugural

Systems Integrator of the Year award has been working with Leggett & Platt Lakeshore for more than 20 years. As a result, Leggett & Platt is able to approach Systematix with automation queries, both big and small, even when the systems integrator has not designed new automation equipment for them for a while. Being familiar with the customer’s products and needs allows Systematix to offer valuable suggestions when designing new automation equipment for them.

When implementing automation, the first roadblock is deciding on where and how to begin the journey. Establishing key relationships at an early stage with suppliers, systems integrators, industry associations and organizations that can help with funding could go a long way in ensuring the success of the project. On February 15, 2023, Manufacturing AUTOMATION is putting together a virtual event that could act as a beginner’s guide to automation implementation. Titled “First Steps in Automation,” the event will feature expert insights on planning what and how to implement, getting approvals from all key decision makers, arranging finances and understanding the best practices. A dedicated Q&A period at the end of the event will allow attendees to connect with the speakers. Check out automationmag.com’s virtual summits page for further details on the event.

Have you already automated your production lines successfully? Tell us about the lessons you learnt along the way. Let us come together to strengthen Canada’s manufacturing industry further. | MA

CONNECT @AutomationMag srayghosh@annexbusinessmedia.com /company/automation-mag

EDITORIAL ADVISORY BOARD

JIM BERETTA, President, Customer Attraction and host of The Robot Industry Podcast

JONATHAN GROSS, Managaing Director, Pemeco Consulting

MIHAELA VLASEA, Associate Professor, Department of Mechanical and Mechatronics Engineering and Research Co-Director, Multi-Scale Additive Manufacturing Laboratory at the University of Waterloo

SHELLEY FELLOWS, Chair, Automate Canada

STEPHANIE HOLKO Director, Project Development at Next Generation Manufacturing Canada

WALTER GARRISON, Former Advanced Manufacturing Business Consultant for City of Mississauga

Your resource for Canada’s industrial automation news

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: 416-510-5113

Fax: (416) 510-6875

email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

EDITOR

Sukanya Ray Ghosh srayghosh@annexbusinessmedia.com Tel: 416-510-5225

ASSOCIATE PUBLISHER

Kathryn Swan kswan@annexbusinessmedia.com Tel: 647-339-4880

GROUP PUBLISHER

Paul Grossinger pgrossinger@annexbusinessmedia.com

MEDIA DESIGNER

Svetlana Avrutin savrutin@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com Tel: 416-442-5600 ext 3221

AUDIENCE DEVELOPMENT MANAGER

Urszula Grzyb ugrzyb@annexbusinessmedia.com 416-510-5180

COO

Scott Jamieson sjamieson@annexbusinessmedia.com

CONTRIBUTING WRITERS

Paul Hogendoorn, Stevano Setiadi, Treena Hein, Syed Belal and Stephanie Holko

Published by Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 • Fax: 416-442-2191

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

SUBSCRIPTION RATES

Canada — $43 per year

United States — $75.50 (US) per year

Foreign — $86 (US) per year

Students — $20.50 per year

ANNEX PRIVACY OFFICER

email: privacy@annexbusinessmedia.com

Tel: 800-668-2374

Occasionally, Manufacturing AUTOMATION will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. The contents of Manufacturing AUTOMATION are © 2022 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Omron adds new certified systems integrator partners

Omron Automation Americas has added Genik and Revtech to its Certified Systems Integrator program. Both partners are based out of Quebec.

Genik offers solutions to end users using its G-KDM (Genik –Kaizen Design Method). With its solutions, it helps its customers eliminate waste, increase quality and reduce cycle times, among other things.

“Génik is proud to collaborate with Omron who is a leader in the industrial automation industry. Since our custom solutions are often a first, we always use the highest quality components on the market to make sure we get the best performance and reliability for the needs of our customers. Omron’s service has always added value to our projects, making them a partner of choice in our engineering team,” says Patrick Gariepy, vice-president of strategy at Génik.

Revtech focuses on production improvement, ROI and easy technological transfer to users. It recently designed, built and implemented a complex, multi-robot production cell using Omron robots, Sysmac control and high-resolution FH vision, as a package for the user. Revtech has collaborated with Omron since the early days of the company. Omron’s product portfolio allowed Revtech to deploy robot and automation solutions across various industries to help clients produce more and help those facing labour shortages to keep up with productivity.

For Omron, systems integrators play a critical role in designing and delivering fully integrated automation solutions. They also possess industry and application expertise in implementing the latest technologies from Omron and providing turnkey system solutions.

“Our certified system integrator

program provides end-users peace of mind when procuring automation solutions,” says Peter Brouwer, vice-president of sales at Omron Automation Americas.

“These companies have proven expertise when it comes to implementing our latest technologies, and they have full access to local training and resources needed to successfully deliver fully integrated automation solutions.”

Rexroth Canada

Bosch Rexroth Canada held a grand opening ceremony on September 15 to inaugurate its new customer experience centre in Burlington, Ontario.

In attendance at the event were top company officials,

including Trevor Osborne, general manager of Bosch Rexroth Canada, Gregory Gumbs, CEO and president of Bosch Rexroth North America, Karl-Philippe Clement, vice-president of sales development at Bosch Rexroth in Germany and John Mataya, C.F.O. and director of operations, finance and administration at Bosch Rexroth Canada. The company also invited its

Your new operating mode selection and access permission system!

customers to the event, offering them a guided tour of the facility and treating them to a day of funfilled activities.

As a company focused on offering automation products, Bosch Rexroth Canada commenced the event in style. A cobot from recently-acquired Kassow Robots untied the ribbon to officially open the customer experience centre. Not to be outdone by the machine, Gumbs and Osborne cut a second ribbon with a giant pair of scissors, amidst a thundering round of applause from the attendees.

Narrating the journey of the new facility, Osborne recalled how four members of the team, including himself, toured the local area in January 2021 looking at potential sites. The current location at 3426 Mainway, Burlington, Ont., was the first site that they visited. It did not have walls or finishing. It was clear to

the team that the location was ideal for the customer experience centre. Osborne shared that the journey to building the centre certainly had its challenges, including COVID-19, city permits, labour strikes, floor coatings and last-minute requirements to get occupancy sign-off, to name a few. He thanked the team involved in bringing the new facility to fruition.

Keeping the experience rich for the customers throughout the day, the Bosch Rexroth team treated all attendees to a sumptuous lunch at noon.

Organized facility tours were arranged in the afternoon when the customers, divided into small groups, were able to take a look at what was on offer for them. The Bosch Rexroth team explained the inspiration behind the colours and design. Customers had an enjoyable time with the interactive product displays arranged for them. They were shown the various collaboration spaces set up for them throughout the facility to come in and work with the company’s team.

The day ended on a high note with the Bosch Rexroth team

taking all customers to the Wayne Gretzky winery in Niagara-onthe-Lake.

ABB invests $13 million USD in Canadian facility expansion

ABB is investing $13 million USD in its Installation Products Division Iberville manufacturing facility in Saint-Jean-sur-Richelieu, Quebec. The funds will be used to increase production capacity and establish a research and development facility for cable tray manufacturing.

ABB explains that this investment will support rising global demand, especially in the data center segment. This is the company’s second multimillion-dollar investment in a Canadian site in the last 12 months.

“ABB’s latest investment is part of a five-year strategy to advance our digital capabilities and foster continued innovation,” said Matthias Heilmann, president of ABB Electrification’s Installation Products division. “Expanding production, integrating new

technology, and bringing together our product design and engineering teams further strengthens our ability to deliver smart, safe and sustainable solutions to Canadian and global customers.”

The Iberville facility employs 300 people, including production, engineering and quality specialists who design and manufacture cable trays for the North American market and international customers.

Planned improvements to the facility include the integration of new automated equipment, ABB robotics technology and an advanced design lab. ABB has also planned for more than 32,500 square feet of building improvements. The company expects these changes and additions to boost the total production capacity of the 102,000-square-foot site by more than 30 percent.

ATS Automation receives second major multimillion dollar EV order

ATS Automation Tooling Systems’s (ATS) industrial automation business recently secured an EV order worth approximately $231 million CAD (as per the current exchange rate).

The company received the order booking from an existing global automotive customer towards expanding the capacity of its automated battery module and pack assembly systems for operations within North America. The booking is valued at approximately US$167 million. It is subject to customary conditions.

“This project furthers our relationship with a key customer, while again demonstrating our ability to solve complex needs within the rapidly evolving EV market,” said Andrew Hider, CEO of ATS. “Our steadfast focus on continuous improvement, bolstered by the use of our ATS Business Model, allows us to adeptly evolve our offerings and embrace new technology to meet the advancing demands of customers while they are shaping the future of electric transportation.”

ATS explained that this order booking is part of a previously disclosed multi-phase enterprise program that includes the design, build and installation of turnkey battery assembly systems. The company will record the order booking in its second quarter of fiscal 2023.

ATS expects to carry out the project execution over the next 15 months.

Vancouver-based Novarc Technologies received Series A investment from Graham Partners Growth, the growth equity strategy of Graham Partners. Novarc is a full-stack robotics company specializing in the design and

commercialization of collaborative robots and AI-based machine vision software and systems for robotic welding applications.

The company states that the capital investment is pivotal to its growth. It will allow Novarc to broaden its robot and AI product line and accelerate its global expansion.

“We’re very excited to have closed this Series A financing

communication and power on one cable

EtherCAT P integrates EtherCAT communication with system and peripheral voltage supply in one 4-wire standard Ethernet cable. The I/O system for EtherCAT P with IP67 protection takes full advantage of One Cable Automation: material and installation costs, as well as the required installation space in drag chains, cable trays and control cabinets are significantly reduced. The compact and robust I/O modules cover a wide signal range, from standard digital I/Os to complex analog signals and measurement technology. More than 100 additional EtherCAT P components are available. Find out more now!

with Graham Partners which will be used to fund the expansion of Novarc’s sales and marketing efforts in North America, Europe and Asia, and continued investment in research and development in AI and robotics,” says Soroush Karimzadeh, CEO of Novarc Technologies. “We have seen global demand steadily increasing for an automation solution like Novarc’s. Today, some of the top companies in the building construction, manufacturing, engineering, energy, off-shore, and shipbuilding industries are employing our invention, the Spool Welding Robot (SWR).”

Karimzadeh explains that this investment allows Novarc to scale its multidisciplinary team in robotics, AI, vision, welding, sales,

ABB Canada has appointed Derek Monk as head of sales for ABB Motion in Canada. Monk will lead and support the efforts of the sales and marketing team for the motors, drives and services divisions. An ABB veteran who has been with the company for over 25 years, Monk’s roles have focused mainly on power electronics and power conversion. He started as director of sales and marketing for power electronics and MV drives and then took over as general manager for power conversion for ABB’s North American arm. Before taking his current position in ABB Motion, he was leading power and water for Canada. With a 30-year career in power engineering, he has extensive expertise and knowledge in running customengineered divisions, such as excitation and high-powered rectifiers, as well as EV charging and hydrogen fuel cell inverter systems. “This is a remarkable business with outstanding and innovative technology,” says

and support to meet the ramp-up in demand for factory automation.

$46 million USD investment

Schneider Electric is investing around $46 million USD in its Lexington, Ky., and Lincoln, Neb., manufacturing plants. The funds will be used to modernize operations and increase circuit breaker and related electrical product output for its customers in Canada and the U.S.

The new investment augments the more than $100 million the company earmarked in 2021 to expedite reshoring its

an enthusiastic Monk.” “I have always admired our Motion team for its talented people and high-quality products. Over 40 percent of electric power consumption in the world comes from motors. Here, we can offer the right technology to help our customers conserve energy and bring more efficiency to many industries.”

WAGO recently promoted Jesse Cox to the position of director of automation sales engineering and development. Cox has been in the company for around 10 years now. Most recently, he was the senior sales and application engineer for Linux and IIOT. As the director of automation sales engineering and development, Cox will continue to serve the company’s sales efforts. Wago is currently focused on a highly technical, solutions-based approach to automation that centers around people and processes. “I want to continue the upward trajectory of growth and innovation to expand the most capable automation team in the market,” says Cox. | MA

manufacturing capability in the North American region.

The modernization efforts at the two facilities will include new equipment and machinery installation with the most current and connected technology and automation. The company also plans to optimize the architecture of these facilities for digitization. This, combined with the newer technology, will help increase the plants’ quality and capacity and make their operations more energy efficient, states Schneider Electric.

The company explains that the upgraded manufacturing facilities enabled by digitization and connectivity will improve operational efficiency and mean time between failures, or the average time between repairable failures of a technology product. Since the new, advanced equipment will be connected, employees will be able to monitor and adjust energy usage and perform online diagnostics and predictive maintenance tasks remotely.

NGen, Trillium Network release new report on digital twins in manufacturing

Next Generation Manufacturing Canada (NGen) and Trillium Network for Advanced Manufacturing jointly published a report on digital twins. The report is titled Digital Twins in Manufacturing: Lessons from Canadian Manufacturers and Technology Providers.

The report builds on previous work done by NGen. It includes terms of reference and background knowledge on the subject. The foreword to the report also states that it includes case studies of three manufacturing companies in Canada – Laval International, CenterLine (Windsor) Limited and Avcorp. The three manufacturing companies have recently adopted digital twin technologies. Insights from technology providers that support digital twins adoption are also included in the document.

The foreword explains that the report aims at leveraging lessons learnt from these manufacturers and technology providers to further explain the benefits and applications of digital twin technology.

Both organizations hope that these insights will encourage and prepare manufacturers considering digital twins and other related advanced manufacturing technologies for their facilities.

The foreword further states: “Both of our organizations wholeheartedly agree that the future of Canadian manufacturing depends on the ability of companies to adopt these technologies. We believe that we are close to a tipping point, whereby companies that are willing to invest in advanced production technologies–technologies that are increasingly necessary to compete and achieve business objectives–will prosper, while those that lag behind will not.”

The ISASecure program announced the new ISASecure certification offering for industrial internet of things (IIoT) components based on the ISA/ IEC 62443 series of standards.

The IIoT Component Security Assurance (ICSA) certification was inspired by recommendations published in the joint ISA Global Security Alliance (ISAGCA) and ISA Security Compliance Institute (ISCI) study. Details of this landmark study are available in the Learning Center section of the ISASecure website and were presented during ISA’s October 2021 webinar. The study and resulting ISASecure IIOT certification scheme address the urgent need for industry-vetted IIoT certification programs.

The ISA Security Compliance Institute has been conducting ISASecure certifications on automation and control systems since 2011 through its network of ISO/IEC 17065 accredited certification bodies. | MA

By Sherief Ibrahim, General Manager, Business Applications at Microsoft Canada

Supply chain disruptions are certainly not new, but their frequency and complexity have vaulted them to the forefront for many organizations as they deal with external disruptions and economic uncertainty. During my nearly 10 years working in the consumer devices sector, supply chain was the difference maker in winning market share during key consumer moments, delivering on gross margin targets and building trust with some of the largest retailers in Canada. Today, increasingly complex supply chains put that difference maker at risk - the problems that can arise are outpacing human resources and the ability to quickly find solutions at an enterprise and global scale. It is becoming imperative for data and AI to assist supply chain professionals in problem spotting and risk mitigation.

But many organizations simply are not prepared for today’s challenges. Enterprises are dealing with data living across numerous legacy systems and solutions, resulting in a fragmented view of the landscape. According to a recent Harvard Business Review (HBR) survey, more than three quarters (76%) of organizations say increasing resiliency of the supply chain is top of mind for their leadership, but only one in 10 (11%) organizations have a single, integrated supply chain platform in place.

To help organizations ensure the resiliency and agility of their supply chains, we’ve introduced the Microsoft Supply Chain Platform. This solution maximizes supply chain data estate investment with an open approach, bringing the best of Microsoft AI, collaboration, low-code, security and SaaS applications in a composable platform.

At the core of the Supply Chain Platform is the Microsoft Supply Chain Center. This solution provides a “command centre” readymade to natively work with supply chain data and applications. It allows practitioners to harmonize data from across existing supply chain systems, like Dynamics 365 and other ERP providers including SAP and Oracle, along with stand-alone supply chain systems. Centralizing an organization’s data estate through Supply Chain Center, unlocks significant potential for AI problem solving to help supply chain practitioners better predict and mitigate risk through insights and “smart news” capabilities. Combined with smart news, supply chain practitioners can make decisions and plan with real-world event information and historical insights for product demands.

Across Microsoft, we are working with many organizations to build their own custom supply chain solutions, including Kraft Heinz. As part of its desire to better address supply chain disruptions, Kraft Heinz is leaning heavily into a digitized approach, shifting the company to a more predictive strategy and rapid response model. Extreme pressures on end-to-end supply chains during the past two years have exposed the need for more connected and collaborative networks between suppliers, buyers, retailers and other parties along the value chain.

“Our collaboration with Microsoft is a critical piece of our supply chain transformation. The platform gives our team the ability to be more agile – assessing risk and opportunities faster than ever before. Simply put, it provides the end-to-end visibility we need to keep our products on people’s tables across North America, and there’s nothing more important,” said Mitch Arends, Executive Vice President, Head of Operations, Kraft Heinz North America.

In addition to mitigating risk and disruption, the digital transformation of supply chains is one of the biggest opportunities for organizations to reduce their carbon footprint. However, it is one of the most challenging areas to address because decision makers (again) lack the data and insights to optimize the selection of suppliers, routes, fulfillment, and products. Using capabilities from Dynamics 365 Supply Chain Management and Order Management in the Supply Chain Center, organizations can make sustainable decisions on product sourcing, package-free returns, transportation logistics, manufacturing, and warehouse automation and more

We believe supply chain agility is critical to persevere in today’s economic climate. This means understanding and taking real-time actions based on supply chain data, securely and with sustainable business practices. We’re excited to deliver on this first step in our commitment to reimagine the supply chain for organizations across Canada.

Learn more at aka.ms/SupplyChainSolutions

Systems

Integrator of the Year Systematix

has built a relationship of trust for more than 20 years to offer continuous automation support to its client Leggett & Platt Lakeshore.

BY SUKANYA RAY GHOSH

When searching for an automation solution,

Leggett & Platt wanted a manufacturer they could build a lasting relationship with. Leggett & Platt relies on its systems integrator for value-added solutions that support cost-effective, quality production. Over their many years working together, Systematix and Leggett & Platt have grown a mutually beneficial partnership of trust and respect. Systematix was founded in 1988 from an industrial fastener company to an automation integrator for window and door manufacturers. Although the company’s customer base has changed over the years, decades later many of these original machines are still in service. In 1993, machine designer Cecil Bauman joined original owner Steve

Errey until Errey’s retirement in 2009. In 2021 Bauman retired and the company was acquired by Samuel Son & Co.

Robert Lague, president of the new Samuel Automation Solutions Group (ASG), comprising Systematix, RAMP and CAID Automation, said Samuel, family-owned since 1855, wished to expand further into automation manufacturing with the acquisition. Under Lague’s guidance, Samuel ASG is developing a group of companies across North America, experienced with large projects but agile enough to exceed customers’ needs. The ASG is actively looking to acquire new divisions, enhance capabilities and extend its reach.

(l-r) Robert Lague, Don Weber, Hajra Shafiq and Lesley Ahopelto. Shafiq and Ahopelto are Systematix project managers that have worked on Legett & Platt projects.

Lague shares that Systematix has evolved to add other manufacturing sectors to its customer base, including transportation, life sciences and consumer products. The company houses a diverse team of over 100 employees who love the problem-solving challenges customers bring to automate custom complex assemblies. Typically, manufacturers are seeking solutions to problems with product quality, reducing risk, increasing throughput, or reducing costs along with any additional value drivers automation solutions can offer. The growing issue Systematix customers are facing is overcoming the labour shortage.

Don Weber, regional sales manager at Systematix, discusses how the team worked with Leggett & Platt on its latest automation projects.

The Leggett & Platt team approached Systematix with a new high volume, multiple component, electric actuator project. Key problems identified for product manufacturing brought concerns with the volume, cycle time and quality. Leggett & Platt was looking

for a supportive partner for the project. The company opted to work with Systematix because of the relationship of trust established over 20 years of working together.

Weber recalls Leggett & Platt presenting the actuator unassembled in a box of about 15 parts. The company explained the components, the assembly order and the critical nature of all of the grease application points. The deliverable focus was to design a solution allowing Leggett & Platt a cycle time of seven seconds, consistently, reliably, with quality and no missing parts.

“Leggett & Platt did not have any preconceived ideas as to how they would want to do it. They left that to us as that’s really our core business,” says Weber.

Setting some parameters, Leggett & Platt provided Systematix with a start-of-production date. Systematix worked with them to create a formal proposal before formally being selected as the systems integrator.

Beth Rocheleau, manufacturing engineering manager at Leggett & Platt Canada, says, “Systematix has built multiple automation work cells for the company. They are willing to work with our design engineers and manufacturing engineers at the beginning of the project and

provide ideas to modify the design for manufacturing. Our manufacturing engineers work with their team throughout the equipment design process, providing feedback from our prototype builds and lessons learned from similar equipment.”

When required, Systematix also builds proof of concept fixtures that Leggett & Platt’s manufacturing engineers review and provide input on.

The concept stage for the project began with 3D models and layout drawings. The Systematix team explained how much floor space the new unit would occupy in the plant. The focus was on minimizing the floor space while ensuring that there was still good access to service the machine.

Early in the process, a project manager was assigned to ensure clear communication flow with Leggett & Platt during the journey. The design team created the complete concept for the automation equipment which was reviewed by Leggett & Platt. Once approved, the manufacturing process began.

“That is when we started machining the parts. We purchased third-party components like PLCs, robots, laser markers and anything else needed. We were also doing the electrical design at the same time,” explains Weber.

Next, the Machine Tool Builder and Integrators (MTBI) assembled the machine. At varying stages of assembly, electricians wire the machine, while the system programming begins in parallel linking interaction between vision, controls, PLC and robots. Weber explains that once the machine was complete the different parts were disassembled and shipped to Leggett & Platt for reassembly.

“We run the machine for approximately eight hours of production to prove to the customer that it is working well (FAT). That is when we received the sign-off from Leggett & Platt. The design intent for the machine was to build something that we can easily take apart and reassemble as needed. So, we tore it down in our facility and transported all the components to their plant. Our team then put it together on their floor and powered it up again,” he says.

At this point, Systematix did another run at the client’s site (SAT) to demonstrate everything was in working order. The entire process took around 40 to 50 weeks, shares Weber.

While the Systematix team loves working on every project that comes in, Weber shares that the Leggett & Platt project was a particularly interesting one.

“There are two electric motors. There are

six different configurations with different shaft sizes. And at the very end, there is a laser welder that basically bonds the two motors together. When putting all the components in there, a very important ingredient is grease. If the grease isn’t correct, the actuator becomes noisy and you can hear it. We had to design the machine in a way that the grease goes into 14 different locations on one of the variants. We were able to do that with a six-axis robot. We were able to dispense it and the dispense points were fully programmable. So, it didn’t matter where they want to grease now and if they want to grease different places in the future. It is easy to program a new location,” explains Weber.

The automation work cells that Systematix built for Leggett & Platt have been very successful, according to Rocheleau.

“We are able to build products with few defects, and we maintain a consistent output with minimal downtime,” she says.

“This is almost impossible to do with an operator. Because the automated machine has custom-designed tooling and programmable motion, it can assemble very quickly and consistently. So, that has been very successful for them for a long time,” he adds.

“This is almost impossible to do with an operator. Because the automated machine has custom-designed tooling and programmable motion, it can assemble very quickly and consistently. So, that has been very successful for them for a long time,” he adds.

All Systematix work cells built over the years have been similarly successful, hitting cycle times and bringing out products below the Leggett & Platt reject target. As an example of the working relationship that the companies have in place, Rocheleau shares how there were a few issues that Leggett & Platt was struggling with at the facility with previously built machines. They met with the Systematix team and requested solutions. The Systematix team developed alternatives and new lines that can help overcome them.

“I do see value in developing partnerships – they are willing to work with us during the early design stages of the product. They are familiar with our equipment requirements and specifications. They build equipment in a consistent style that makes it easier for our maintenance team to troubleshoot issues on new work cells,” explains Rocheleau.

It is easier to request a partner to come in, work on a design and offer a free cost analysis of the design, she adds. Leggett & Platt’s trust in its partner continues. The company is already working with Systematix to build an additional line on a previous machine. | MA

BY PAUL HOGENDOORN

Paul Hogendoorn co-founded FreePoint Technologies with the goal of giving manufacturers the benefit of information technologies that inform, empower and motivate their most critical asset – their people. He can be reached at hogendoorn. paul@gmail.com or linkedin.com/in/paulhogendoorn.

The popular notion that electric vehicles (EVs) will help reverse the tide of climate change, pollution and other environmental issues, exists for a number of reasons.

It is something that people truly want to believe.

It is something that people can believe because they’ve seen tangible proof. They’ve seen, driven or have been ridden in an electric vehicle themselves.

And it’s a notion supported by large and influential organizations, including governments, media technology leaders and the growing EV sector itself.

But is it actually true today?

If we stick with it, fueled by our commitment to what we want to believe, and having seen enough physical ‘proof’ that the technology does work, and supported by the alignment of support between governments, the social influence industry and the growing EV industry itself, can it be true someday?

I write this from the perspective of someone that is truly interested in sustainable environmental technologies. The advancement of all the various technologies continues to fascinate me and I truly applaud those driven in this direction by their desire and commitment to make the world a cleaner and better place. And, I offer some ideas about how we may get just a little closer to achieving our green objectives. However, with all the hope, hype and effort to shift our personal mobility choices away from internal combustion engines to an EV world, is it actually going to make a difference? It is something most of us want to believe, but it’s not a notion that I can fully embrace without questions.

So, here are my problems with that notion.

Sixty percent of electric power generated in the U.S. is generated by burning fossil fuels and 20 percent is generated by burning nuclear fuel. Burning fossil fuel on the one end (generation) to replace the burning of fossil fuel at the other (in a car) does not seem to be a net gain to me. Every time energy is transformed from one form

electricity and the availability of electricity for granted. But as amazing and wonderful as it is, it is not ‘efficient’. There are line losses and transformer losses, but that’s not where the big inefficiencies are. The grid is powered by large generating stations – about 60 percent fossil fuel, 20 percent nuclear and 20 percent ‘renewable.’ Many of the power generation sources cannot be quickly ramped up or down to meet demand quickly. This means there is an over generation of electricity all the time. Of the renewable sources, only hydro at 6.3 percent and biomass at 1.3 percent are ‘predicable’. The other sources depend on changing conditions such as wind and sunlight. They can’t be synchronized to meet demand peaks.

We can’t stop aiming for a better, greener solution, but we shouldn’t convince ourselves that we are there yet.

to another, there is a loss of efficiency –in other words ‘waste’, which in and of itself, is pollution. In the EV world, fossil fuels are burned as a heat source to create steam energy. Steam energy is then converted to mechanical energy through turbines or motors. The turbines then drive generators to create high-voltage AC electricity. The high-voltage AC electricity is transported hundreds of miles through power lines, being transformed to different useable voltage levels along the way. Finally, it is converted to DC to charge the battery in an electric vehicle. When you drive an electric vehicle, the DC power is then transformed into the appropriate electrical voltage and current to drive the motor, which then converts it back to mechanical energy. That’s a lot of power conversion points and a lot of distance between where the power is initially created (by burning fossil fuel) and where it actually does the useful work of moving a car. Contrast that to an internal combustion engine, which burns fossil fuel, but does so “on demand,” at the precise time the power is needed and at the exact location the power is needed.

Another problem with the current notion that EVs will make us ‘greener’ is the grid itself. The grid is amazing in how it delivers power so reliably to all parts of our continent. We take

So, what are the ultimate answers? My opinion is that we can’t stop aiming for a better, greener solution, but we shouldn’t convince ourselves that we are there yet. The long-term solution likely includes a changing understanding of what society should understand and expect as far as personal mobility is concerned. In the shorter term, I see at least two areas where we can take a good step forward. The first is improving the conversion of steam energy to mechanical (and therefore electrical) energy. Interestingly, steam is the intermediate step in both fossil fuel and nuclear power generators. And the second is blending IIoT technologies into the grid and automobiles so that charging EVs is throttled according to the availability of green electricity (or surplus power) on the grid, in effect using the batteries in all the EVs as the energy storage capacity that wind and solar generation solutions need to be effective.

I am encouraged by how quickly the whole automotive industry has responded to the opportunity and challenge of satisfying their customers’ appetite for EVs - some brands obviously leading the innovation, but all brands following in quick pursuit. However, as far as “green mobility” is concerned, we are not there yet. Far more needs to be done on how electricity is generated before we herald EVs as the ultimate answer to the problem. | MA

BY STEVANO SETIADI

Stevano Setiadi graduated from Humber College in 2016, specializing in electromechanical engineering. With his knowledge in robotics, automation, control circuits, hydraulics, pneumatics and mechatronics, he was hired by DMG MORI Canada as a service technician right out of college. He is currently the product sales manager for 5-axis milling for the company’s North American division.

Working together builds progress.

This was the primary motivating factor behind DMG MORI’s decision to partner with Humber College in 2018. The focus of this partnership is to provide students with the tools necessary to support them in their learning and develop their abilities prior to entering the manufacturing sector. Through this partnership, the company is investing in solutions to meet the skilled labour needs that the Canadian manufacturing sector requires today.

As part of this investment, DMG MORI has installed cutting-edge machine tooling technology at its lab in the Barrett Centre For Technology Innovation (Barett CTI). This includes a DMU50 5-axis simultaneous CNC Machining Centre with a control system that is Industry 4.0 ready to support data management. The 5-axis CNC machine is used to create prototypes for innovative projects

Through its innovation lab, DMG MORI is helping to create education and employment pathways and recruitment opportunities for Humber’s students and graduates. The lab is used to support applied research and capstone projects that help SMEs tackle their challenges, particularly around prototyping work pieces and metal fabrication.

The partnership has several other value additions. The company is constantly collaborating with Humber and the BCTI on STEM outreach activities. Encouraging the future workforce is as essential as training them with the tools of the future. For this purpose, the company is involved in several student awards and scholarships, including the DMG MORI Awards.

A good manufacturer is only as good as its tools. With more

automation being adopted, it’s necessary to make sure that business equipment is running optimally.

As an example, DMG MORI’s Conditional Analyzer app is the hub for all its monitoring technologies. This includes Machine Protection Control (MPC) which detects machine vibrations due to wrong part setup and incorrect workpiece overhang or from tool wear. With MPC, the machine can shut down or switch over to a sister tool to improve the process, avoiding premature spindle wear or chatters on the workpiece. By installing monitoring technologies, companies can prevent downtime and costly repairs to their machinery.

The increasing number of automation possibilities is why DMG MORI felt it was important to work with Humber College. The team is supporting Humber College with an upcoming project using the company’s existing DMU 50 third-generation 5-axis milling machine. The goal is to create a small-scale manufacturing plant within the Humber College facility that can assemble

components to build a final product. The DMU 50 can be used to produce fixturing to clamp down components or tooling and to help make special tools required on the assembly line to assemble the products. Including capstone projects, the DMG MORI team at the Barrett CTI has collaborated on several training and industry workshops aimed at Humber faculty and staff as well as external industry participants.

Humber College equips its students with the proper skills needed to enter the manufacturing workspace. Through its innovation lab, DMG MORI provides experiential learning opportunities to students that will reflect work in the real world. To be able to do that, students need to work confidently with the tools of today. Those tools must be able to meet the performance needs of students and businesses reliably. This is especially true as automation becomes a mainstay of manufacturing processes. Through its innovation lab, DMG MORI is preparing

Humber’s students for careers that involve hands-on experience, equipping them with the underlying foundational knowledge required to conceive, design, manufacture and operate CNCs. The lab prepares students for careers in programming (CNC) machine tools using computer-aided manufacturing (CAM) software. Students acquire knowledge in areas related to mechanical design, advanced manufacturing technologies, design of engineering systems, mechanical maintenance and modelling, among other things.

The future is built with the hands of today. The specialized world of machine tools is globalized now. The company understands the need to collaborate with industry and education partners to identify new ways to improve productivity.

Working with the Barrett CTI builds on DMG MORI’s long relationship with Humber. It creates the opportunity to work with different stakeholders to help make Canadian manufacturing competitive in the global market. | MA

BY TREENA HEIN

Motion control systems – as a whole and their component parts – continue to be updated, along with all other robotic technologies used across manufacturing.

Hot demand is driving healthy competition for new designs. According to Warren Osak, president of Electromate in Vaughn, Ont., demand for motion control is staying at historic levels. This is due to the economic recovery and pent-up demand that’s flowed after pandemic lockdowns, he says, as well as “the rush to automate factories to avoid further production disruptions in the event of future lockdowns.”

Lafert North America also confirms a rising market demand for packaged motor and drive solutions, says Lafert sales engineer Matthew Temple.

Before we do a deep dive into specific motion control system trends for 2023, let’s take a quick look at where demand is hottest. Like many others, Osak points to automated guided vehicles (AVG) and autonomous mobile robots

(AMR) as one of the two fastest-growing markets, where technology has to meet the growing and aggressive expectations for speed, positional accuracy and service life. Demand in this area is also high for compact designs that can handle high loads.

Automated vertical indoor farming (‘controlled environment’ crop cultivation in greenhouse or warehouse settings) is the other fastest-growing market, in Osak’s view. “Sophisticated robotic solutions like cartesian systems coupled with a distributed controls architecture are transforming this industry,” he says. “These robotic solutions track the health and quality of the plants, collect plant images for analysis and perform material handling functions.”

Here are the top five trends in motion control systems that will roll out in 2023.

1.

According to Temple, motion control systems are trending towards high-performance motors with integrated drive electronics or gear elements.

“Customer partners for both our Industrial Automation and Energy Efficiency business units are demanding power drive system solutions which grant improvements in energy efficiency, space and weight,” he says. “We note the market increasingly demands motor and drive packages which yield these system improvements from reduced investments of time and engineering resources.”

More use of ceramic is also beginning to trend due to the higher performance offered by this material. Osak reports that a few gearbox manufacturers have now replaced case-hardened and steel and alloy gears with ceramic gears. “We’re also seeing ceramic shafts and bits such as pins in gearboxes as well,” he says. “Ceramics have a lot of unique properties, the most important being noise reduction…and they have a lower coefficient of heat expansion, so exhibit less stress than metal alloys when hot. Because ceramic components don’t expand as much, they also have tighter backlash and runout tolerances than comparable internals made of metal.”

Osak adds that ceramic subcomponents make particular sense in smaller-frame gearboxes, especially those destined for specialty applications where minimization of noise/ vibration and high load capacity are critical.

Osak and his team are also seeing the widespread adoption of Planetary Roller Screws. They’re more efficient than traditional forms of actuation such linear bearing systems and round-rail bearing systems paired with ball screw and acme screw drives, says Osak. “Increasing linear servo-actuator efficiency allows design engineers to use more compact, yet higher thrust, actuators in applications traditionally driven by hydraulic actuation. In fact, electric linear actuators with roller-screw drive mechanisms can in some cases replace hydraulic drives even in very high-powered systems.”

Motion control is trending towards an integrated approach to motors and controls.

As an example, Temple explains that following years of co-engineering battery-powered servo motors and drives with AGV OEMs, his firm launched the ‘Smartris’ system for AGV/AMR wheel drives in 2021. It integrates a drive/controller, servo motor, wheel and ‘Cyclo’ gearbox, targeted at unit load carriers, tow vehicles and assembly line trucks up to about 6500 lbs.

Osak says he is now seeing fully-featured embedded servo drives built into rotary actuators, linear actuators and servo motors. Examples include Maxon’s new IDX motor and Harmonic Drive’s new FHA mini actuator.

There is also increasing demand for finished, integrated sub-assemblies. “Customers who once preferred to do the bulk of their component production assembly inhouse are now asking for kitted or bespoke modular sub-assemblies,” says Osak. “The

components into a customized mechatronic-housed solution provides OEM customers with a means of streamlining their manufacturing process. By reducing the number of SKUs and assembly steps they simplify their production which ultimately saves cost, reduces waste and drives production efficiency.”

Motion control systems will be affected by continued consolidation and standardization of the industrial ethernet communication protocols, says Temple. “The market is trending towards increased interchangeability and compatibility of components,” he says, “to realize the promised potential of Industry 4.0 and the Industrial Internet of Things.”

Osak points out that the adoption of Codesys as a universal standard for motion control communication is increasing.

As with all other areas of manufacturing, more efficiency is also trending in motion control. Brushless motors, for example, are becoming more popular due to their energy efficiency and heat reduction capabilities compared to AC motors for speed control applications.

On the sensor side, Osak points to the relatively new application of the Wiegand Effect in using pulse energy harvesting to provide battery-less operation of an absolute encoder while still maintaining position information in a power-off state.

In the case of POSITAL’s Wiegand sensors, bipolar magnetic sensing is used without the need for any external voltage or current to be applied. “The material properties of the sensor mean that consistent pulses are produced every time the magnetic field polarity switches,” says Osak. “This makes it the perfect magnetic sensor for low-power and

However, the consistency of the pulses produced by Wiegand sensors can also be used to provide energy for ultra-low power electronics to be operated using a single pulse. “In addition, successive pulses to be stored to offset energy demand of low-power energy circuits,” Osak explains. “Alternatively, the pulses can be used to trigger or ‘wake up’ intermittently-powered electronic circuits. It is also possible for applications to exploit both functions of the pulses (magnetic sensing and energy harnessing), using the pulse energy to power ultra-low power circuits which use the timing of the pulses to perform tasks – for example, count event data.”

Temple adds that their ultra-compact servo motors enable overall length to be decreased by up to 20 percent while torque density is increased by up to 30 percent.

Customization in motion control is nothing new but continues to intensify. Osak says motion control manufacturers would be wise to listen to the voices of their customers and modify their products to better fit customer needs. One customizable product that Osak is seeing is the turnkey cobot (collaborative robot) application kit. “They’re ideal for end users and integrators because all of the engineering, testing and trial/error have all been done for the customer,” he says. “The synergistic partnerships formed between the robot manufacturers and robotic accessory companies mean the packaged system price helps to keep the buyer’s costs down..But that doesn’t mean a customer is locked into a specific configuration. Each kit is customizable to fit the application needs.” Another technology supporting increased customization is a frameless motor. Generally compact and lacking traditional housing, these motors lend themselves easily to highly-customized motion control solutions. | MA

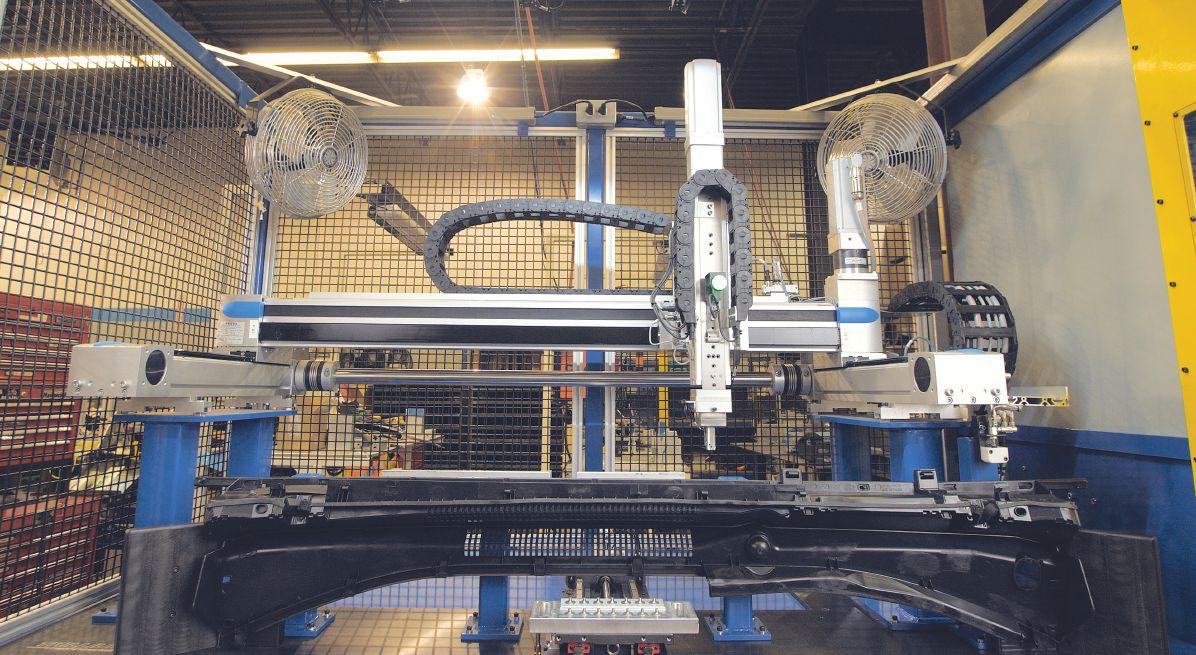

A custom machine builder improves performance specs promised to its customer with the support of its vendor.

BY DAVID GERSOVITZ

For a custom machine builder, managing customers’ Oliver Twist demands can make or break a oneoff automation project. Whenever a customer says “More please,” timelines and profits can take a hit. It’s one thing if the customer becomes enamoured with adding capabilities outside the scope of the original quote. That’s billable. It’s quite another when it wants to push the performance of what was ordered beyond what the machine builder promised, an additional investment of the latter’s time that often gets written off as goodwill. As Mike Hamelin, president of Windsor, Ontario-based Trillium Machine and Tool can attest, that’s when hands-on manufacturer support of its products can be a difference-maker. Who knows those products better?

An extended ask and task

Trillium had developed an automated handling solution with a Festo 3D gantry for a Tier 1 manufacturer of molded auto parts in the Windsor area to attach felt liners to molded windshield cowls.

Originally, the job was specified with a 37-second cycle time for the gantry to apply 14 pal nuts to secure the liner to the cowl. After the cell was installed, the real world intervened. Trillium’s customer felt that even after automating the fastening function, it wanted a bigger productivity gain. Automated fastening was faster than manual fastening. However, by the time an operator loaded the cowl, liner and nest of pal nuts for the gantry, turning around a finished workpiece was still taking 80 seconds, give or take. In addition, the Tier 1 manufacturer couldn’t push the

Trillium Machine and Tool, working with Festo Canada engineers, was able to reduce the gantry’s cycle time by 25 percent below the original specs.

operator to work much faster. Eliminating the repetitive strain on the latter was another key project objective.

“So, their focus basically turned to how the gantry’s cycle time could be shortened,” says Hamelin. “Essentially, they thought that if they couldn’t change their operator, maybe they could change the machine.”

Since the cell went operational last fall, Trillium’s controls engineers, in collaboration with engineering support from Festo Canada, have been able to trim 10 seconds off the cycle time. “We also added some mechanical features to assist the operators in speeding up a bit,” notes Hamelin.

The application itself is pretty straightforward. The operator has to load a blank cowl, place the felt liner, which is over five feet long, on molded pegs on the cowl and put the tray of nuts in place for the gantry to pick. He exits through a light curtain and swipes a banner button. The gantry picks and places two nuts at a time, moving horizontally over the pegs, retracting vertically after each pass for seven passes in all.

Using Festo’s Handling Guide Online configurator, Trillium had first conceived of a gantry with a pneumatic Z axis. That provided a fast quote and CAD for the original bid early last summer. As Festo Canada engineers reviewed the proposal, the design shifted to a YXCR modular gantry with an electric Z

axis to guarantee sufficient pressure to fully affix each fastener. Trillium ordered the gantry with the Festo Motion Control Package (FMCP) to synchronize the axes.

Early on, Festo had done a cycle time analysis of the gantry. “Based on that analysis, the end user was promised 37 seconds, in practice, 32 was achieved, then the end user wanted to go faster,” says William Debono, senior project lead (mechanical) at Festo Canada. “During the commissioning phase, we were able to get to 27.5 seconds with some optimizations using the motion control package – this included blending some motions, reducing the safe height and optimizing the tool path.”

That tweaking made the travel path of the gantry “less cartesian, less square, more fluid,” says Hamelin. “Festo engineers could dial right into the unit to optimize inertias, acceleration and deceleration rates per movement.”

According to the Trillium team, a 3D gantry was the logical choice for this application. Mounting the cowl on a moving nest and then having a 2D gantry press on the nuts still would have meant controlling three axes simultaneously, says Debono. Using a small articulated or SCARA robot would have

added cost and complexity to an otherwise simple application.

YXCR gantries are an assembly of axis modules. The X module (EHMX) is comprised of two parallel tooth belt axes which are connected to one another by a connecting shaft. For each module, there are multiple actuators from which to choose, flexibility on axis sizing and selection which proved to be fortuitous in this project. Festo first suggested an ELCC cantilever actuator for the Z module, but as time became an issue, swapped it out for an EGSL ball screw axis that was equally suitable and had an earlier delivery date. That enabled Trillium to keep the project on schedule and still meet the cycle time.

The YXCR was delivered fully assembled with lifting lugs so Trillium staff just had to hoist it into its frame. The FMCP was pre-configured for the specific project kinematics, which greatly reduced the setup and commissioning time. The latter package includes servo drives, power supply and circuit protection for controlling all gantry motion, pre-installed in its own cabinet.

→ Offers superior protection of HMI devices from UV and harsh environmental conditions

→ Excellent and easy hands-free screen visibility

→ Innovative, durable, and designed for use with all enclosure material types

→ Maintains NEMA Type 4/4X enclosure rating when paired with Type 4/4X HMI equipment

→ UL Listed–File #E64358

The FMCP, developed by Festo in Canada four years ago, is now offered worldwide as an option with the manufacturer’s handling solutions. An FMCP can control up to six axes, so it can manage a single or multiple H, T, 2D or 3D Festo standard gantry. Cartesian motion applications can be configured (or reconfigured) and integrated quickly with function blocks or AOIs for various controller brands.

The FMCP wasn’t part of Trillium’s original bid. “We were thinking strictly Cartesian style,” says Hamelin. “But our controls guy strongly suggested that we were going to need it to meet that cycle time that was laid out. So, we went for it. And, obviously, we’re 10 seconds quicker with it” because of the flexibility it provided to optimize the gantry without taking it out of service.

Festo Canada’s engineering team provides a great backstop for his team, says Hamelin. “Having their engineers dial in and do a live view of our program or settings or adjust the gantry for a one-off project like this is pretty remarkable.” | MA

BY SYED BELAL

Automation in manufacturing refers to the use of equipment to automate systems or production processes. Manufacturing automation aims to achieve greater efficiency by increasing production or reducing operations costs, and sometimes, both. Today, automation is used more widely to increase efficiency.

Today, automation technology is used widely to create connected digital factories that gather valuable data. In an environment driven by the Industrial Internet of Things (IIOT), the risks are many and varied. A major concern in recent years has been a significant rise in cyberattacks, especially from hostile external sources. As such, it is even more crucial today to protect against such threats with cybersecurity measures.

The manufacturing automation network includes operational technology (OT) such as industrial control systems (ICS), supervisory control and data acquisition (SCADA), sensors, networked machines, critical data, software, etc. Changes to these systems (whether made intentionally, accidentally or by attackers) can result in safety incidents and physical changes in materials, parts and environments.

That said, cyberattacks pose a growing threat to manufacturing automation, and cybersecurity for manufacturing requires serious attention. The manufacturing sector presents special security challenges because of the unique nature of operational technology

The top five challenges to adopting cybersecurity measures in manufacturing facilities are discussed here.

1. Legacy systems: Most industrial control systems currently in use in manufacturing were designed more than three decades ago before there was a clear understanding of how to build cyber resilience into those systems. The traditional ICS devices were designed to have a decades-long lifecycle and be purpose-built, stand-alone systems designed for reliability, not security. These legacy systems make it difficult for manufacturing sectors to secure their ICS. While IT systems have been more actively managed, with firmware and patches frequently upgraded, OT systems are usually not upgraded or replaced until significant failures. Due to the lacking security patches, these legacy systems are often unprepared to withstand IT security threats. That brings the concern of the absence of network visibility. Many manufacturing units don’t have the necessary technologies to gain visibility over their operational technology networks. As a result, they don’t necessarily know what to protect or what’s happening to their legacy systems. This minimizes these units’ ability to protect critical assets.

2. Vulnerabilities in OT/ICS: The manufacturing automation networks have specialized machines such as sensors, remote terminal units, SCADA, etc. that manage the lifecycle of industrial equipment and processes. Unlike IT, most of these controllers do not require authentication to make changes. Most of them do not support encryption communication. That said, threats such as a hacker, a malicious insider or a careless automation engineer can make changes and go undetected. Moreover, there are known vulnerabilities that are announced and published in the NIST National Vulnerability Database (NVD). Most of the ICS critical vulnerabilities can be exploited remotely and/or the attack complexity is low. It is easier now than it was in the past for a potential attacker to gain knowledge about system vulnerabilities, check if they exist and then exploit them. Understanding that some mitigations require system upgrades or architectural changes, it is sometimes not possible for the manufacturing sector to apply the remediations.

3. Convergence of IT and OT: Traditionally, ICS networks were air-gapped from the enterprise network. The threats were limited to accidental changes, natural disasters, physical sabotage, etc. Today, air gapping can no longer be considered a security measure due

to IT and OT convergence. The increasing convergences of IT and OT create opportunities for accessing them remotely and for exploitation. ICS is very attractive to potential attackers because the exploitation could lead to catastrophic incidents such as loss of life, environmental damage and disruption to the manufacturing infrastructures.

4. IT security techniques in OT network: OT administrators are not in support of deploying IT security techniques such as zero-trust solutions because of the complexity and overhead that usage will introduce to the rest of the critical infrastructures. The IT security techniques were not built for controllers or RTUs and can pose several challenges in an OT environment. Actively scanning the OT can freeze the controllers. The number of false positives can be high, and testing patches can interrupt critical operations. While the gaps between IT and OT are shrinking, the security gap between IT and OT is increasing.

5. Difficult to secure the lower layer protocols: The lower layer protocols that configure automation controllers, make changes to

logic or update firmware are comprised of proprietary vendor-specific protocols. Each OT/ICS vendor uses its proprietary implementation that is rarely documented. Attackers execute actions on these proprietary vendor-specific protocols and there is no established way to monitor the lower-layer activities. As a result, the changes made by an attacker, a malicious insider, or accidentally, can go undetected until the damage occurs.

The convergence between the OT and IT has been beneficial to improving plant productivity, and manufacturing sectors need to leverage them though the security risk is increasing. With every change – such as implementing IT techniques on the OT network – the OT risks change and often increase. That said, companies can implement five key strategies to tackle OT cybersecurity challenges.

1. Asset inventory management: You cannot secure what you cannot see. The inventory should not be limited to the IP/MAC address of the IT machines, such as windows and network

devices. In-depth inventory includes, but is not limited to, manufacturer, model, version number, serial number, revision/patch level, history, etc. Moreover, the manufacturing sector needs to ensure that all the assets, hardware, firmware and software components at all the layers in the automation and control system, are verified, documented and maintained. Finally, any changes made to any asset or the properties of its components such as manufacturer, model, version number, serial number, revision/patch level, history, etc. need to be logged and verified – and if required, investigated. The inventory management tool should be designed for OT/ ICS systems. Implementing IT software such as actively scanning tools on OT/ICS systems may impair the operations, and at the same time, it becomes difficult to have full visibility of the OT network.

2. Vulnerability management: ICS vulnerability management is a continuous process that includes proactive OT/ICS asset discovery, continuous monitoring, registering risks/ vulnerabilities, mitigation, remediations and defence tactics such as alternative controls to protect critical infrastructure such as SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

CARLO GAVAZZI has the solution for your application needs, whether it’s our industry leading solid state relays, energy meters, contactors, motor controls, monitoring relays or sensors, now available with IO-Link communications. Contact us today, and one of our field sales representatives will show you why we are one of the fastest growing automation companies worldwide. We’ll even provide a free evaluation sample to qualified customers.

manufacturing sectors from OT cyber-attacks. That said, the vulnerability management tool should have attack surface features such as their locations, devices, inventory, patches, CVE details, etc. Moreover, having attack complexity, privilege/authentication to exploit them and user interaction detailed will help asset owners to identify the vulnerabilities that need immediate attention.

3. Configuration and change management: Configuration management is incomplete without baselines and change management. Baselines are the most powerful tool. The baselines are snapshots taken that include critical controllers’ configurations and asset properties such as software, firmware, version number, hardware model, type, etc. The baseline configuration can be used in the worst-case scenario for either restoring or comparing to the latest configuration to identify inadvertent changes. The other important method of configuration management is change management. Every change needs to be logged and verified – and if required, investigated. Changes are the only constant in the ICS network. It is recommended to identify, at

least, the critical changes and ensure it was not done inadvertently or by hackers.

4. Incident response: Manufacturing sectors can be the target of new groups and different types of threats. While elaborate attacks from hostile countries are still a risk, they are far outnumbered by ransomware attacks from criminal groups, who prey on poor cybersecurity practices and low awareness. It is not the question of if a cyber-attack will happen, the question is when the cyber-attack will happen, and how severe the consequence will be. Manufacturing sectors should be ready with a detailed incident response plan and procedure that includes a detailed step-bystep procedure on how to detect the attack at an early stage and restrict it before the actual damage occurs. The procedure should consider recovery time/point objects by understanding the criticality of the assets.

5. Training the automation team: The human element is often the weakest link in cybersecurity. Most cyberattacks are successful due to human error, lack of awareness, or accidental changes. Your team needs to know your OT

network more than anyone else, especially the attackers. The manufacturing automation team needs to be trained to ensure they know what they are doing and to identify abnormal situations or changes. Training will help them to avoid inadvertent engineering. And secondly, they will be able to identify abnormal situations such as high utilization of network devices, controllers, etc., pumps being shut down out of order, etc. Moreover, your team needs to be trained to use tools such as inventory management, vulnerability management, configuration management and enacting the incident response plan effectively to get the most value out of them.

Implementing cybersecurity measures can be expensive in terms of network utilization and overhead. However, effective cybersecurity starts with implementing and training employees on OT cybersecurity techniques that are designed after understanding the characteristics of ICS networks. | MA

The Bay of Quinte Region is home to a large cluster of manufacturing facilities including many well-known multi-national corporations. Strategically located, the region is known as a prime Canadian logistics and manufacturing hub that provides fast access to major Canadian and US Markets.

To learn why manufacturing works here and what is Proudly Made in Bay of Quinte, visit madeinquinte.ca

Applied Motion Products’ new PH series mini planetary gearmotors are suitable for use with small step motors in NEMA eight, 11, and 14 frame sizes. The small gearheads are designed to be paired with small motors. The products are used in applications where space is critical. PH mini planetary gearmotors are available in three frame sizes –22, 28 and 35 millimetres. Each component of the gearbox is machined to exacting tolerances before being assembled into the final reducer. Features include planetary design, precision cut gears, all-metal construction, high torque and precise positioning, miniature design and standard ratios from 4:1 to 36:1. electromate.com

Vention’s new software-assisted deployment digital twin MachineCloud leverages the digital twin data of the machine already present on Vention’s Manufacturing Automation Platform. Vention can now offer a complete customized deployment flow by eliminating the need for hardware and software commissioning. The software is designed to allow users to program their

MachineLogic sequences and deploy them on their automated equipment from anywhere in the world with MachineCloud’s remote control capabilities. MachineCloud offers real-time visibility of the machine operations such as status and e-stop events. Other MachineCloud features include software-assisted setup for hardware and wiring, remote access to MachineMotion data log file, machine configuration checker and application checker. vention.io

ABB’s new IRB 1010 robot is its smallest ever industrial robot. The IRB 1010 is designed to suit the narrow spaces and special-purpose machines typical of electronics production environments. With a reach of 370 millimetres and a footprint of 135 millimetres by 250 millimetres, the IRB 1010 is 30 percent smaller than ABB’s current smallest robot, the IRB 120. These compact dimensions increase the number of cells that can be fitted into production spaces. The robot is designed to handle loads up to 1.5 kilograms. This payload capacity – coupled with a larger diameter air hose that provides added power for vacuum suction – enables simultaneous handling of multiple objects. The robot features the OmniCore E10 controller which consumes up to 20 percent less energy compared to ABB’s previous IRC5C controllers. According to ABB, the

robot is suitable for electronics manufacturing, including smartwatches, earphones, sensors and health trackers. new.abb.com

HMS Networks’ newly expanded second-generation Anybus Communicator product range features thirteen new versions for data connectivity between EtherCAT, EtherNet/IP, Modbus TCP, PROFIBUS and PROFINET. The Anybus NP40 industrial network processor is designed to ensure that the communicators meet demanding requirements in terms of industrial performance, reliability and security. Featuring new hardware and software, the gateways allow instant data transfer – up to 10 times faster than their predecessors. Users can also exchange significantly more data between the networks as the gateways transfer up to 1,500 bytes

to and from connected PLCs. anybus.com