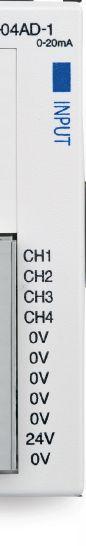

We’ve taken our most practical, most popular PLC family and supercharged it with features you wouldn’t expect from a simple low-cost controller. Data logging, Wi-Fi connectability, MQTT communication and increased security measures are just a few of the impressive features offered with the new CLICK PLUS PLC series. With a starting at price of only $89.00 and free easy-peasy programming software, CLICK PLUS PLCs are a “must have” for simple, affordable control...with a kick!

Add up to 8 additional I/O modules for applications with larger I/O needs.

For custom stand-alone PLC I/O configurations that exactly match your application (option module sold separately).

Our shipping policies make it easier than ever to order direct from the

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

Funding

Three

Can

Advances in collaborative robotics are allowing manufacturers to deploy automation in finely targeted areas. This incremental approach is allowing SMEs to get into the game

By Jacob Stoller

How today’s PLCs, PACs and edge controllers enable plant connectivity and extract value from data

By Karen Smock

Automation and robotics adoption must increase to grow the manufacturing sector, says NGen report

By Kristina Urquhart

Collaboration, convergence key to automation success: A3 conference By

Kristina Urquhart

It was welcome news at the end of March when French-owned pharmaceutical giant Sanofi announced plans to construct a $925-million influenza vaccine manufacturing facility in Toronto — though not only for the new jobs it would bring, or the economic boost it would inject into a challenged economy coming out of COVID-19.

It also wasn’t only about Canada having domestic vaccine production in the event of another pandemic — though that is very welcome news indeed. No, Sanofi choosing to add another facility in Canada when the company also has a presence in 99 other countries showed the world that Canada is worth investing in.

Consider this: a report on the future of Canada’s post-pandemic supply chain targets the advanced manufacturing sector as a prime market for growth — and a place where automation solutions can take centre stage.

Invest in Canada, a federal body charged with attracting foreign investment, recently commissioned KPMG to analyze which of the country’s supply chains offer the best opportunities. The study, called Advantage Canada: Reshaping Supply Chain Investment Opportunities After COVID-19, identified advanced manufacturing in particular as primed for expansion: 40 per cent of manufacturers in Canada use advanced technologies, and GDP growth in advanced manufacturing was 3.7 per cent between 2017 and 2019.

supply chains” that bring products and supply networks closer to customers, cutting down on delivery costs and reducing supply shortages.

The report authors say potential investors should consider Canada as they redistribute their supply chains, because it is a stable democracy and has trade agreements in place with North America, South America, Europe and Asia. Canada offers access to water, energy and other resources, and employs a high-talent workforce as a result of quality schools and open immigration. There are policies in place to protect intellectual property, and the made-in-Canada brand is recognized around the world as one of high standards. Canada is also home to manufacturing sectors that need reinvention, such as aerospace and automotive.

An ecosystem of suppliers will be required to get construction and machine building underway, and to support Sanofi’s plant once its up and running.

The pandemic highlighted just how much risk global supply chains are under — the reliance on low-cost production with “just-in-time” delivery has, over time, led to offshoring, with “lean” distribution centres located closer to end customers. While manufacturers have been able to save on cost of labour by driving production away from Canada, the product bottlenecks felt during the COVID crisis revealed there can be hidden costs to operating with long supply chains.

As global supply chains shift to more regional or local ones, companies are establishing “micro

Your resource for Canada’s industrial automation news

Reader Service

Print and digital subscription inquires or changes, please contact:

Urszula Grzyb, Audience Development Manager

Tel: (416) 510-5180

Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

EDITOR

There are still supply chain risks for investors to be aware of such as border closures, which at the time of this writing have been in effect since the beginning of the pandemic. Ongoing geopolitical issues with the U.S. and China and the ensuing unpredictability could possibly affect Canada’s export markets.

But the benefits outnumber the risks, says KPMG — and the quick response of the manufacturing supply chain to retool and produce medical supplies needed for COVID-19 means there are key investment opportunities for international automation vendors as well. The concentration of manufacturers and suppliers between the Windsor-to-Quebec corridor allows for direct access to OEMs while still being close to Canada’s biggest consumer bases.

The new Sanofi plant, for example, will create 1,225 jobs by the time it is completed in 2027. But an entire ecosystem of suppliers will be required to get the construction and machine building underway, and to support it once its up and running. Good news for the automation suppliers here at home: you’re already invested in Canada. Time to start preparing your bids. | MA

@AutomationMag/company/automation-mag kurquhart@annexbusinessmedia.com

EDITORIAL ADVISORY BOARD

AL DIGGINS, Chairman of the Board, Treasurer and General Manager, Excellence in Manufacturing Consortium

DAVID GREEN, Technology and Business-to-Business Consultant

SHELLEY FELLOWS, Chair, Automate Canada

KARIN LINDNER, Founder and Owner of Karico Performance Solutions

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Support Systems Developer, KINITO Support Systems

Kristina Urquhart kurquhart@annexbusinessmedia.com Tel: 416-442-5600

ASSOCIATE PUBLISHER

Kathryn Swan kswan@annexbusinessmedia.com Tel: 647-339-4880

GROUP PUBLISHER

Paul Grossinger pgrossinger@annexbusinessmedia.com

MEDIA DESIGNER

Graham Jeffrey gjeffrey@annexbusinessmedia.com

ACCOUNT COORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com Tel: 416-442-5600 ext 3221

COO Scott Jamieson sjamieson@annexbusinessmedia.com

CONTRIBUTING WRITERS

Alena Barreca, Thomas Burke, Paul Hogendoorn, Karen Smock, Jacob Stoller, Lyall Watson

Manufacturing AUTOMATION is published seven times a year by:

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 Fax: 416-442-2191

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

SUBSCRIPTION RATES

Canada — $43 per year

United States — $75.50 (US) per year

Foreign — $86 (US) per year

Students — $20.50 per year

ANNEX PRIVACY OFFICER email: privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Manufacturing AUTOMATION will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Manufacturing AUTOMATION are © 2021 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 Association Partner

Ongoing closures at the Canada-U.S. border have the manufacturing supply chain frustrated, say representatives from industry associations.

The Windsor-Essex Border Task Force, represented by the Canadian Association of Mold Makers (CAMM), the Canadian Tooling & Machining Association (CTMA) and Automate Canada, with the support of Chris Lewis, MP for Essex, have presented a petition to the Canadian government’s Special Committee on the Economic Relationship between Canada and the United States.

They’re calling for the supply chain’s provincial status as essential to the manufacturing industry to be recognized federally so work can continue across the border. The petition is signed by thousands of professionals with U.S. work visas in the Windsor-Essex region who generate over $1 billion in U.S. exports to Canada’s annual GDP.

The task force – which represents manufacturing OEMs and supply chains as well as two major advanced manufacturing clusters – has also filed another petition online to the minister of public safety and emergency preparedness, asking for exemptions from quarantine for essential workers who receive negative rapid test results or who are vaccinated against COVID-19, and who agree

to self-monitor.

“The industrial automation industry continues to struggle at the border,” says Shelley Fellows, chair of Automate Canada.

“The reality is that industrial automation companies ‘make the things that make things.’ We are an essential pillar to the North American manufacturing sector.”

Border restrictions barring travel between Canada and the U.S. have been in place since Mar. 21, 2020 to stop the spread of COVID-19, and now, only some “essential workers” are able to cross without a mandatory two-week quarantine. Currently, workers employed by suppliers in the manufacturing value chain must quarantine for two weeks upon entry back into Canada.

They’re also routinely denied access to cross, depending on how border officials interpret the rules of a federal legal order called the Orders in Council, which contains ambiguous wording indicating that manufacturing and industrial automation workers may only cross the border without quarantining if their “regular” employment is based in the U.S.

“This is interpreted to mean that they must cross the border at least weekly in order to be considered ‘regular’ workers. While the understanding is that Canadian workers must cross into the U.S. to take care of U.S. manufacturing customers, frequency is dictated by the requirements of a contract, not a calendar,” Fellows says.

“The same goes for workers for U.S. manufacturers who come into Canada to discuss designs, inspect equipment or get training on software.”

Fellows says the restrictions are creating a trade barrier – and when U.S. manufacturers can’t access the equipment and software support they have been relying on, they are turning to U.S.-based suppliers instead, leaving Canadian companies behind.

The tool, die, mold, and gauging and automation manufacturers represented by the task force contribute to a combined Canadian manufacturing GDP of $30.8 billion and provide 188,000 jobs in manufacturing (OEMs and supply chains) – but over 80 per cent of their goods are exported to the U.S.

“This means the gradual erosion of our domestic industrial automation sector. When projects in the millions of dollars are lost

to U.S. companies, Canadian companies must cut back and rethink their business strategies,” Fellows says.

“It really is heartbreaking to hear their stories and to know that the big picture is the eventual decline of our highly valued and innovative manufacturing technology sector.”

N95 respirators have started rolling off the production line at 3M’s Brockville, Ont. plant.

About 700,000 N95 respirators were shipped from the plant during the week of Apr. 5, with the first wave of PPE sent to health care, education and other public-sector institutions.

The first shipment came eight months after the governments

of Canada and Ontario reached a five-year agreement with 3M last August for the provision of 55 million respirators annually to meet demand for frontline healthcare workers in Ontario and across Canada.

Through this partnership, 3M expanded its Brockville manufacturing facility to produce the made-in-Ontario N95 respirators. Each level of government invested $23.33 million to support 3M’s capital investment of $70 million.

The Brockville facility will produce enough respirators to meet private sector, provincial and North American market demand throughout the pandemic and beyond. The project created 30 jobs in Brockville, including production operators, maintenance technicians, process engineers, supervisors and quality assurance professionals.

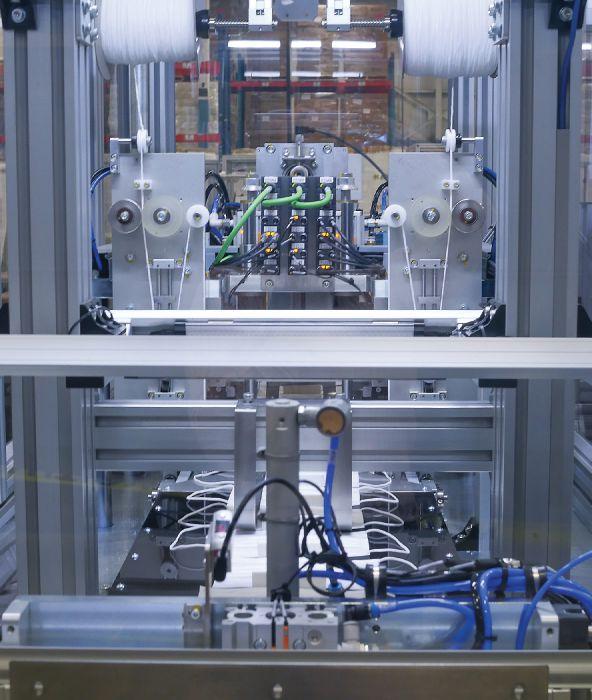

The Canadian Shield has launched newly designed, made-in-Canada medical mask automation and vision systems.

The technology enables The Canadian Shield, a Waterloo, Ont.–based PPE manufacturer, to compete with overseas companies, and sell their turnkey medical mask manufacturing lines and vision systems to other producers around the world to improve their operations.

Born out of the COVID-19 crisis, The Canadian Shield quickly scaled its team and built strategic partnerships with several local automation companies. These partnerships have helped to rapidly design new technologies and optimize automation solutions for global sale.

As a result of pandemic-related supply shortages, countries across the globe have invested in domestic PPE manufacturing capacity to ensure supply and production capabilities in the event of future crises.

The manufacturing machinery required for producing personal

protective equipment, like medical masks themselves, were previously made almost exclusively in Asia.

Typical imported systems cost between $70,000 and $85,000 depending on the upgrades and rework required to bring them to Canadian standards. These systems, though advertised at much higher speeds, cap out at around 75 parts per minute, can have large downtimes and scrap rates between 15 and 30 per cent.

Starting at $300,000 with full safety certification, The Canadian Shield mask automation system produces double the number of masks per day with one operator. Inline vision and part rejection ensures that only quality masks leave the machine.

The new systems, which offer 90-plus parts per minute, less than four per cent scrap, and 91 per cent OEE, are now available to order.

The vision system is also sold separately as a modular addition for inline mask inspection and rejection.

Dimachem, a chemical blending and packaging manufacturer based in Windsor, Ont., will receive nearly $850,000 from the province to locally produce Pine-Sol Multi-Surface Cleaner-Disinfectant.

The disinfectant has been proven to be effective in killing SARS-CoV-2 (the virus that causes COVID-19) on frequently used hard, non-porous surfaces.

Dimachem has entered a multiyear toll manufacturing contract with The Clorox Company to manufacture 12 million bottles of Pine-Sol per year.

Dimachem will establish a new production line and modify its facility in Windsor to make the product in-house. Dimachem will also purchase new blow molding equipment to produce polyethylene terephthalate (PET) bottles and packaging on-site.

PET belongs to the polyester family of polymers used in things

including fibres for clothing, containers for liquids and foods. This will enable a high-speed, fully integrated bottling system to increase the company’s competitive advantage in the long term.

It will also have greenhouse gas reduction and environmental benefits, as empty bottles do not have to be shipped from other sources, equaling 19,400 tonnes of reduced of CO2e emissions.

The company will create 14 jobs as a result of the investment made through the Ontario Together Fund, which was established to help businesses retool or adopt the technological changes needed to produce supplies and equipment or for organizations developing solutions for other critical public services. The province has now committed an additional $50 million in the Ontario Together Fund in 2021-22 to support projects like this and to allow local businesses to further enhance domestic supply chain capacity.

The governments of Canada and Ontario have announced a $955-million influenza vaccine manufacturing plant will be built in Toronto, in partnership with Sanofi Pasteur Ltd.

The new production facility will be constructed by 2027.

“When it comes to the next pandemic flu we should be self-sufficient,” said Francois-Philippe Champagne, Canada’s innovation minister. “If there’s one lesson learned from the current COVID pandemic it is that we need to have a strong Canadian biomanufacturing sector.”

Should there be another pandemic, this plant would be able to manufacture enough vaccines for all Canadians within approximately six months, according to government sources.

The federal government will invest $415 million, the Ontario government $55 million and Sanofi over $455 million to build

the new plant, which will create over 1,200 jobs.—with files from The Canadian Press

Kruger starts up $575M tissue plant, invests additional $240M

Kruger Products has successfully commissioned its new $575-million tissue manufacturing plant in the Brompton, Que. region.

Construction is complete on the new Sherbrooke manufacturing facility, which contains Canada’s largest and most modern throughair-dry (TAD) tissue machine. The new facility also comprises three converting lines, all of which have been successfully started up.

Construction of the facility began in May 2019. At maturity, the TAD tissue machine will increase the company’s annual output by approximately 70,000

metric tonnes of bathroom tissue and paper towels for the Canadian and U.S. markets.

Kruger Products also announced an additional investment of $240 million to expand the Sherbrooke operation with new production lines and to construct another tissue manufacturing facility over the next three years. This investment is supported by $165 million in loans by the Quebec government through Investissement Québec.

Construction of the additional facility is anticipated to start in the summer of 2022 on a site adjacent to the Sherbrooke plant.

Beckhoff Automation has moved its Canadian headquarters from Mississauga to Cambridge, Ont.

The 11,000-square-foot office offers space for customer training, seminars, sales activities and technical support.

The “Innovation Lab” can be used for application testing and proof-of-concepts with the latest Beckhoff technologies, including the XPlanar Flying Motion system and the eXtended Transport System (XTS). The new facility also offers the subsidiary a larger central warehouse, ensuring more on-hand stock.

Beckhoff says it moved to Cambridge to be connected to the Waterloo region, which houses Canada’s largest cluster of robotics and automation companies and a preeminent engineering school and research centre focused on robotics, automation and AI.

The new office sits right off Highway 401, making it convenient for local visitors and those arriving from Toronto Pearson International Airport.

Motion has appointed Aurelio Banda as the new group vice-president of automation.

“Aurelio’s extensive industry background in automation distribution and manufacturing, combined with his education and training, make him a perfect fit to lead our automation strategy and accelerate growth,” says Randy Breaux, Motion’s president.

Banda most recently served as president and CEO of PHD Inc., a global manufacturer of electric, pneumatic and hydraulic industrial automation actuators of various types in Fort Wayne, Ind. Prior to leading PHD, he served as president and CEO – North America for Beckhoff Automation. | MA

SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

CARLO GAVAZZI has the solution for your application needs, whether it’s our industry leading solid state relays, energy meters, contactors, motor controls, monitoring relays or sensors, now available with IO-Link communications.

Contact us today, and one of our field sales representatives will show you why we are one of the fastest growing automation companies worldwide. We’ll even provide a free evaluation sample to qualified customers.

BY ALENA BARRECA

is a marketing coordinator at Mentor Works, a business support organization specializing in Canadian government funding. To find out your business’s eligibility for grants and tax credits, visit mentorworks.ca.

Did you know that Canadian manufacturing and technology sector businesses are in a key demographic to benefit from government funding? With a substantial range of programs available, government grants and loans for manufacturing companies can help offset costs of important capital investment, technology adoption, and research and development projects. By investing in a funding strategy to obtain assistance for strategic innovation projects, organizations can leverage financial support to help meet their goals at a faster, and oftentimes, more successful rate. Eligible organizations can access funding for technology adoption projects such as installing new software, equipment and/or machinery to improve systematic and everyday processes. Similarly, research and development funding programs are available to support strong technology development projects that can highlight Canada’s position as a global leader in innovation.

Delivered through the federal and provincial governments, the following are five of the top government funding programs available to help Canadian manufacturing businesses with high growth-potential projects focused on technology adoption and development.

There are two BSP streams that are separated through the regional agencies FedDev Ontario and Western Economic Diversification Canada (WD). Offering slightly different levels of support, both focus on helping Canadian businesses with high-growth-potential projects to adopt and/or adapt innovative processes in advanced manufacturing, digital technology, value-added agriculture and clean technology that support productivity, grow operations and increase exports to global markets.

The FedDev Ontario BSP program provides southern Ontario businesses with expansion loans of up to 35 per cent of project costs to a maximum $10 million. Applications are accepted on an ongoing basis with no submission deadlines.

Government grants and loans for manufacturing companies can help offset costs of important capital investment, technology adoption, and R&D projects.

The WD BSP provides up to 50 per cent of eligible project expenses to a maximum $5 million per project and $10 million per applicant for businesses located in Western Canada. The next application period has yet to be announced, but there are typically at least two intakes per fiscal year.

The National Research Council of Canada’s Industrial Research Assistance Program (IRAP) exists to accelerate the research and development projects of Canadian innovators from all industry sectors. The primary targets to receive research funding support through IRAP are Canadian businesses that are developing and implementing process improvements for their operations.

Additionally, IRAP often also supports large-scale technology adoption projects that lead to new capabilities such as advanced operations systems.

Incorporated small or medium-sized business with 500 or less full-time employees that plan to pursue growth and profit by developing innovative products, services or processes can receive up to 60-80 per cent to a maximum of $10 million per application for internal technical labour and subcontractor expenses towards a specific technology innovation project.

The Next Generation (NGen) Manufacturing Supercluster provides support for collaborative technology development projects that help Canadian manufacturing businesses compete globally. As administered by NGen Manufacturing Canada, the program supports groups of businesses that research and develop high potential, innovative technologies to generate groundbreaking process transformation to de-risk the adoption of new technology.

Through the NGen Manufacturing Program, innovative partnerships, comprising of an eligible business working with at least three private sector partner companies, can receive up to 44.4 per cent of eligible costs for projects valued between $500,000 and $20 million.

Eligible projects typically span 18-36 months and are complete upon the successful implementation of a new, technology-based manufacturing innovation.

The Strategic Innovation Fund (SIF) is a program uniquely targeted to support Canadian industrial and technology sector businesses. The program offers financial support (both grants and loans) of up to 50 per cent of project costs for activities that drive sustained productivity and economic benefits. SIF focuses on large-scale projects that request at least $10 million in contributions, meaning the minimum project size must be at least $20 million.

There are five streams of funding provided through SIF, and applicants can align their projects to address one of the following areas: (1) Research, Development and Commercialization, (2) Business Growth and Expansion, (3) Investment Attraction and Retention, (4) Collaborative Technology Development and Demonstration, and (5) National Ecosystems.

The SIF Program is open to businesses from all sectors across Canada, but potential applicants should keep in mind that this is an extremely competitive program. While an eligible company may qualify for funding, it must also demonstrate high growth potential and the ability to drive innovation in a strong technological development project.

5. Supply Chains and Logistics Excellence AI (SCALE.AI) Program Canada is quickly progressing in artificial intelligence (AI)

advancement as it is home to many of the world’s most advanced AI organizations and businesses. The Supply Chains and Logistics Excellence AI (SCALE.AI) Program enhances Canada’s existing supply chain practices by boosting economic development through faster technology adoption and integration of artificial intelligence (AI).

The program seeks to connect

researchers and innovative businesses from a range of sectors to establish Canada as a global leader in AI innovation. Eligible applicants can access up to 40 per cent of costs for projects that accelerate the technology adoption and commercialization of AI for supply chains.

There is no minimum or maximum investment allocated per project, but there must be a

minimum 2:1 cash match from the applicant and/or private sector partner contributions. If you are interested in any of the technology adoption and development focused government funding programs listed above, you can learn more about your business’ eligibility and how to optimize an application by connecting via the contact information at the top of the opposite page. | MA

BY PAUL HOGENDOORN

The lockdowns have now been going on for over a year. Some manufacturing companies have survived quite well, some have thrived, and some have struggled, stalled or failed. The same is true for our local economies; restaurants, hair salons, small retail shops and many other small businesses are failing, never to reopen.

It is catastrophic to many communities and many families. Governments are promising relief programs and stimulus budgets, but these things are temporary in nature and won’t lead to a sustainable recovery.

Three often misunderstood words come to my mind as being critical to our economic recovery: entrepreneurism, capitalism and leadership. Entire books have been written about all three of them, but let’s look at the essence of each to discover their relevance and importance now.

An “entrepreneur” is someone that creates something from nothing for the economic benefit of many. There was nothing there before, but something tangible then got created, and that in turn creates an economic benefit for many. That’s entrepreneurship, plain and simple.

There are all sorts of other people with different skills and abilities that can then lend a hand to grow the enterprise and economic benefit, but it was an entrepreneur – someone likely wired a just bit differently (which is why “entrepreneurship” is almost impossible to teach) – that created the initial economic something.

“Capitalism” is not a popular word with many in society these days, but that is because its wrongly interpreted as greed, or enterprises built for profit above all else. Greed is greed in any “ism.” It is prevalent in all forms of societal systems – socialism, communism, any “ism” – because it is a human trait, plain and simple. Whatever societal system binds human beings together in communities or countries, greed will be present. A capitalist is simply someone that puts capital to work. The opposite of a capitalist is a “consumer.”

I recently helped my 30-something

Paul Hogendoorn co-founded FreePoint Technologies with the goal of giving manufacturers the benefit of information technologies that inform, empower and motivate their most critical asset – their people. He can be reached at paul.hogendoorn@getfreepoint.com.

to understand the

Rank may designate you as the leader, but being able to find a way is actually what makes you a leader.

They were renting homes, entertainment systems and financing a variety of somewhat temporary “life-enhancing” purchases. After calculating what they paid in rent and monthly payments for everything else, we quickly deduced that same amount of money would cover the principal, interest and taxes on a nice home that they could own themselves, and that would increase in value and grow equity. I encouraged them to think like pure capitalists (i.e. put money to work for them, building value), rather than purely like consumers (spending their money on temporary goods and services, depleting value). Capitalism isn’t the pursuit of money; it’s putting money to work to create value.

And finally, “leadership.” There are books, training courses, and certification programs to develop, improve, or identify and designate the leader. But for me, the best description I have heard of what a true leader is and needs to do is “leaders find a way.” A hockey team that wins the Stanley Cup will have a few of these leaders on the team. It doesn’t have to be the person wearing the “C” that’s the leader – it’s the players who found a way to win, and their teammates responded. If you escaped from a foxhole in 1918 after being pinned

down for days by enemy fire, the leader is the one who found a way and led the others out. Rank may designate you as the leader, but being able to find a way is actually what makes you a leader.

Today’s world is filled with designated leaders that are focused on showing they are in charge and in control –which may be good in “normal” status quo times, but if you are in a crisis, or want to accomplish something really significant, you need a leader that can find a way. Just like an entrepreneur, this type of leadership is hard to define, probably can’t be taught, and is often difficult to understand.

It seems every evening, we hear our leaders talk about how much more money (capital) they are going to spend on short-term measures, with the inference that the bigger the numbers in their announcements, the better their leadership is.

Unfortunately, we can’t do too much to change the way our governments are trying to “lead” us out of this and into a recovery, but there’s a lot we can do for ourselves and for our companies. All it takes is a little entrepreneurship, putting capital to work wisely, and leadership that recognizes the value of both and finds a way. Three key words that make all the difference. | MA

BY LYALL WATSON

IIn 2017, Humber College approached SEW-EURODRIVE with a concept for the Barrett Centre for Technology Innovation. The concept was based on creating an environment where the educational sector and advanced manufacturing industry would work together to actively develop and test applied research projects in a state-of-the-art facility.

After the partnership signing, both parties immediately went to work to create a vision for manufacturing of the future. The end result was the creation of the Ernst Blickle Innovation Lab, named for the founder of SEW-EURODRIVE.

The goal of the Innovation Lab was to showcase advanced manufacturing and Industry 4.0-ready technology that SEW-EURODRIVE is currently using in its own facilities around the world. It also needed to have the ability to be modified and adjusted for other projects between Humber College and end users looking to upgrade their manufacturing capabilities.

The Innovation Lab emphasizes the coexistence of robots and humans, hence the term “cobots.” These cobots work alongside their human counterparts instead of replacing them. Humans perform the value part of the manufacturing, while the cobots perform the monotonous, labour-intensive or hazardous tasks.

When entering the lab, you will first see Paula and Bianca, two automated guided vehicles (AGVs) that are used as assembly assistants. The AGVs operate 24/7 without ever being taken offline to recharge as they charge on the fly using contactless inductive charging or wireless charging.

The Innovation Lab displays two of the five modular approaches to manufacturing that SEW-EURODRIVE uses at its own manufacturing and assembly centres globally – in this case, the assembly manufacturing and test manufacturing modules. A complete process would normally include a warehouse module, a packaging module and a shipping module. The complete setup can be viewed on a video being displayed on the screen inside of the lab.

Lyall Watson is sales manager, Central Canada at SEW-EURODRIVE Canada, an automation provider for solutions ranging from machine automation components to full automated systems. l.watson@ sew-eurodrive.ca

In this real and functional setup, the lab showcases the assembly of SEW-EURODRIVE’s own line of variable frequency drives, the MOVI-C, by using Industry 4.0 manufacturing concepts.

Industry 4.0 is about interconnectivity and real-time process data transfer between all the parts of the manufacturing process/ cycle.

Industry 4.0 is about interconnectivity and real-time process data transfer between all the parts of the manufacturing process/cycle, from the high-level IT infrastructure such as WMS from companies like SAP or Oracle, to the factory production line between individual machines on the plant floor. During any point in the process, the product configuration can be changed in real-time, highlighting a key benefit of Industry 4.0.

The Innovation Lab shows the process from the product configuration all the way through to the assembly of the products in the assembly module. Once the product configuration is complete, the cobots use their LiDAR sensors along with SEW-EURODRIVE’s own guidance system to autonomously drive themselves to the different modules without any human interaction.

Once the cobot enters the assembly cell, the smart racking (pick by light LED system) will display which parts are to be picked. Since the entire process is connected, the smart racking

knows which order is being processed by the human assembler and highlights the appropriate components at the right time.

The assembler wears a Microsoft HoloLens augmented reality headset that works in real-time to show assembly instructions in the headset and guides the assembler while assembling the product. Since the instructions are displayed step-by-step, the worker can assemble a variety of complex products during a single shift, instead of being trained to assemble the same thing over and over.

The Innovation Lab is set up to enable not just Humber College students to re-configure the lab for educational purposes, but also for real-world prototyping of manufacturing concepts with other partners and end users. This helps the Barrett Centre for Technology Innovation fulfill its purpose of connecting industry and students by giving them real-world experience in advanced manufacturing and helping to prepare them for jobs of today and tomorrow. | MA

This article is part of a series giving manufacturers a look behind the walls of the Barrett Centre for Technology Innovation. For more information on the Centre, please contact askbarrettcti@humber.ca

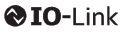

Advances in collaborative robotics are allowing manufacturers to deploy automation in finely targeted areas. This incremental approach is allowing SMEs to get into the game

BY JACOB STOLLER

Arobotic arm that helps an operator polish speaker cabinets might not sound like much. What’s interesting is that this application typifies a trend that is driving a huge expansion of robotic deployment, particularly by SMEs.

T he need for a finishing robot arose when Mississauga-based audio manufacturer Paradigm Electronics, which employs 250 across Canada, introduced a lacquer-finished speaker cabinet that requires multiple layers of finish and much sanding and polishing. Facing a shortage of skilled workers, the company brought in Barrie-based integrator Advanced Motion & Controls to implement a Universal Robotics (UR) collaborative robot to work side-by-side with a skilled operator. The project, implemented in a little over a month, increased the throughput of the cell by 50 per cent and achieved a 14-month ROI.

Until recently, long deployment time, the need for programming skills and safety concerns would have made this project impractical. Today, the technology is opening up thousands of opportunities for SMEs in areas like machine tending, material handling, packaging, quality monitoring, routine welding and finishing.

The difference has been the collaborative robot or cobot, which is designed, tested and certified to operate safely in proximity to human workers

without fencing, safety guards or other intervening devices. This has made it much more practical, and economical, to introduce robotics in existing work environments.

“ With traditional robotics, you couldn’t intermingle manual processes with automation, so you had to solve an entire problem from front to back,” says Joe Campbell, senior manager, strategic marketing and application development at UR.

The new approach makes it cost effective to automate work cells on a one-off basis, opening the door to SME adoption. “Companies like Ford and GM have been installing automation for four decades, whereas the average SME has been relying on manual labour on the manufacturing floor,” says Kristian Hulgard, general manager, Americas, for Odense, Denmark–based OnRobot.

Canadian SME adoption lags the US, but the pandemic and a shortage of skilled workers have helped accelerate buy-in, according to Mike Daly, VP of sales, Canada and USA, at Montreal-based integrator Rotalec. “Collaborative is becoming very large, and I think in the next one to three years, it’s probably going to double or triple.”

Contrary to what many believe, the growth of robotics is not about eliminating people. A StatCan study released last November linked robotic deployment with a modest increase in headcount. What the push is really about, the researchers found, is productivity.

Recent events have accentuated this trend. A Chicago-based company, under staffing pressures during the pandemic, brought in collaborative robots that allow an operator to handle three machines instead of one. “Now the operator does all the setup and programming, and the cobots do all the loading and unloading,” says Campbell. “So they immediately got themselves out of the labour headache that they were facing because they couldn’t hire enough people.”

The technology also helps increase output when there’s no opportunity to grow without adding floorspace. “A lot of these machine shops are landlocked, and they can’t expand,” says Campbell. “So if you squeeze more output out of that same footprint, that’s a significant win.”

A changing vendor landscape The shift to smaller-scale incremental solutions is rapidly expanding available product options. OnRobot’s evolution

since its founding in 2015 from a gripper manufacturer to a collaborative solution provider shows how rapidly the market is shifting. “We initially focused on the CNC market,” says Hulgard, “but now, we supply so many products that CNC is only 12 per cent to 18 per cent of our total turnover.” Today, Hulgard notes, 70 per cent of the company’s business comes from SMEs.

Rapid-deployment software tools make it easier to build solutions –perhaps a gripper, robot and mobile cart combination – in a modular fashion and align them with existing machine tools.

“Everything boils down to minimizing deployment time,” says Hulgard, “and one of the ways you can do this is by making plug and play products to complement the robot. And I’m not only talking about tools. It can be sensors, it can be cameras, it can be conveyors, it can be safety features around the robot – anything that needs that complements the

robot in that application has to be plug and play.”

Thanks to rapid deployment, Daly is seeing ROI of six to eight months on projects in his customer base. “It’s fairly quick, because implementation time is only two to four weeks,” he says, “and more importantly, it’s flexible, so it can be used for multiple applications [that] you can program in house. There also isn’t the high safety investment that you needed with industrial robotics.”

As robotic solutions become more granular, an ecosystem of vendors and integrators is emerging. In February, UR launched a virtual cobot expo focusing on machine tending. The portal allows visitors to browse virtual booths and examine dozens of software tools and gadgets including mobile multi-drawer parts cabinets, loading and unloading systems, automatic vices for CNC machines, and ready-made interfaces for common machine tools.

As is the case with IT, SMEs tend to operate with limited technical staff and rely on vendors to provide complete solutions. “Manufacturers are not thinking about a robot or a gripper or a camera,” says Hulgard. “They are thinking about the solution – does it solve my problem or not?”

Accordingly, Canadian resellers are assuming a larger role. Rotalec, for example, maintains a staff of technical sales reps, robotic application specialists and design engineers. Colleges and universities are also adapting their programs to support the new technology.

Neal Mohammed, director of the Barrett Centre for Technology Innovation at Humber College, says the school’s Engineering Technology program offers robotics training. The training is also being deployed to the college’s continuing education programs for industry workers looking to reskill. “We’re going to see more and more of these robots taking an important role, especially in SMEs,” he predicts. | MA

BY KAREN SMOCK

In the drive toward digital transformation in manufacturing, industrial controllers are at the centre of the push away from legacy systems and the pull toward the benefits of new technology. Controllers are continually evolving; the latest trends reflect standardization, IoT capabilities and the strategic use of edge computing.

Traditionally, PLCs (programmable logic controllers) controlled equipment; PACs (programmable automation controllers) controlled production lines or plants. There used to be dividing lines, with PLCs using proprietary programs, and

PACs offering more standardization, openness, modularity and communication protocols. Today, those lines are blurred. OEMs and plant operators have a wide range of controllers available that conform to standards such as IEC 61131, provide openness and modularity, and use popular communication protocols.

“ PLCs today are used in such a variety of automation applications from automating processes, just simple machine functions and even entire production lines. When it comes to programming, all the programming languages now are standardized,” says Andrew Cortese, product manager, factory automation at Siemens Canada.

“ When PLCs first started coming in, all the different manufacturers had different programming languages,” explains Cortese. “A big one is ladder diagrams, now called ladder

“One misconception or something that maybe people don’t consider is the impact of this data collection on the performance of the machine controller,” says Gremillion.

logic. So it’s all standardized across all of the different manufacturers, as well as function block diagrams.”

S tandardization provides future-proofing so that controllers can accommodate a wide range of new functionality. “Standardization of connectivity is one focus,” says Roger Hart, R&D engineering manager at Siemens. “Several standards have become more mature in the past few years. For example, OPC UA and MTConnect offer enhanced capabilities including support for robotics and additive manufacturing. The controllers, both PLC and CNC, offer a broader set of data at higher frequencies, especially through edge computing devices.”

D oug Browne, technology development engineering manager at Omron Automation, relates the evolution of controllers to computers. “All computers are powerful enough nowadays that they can run the latest operating system, and I think you’re seeing a similar trend in the world of PLCs.

“ There is a harmonization and a homogenization from where the features that you’re seeing in the highest end of PLC, PAC, MAC – whatever you want to call it – are the same feature set that you’re seeing on the lowest-level entry unit,” explains Browne He says some examples of when users would need an upgraded CPU or higher-performance PLC is if they have a lot of motion axes, or if they’re mixing features like pushing data to the cloud, performing safety functions, and AI.

A key determining factor in controller selection is performance. “I think the only thing you really need to look at these days when selecting a PLC is maybe the size of the performance aspect of it – if you’re planning on expanding it a lot in the future for different applications and more inputs and outputs and technology modules,” says Cortese.

C arrie Lee, product manager, controllers, at Omron Automation, says higher-performance PLCs lead to better results. “What people don’t

realize is when you have fast processor speeds, it allows you to have better quality data. People think, ‘Oh, it’s impossible. I can’t get time series data out of a PLC.’ Not only can you, it’s there. You don’t have to do any extra work. Same thing with connecting your PLC directly to a database. That’s something that we have the capability to do.”

The ability to capture, analyze and share data is the promise of digital transformation and the Internet of Things. However, proper implementation requires strategic planning about what data needs to be collected, where and how it will be stored and shared, and, of course, security.

“One misconception or something that maybe people don’t consider is the impact of this data collection on the performance of the machine controller,” says Gus Gremillion, partner manager, Siemens Industry Inc.

“ We’ve had customers who are trying to get some process data off of a machine that has 24 axes. And so when you’re trying to sample that much data a few times a second using something like OPC UA, it’ll actually degrade the performance of the machine tool,” explains Gremillion. “If you’re needing to get data every five or 10 seconds or 30 seconds, OPC UA could be just fine. But if we’re starting to look at this high-frequency data, where we’re wanting to be getting things like motor currents a few times a second or potentially hundreds of times per second, OPC UA is probably not going to be able to do that.”

He says that the capability to capture high-frequency data and summarize or condense it before sending it over a network is an example of why edge devices are coming into their own.

Sensor data is also easing operation – for instance, plant operators can use vision capabilities for training and error detection. “An area advancing rapidly is vision combined with artificial intelligence. Machine

learning algorithms can be trained to classify characteristics from captured images,” says Hart. “These trained models can be subsequently used in real time for process automation. Edged computing or dedicated PLC hardware acceleration modules are ideal platforms for hosting these algorithms.”

Hart explains that with machine learning, you can train using vision for applications such as tool -wear detection or proper part setup. “With the edge devices, it allows us to offload that AI or vision-type computing from the CNC controller or PLC and do that in the edge device,” adds Gremillion.

E dge controllers are also evolving to provide operations with high performance and security. “Vendors like us who have these systems of controllers are putting more processing power closer to the asset to ensure the processing of controllers is always available so that edge controllers will also incorporate the latest cybersecurity protections,” says Srikumar Srinivasan, vice-president and general manager at Honeywell Process Measurements and Controls.

“ So with specific protocols like MQTT, AMQP and other IoT protocols, these edge controllers will serve as data collectors and concentrators, but they can also do some controls and analytics right in the process of the equipment itself.”

The ability of edge controllers to do processing is reducing the bandwidth requirements of sending all the raw data to the cloud.

“All the processing is done with the edge controller itself because they made it more powerful and now it’s not just data going to the cloud – but the data is converted to good analytical information and only limited information goes to the cloud; hence, bandwidth requirements are less,” Srinivasan says. “That’s basically why edge controllers are really becoming a big-time move now.” | MA

Automation and robotics adoption must increase to grow the manufacturing sector, says NGen report

BY KRISTINA URQUHART

The growth of Canada’s manufacturing sector depends on the implementation of automation and robotics, but many companies still find technology implementation “unappealing,” says a new report by Next Generation Manufacturing Canada (NGen).

The Canada’s Automation and Robotics Landscape report encourages information sharing within the sector to ensure Canada’s competitiveness as a whole, says Stewart Cramer, chief manufacturing officer at NGen.

The industry-led organization, which facilitates funding for Canada’s Advanced Manufacturing Supercluster and de-risks technology transformation projects, recently formed an Automation & Robotics Advisory Board with 20 of its members.

Participants included AIS Technologies Group, Automate Canada, Clearpath, Eclipse Automation, Siemens, Festo, Humber College and ABB, among others. The group initially met in October 2020, then completed an online survey and participated in one-on-one conversations with NGen to discuss ways to advance technology adoption in Canada.

“Automation and robotics have the potential to be transformative for companies large and small,” Cramer says. “[NGen hopes] to offer reliable and vendor-agnostic information to help organizations to succeed in their respective Industry 4.0 journeys.”

‘Few Canadian exemplars’ Automation and robotics are most frequently

used in Canada for handling and assembly tasks, as well as vision-guided quality control, teleoperation and additive manufacturing.

But the survey respondents – comprised of OEMs, automation vendors and system integrators – indicated that beyond the automotive sector, use of automation and robotics decreases significantly.

“Most smaller companies in Canada have not fully automated their processes, certainly [not] beyond ‘islands of automation’ (e.g. material feeding a machine),” notes the report. “Fully connected enterprises – using Industry 4.0 digital data and sensors (Internet of Things) internally and externally – often seems to be somewhere on the Gartner hype curve, with few Canadian exemplars.”

Because of strong automotive sector adoption, Canada’s robot density (robots installed per 10,000 employees) is 165, which is higher than the global average of 113, the report says. Outside of the automotive sector, Canada’s robot adoption is indeed lagging – 71 as opposed to the U.S.’s 139.

Canada also has a slower rate of adoption –over the past four years, average robot density

increased 20 per cent, whereas in the U.S., it jumped 39 per cent. Canada is also 44 per cent below the “expected” robot adoption rate, which is measured using payback relative to national wage levels.

“ The only certainty is that if Canada can maintain its vehicle assembly market then new automation and robotics investment and innovation will follow,” says the report. “Canada cannot afford to lose its automotive industry.”

Survey respondents cited several reasons for slow automation and robotics adoption, chief among them the availability of funding. Also suggested were people and their attitudes toward innovation, regulations, global competitors and the impact of COVID-19.

Collaboration within the industry, availability of raw materials, reliability of the supply chain and the presence of U.S. competitors were also noted as barriers, but to a lesser degree.

Three additional challenges consistently came up:

1. Lack of training.

The advisory board was not confident that students and future workers are receiving the necessary skills to prepare them for careers in automation and robotics. And in order to adopt these technologies, SMEs themselves need to improve their programming and simulation expertise, as well as their business case analysis.

“As one survey respondent noted, while the robot manufacturers are the driver, and the SME is the adopter, there is still an application knowledge gap that cannot be filled with three days’ manufacturer training,” the report says.

Nearly all respondents said they spent between a moderate amount and a great deal of time educating customers on the applications and benefits of their technology and services.

2. Perceived high costs.

Respondents said that overall, Canadian industry is “somewhat aware” of the capability and cost of automation, but nearly 60 per cent of those surveyed also said their customers underestimate the costs of automation integration projects.

The report notes that a “low-cost” solution can still total several years’ minimum-wage salary, which can be difficult for companies to justify.

3. Relative lack of flexibility

Many SMEs have high-mix, low-volume production. This differs from large automotive companies that enable low-mix, high-volume production, which can be better served by “inflexible” automation such as industrial robots and conveyors.

However, as the autom otive industry

transitions to more electric vehicle production, there will be a wider range of products due to the variety of electric motor sizes. This means the automotive sector too will need flexible options. AI and machine vision are expected to provide that flexibility, the report says.

In NGen’s follow-up interviews, a respondent said that “time, money and talent” are the main reasons why their customers don’t implement automation and robotics.

“It was very much to the point and very much aligned with the feedback from other Automation & Robotics Advisory Board members,” says Cramer. “It is a recurring theme with SMEs when considering their need to adopt emerging technologies and processes, and how they lack the know-how and resources required to do it right.”

The report also noted a pervasive attitude among SMEs: “The feeling is often that there is no need to act now, that ‘the business is not going to die today or tomorrow,’ and there is ‘always a bigger emergency to focus on.’”

NGen already provides government matching funding to de-risk automation and robotics implementation, offer financial support for training programs and facilitate information sharing.

The organization asked respondents what else can be done to dismantle the barriers to adoption. One suggestion was for a national body to partially fund the cost of prototype systems so that customers could visit proof-ofconcept solutions. Another was for a “mobile road show” that could travel directly to manufacturers to showcase smaller-scale solutions.

Respondents noted that their Canadian customers tend to want to see the technology in action over a simulation. As a result, opinion was divided on whether or not additional demonstration facilities would increase adoption.

NGen is planning a web portal for its members to help determine whether automation or robotics are suitable for their operations, and to also create awareness within the industry. The portal could reduce the burden on suppliers having to start the technology implementation conversation from scratch.

The organization is looking at a dual-pronged approach, with education modules to prepare companies for adoption through webinars, case studies and white papers, and marketplace modules that showcase demonstration projects and connect manufacturers with experts and service providers. Depending how users answer an initial checklist, automated answers would lead to case studies and payback calculators that align with their goals.

Cramer says that NGen is working to roll out a new collaboration platform by this summer, with early versions of two “Technology Adoption Portals” (TAP) – one for additive manufacturing and the other for automation and robotics.

“We also hope that by publishing this type of report and facilitating a conversation around advanced manufacturing, we do raise awareness of the challenges that Canada’s manufacturers face in staying competitive,” says Cramer.

“Should new opportunities for support arise, we will be well-placed to ensure that manufacturers are well-informed and able to respond appropriately.” |

BY KRISTINA URQUHART

To successfully deploy automation, manufacturers should seek reliable collaborators and plan for a convergence of technologies, said industry experts at the A3’s Automate Forward conference last month.

The Association for Advancing Automation (A3) hosted the online event Mar. 22-26 in place of the biennial in-person Automate Show due to ongoing COVID-19 restrictions.

In a roundtable on the state of the automation industry, Mike Cicco, president and CEO of FANUC America, acknowledged that manufacturers and vendors have been preoccupied over the past year with keeping production running and goods flowing, as well as with following safety protocols and ensuring employees are supported.

But all experts agreed that it’s time to plan for next steps.

“ What this last year has really revealed is some things that we thought would be multiple years out, we’re doing them now. This probably won’t be the last big business continuity interruption that we will see,” said Christine Boles, vice-president, Internet of Things group at Intel Corporation. “Manufacturers need to step back. They have limited capital expenditures and they need to plan how they are going to incorporate them.”

With the pandemic underscoring the need for additional visibility across supply chains and on production floors, the use of technologies such as machine vision and artificial intelligence will increase, she said. “Manufacturers are recognizing that capability is critical to have in place. [They need to be thinking] what have I learned? What are some of the things I need to shore up?”

Patrick McDermott, president, North America for B&R Automation, said that partnerships

will prove useful as companies begin to harness the technologies available to them.

Boles said collaborations are pushing the development of those technologies – but that vendors need to be careful to not overpromise capabilities without a common platform or standardization in place. “The industry has to work very differently together,” she said, citing how smartphones and apps work together on open platforms as an example. “Having a more foundational platform and approach will allow for the scalability.”

In a panel discussion on drivers of automation growth, Ted Dengel, managing director, operations technology and innovation at FedEx Ground, said partnering with vendors that are further along with commercialization will help to future-proof automation choices. “To get real success out of the gate, you have to partner with someone who is ready to commercialize and ready to put [the technology] in and support it. It has to be a real savings, have real support and become part of your production process.”

The experts advised that automation implementation is a journey, not a destination.

“ When we started talking about it years ago, I thought adoption would happen at a more rapid pace,” said Cicco. “It’s clear that it’s a more challenging journey. But 5G and wireless will accelerate [adoption].”

“ We are seeing companies accelerate their strategies but haven’t seen that translate to

equipment yet, because it’s capital investment,” said John Bubnikovich, chief regional officer North America for KUKA Robotics. “There’s still a lot of fragility in the economy.” He estimated that automation investments will ramp up over the next two years.

T he need for flexibility has made it difficult to use traditional automation in many applications, said John Dulchinos, vice-president of Jabil. Variations in product sizes and shapes require more advanced tools to automate, such as artificial intelligence, vision and machine learning.

I n a panel discussion on collaborative automation, Milton Guerry, president of SCHUNK USA and president of the International Federation of Robotics, said that as collaborative robots incorporate those advanced tools such as AI and machine vision, suppliers will need to bundle solutions to get manufacturers on board. “The industry doesn’t want a science project where you bring in these things and try to make it work,” he said.

Cobots are a good entry point for manufacturers looking to automate processes at a lower cost, Guerry said.

Another way to automate without significant cost or time investments is 3D printing, said Dulchinos. He also stressed the need for manufacturers to understand the direction the market is heading. “It’s important to think about the long-term trends and align around those trends, like two-day delivery to compete with Amazon,” he said. “It’s key to be flexible.”

B oles sees a heightened need for more augmented and virtual reality applications coming out of the pandemic. “We’re changing way of the workforce – you can’t have experts everywhere,” she said.

“Shops as small as a few people are realizing the benefits of automation every day,” said Cicco. “My overall prediction is heavy users of automation will continue to find new ways to use it, and there will continue to be growth in small users as automation be comes easier to use and so much more accessible.” | MA

Canadian Manufacturing Demo Days puts the power of Annex Business Media’s manufacturing brands to work to showcase your product videos through a single online source. Promoted through database, online, editorial and social media drivers across 17 manufacturing titles to ensure you receive the leads of decision makers interested in your products.

For More Information Visit: canadianmanufacturing. com/demo-days/

Parker Hannifin has released the PCH Network Portal, an Ethernet node with IO-Link master capability that supports multiple Industrial Ethernet communication protocols (EtherNet/IP, PROFINET, Modbus TCP and EtherCAT). The portal is classified as a cyberphysical system for its ability to

Magliner has added a powered lifting hand truck to its lineup, allowing operators to easily lift and lower heavy loads up to 200 lbs. The hand truck has a 500-pound overall load capacity when used as a traditional hand truck, as the design includes many familiar components used in the Magliner portfolio. The hand truck, while having a lower lifting capacity compared to the LiftPlus units, can be used in tight areas where other stackers, or fork trucks may be too

communicate across machinery while offering maximum function integration. The PCH Network Portal was engineered with configurable I/O with true PNP / NPN circuitry switching and the open protocol, IO-Link, on each port for machine design changes. With built-in configurable IO-Link master ports all packed into an IP65, weld splatter-resistant housing, the PCH Network

Portal features programming functions such as debounce timers and time-stamped rolling 40 errors, warnings and events logs. Configuration can be done via a laptop, tablet or phone via a secure and lockable Bluetooth connection, providing remote control of the PCH Network Portal to enhance safety, especially when dealing with robot controllers or end effector tooling. parker.com

Trio Motion Technology has launched new I/O slices that enable OEMs to measure and control temperature as well as connect three-wire devices within a compact footprint. A 16-bit resolution is suitable for

large or unwieldly. The lithium battery–powered unit lifts up to 40 inches high, making it ideal for lifting items, loading vehicles and so much more. The lifting nose, handle and wheels can be chose to fit the application. All units come standard with stair climbers to assist with transporting loads up and down stairs and an integrated kick bar to help with heavy loads. magliner.com

Emerson has unveiled a new industrial edge and analytics solution called PACEdge 2.0, which turns the data that’s collected at the machine into insights that manufacturers can act on. PACEdge IIoT software provides developers with a secure platform for creating, deploying and scaling applications, ensuring a single source of truth across IT, OT

multiple applications, from temperature measurement and monitoring to control of hot melt glue and sealing applications. Four thermocouple inputs feature alongside four outputs for control of a heater or other switched load. Trio is also releasing the P362 Power Connect module for integration of sensors, relays and output devices. The module simplifies connection of three-wire sensors into the I/O system, with two banks of 10 x 24 V and 0 V connectors. Larger machines using Trio’s Motion Coordinators, which control up to 128 axes, can access decentralized control via Trio’s EtherCAT I/O Flexslice coupler. Trio’s distributed I/O allows local connection to sensors and actuators. triomotion.com

Exceltec has released the Magna-Plug connector, which disconnects automatically when

and enterprise-level

The PACSystems RX3i CPL410 edge controller provides edge control technology, combining real-time, deterministic control with advanced, Linux-based applications in a single device,

pulled from a cable. MagnaPlug is ideal for manufacturing applications such as temperature probes, low-voltage, 4-20mA, Ethernet and communications. The Magna Plug has two connectors: a male connector and a female connector. It also has a female connector variant for panel mounting. The body of the connectors is made of food-grade Teflon. exceltecinc.com

providing a foundation for industrial IOT. The RX3i uses the PACSystems control engine and programming environment to provide application portability across all of Emerson’s PLC hardware platforms. These solutions can be combined with the company’s line of sensors and pneumatics, as well as I/O technology solutions that offer connectivity between control, valve systems and sensors. emerson.com

The softMC compact microcontroller, developed by Servotronix with an EtherNet/ IP interface from STXI Motion, enables any major OEM programmable logic controller (PLC) to seamlessly control any motion control component, including robots, drives and motors for packaging systems. The new softMC lets packaging machine-builders interface with Rockwell Automation PLCs and EtherNet/IP networks to add multi-axis motion control to any existing system. A centralized method for designing and integrating additional motion axes and/or robotics capabilities lets machine builders design and use standard robot models such as delta, SCARA, and cartesian/ gantry robots. The controller provides motion control of the motors, robots or robotic controllers while handling

Eaton has released the Power Xpert SPD surge protective device to help protect critical equipment. The device has advanced monitoring display and communication capabilities in addition to historical surge logging. The Power Xpert SPD enables customers to capture and categorize surge events by low, medium and high categories

all communication between material handling systems and the Allen-Bradley PLC. stxim.com

Moog Animatics has released the DS2020 digital servo drive with Combitronic capability. This single-axis drive operates a Moog CD series motor, providing

high torque capabilities for large axes of motion and other demanding applications. The DS2020 drive with Combitronic expands the standard drive’s capabilities by allowing it to act as a follower device on the Combitronic network, which means the drive can be easily controlled by any SmartMotor on that network. This allows the DS2020 Combitronic drive to fit and work seamlessly in SmartMotor-based machines and applications, while supporting SMI software and AniBasic programming language to configure and program the entire system. moog.com

Wi-Fi data concentrator ICP DAS USA has released the wireless Modbus data concentrator, MDC-211-WF. MDC-211WF features Ethernet, RS-232 and RS-485 communication interfaces and Wi-Fi capabilities. The data concentrator is used to link multiple Modbus RTU devices to an Ethernet control/ communication network. MDC-211-WF reads the data on connected Modbus RTU devices according to the user-defined command table then integrates the data from different Modbus RTU

devices, concentrating all the data onto one device. The remote Ethernet host can then connect to MDC-211-WF over wired Ethernet or Wi-Fi to access the data from multiple Modbus RTU devices from one network location. This device centralizes Modbus data management, making it easier to establish a stable remote monitoring system; it reduces the Ethernet network traffic load, and enhances system efficiency. The MDC-211-WF Modbus data concentrator is ideal to work with SCADA systems. icpdas-usa.com

Nexen Group has launched NexSafe Certified Safety Products for machine builders to increase the safety of processes and machines. NexSafe rail brakes, servomotor brakes, and rod locks have earned the Intertek Functional Safety (FS) mark. They are certified to comply with ISO 13849-1, Categories B through 4 and Performance Levels PLa through PLe. With spring-engaged, air-released functionality, NexSafe products

are default to lock, making them ideal for emergency stopping and holding. NexSafe can be mounted to servo motors, linear devices, pneumatic cylinders, round rails, linear rods, round shafts and linear guide systems. nexengroup.com

according to IEEE standard C62.41. The connected solution enables customers to remotely monitor surge data in real time or store events in a log with time and date stamps they can use to predict future surge events or enact proactive maintenance of critical equipment. The Power Xpert SPD is also designed to ensure the highest level of cybersecurity available. eaton.com

BY THOMAS BURKE

Connectivity is the key word when talking about digital manufacturing.

In fact, communication is the backbone of all the industrial components used to realize the Industrial Internet of Things (IIoT), as it brings together different entities on the factory floor, e.g. hardware devices, software tools and people, as well as higher enterprise level systems. It allows them to collect, communicate and analyze data. By doing so, the industrial machines and the entire enterprise become intelligent systems, able to improve plant performance, productivity and flexibility.

Industrial Ethernet offers the possibility to create different plant topologies and is easier to configure and expand.

Within this framework, a suitable network technology can go a long way towards boosting the capabilities of a factory, as it enables direct communication between manufacturing and management systems, resulting in the ability to control and make adaptive decisions based on real-time information. This is an essential prerequisite to achieving manufacturing-on-demand for a range of increasingly user customizable products.

The foundations of a network for the future

As a large volume of devices should be seamlessly interconnected in the Factory of the Future, keeping the costs down while ensuring good connectivity is essential. Currently, the most attractive physical layer available is Ethernet. Compared to traditional fieldbus, this network technology is economical and faster. Therefore, Industrial Ethernet provides

Thomas

a better price/performance ratio. In addition, Industrial Ethernet offers the possibility to create different plant topologies and it is generally easier to configure and expand, factors that are crucial when defining an enterprise’s automation strategy.

Not any kind of Industrial Ethernet is sufficient, though. In order to establish an IIoT-enabled manufacturing line, large amounts of data from multiple devices need to be collected and transferred in real-time. Therefore, having enough network bandwidth capacity is critical to the successful operation of these systems. More precisely, full gigabit networks are becoming the standard for industrial automation going forward.

In addition, the networking solution should be able to address different standards, as factories tend to adopt field devices and machines from different manufacturers to satisfy their production needs. As a result, open networks are key, as they provide the only solution to accommodate products from multiple vendors.

To address this aspect, the CLPA has increased the openness of its gigabit Ethernet technology CC-Link IE by developing specifications that increase the network’s interconnectivity and compatibility with other solutions. For example, an interoperability specification allows CC-Link IE and PROFINET to communicate with one another, thus allowing individual devices to be connected to either network. Also, the companion specification between the CLPA’s CSP+ for Machine

technology and OPC UA enables further communication options.

Looking ahead, it is safe to assume that in many cases the network of the future will be a 1 Gbps Ethernet-based solution in line with the latest advances in technology, such as Time-Sensitive Networking (TSN). As well as offering real-time, deterministic communications, it should also offer an open protocol structure to allow collaborative future development and hence futureproofing. Currently, the only industrial network to meet all these requirements is CC-Link IE TSN, developed by CLPA, the first open industrial network combining gigabit Ethernet performance with TSN functionalities.

Seamless communication across all levels of automation

An open architecture is a must for networks to accept devices from a number of manufacturers. However, this is not enough for the network of the future, which should maximize its compatibility on different fronts.

Not all installations are new and compatibility with legacy systems and devices is often required in “real world” applications. Plus, there is always a transition period to be managed for any existing plant and machinery, which can include 100Mbit only connections.

The ideal system should support the convergence of information technology (IT) and operational technology (OT). It is essential to ensure that the data generated on the plant floor is accessible across all higher-level systems, from the control, supervisory and enterprise levels. This requires seamless vertical network integration, which can be obtained by using a single protocol that can span across all levels of the enterprise.

This means that, in addition to having a large bandwidth, the industrial communications network needs to be able to schedule different types of data traffic in a highly effective manner. In particular, time-critical control data should be prioritized to support determinism and reliability on the factory floor.

The key design principles for digital manufacturing are real-time information transfer capabilities as well as data transparency and availability across the enterprise for advanced analytics. To implement these functionalities, it is essential to select the right industrial network. This should be able to accommodate different types of traffic generated by a broad range of devices while ensuring the timely delivery of each data packet. | MA

Have company news, case studies, events or story ideas to share? Send to kurquhart@annexbusinessmedia.com and you could be featured in Manufacturing AUTOMATION!

• 4 GB onboard Flash, 32 GB SD card

• 1 GHz Cortex A8 processor

• Program with standard PLC languages: ladder, structured text, function block and more

• Built-in HTML5 web server for dynamic operator interface

www.wago.com/ca-en/pfc200